Steelmaking residual heat step recycling method

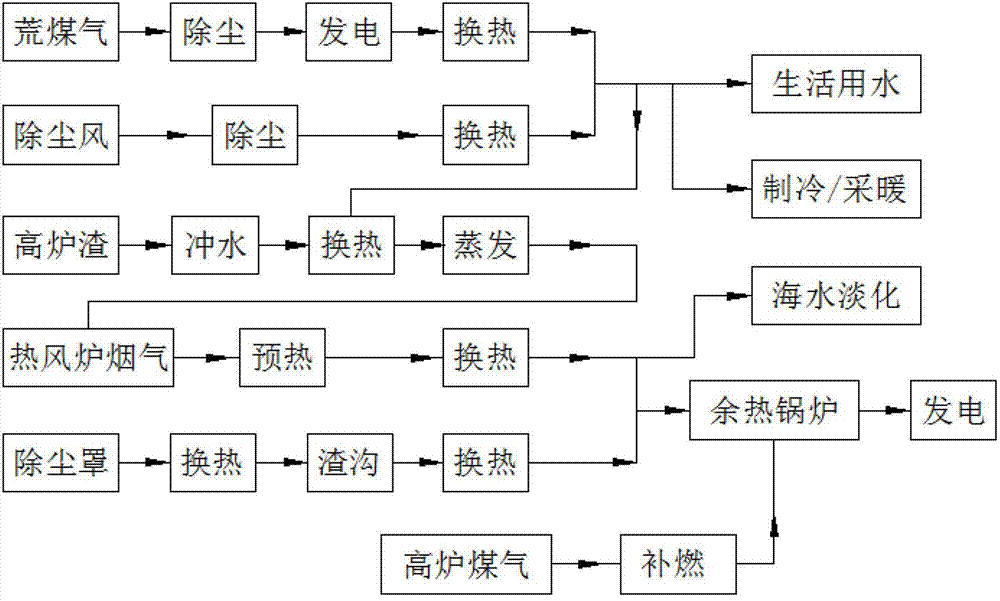

A cascade recovery and waste heat technology, which is applied in the field of utilization of ironmaking waste heat and waste energy in the iron and steel industry, can solve the problems of cascade recovery and high-efficiency utilization of waste heat that cannot be systematically solved, and achieve the effects of improving comprehensive utilization efficiency, optimizing system energy structure, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

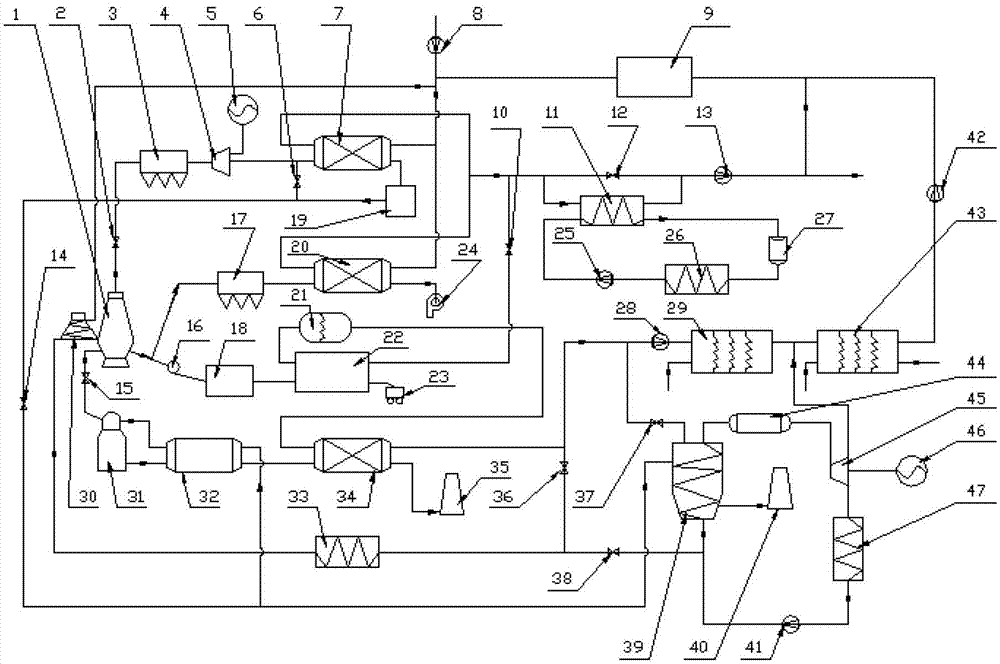

[0030] see Figure 2~3 , the method for cascaded recovery and utilization of ironmaking waste heat provided by the embodiment of the present invention, the specific implementation method is as follows.

[0031]The raw gas from the blast furnace 1 passes through the cut-off valve 2 of the gas main pipe, enters the gas dry dust collector 3 for dry low-pressure pulse dust removal, and then enters the residual pressure turbine 4 to drive the generator 5 for residual pressure power generation. After the residual pressure power generation, the gas It is divided into two paths, one path first enters the gas waste heat exchanger 7, and enters the gas cabinet 19 after waste heat recovery, and the other path passes through the gas branch pipe regulating valve 6, and after being merged with the gas of the previous path, the flow is adjusted by the gas main regulating valve 14, and the path passes through After the gas heat pipe heat exchanger 32 is preheated, it enters the hot blast stov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com