Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

288 results about "Stability index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A requirement stability index (RSI) is a metric used to organize, control, and track changes to the originally specified requirements for a new system project or product.

Durable nanoweb scrim laminates

A filter media comprising a nanofiber layer and a substrate layer; the nanofiber layer comprising a polymer material and having a fiber diameter of about 0.01 to 1.0 micron, a basis weight of about 0.5 to 30 gsm, and a thickness of at least about 2 microns, the nanofiber layer further having a surface stability index of at least about 5 kN / m, the media further being pleated.

Owner:DUPONT SAFETY & CONSTR INC

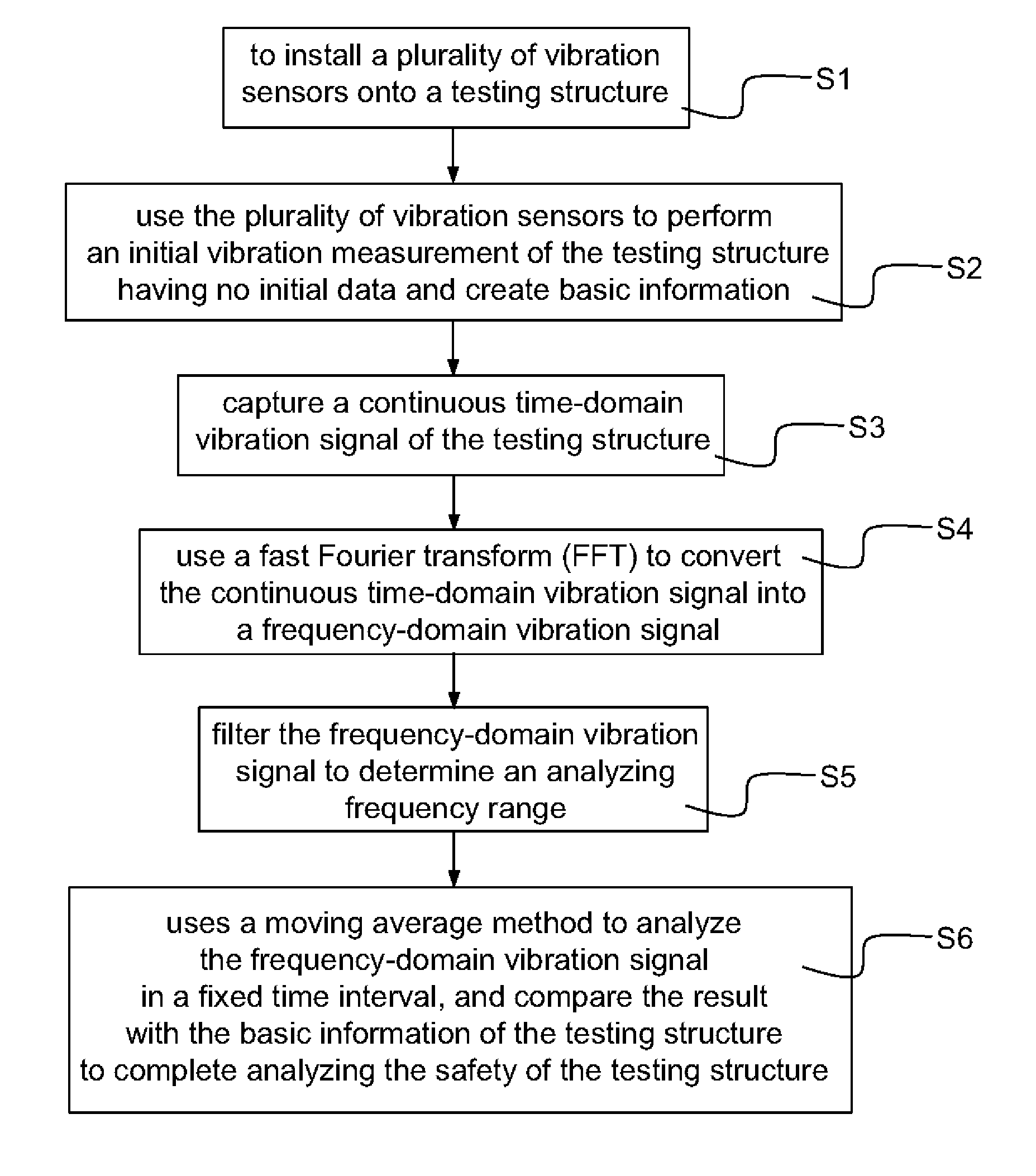

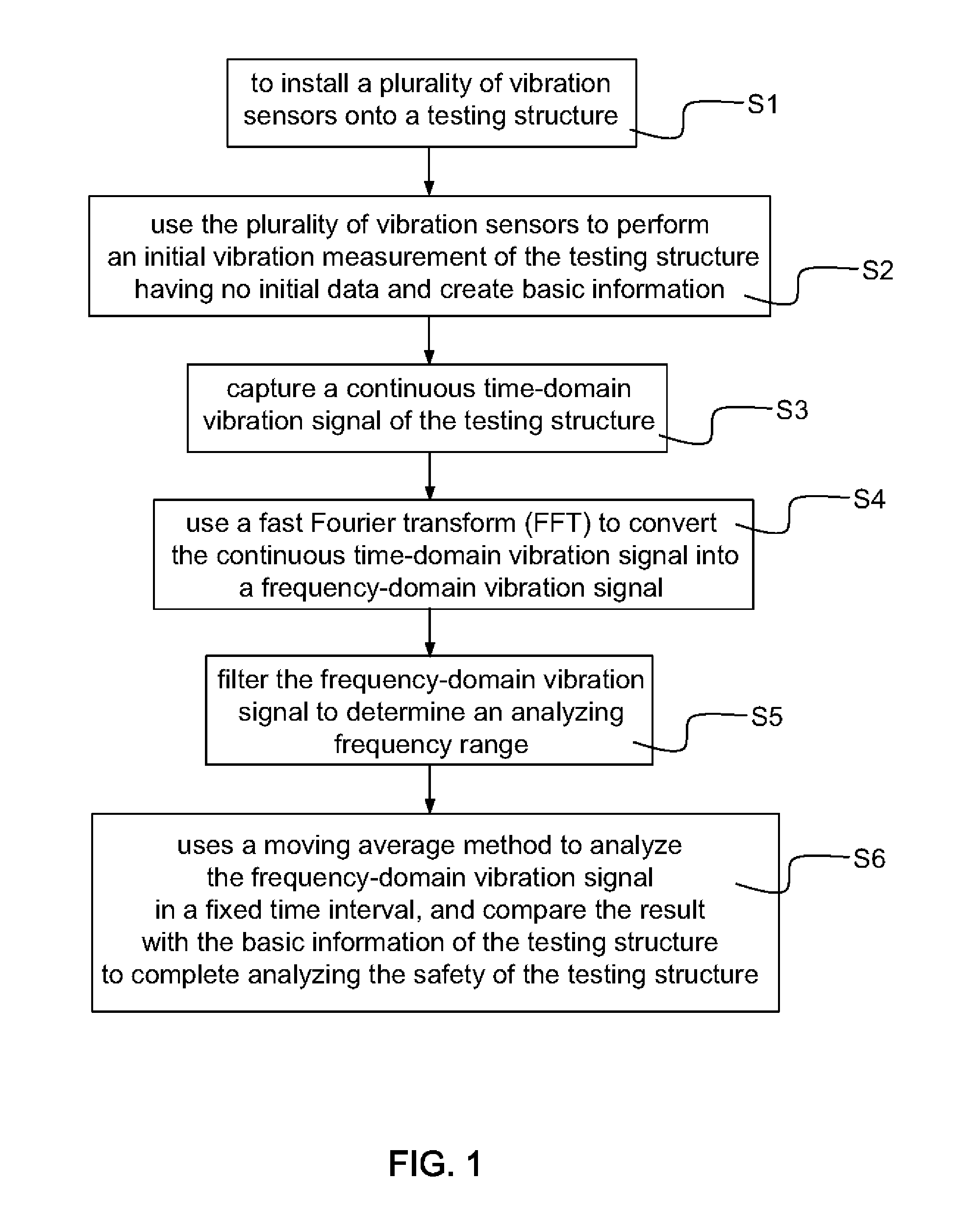

Method for analyzing structure safety

InactiveUS20120204646A1Guarantee structureMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial strength using single impulsive forceVibration measurementStability index

The present invention discloses a method for analyzing structure safety, and the method uses valid vibration measurement signals to obtain mutual feedbacks for a structural model analysis and a calibrated structural model to simulate a disaster situation to obtain the critical force exertion and deformation scale of a structure. The method is applied to capture the stability index of the structure to analyze the structure safety or applied for a structure safety evaluation or a health monitoring, or even for a structure multi-hazards safety determination.

Owner:NAT TAIWAN UNIV OF SCI & TECH

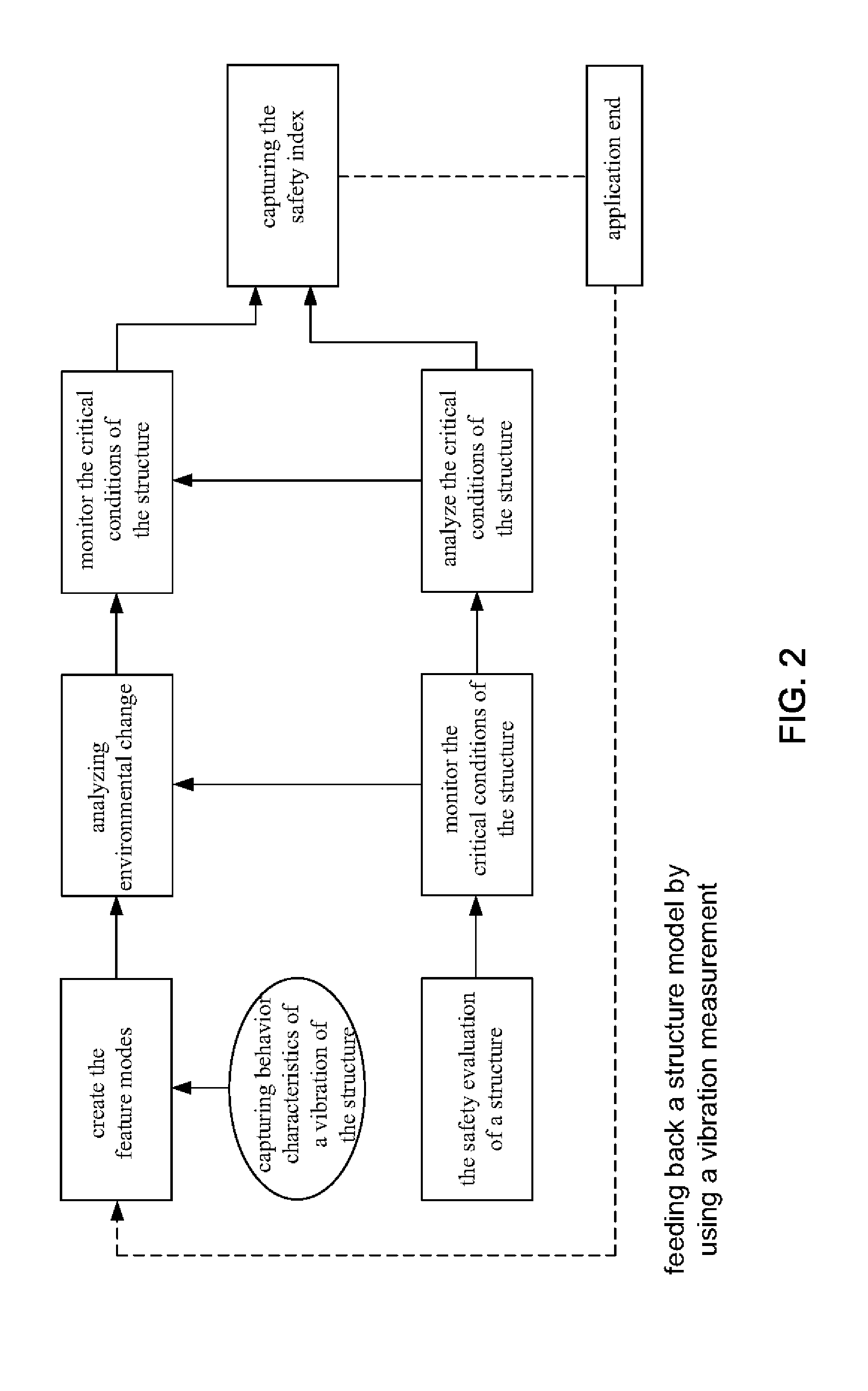

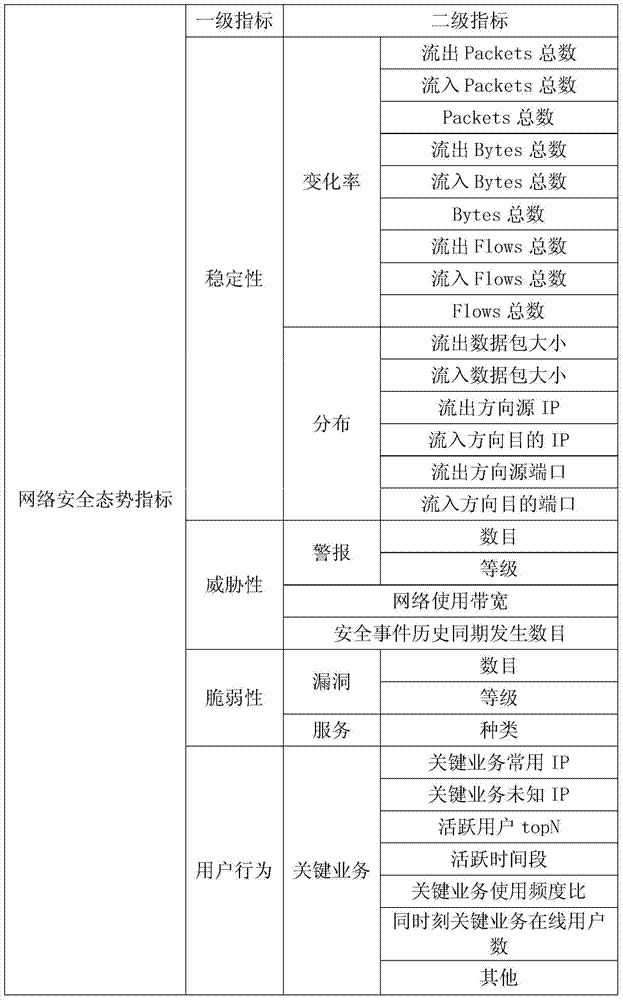

Network security situation awareness method and system

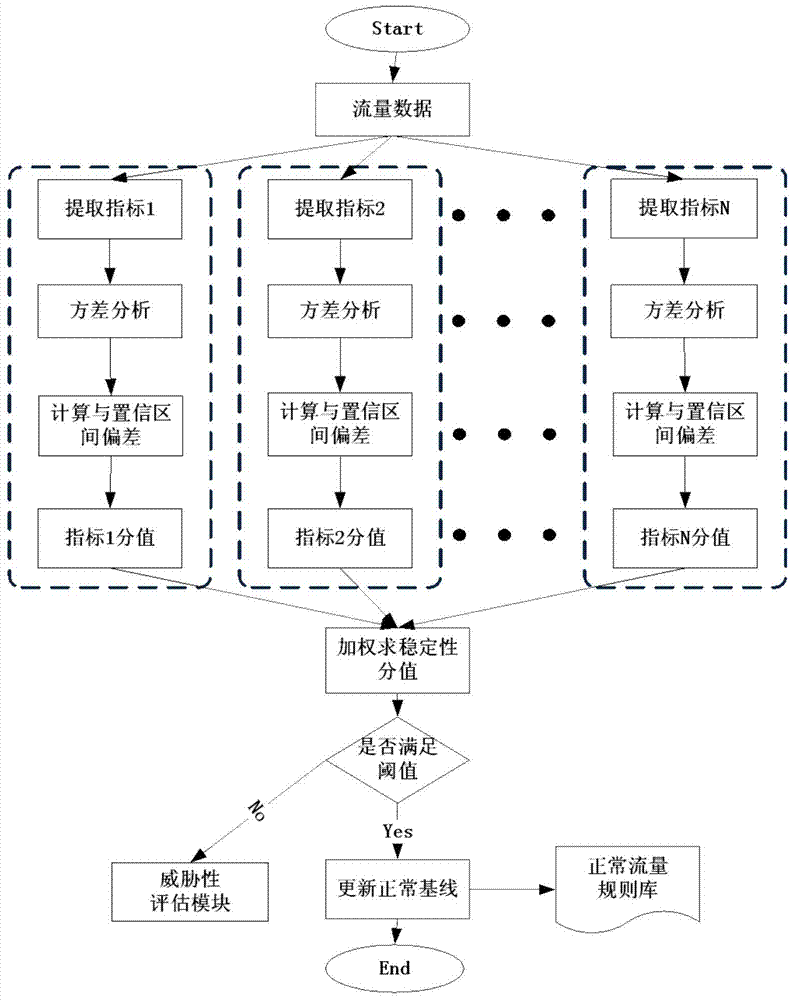

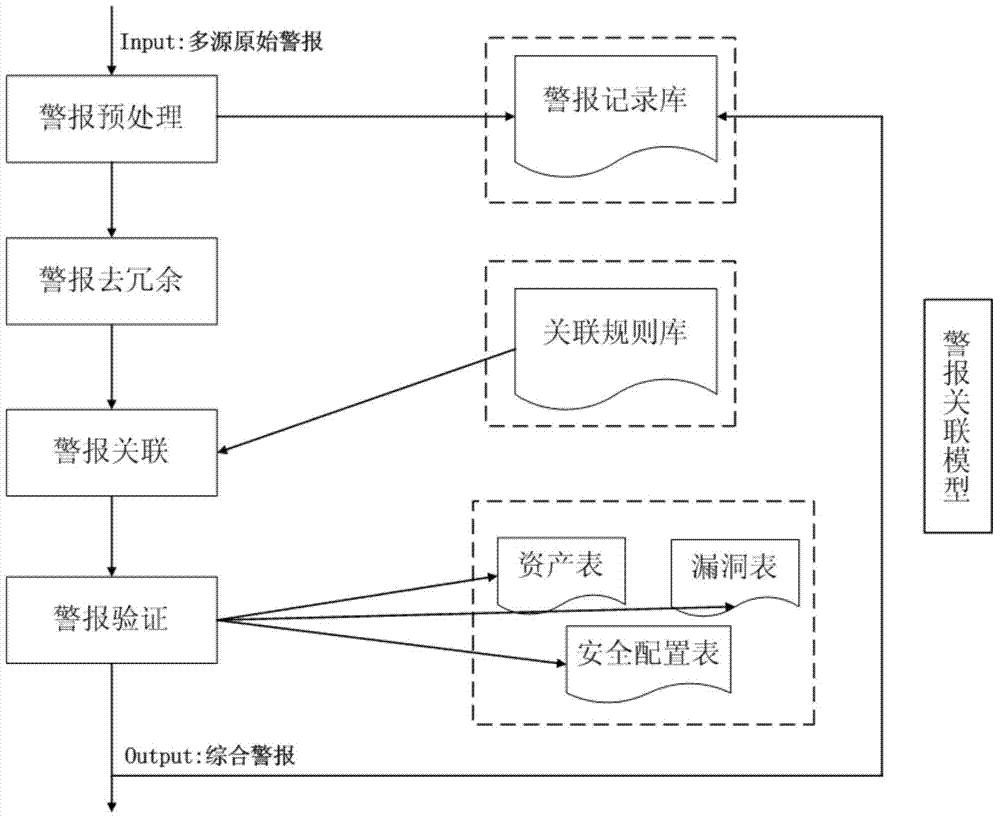

ActiveCN103581186AStability RefinementEasy to implementData switching networksStability indexVulnerability index

The invention relates to a network security situation awareness method and system. The network security situation awareness method comprises the steps that key elements capable of being used for describing the network security situation are extracted, including network flow stability, threatening, vulnerability and user behaviors, second-level index score calculation and first-level index score calculation are carried out on the extracted key elements, first-level index scores include a network flow stability index score SS, a threatening index score TS, a vulnerability index score VS and a user behavior index score US, and finally the value of the entire network security situation is calculated by utilizing the weighted sum. The network security situation awareness method and system aim to establish comprehensive network security situation awareness indexes and improve the effectiveness and the real-time performance of the network security situation awareness.

Owner:SHANGHAI YINGLIAN SOMATOSENSORY INTELLIGENT TECH CO LTD

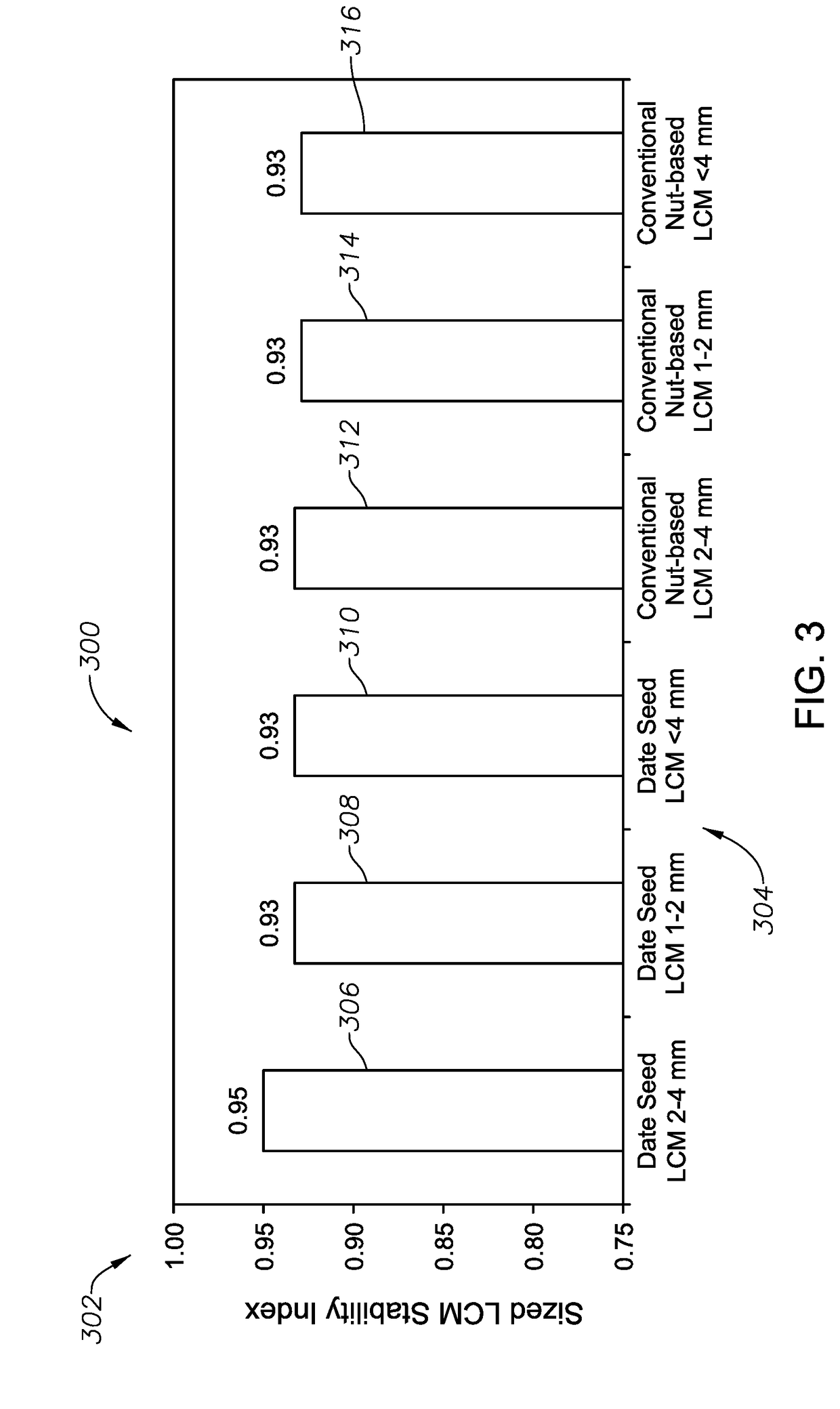

Date Palm Seed-Based Lost Circulation Material (LCM)

