Waste heat recovery product well system for ISC and operation method thereof

A technology for underground gasification and waste heat recovery, applied in coal gasification, underground mining, earth-moving drilling, etc., can solve the problems of no easy recovery and reusable product well equipment, blockage of product wells, and reduction of energy consumption, etc. Effective recycling and comprehensive utilization, easy recycling, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

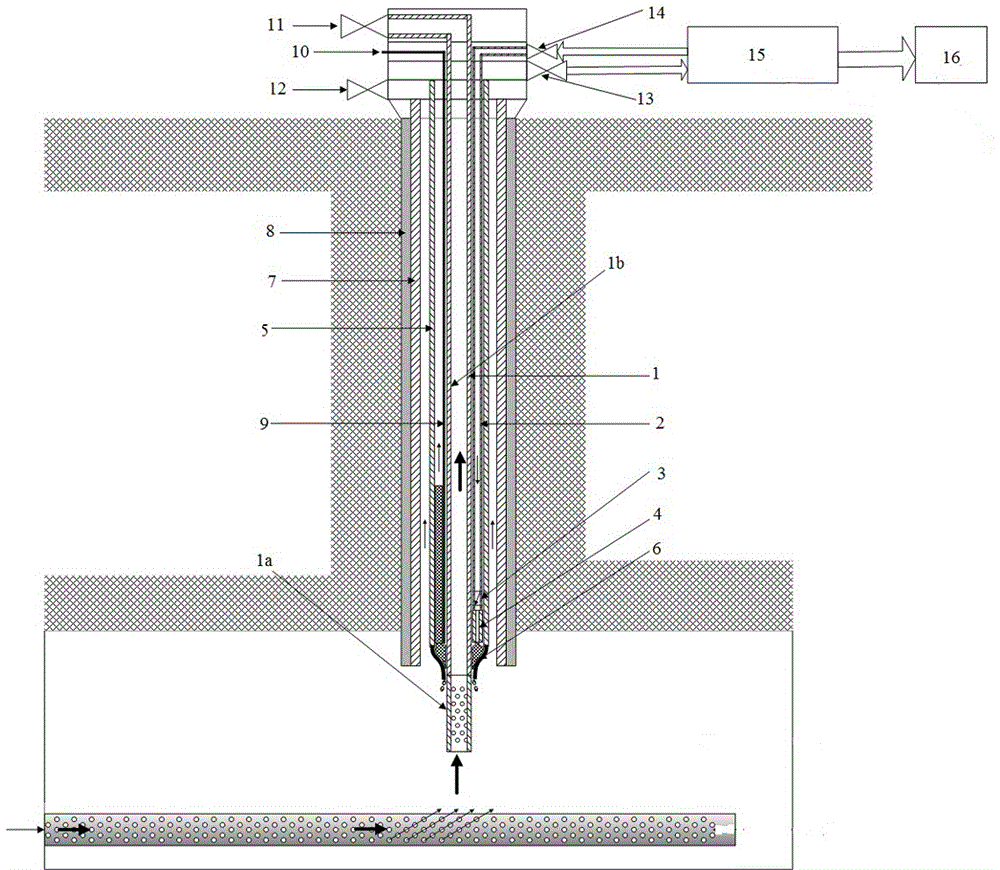

[0053] Such as figure 1 As shown, a waste heat recovery product well system for an underground coal gasification process is based on a vertical waste heat recovery product well of an underground coal gasification unit (ISC). The waste heat recovery product well system includes the following components:

[0054] A wellhead hanger, fixed on the wellhead of the product well, used to hang the relevant components of the waste heat recovery product well system;

[0055] A product pipe 1 is located in the product well and hangs freely on the wellhead hanger. The end part of the product pipe 1 is designed with holes and is provided with a number of air holes to facilitate the crude synthesis gas to enter the product pipe through the air holes and flow to the ground outlet;

[0056] A jacketed pipe 5, freely suspended on the wellhead hanger, located outside the product pipe 1 and coaxially arranged with the product pipe 1, an annular channel is formed between the jacketed pipe 5 and th...

Embodiment 2

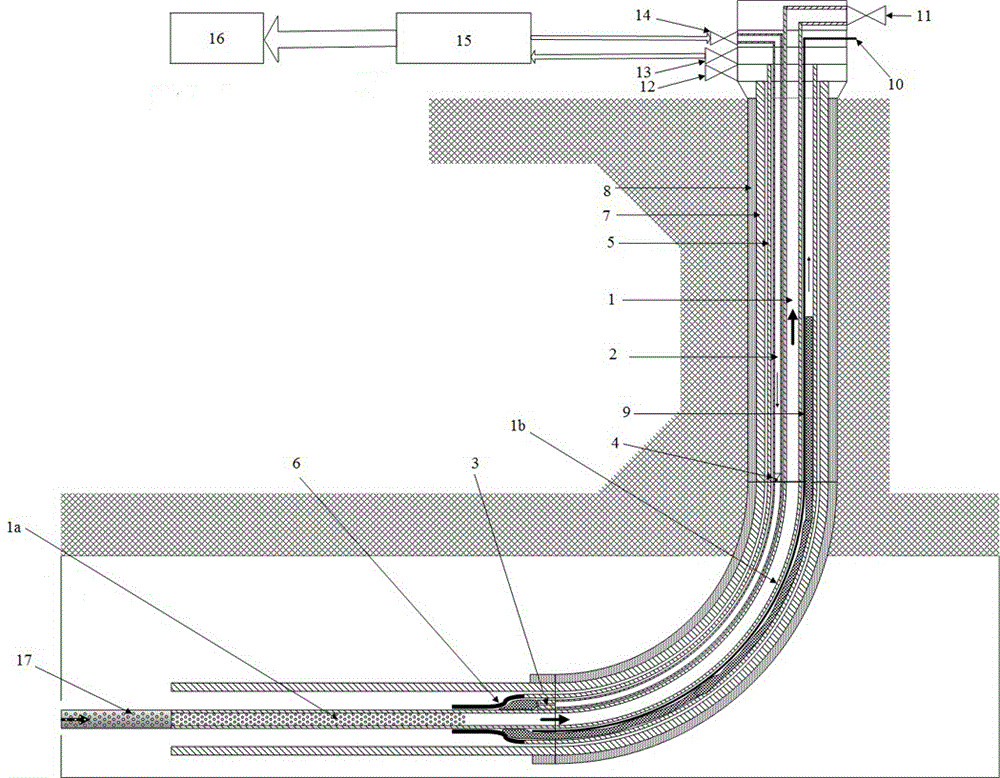

[0103] Such as figure 2 As shown, a waste heat recovery product well system for an underground coal gasification process is based on a directional waste heat recovery product well of an underground coal gasification unit, including a vertical section, an arc section, and a horizontal section. The waste heat recovery product well system The components and technical requirements including the components are basically the same as in Embodiment 1, the differences are as follows:

[0104] (a) The product pipe 1, jacket pipe 5, water-cooled pipe 2 and product well casing 7 are all in the same shape as the directional waste heat recovery product well, that is, they all include vertical sections, arc sections and horizontal sections. 1. The vertical sections of the jacketed pipe 5 and the water-cooled pipe 2 are freely suspended by the wellhead hanger, the curved section is supported by the curved section of the product well casing 7, and the horizontal part is supported by the horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com