Power generation device through low temperature exhaust heat

A power generation device and low-temperature waste heat technology, applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of low power generation cost, high power generation efficiency, small power generation limitation, etc., and achieve low power generation cost, high power generation efficiency, The effect of small power generation limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

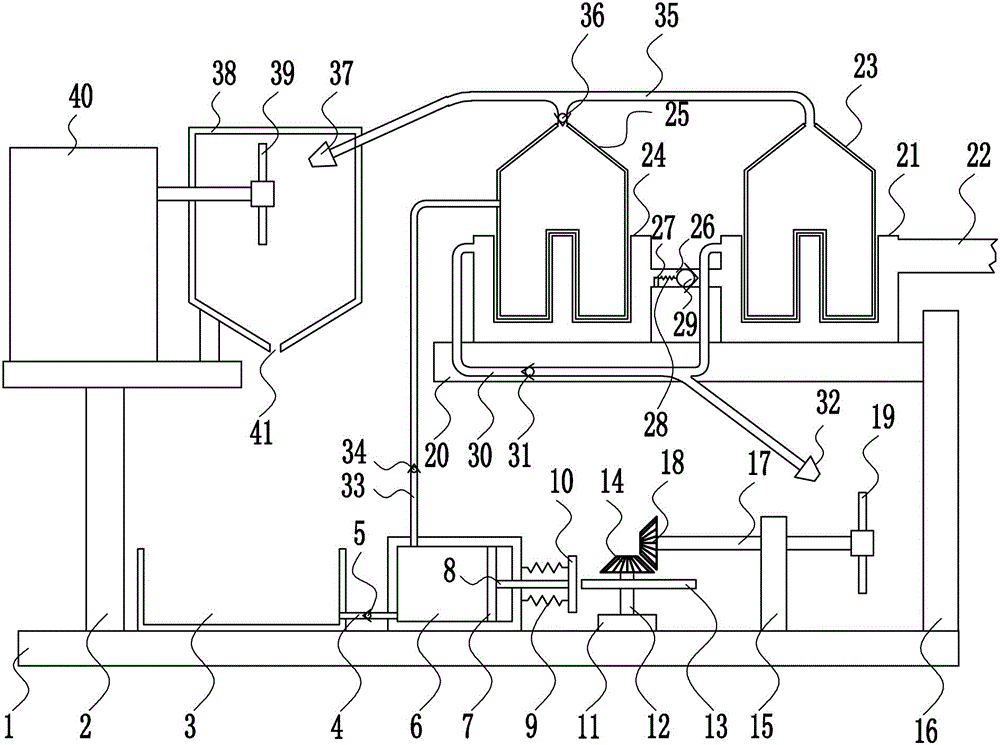

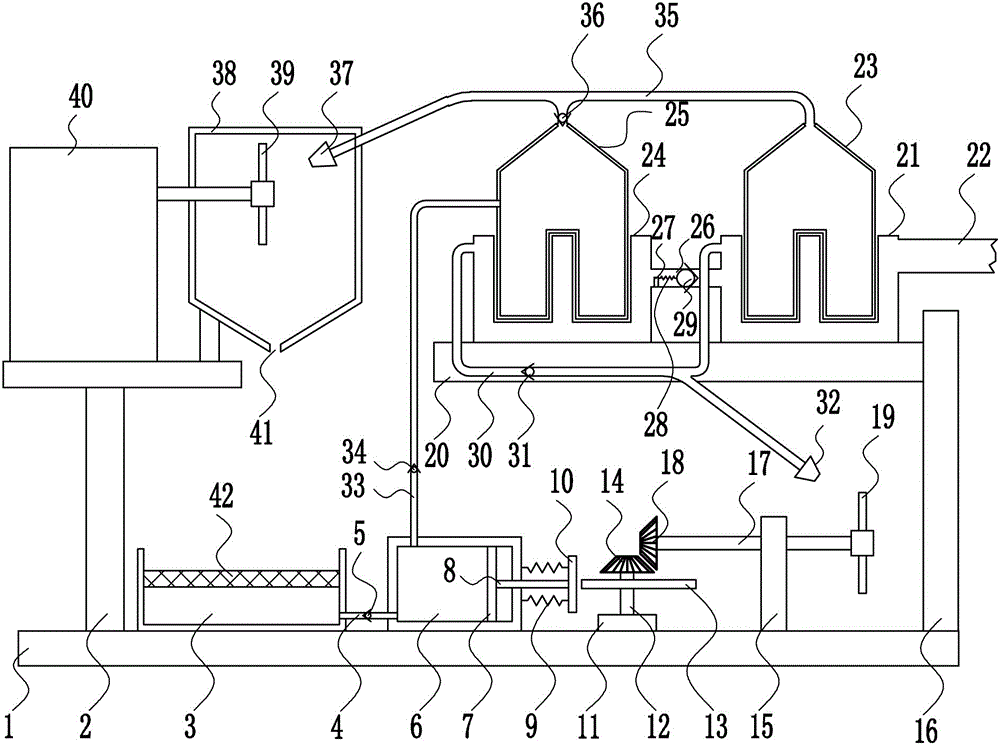

[0018] A low-temperature waste heat power generation device, such as Figure 1-2 As shown, it includes bottom plate 1, mounting bracket 2, pool 3, water inlet pipe 4, one-way valve I5, cylinder body 6, piston 7, moving rod 8, spring I9, pressure plate 10, bearing seat I11, rotating shaft I12, and cam 13 , bevel gear Ⅰ14, bearing seat Ⅱ15, bracket 16, rotating shaft Ⅱ17, bevel gear Ⅱ18, fan Ⅰ19, fixed plate 20, heating furnace Ⅰ21, intake pipe 22, boiler Ⅰ23, heating furnace Ⅱ24, boiler Ⅱ25, pressure relief pipe 26, gear Block 27, spring II28, one-way valve II29, air outlet pipe I30, one-way valve III31, air nozzle I32, water outlet pipe 33, one-way valve IV34, air outlet pipe II35, one-way valve V36, air nozzle II37, condensation box 38, Fan II 39, generator set 40 and water outlet 41, the top of bottom plate 1 is provided with installation frame 2, pool 3, cylinder body 6, bearing seat I11, bearing seat II15 and bracket 16 in sequence from left to right, and the top of instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com