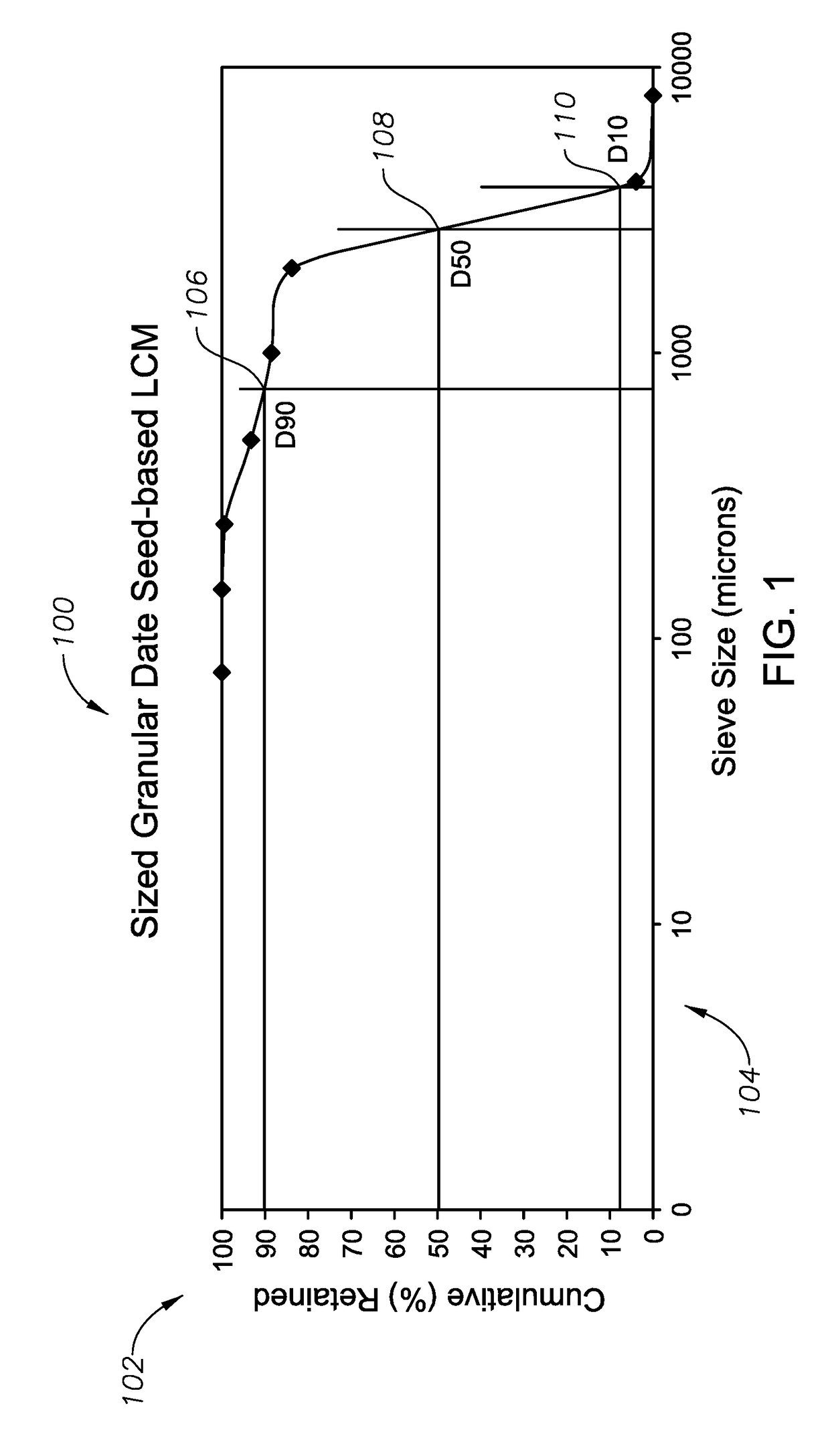

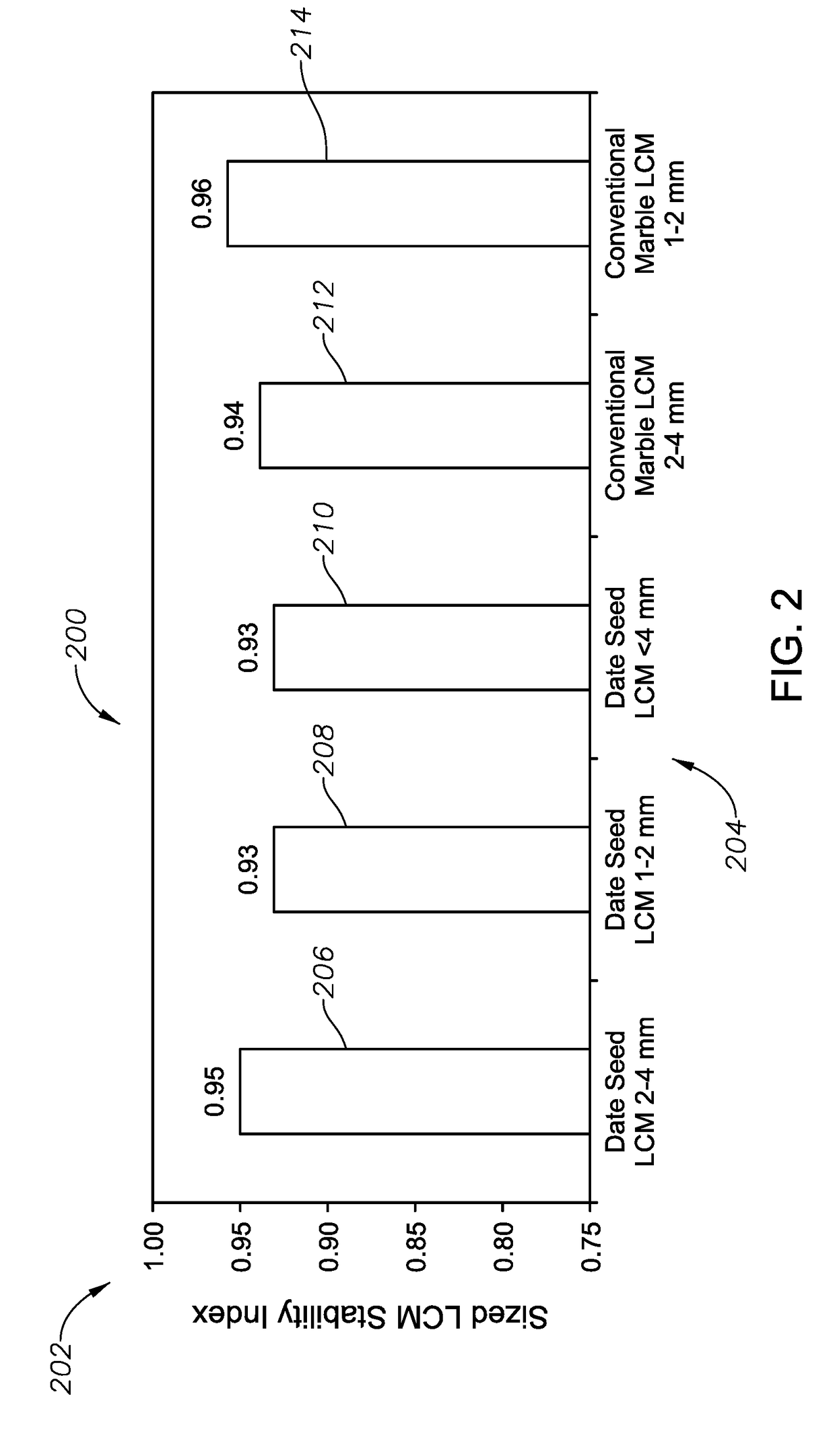

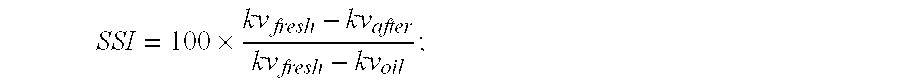

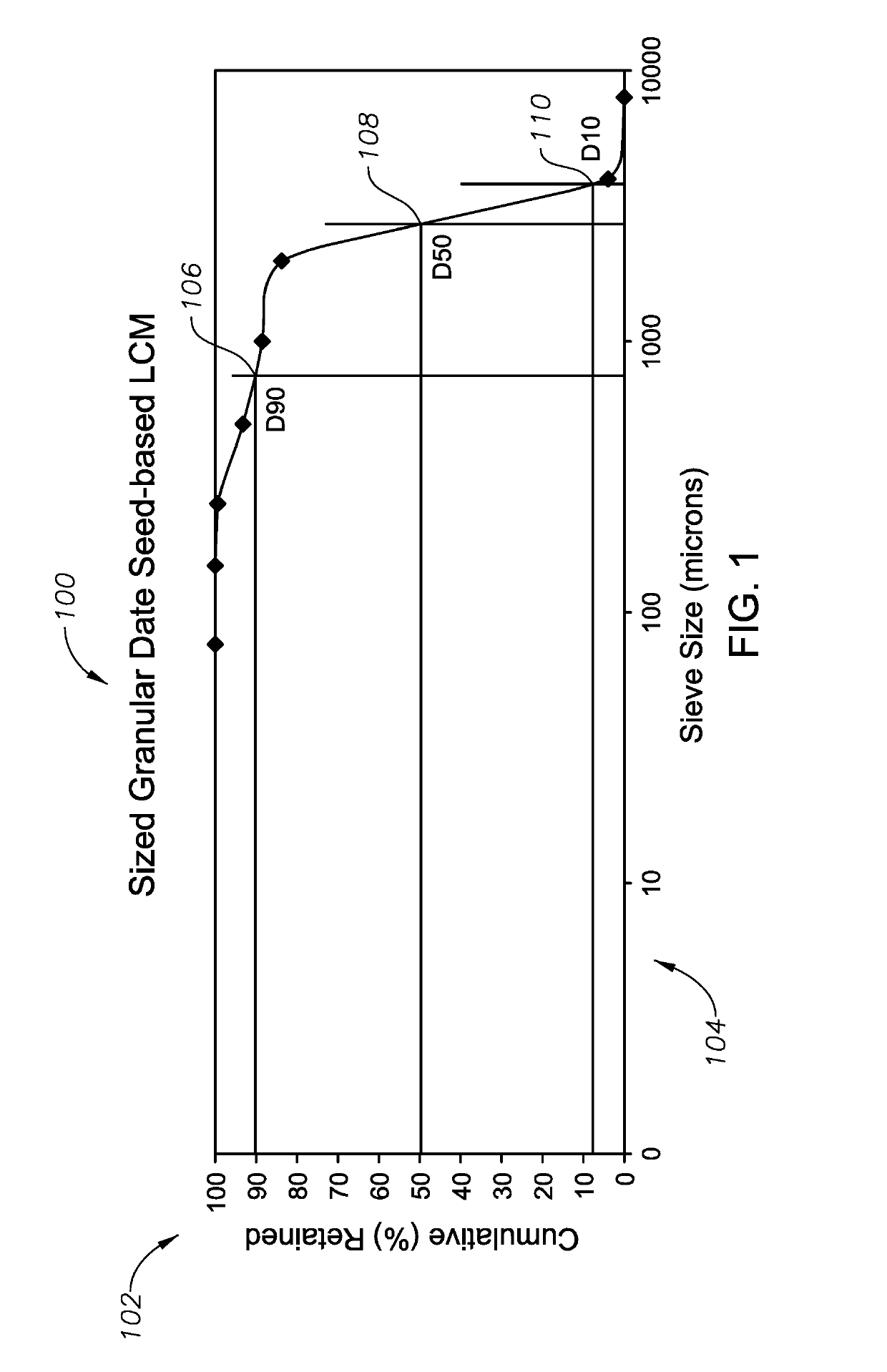

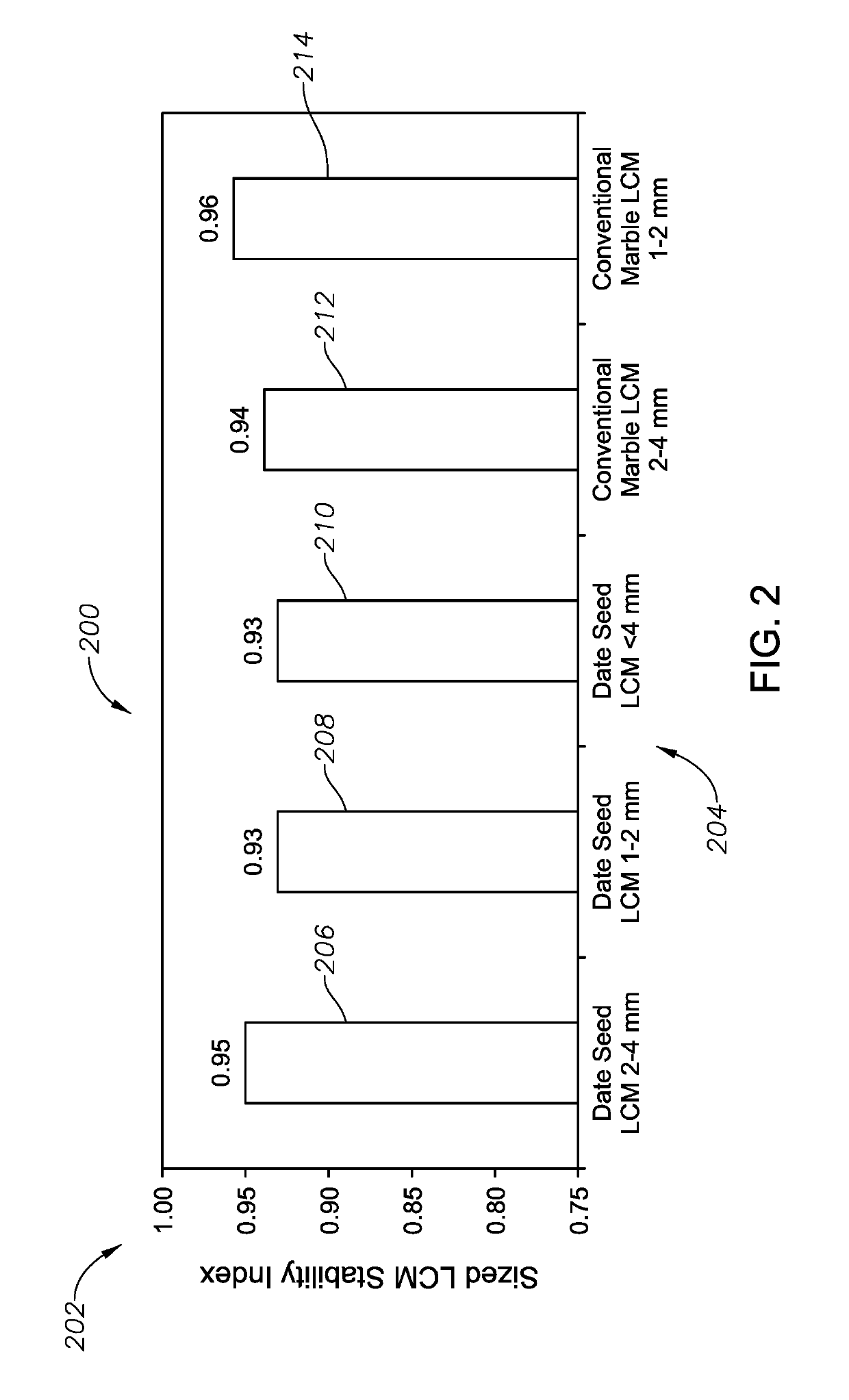

A date palm seed-based lost circulation material (LCM) is provided. A date palm seed LCM may be manufactured by drying date palm seeds and grinding the dried date palm seeds to create a plurality of particles. The particles may have sizes less than 4 mm, from 1 mm to 2 mm, or from 2 mm to 4 mm. The date palm seed LCM may have a volumetric swelling greater than an LCM formed from tree nuts and may have a volumetric swelling of at least 0.3 cubic centimeters per gram. The date palm seed LCM may have a D50 shift factor less than an LCM formed from calcium carbonate and may have a D50 shift factor of at least 0.38%. The date palm seed LCM may have a stability index of at least 0.95. Methods of lost circulation control and manufacture of a date palm seed LCM are also provided.

