Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

756 results about "Boiler (power generation)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed boilers and worked at low to medium pressure (7–2,000 kPa or 1–290 psi) but, at pressures above this, it is more usual to speak of a steam generator.

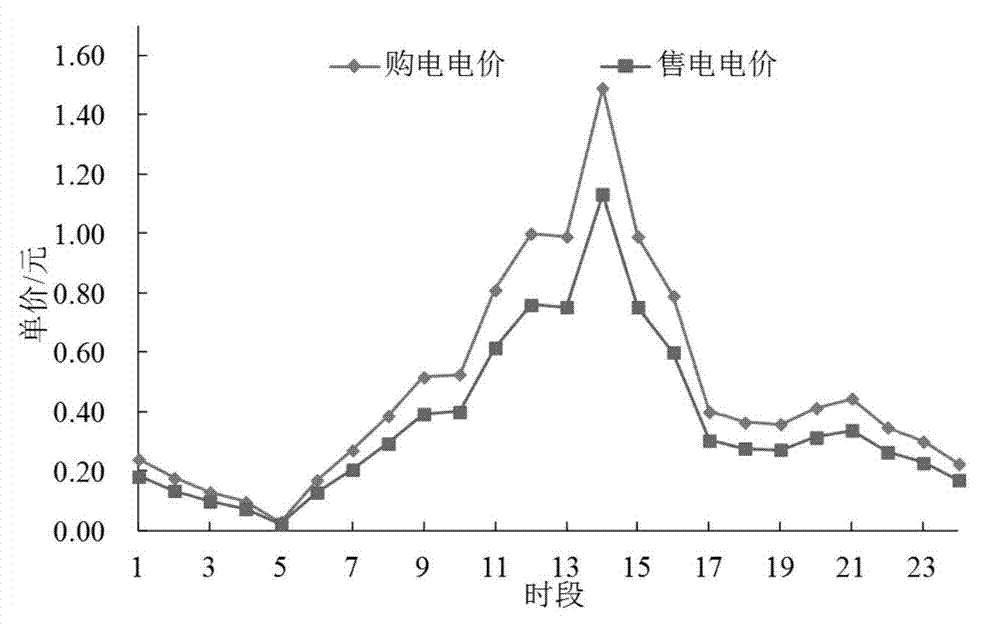

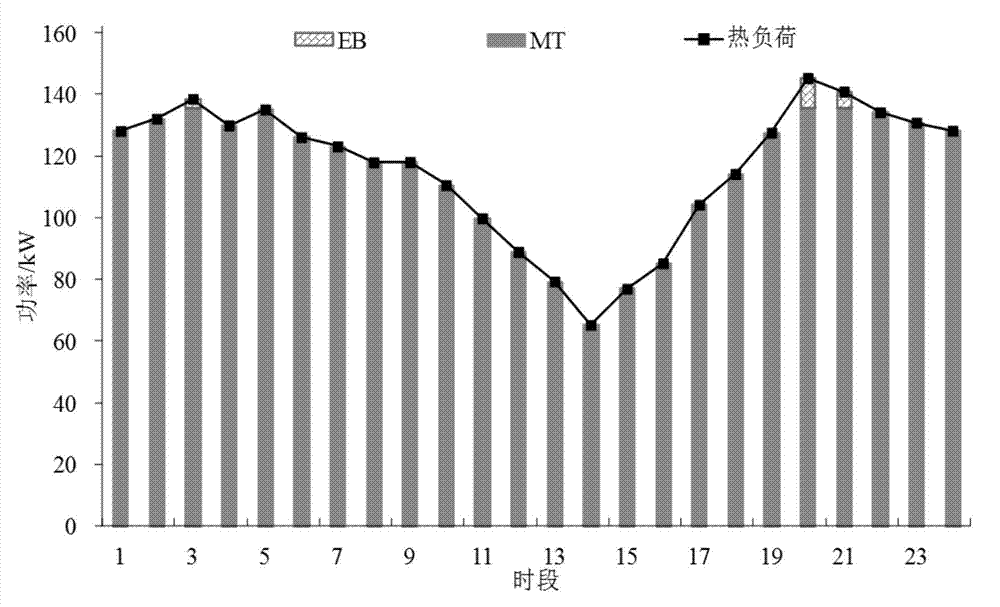

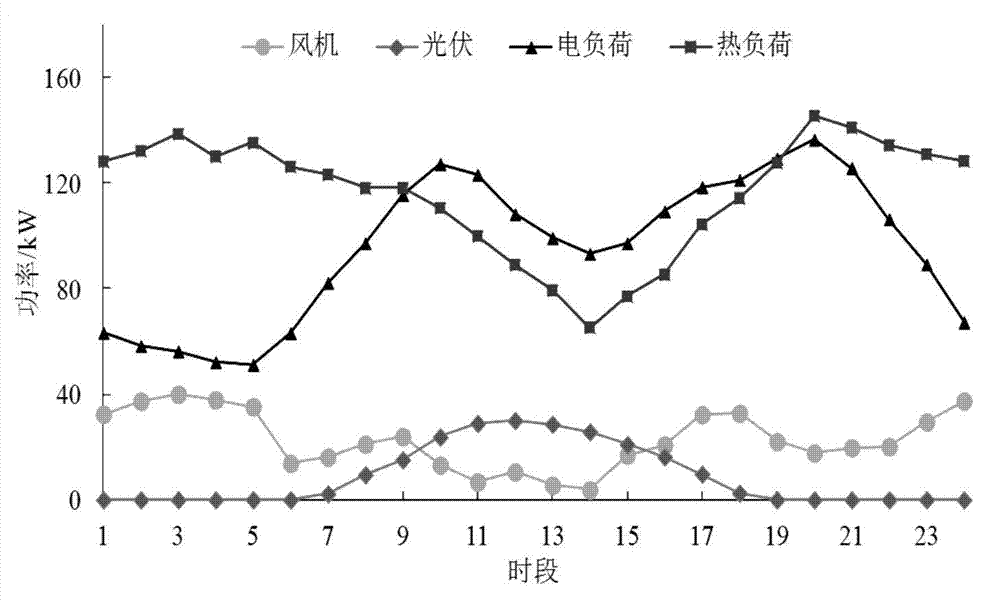

Microgrid running optimization system and method based on power and heat combined dispatching

ActiveCN104734168AIncrease profitLow running costEnergy storageAc network load balancingDistributed generatorInteger non linear programming

The invention discloses a microgrid running optimization system and method based on power and heat combined dispatching. Running restrains such as the output force characteristic, start, stop and climbing of a distributed type generator set and the charge and discharge characteristics of power and heat energy storage are comprehensively considered, a microgrid power and heat combined dispatching model containing a fan, a photovoltaic cell, a combined heat and power generation system, an electric boiler, a fuel cell and an energy storage (electrical energy storage and heat energy storage) is built, the 0-1 mixed integer nonlinear programming method is adopted for solving the optimal output force and total running cost of all units in the network, and power and heat dispatching contrastive analysis is carried out on the system and a traditional separated generation and combined generation optimization model. In addition, the influences of the heat and power reliability difference on the running are analyzed and discussed, and therefore the heat and power dispatching module is more reasonable, comprehensive and universal.

Owner:SHANDONG UNIV

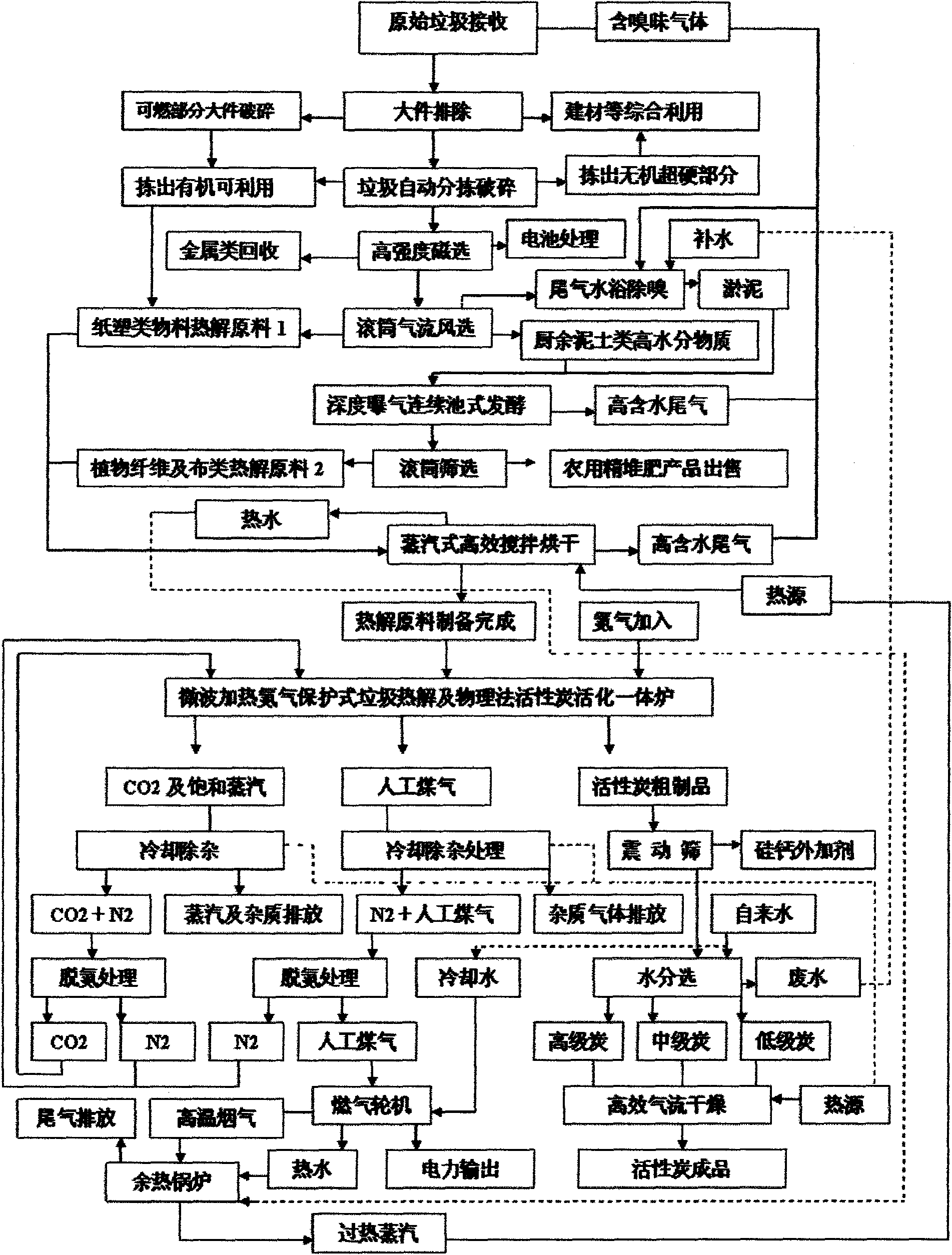

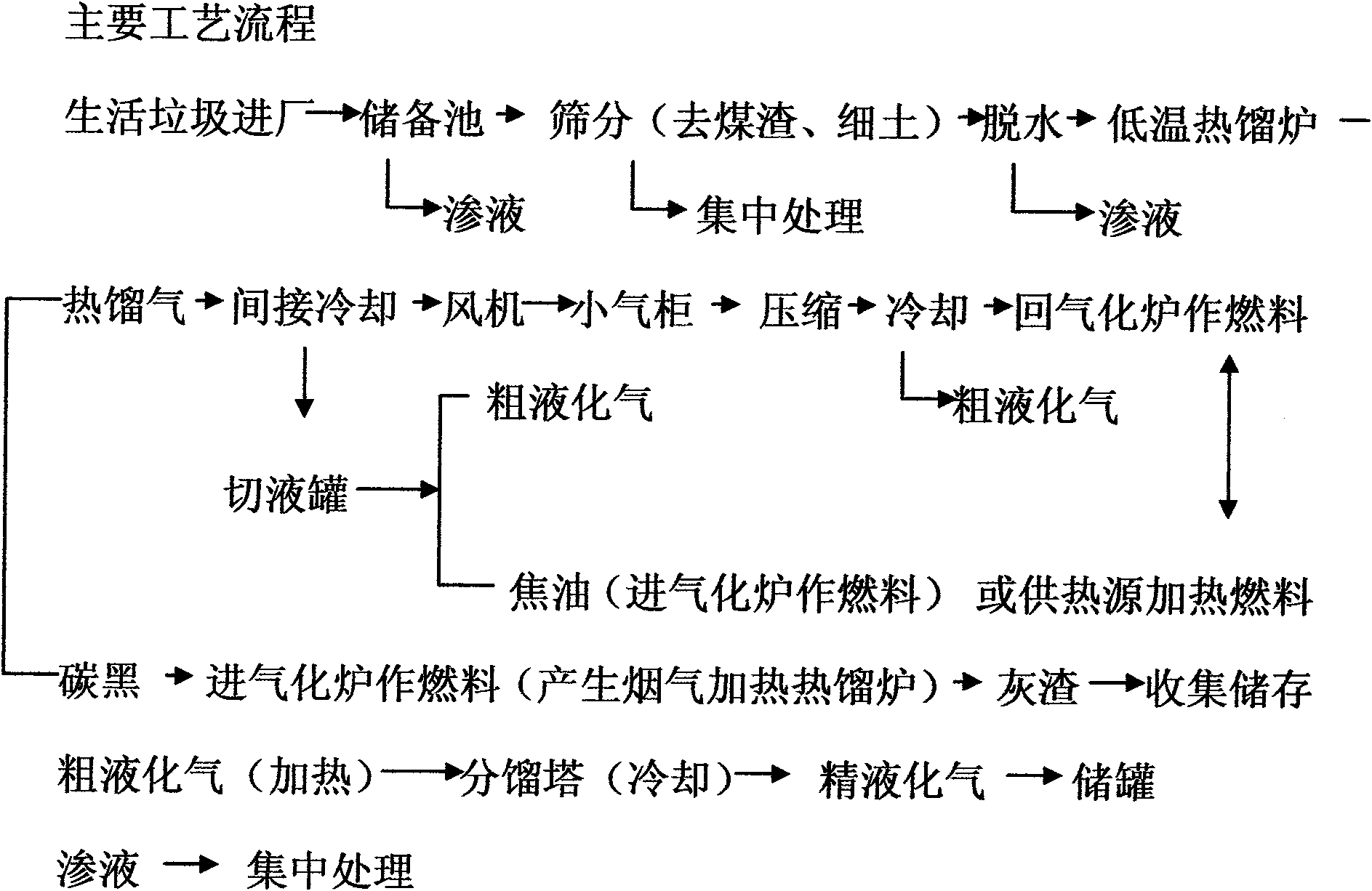

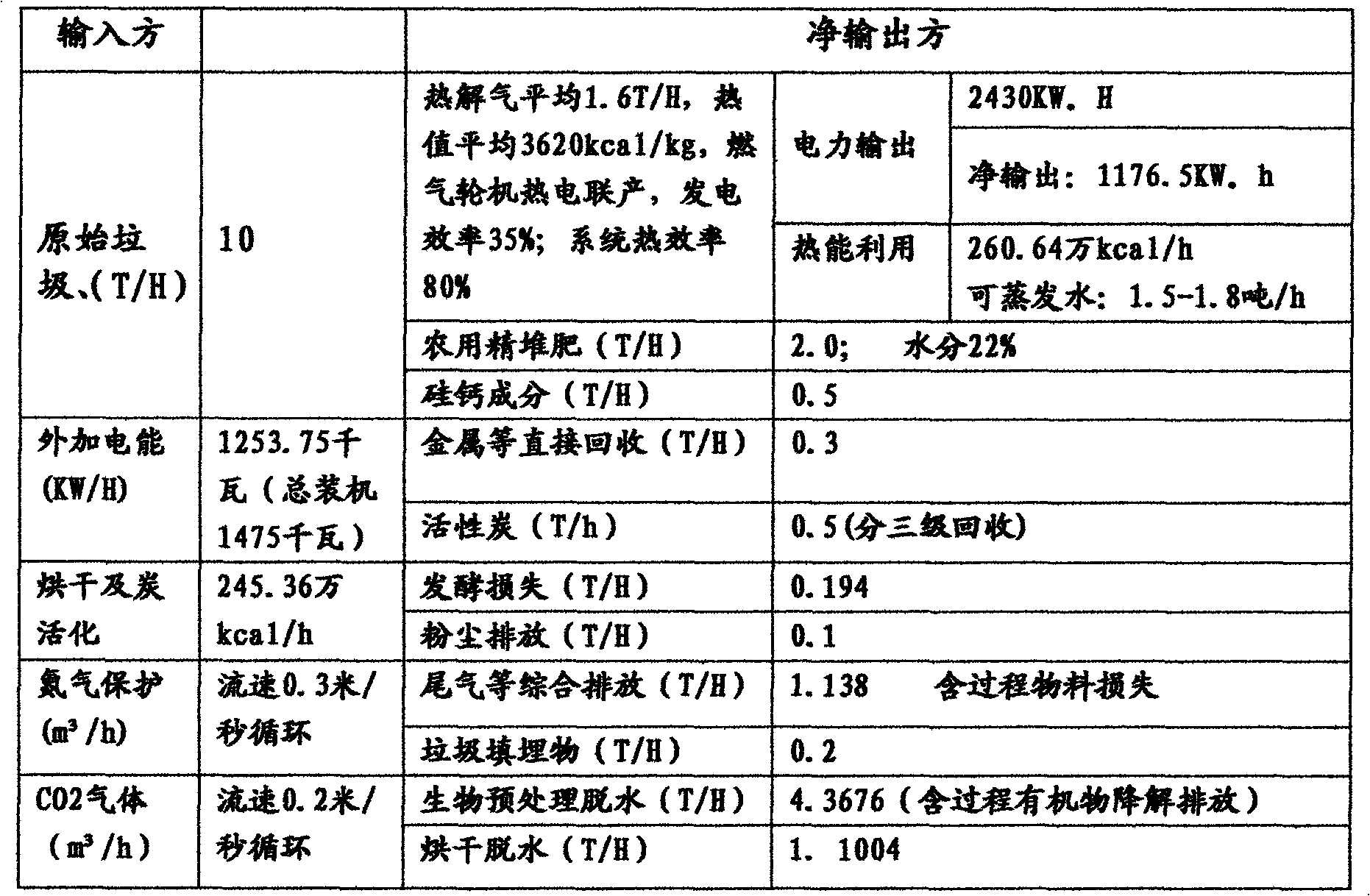

Technological method of comprehensive utilization of separation and pyrolysis treatment of garbage

InactiveCN101618392AAchieve harmless disposal rateReduce energy consumptionDrying solid materials with heatCarbon compoundsEvaporationOxygen

The invention relates to a technological method of comprehensive utilization of separation and pyrolysis treatment of garbage, which solves the problem of comprehensive utilization of separation pretreatment and pyrolysis gas in the process of separation treatment of garbage. The method comprises the following steps: separating and crushing the garbage for secondary classification; classifying the available components in the garbage into three classes, wherein the first class comprises paper, plastic and the like which are used as pyrolysis raw materials 1, the second class comprises the mixture of soil, kitchen wastes and the like, and the third class comprises the mixture of rag, fresh branches, vines and the like; chopping the mixture of the third class, and mixing the chopped mixture of the third class with the mixture of the second class; treating the mixture of the second class and the mixture of the third class by aerobic fermentation, and using penetrant for direct back-spraying and evaporation in high-temperature regions; treating the obtained product by secondary sieving to obtain pyrolysis raw materials 2; mixing and drying the pyrolysis raw materials 1 and the pyrolysis raw materials 2; condensing the generated steam to obtain hot water which back flows into a waste heat boiler of a power generating system to be used as supplemental water; commercializing and recovering the pyrolysis raw materials; and burning the obtained combustible gas for power generation. The invention has the advantages of high recovery rate, low energy consumption and no pollution caused by discharge.

Owner:SHEN ZHEN A MART IND

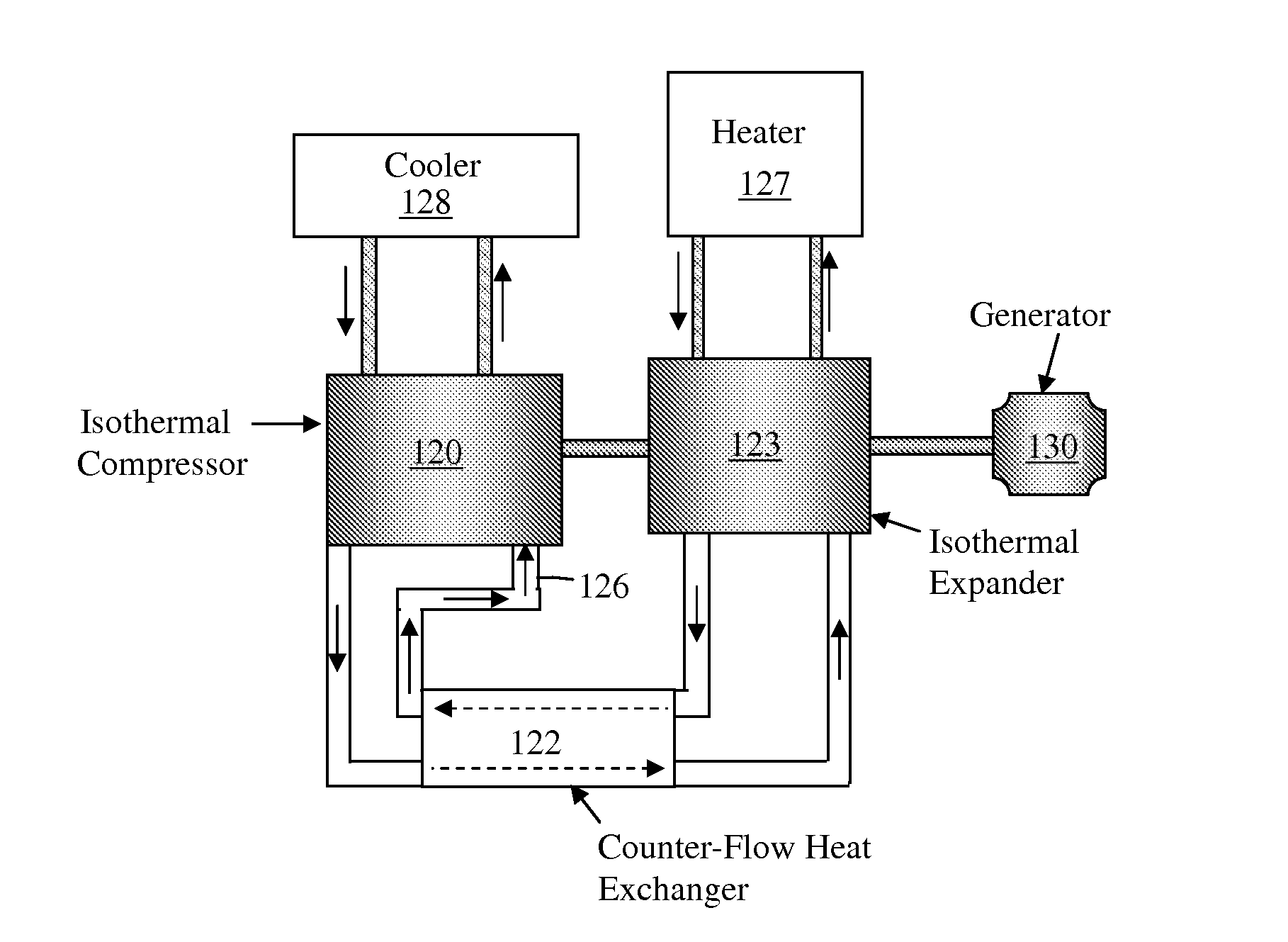

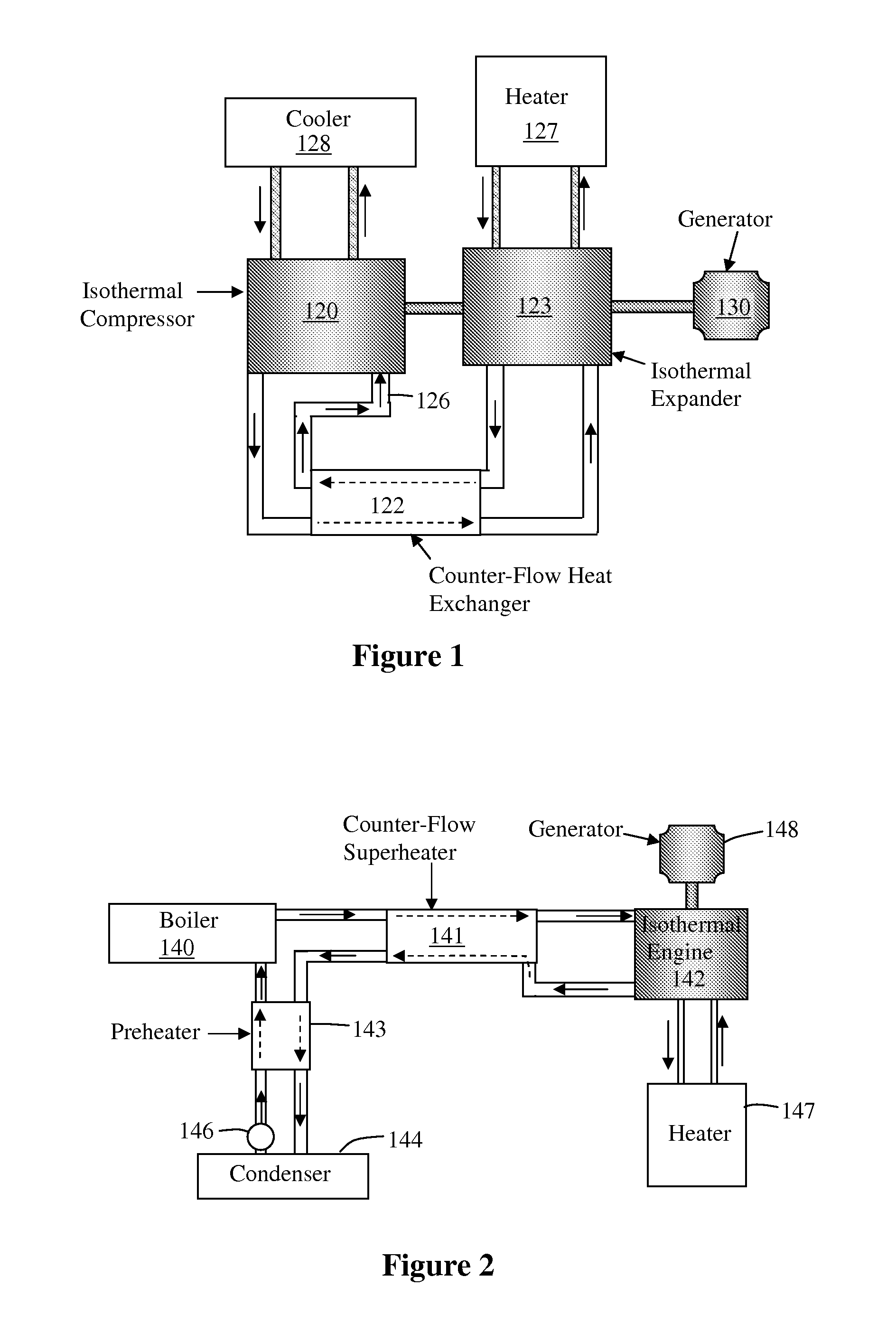

Isothermal power

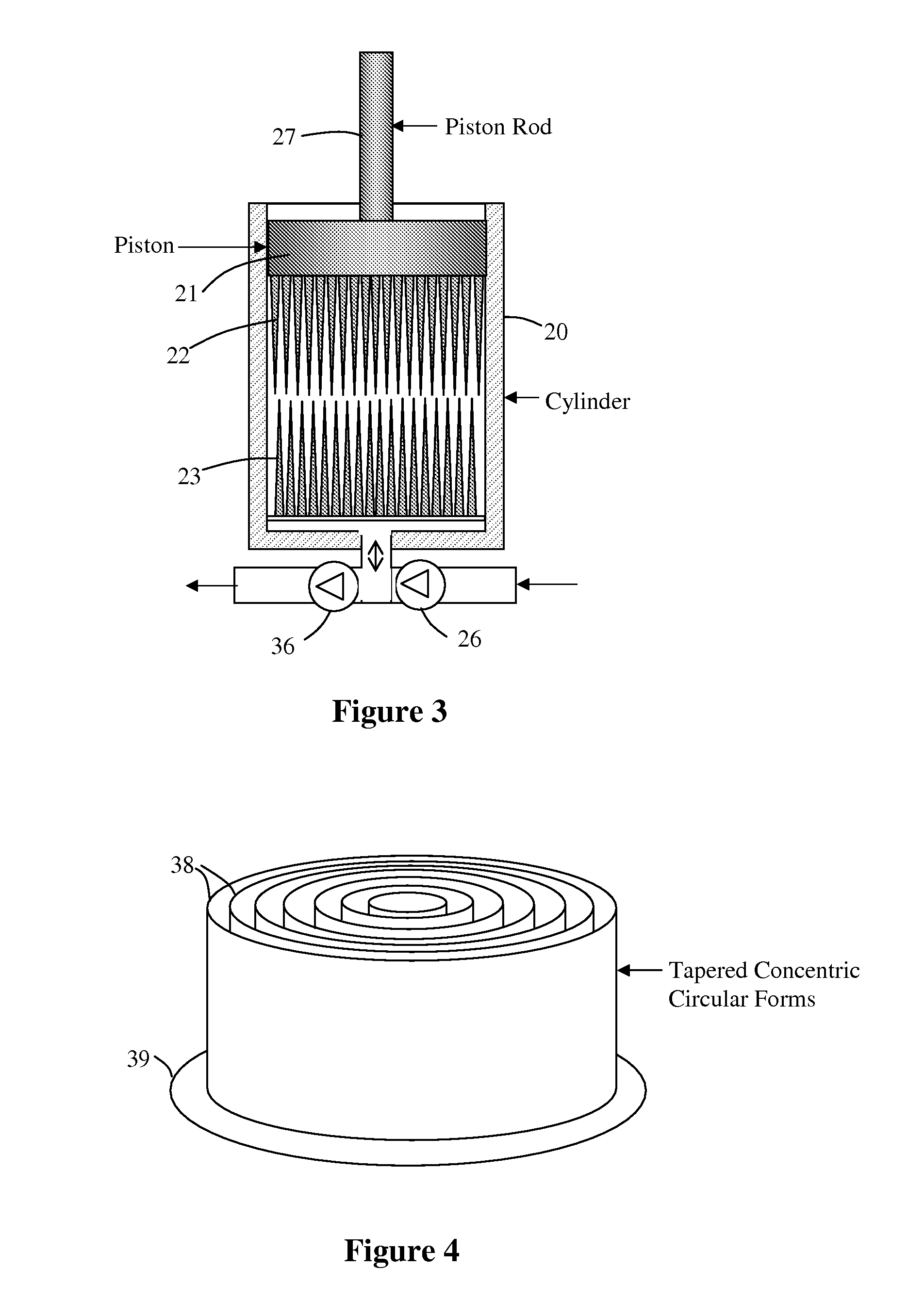

InactiveUS20080264062A1Reducing mechanical lossEfficient productionSteam engine plantsMechanicsBoiler (power generation)

This invention provides means for producing power by using isothermal compressors and isothermal expanders. One embodiment has an isothermal compressor that compresses air (or other gas), passes the air through a counter-flow heat exchanger, which heats the air, uses the heated air to drive an isothermal expander for power generation, and transfers the expander exhaust back through the counter-flow heat exchanger to heat the input air to the expander. Another embodiment has a boiler that produces vapor that flows through a counter-flow heat exchanger to superheat the vapor. The vapor then flows through an isothermal expander for power generation. The exhaust from the isothermal expander flows back through the counter-flow heat exchanger to supply heat to the vapor coming from the boiler and then flows through another heat exchanger that preheats the feed liquid flowing to the boiler.

