Method for preparing ionic liquid plasticized composite polymer electrolyte for lithium ion battery

A composite polymer and lithium-ion battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of not meeting the requirements of electrical conductivity, environmental hazards of organic solutions, and poor mechanical properties of the membrane, so as to improve electrical conductivity , The process is simple and easy to control, and the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

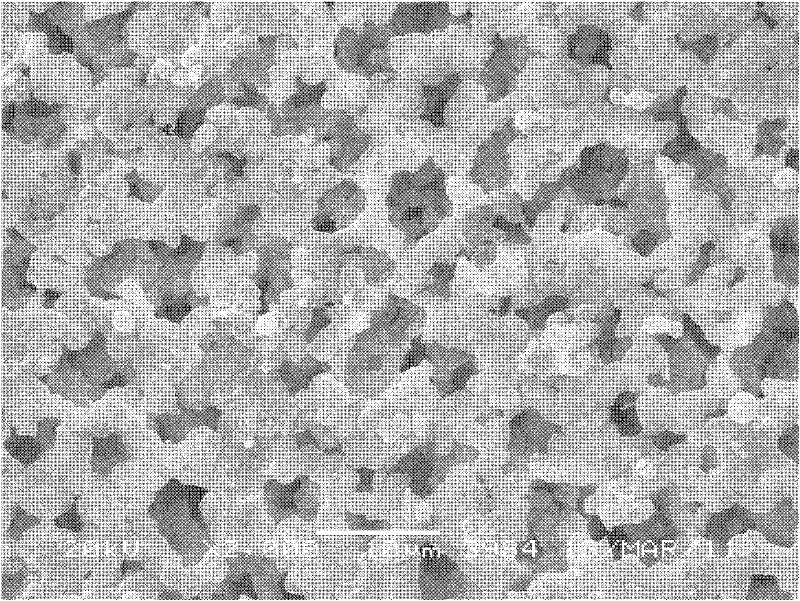

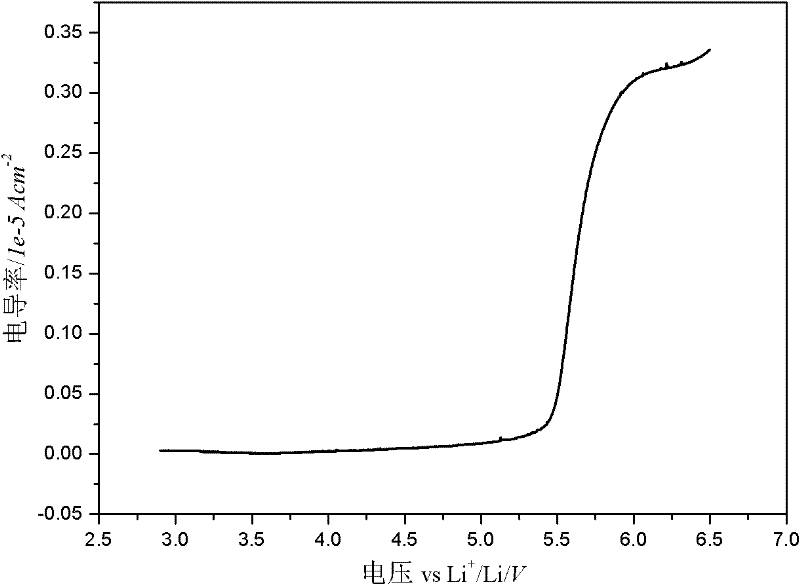

[0031] After the molecular sieve ZSM-5 was dispersed by ultrasonic oscillation in the solvent DMF for 30 minutes, an appropriate amount of polymer matrix PVDF-HFP and pore-forming agent PEG-200 were weighed and added to the dispersed solution, wherein ZSM-5: PVDF-HFP: The mass ratio of DMF:PEG-200 is 0.1:10:40:0.1. The homogeneous and transparent gel obtained after stirring vigorously at 40°C for 4 hours was left to stand for 30 minutes, then vacuum degassed, and cast on a polytetrafluoroethylene mold to form a film. After exchanging and forming a film in a steam bath for 4 hours, the obtained film body was dried under vacuum at 80°C to remove excess DMF and water to form a film, and the inorganic particle-doped PVDF-HFP-based microporous film was obtained. The above microporous membrane prepared in BMIPF 6 : LiPF 6 After soaking in the mixed solution with a mass ratio of 2:1 for 30 min, the ionic liquid plasticized gel-type composite polymer electrolyte membrane was obtaine...

Embodiment 2

[0033]After the molecular sieve ZSM-5 was dispersed by ultrasonic oscillation in the solvent DMF for 30 minutes, an appropriate amount of polymer matrix PVDF-HFP and pore-forming agent PEG-200 were weighed and added to the dispersed solution, wherein ZSM-5: PVDF-HFP: The mass ratio of DMF:PEG-200 is 0.1:10:40:0.1. The homogeneous and transparent gel obtained after stirring vigorously at 40°C for 4 hours was left to stand for 30 minutes, then vacuum degassed, and cast on a polytetrafluoroethylene mold to form a film. After exchanging and forming a film in a steam bath for 4 hours, the obtained film body was dried under vacuum at 80°C to remove excess DMF and water to form a film, and the inorganic particle-doped PVDF-HFP-based microporous film was obtained. The above microporous membrane prepared in EMIBF 4 : LiPF 6 After soaking in the mixed solution with a mass ratio of 2:1 for 30 min, the ionic liquid plasticized gel-like composite polymer electrolyte membrane (maintaining...

Embodiment 3

[0035] After the molecular sieve MCM-41 was dispersed by ultrasonic oscillation in the solvent DMF for 30 minutes, an appropriate amount of polymer matrix PVDF-HFP and pore-forming agent PEG-200 were weighed and added to the dispersed solution, wherein ZSM-5: PVDF-HFP: The mass ratio of DMF:PEG-200 is 0.1:10:40:0.1. The homogeneous and transparent gel obtained after stirring vigorously at 40°C for 4 hours was left to stand for 30 minutes, then vacuum degassed, and cast on a polytetrafluoroethylene mold to form a film. After exchanging and forming a film in a steam bath for 4 hours, the obtained film body was dried under vacuum at 80°C to remove excess DMF and water to form a film, and the inorganic particle-doped PVDF-HFP-based microporous film was obtained. The above microporous membrane prepared in BMIPF 6 : LiPF 6 After soaking in the mixed solution with a mass ratio of 2:1 for 30 min, the ionic liquid plasticized gel-like composite polymer electrolyte membrane (maintaini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com