Supercritical Freon heat exchange experiment system and experiment method thereof

A freon and supercritical technology, which is applied in the research field of supercritical nuclear reactor thermal hydraulic verification experiments, can solve the problems that supercritical fluid heat transfer experiments cannot be carried out, and achieve the effect of simple and reliable structure and perfect system functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

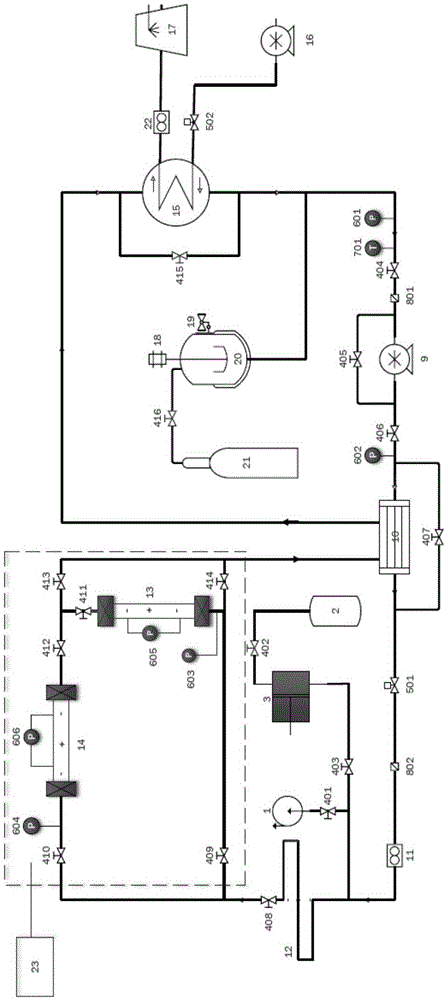

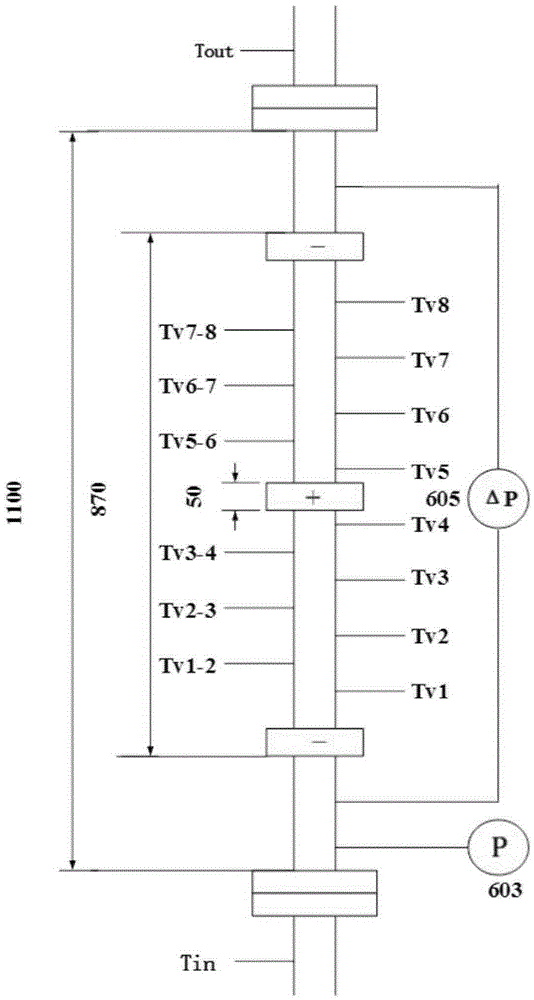

[0058] Such as figure 1As shown, a supercritical freon heat exchange experimental system of the present invention includes a first valve 401 connected to the main circuit through a pipeline and a vacuum pump 1 connected to the upstream pipeline of the first valve 401, and the first valve 401 communicates with the vacuum pump suction port and the main circuit , to form the vacuum module of the system; the refrigerant tank 2, the second valve 402 installed on the top pipeline of the refrigerant tank 2, the refrigerant recovery filling machine 3 downstream of the second valve 402 through pipelines, and the third valve on the downstream pipeline. The valve 403 and the third valve 403 are connected to the main circuit through pipelines to connect the refrigerant tank 2 and the refrigerant recovery filling machine 3 with the main circuit to form the Freon filling modu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com