Owner:PRUEITT MELVIN L

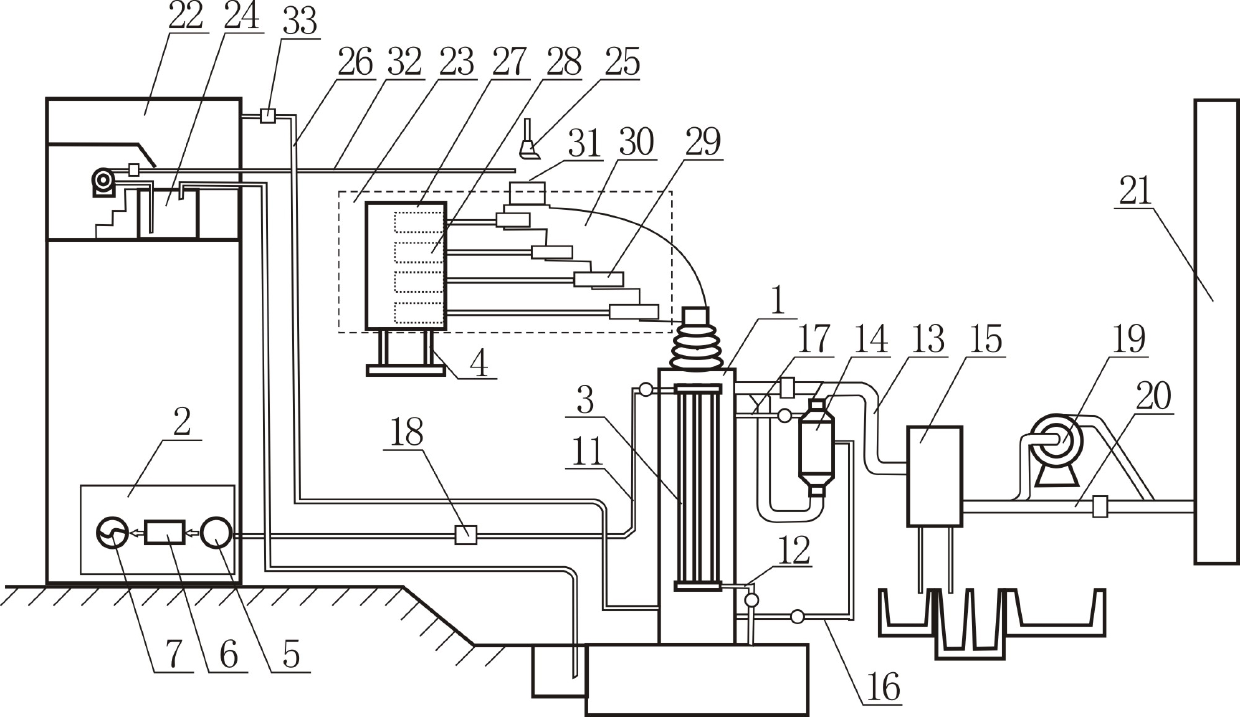

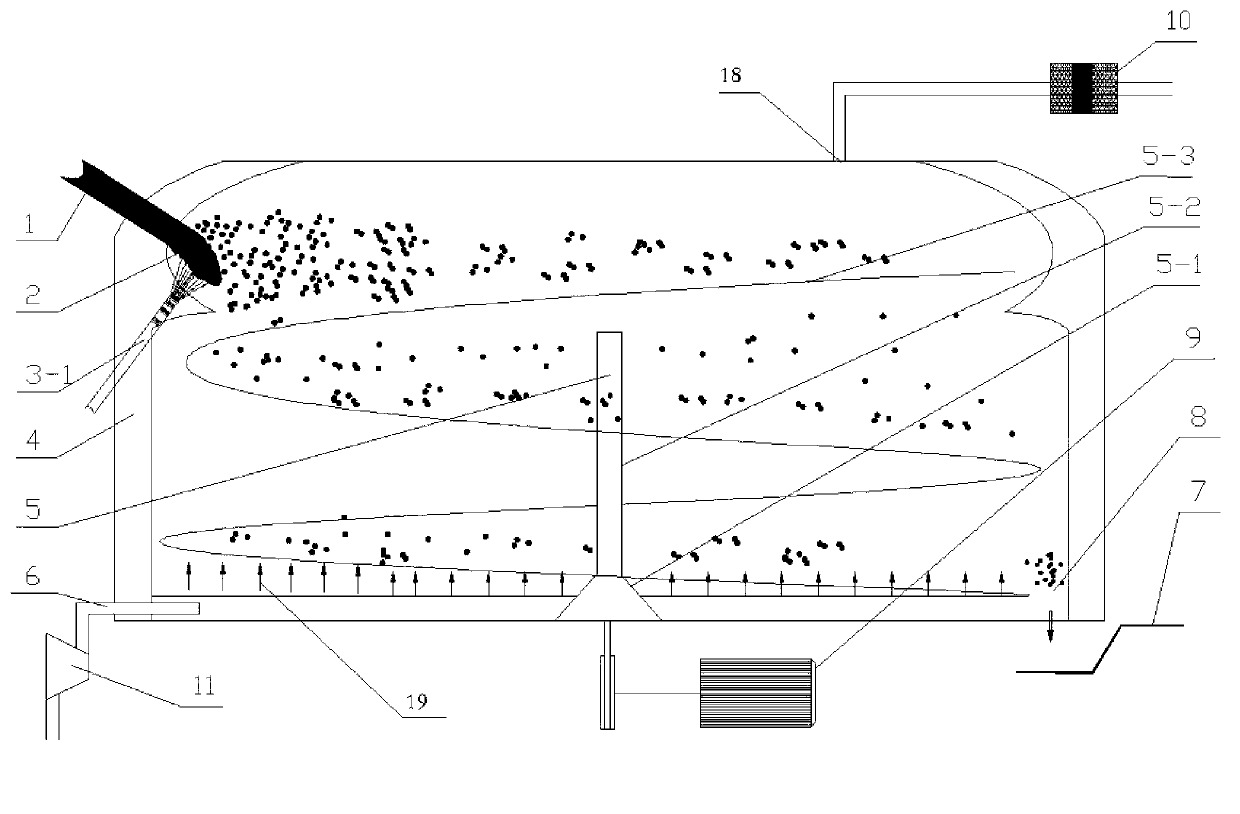

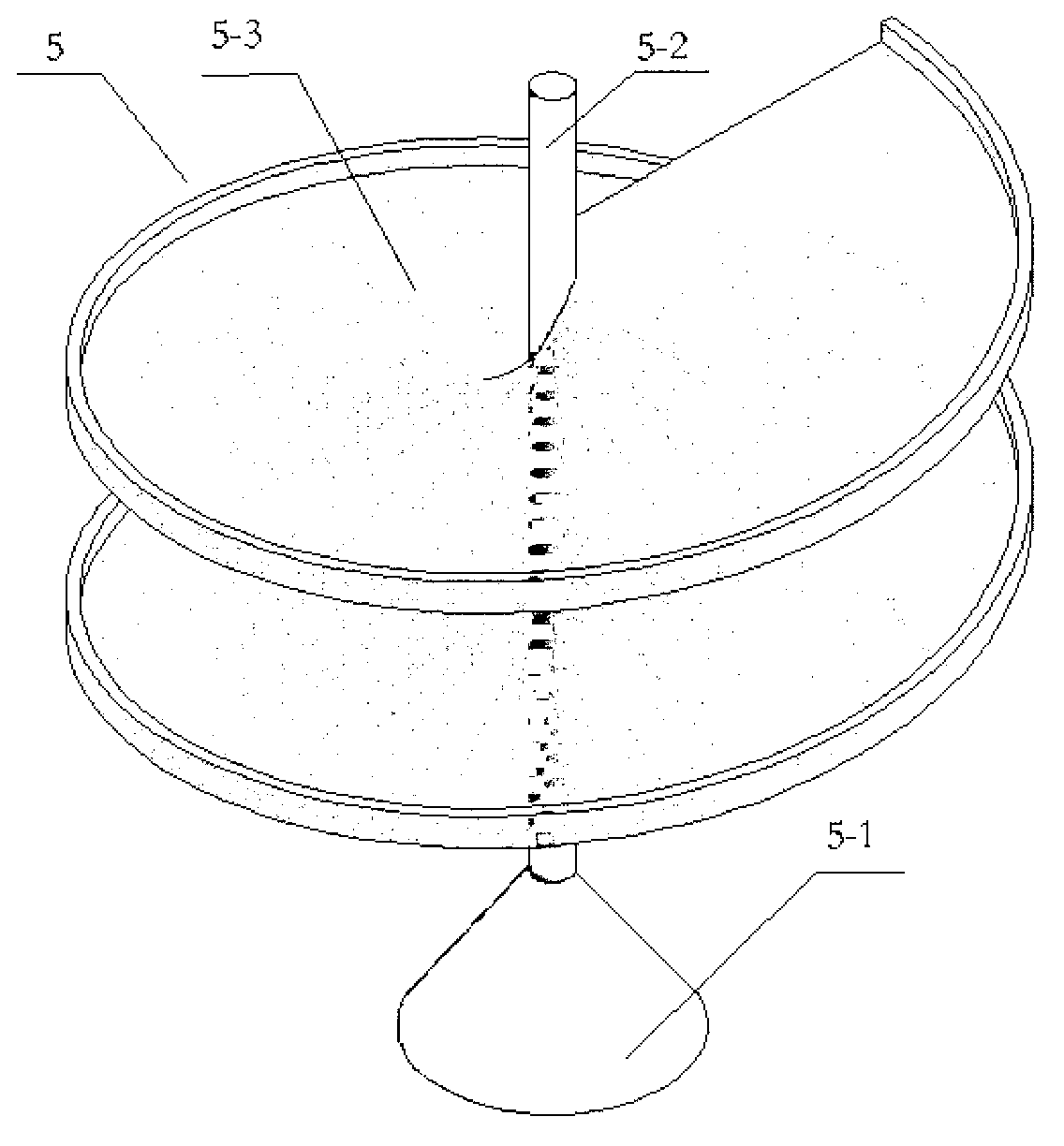

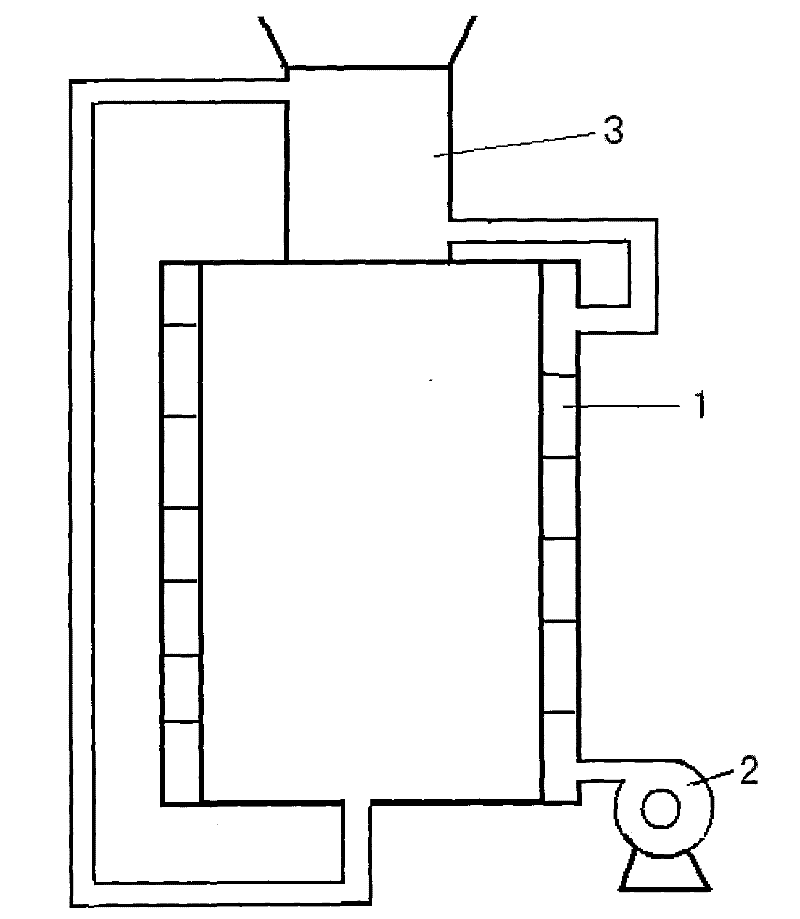

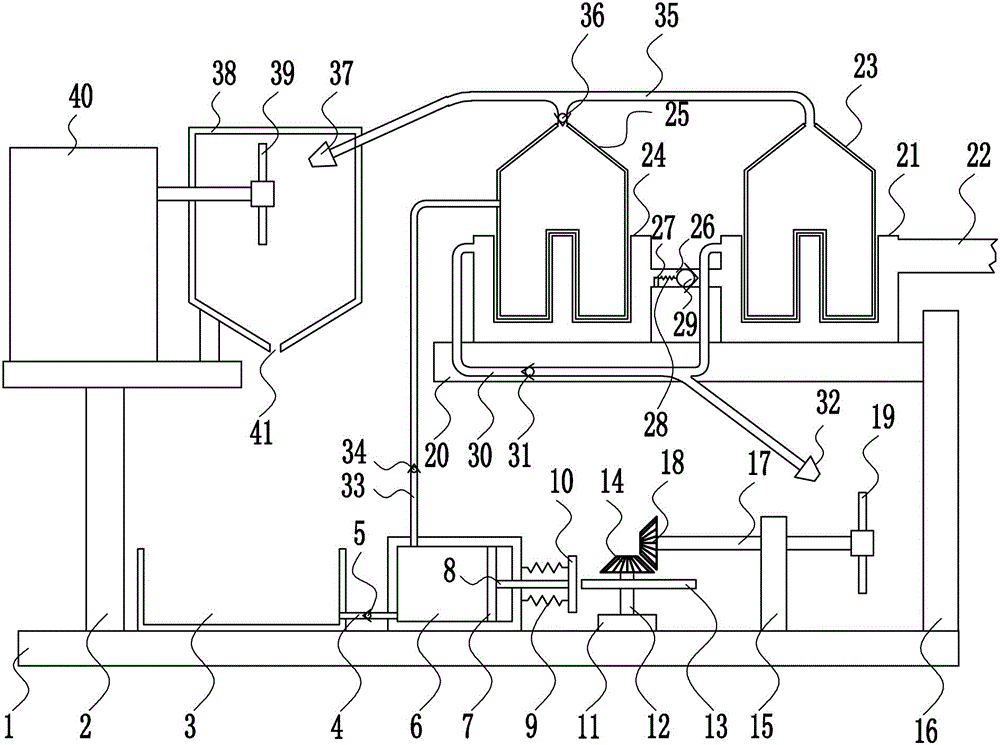

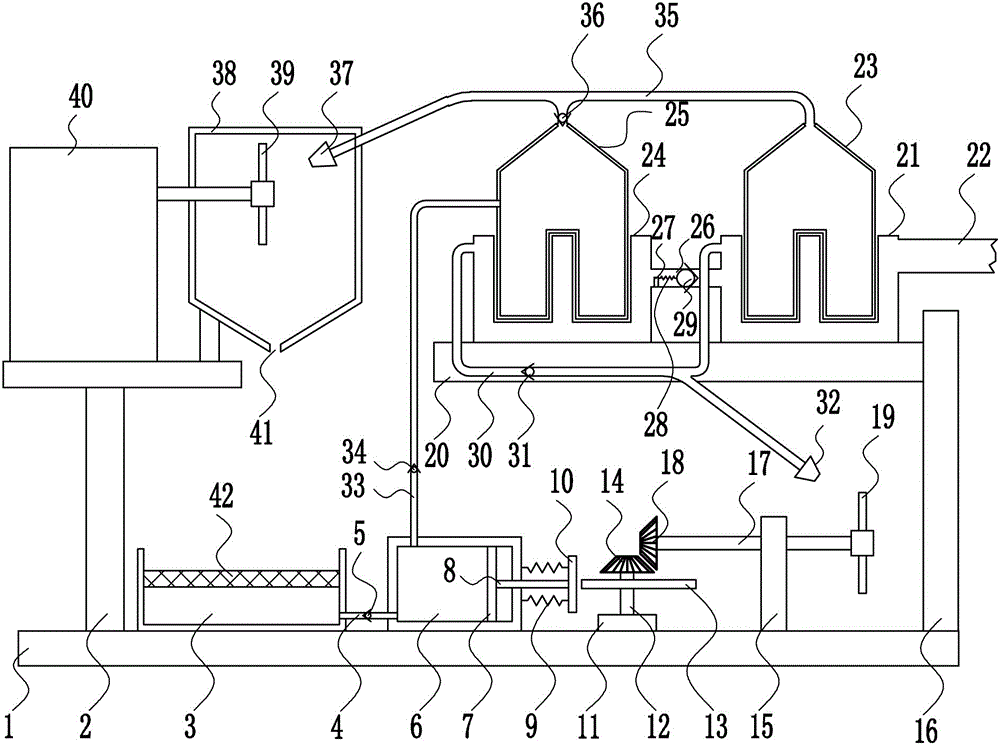

Integrated method and device for sludge drying incineration and power generation

InactiveCN101817629AHigh thermal efficiencyCompact and reasonable connectionSludge treatment by de-watering/drying/thickeningIncinerator apparatusThermal energySludge

The invention discloses an integrated method and device for sludge drying incineration and power generation. The device of the invention comprises a screw rotary type sludge drier; dried sludge enters a fluidized bed boiler to be performed with incineration; steam generated by incineration is used for carrying out power generation; exhaust steam from a small steam turbine is adopted to dry the sludge, thereby realizing cascade utilization of steam heat energy; the electric energy generated by a small generator set can sufficiently meet power utilization in the operation of equipment, thus reducing the operating cost and fully saving energy; and sludge drying incineration and power generation are integrated into a whole. In the invention, the screw rotary type sludge drier is used for feeding the fluidized bed incineration boiler, the steam generated by incineration is used for carrying out power generation, and the low-grade exhaust steam from the steam turbine is adopted as the heat source of the drier, thereby greatly improving the heat efficiency of a steam power device; meantime, the electric energy generated by the small generator set can sufficiently meet power utilization in the operation of the equipment, thus reducing the operating cost; and with the integration design, the system has reasonable and compact connection of the integrated device, mature equipment structure and better economical efficiency.

Owner:ZHEJIANG UNIV +1

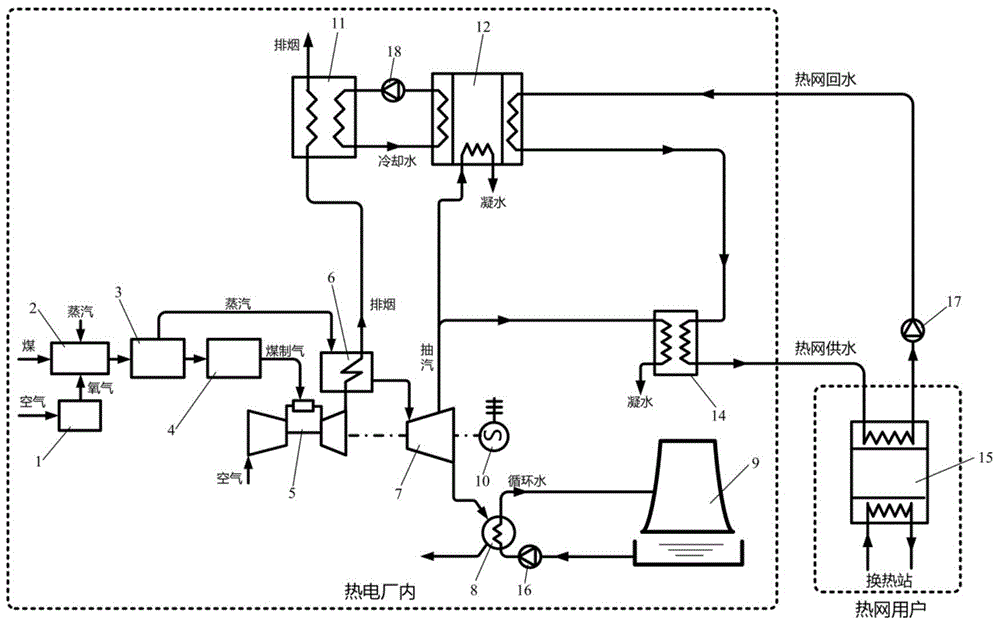

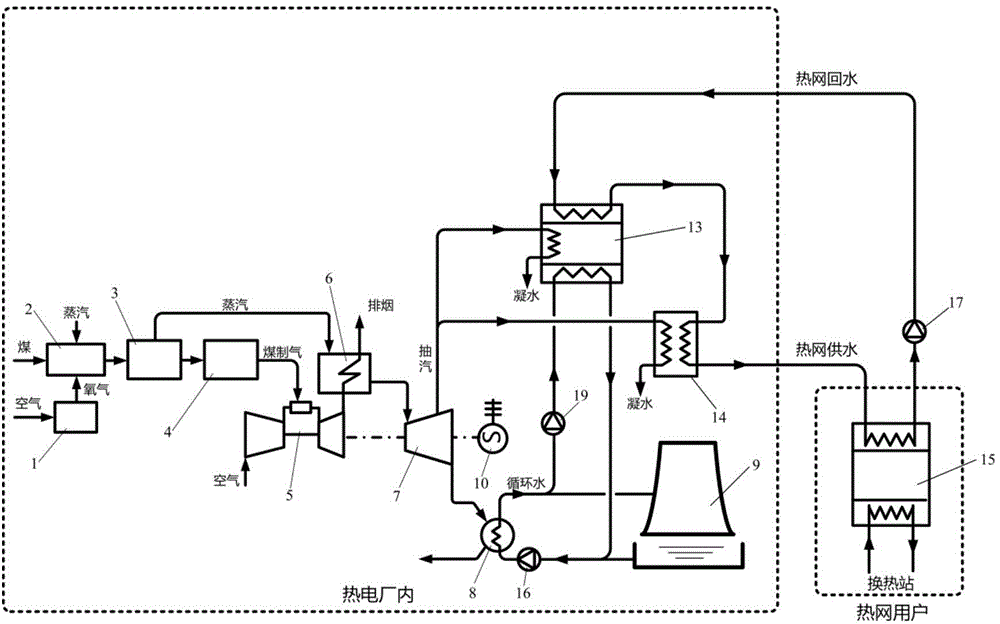

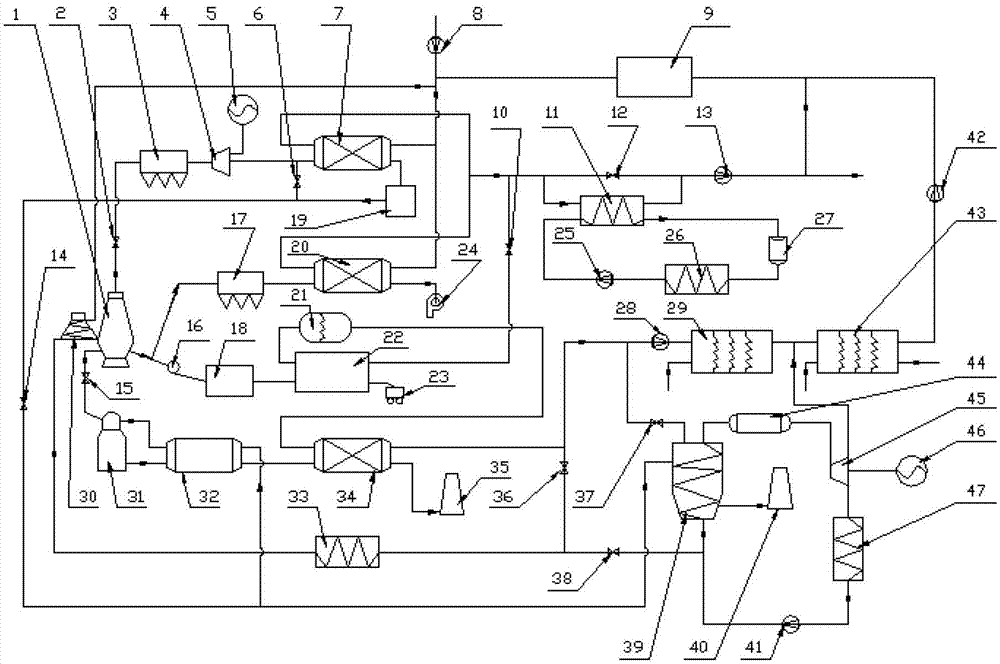

Waste heat recovery IGCC (integrated gasification combined cycle) combined heat and power generation central heating system and method

ActiveCN104533551AImprove economyGuaranteed annual power generation hoursLighting and heating apparatusSteam useCooling towerMature technology

The invention discloses a waste heat recovery IGCC (integrated gasification combined cycle) combined heat and power generation central heating system and method. The system comprises an air separation unit, a gasification furnace, a gas cooler, a purification plant, a gas turbine, a waste heat boiler, an absorption heat pump and a heat exchanger, which are connected successively. An exhaust smoke outlet of the waste heat boiler is emptied or is connected with a smoke inlet of a smoke condensation heat exchanger; a steam outlet of the waste heat boiler is connected with an inlet of a steam turbine; an exhaust steam outlet of the steam turbine is connected with a steam inlet of a condenser; a circulating water outlet of the condenser is connected with a cooling tower; a low-pressure extracted steam outlet of the steam turbine is divided into three paths, two paths or one path of temperature drop, and heat supply network return water is conveyed to a heat supply network for use after being heated. The invention also provides a central heating method. Clean and efficient IGCC is combined with extracted steam heat supply of the steam turbine, the extracted steam of the steam turbine is used for driving the absorption heat pump, the exhaust steam waste heat of the steam turbine and the smoke waste heat are recycled, and the extracted steam heat of the steam turbine and the recycled waste heat are utilized for central heating. The recovery waste heat IGCC combined heat and power generation central heating system and method have the characteristics of cleanliness, high efficiency, mature technology, high recycled waste heat amount, and capability of recycling smoke condensate water.

