Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Meet the power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

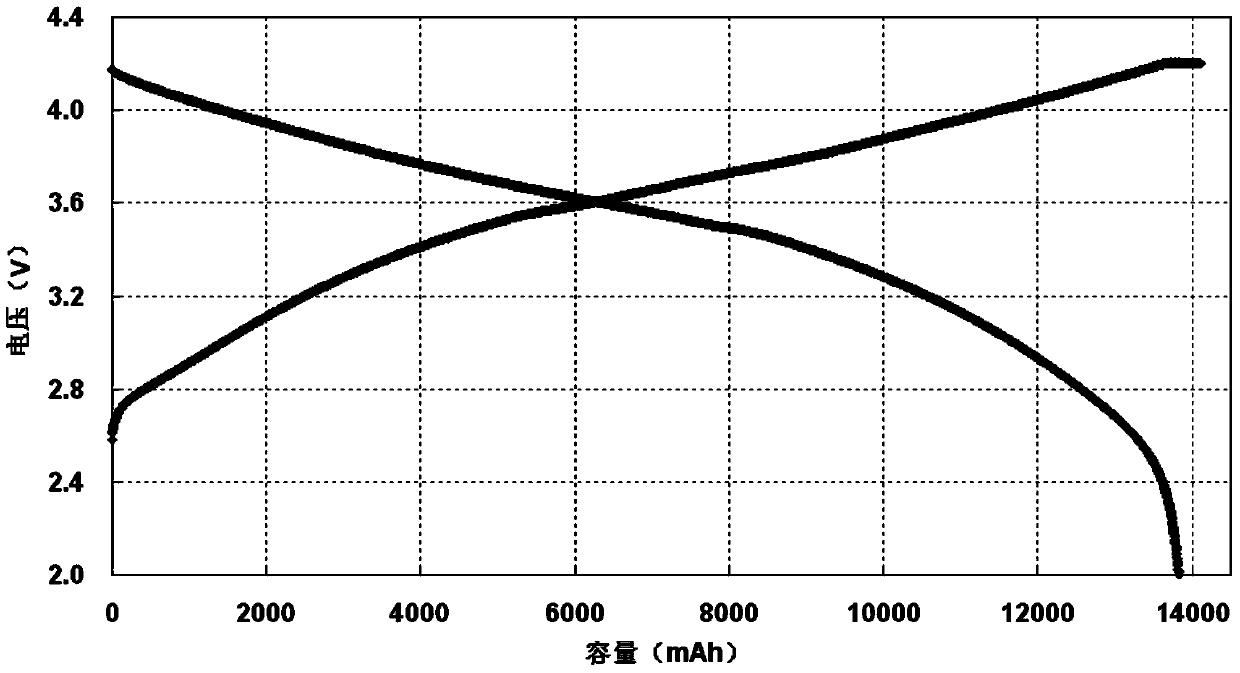

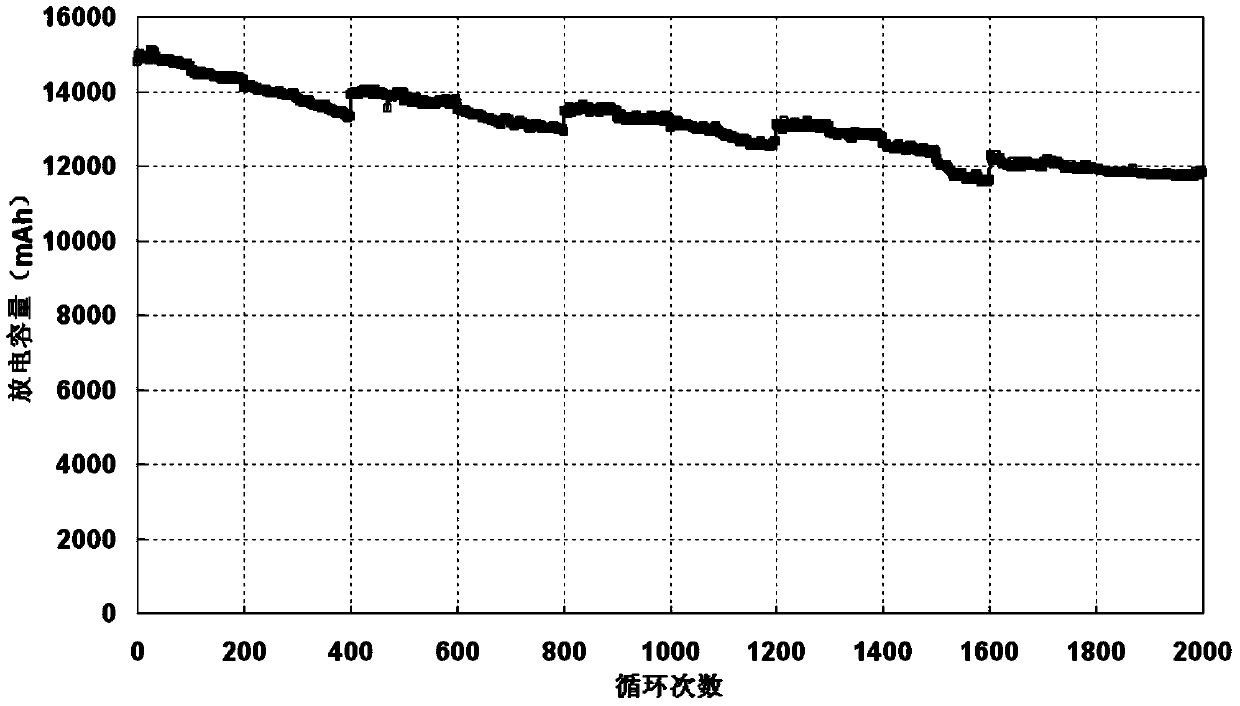

Power and energy storage lithium-ion battery and preparation method thereof

ActiveCN103441305AImproved gram capacity playIncrease capacityFinal product manufactureElectrolyte accumulators manufactureGramEngineering

The invention relates to a preparation method of a power and energy storage lithium-ion battery. A negative active substance of the power and energy storage lithium-ion battery comprises soft carbon, hard carbon, a mixed material of soft carbon and graphite and a mixed material of hard carbon and graphite. The designing method of the battery comprises the steps of designing the gram volume of the negative active substance as the primary lithium-embedding gram volume, designing the gram volume of the positive active substance as the primary lithium-removal gram volume, designing the ratio of the capacity of the positive electrode and the capacity of the negative electrode to be (1: 1) to (1.5: 1). By adopting the designing method, the capacity and comprehensive performance of the battery can be remarkably improved, and excellent lithium-embedding and lithium-removal capacity of the soft carbon material and the hard carbon material can be adequately exerted. Compared with the existing lithium battery technology, the prepared power lithium battery has long service life, high multiplying power, high safety performance and excellent low-temperature performance and can be widely applied to the fields such as electric tools, various portable devices, spaceflight, starting power supply and the like.

Owner:BTR NEW MATERIAL GRP CO LTD

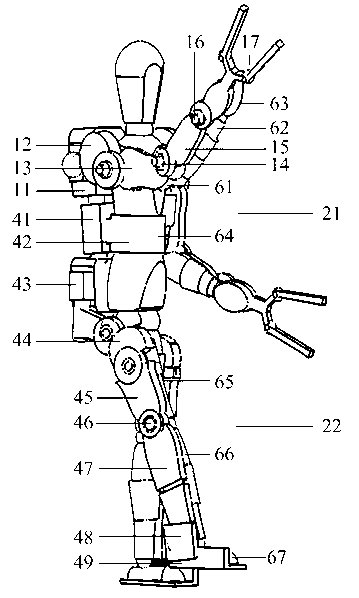

Wearable heavy material handling power-assisting bionic exoskeleton

InactiveCN102793595ASatisfy the rapidity of movementFulfil requirementsProsthesisMotor driveKnee Joint

The invention discloses a heavy material handling power-assisting bionic exoskeleton which can be worn on limbs of a human body. The heavy material handling power-assisting bionic exoskeleton can assist the human body in rapidly completing the task of carrying large-heavy materials under the harsh working condition and comprises an upper limb exoskeleton and a lower limb exoskeleton. The upper limb exoskeleton is a 7-degree-of-freedom system and consists of 3-degree-of-freedom shoulder joints, 1-degree-of-freedom elbow joints, 2-degree-of-freedom wrist joints, 1-degree-of-freedom hands and a motor driving system box of the back; and the 7 degrees of freedom are all driven by a motor. The lower limb exoskeleton is a 6-degree-of-freedom system and consists of a 3-degree-of-freedom hip joint, 1-degree-of-freedom knee joints, 2-degree-of-freedom ankle joints and an electrohydraulic driving system box of the back; and the 6 degrees of freedom are all driven by the hydraulic pressure. After the human body wears the complete set of exoskeleton equipment, when the materials are moved, the efficiency and the flexibility can be greatly improved by mechanical power such as the motor or the hydraulic pressure and the like so as to fulfill the aim of saving time and labor.

Owner:ZHEJIANG UNIV

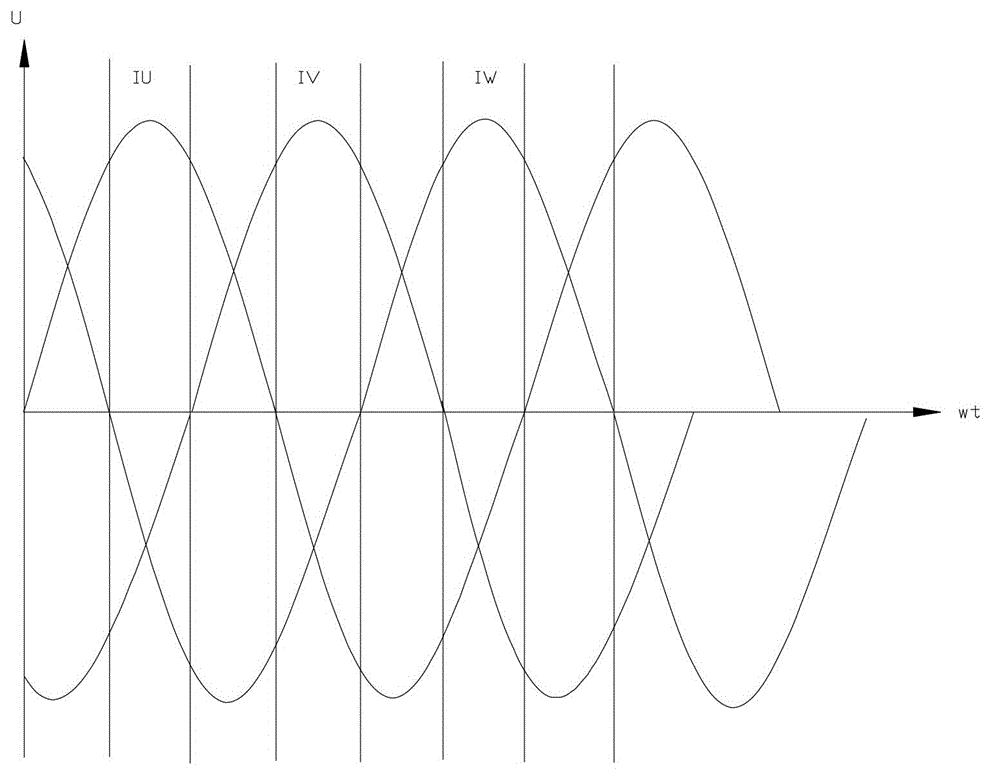

Insulated gate bipolar transistor (IGBT) over-current protection circuit

InactiveCN103066819AQuick protectionReduce occupancyEmergency protective circuit arrangementsPower conversion systemsCurrent limitingFull wave

The invention provides an insulated gate bipolar transistor (IGBT) over-current protection circuit which comprises a current sampling unit, a full-wave rectification unit, a peak value acquiring unit, a current comparing unit, a control unit and an IGBT drive unit. The current sampling unit is used for acquiring a three-phase output current. The full-wave rectification unit is used for respectively converting the three-phase output current to three single-direction currents. The peak value acquiring unit is used for acquiring the largest current in the three single-direction currents and outputting the largest current. The current comparing unit is used for respectively comparing the current output by the peak value acquiring unit with a quick current-limiting protection point and a limit protection point. The control unit is use for enabling the IGBT drive unit to block an IGBT or open the IGBT according to output of the current comparing unit. According to the IGBT over-current protection circuit, after the sampled three-phase output current is subjected to full-wave rectification, the peak value is used as the reference for over-current comparing, and the IGBT can be protected in a quick current-limiting mode and in a limit mode.

Owner:SHENZHEN INOVANCE TECH +2

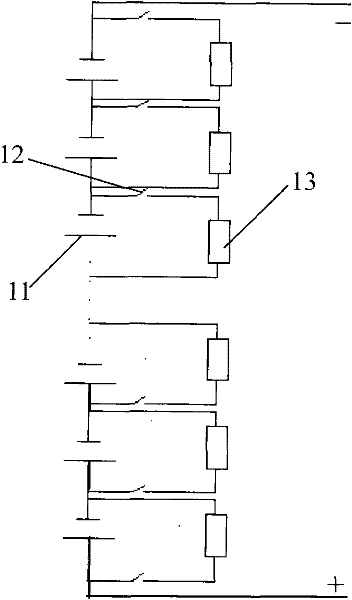

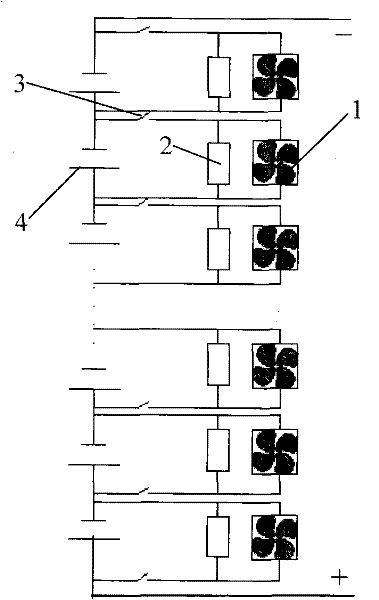

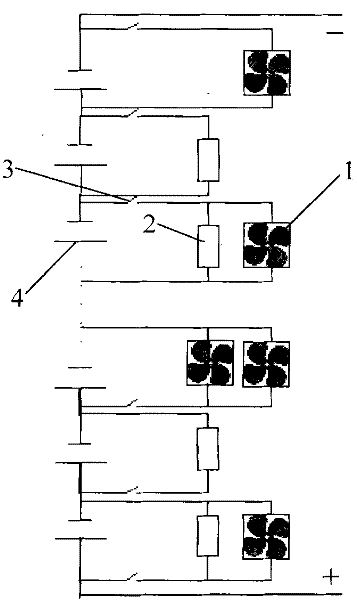

Equalizing device and method of battery management system

InactiveCN101752890AIngenious designSimple structureBatteries circuit arrangementsElectric powerData informationEqualization

The invention relates to an equalizing device of a battery management system, which comprises a bypass unit, wherein the bypass unit comprises a plurality of bypass devices, at least one part of the bypass devices are energy storage and energy conversion devices, preferably, the energy storage and energy conversion devices can be fans, super capacitors or quadratic chemical power sources, the bypass devices are used in an individual, parallel connection or parallel and series connection way, and the bypass unit also comprises a bypass indicating unit, a switch matrix unit, a battery unit, a data information acquisition unit and a central control unit. The invention also provides an equalizing method of the battery management system; through the invention, the equalizing efficiency is greatly improved under an equal condition, thereby not only shortening the equalizing time, but also satisfying the requirement for automatic and full heat dispersion of a power resistor. The invention enables the heat dispersion and the equalization of the system to be automatically realized without individually providing radiating device, can fully reduce the temperature of an equalizing system, and enables the case and bag design of a battery pack to be simpler and easier to operate and the productionization and the practicalization of a battery system to be further improved.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

