Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

851 results about "Steam power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

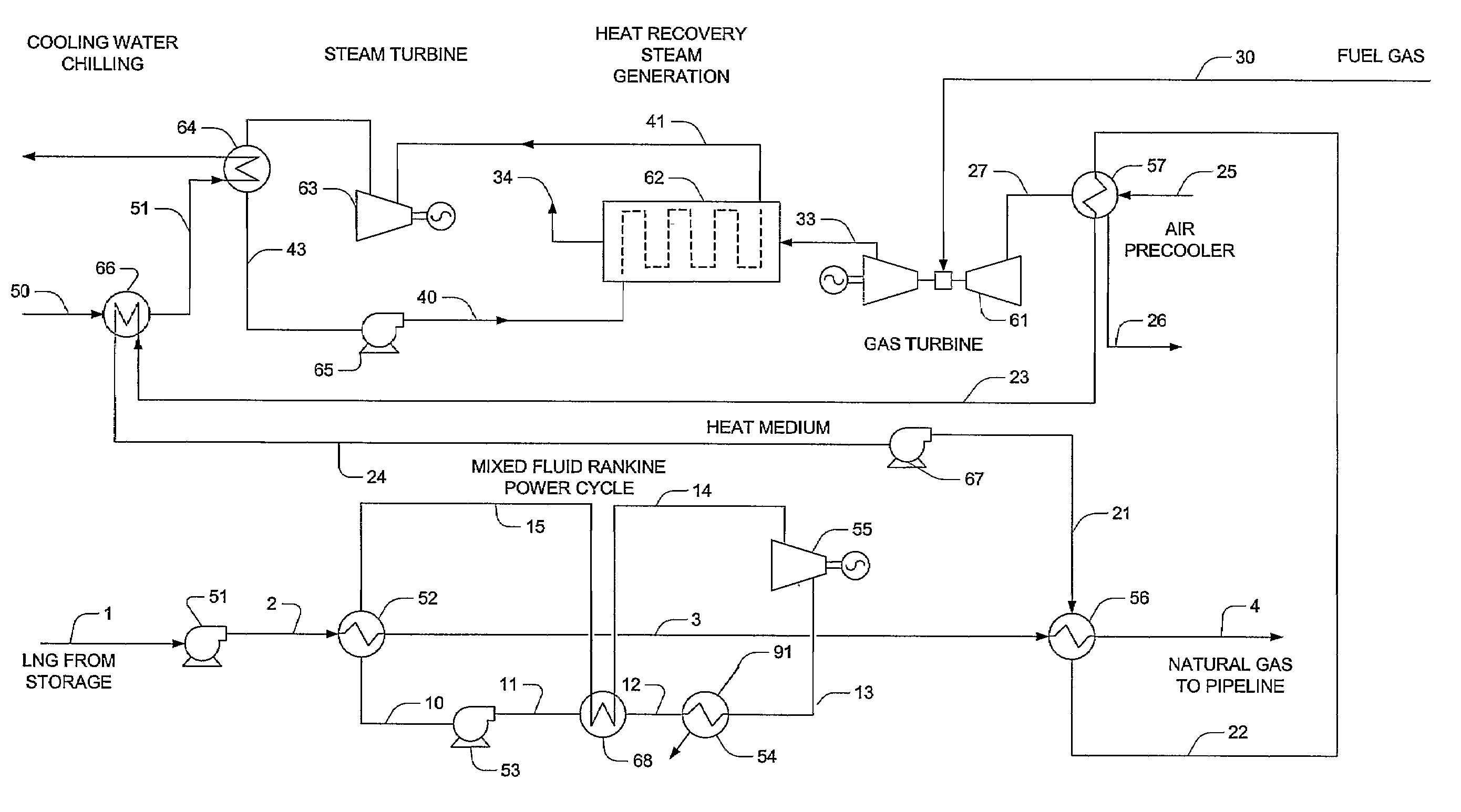

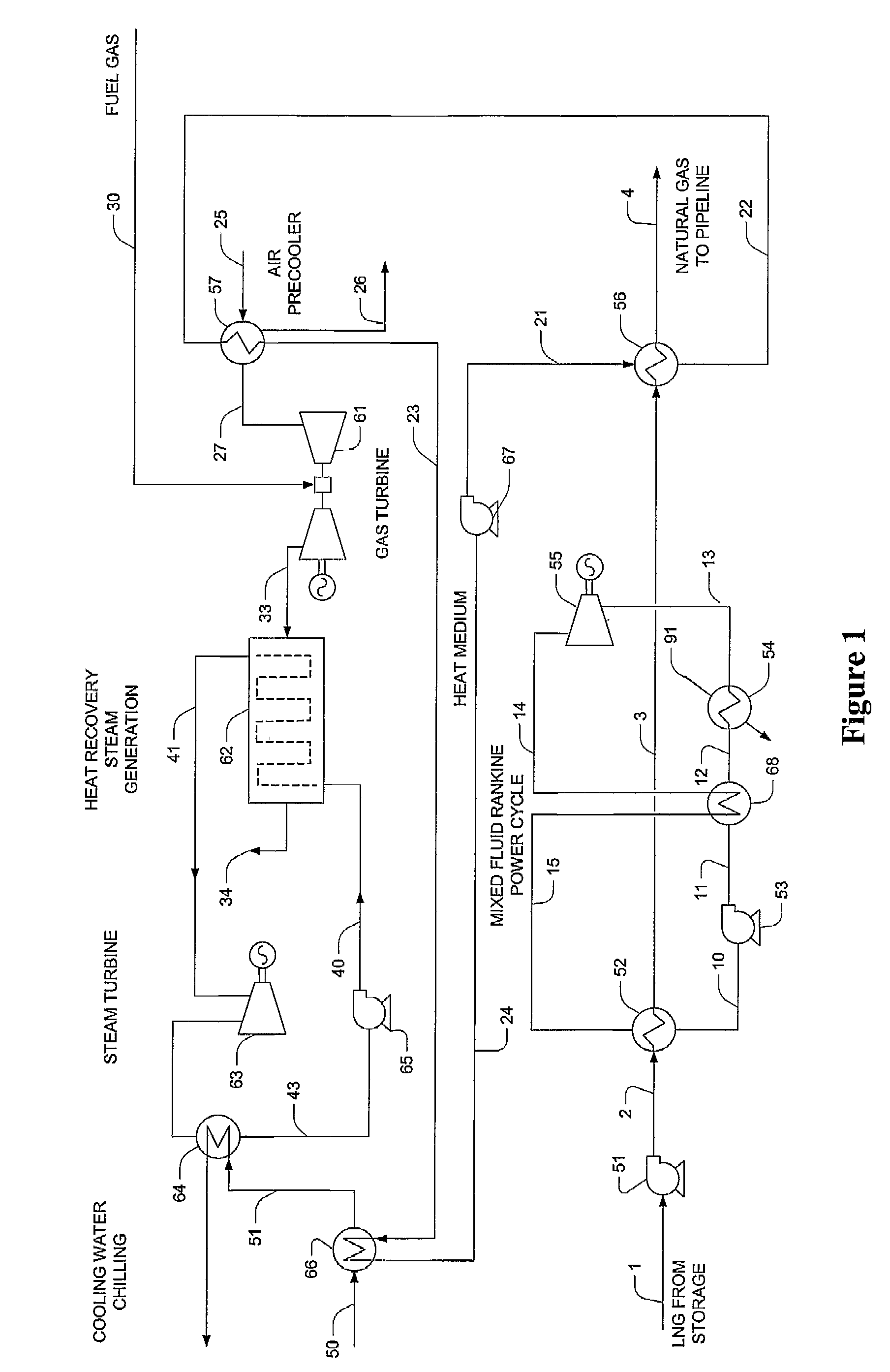

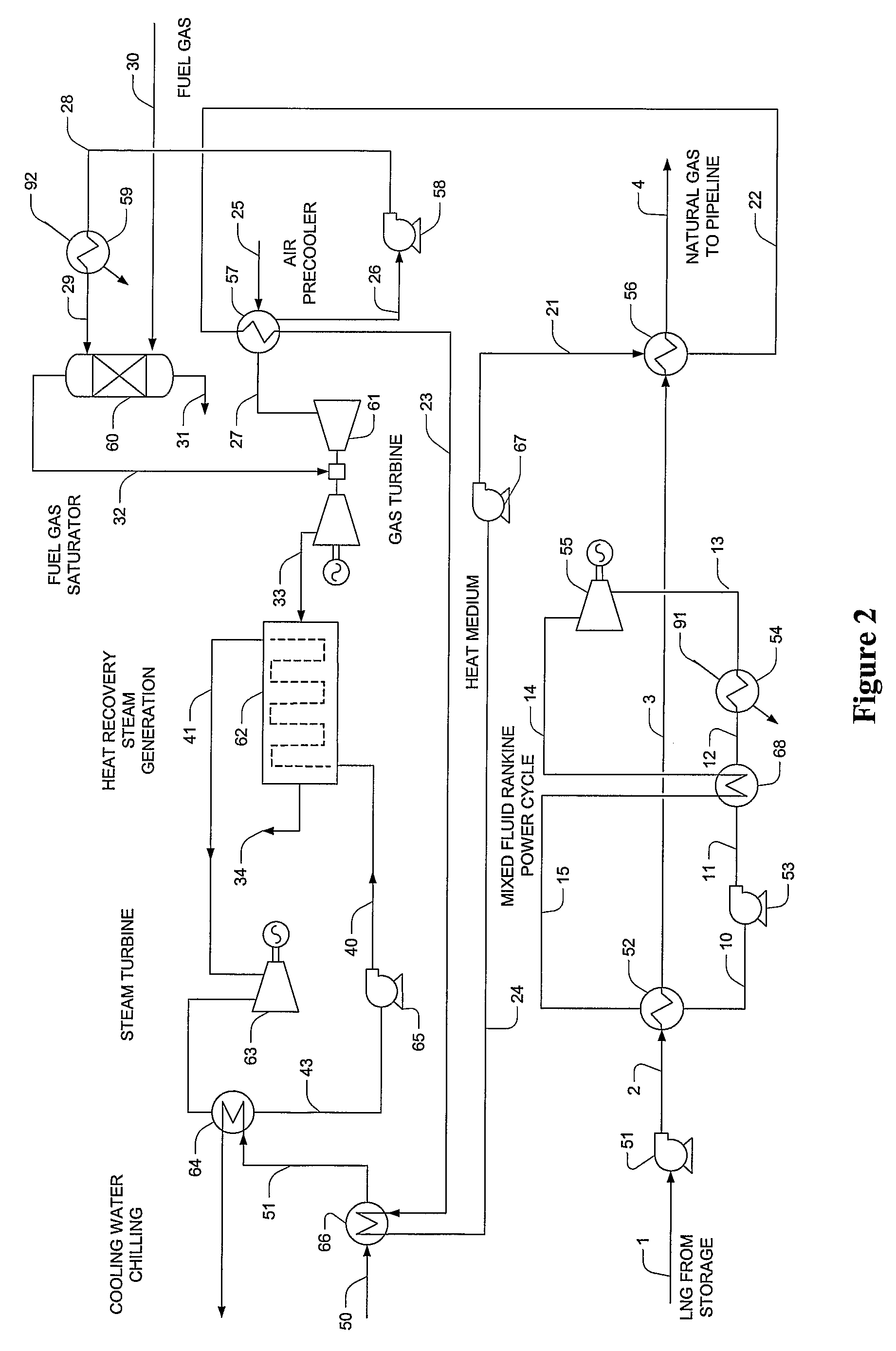

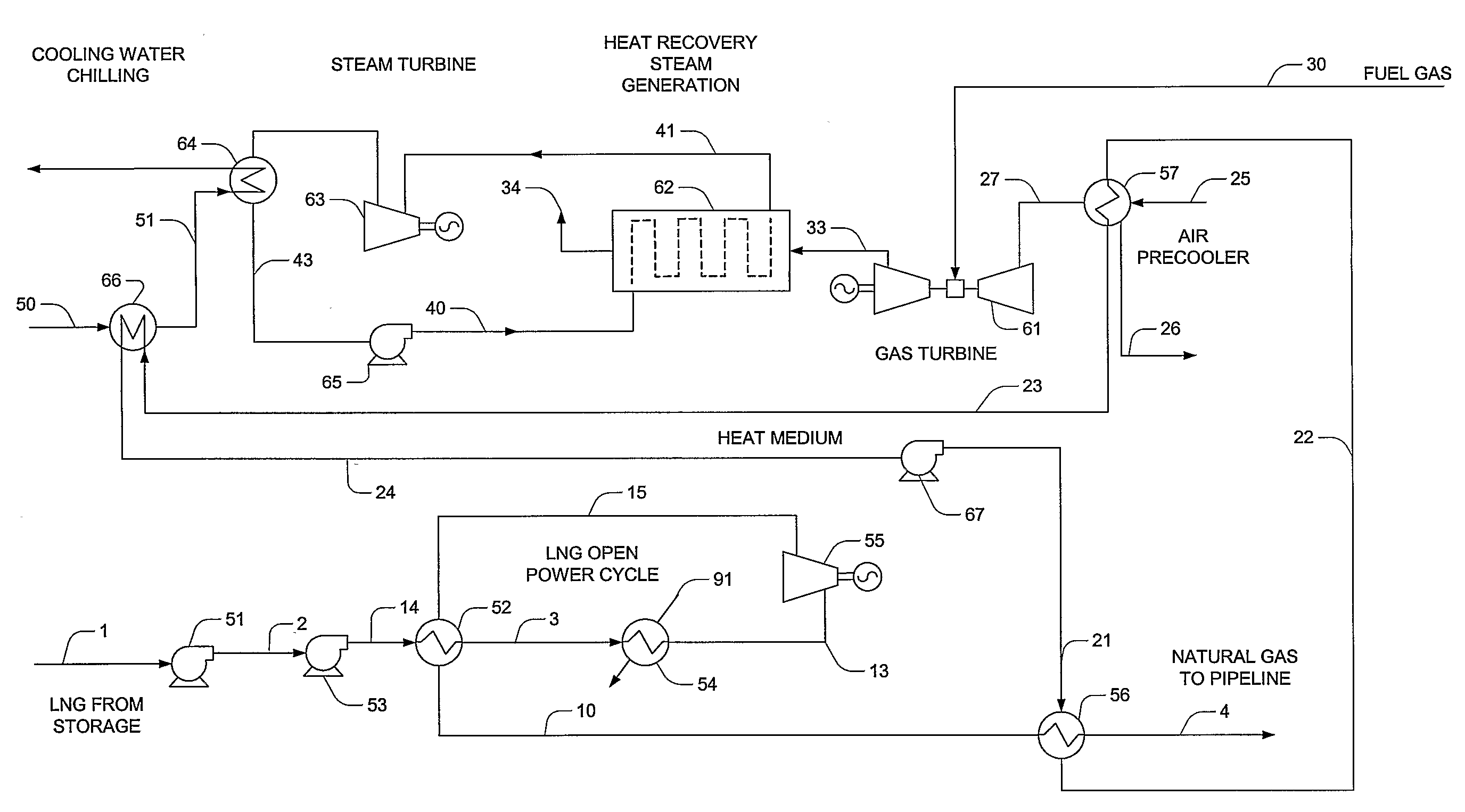

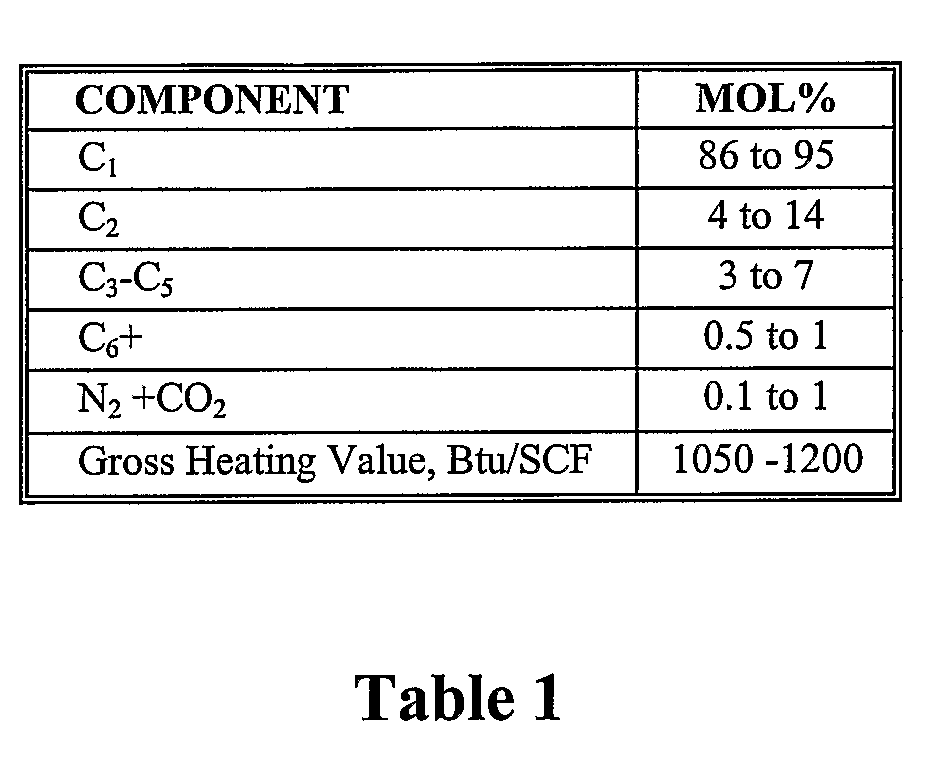

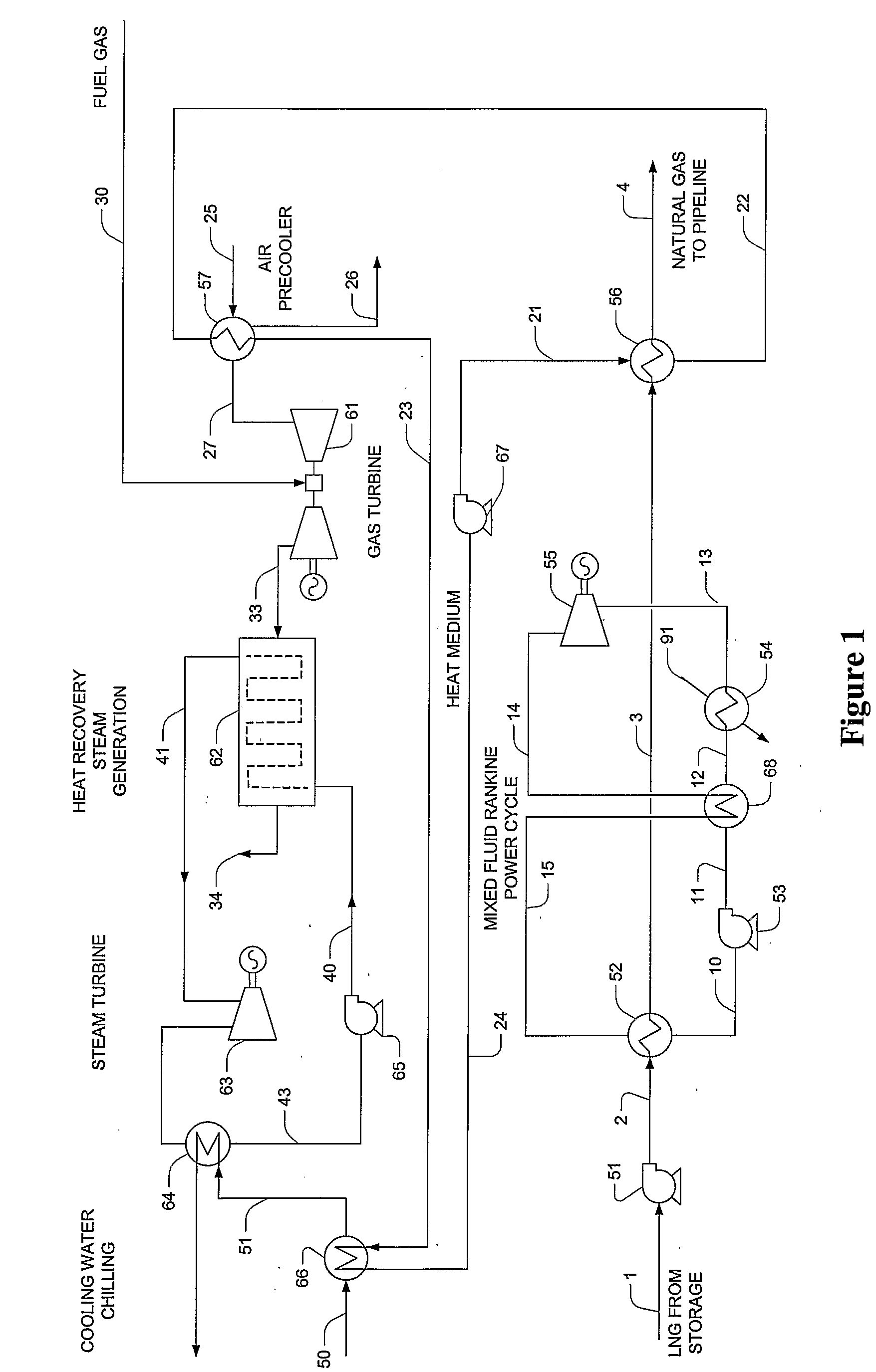

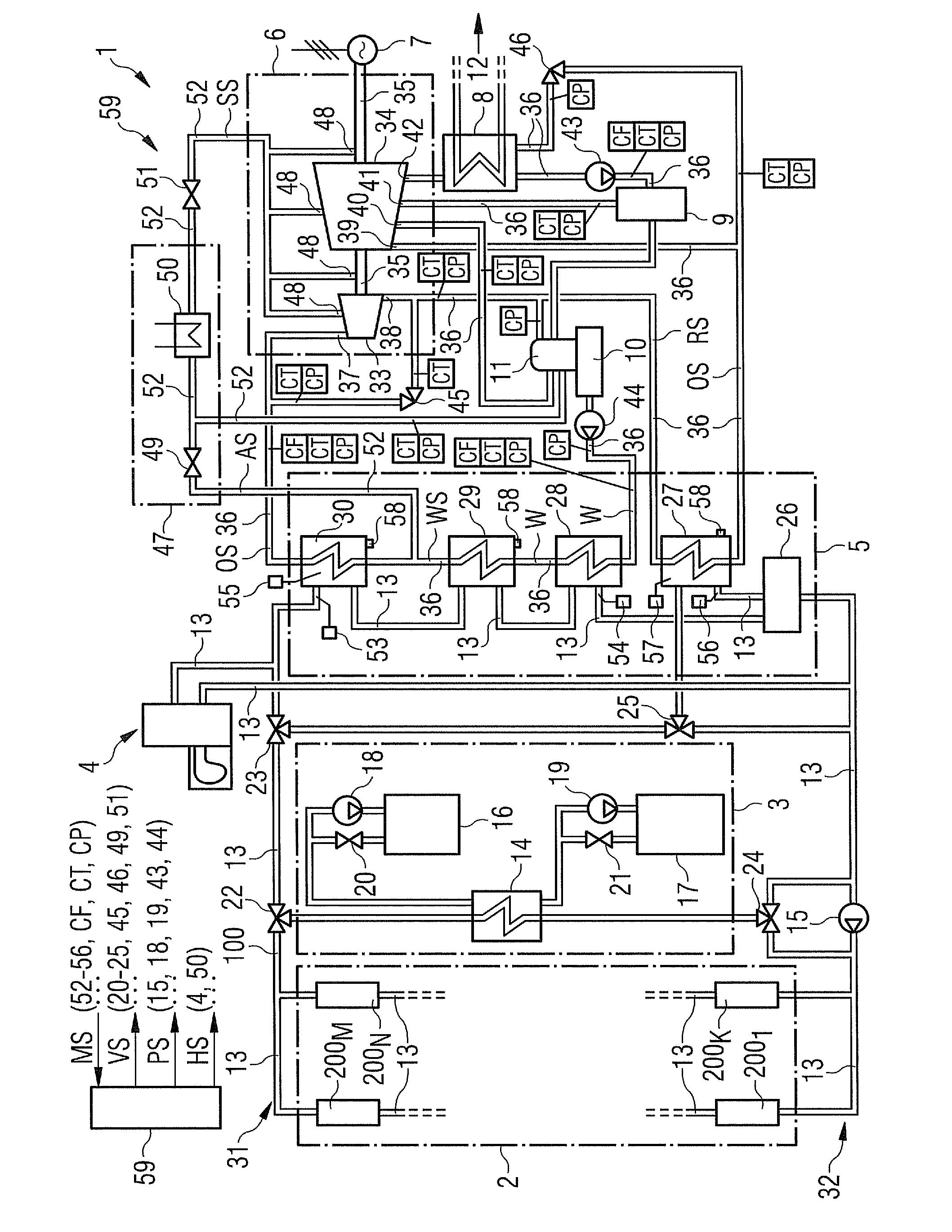

Configurations and methods for power generation with integrated LNG regasification

Owner:FLUOR TECH CORP

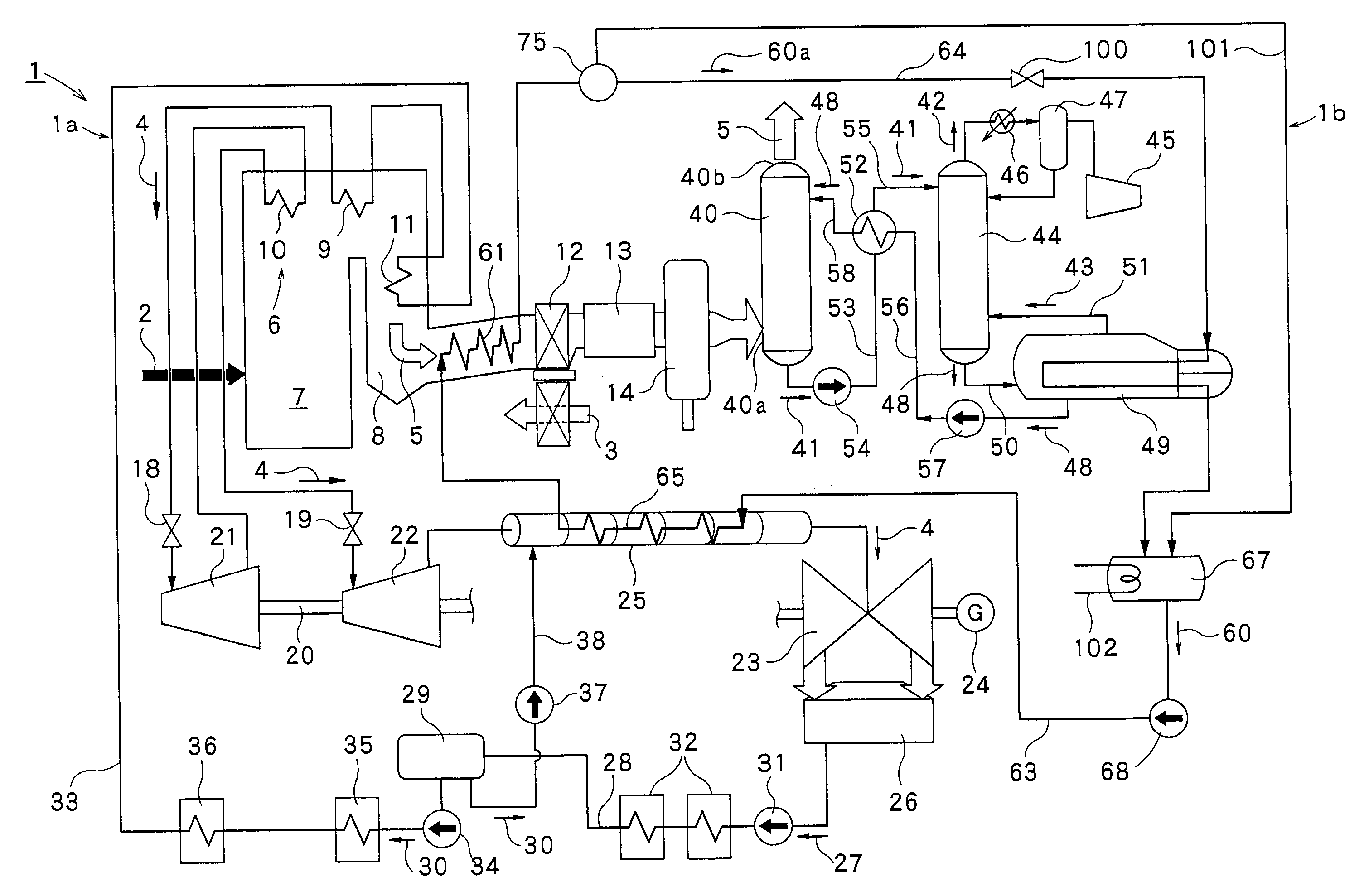

Carbon-dioxide-capture-type steam power generation system

InactiveUS20100050637A1Avoid power generation efficiencyImprove efficiencyLiquid degasificationCarbon compoundsCo2 absorptionReboiler

