A process for producing combustible gas from sludge

A sludge and gas technology, applied in the direction of manufacturing combustible gas, sludge treatment, biological sludge treatment, etc., can solve the problems of high cost, low energy conversion rate, poor flammability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

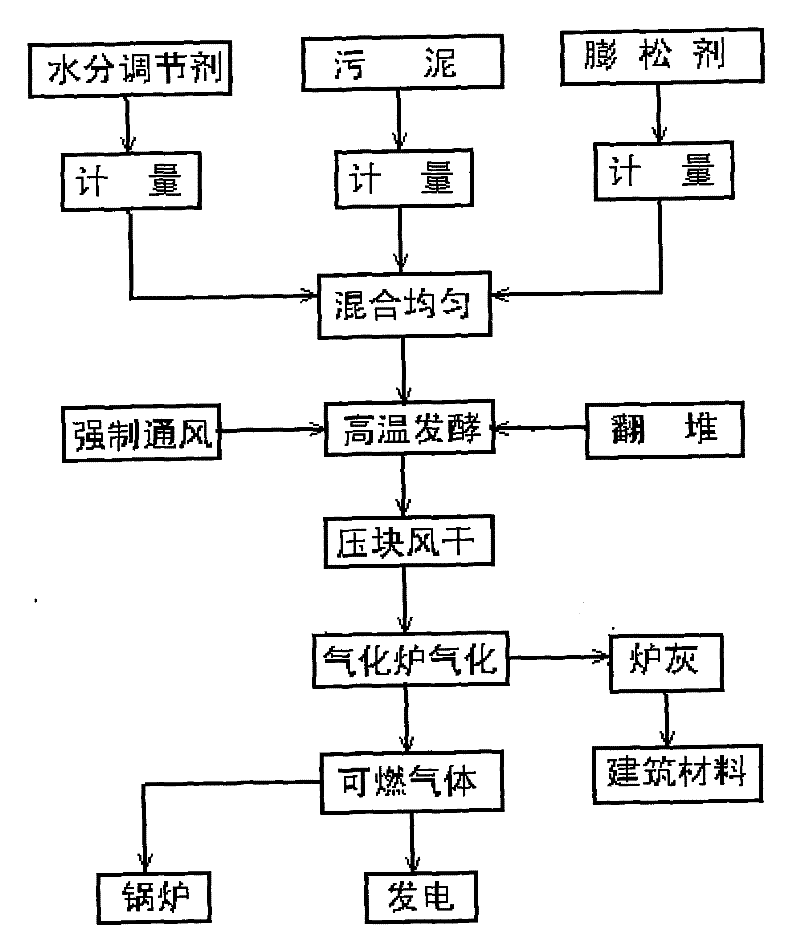

[0014] (1) Take 75 tons of dewatered sludge (water content 70%-80%) discharged from the sewage plant, and add 20 tons of cotton straw powder (water content 15%-30%) as a moisture regulator, with a length of 1-5cm Add 5 tons of leavening agent to the thin bamboo pole section. Thorough mixing is carried out to form the fermented mass.