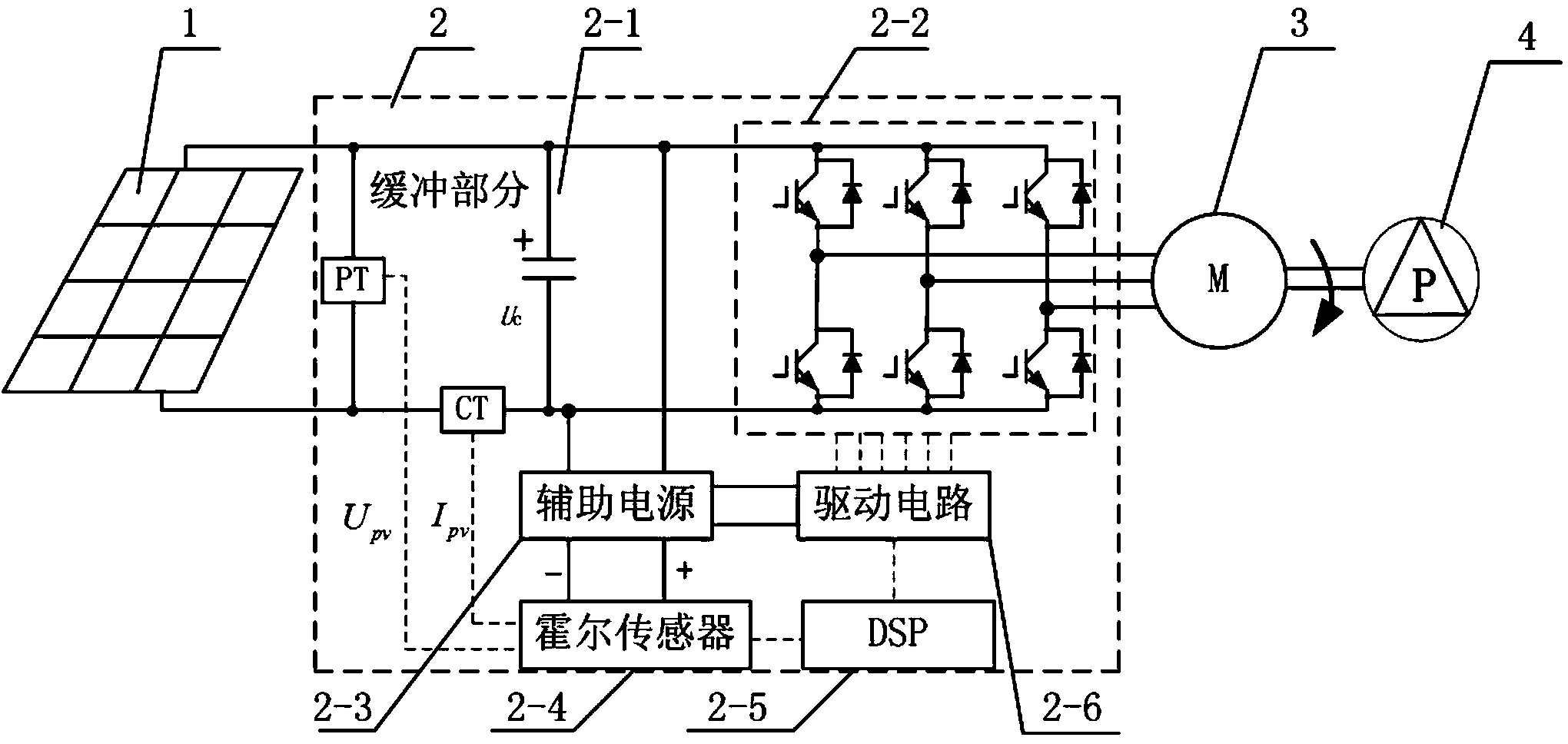

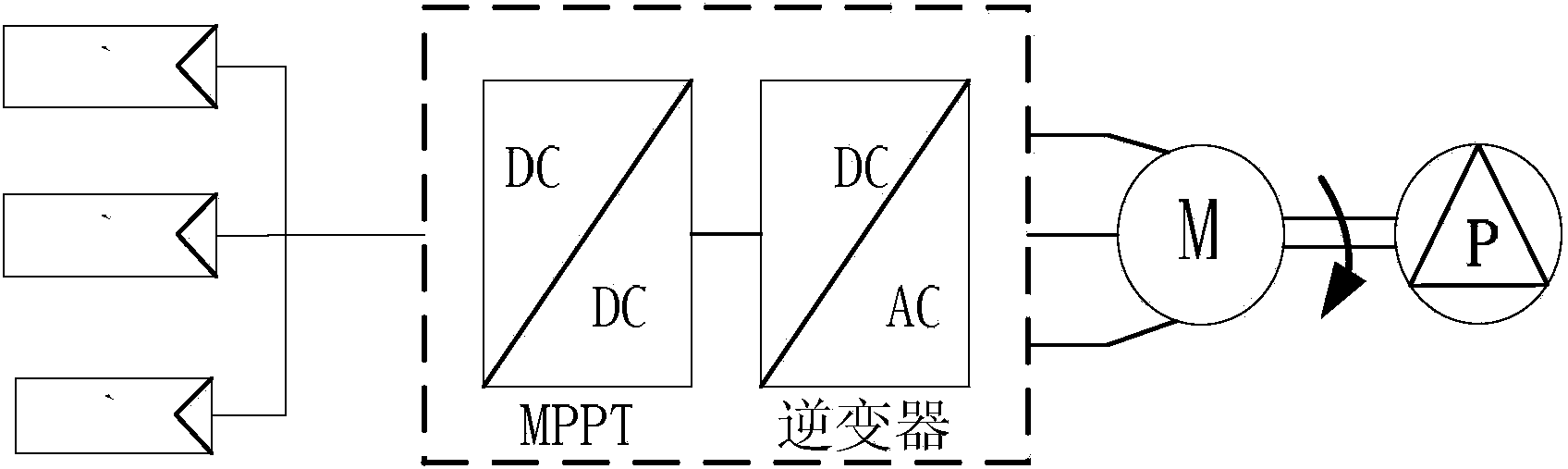

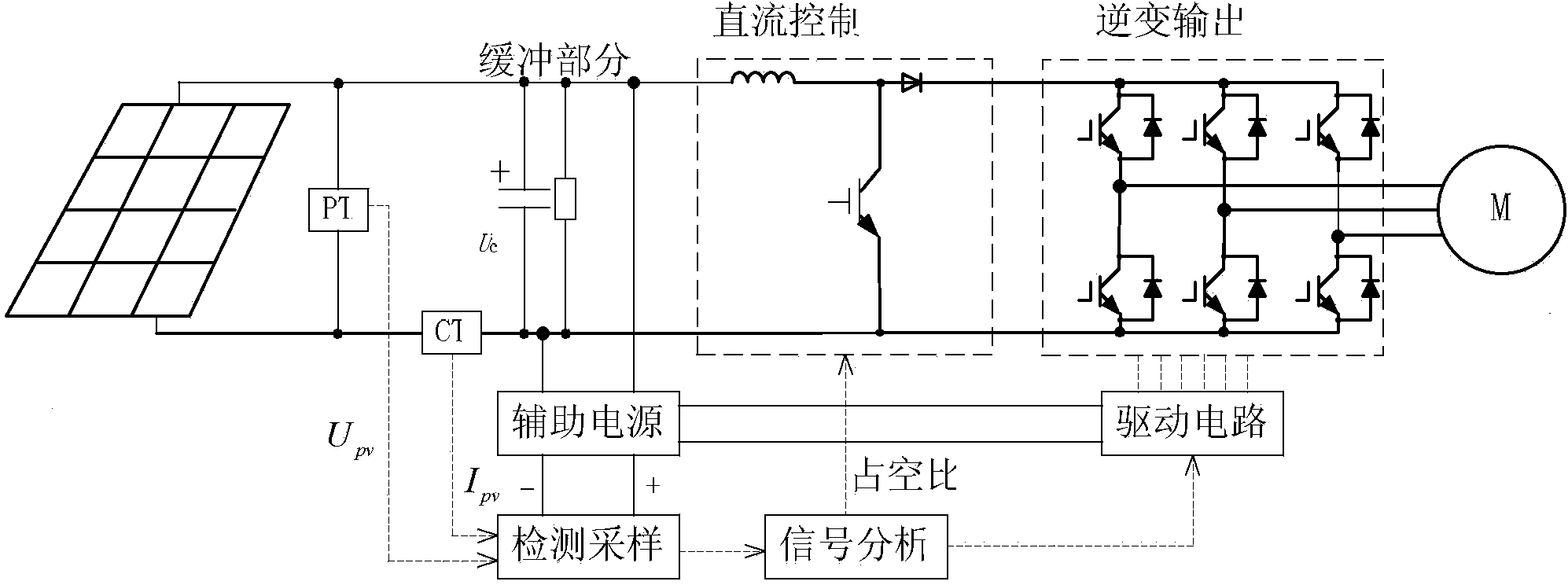

Single-stage type photovoltaic water pump control system and method

InactiveCN104079232AAchieve powerRealize functionAC motor controlPhotovoltaicsSingle stageControl system

The invention relates to the field of photovoltaic driving control, in particular to a single-stage type photovoltaic water pump control system and method solving the problems that a photovoltaic frequency converter of a traditional photovoltaic water pump system is complex in structure and high in control cost. An inversion frequency converter of the single-stage type photovoltaic water pump control system is an energy level, the direct current change link in the traditional photovoltaic water pump frequency converter is structurally removed, and the maximum power tracking and energy buffering functions in the original direct current converting link are achieved through the control function. The condition that the frequency disturbing method is adopted to carry out photovoltaic output to a water pump motor to output energy in control is utilized, and therefore maximum power output and stable system operation can be met. The control method is used for controlling the system frequency f, and priority is given to the maximum photovoltaic side power tracking method for frequency control. The frequency f is approximately in direct proportion with the revolving speed of the motor, the cube of the revolving speed of the motor is in direct proportion with the output power P of a load water pump, the frequency is adjusted, transmission power control can be achieved, and therefore a photovoltaic part can be output with maximum power.

Owner:HARBIN INST OF TECH

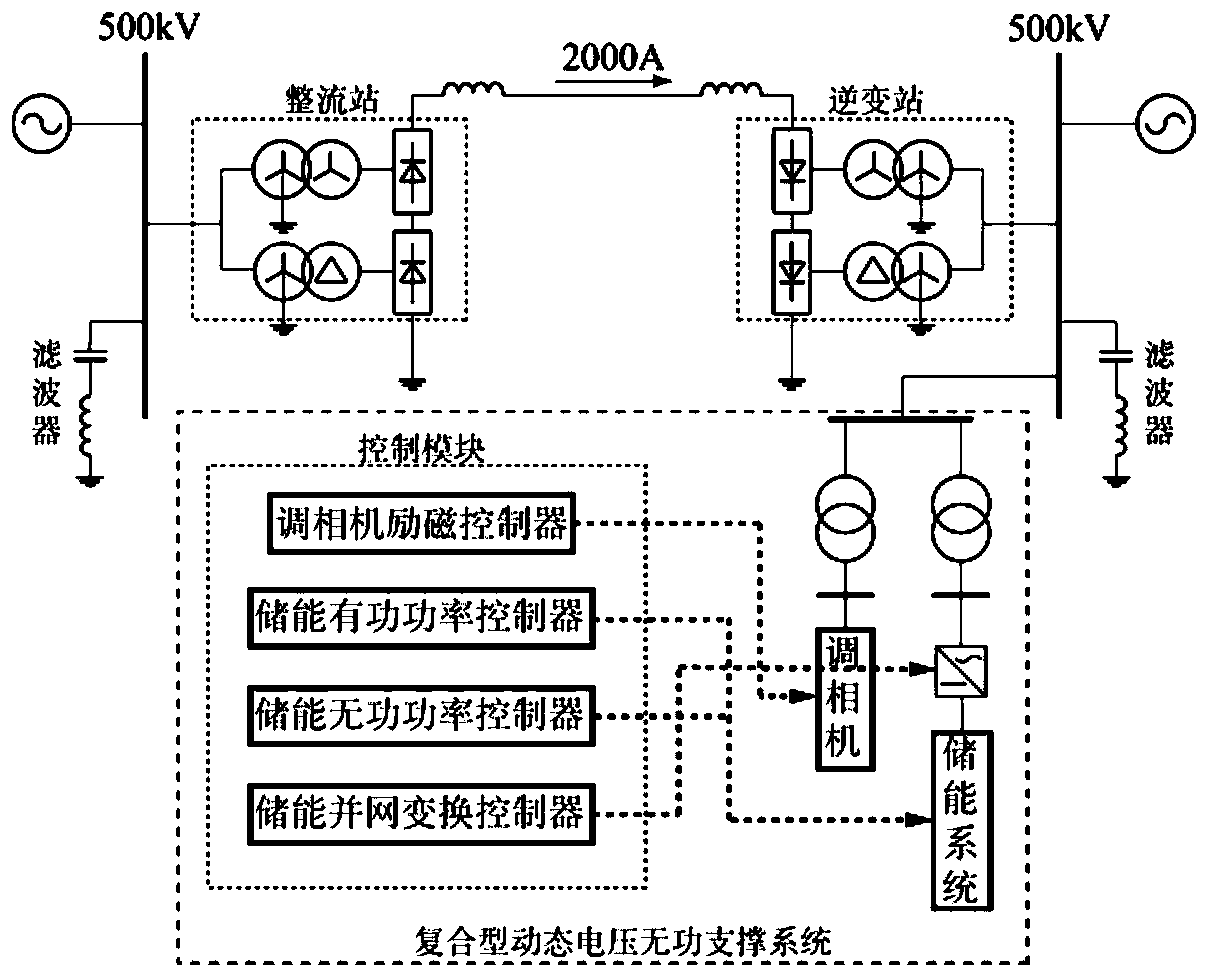

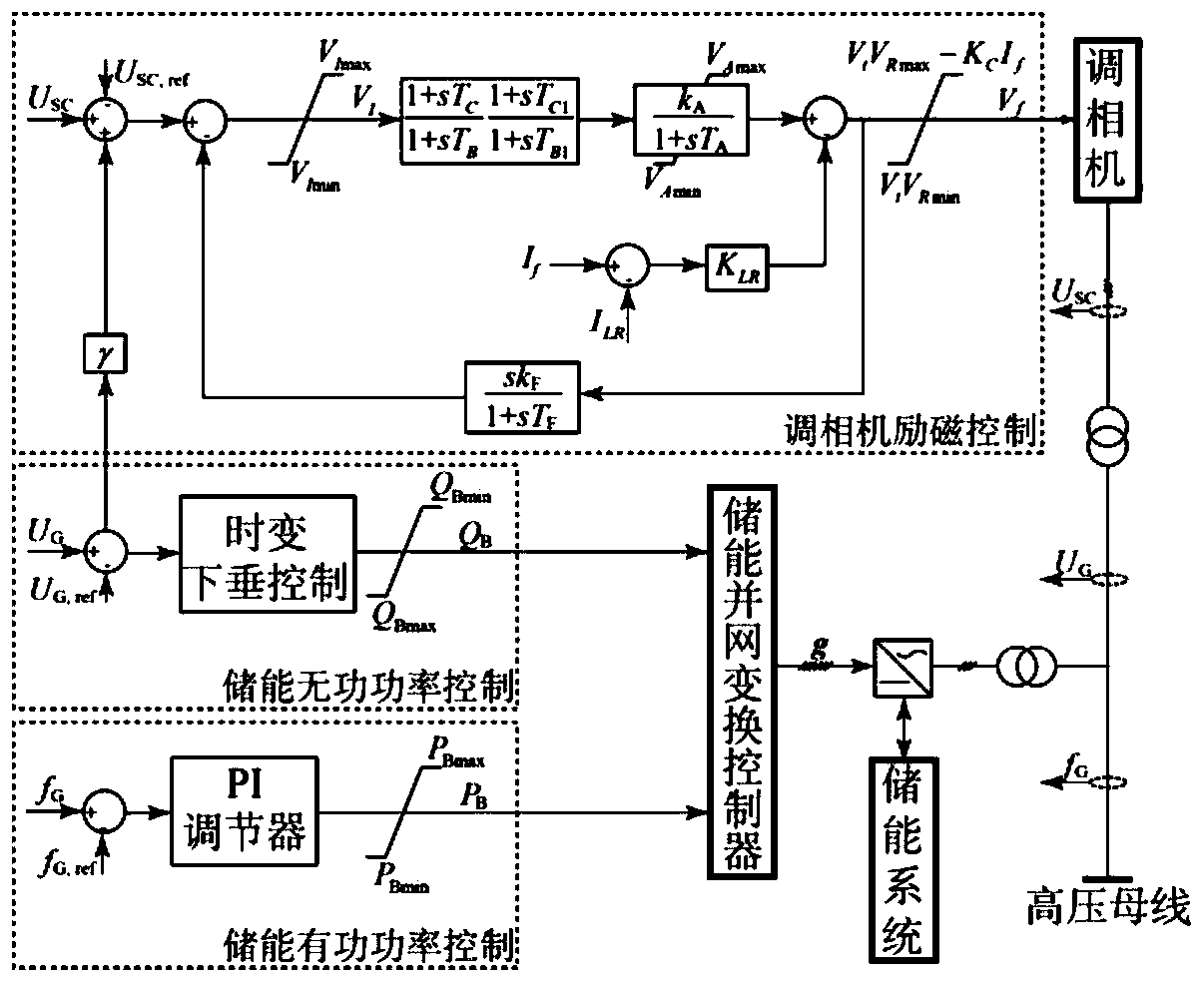

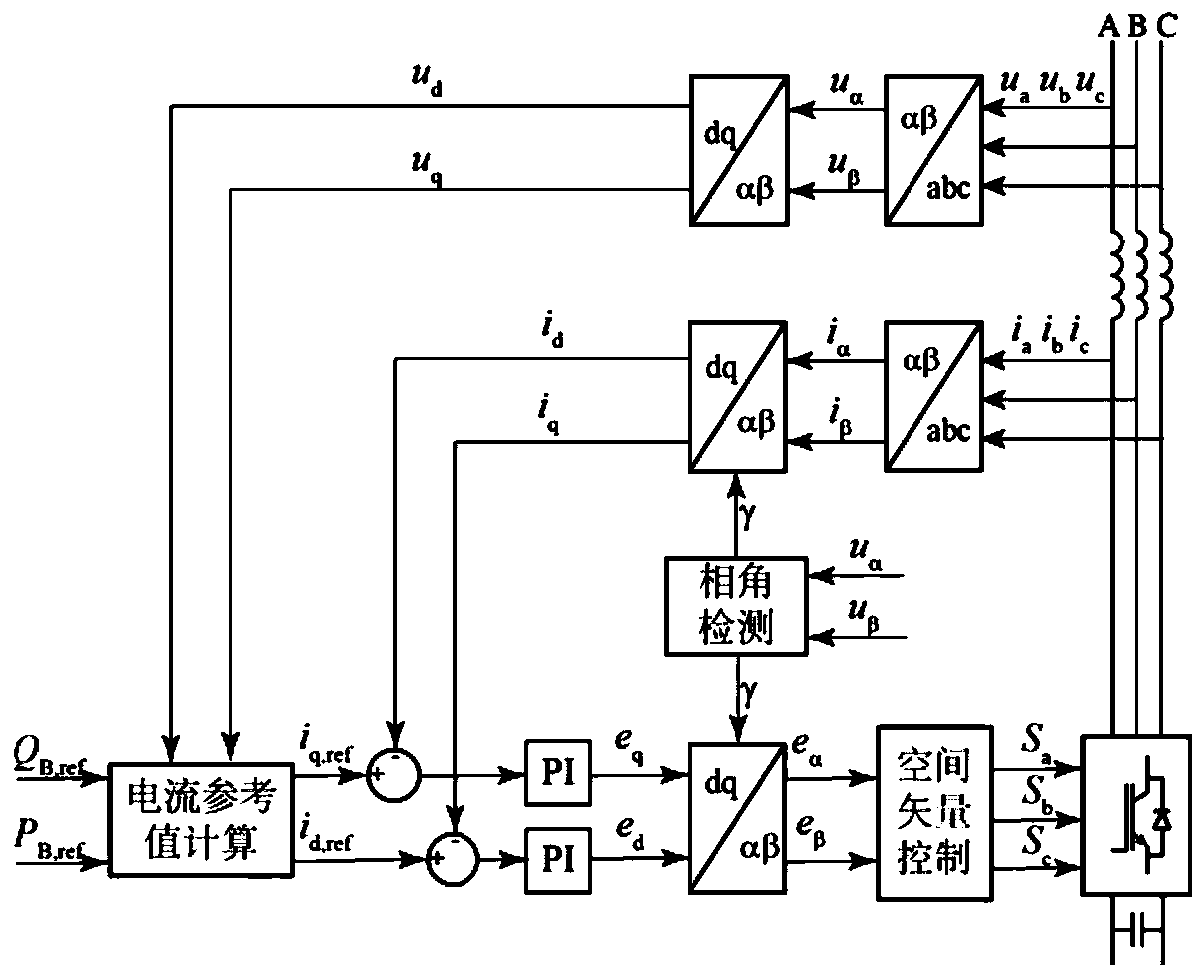

Composite dynamic power supporting system and coordination control method thereof

ActiveCN110661274AGuaranteed reasonablenessHigh speedFlexible AC transmissionAc network load balancingElectrical batteryControl theory

The invention discloses a composite dynamic power supporting system suitable for a high-voltage direct-current power transmission weak receiving end system and a coordination control method thereof. The system comprises a phase modifier, a battery energy storage system, an energy storage bidirectional grid-connected converter and a control module. Through energy storage active power control, energy storage reactive power control, bidirectional grid-connected conversion control and phase modifier excitation control, an energy storage output active power reference value, an energy storage outputreactive power reference value, an energy storage output power actual value and an excitation voltage of the phase modifier are respectively controlled. The system is advantaged in that sufficient active power and reactive power can be quickly provided at the same time, so lowest points of the voltage and the frequency of a receiving-end alternating-current system after commutation failure of a direct-current power transmission system are improved, the recovery process is accelerated, and the requirement of the high-voltage direct-current transmission weak receiving end alternating-current power grid for high-capacity active power and reactive power storage is met.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

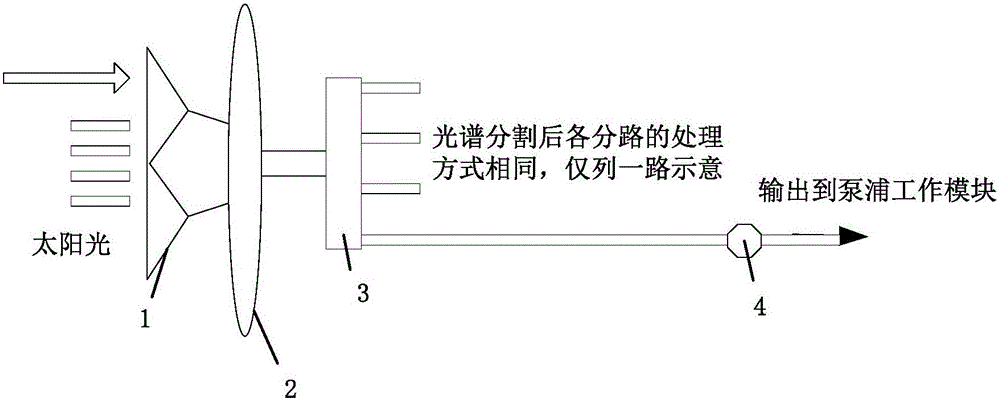

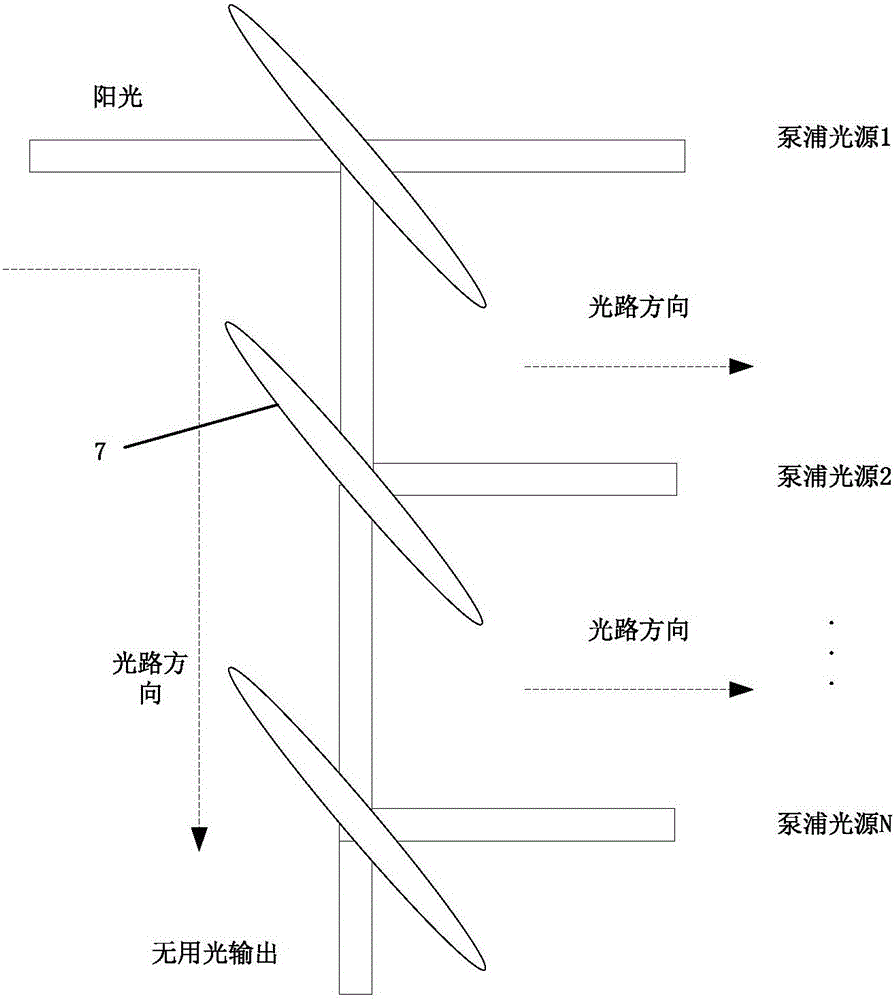

Communication system based on sunshine direct pumped space optical carrier generator

ActiveCN105915282AWith multiple wavelengthsImprove output qualityLine-of-sight transmissionElectromagnetic transmittersCommunications systemCarrier signal

The invention provides a communication system based on a sunshine direct pumped space optical carrier generator. The communication system comprises a sunshine aggregation segmentation module, a pumping work module and a modulation communication module. The sunshine aggregation segmentation module is used for aggregating sunshine energy, and after segmenting the sunshine energy according to different frequency ranges, transmitting the segmented sunshine energy to the pumping work module; the pumping work module is used for converting the segmented sunshine to multipath optical carrier waves; and the modulation communication module is used for modulating communication information to carrier waves generated by the pumping work module, and after shaping light beams, outputting the light beams. According to the system provided by the invention, the sunshine energy is utilized as the only energy source of the multipath optical carrier waves, the requirements for power and light beam indexes of conventional satellite optical communication are satisfied, and at the same time, the heat control problem and the low energy efficiency problem in a conventional electric pump light communication technology are reduced.