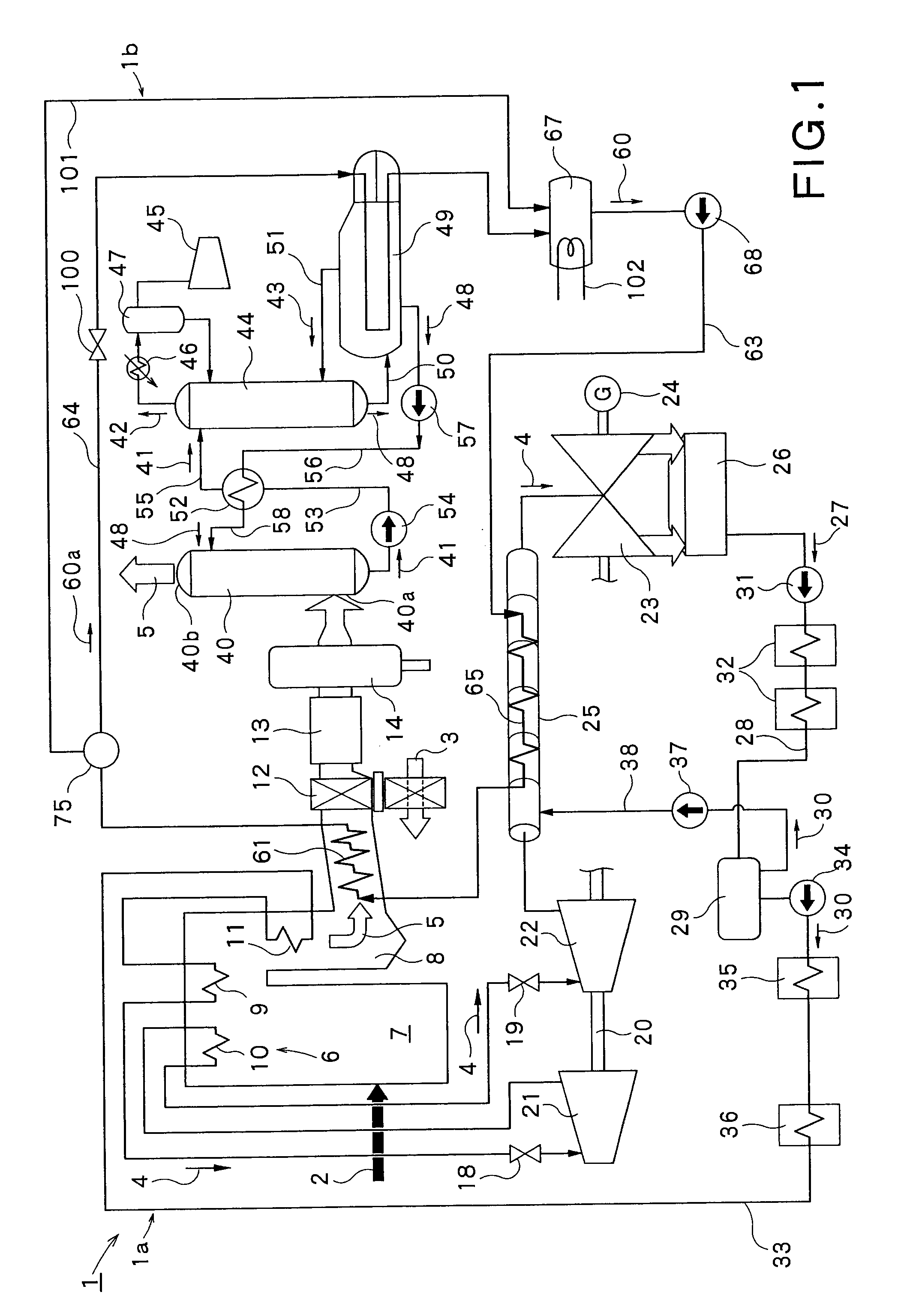

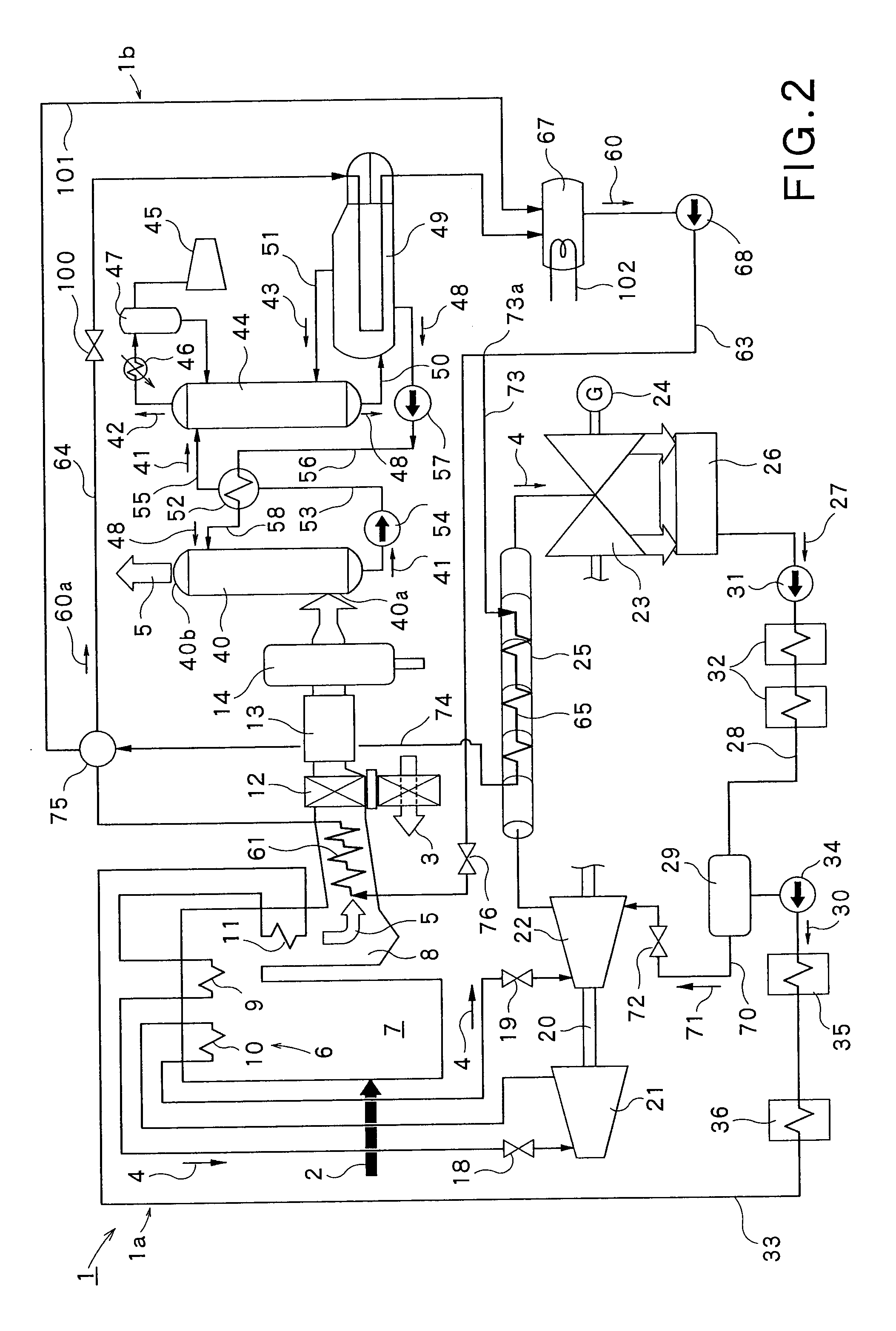

A carbon-dioxide-capture-type steam power generation system 1 according to the present invention comprises a boiler 6 producing an exhaust gas 5 by combusting a fuel 2 and having a flue 8; an absorbing unit 40 being configured to absorb the carbon-dioxide contained in the exhaust gas 5 into an absorbing solution; and a regenerating unit 44 being configured to release the carbon dioxide gas from the absorbing solution absorbing the carbon dioxide and discharge the released carbon dioxide gas. Further, in this system, a reboiler 49 is provided for receiving a heating-medium as heat source, producing a steam 43 and supplying the produced steam 43 to the regenerating unit 44. Additionally, in the flue 8 of the boiler 6, a boiler-side heat exchanger 61 is provided for heating the heating-medium by the exhaust gas 5 passing therethrough.

Owner:KK TOSHIBA

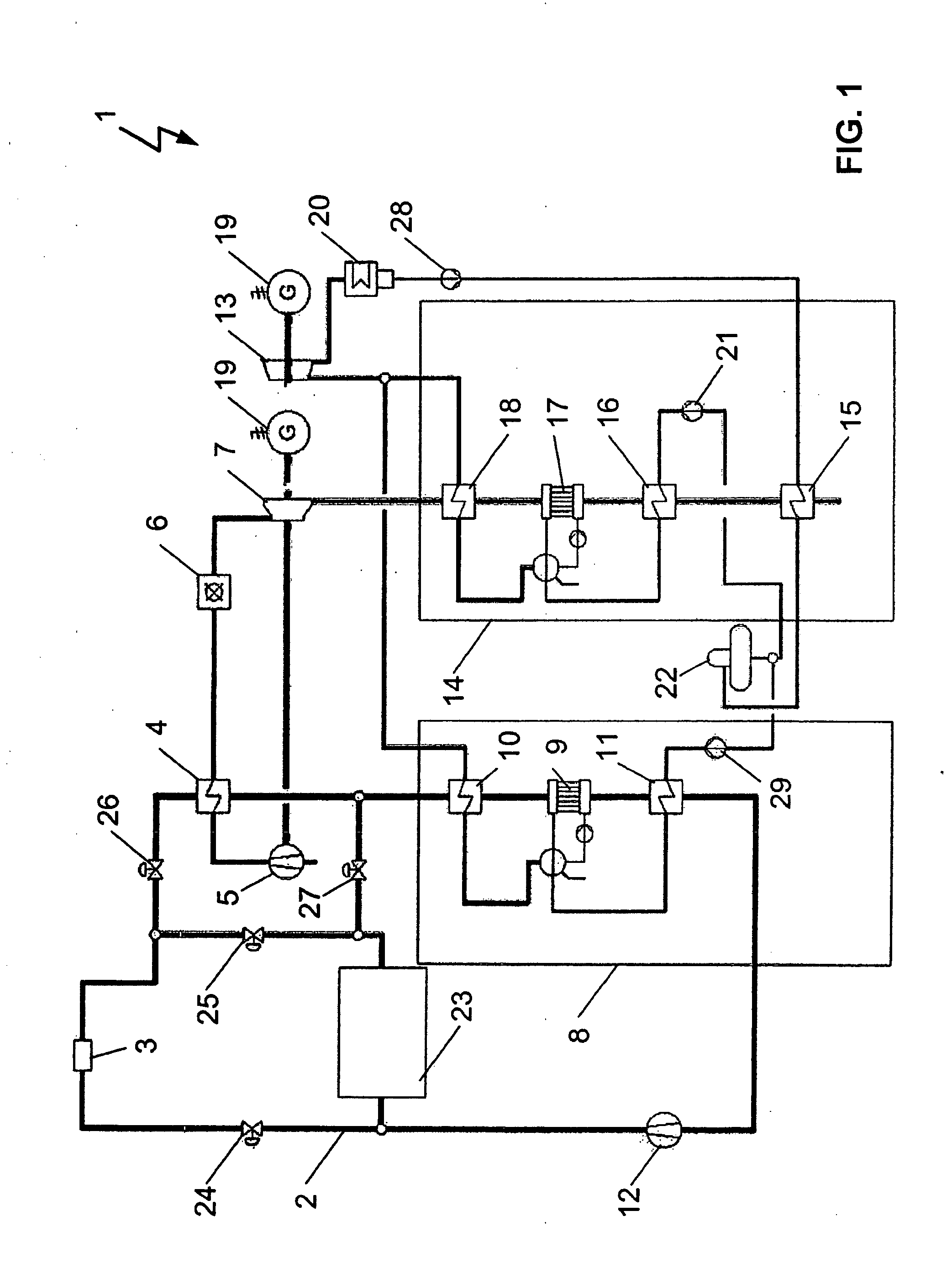

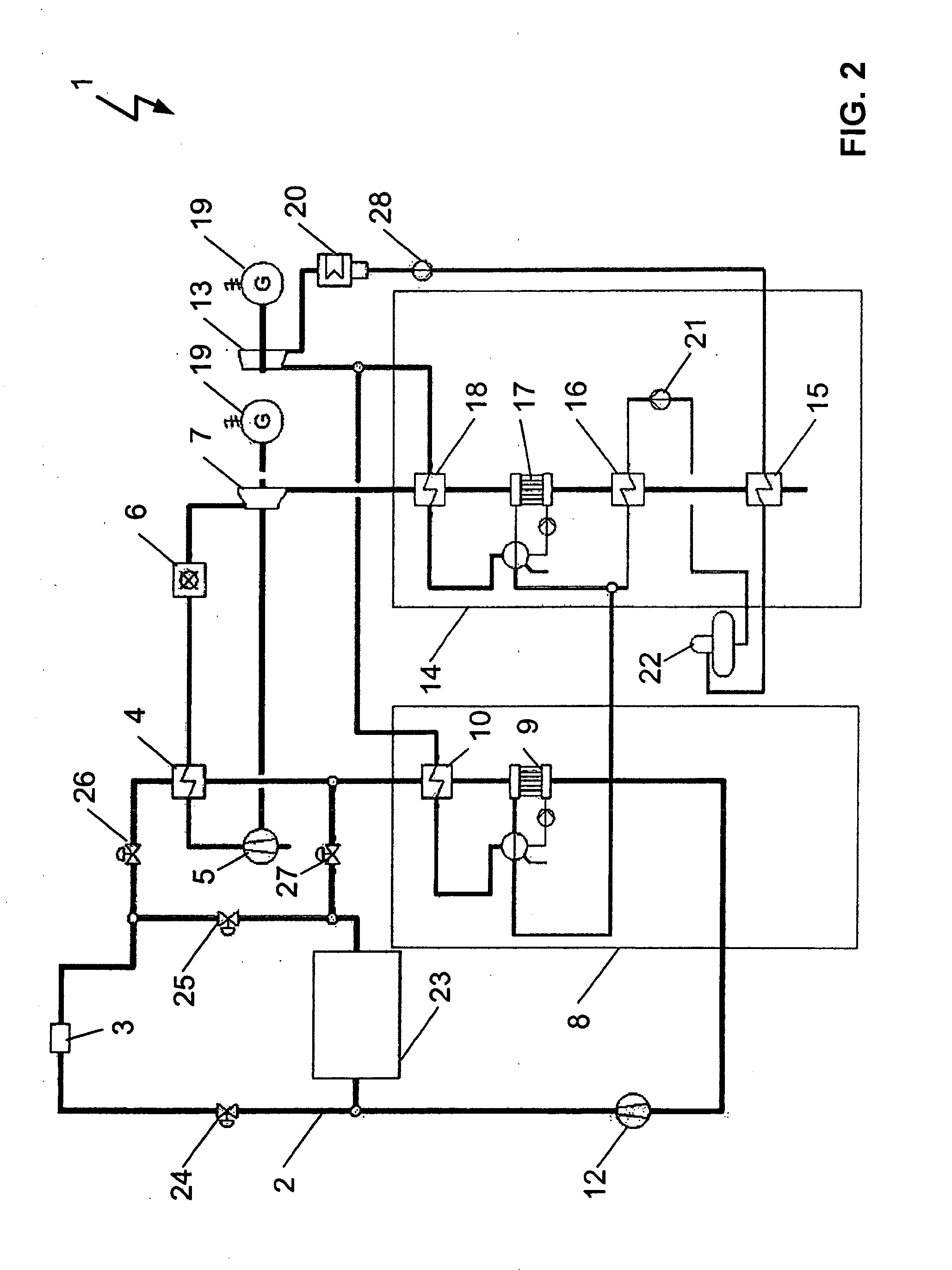

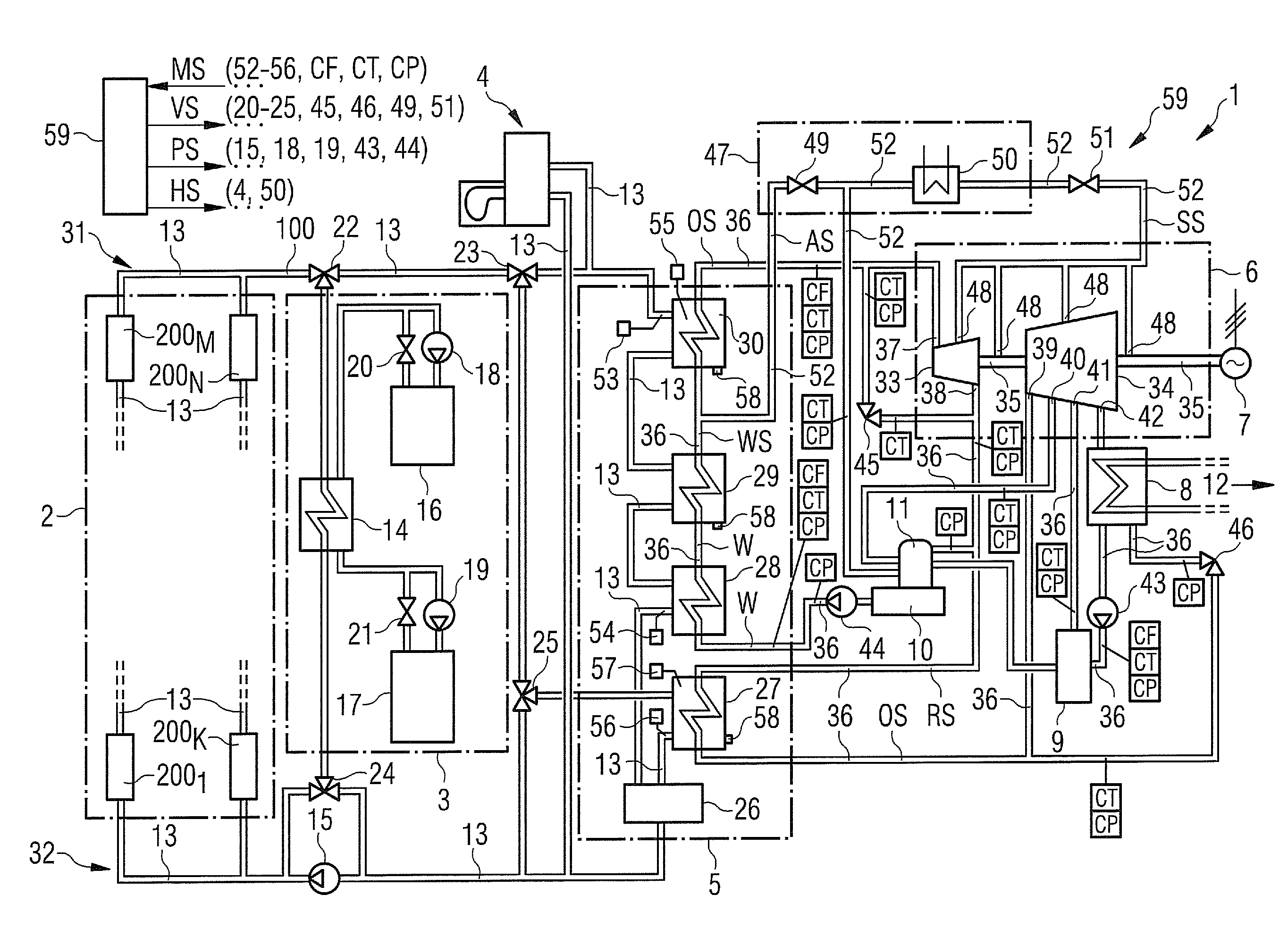

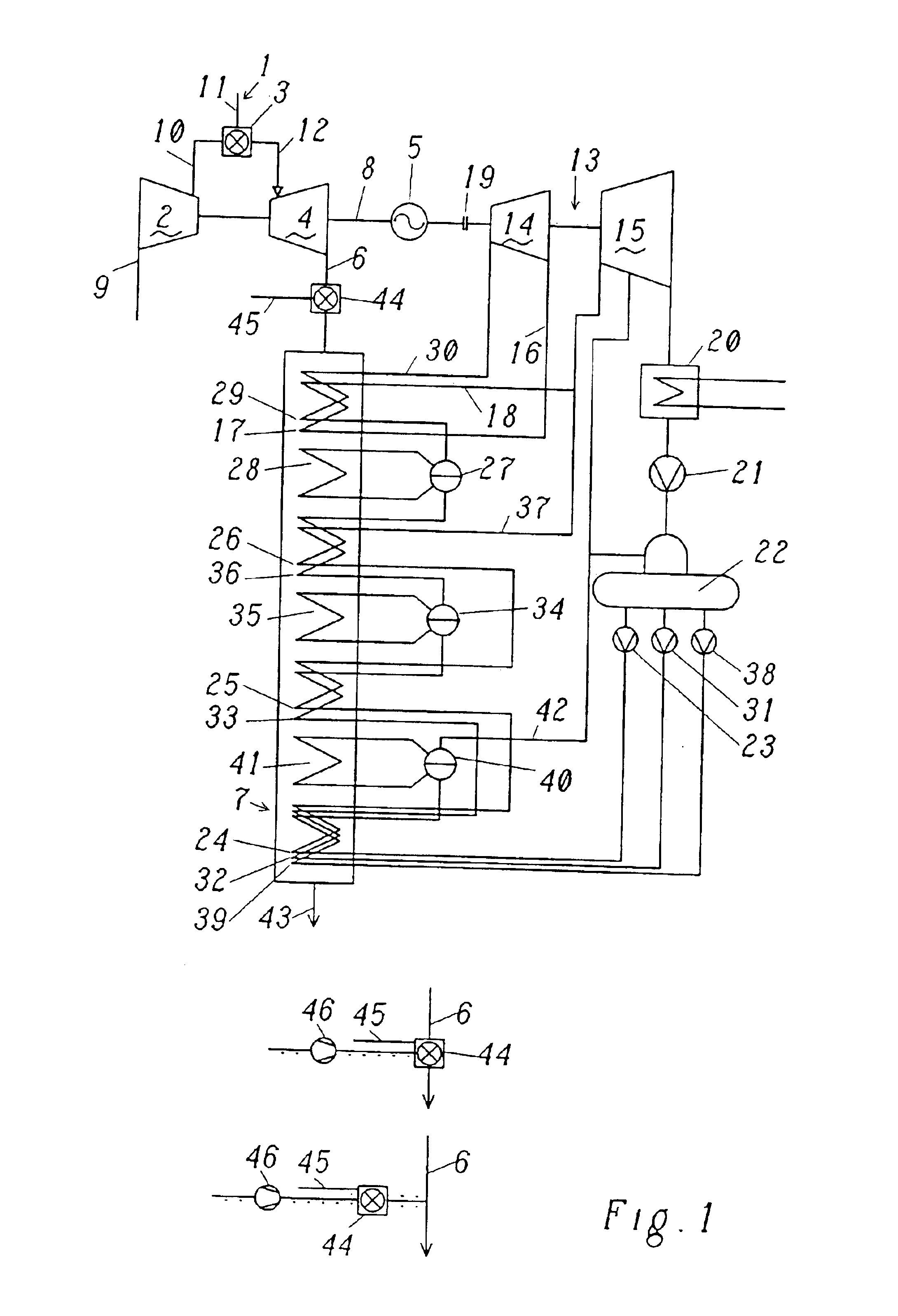

Method and device for operating a gas turbine with a fossil-fuel fired combustion chamber

InactiveUS7299637B2Reduce nitrogen oxide contentRisk minimizationGas turbine plantsDirect carbon-dioxide mitigationSteam-electric power stationCombustion chamber

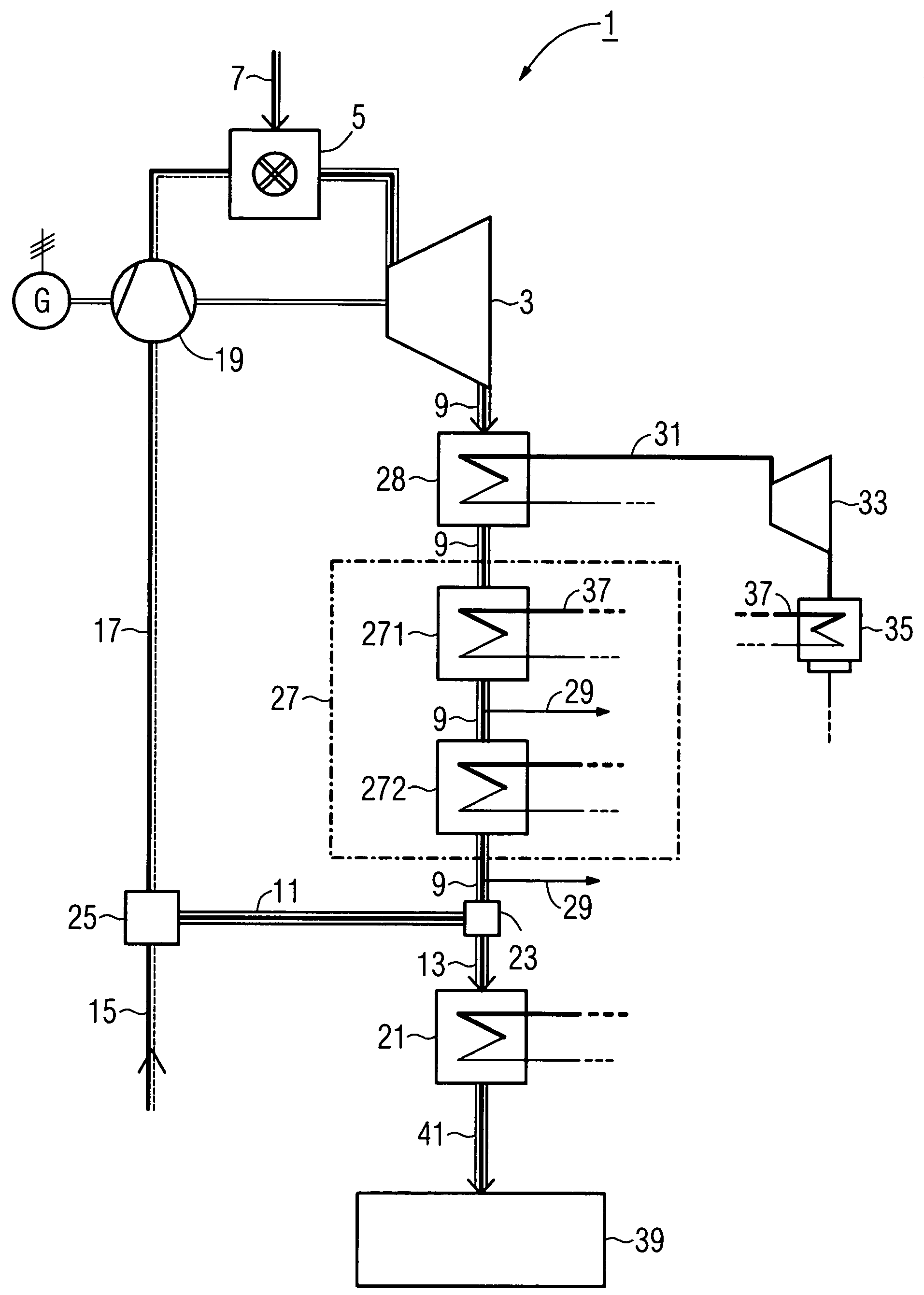

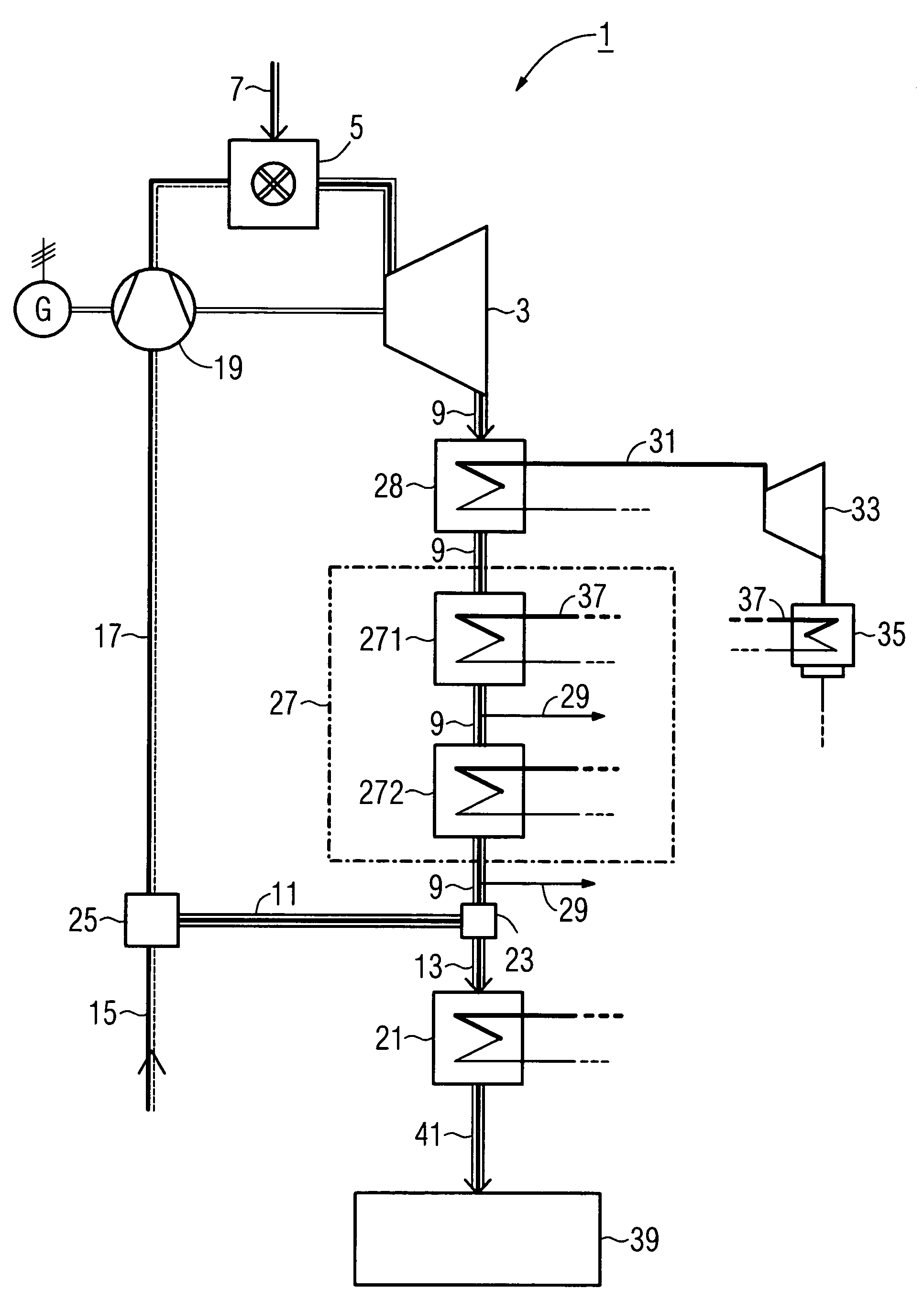

A method according to the invention or a corresponding device (1) provides for dividing exhaust gas (9) exiting the gas turbine into a first (11) and a second partial stream (13), for mixing the first partial stream (11) with combustion air (15), and for channeling the resulting mixture (17) to the combustion chamber (5) and the second partial stream (13) to a carbon dioxide precipitation plant (21).In an advantageous embodiment the exhaust gas (9) exiting the gas turbine (3) is previously used to generate process steam (31) for a steam turbine (33) (gas and steam power station) then cooled before the exhaust gas (9) is divided into said partial streams (11,13). Water (29) precipitating during cooling is removed.