Owner:SAUDI ARABIAN OIL CO

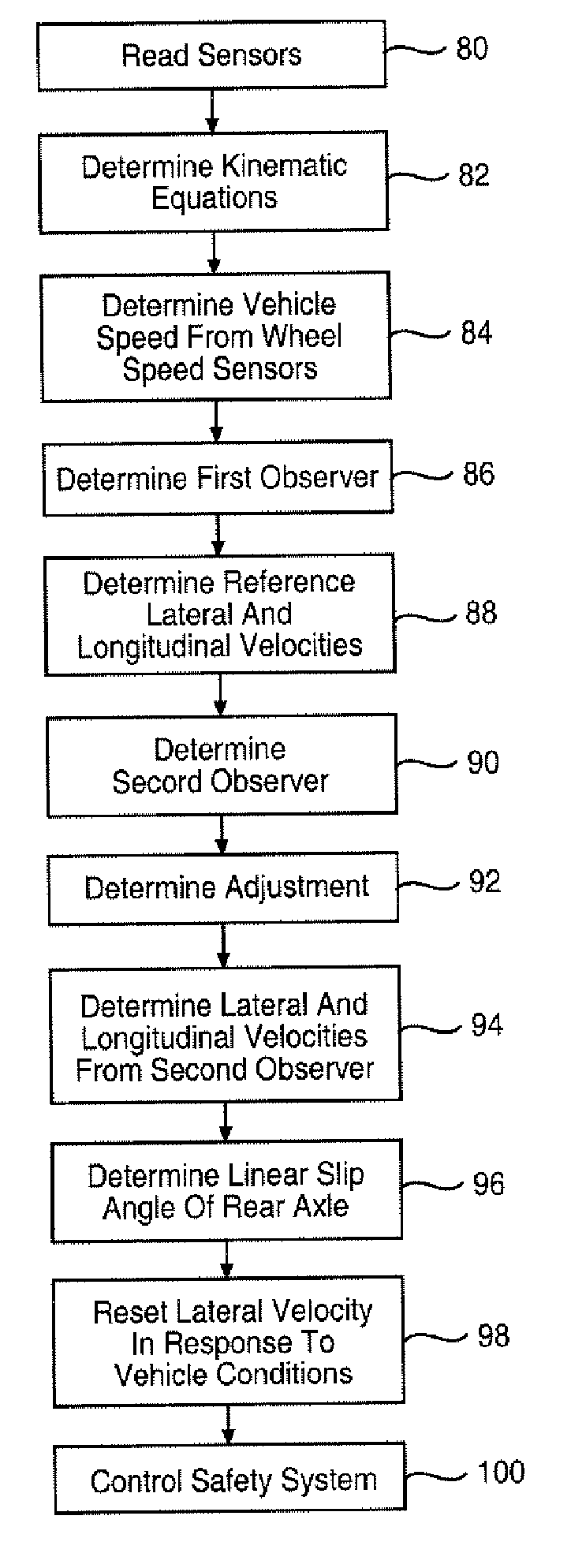

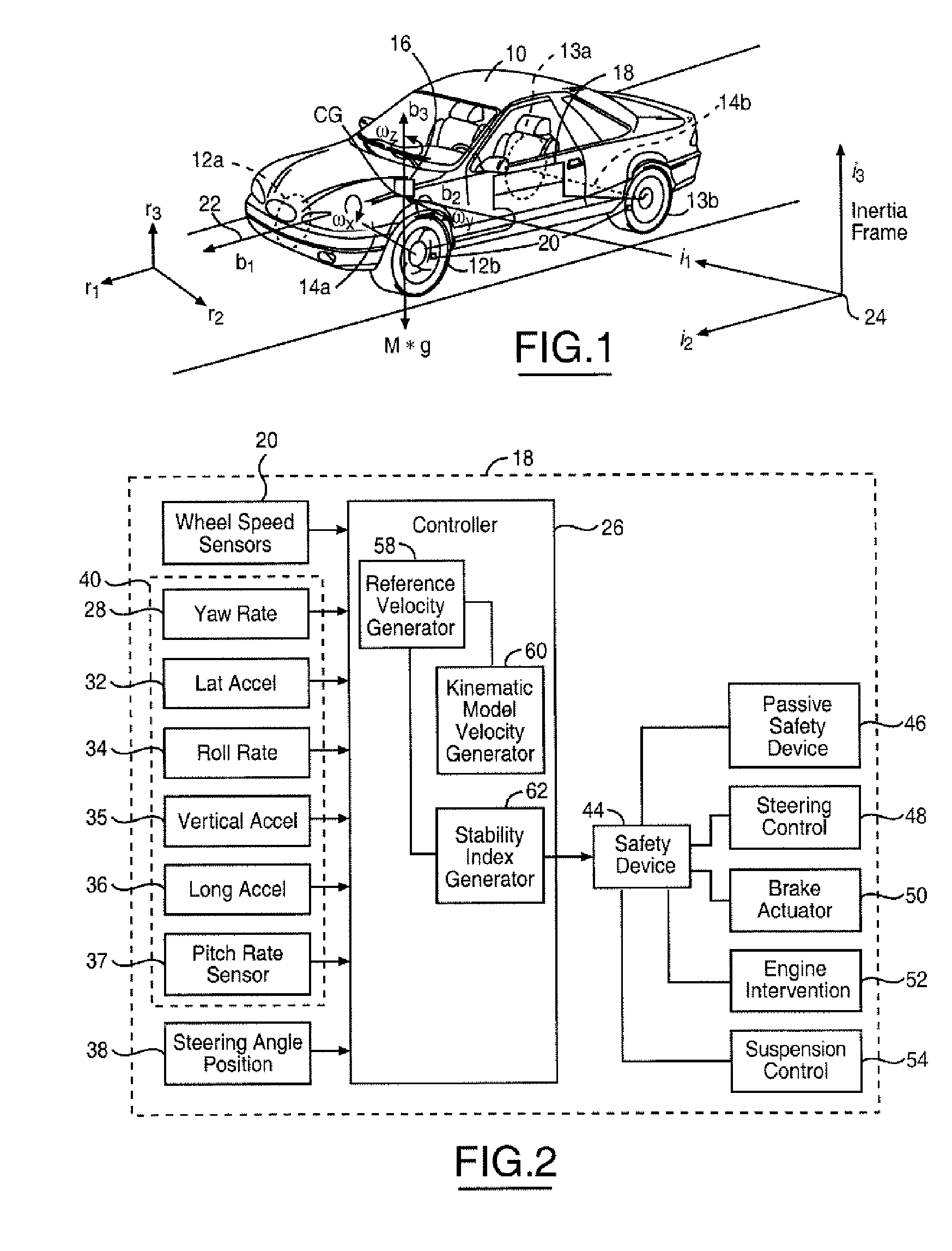

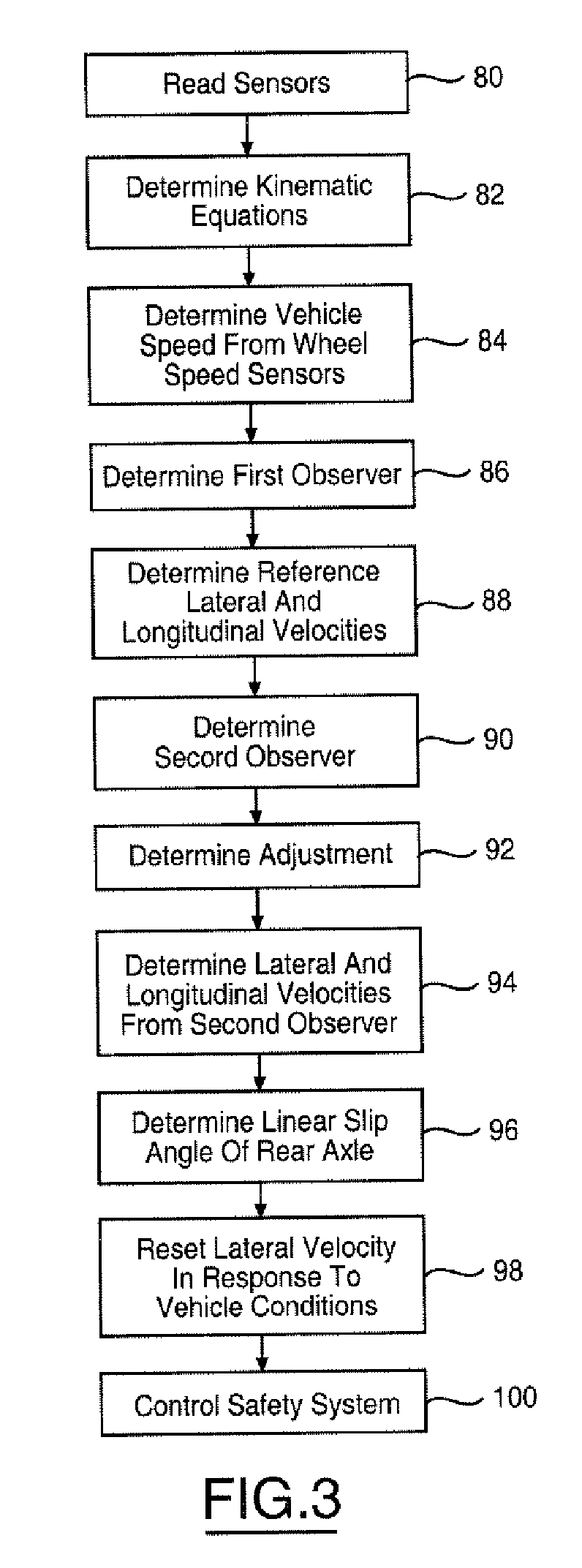

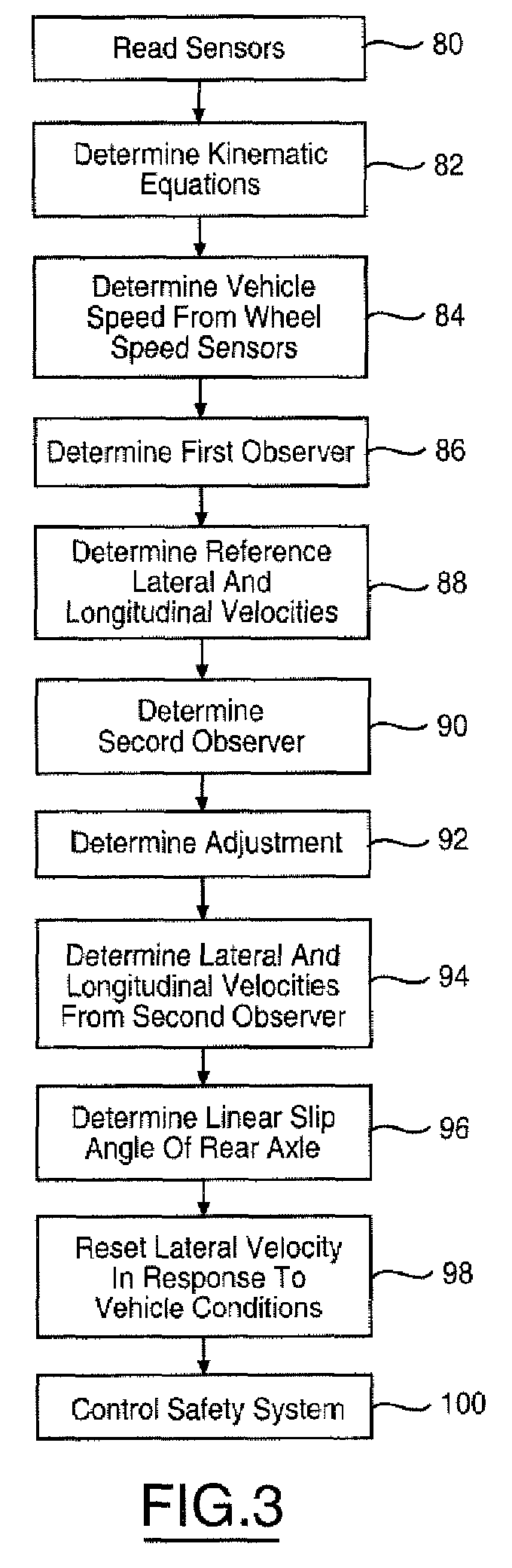

Lateral and longitudinal velocity determination for an automotive vehicle

InactiveUS20070005212A1Low costAccurate estimateAnalogue computers for trafficPedestrian/occupant safety arrangementStability indexWheel speed sensor

A system (18) for controlling a safety system (44) of an automotive vehicle (10) includes a longitudinal acceleration sensor (36), a vehicle speed sensor (20), a lateral acceleration sensor (32), a yaw rate sensor, and a controller (26). The controller (26) determines a stability index and provides a first observer that determines a reference longitudinal velocity in response to the longitudinal acceleration signal, the yaw rate signal, a pitch attitude and vehicle speed from wheel speed sensors. The controller (26) determines a reference lateral velocity in response to the lateral acceleration signal, the yaw rate signal, a roll attitude, a pitch attitude and vehicle speed from the wheel speed sensors. The controller provides a second observer that determines a second longitudinal velocity in response to the longitudinal acceleration signal, the yaw rate signal, a lateral velocity, the pitch attitude and a first adjustment based on the longitudinal reference velocity. The controller determines a second lateral velocity in response to the lateral acceleration signal, the yaw rate signal, a roll attitude, a pitch attitude and a second adjustment based on the lateral reference velocity. The controller determines an output lateral velocity and an output longitudinal velocity in response to the first observer, second observer and the stability index. The controller controls the safety system in response to the output lateral velocity and the output longitudinal velocity.

Owner:FORD GLOBAL TECH LLC

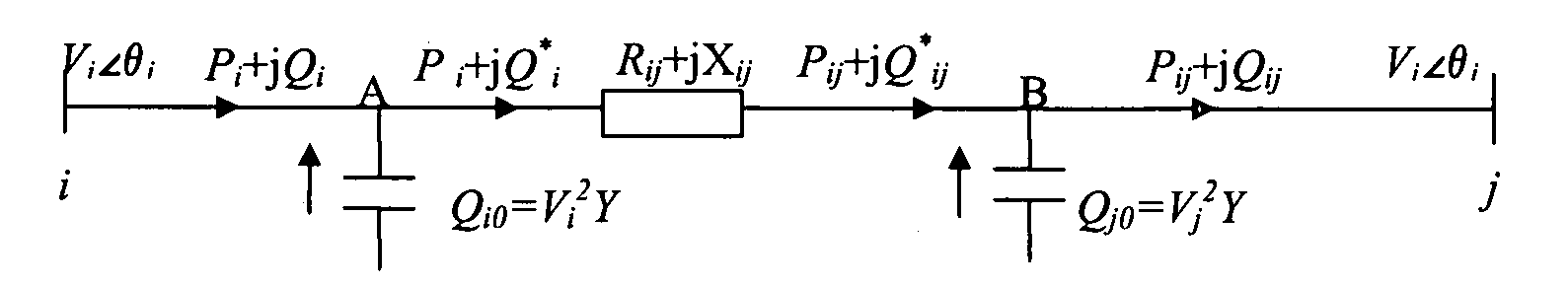

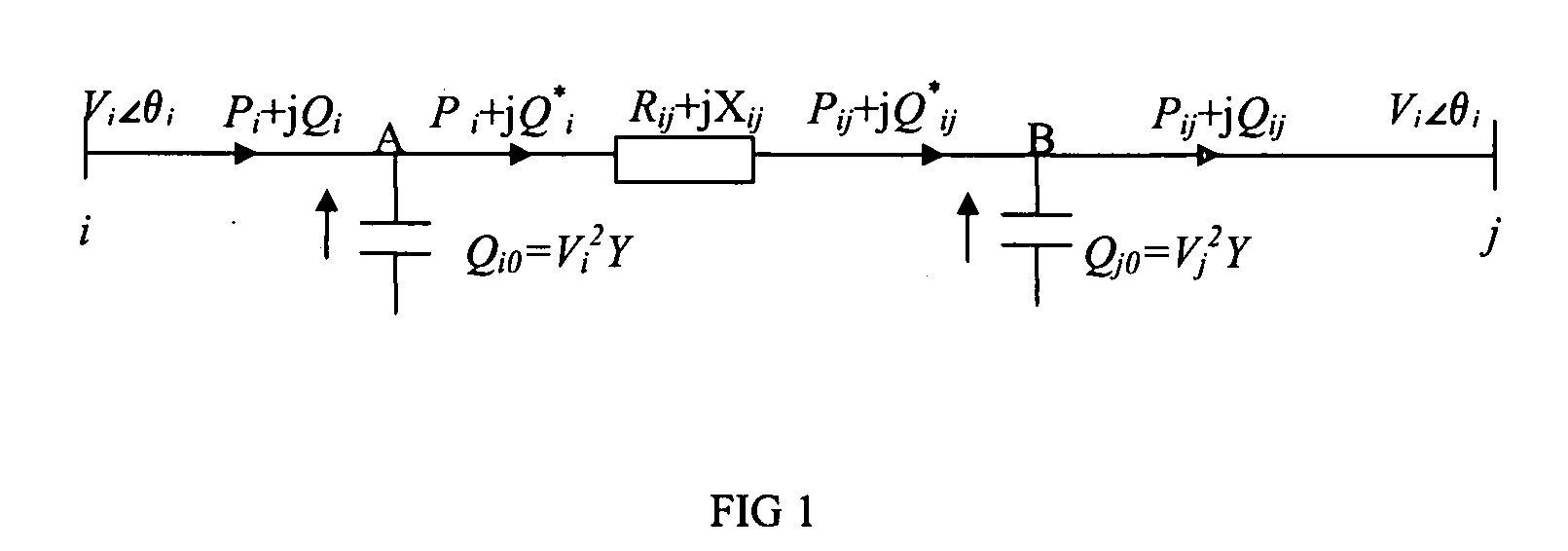

Method and system for real time identification of voltage stability via identification of weakest lines and buses contributing to power system collapse

ActiveUS20090027067A1Voltage-current phase angleImpedence measurementsStability indexElectric power system

Owner:BRITISH COLUMBIA HYDRO & POWER AUTHORITY

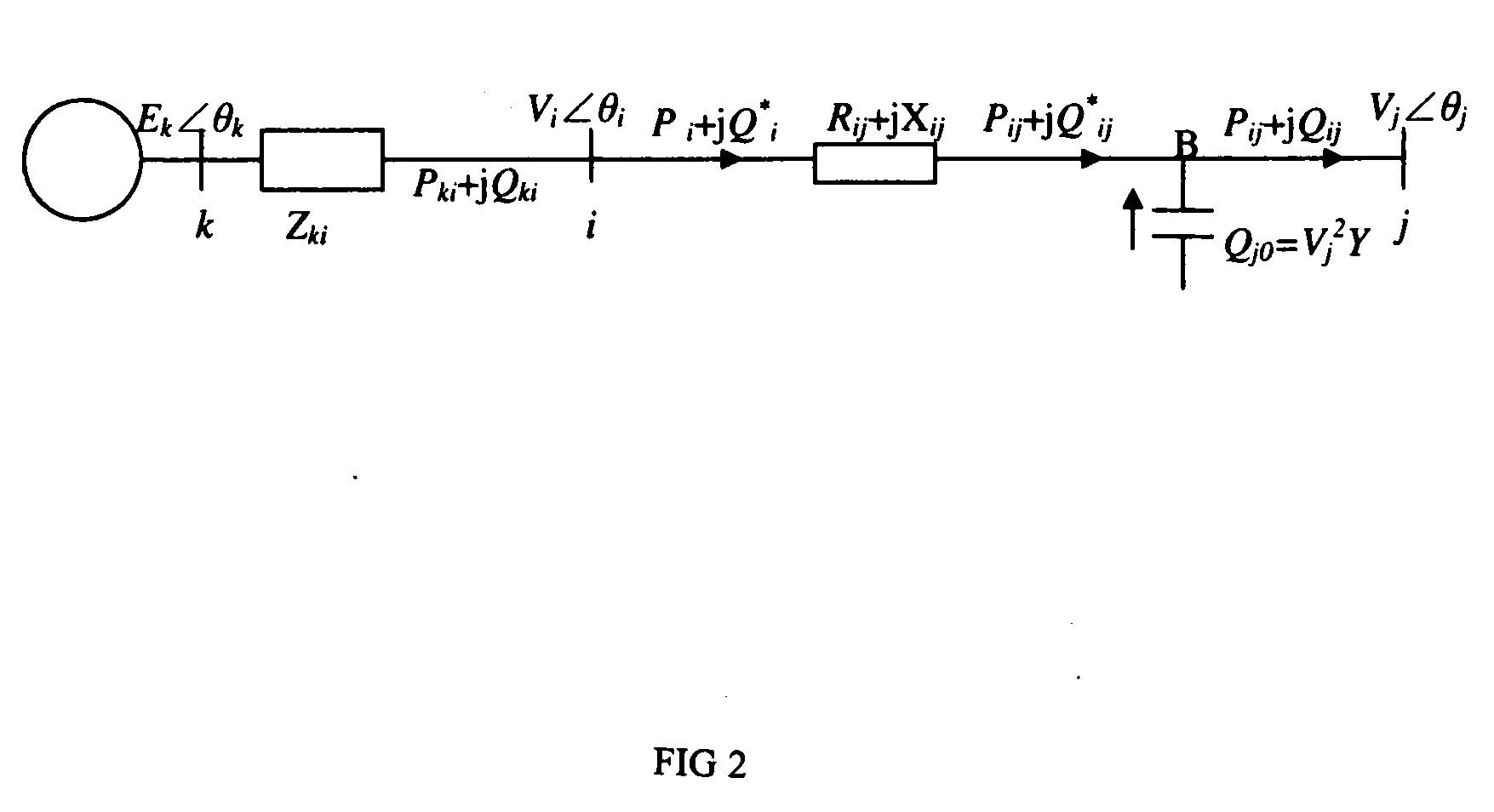

Server integration method oriented to minimum energy consumption

ActiveCN104298339AReduce in quantityRealize the purpose of energy savingPower supply for data processingStability indexCost prediction

The invention provides a server integration method oriented to minimum energy consumption. The server integration method oriented to minimum energy consumption includes that resource states and performance data of servers and virtual machines on the servers are periodically obtained, and meanwhile, energy consumption of the servers is periodically measured by an external-connected wattmeter on a physical server to be stored; resource state data of the servers, resource state data of the virtual machines, performance data of the servers and the performance data of the virtual machines are periodically collected, and data pre-processing is performed; a server energy consumption model is established; a virtual machine transfer cost prediction model is established; transfer cost prediction value of each virtual machine is obtained; virtual machine comprehensive assessment is performed by means of an improved analytic hierarchy process; service stability index of the servers is calculated; a server integration scheme is determined; server integration is performed. According to the server integration method oriented to minimum energy consumption, the virtual machines are transferred to proper servers by means of a dynamic packing algorithm according to virtual machine resource required quantity and server resource surplus, and the number of starting servers is the minimum under the condition of stable service operation.

Owner:北京点为信息科技有限公司

Lateral and longitudinal velocity determination for an automotive vehicle

InactiveUS7451033B2Accurate estimateImprove vehicle performanceAnalogue computers for trafficPedestrian/occupant safety arrangementMobile vehicleStability index

A system (18) for controlling a safety system (44) of a vehicle (10) is disclosed herein. The system includes a longitudinal acceleration sensor (36), a vehicle or wheel speed sensor(s) (20), a lateral acceleration sensor (32), a yaw rate sensor (28), and a controller (26). The controller determines a stability index and provides a first observer that determines a reference longitudinal velocity in response to the sensors. The controller determines a reference lateral velocity in response to the sensors. The controller provides a second observer that determines a second longitudinal velocity in response to the sensors and a first adjustment based on the reference longitudinal velocity. The controller determines a second lateral velocity in response to the sensors and a second adjustment based on the reference lateral velocity. The controller determines an output lateral velocity and an output longitudinal velocity in response to the first and second observers and the stability index and accordingly controls the safety system.

Owner:FORD GLOBAL TECH LLC

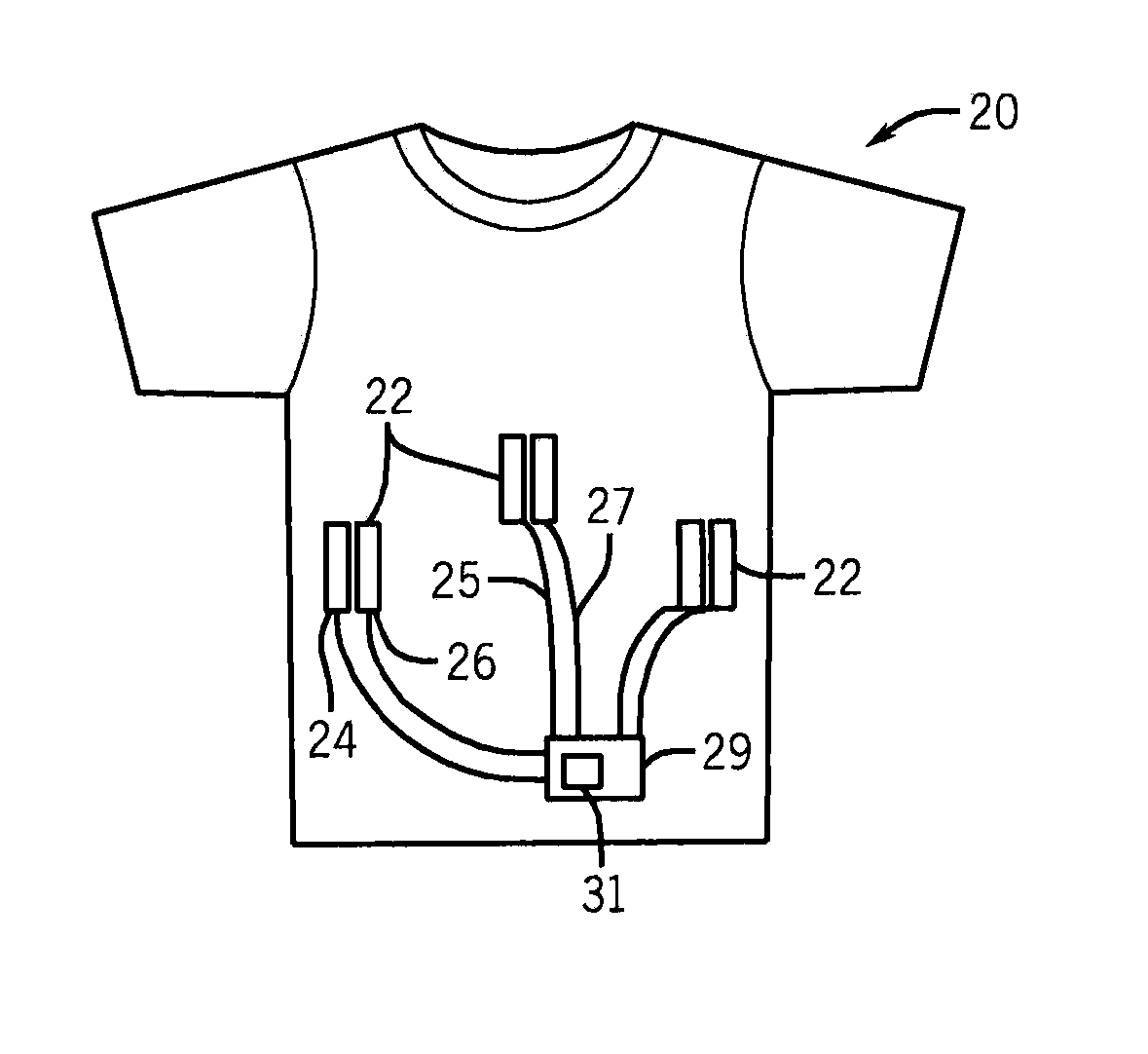

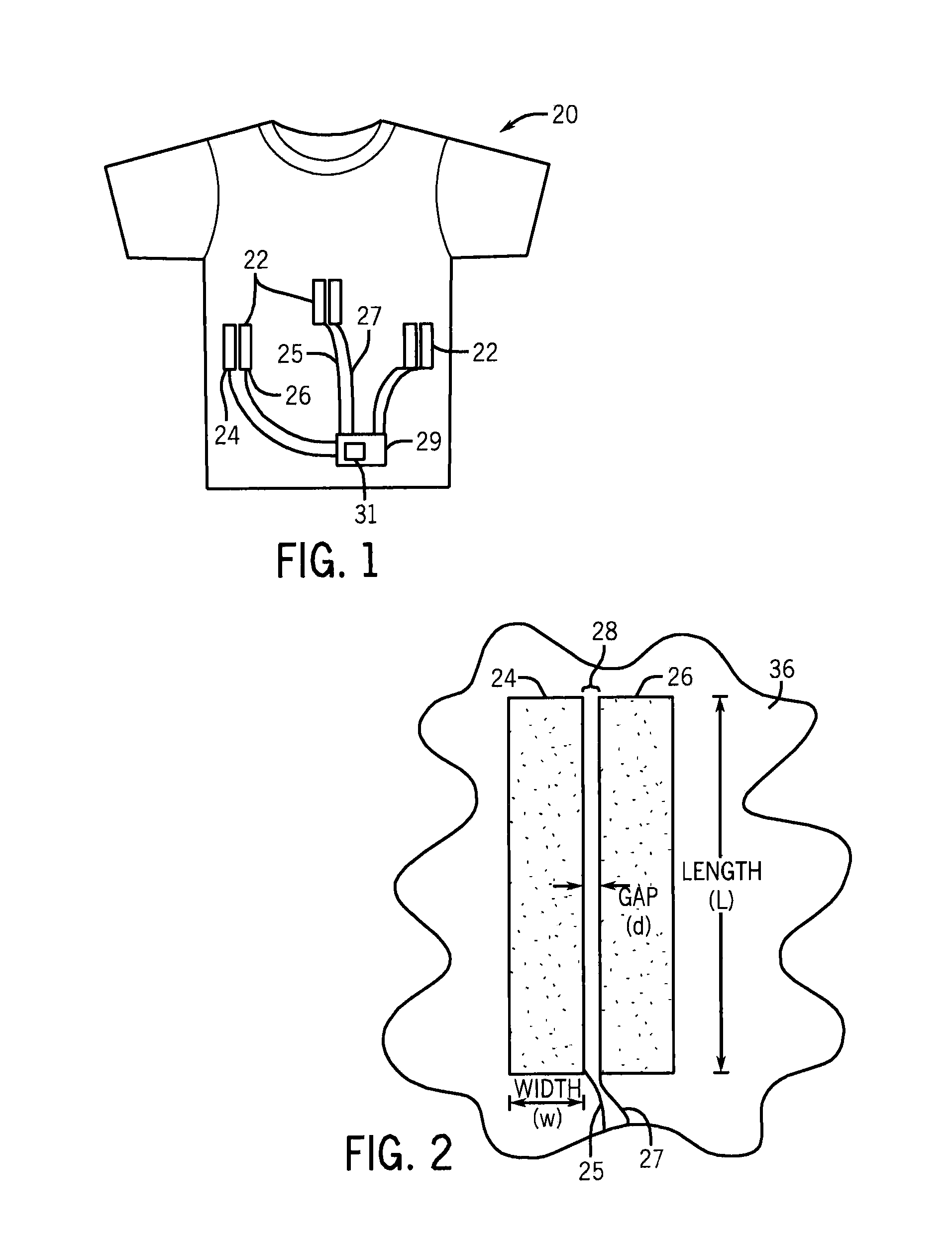

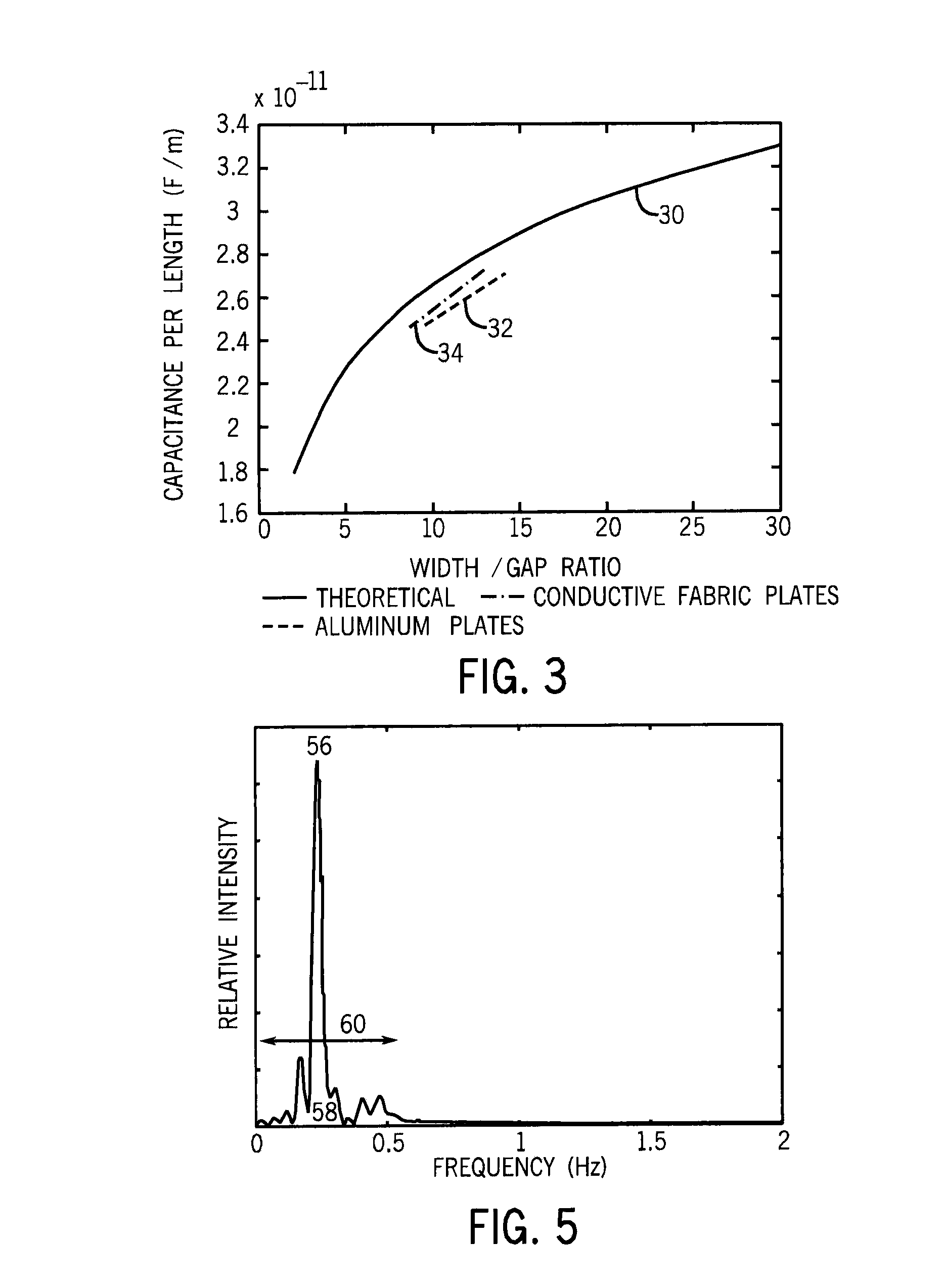

Systems and methods to monitor and quantify physiological stages

InactiveUS20140213937A1Accurately monitor sleep healthAccurate healthPerson identificationRespiratory organ evaluationStability indexMonitoring system

Systems and methods detect respiration of a subject, process respiration data, and based on the processed respiration data, perform extended monitoring. A monitoring system is configured with sensors that can be worn by the subject to provide the respiration data. The respiration data is processes to create a stability index. The stability index is used to, for example, determine sleep stages.