Owner:SHANGHAI SATELLITE ENG INST

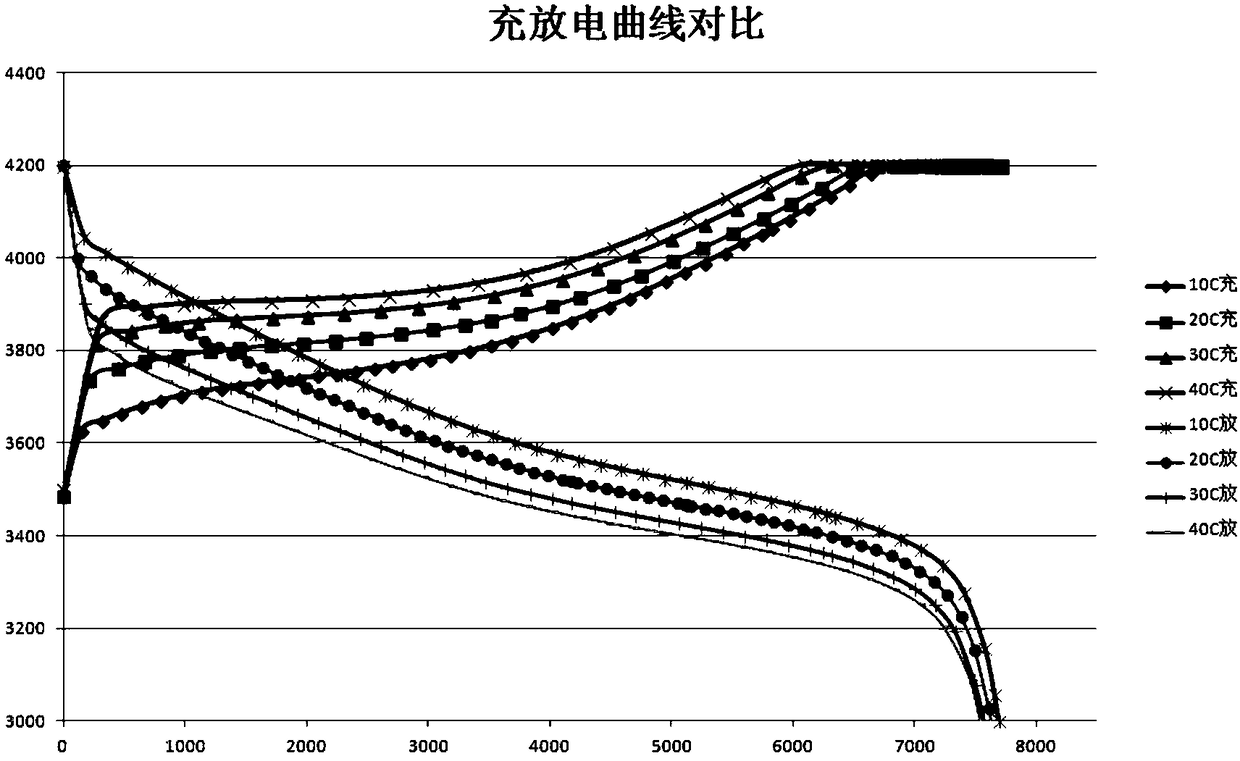

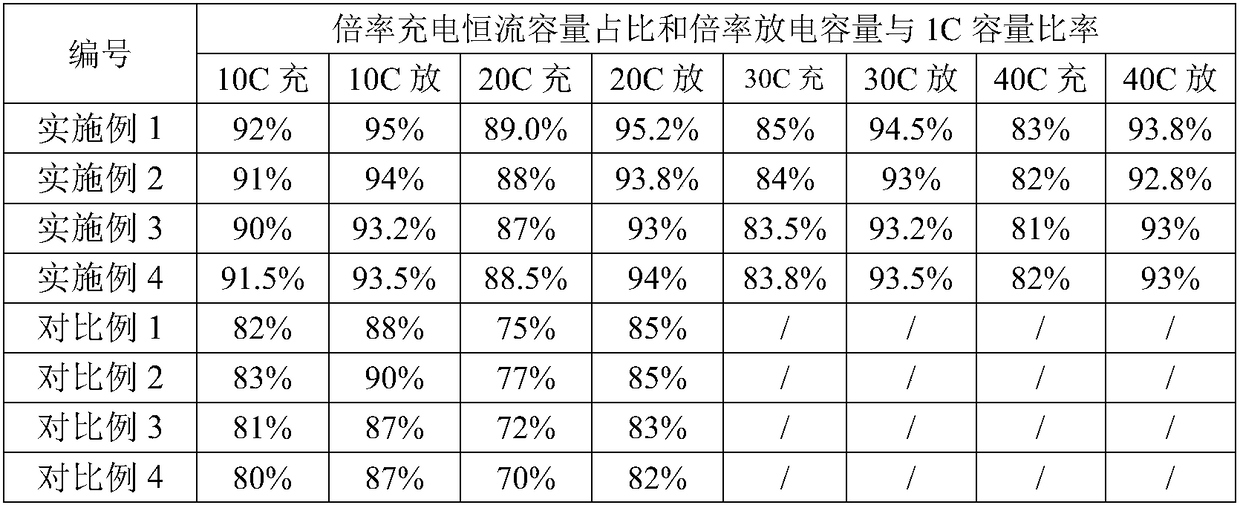

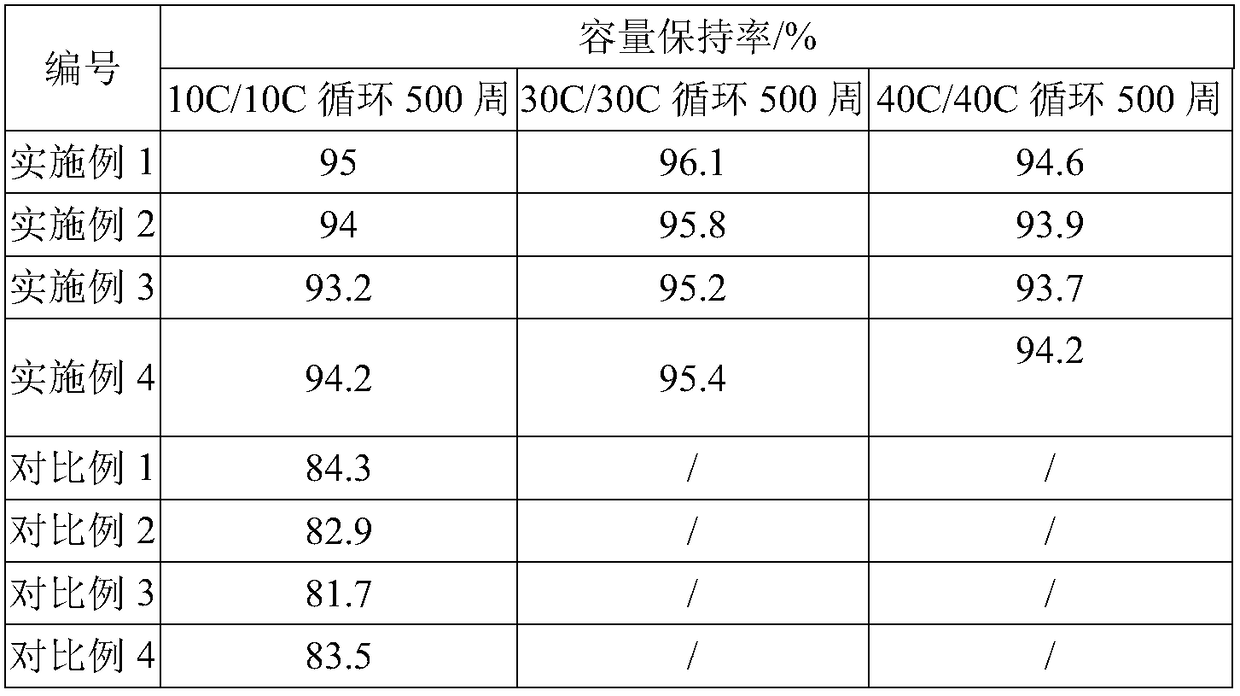

High rate ternary system starting and stopping lithium ion battery and preparation method thereof

InactiveCN108511788AShorten embedding and embedding distanceIncreased diffusion rateFinal product manufactureElectrolyte accumulators manufactureHigh rateElectrical battery

The invention belongs to the technical field of lithium ion batteries, and relates to a high rate ternary system starting and stopping lithium ion battery, comprising a positive plate, a negative plate, a diaphragm, electrolyte and an aluminum-plastic film, wherein the positive plate comprises a positive current collector and a positive mixture layer, wherein the positive current collector is coated with the positive mixture layer; the negative plate comprises a negative current collector and a negative mixture layer, wherein the negative current collector is coated with the negative mixture layer; the coating surface density of the positive mixture layer is 0.96-1.60g / dm<2>, and the coating surface density of the positive mixture layer is 0.5-0.8g / dm<2>. In addition, the invention also provides a preparation method of the high rate ternary system starting and stopping lithium ion battery. Compared with the prior art, the high rate ternary system starting and stopping lithium ion battery has higher-rate charge-discharge property, thus meeting the instantaneous high power output and input requirements of the starting and stopping for the battery.

Owner:SHENZHEN HAIYING TECH

Double-stator variable frequency speed regulation asynchronous motor

InactiveCN104767330AIncrease load capacityMeet the operating environment requirementsDynamo-electric machinesConstant powerEngineering

The invention provides a double-stator variable frequency speed regulation asynchronous motor and solves the problems that a current load motor used for a testbed is large in power and wide in constant power range. The motor is a dual independent coil, namely independent stators and independent rotors, the independent stators and the independent rotors share a motor seat, double overhead draught fans force ventilation and cooling, an ejection wire box structure is used in common, import bearings are adopted, a velocity measurement encoder is installed at the non-transmission end of the motor, and the motor bearings and the coil are each provided with a temperature sensor. According to the motor, by selecting the electromagnetism parameters and mechanical structure of the motor reasonably, the requirements of large power (2 * 1200 kW) and wide constant power range (41.6 - 106 Hz) are satisfied, the load capacity of the motor at a high velocity section is improved, the operating environment requirements of the experimental motor are satisfied, and relevant technological standards of the asynchronous motor are satisfied. The motor has a certain potential market, and by referring to the designing and manufacturing experience of the motor, certain economic benefits can be obtained by applying the experience to other fields.

Owner:CRRC YONGJI ELECTRIC CO LTD

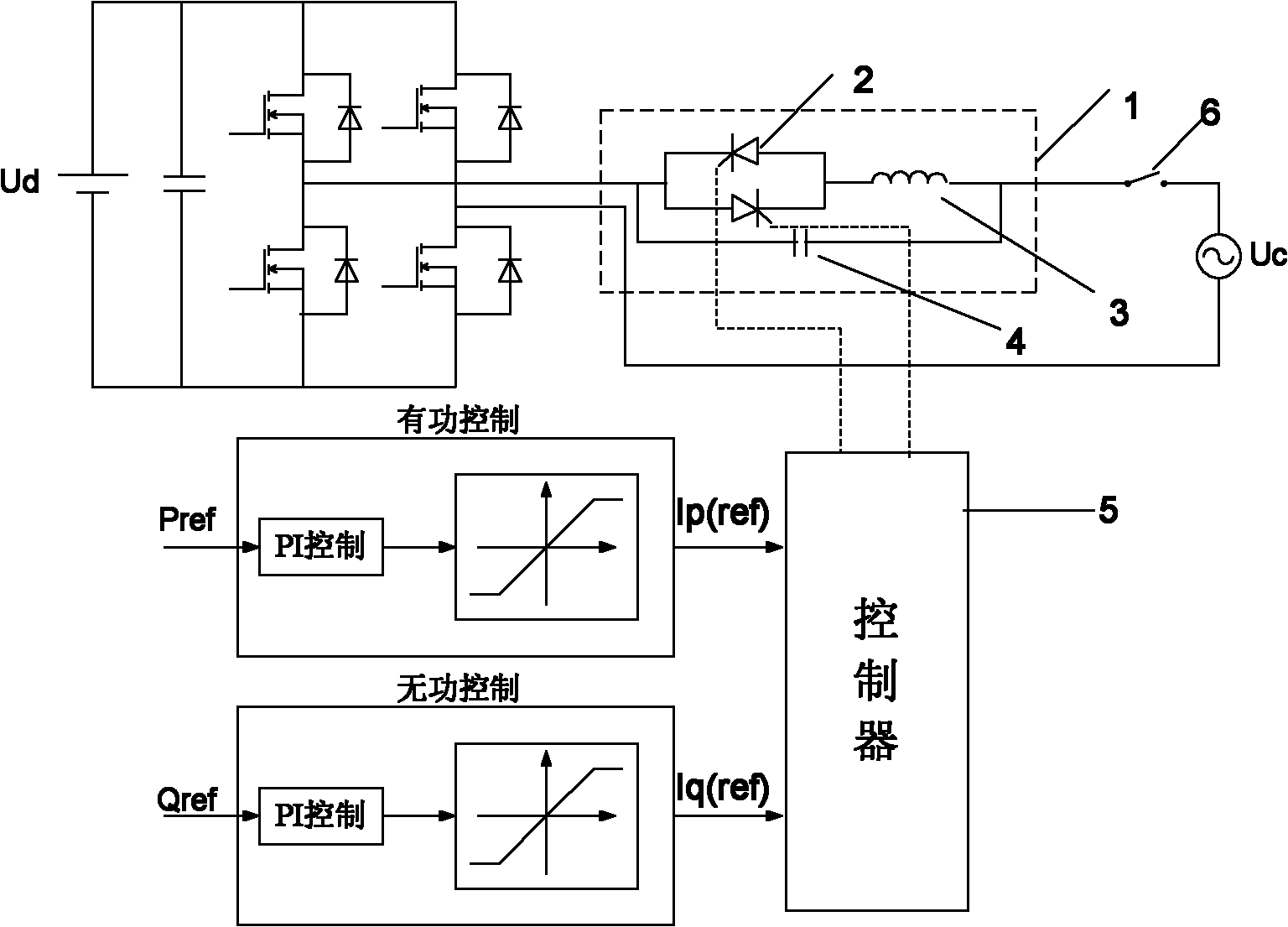

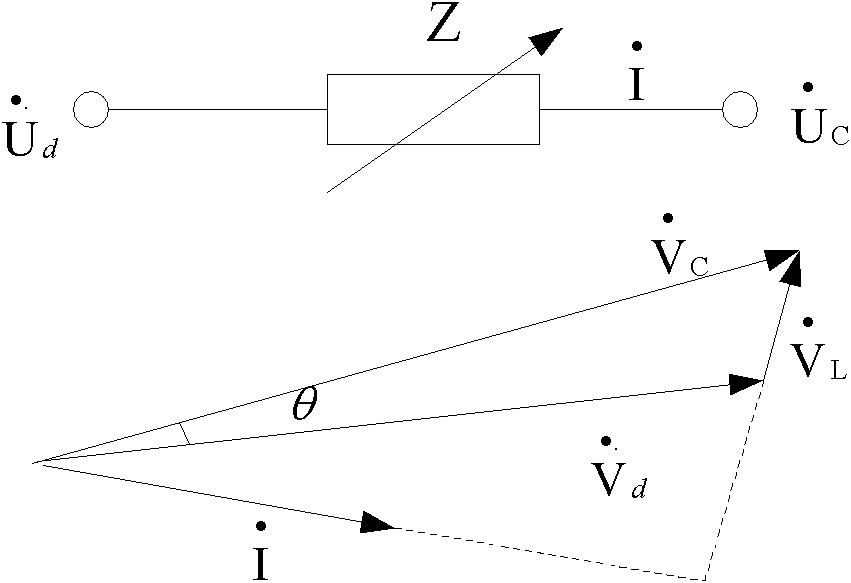

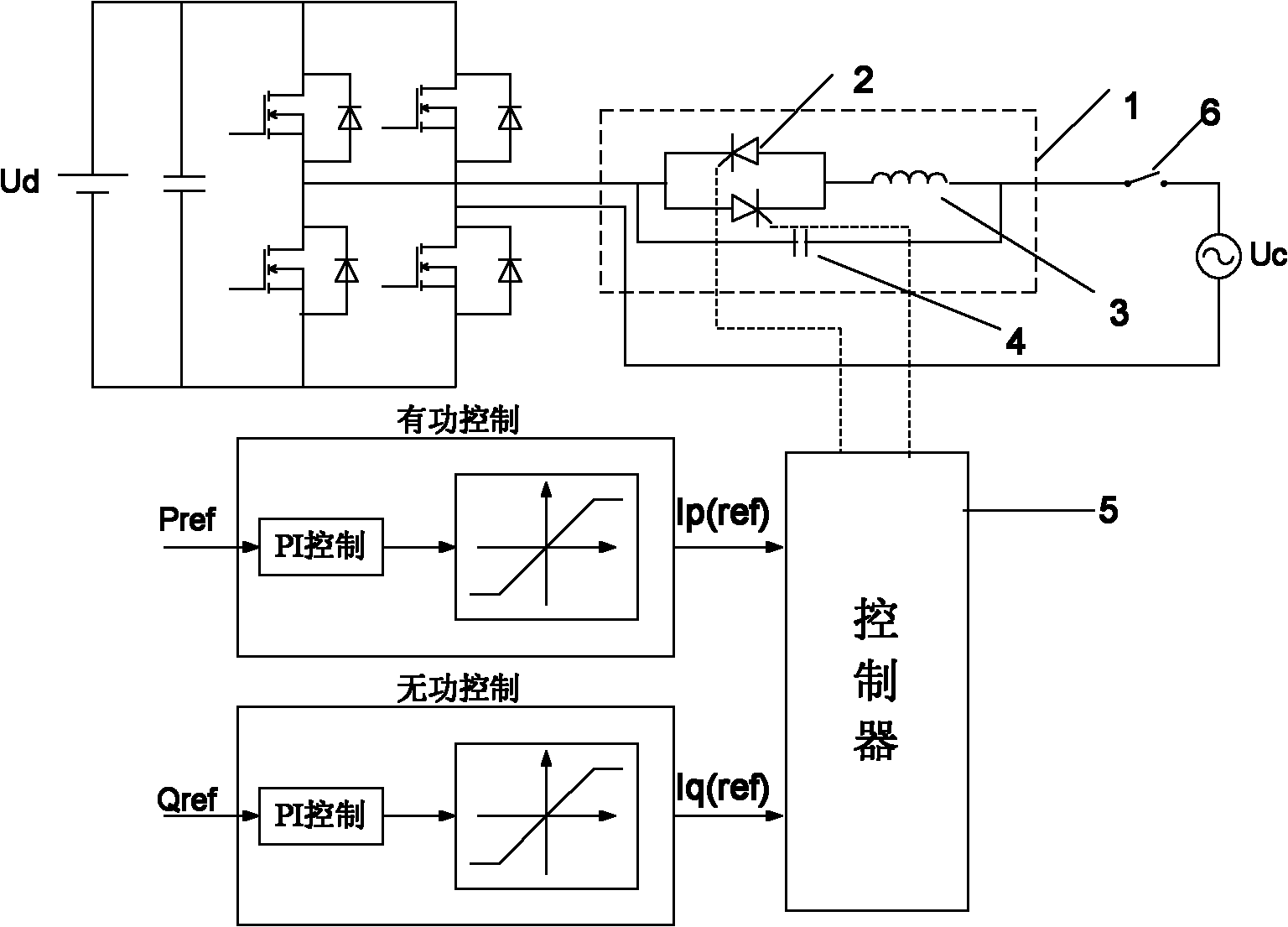

Hosting mode-based distributed power supply synchronizing method and device

ActiveCN102074973AMeet the powerRealize grid connectionSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationThyratronVoltage variation

The invention provides a hosting mode-based distributed power supply synchronizing method and a hosting mode-based distributed power supply synchronizing device. The synchronizing device consists of a thyristor control reactor, a controller and a switch, wherein the thyristor control reactor comprises two thyristors; the controller is connected with the thyristor control reactor through the thyristors; and the switch is connected in series with the thyristor control reactor. The invention overcomes the influence of voltage change due to the fact that the distributed power supply accesses a main network, ensures that the distributed power supply transmits the active power and the passive power to the main network, provides convenience for scheduling operation of the main network, and realizes the synchronization of the distributed power supply.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

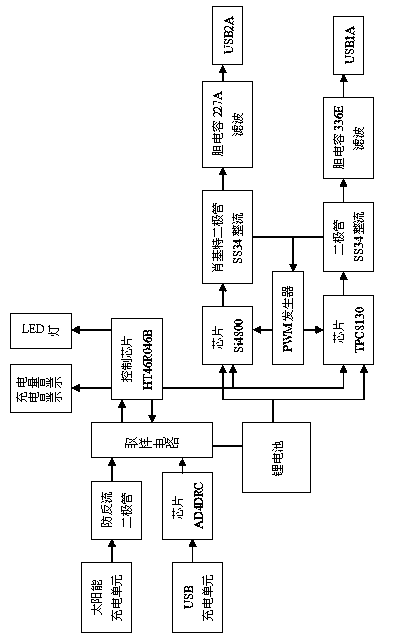

Protection control system of solar energy power bank

InactiveCN103855730AAvoid bulgingAvoid electrical propertiesBatteries circuit arrangementsElectric powerElectricityControl system

The invention provides a protection control system of a solar energy power bank. The system comprises a charging module, a protection control module, a lithium battery and an output module. A sampling circuit provides a simulation sampling value, the simulation sampling value is then sent to a control chip HT46R046B, the control chip HT46R046B reads the data value of each point and then controls an interface, such as a temperature protection critical point value, an electricity quantity indication value, an over-charge value, an over-discharge value and a short circuit electrical value, and LED mode indication and keyboard control are both finished by a program compiled by the control chip HT46R046B. The protection control system of the solar energy power bank can realize the over-current charge, over-charge and over-discharge protection, standard charge program control, output short circuit protection, and over-current or over-voltage discharge protection of the solar energy power bank. Besides, a battery bulge easily caused by overheat due to over 50-degree working temperature of the lithium battery is avoided, and at the same time, difficult battery capacity recovery or discarding because the solar energy power bank is lower than a termination voltage for a long time can be avoided.

