Combined power circulating method capable of catching carbon dioxide (CO2) by using LNG (Liquefied Natural Gas) cold energy and system thereof

A liquefied natural gas and combined power technology, which is applied in the field of combined power cycle method and system, can solve the problems of large consumption of LNG cold energy, large amount of LNG cold energy, and high energy consumption for oxygen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

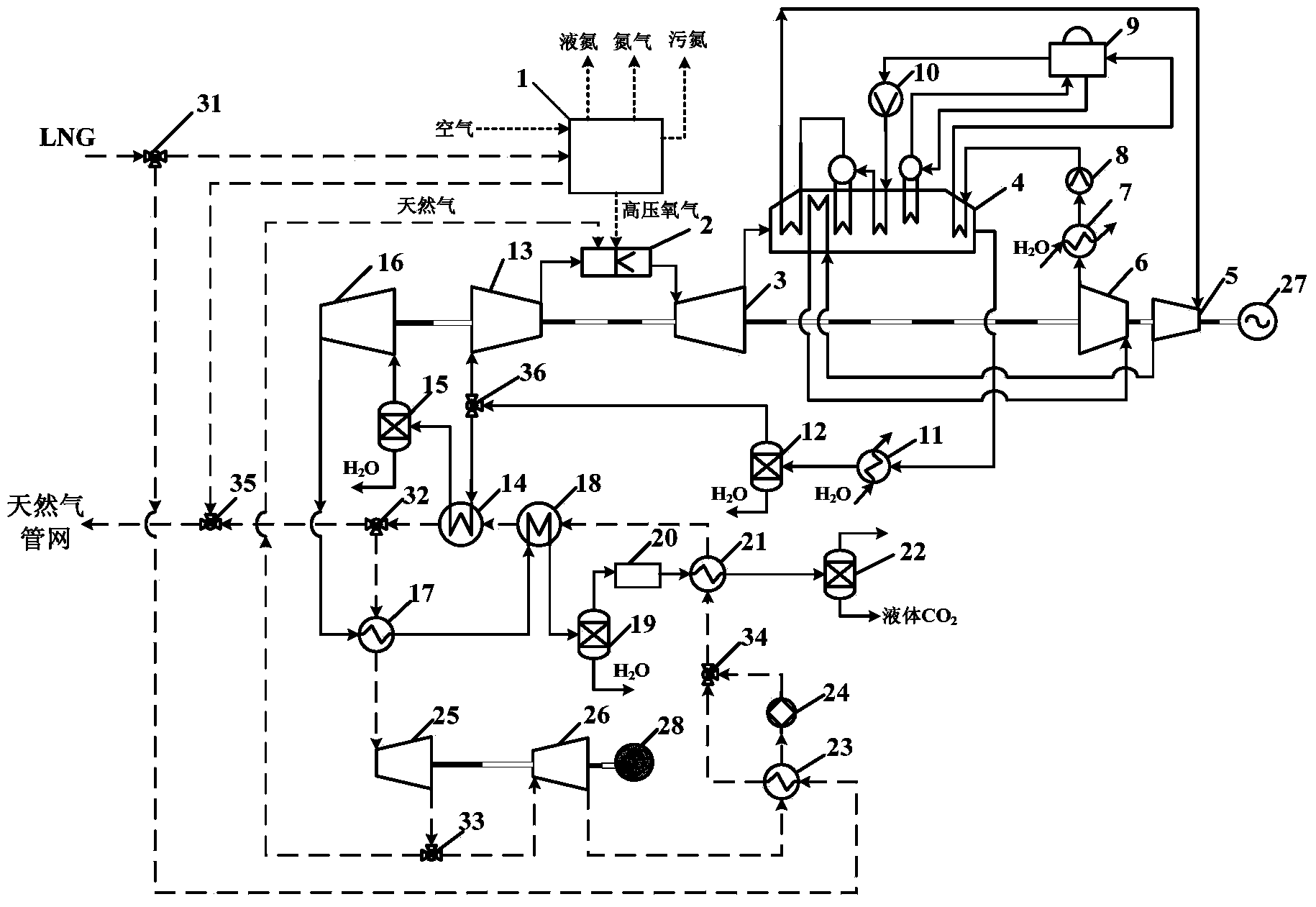

[0097] A combined power cycle system that uses the cold energy of liquefied natural gas to capture carbon dioxide, its process flow is as follows figure 1 shown.

[0098] The pressure of LNG from the receiving station of liquefied natural gas (LNG) is 11.0MPa (absolute pressure), the temperature is -140.0°C, and its volume composition is: methane 96.64%, ethane 2.77%, propane 0.34%, isobutane 0.07%, Butane 0.08%, nitrogen 0.10%; the lower heating value (LHV) of LNG after vaporization is 49.785MJ / kg. The isentropic efficiencies of circulating flue gas compressors, gas turbines, steam turbine high-pressure turbines, steam turbine low-pressure turbines, natural gas high-pressure turbines, and natural gas medium-pressure turbines are 0.88, 0.90, 0.891, 0.90, 0.75, and 0.75, respectively. Take 0.98, 0.99, 0.99, 0.99, 0.98, 0.98 respectively. The isentropic efficiencies of condensate pumps, boiler feed water pumps and LNG pumps are all 0.80, and the mechanical efficiencies are all...