Owner:THE GENERAL HOSPITAL CORP

Durable nanoweb scrim laminates

Owner:DUPONT SAFETY & CONSTR INC

Particulate superabsorbent polymer composition having improved stability

The present invention relates to a particulate superabsorbent polymer composition comprising a polymer comprising a neutralized aluminum salt solution applied to the surface of a particulate superabsorbent polymer; wherein an aqueous solution of the neutralized aluminum salt has a pH value from about 5.5 to about 8 and the particulate superabsorbent polymer composition has a mean particle size distribution of from 300 to 400 μm, an original Free Swell Gel Bed Permeability (FSGBP) of about 20×10−8 cm2 to about 200×10−8 cm2; and subsequent to subjecting the particulate superabsorbent polymer composition to the Processing Test, the particulate superabsorbent polymer composition has a permeability stability index of from about 0.60 to about 0.99 and having particles having a particle diameter of larger than 600 μm in an amount of less than about 15 wt % of the particulate superabsorbent polymer composition and as specified by standard sieve classification.

Owner:EVONIK SUPERABSORBER LLC

Lubricating oil compositions

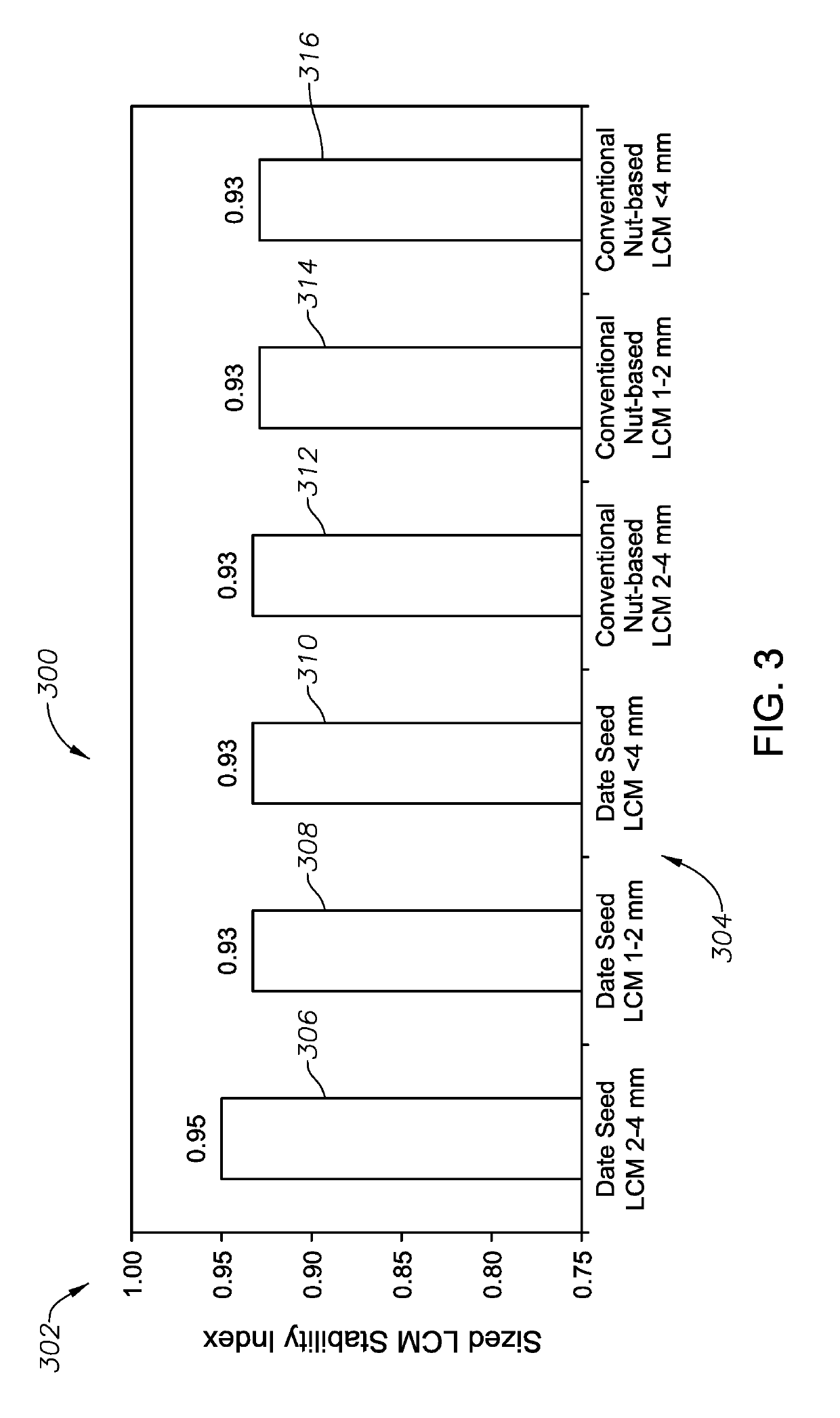

Lubricating oil compositions and viscosity index (VI) improver concentrates containing combinations of first polymers that are amorphous ethylene α-olefin copolymers; and second polymers that are star polymers, the arms of which are derived from diene, and optionally vinyl aromatic hydrocarbon monomer, wherein the star polymers have a Shear Stability Index (SSI) of from about 1% to about 35% (30 cycle).

Owner:TSE KWOK LEUNG +2

Date Palm Seed-Based Lost Circulation Material (LCM)

A date palm seed-based lost circulation material (LCM) is provided. A date palm seed LCM may be manufactured by drying date palm seeds and grinding the dried date palm seeds to create a plurality of particles. The particles may have sizes less than 4 mm, from 1 mm to 2 mm, or from 2 mm to 4 mm. The date palm seed LCM may have a volumetric swelling greater than an LCM formed from tree nuts and may have a volumetric swelling of at least 0.3 cubic centimeters per gram. The date palm seed LCM may have a D50 shift factor less than an LCM formed from calcium carbonate and may have a D50 shift factor of at least 0.38%. The date palm seed LCM may have a stability index of at least 0.95. Methods of lost circulation control and manufacture of a date palm seed LCM are also provided.

Owner:SAUDI ARABIAN OIL CO

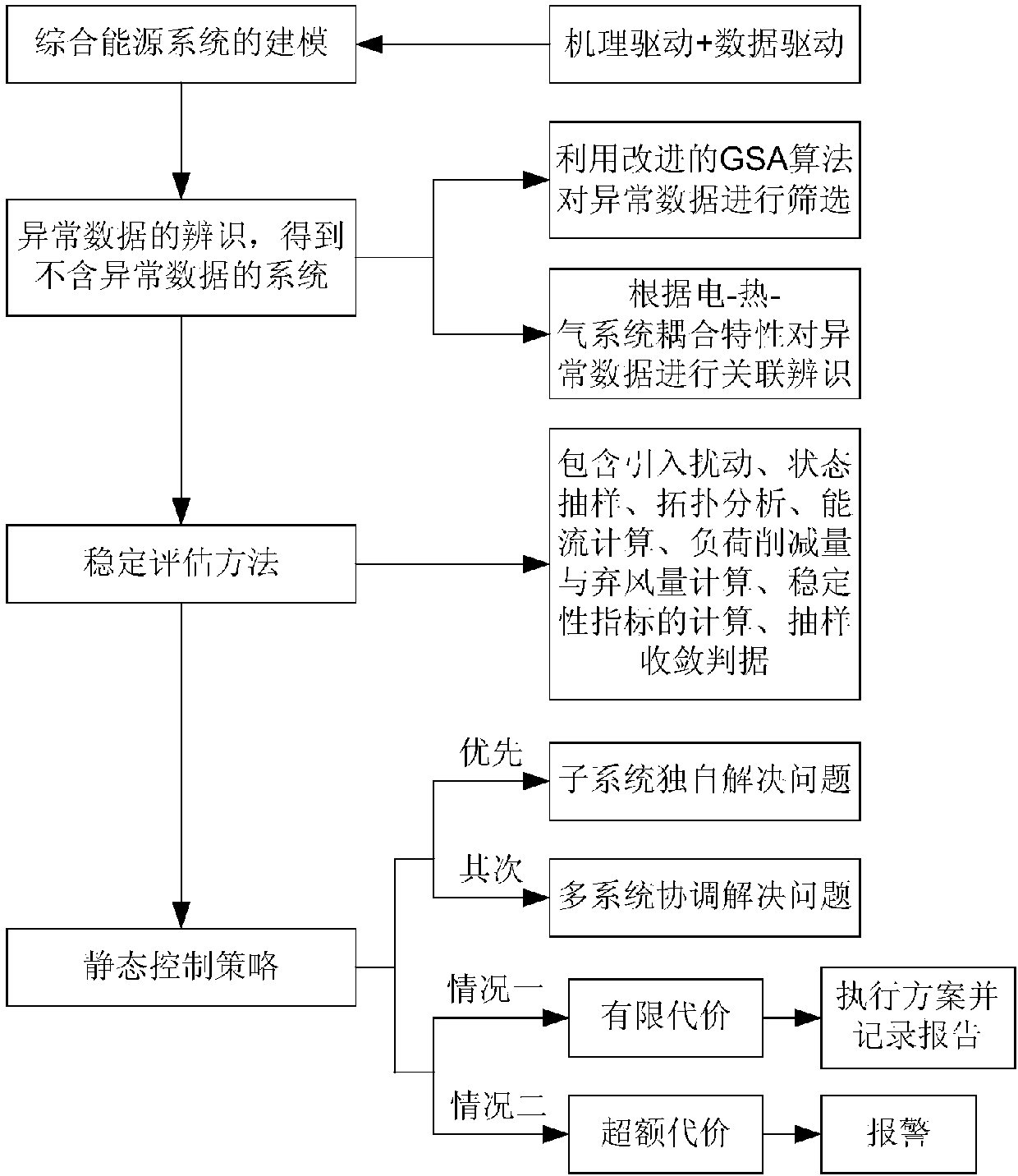

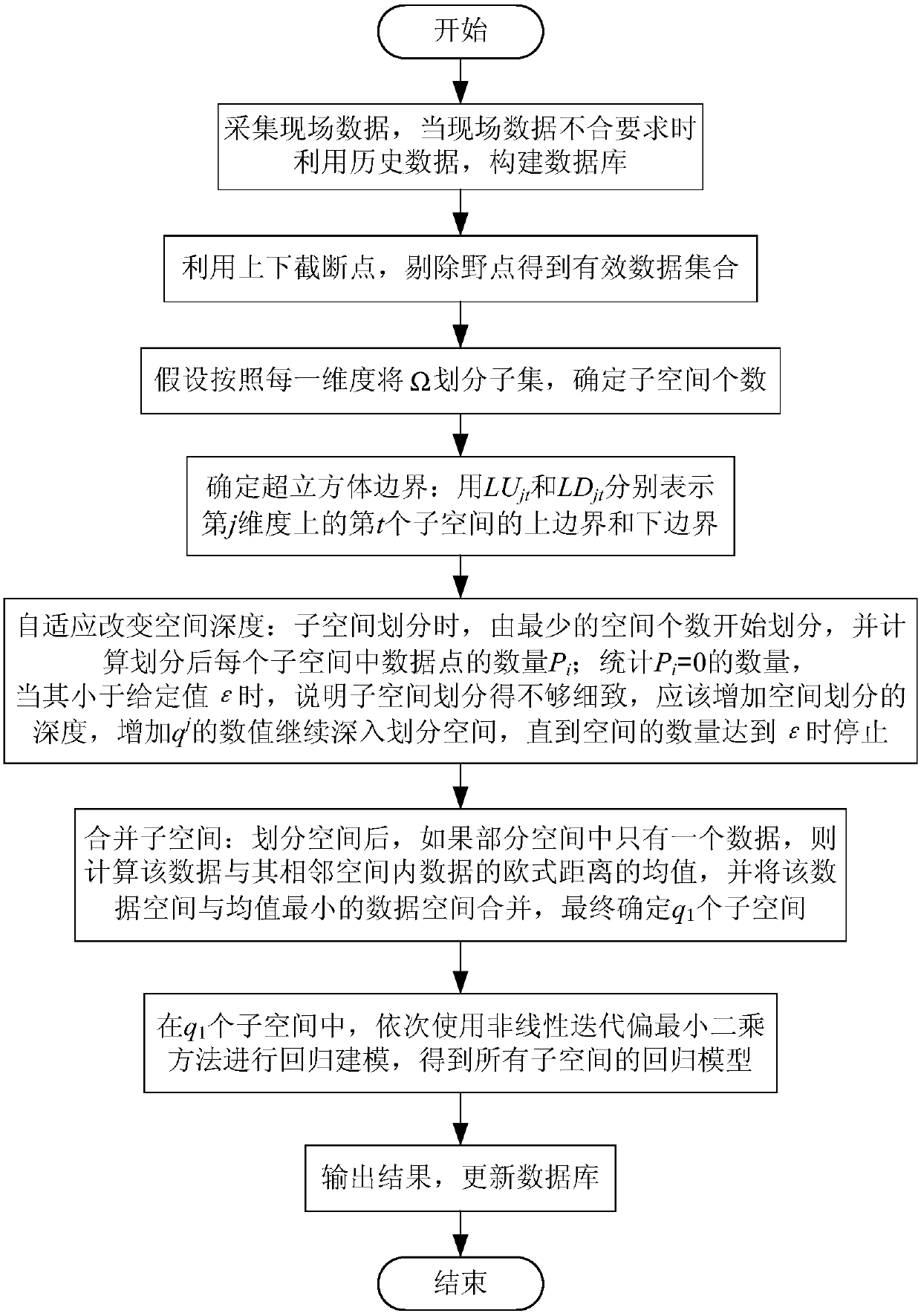

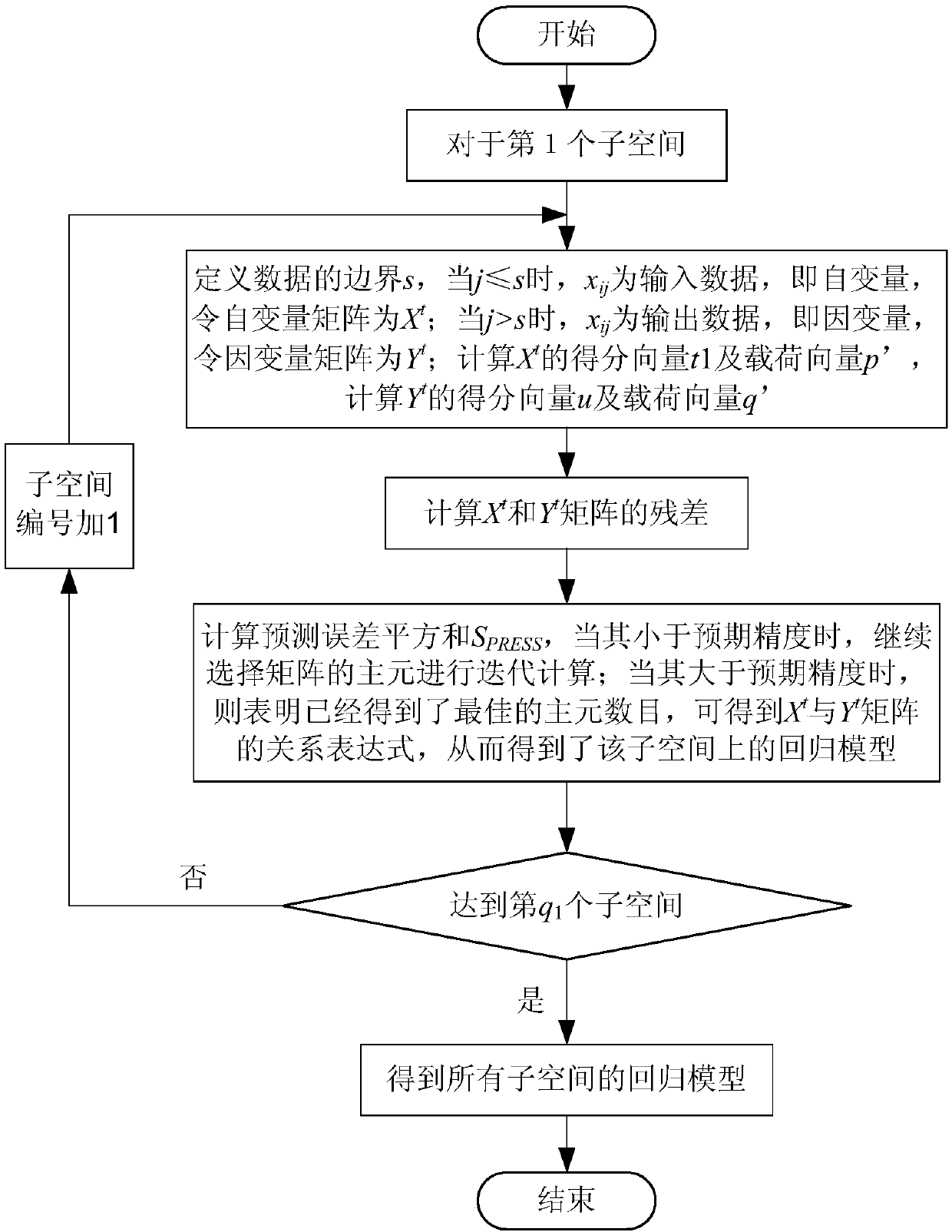

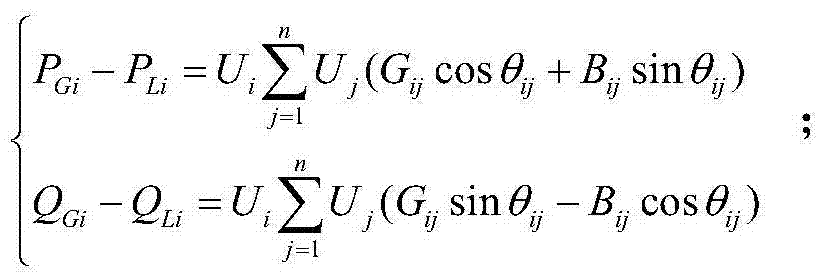

Stable evaluation and static control method for electro-thermal-gas integrated energy system

ActiveCN108494021AReasonable controlLoad forecast in ac networkSingle network parallel feeding arrangementsPower flowIntegrated energy system

The invention, which relates to the technical field of the integrated energy system, provides a stable evaluation and static control method for an electro-thermal-gas integrated energy system. The method comprises: S1, modeling is carried out on an electro-thermal-gas integrated energy system by means of combination of data driving and mechanism driving; S2, screening and correlation identification of abnormal data are carried out; S3, a stable evaluation method is implemented; to be specific, a calculation formula of a stability index is defined by taking power flow calculation of an energy flow and load reduction quantity and wind curtailment quantity calculation as priorities and using determination of exceeding the limit by the energy flow as an evaluation criterion and a system stability evaluation standard comparison table is provided; and S4, static control is carried out, so that a sub-system independent solution problem and a multi-system coordinated solution problem are solved. According to the invention, with the integrated energy system model established by combination of data driving and mechanism driving, prediction of the load changing situation and dual identification of abnormal data of the system are realized, so that stability evaluation and static controlling are carried out on the system accurately and reasonably.