Owner:HUANENG CLEAN ENERGY RES INST +1

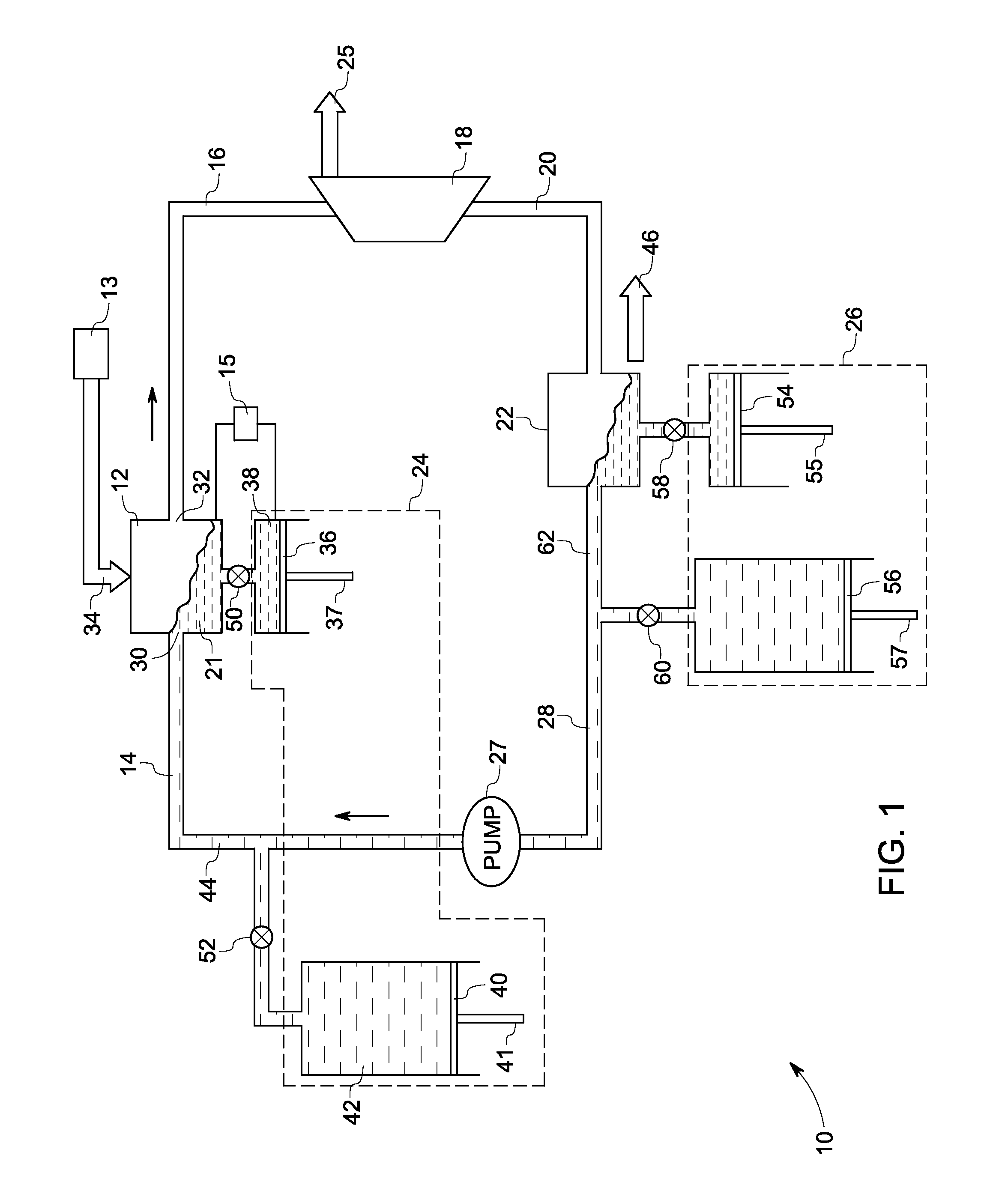

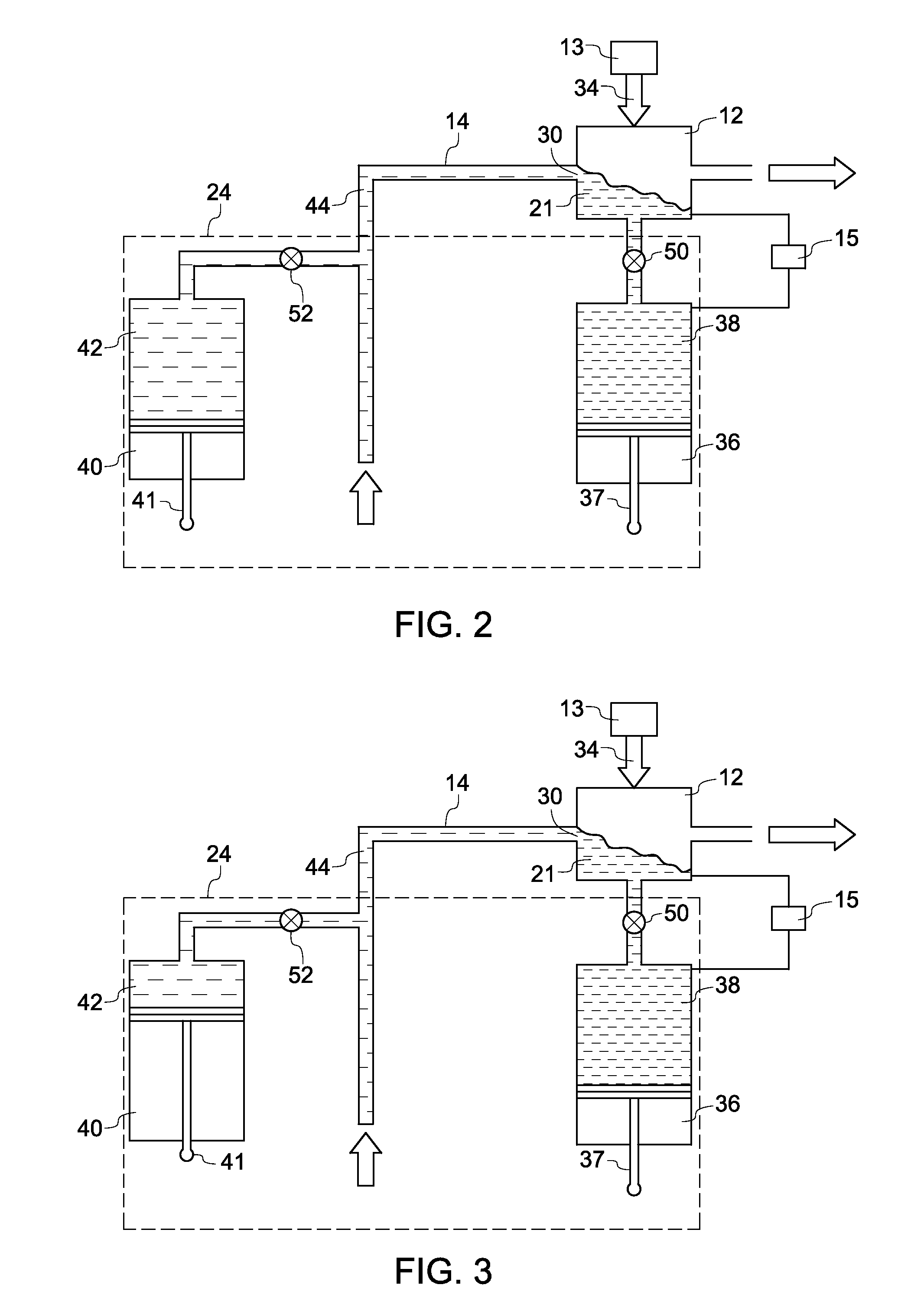

System and method for power generation in Rankine cycle

A system for power generation includes a boiler configured to receive heat from an external source and a liquid stream and to generate a vapor stream. The liquid stream comprises a mixture of at least two liquids. The system also includes an expander configured to receive the vapor stream and to generate power and an expanded stream. A condenser is configured to receive the expanded stream and to generate the liquid stream. The system further includes a supply system coupled to the boiler or the condenser and configured to control relative concentration of the two liquids in the liquid stream.

Owner:AI ALPINE US BIDCO INC

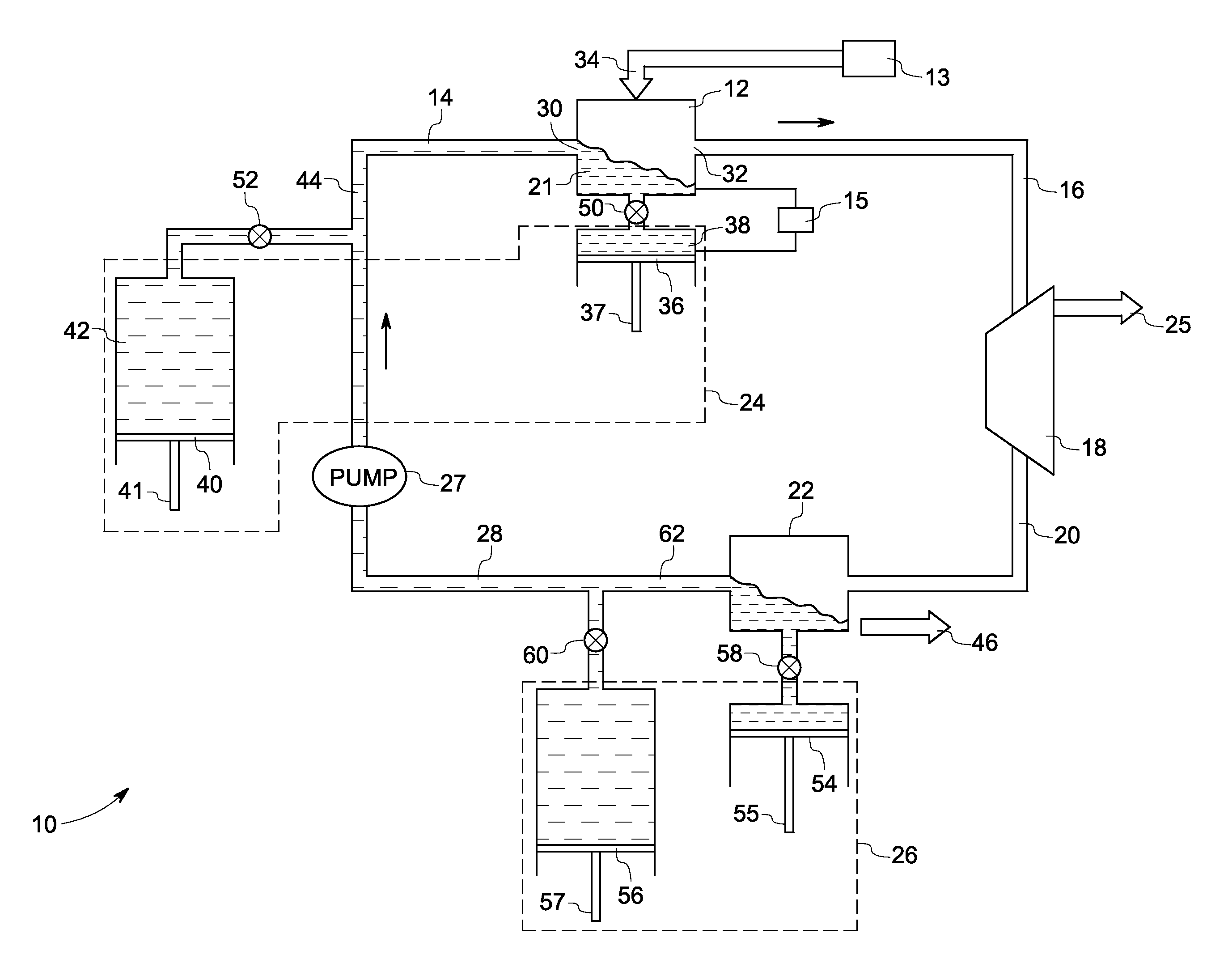

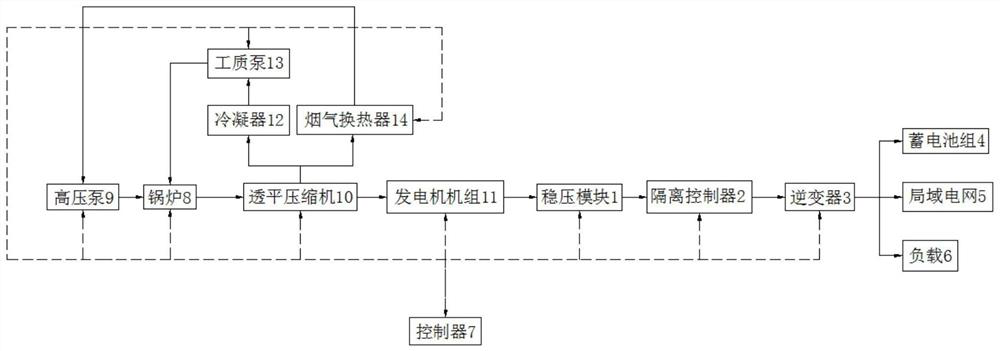

Organic Rankine cycle power generation system for oil field waste heat

PendingCN111911255ATake advantage ofImprove powerFeed water supplyPump controlOrganic Rankine cycleProcess engineering

The invention discloses an organic Rankine cycle power generation system for oil field waste heat. The organic Rankine cycle power generation system involves a turbine compressor, a power generator set, a voltage stabilizing module, an isolation controller and an inverter, wherein a boiler is used for receiving the oil field waste heat, and enabling an organic working medium to absorb heat from waste heat flow in the boiler to generate steam with certain pressure and temperature, a gas inlet of the turbine compressor is connected to a gas outlet of the boiler, and the generator set is used forreceiving high-pressure gas from the turbine compressor and pushing blades of the generator set to rotate, so that the generator set generates electric energy. According to the organic Rankine cyclepower generation system for the oil field waste heat, the controller intelligently controls the operation of each equipment, so that the oil field waste heat is utilized more sufficiently, and throughpressurization and acceleration of the steam, the electric quantity of electric energy generated by the steam to the generator set can be increased, and great economic benefits are generated.

Owner:WUHAN UNIV OF TECH

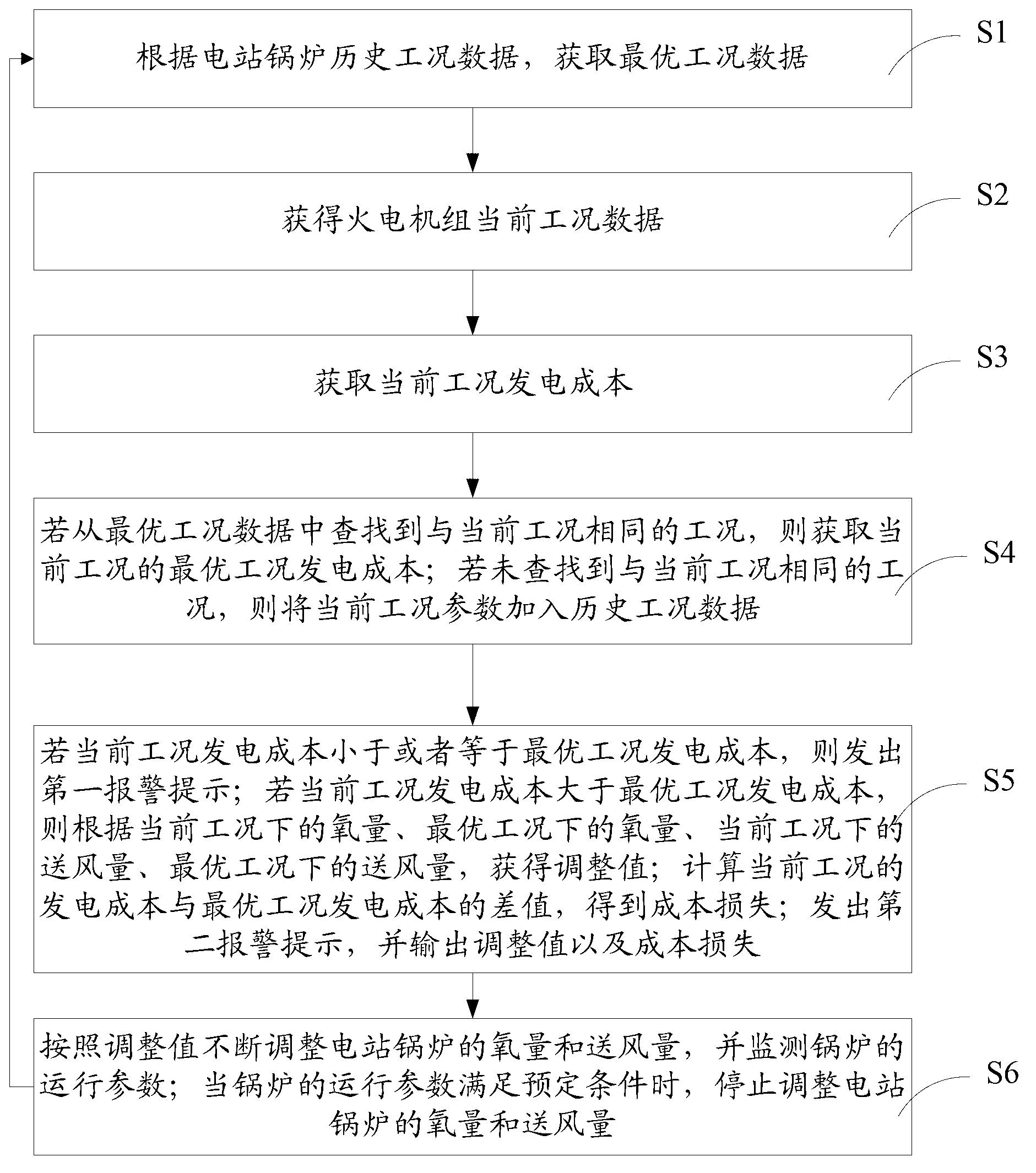

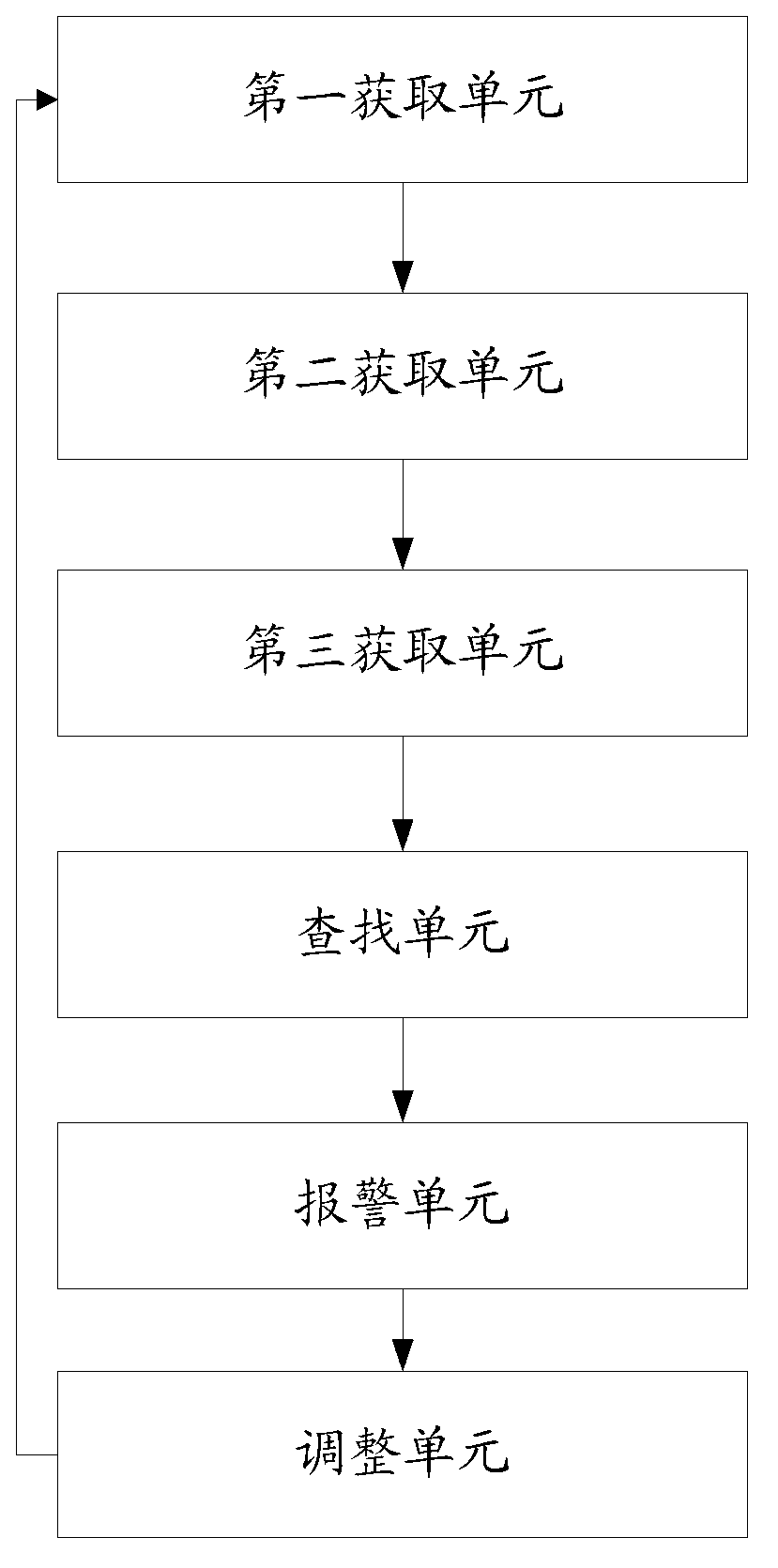

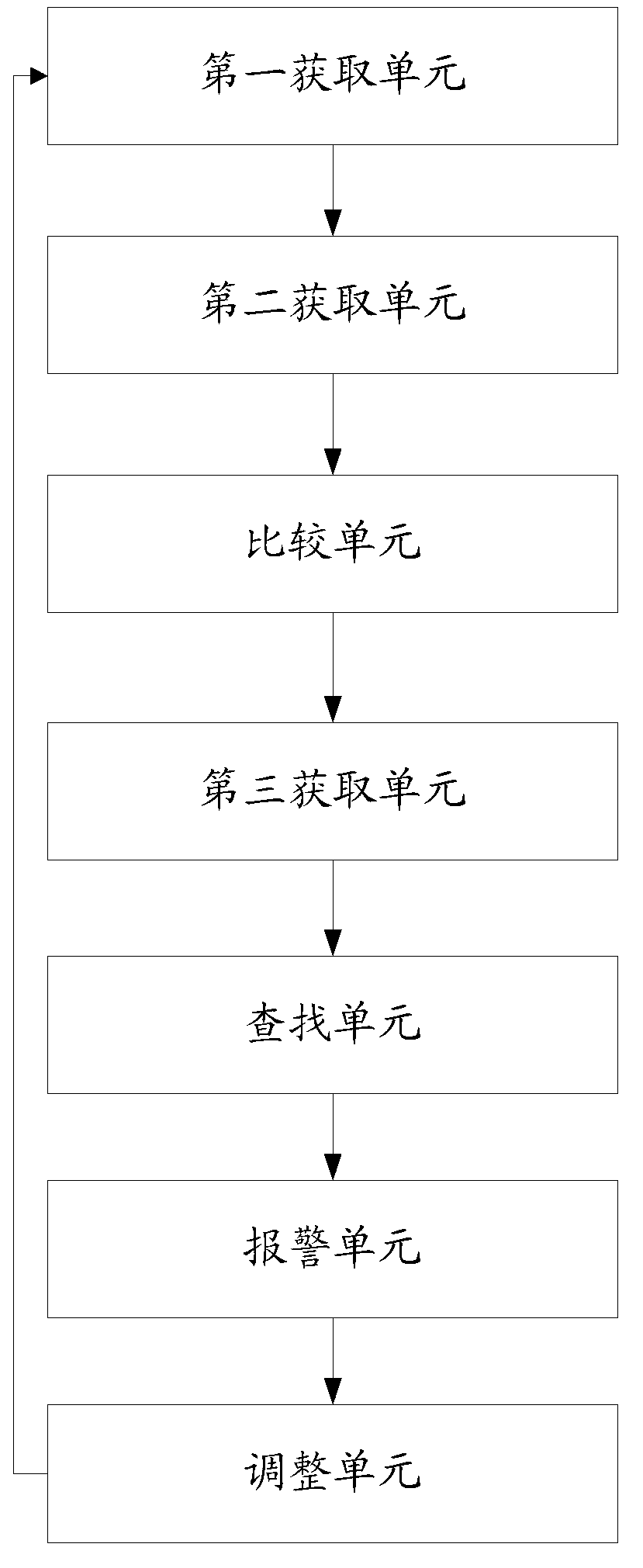

Optimization method and device of operation of power station boiler

The invention provides an optimization method of the operation of a power station boiler. The optimization method comprises the following steps: obtaining optimal operating condition data; obtaining current operating condition data of a thermal power generating unit; when safety index parameters, stability index parameters and environment-friendly index parameters all meet pre-set conditions, obtaining a power generation cost of a current operating condition; if finding an operating condition which is the same as the current operating condition from the optimal operating condition data, obtaining an optimal operating condition power generation cost of the current operating condition; if not finding, adding current operating condition parameters into historical operating condition data; if the power generation cost of the current operating condition is less than or equal to the optimal operating condition power generation cost, sending out a first alarming prompt; otherwise, obtaining an adjusting value and obtaining a cost loss; sending out a second alarming prompt and outputting the adjusting value; continuously adjusting an oxygen amount and an air feeding amount according to the adjusting value; and when meeting a pre-set condition, stopping adjusting. The invention further provides an optimization device of the operation of the power station boiler and the stability of optimizing the power station boiler is improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

