Waste heat recovery IGCC (integrated gasification combined cycle) combined heat and power generation central heating system and method

A central heating and combined heat and power generation technology, applied in hot water central heating systems, heating systems, heating methods, etc., can solve problems such as high investment IGCC, improve economics, reduce water consumption, and increase energy utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

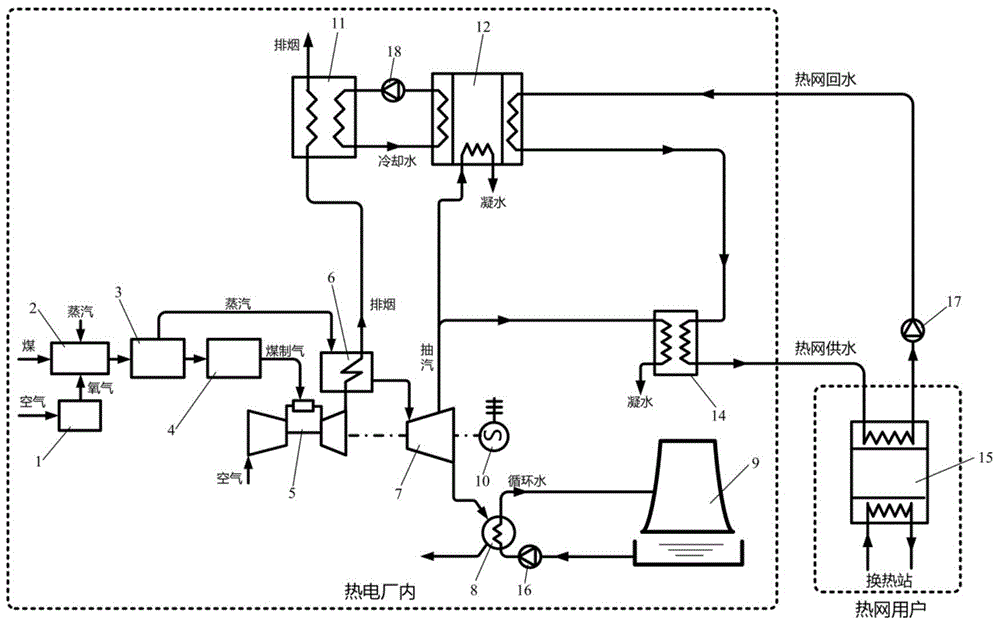

[0033] Such as figure 1 As shown, this embodiment is an IGCC cogeneration central heating system for recovering waste heat, which combines clean and efficient IGCC with steam extraction and heat supply of steam turbine, and uses steam extraction of steam turbine to drive an absorption heat pump, and recovers waste heat and smoke from exhaust steam of steam turbine The waste heat of the gas is centrally supplied by using the steam extraction heat of the steam turbine and recovering the waste heat. The central heat supply method is as follows: the air separation unit 1 generates oxygen, and after the coal is gasified with oxygen and steam in the gasifier 2, it passes through the gas cooler. 3 After cooling down, the purification device 4 removes pollutants such as sulfides, nitrides, and dust in the crude gas to become clean and medium-low calorific value coal-based gas (mainly CO and H 2 ), enter the gas turbine 5 to generate electricity, the gas turbine exhaust enters the wast...

Embodiment 2

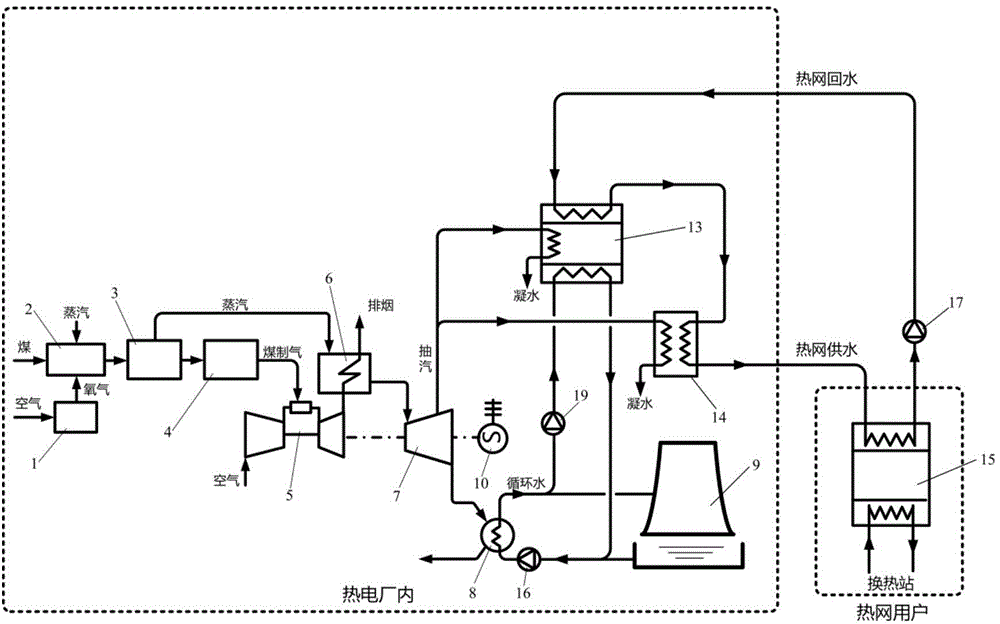

[0035] Such as figure 2 As shown, the present embodiment is an IGCC cogeneration central heating system for recovering waste heat. The central heating method is as follows: the air separation unit 1 generates oxygen, and after the coal is gasified with oxygen and steam in the gasifier 2, After the gas cooler 3 cools down, the purification device 4 removes pollutants such as sulfides, nitrides, and dust in the crude gas to become clean and medium-low calorific value coal-based gas (mainly CO and H 2 ), enter the gas turbine 5 to generate electricity, the gas turbine exhaust enters the waste heat boiler 6 to generate steam to drive the steam turbine 7 to generate electricity, the steam turbine exhaust enters the condenser 8 and condenses after exchanging heat with circulating water, and the circulating water cools down in the cooling tower 9; from the steam turbine 7 The low-pressure steam is extracted, and the steam is divided into two paths. One path is used to heat the retur...

Embodiment 3

[0037] Such as image 3 As shown, the present embodiment is an IGCC cogeneration central heating system for recovering waste heat. The central heating method is as follows: the air separation unit 1 generates oxygen, and after the coal is gasified with oxygen and steam in the gasifier 2, After the gas cooler 3 cools down, the purification device 4 removes pollutants such as sulfides, nitrides, and dust in the crude gas to become clean and medium-low calorific value coal-based gas (mainly CO and H 2 ), enter the gas turbine 5 to generate electricity, the gas turbine exhaust enters the waste heat boiler 6 to generate steam to drive the steam turbine 7 to generate electricity, the steam turbine exhaust enters the condenser 8 and condenses after exchanging heat with circulating water, and the circulating water cools down in the cooling tower 9; from the steam turbine 7 The low-pressure steam is extracted, and the steam is divided into two paths. One path is used to heat the return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com