Owner:NORTHEASTERN UNIV

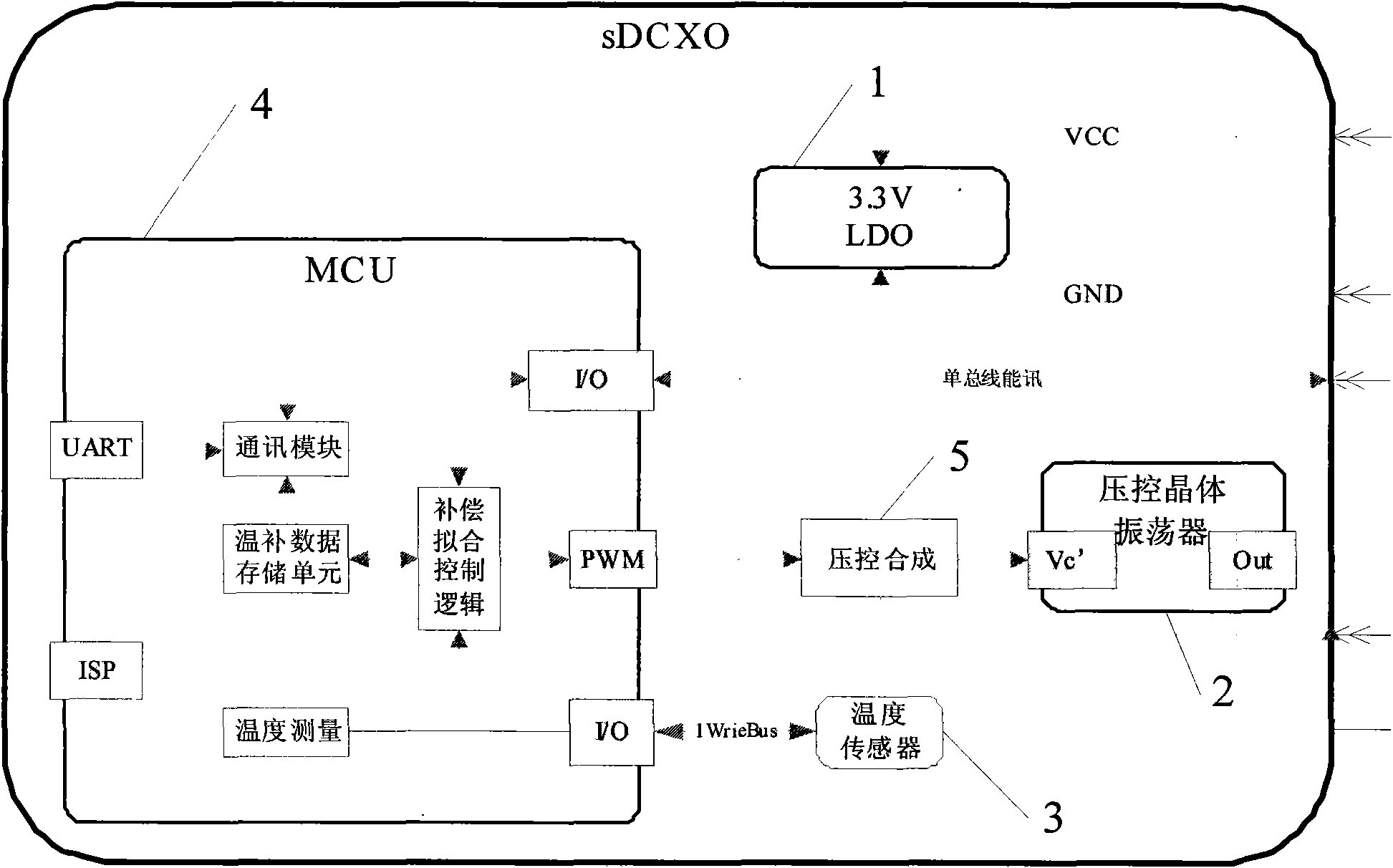

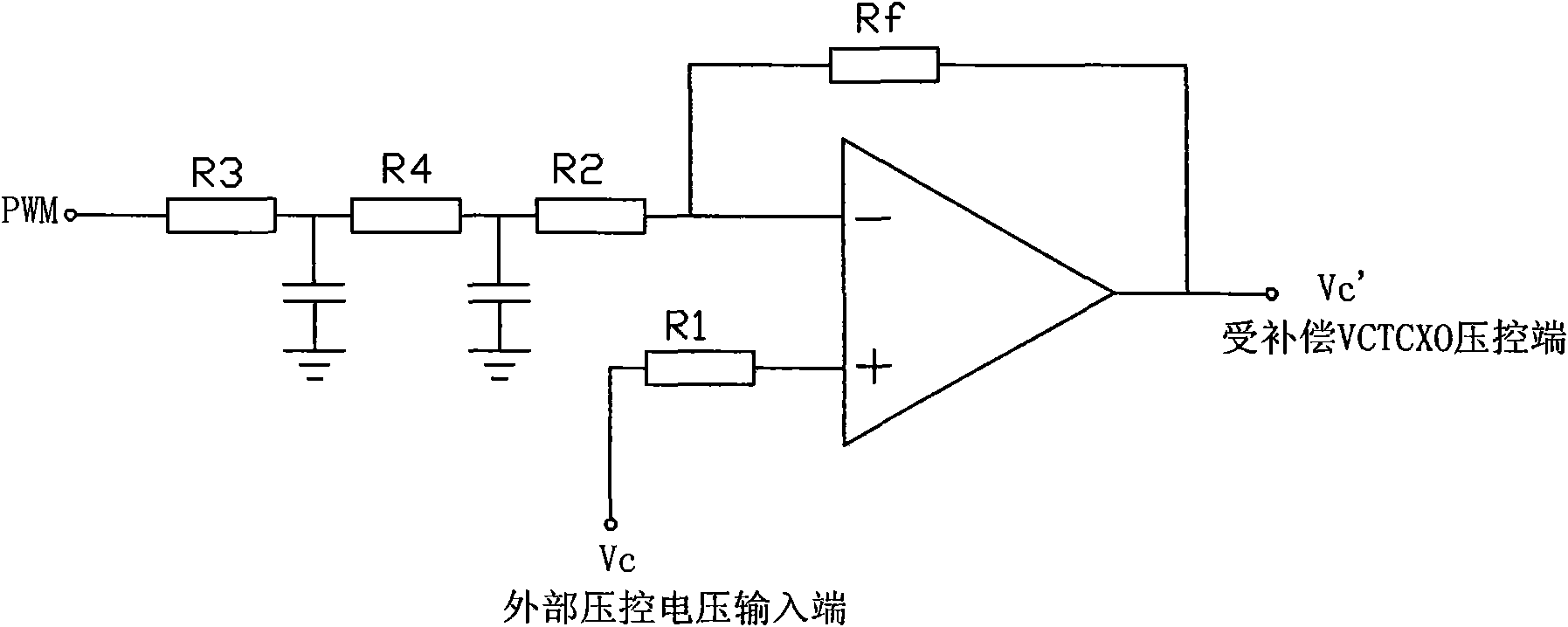

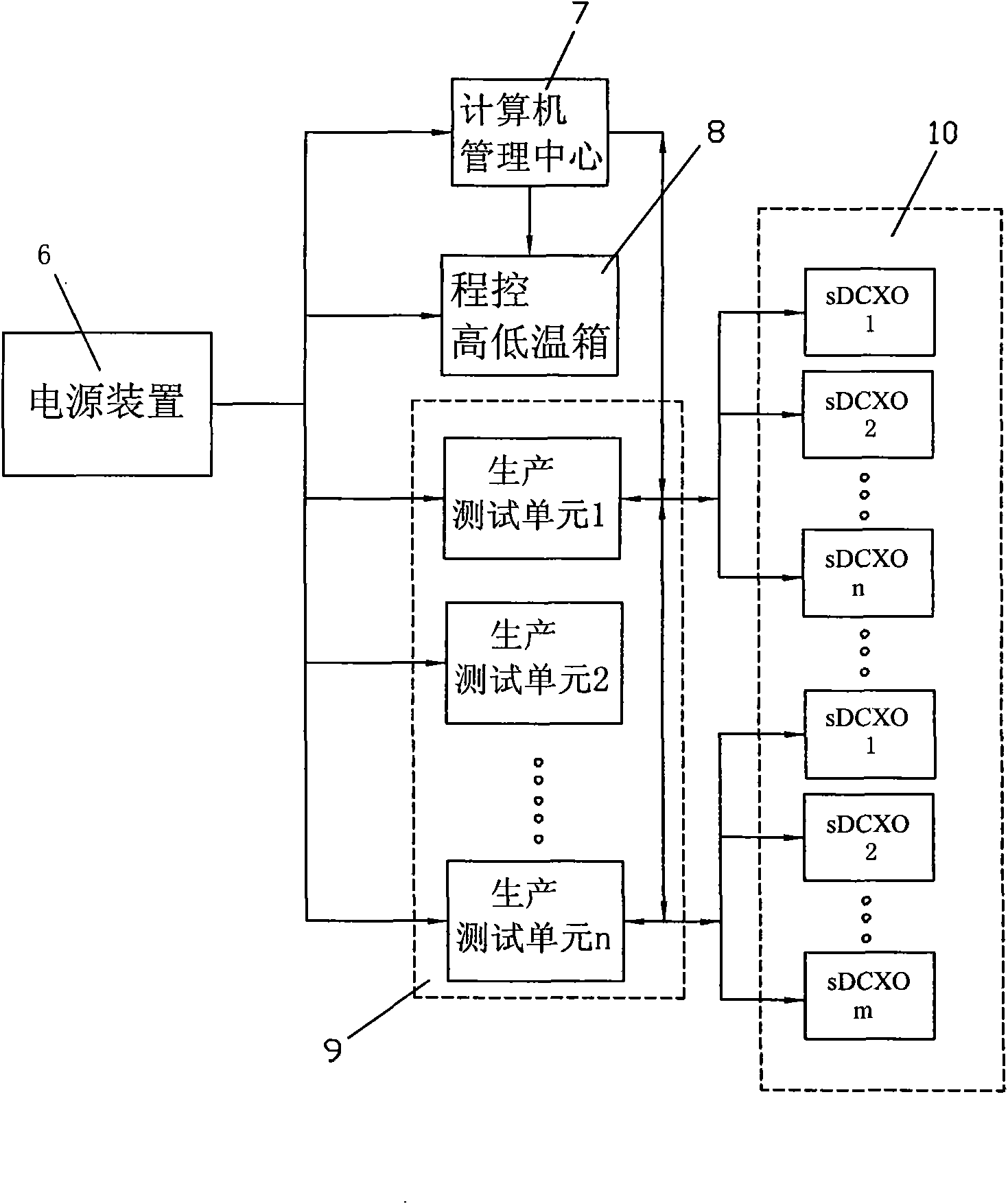

Self-fitting digital temperature compensation crystal oscillistor and system and realization method thereof

InactiveCN101604970AImprove accuracyEnsure consistencyElectronic circuit testingGenerator stabilizationThree levelStability index

The invention discloses a self-fitting digital temperature compensation crystal oscillistor and a system and a realization method thereof, which uses resources thereof, finishes the temperature compensation fitting process in an autonomous manner, thus ensuring the consistency of the product inner environment and production environment, improving the accuracy of the temperature compensation data and ensuring the frequency temperature stability precision. The fitting test process has the advantages of avoiding the whole-process control from computers, improving the production efficiency in each unit time and preventing the risks caused by abnormal peripheral or manual misoperation. In the invention, the temperature property index of the pilot production product is -40 DEG C to +85 DEG C, has better property with all being less than plus or minus 0.05ppm, exceeds 10-20 times than the like products, is higher than the frequency temperature stability index of three-level clock constant-temperature crystal oscillistor, and ensures the frequency temperature stability precision to get the optimal effect.

Owner:广州市天马电讯科技有限公司

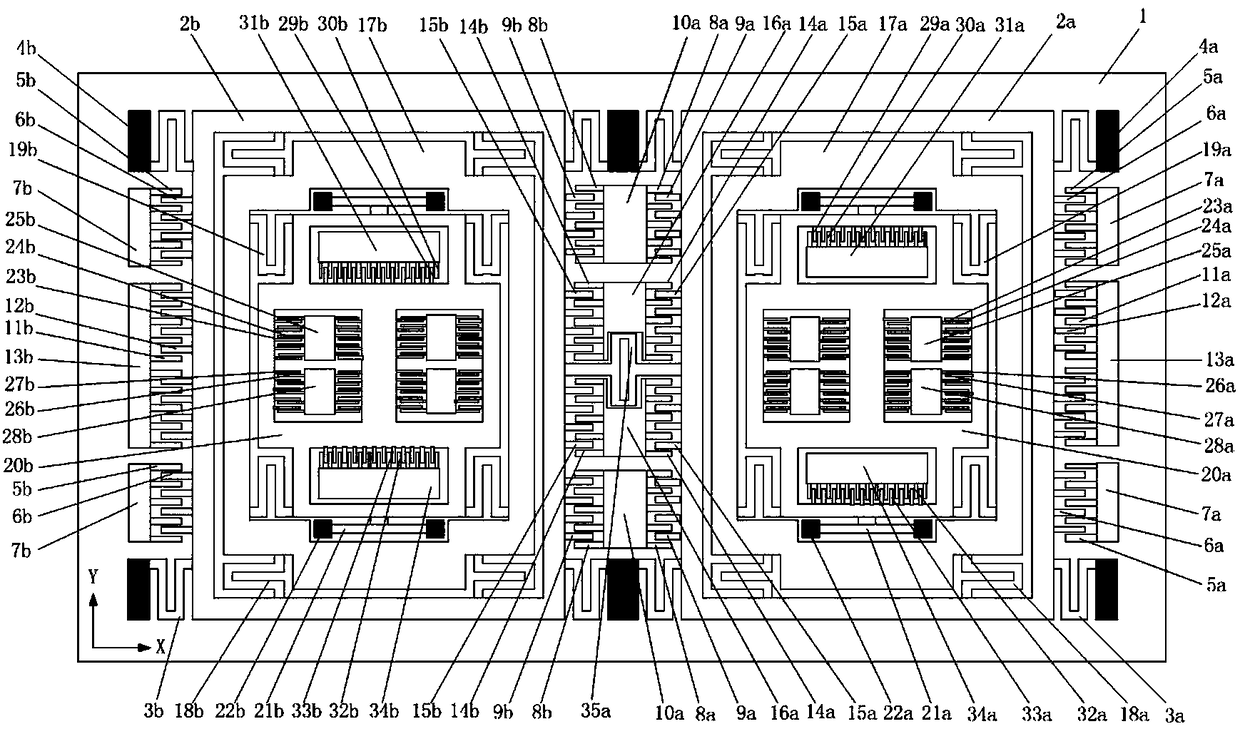

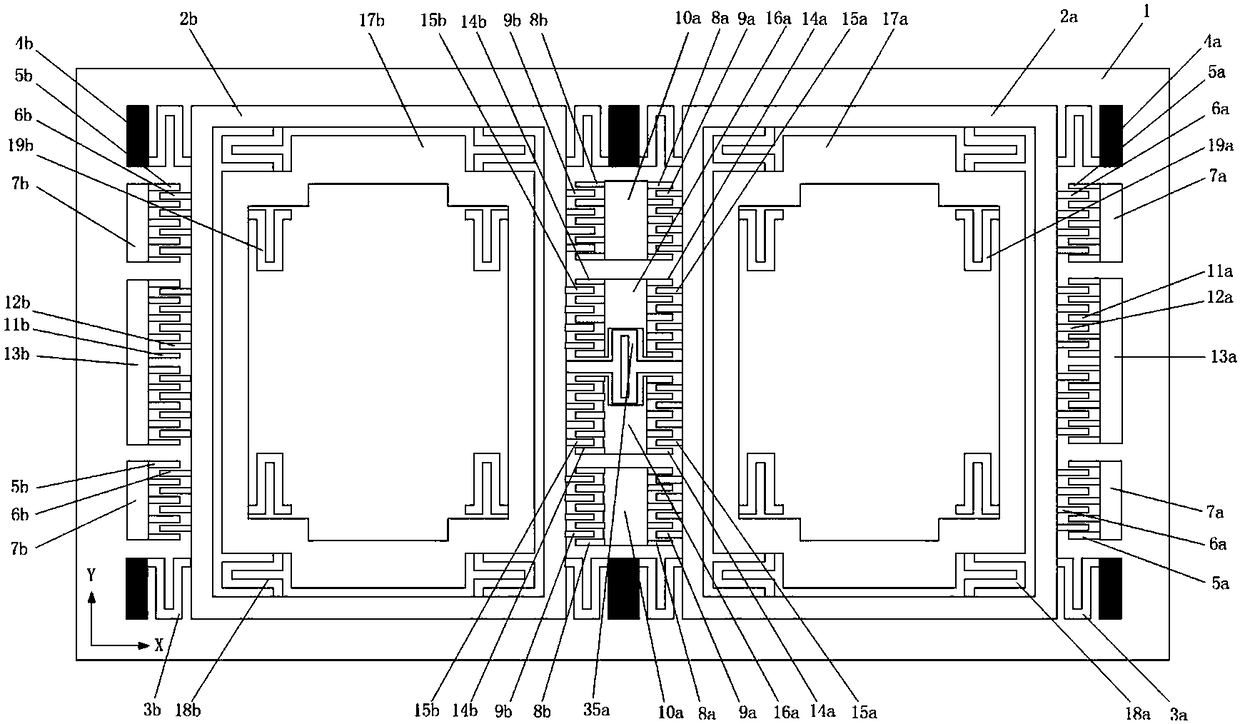

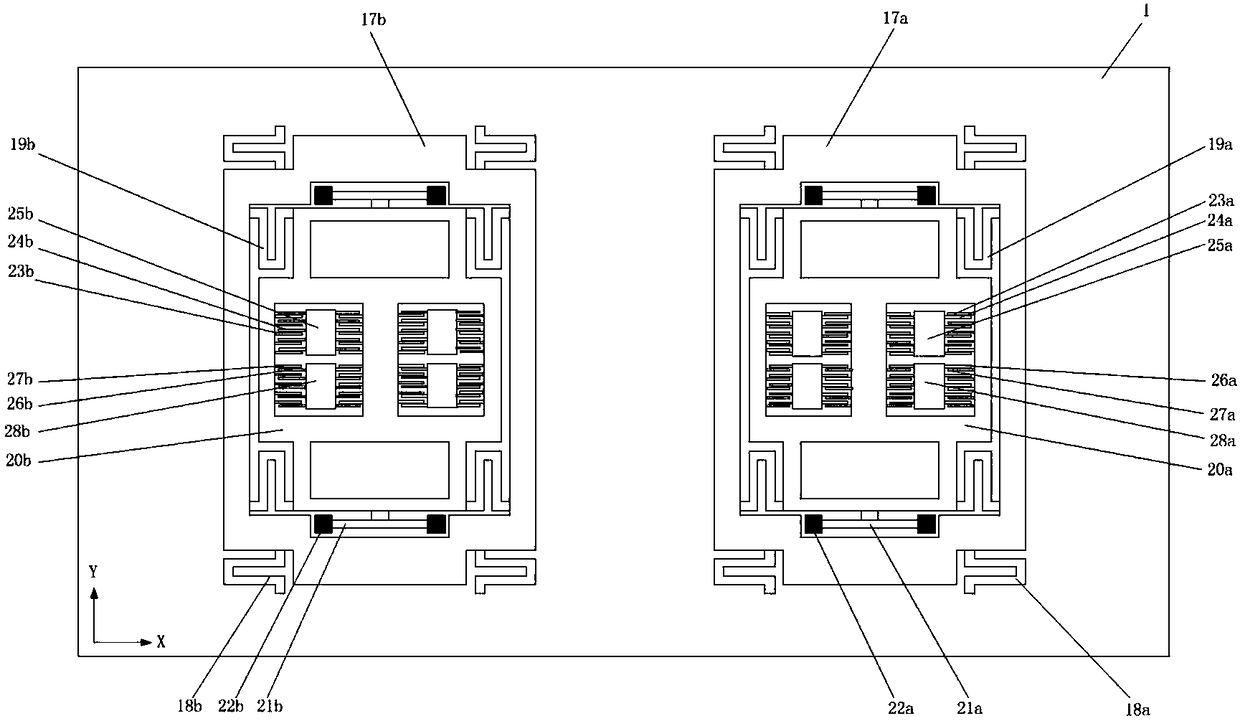

MEMS (micro-electro-mechanical system) fully decoupled closed-loop gyroscope

PendingCN108507555AImprove partial stability indexGood ability to resist cross error interferenceSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesStability indexClosed loop

The invention discloses a MEMS (micro-electro-mechanical system) fully decoupled closed-loop gyroscope. The gyroscope comprises a substrate and a sensitive device layer, wherein an insulating layer isarranged between the substrate and the sensitive device layer; the sensitive device layer comprises a first substructure, a second substructure and a coupling connection beam; each of the first substructure and the second substructure comprises a driving frame, driving folding beams, driving decoupling beams, a Coriolis mass block, a detection frame, detection beams, detection decoupling beams, driving fixed comb teeth, driving movable comb teeth, driving detection fixed comb teeth, driving detection movable comb teeth, detection fixed comb teeth, detection movable comb teeth, force feedbackfixed comb teeth, force feedback movable comb teeth and anchor points. Generation of quadrature error signals is suppressed, and the zero bias stability index of the MEMS gyroscope is improved; the gyroscope has compact structure and small chip area, and can prevent a detection-mode sensitive mass from twisting due to larger displacement, thereby having good overall linearity and high measurementaccuracy.

Owner:四川知微传感技术有限公司

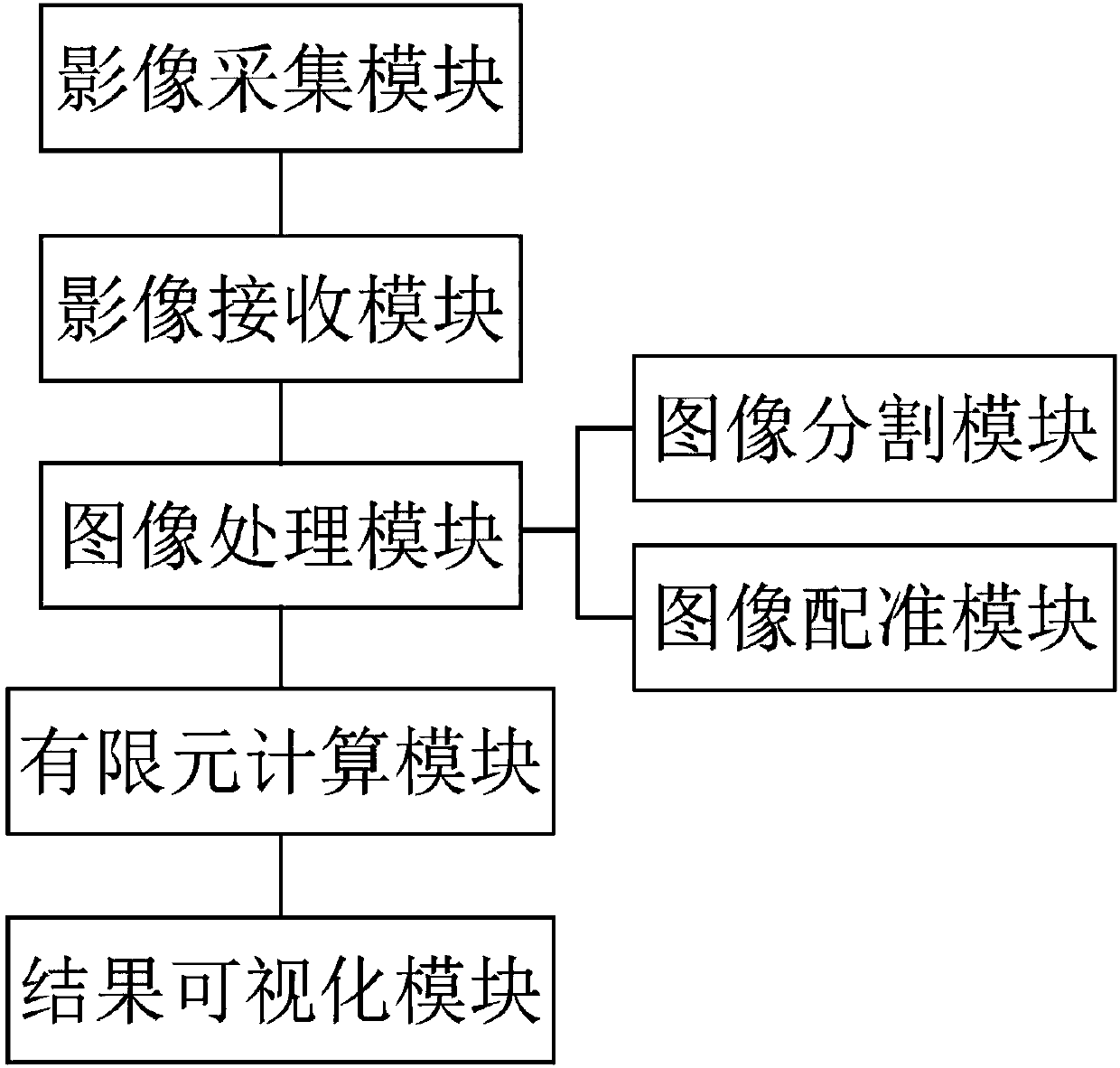

Medical image sequence plaque stability index-based quick calculation method and system

ActiveCN108038848AObserve comprehensivelyObserve completeImage enhancementReconstruction from projectionStability indexIn vivo

The invention provides a medical image sequence plaque stability index-based quick calculation method and system. The system comprises an image collection and receiving module, an image processing module, a plaque stability calculation module and a result visualization module. The image collection and receiving module is used for collecting, receiving and transmitting a dynamic two-dimensional vascular image sequence; the image processing module is used for performing local feature or global image registration based on dynamic information of artery real-time deformation in a two-dimensional image to obtain a displacement field function of space transformation; and the plaque stability calculation module performs calculation by utilizing the displacement field function to obtain a time-varying vascular diameter sequence, a lumen central line, a contour deformation parameter and a mechanics index. Based on an existing medical image function, information such as the time-varying vasculardiameter sequence, a lumen contour, area strain and stress, and the like is added to the two-dimensional image directly, so that the in-vivo assessment of plaque stability is simplified and effectively realized.