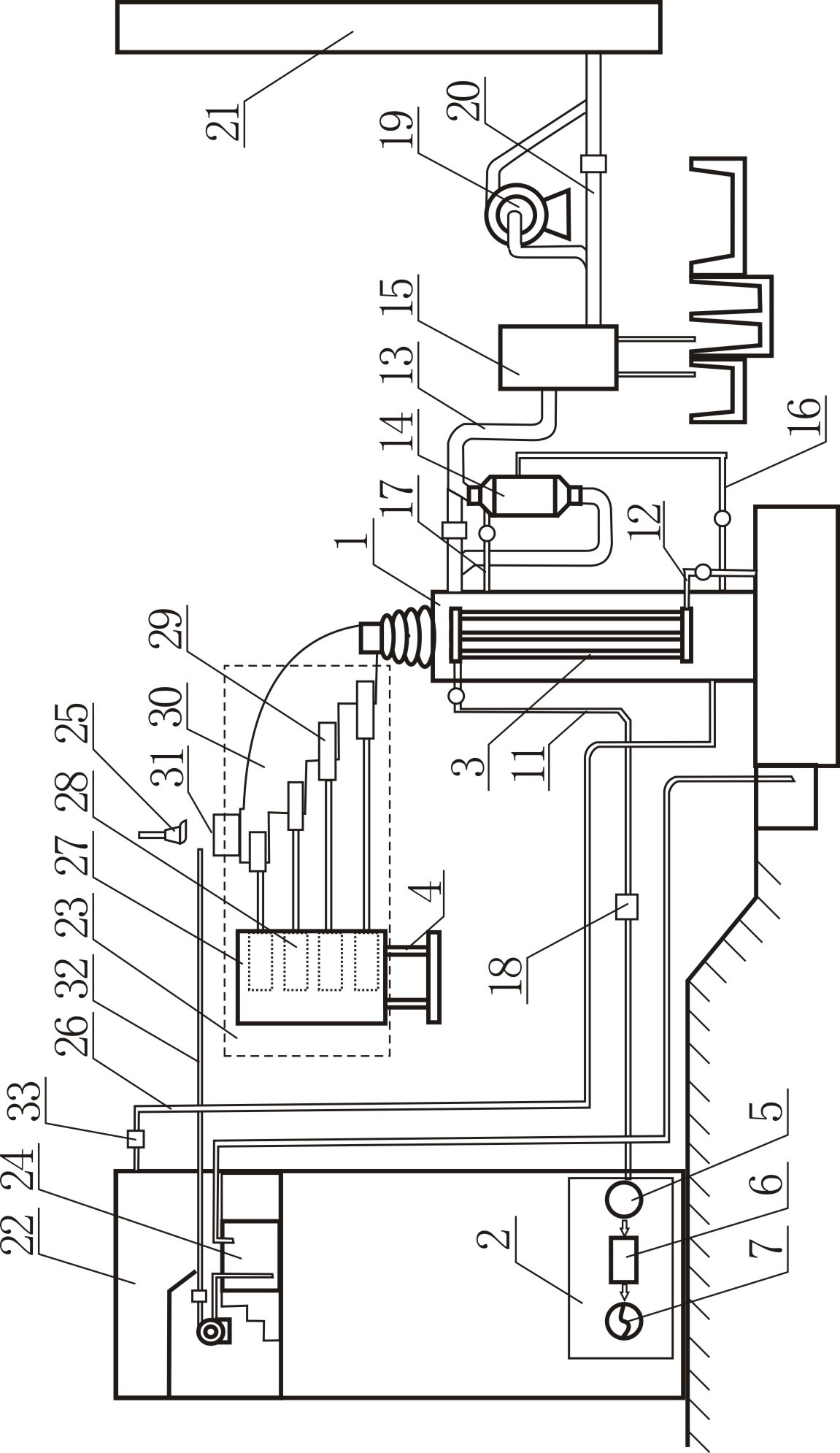

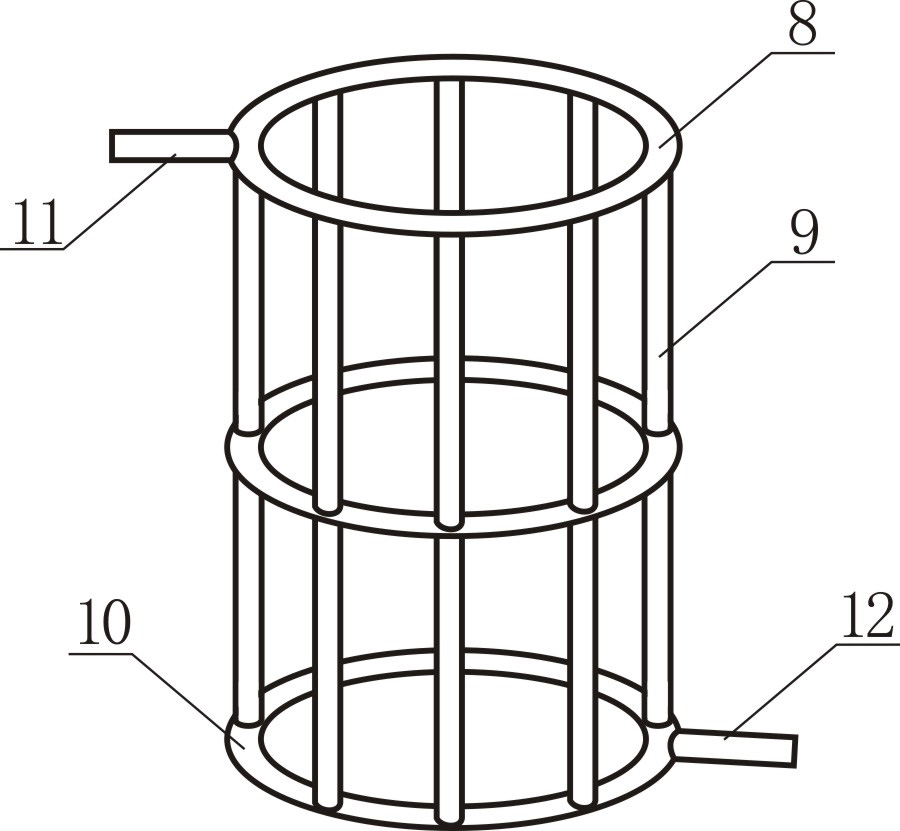

Garbage disposal waste heat power generation system with internal steam pipe

InactiveCN102606236AMaximize recoverySimple structure and processEnergy inputSteam engine plantsFlue gasSteam power

The invention discloses a garbage disposal waste heat power generation system with an internal steam pipe, which comprises a garbage gasifier and a turbine steam power generation device. The turbine steam power generation device comprises a steam generator, a steam discharge pipe, a steam drum, a steam turbine and a power generator, wherein the steam drum, the steam turbine and the power generator are sequentially connected, and the steam generator is arranged in the garbage gasifier and is of a cylindrical cage type structure comprising an upper annular pipe, a plurality of straight pipes and a lower annular pipe. As the steam generator is arranged in the garbage gasifier to realize primary heat exchange and a heat exchanger is additionally arranged in a flue gas channel to realize secondary utilization, heat generated in garbage disposal is used to the maximum extent, the technique with low heat utilization rate of a waste heat boiler for traditional garbage disposal steam power generation in the past is thoroughly changed, and garbage disposal heat recovery is maximized. Owing to a four-step hydraulic pusher, garbage is increasingly looser in the process of entering the garbage gasifier, and is not blocked.

Owner:SHENZHEN JUNENG BIOMASS GASIFICATION TECH

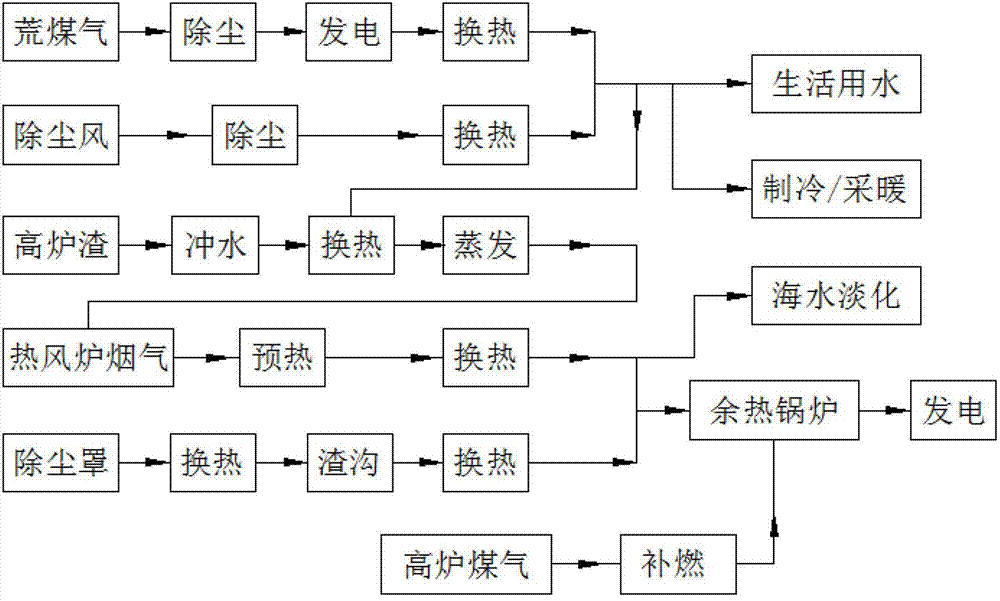

Steelmaking residual heat step recycling method

ActiveCN102851420ASolve effective useEnable fair useBlast furnace detailsIncreasing energy efficiencySteelmakingDitch

The invention discloses a steelmaking residual heat step recycling method. The invention belongs to the technical field of steel industry iron-making residual heat and residual energy utilization. The method is adopted under a condition for further utilizing iron-making low-grade residual heat, and comprises step recycling and high-efficiency utilizations of blast furnace gas residual heat, dust removal air residual heat, water slag residual heat, hot air furnace low-temperature flue gas waste heat, and dust cover and slag ditch residual heat. According to the technical scheme, blast furnace gas residual heat and dust removal air residual heat obtained after furnace top residual pressure power generation are connected in parallel, and are supplied for domestic water, cooling, or heating. Recycled water slag residual heat and flue gas residual heat obtained after hot air furnace gas heat exchanger are connected in parallel, and are used for supplying a heat source for low-temperature seawater desalination. Recycled dust cover residual heat and slag ditch surface radiation heat are connected in parallel, and are supplied for blast furnace gas supplementary firing residual heat boiler power generation. After powder generation, high-temperature seawater desalination is realized by a steam method. Cooling water and domestic water are treated and are adopted as inlet water replenishment. Through step recycling and graded utilization of the low-grade residual heat and residual energy, steel system comprehensive energy consumption can be reduced to a maximal extent, and energy resource reasonable utilization and comprehensive optimized utilization can be realized.

Owner:SHOUGANG CORPORATION

Method and device for recycling waste heat in discharged smoke of marsh gas power generation

ActiveCN101586513AOvercome limitationsEasy to implementInternal combustion piston enginesEnergy industryElectric networkEngineering

The present invention discloses a method and a device for recycling the waste heat in the discharged smoke of marsh gas power generation. According to the method of the invention, the discharged smoke after power generation of a marsh gas internal combustion engine (3) enters a waste heat boiler (4) for heat exchanging with the water, and the smoke after temperature reduction is discharged; the steam generated after heat absorption of the water enter a screw bolt expansion power machine (6) and a generator (7) for expanding, work applying and power generating, the discharged steam enters a condenser (8), and the condensed water enter the waste heat boiler (4) for recycling. Compared with the prior art, the invention uses the waste heat of the discharged smoke after marsh gas power generation for generating the steam. Then the steam enters a low-grade heat energy power machine-screw bolt expansion power machine for expanding, work applying and power generating. The low-grade heat is directly converted to the electric energy. The generated electric power can be combined with the electric power generated by the marsh gas internal combustion engine and sent to the electric network. The method and the device of the invention have the advantages of easy implement, strong operability and no effect by the position of the marsh gas power generating plant. The heat can be directly converted to the electric power and transmitted to the outside. The limitation of waste gas utilization mode of traditional smoke discharging is overcome.

Owner:CHINA HUADIAN ENG +1

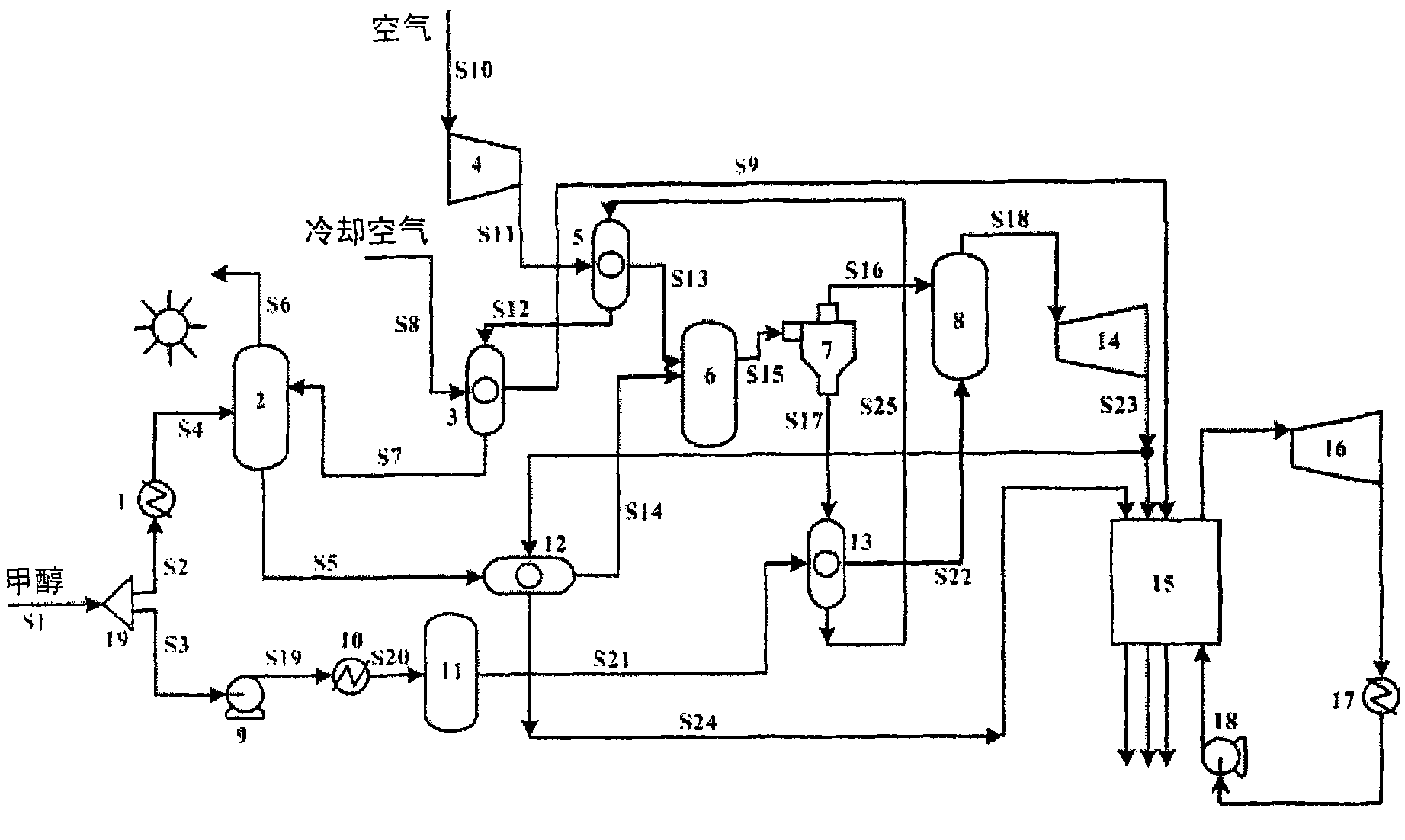

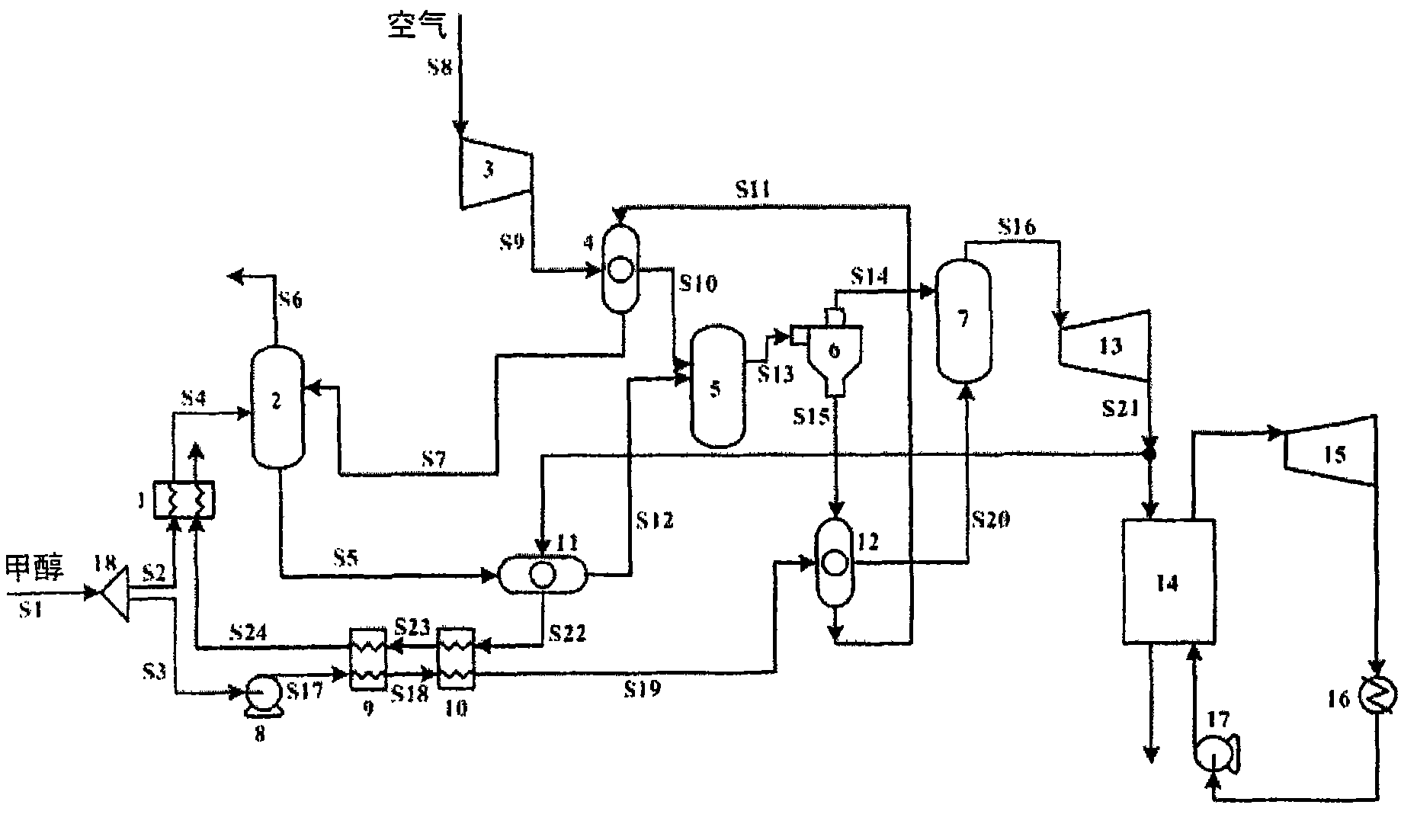

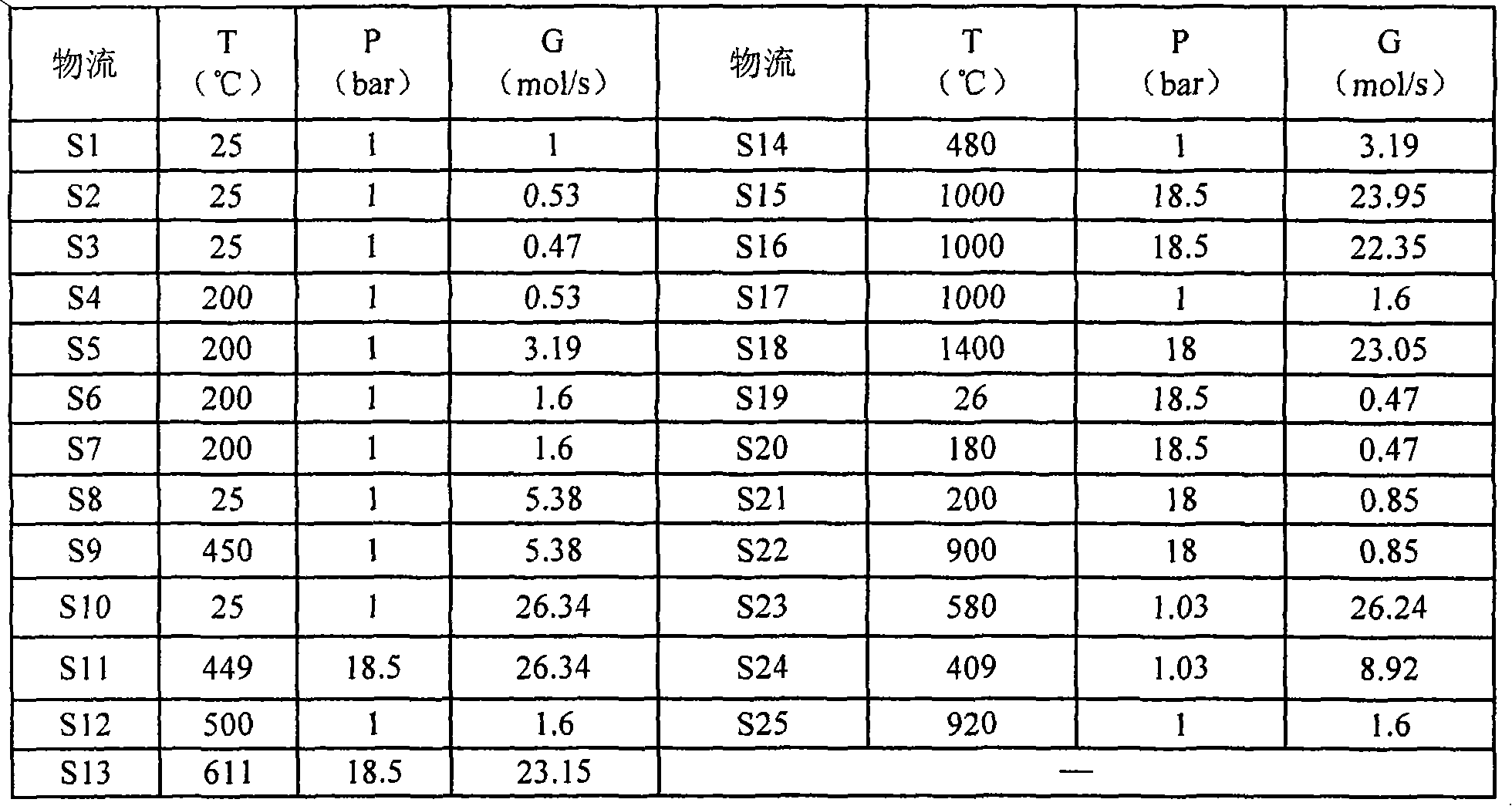

Solar energy and methanol fuel chemical-looping combustion power generation system and method

ActiveCN101888194ARealize cascade utilizationOvercoming the problem of low initial temperatureSteam engine plantsLight radiation electric generatorCombustion chamberChemical reaction

The invention relates to the technical fields of the solar thermal power generation and energy, in particular to a solar energy and methanol fuel chemical-looping combustion power generation system and method used for controlling CO2 emission. The intermediate-low temperature solar thermochemical process and the chemical-looping combustion power cycle are coupled organically to form the system ofthe invention. The system comprises a solar heat collecting-reduction reactor, a solar heat collecting-decomposition reactor, an oxidation reactor, an afterburning combustion chamber, a gas turbine, a steam turbine, an exhaust-heat boiler, a heat exchanger and the like. By using the device of the invention, the graded use of energy resources with different qualities can be realized; the zero-energy separation of CO2 can be realized through simple condensation; the combustion method can reduce the fuel grade to FeO grade, thus reducing the fuel loss in the combustion process and increasing theefficiency of the system; the solar thermochemical reaction is adopted to improve the grade of intermediate-low temperature solar energy; and afterburning is adopted so as to solve the problem that the gas turbine inlet has low initial temperature caused by the limit of the cycle material in the chemical-looping combustion power system.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Steel slag dry processing and waste heat recovery and power generation method

ActiveCN107916312AAvoid pollutionSolve pollutionRecycling and recovery technologiesSteam engine plantsSlagWater resources

The invention relates to a molten steel slag dry processing and waste heat recovery and power generation method. According to the method, a cooling mode using a large amount of water in wet processingis completely abandoned, sealed equipment is used, air is used as a medium so as to perform dry processing on high-temperature steel slag, the steel slag is cut and granulated by an air knife in thesealed equipment, solid-gas waste heat exchange is completed at the same time, the steel slag is cooled, waste heat is carried by hot smoke after heat exchange so as to enter a waste heat boiler afterbeing dedusted, and then gas-liquid heat exchange is completed so as to obtain saturated steam which can be used for supplying heat, drying and generating power. By adopting the method, the problemsof waste of heat resources, high consumption of water resources and dust blowing in the wet processing can be solved, the method is suitable for reforming steel slag processing lines of existing coldabandon methods, hot splashing methods, water granulation methods, air granulation methods, hot stuffy methods and the like, short for a two-step air brittle method, and the method is a novel technique of completely utilizing three resources including steel slag, waste heat and tailings in a comprehensive utilization technique of smelting steel slag resources at present.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

