High rate ternary system starting and stopping lithium ion battery and preparation method thereof

A lithium-ion battery and ternary system technology, applied in the field of lithium-ion batteries, can solve the problems of no significant improvement in high-rate charging performance, no significant increase in conductivity, and restrictions on the use of high-rate requirements, and meet instantaneous high power requirements. Effects of output and input requirements, shorter embedding and embedding distances, and improved film thickness and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

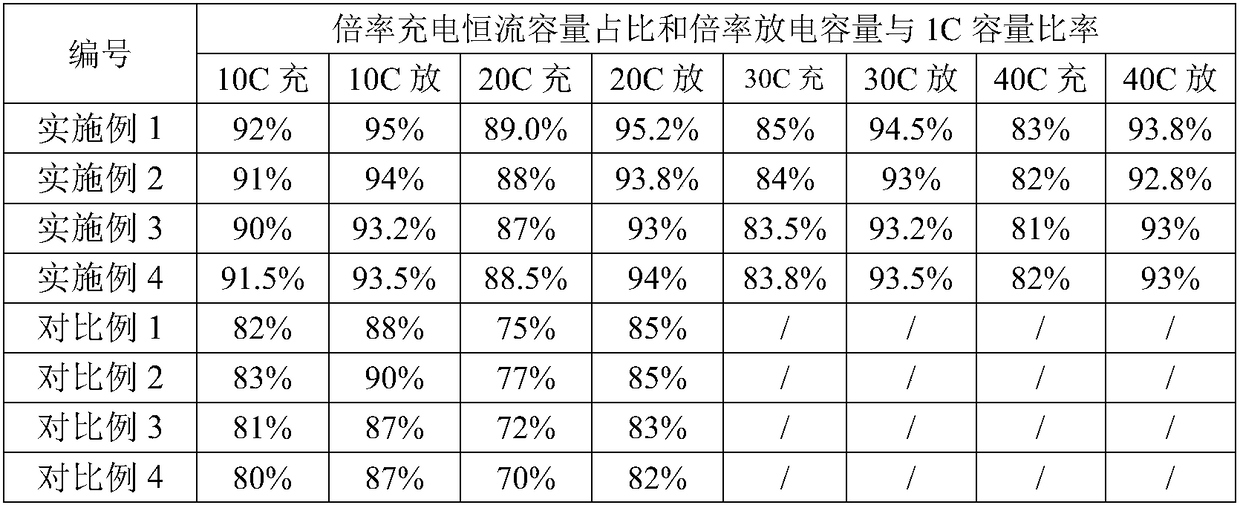

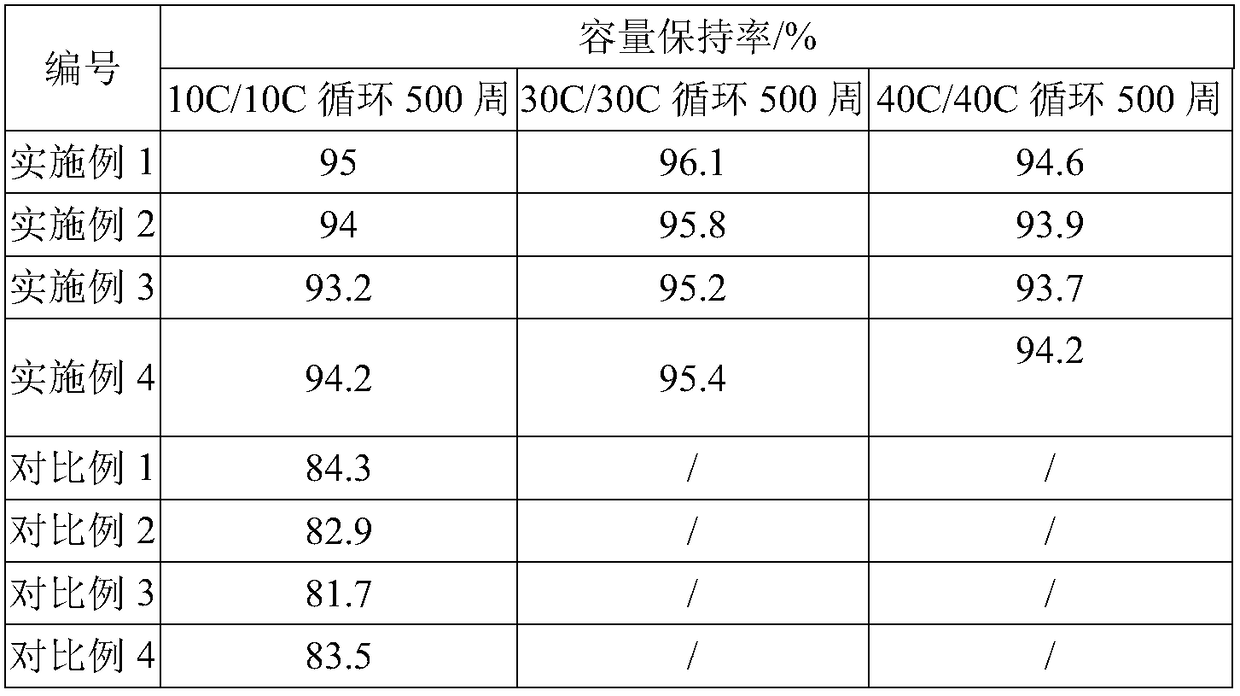

Examples

Embodiment 1

[0029] 1) Prepare 90wt% LiNi in proportion 1 / 3 co 1 / 3 mn 1 / 3 o 2 (positive active material), 6.3wt% of conductive carbon black and carbon nanotube mixture (positive electrode conductive agent), 3.5wt% of polyvinylidene fluoride (positive electrode binder) and 0.2wt% of polyvinylpyrrolidone (dispersant ), then the mixture of conductive carbon black and carbon nanotubes and polyvinylpyrrolidone are dissolved in N-methylpyrrolidone solvent, high-speed dispersion is made into a positive electrode conductive emulsion with a solid content of 5%, and then LiNi is added to the positive electrode conductive emulsion 1 / 3 co 1 / 3 mn 1 / 3 o 2 Disperse with polyvinylidene fluoride at a high speed to form a positive electrode mixture, evenly coat the positive electrode mixture on carbon-coated aluminum foil, and form a positive electrode sheet after drying and rolling. The coating surface density of the positive electrode mixture is 0.96-1.60g / dm 2 ;

[0030] 2) Prepare 90wt% artificia...

Embodiment 2