Owner:江苏天宇光伏科技有限公司

Efficient energy-saving amorphous iron core transformer

InactiveCN102623150AHigh frequencyIncrease powerTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerFuel tank

The invention relates to an efficient energy-saving amorphous iron core transformer, which comprises an iron core assembly, wherein a primary winding and a secondary winding are wound in sequence on the iron core assembly. The efficient energy-saving amorphous iron core transformer is characterized in that: an epoxy strut angle is arranged between the iron core assembly and the primary winding, so that a primary oil channel is formed; an epoxy strut angle is arranged between the primary winding and the secondary winding, so that a primary oil channel is formed; the iron core assembly comprises an amorphous iron core; the amorphous iron core is arranged in a protective box; one side of the protective box is provided with an epoxy cover plate; and the protective box and the epoxy cover plate are encircled into an enclosed space for accommodating the amorphous iron core. In the efficient energy-saving amorphous iron core transformer, the protective box is arranged outside the amorphous iron core, so that the phenomenon of high-pressure fire striking caused by floating of broken pieces of a broken amorphous iron core in an oil tank is prevented; and these problems are solved by using a method for forming oil channels between the iron core assembly and the primary winding of the transformer as well as between the primary winding and the secondary winding and preventing a solenoid from being impregnated.

Owner:无锡希恩电气有限公司

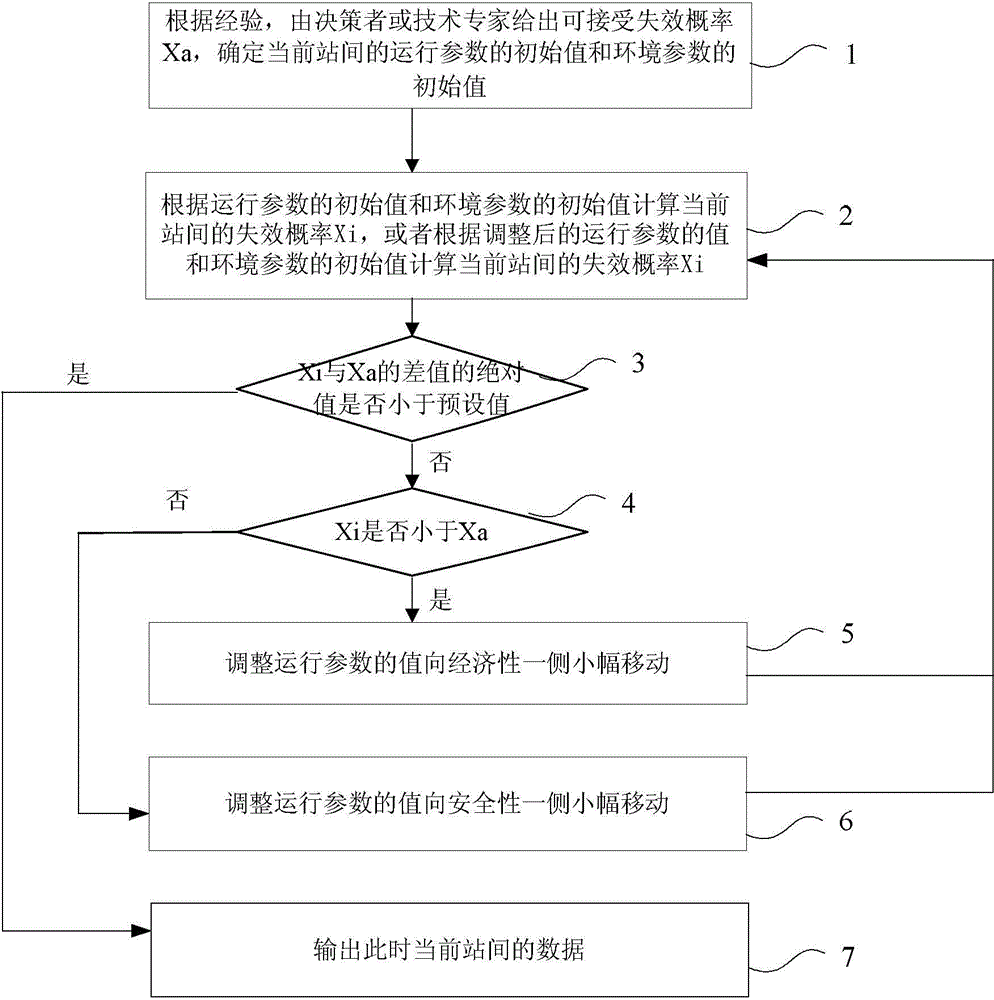

Method and device for determining running parameters of waxy crude oil pipeline

ActiveCN103953854ASatisfy operational safetyReduced operational safetyPipeline systemsEngineeringHeating furnace

The embodiment of the invention provides a method and a device for determining running parameters of a waxy crude oil pipeline. The method comprises the following steps of presetting the standard failure probability of a pipeline between heating stations, wherein the pipe condensing accident occurrence probability of the pipeline between the heating stations during running is less than a first preset value through the standard failure probability, and the power of a heating furnace in each heating station is less than a second preset value; determining the initial value of the running parameter and the initial value of the environment parameter of the pipeline between the heating stations; according to the determined initial value of the running parameter and the initial value of the environment parameter, calculating the initial failure probability of the pipeline between the heating stations; according to the size relationship between the standard failure probability and the initial failure probability of the pipeline between the heating stations, adjusting the value of the running parameter of the pipeline between the heating stations, wherein the absolute value of the difference between the standard failure probability and the failure probability which is calculated according to the adjusted value of the running parameter and the initial value of the environment parameter is less than a third preset value. By adopting the method and the device disclosed by the embodiment of the invention, the running safety and economy of the whole pipeline can be balanced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

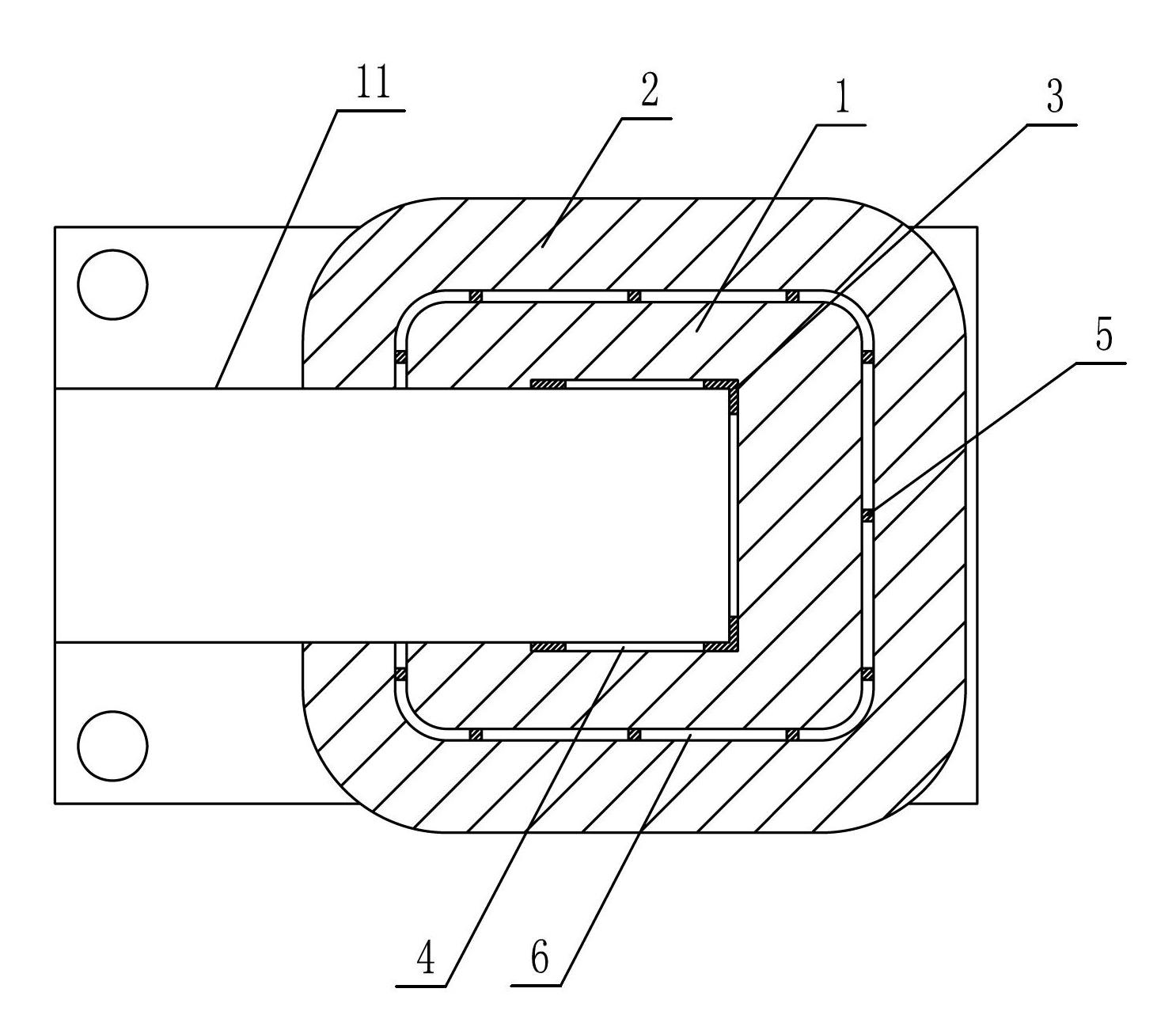

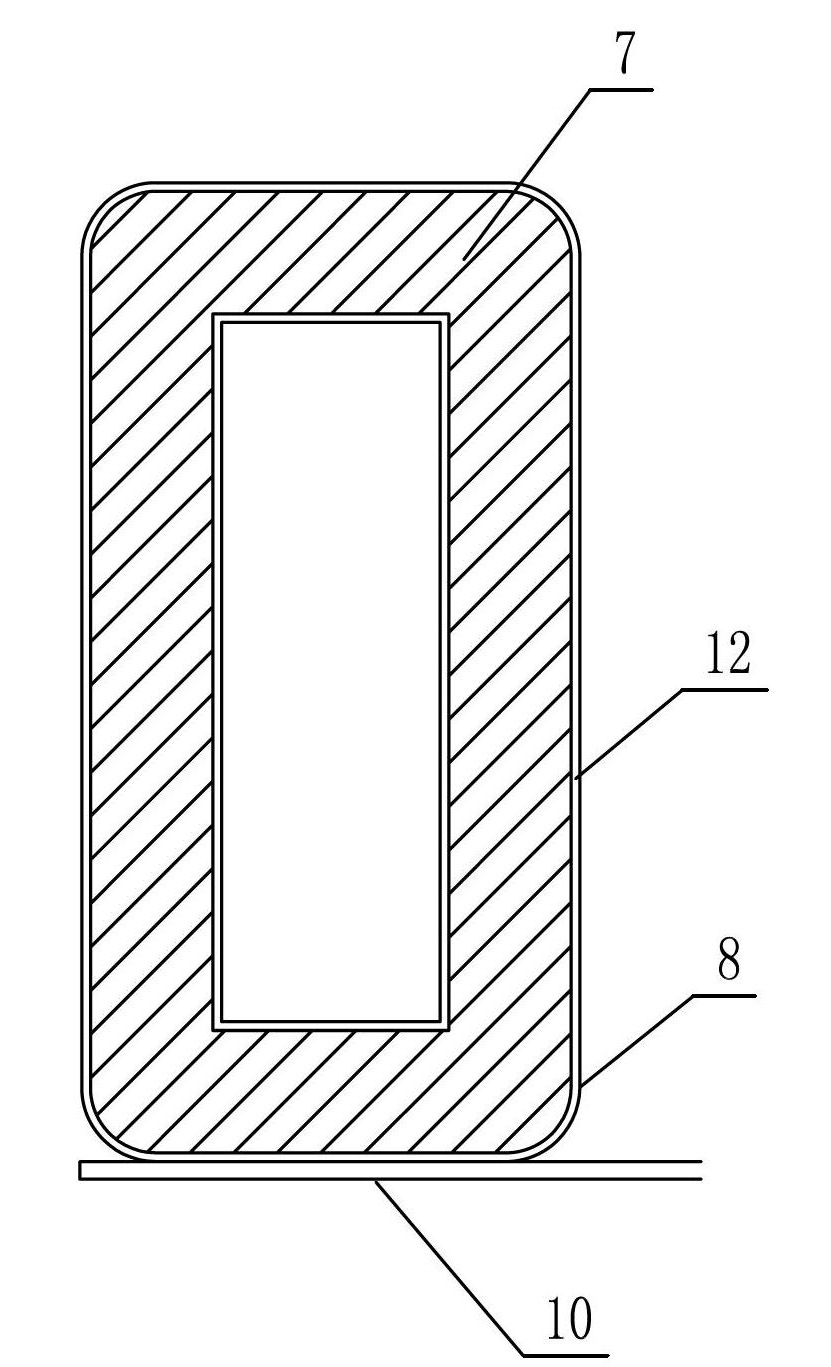

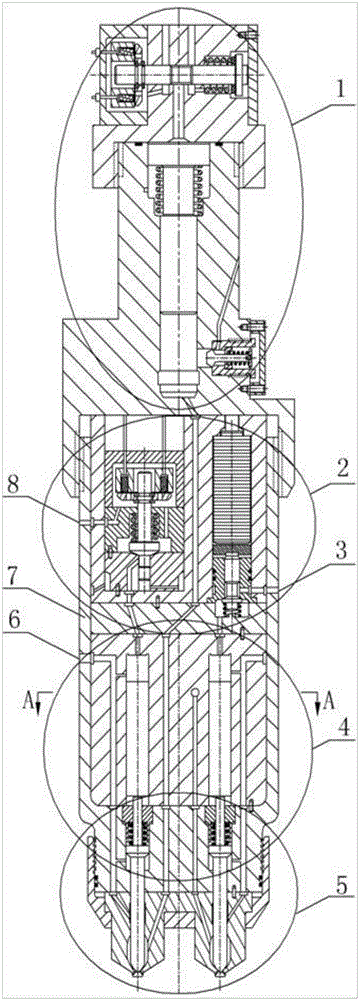

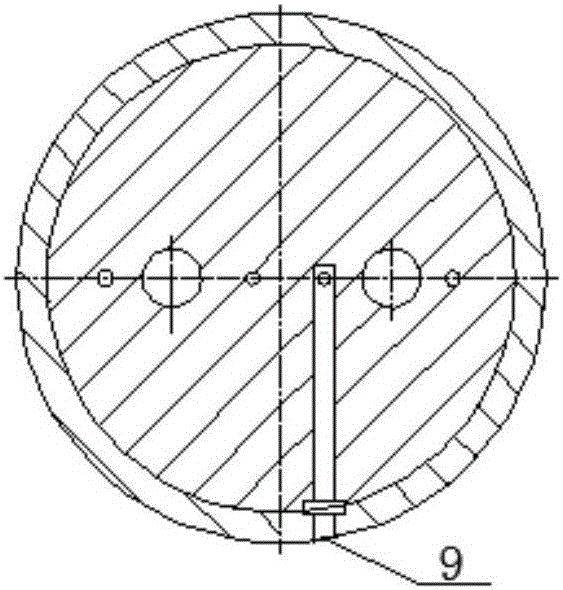

Combined piezoelectric and pressurizing electromagnetic fuel gas injection device

ActiveCN105756811AAdjustable maximum liftMeet the control precision requirementsInternal combustion piston enginesFuel supply apparatusElectricityWork cycle

The invention provides a combined piezoelectric and pressurizing electromagnetic fuel gas injection device which comprises a pressurizing part, an electromagnetic-piezoelectric control part, a double-piston part, a double needle valve nozzle part and an injection device shell.Electromagnetic valves and a piezoelectric control valve are adopted to control the fuel gas injection process of two nozzles respectively; the nozzle controlled by the electromagnetic valves can be switched between a pressurizing mode and a non-pressurizing mode flexibly, adjustable gas injection pressure and gas injection quantity of the gas injection device can be achieved in a work cycle by adjusting the work state and work order of the pressurizing electromagnetic valve, the nozzle electromagnetic valve and the piezoelectric control valve, and the power requirements of an engine under different working conditions and series engine power requirements are met.A seal band is designed between each needle valve and a corresponding needle valve seat, part of control oil is introduced to the seal bands through an oil duct to seal fuel gas, leakage of fuel gas can be effectively prevented, meanwhile control oil in a control cavity and sealing oil at the needle valves are the same, and static leakage of the fuel oil in the control cavity and the sealing bands can be effectively prevented.