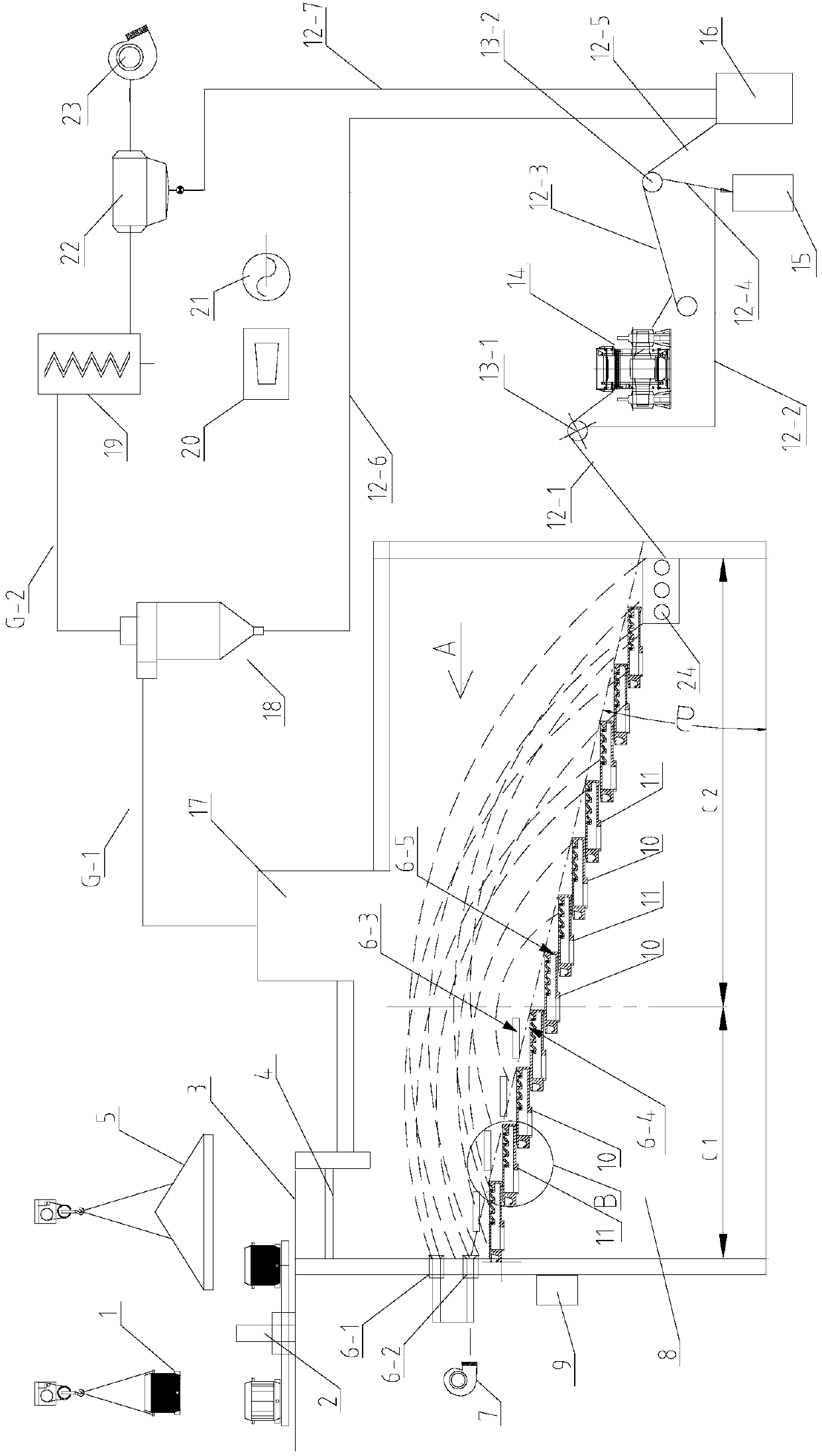

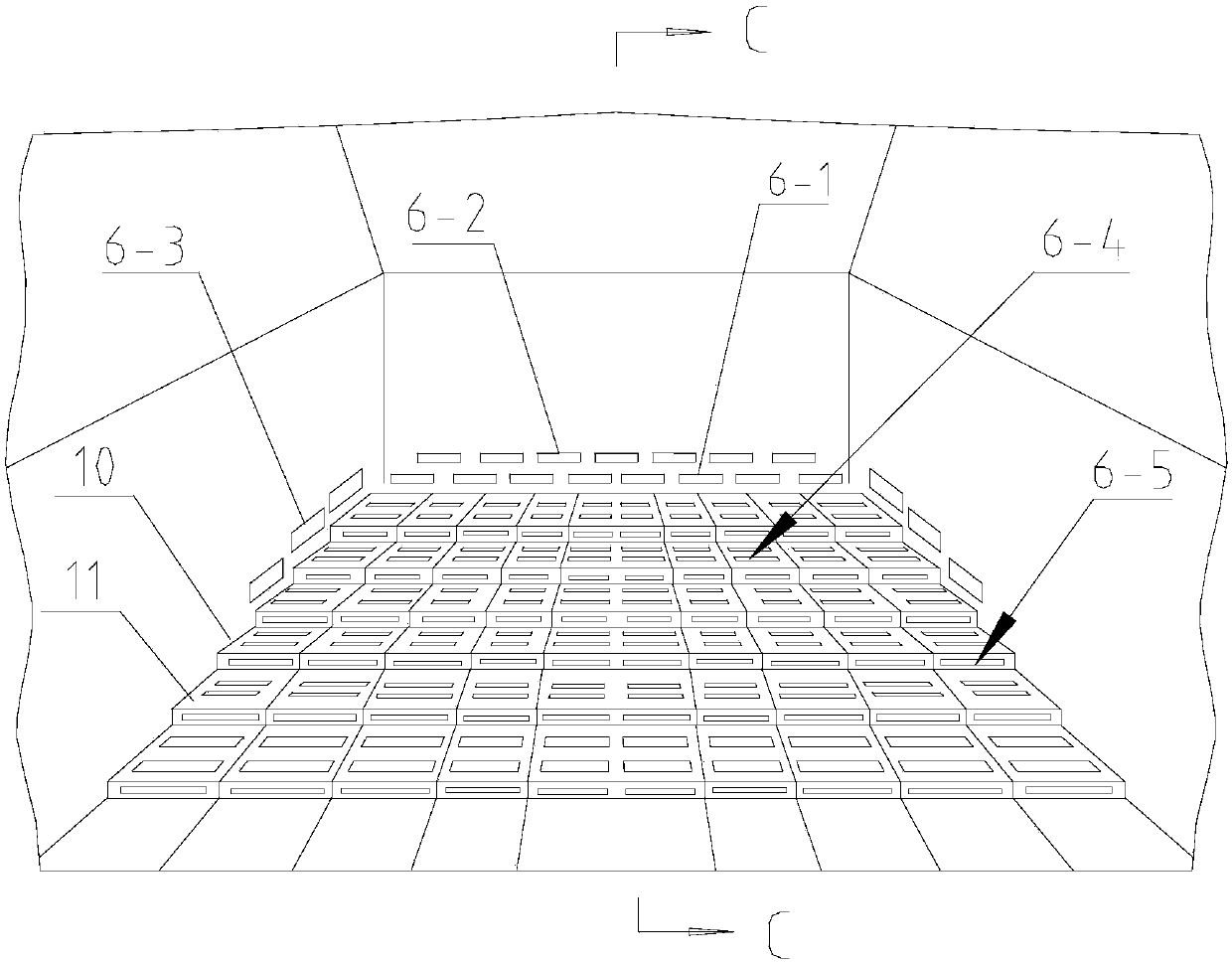

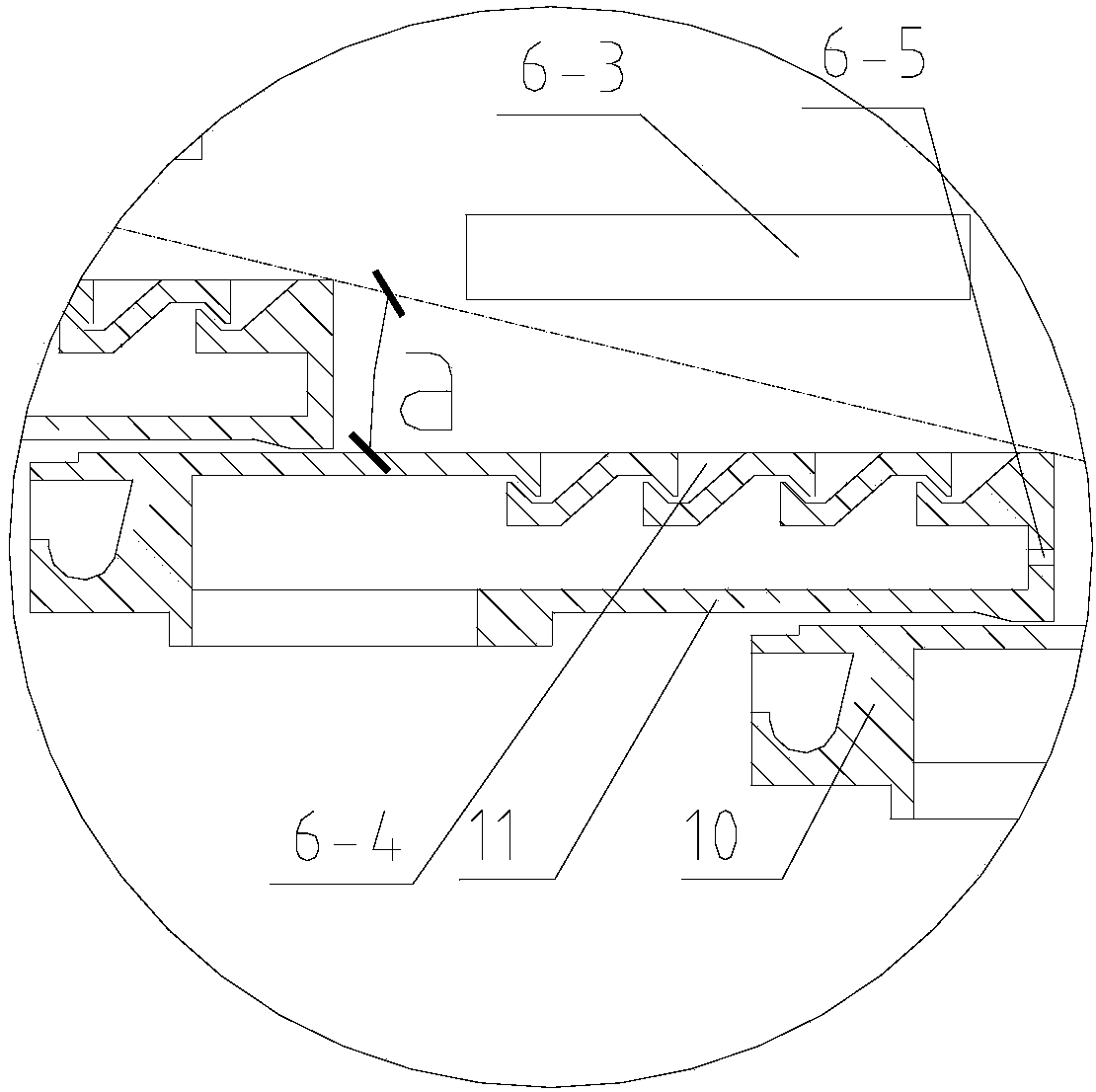

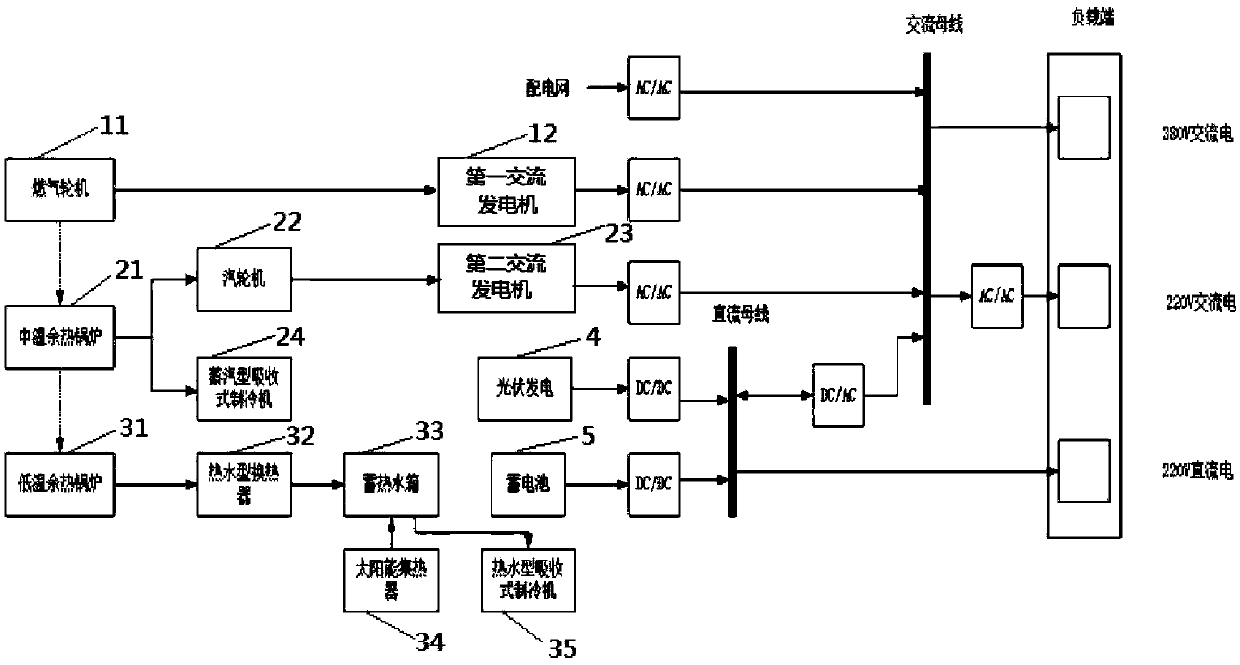

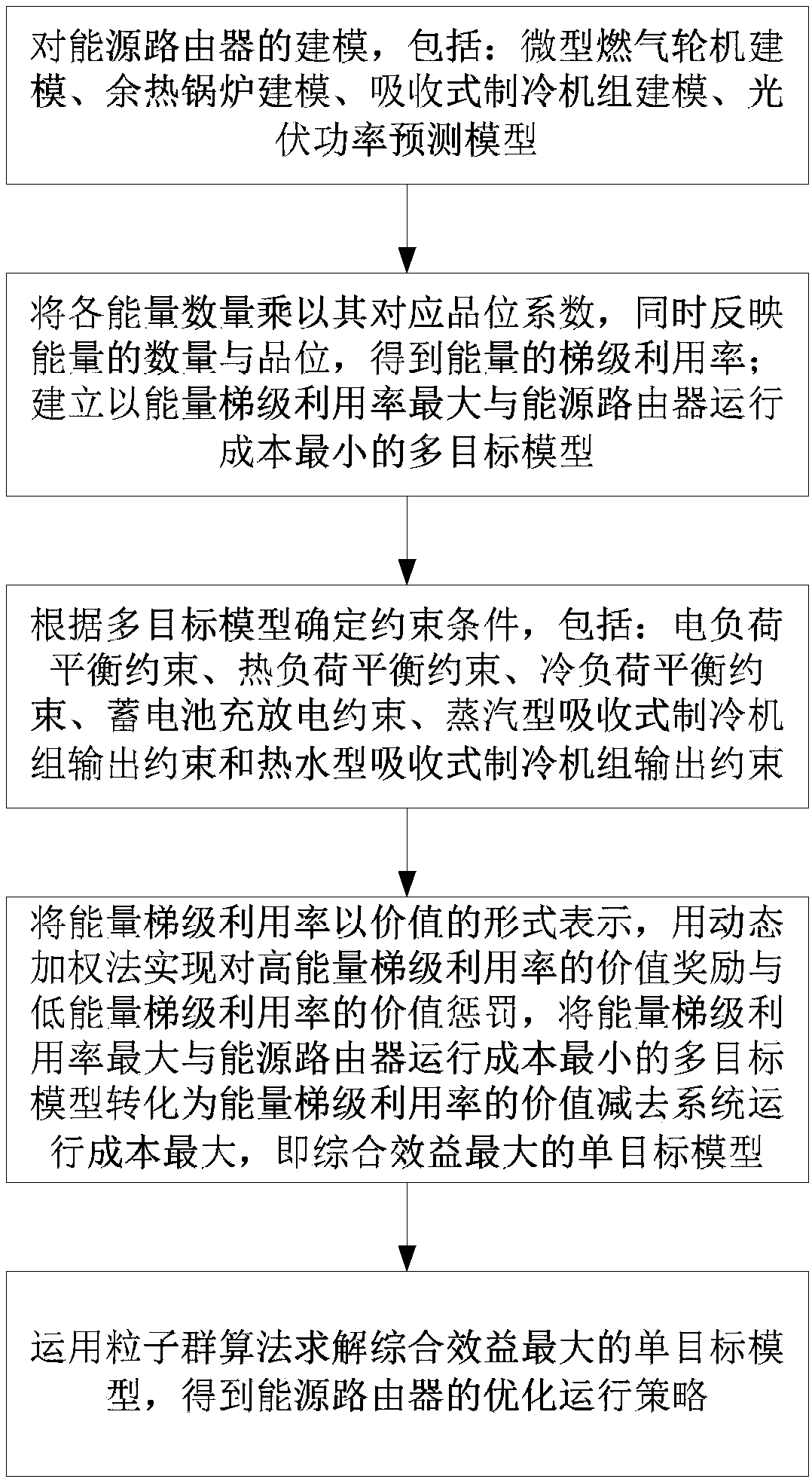

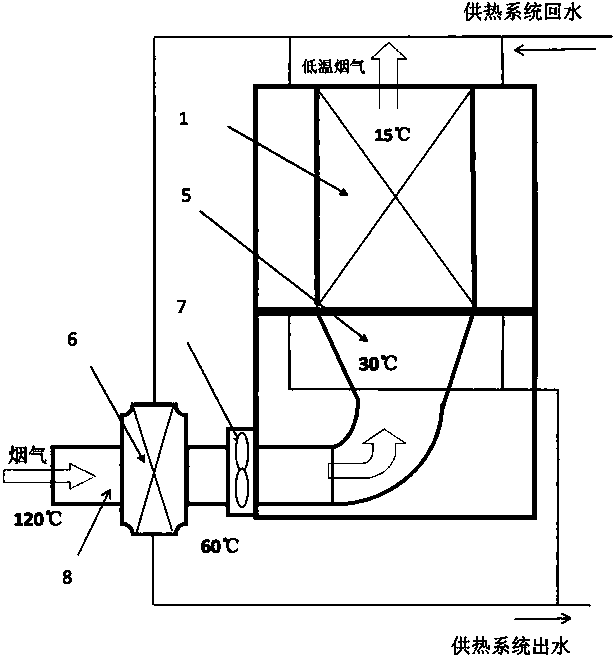

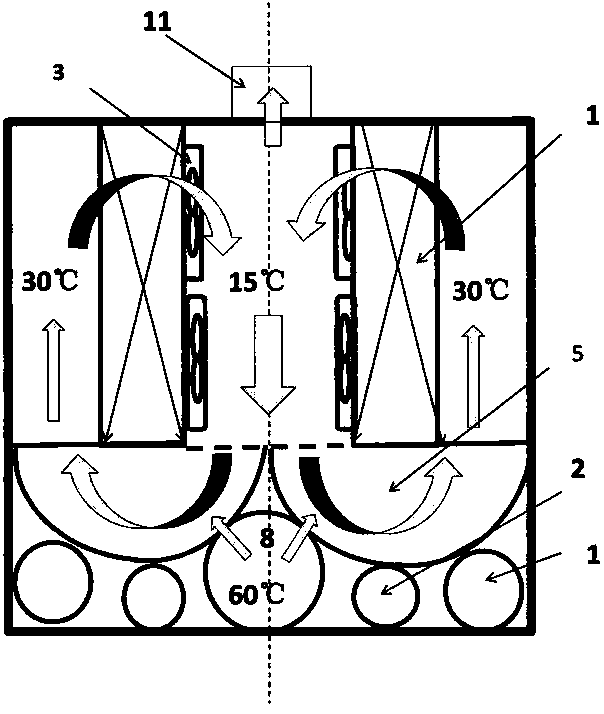

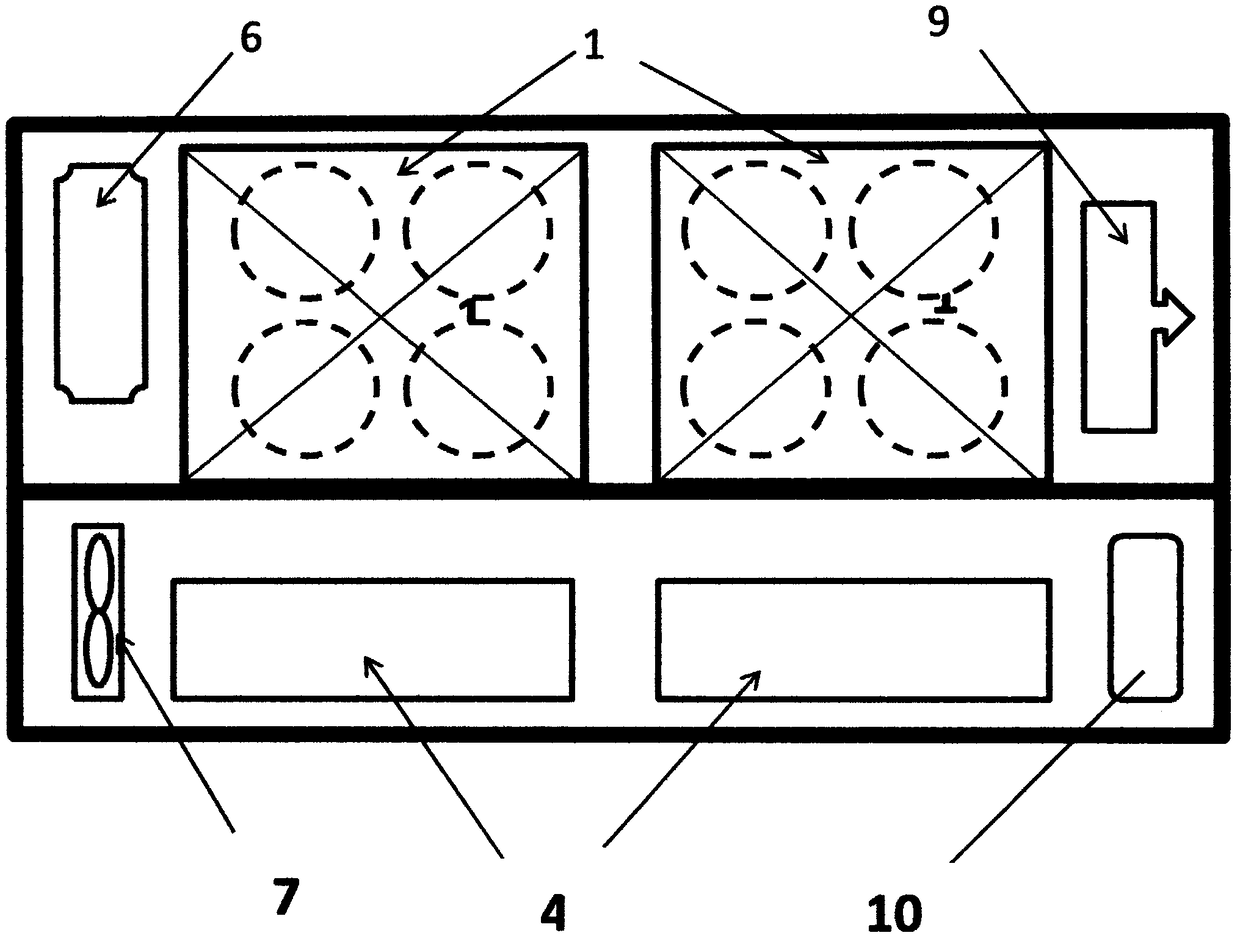

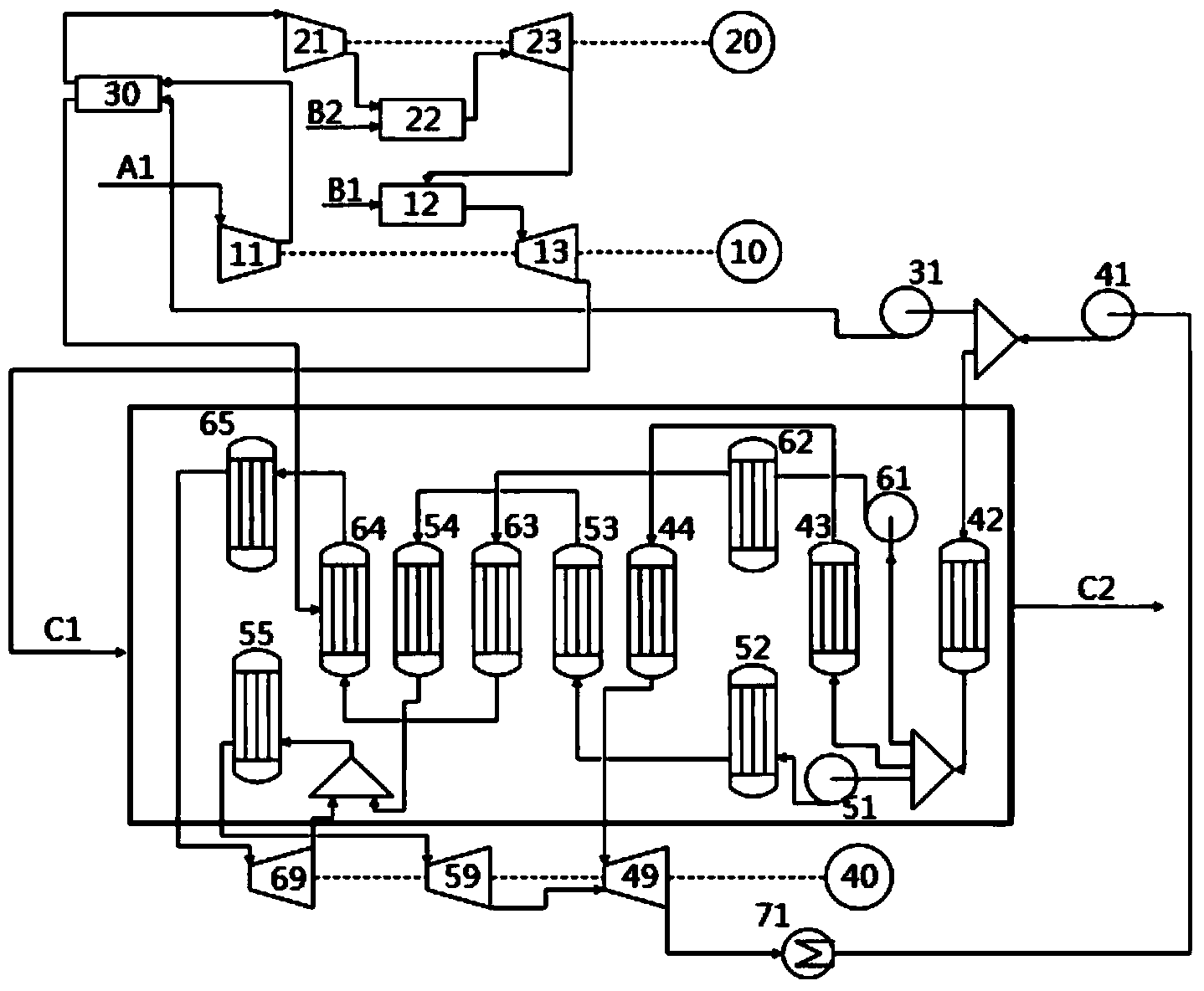

Energy router based on energy gradient utilization and operation optimization method thereof

ActiveCN108206543ARealize comprehensive utilizationGood use effectSingle network parallel feeding arrangementsGas turbine plantsEnergy gradientEnergy source

The invention discloses an energy router based on energy gradient utilization and an operation optimization method thereof. The energy router comprises a gas turbine, a steam turbine, a waste heat boiler, an absorption refrigerating machine, a heat exchanger, a storage battery, a heat storage water tank and a photovoltaic battery. The system converts the fuel into electric energy according to thequality and the grade of the energy, and the waste heat is used for refrigeration, heat supply or power generation, so as to realize the gradient utilization of energy sources. According to the operation optimization strategy of the system, an optimized objective function is established by establishing a system model of the energy router, and optimizing scheduling solving is carried out after an optimization scheduling constraint condition is selected, and an optimized scheduling strategy is finally obtained, so that the system equipment can be correspondingly controlled according to the change of the user demands, and the optimization goal of maximizing the energy gradient utilization rate and minimizing the operation cost is achieved.

Owner:NORTHEASTERN UNIV

Natural gas smoke waste heat complete heat recovery device

PendingCN108131867AAchieve recyclingReduce consumptionHeat pumpsFeed water supplyCogenerationEngineering

The invention provides a natural gas smoke waste heat complete heat recovery device, belongs to the technical field of energy, and particularly relates to a technology for completely recovering smokewaste heat emitted by fuel gas burning devices (boilers, direct-fired machines, gas engines, gas turbines and the like). Aiming at the status-quo that the heat energy utilization rate of a current natural gas boiler is low, a three-grade cooling two-grade heat exchanging technological process is adopted, cascaded cooling is conducted on smoke through a heat exchanger and a heat pump, particularlylatent heat for vaporization in the smoke is recovered and reused, the smoke emission temperature of a natural gas boiler is decreased to be the temperature the same as the natural gas entering the boiler, and complete utilization of the heat energy of the natural gas is truly achieved. In the processes of smoke cooling and heat energy recovering, a great deal of condensed water is recovered, partof sulfide and nitric oxide in the smoke is dissolved in the water, and thus emission of pollutants is reduced. When the natural gas smoke and waste heat complete heat recovery device is applied to combined heat and power generation power plants, less electric energy can be consumed in the heating period, the heating area can be increased by 30% or above, and the consumption amount of heating fuel gas can be reduced by 10-15%.

