Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

901 results about "Stirling engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Stirling engine is a heat engine that is operated by a cyclic compression and expansion of air or other gas (the working fluid) at different temperatures, such that there is a net conversion of heat energy to mechanical work. More specifically, the Stirling engine is a closed-cycle regenerative heat engine with a permanently gaseous working fluid. Closed-cycle, in this context, means a thermodynamic system in which the working fluid is permanently contained within the system, and regenerative describes the use of a specific type of internal heat exchanger and thermal store, known as the regenerator. Strictly speaking, the inclusion of the regenerator is what differentiates a Stirling engine from other closed cycle hot air engines.

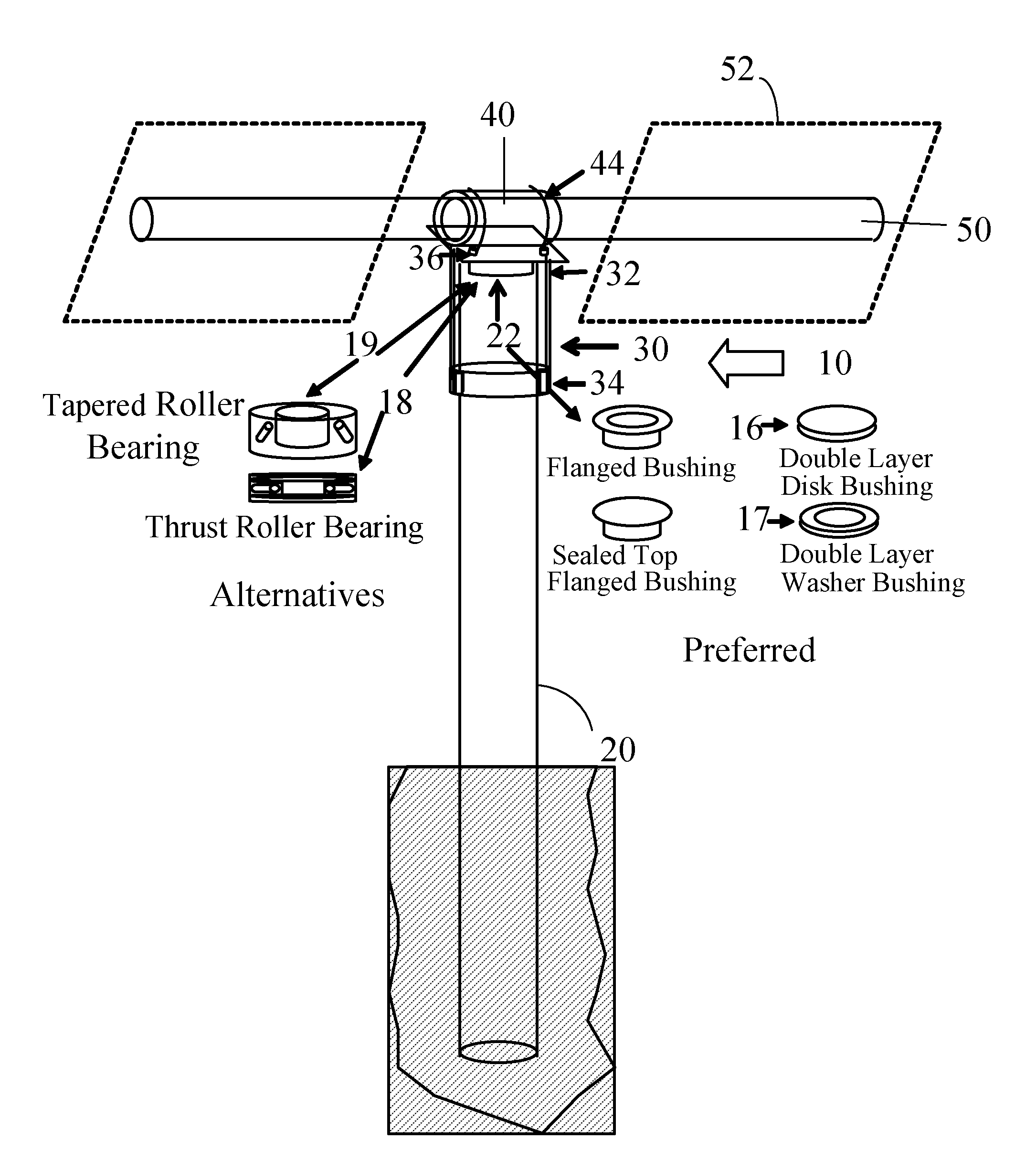

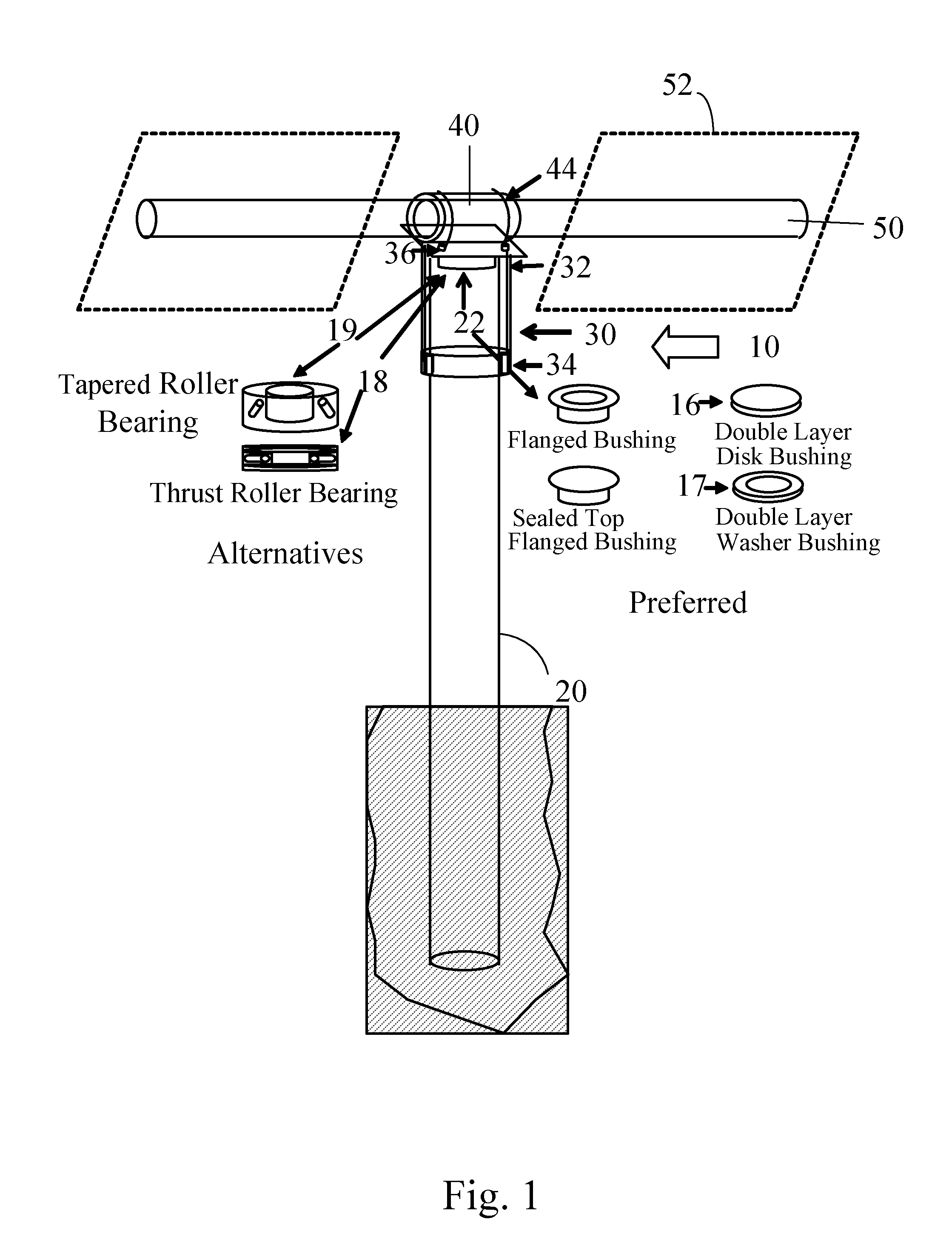

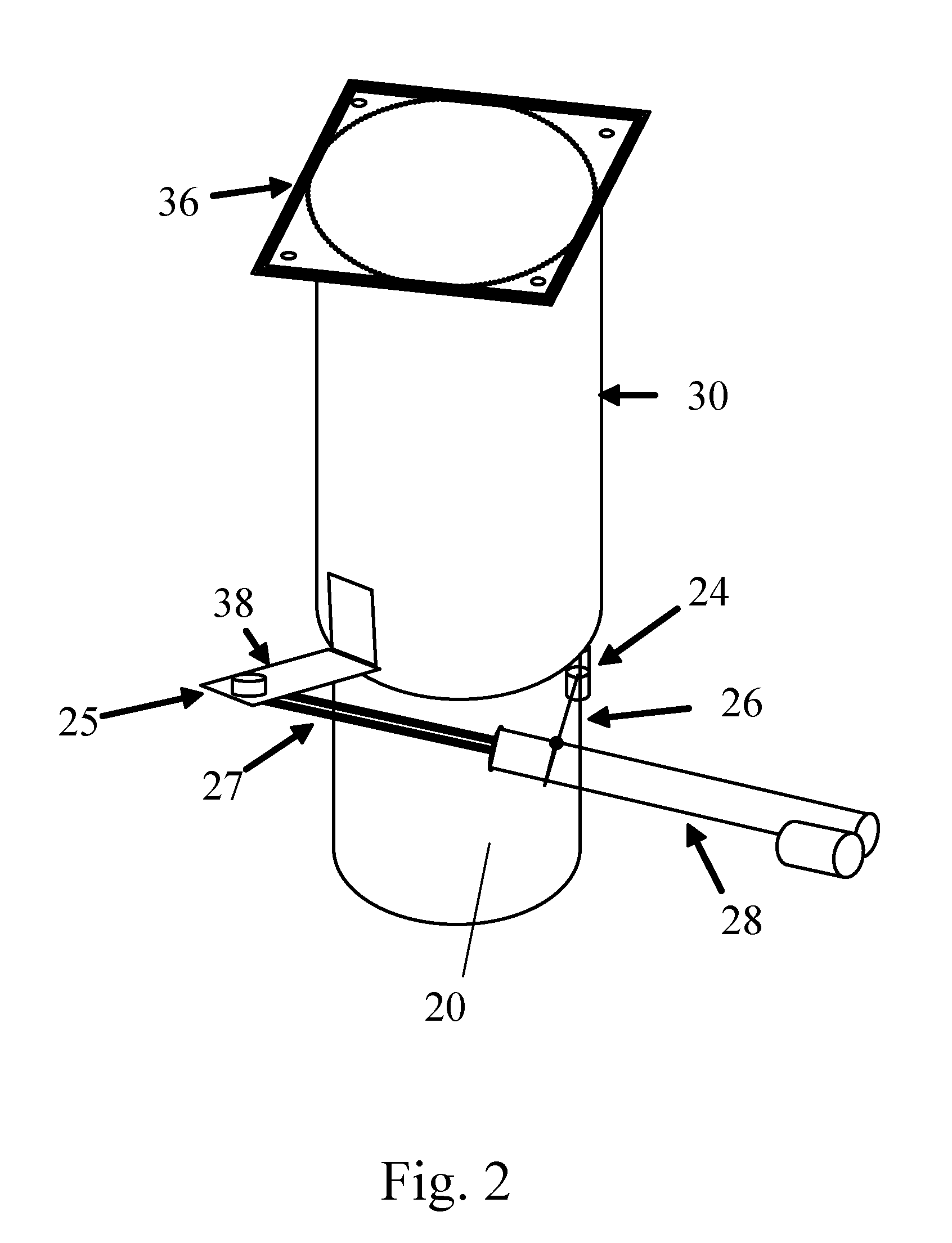

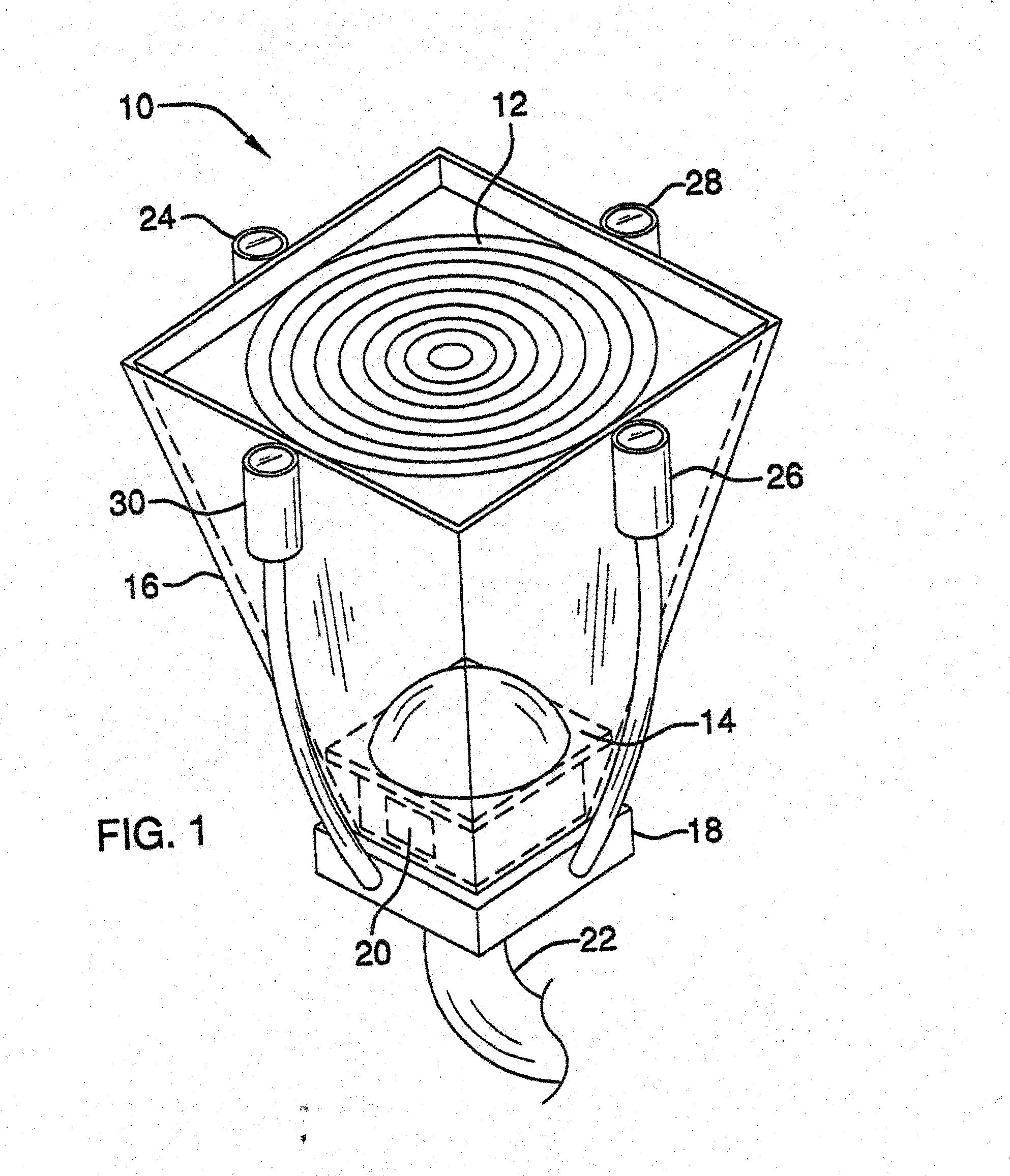

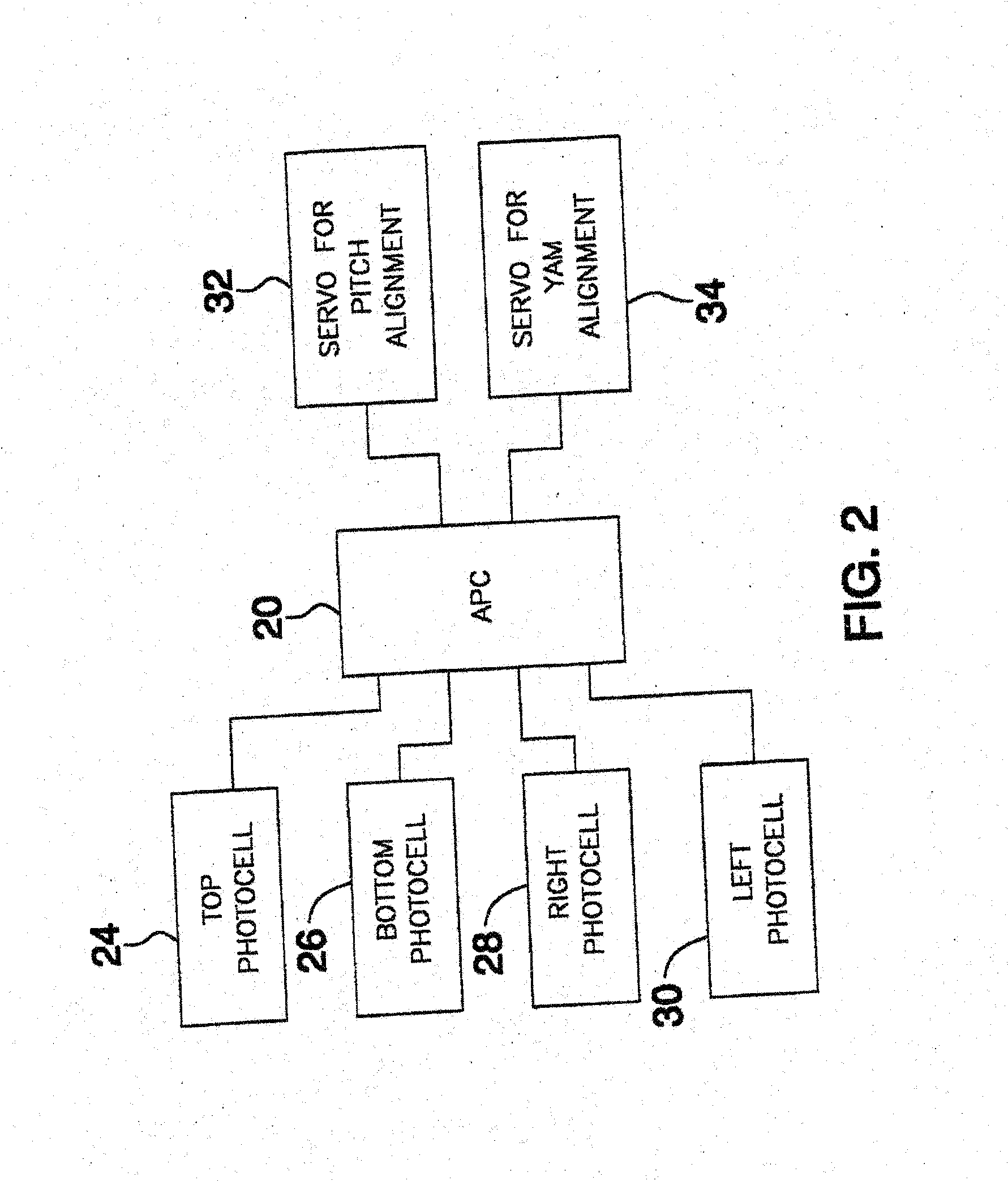

Two-Axes Solar Tracker System and Apparatus for Solar Panel and Likes

InactiveUS20110041834A1Easy to installProlong lifePhotovoltaic supportsSolar heating energyHeliostatEngineering

The present invention relates to a simplified and lower cost two-axes tracker for solar PV (photovoltaic) or CPV (concentrated photovoltaic) solar panel, as well as heliostat solar reflectors and solar Stirling engine. In particular, the disclosure addresses a simplified and gravity centered tracker structure with low cost single or dual linear actuators mounted on the side of ground post which is easier for replacement and maintenance at lower cost.