Owner:PULSE MEDICAL IMAGING TECH (SHANGHAI) CO LTD

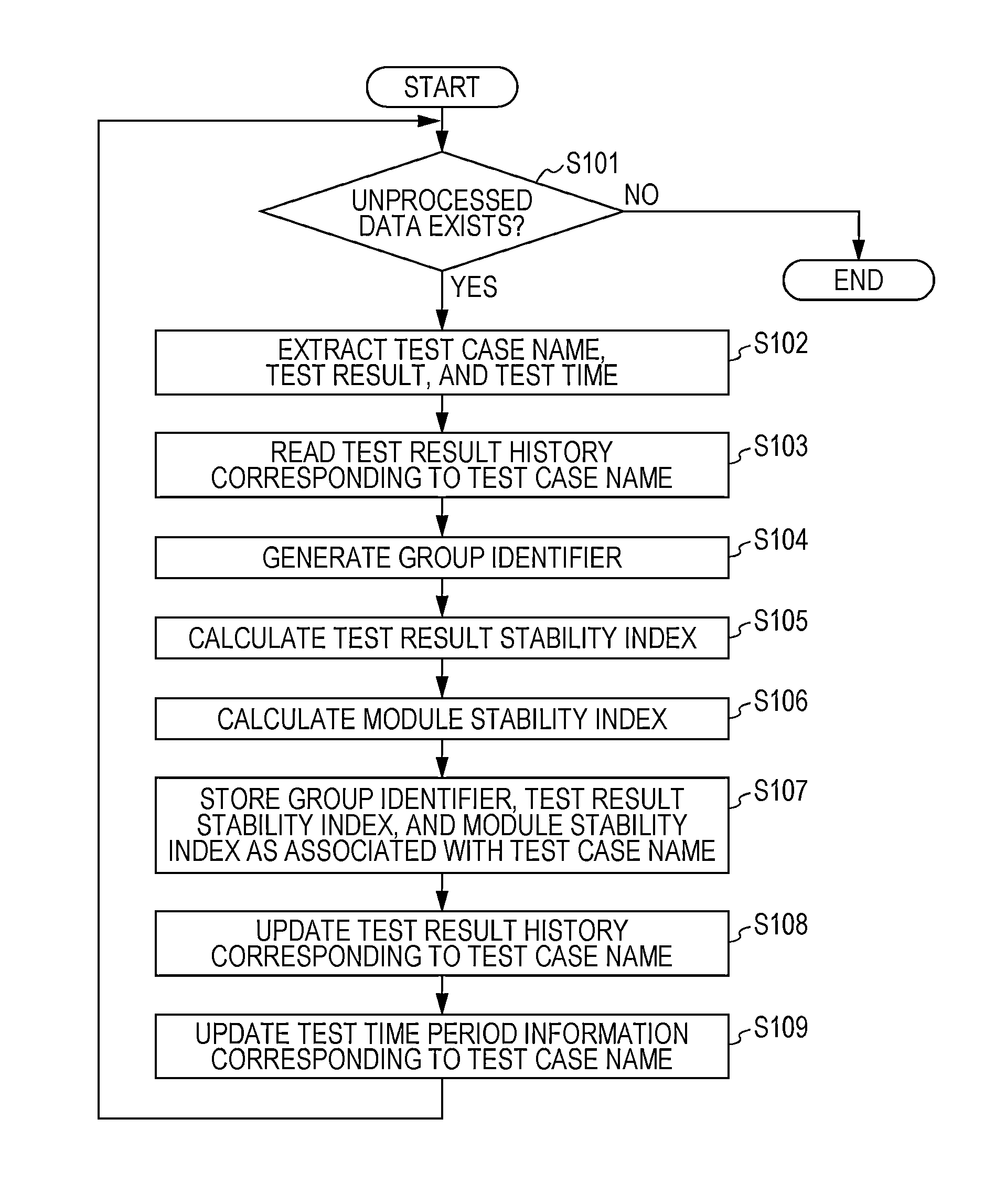

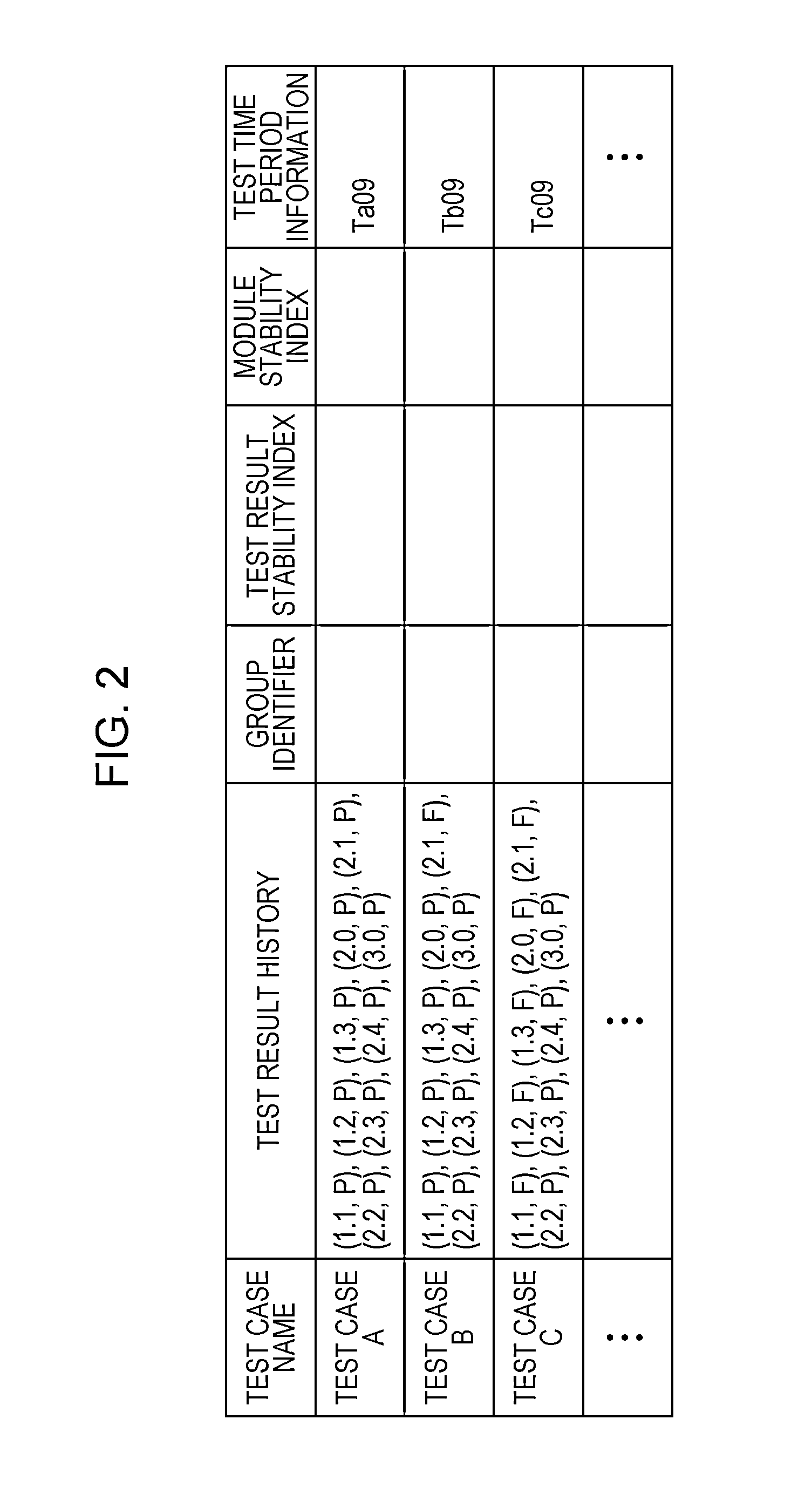

System for testing operation of software

InactiveUS8479165B1Error detection/correctionSpecific program execution arrangementsStability indexContinuous release

A system for implementing a method for processing test results from testing operation of software. A test result of pass, fail status, or unperformed is received for each test case of a test performed for each release of the software. A group to which each test belongs is ascertained. A test result stability index is calculated for each test case as being proportional to a total number of consecutive releases that include and are prior to the last release of the software such that the test result for each of the consecutive releases denotes a pass. A module stability index is calculated for each test case as being a summation over a product of a weight at each release and a binary stability indicator of 0 at each release for which the test result is changed from that of the immediately prior release and 1 at every other release.

Owner:KYNDRYL INC

Low-temperature drafting production process for high-modulus and low-shrinkage polyester industrial yarn

ActiveCN103668493ALow strength retentionExcellent retention rateArtificial filament heat treatmentMelt spinning methodsPolyesterYarn

The invention relates to a low-temperature drafting production process for high-modulus and low-shrinkage polyester industrial yarn, and belongs to the technical field of polyester industrial yarn manufacturing. According to the process, firstly, amorphous-form polyester chips are tackified through solid phase polycondensation, high-viscosity polyester chips are obtained, and then the high-modulus and low-shrinkage polyester industrial yarn product is obtained through melt spinning and drafting winding. After the high-modulus and low-shrinkage polyester industrial yarn is subjected to thread twisting and cloth weaving secondary-bath gum dipping, the brute force maintaining rate of rubberized cords of the high-modulus and low-shrinkage polyester industrial yarn is larger than 100% relative to the brute force of cord threads after the wire twisting, and the stability index of the size of the gum dipping core threads is smaller than 6.0%. According to the process, the brute force maintaining rate and the size stability index of the rubberized cords of the high-modulus and low-shrinkage polyester industrial yarn are superior to those of spinning drafting products produced with a conventional high-temperature drafting process. According to the process, in the spinning process, due to the fact that the temperature of a hot roller is low, energy consumption is saved.

Owner:WUXI TAIJI IND

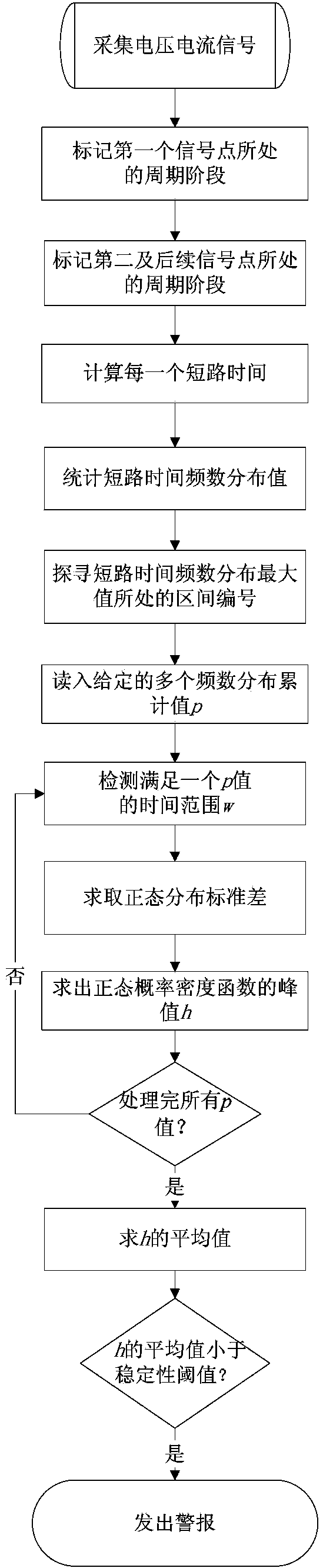

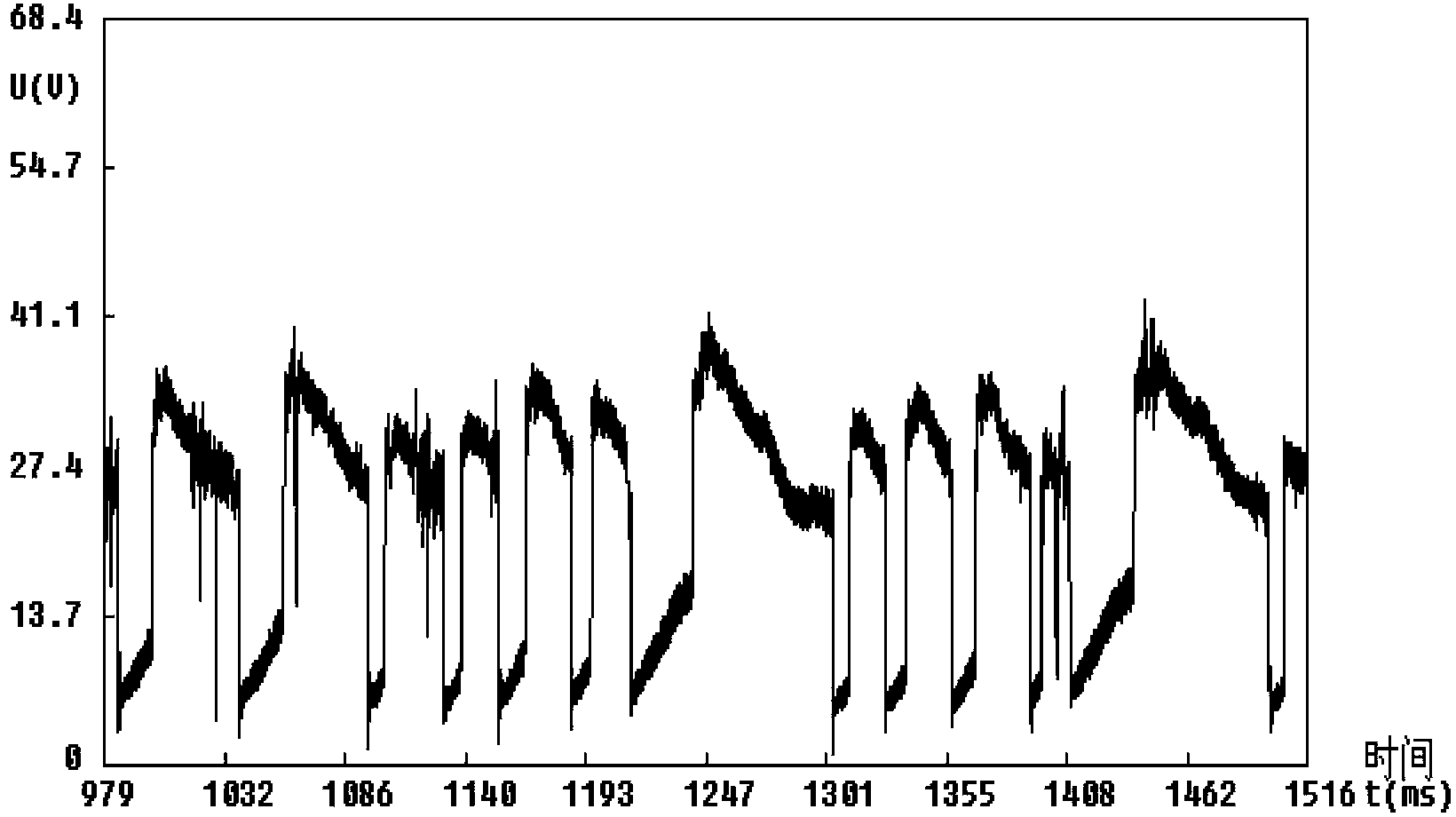

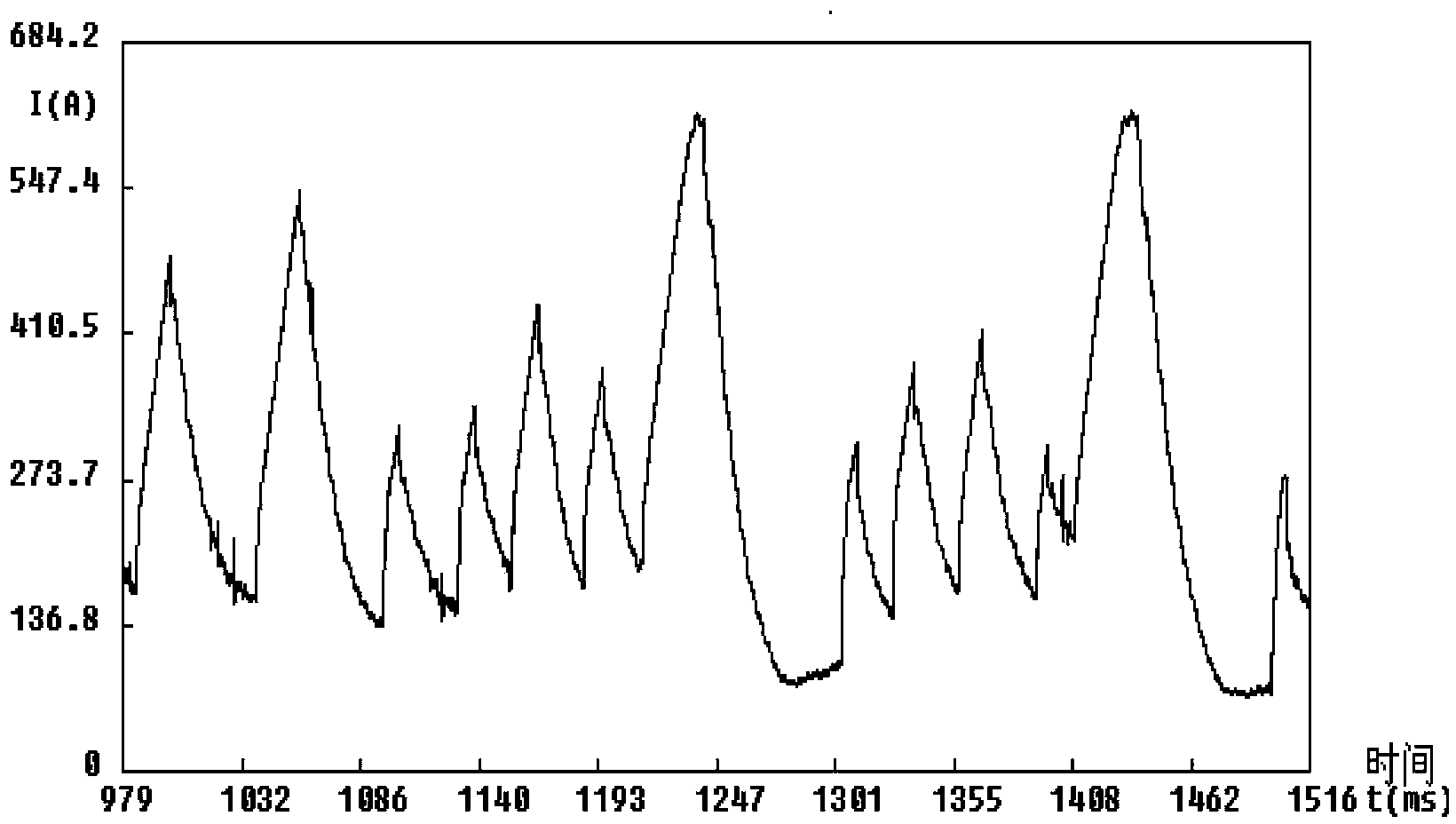

Automatic stability detecting method for process of CO2 electric arc welding short circuit transition welding

The invention discloses an automatic stability detecting method for the process of CO2 electric arc welding short circuit transition welding, which comprises the following steps: collecting the arc voltage value and the welding current value in the CO2 electric arc welding short circuit transition welding process, and storing the arc voltage value and the welding current value as a signal sample; performing cycle phase judgment to the voltage value of each signal point in the signal sample; counting the short circuit time in the signal sample, computing and obtaining the frequency distribution value of short circuit time through segmenting 5-10,000 inter-cells; setting 3-1,000 frequency distribution accumulation values, and detecting the time range meeting each frequency distribution accumulation value; getting normal distribution standard deviation, so as to obtain and take the average value of the peak value of a normality probability density function as the stability index in the CO2 electric arc welding short circuit transition welding process; sending an alarm signal when the stability index is smaller than the stability threshold value. The stability detecting method provided by the invention has the characteristics of objectification and quantification, can be realized by adopting a testing platform with a simple structure only, and has strong practicability.

Owner:GUANGZHOU UNIVERSITY OF CHINESE MEDICINE

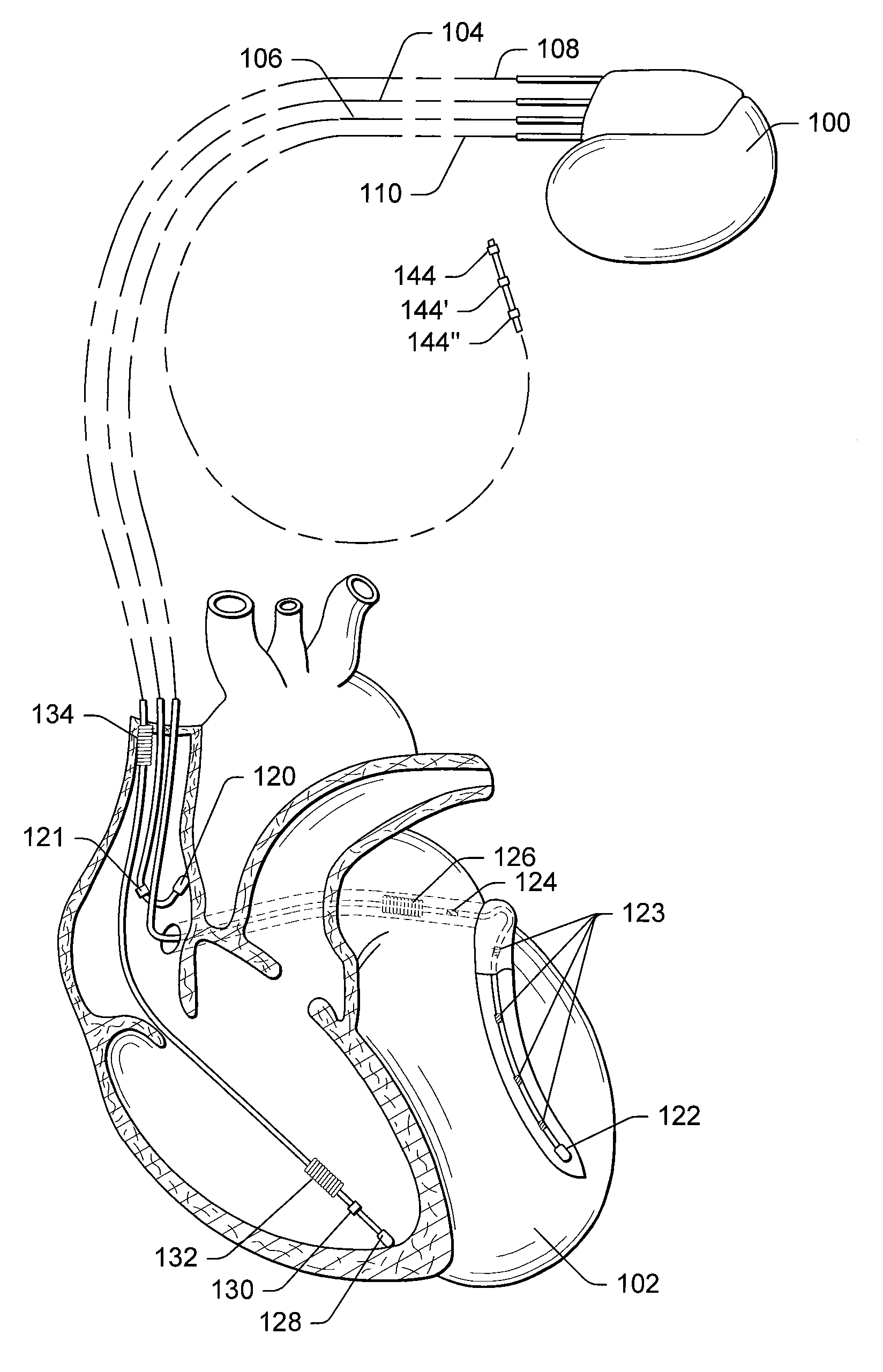

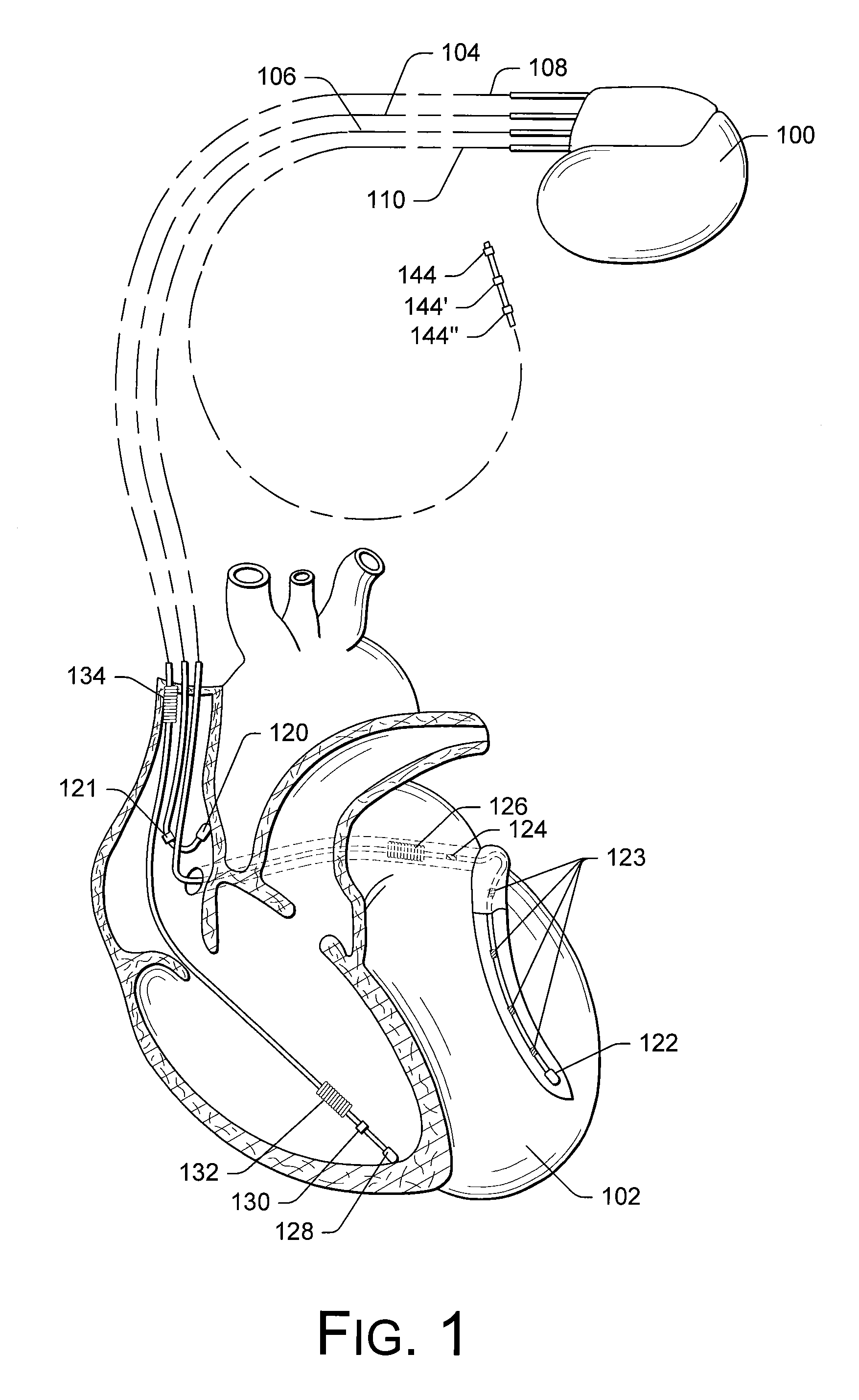

Electrode and lead stability indexes and stability maps based on localization system data