Embodiment 2

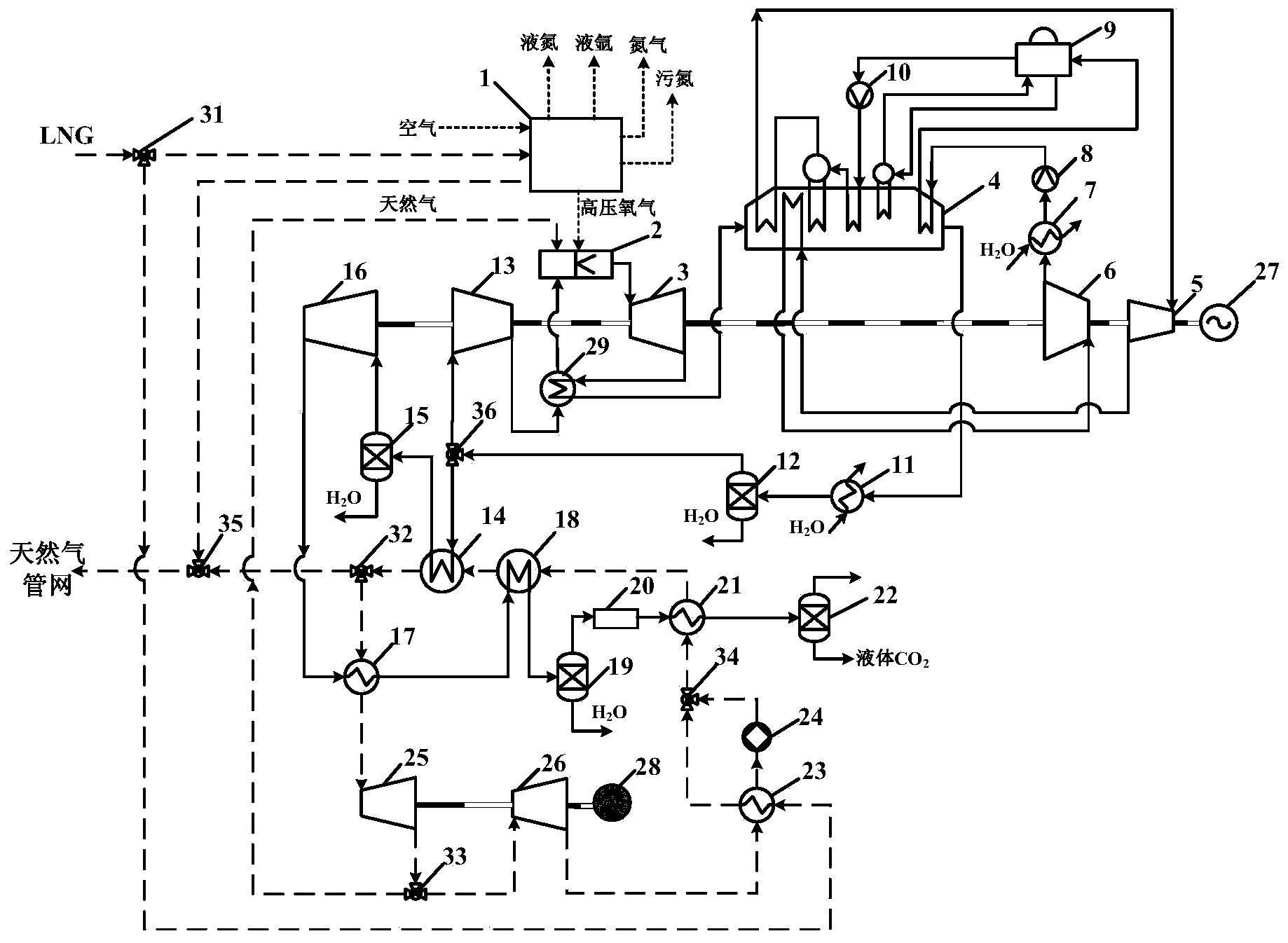

[0117] A combined power cycle system that uses the cold energy of liquefied natural gas to capture carbon dioxide, its process flow is as follows figure 2 shown.

[0118] The pressure of LNG from the receiving station of liquefied natural gas (LNG) is 6.0MPa (absolute pressure), the temperature is -157.0℃, and its volume composition is: methane 96.64%, ethane 2.77%, propane 0.34%, isobutane 0.07%, Butane 0.08%, nitrogen 0.10%; the lower heating value (LHV) of LNG after vaporization is 49.785MJ / kg. The isentropic efficiencies of circulating flue gas compressors, gas turbines, steam turbine high-pressure turbines, steam turbine low-pressure turbines, natural gas high-pressure turbines, and natural gas medium-pressure turbines are 0.88, 0.90, 0.891, 0.90, 0.75, and 0.75, respectively. Take 0.98, 0.99, 0.99, 0.99, 0.98, 0.98 respectively. The isentropic efficiencies of condensate pumps, boiler feed water pumps and LNG pumps are all 0.80, and the mechanical efficiencies are all ...