Owner:LIAO HENRY H

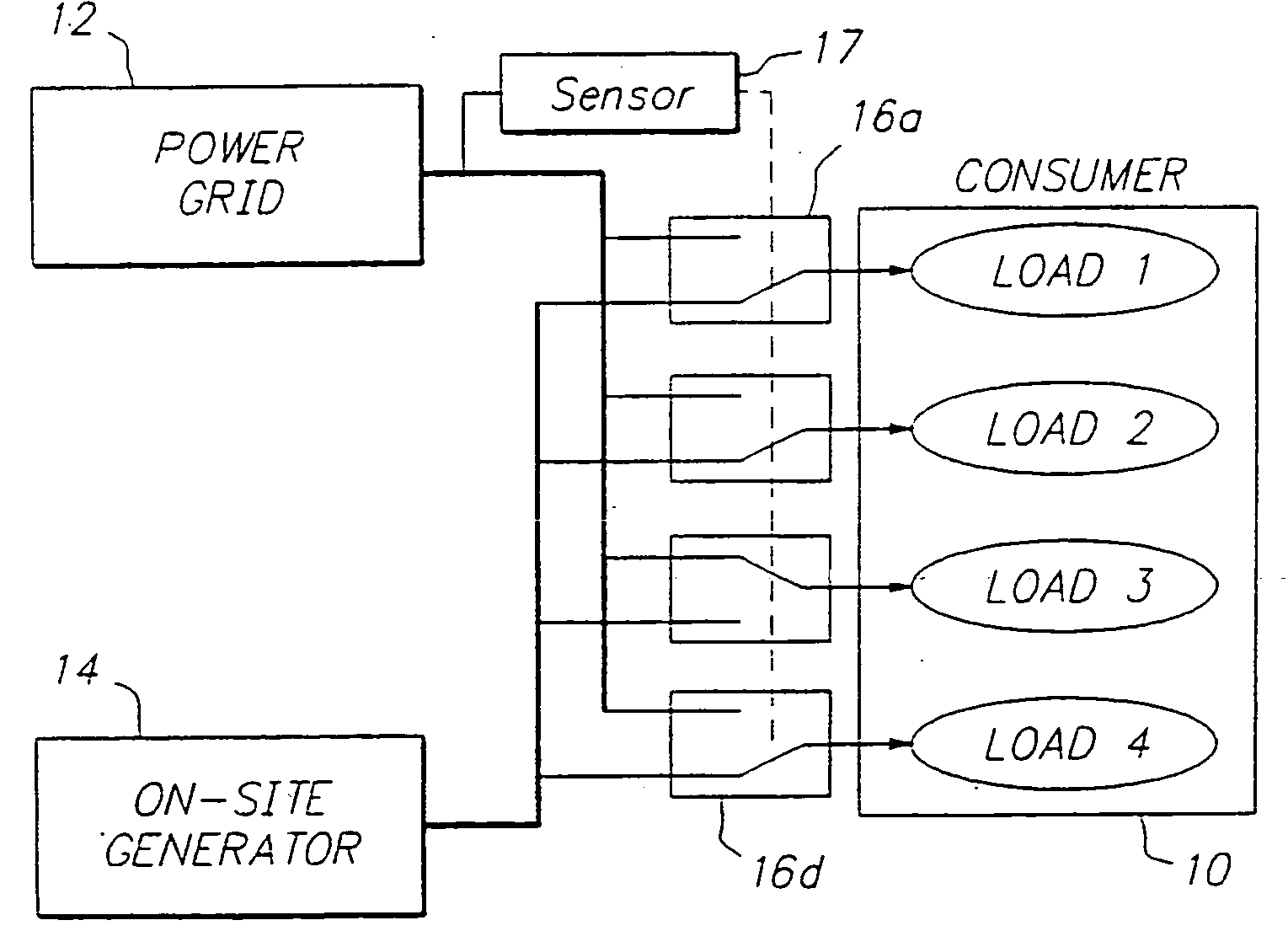

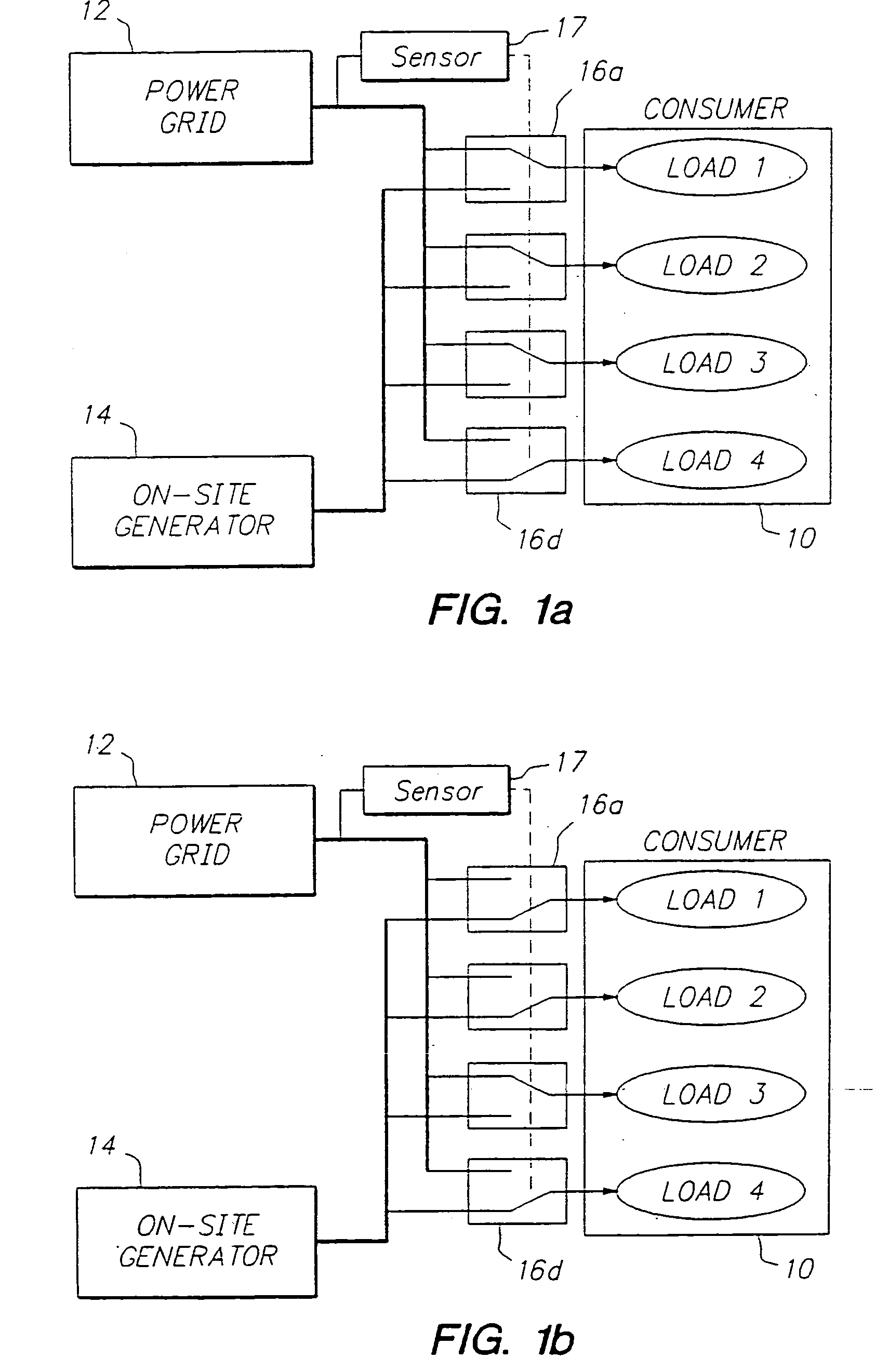

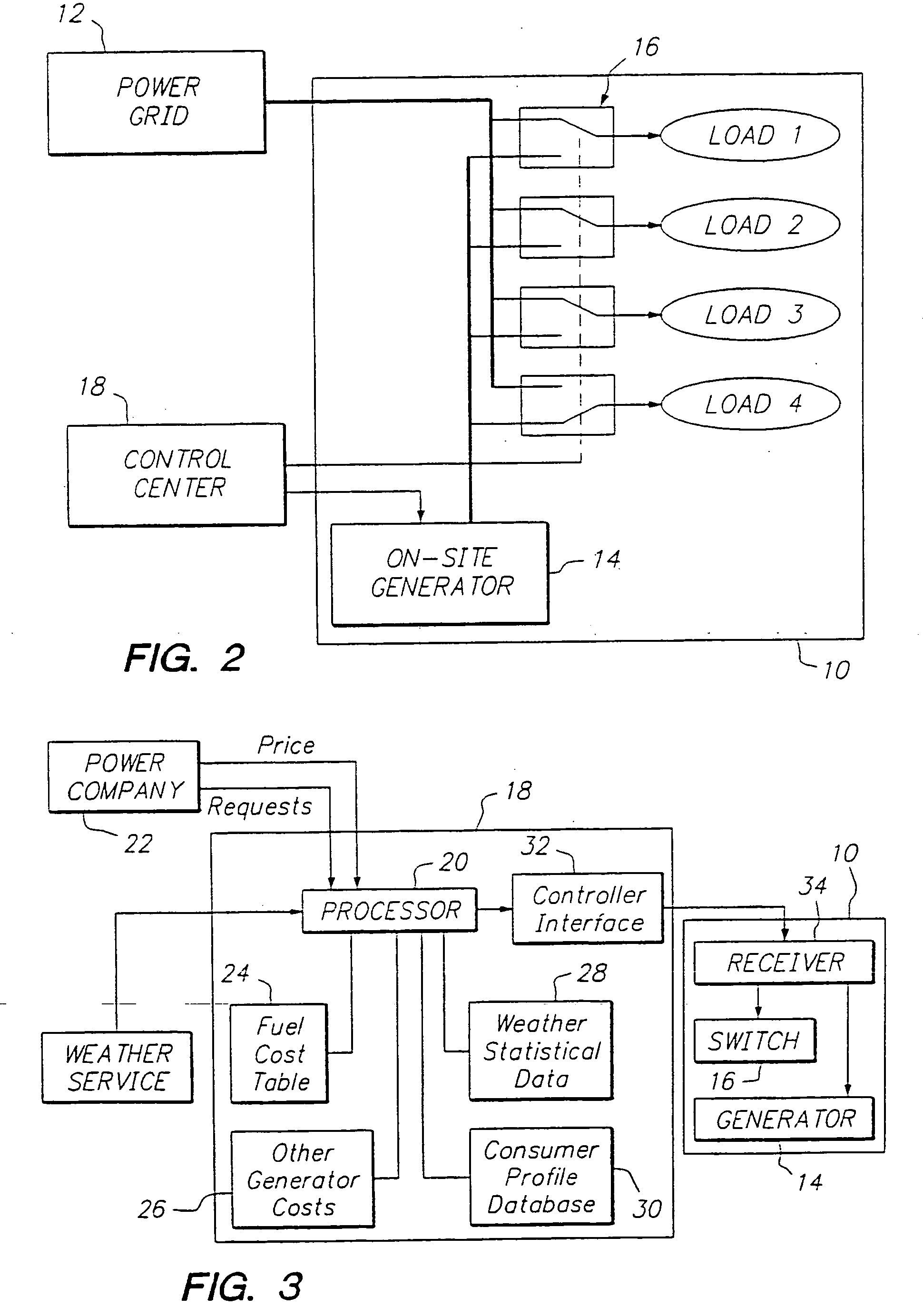

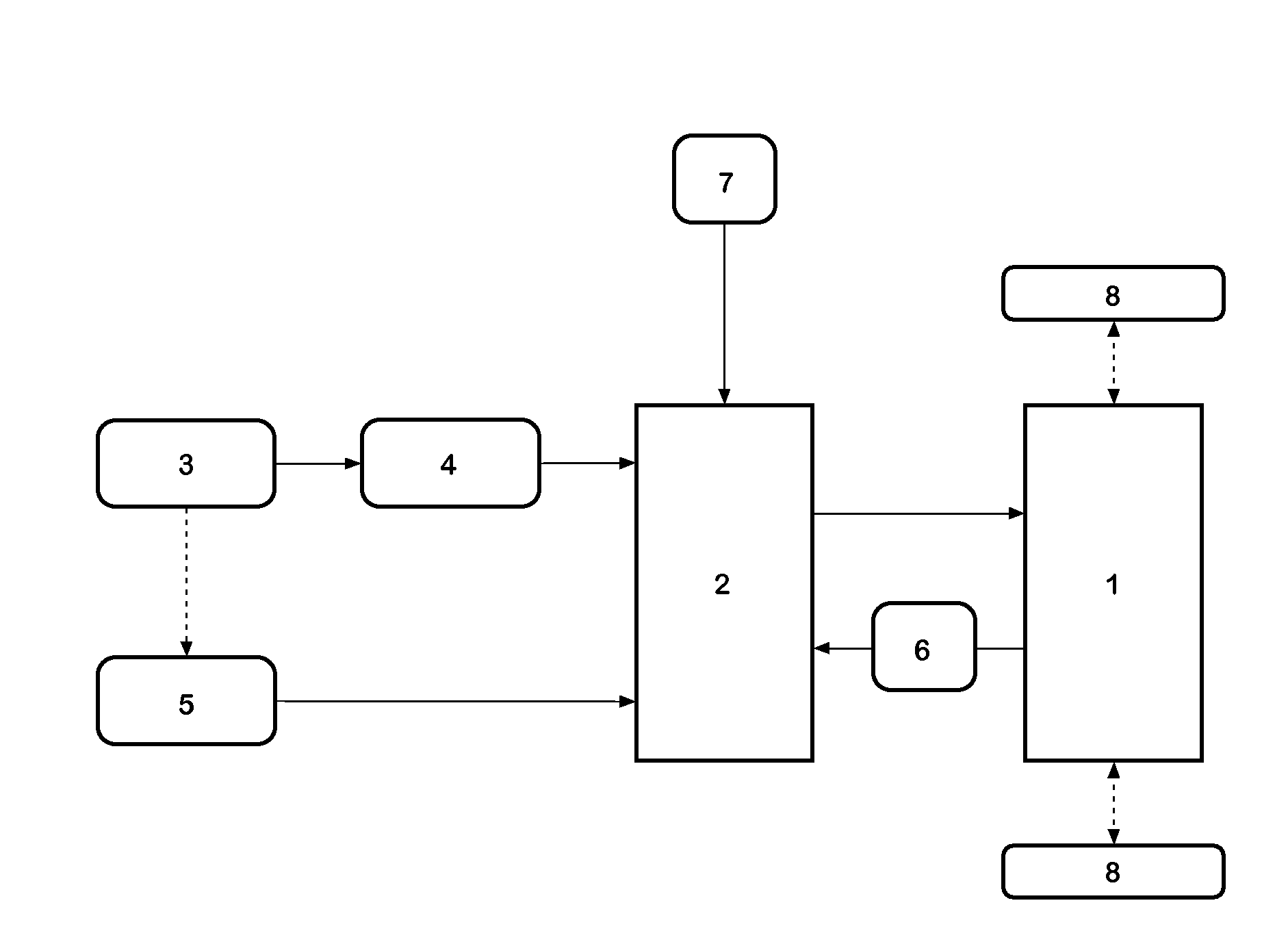

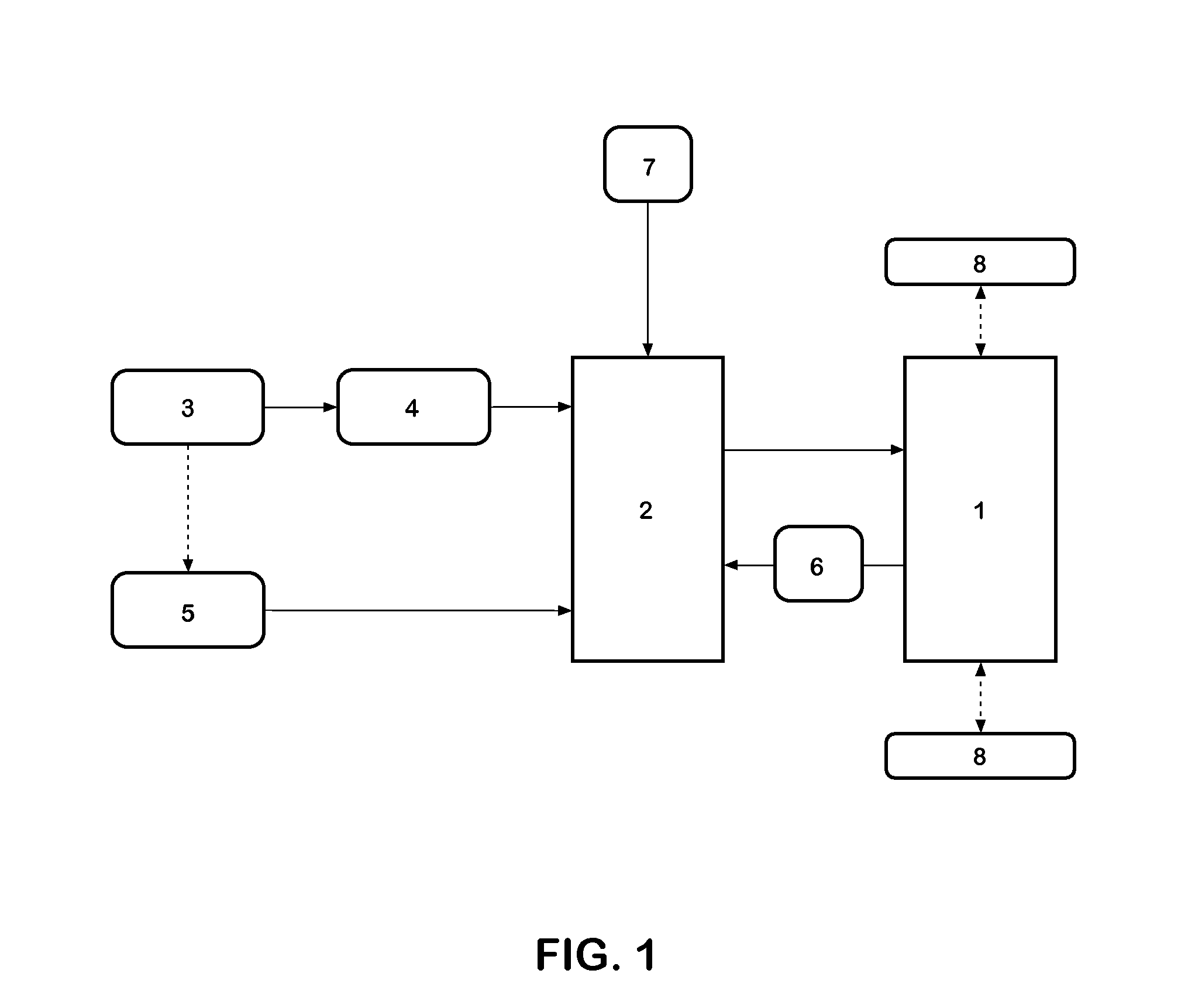

Power distribution/generation system

A power distribution / generation system is disclosed for supplying electrical power to a number of sites (32, 33, 34), one or more of which has a generator (53, 1) such as a Stirling engine (1) which is capable of generating electrical power. The generators (53, 1) are linked together on a local network that is connectable to an external power grid (31). A controller (35) can hold the distribution of power so that a site is supplied with electrical power from the local network if its power demand exceeds the power generated by the generators in that network. However, if the total power demand of all the sites in the network exceeds the total power available from the generators in that network, then the controller (35) causes power to be drawn from the grid (31) instead.

Owner:MICROGEN ENERGY

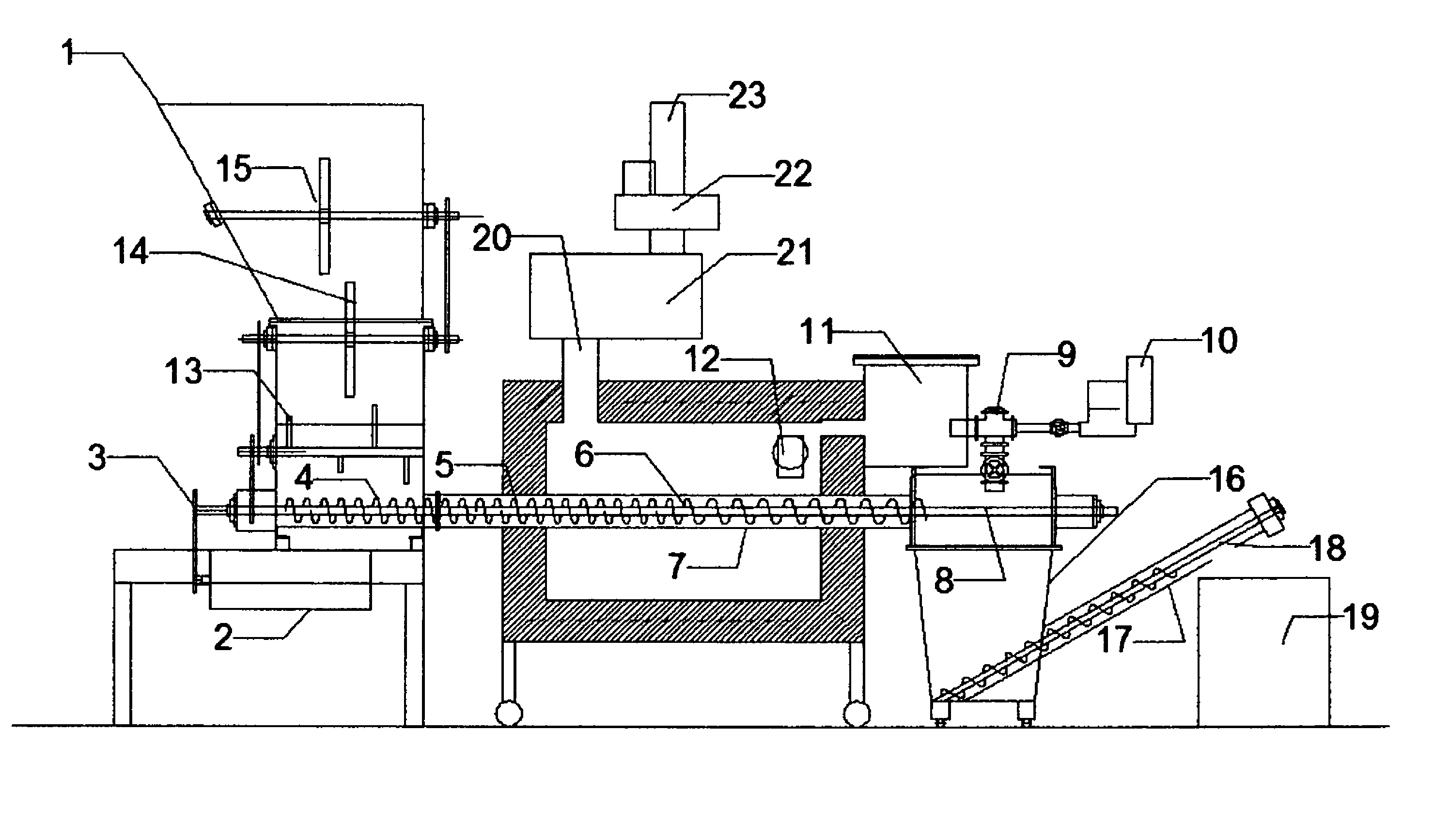

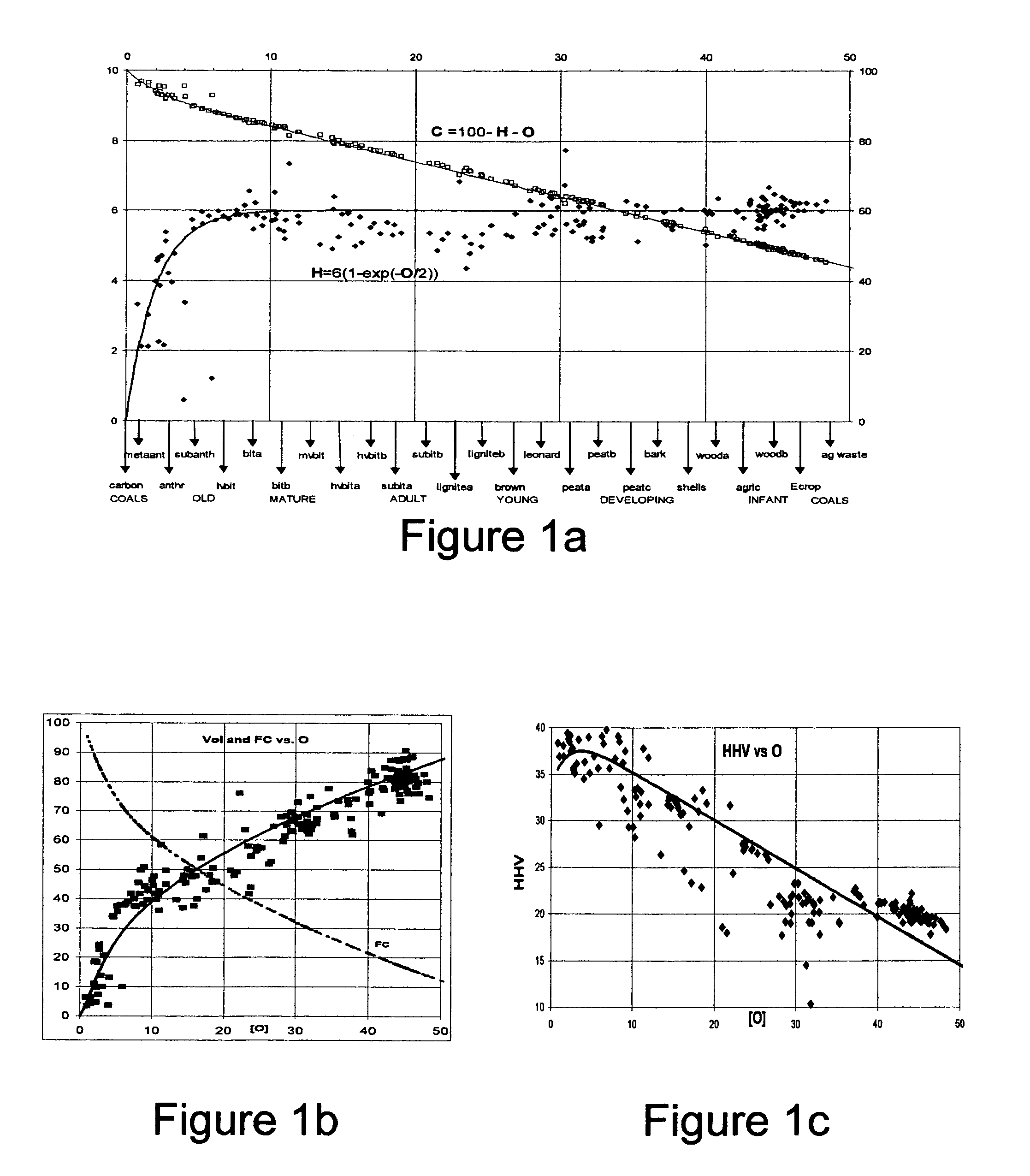

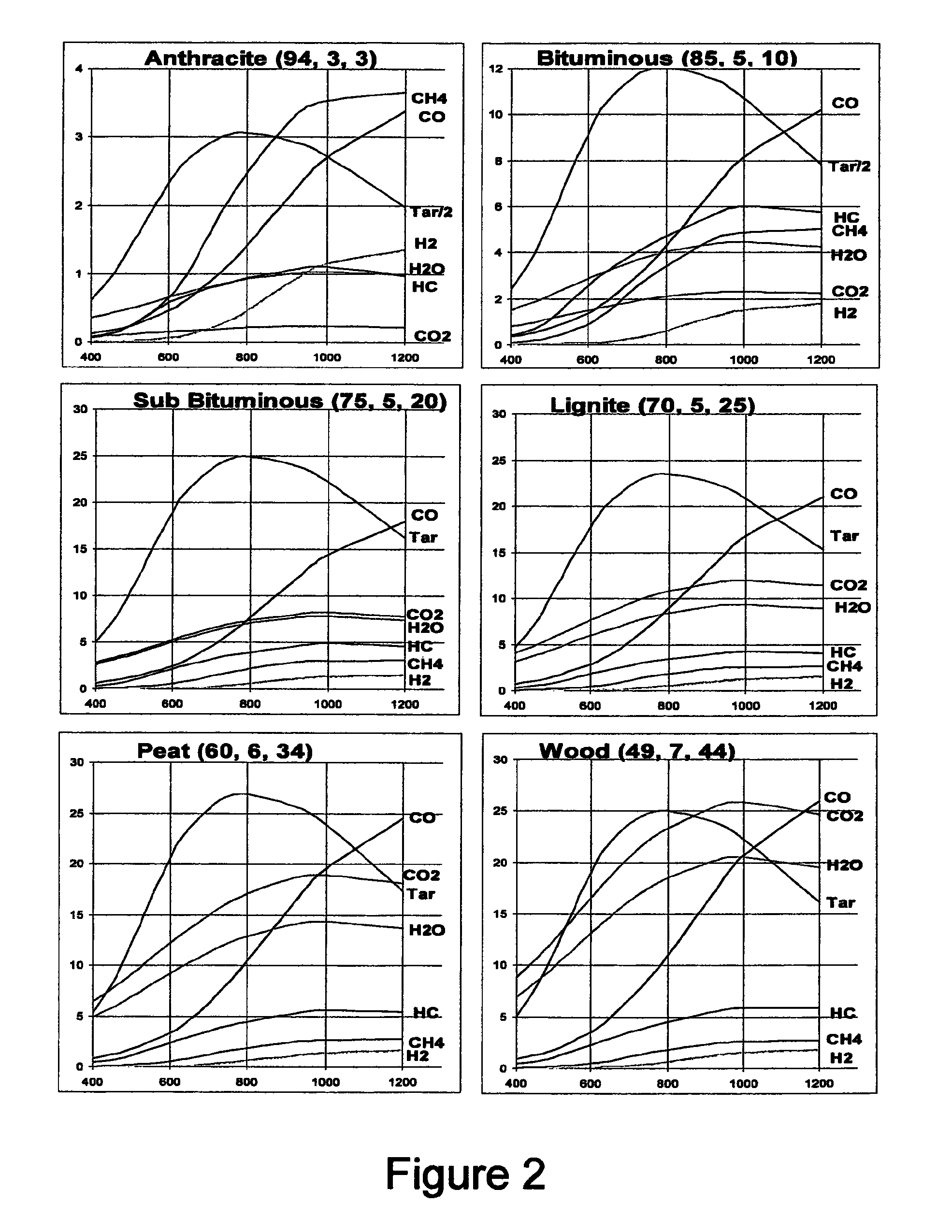

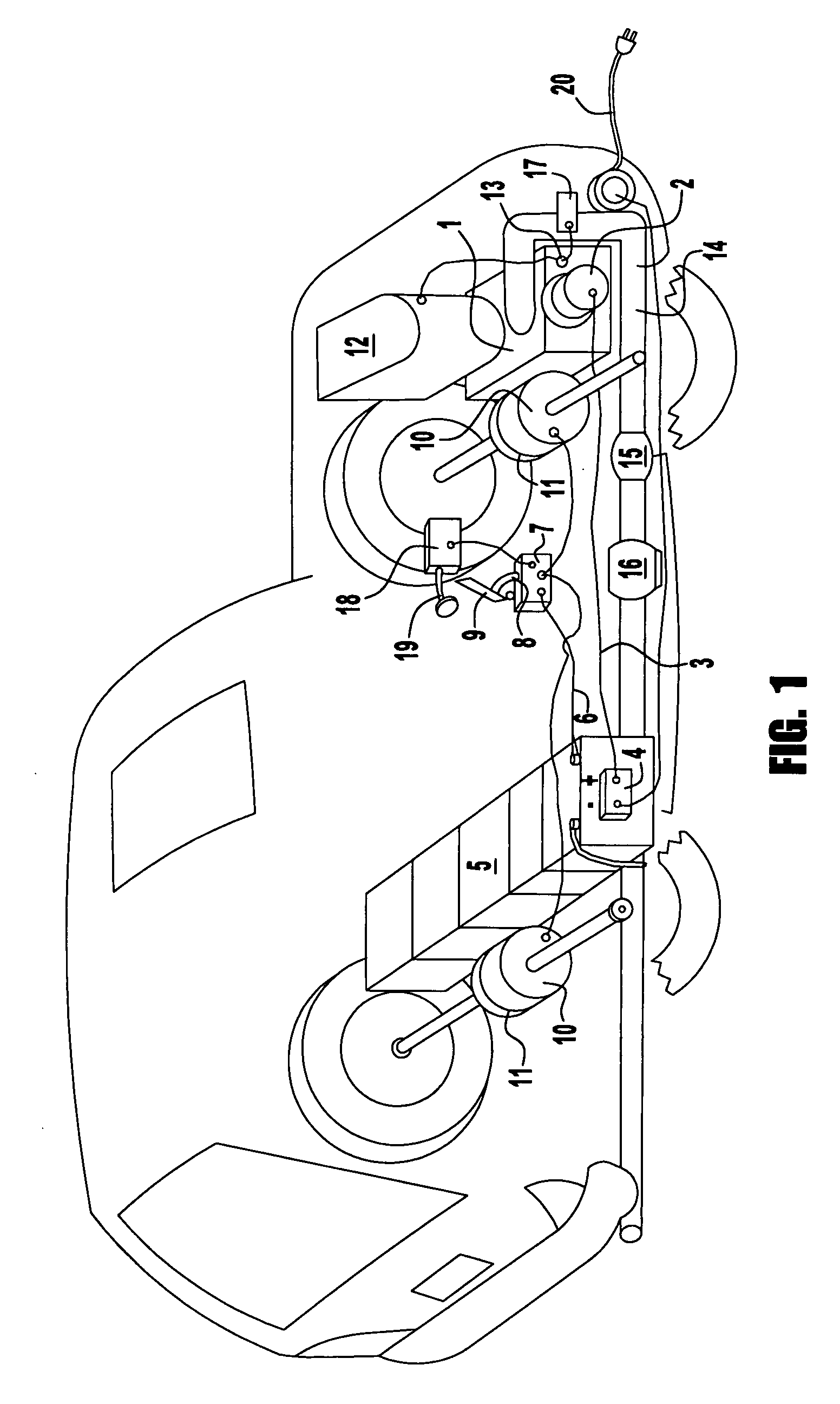

Process and device for the pyrolysis of feedstock

InactiveUS7947155B1Thermal non-catalytic crackingCombustible gas coke oven heatingVolatilesEngineering

This invention involves pyrolysis of feedstock by introducing carbonaceous feedstock, into a hopper and moving it into a reactor tube enclosed in an oven, generating heat within the oven that is in part transferred to the feedstock, heating it to sufficient temperature to pyrolyze the feedstock into useful volatiles and char. A Venturi system produces a negative pressure directing volatiles into a pyro-gas oven producing heat necessary for pyrolysis and generating useful excess heat. The extruded pyrolysis char has uses including charcoal fuel, soil amendments, and activated charcoal while liquids can be produced for processing into fuels. Excess heat may be used to heat water, steam, and air, may be used in air heating and cooling systems, perform mechanical work with a Stirling engine or generate electricity on the order of 100 kW and higher. The system may be operated in a carbon neutral or even carbon negative manner, allowing sequestration of atmospheric carbon dioxide.

Owner:GREEN LIQUID & GAS TECH

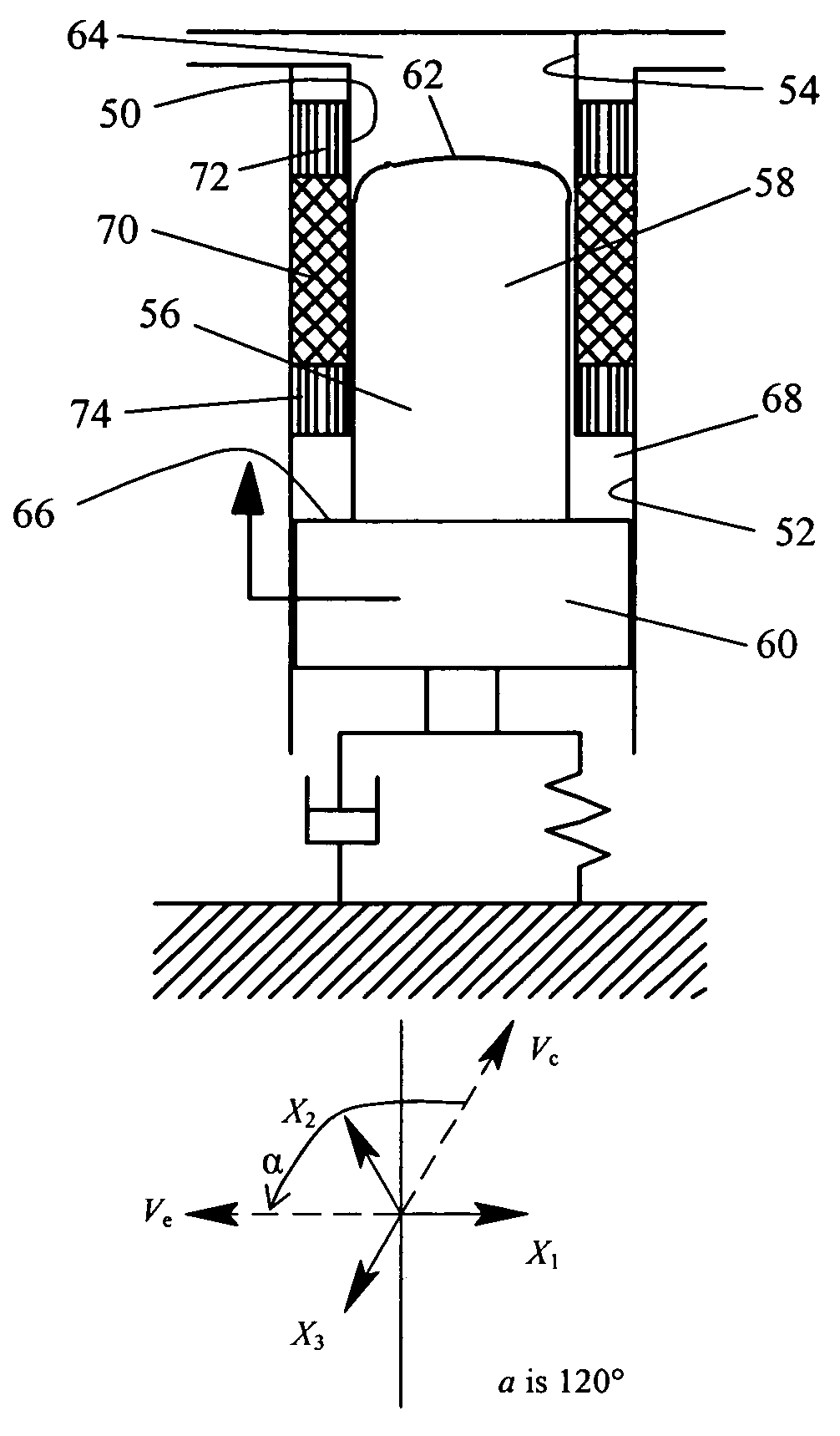

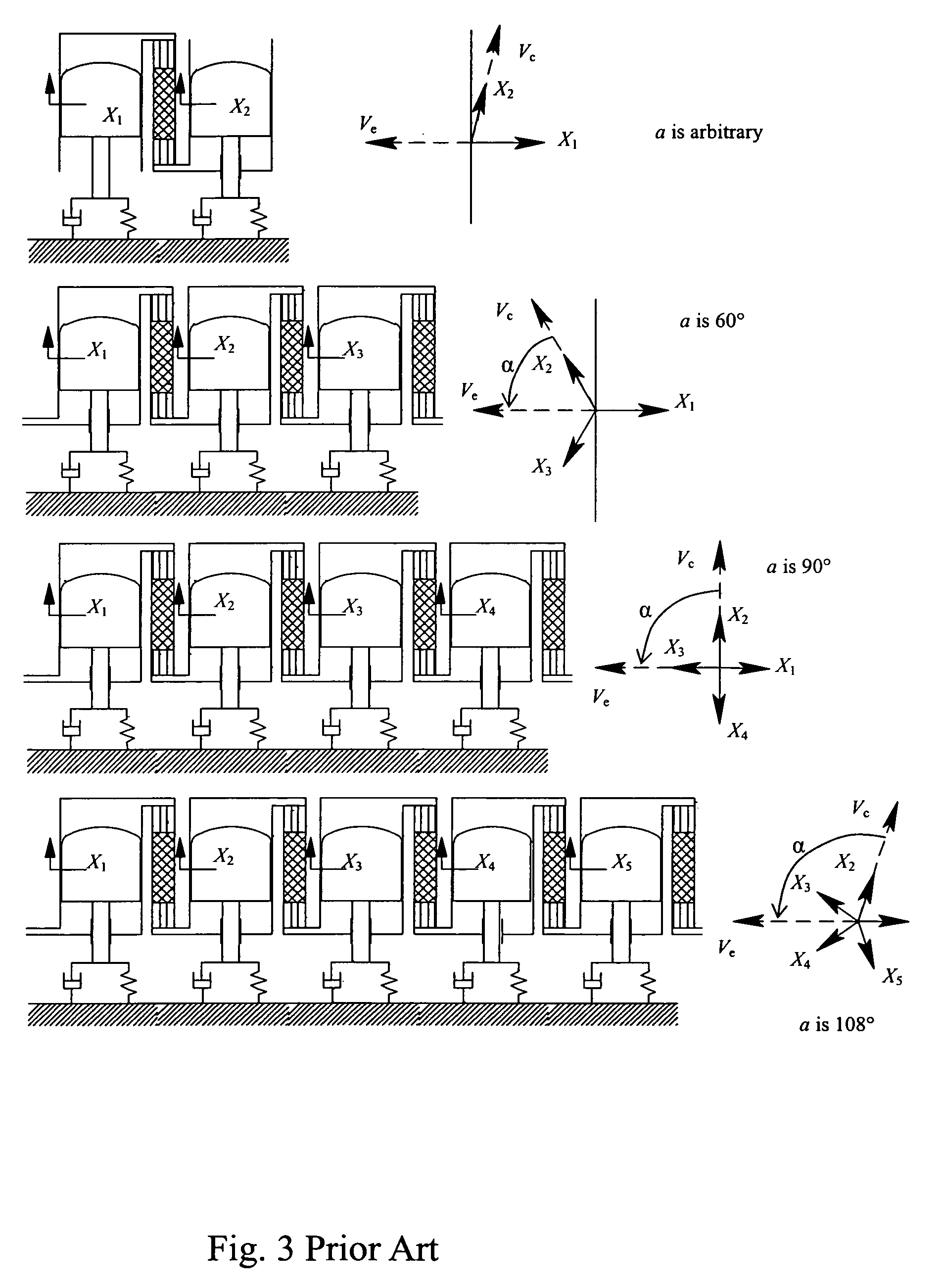

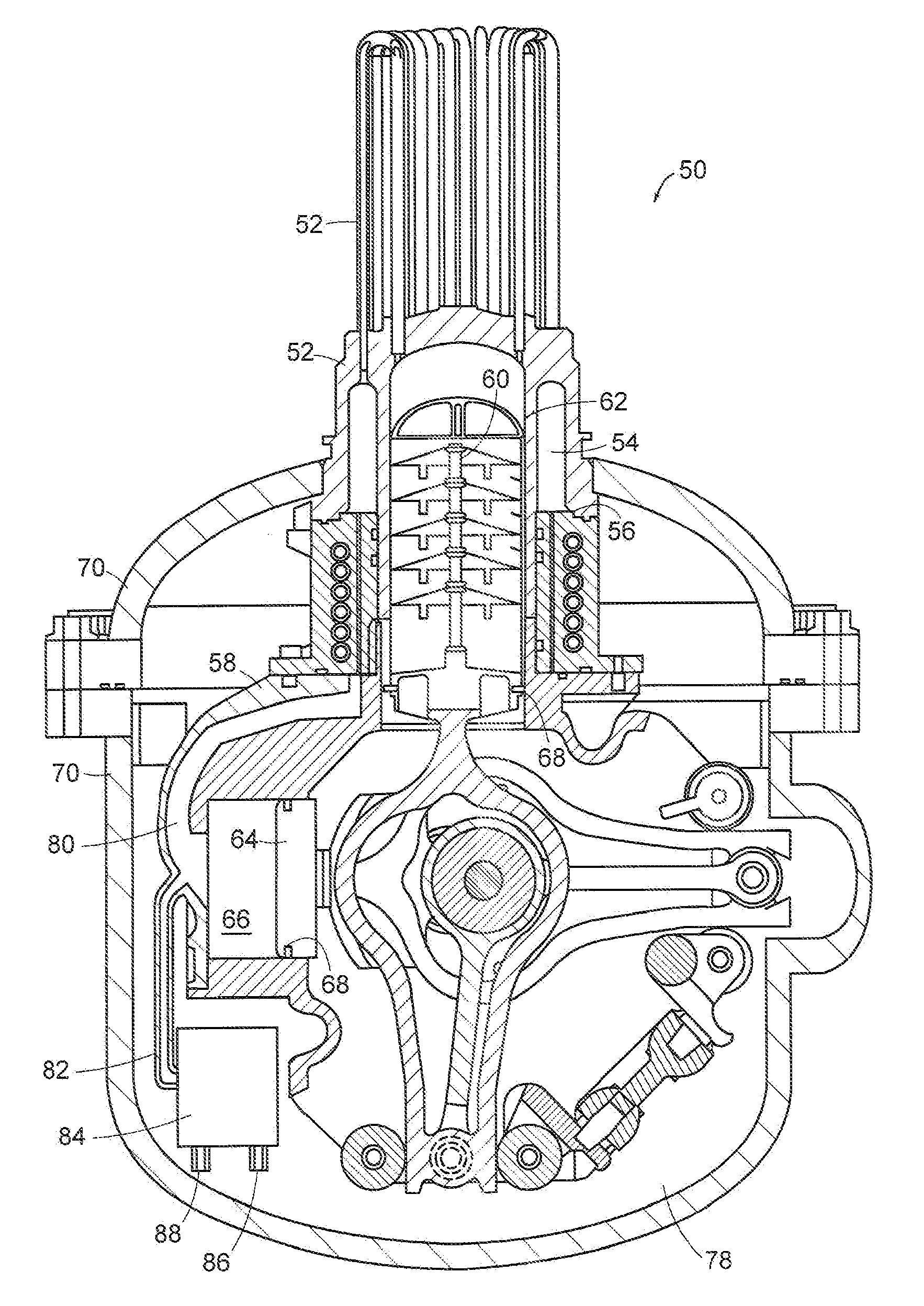

Multiple-cylinder, free-piston, alpha configured stirling engines and heat pumps with stepped pistons