Owner:SIEMENS AG

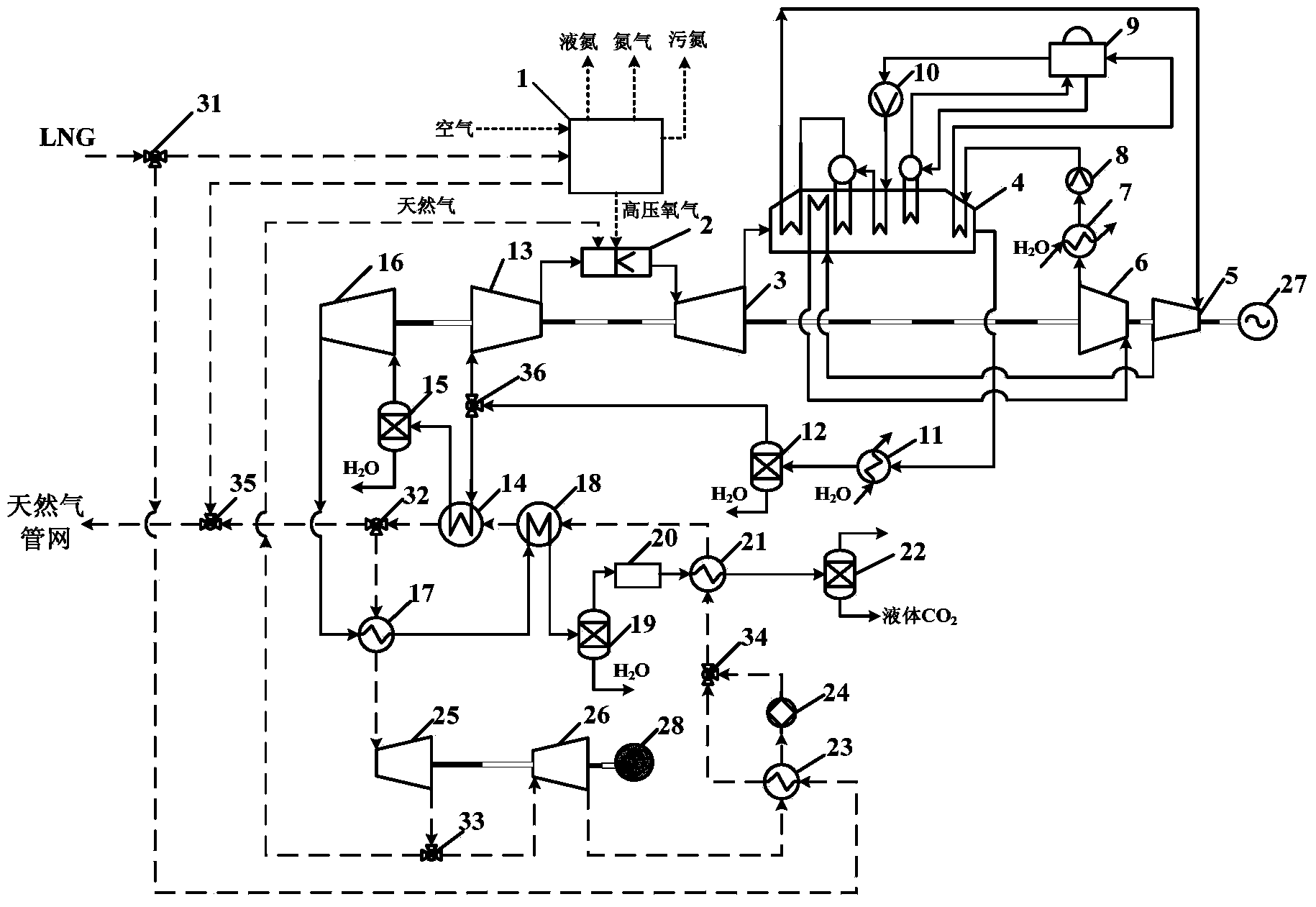

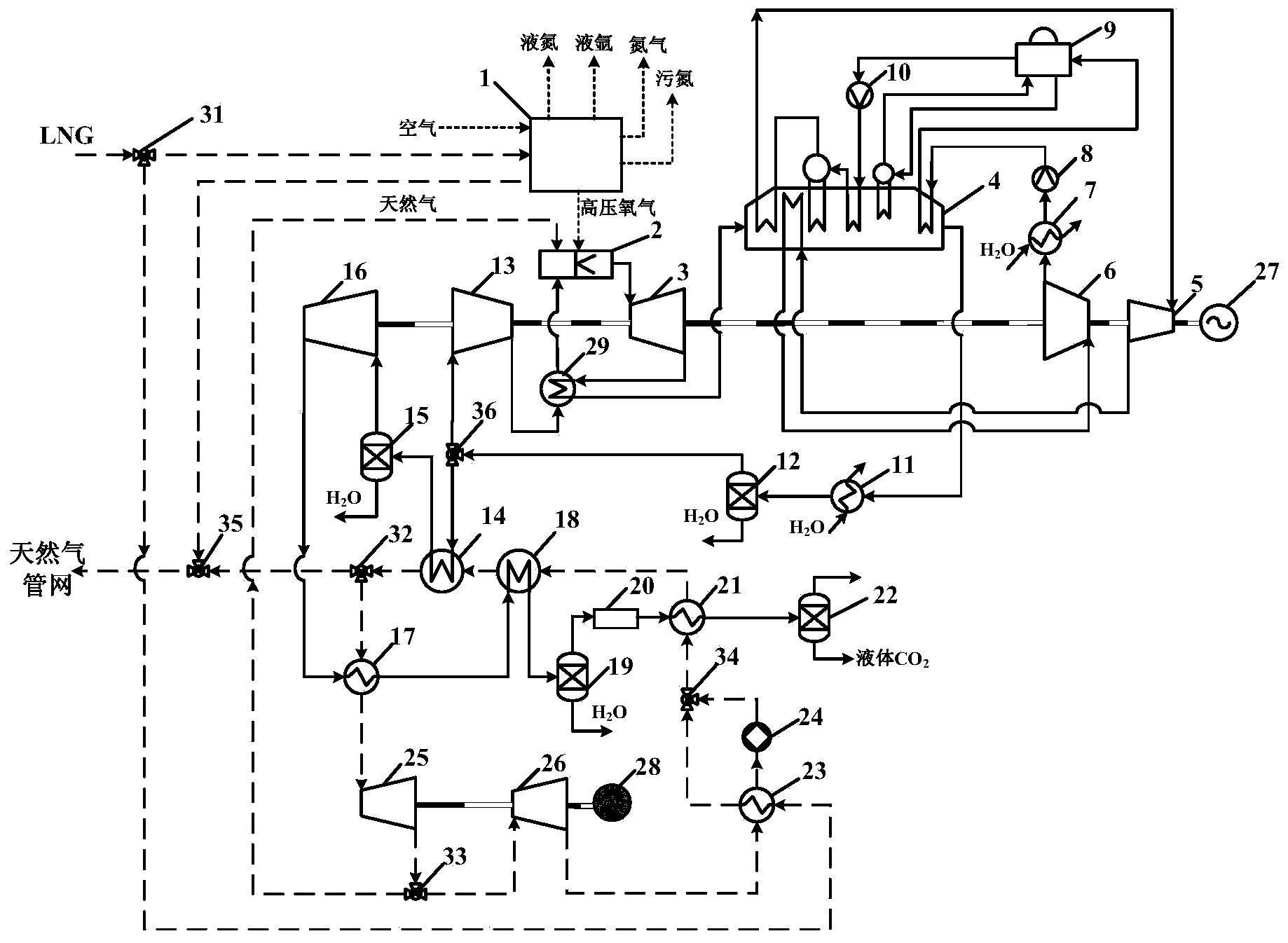

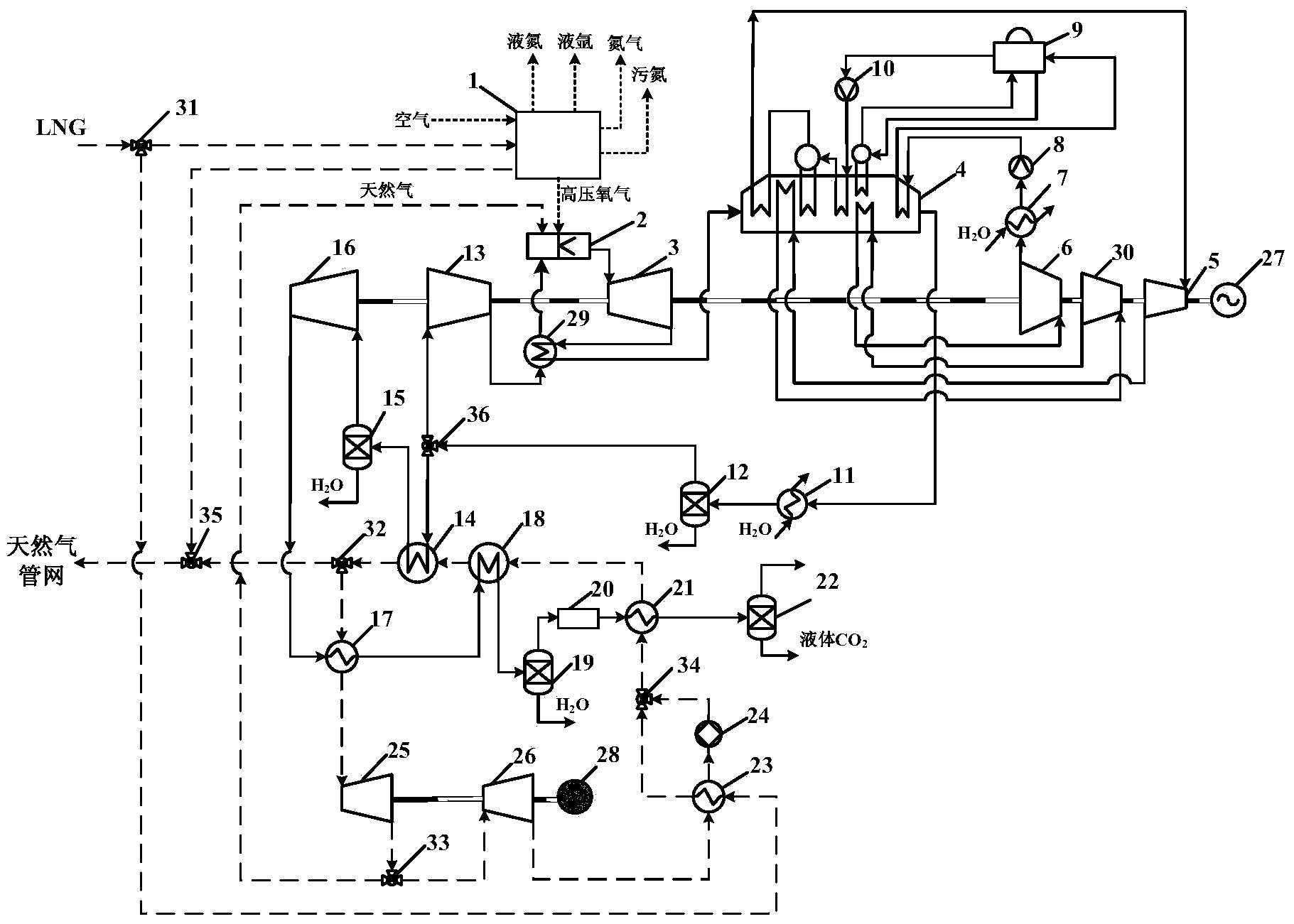

Combined power circulating method capable of catching carbon dioxide (CO2) by using LNG (Liquefied Natural Gas) cold energy and system thereof

ActiveCN103628982AImprove power generation efficiencyIncrease capture rateSolidificationLiquefactionPower cycleHigh pressure

The invention discloses a combined power circulating method capable of catching carbon dioxide (CO2) by using LNG (Liquefied Natural Gas) cold energy and a system thereof. The system comprises an air separation device, an oxygen-enriched-combustion gas turbine circulation device, a high-pressure steam power circulation device, a CO2 separation and liquefaction device and an LNG cold energy power circulation device, wherein the air separation device, the oxygen-enriched-combustion gas turbine circulation device, the high-pressure steam power circulation device, the CO2 separation and liquefaction device and the LNG cold energy power circulation device utilize the LNG cold energy. According to the method and the system, electricity and high-temperature fume which is rich in CO2 and water are generated from LNG through the oxygen-enriched-combustion gas turbine circulation device, and heat is recovered from the fume through the high-pressure steam power circulation device, so as to produce high-temperature and high-pressure steam with the pressure over 18MPa and increase the power generation efficiency of natural gas; moreover, the LNG cold energy is sequentially applied to the air separation device, the LNG cold energy power circulation device and the CO2 separation and liquefaction device, and the energy consumption for CO2 catching is lowered by making full use of the LNG cold energy, so that combined power cycle has relatively high power generation efficiency and relatively high CO2 catching rate, and the efficient utilization of the LNG cold energy is realized.

Owner:JINAN UNIVERSITY

Configurations and Methods for Power Generation with Integrated Lng Regasification

InactiveUS20080190106A1Increase power generationGas handling applicationsGas turbine plantsCombustionPower station

LNG cold is used in a plurality of cycles in a combined power plant to increase power output. Especially preferred plant configurations integrate a combined cycle power plant with a regasification operation in which in a first stage LNG cold provides cooling in an open or closed power cycle. Most preferably, a significant portion of the LNG is vaporized in the first stage. In a second stage LNG cold provides cooling for a heat transfer medium that is used to provide refrigeration for the cooling water to a steam power turbine and for an air intake chiller of a combustion turbine in the power plant.

Owner:FLUOR TECH CORP

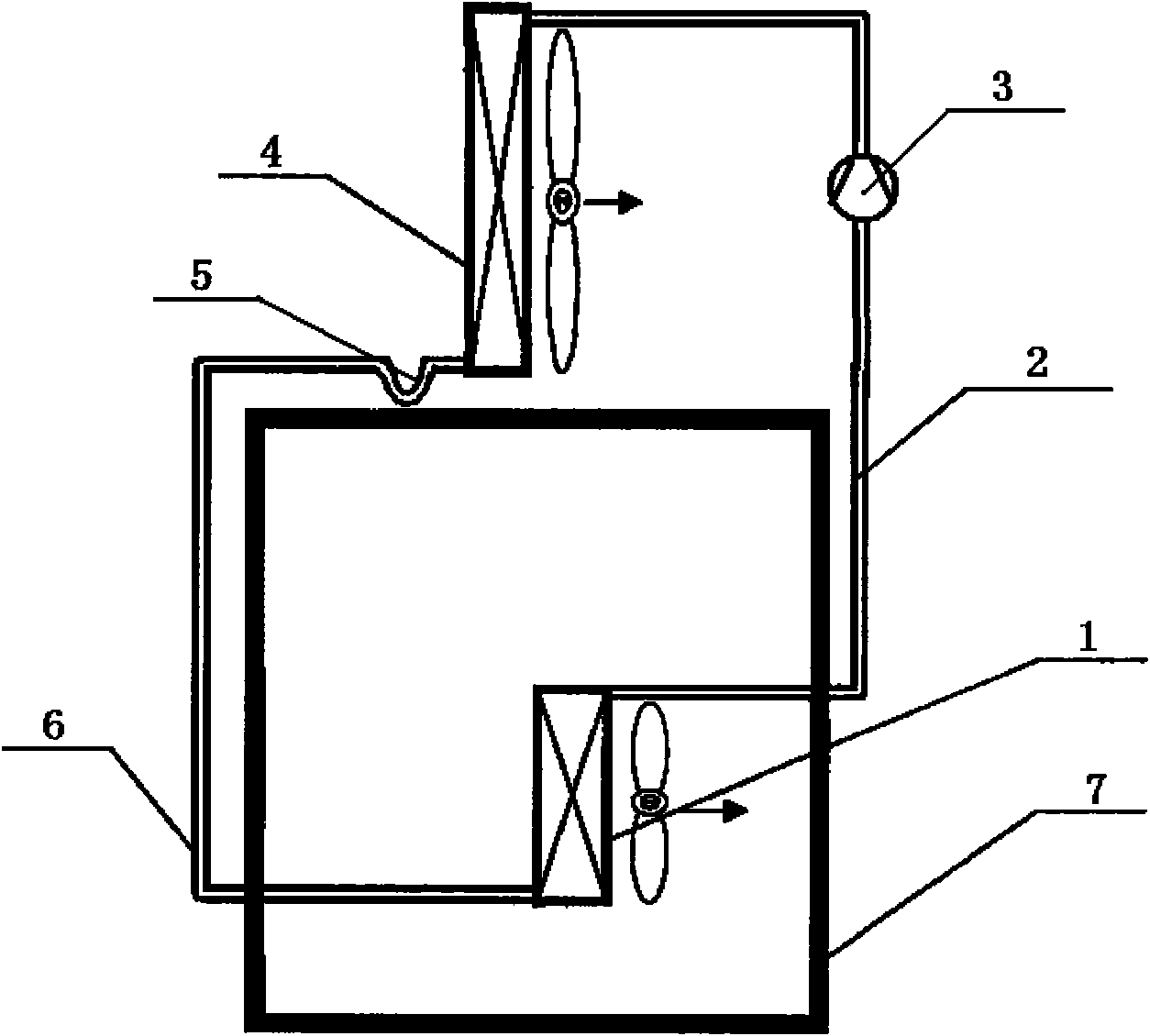

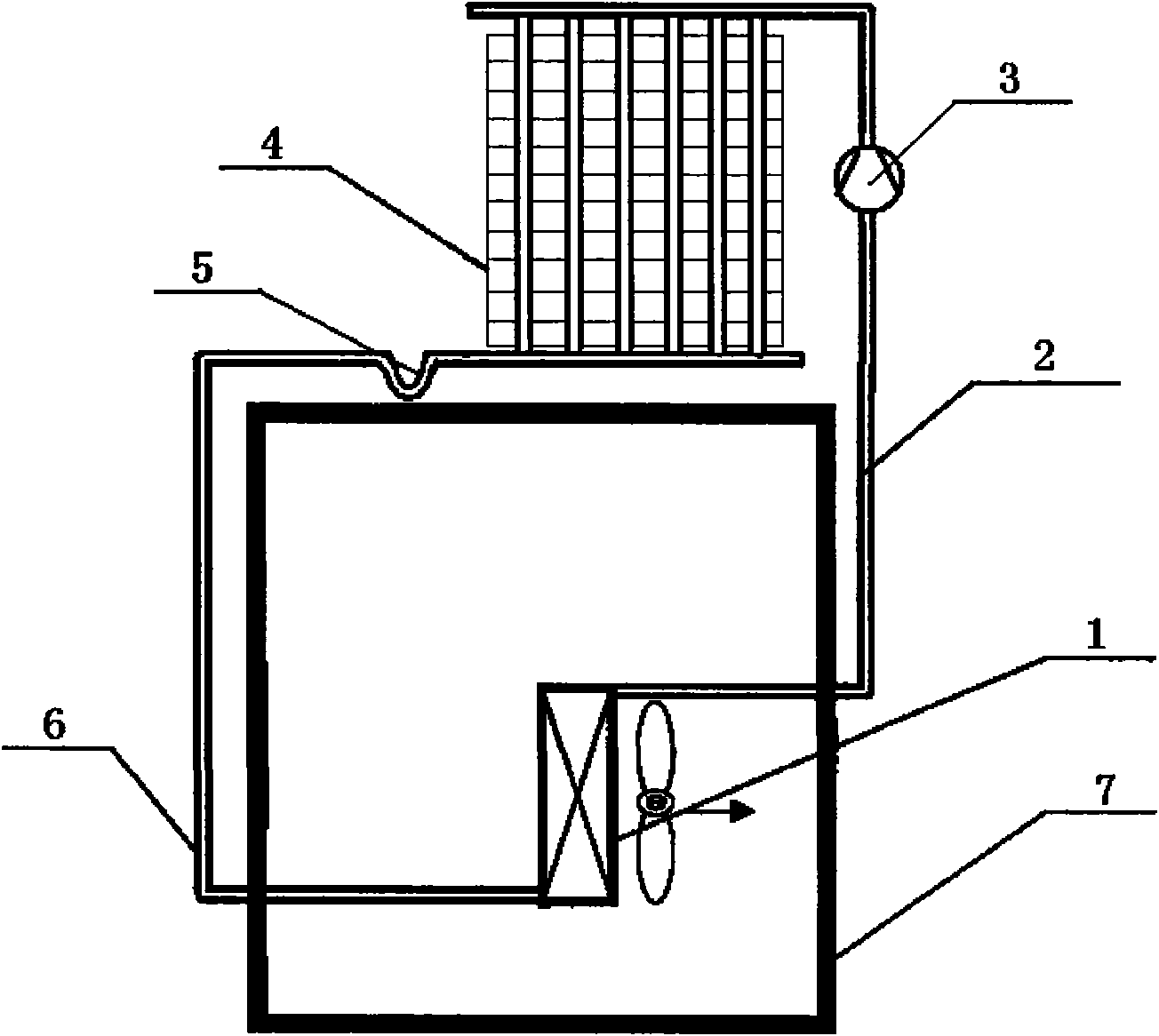

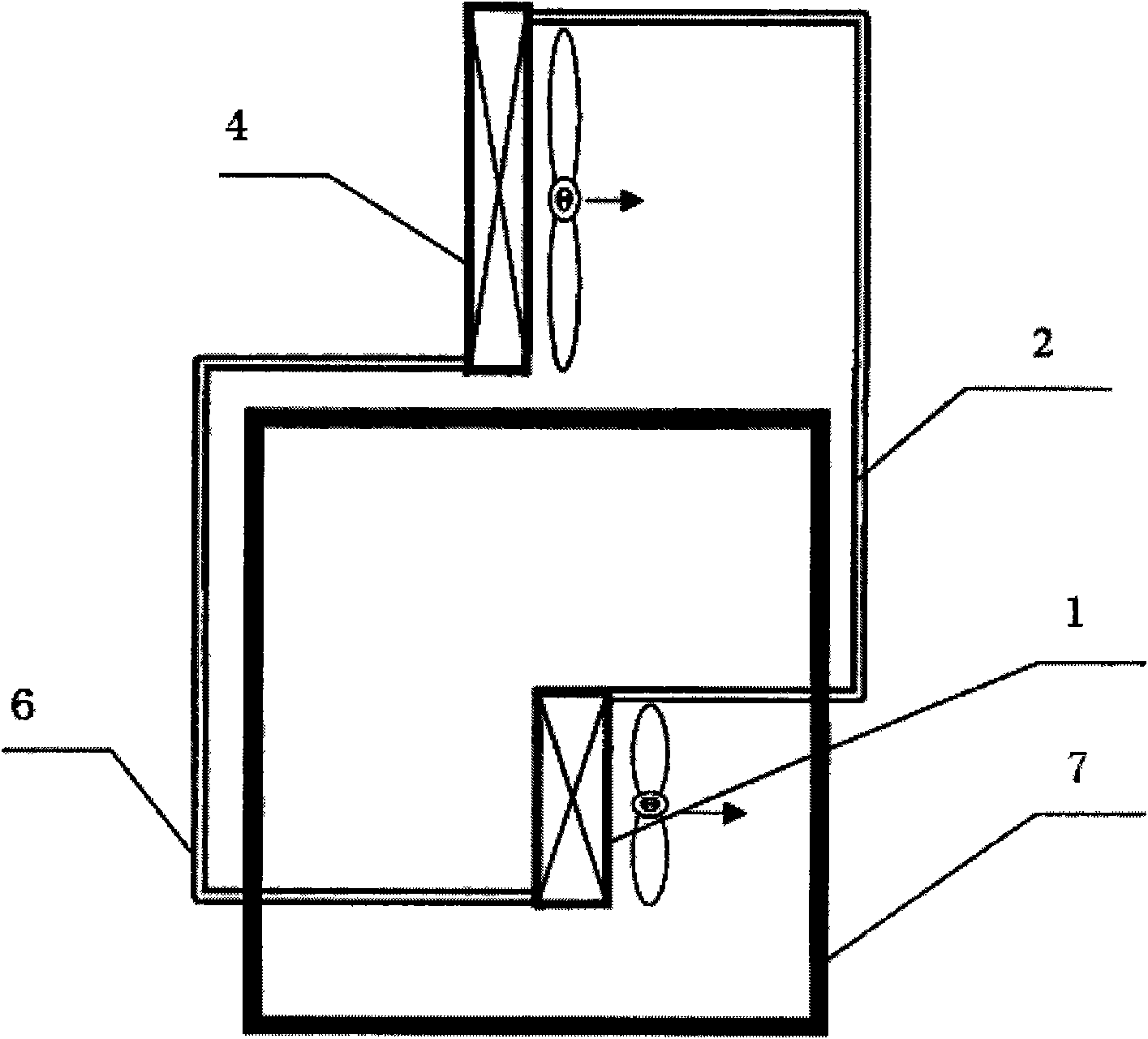

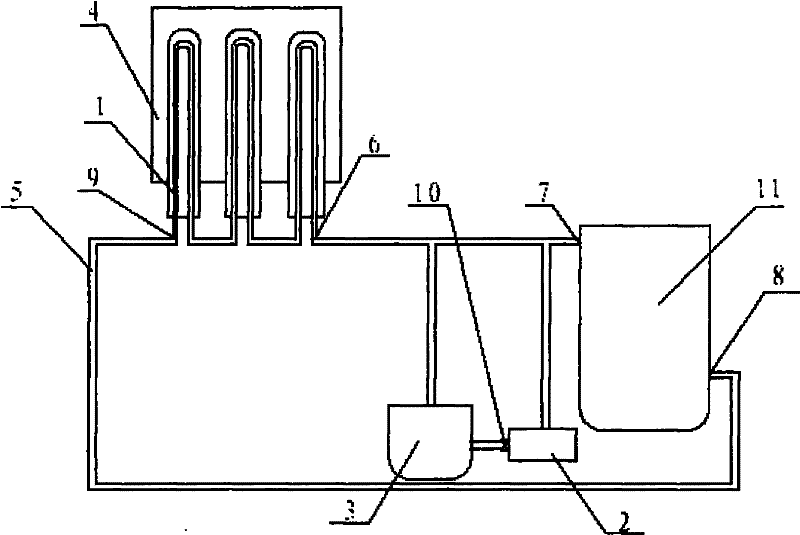

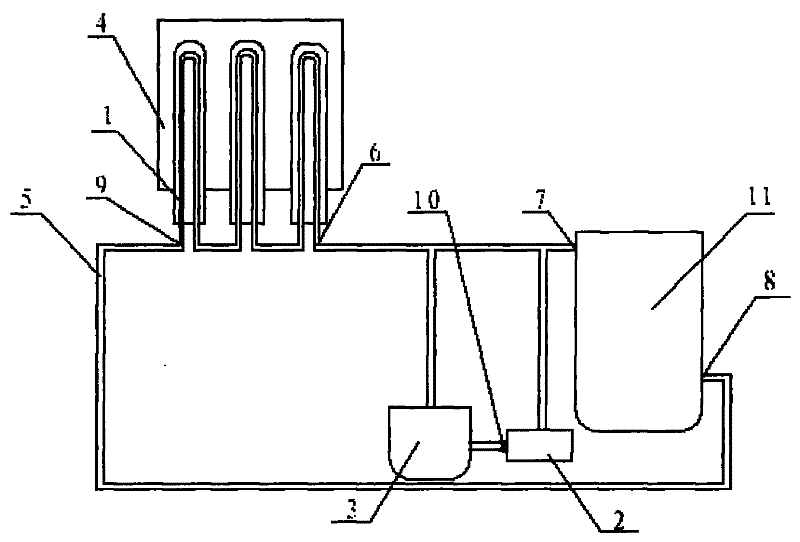

Heat radiator with air pump separate type thermosiphon for machine room or machine cabinet

ActiveCN101619879ASolve the cooling problemImprove work efficiencyLighting and heating apparatusHeat-exchange elementsAtmospheric airAir pump

The invention relates to a heat radiator with an air pump separate type thermosiphon for a machine room or machine cabinet, which belongs to the technical field of heat exchange of heat radiators. The heat radiator comprises an evaporator (1), a condenser (4), a liquid collecting pipe (6), a steam pipe (2), an air pump (3) and a liquid storage bend (5), wherein the condenser (4) is positioned on the upper part of the evaporator (1), the upper part of the evaporator (1) is communicated with the condenser (4) by the steam pipe (2) and the air pump (3), the bottom of the evaporator (1) is communicated with the bottom of the condenser through the liquid collecting pipe and a liquid storage bend, a seal space is formed in the hear radiator, and liquid working media are filled into the seal space. After the evaporator absorbs heat, the internal liquid working media in the seal space are gasified, steam is transmitted to the condenser by the air pump through the steam pipe, the liquid working media change into liquid after radiating heat to air around in the condenser and flow back to the evaporator through the liquid storage bend and the liquid collecting pipe, and thus, the heat radiator can radiate internal heat of a seal machine room to the atmosphere, increases the steam power of the working media and the utilization ratio of the condenser and has better heat radiating performance in a larger heat radiating range.