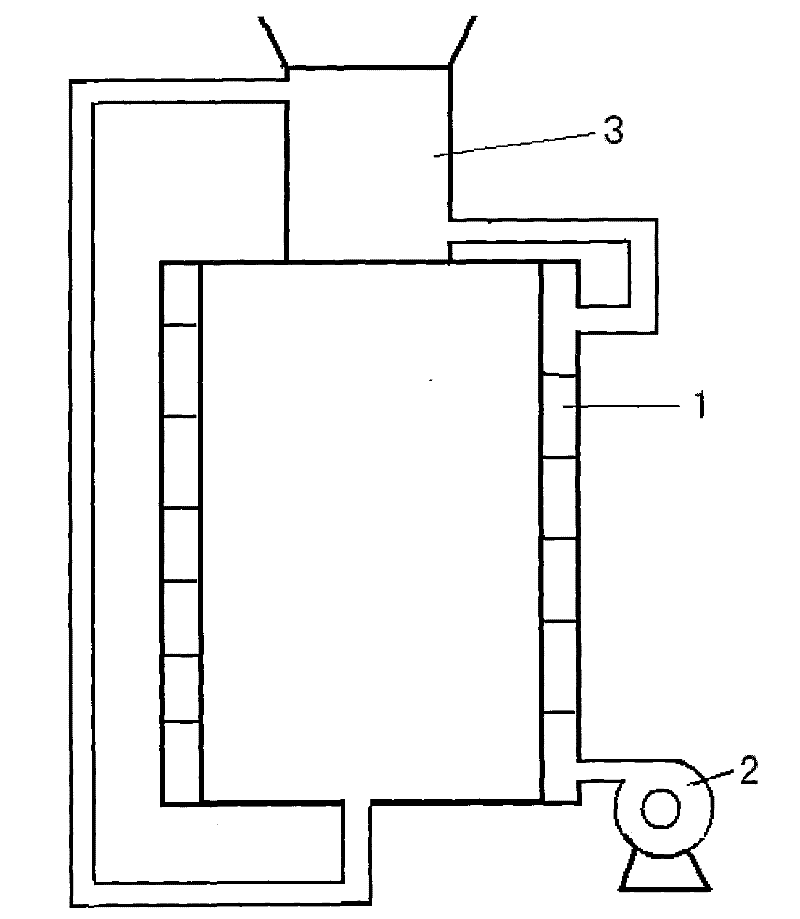

[0015] (2) Move the fermented material obtained in step (1) into a fermenter for aerobic fermentation. The bottom of the fermenter is provided with forced ventilation facilities, and the upper part is equipped with a material overturning machine. The tipping machine tipped over once a day, and the blower blasted it every 6 hours. Fermentation is completed in 4-7 days, so that the moisture content of the material reaches below 30%, and the harmful bacteria are killed to remove the stench. Sieve the fermented material to make fuel powder. Sieve out the larger sundries and leavening agent (thin bamboo pole section) and reuse after drying to remov...

Embodiment 2

[0018] (1) Take 70 tons of dewatered sludge (moisture content 70%-80%) discharged from the sewage plant, add 30 tons of sawdust (moisture content 15%-30%) as a moisture regulator and leavening agent, and fully mix to form fermented material.

[0019] (2) Pile the fermented material prepared in step (1) into strips for aerobic fermentation, turn over the pile 1-2 times a day, and complete the fermentation in 4-7 days, so that the moisture content of the material reaches below 40% and kills harmful bacteria Removes foul odors. The fermented material is sieved to remove impurities, and then air-dried to reduce the moisture content to below 30% to make fuel powder.

[0020] (3) The fuel powder obtained in step (2) is pressed into blocks to make fuel blocks, and stacked into strips for further air-drying. Put the air-dried fuel block into the gasification furnace, and carry out high-temperature or medium-temperature pyrolysis and gasification under the condition of restricted ven...

Embodiment 3

[0022] (1) Take 70 tons of dewatered sludge (water content 70%-80%) discharged from the sewage plant, add 25 tons of mushroom slag (water content 15%-30%) as a moisture regulator, and use peanut shells as a leavening agent Add 5 T. Thorough mixing is carried out to form the fermented mass.

[0023] (2) Move the fermented material obtained in step (1) into the fermenting field and pile it up into strips for aerobic fermentation. Turn the heap 1-2 times a day with a walking-type turning and throwing machine, and complete the fermentation in 4-7 days to increase the moisture content of the material. Drop below 30% and kill bad bacteria to remove bad smell. Sieve the fermented material to make fuel powder.

[0024] (3) The fuel powder obtained in step (2) is pressed into blocks to make fuel blocks, and stacked into strips for further air-drying. Put the air-dried fuel block into the gasification furnace, and carry out high-temperature or medium-temperature pyrolysis gasificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com