ActiveUS7171811B1Reduce weightReduce in quantityStirling type enginesClosed-cycle gas positive displacement engine plantIsoetes triquetraReciprocating motion

An improved, free-piston, Stirling machine having at least three pistons series connected in an alpha Stirling configuration. Each cylinder is stepped so that it has a relatively larger diameter interior wall and a coaxial, relatively smaller diameter interior wall. Each piston is also stepped so that it has a first component piston having an end face facing in one axial direction and matingly reciprocatable in the smaller diameter cylinder wall and a second component piston having an end face facing in the same axial direction and matingly reciprocatable in the larger diameter, cylinder wall. One of the piston end faces bounds the compression space and the other end face bounds the expansion space. Preferably, each stepped piston has peripheral, cylinder walls that are axially adjacent and joined at a shoulder forming the end face of the larger diameter component piston. Stirling machines with these stepped features are also arranged in various opposed and duplex configurations, including arrangements with only one load or prime mover for each opposed pair of pistons. Improved balancing or vibration reduction is obtained by connecting expansion and compression spaces of a four cylinder in-line arrangement in a 1, 3, 2, 4 series sequence. Three cylinder embodiments provide a highly favorable volume phase angle of 120° and are advantageously physically arranged with three, parallel, longitudinal axes of reciprocation at the apexes of an equilateral triangle.

Owner:GLOBAL COOLING

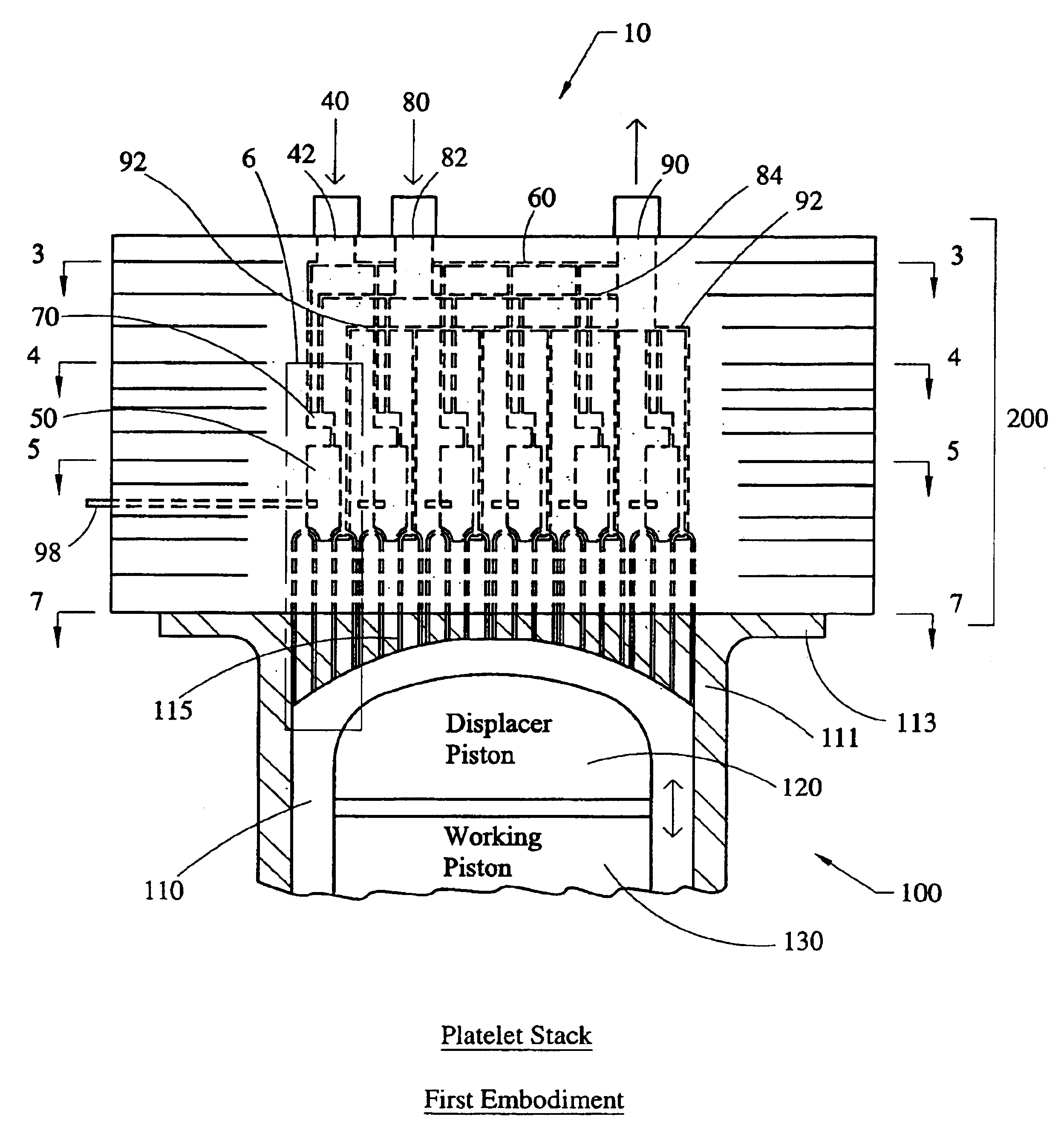

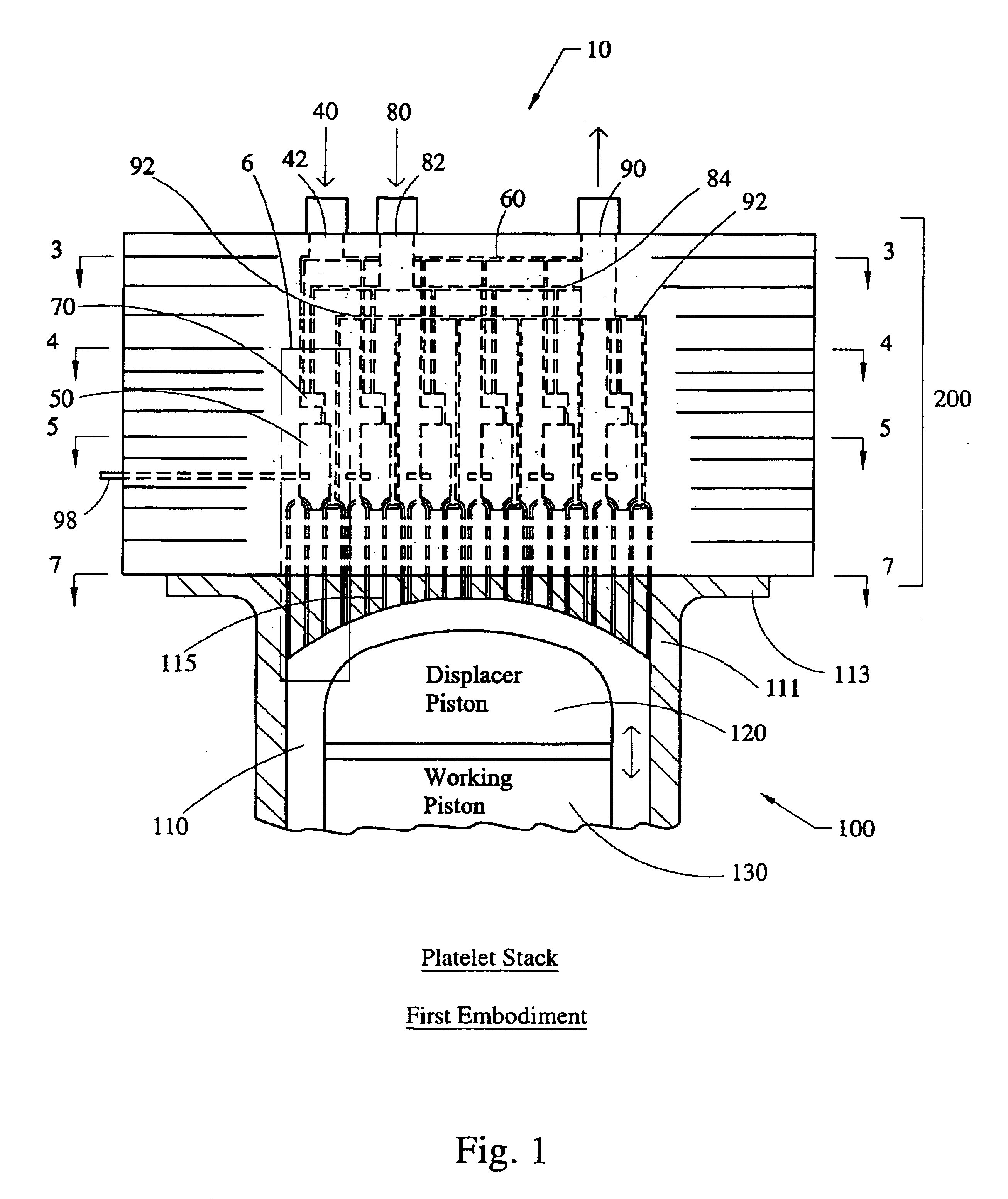

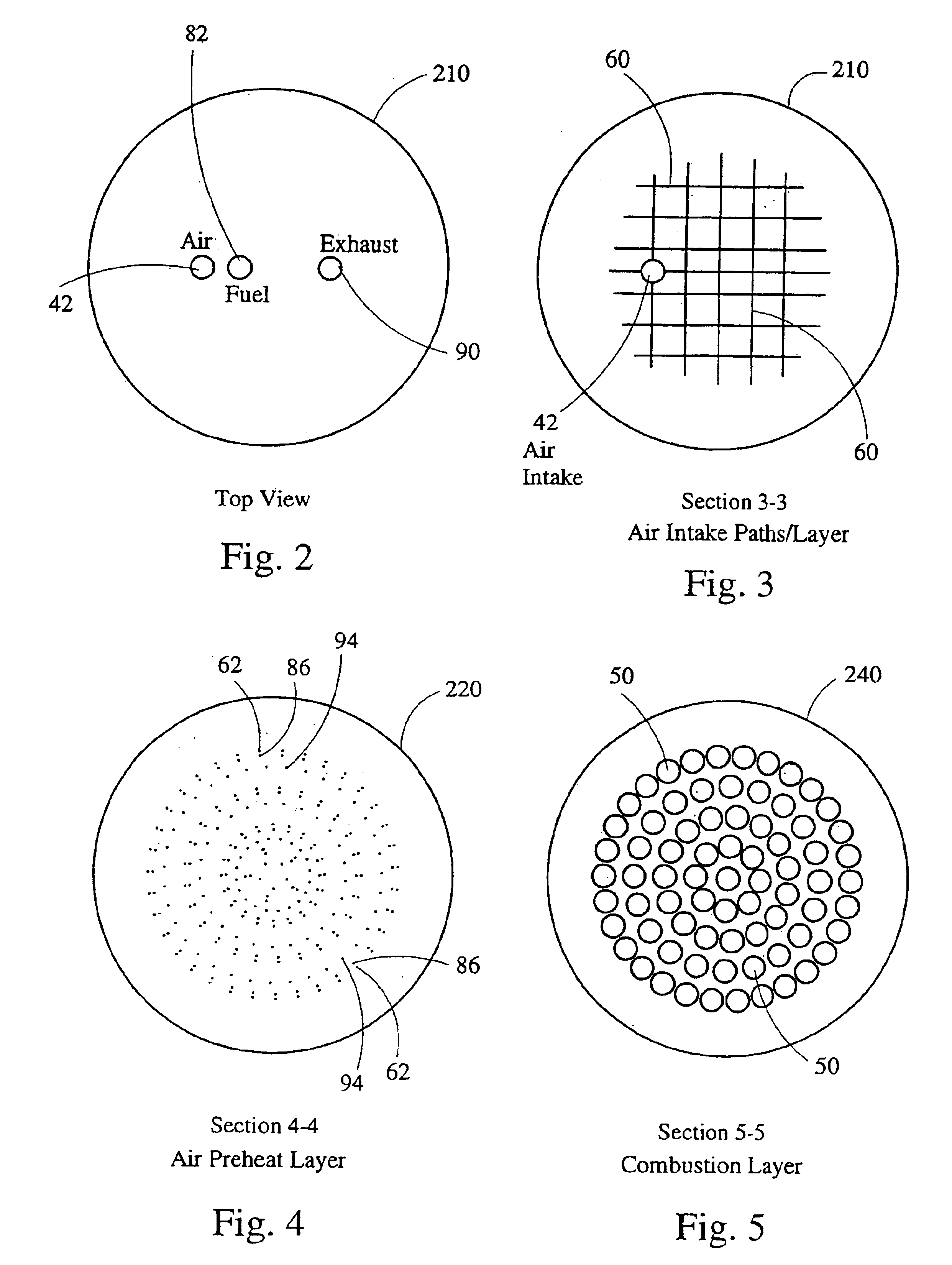

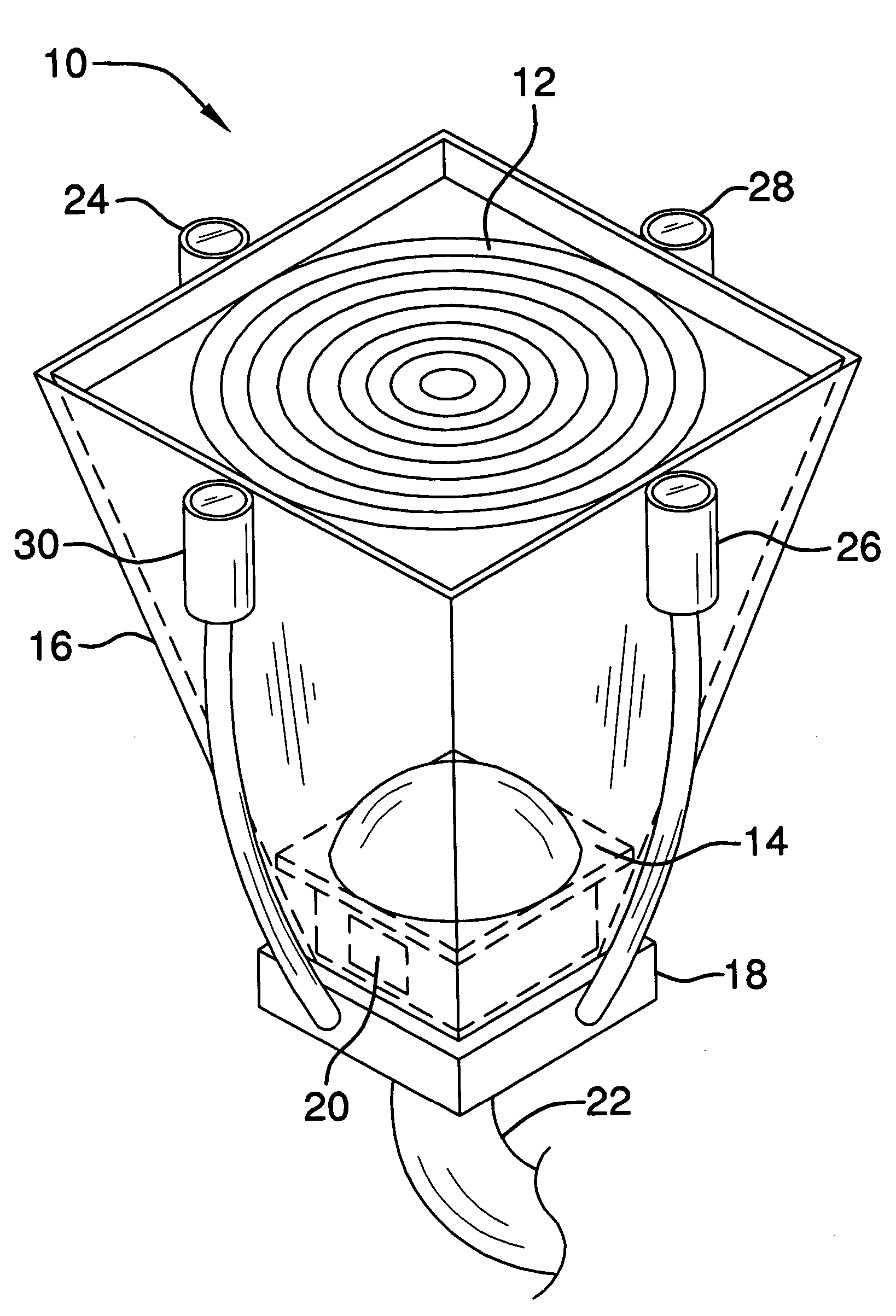

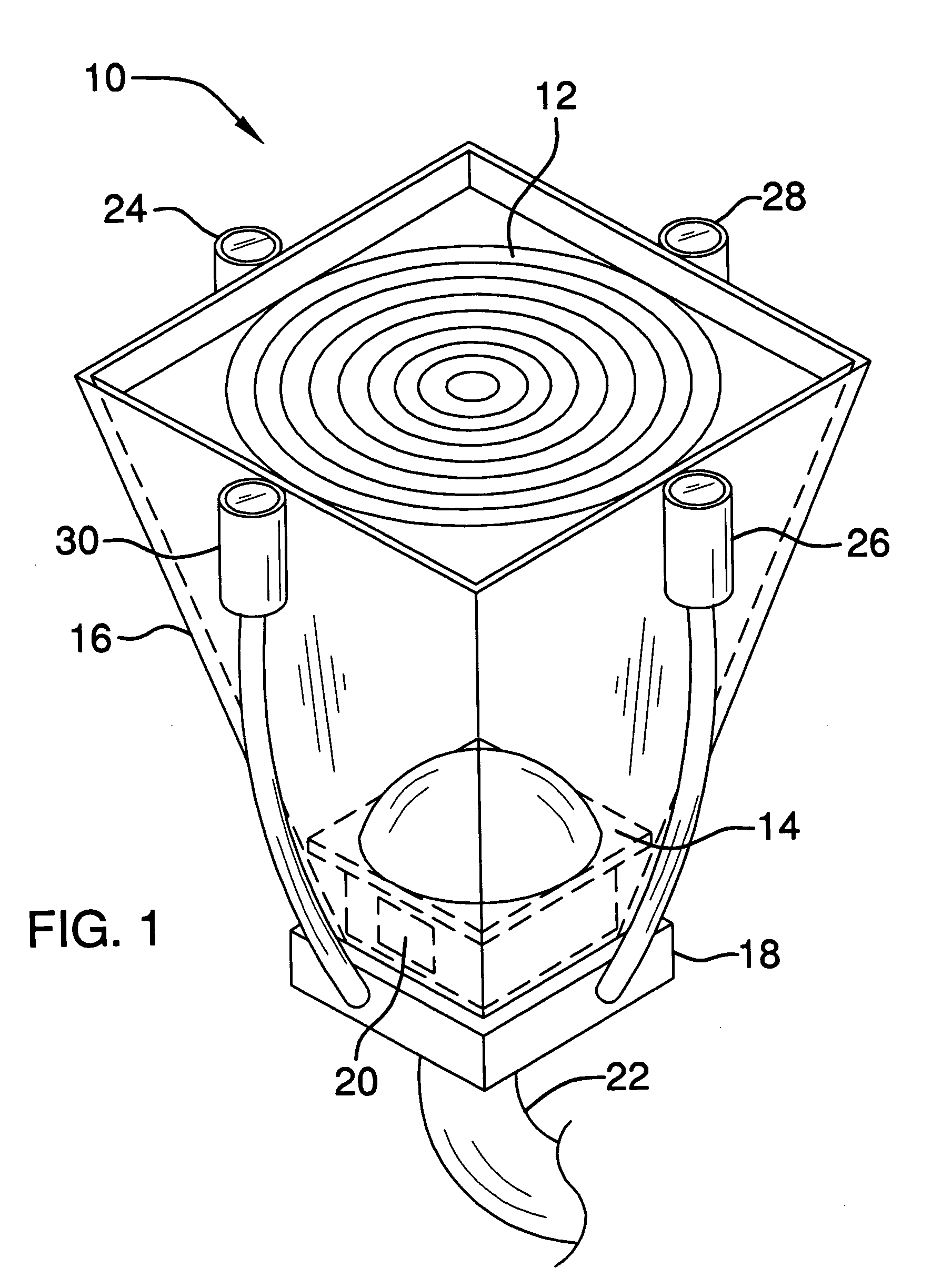

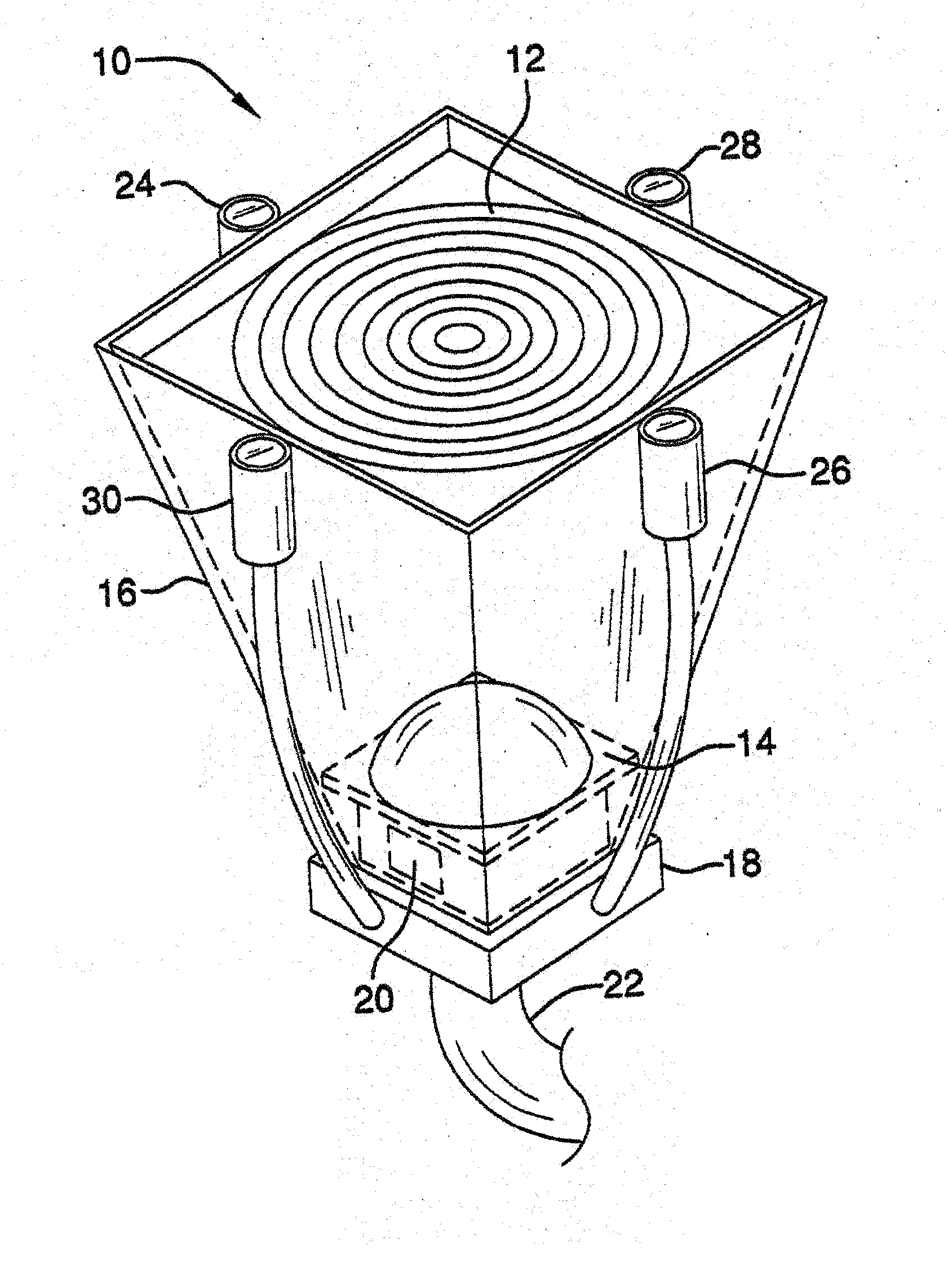

Stirling engine having platelet heat exchanging elements

InactiveUS6931848B2Guaranteed uptimeEfficient heat transferSolar heating energySolar heat devicesEngineeringStaged combustion

The present invention provides heat exchanging elements for use in Stirling engines. According to the present invention, the heat exchanging elements are made from muliple platelets that are stacked and joined together. The use of platelets to make heat exchanging elements permits Stirling engines to run more effiecient because the heat transfer and combustion processes are improved. In one embodiment, multi-stage combustion can be introduced with platlets, along with the flexibility to use different types of fuels. In another embodiment, a single component constructed from platelets can provide the heat transfer rquirements betweeen the combustion gas / working gas, working gas in the regenerator and the working gas / coolant fluid of a Stirling engine. In another embodiment, the platelet heat exchanging element can recieve solar energy to heat the Stirling engine's working gas. Also, this invention provides a heat exchanging method that allows for multiple fluids to flow in opposing or same direction.

Owner:DISENCO +1

Hydrogen Energy Systems

InactiveUS20070039815A1Avoid overall overheatingEfficiently safely easily provideCellsAluminium compoundsPetroleumDiesel engine

A hydrogen energy system comprising galvanic hydrogen generators and hydrogen input manifolds for vehicle engines. The galvanic hydrogen generators generate hydrogen gas, magnesium hydroxide, and heat by the galvanic reaction of magnesium anodes with steel cathodes in salt water. Heat exchangers channel excess heat to a heat sink such as a thermocouple, Stirling engine, hot water system, etc. The hydrogen input manifold is bolted between the engine block and the air intake manifold of a gasoline or diesel engine. Hydrogen gas is injected into the hydrogen input manifold to provide supplementary fuel to the engine, lowering the amount of petroleum that is used.

Owner:BARTEL BRIAN G

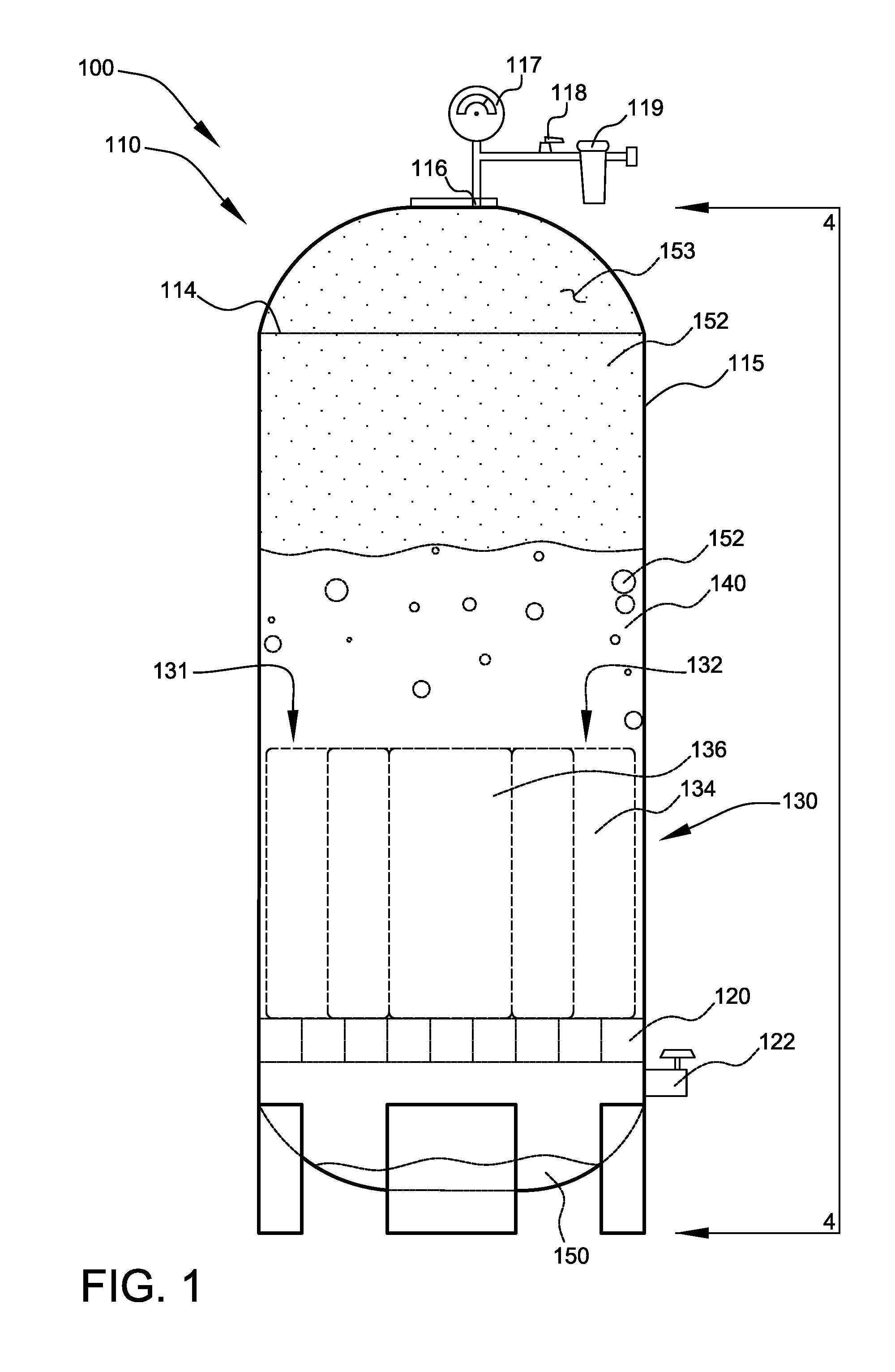

Thermal energy storage device

A thermal energy storage (“TES”) device including a vessel housing a continuous volume of a TES media, an input portion, an output portion, and a plurality of thermal energy transport members connected to the input portion and / or the output portion. The input portion receives thermal energy from a thermal energy source. The received thermal energy is transported by one or more of the thermal energy transport members to the output portion and / or the TES media for storage. One or more of the thermal energy transport members connected to the output portion transport stored thermal energy from the TES media to the output portion. The output portion is coupled to an external device, such as a Stirling engine, and configured to transfer thermal energy the external device. Optionally, selected ones of the thermal energy transport members connected to both the input and output portions may be insulated from the TES media.