Owner:BEIJING UNIV OF TECH

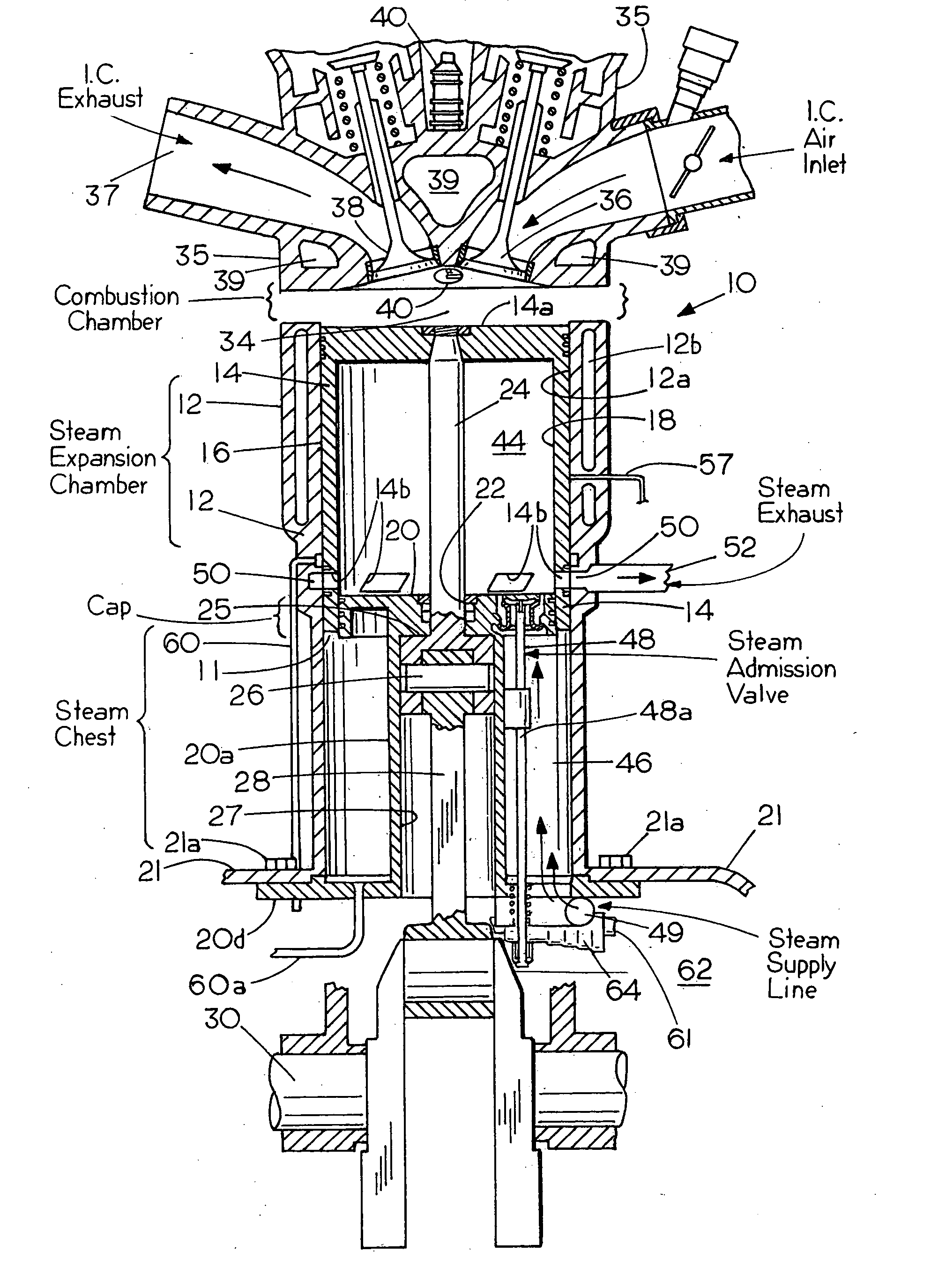

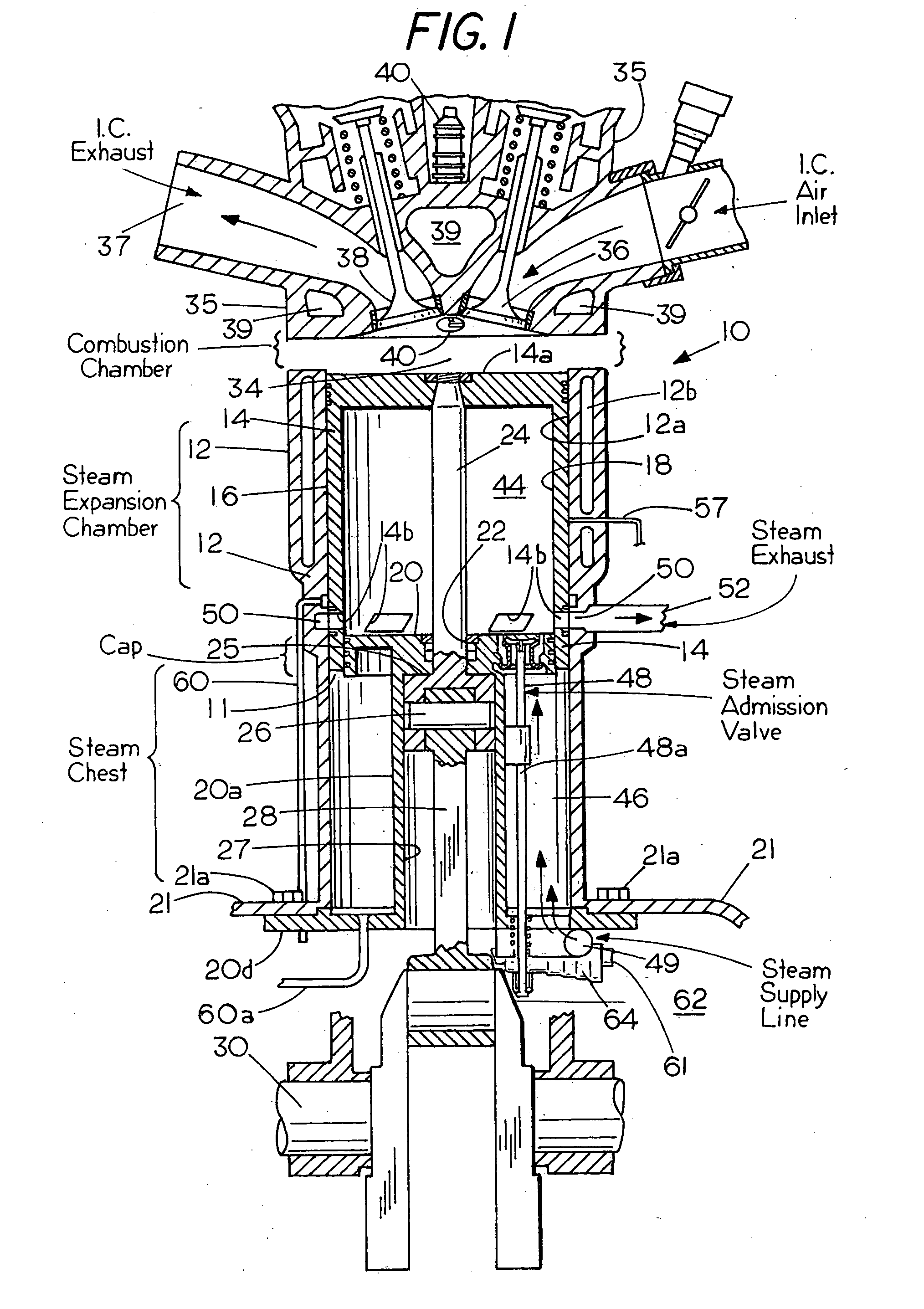

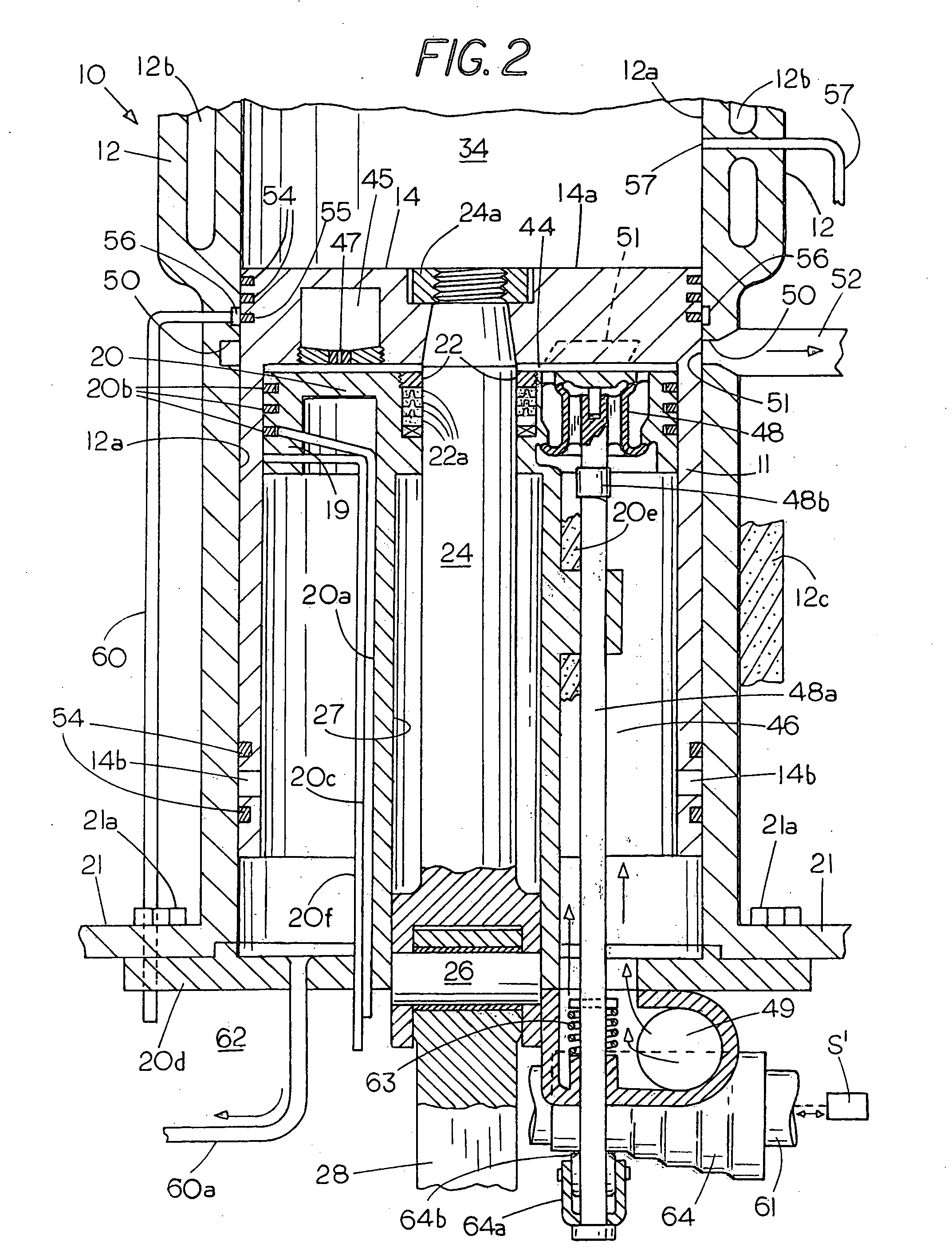

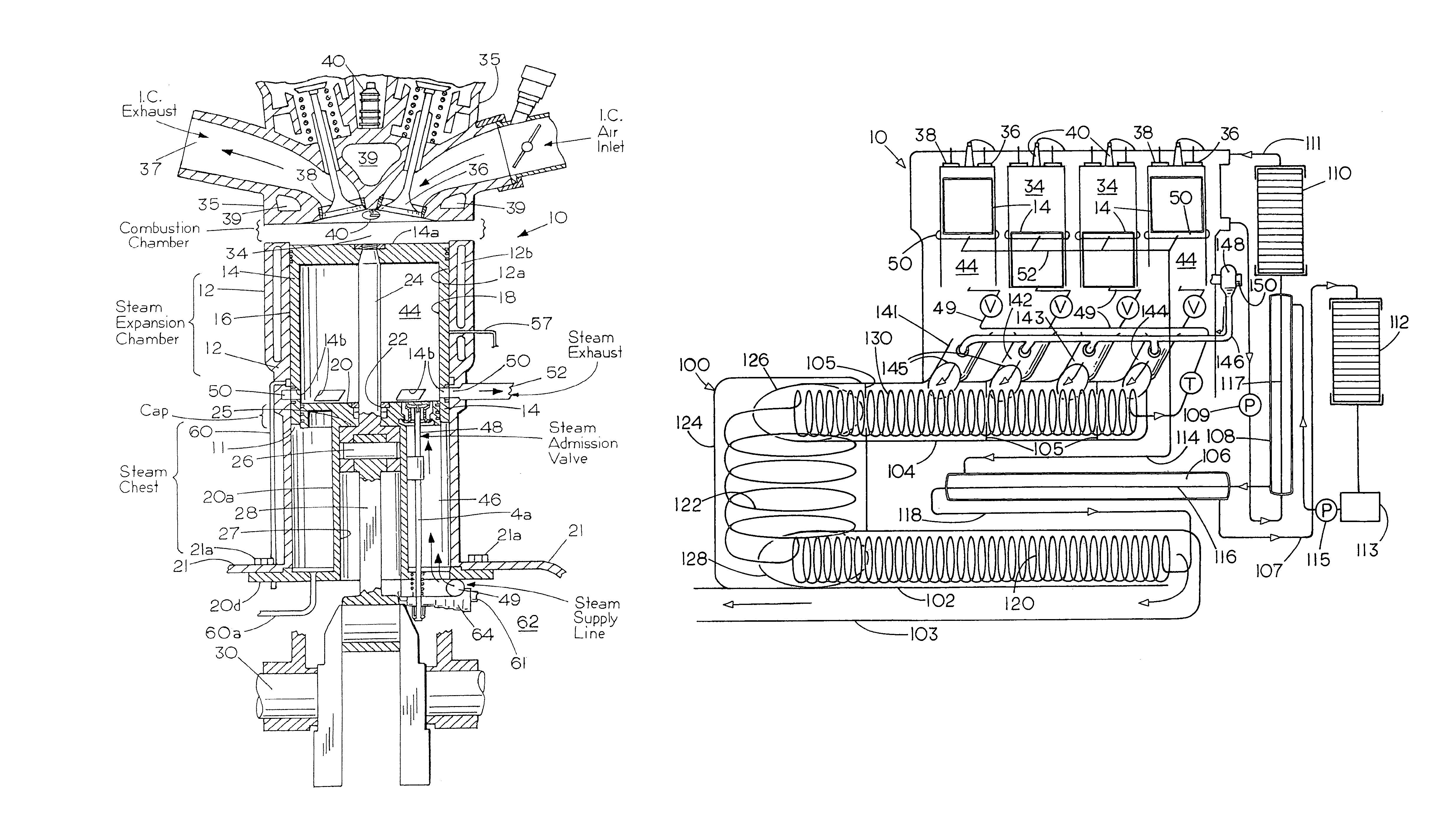

High efficiency dual cycle internal combustion engine with steam power recovered from waste heat

ActiveUS20090205338A1Operation efficiency can be improvedImprove efficiencyInternal combustion piston enginesSteam useCombustion chamberExhaust valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder having a piston mounted for reciprocation therein with an internal combustion chamber outward of the piston, a fixed cylinder cap sealingly and slideably mounted within the piston and a steam expansion / recompression chamber inside the piston adjacent the cylinder cap. The cylinder cap can be unheated or heated externally to reduce condensation of steam entering the steam chamber from a steam generator fired by waste combustion heat. Steam remaining in the cylinder when a steam exhaust valve closes at the top center position is recompressed during an inward stroke of the piston up to admission pressure prior to admitting the next charge of steam. One valve or a pair of retractable steam inlet valves connected in series within the cylinder cap act in cooperation with steam recompression and clearance volume to achieve an effective zero steam chamber clearance and a gain in mean Rankine cycle temperature to maximize efficiency. The amount of steam admitted each outward stroke is continuously regulated, e.g. by shifting the phase of one steam admission valve of a pair to vary their overlap for determining the steam mass admitted during each cycle to reduce specific fuel consumption. Other valves balance steam displacement with the steam generator output to use steam more efficiently. Engine coolant can be evaporated in a combustion chamber cooling jacket to form steam which is then superheated in a combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

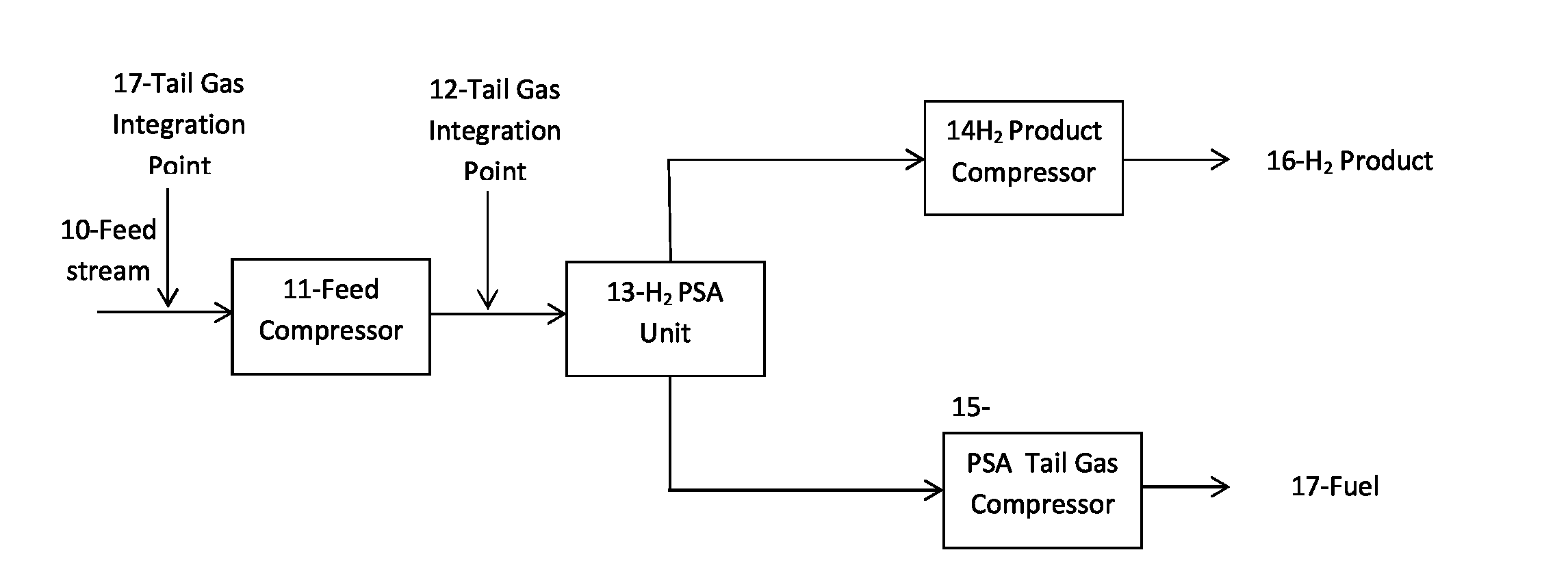

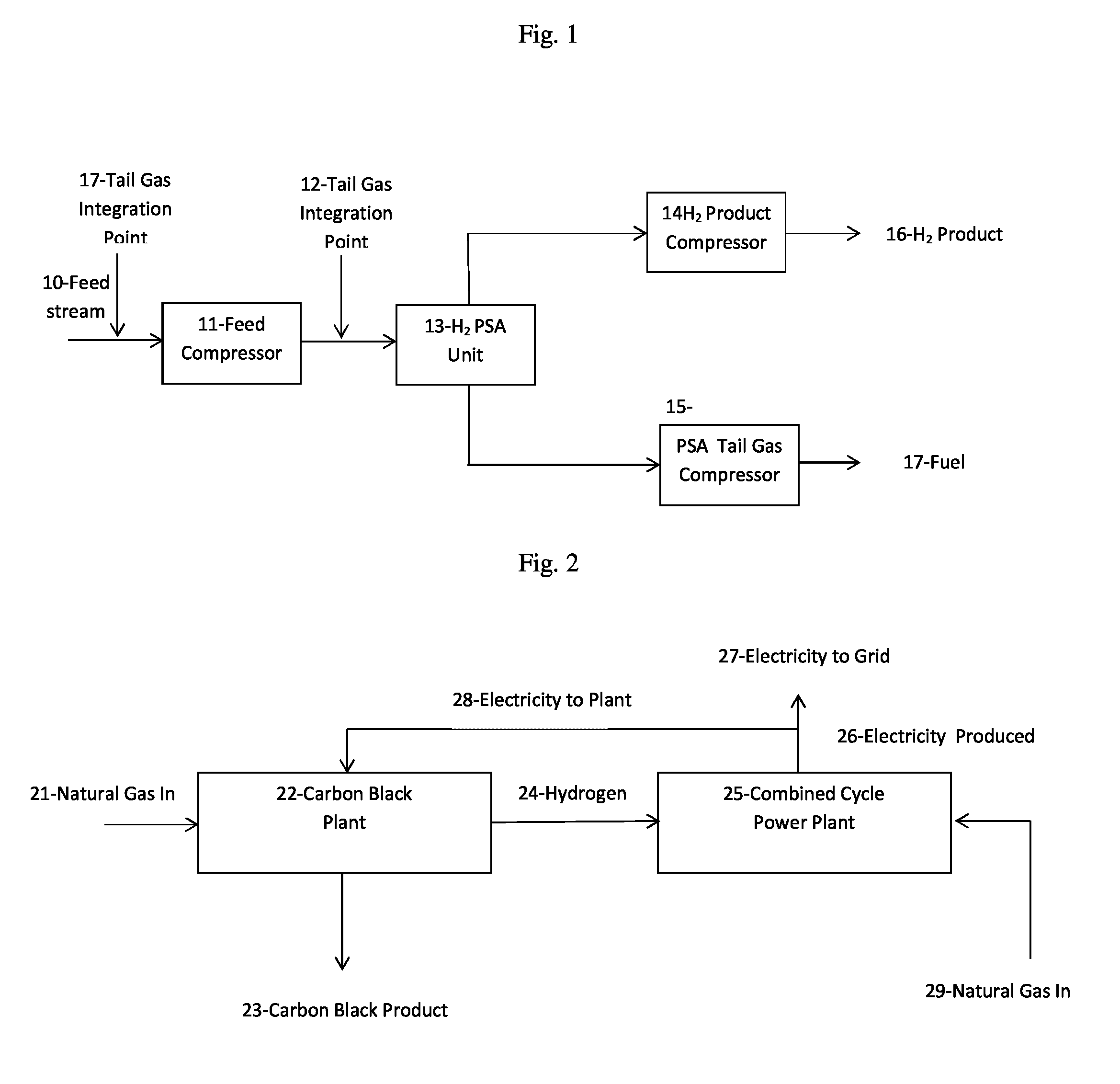

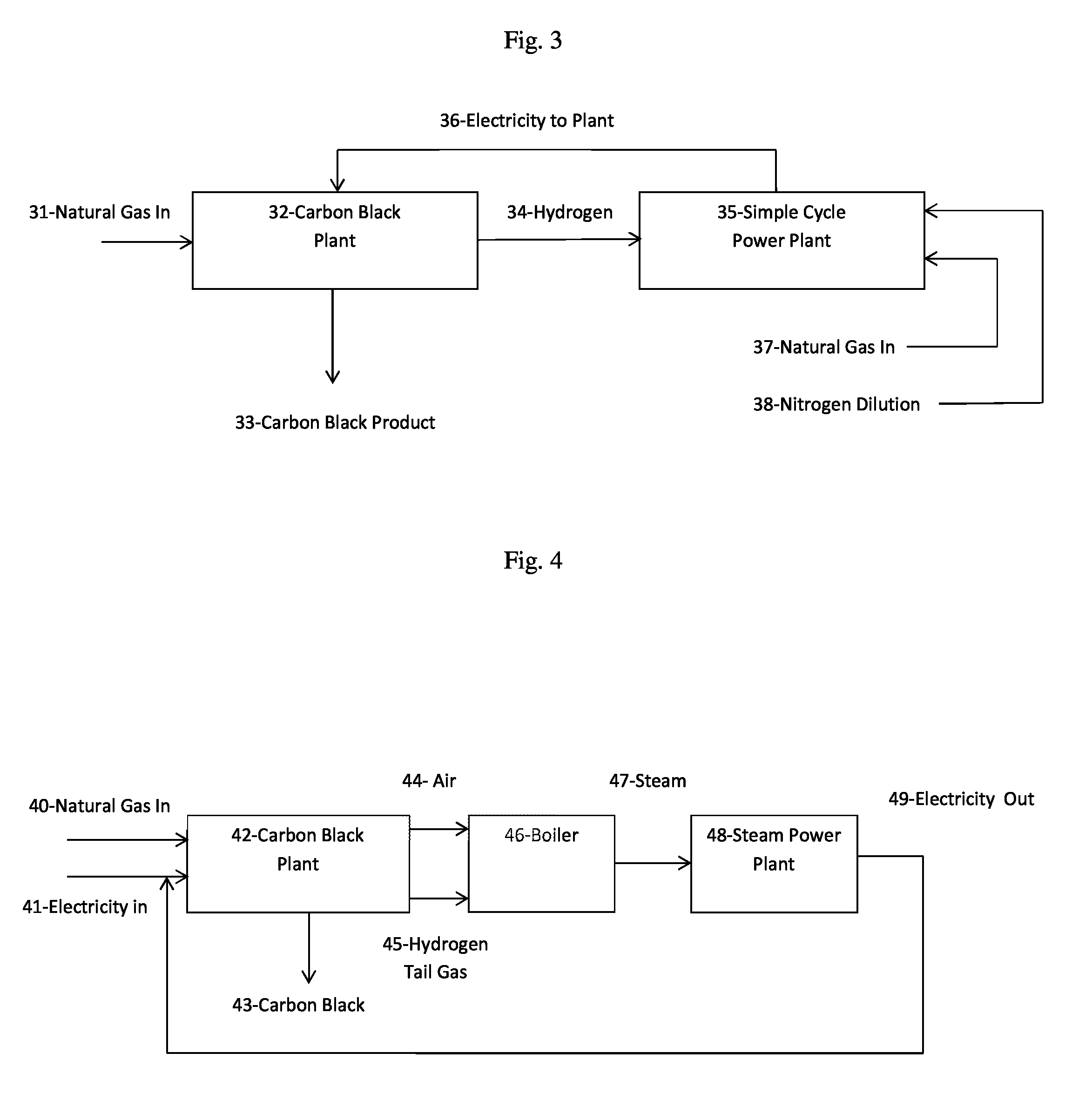

Integration of plasma and hydrogen process with combined cycle power plant, simple cycle power plant and steam reformers

InactiveUS20150211378A1Reducing net air emissionReduce coal consumptionPigmenting treatmentProductsSteam reformingElectric power

The integration of plasma processes with combined cycle power plant, simple cycle power plant, and steam reforming processes. A method of producing purified hydrogen gas and fuel is described including compressing a feed stream of hydrogen, adding tail gas from a plasma process to the feed stream, passing the tail gas modified feed stream into a pressure swing adsorption system generating a purified hydrogen product and a pressure swing adsorption tail gas, separating and compressing the purified hydrogen product, and separating and compressing the pressure swing adsorption tail gas for use as fuel. A method of generating and recapturing electricity from a single or combined cycle power plant is also described including flowing natural gas into a plasma process and hydrogen generating plant, flowing the hydrogen produced into the power plant, flowing natural gas into the power plant, resulting in the production of electricity. The electricity is flowed back into the plasma process plant, and in the case of the combined cycle power plant the electricity is partially flowed into a power grid as well. A method of generating and recapturing electricity from a steam power plant is also described, including inputting electricity and natural gas into a plasma process air and hydrogen generating plant, flowing the air and hydrogen produced into a steam generating boiler, flowing the steam generated into a steam power plant, resulting in the production of electricity which is flowed back into the plasma process plant.

Owner:MONOLITH MATERIALS

Solar hybrid combined cycle gas and steam power plant

ActiveUS20110185742A1Easy to installFacilitate heat transfer and coupling of heatAuxillary drivesFrom solar energyPower stationSteam power

A solar hybrid combined cycle gas-steam power plant and method including a solar unit, a gas turbine unit and a steam turbine unit. The solar unit includes a receiver. The gas turbine unit includes a gas turbine with a waste heat boiler arranged downstream, and a steam turbine with a feed water heater. The power plant includes a heat transfer medium cycle for transferring solar heat. The heat transfer medium cycle is coupled to the gas turbine unit through a gas turbine heat exchanger and to the steam turbine unit through a solar boiler. Alternatively to the gas turbine unit and the steam turbine unit, the solar hybrid combined cycle power plant includes an integrated gas-steam turbine having a waste heat boiler arranged downstream, wherein the heat transfer medium cycle is coupled to the integrated gas-steam turbine through the gas turbine heat exchanger and through the solar boiler.

Owner:DRESDEN UNIVERSITY OF TECHNOLOGY

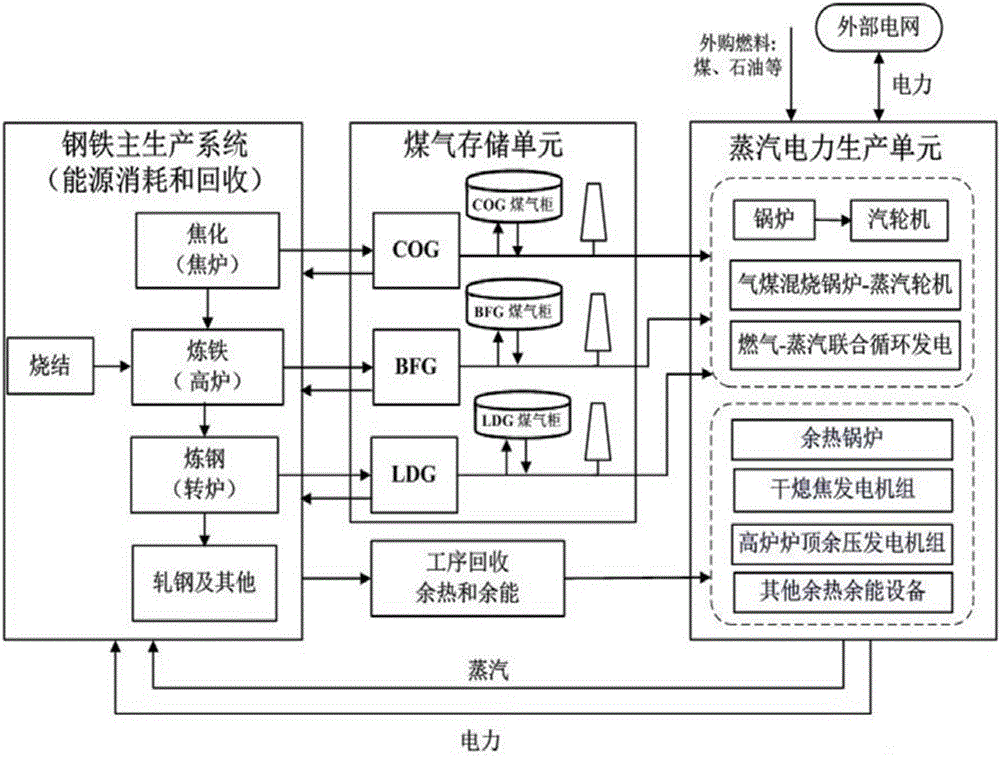

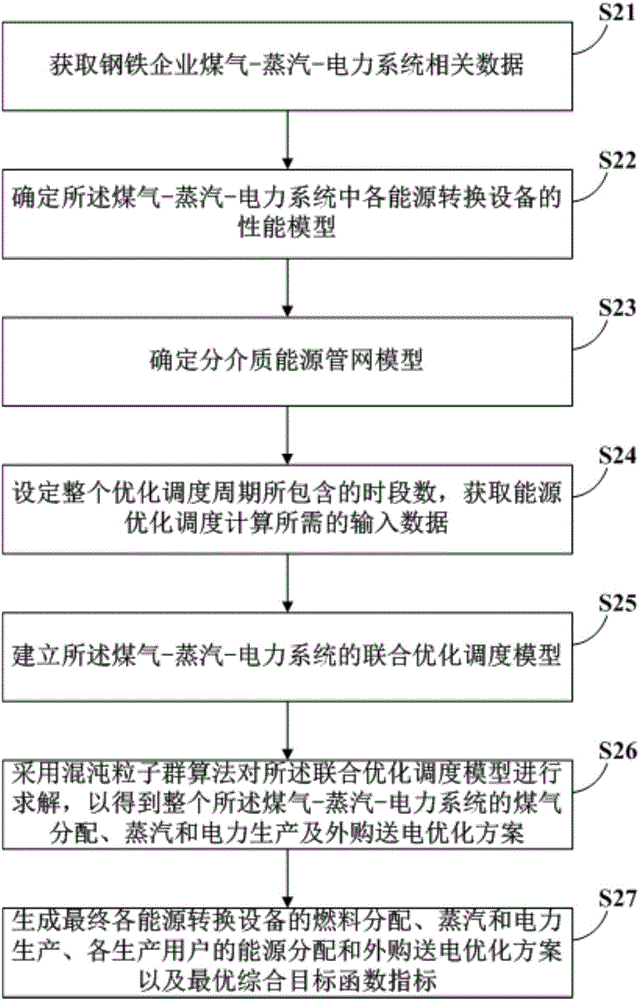

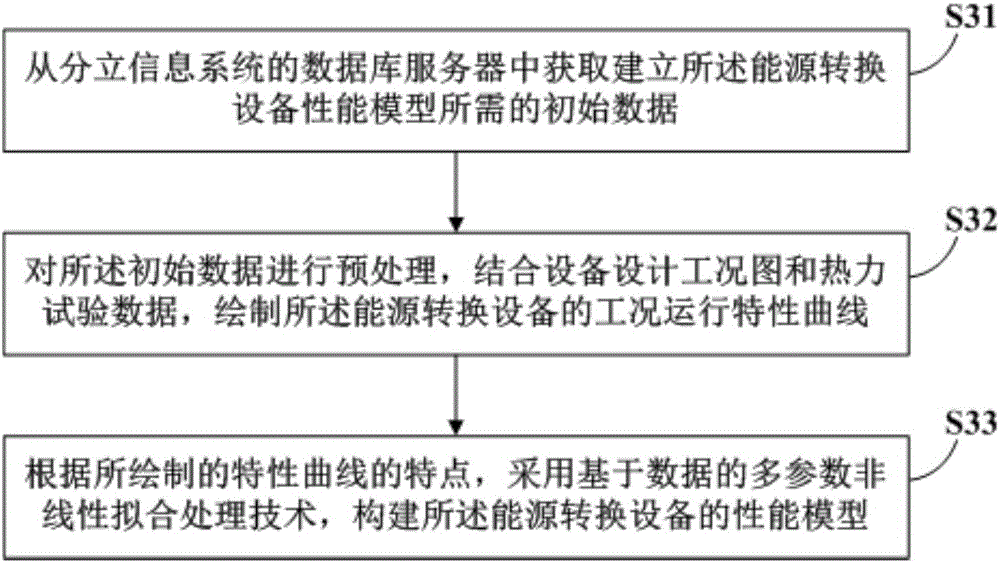

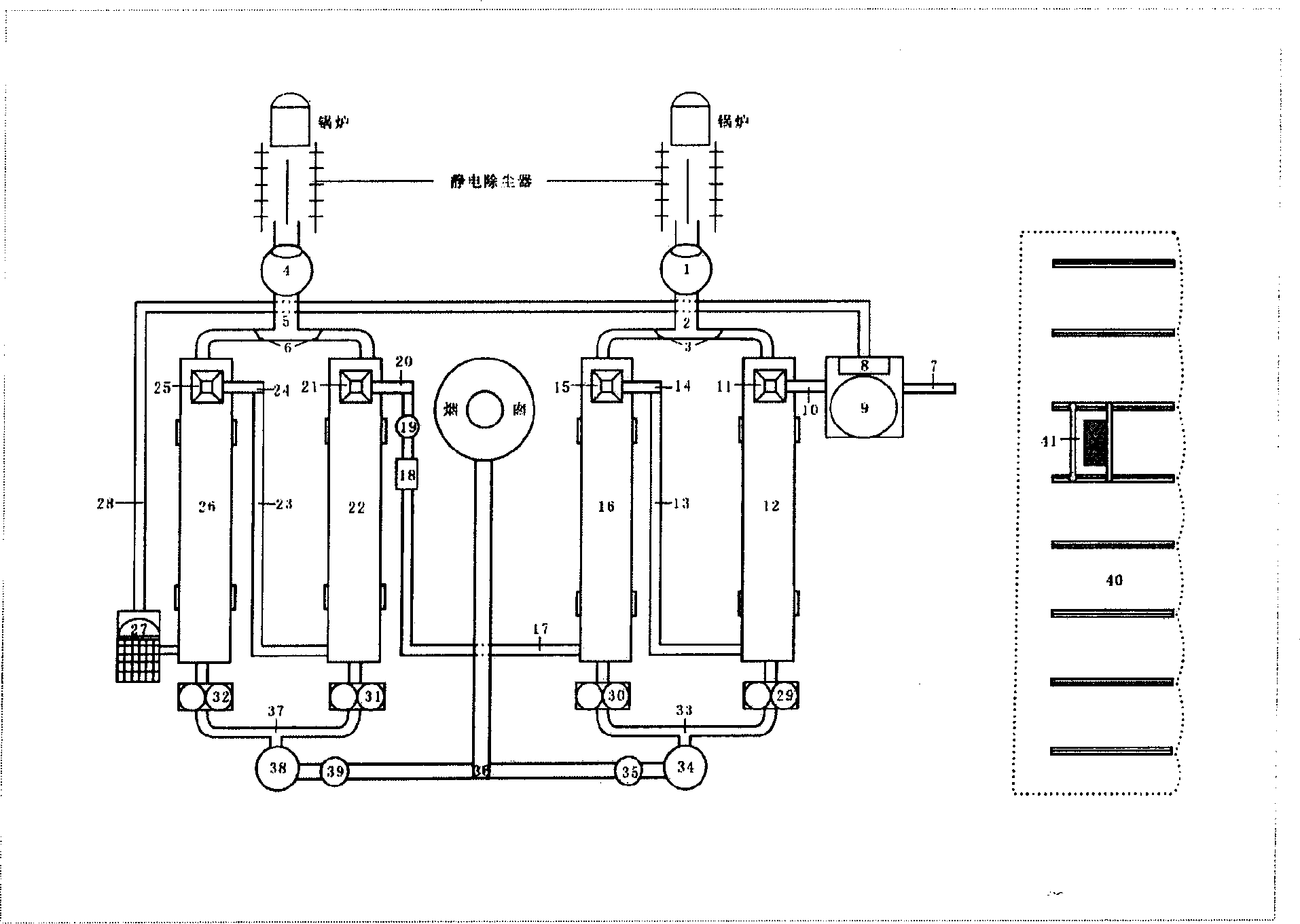

Multi-system joint optimization dispatching method and device

ActiveCN106773704AImprove accuracyImprove representationAdaptive controlElectric power systemNetwork model

