Method for preparing ultralight ceramsites from clay iron-containing tailings

A technology of ultra-light ceramics and tailings, applied in applications, ceramic products, household appliances, etc., can solve the requirements of raw material formulations are very strict, the total solid waste ultra-light ceramsite is less, and the total solid waste ultra-light ceramsite has not been found yet, etc. problems, to achieve significant economic benefits, high cost performance, and strong market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further describe the present invention, a method for preparing ultra-light ceramsite by using clay iron-containing tailings of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0037] Table 1 is a chemical composition list of raw materials used in a method of preparing ultra-light ceramsite by utilizing clay iron-containing tailings in the present invention.

[0038] Table 1 Chemical composition of raw materials used (%)

[0039]

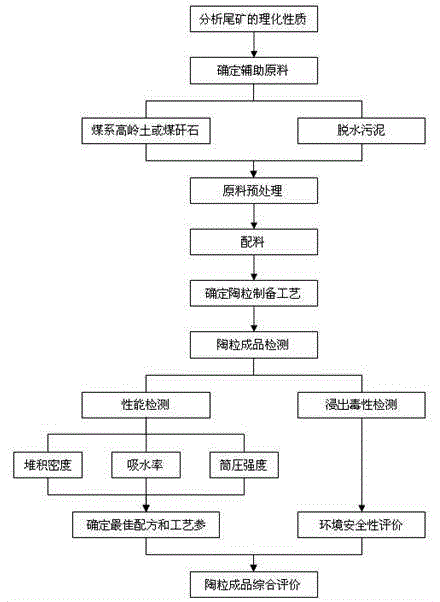

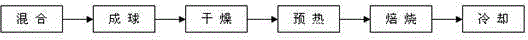

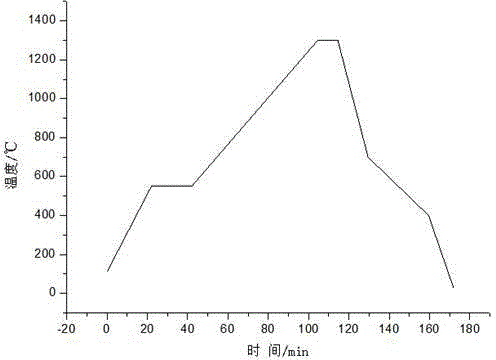

[0040] Depend on figure 1 A technical roadmap for the method of preparing ultra-light ceramsite by utilizing clay iron-containing tailings in the present invention and combining figure 2 It can be seen that a kind of technique and parameters adopted in the method of utilizing clay iron-containing tailings to prepare ultra-light ceramsite in the present invention are:

[0041] (1) Raw material selection

[0042] When firing ultra-light ceramsite, the che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com