Owner:RICOR GENERATION

Electronic controller matching engine power to alternator power and maintaining engine frequency for a free-piston stirling engine driving a linear alternator

InactiveUS20080122408A1AC motor controlConversion with intermediate conversion to dcStirling engineElectric generator

A feedback control method and circuit for inclusion in a control system of an electrical power generating source that comprises a free piston Stirling engine driving a linear alternator. An instantaneous value of a variable, Vinternal, is continuously derived from other sensed and computed parameters and used in a negative feedback control loop of the control system to control engine piston stroke in order to maintain the power produced by the engine equal to the power transferred from the engine to the alternator. Vinternal is the sum of the voltage induced on the alternator winding and the voltage across the equivalent circuit lumped resistance of the alternator winding.A switching mode rectifier connects the alternator winding to an energy storage capacitor or battery. A negative feedback, alternator current control loop has an output connected to the pulse width modulator of the switching mode rectifier and has a feedback circuit comprising a current sensor for sensing instantaneous alternator current. A negative feedback, Vinternal control loop has a feedback circuit including a piston position or velocity sensor connected to a computing circuit that the current sensor is also connected to. The computing circuit computes a signal representing Vinternal for use as the feedback signal of the Vinternal control loop. The output of the Vinternal control loop is connected as the command input to the current feedback control loop.

Owner:SUNPOWER

Coil tube heat exchanger for a tankless hot water system

A novel water heat exchanger with a helix coil incorporated into a stainless steel elongated variable diameter cylindrical housing. A buffer tank is incorporated within the lumen of the helix coil. In one embodiment, the heat exchanger utilizes a radial direct-firing burner and a blower-driven hot flue gas to heat water for domestic and commercial use. In one embodiment, at least a rope seal is disposed between adjacent coil loops of a portion of the helix coil for enhancing heat transfer to the helix coil. In one embodiment, solar and electric heating systems are combined with the helix coil heat exchanger and disposed within the buffer tank to provide supplemental heating. In another embodiment, the heat exchanger further comprises a Stirling engine comprised of a free piston having hot and cold ends that is disposed within the cavity taken up the buffer tank, wherein the hot end receives heat from the burner and the cold end is cooled by the incoming cold water line to form an electric power generator.

Owner:INTELLIHOT

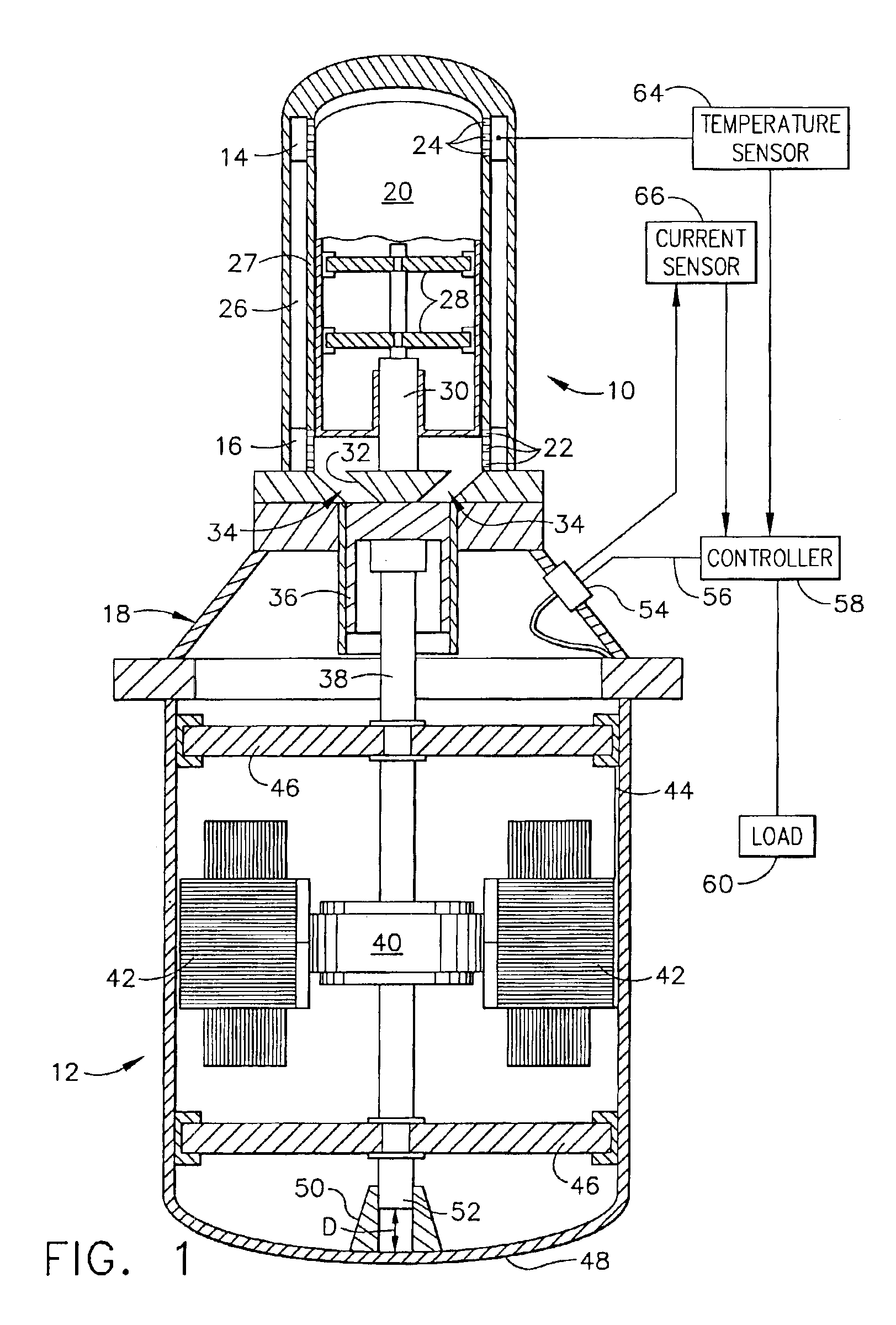

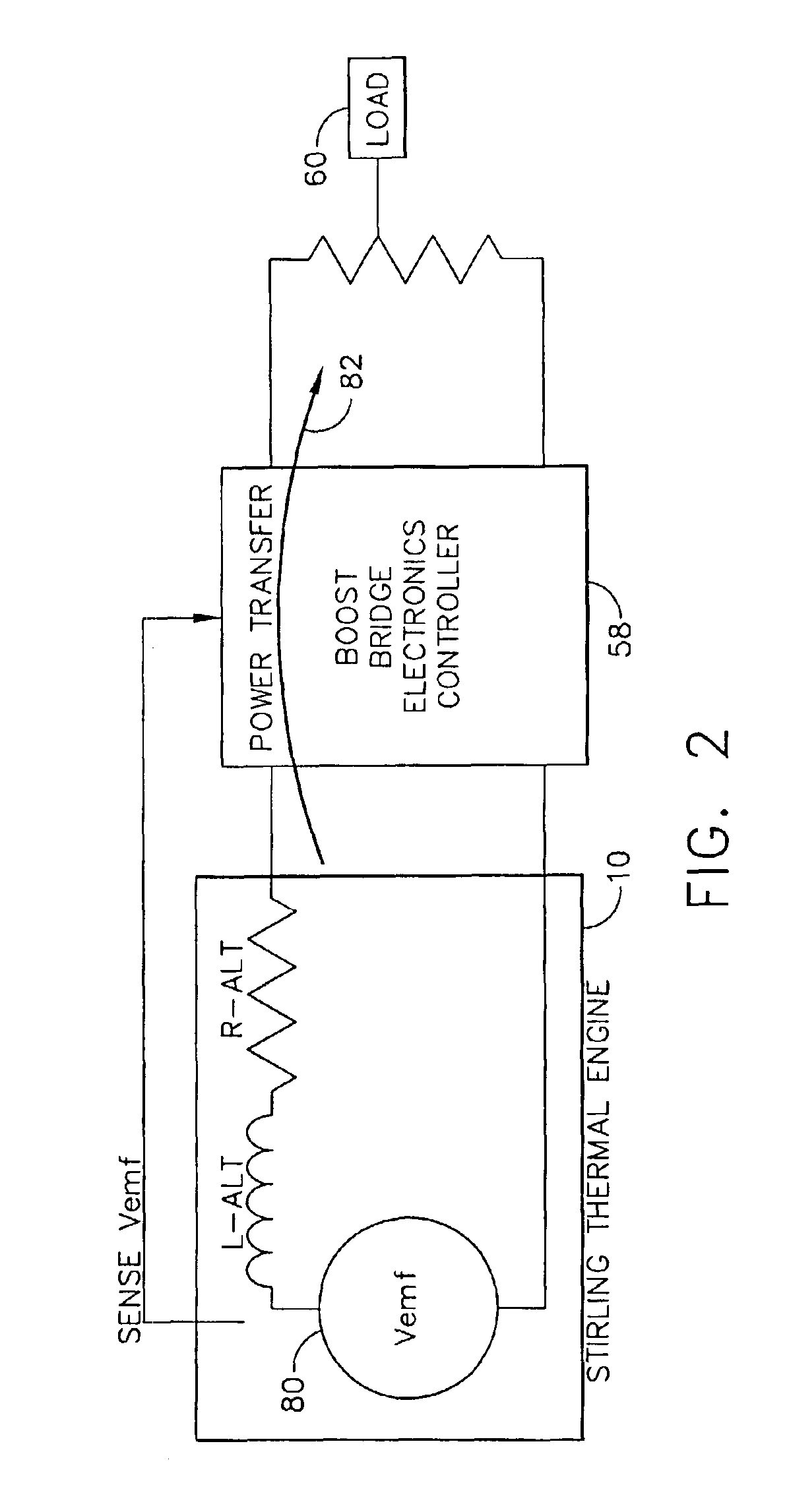

Thermal cycle engine boost bridge power interface

InactiveUS6871495B2Good power deliveryLarge power factorAC motor controlClosed-cycle gas positive displacement engine plantCurrent loadAlternator

A system and method for controlling a thermal dynamic cycle engine, such as a Stirling engine. The system includes a controller able to execute a program to alter certain aspects of the system to provide for a maximum power transfer and substantially stall free start up of the thermal dynamic cycle engine. Generally the controller is able to alter the current load to achieve a selected stroke length, pattern or temperature of a heater head of the engine. The system allows for generally stall free start-up and continuous control for maximum power (with maximum power factor) transfer from the thermal cycle engine or the associated alternator.

Owner:THE BOEING CO

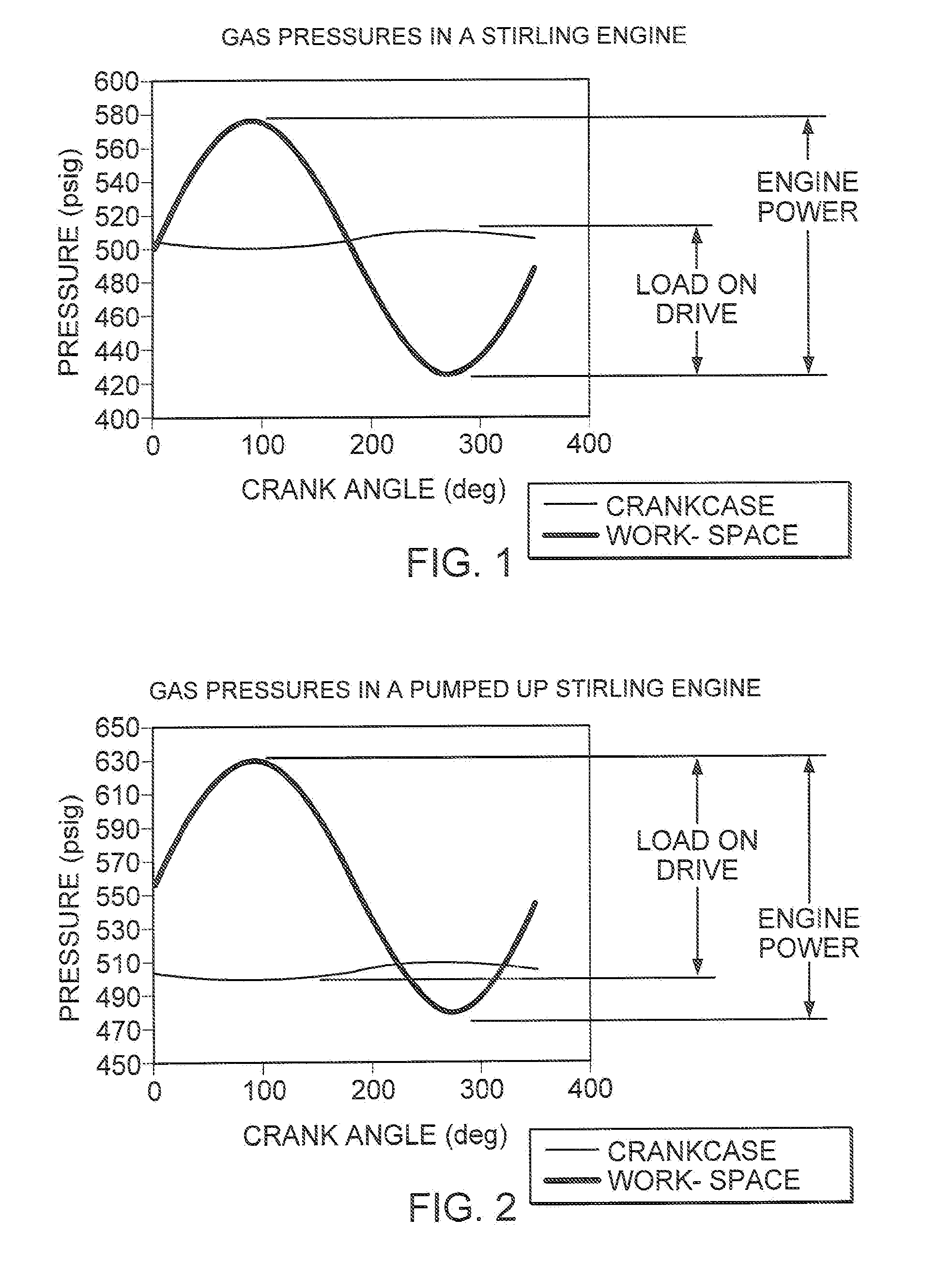

Work-space pressure regulator

ActiveUS7310945B2Reduces mean pressure differenceReduce differential pressurePump controlPositive-displacement liquid enginesEngineeringCrankcase

Owner:NEW POWER CONCEPTS

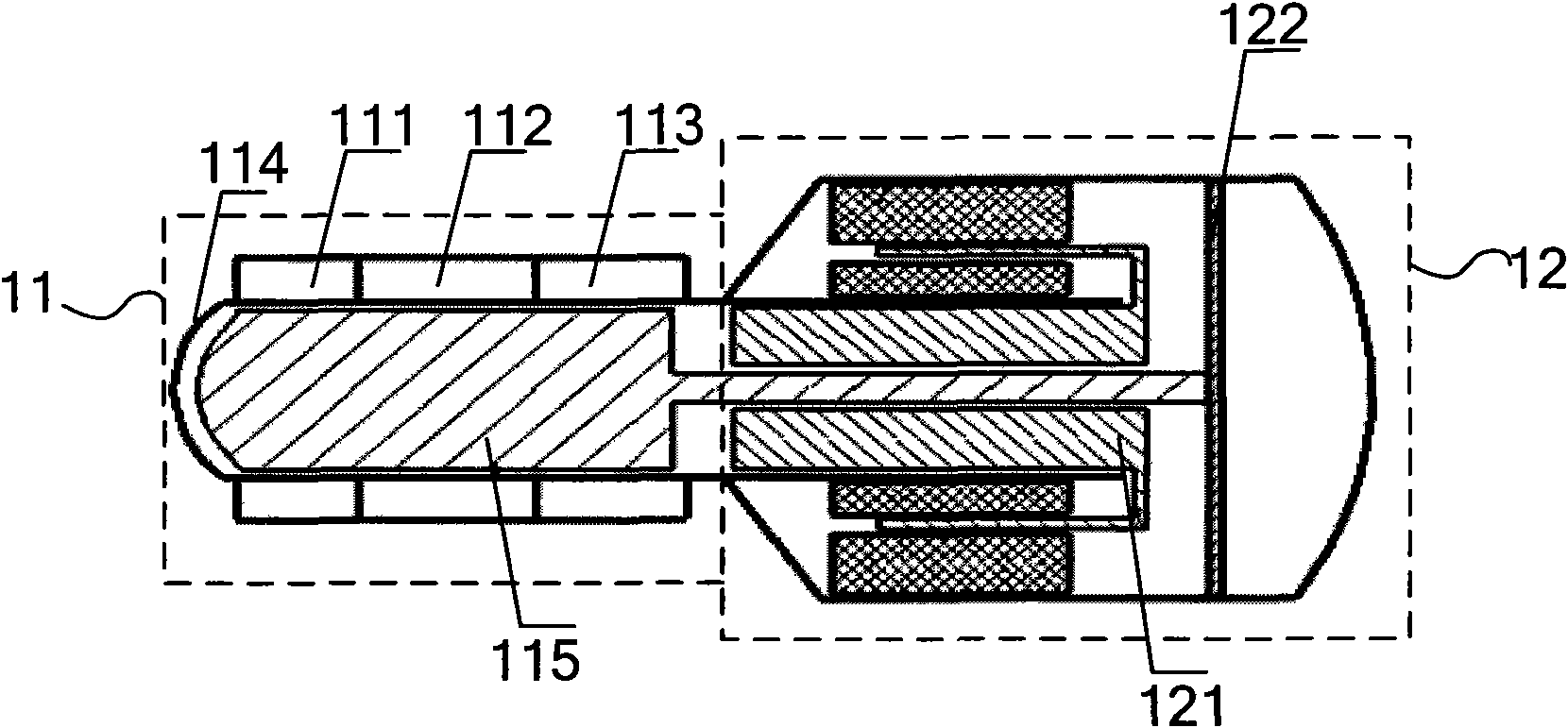

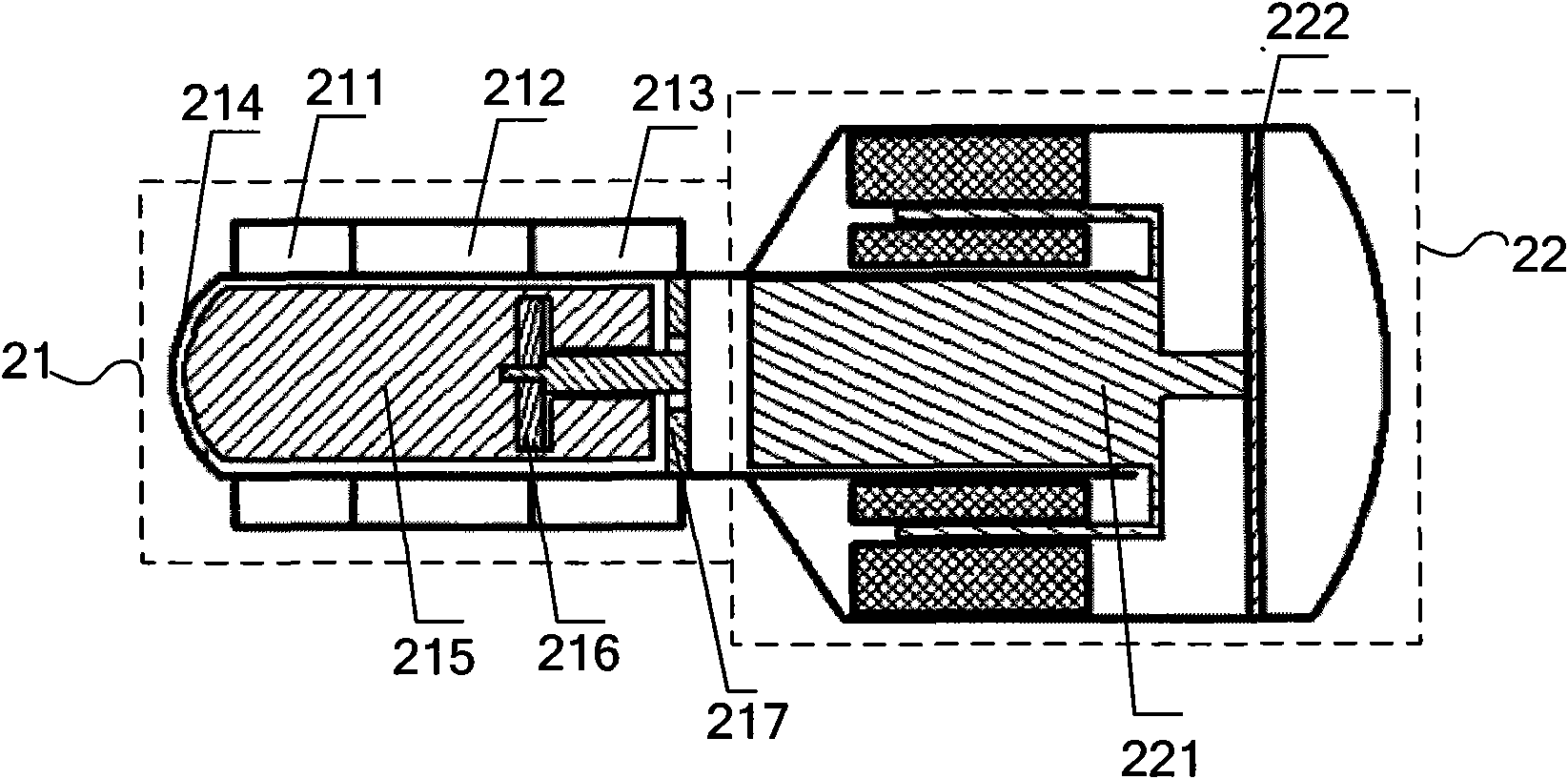

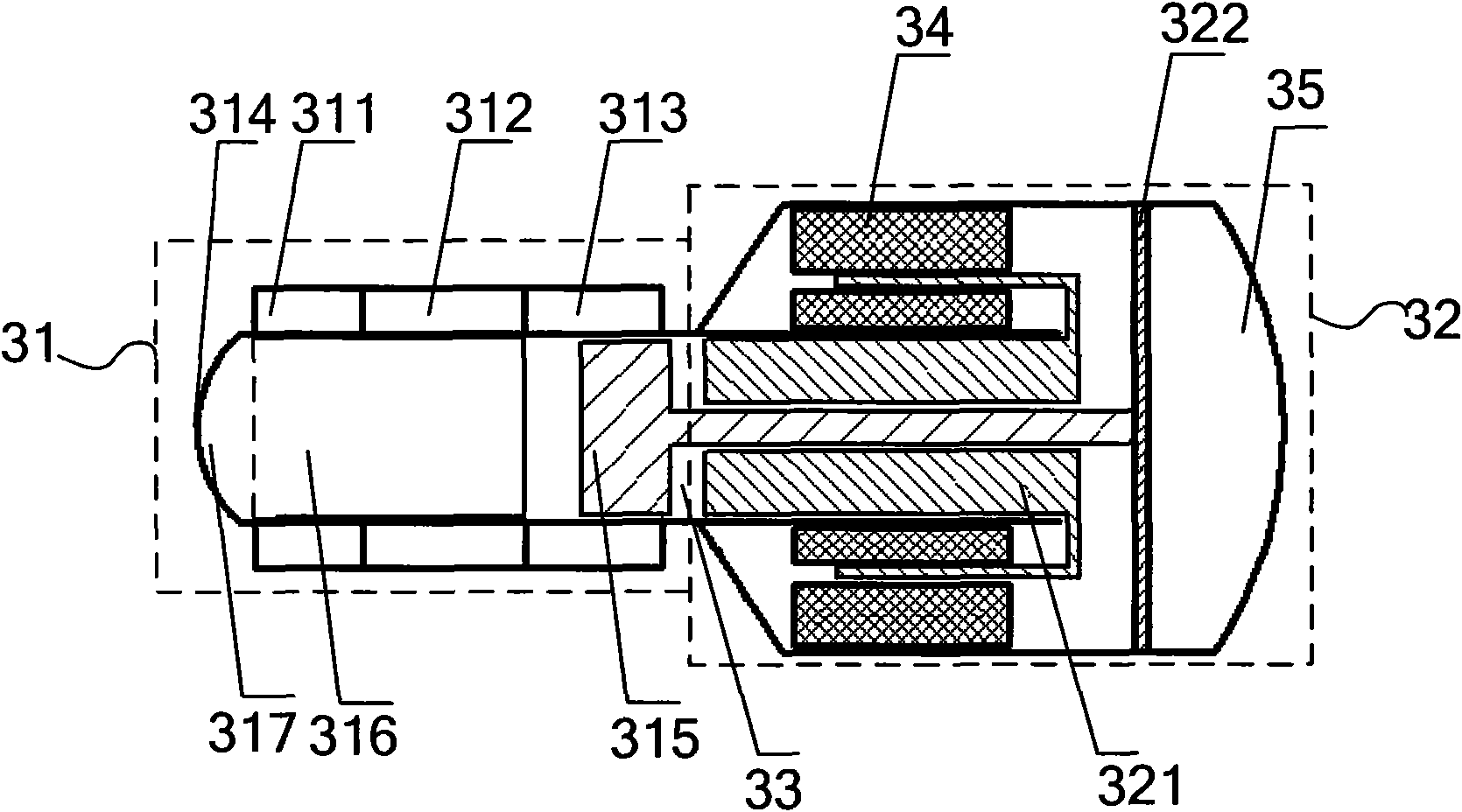

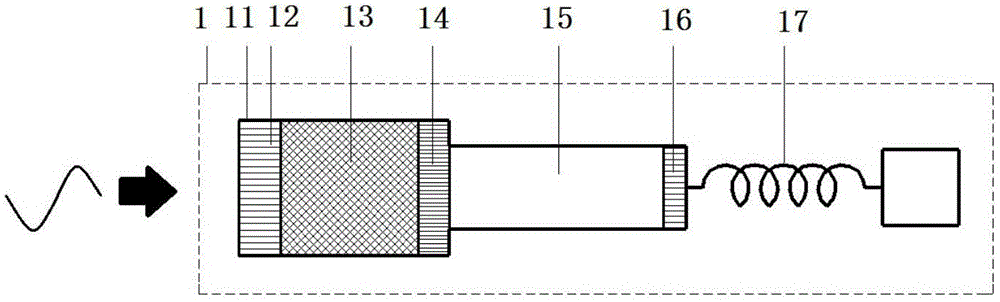

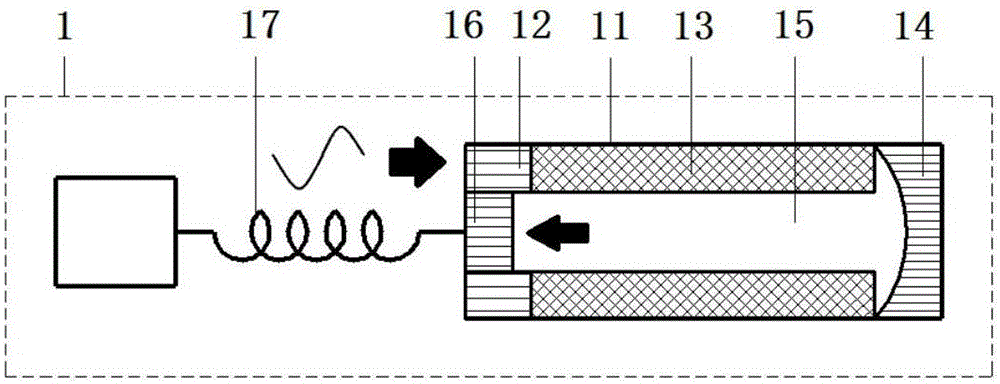

Piston-free Stirling engine system

InactiveCN101619687AReduce machining accuracyReduce assembly accuracyHot gas positive displacement engine plantsRoom temperatureEngineering

The invention discloses a piston-free Stirling engine system comprising a power driving device and a power transmission device, wherein the power driving device comprises an air cylinder and a thermoacoustic converter, and the thermoacoustic converter comprises a high-temperature end heat exchanger, a heat accumulator and a first room-temperature end heat exchanger; the power transmission device comprises an active piston and a first elastic piece far away from one end of the power driving device; the power driving device also comprises a heat buffer tube and an ejector which are sequentially arranged in the air cylinder, wherein the heat buffer tube is positioned on a position corresponding to the high-temperature end heat exchanger which is wrapped on the outer wall of the air cylinder and the heat accumulator; and the ejector is positioned on a position corresponding to the first room-temperature end heat exchanger which is wrapped on the outer wall of the air cylinder in the air cylinder. The invention replaces a part of the ejector, which is higher than a room-temperature end, with the heat buffer tube so that the ejector works in a room-temperature state, thereby enhancing the processing and assembling precision of the ejector and effectively prolonging the service life of the ejector.

