Heat radiator with air pump separate type thermosiphon for machine room or machine cabinet

A heat dissipation device and thermosiphon technology, which is applied in household heating, application, heating methods, etc., can solve problems such as insufficient kinetic energy and unsatisfactory heat dissipation effect, and achieve prolonging service life, solving low utilization rate, and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

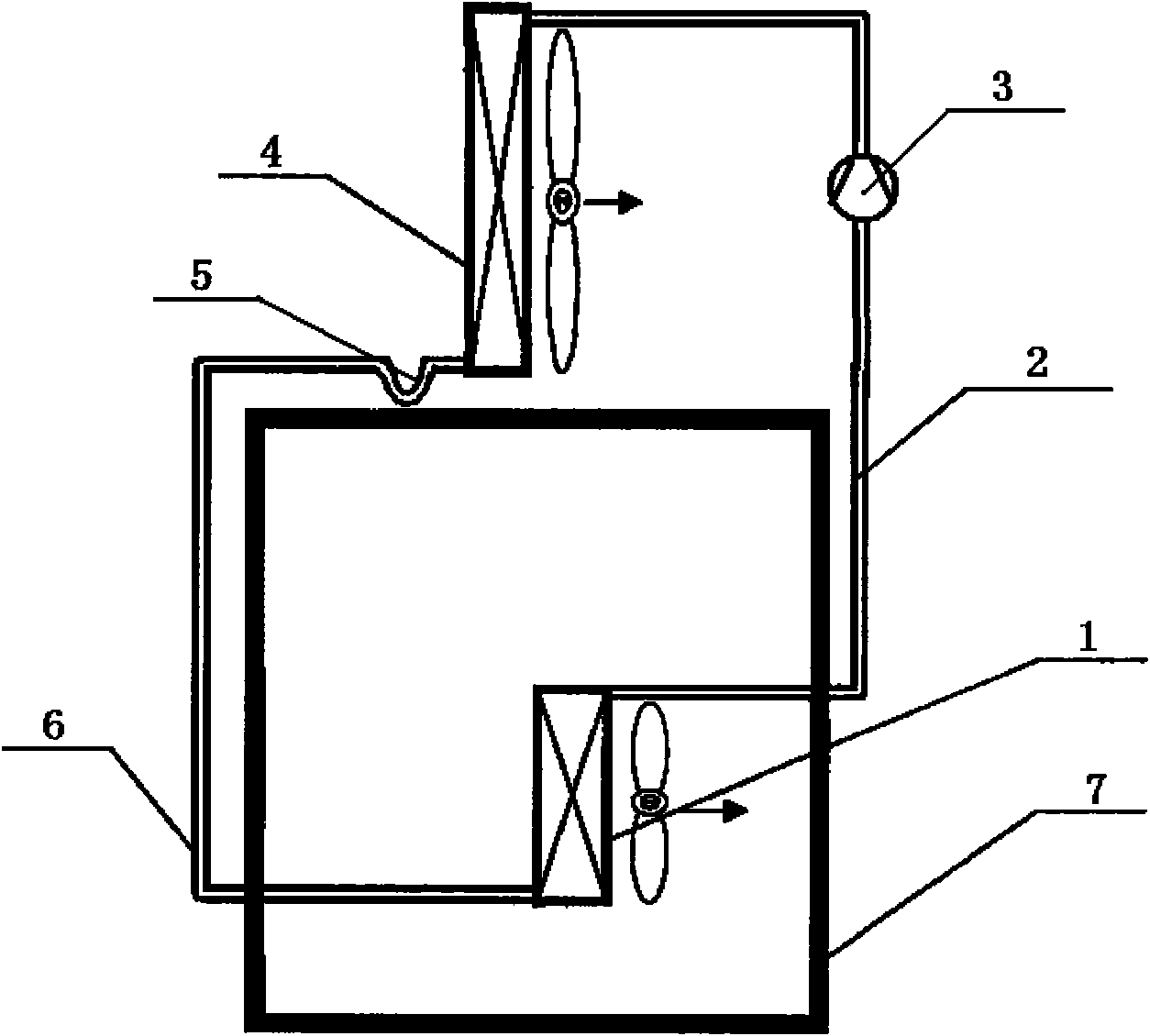

[0022] Embodiment 1: Heat exchanger with forced convection with air pump separate thermosiphon cooling device such as figure 1 As shown, the device includes an evaporator 1 with a fan installed in a machine room or cabinet 7, a forced convection condenser 4 installed outdoors, and an air pump 3 installed on a steam pipe 2; the upper part of the evaporator 1 passes through the steam pipe 2 The air pump 3 communicates with the upper part of the condenser 4; the bottom of the condenser 4 communicates with the bottom of the evaporator 1 through the liquid collecting pipe 6 and the U-shaped liquid storage bend 5; fans are installed on the evaporator 1 and the condenser 4 , using forced convection heat transfer. When the device is running, the fan of evaporator 1 starts, and the hot air in the machine room or cabinet 7 flows through the evaporator 1, heating the evaporator 1 to make the working fluid in it absorb heat and boil, at the same time, the hot air flowing through the evap...