Owner:HARBIN ENG UNIV

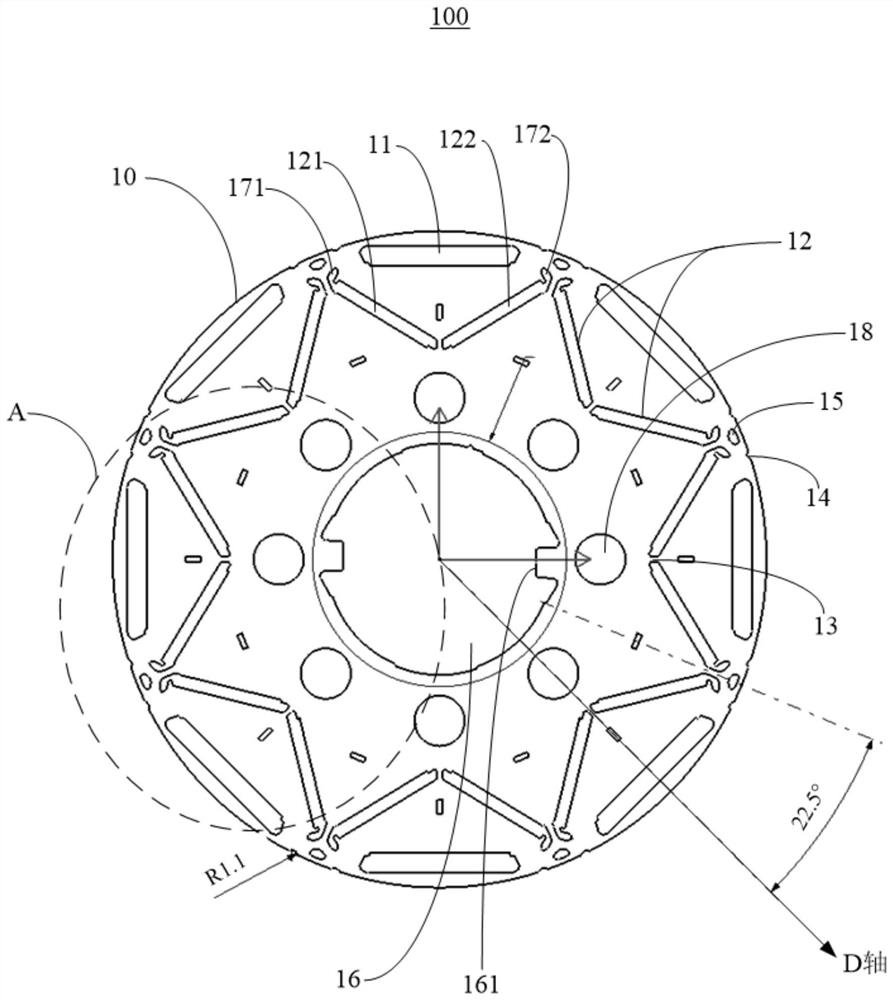

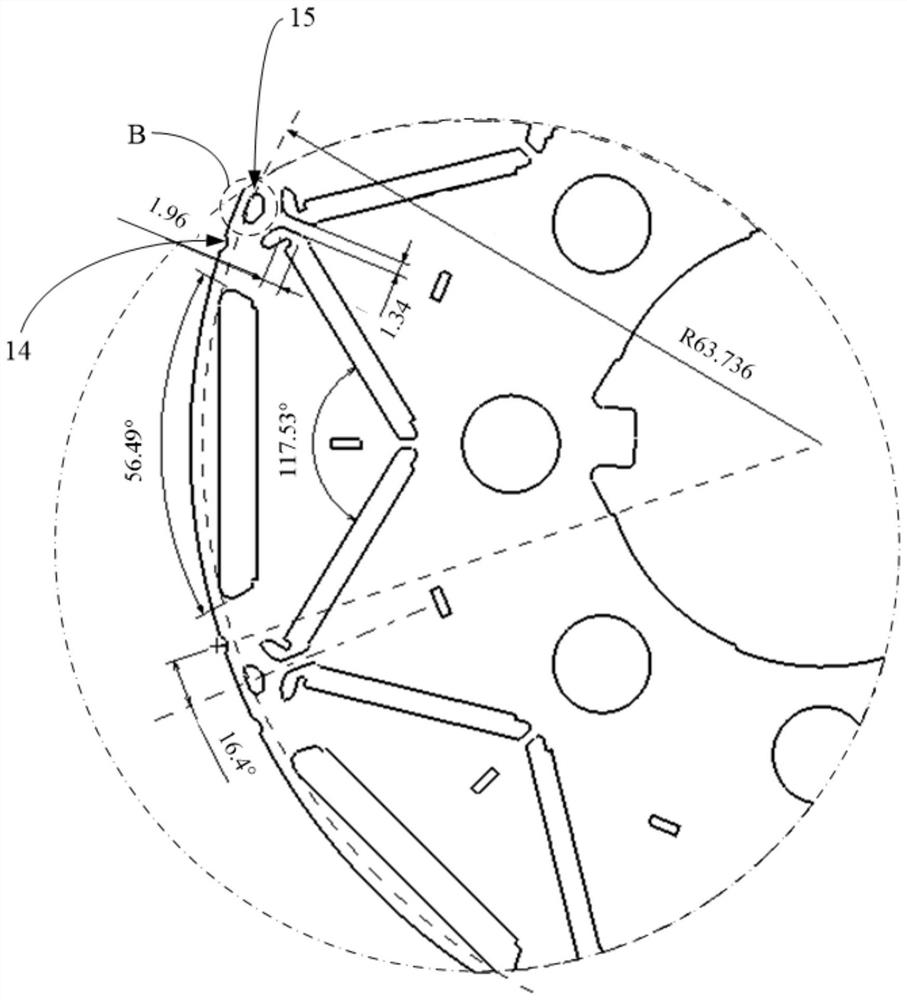

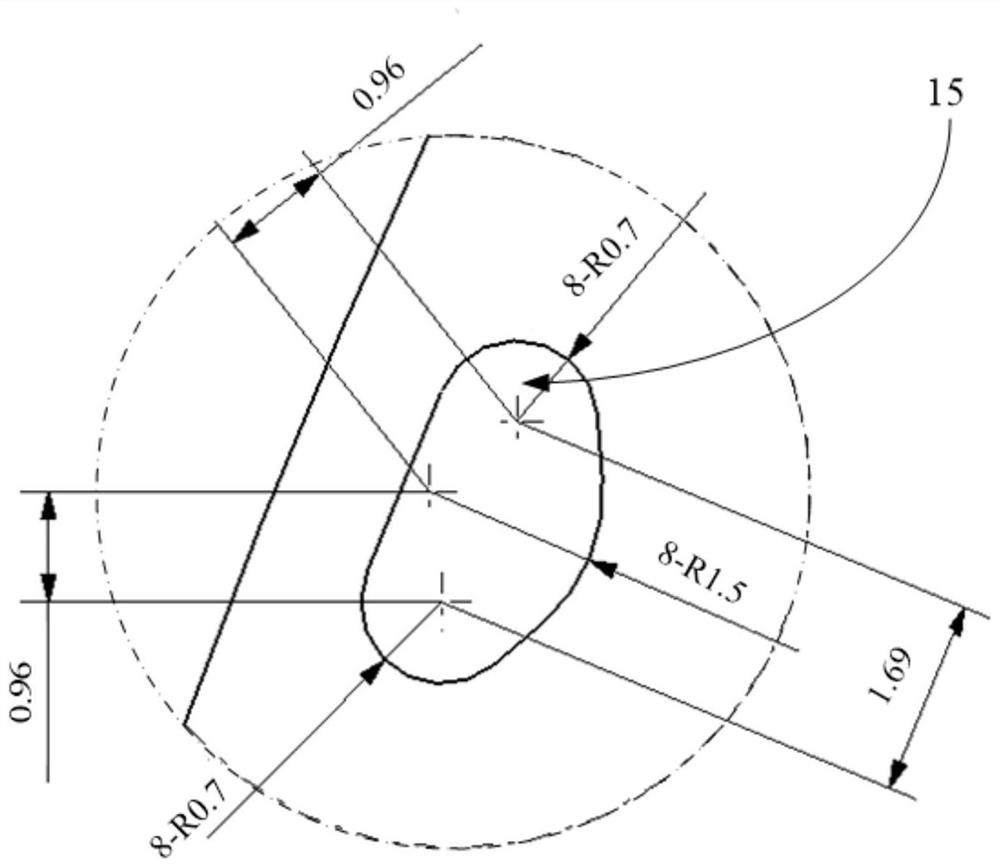

Motor rotor punching sheet and motor rotor assembly system

InactiveCN111654133AHigh strengthSolve the strength problemMagnetic circuit rotating partsElectric machineClassical mechanics

The invention discloses a motor rotor punching sheet and a motor rotor assembly system. The motor rotor punching sheet comprises a rotor punching sheet body, wherein a plurality of groups of magneticsteel grooves, a plurality of groups of auxiliary grooves and a plurality of harmonic wave removing holes are formed in the rotor punching sheet body, the plurality of groups of magnetic steel groovesare arranged at intervals along the circumferential direction of the rotor punching sheet body, each group of magnetic steel grooves comprises a first magnetic steel groove and a second magnetic steel groove, the first magnetic steel groove and the second magnetic steel groove are sequentially arranged at intervals from the edge to the center of the rotor punching sheet body, the second magneticsteel groove comprises a first section and a second section, and a magnetic bridge is arranged between the first section and the second section; the plurality of groups of auxiliary grooves are arranged corresponding to the plurality of groups of magnetic steel grooves, and each group of auxiliary grooves comprises two open grooves which are correspondingly positioned at two ends of one first magnetic steel groove; and the plurality of harmonic wave removing holes are correspondingly arranged between every two adjacent first magnetic steel grooves. The motor rotor punching sheet solves the problems of weak strength and high risk caused by the temperature rise of the motor rotor and the reduction of the yield strength of the rotor punching sheet in the continuous height rotation process ofthe motor.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Photovoltaic millimeter wave power synthesis circuit

InactiveCN102522958ALower equivalent junction capacitanceMeet the powerHigh frequency amplifiersPower amplifiersComputer modulePhotoelectric conversion

The invention discloses a photovoltaic millimeter wave power synthesis circuit, which comprises a first load, a second load, a micro-strip line group and photoelectric conversion modules, wherein the micro-strip line group is formed by sequentially connecting N micro-strip lines in series; one end of the micro-strip group is connected to one end of the first load, while the other end of the micro-strip line group is connected with one end of the second load; both the other end of the first load and the other end of the second load are grounded; a common connection end of every two adjacent micro-strip lines in the micro-strip line group is connected with one photoelectric conversion module; each photoelectric conversion module is grounded; and each photoelectric conversion module is formed by sequentially connecting M photoelectric conversion units in series, wherein the N is greater than or equal to 3, and the M is greater than or equal to 2. The photovoltaic millimeter wave power synthesis circuit has the advantages that not only photoelectric conversion output power is increased but also output cutoff frequency is increased, so that work bandwidth is widened.

Owner:NINGBO UNIV

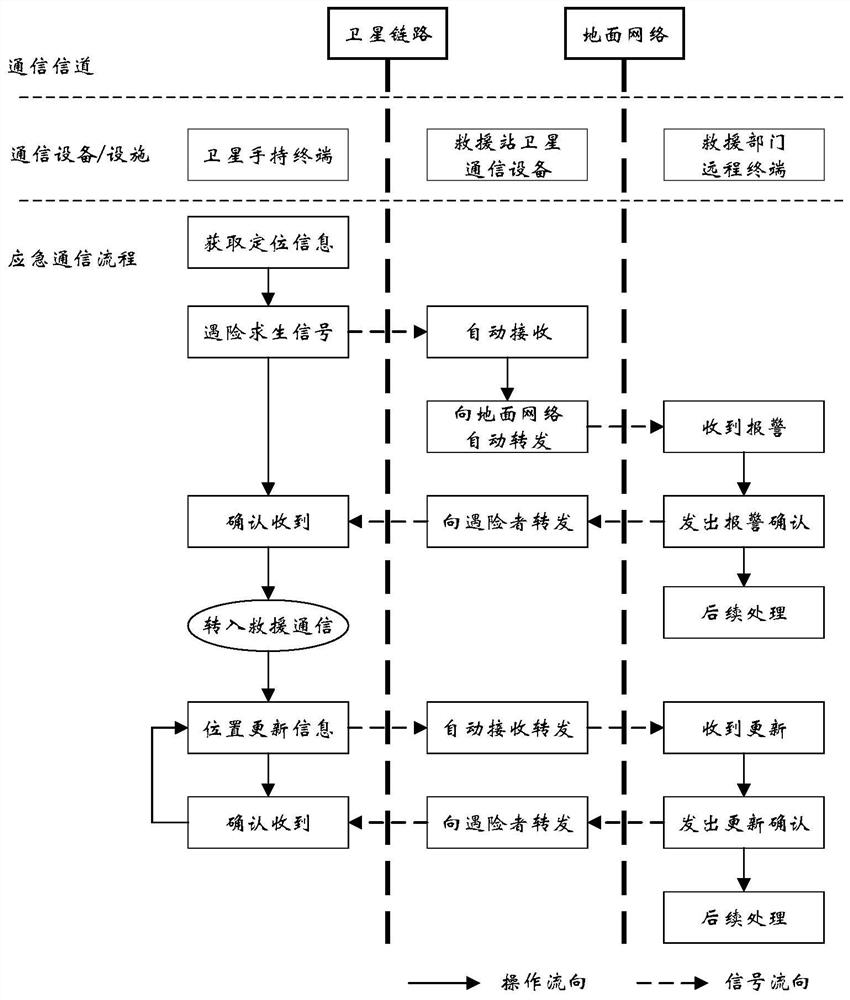

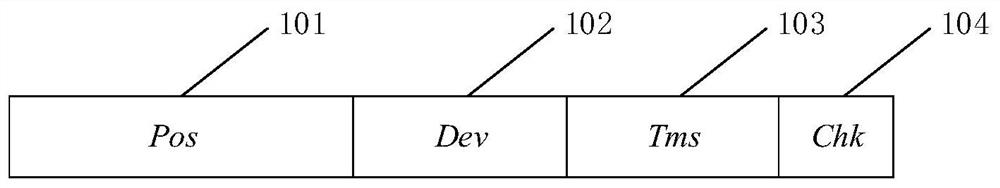

Emergency lifesaving communication method based on multi-beam communication satellite

ActiveCN112865854AEasy transferPromote rapid developmentRadio transmissionAlarmsAlarm messageTelecommunications

The invention discloses an emergency lifesaving communication method based on a multi-beam communication satellite. The emergency lifesaving communication method comprises the specific steps that a person in distress obtains self positioning information through a satellite handheld terminal carried by the person; the satellite handheld terminal carried by the person in distress forms distress alarm information and sends a distress survival signal; the rescue station satellite communication equipment automatically forwards the signal to a remote terminal of a rescue department; the rescue department forms alarm confirmation information and sends the alarm confirmation information to the rescue station satellite communication equipment through the remote terminal; and after receiving the alarm confirmation information, the rescue station satellite communication equipment automatically forwards the alarm confirmation information to the satellite handheld terminal of the person in distress, and the two parties transfer to rescue communication. Special channel resources are reserved for emergency communication, rapid transmission of distress survival messages can be effectively guaranteed, alarm signals are processed in an automatic guarding mode, the processing and forwarding speed is guaranteed, and it is guaranteed that long-distance alarm, positioning and communication can be rapidly carried out.

Owner:军事科学院系统工程研究院网络信息研究所

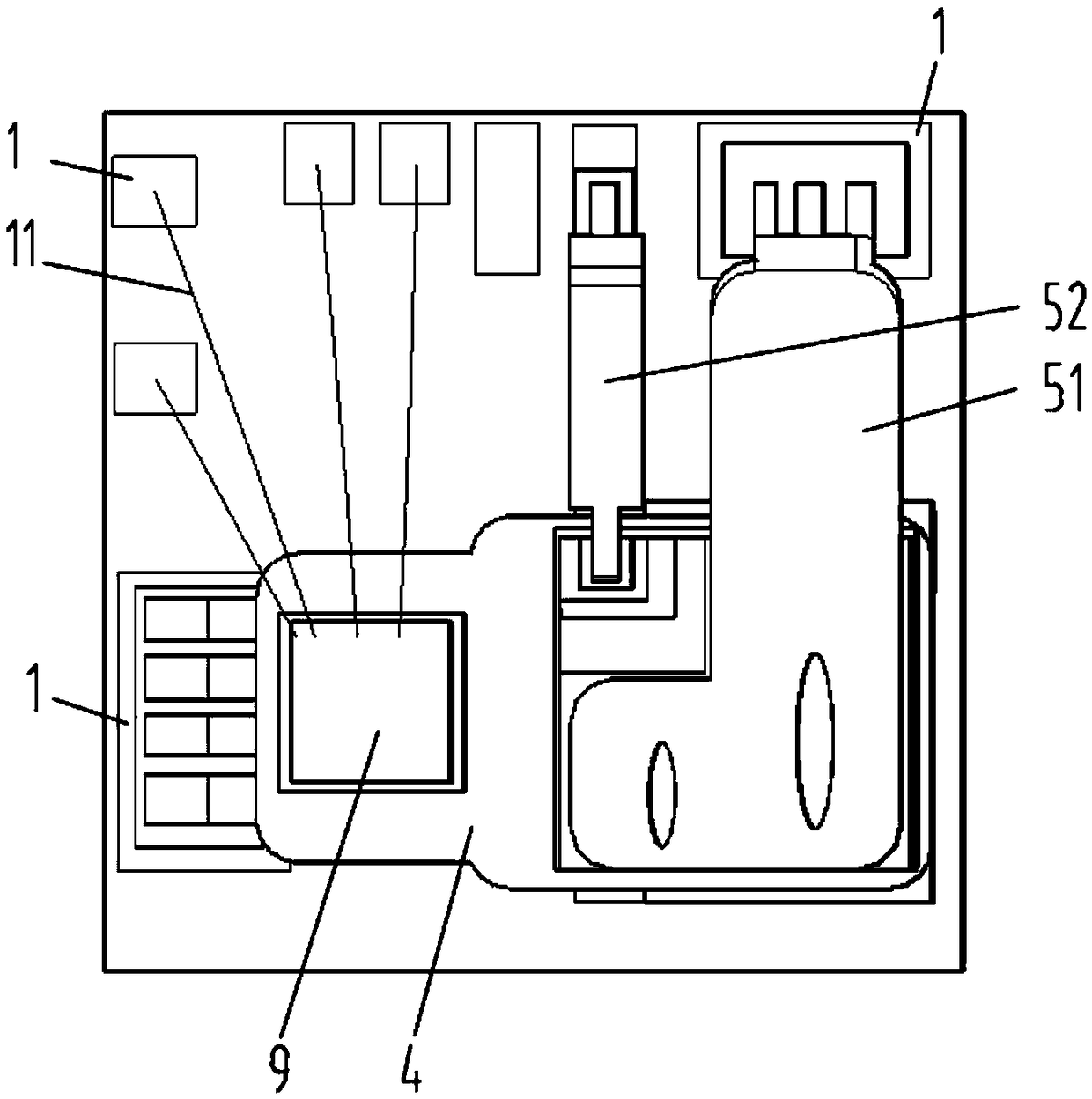

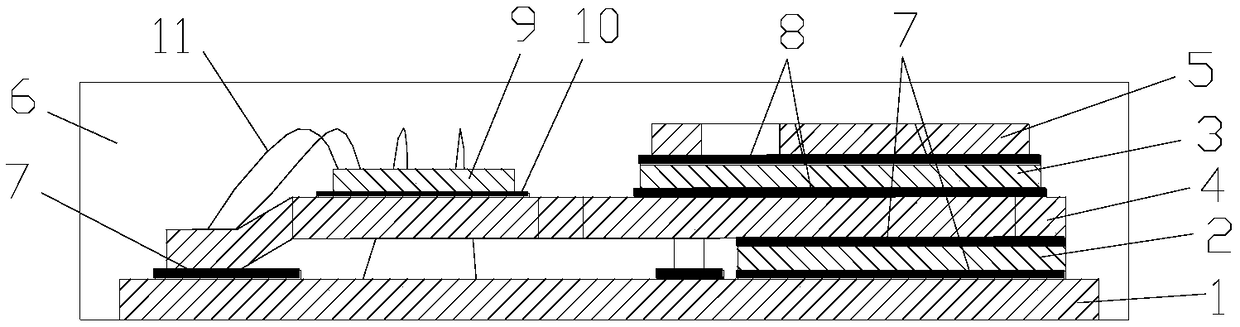

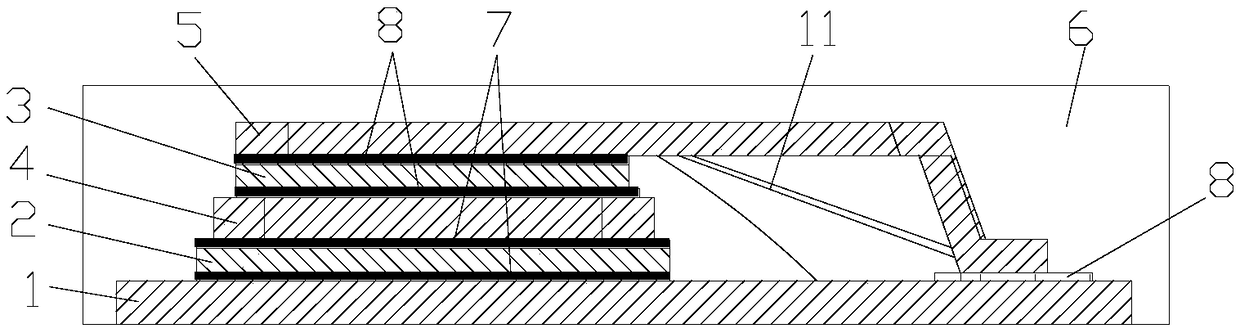

Copper clip stacking chip structure and packaging method thereof

PendingCN109494205ASmall sizeMeet the powerSemiconductor/solid-state device detailsSolid-state devicesMelt temperaturePower flow

The invention relates to a copper clip stacking chip structure and a packaging method thereof. The copper clip stacking chip structure comprises a lead frame, a first chip, a second chip, a first copper clip, a second copper clip and a molding material. The first chip is fixed to the lead frame by a first welding material; the first copper clip is fixed on the lead frame and / or the first chip by the first welding material; the second chip is fixed to the first copper clip by a second welding material; and the second copper clip is fixed on the second chip by the second welding material. The solder melting temperature of the first welding material is greater than that of the second welding material. According to the invention, the copper clip connection mode is applied to the stacked chip;different stacked chips are connected by stacked copper clips to realize connection of the stacked chips and the lead frame, so that the requirements of high power and high current are met. The copperclip stacking chip structure has advantages of low power consumption and high heat dissipation efficiency. The size of the packaged product is reduced and the product output and yield are improved.