The invention discloses a multi-system joint optimization dispatching method and device. The method comprises the steps of obtaining related data of a gas-steam-power system of an iron and steel enterprise; determining performance models of various energy conversion devices in the gas-steam-power system; determining a sub-medium energy pipe network model; setting the number of time frames included in the whole optimization dispatching cycle to obtain input data; building a joint optimization dispatching model of the gas-steam-power system; solving the joint optimization dispatching model by adopting a chaos particle swarm algorithm to obtain optimization schemes of gas distribution, steam and power production and purchased power transmission of the whole gas-steam-power system; and generating final optimization schemes of gas distribution of various energy conversion devices, steam and power load distribution, energy distribution of various production users and purchased power transmission and an optimal comprehensive target function index. According to the multi-system joint optimization dispatching method and device, joint optimization of a multi-energy medium is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

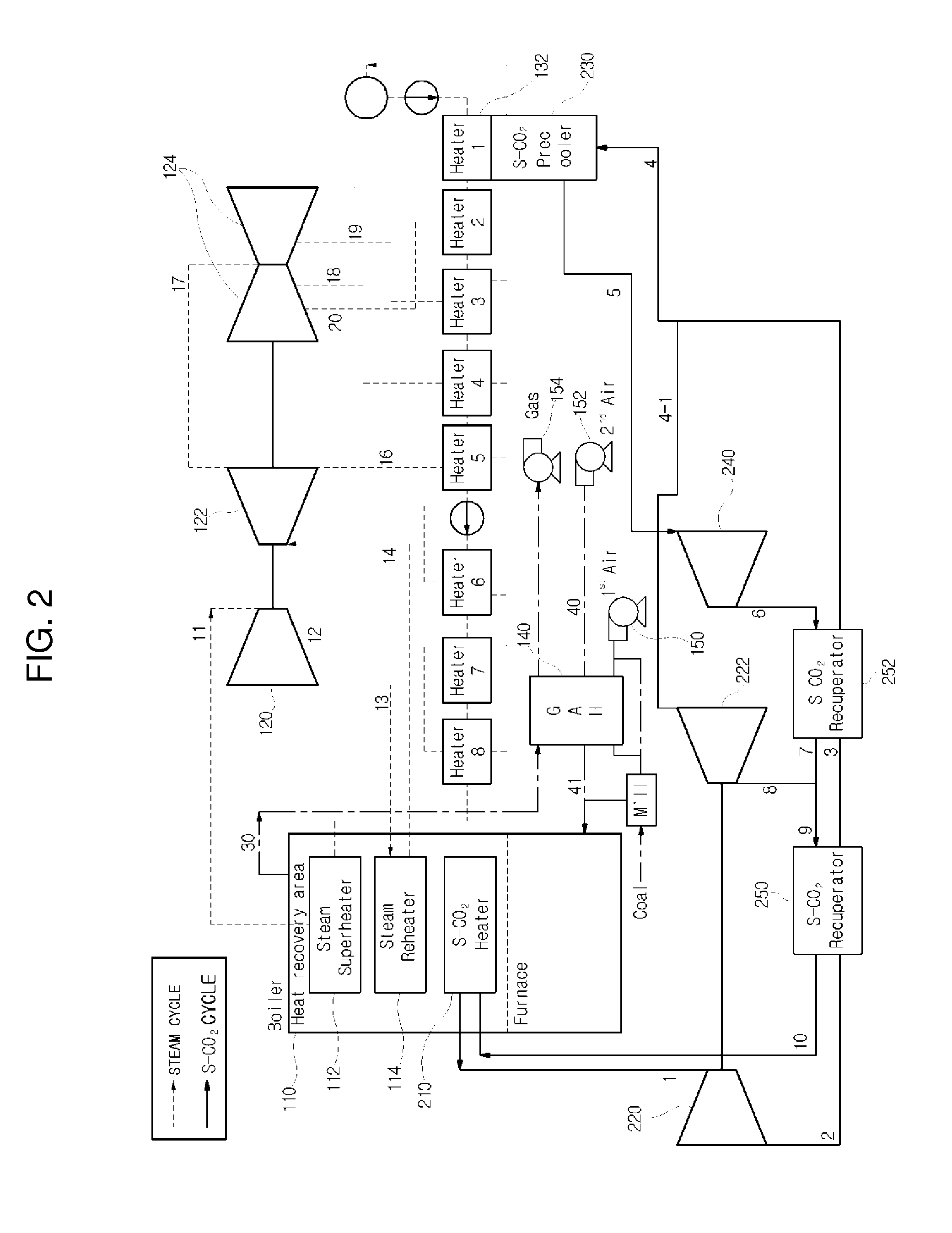

Hybrid power generation system and method using supercritical co2 cycle

ActiveUS20160010513A1Improve efficiencyReciprocating combination enginesCombination enginesSteam powerEngineering

A hybrid power generation system using a supercritical CO2 cycle includes a steam power generation unit including a plurality of turbines driven with steam heated using heat generated by a boiler to produce electric power, and a supercritical CO2 power generation unit including an S—CO2 heater for heating a supercritical CO2 fluid, a turbine driven by the supercritical CO2 fluid, a precooler for lowering a temperature of the supercritical CO2 fluid passing through the turbine, and a main compressor for pressurizing the supercritical CO2 fluid, so as to produce electric power. The steam power generation unit and the supercritical CO2 power generation unit share the boiler. The hybrid power generation system may improve both the power generation efficiencies of the steam cycle and the supercritical CO2 cycle by interconnecting the steam cycle and the supercritical CO2 cycle.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

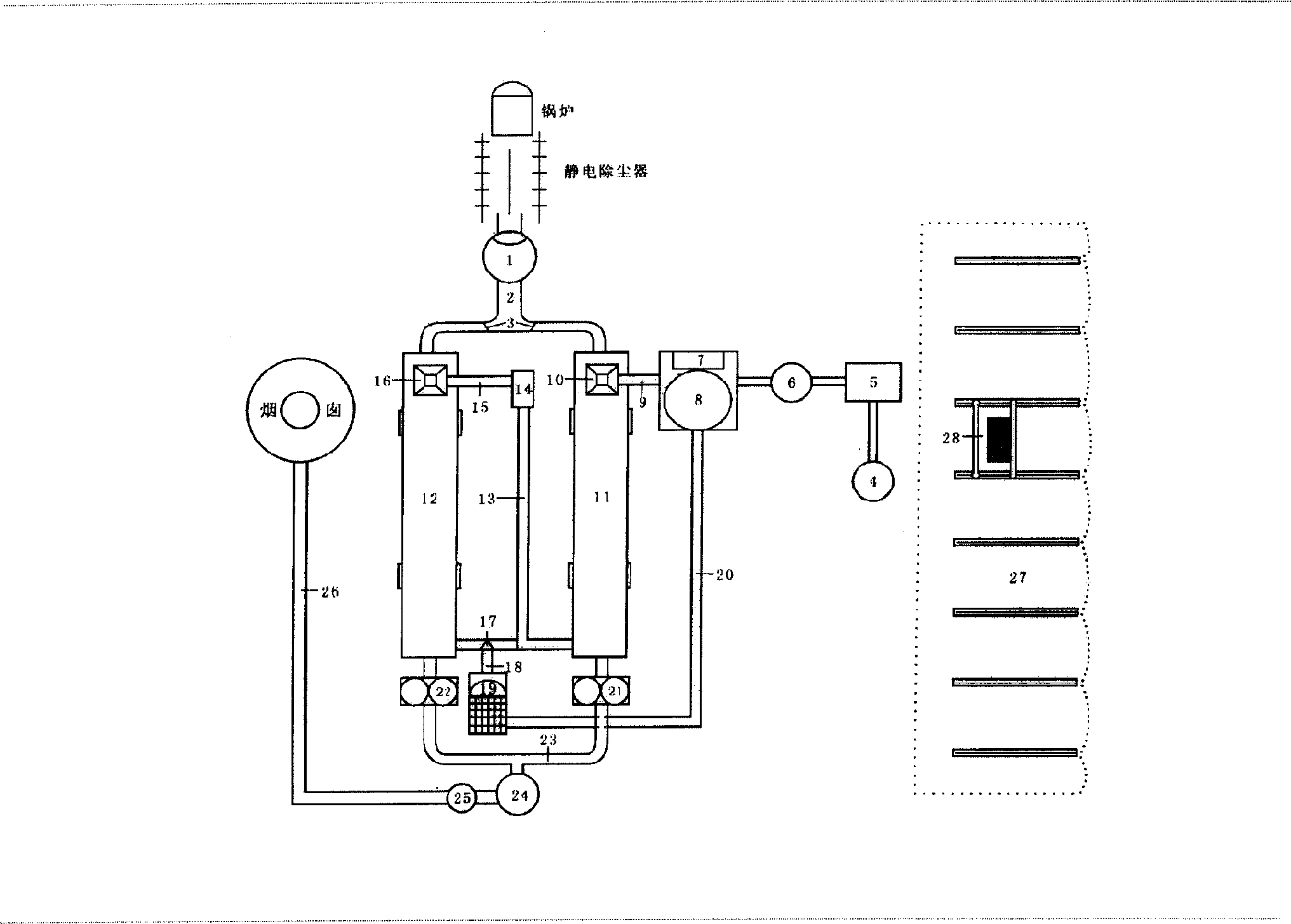

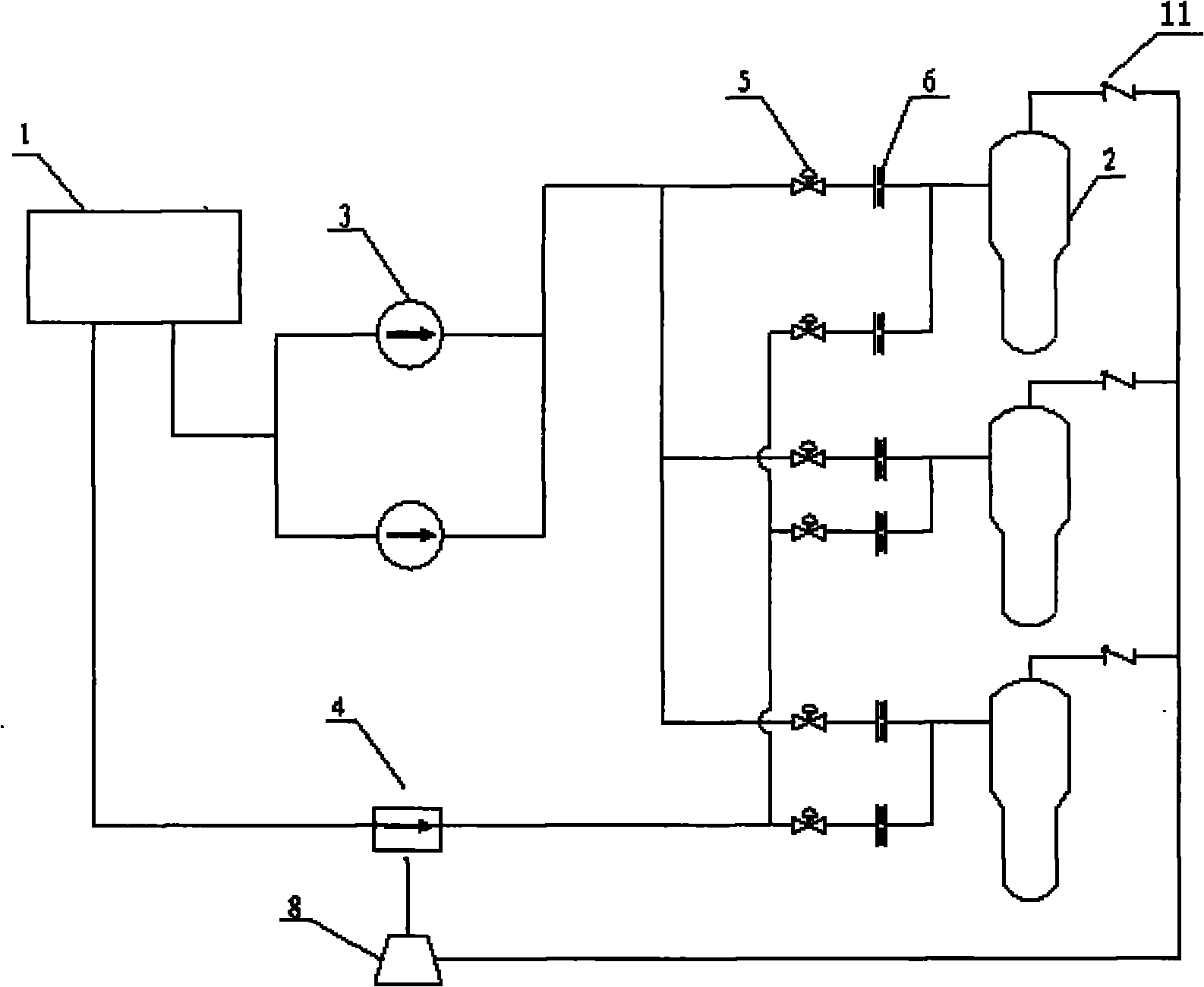

Tandem type anhydration system for sludge by using remaining heat of flue gas from steam power plant

InactiveCN1686879AWill not affect normal operationEffective controlSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFlue gasSludge

The present invention discloses a series-connected sludge anhydration system by utilizing waste heat of steam-power plant smoke. Said series-connected sludge anhydration system includes heat supply system, sludge pretreatment system, feeding system, sludge anhydration and granulation system and dust-removing and gas-removing system.

Owner:ZHEJIANG UNIV

Integrated method and device for sludge drying incineration and power generation

InactiveCN101817629AHigh thermal efficiencyCompact and reasonable connectionSludge treatment by de-watering/drying/thickeningIncinerator apparatusThermal energySludge

The invention discloses an integrated method and device for sludge drying incineration and power generation. The device of the invention comprises a screw rotary type sludge drier; dried sludge enters a fluidized bed boiler to be performed with incineration; steam generated by incineration is used for carrying out power generation; exhaust steam from a small steam turbine is adopted to dry the sludge, thereby realizing cascade utilization of steam heat energy; the electric energy generated by a small generator set can sufficiently meet power utilization in the operation of equipment, thus reducing the operating cost and fully saving energy; and sludge drying incineration and power generation are integrated into a whole. In the invention, the screw rotary type sludge drier is used for feeding the fluidized bed incineration boiler, the steam generated by incineration is used for carrying out power generation, and the low-grade exhaust steam from the steam turbine is adopted as the heat source of the drier, thereby greatly improving the heat efficiency of a steam power device; meantime, the electric energy generated by the small generator set can sufficiently meet power utilization in the operation of the equipment, thus reducing the operating cost; and with the integration design, the system has reasonable and compact connection of the integrated device, mature equipment structure and better economical efficiency.

Owner:ZHEJIANG UNIV +1

Internal combustion engine with auxiliary steam power recovered from waste heat

ActiveUS7997080B2Effectively economizeImprove efficiencyInternal combustion piston enginesSteam regenerationExternal combustion engineEngineering

Owner:THERMAL POWER RECOVERY

Run-up method for a solar steam power plant

InactiveUS20120137683A1Quality of steamReduce the amount of waterAuxillary drivesFrom solar energyPower modePower station

A run-up method for a solar steam power plant is proposed. In the run-up method an auxiliary steam is used to generate seal steam for a steam-turbine of the power plant. The auxiliary steam is produced by a heat-exchanger-system that is to provide, during a subsequent power-mode, overheated steam for driving the steam-turbine.

Owner:SIEMENS AG

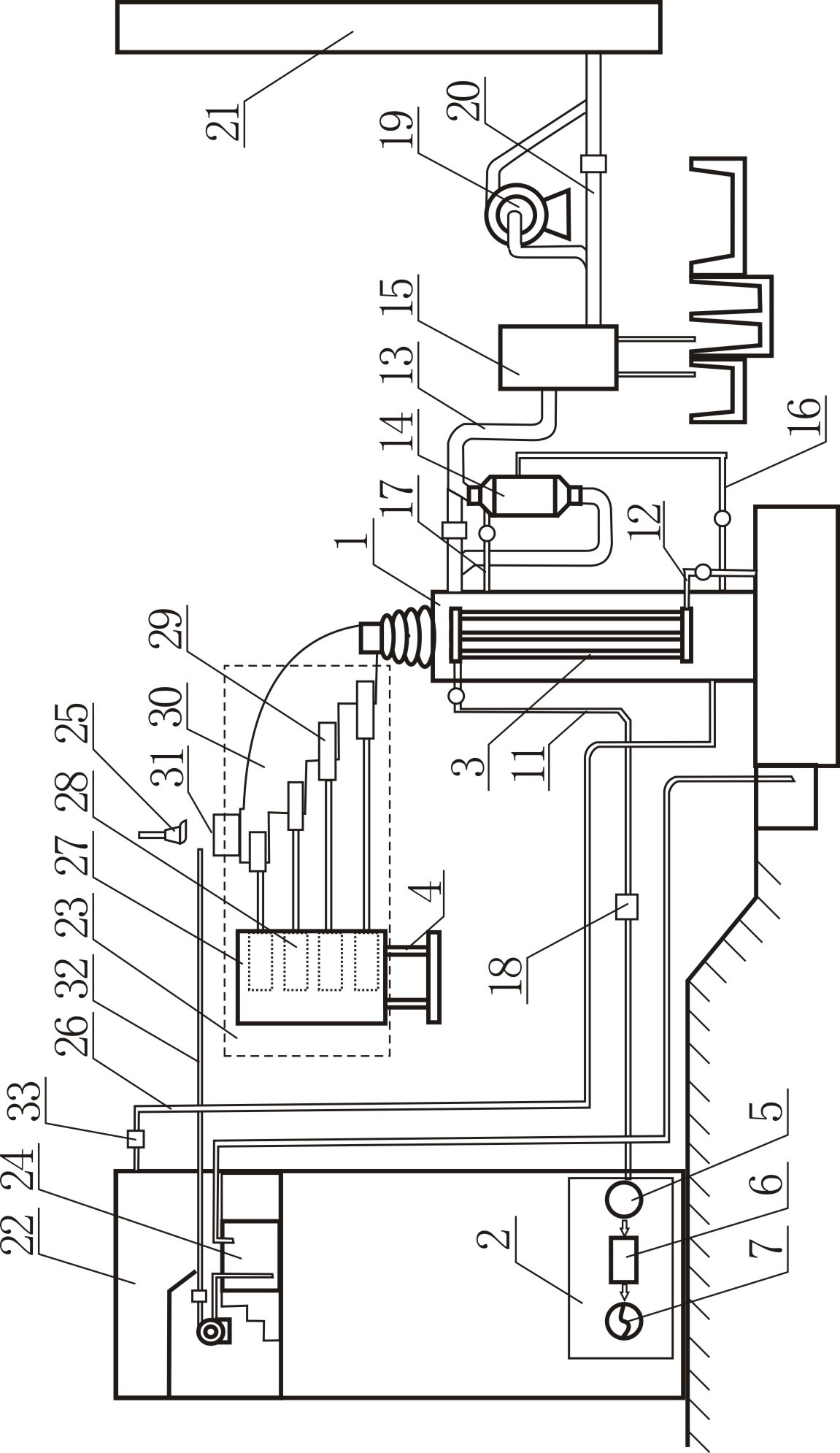

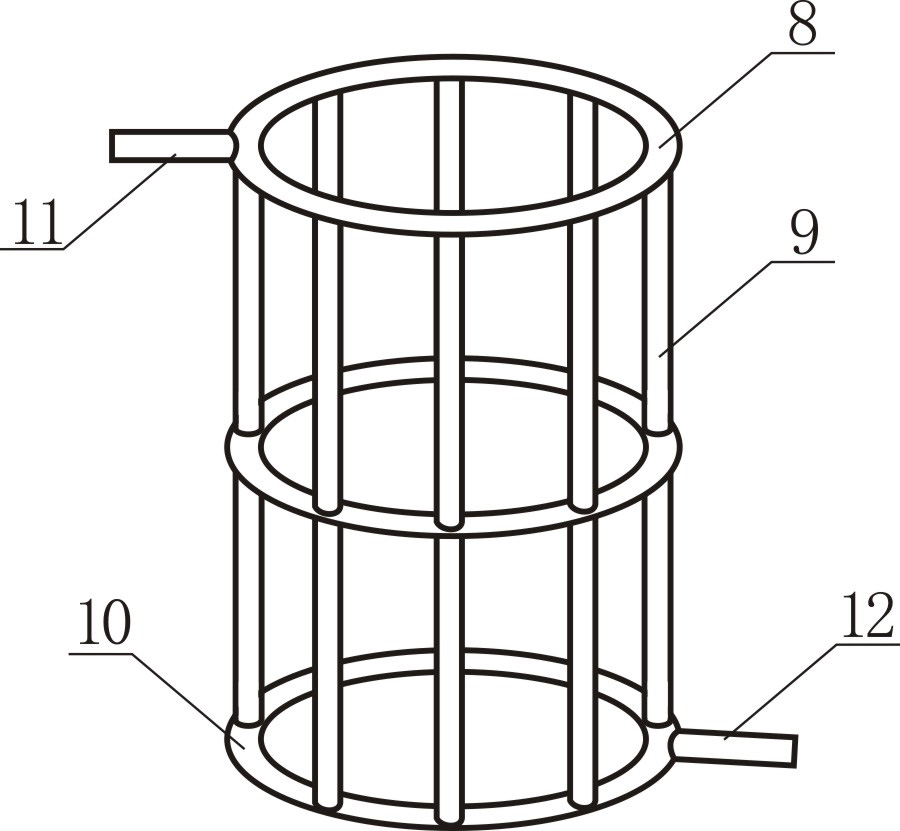

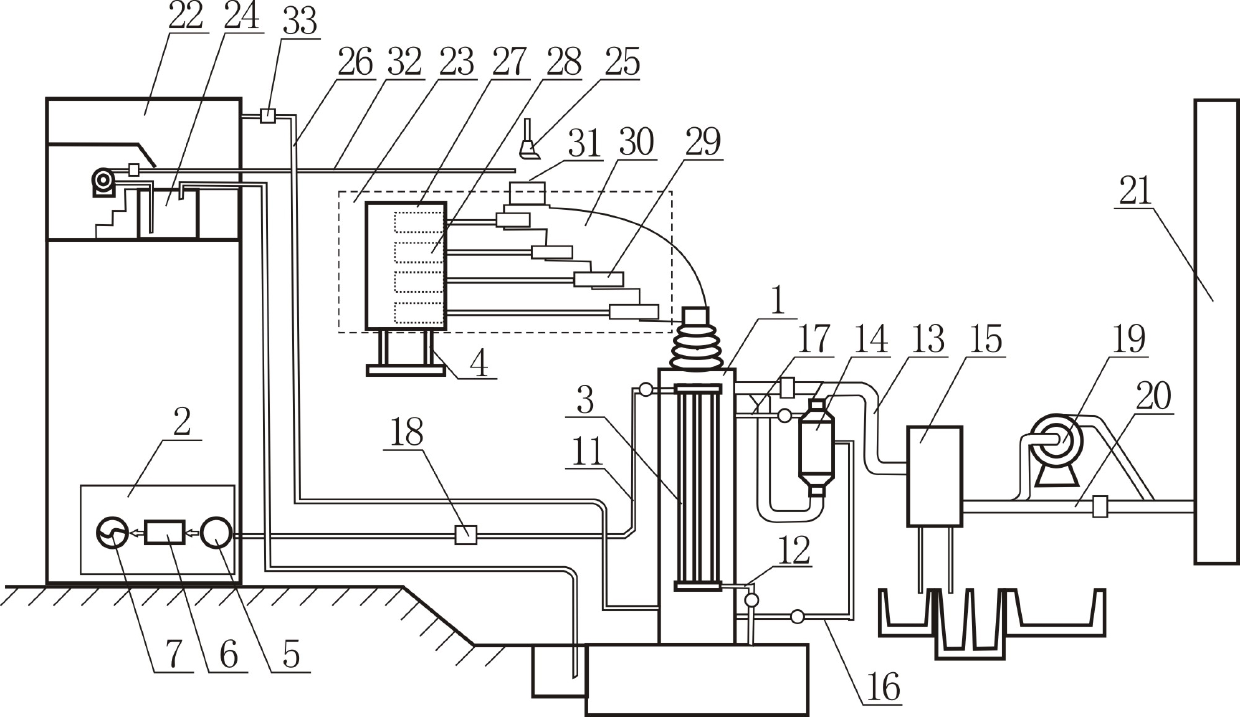

Garbage disposal waste heat power generation system with internal steam pipe

InactiveCN102606236AMaximize recoverySimple structure and processEnergy inputSteam engine plantsFlue gasSteam power

The invention discloses a garbage disposal waste heat power generation system with an internal steam pipe, which comprises a garbage gasifier and a turbine steam power generation device. The turbine steam power generation device comprises a steam generator, a steam discharge pipe, a steam drum, a steam turbine and a power generator, wherein the steam drum, the steam turbine and the power generator are sequentially connected, and the steam generator is arranged in the garbage gasifier and is of a cylindrical cage type structure comprising an upper annular pipe, a plurality of straight pipes and a lower annular pipe. As the steam generator is arranged in the garbage gasifier to realize primary heat exchange and a heat exchanger is additionally arranged in a flue gas channel to realize secondary utilization, heat generated in garbage disposal is used to the maximum extent, the technique with low heat utilization rate of a waste heat boiler for traditional garbage disposal steam power generation in the past is thoroughly changed, and garbage disposal heat recovery is maximized. Owing to a four-step hydraulic pusher, garbage is increasingly looser in the process of entering the garbage gasifier, and is not blocked.