Owner:LIHAN THERMOACOUSTIC TECH SHENZHEN

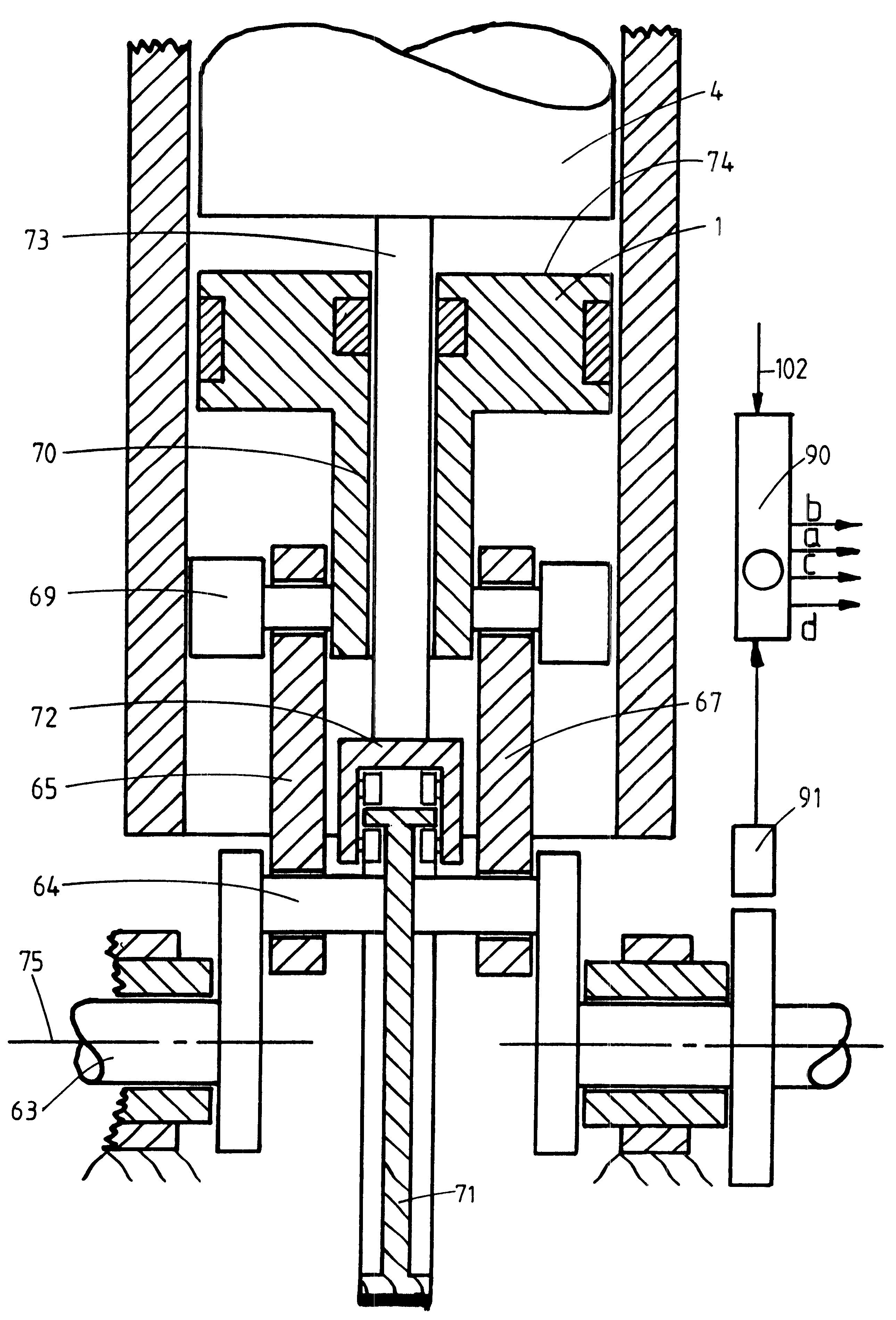

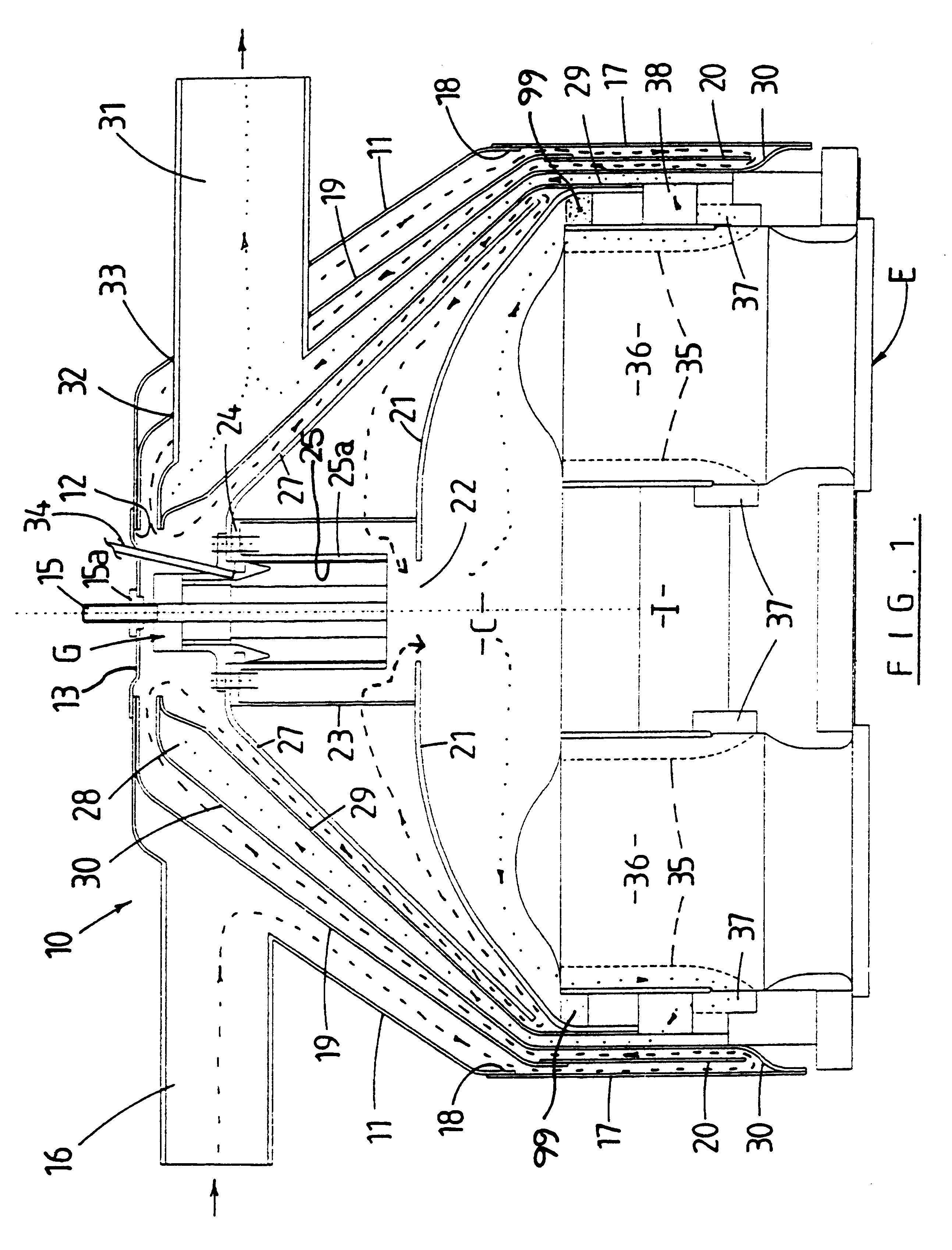

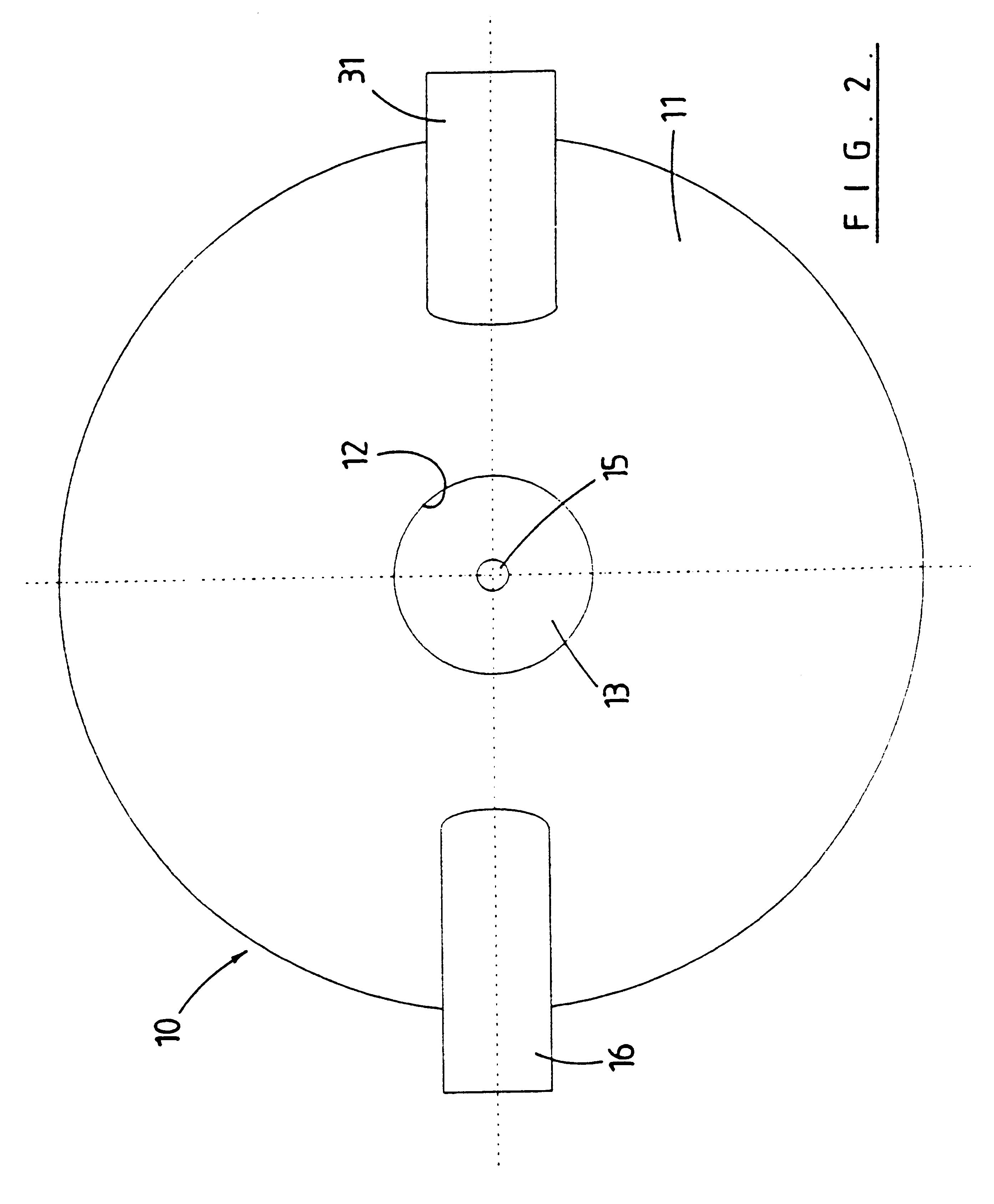

Stirling engine

InactiveUS6910331B2Increase freedomImprove applicabilityStirling type enginesEngine componentsEngineeringActuator

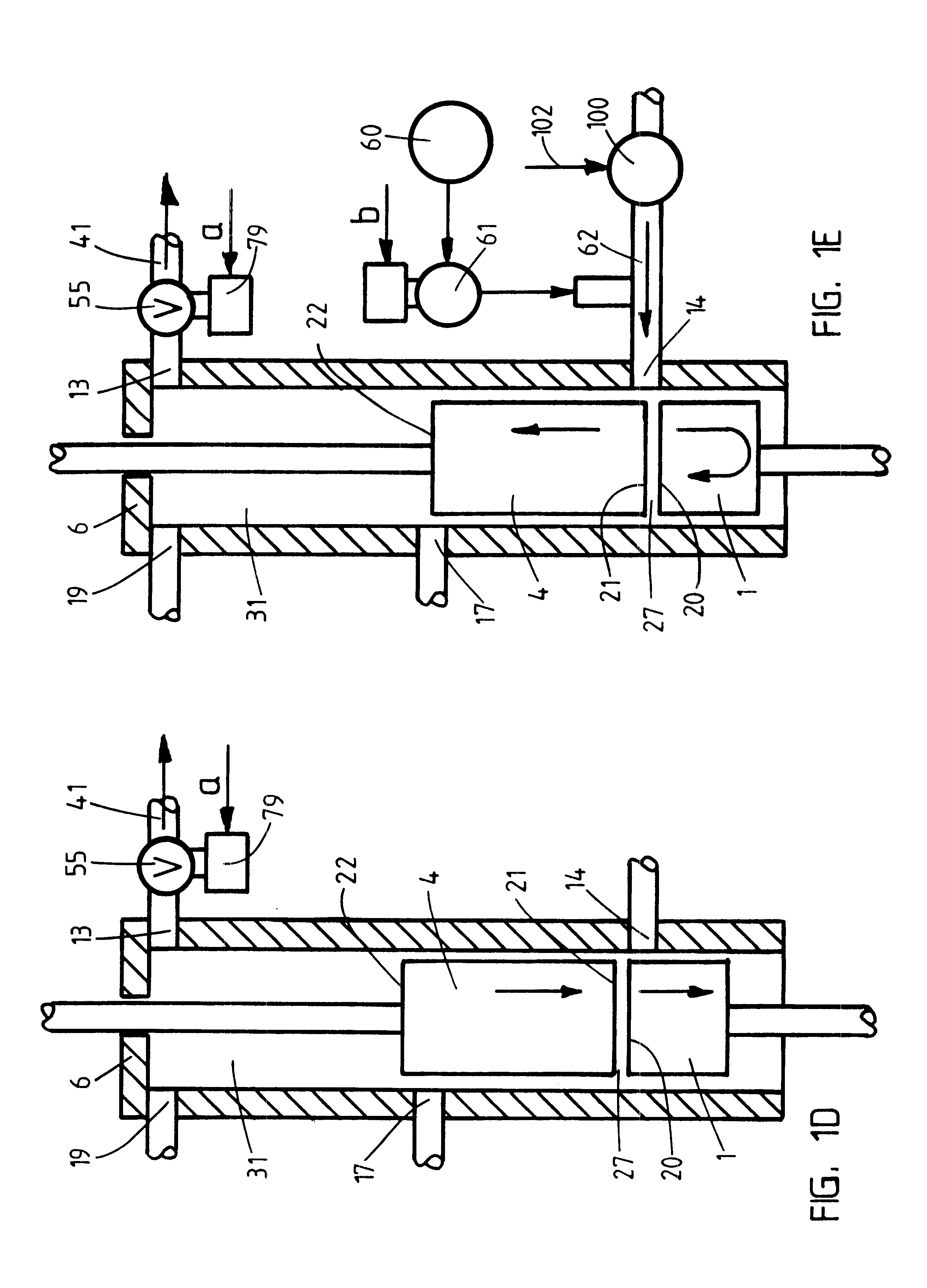

To provide a Stirling engine and a control unit for a Stirling engine capable of disposing a displacer unit and a power cylinder unit separately from each other, thereby increasing the degree of freedom of layout thereof. A displacer unit and a power cylinder unit of a Stirling engine E are disposed separately from each other. A compression chamber of the displacer unit is connected to an operation chamber of the power cylinder unit via a pressure conduit. A control actuator capable of arbitrarily controlling the displacer piston of the displacer unit is connected to the displacer piston.

Owner:HONDA MOTOR CO LTD

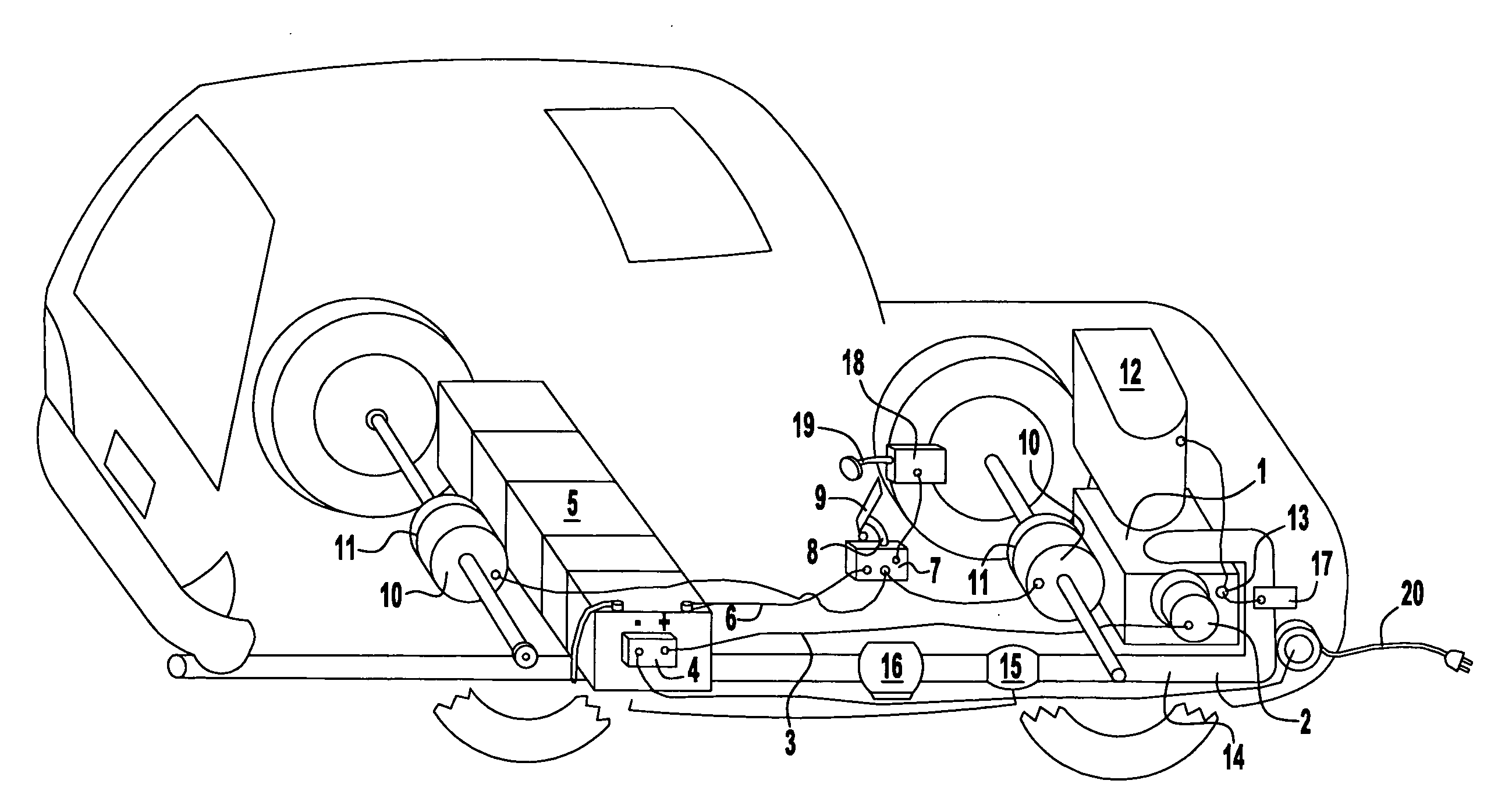

Hybrid electric vehicle and towable trailer that uses renewable solid fuel

InactiveUS20090090573A1SmallIncrease mileageInternal combustion piston enginesElectric propulsion mountingCelluloseElectrical battery

A hybrid electric vehicle having an array of batteries that recharge with a generator connected to a Stirling engine, steam engine and / or steam turbine powered by combusting a solid fuel product. The battery array for this vehicle, which is a series hybrid, can be recharged using residential electrical current. A preferred solid fuel product for burning in the generator-charging engine of this vehicle is selected from cellulose, lignin and combinations thereof, most preferably in the form of pellets or small logs.

Owner:BOONE DANIEL J

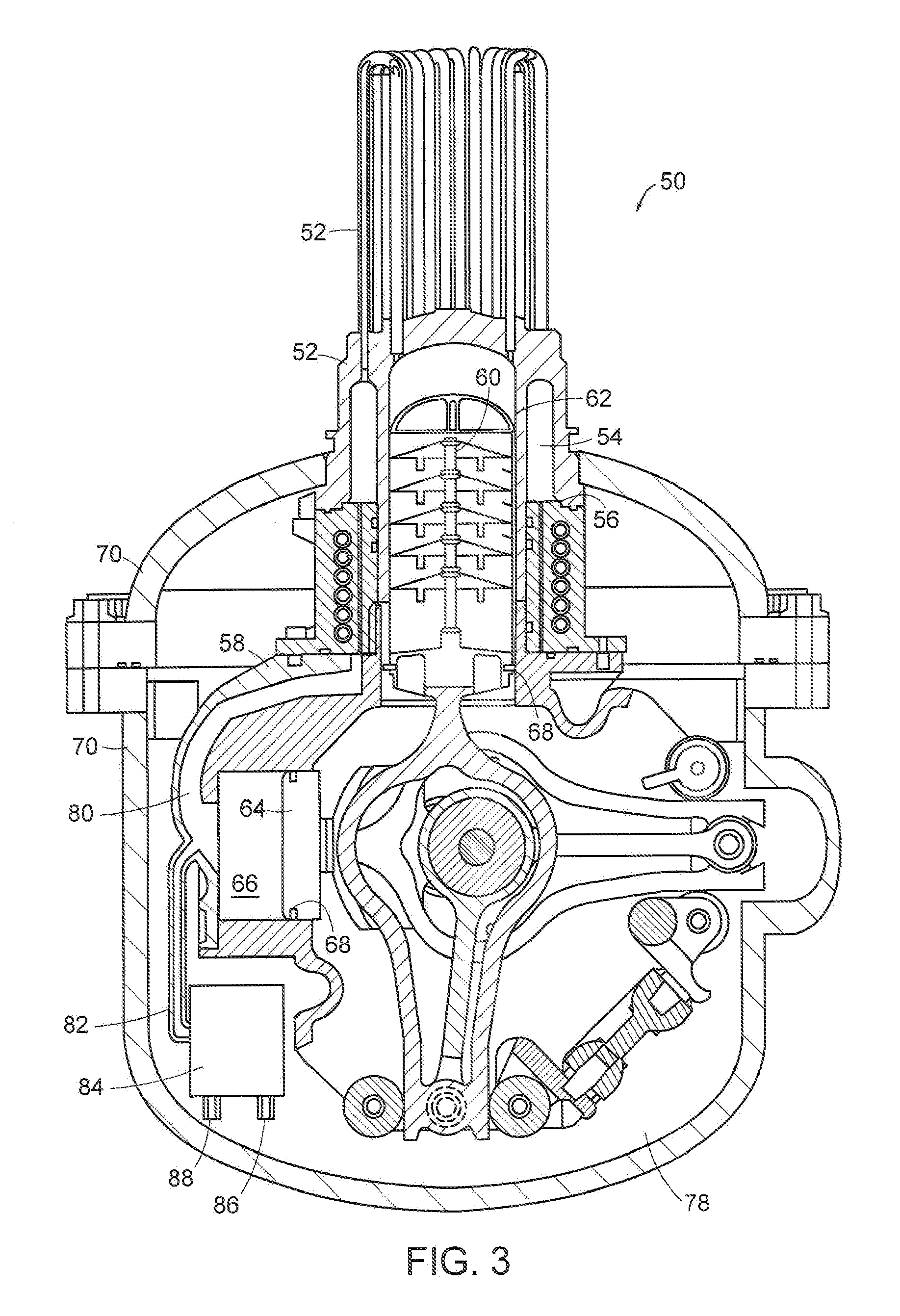

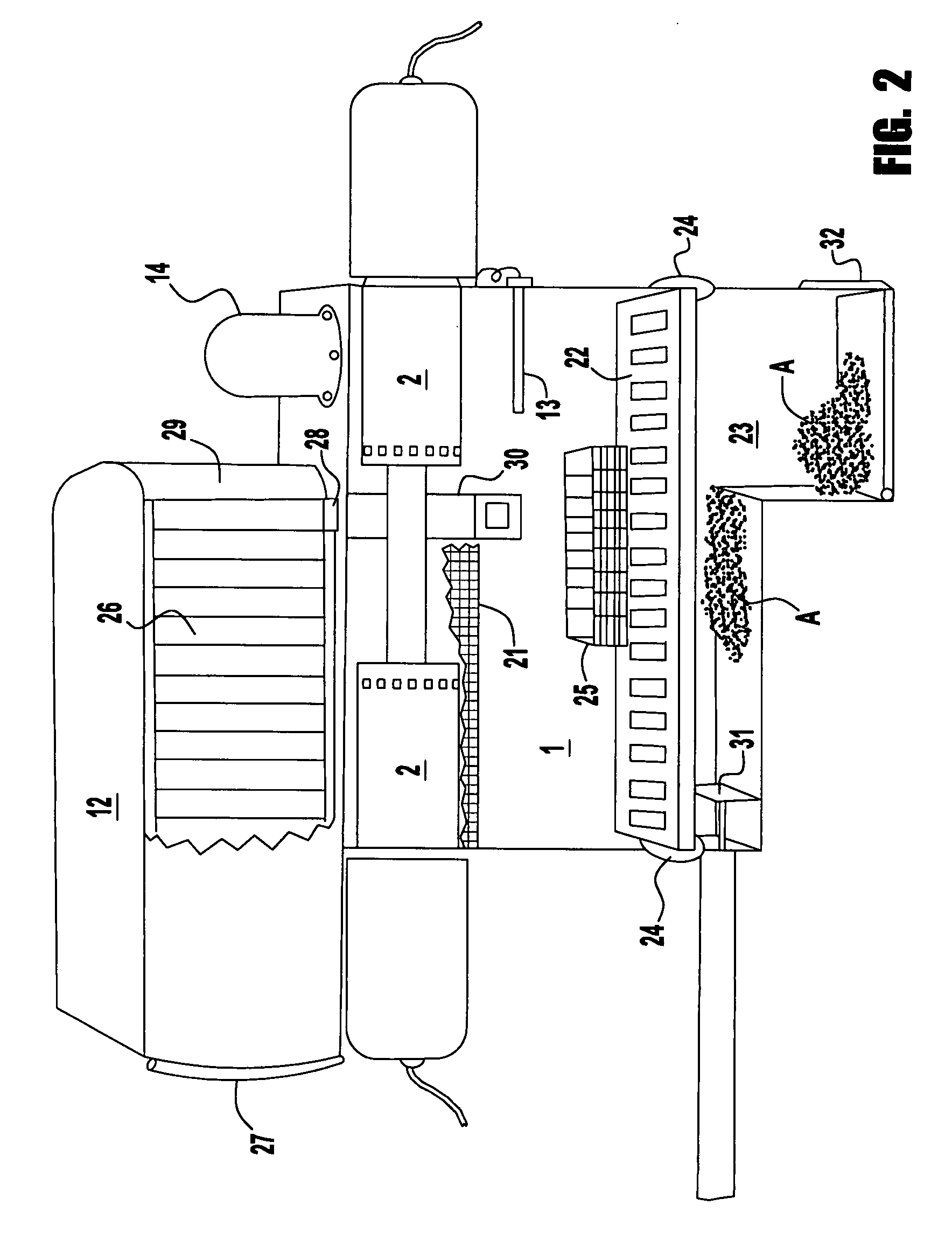

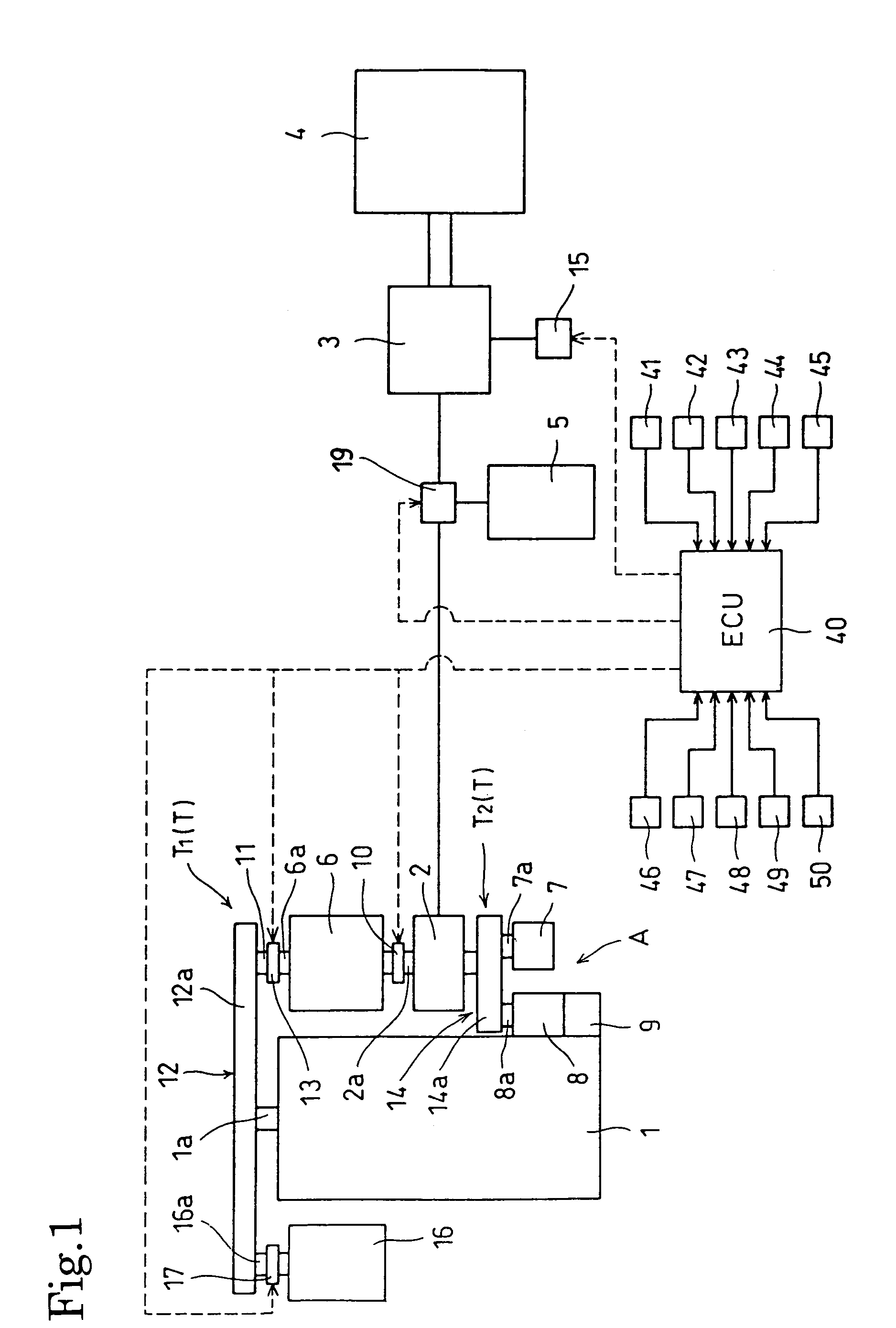

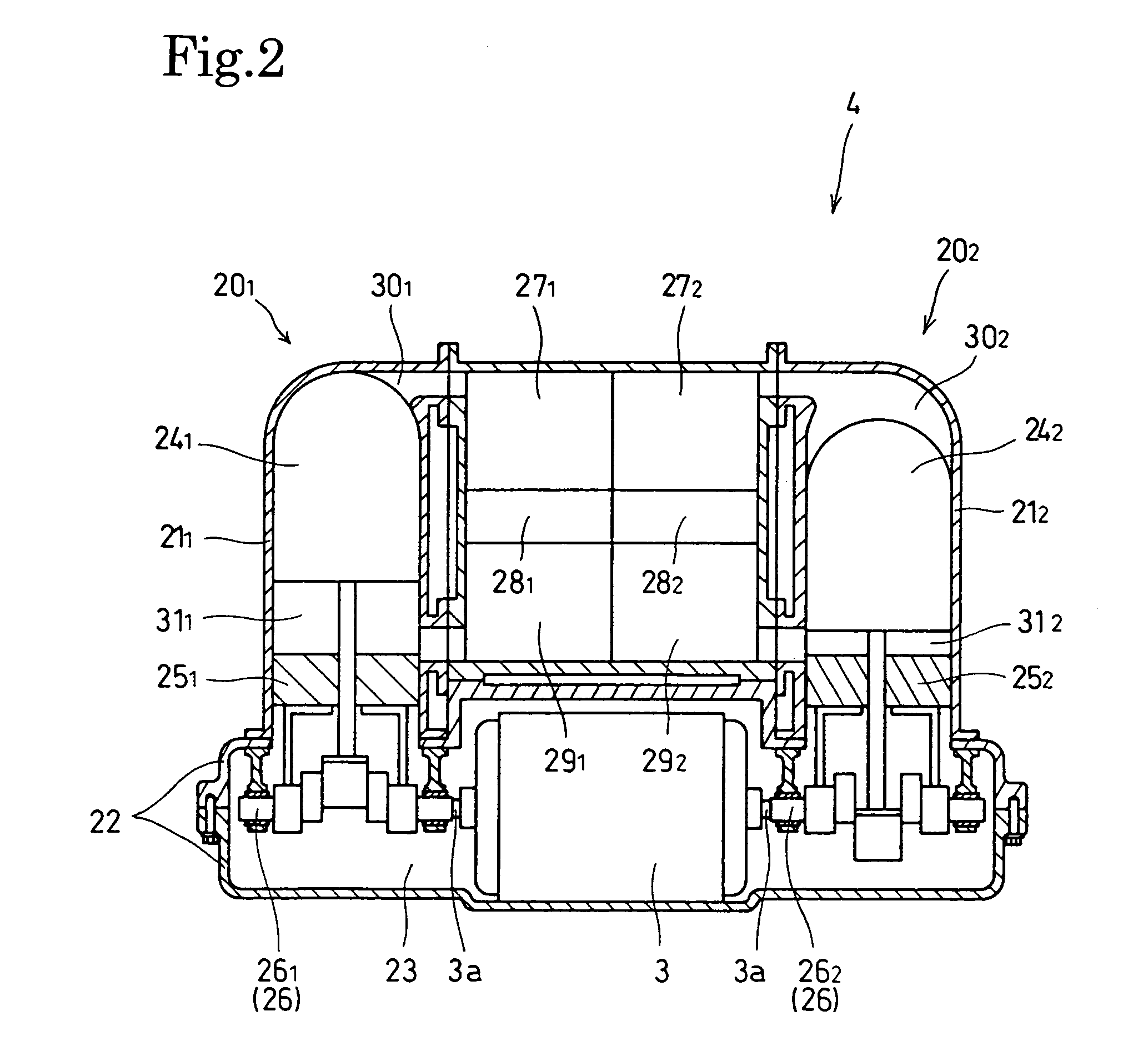

Power device equipped with combustion engine and stirling engine

InactiveUS7181912B2Reduce fuel consumptionRecover energyReciprocating combination enginesInternal combustion piston enginesCombustionEngineering

A power unit for a vehicle, such as an automobile, includes an internal combustion engine 1 as a prime mover for the vehicle, a generator 3, and a Stirling engine 4 for driving the generator 3. The Stirling engine 4 uses the exhaust gas discharged by the internal combustion engine 1 as a high-temperature heat source. Power generated by the generator 3 is supplied to an electric motor 2 for driving auxiliary machines 7, 8 and 9, and to a battery 5 for supplying power to the electric motor 2. The engine speed of the Stirling engine 4 is controlled through the control of the load on the generator 3 by a field regulator 15. An optimum engine speed of the Stirling engine 4 is determined such that the brake horsepower of the Stirling engine 4 increases to a maximum or substantially maximum brake horsepower. The fuel consumption of the internal combustion engine 1 as the prime mover that produces waste heat as a high-temperature heat source for the Stirling engine 4 is reduced, and the auxiliary machines are driven so as to fully exercise their functions even in a state where the brake horsepower of the Stirling engine 4 is low.