Embodiment 3

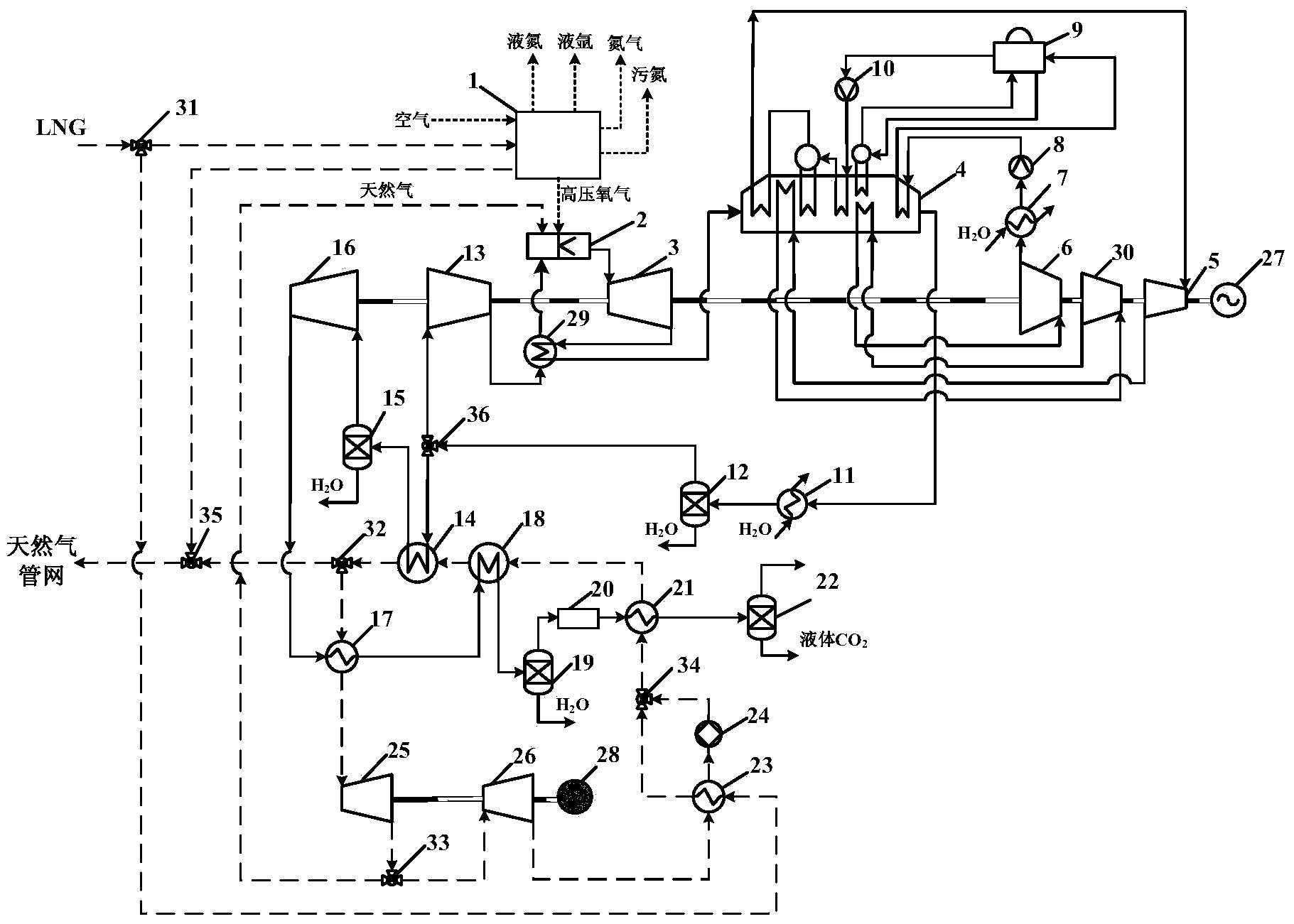

[0137] A combined power cycle system that uses the cold energy of liquefied natural gas to capture carbon dioxide, its process flow is as follows image 3 shown.

[0138] The LNG from the liquefied natural gas (LNG) receiving station has a pressure of 10.0MPa and a temperature of -153.0°C. Its volume composition is: methane 96.64%, ethane 2.77%, propane 0.34%, isobutane 0.07%, butane 0.08% , nitrogen 0.10%; the lower heating value (LHV) of LNG after vaporization is 49.785MJ / kg. The isentropic efficiencies of circulating flue gas compressors, gas turbines, steam turbine high-pressure turbines, steam turbine medium-pressure turbines, steam turbine low-pressure turbines, natural gas high-pressure turbines, and natural gas medium-pressure turbines are 0.88, 0.90, 0.891, 0.90, 0.90, 0.75, 0.75, the mechanical efficiency is 0.98, 0.99, 0.99, 0.99, 0.99, 0.98, 0.98 respectively. The isentropic efficiencies of condensate pumps, boiler feed water pumps and LNG pumps are all 0.80, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com