A method includes selecting an electrode located in a patient wherein the electrode comprises a lead-based electrode; acquiring position information with respect to time for the electrode, during both loaded and unloaded conditions of the lead, where the acquiring uses the electrode for repeatedly measuring electrical potentials in an electrical localization field established in the patient; calculating a both loaded and unloaded stability metrics for the electrode based on the acquired position information with respect to time; and comparing the unloaded and loaded stability metrics to decide whether the electrode, as located in the patient, comprises a stable location for delivery of therapy.

Owner:PACESETTER INC

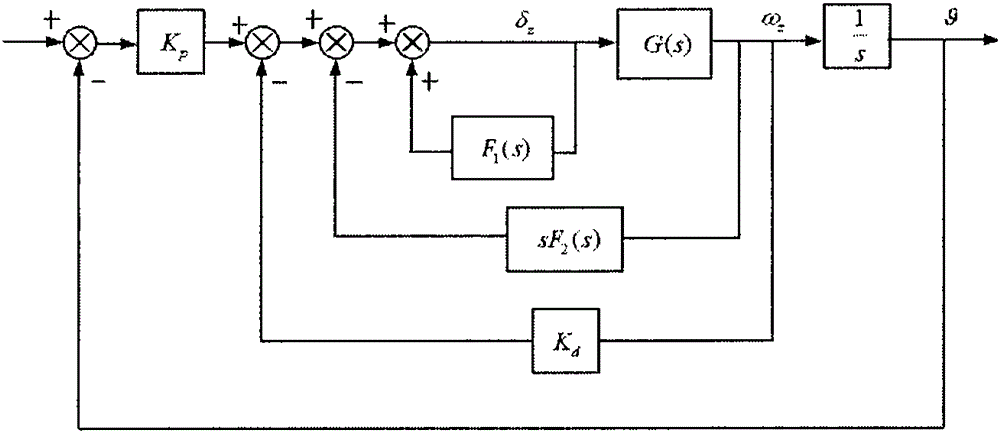

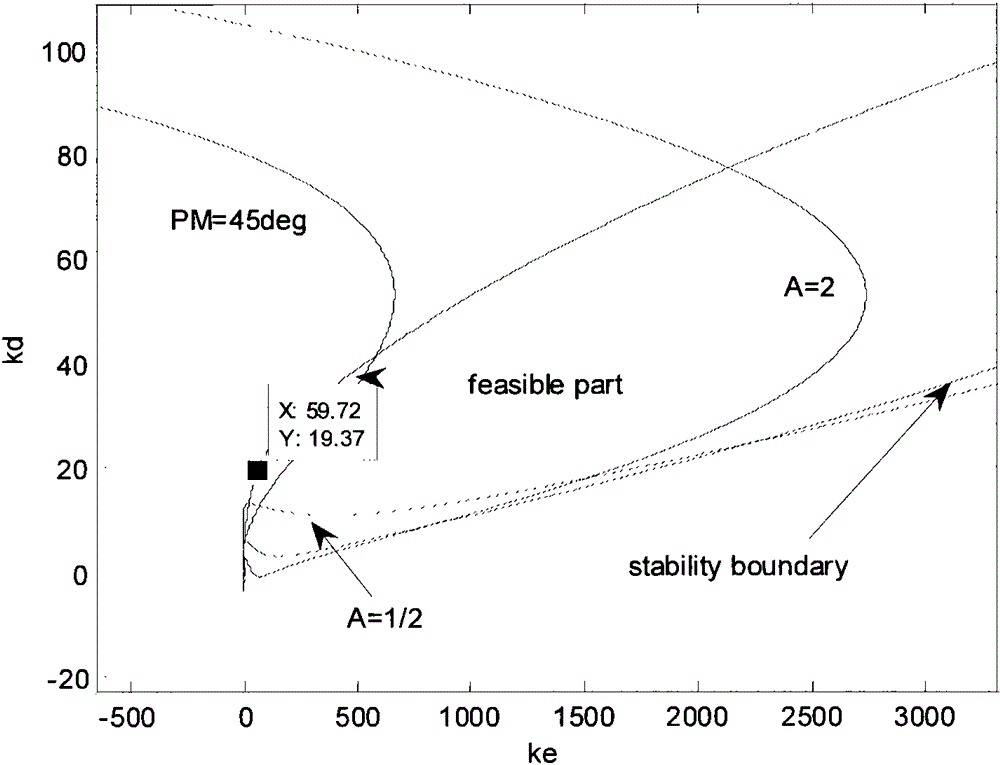

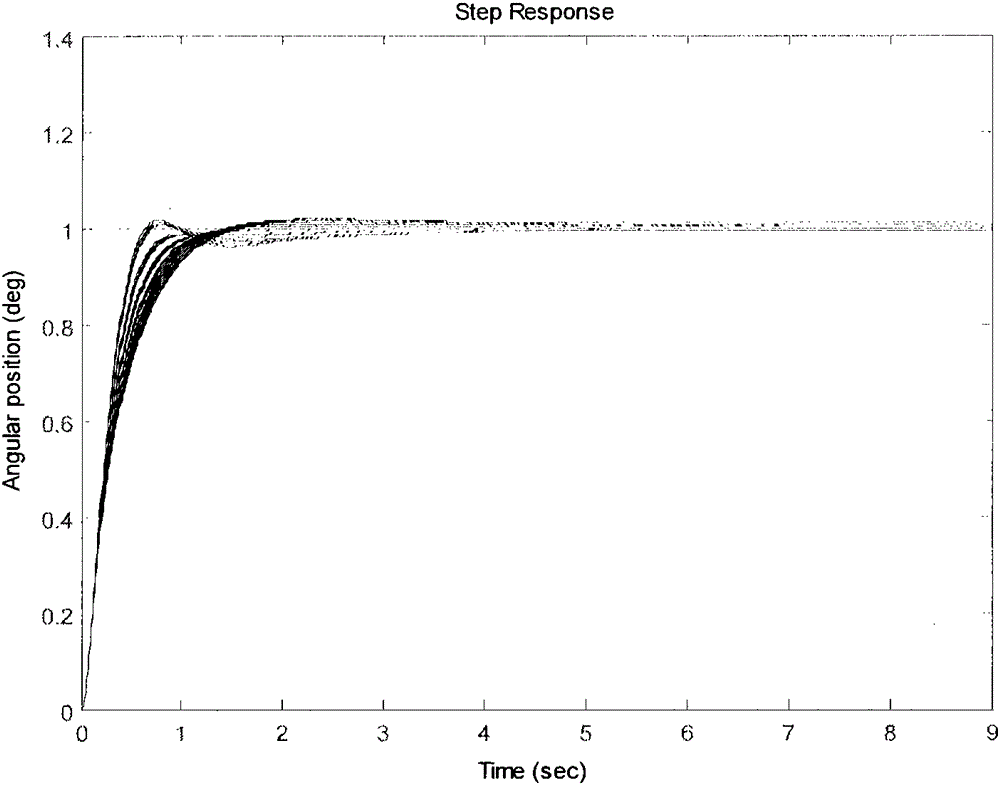

Linear active disturbance rejection control (ADRC) design and parameter tuning of aircraft pitch attitude

The present invention provides a linear active disturbance rejection control (ADRC) design and parameter tuning of aircraft pitch attitude. The linear active disturbance rejection control (ADRC) design and parameter comprises the steps of (1) establishing direct and indirect influence relations which describe an elevator influence pitch angle directly for a pitch nonlinear kinetic equation, (2) for the pitch channel kinetic equation obtained in the step (1), taking all indirect influence items as disturbance, designing a linear expansion state observer, estimating and compensating a linear expansion state observer, and using a simple PD control strategy for a compensated system, (3) using a small perturbation hypothesis principle to carry out linearization to obtain a kinetic coefficient for the nonlinear equation obtained in the step (1), (4) carrying out graphical tuning of a control parameter according to a robust stability index and a dynamic performance index. According to the method, on the basis of ensuring the stable robustness and good dynamic quality of a controller, the form is very simple, at the same time, the pattern parameter tuning method based on a stable margin test factor has a visual characteristic, and the blindness of parameter debugging is avoided.

Owner:孙明玮 +1

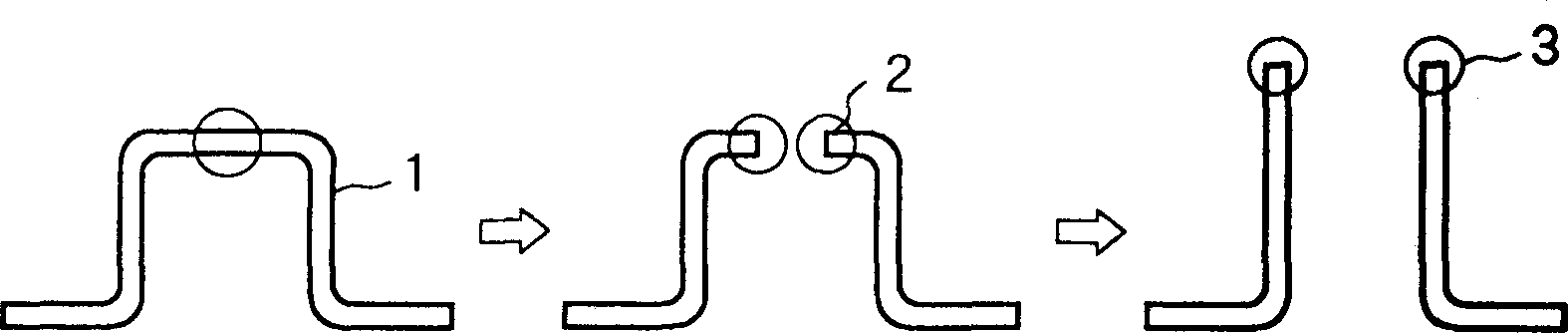

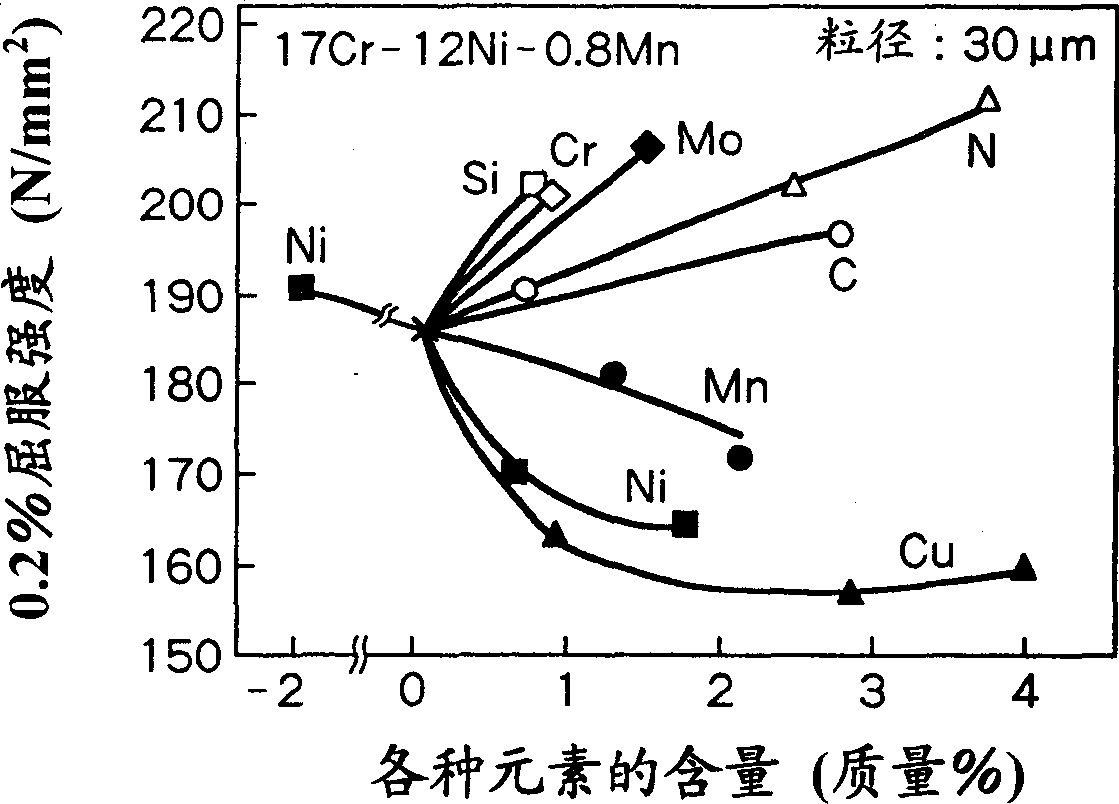

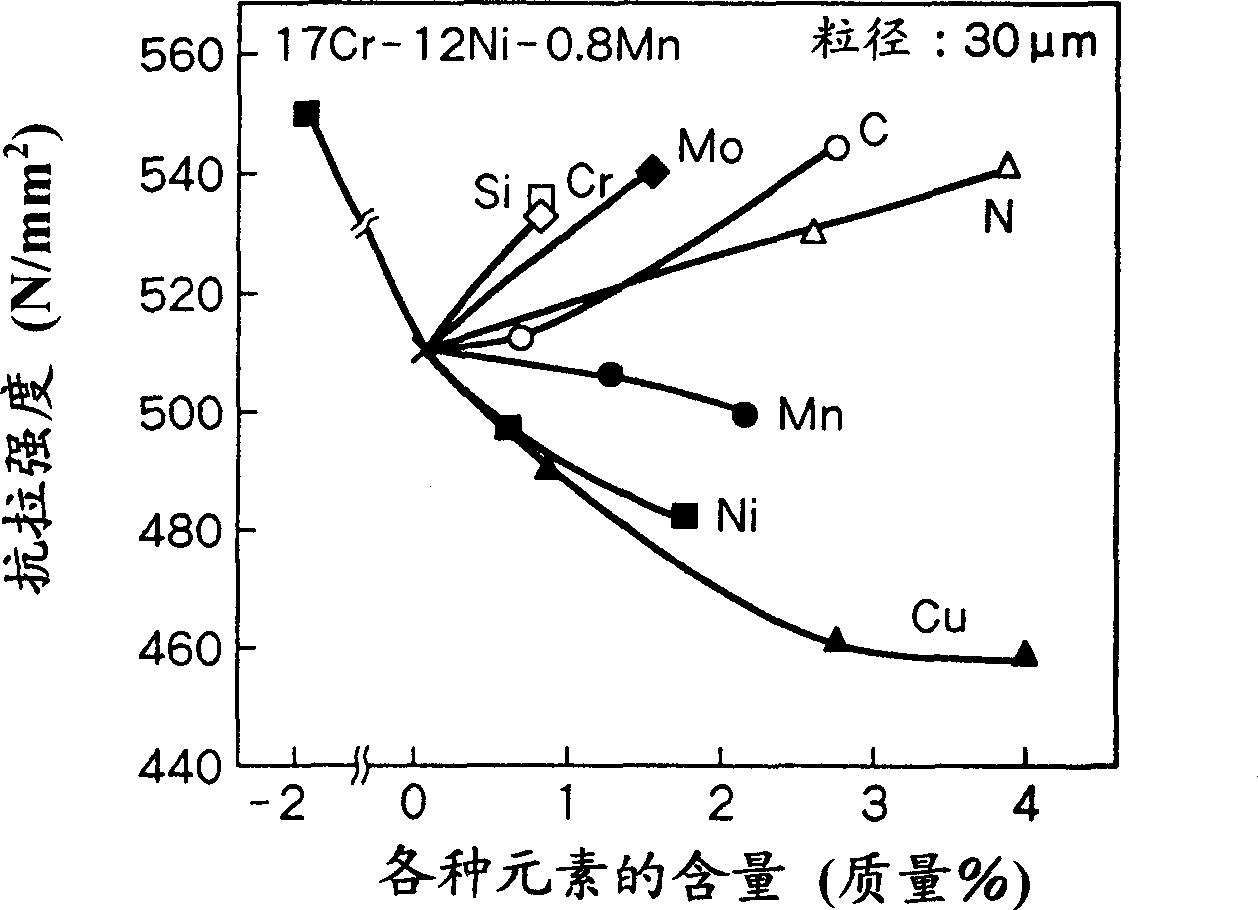

Fine processing property soft stainless steel

A new soft stainless steel plate has an austenite stability index Md30 controlled in the range of -120 to -10 and a stacking fault formability index SFI controlled at not less than 30, and contains a Cu concentration controlled at Precipitation not greater than 1.0% is used to maintain the dissolved Cu concentration at 1-5%. The stainless steel plate preferably contains up to 0.06% (C+N), up to 2.0% Si, up to 5% Mn, 15-20% Cr, 5-9% Ni, 1.0-4.0% Cu, up to 0.003% Al, up to 0.005% S and optionally up to 0.5% Ti, up to 0.5% Nb, up to 0.5% Zr, up to 0.5% V, up to 3.0% One or more of Mo, up to 0.03% B, up to 0.02% REM (rare earth metal) and up to 0.03% Ca. The stainless steel plate can be plastically deformed into the intended shape by multi-stage deep rolling or compression deformation, and there is no crack even in the severe processing part. Md30(℃)=551-462(C+N)-9.2Si-8.1Mn-29(Ni+Cu)-13.7Cr-18.5MoSFI(mJ / m2)=2.2Ni+6Cu-1.1Cr-13Si-1.2Mn +32