Owner:苏桐梅

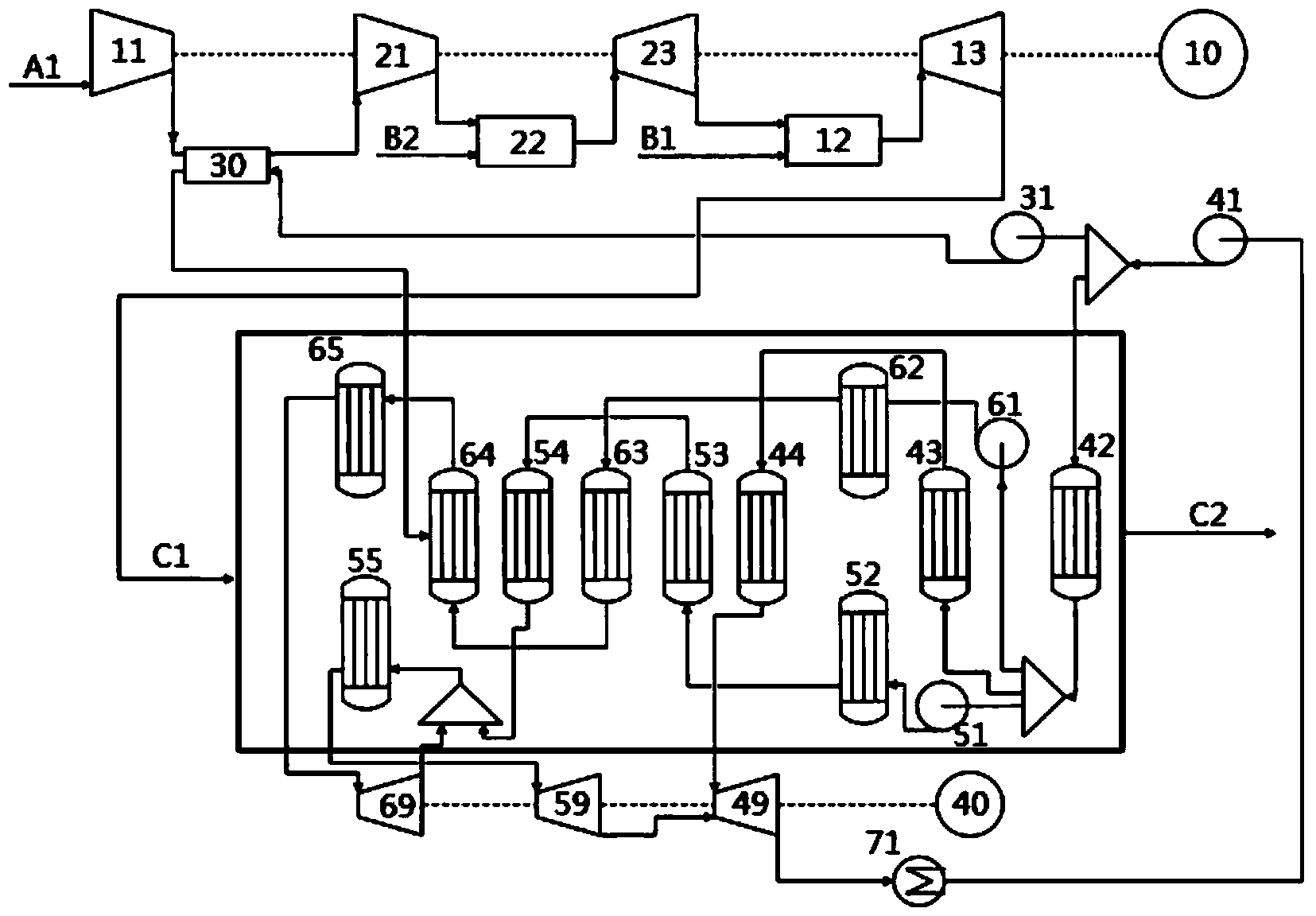

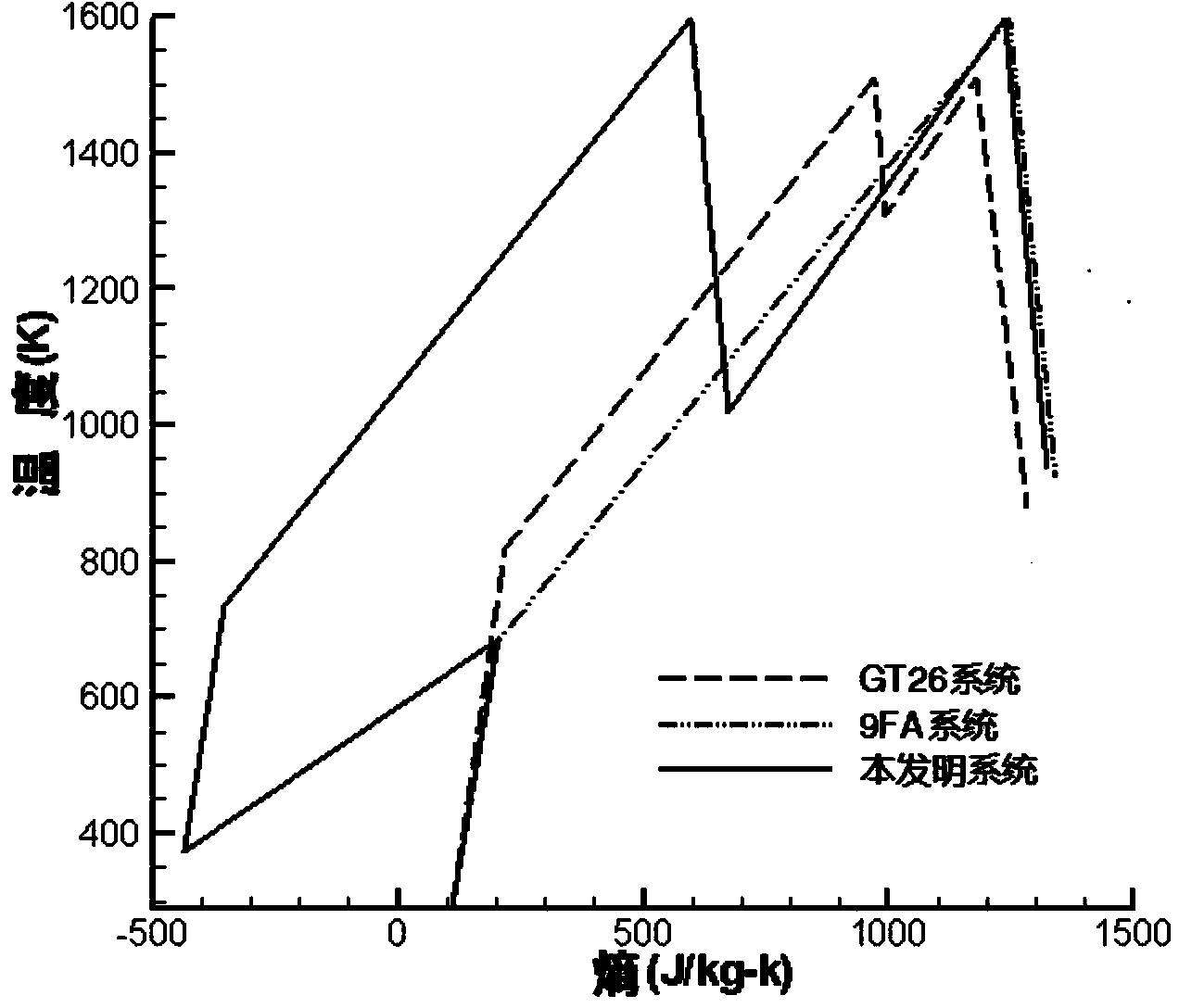

High-pressure reheating gas-steam combined cycle power generation system and power generation method

ActiveCN103711587AAvoid undragable conditionsReduce the difficulty of startingGas turbine plantsSteam engine plantsThermal energyCombustion chamber

The invention relates to a high-pressure reheating gas-steam combined cycle power generation system and a power generation method. The system consists of a gas turbine subsystem and a steam turbine subsystem, wherein the gas turbine subsystem comprises a device used for two-stage air compression, twice combustion as well as high-pressure and medium-pressure twice turbine acting; after primary acting of high-temperature gas, the high-temperature gas enters a medium-pressure combustion chamber and is reheated for secondary acting, so that the average heat absorption temperature of the whole cycle is improved; and at least a one-stage intercooler is arranged between two-stage compressors, and heat flow of the intercooler is connected with the two-stage compressors. The steam turbine subsystem adopts a three-pressure reheating type boiler and a steam turbine, cooling water of the intercooler is connected with high-pressure water, and high-pressure, medium-pressure and low-pressure water as well as the cooling water of the intercooler absorb heat in a staged manner for multiple times, so that heat energy is efficiently utilized. When the high-pressure reheating gas-steam combined cycle power generation system provided by the invention operates with the best parameters, the combined cycle efficiency is increased by 3-5 percentage points compared with a combined cycle system which mainly adopts a gas turbine class F, and the single-machine output power is increased by more than 70%, and reaches 800MW class.

Owner:GUODIAN NEW ENERGY TECH INST

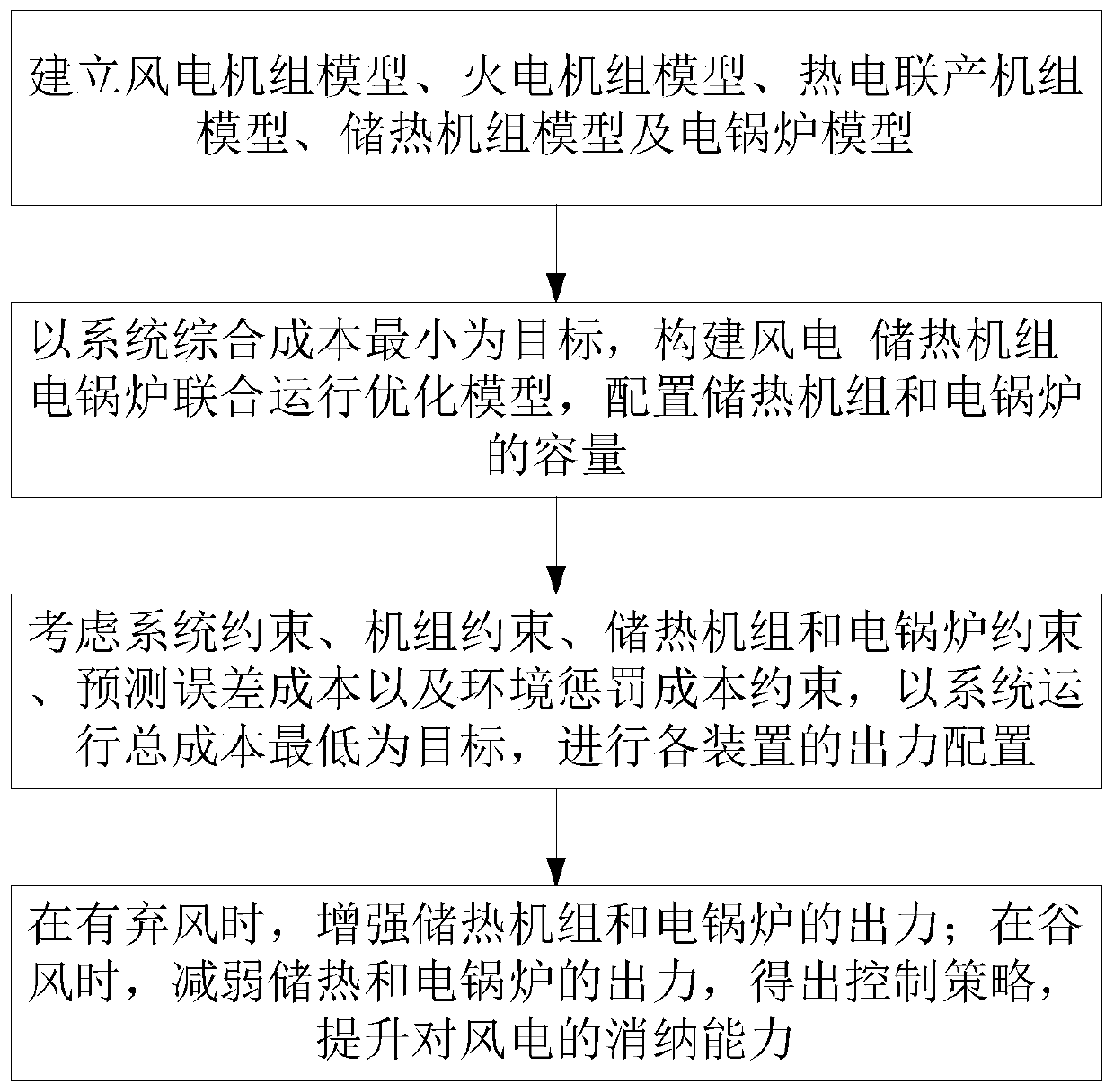

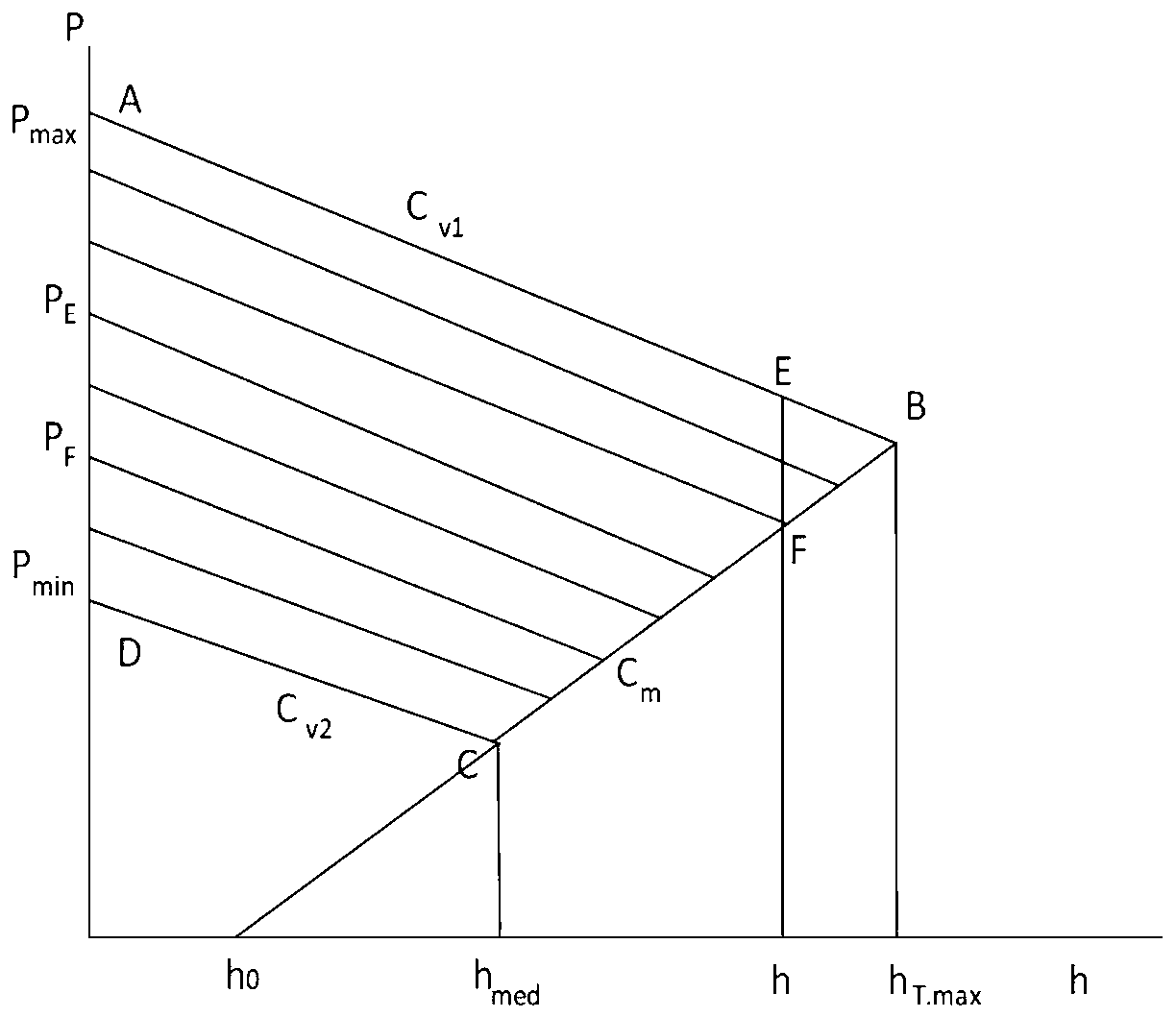

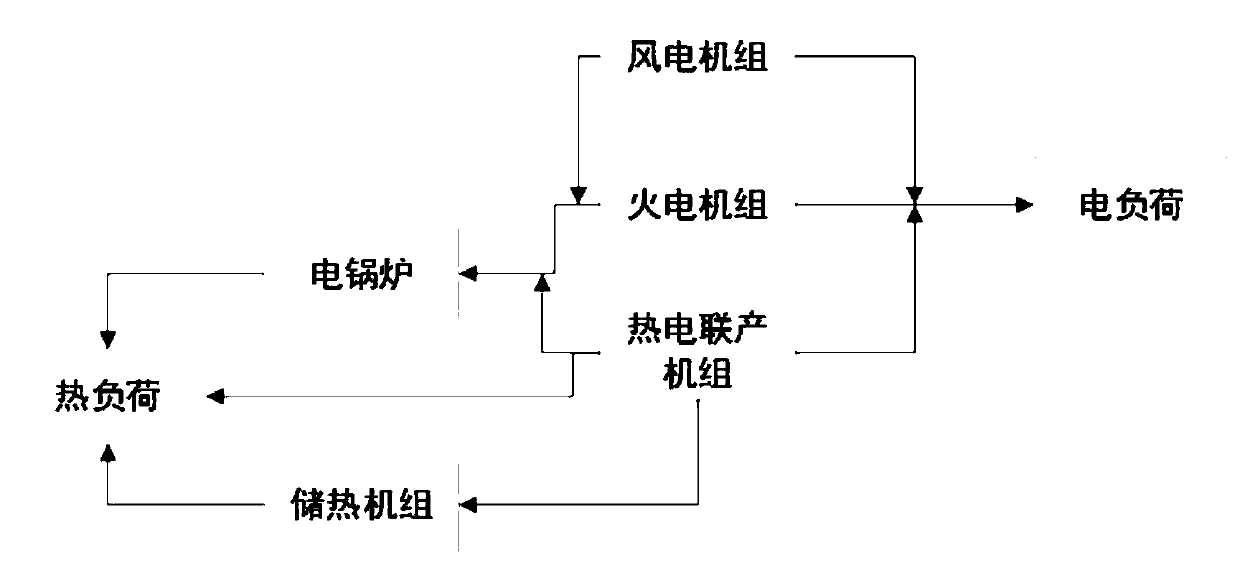

Optimal scheduling method considering wind power-heat storage unit-electric boiler combined operation

PendingCN110676847ALow running costImprove thermal powerForecastingSingle network parallel feeding arrangementsOptimal schedulingCogeneration

The invention discloses an optimal scheduling method considering wind power-heat storage unit-electric boiler combined operation. The method comprises the steps of 1, establishing a wind power unit model, a thermal power unit model, a combined heat and power generation unit model, a heat storage unit model and an electric boiler model; 2, taking minimum system comprehensive cost as a target, constructing a wind power-heat storage unit-electric boiler combined operation optimization model, and configuring capacities of the heat storage unit and an electric boiler; 3, considering system constraints, unit constraints, heat storage and electric boiler constraints, predicting error cost constraints and environmental penalty cost constraints, and carrying out output configuration of each deviceof the system by taking lowest total cost of system operation as the target; and 4, when wind curtailment exists, enhancing the output of the heat storage and the electric boiler; and during valley wind, reducing heat storage and the output of the electric boiler, and increasing a wind power consumption capacity. In the method, the environmental penalty cost is added into the model, and a description method of thermal power and thermoelectric unit operation cost is improved so that a scheduling model is closer to an actual situation.

Owner:FUXIN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER +2

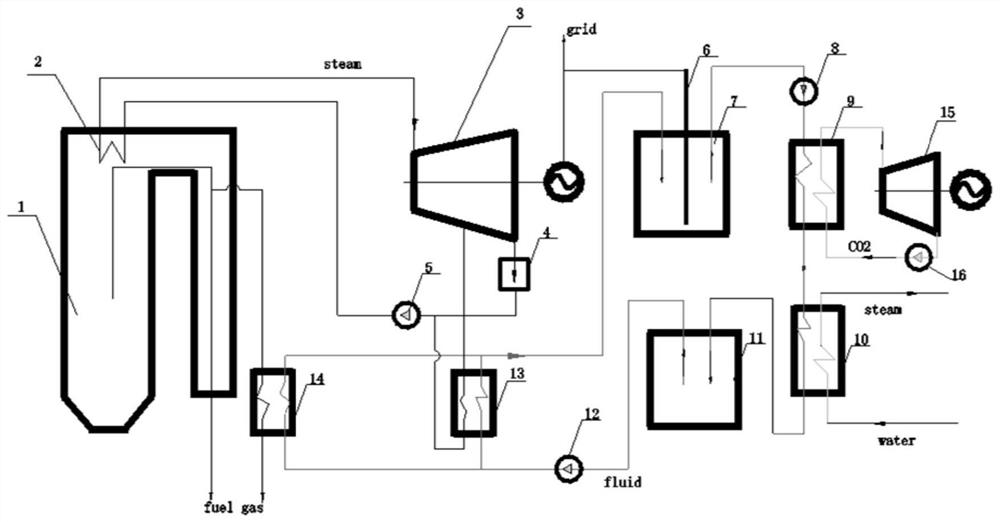

Power plant boiler heat storage and carbon dioxide power generation integrated deep peak shaving system and method

InactiveCN112984598AReduce heat loadOvercoming the limitation of heating surfaceCentral heating with accumulated heatLighting and heating apparatusFlue gasProcess engineering

The invention discloses a power plant boiler heat storage and carbon dioxide power generation integrated deep peak shaving system and method. The power plant boiler heat storage and carbon dioxide power generation integrated deep peak shaving system comprises a power plant boiler, a high-temperature flue gas heat exchanger, a low-temperature heat storage tank, a high-temperature flue gas heat exchanger, a high-temperature heat storage tank, a high-temperature heat storage steam heat exchanger, a steam turbine generator unit, a carbon dioxide heat exchanger, a low-temperature heat exchanger and a carbon dioxide turbine generator unit. Boiler flue gas heat can be utilized to the maximum extent, heat storage media are adopted for heat storage in combination with steam extraction heat of the steam turbine, electricity generated through the minimum steam flow of the steam turbine can be also stored in the heat storage tank, such that zero output of the unit is achieved.

Owner:HUANENG CLEAN ENERGY RES INST

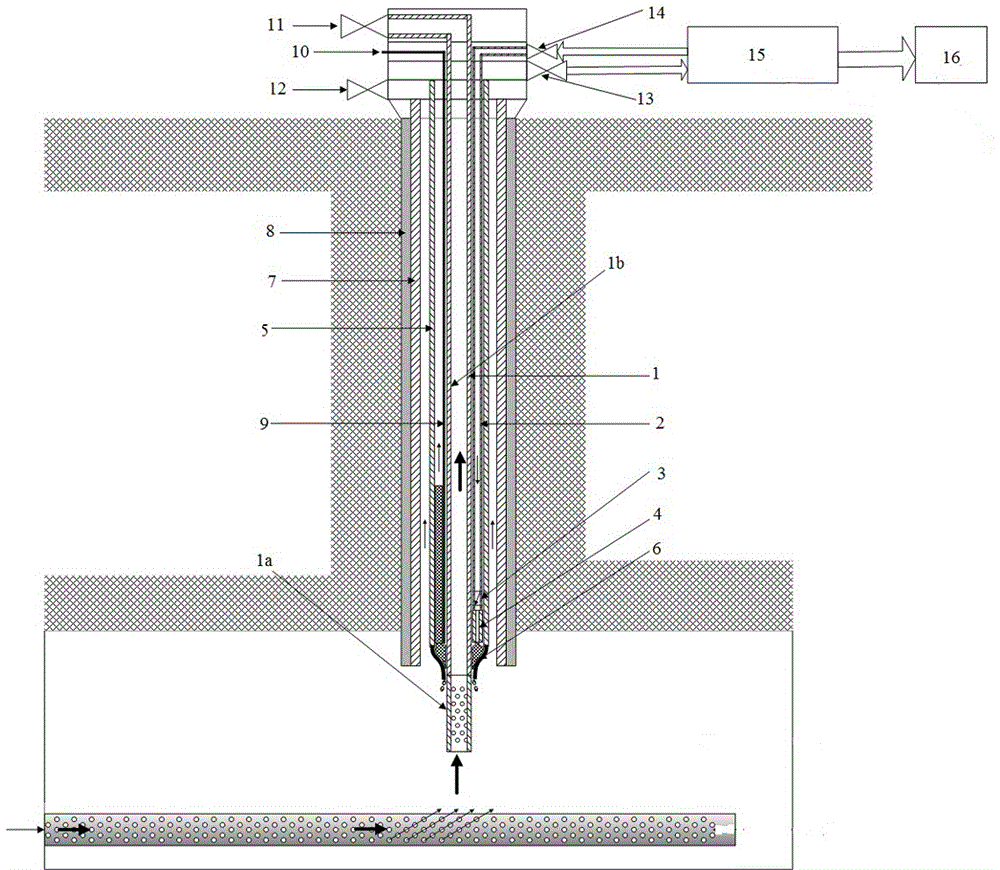

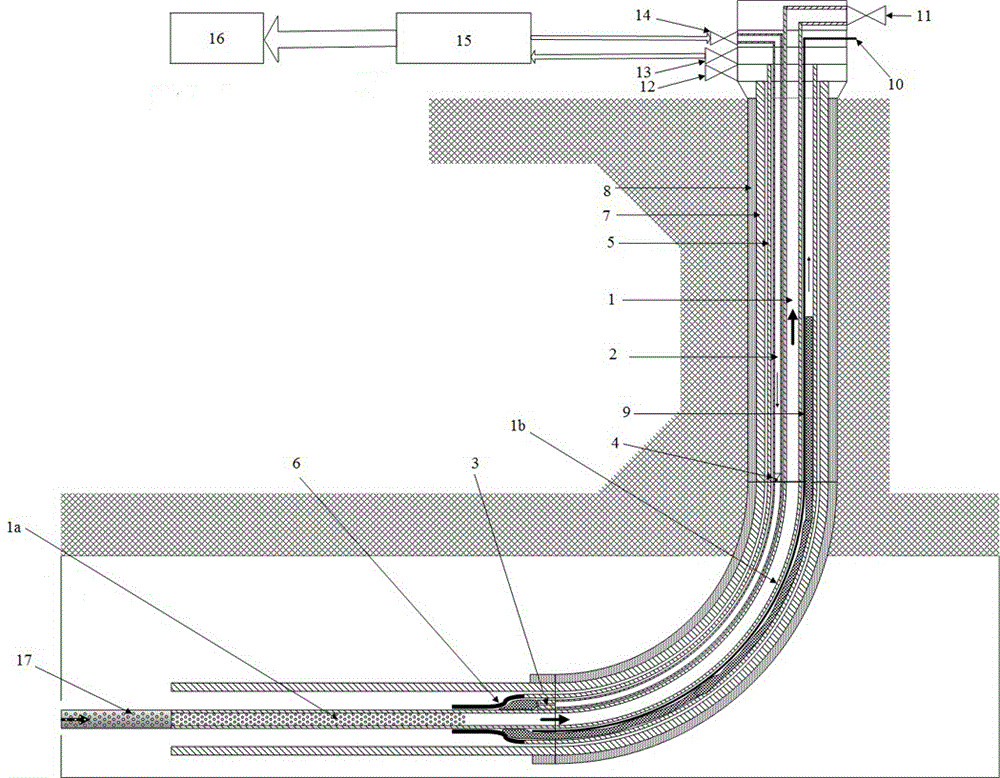

Waste heat recovery product well system for ISC and operation method thereof

The invention provides a waste heat recovery product well system for ISC and an operation method of the waste heat recovery product well system for the ISC. The waste heat recovery product well system for the ISC comprises a product pipe, a jacketed pipe, a water cooling pipe, a monitoring instrument system, a product well bushing, a high-temperature high-pressure wellhead device, a ground waste heat recovery device and the like. Each component in the product well system is easy to recycle and reutilize. Heat carried out by high-temperature high-pressure downhole steam can be used for the ground production technology, turbine power generation, boiler power generation, other ground public facilities or plant life purposes and the like. By the adoption of the waste heat recovery product well system for the ISC and the operation method of the waste heat recovery product well system for the ISC, effective monitoring, control and protection of a product well can be achieved, waste heat of high-temperature crude synthesis gas is reliably and effectively recycled and comprehensively utilized, the consumption of cooling water is significantly reduced, and the requirement for downstream waste water treatment is lowered, comprehensive and efficient utilization of coal is achieved, the energy consumption of the whole ISC is lowered, and the technical problems faced by the existing ISC are finally solved.