Owner:GUANGDONG CHIPPACKING TECH

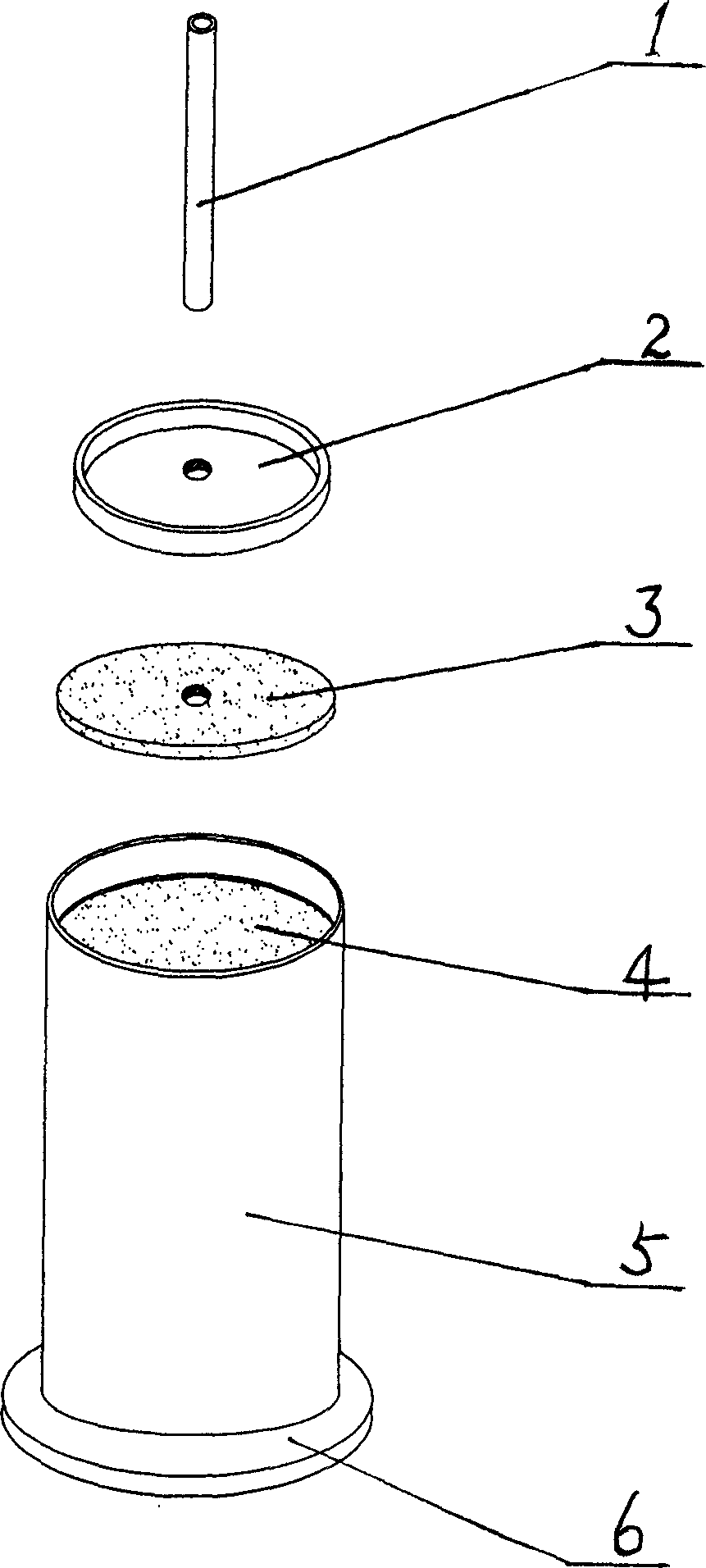

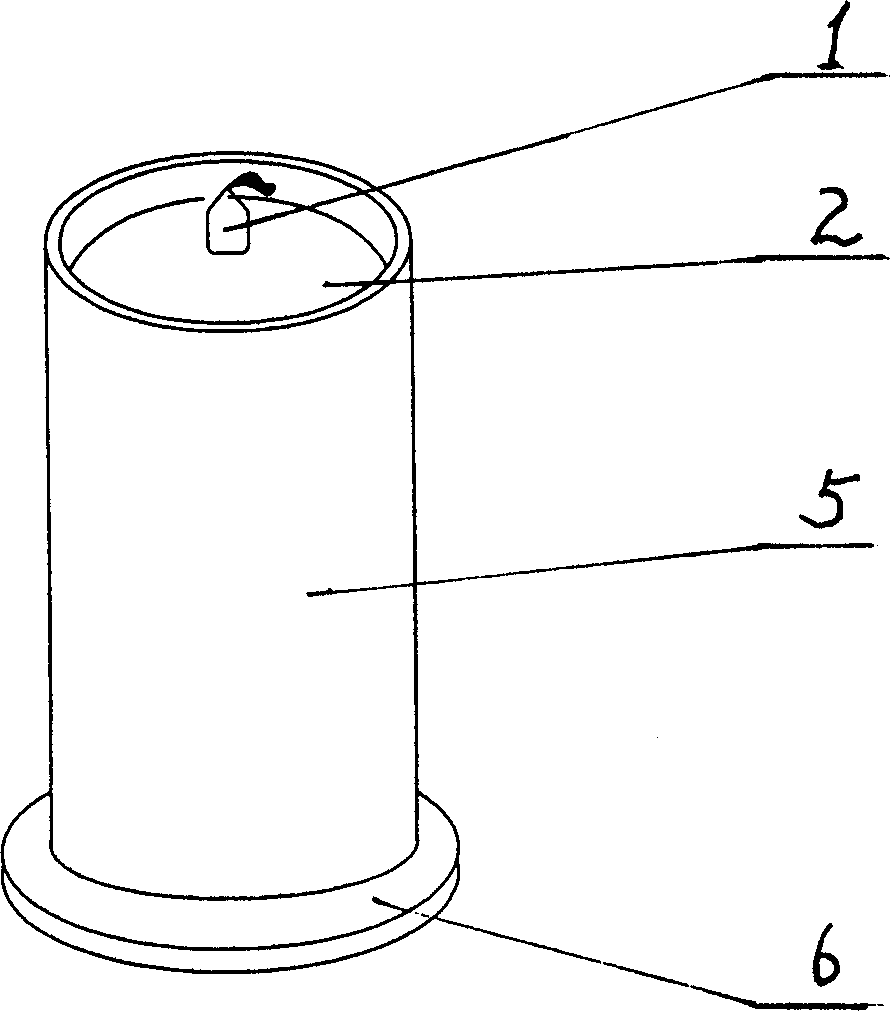

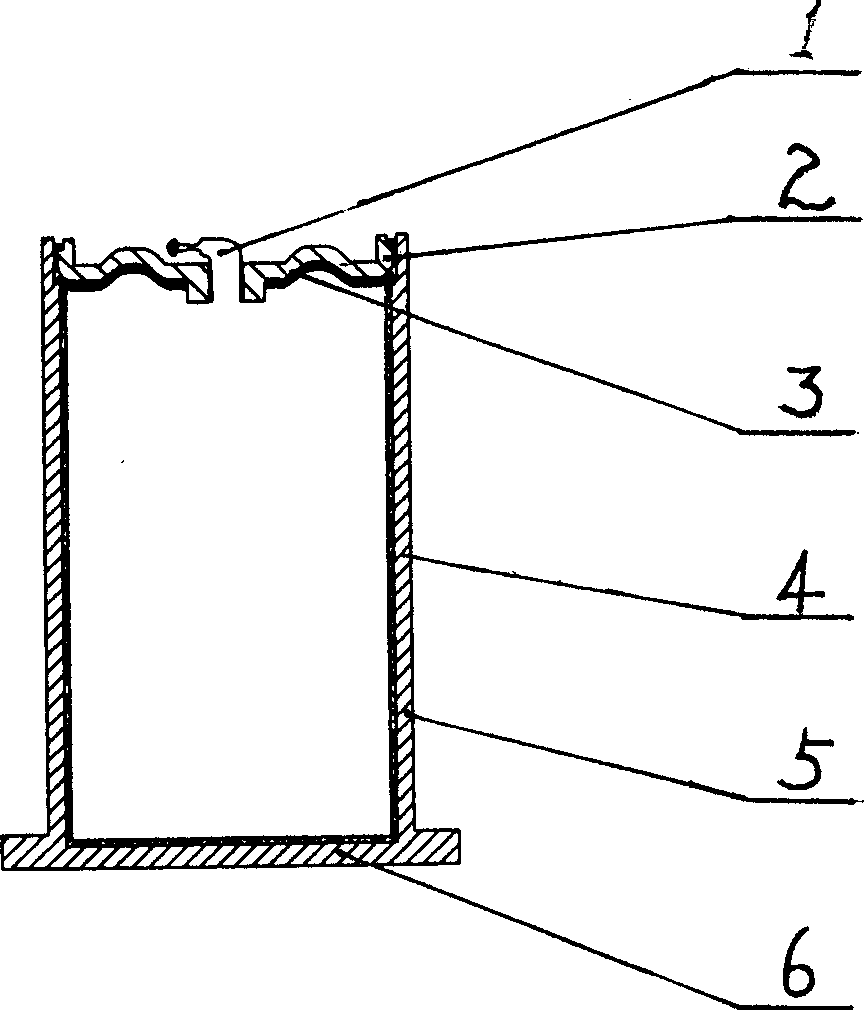

Cylindrical heat pipe

InactiveCN1731065ASmall fluctuationUniform temperature up and downIndirect heat exchangersWorking fluidEvaporation

The columnar heat pipe has sealed vacuum cavity comprising gas exhaust pipe, top cover, tube and bottom board; and has bottom board below the tube, step in the upper end of the tube, capillary cover mounted in the step, top cover on the capillary cover, sealed gas exhaust pipe on the top cover, sintered porous capillary layer in the inner wall of the tube and the inner surface of the bottom board to form work liquid circulating passage together with the capillary cover and work liquid adsorbed to the sintered layer and the capillary cover. The present invention has the beneficial effects caused by the phase change heat transfer of the evaporation and condesation of work fluid inside the columnar heat pipe, including fast heat transfer rate, great heat transfer capacity, homogeneous temperature, high stability, etc.

Owner:嘉善华昇电子热传科技有限公司

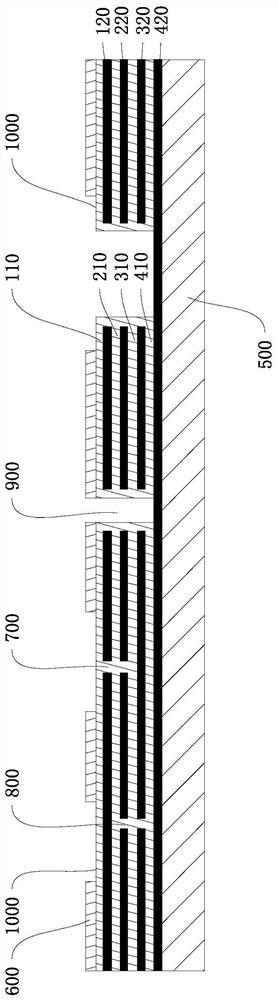

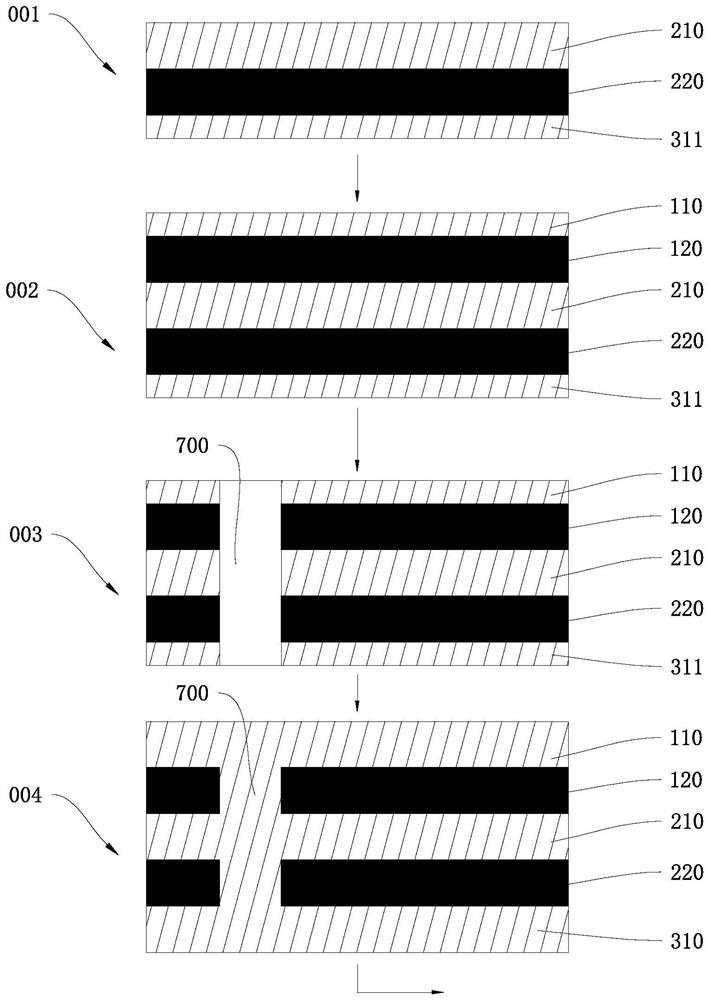

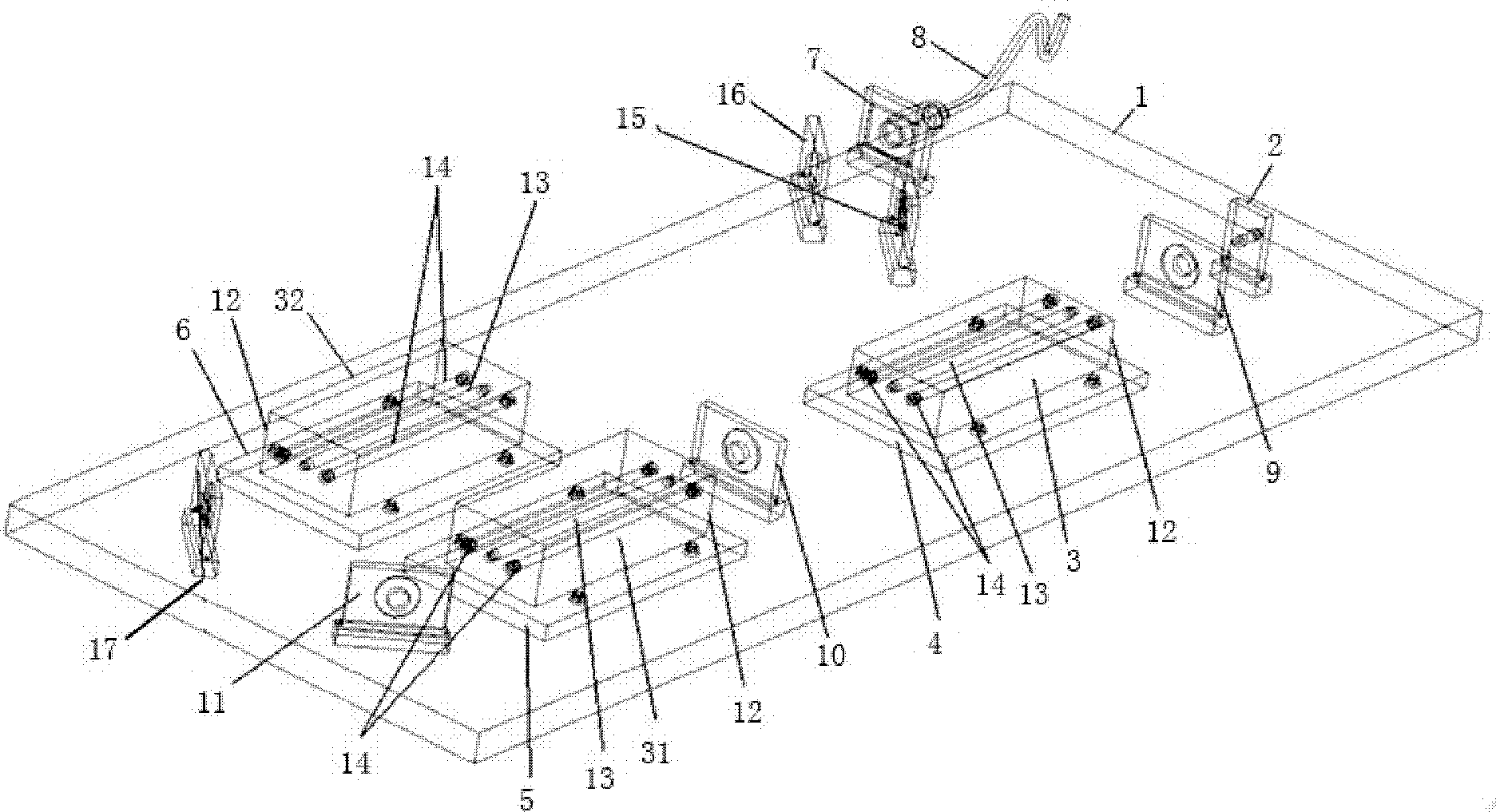

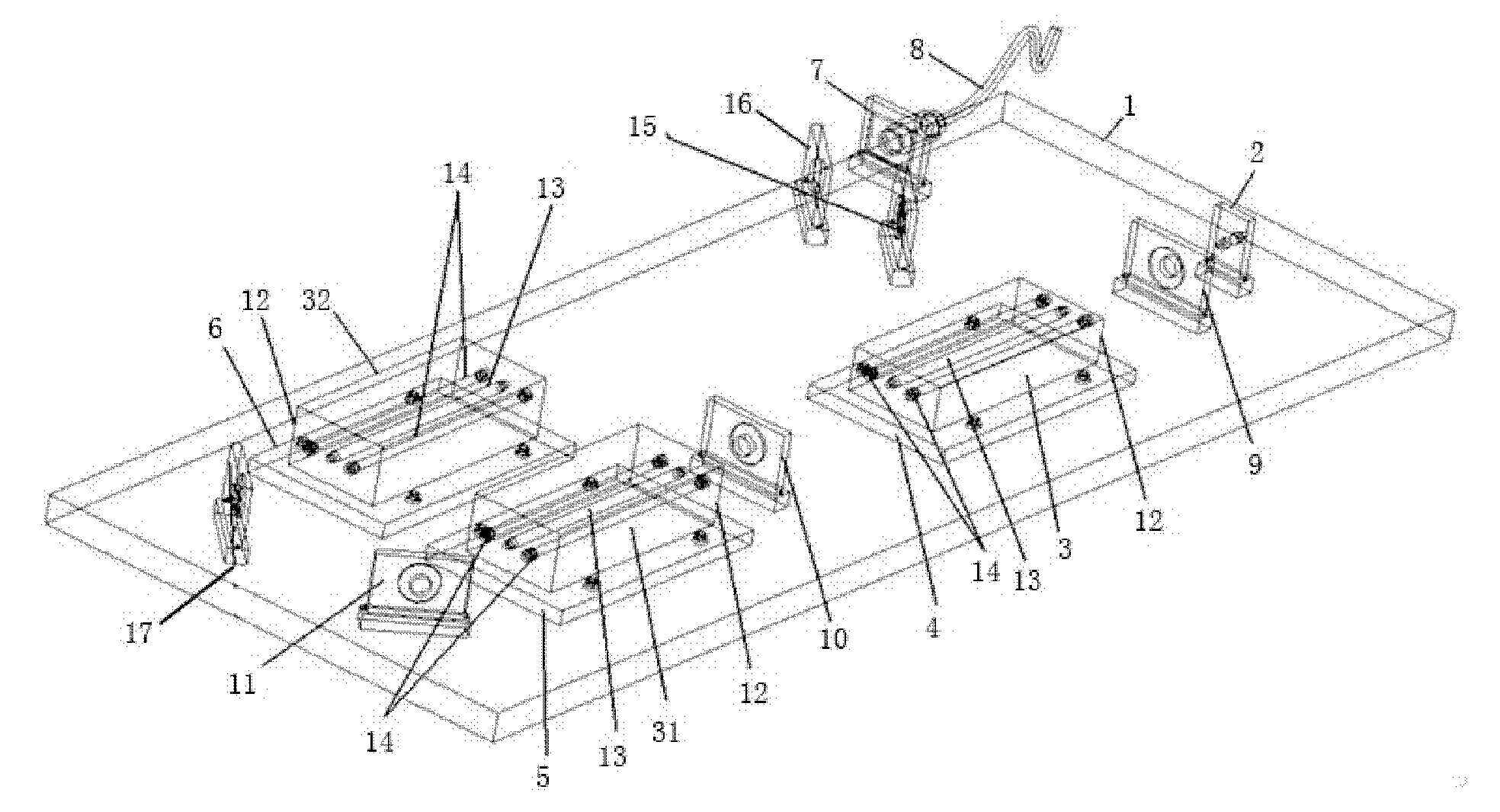

Manufacturing process of heat-conducting circuit board

ActiveCN113286452AImprove thermal conductivityImprove featuresMultilayer circuit manufacturePrinted element electric connection formationThermodynamicsHemt circuits

In order to solve the problem of poor heat conduction capability of a circuit board in the field of printed circuits, the invention provides a manufacturing process of a heat-conducting circuit board. The process comprises the steps of first pressing, first processing, second pressing, first drilling, first electroless plating copper thickening, second processing, third pressing, second drilling, second electroless plating copper thickening, third processing and fourth pressing. And finally, the heat-conducting circuit board with a nine-layer structure including a first copper foil layer, a first insulating layer, a second copper foil layer, a second insulating layer, a third copper foil layer, a third insulating layer, a fourth copper foil layer, a fourth insulating layer and an aluminum base layer is formed. According to the manufacturing process of the heat-conducting circuit board, the heat-conducting circuit board is formed by laminating the multiple layers of heat-conducting resin and the aluminum-based material, heat generated by long-time work of equipment can be quickly transferred, and the heat-conducting capacity is good; and multiple layers are electrically connected through a first heat conduction hole and a second conduction hole after being mixed and pressed, so that complex circuit wiring can be accommodated.

Owner:ZHUHAI KINGROAD ELECTRONICS

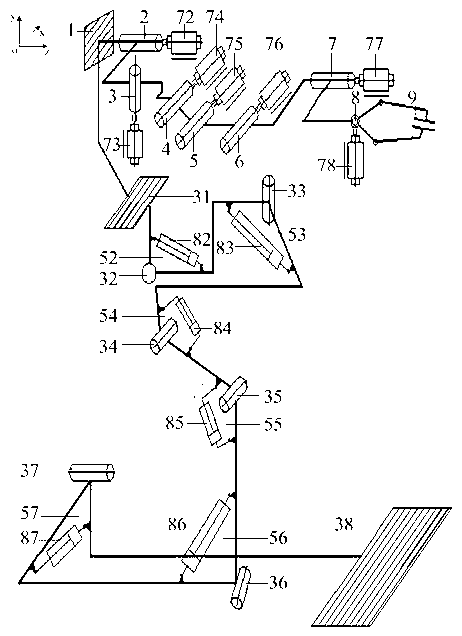

Kilowatt-level high power pulse Nd:YAG (neodymium-neodymium aluminum garnet) laser with one-level resonance and two-level amplification

The invention discloses a kilowatt-level high power pulse Nd:YAG (neodymium-neodymium aluminum garnet) laser with one-level resonance and two-level amplification. An MOPA (master oscillator power amplifier) system structure with the one-level resonance and two-level amplification and an optical flexible output way are adopted, and the laser concretely comprises a laser alignment system, a resonance level, a one-level amplification stage, a two-level amplification stage and a flexible output system which are arranged on a base, wherein the one-level amplification stage is arranged on the central line of an output end of the resonance level; the two-level amplification stage is arranged at one side of the one-level amplification stage, and parallel to the one-level amplification stage; the flexible output system is arranged on an output end of the two-level amplification stage; and the laser alignment system is arranged on the central line of an input end of the resonance level. The laser has the advantages of high beam quality, stable power, availability of flexible output and the like, can meet demands of high-power industrial production and flexible processing, and has obvious economic benefits and social benefits.