Owner:SHENZHEN JUNENG BIOMASS GASIFICATION TECH

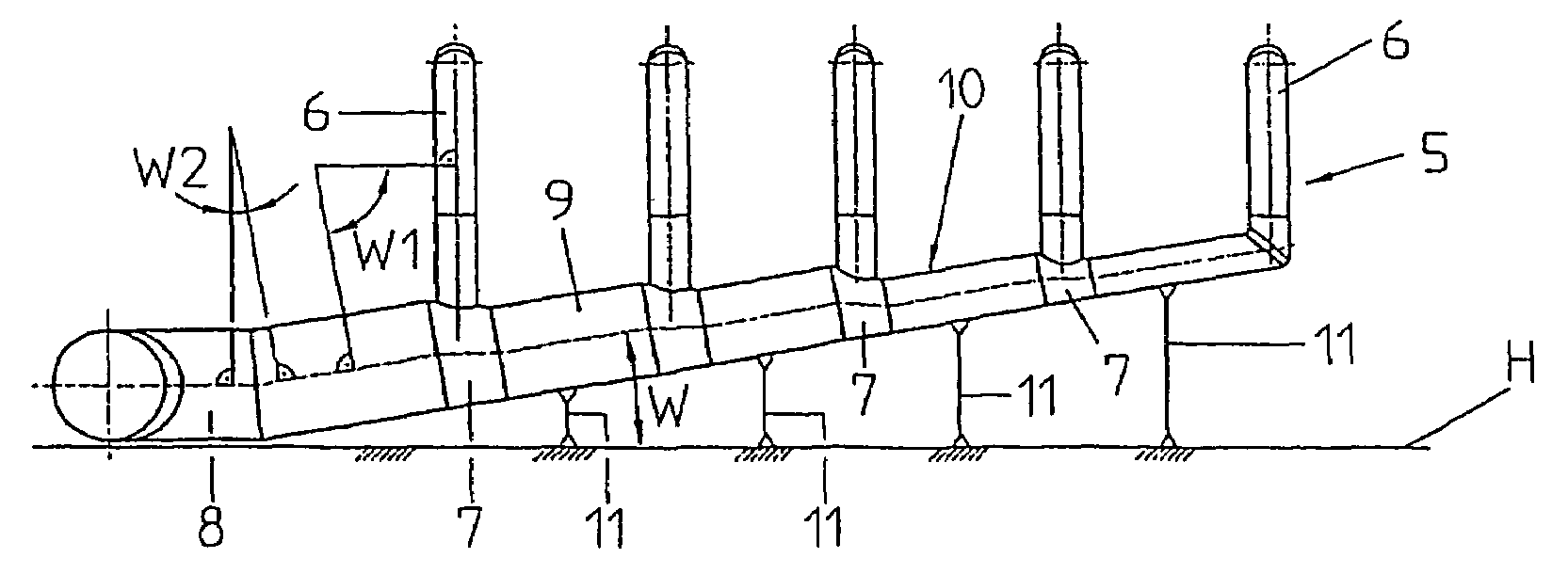

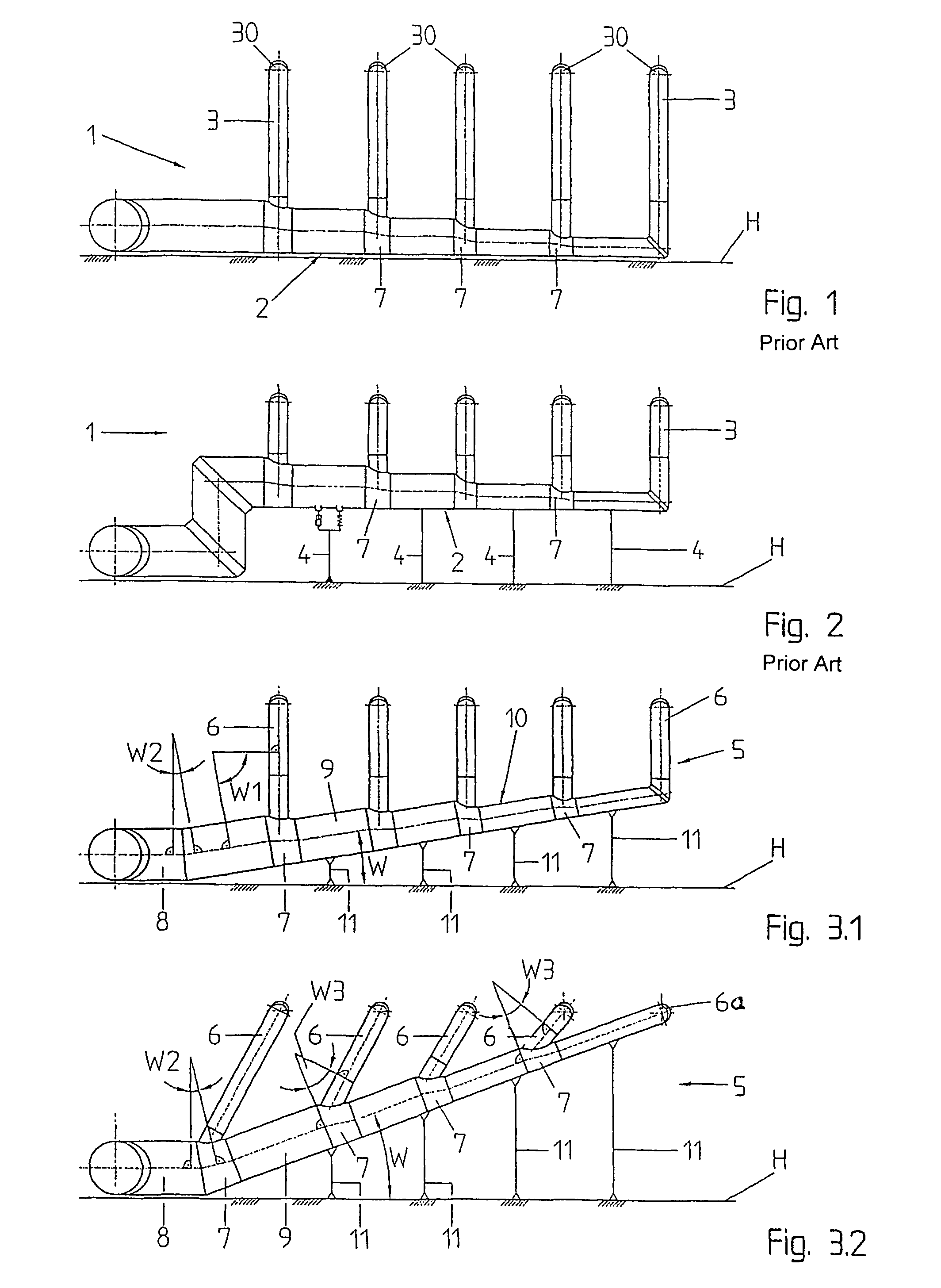

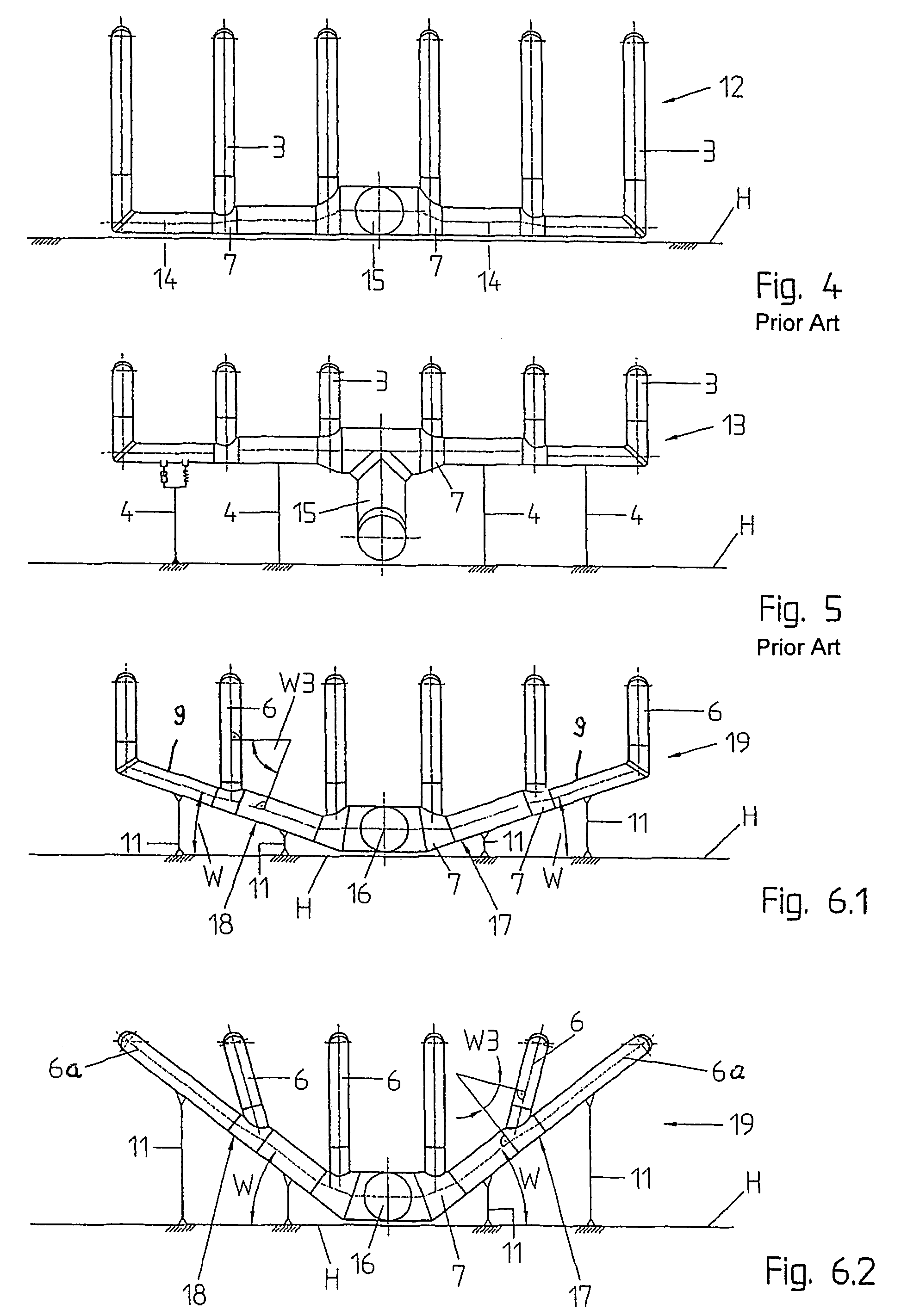

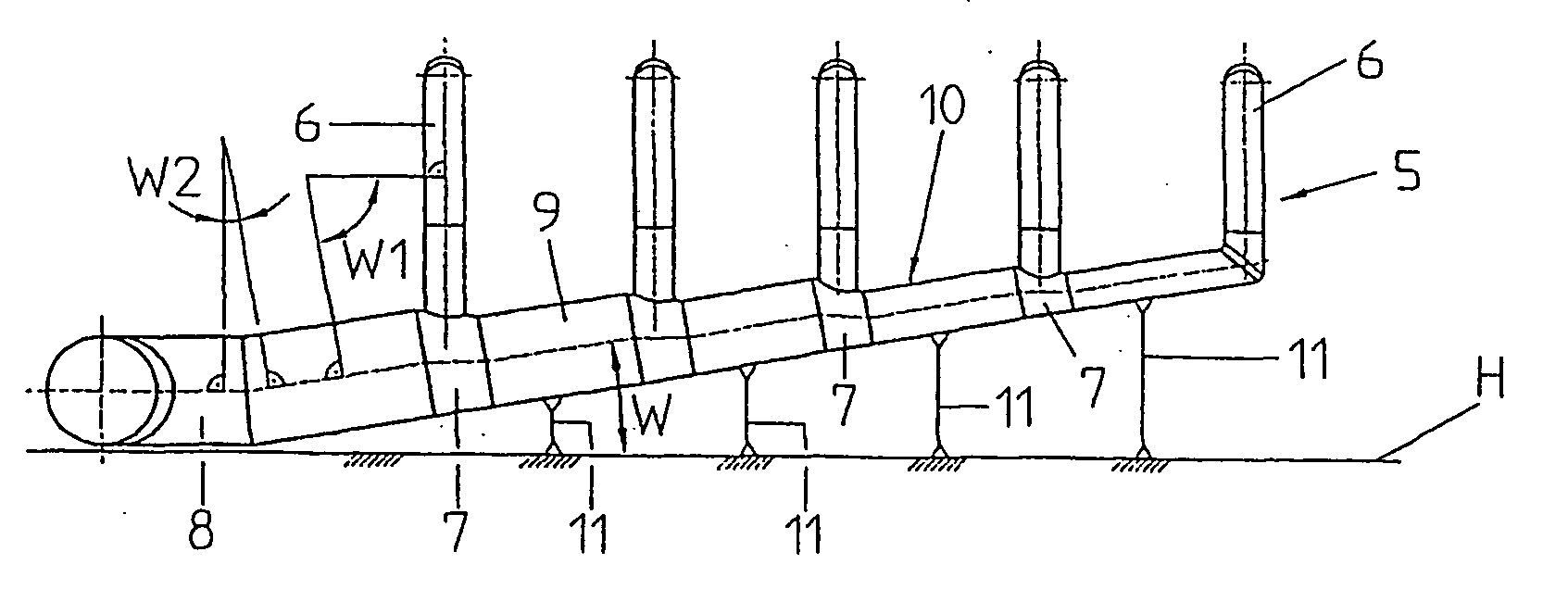

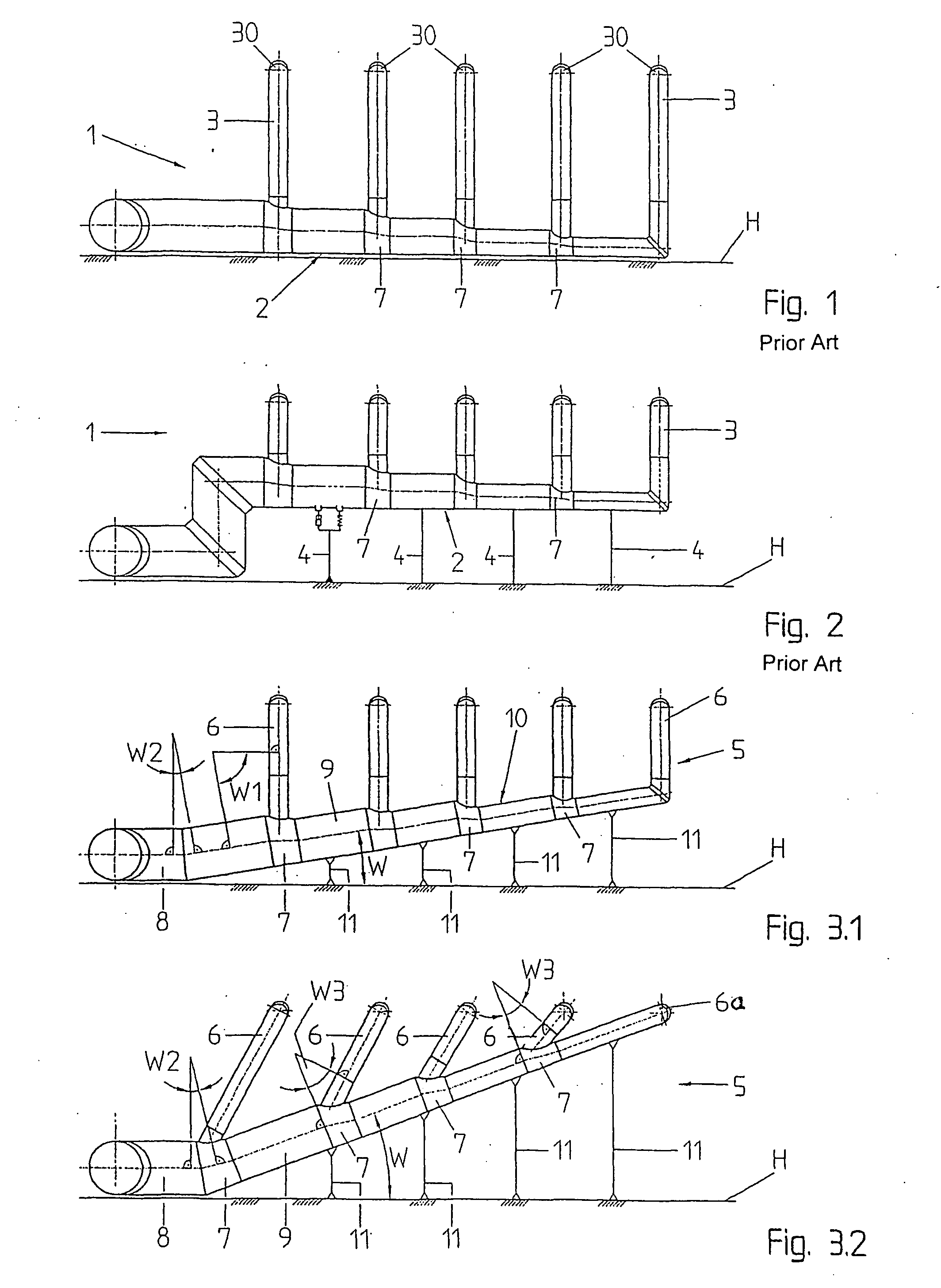

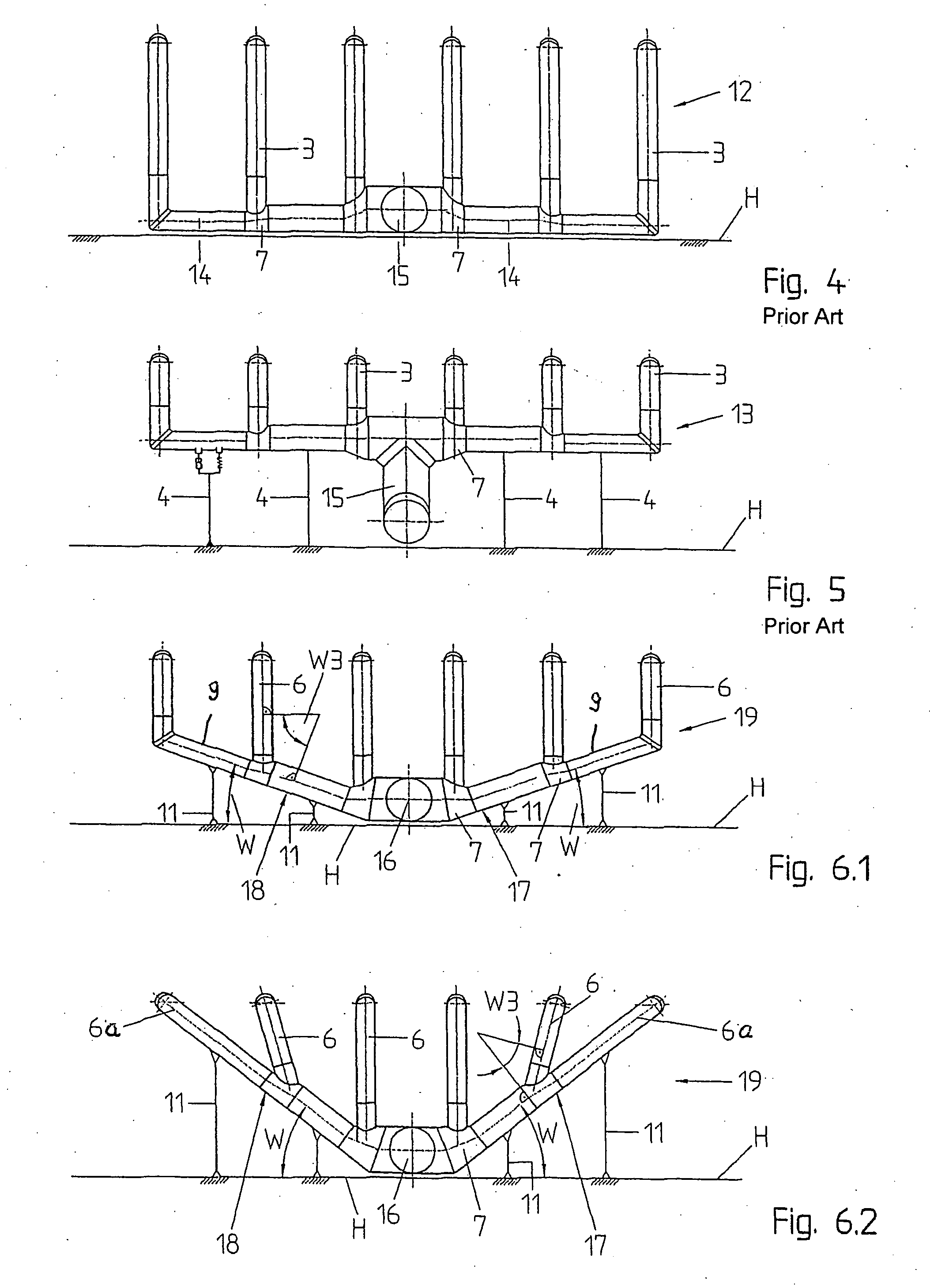

Exhaust-steam pipeline for a steam power plant

ActiveUS7168448B2Shorten the length of the flow pathShorten the lengthPipe supportsServomotor componentsSteam linePower station

An exhaust steam pipeline for steam power plants includes a main steam line and at least two branch lines which are fluidly connected to respective condenser elements of the steam power plant and branch off from the main steam line at connection zones in spaced-apart relationship. The main steam line has a cross section, which decreases following each of the connection zones, and is constructed to ascend at an angle to a horizontal in flow direction of the exhaust steam.

Owner:ENEXIO ACC GMBH

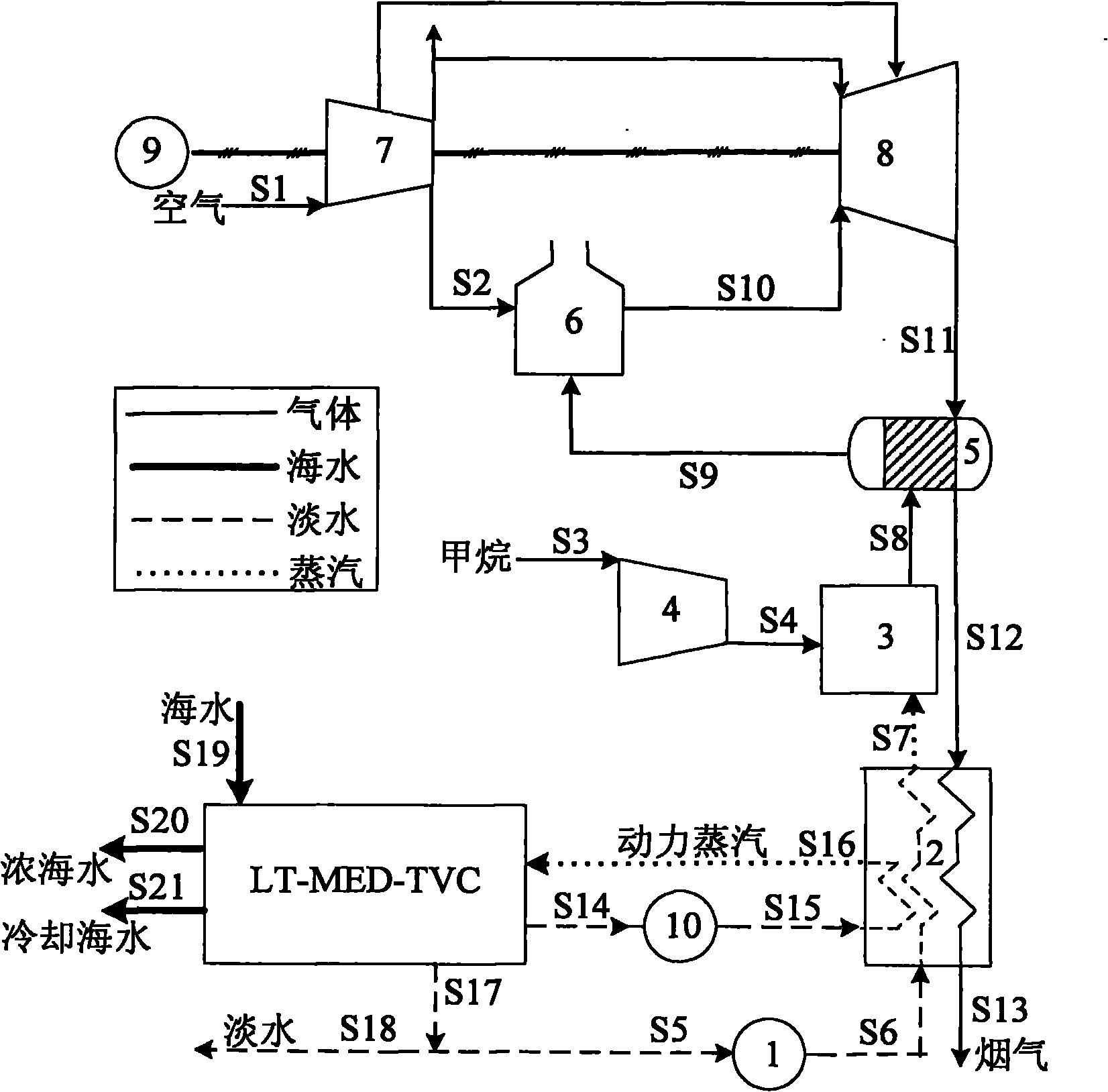

Regenerative cycle and low-temperature multi-effect distillation seawater desalinization thermodynamic cycling device and method

ActiveCN102060267ASolve the problem of large water consumption in chemical reheating cycleHydrogenGeneral water supply conservationDistillationSeawater

The invention discloses a regenerative cycle and low-temperature multi-effect distillation seawater desalinization thermodynamic cycling device, which is formed by coupling a chemical regenerative cycle and a low-temperature multi-effect distillation seawater desalinization system, wherein the flue gas waste heat of the chemical regenerative cycle is used for producing steam power to drive the low-temperature multi-effect distillation seawater desalinization system; fresh water produced by the low-temperature multi-effect distillation seawater desalinization system is supplied to satisfy the needs of reaction in the chemical regenerative cycle; the advantages of the chemical regenerative cycle and the low-temperature multi-effect distillation seawater desalinization system are complemented; and the system realizes integrated optimization. In the process of recycling the flue gas waste heat, a regenerator, a reformer and a waste heat boiler are arranged according to temperature corresponding and energy cascade-utilization principles, and as reforming temperatures of different fuels such as natural gas and methanol, a system structure is required to be correspondingly regulated to realize optimal heat exchange matching. Compared with a separate production system with the same output, the system can improve the efficiency by 5 to 9 percent and save 11 to 19 percent of fossil fuels. Therefore, the device has high economy and vast engineering application prospect.

Owner:青岛艳阳天环保科技有限公司

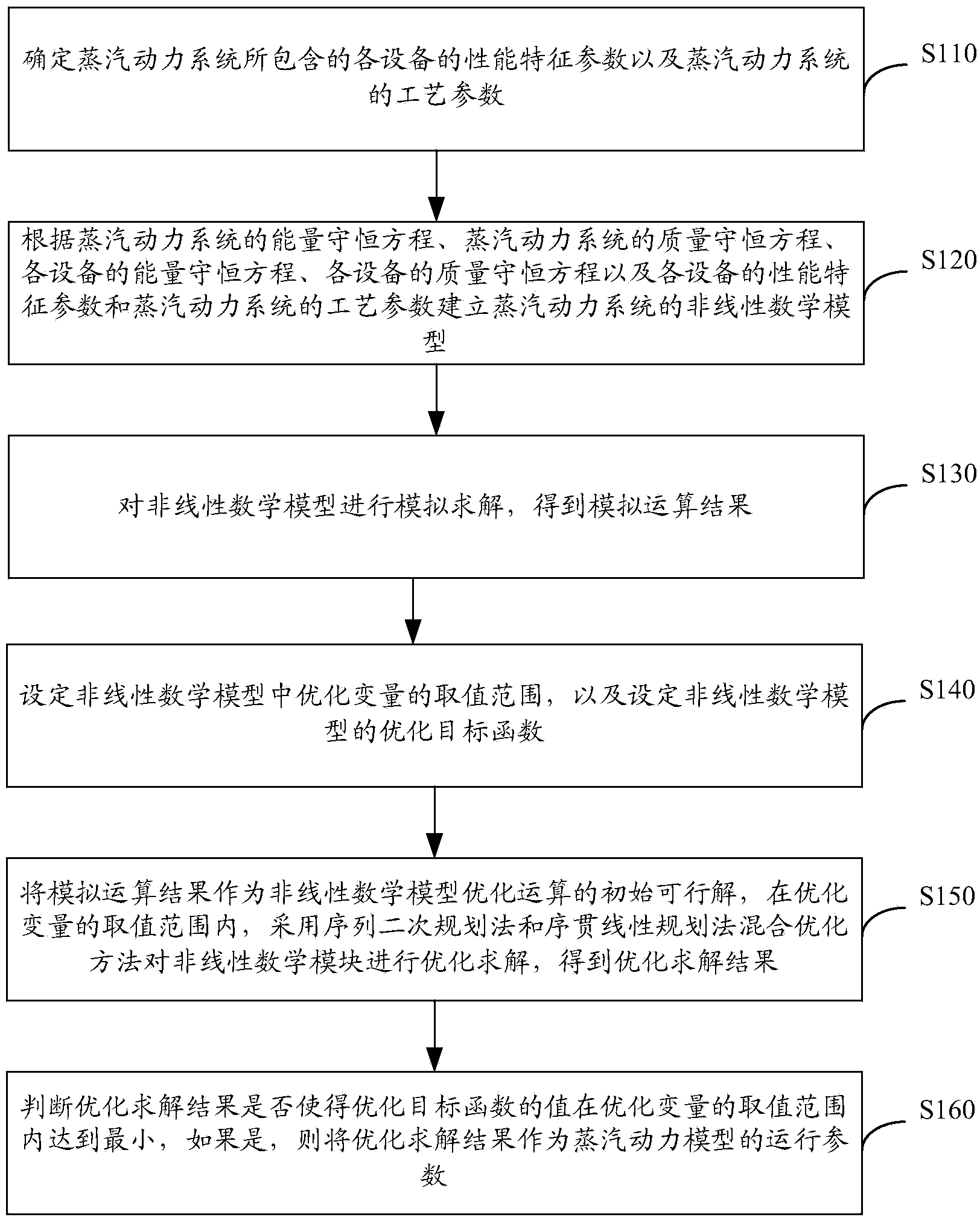

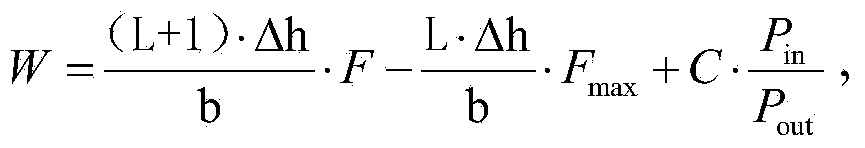

Method and device for operation optimization of steam power system

ActiveCN103544551AEnsure feasibilityEnsuring Computational EfficiencyForecastingMathematical modelSteam power

The invention discloses a method and device for operation optimization of a steam power system. The method includes the steps that performance characteristic parameters and technological parameters of various devices of the steam power system are determined; a nonlinear mathematical model of the steam power system is established according to the energy conservation equation, the mass conservation equation and the performance characteristic parameters and technological parameters of the devices; solution simulation is carried out on the nonlinear mathematical model to obtain a simulation calculation result; the value ranges of optimization variables in the nonlinear mathematical model and the optimized objective function of the nonlinear mathematical model are set; the simulation calculation result serves as an initial feasible solution of the nonlinear mathematical model, optimized solution is conducted on the nonlinear mathematical model through a mixed optimization method of a sequential quadratic programming method and a sequential linear programming method within the value ranges of the optimization variables to obtain an optimized solution result; whether the optimized solution result enables the optimized objective function to be minimum within the value ranges of the optimization variables or not is judged, and if the optimized solution result enables the optimized objective function to be minimum within the value ranges of the optimization variables, the optimized solution result is used as an operating parameter of a steam power model.

Owner:PROCESS INTEGRATION

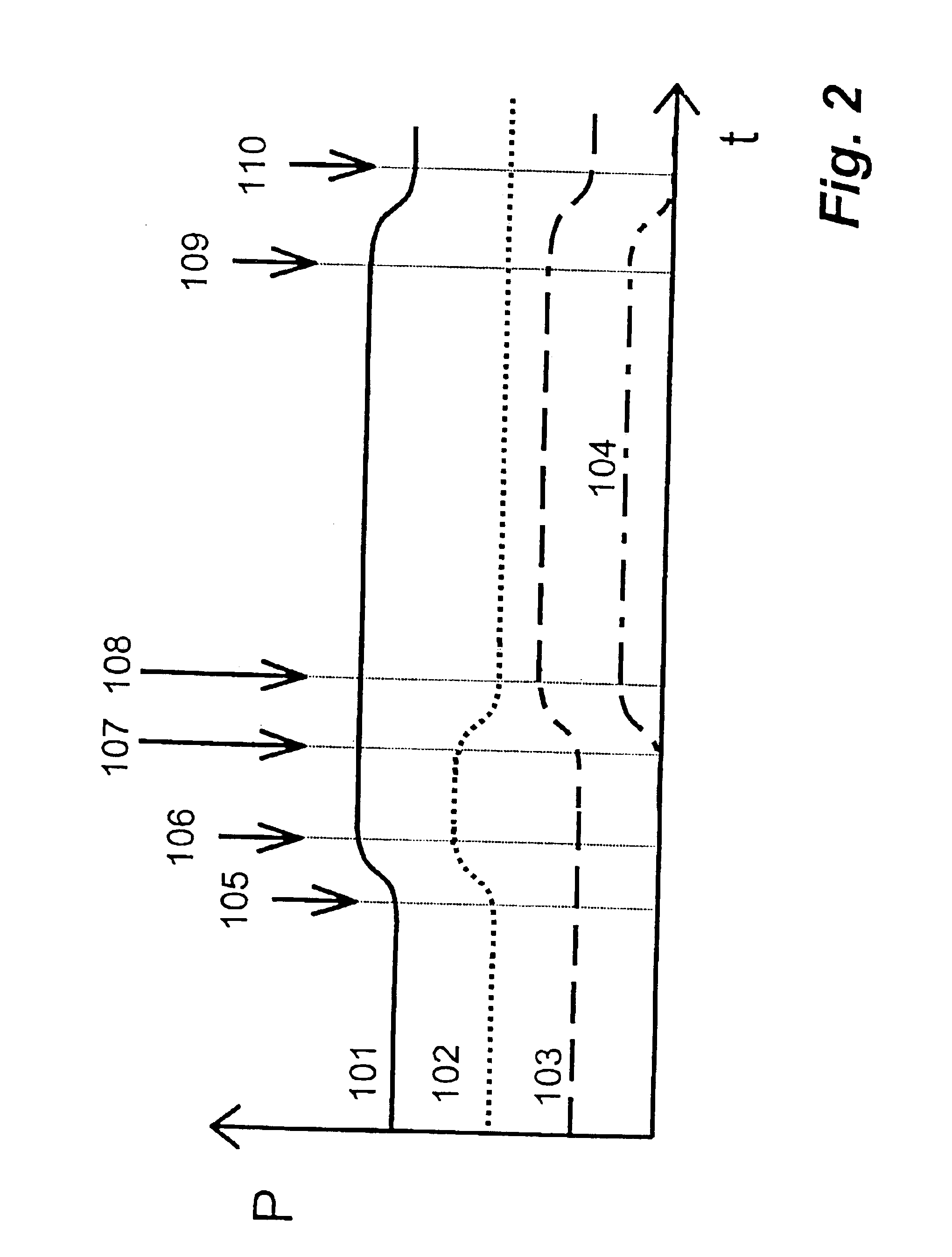

Steam power plant turbine and control method for operating at low load

In a system for effecting pressure control in a thermal power plant operated at low load connected fluidly in series, a relief conduit is disclosed herein. The relief conduit selectively transfers steam from a cold reheat conduit to the second extraction conduit. The plant further includes a boiler, a high-pressure turbine, an intermediate pressure turbine, a low pressure turbine, a main steam conduit for feeding steam from the boiler to an inlet of the high pressure turbine, a cold reheat conduit for feeding steam from an outlet of the high-pressure turbine through a reheat flow path in the boiler, and a first and second high pressure heaters. A first extraction conduit connects the cold reheat conduit to a first high pressure heater to transfer heat, and a second extraction conduit connects the intermediate pressure turbine to the second high pressure heater, to transfer heat.

