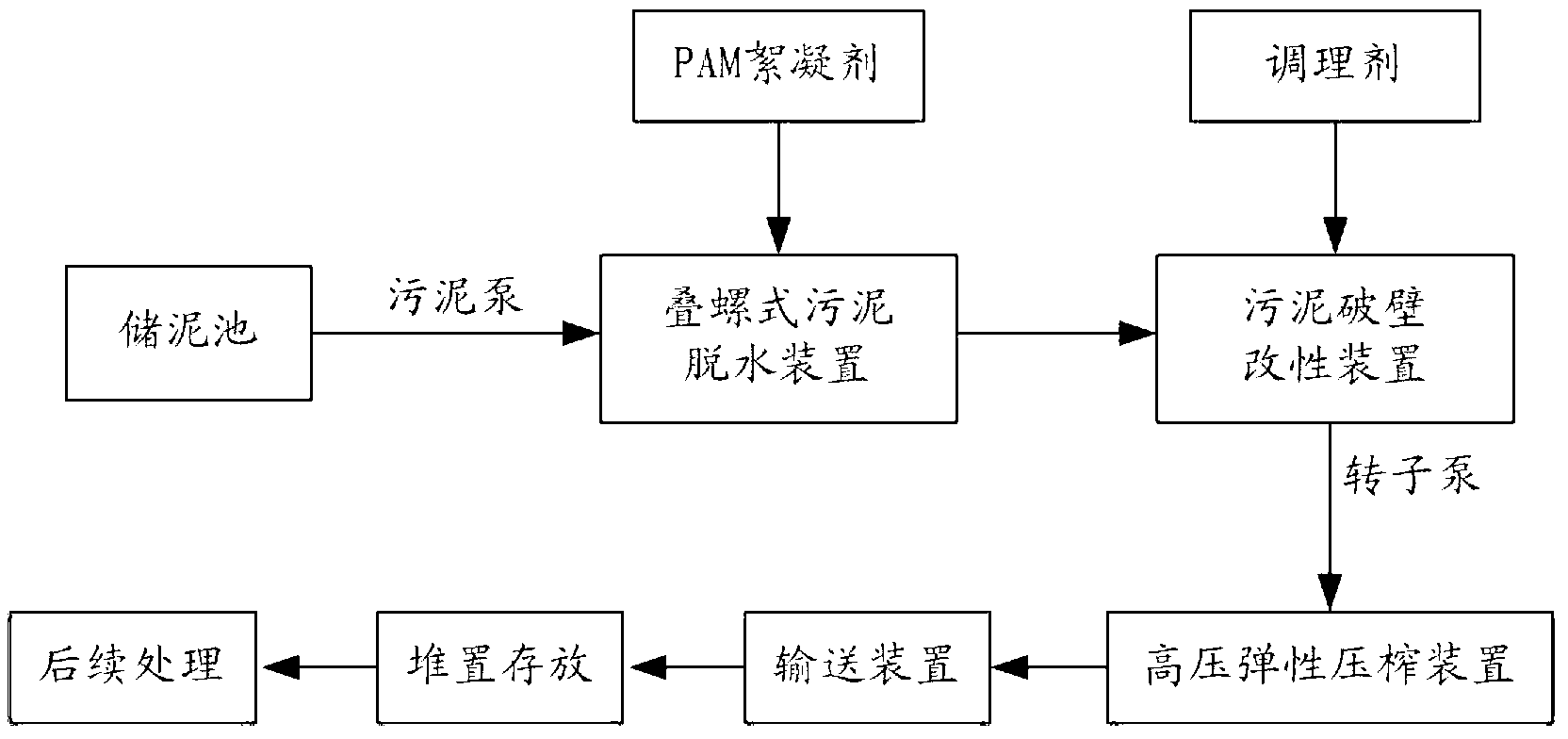

Sludge deep dewatering treatment system and process

A technology of deep dehydration and treatment process, applied in the direction of dehydration/drying/concentrated sludge treatment, which can solve the problem of large heat loss and achieve the effect of high energy utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: adopt the sludge advanced dehydration treatment process of the present invention to process the sludge data as follows:

[0033] Sludge properties: residual sludge from municipal sewage treatment plants, sludge moisture content 99.2%

[0034] Processing scale: 5000 tons / day

[0035] Running time: three shifts a day, running time 20h

[0036] Treatment goal: reduce the moisture content of sludge to less than 60%, which is convenient for subsequent resource treatment.

[0037] Operating costs: mainly include pharmaceutical costs, electricity costs, labor costs, etc.

[0038] 1. Material cost: The cost of flocculant is about 30,000 yuan / t, the dosage is 4‰ of the absolute dry sludge, and the cost of chemicals per ton of sludge is 24 yuan / t. The cost of conditioning agent is about 800 yuan / t, the dosage is 5%, and the cost of agent for ton of sludge is 40 yuan / t.

[0039] 2. Electricity fee: The total installed power of the equipment is 79kW, and the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com