Owner:SOUTH CHINA NORMAL UNIVERSITY

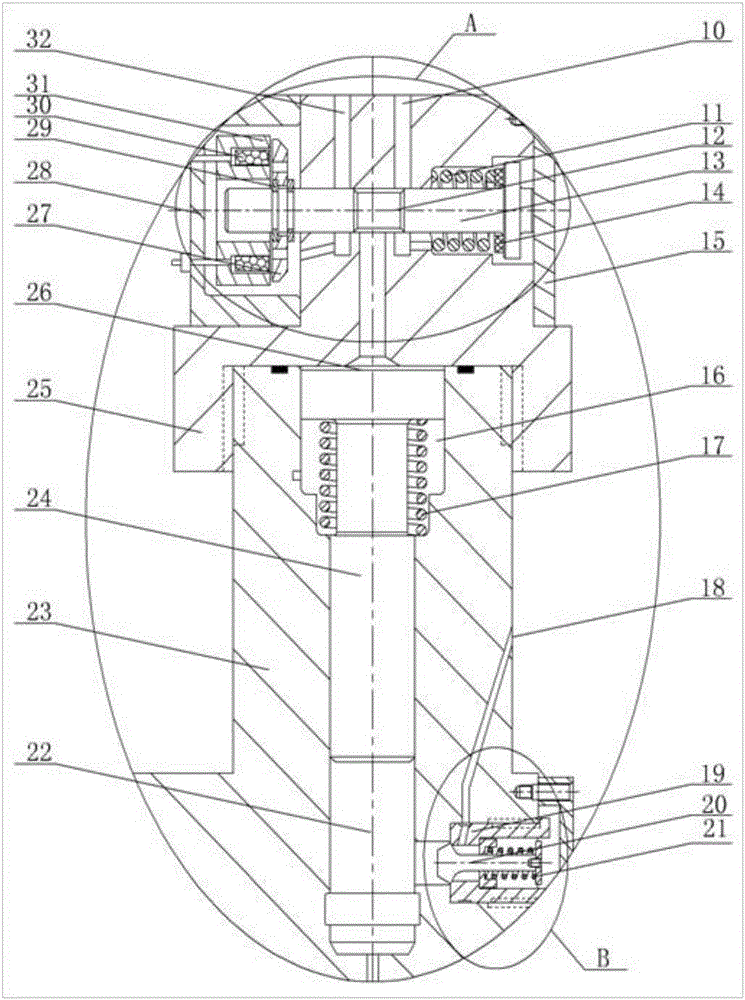

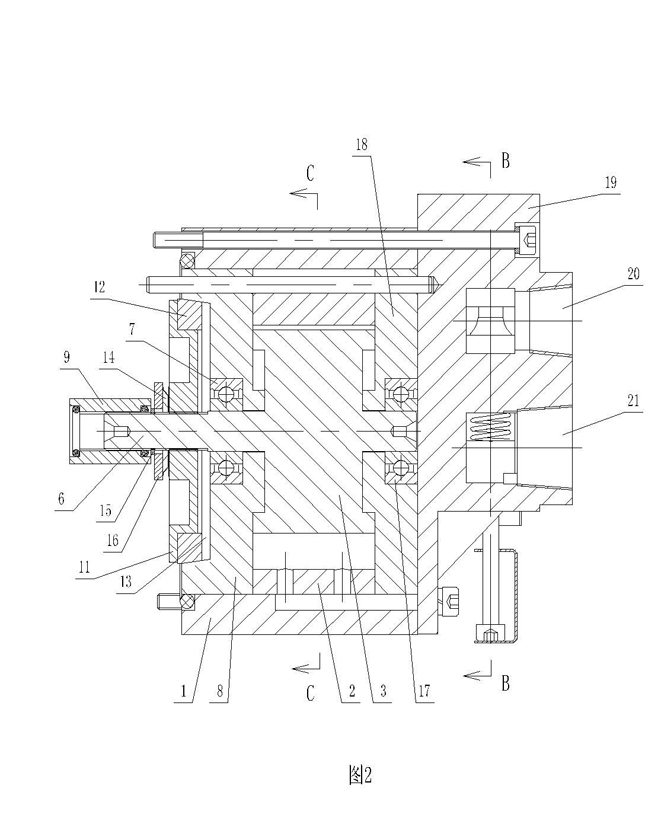

Braking integrated pneumatic motor

InactiveCN102071974ACombination design is compactSmall sizeSafety/regulatory devicesRotary piston enginesEngineeringPneumatic motor

The invention discloses a braking integrated pneumatic motor, belonging to the technical field of pneumatic motors. The pneumatic motor comprises a stator installed in a shell and a rotor eccentrically arranged in the stator, wherein blade grooves are arranged on the rotor; and blades are arranged in the blade grooves in a matching manner and can move in the radial direction. The pneumatic motor is characterized in that an output shaft of the rotor is supported on a front end cover of the shell via bearings 1; the front end of the output shaft extends out of the front end cover; shaft sleevesare arranged at the front end of the output shaft; a section of outer splines are arranged on the output shaft between the front end cover and the shaft sleeves; braking bases are arranged on the outer splines in a matching manner; friction plates are arranged at the rear ends of the braking bases; wedge-shaped grooves are arranged at the front end of the front end cover and are matched with the friction plates; and resetting devices are arranged between the shaft sleeves and the braking bases. The pneumatic motor is sensitive to respond and has good braking effect, high safety property, highlifting speed and compact structure.

Owner:陈树忠

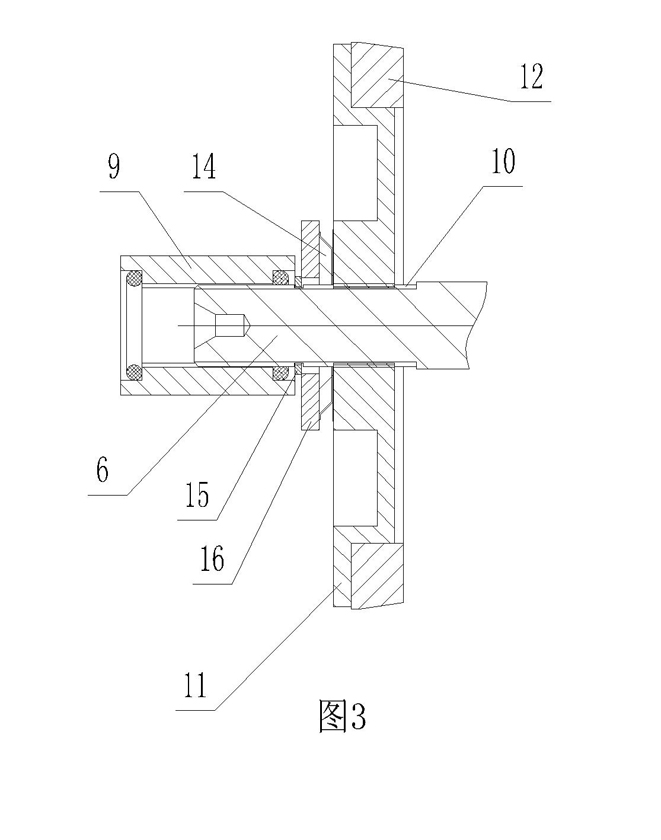

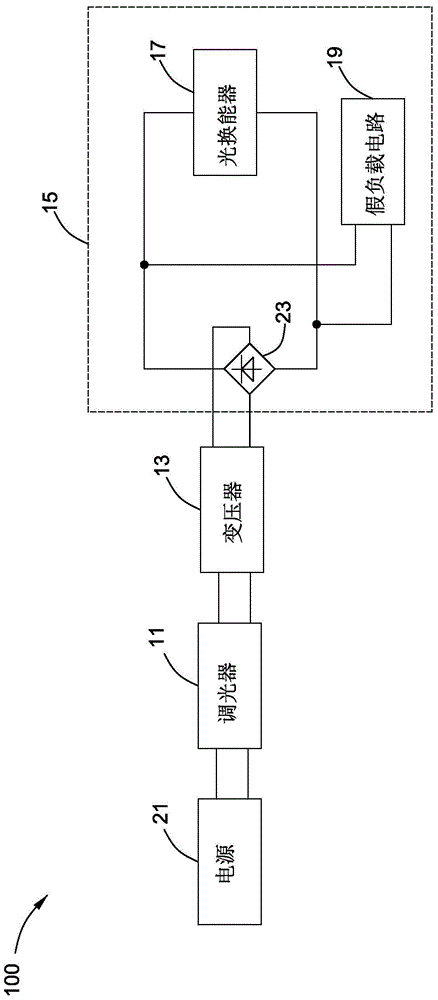

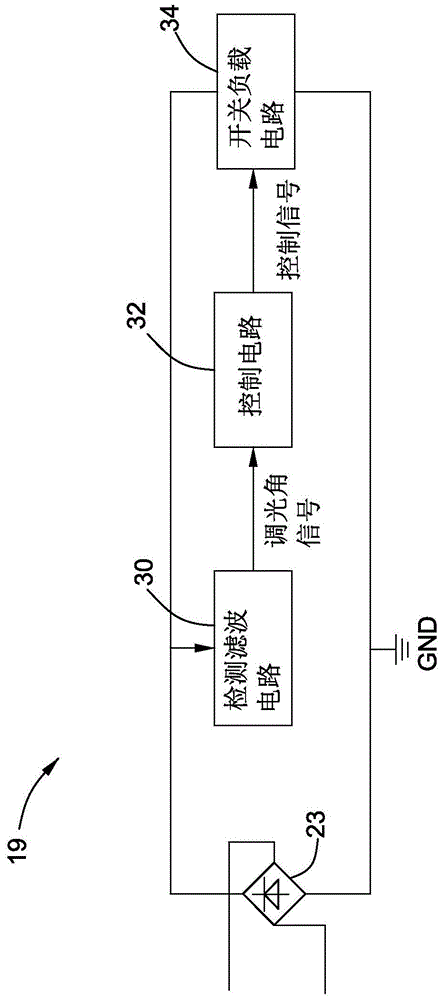

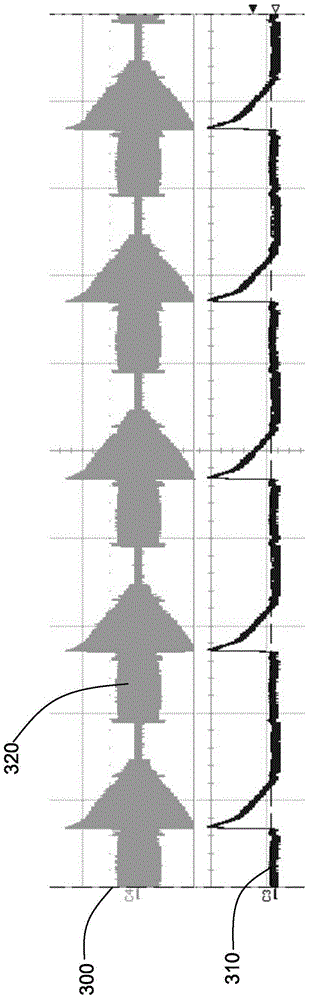

Control system, dummy load circuit and dummy load control method

ActiveCN104602387AMeet the powerReduce flickerElectric light circuit arrangementLoad circuitEngineering

The invention relates to a control system. The control system comprises a light transducer, a light modulator electrically connected with the light transducer, a transformer electrically connected between the light modulator and light transducer in series, the dummy load circuit connected with the light transducer in parallel, a control circuit connected with a detection filter circuit and used for converting light angle adjusting signals into control signals, and a switch load circuit connected with the control circuit, wherein the dummy load circuit comprises the detection filter circuit connected with the transformer and used for detecting light adjusting angles of the input voltage from the transformer and generating light adjusting angle signals, and the switch load circuit comprises a load, and the load current passing the load is changed according to the control signals.

Owner:GENERAL ELECTRIC CO

Combustion method of ethanol-diesel double direct injection engine

InactiveCN103277200AMeet the replacement rateMeet the powerInternal combustion piston enginesEngine controllersCombustionEngineering

The invention discloses a combustion method of an ethanol-diesel double direct injection engine and relates to the field of engines. The combustion method of the ethanol-diesel double direct injection engine includes three combustion modes of premix quantity ignition combustion, diffusive combustion and diffusive combustion of a portion of a premix ignition portion. The ethanol-diesel double direct injection engine can selectively use the three combustion modes of the premix quantity ignition combustion, the diffusive combustion and the diffusive combustion of the portion of the premix ignition portion and can convert work modes among the three combustion modes according to working condition needs, and requirements of dynamic performance, economical efficiency and emission performance when uses ethanol-diesel double fuel to work, so that the combustion method of the ethanol-diesel double direct injection engine can satisfy requirements of substitution rate, power and emission according to different working conditions and achieve flexible application of ethanol in a diesel engine.

Owner:GUIYANG UNIV +1

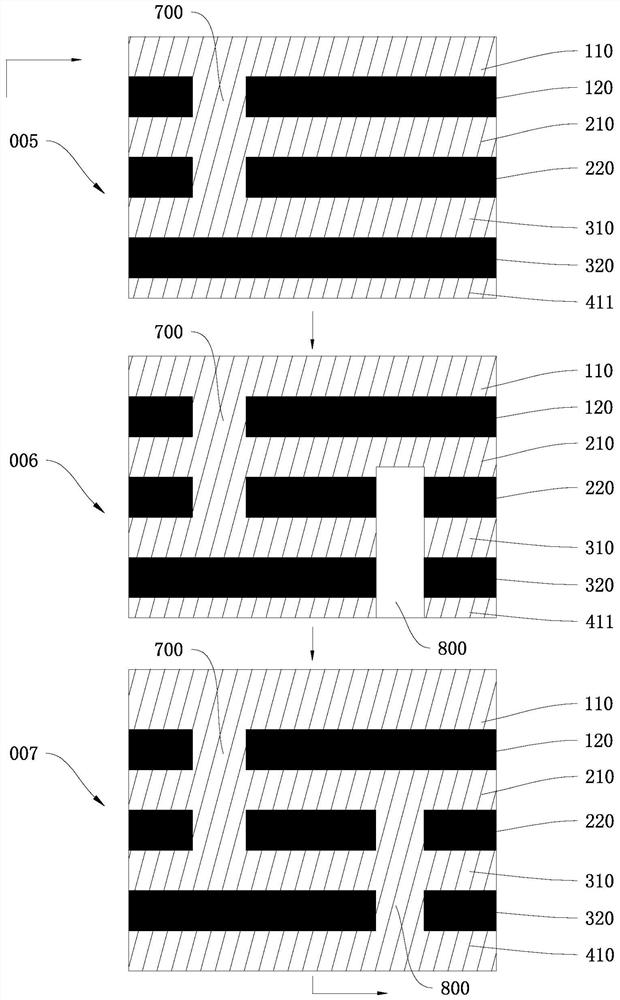

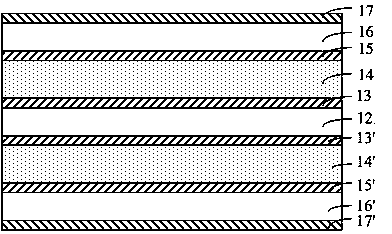

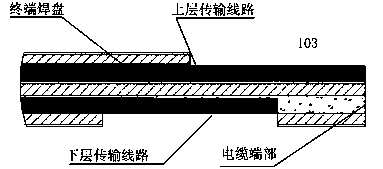

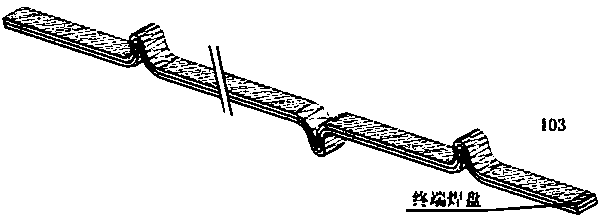

Flat-type double-layer power signal transmission cable and forming method thereof

ActiveCN103514988AMeet the powerMeet needsFlat/ribbon cablesCable/conductor manufactureEngineeringSolar cell

The invention provides a flat-type double-layer power signal transmission cable and a forming method of the cable. The flat-type double-layer power signal transmission cable comprises a middle insulating layer which is a polyimide film, an upper layer power signal transmission layer pasted to the upper surface of the middle insulating layer, a lower layer power signal transmission layer pasted to the lower surface of the middle insulating layer, an upper layer insulating layer pasted on the other surface of the upper layer power signal transmission layer, a lower layer insulating layer pasted on the other surface of the lower layer power signal transmission layer, an upper layer elemental oxygen protective layer located on the other surface of the upper layer insulating layer, and a lower layer elemental oxygen protective layer located on the other surface of the lower layer insulating layer, wherein the thickness of the middle insulating layer is 25 microns to 75 microns, and the upper layer power signal transmission layer and the lower layer power signal transmission layer are made of copper material. The flat-type double-layer power signal transmission cable can meet the large-power and multipath signal transmission requirements for solar cell arrays on spacecrafts.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