Owner:GENERAL ELECTRIC TECH GMBH

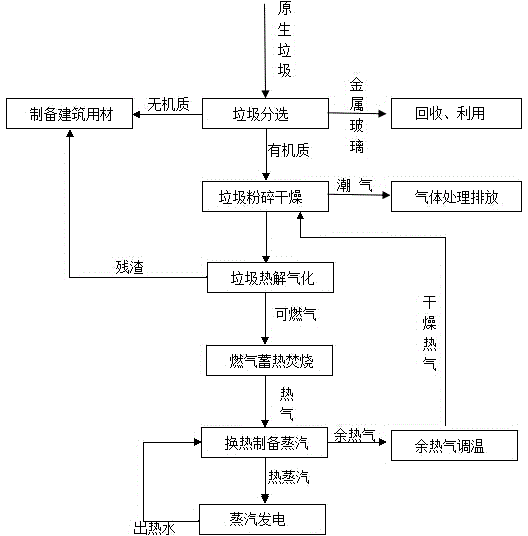

Power generation technique based on pyrolyzation and gasification of household refuse and incineration of fuel gas

InactiveCN105351941AHigh heat conversion rateImprove power generation efficiencySolid waste disposalIncinerator apparatusCombustible gasSteam power

The invention discloses a power generation technique based on pyrolyzation and gasification of household refuse and incineration of fuel gas. The power generation technique comprises the steps that the household refuse is sorted, pulverized and dried; then pyrolyzation and gasification are conducted on the household refuse, so that combustible gas is generated; the combustible gas is incinerated; steam is prepared from hot air obtained through incineration through heat exchange; and the steam is introduced into a steam power generator for power generation. According to the power generation technique based on pyrolyzation and gasification of the household refuse and incineration of the fuel gas, the heat energy conversion rate of pyrolyzation and gasification is higher, the power generation efficiency is greatly improved, and the cost caused by procedure increment can be counteracted by the increased economic benefits; the refuse is subjected to pyrolyzation and gasification under an oxygen-free or oxygen-deficient condition firstly after being dried instead of being directly incinerated, and thus the amount of generated dioxin is greatly reduced; the dioxin can be evenly decomposed by conducting heat-storage incineration of the generated combustible gas through secondary gas at the temperature over 850 DEG C. Tail gas is used for dying the refuse, and smoke emission hardly exists under the adsorption action of the pulverized refuse.

Owner:FUJIAN ZHENGREN ENVIRONMENTAL PROTECTION

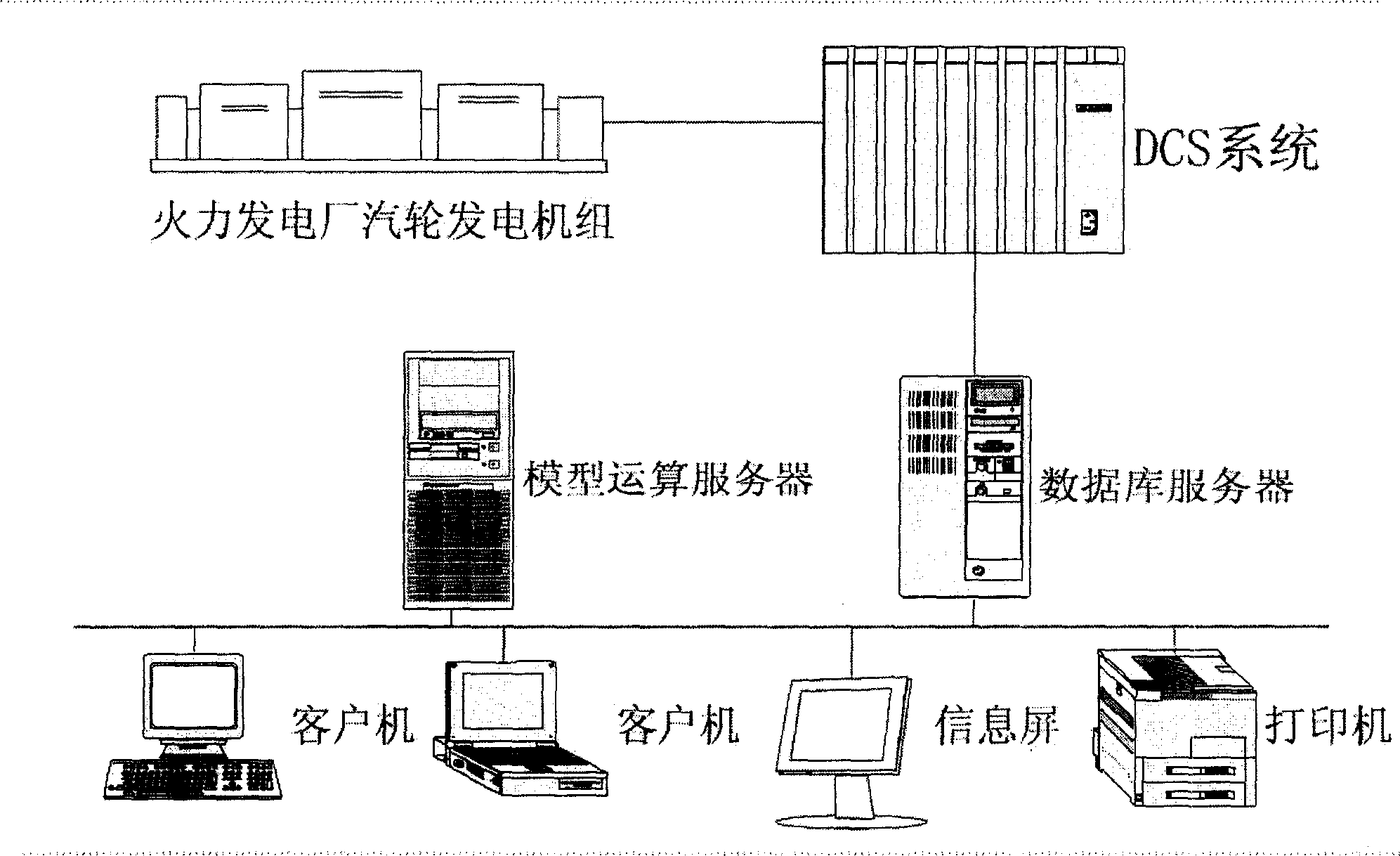

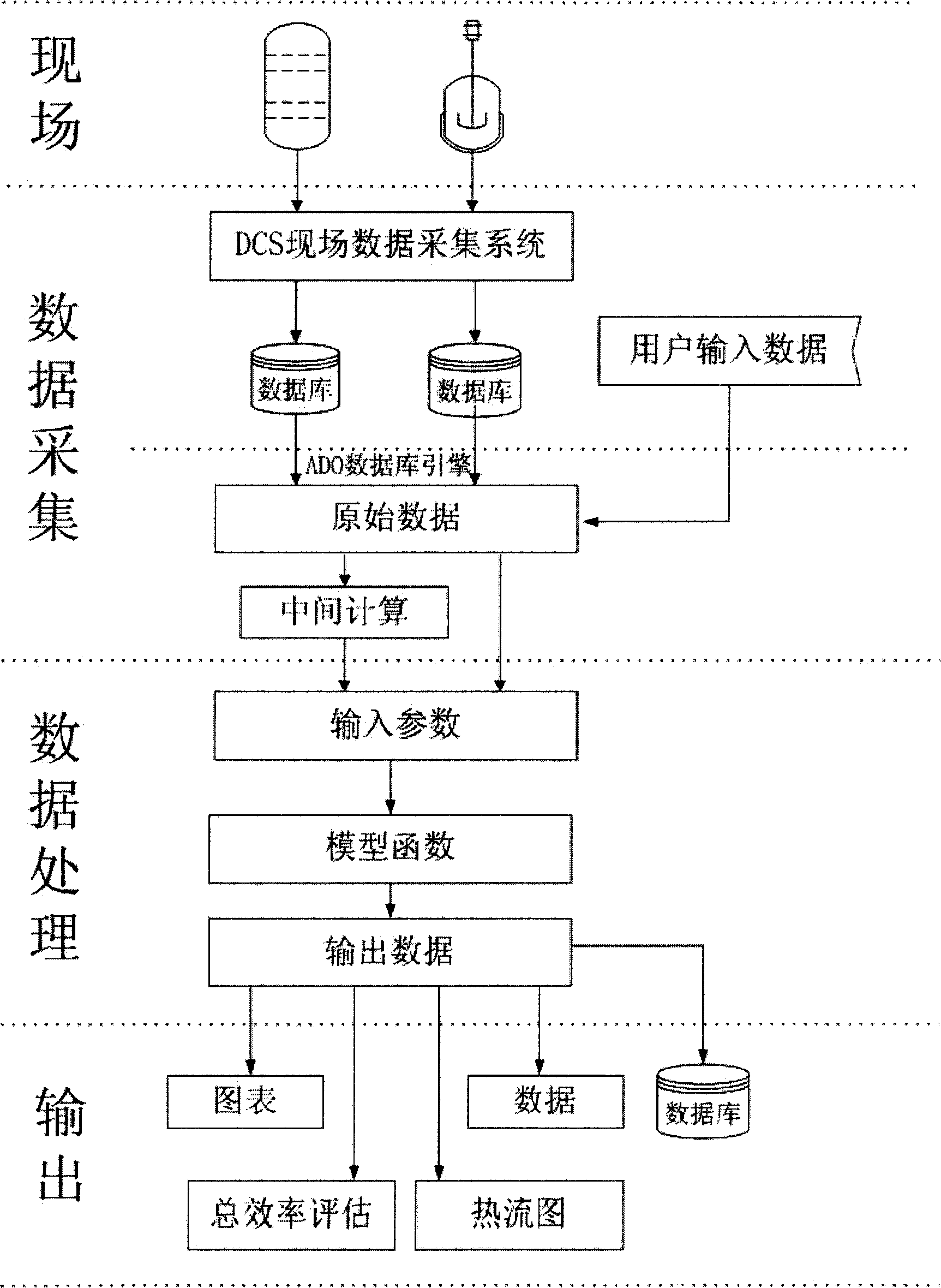

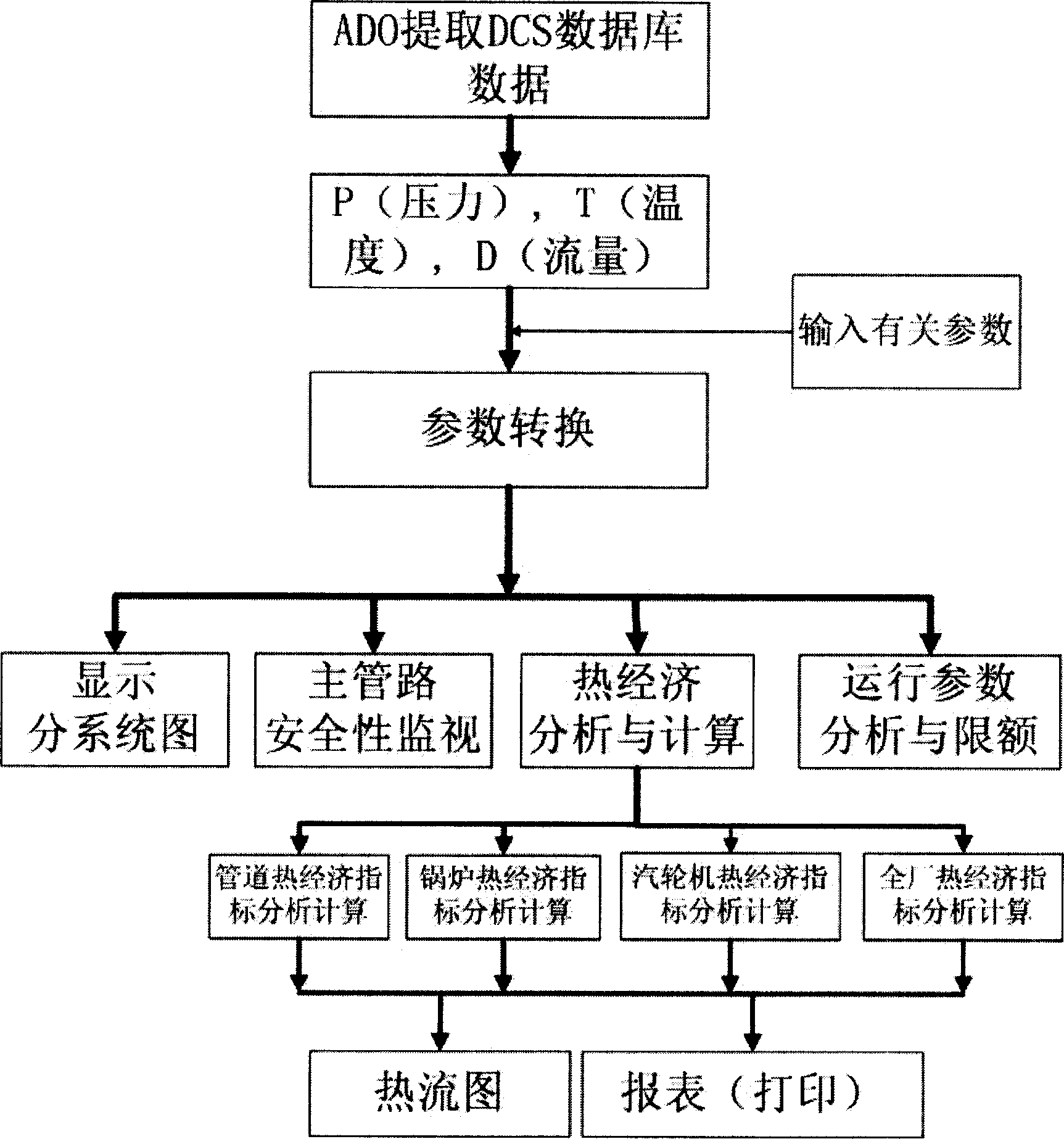

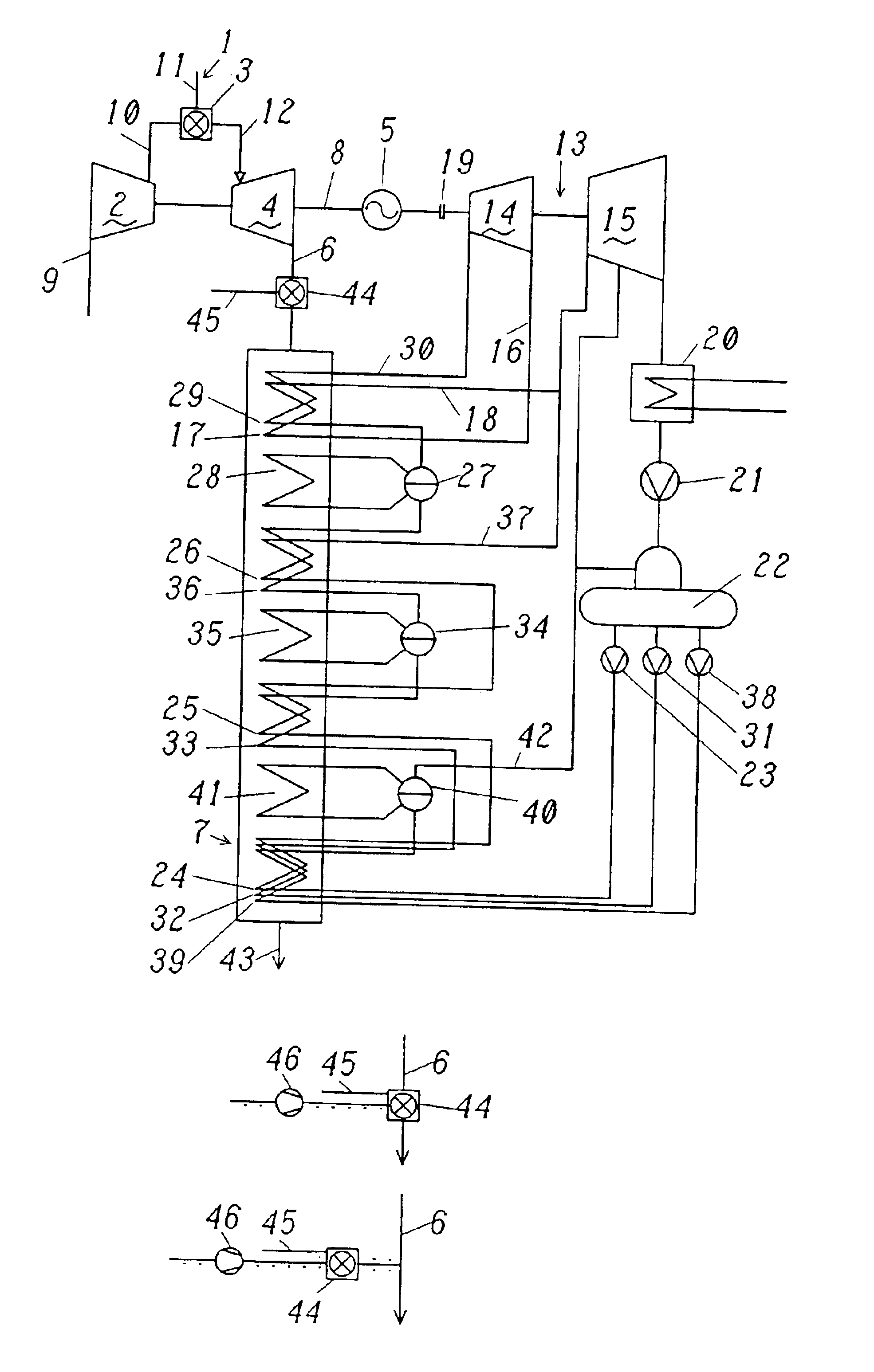

On-line analysing-monitoring system for heat-engine plant pipeline heat-efficiency

InactiveCN1581151AMonitor heat lossIncrease computing speedSpecial data processing applicationsThermal energyData acquisition

The present invention is characterized by that a pipeline heat-efficiency on-line analysis and monitoring system is designed for steam power plant. Said system is mainly formed from data acquisition system, data base server, model operation server, and input / output equipment, and the steam power plant pipeline heat-efficiency counterbalance heat-efficiency calculation formula can e used in said system, so that its pipeline heat-efficiency and thermal less distribution can be calculated, and its analytical report or characteristic curve can be displayed on the information screen and customer's machine. Said system can implement on-line mointoring of working state of main pipeline system of steam power plant.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for operating a combined-cycle power station

In a method for increasing the power output of a combined-cycle power station, comprising at least one gas turbo group, at least one heat recovery steam generator and at least one steam turbo group, with the gas turbo group comprising at least one compressor, at least one combustion chamber and at least one gas turbine, the heat recovery steam generator having at least one pressure stage and the steam turbo group comprising at least one steam turbine, in which combined-cycle power station air is compressed in a compressor, is then supplied as combustion air to a combustion chamber, the hot gas which is produced there is passed to a gas turbine, and the exhaust gas from the gas turbine is used in a heat recovery steam generator to produce steam for a steam turbo group, an immediate and rapid increase in the power output is achieved, and an additional power output from the combined-cycle power station is maintained in safe operating conditions, in that an supplemental firing is arranged to provide additional heating for the exhaust gas from the gas turbine and in that the combustion chamber or the gas turbo group is supplied with more fuel, and the supplemental firing is switched on at the same time, for immediately, rapidly and temporarily increasing the power output of the combined-cycle power station, and in that the power output of the gas turbo group is reduced again to the extent that the additional steam power produced as a result of the supplemental firing is also provided via the steam turbo group as power.

Owner:ANSALDO ENERGIA IP UK LTD

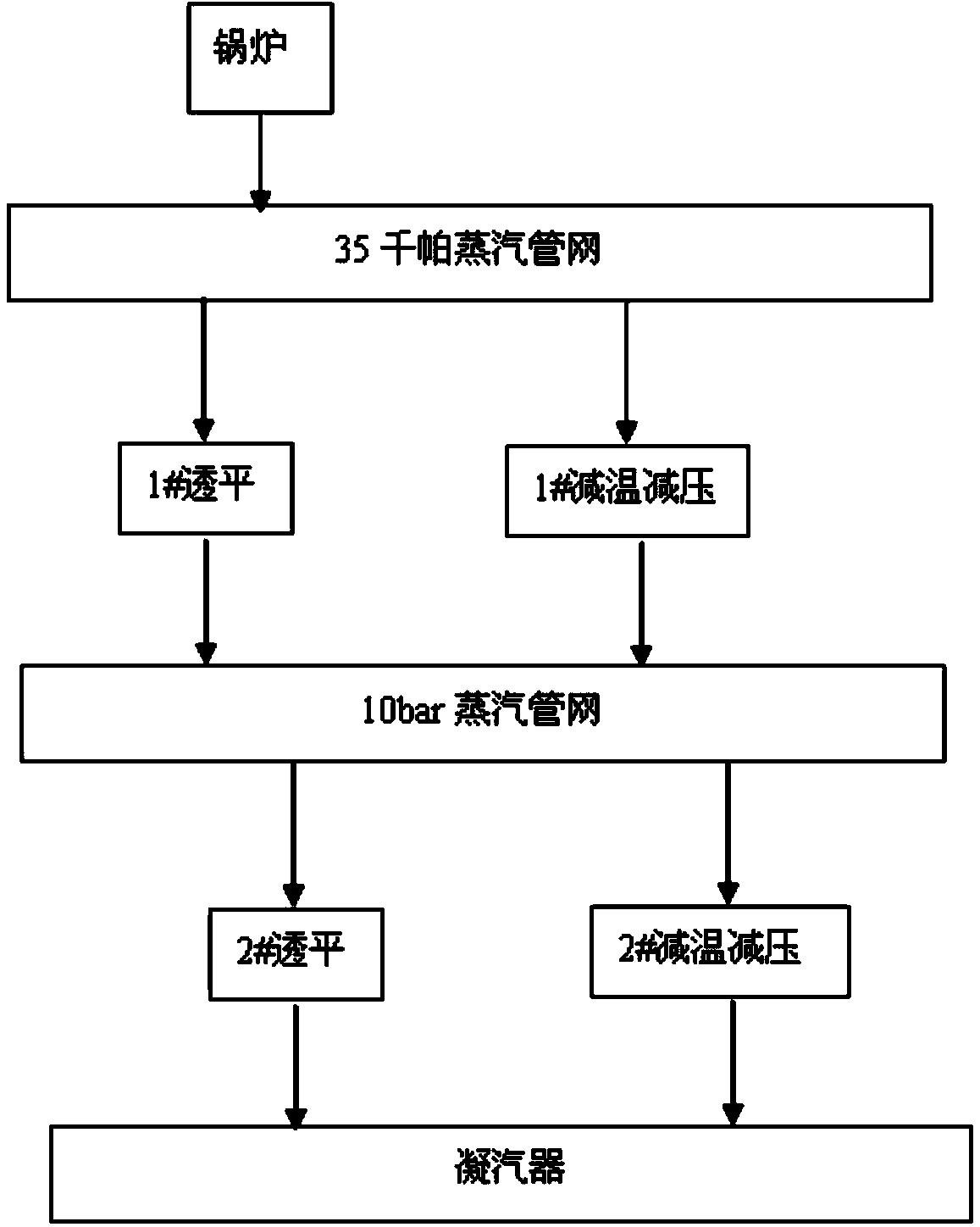

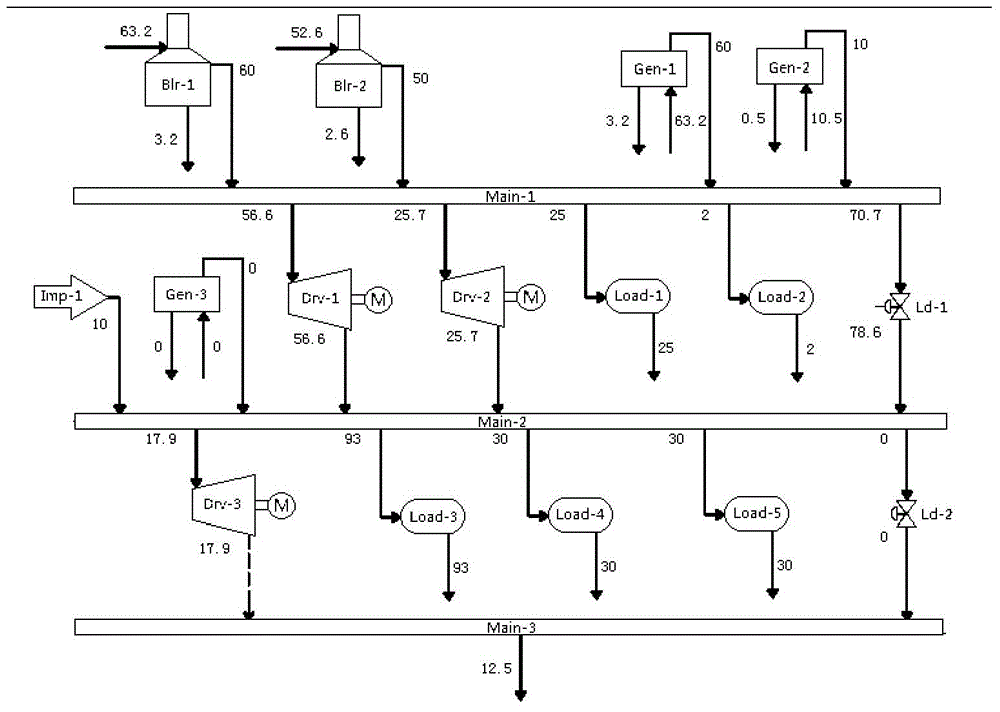

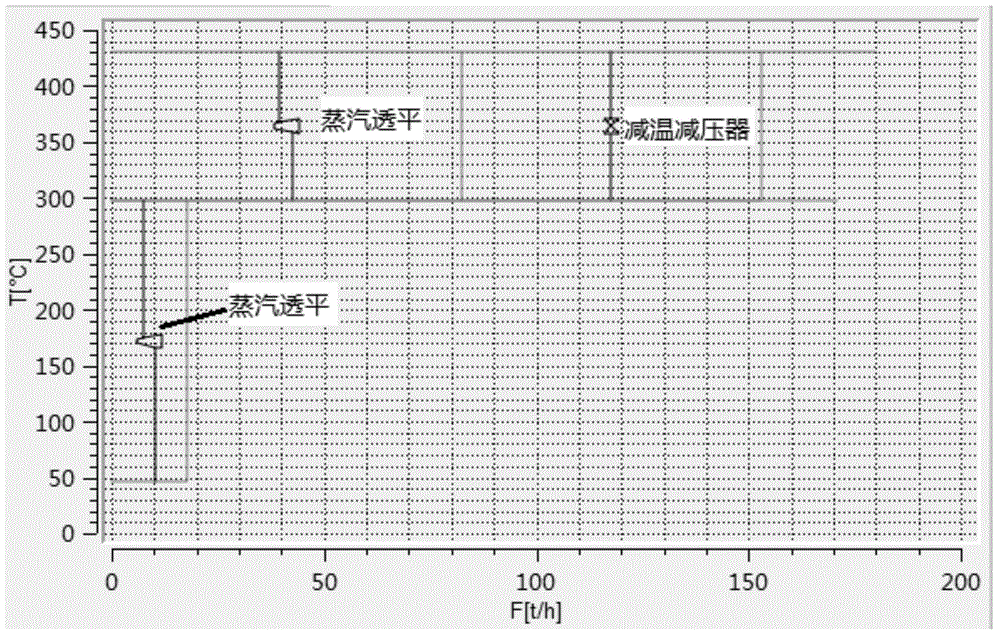

Diagrammatized steam power system analysis and optimization method and device

The invention discloses a diagrammatized steam power system analysis and optimization method and device. The method includes the following steps that process parameters of a first steam power system are collected under different working conditions; a first nonlinear mathematical model is established according to equipment composition and the process parameters of the first steam power system; simulation solution is conducted on the first nonlinear mathematical model, so that first simulation results of all devices and streams in the first steam power system are obtained; according to the first simulation results, steam generation and use data of all grades of steam boilers, steam turbines, turbines and temperature and pressure reducers in the first steam power system are obtained in a statistic mode, a load allocation diagram of the first steam power system is generated, and the load allocation diagram takes temperature as vertical coordinates and takes flow as horizontal coordinates; according to the load allocation diagram and the first simulation results, the running state and structural reasonability of the first steam power system are analyzed, composition of the first steam power system is improved according to the analysis result, and a second steam power system is obtained.

Owner:PROCESS INTEGRATION

Anhydration system for sludge by using remaining heat of flue gas from steam power plant

ActiveCN1686878AWill not affect normal operationEffective controlSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFlue gasSludge

The present invention discloses a sludge anhydration system by utilizing waste heat of steam power plant smoke. Said sludge anhydration system includes heat supply system, sludge pretreatment system, feeding system, sludge, anhydration and granulation system and dust-removing and gas-removing system.

Owner:ZHEJIANG UNIV

Exhaust-steam pipeline for a steam power plant

ActiveUS20050161094A1Lowered platform heightReduction of steel construction costServomotor componentsSteam/vapor condensersPower stationSteam line

An exhaust steam pipeline for steam power plants includes a main steam line and at least two branch lines which are fluidly connected to respective condenser elements of the steam power plant and branch off from the main steam line at connection zones in spaced-apart relationship. The main steam line has a cross section, which decreases following each of the connection zones, and is constructed to ascend at an angle to a horizontal in flow direction of the exhaust steam.