Owner:HONDA MOTOR CO LTD

Two-axes solar tracking system and device for solar panels

InactiveCN101997453ANo need to expend strengthExtend your lifePhotovoltaic supportsSolar heating energyGravity centerEngineering

The present invention relates to a simplified and lower cost two-axes tracker for solar PV (photovoltaic) or CPV (concentrated photovoltaic) solar panel, as well as heliostat solar reflectors and solar Stirling engine. In particular, the disclosure addresses a simplified and gravity centered tracker structure with low cost single or dual linear actuators mounted on the side of ground post which is easier for replacement and maintenance at lower cost.

Owner:廖恒俊

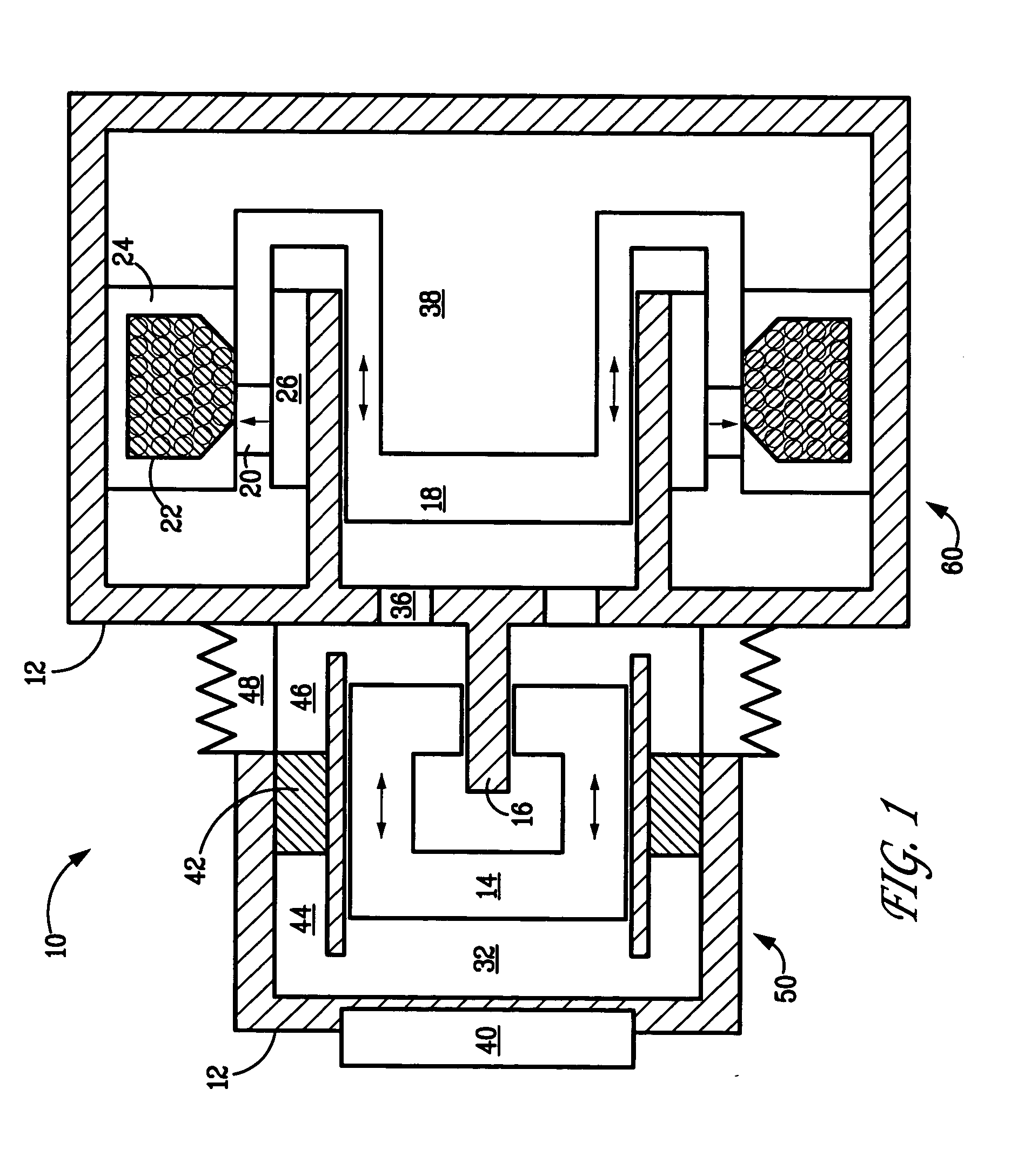

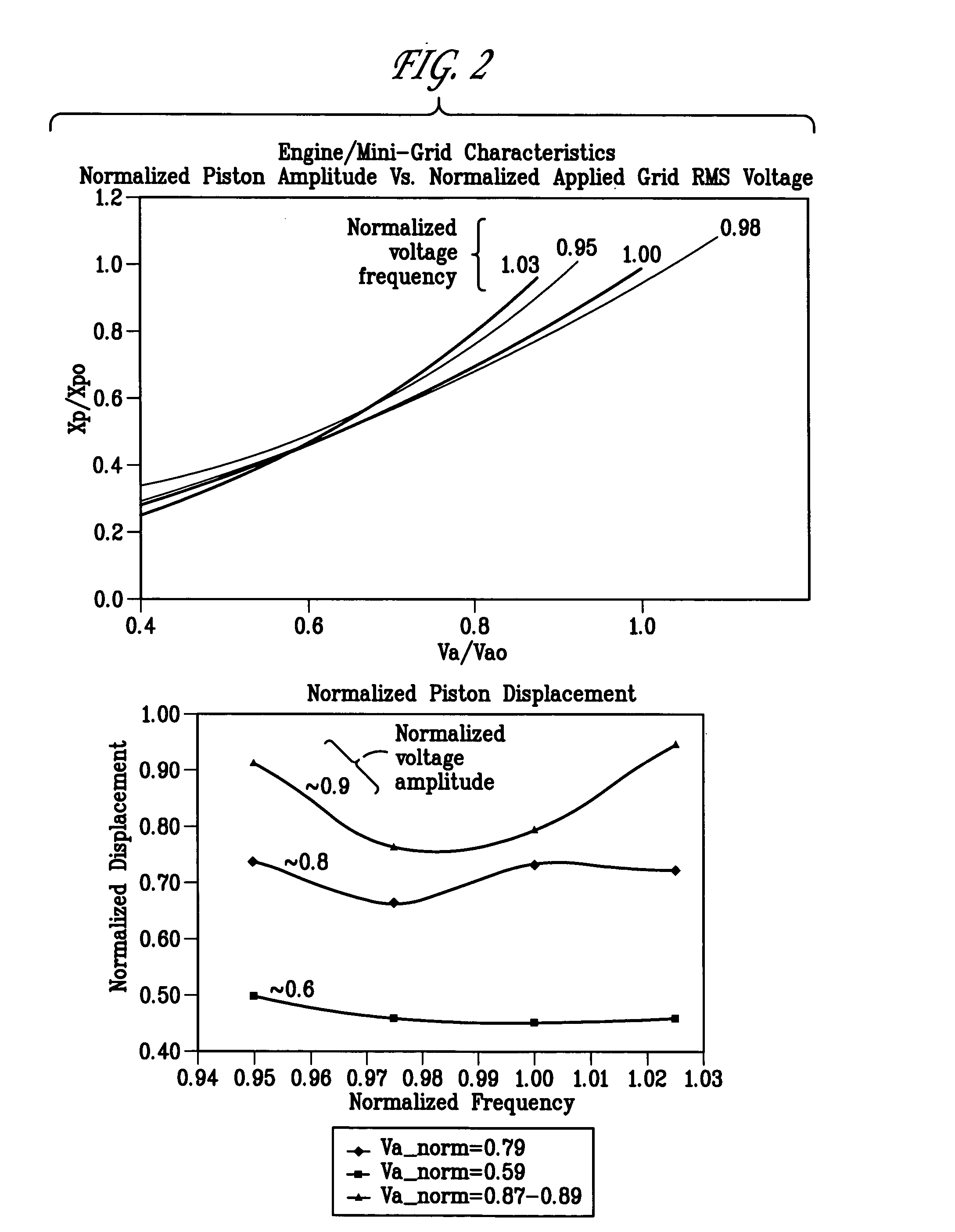

Free piston Stirling engine control

InactiveUS20050028520A1Large and heavy and expensiveAC motor controlEngine componentsVoltage amplitudeElectric power system

A control system for a Stirling engine including the use of a synchronous power converter (“SPC”) which is connected to the terminals of the alternator in a linear alternator / FPSE power system. According to the teachings of the present invention, the attached SPC is small and portable and further ensures that piston and displacer excursion within the system remain within design limits. The system and method are designed such that it is possible to adjust both the voltage amplitude and the waveform frequency at the terminals of the linear alternator. By controlling these operational aspects, both the speed and the range of travel associated with the piston and the displacer in the FPSE can be controlled.

Owner:TIAX LLC

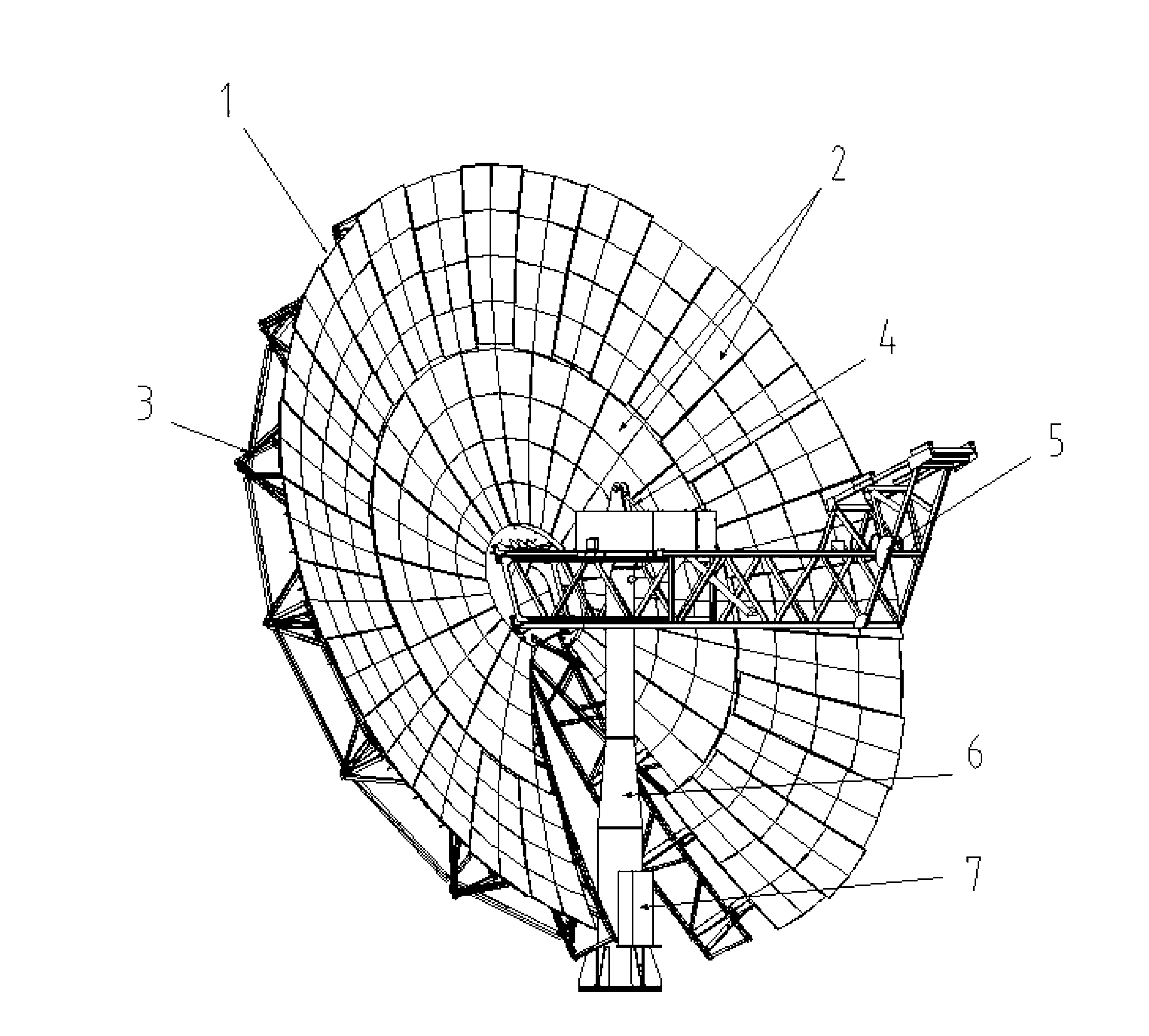

Horizontal solar disk-type light condensation system and solar power generation system adopting same

InactiveCN102705187AReduce the impactReduce wasteFrom solar energyMachines/enginesControl systemElectrical control

The invention discloses a horizontal solar disk-type light condensation system and a solar power generation system adopting the horizontal solar disk-type light condensation system. The horizontal solar disk-type light condensation system comprises a light condensation reflecting lens system, a back support, a Stirling engine support, a double-shaft solar tracker, a support upright column and an electrical control system, wherein the light condensation reflecting lens system is segmented to sectors and multiple sector-shaped light condensation reflecting lens groups are spliced to form a rotating paraboloid structure; the back support is used for supporting and installing the light condensation reflecting lens system; the Stirling engine support is fixedly connected with the back support; the double-shaft solar tracker is arranged at the top of the support upright column and connected with the back support; the support upright column is fixed on foundation; and the electrical control system is electrically connected with the double-shaft solar tracker and controls the running of the horizontal solar disk-type light condensation system.

Owner:DALIAN GREAT OCEAN NEW ENERGY DEV

Thermally driven pulse tube refrigerator system

ActiveCN105066500AReduce vibrationReduce processing difficultyCompression machinesPulse tube refrigeratorCore component

The invention discloses a thermally driven pulse tube refrigerator system which comprises one or two free piston stirling engines, one or two pulse tube refrigerators and one or two acoustic resonance tubes, wherein each acoustic resonance tube is a first-class diameter or variable diameter pipe; each free piston stirling engine and each pulse tube refrigerator are respectively connected to two sides of each acoustic resonance tube; acoustic power generated by the free piston stirling engines is transmitted to the pulse tube refrigerators through the acoustic resonance tubes; the pulse tube refrigerators generate the refrigerating effect; the acoustic resonance tubes not only can play an acoustic power transmission role, but also can play an acoustic field phase modulation role; the acoustic fields in thermo-acoustic and acoustic-cold conversion core components, namely refrigerator regenerators, of the thermally driven pulse tube refrigerator are traveling wave phases; the thermal efficiency is high; meanwhile, no mechanical motion component is arranged in the pulse tube refrigerator; the thermally driven pulse tube refrigerator system has low vibration and high reliability; the refrigerating capacity from hectowatts to kilowatts or even higher can be obtained within a temperature region of 60-150K.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Multifuel internal combustion stirling engine

InactiveUS6457309B1Adequate fuel efficiencyExpensive heat exchanger is avoidedStirling type enginesEngine componentsParticulatesInternal combustion engine

A multifuel internal combustion Stirling engine is described, wherein a compressor piston and a displacer piston reciprocate, within a common cylinder, to enclose a variable air volume, and a variable burned gas volume. Motion of these two pistons, creates a power producing cycle, of compression, combustion, expansion, and scavenge, wherein the burned gases do not contact those cylinder portions over which the compressor piston moves. In this way low engine wear can be obtained when using fuels such as coal, which produces abrasive particulates in the burned gases. A multifuel internal combustion engine of this invention can be readily adapted to operate on a wide variety of fuels, such as, natural gas, diesel fuel, residual petroleum fuel, and coal. Widespread use of these engines would introduce economic competition between these now separately competing fuels. This is a clear route to national energy independence, since coal reserves greatly exceed petroleum reserves, nationally and internationally.

Owner:FIREY JOSEPH CARL

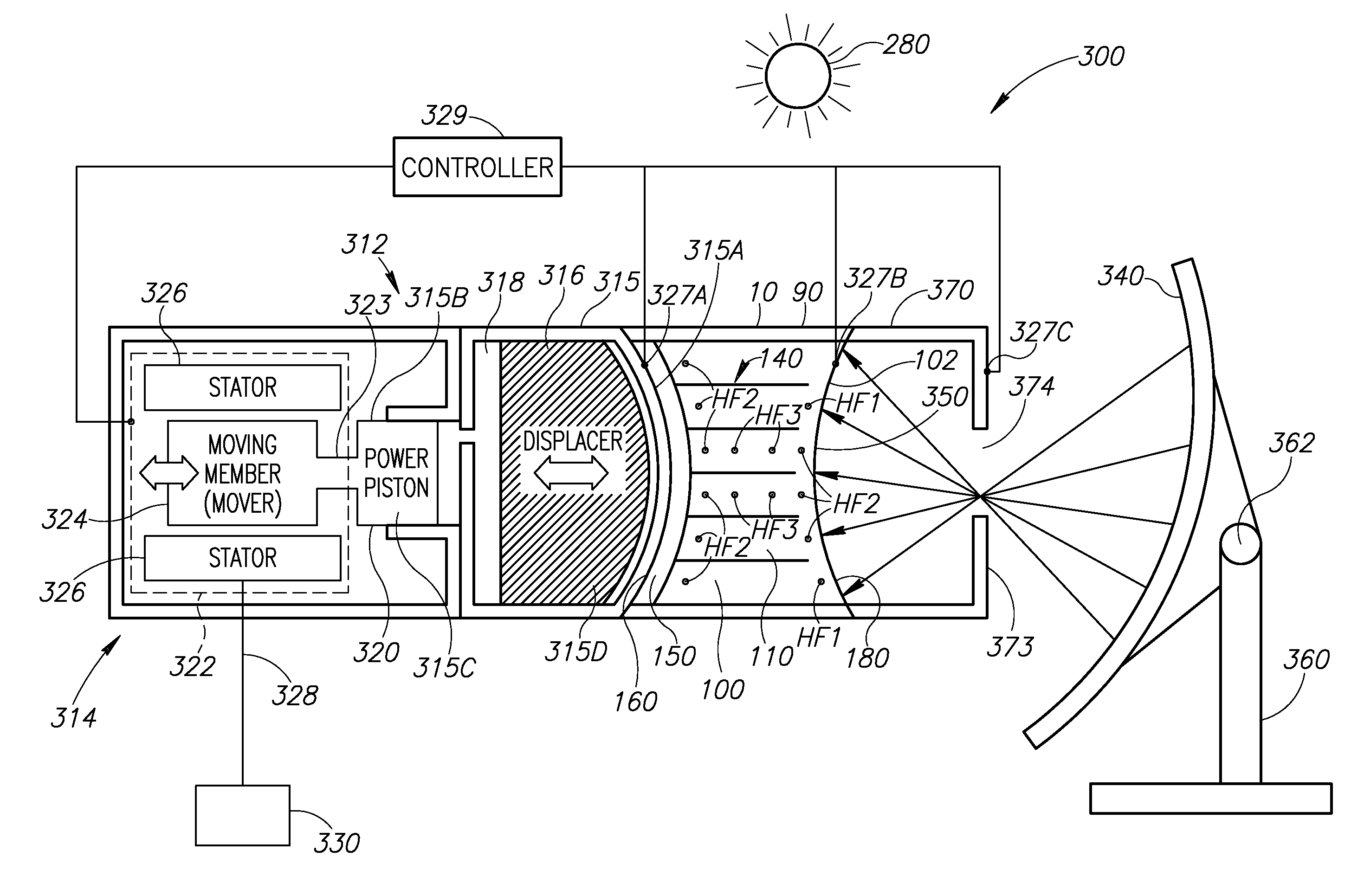

Solar thermal aircraft

A solar thermal powered aircraft powered by heat energy from the sun. A heat engine, such as a Stirling engine, is carried by the aircraft body for producing power for a propulsion mechanism, such as a propeller. The heat engine has a thermal battery in thermal contact with it so that heat is supplied from the thermal battery. A solar concentrator, such as reflective parabolic trough, is movably connected to an optically transparent section of the aircraft body for receiving and concentrating solar energy from within the aircraft. Concentrated solar energy is collected by a heat collection and transport conduit, and heat transported to the thermal battery. A solar tracker includes a heliostat for determining optimal alignment with the sun, and a drive motor actuating the solar concentrator into optimal alignment with the sun based on a determination by the heliostat.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Scroll-type expander having heating structure and scroll-type heat exchange system employing the expander

InactiveUS7124585B2No reduction in efficiencyMinimizes difference in temperatureRotary/oscillating piston combinations for elastic fluidsInternal combustion piston enginesWorking fluidEngineering