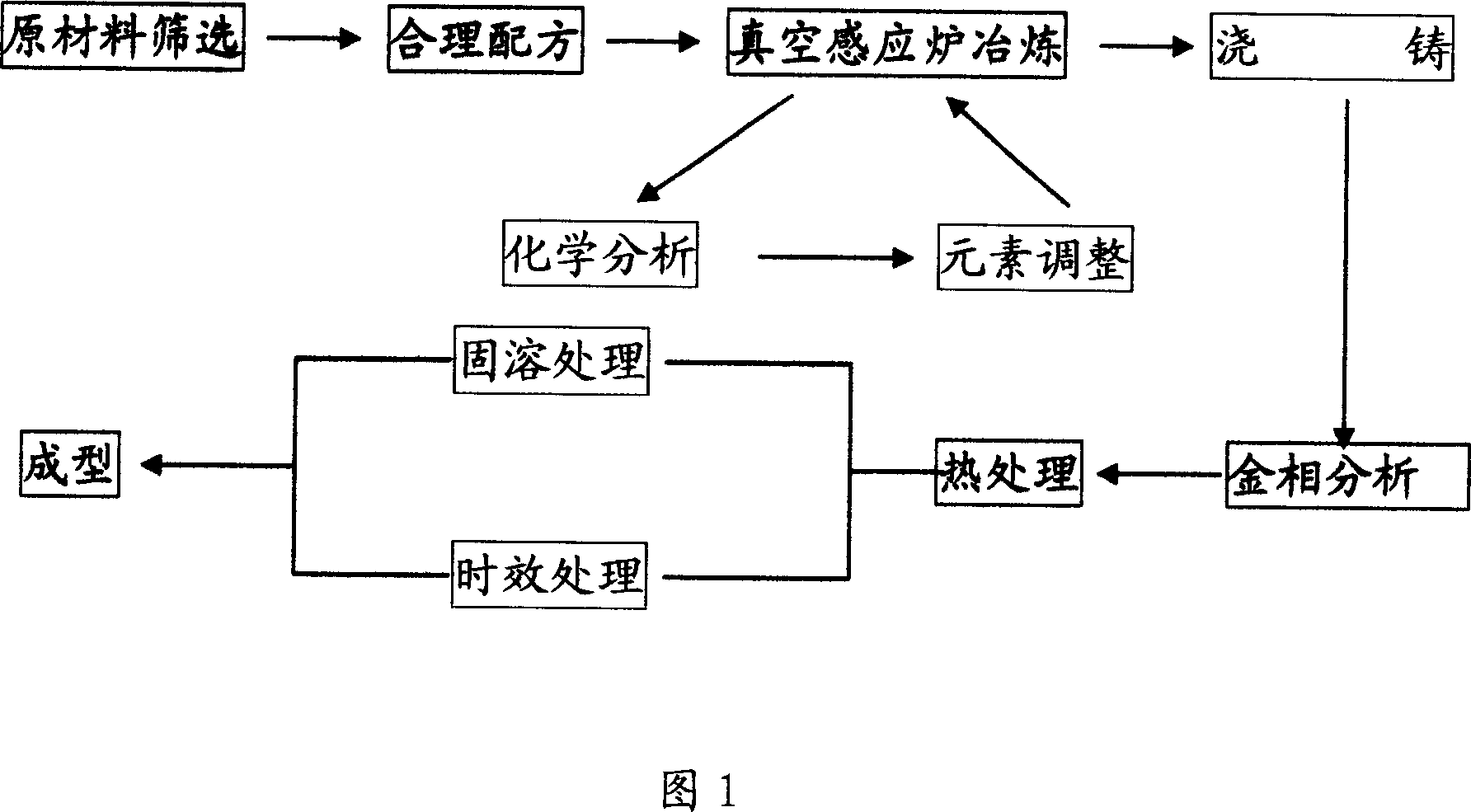

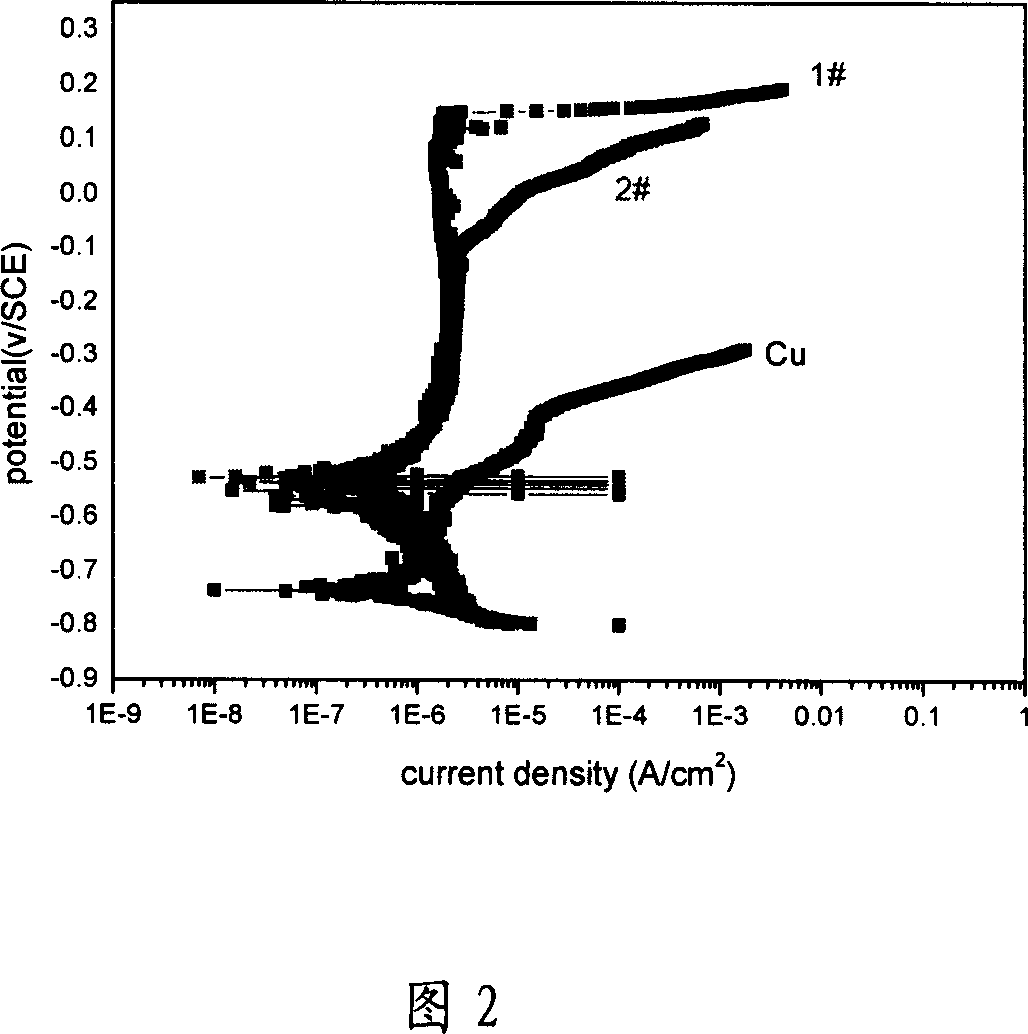

Vacuole corrosion resistant hardening casting

A kind of sclerotic casting, which can bear vacuole corrode, the components and their weight percent are as following: Carbon: 0.02-0.10; Silicon: 0.1-1.5; Manganese: 0.5-2.5; Chromium: 11.0-15.0; Nickel: 5.5-8.5; Molybdenum: 1.5-3.0; Copper: 1.5-3.5; Niobium: 0.2-0.4; the other is iron. The zero gravity index at strong corrode of the sclerotic casting, which can bear vacuole corrode, and made according to this patent, such as airscrew, sea water pump and lamina of impeller, is only 1.0mg / 2h. They own excellent sea decay resistance ability and vacuole decay resistance ability is high in sea, the intensity of them is high and tenacity is well. They can fulfil the demands of large mainframe and large ship airscrew, and it also can fulfil the need of war industry.

Owner:JIANGSU LIXIN ALLOY IND GENERAL

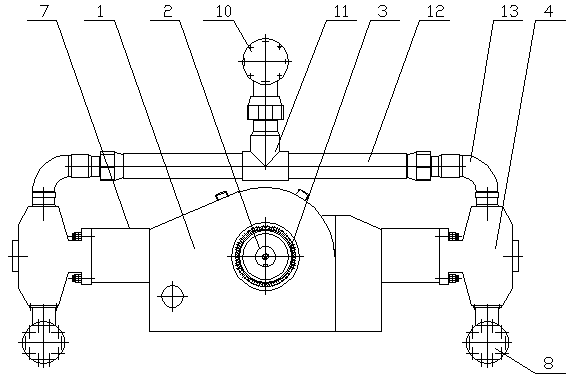

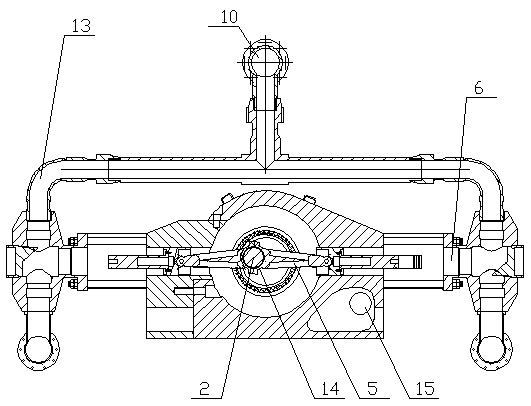

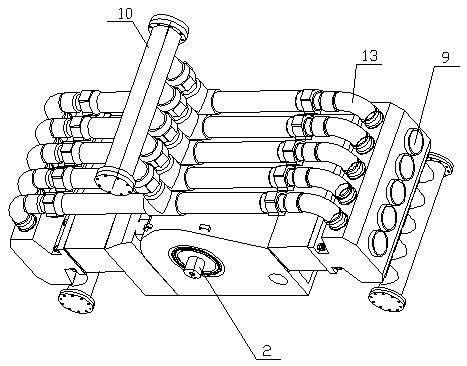

Split-type ten-cylinder reciprocating pump

PendingCN108035856AImprove suction performanceExtended service lifePositive displacement pump componentsPositive-displacement liquid enginesWell drillingEngineering

The invention relates to a reciprocating pump, in particular to a split-type ten-cylinder reciprocating pump. The split-type ten-cylinder reciprocating pump is composed of a shell, a crankshaft, a cylindrical bearing, fluid end assemblies, a connecting rod and a medium rod. A shell upper cover is arranged on the shell. The fluid end assemblies are mounted on the two sides of the shell through dustproof shells. A suction main pipe is arranged below each fluid end assembly. The suction main pipes communicate with the corresponding fluid end assemblies. A discharge main pipe is arranged above theshell upper cover. The split-type ten-cylinder reciprocating pump is simple in structure and good in practicability, the problems that due to flow cutoff desilting and large flow fluctuation in the suction process and the large pressure pulse in the discharge process of an existing reciprocating pump, the reciprocating pump is poor in suction and discharge performance and reliability and high infailure rate are solved, and the split-type ten-cylinder reciprocating pump is especially suitable for being used for crude oil transportation, well washing, well drilling, water injection and formation fracturing operations.

Owner:YANGTZE UNIVERSITY

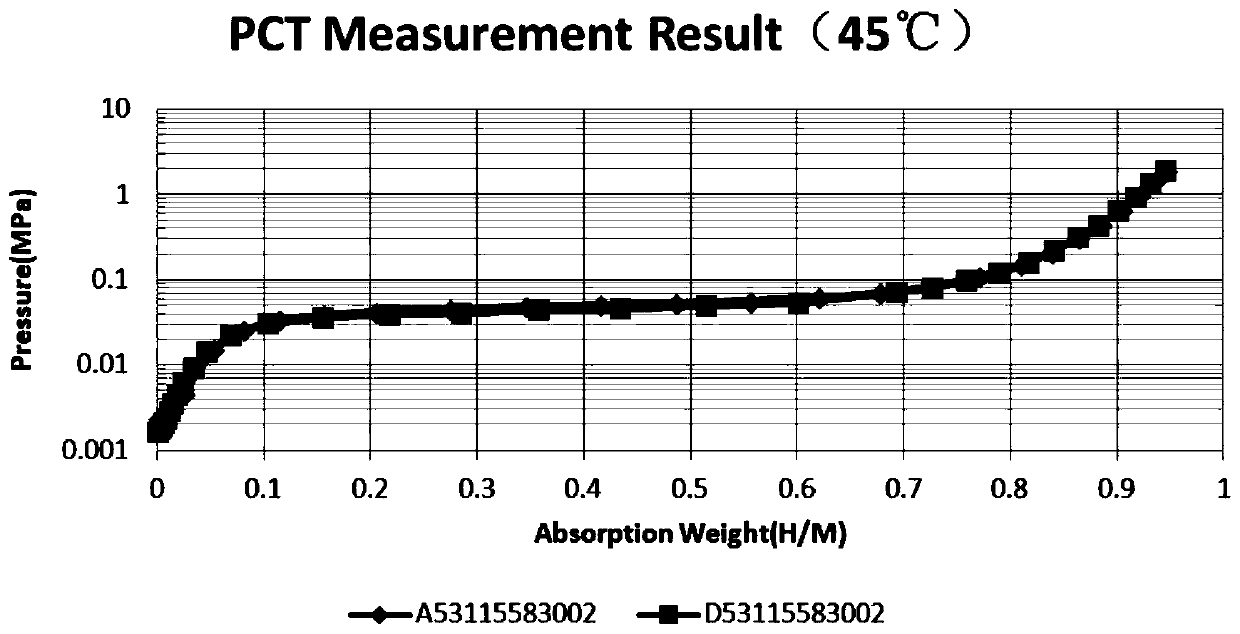

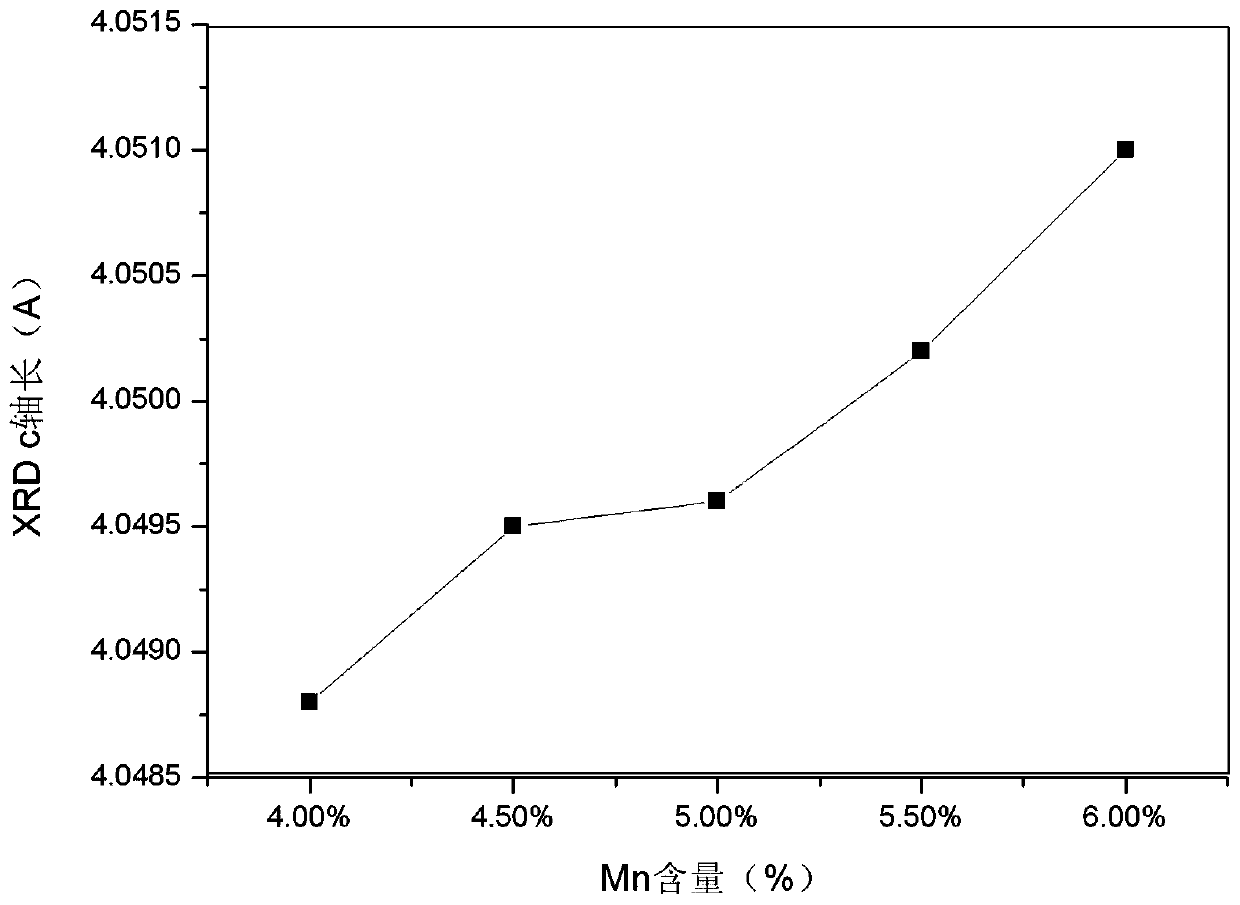

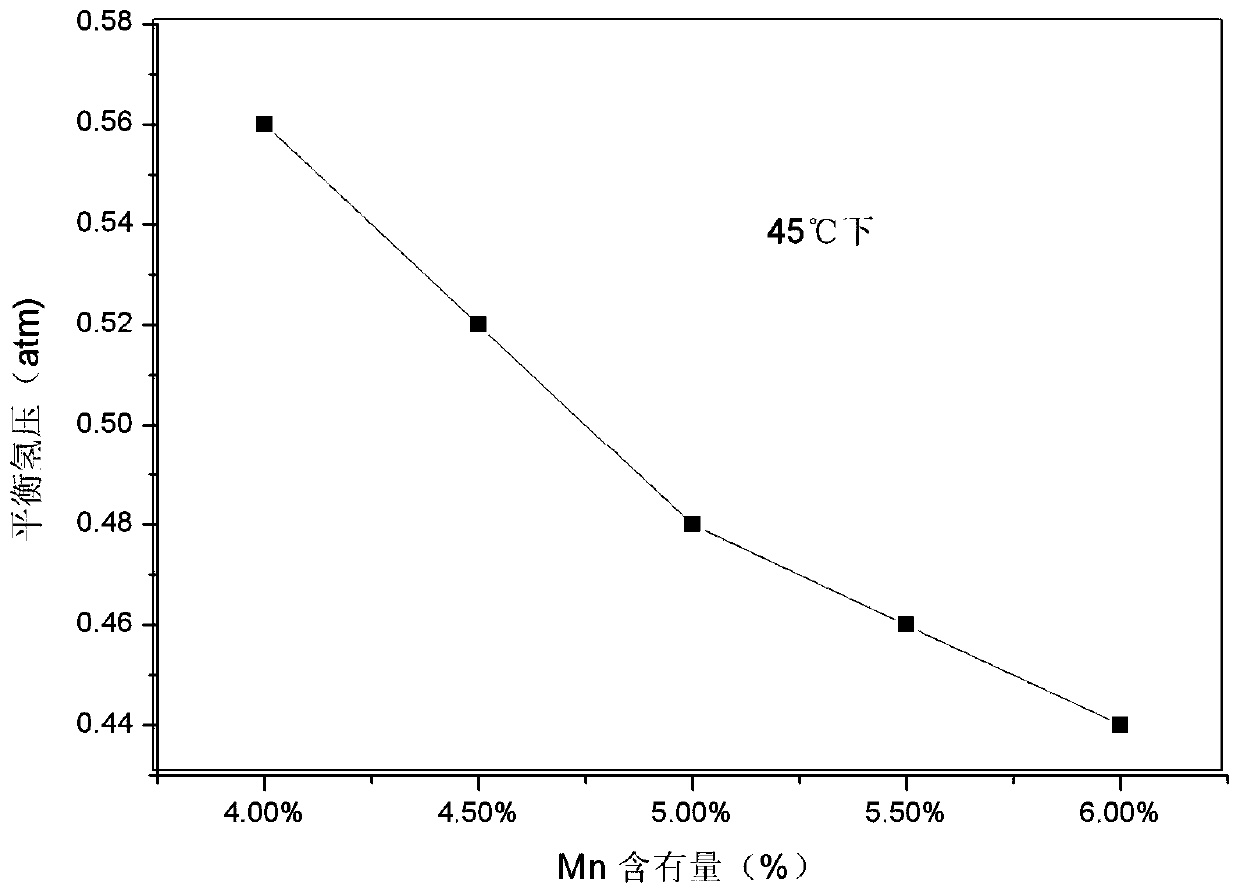

High-performance low-cost hydrogen storage alloy powder for nickel-hydrogen power battery and preparation method thereof

ActiveCN110265655AImprove performanceLow costCell electrodesNickel accumulatorsPower batteryMaterials science

Owner:LANZHOU JINCHUAN KELIYUAN BATTERY

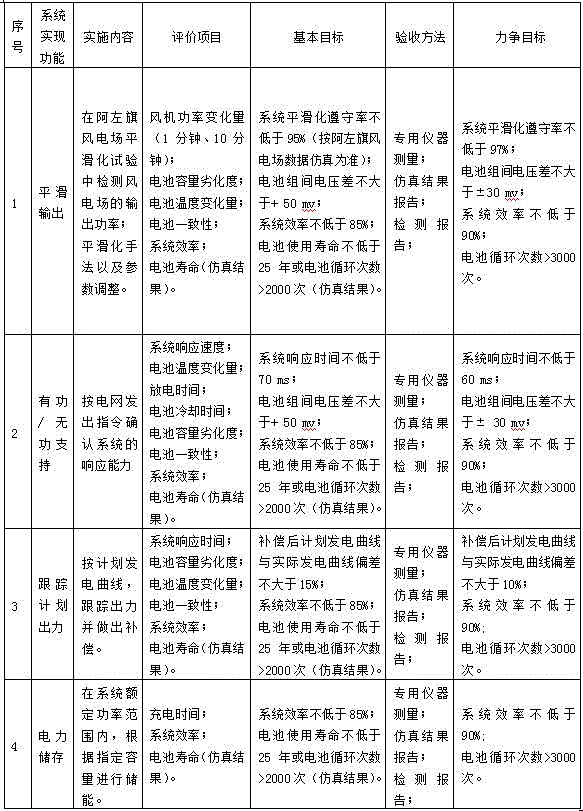

Container type energy storage system for wind power generation

InactiveCN105490293AScale upSolution to short lifeSingle network parallel feeding arrangementsEnergy storageNew energyPower grid

A container type energy storage system for a wind power generation is disclosed. The container type energy storage system comprises an energy storage battery pack container, a bidirectional power conversion system (PCS) container and a boosting transformer, wherein the battery of the energy storage battery pack container adopts a lithium ion energy storage battery; after the lithium ion energy storage battery is subjected to completion of alternating current / direct current conversion through the PCS container, the lithium ion energy storage battery is boosted to 35KKV and connected to a 35KV busbar of a substation; the PCS apparatus can realize bidirectional flow; under a charging state, the PCS is used as a rectifying apparatus for converting the alternating current into direct current to be stored in a storage apparatus; and under a discharging state, the PCS is used as an inverter for converting the direct current stored by the storage apparatus into alternating current to be transmitted to a power grid. According to the container type energy storage system, an energy storage technology with large scale, long service life, high efficiency and low cost is realized; the electric energy quality of new energies in grid connection is greatly improved, a certain energy loss caused by limited power is reduced, and the influence on the power grid caused by large-scale new energy power generation and grid connection is relieved.

Owner:中铝宁夏能源集团有限公司 +1

Portable multistage negative pressure suction device

PendingCN114082012AWide negative pressure rangeSave human effortSuction devicesPhysicsClinical nursing

The invention belongs to the technical field of clinical nursing, and particularly relates to a portable multistage negative pressure suction device. The device comprises a base plate and a negative pressure bag which is arranged on the base plate and can do reciprocating telescopic motion in the axial direction, and is characterized in that an energy release assembly which can do axial reset motion in the axial direction of the negative pressure bag is further arranged on the base plate and comprises an elastic reset piece and a limiting part used for fixing the elastic reset piece; the limiting part can always restrain the elastic reset piece to be in a compressed state; and a matching piece located on the axial reset path of the elastic reset piece is arranged on the negative pressure bag, and when the limiting part removes constraint on the elastic reset piece, the elastic reset piece generates the axial reset action and ejects the matching piece, and then the negative pressure bag is pushed to generate the axial stretching action. The device can perform continuous negative pressure operation without power supply, and has the advantages of wide negative pressure range and adjustable negative pressure.

Owner:ANHUI PROVINCIAL HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com