Owner:ENEXIO ACC GMBH

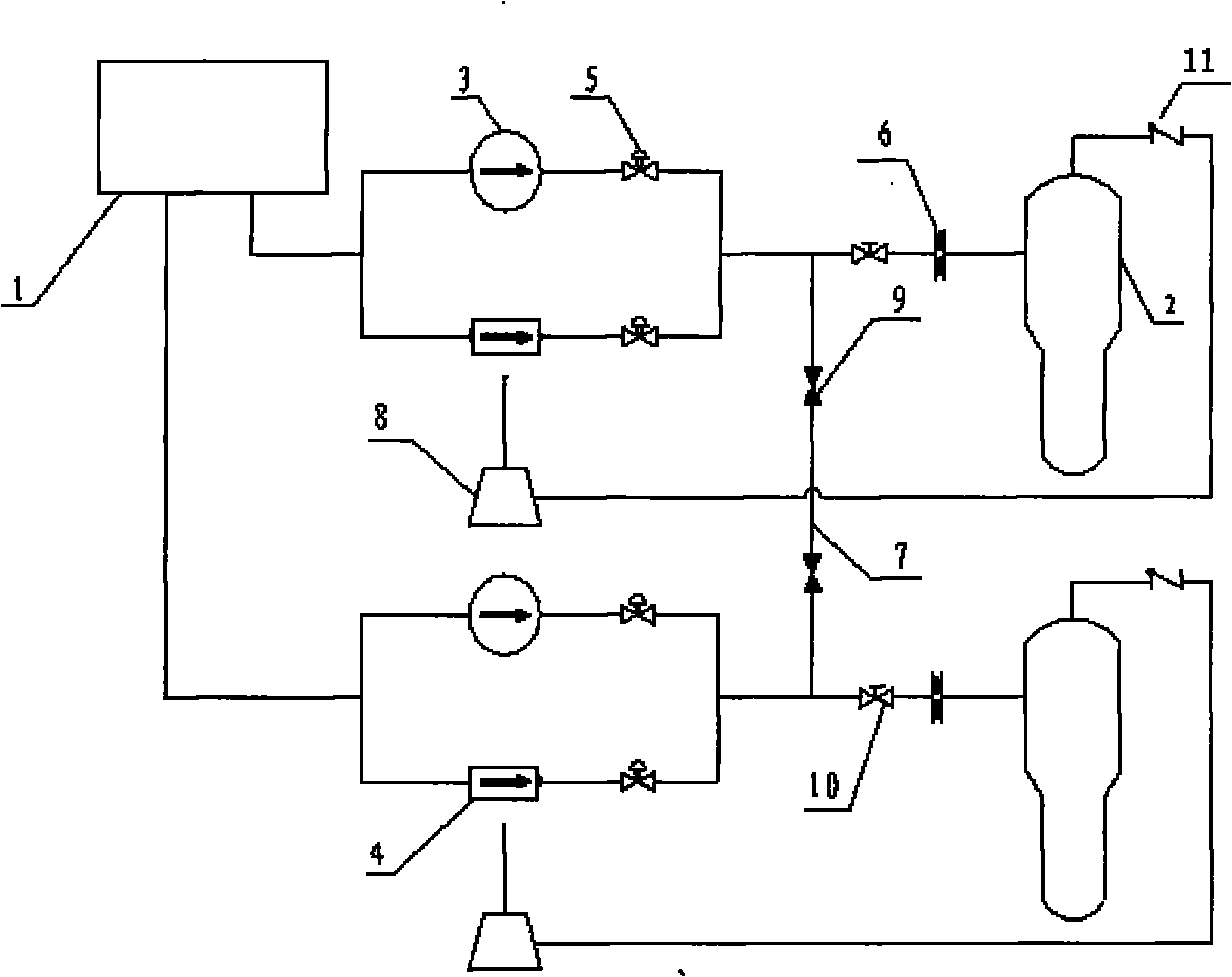

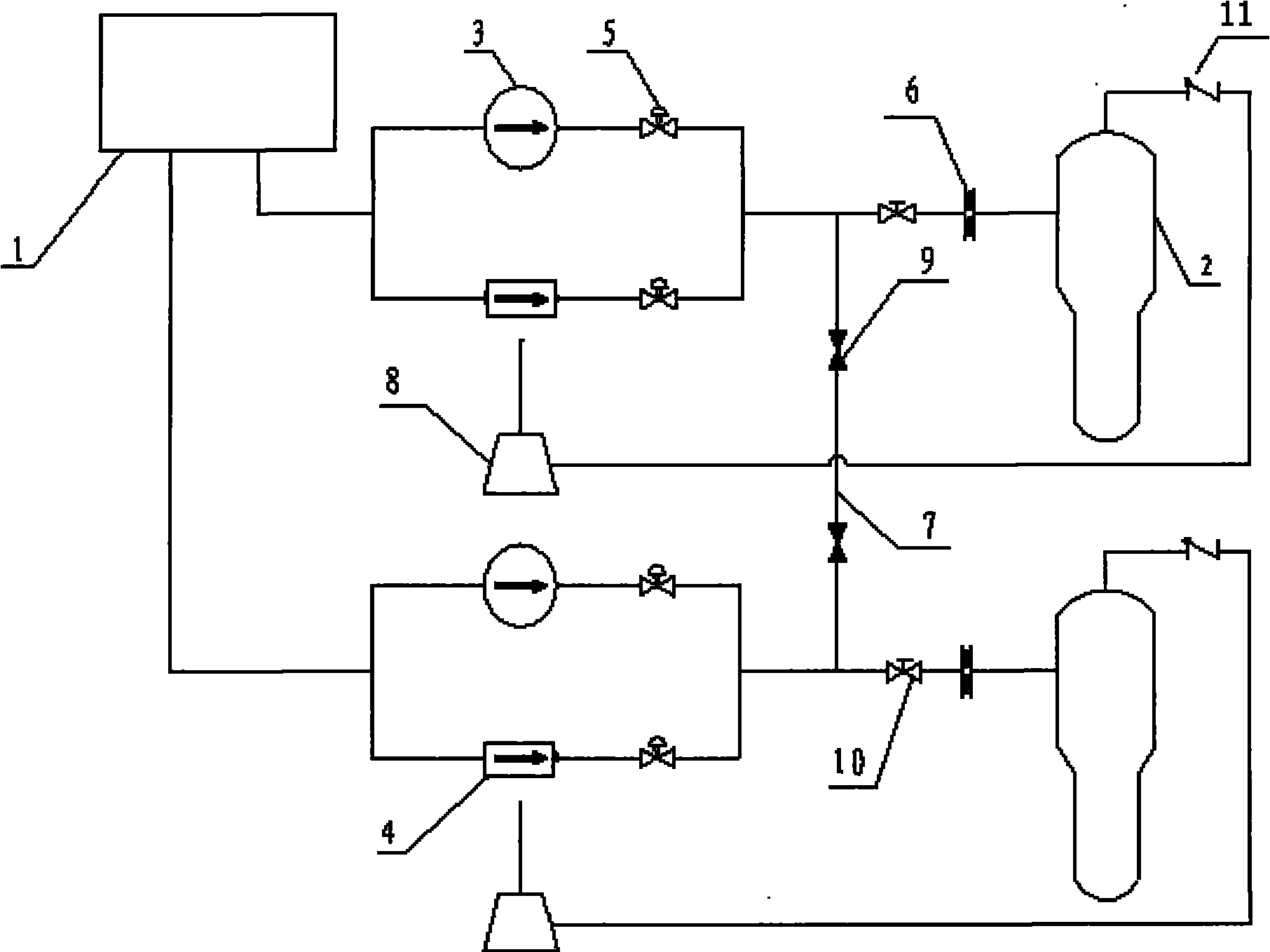

Auxiliary water supply system used for nuclear power station single reactor and actuating safety function

InactiveCN101800085AReduce lossesExtension of timeNuclear energy generationCooling arrangementIsolation valvePressurized water reactor

The invention belongs to auxiliary water supply systems of nuclear power stations, and particularly relates to an auxiliary water supply system used for a nuclear power station with single reactors and actuating safety function. The auxiliary water supply system comprises an auxiliary water supply tank, and two water supply series connecting the auxiliary water supply tank with an evaporator. Each water supply series comprises an electric pump and a pneumatic pump which are connected in parallel, each pump is provided with a regulating valve, and an isolating valve is arranged on a pipeline between the regulating valve and a pore plate. The evaporator supplies steam power for the pneumatic pumps through a steam turbine, a connecting valve and a connecting pipe are installed between the two water supply series, the joint points between the connecting pipe and water supply pipelines are arranged on the pipeline between the regulating valve and the isolating valve. Because each water supply pipeline in the two water supply series comprises one 100 percent of electric pump and one 100 percent of pneumatic pump which are connected in parallel, the safety of the system is increased. The auxiliary water supply system is especially suitable for the auxiliary water supply system in a nuclear power station with pressurized water reactors, and can efficiently increase the safety of the nuclear power station.

Owner:CHINA NUCLEAR POWER ENG CO LTD

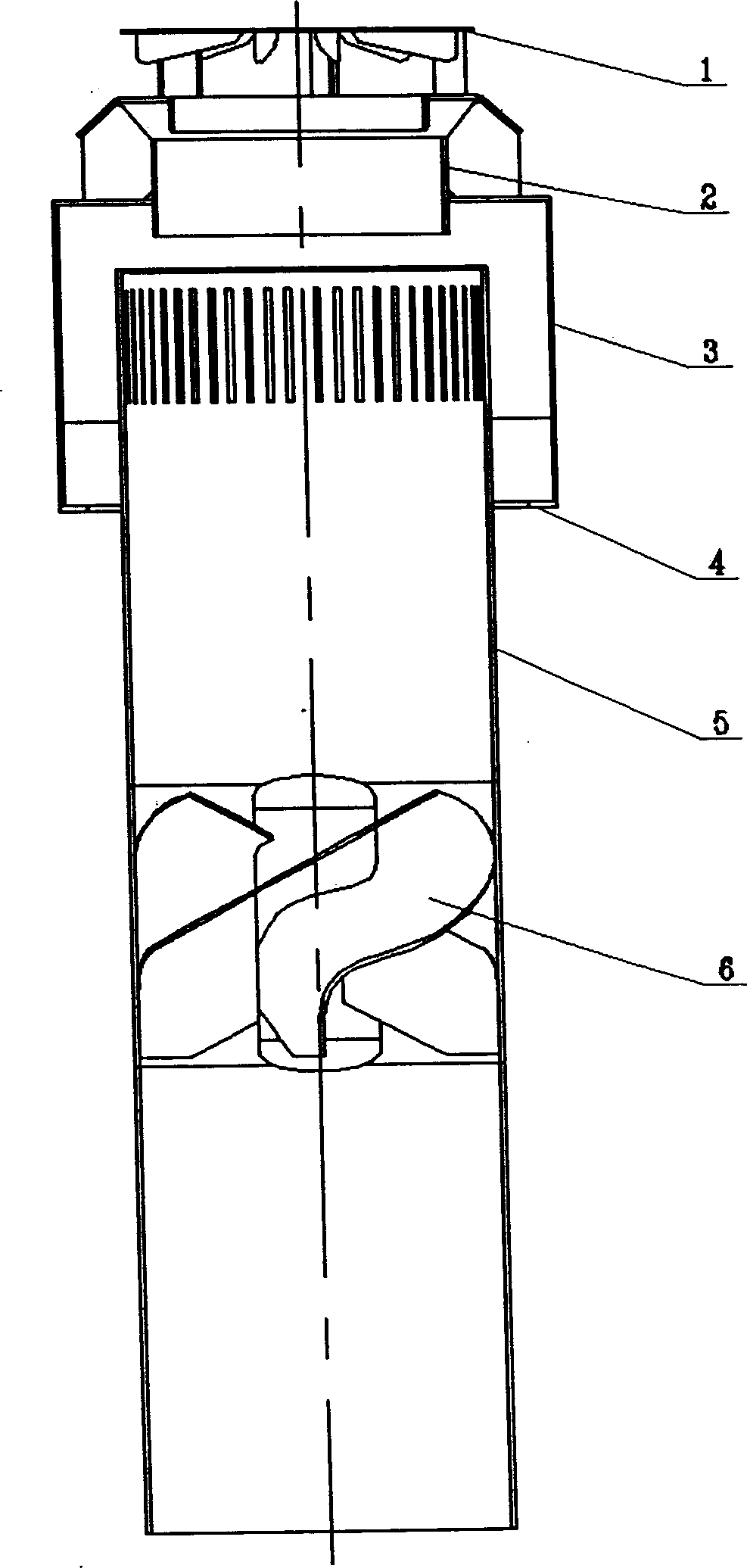

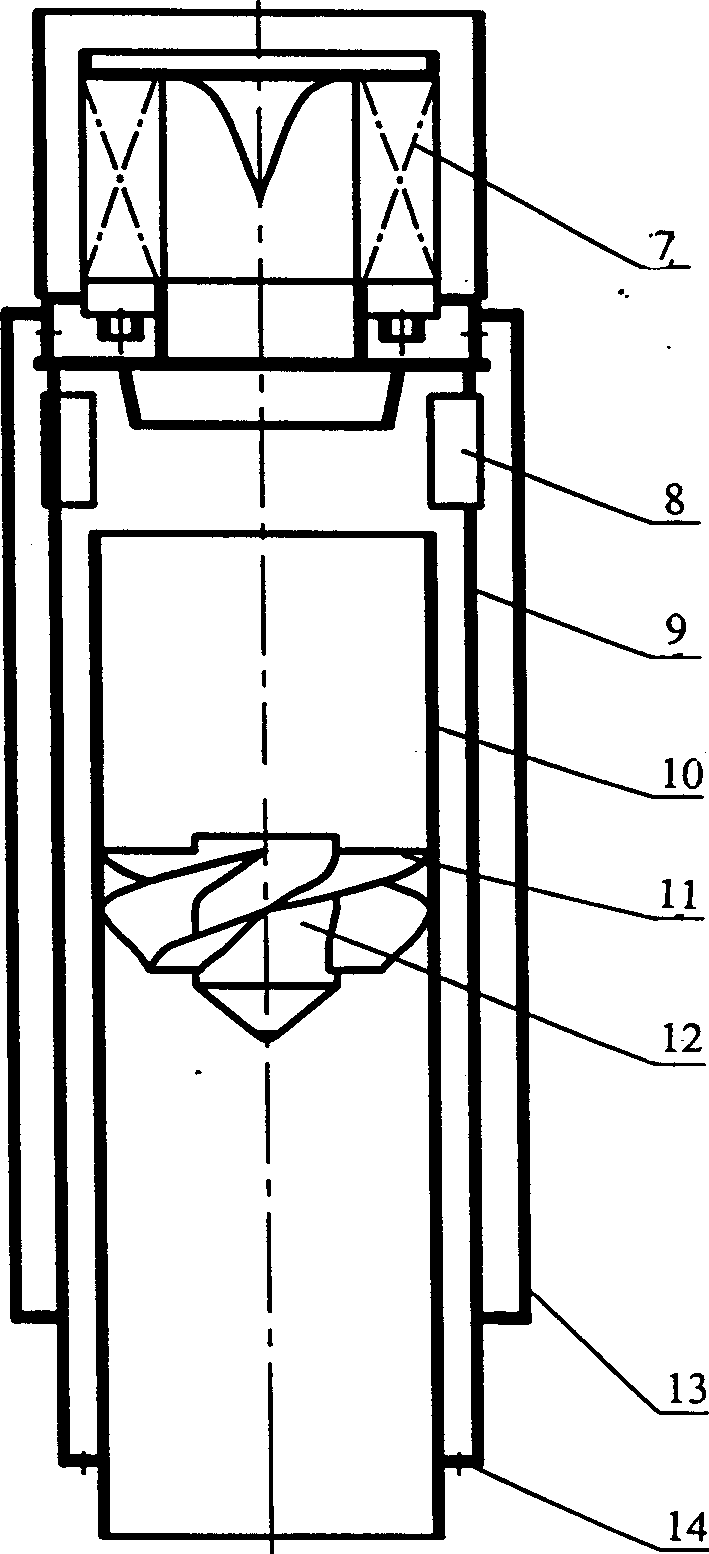

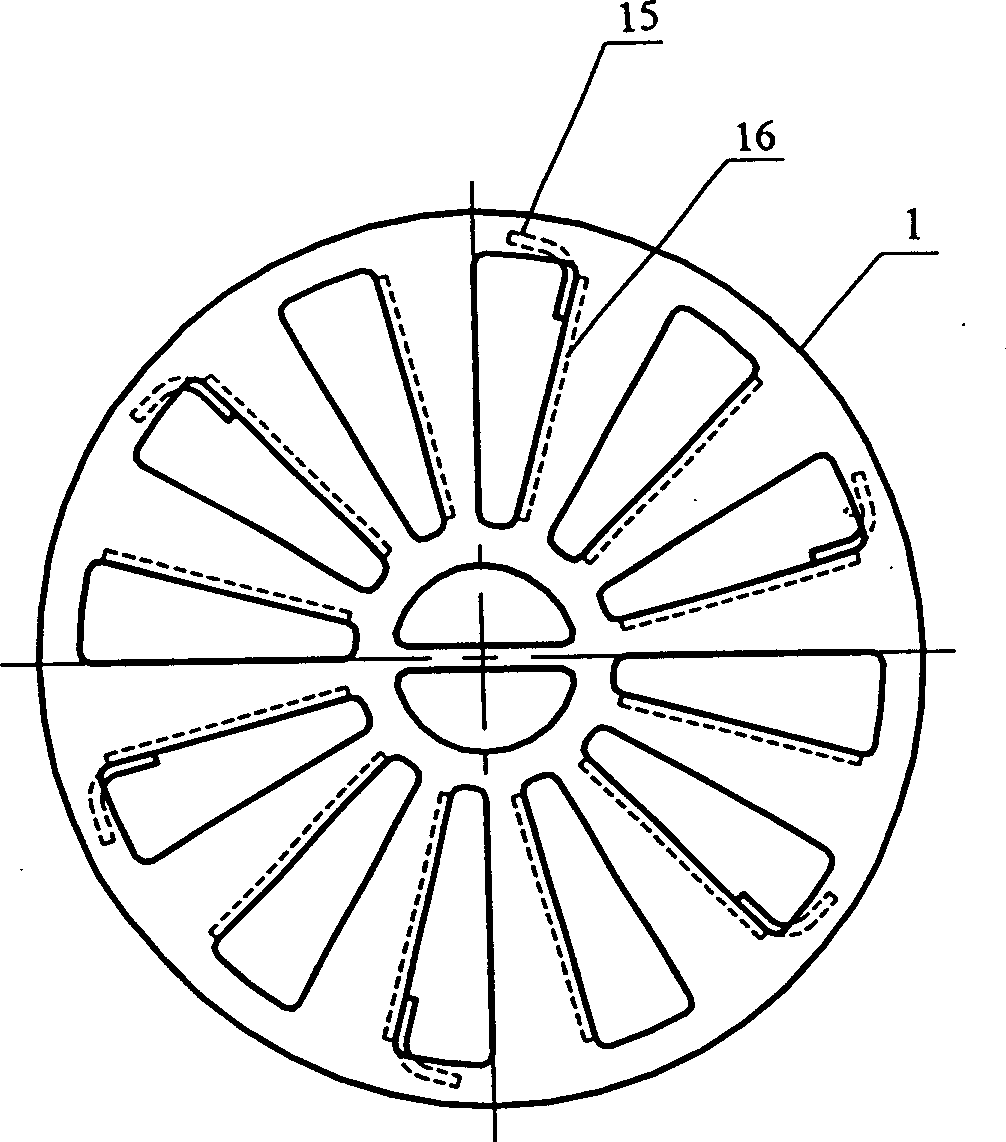

Vapour and water separator

ActiveCN1778451AReduce rotational kinetic energyImprove separation efficiencyDispersed particle separationNuclear engineeringSteam power

A steam-water separator for the steam generator in nuclear power plant and the boiler in steam power plant is composed of a separating cylinder with central column and dual oblique blades installed to said central column, a sleeve barrel outside the separating cylinder with a hydrophibic flow limiting ring at its bottom end, a steam outlet barrel above said separating cylinder, and a diverter cover above said steam outlet barrel and with radiating blades. Its advantage is high critical flow seed of steam and separating efficiency.

Owner:RES INST OF NUCLEAR POWER OPERATION

Solar steam power device

InactiveCN102252303ALow costNovel structureSteam generation heating methodsSolar heat devicesElectricityHeat conducting

The invention relates to a solar steam power device. The solar steam power device mainly consists of a solar heat collector, an electric heating apparatus, a heat storage tank and a steam generator, wherein solar heat collecting plates, or U-shaped metal heat collecting tubes serially connected inside a solar vacuum tube, form the solar heat collector, the solar heat collector is internally provided with a heat conducting liquid, the heat conducting liquid outlet of the solar heat collector is connected with the inlet of the heat storage tank, the outlet of the heat storage tank is connected with the solar steam generator, the heat conducting liquid outlet of the solar steam generator is connected with the inlet of the solar heat collector to form a loop, and the electric heating apparatus and a high-temperature circulating pump are connected between the heat storage tank and the solar heat collector. The invention provides brand-new high-efficiency and low-cost solar technical equipment for energy saving and emission reduction as well as clean energy application in China.

Owner:李泽明 +1

Steam power plant

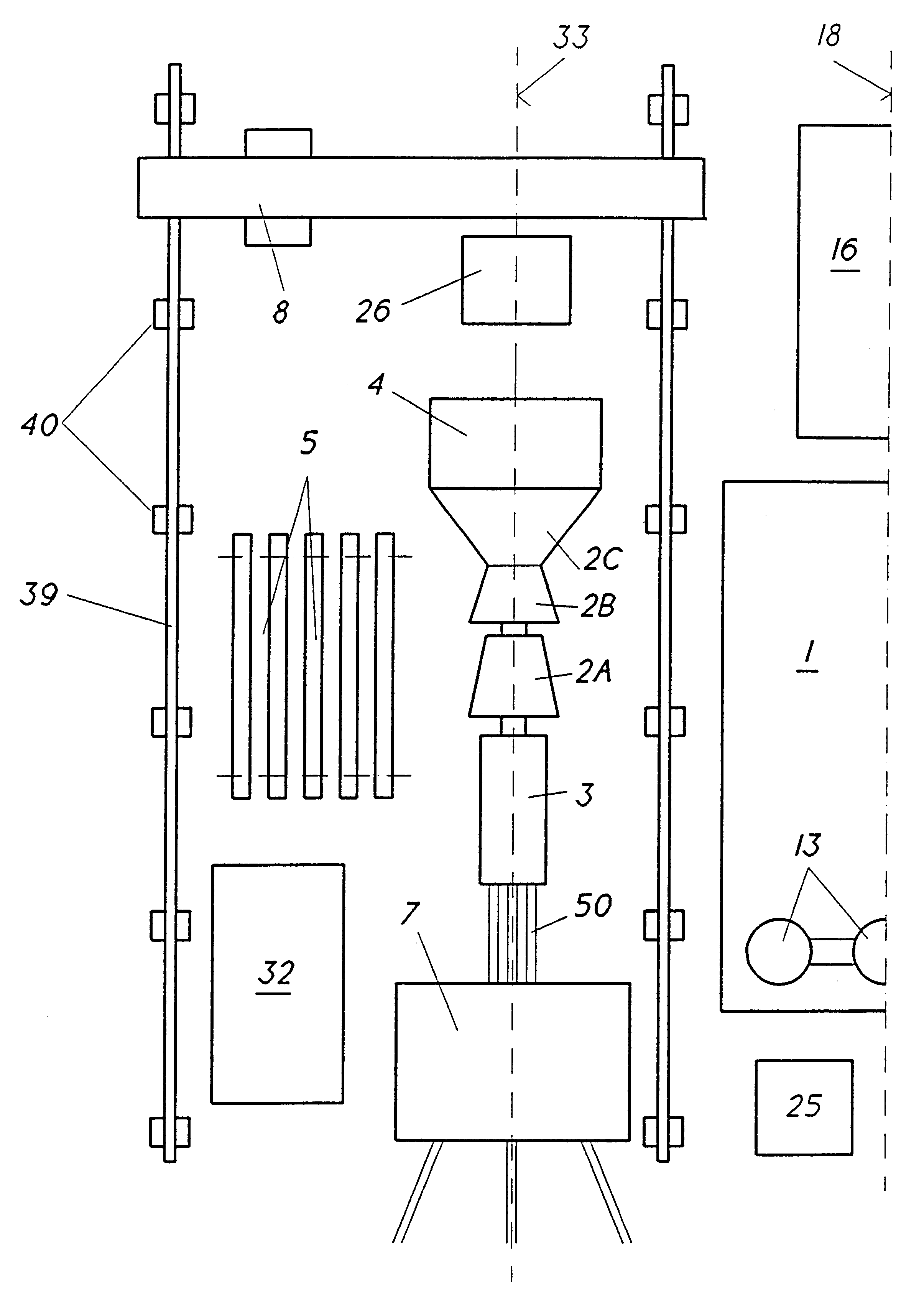

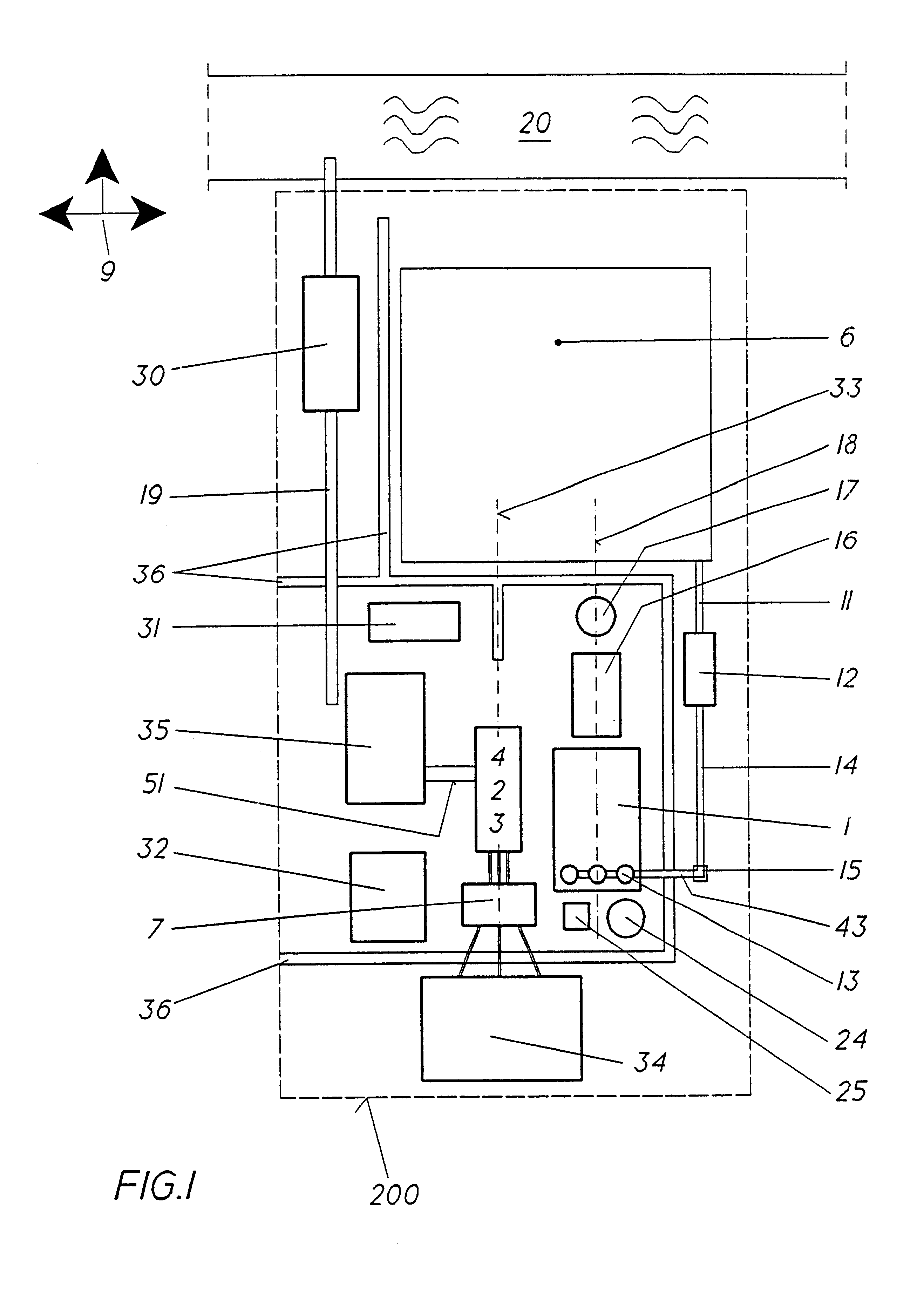

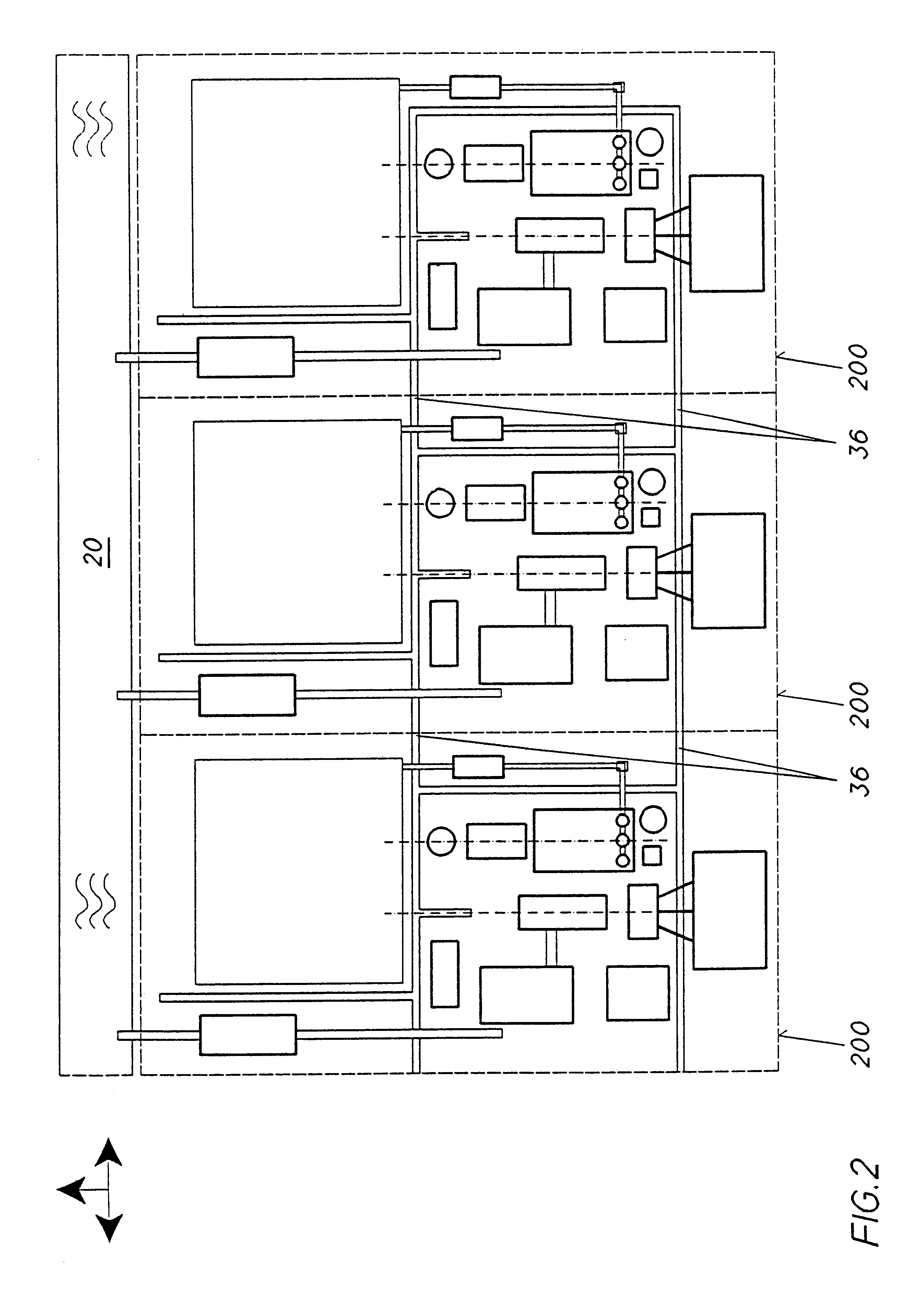

The invention relates to a steam power plant which consists essentially of a steam generator (1), a turbo group comprising a condensing steam turbine (2) and generator (3), a water-cooled condenser (4) and a bled-steam-heated preheating system. In said steam power plant all components, including the fuel storage area (6), are situated at ground level and in the open air. The turbo group (2, 3) and the condenser (4), the preheating system with associated pumps and the transformers (7) are arranged such that a gantry crane is able to pass over them. The steam generator (1), flue gas cleaning system (16) and the chimney (17) are positioned in a row along a common flue gas axis (18) and the turbo group (2, 3) arranged in the immediate vicinity and parallel thereto. As seen from the main wind direction (9), the coal storage area (6) is positioned downwind from the turbo group (2, 3) and the steam generator (1).

Owner:GENERAL ELECTRIC TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com