Owner:ZHONGWEI SHANGHAI ENERGY TECH CO LTD

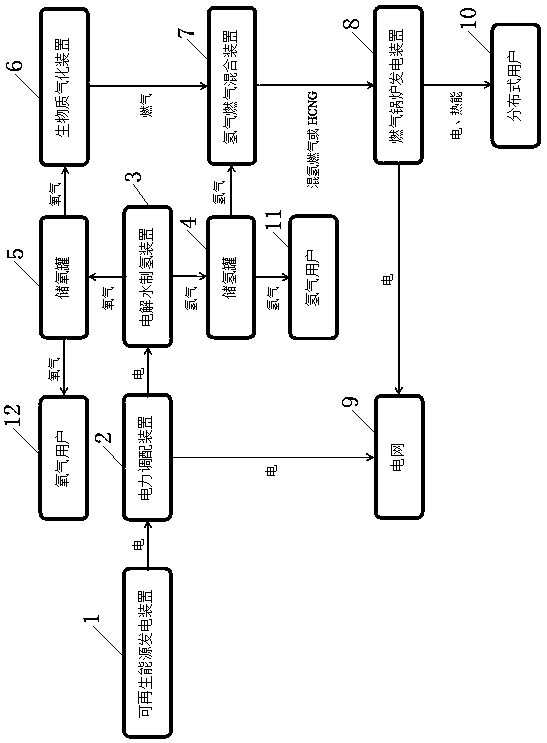

Power generation system based on coupling of renewable energy hydrogen production and biomass gasification and working method

PendingCN110649650AFull and efficient useLow costMachines/enginesWind energy generationElectrolysisRenewable power generation

The invention discloses a power generation system based on the coupling of renewable energy hydrogen production and biomass gasification and a working method. The power generation system comprises a renewable energy power generation device, a power distribution device, a water electrolysis hydrogen production device, a hydrogen storage tank, an oxygen storage tank, a biomass gasification device, ahydrogen and gas mixing device and a gas-fired boiler power generation device. The renewable energy power generation device, the power distribution device and the water electrolysis hydrogen production device are connected in sequence. The water electrolysis hydrogen production device is connected with the hydrogen storage tank and the oxygen storage tank. The oxygen storage tank is connected with the biomass gasification device. The hydrogen storage tank and the biomass gasification device are both connected with the hydrogen and gas mixing device. The hydrogen and gas mixing device is connected with the gas-fired boiler power generation device. The power distribution device and the gas-fired boiler power generation device are connected with a power grid. Through water electrolysis hydrogen production by means of electricity abandoning, large-scale storage and consumption of renewable energy sources can be achieved, the water electrolysis hydrogen production cost is reduced, generated hydrogen and biomass gasified fuel gas are mixed for power generation, and the biomass power generation industry layout is accelerated.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Integrated gas turbine, sagd boiler and carbon capture

InactiveUS20120222426A1Reduce the temperatureAvoid highBiofuelsGas turbine plantsFlue gasExhaust fumes

An integrated power generation system for reducing carbon dioxide emissions is provided. The integrated system comprises a gas turbine having an air inlet, a fuel inlet and an exhaust gas outlet; a steam-assisted gravity drainage (SAGD) boiler having an inlet connected to the exhaust gas outlet of the gas turbine, a fuel inlet, an optional air inlet, and a flue gas outlet; and a carbon dioxide capture system connected to the flue gas outlet of the SAGD boiler. A method for capturing the carbon dioxide exhausted from a gas turbine and a SAGD boiler is also provided.

Owner:CONOCOPHILLIPS CO

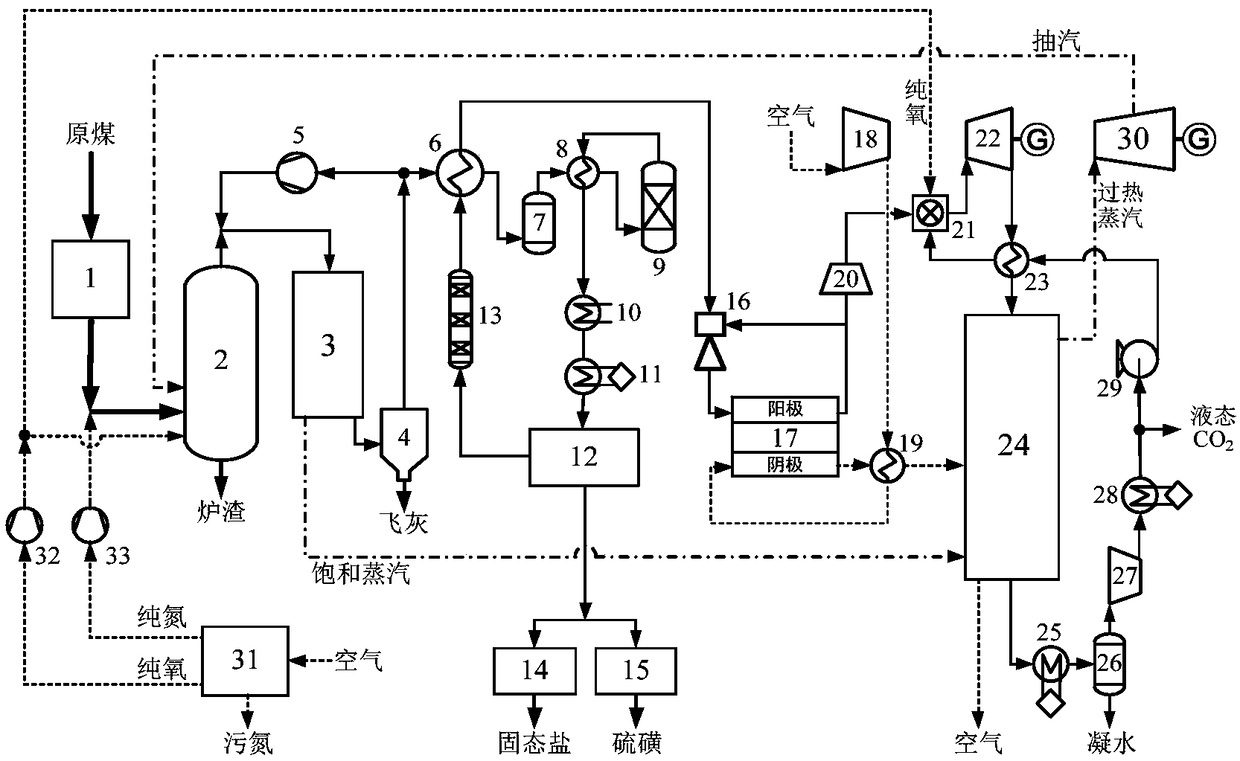

Overall gasification fuel cell power generation system and method adopting supercritical CO2 bottom circulation

PendingCN109266396AImprove power generation efficiencyReduce volumeEnergy inputGasification processes detailsGas compressorGas cooler

The invention provides an overall gasification fuel cell power generation system and method adopting supercritical CO2 bottom circulation. The system comprises a coal preparation unit, a gasifier, a gas cooler, a circulation gas compressor, an ejector, a fuel cell, a cathode air compressor, a cathode backheating device, a compressor, a pure oxygen burner, a CO2 gas turbine, a backheating device, awaste heat boiler and a turbine; on the basis of the overall gasification fuel cell power generation system, CO2 gathering is added, a CO2 cooling pressurizing device is utilized for converting CO2 gas into supercritical state CO2, supercritical state CO2 is adopted as bottom circulation to react with pure oxygen and tail gas at a fuel cell anode outlet inside the pure oxygen burner, generated high temperature and high pressure gas acts and generates electricity in the CO2 gas turbine; according to the structure, on the basis of efficient electricity generation of fuel cell electricity generation, the electricity generation efficiency is further improved; meanwhile, the system has the CO2 gathering function, and coal power generation CO2 emission reduction can be achieved efficiently withlow cost.

Owner:HUANENG CLEAN ENERGY RES INST

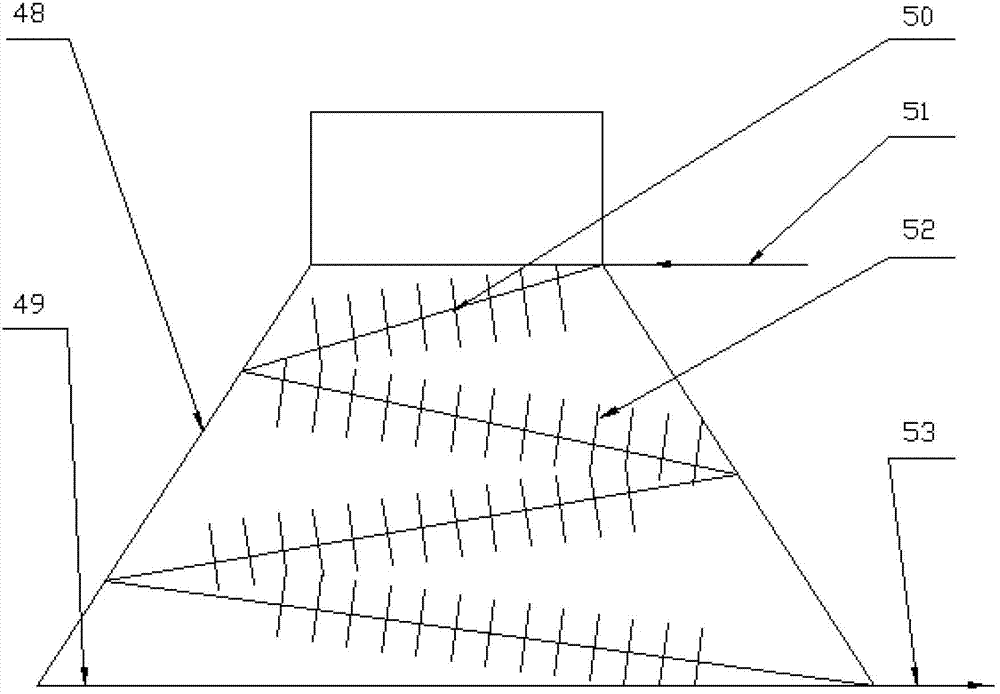

Spiral vibrating bed waste heat recovery device in melted blast furnace slag granulation process

InactiveCN103060495AIncreased flow distanceSmall sizeIncreasing energy efficiencyRecycling and recovery technologiesWaste heat recovery unitHot air oven

The invention discloses a spiral vibrating bed waste heat recovery device in a melted blast furnace slag granulation process. The device consists of a spiral vibrating bed rapid cooling unit in a granulation stage and a waste heat recovery unit. The spiral structure of the spiral vibrating bed rapid cooling unit in the granulation stage can prolong landing distances of melted blast furnace slag particles after the melted blast furnace slag particles are subjected to dry-method granulation process, bottom circulating cooling air and the melted slag particles are subjected to heat exchange through pores on a screening bed surface in a countercurrent way, so that the cooling speed is improved, a target of quenching the blast furnace slag is realized, the bonding between the melted slag particles and between the slag particles and a vibrating bed surface is effectively prevented, and the blast furnace slag particles with glass structures are obtained as many as possible; and the waste heat recovery unit comprises a matched dedusting and air supply system, a secondary cooling device and a waste heat utilization device. High-temperature air recovered by the spiral vibrating bed rapid cooling unit in the granulation stage is provided for a hot air furnace through a dust remover and an air supply pipeline part, the rest of high-temperature air is fed into the secondary cooling device for continuous heat exchange and heating up, and the high-temperature air at a temperature of 700 DEG C enters a waste heat boiler for generating steam for power generation.

Owner:UNIV OF SCI & TECH BEIJING

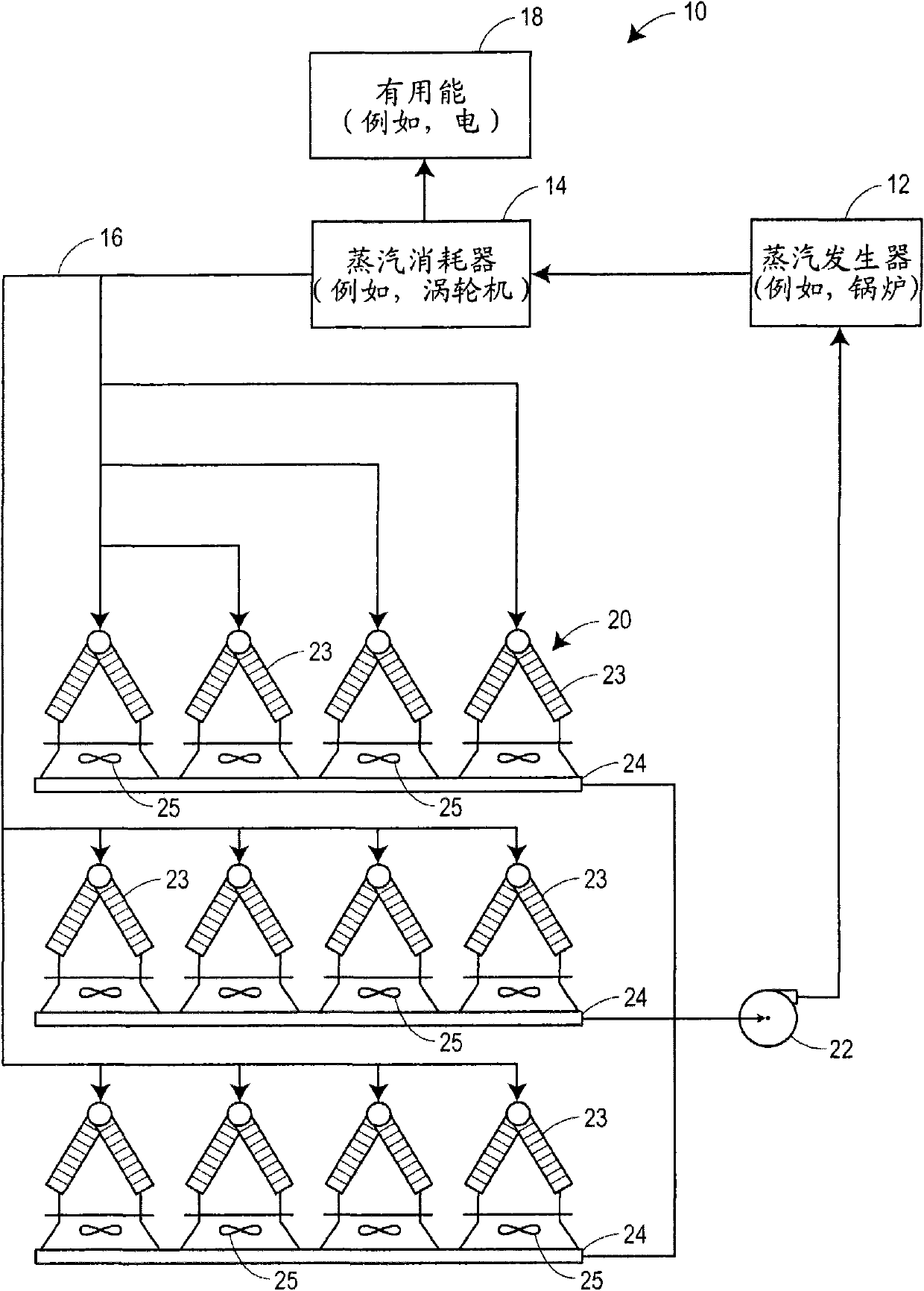

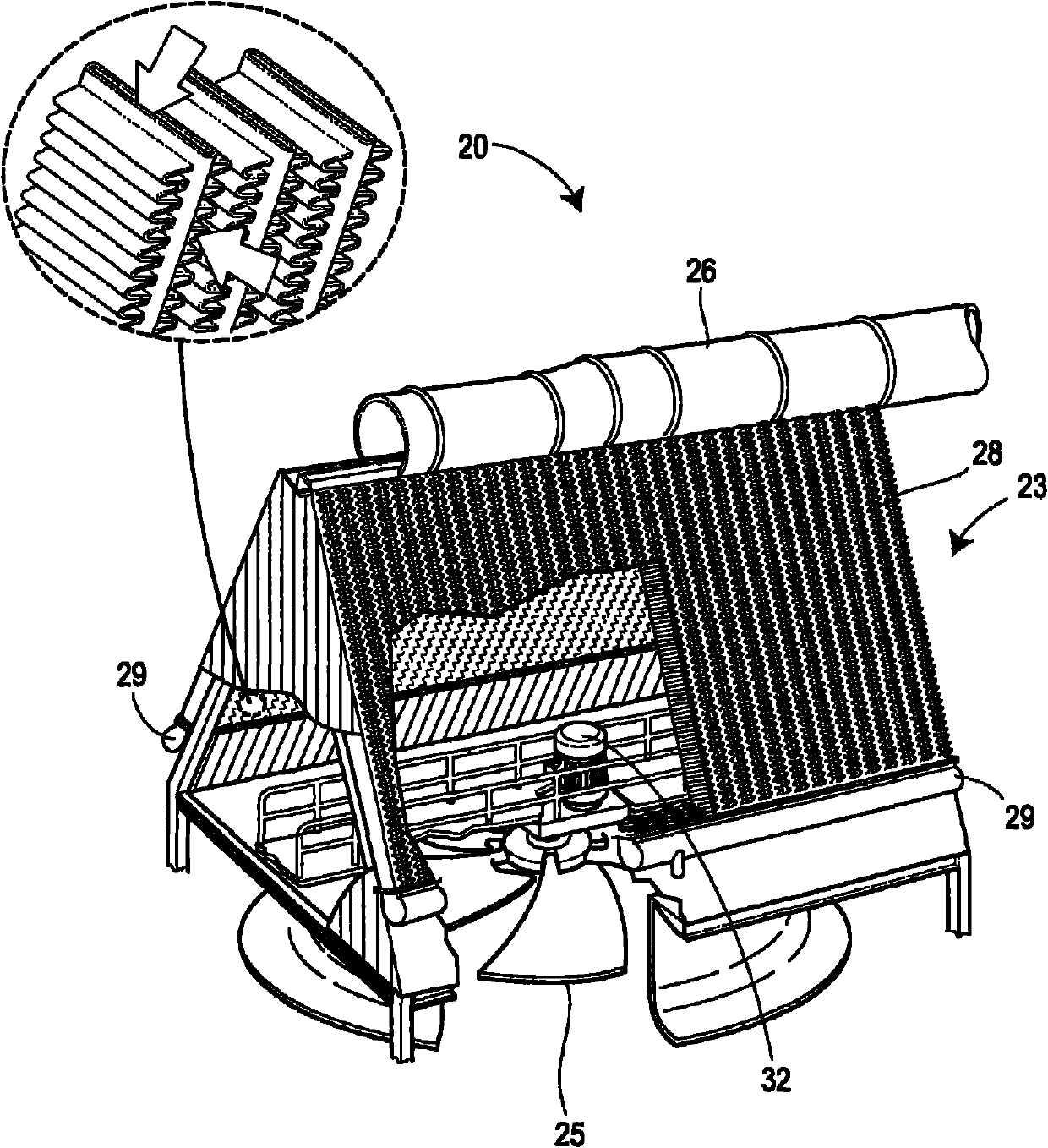

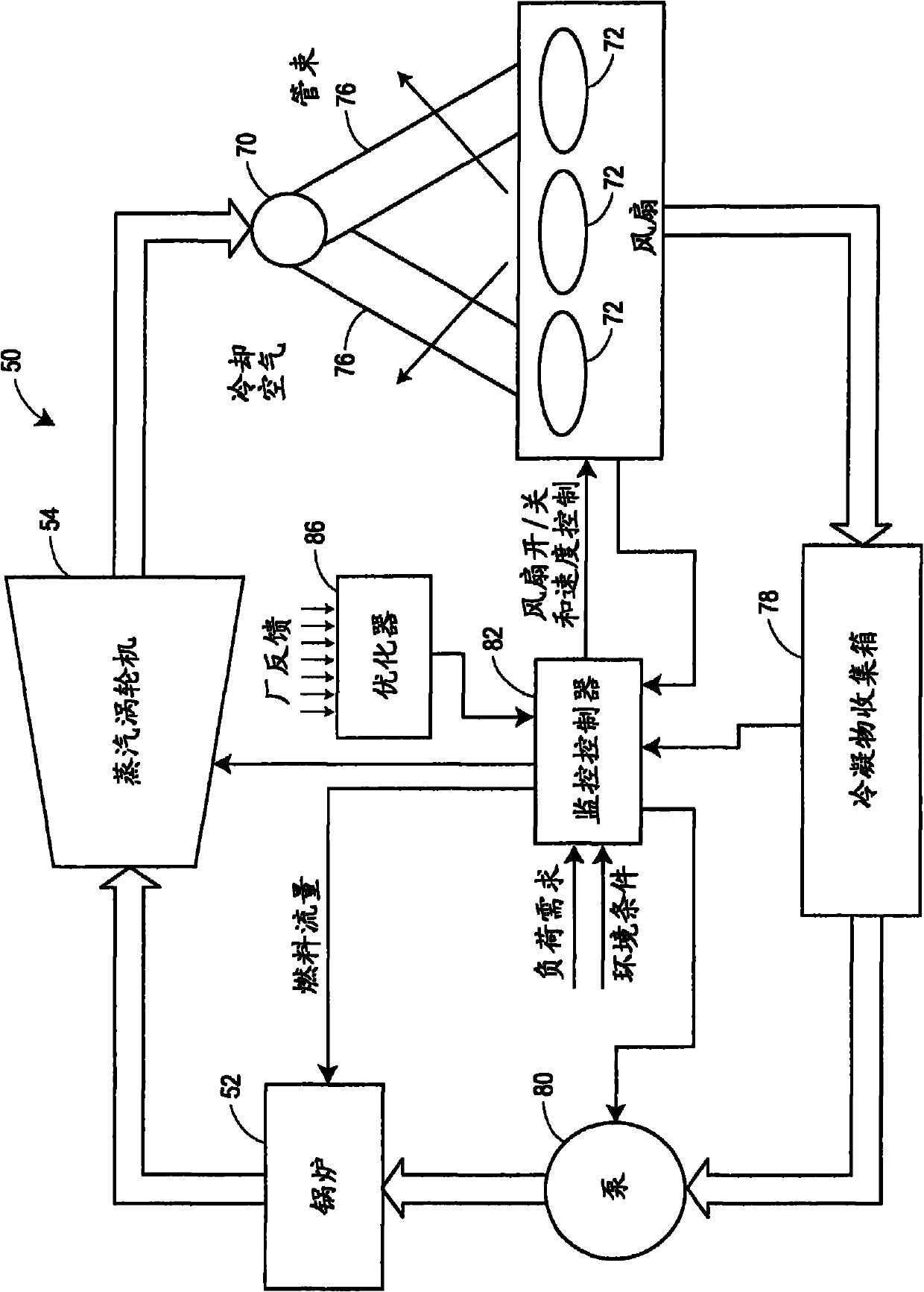

Optimized control of power plants having air cooled condensers

An optimization and control system for a utility plant that uses fan based air cooled condensers controls the operation of the power generation system at the plant in conjunction with the operation of the air cooled condensers so as to run the power plant at an optimum operating point associated with minimizing or reducing the cost of each kilowatt-hour of energy or other useful energy produced by the plant. The optimization and control system includes an optimizer having a numerical solver that determines values for a set of control variables associated with an optimal operating point of the plant and an expert system that oversees and modifies the control variable settings prior to providing these settings to a plant controller. The numerical solver uses an objective function and one or more models of plant equipment to determine the operating point of the plant that minimizes the cost per unit of useful energy generated by the plant. As part of determining the optimal plant operating point, the numerical solver may determine the number of fans to run within the air cooled condensers of the plant and / or the speed of the fans to use in the air cooled condensers in conjunction with the amount of fuel to burn in the boiler, the desired temperature of the steam at the input of the steam turbine, etc., all required to produce a given amount of power (load demand) at the particular environmental conditions currently experienced at the plant. The expert system may modify these outputs by determining which fans to actually use at any particular time based on, for example, the availability of or the operational status of the fans, the wear of the fans and fan motors, etc.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

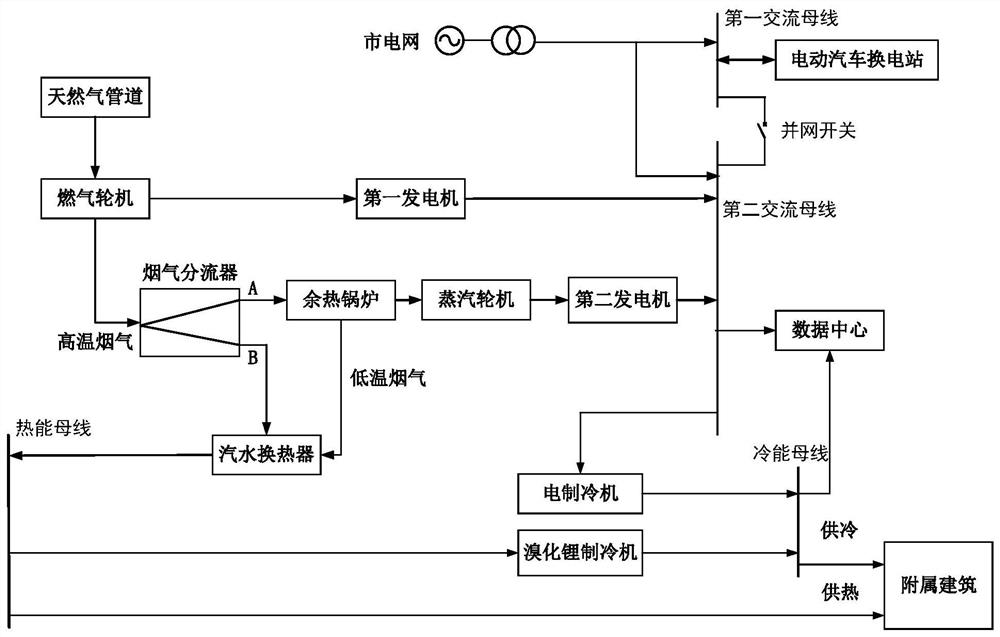

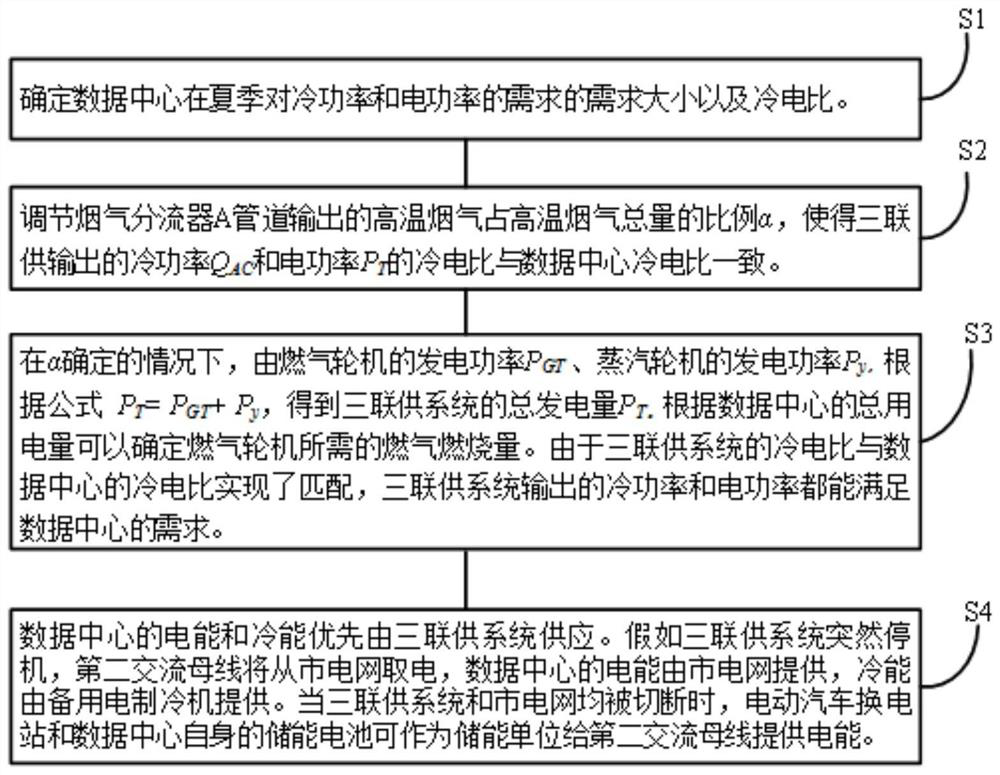

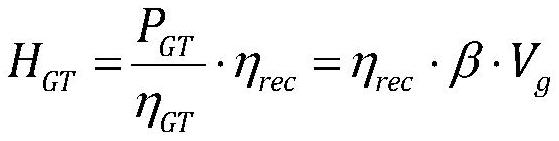

Data center multiple energy guarantee triple generation system and control method thereof

ActiveCN111963315AAdjust the cooling and electric power ratioMeet the powerEnergy efficient heating/coolingGas turbine plantsData centerLithium bromide

The invention discloses a data center multiple energy guarantee triple generation system and a control method thereof, and belongs to the field of energy optimization. The data center multiple energyguarantee triple generation system includes a gas turbine power generation system, a steam turbine power generation system and a city power grid which are connected to the data center through a secondAC bus; an electric vehicle battery changing station and the city grid are connected to a first AC bus; the first AC bus and the second AC bus are connected by a grid-connected switch; lithium bromide refrigerating machines and electric refrigerating machines produce cold energy; and a high-temperature flue gas splitter realizes the split control of flue gas. The data center multiple energy guarantee triple generation system supplements the waste heat boiler-steam turbine power generation system, splits the high-temperature flue gas produced by the gas turbine, and adjusts the ratio of the cold energy and electric power output by the triple generation system, so as to adapt to the demand ratio of cold energy and electric energy of the data center, and realize the cascade utilization of the energy at the same time. The invention considers that the data center is constructed relying on the electric vehicle battery changing station, and uses the power batteries of the battery changing station as a reliable energy storage device for the data machine room, which provides further guarantee for the stable power supply of the data center.