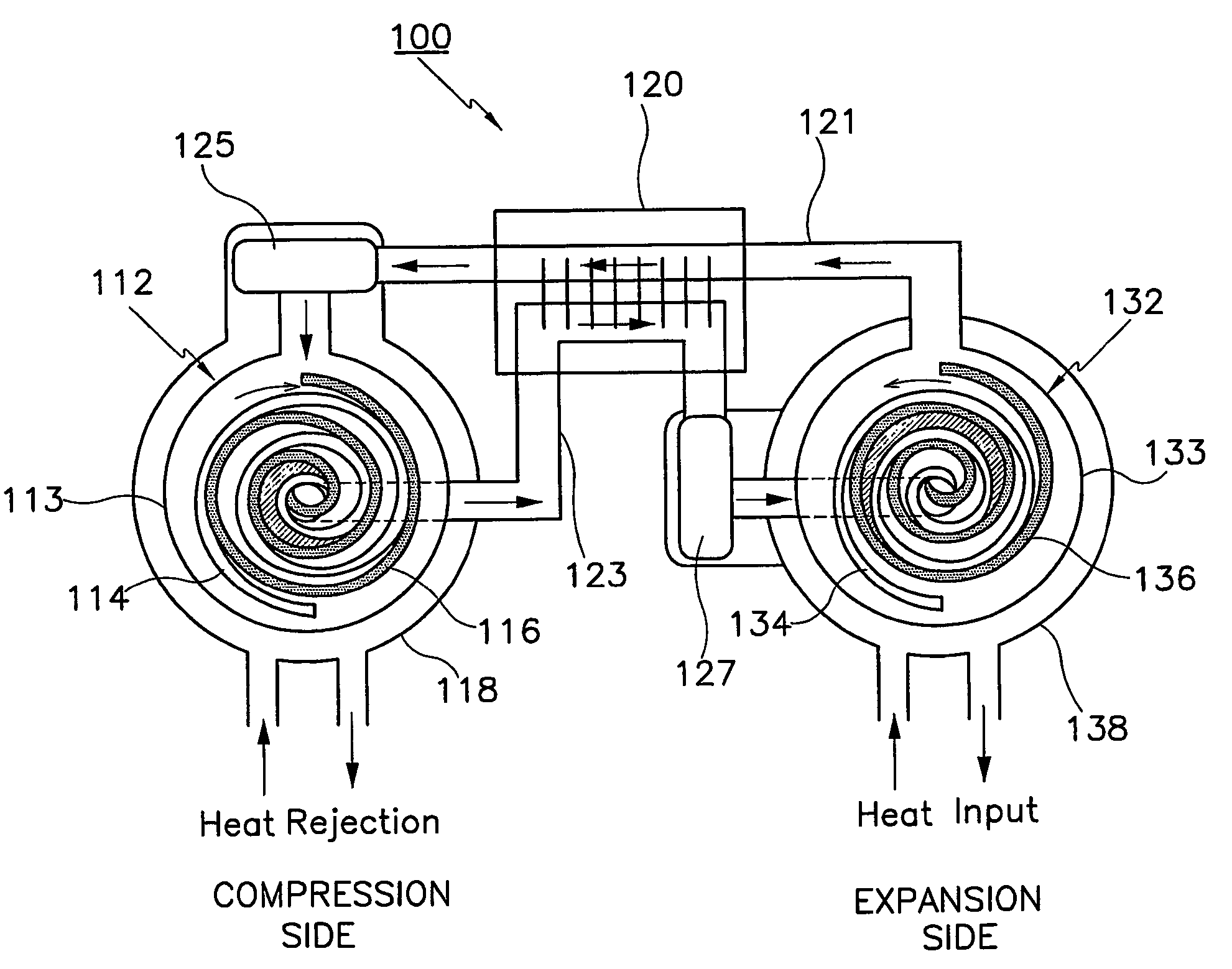

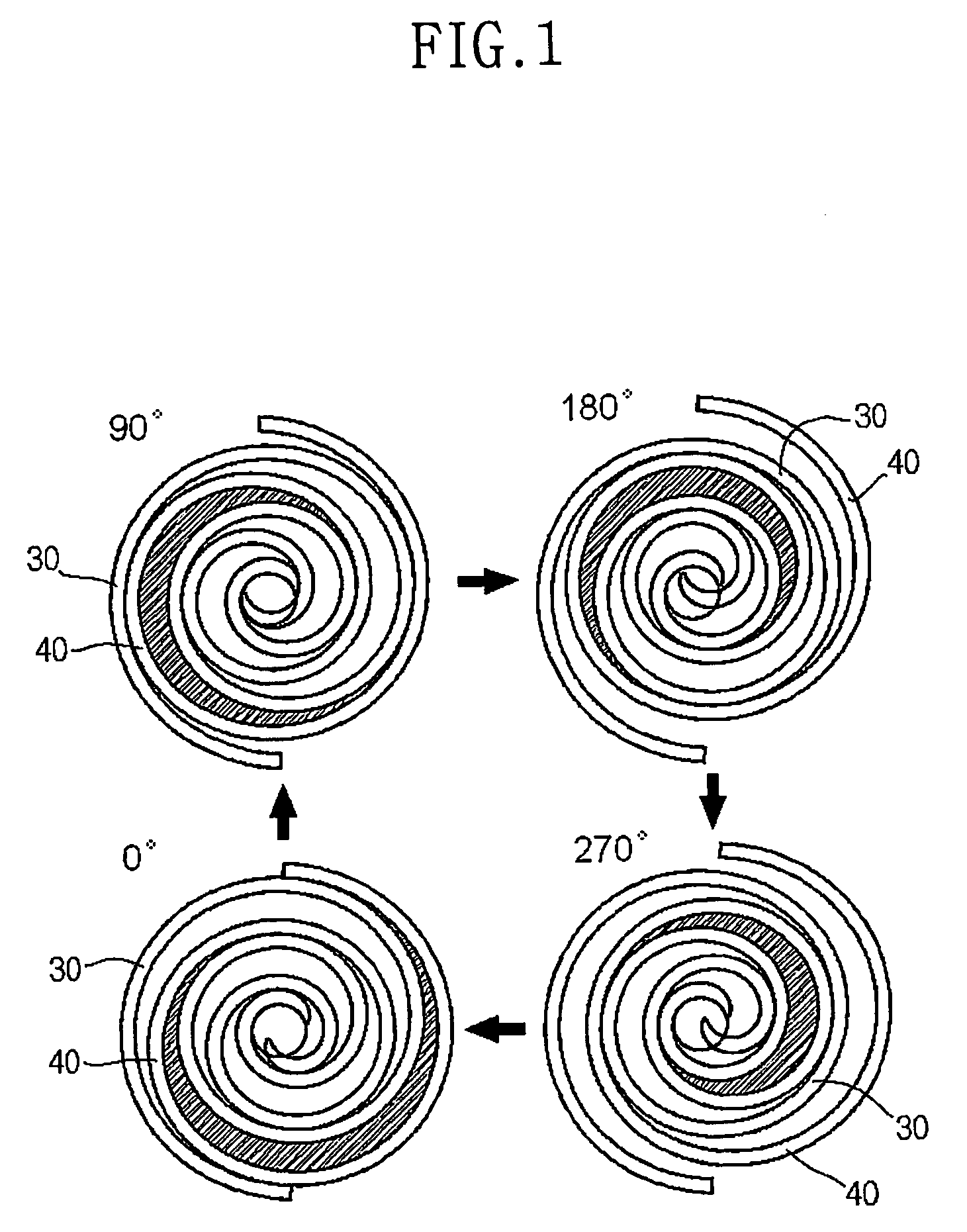

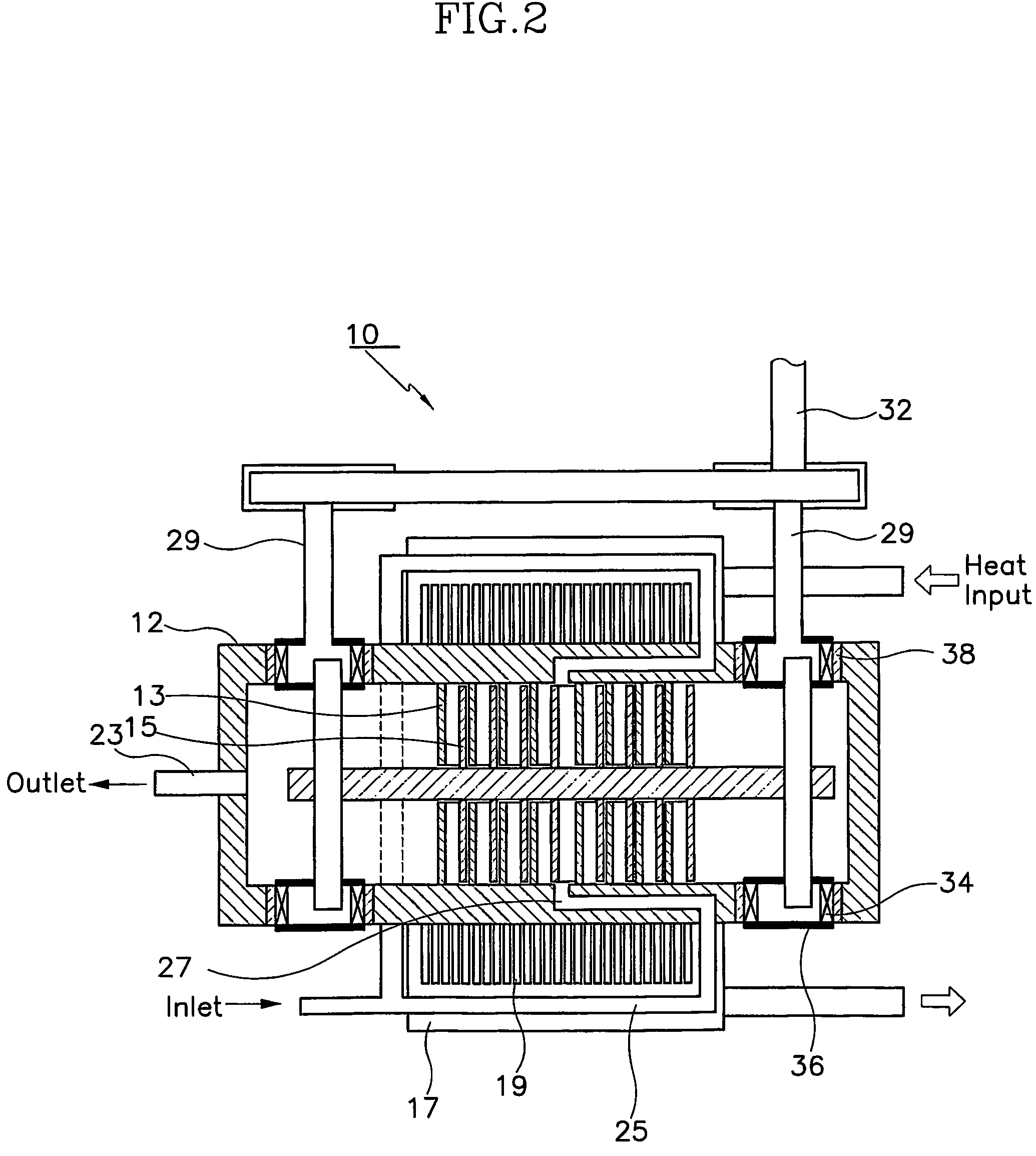

The present invention provides a scroll-type expander that simultaneously performs expansion and re-heating such that efficient expansion is realized and there is no reduction in efficiency caused by pressure loss occurring during the supply of an working fluid to the scroll-type expander, and that minimizes a difference in temperature between a stationary scroll member and a rotating scroll member, as well as a temperature distribution of a scroll wrap. The present invention also relates to a heat exchange system that uses a scroll-type expander to replace pistons in a conventional reciprocating Stirling engine or refrigerator with a pair of scroll-type compressor and expander such that the heat exchange system may be used as a Stirling engine or refrigerator. The present invention also provides a steam engine, in which a steam turbine in the conventional steam engine (Rankine system) is replaced with a scroll-type expander such that the steam cycle has both a re-heating cycle and a regeneration cycle.

Owner:KOREA INST OF MACHINERY & MATERIALS

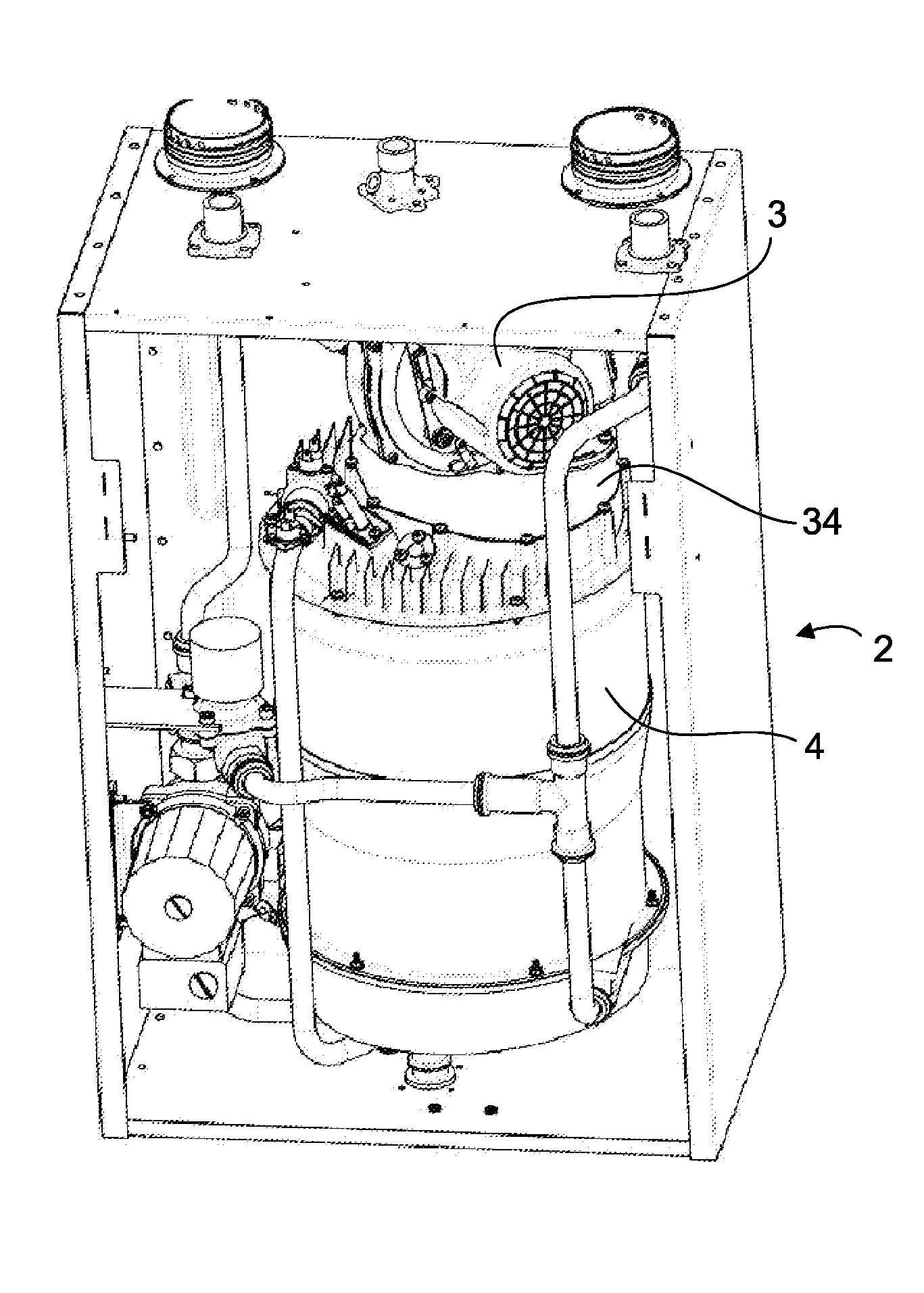

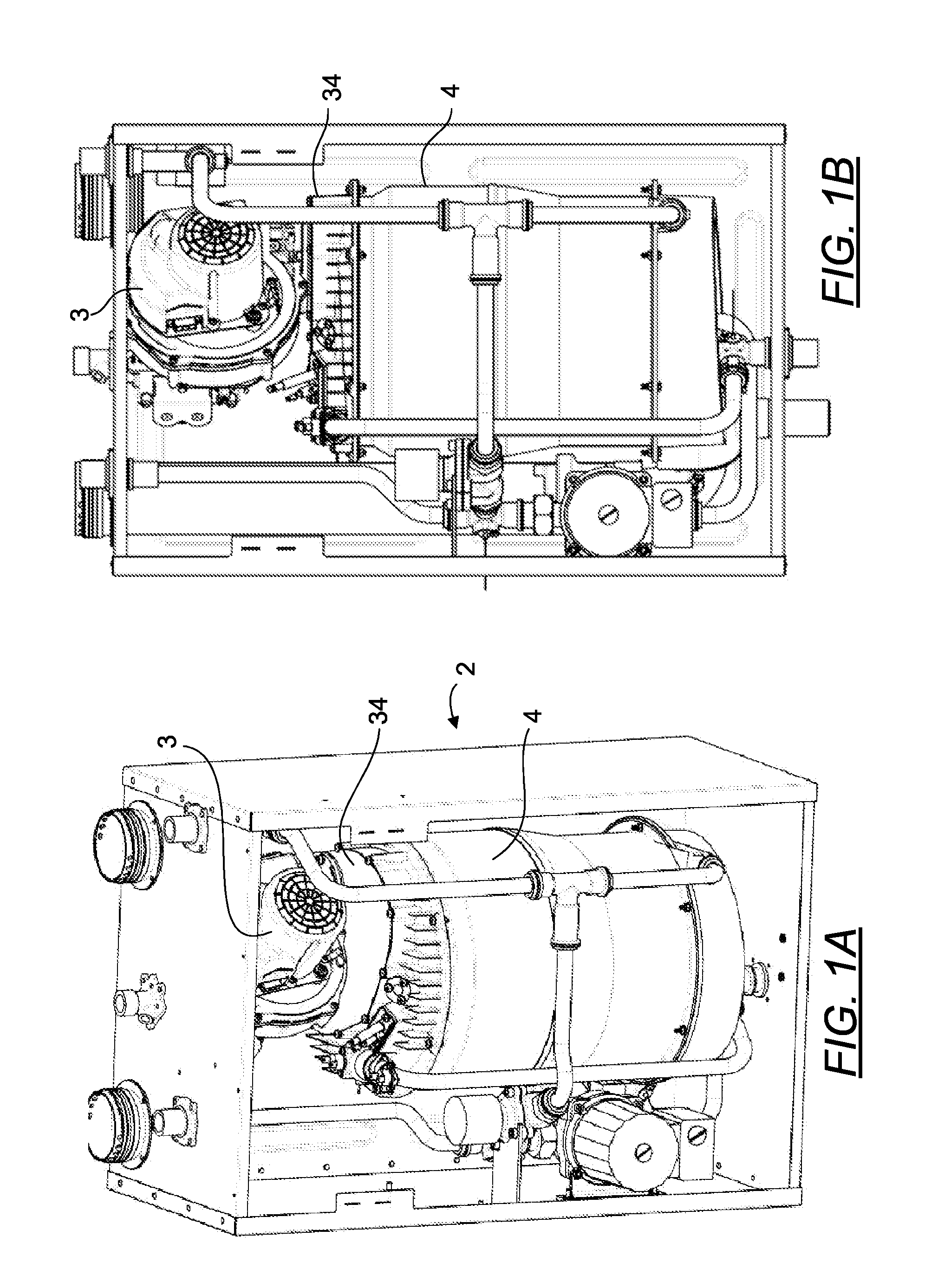

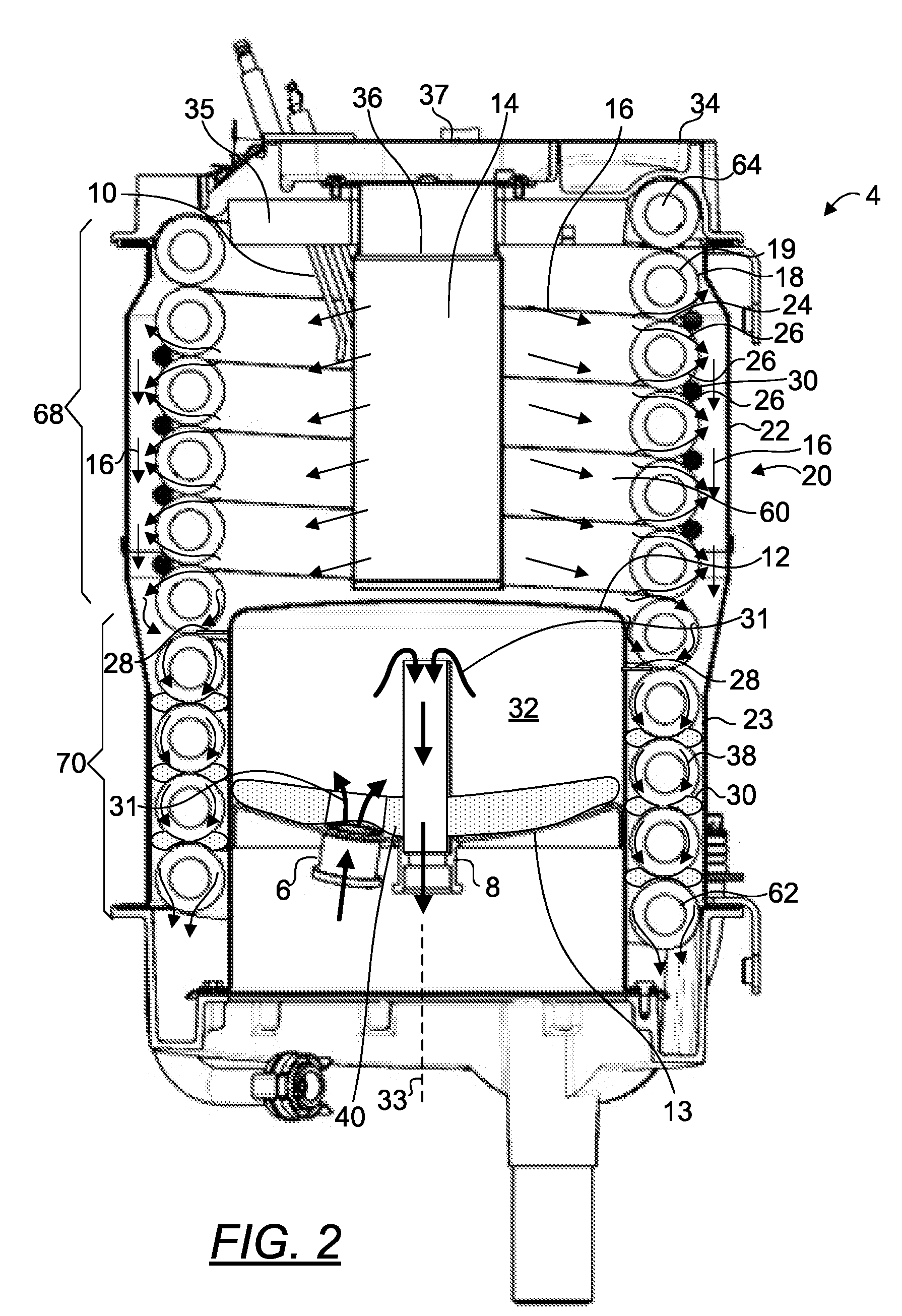

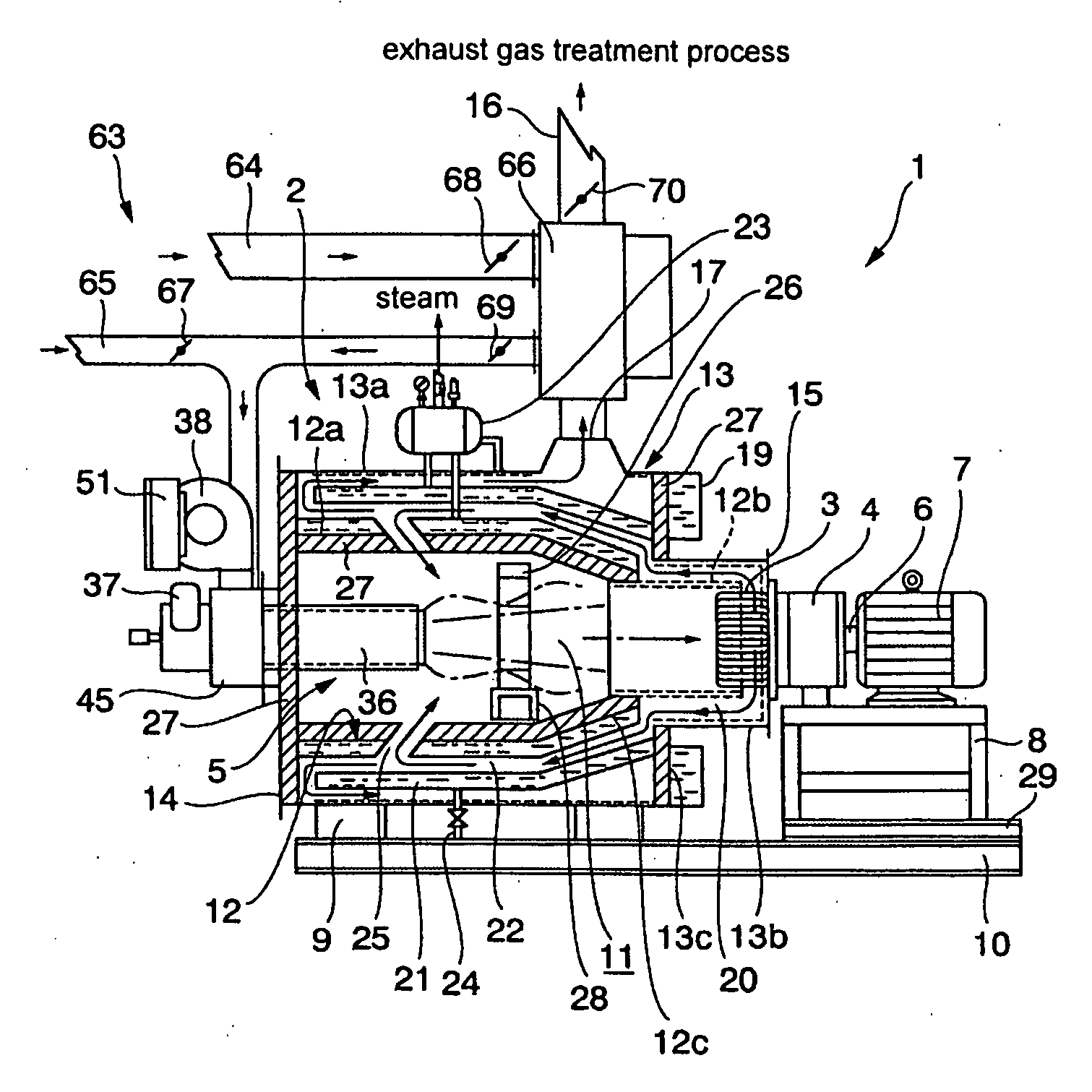

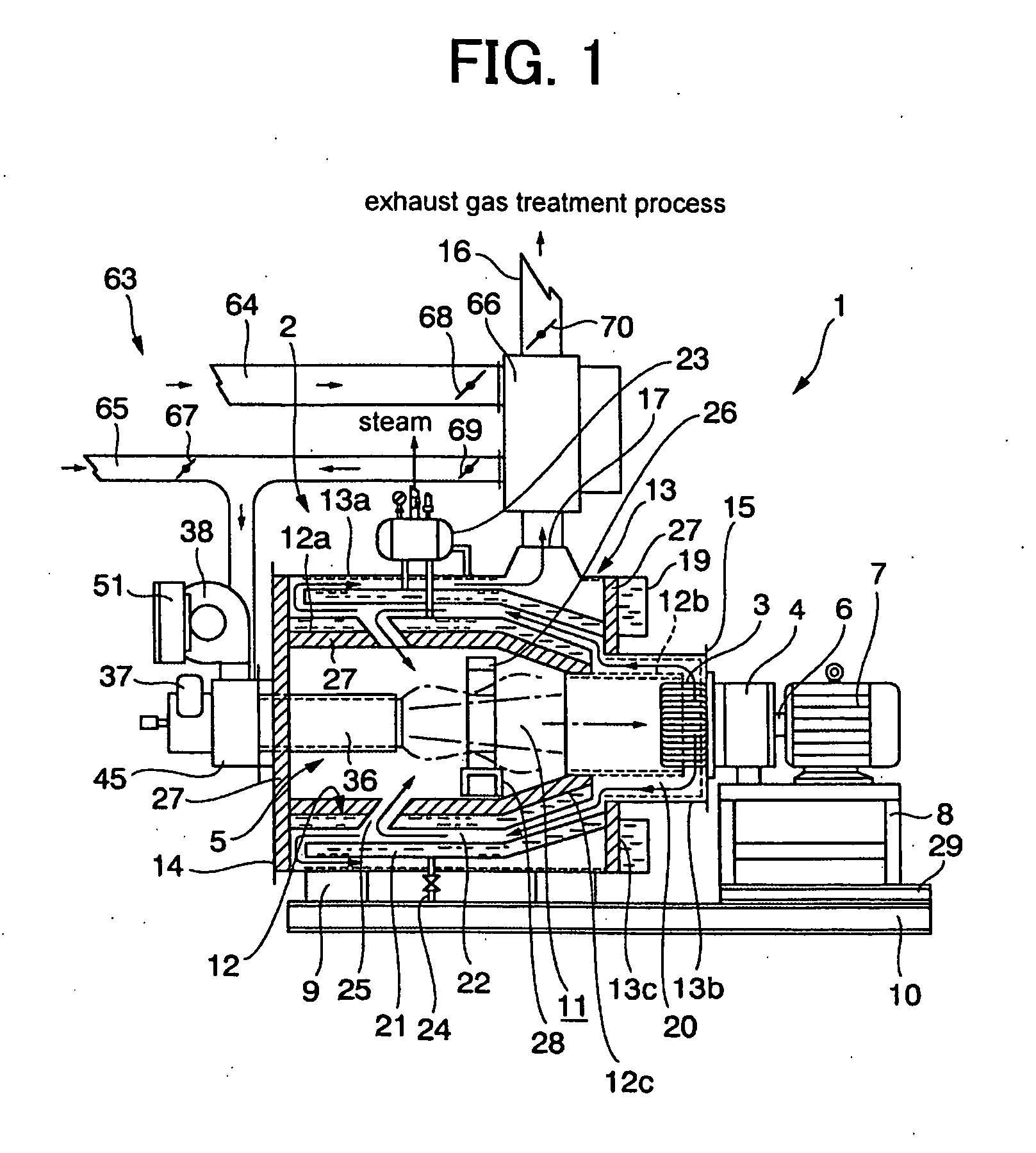

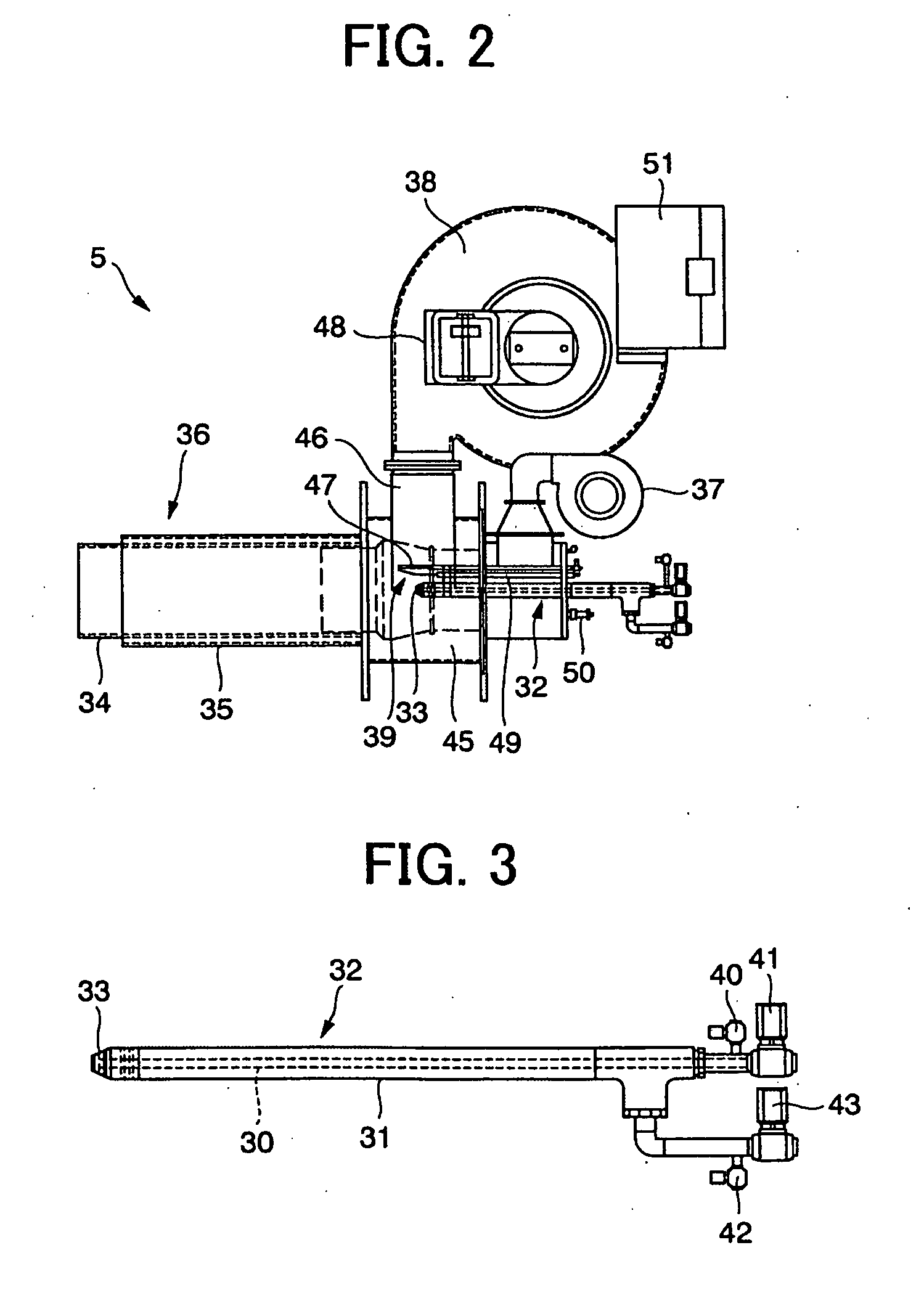

Cogeneration system

InactiveUS20060213196A1Speed up the flowImprove efficiencyBiofuelsLiquid carbonaceous fuelsThermal energyWorking fluid

A Stirling engine-equipped cogeneration system is capable of utilizing thermal energy, without waste, and of offering high thermal usage efficiency at every stage of the thermal energy utilization process. The system includes a combustion chamber (11), a burner unit (5) installed to the combustion chamber, the burner unit driving combustion to generates exhaust gas within the combustion chamber, a liquid media jacket (21) that envelopes the combustion chamber, a liquid media flowing within the liquid media jacket and absorbing thermal energy from the burner-generated exhaust gas, a Stirling engine (4) operating from a sealed operating fluid heated by the heater (3) which is located within the combustion chamber facing the burner and subjected to the flow of exhaust gas generated within the combustion chamber, an exhaust gas flow channel (20) through which flows burner-generated exhaust gas after having flowed through and heating the heater, and an exhaust gas passage (22) having an entrance connected to the exhaust gas flow channel as means of allowing the exhaust gas to heat the liquid medium in the liquid media jacket. The exhaust gas generated from the burner-driven combustion flows into the heater to transfer thermal energy thereto, then flows into the exhaust gas passage, through the exhaust gas flow channel to transfer the thermal energy to the liquid medium, thereby heating the liquid medium and heater simultaneously.

Owner:SUGIOKA TETUO

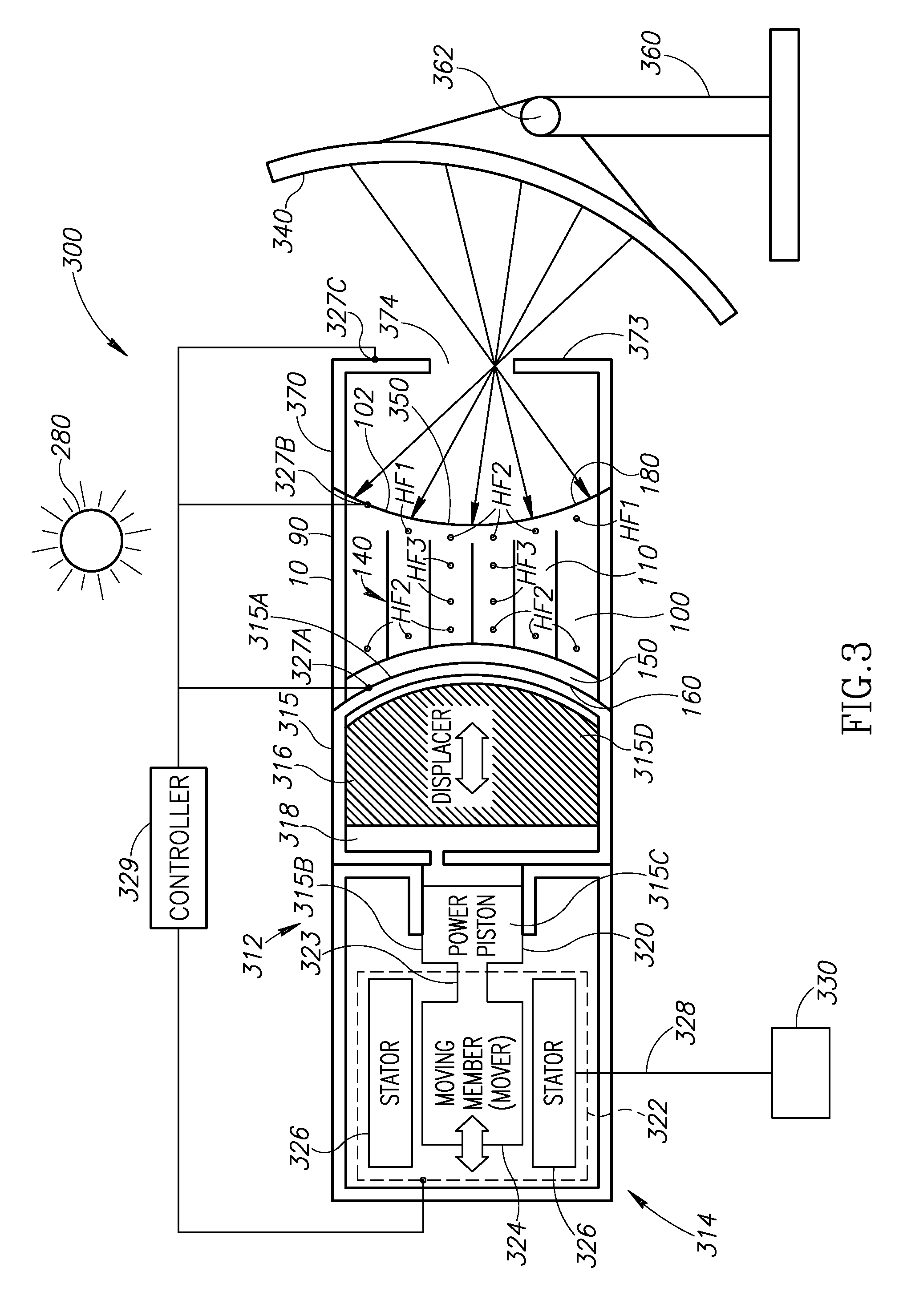

Mechanical-thermal solar power system

InactiveUS20050039791A1Reduce in quantityKeep the heatAuxillary drivesFrom solar energyFiberLight energy

A mechanical thermo-voltaic solar power system (MeTSoPoS) that uses a mechanical generator, instead of the photovoltaic panel commonly in use today, is disclosed. The system is comprised of three major subsystems: (1) a light collector array, (2) a mechanical thermo-voltaic generator, and (3) a storage and retrieval system. At the center of the system is the light collection array comprised of solar collector elements. These collector elements are connected to optical conduits (fiber optic cables) that carry the light energy to a mechanical generator. An automatic aiming system is used to align the collector elements directly at a light source for maximum light output. Each light collector element is comprised of a set of lenses that focus a larger area of light down to a point small enough to inject into an optical conduit. The optical conduit is then used to carry the light from each collector element to the generator. The system can use either a steam turbine or a Stirling engine type of mechanical generator, which is connected to a standard AC generator for generating electrical power. The heating chamber involves an outer shell where the optical conduits attach and allows the light to shine through to the heating area of either the boiler of a steam turbine or the hot node of a Stirling engine. Additionally, a small hole is provided in the bottom of the heating chamber where a gas burner is mounted to provide an auxiliary means of providing heat to the system. The burner can be fueled by natural gas or from stored hydrogen from the system. Electricity from the system that is not used immediately is redirected to a storage unit, such as a bank of batteries. In the system, electricity can be taken directly form the generator or can be used to charge the batteries and taken from them when needed. The overall system has a means of monitoring the amount of energy being generated and if that is less than is being used for auto aiming and other nonessential functions, it will shut down those functions and switch into energy retrieval mode.

