Fine processing property soft stainless steel

A kind of stainless steel plate, processability technology, applied in the field of soft stainless steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Various stainless steels having the compositions shown in Table 1 were refined, continuously cast into slabs, and hot rolled to a thickness of 3 mm at an extraction temperature of 1230°C. The hot-rolled steel strip was annealed at 1150° C. for 1 minute, pickled, and then cold-rolled to a thickness of 0.4 mm. Then, the cold-rolled steel strip was annealed at 1050° C. for 1 minute, and pickled again.

[0069] The various cold-rolled steel strips produced in this way had the mechanical properties shown in Table 2.

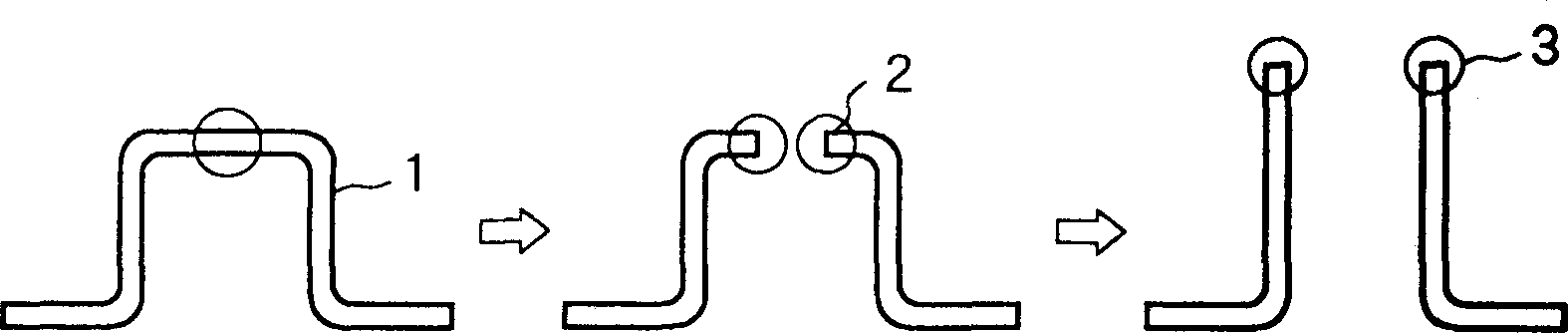

[0070] Cut blanks with a diameter of 74mm from various stainless steel plates, and use a cylindrical punch with a diameter of 33mm with a punch radius of 3mm and a die with a diameter of 35mm with a die radius of 3mm to hold the pressure of 1 ton to a height of 7mm. . Then as Figure 4 As shown, an opening with a diameter of 10 mm was formed in the center of the rolled billet, and then a spherical punch with a diameter of 35 mm and a diameter of 35 mm with a...

Embodiment 2

[0081] Various stainless steels having the compositions shown in Table 5 were refined, continuously cast into slabs, and hot rolled to a thickness of 3 mm at an extraction temperature of 1230°C. After hot rolling, the steel strip was annealed at 1150 °C for 1 minute, pickled and cold rolled to a thickness of 0.4 mm. Thereafter, the cold-rolled strip was final annealed at 1050° C. for 1 minute and pickled again.

[0082] The blanks sheared from various steel strips were observed by microscopy and the SiO of precipitated non-metallic inclusions in the matrix was measured by EPMA analysis 2 and Al 2 o 3 concentration. Results and the austenite stability index Md 30 It is shown in Table 6 together with the stacking fault formability index SFI. The copper concentration in the precipitate measured by EDX analysis in the field of TEM is also shown in Table 6. Table 7 on the other hand shows the mechanical properties of various stainless steel plates.

[0083] Cut blanks with a...

Embodiment 3

[0092] Various stainless steels having the compositions shown in Table 9 were refined, continuously cast into slabs, and hot rolled to a thickness of 5 mm at an extraction temperature of 1230°C. After the hot-rolled steel strip was annealed at 1100°C for 1 minute, it was pickled.

[0093] Columnar test block samples having an outer diameter of 3.0 mm and a height of 4 mm were taken from each stainless steel plate. In order to investigate the relationship between true strain and true stress during compression deformation, the test block was compressed along the axial direction of the column at a strain rate of 0.01 / sec.

[0094] Table 10 shows the value of the true stress when the true strain becomes 1 under the time period when the height of each test block is reduced by 60% compared to the original height. It can be appreciated that steels A and B of the present invention exhibit resistance to deformation (as represented by true stress) of less than 1200 MPa, whereas the def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com