Optimization method and device of operation of power station boiler

A power plant boiler and optimization method technology, applied in the direction of instruments, adaptive control, control/regulation system, etc., can solve the problems of economic loss, low reliability, high cost of power plant boilers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

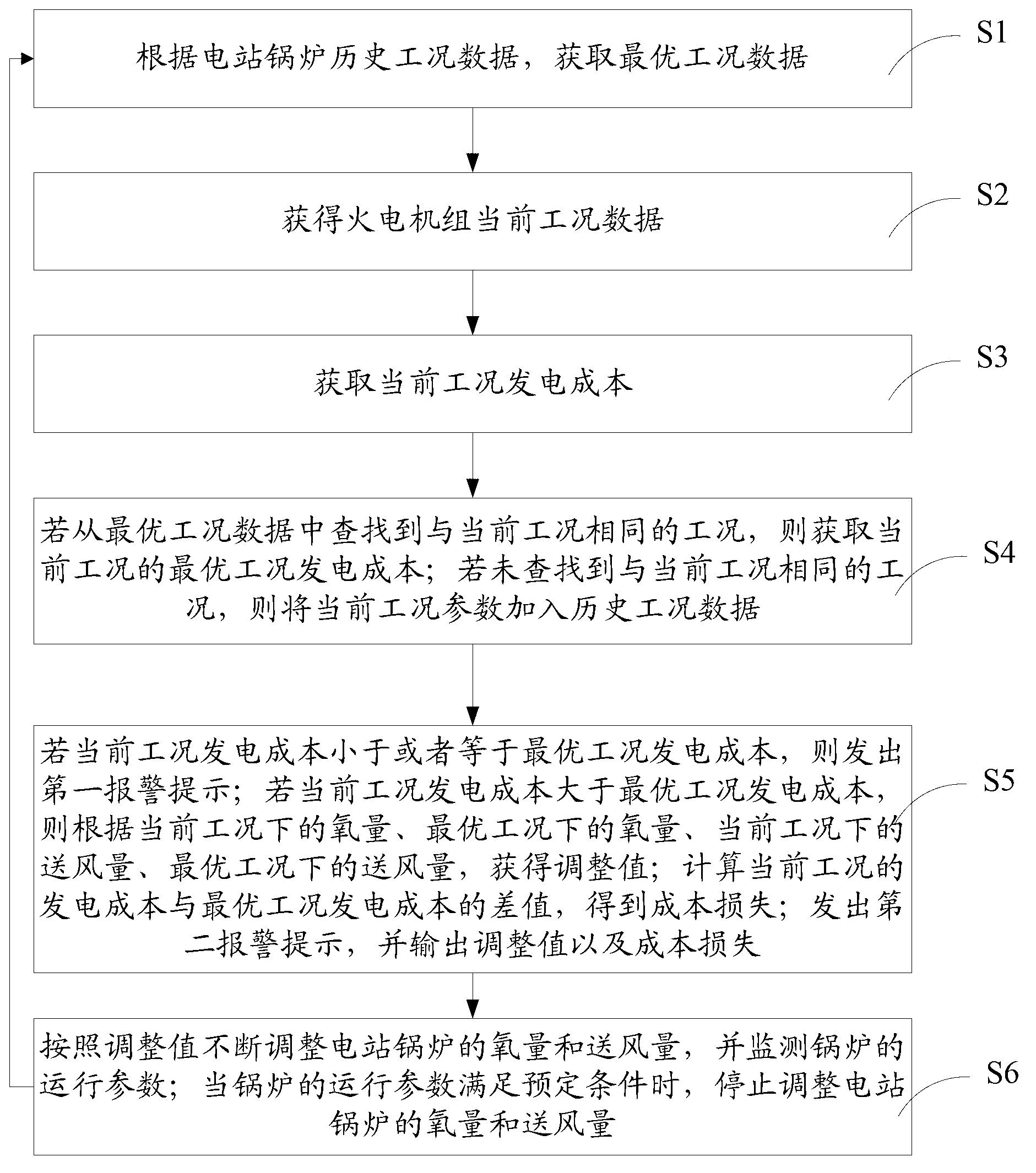

[0025] The present invention proposes a method for optimizing the operation of power plant boilers, and the implementation process may refer to figure 1 , including the steps:

[0026] S1. Obtain the optimal working condition data according to the historical working condition data of the power plant boiler;

[0027] Among them, the optimal working condition data includes: the optimal working condition score, the optimal working condition air supply volume, the optimal working condition oxygen amount and the optimal working condition power generation cost under the same equipment combination in the same load section;

[0028] S2. Obtain the current working condition data of the thermal power unit;

[0029] Obtain the current working condition data of the thermal power unit; among them, the current working condition data includes: load, equipment combination mode, safety index parameters, stability index parameters, environmental protection index parameters, economic index para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com