Owner:JOHNSON D ALAN E

Hybrid electric vehicles using a stirling engine

A personal vehicle for transporting a user over a surface including an external combustion engine. The vehicle includes a generator for converting the mechanical energy produced by the external combustion engine to electrical energy and an energy storage device for storing power provided by the generator and for providing power to the external combustion engine and the assembly. The personal vehicle includes a controller for controlling a total power load placed on the external combustion engine providing short term regulation of external combustion engine parameters.

Owner:NEW POWER CONCEPTS

Stirling-Electric Hybrid Automobile

ActiveUS20080276610A1Improve fuel economyFew harmful emissionReciprocating combination enginesElectric propulsion mountingExternal combustion engineFuel efficiency

The Stirling-Electric Hybrid automobile herein disclosed utilizes an electric drive motor which is powered by electric storage device. The electric storage device is kept at suitable charge by electric generator mechanically driven by external combustion of Stirling engine type, by thermoelectric generator thermally coupled to the exhaust of the Stirling engine and to kinetic energy recovery system which during deceleration of the automobile utilizes the electric drive motor as a generator and recovering the electrical energy generated by deceleration to the electric storage device. Almost any clean combusting liquid or gaseous fuel may be utilized by the Stirling engine with greater fuel economy and less atmospheric pollution than internal combustion engines presently used. The utilization of thermoelectric generator to recover heat from exhaust of the Stirling engine and utilization of kinetic energy recovery system provides even better fuel efficiency and reduced pollution.

Owner:MCDOWELL JOSEPH SHEA

Mechanical/Thermo-Voltaic Solar Power System

InactiveUS20080078435A1Easy and efficient to manufactureReduce manufacturing costFrom solar energyThermoelectric device with peltier/seeback effectThermopileLight energy

A mechanical / thermo-voltaic solar power system (MeTSoPoS) that uses a thermopile generator, instead of the photovoltaic panel commonly in use today, is disclosed. The system is comprised of three major subsystems: (1) a light collector array, (2) a thermopile thermo-voltaic generator, and (3) a storage and retrieval system. At the center of the system is the light collection array comprised of solar collector elements. These collector elements are connected to optical conduits (fiber optic cables) that carry the light energy to a thermo-electrical generator, such as a thermopile or a thermo-mechanical engine couple with an electrical generator. An automatic aiming system is used to align the collector elements directly at a light source for maximum light output. Each light collector element is comprised of a set of lenses that focus a larger area of light down to a point small enough to inject into an optical conduit. The optical conduit is then used to carry the light from each collector element to the generator. The heating chamber involves an outer shell where the optical conduits attach and allows the light to shine through to the heating area of either the boiler of a steam turbine, the hot node of a Stirling engine or thermopile. Additionally, a small hole is provided in the bottom of the heating chamber where a gas burner is mounted to provide an auxiliary means of providing heat to the system. The burner can be fueled by natural gas or from stored hydrogen from the system. Electricity from the system that is not used immediately is redirected to a storage unit, such as a bank of batteries. In the system, electricity can be taken directly form the generator or can be used to charge the batteries and taken from them when needed. The overall system has a means of monitoring the amount of energy being generated and if that is less than is being used for auto aiming and other nonessential functions, it will shut down those functions and switch into energy retrieval mode. A flow controller can be used to improve performance and runtime of the system by managing the flow of a thermally conductive fluid through various thermal exchange loops and then through the hot and / or cold nodes of the system.

Owner:JOHNSON D ALAN E

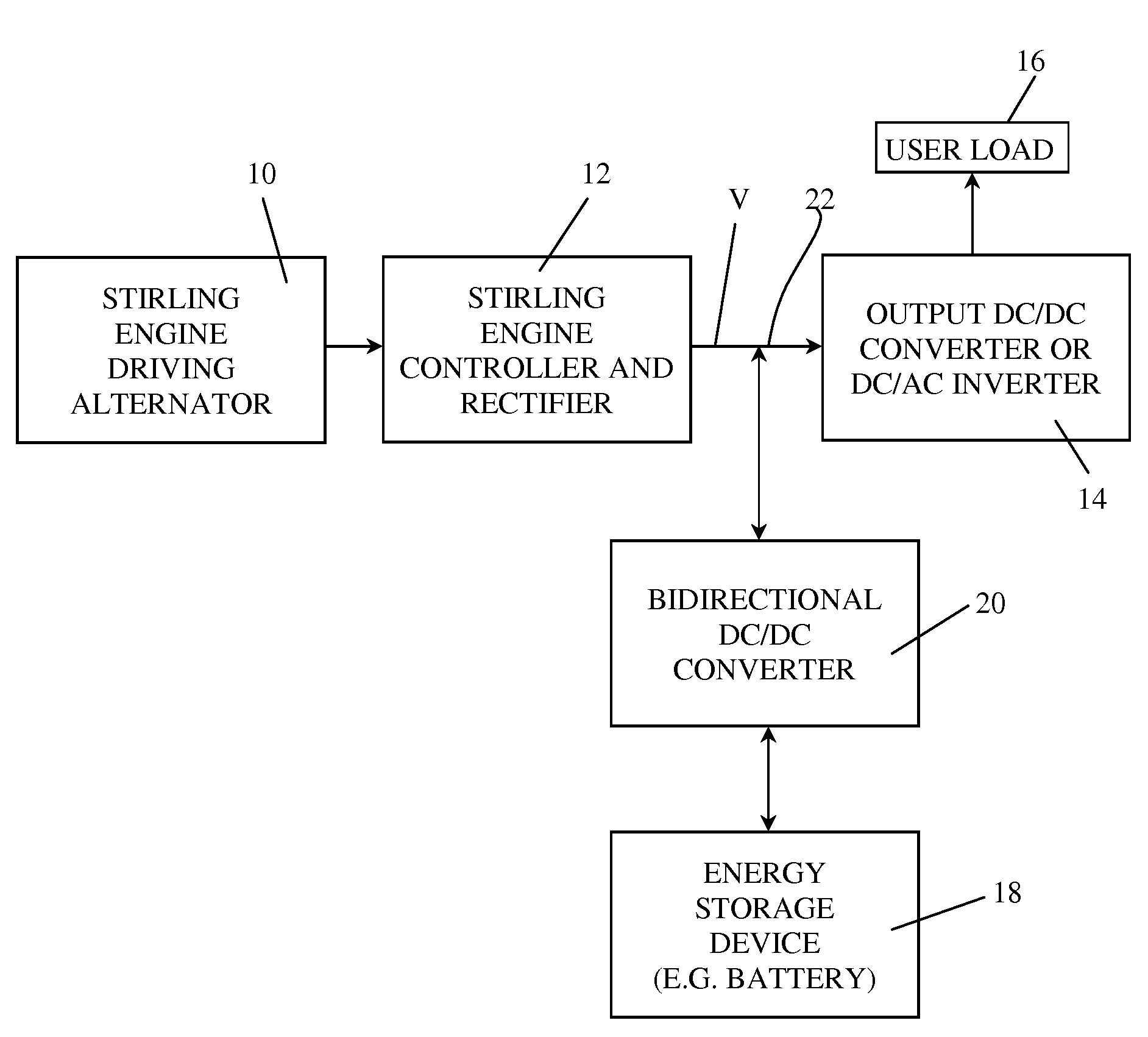

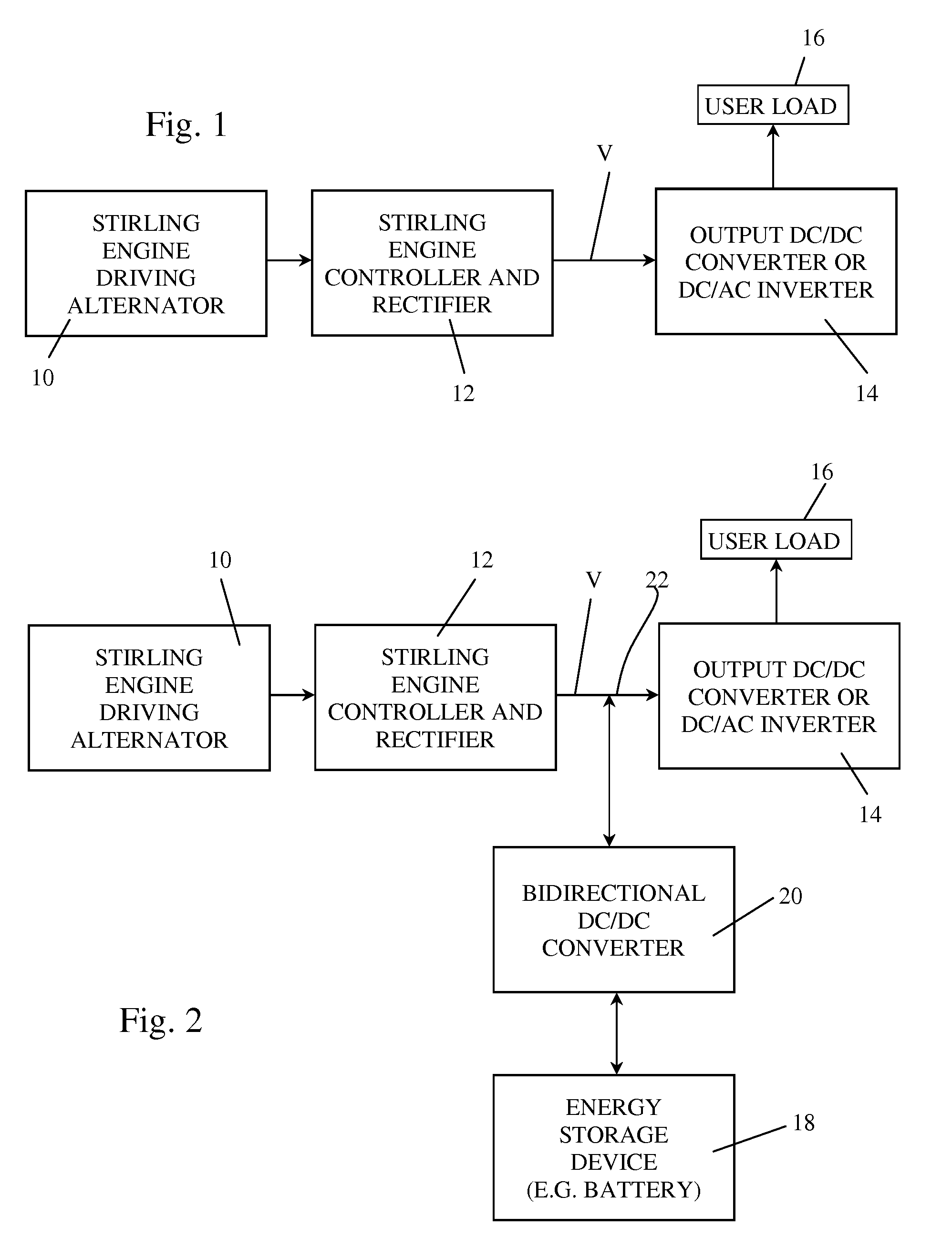

Hybrid electrical power source combining stirling engine driven alternator with supplementing electrical energy storage

InactiveUS20090206667A1Batteries circuit arrangementsGas pressure propulsion mountingBattery chargeAlternator

An electrical power source including a free-piston Stirling engine driving an alternator to supply power through a bus to a user load and controlled by an engine / alternator controller. A bidirectional DC / DC converter is connected between a battery and the bus. The stroke of the engine piston is modulated between a maximum and a minimum stroke to maintain the bus voltage at a design nominal bus voltage (V1), and charge the battery if it is not charged, when and so long as the bus voltage does not fall below a design nominal bus voltage (V1). The Stirling engine is operated at its maximum piston stroke, and the battery is charged if it is not charged, when the bus voltage is in the range between the design nominal bus voltage (V1) and a design minimum battery charging bus voltage (V2). The Stirling engine is operated at its maximum piston stroke and the battery is disconnected from the bus so it can not charge when the bus voltage is in the range between the design minimum battery charging bus voltage (V2) and a design minimum bus voltage (V3). The Stirling engine is operated at its maximum piston stroke and power is applied from the battery to the bus for maintaining the bus voltage at the design minimum bus voltage (V3) when the power supplied from the alternator operating at its maximum stroke is less than the power demand of the load.

Owner:SUNPOWER

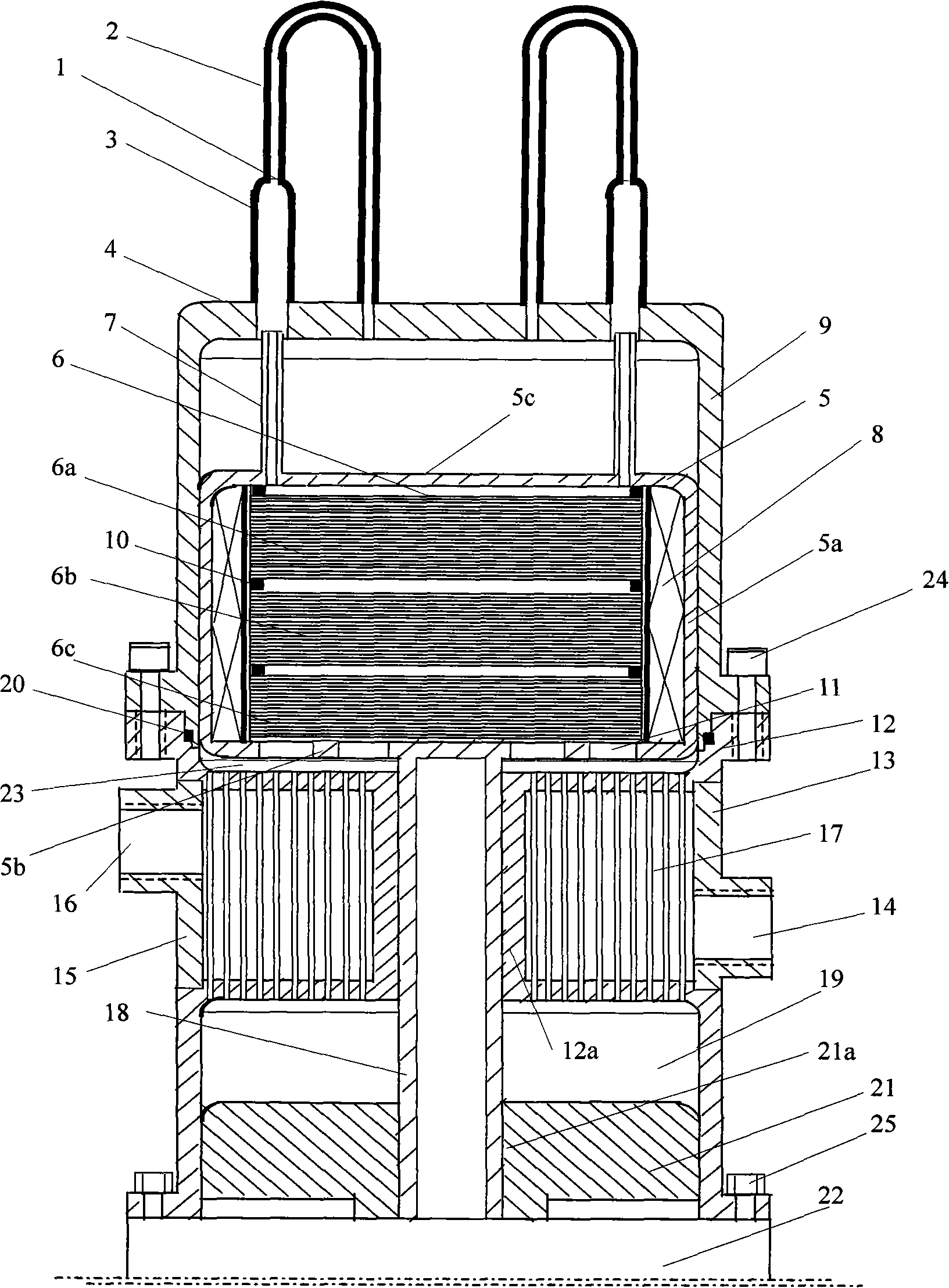

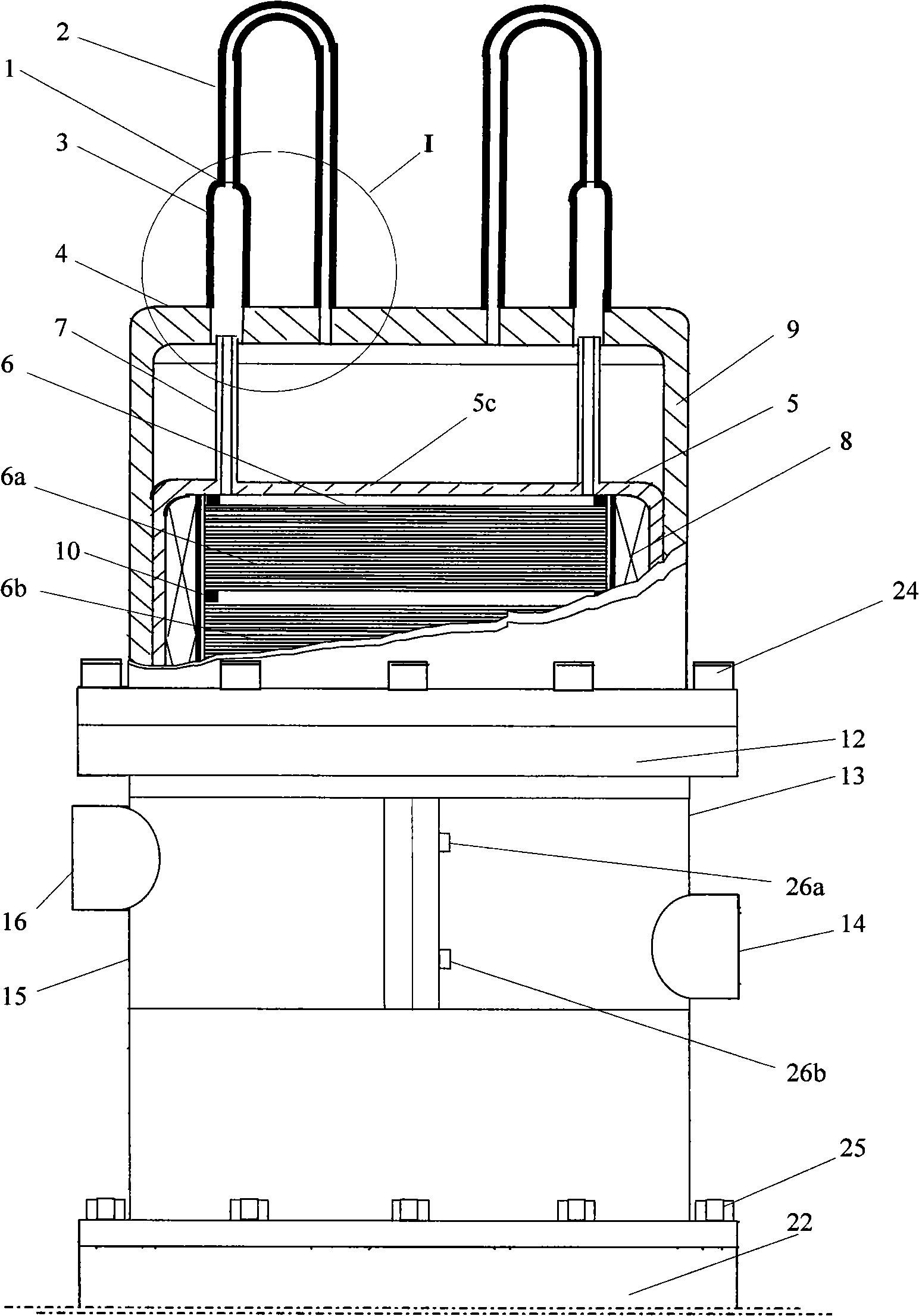

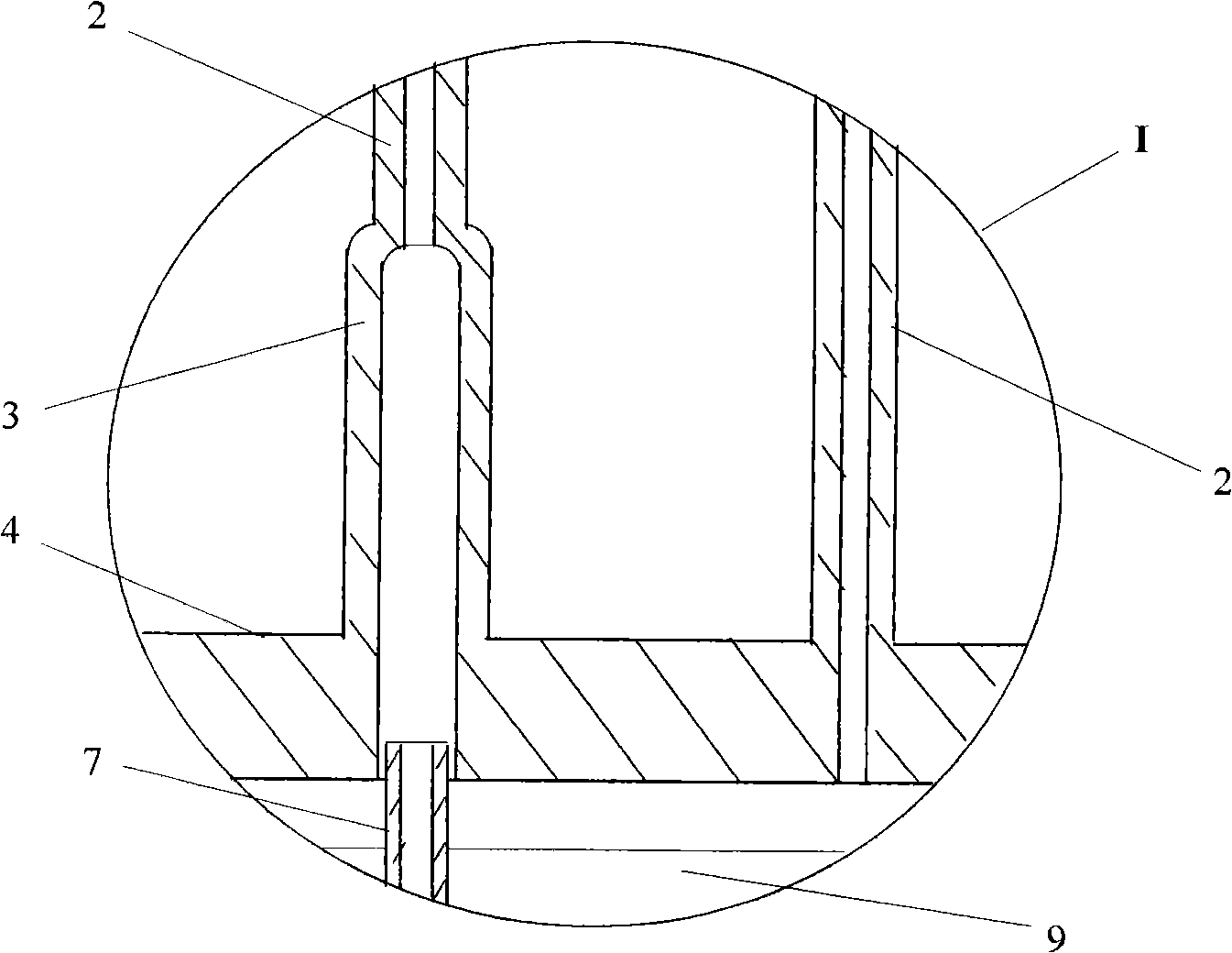

Gas distribution piston type Stirling engine

InactiveCN101280737AReduce volumeReduce weightHot gas positive displacement engine plantsRenewable biomassEngineering

The invention discloses an air distribution-piston stirling engine. A heat regenerator 6 is arranged in an air distribution piston cylinder body 5a and moves with an air distribution piston 5; a tube stack of a cooling tube 17 divides a cold cavity cylinder into an upper cold cavity cylinder 23 and a lower cold cavity cylinder 19; an air distribution piston rod 18 runs through a guide tube 12a of the air distribution piston rod on a cooler 12 and a guide hole 21a of the air distribution piston rod on a power piston 21 and slides in the guide tube 12a of the air distribution piston rod and the guide hole 21a thereof on the power piston 21. The improved mechanical structure of the invention reduces the volume, weight and manufacturing cost of the air distribution-piston stirling engine and enhances the efficiency and lengthens the service life of the air distribution-piston stirling engine. The air distribution-piston stirling engine of the invention can use solid, liquid and gaseous fuels and renewable biomass fuels and heat resources such as solar energy, and is characterized by wide source range of fuels and heat resources, high heating efficiency and environmental friendliness, which will be widely applied through future social production practice.

Owner:白坤生

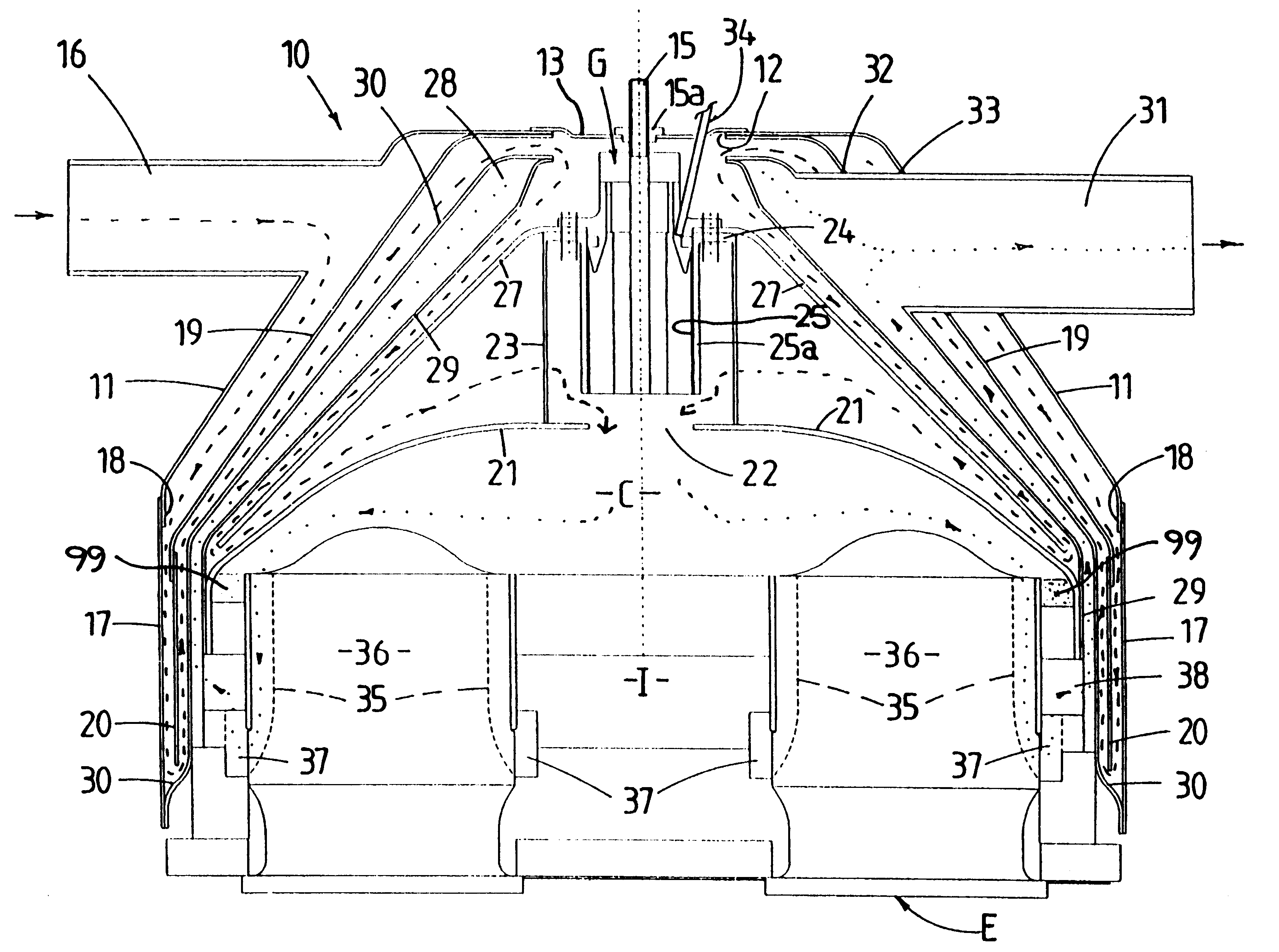

Stirling engine burner

A burner for an external combustion engine using liquid or gaseous fuel, the burner being arranged for heat exchange between the inlet air to the burner and the exhaust air from the burner. The burner includes an external housing, a shroud within this housing, which shroud forms part of the centrally positioned combustion chamber. The burner includes air inlet apparatus and guide apparatus for guiding the inlet air to the combustion chamber, an igniter and fuel inlet apparatus and gas exhaust apparatus. The external housing, an element of the inlet apparatus, the guide apparatus, and heat exchange elements are formed as inverted shaped dishes or shells about the combustion chamber.

Owner:WHISPER TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com