Owner:NIPPON STEEL STAINLESS STEEL CORP

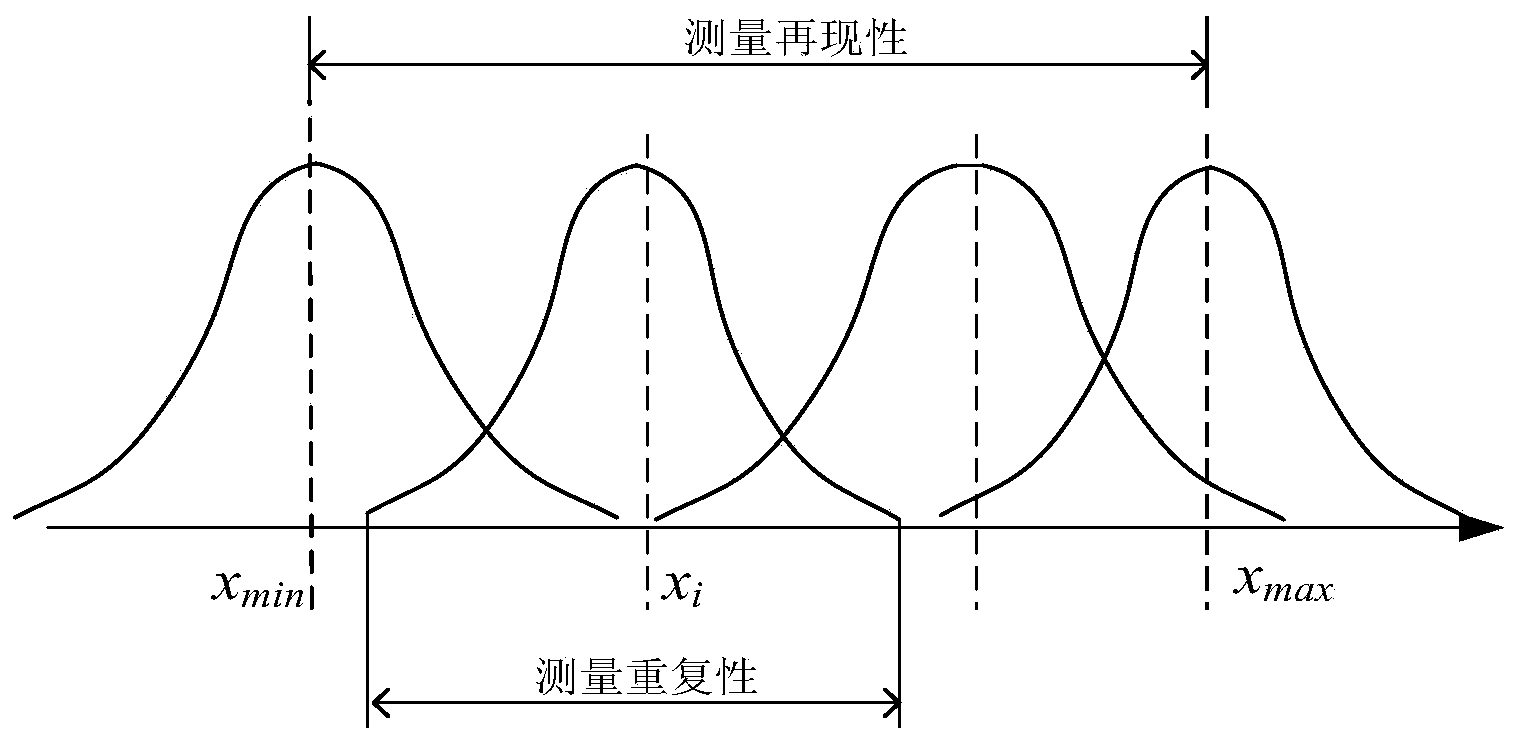

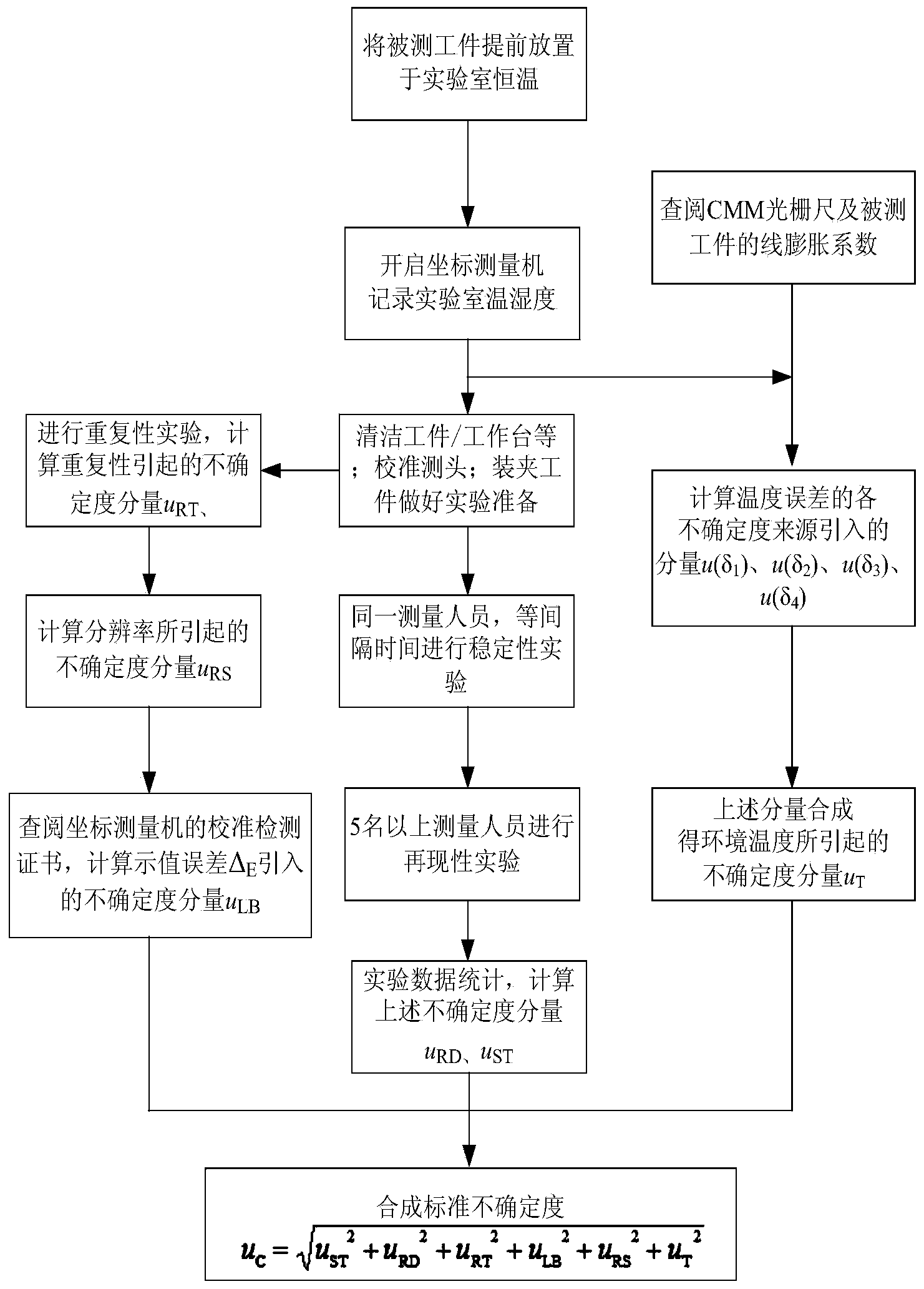

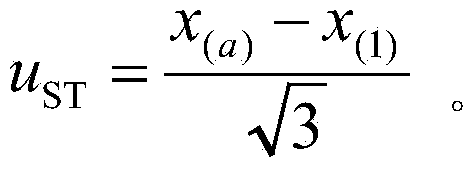

Method for assessing measurement uncertainty of coordinate measuring machine

InactiveCN104376211AUncertainty is accurate and reliableFull uncertaintySpecial data processing applicationsGratingStability index

The invention discloses a method for assessing measurement uncertainty of a coordinate measuring machine. The method of avoiding the complex relation among error sources of the coronate measuring machine and unknown transmission rules between the error sources is adopted, the method of analyzing characteristic indexes of a measurement system of the coordinate measuring machine is adopted, the method and approach of verifying or obtaining corresponding system characteristic index values of the measurement system, an integral calibration method and a detail experiment scheme for obtaining a stability index and a reproducibility index of the coordinate measuring machine are designed, the influence degree of actual temperature in temperature compensation, a standard grating rule and a linear expansion coefficient of a tested workpiece on a measurement result is considered, and the relatively integral measurement uncertainty of the coordinate measuring machine is obtained through synthesis in the root of square sum.

Owner:HEFEI UNIV OF TECH

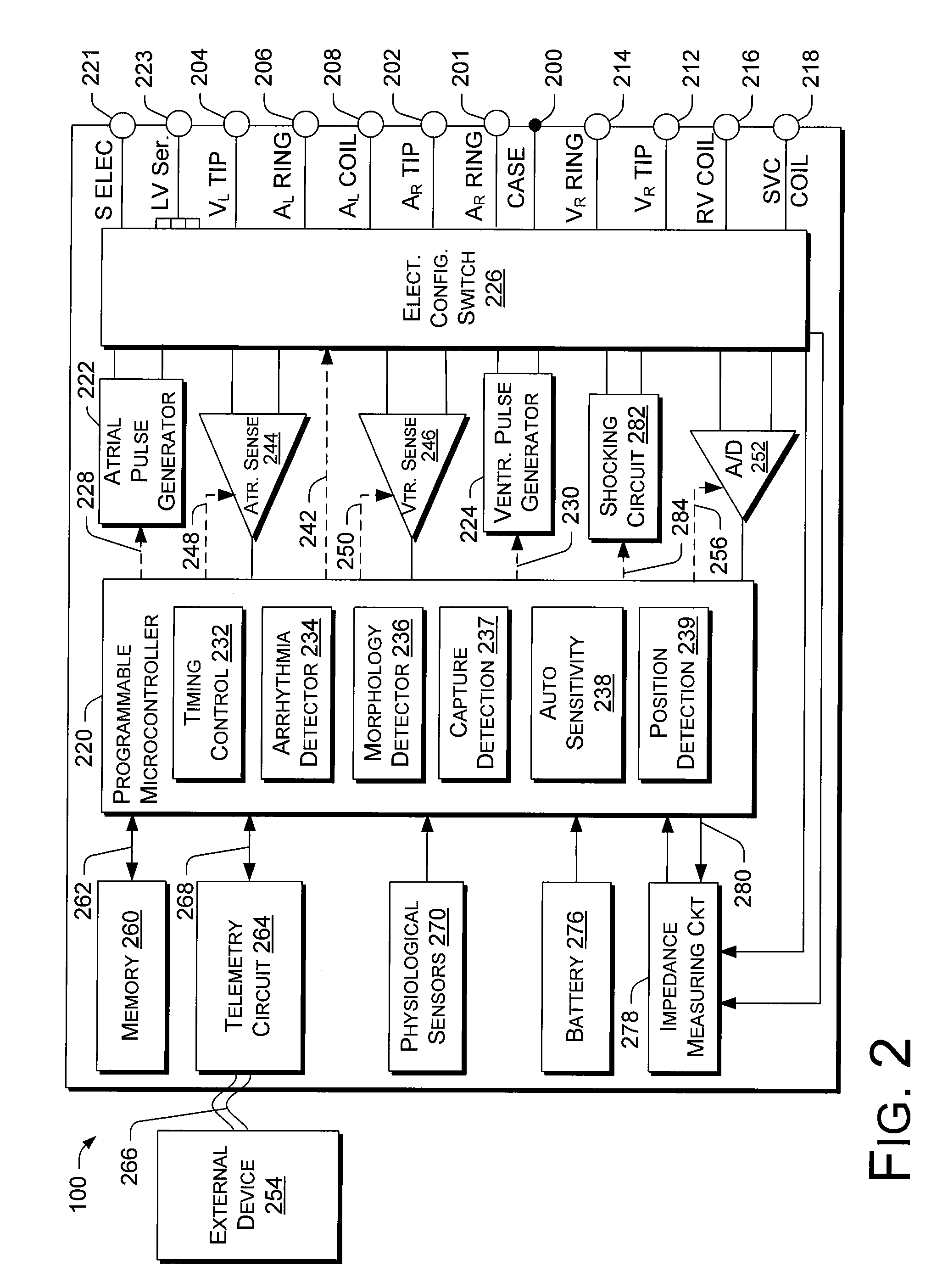

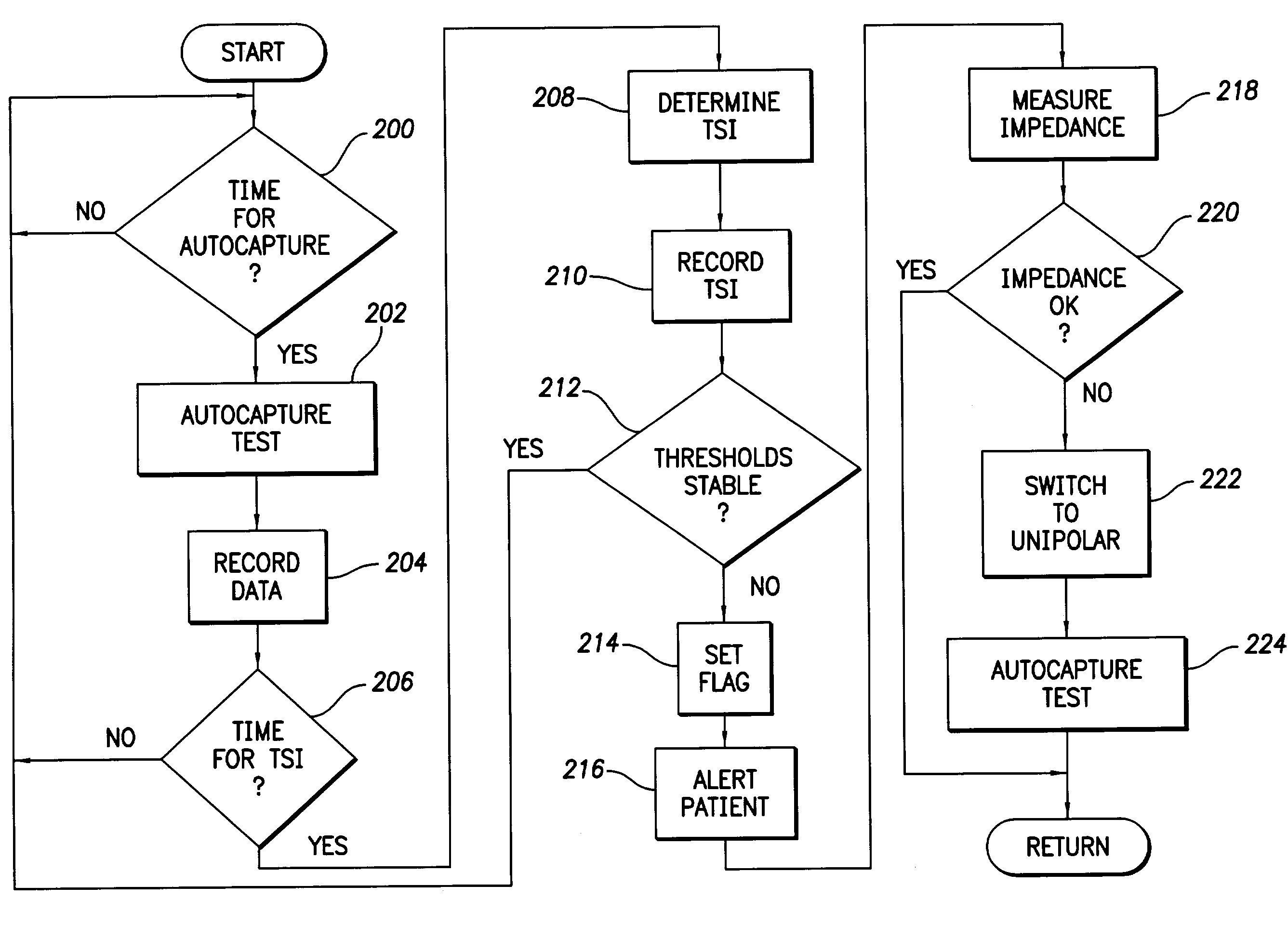

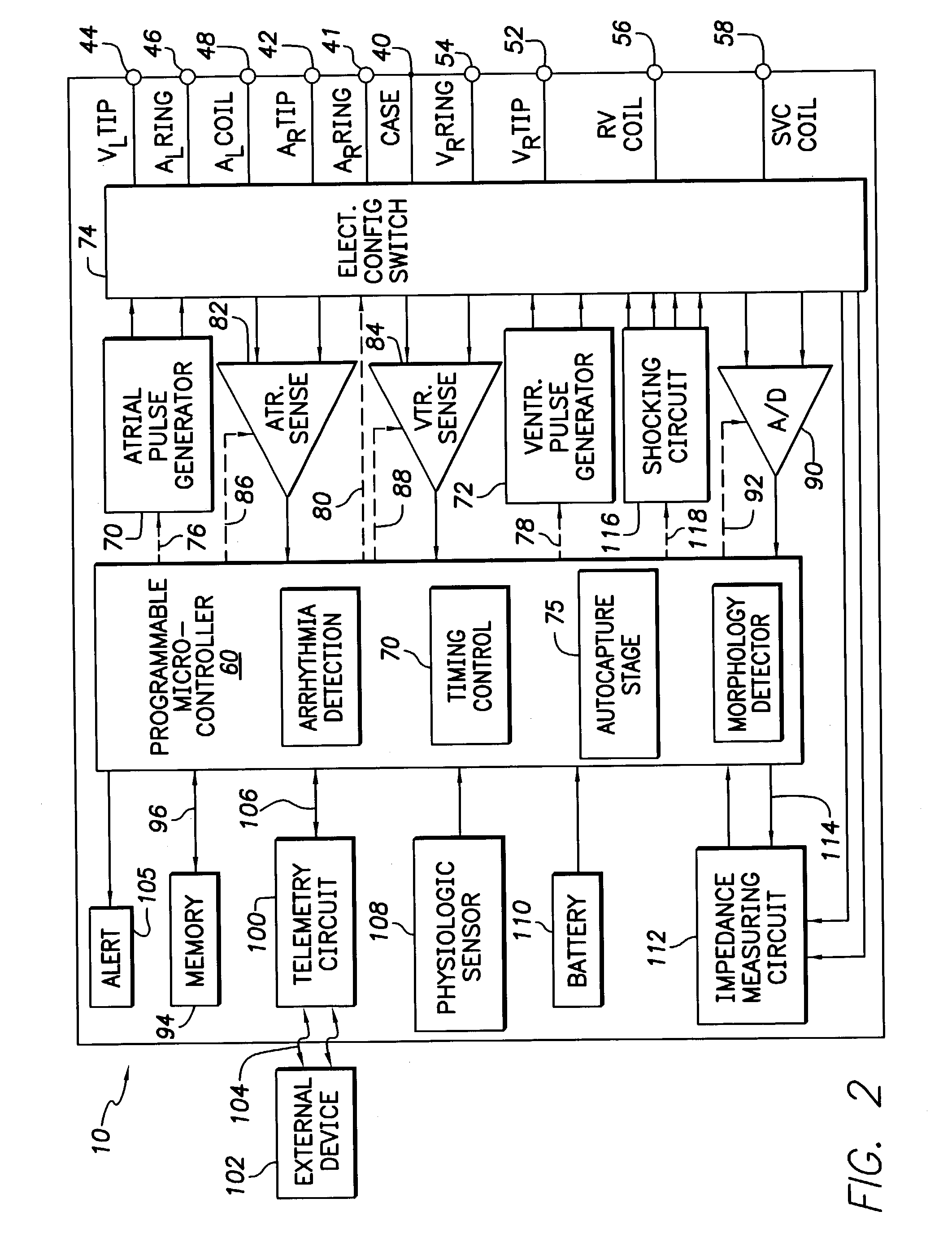

Implantable cardiac stimulation system providing capture threshold stability assessment and method

An implantable cardiac stimulation system provides capture threshold stability assessment. The system includes an implantable pulse generator that provides pacing stimulation pulses, an implantable lead system that couples the pulse generator to a patient's heart, and a capture threshold test circuit that performs capture threshold tests with the pulse generator and provides capture thresholds at spaced apart times. A capture threshold processor responsive to the capture thresholds provides capture threshold stability indicia. The capture threshold stability indicia may be a threshold stability index equal to the ratio of the peak-to-peak threshold fluctuation and the mean capture threshold. The threshold stability index may be compared to a given standard to determine if the capture thresholds are unstable.

Owner:PACESETTER INC

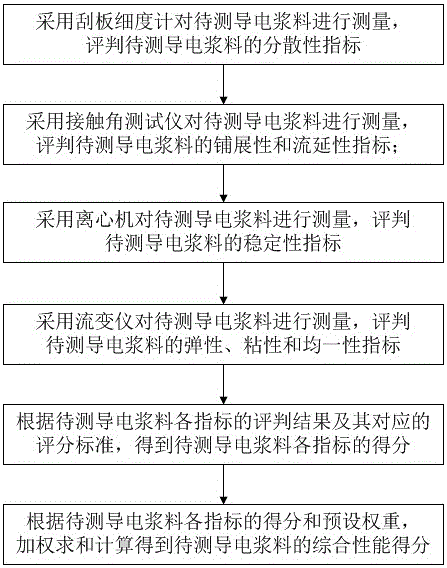

Comprehensive performance evaluation method for conductive slurry of lithium ion battery

The invention provides a comprehensive performance evaluation method for a conductive slurry of an lithium ion battery. The method comprises the following steps: a scraper blade fineness gauge is adopted to measure the conductive slurry, and a dispersibility index of the conductive slurry is evaluated; a contact angle tester is adopted to measure the conductive slurry, and spreadability and flow ductility indexes of the conductive slurry are evaluated; a centrifugal machine is adopted to measure the conductive slurry, and a stability index of the conductive slurry is evaluated; a rheometer is adopted to measure the conductive slurry, and elasticity, viscosity and uniformity indexes of the conductive slurry are evaluated; according to evaluation results of the various indexes of the conductive slurry and a corresponding scoring standard thereof, scores of the various indexes of the conductive slurry are obtained; and, according to the scores and preset weights of the various indexes of the conductive slurry, a comprehensive performance score of the conductive slurry is obtained through a weighted summation calculation. The method has the advantages of easy operation, high practicality, high testing result accuracy, high reliability and good reproducibility; and the method can provide an accurate reference for comprehensive performance of the conductive slurry of the lithium ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

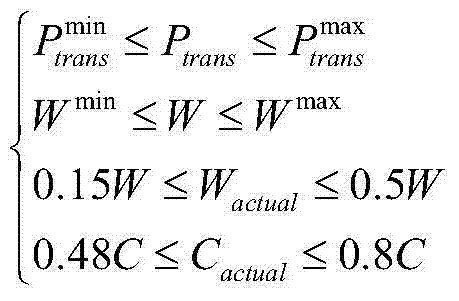

Transmission capacity and wind and fire bundling transmission optimization method of extra-high voltage channel

InactiveCN104751236AEasy to calculateEasy for quantitative analysisForecastingElectricity priceMathematical model

The invention relates to a transmission capacity and wind and fire bundling transmission optimization method, and in particular relates to the transmission capacity and wind and fire bundling transmission optimization method. The invention firstly establishes an index system considering receiving end power grid electricity power demand, static security index, transient stability index, economic index and power transmission electrovalence. The indexes are quantized for establishing mathematical model of multi-objective functions and the multi-objective optimization algorithm is adopted for computing. During the solving process, multi-objective functions are solved simultaneously and computed for obtaining alternative solution meeting constraint condition, and the entropy function method is adopted for confirming the optimal compromise solution. The index system considering receiving end power grid electricity power demand, static security index, transient stability index, economic index and power transmission electrovalence is adopted, the evaluation index is convenient to compute and analyze in a quantitative manner, the transmission capacity of the electric transmission line and the influence to the receiving end power grid from sending end wind and fire bundling ratio can be reflected synthetically.

Owner:STATE GRID CORP OF CHINA +4

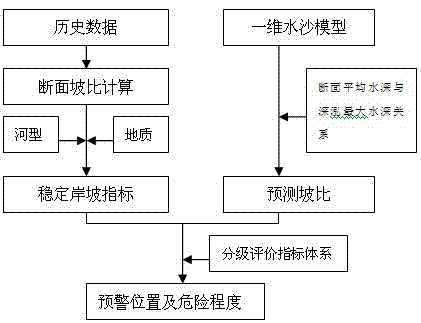

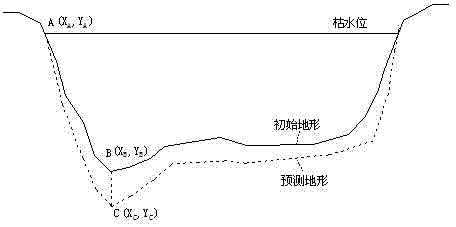

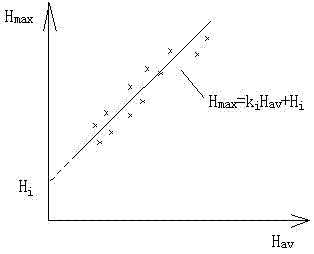

Alluvial river bank collapse early warning method

The invention discloses an alluvial river bank collapse early warning method. Aiming at collapse of a binary structure bank of an alluvial river under long-term action of water flow, the position of bank collapse can be forecasted early; meanwhile, rolling forecast can be continuously performed by utilizing the characteristics that river section data is relatively easily acquired and more forecasting times are present, and the forecast accuracy is improved. The method comprises the following steps of: determining a river bank stability index, forecasting river bed deposition and erosion change and performing early warning and judgment on the bank collapse. By using the bank slope stability index determining and judging standard, comparing with a forecast slope and combining with a gradingjudgment index system, the position of a dangerous bank section can be early warned, and technical support is provided for dike maintenance and management.

Owner:WUHAN UNIV

Testing method for interface adhesion performance of road asphalt mixture

The invention discloses a testing method for the interface adhesion performance of a road asphalt mixture. The method comprises the steps of performing sample preparation on original asphalt; performing short-term aging and sample preparation; performing pressure aging and sample preparation; performing a water freezing and thawing testing and salt freezing and thawing testing; preparing an aggregate test specimen; testing surface free energy parameters of asphalt and the aggregate test specimen; determining the asphalt and aggregate interface adhesion performance; comparing interface adhesion performance indexes of various asphalt and aggregates on different conditions so as to select asphalt road materials suitable for being used under different climate environments. According to the testing method, asphalt and aggregate interface adhesion work on the drying condition, peeling work of an asphalt and aggregate interface on the water condition and a water stability index determined by the ratio of the adhesion work to the peeling work can be effectively calculated and obtained for different asphalt and aggregates under the different temperatures, aging conditions and different freezing and thawing cycle condition effects; scientific basis is provided for quality inspection and engineering characteristic evaluation of a cold region asphalt road material product.

Owner:INNER MONGOLIA UNIV OF TECH

Ethylene-propylene copolymer viscosity index improver and preparation and application thereof

ActiveCN101082012AGood cryogenic pumpabilityImprove shear resistanceAdditivesPolymer scienceStability index

The present invention provides one kind of viscosity index improver of ethylene-propylene copolymer. The viscosity index improver is prepared with base oil in 75-88 wt% and ethylene-propylene rubber in 12-25 wt%, and through mixing in a normal pressure sol degrading kettle, heating to 95-140 deg.c slowly, and stirring at constant temperature for 3-10 hr. The viscosity index improver for modulating high grade internal combustion engine oil has high thickening capacity of 0.85-0.96 sq mm / s, low shear stability index below 20 %, outstanding low temperature performance, and small added amount of 6.5-8 %.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com