Owner:NANJING UNIV OF POSTS & TELECOMM

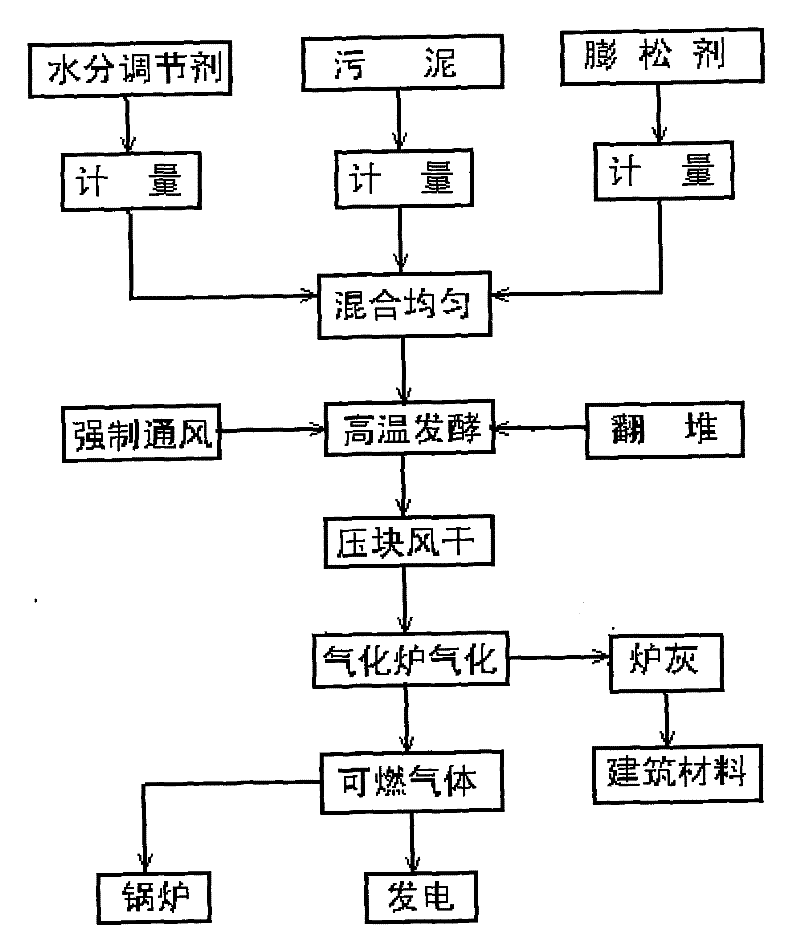

A process for producing combustible gas from sludge

The invention relates to a process for producing combustible gas from sludge. The invention belongs to the field of harmless resource utilization of sludge. Combustible gas is produced from sludge with a water content of 70%-80% and a large amount of harmful bacteria and heavy metals. The specific process is: add a moisture regulator and a fluffing agent to the dewatered sludge discharged from a sewage treatment plant and mix evenly to adjust the moisture content. To 40%-70%, aerobic fermentation is carried out under the conditions of regular overturning and forced ventilation. Kill harmful bacteria through fermentation, remove foul smell and reduce the moisture content to 20%-40%, after air-drying or directly briquetting to make fuel blocks, stack them into strips and store them for further air-drying. Put the air-dried fuel block into the gasification furnace, and carry out high-temperature or medium-temperature pyrolysis and gasification under the condition of restricted ventilation to generate mixed combustible gas for use in boilers and power generation, and its ash is used as building materials.

Owner:高增芳

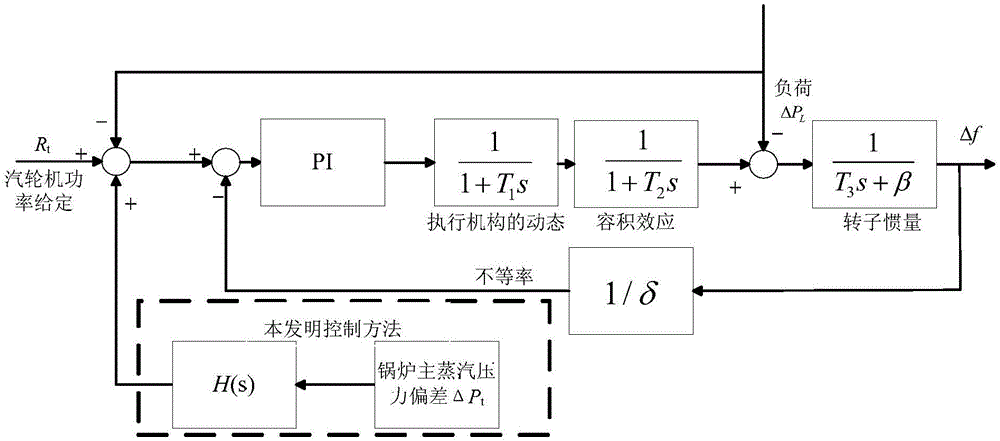

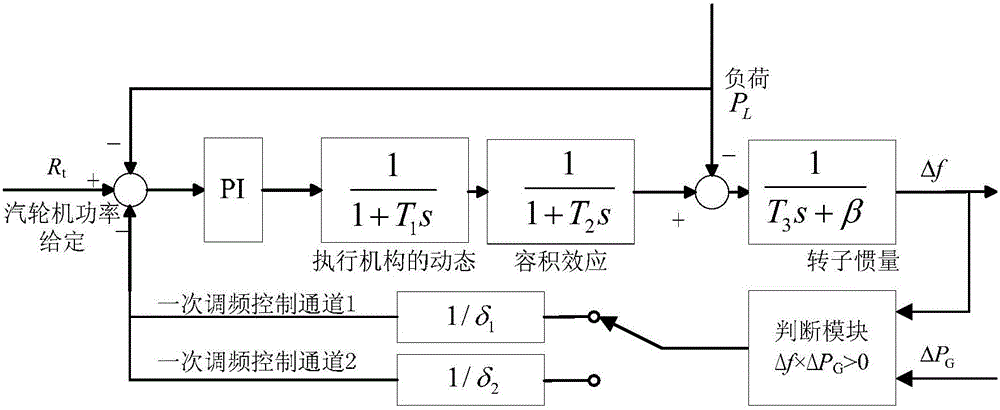

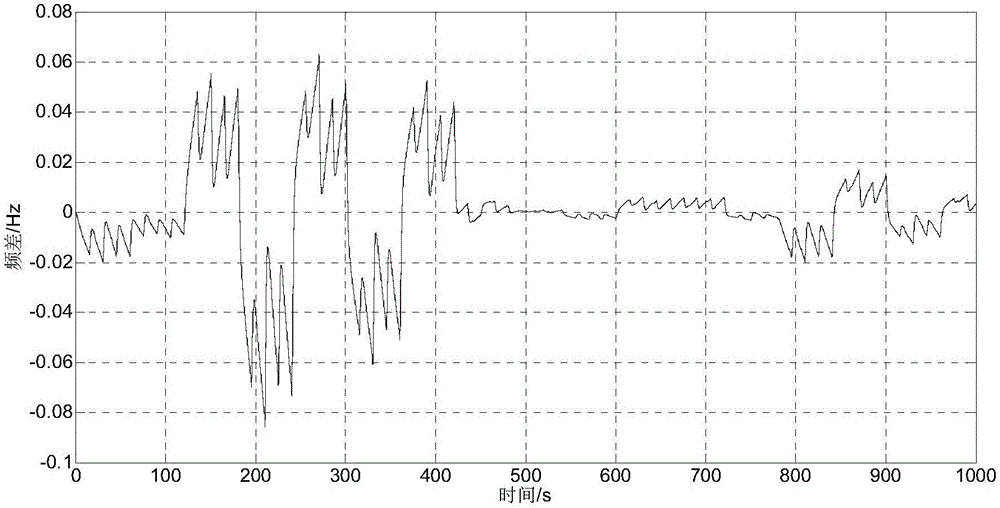

Once-through boiler, steam turbine and power grid coordinated control method for primary frequency modulation analysis

InactiveCN106780103AExtend your lifeEnergy utilization is reasonableForecastingPower gridEngineering

The invention relates to a once-through boiler, steam turbine and power grid coordinated control method for primary frequency modulation analysis. The invention aims to solve a problem that characteristics of the boiler are not considered in the prior art so that great resistance is brought to participation of a high-capacity high-parameter thermal power generation unit in primary frequency modulation and safe and stable running of an electric power system is not facilitated. The method comprises the steps of firstly, performing once-through boiler energy state analysis so as to determine the once-through boiler energy state; secondly, performing power grid energy state analysis so as to determine the power grid energy state; and thirdly, determining a grid source energy coordinated control strategy according to the once-through boiler energy state determined in the step one and the power grid energy state determined in the step two. The once-through boiler, steam turbine and power grid coordinated control method enables the thermal power generation unit to not only sufficiently participate in frequency modulation, but also be operate safely and efficiently under the premise of meeting a requirement of safe running of a power grid. The once-through boiler, steam turbine and power grid coordinated control method is applied to the field of primary frequency modulation analysis.

Owner:HARBIN INST OF TECH

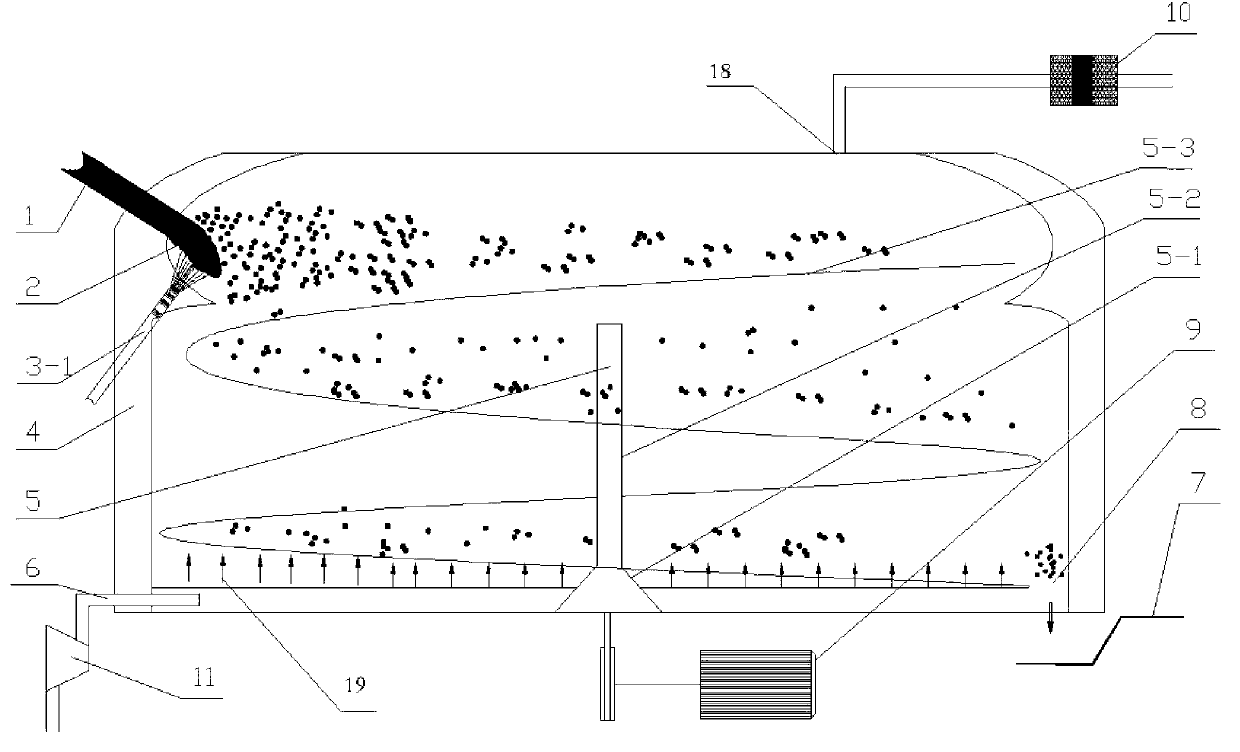

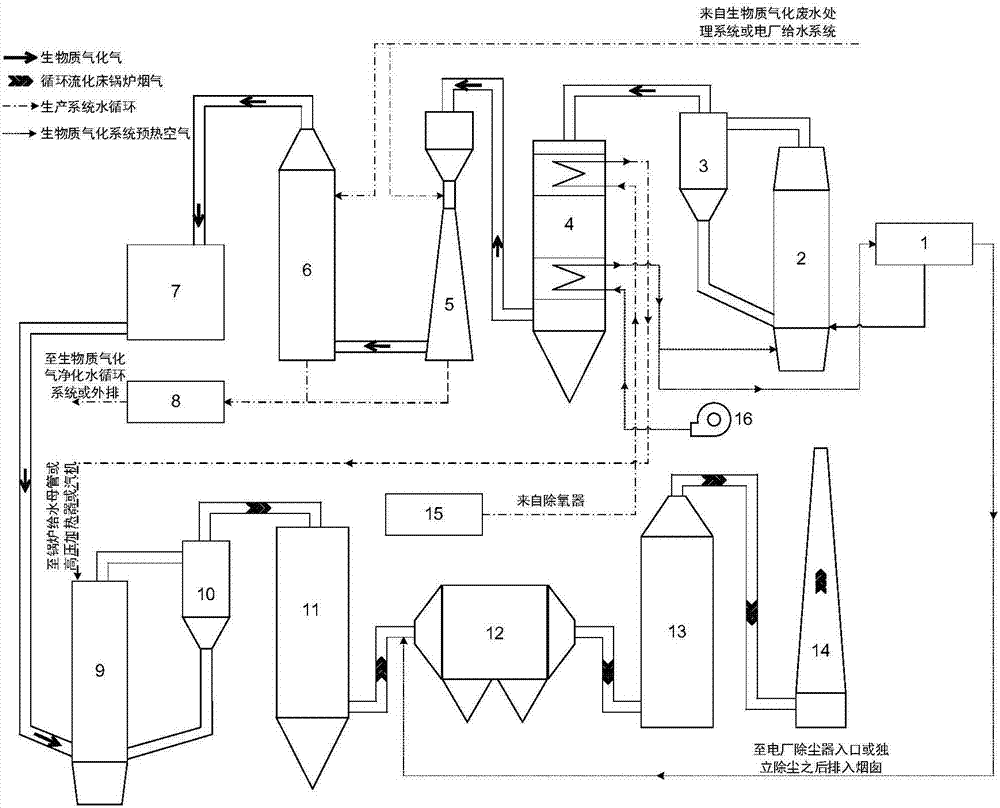

Biomass gasification-circulating fluidized bed boiler combined power generation system and working method thereof

PendingCN107245353ALow costImprove adaptabilityEnergy inputGasification processes detailsInternal combustion engineBoiler (power generation)

The invention discloses a biomass gasification-circulating fluidized bed boiler combined power generation system and a working method thereof, belonging to a biomass efficient utilization and power generation technique. At present, the biomass direct combustion power generation technique has the problems of high cost and small scale; the biomass blend combustion technique has the problems of low blend combustion ratio, technical difficulties and high cost; and the gasification power generation technique has the problems of higher technical requirements for power generating equipment (gas turbines, internal combustion engines and the like), low energy utilization efficiency and higher cost. In order to solve the technical problems above, the coproduction of the biomass gasification technique and the circulating fluidized bed boiler power generation technique is utilized to avoid the biomass direct combustion power generation and blend combustion; a thermal circulation loop is arranged between a biomass gasification system and a fluidized bed boiler power generation system to perform high-temperature combustible gas waste heat recovery; and an air preheating system is arranged at the waste heat recovery low-temperature section of the biomass gasification system, thereby enhancing the charged medium temperature of a gasification furnace, and increasing the energy utilization efficiency of the system. The biomass gasification-circulating fluidized bed boiler combined power generation system provides a convenient, low-cost, safe and efficient way for development and utilization of biomass resources.

Owner:HUANENG CLEAN ENERGY RES INST +1

Power generation device through low temperature exhaust heat

InactiveCN106014513AImprove power generation efficiencyReduce power generation costsSteam engine plantsEngineeringCam

The invention relates to a power generation device, in particular to a power generation device through low temperature exhaust heat, and provides the power generation device through low temperature exhaust heat which is high in power generation efficiency, low in power generation cost and small in power generation limitation. The power generation device through low temperature exhaust heat comprises a bottom plate, a mounting rack, a water pool, a water inlet pipe, a one-way valve I, a cylinder body, a piston, a moving rod, a spring I, a pressing plate, a bearing seat I, a rotating shaft I, a cam, a bevel gear I, a bearing seat II, a bracket, a rotating shaft II, a bevel gear II, a fan I, a fixing plate, a heating furnace I, an air inlet pipe, a boiler I, a heating furnace II, a boiler II, a pressure relief pipe, a check block, a one-way valve III, an air nozzle I, a water outlet pipe, a one-way valve IV, an air outlet pipe II, a one-way valve V, an air nozzle II, a condensing tank, a fan II, a generating unit and a water outlet. According to the power generation device, the effects that the power generation efficiency is high, the power generation cost is low and the power generation limitation is small are achieved.

Owner:蔡学斌

Hot water recirculation system used for flue gas waste heat recovery

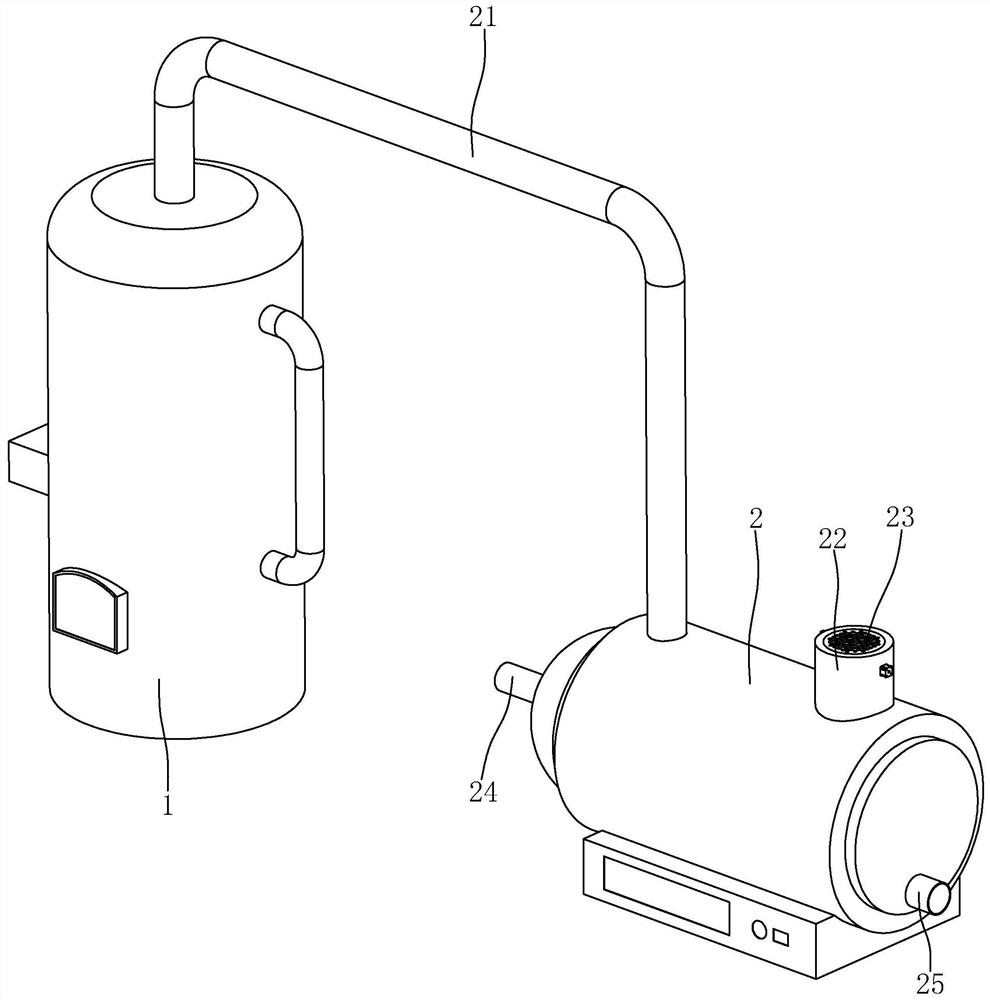

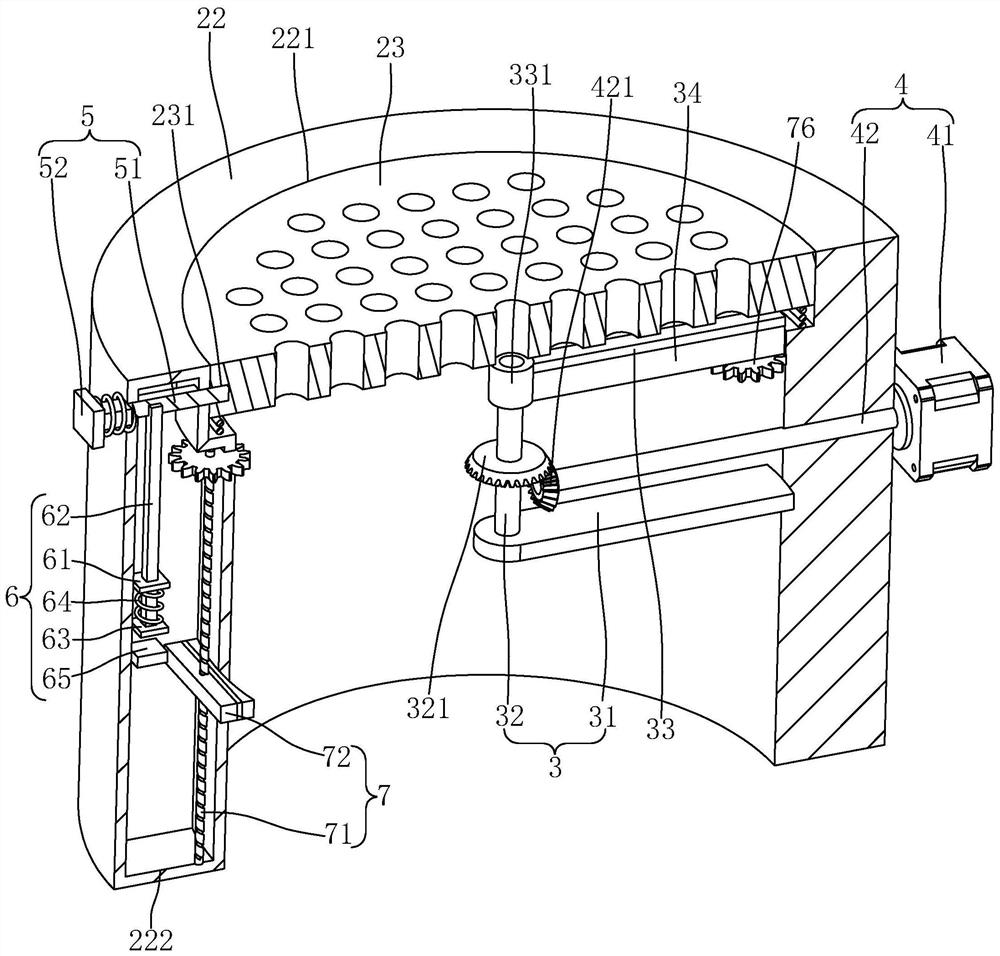

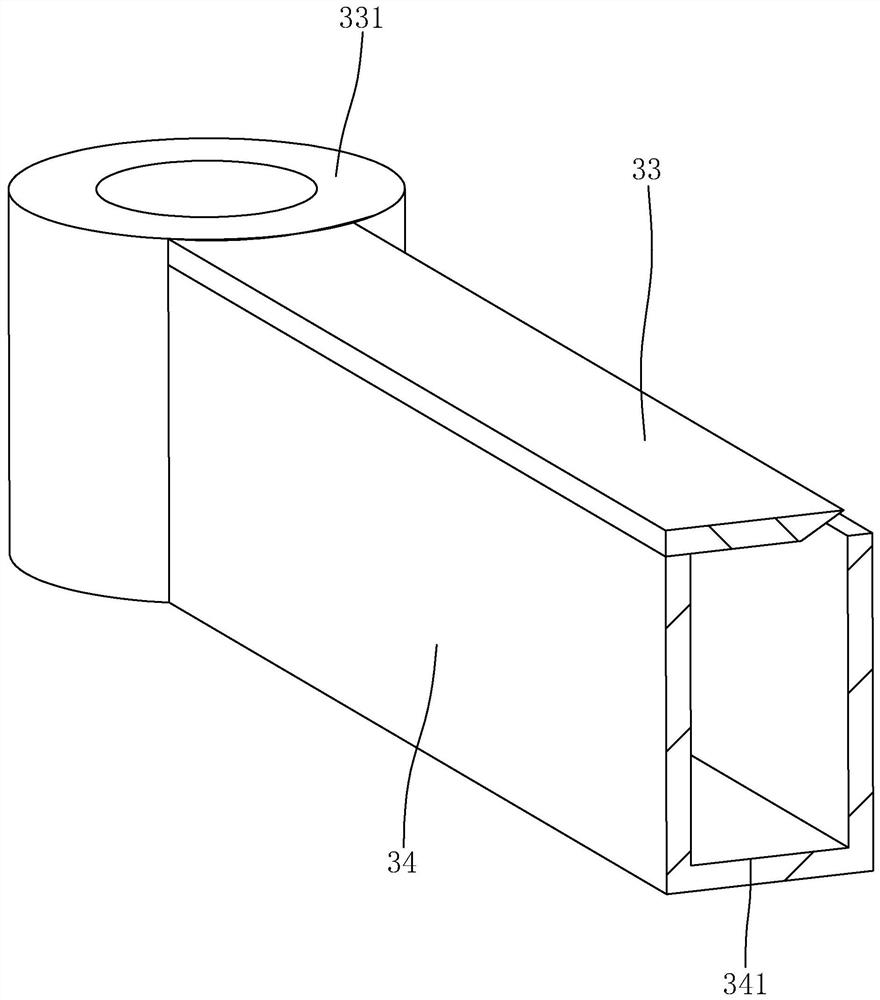

PendingCN113587130AImprove easy cloggingAchieve disassemblyDispersed particle filtrationLighting and heating apparatusFlue gasThermal water

The invention relates to a hot water recirculation system used for flue gas waste heat recovery, and relates to the field of thermal power generation energy conservation. The hot water recirculation system comprises a boiler body and a flue gas waste heat recovery shell body installed on the boiler body, the flue gas waste heat recovery shell body communicates with the boiler body through a gas inlet pipe, a gas outlet pipe is fixedly connected to the top of the flue gas waste heat recovery shell body, a filtering piece is installed at a pipe opening of the gas outlet pipe, a cleaning component used for cleaning the filtering piece is installed on the gas outlet pipe, the cleaning part comprises a fixed plate which is fixedly connected to the inner wall of the air outlet pipe, a rotating shaft which is rotationally installed on the fixed plate and a scraping plate which is installed on the rotating shaft, the side wall of the scraping plate makes contact with the side wall of the filtering piece, and a driving part used for driving the rotating shaft to rotate is installed on the air outlet pipe. Through the hot water recirculation system, the problem that filtering holes in the filtering piece are prone to being blocked is solved.

Owner:宁波众茂杭州湾热电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com