Embodiment 2

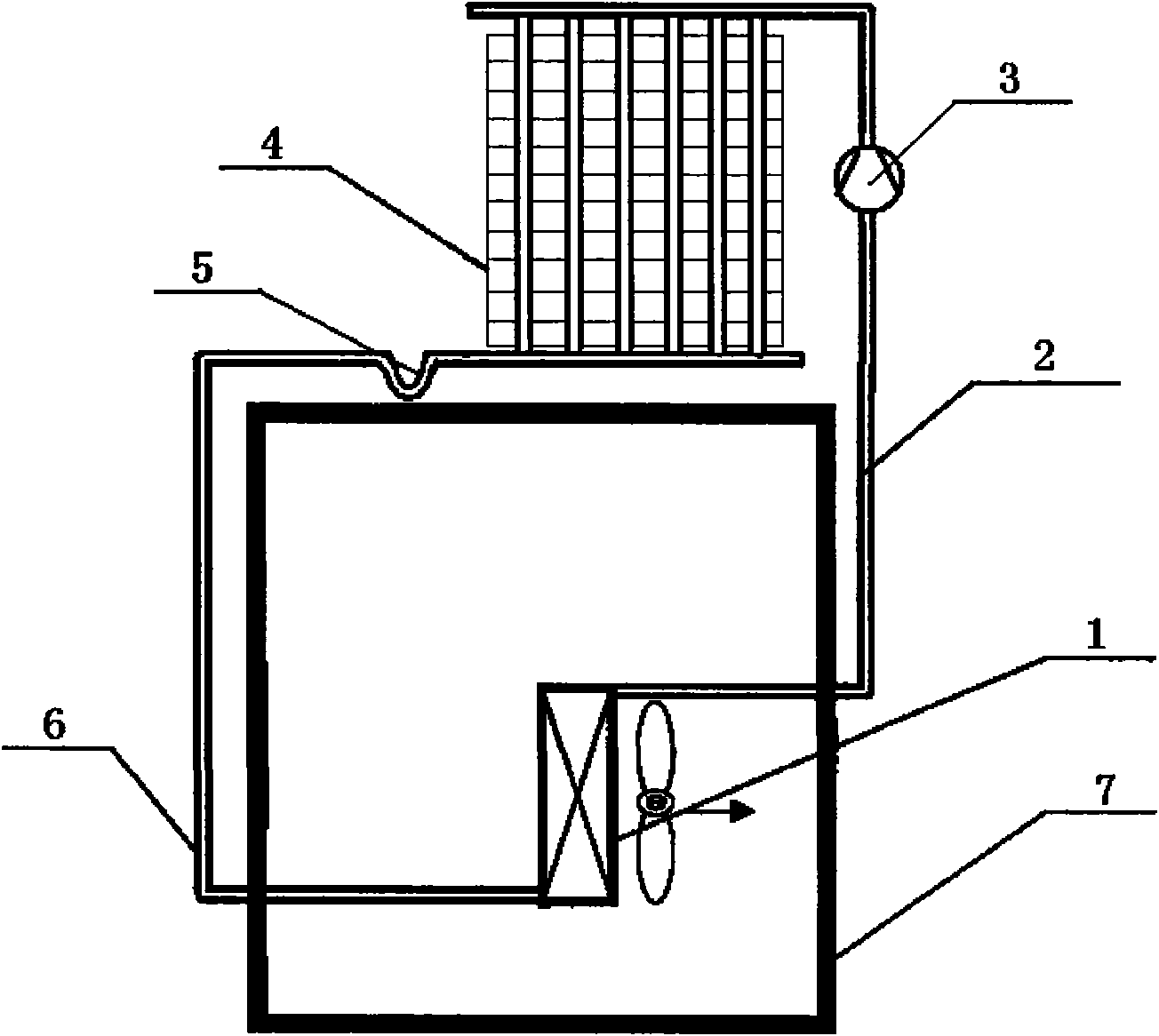

[0023] Embodiment 2: Heat exchanger natural convection with air pump separate type thermosiphon cooling device such as image 3As shown, the device includes an evaporator 1 with a fan installed in a machine room or cabinet 7, a natural convection condenser 4 installed outdoors, and an air pump 3 installed on a steam pipe 2; the upper part of the evaporator 1 passes through the steam pipe 2 The air pump 3 communicates with the upper part of the condenser 4; the bottom of the condenser 4 communicates with the bottom of the evaporator 1 through the liquid collecting pipe 6 and the U-shaped liquid storage bend 5; the evaporator 1 is equipped with a fan; the condenser 4 does not have The fan adopts natural convection heat exchange, such as a flat plate heat exchanger. When the device is in operation, the fan of evaporator 1 starts, and the hot air in the machine room or cabinet 7 flows through the evaporator 1 to heat the evaporator 1, and the working fluid in the evaporator 1 boils...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com