Paste solder for hard soldering of SiCp/Al composite material and preparation method and use method thereof

A technology of paste solder and composite materials, which is applied in the direction of welding/cutting media/materials, welding equipment, welding media, etc., and can solve the problem of welding irregular, small or complex geometric parts, strips, etc. Shaped or foil-shaped solder is unfavorable to the automation of the brazing process, and it is beneficial to automation, saving solder, and increasing the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

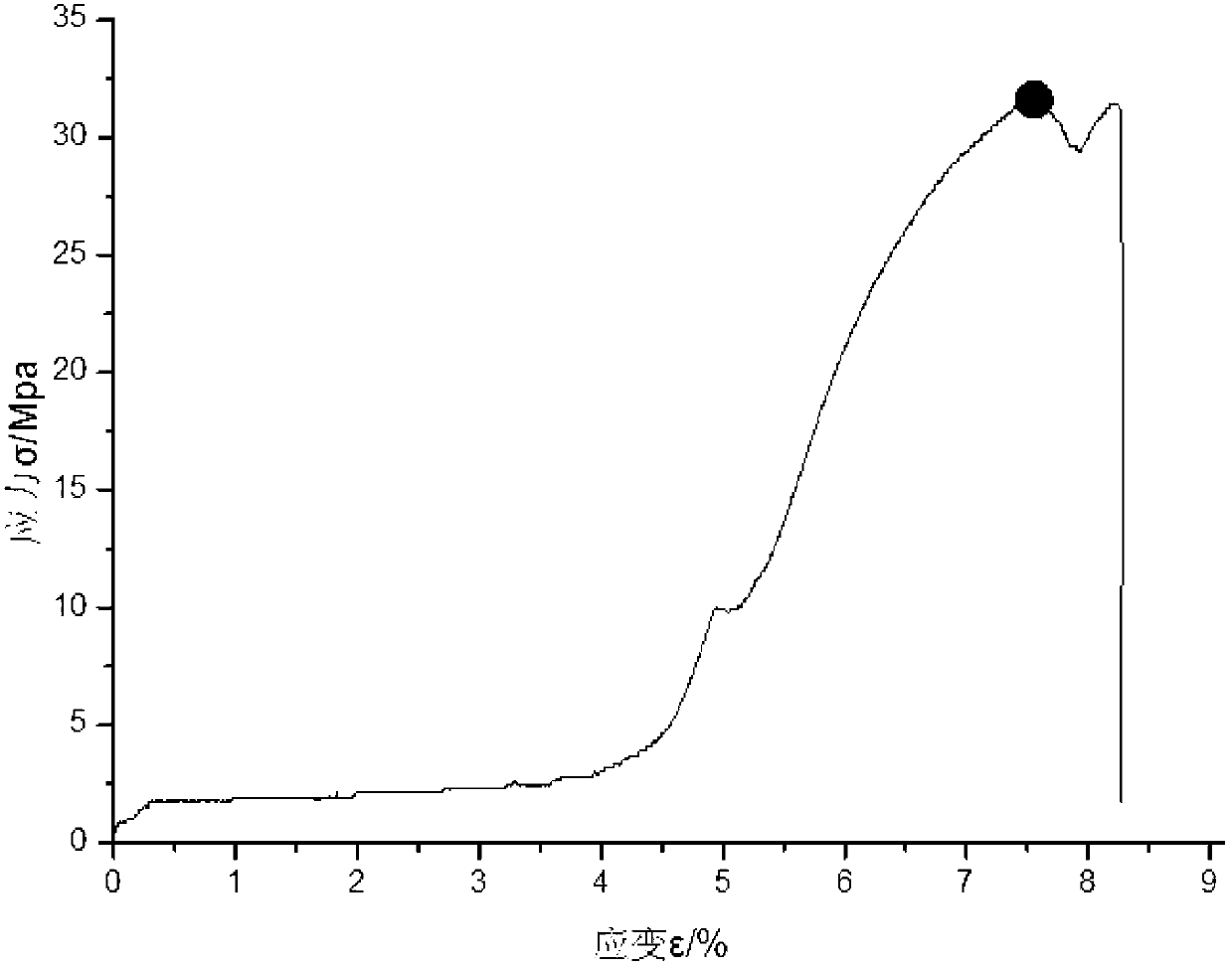

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment 1: This embodiment is a paste solder used for brazing of SiCp / Al composite materials, which consists of 30% to 35% alloy solder powder, 35% to 40% flux and 25% to 35% binder is mixed.

[0020] The alloy solder powder described in this embodiment consists of 21% to 25% of Cu, 4% to 6% of Si, 1% to 2% of Mg, 0.3% to 0.7% of Ni and 66% to 74% by mass percentage. % Al prepared.

[0021] The flux described in this embodiment is based on KF-AlF 3 Eutectic aluminum flux is added K 2 SiF 6 Mixed as a surfactant, wherein the KF-AlF 3 Eutectic aluminum flux with K 2 SiF 6 The mass ratio is 1:(0.074~0.131).

[0022] The binder described in this embodiment is prepared by mixing 85% to 90% of white oil, 6% to 10% of rosin resin, 2% to 5% of glycerin and 0.5% to 1.5% of hydrogenated castor oil according to the mass percentage. become.

[0023] The brazing alloy powder in this embodiment has a particle size of 5 μm to 25 μm.

[0024] The viscosity of the ...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the white oil has a flash point of 180° C. to 190° C. and a viscosity of 3.5 cp to 5 cp. Others are the same as the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the present embodiment is a kind of preparation method for the paste solder of SiCp / Al composite material brazing, specifically is finished according to the following steps:

[0032] 1. Preparation of alloy solder powder: ① Preparation of materials: Firstly, cut or crush the raw materials containing Cu, Si, Mg, Ni and Al to a particle size of 5mm-20mm, and then put them into alcohol for ultrasonication Clean for 15min to 25min, then prepare materials according to the mass percentage of 21% to 25% Cu, 4% to 6% Si, 1% to 2% Mg, 0.3% to 0.7% Ni and 66% to 74% Al ; ②Nitrogen atomization: put the materials prepared in step ① into an intermediate frequency induction furnace for smelting, -3 Pa~1.5×10 -3 Pa and heating rate of 40°C / min~60°C / min are melted into molten metal, and then the molten metal is passed through the annular nozzle. mm, and the annular seam gap of the annular seam nozzle is 0.5mm to carry out nitrogen atomization to obtain sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com