[0033] 1) Prepare 92wt% LiNi in proportion 0.5 co 0.2 mn 0.3 o 2 (positive active material), 5.3wt% conductive carbon black and Ketjen black mixture (positive electrode conductive agent), 2.5wt% polyvinylidene fluoride (positive electrode binder) and 0.2wt% polyvinylpyrrolidone (dispersant ), then the mixture of conductive carbon black and ketjen black and polyvinylpyrrolidone are dissolved in N-methylpyrrolidone solvent, high-speed dispersion is made into a positive electrode conductive emulsion with a solid content of 4%, and then LiNi is added to the positive electrode conductive emulsion 0.5 co 0.2 mn 0.3 o 2 Disperse with polyvinylidene fluoride at a high speed to form a positive electrode mixture, uniformly coat the positive electrode mixture on carbon-coated aluminum foil, and form a positive electrode sheet after drying and rolling. The coating surface density of the positive electrode mixture is 0.96-1.60g / dm 2 ;

[0034] 2) Prepare 92wt% artificial graphite (n...

Embodiment 3

[0037] 1) Prepare 94wt% LiNi in proportion 1 / 3 co 1 / 3 mn 1 / 3 o 2 and LiNi 0.5 co 0.2 mn 0.3 o 2 mixture (positive electrode active material), 3.8wt% Ketjen black and carbon nanotube mixture (positive electrode conductive agent), 2wt% polyvinylidene fluoride (positive electrode binder) and 0.2wt% polyvinylpyrrolidone (dispersion agent), then dissolve the mixture of Ketjen black and carbon nanotubes and polyvinylpyrrolidone in N-methylpyrrolidone solvent, and disperse at a high speed to make a positive electrode conductive emulsion with a solid content of 6%, and then add LiNi to the positive electrode conductive emulsion 1 / 3 co 1 / 3 mn 1 / 3 o 2 and LiNi 0.5 co 0.2 mn 0.3 o 2 The mixture and polyvinylidene fluoride are dispersed at high speed to form a positive electrode mixture. The positive electrode mixture is evenly coated on the carbon-coated aluminum foil, and the positive electrode sheet is formed after drying and rolling. The coating surface density of the pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com