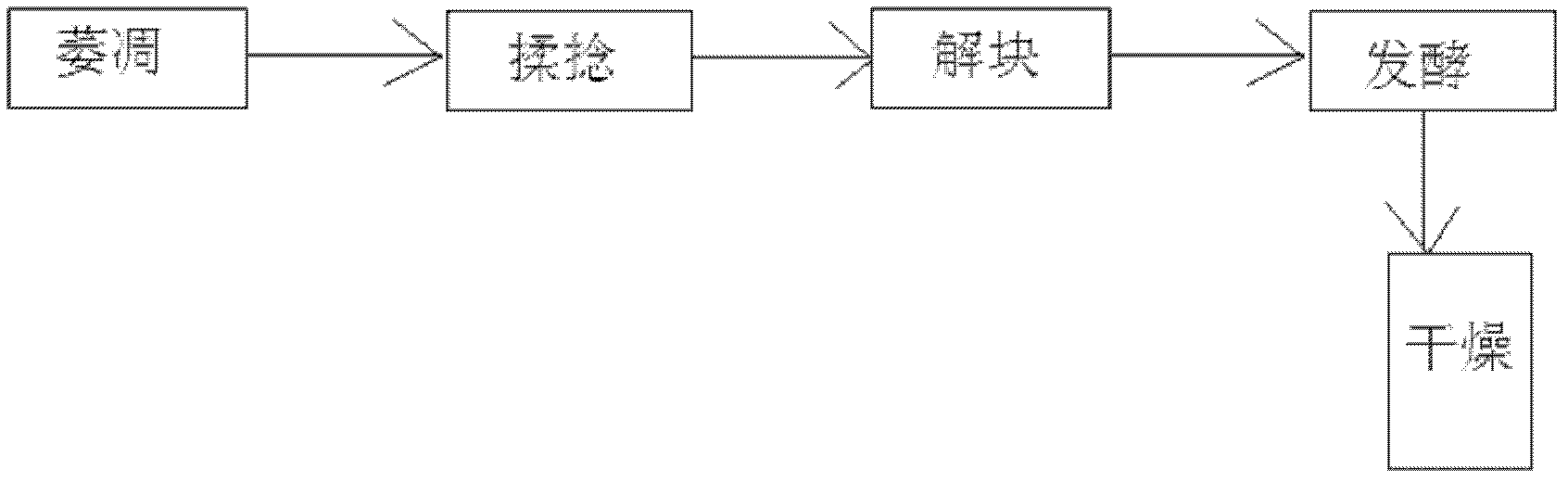

Automated Congou black tea production process

A technology of Gongfu black tea and production process, which is applied in the field of automatic production process of primary production of Gongfu black tea, which can solve the problems of difficult food processing sanitation, tea leaves scattered on the ground, and high labor intensity, so as to improve the processing sanitation environment, uniform fermentation, and realize automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A kind of Gongfu black tea automatic production line is characterized in that:

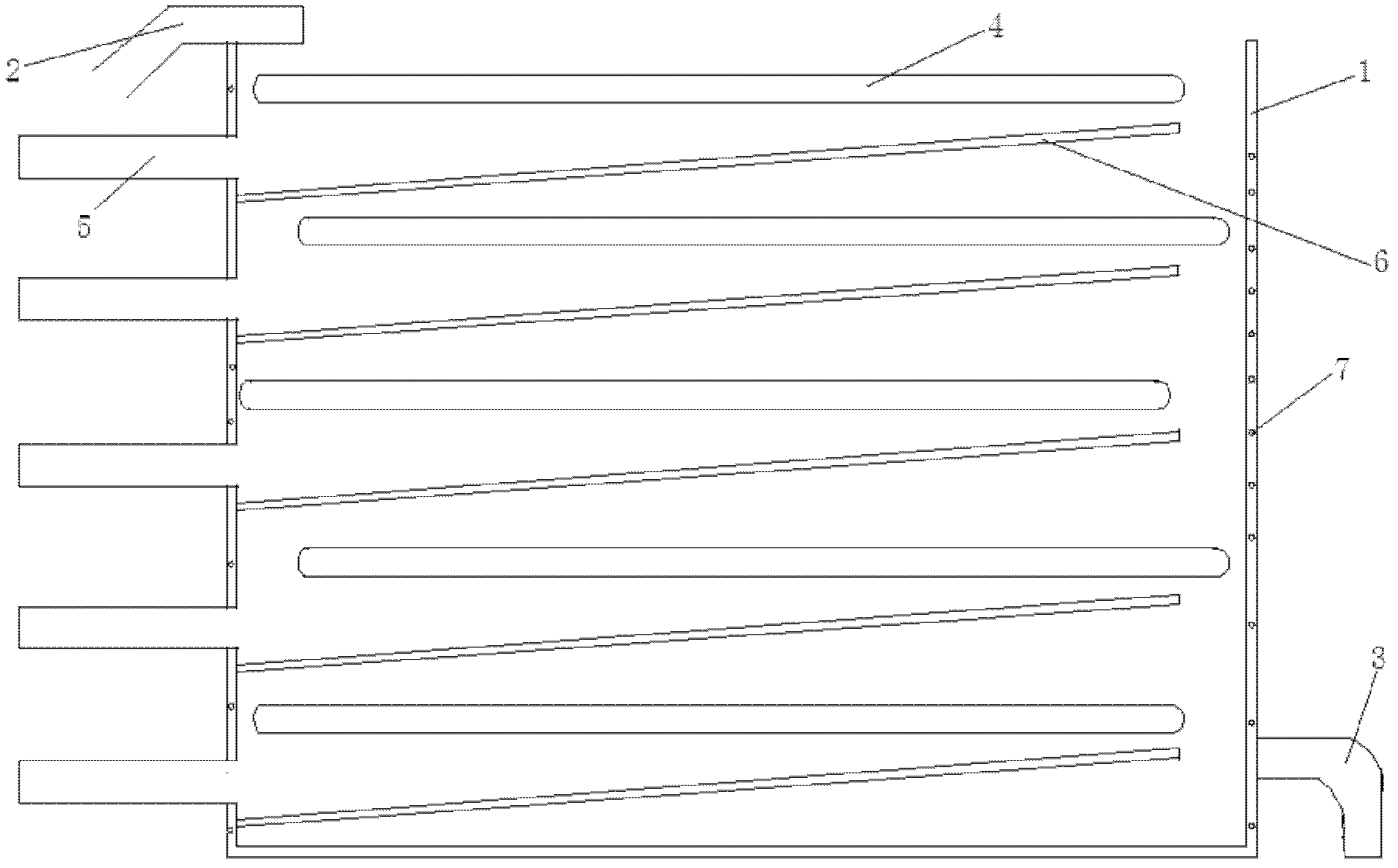

[0025] (1) Segmented dynamic withering, consisting of four automatic vertical withering machines, connected in pairs to control different temperature ranges, the leaves enter the first withering machine (hot air temperature ≤ 35°C, time 2-3h) to complete the internal chemical After the withering process, enter the next withering machine to continue withering (hot air temperature ≤ 30°C, time 2-3h) to moderate.

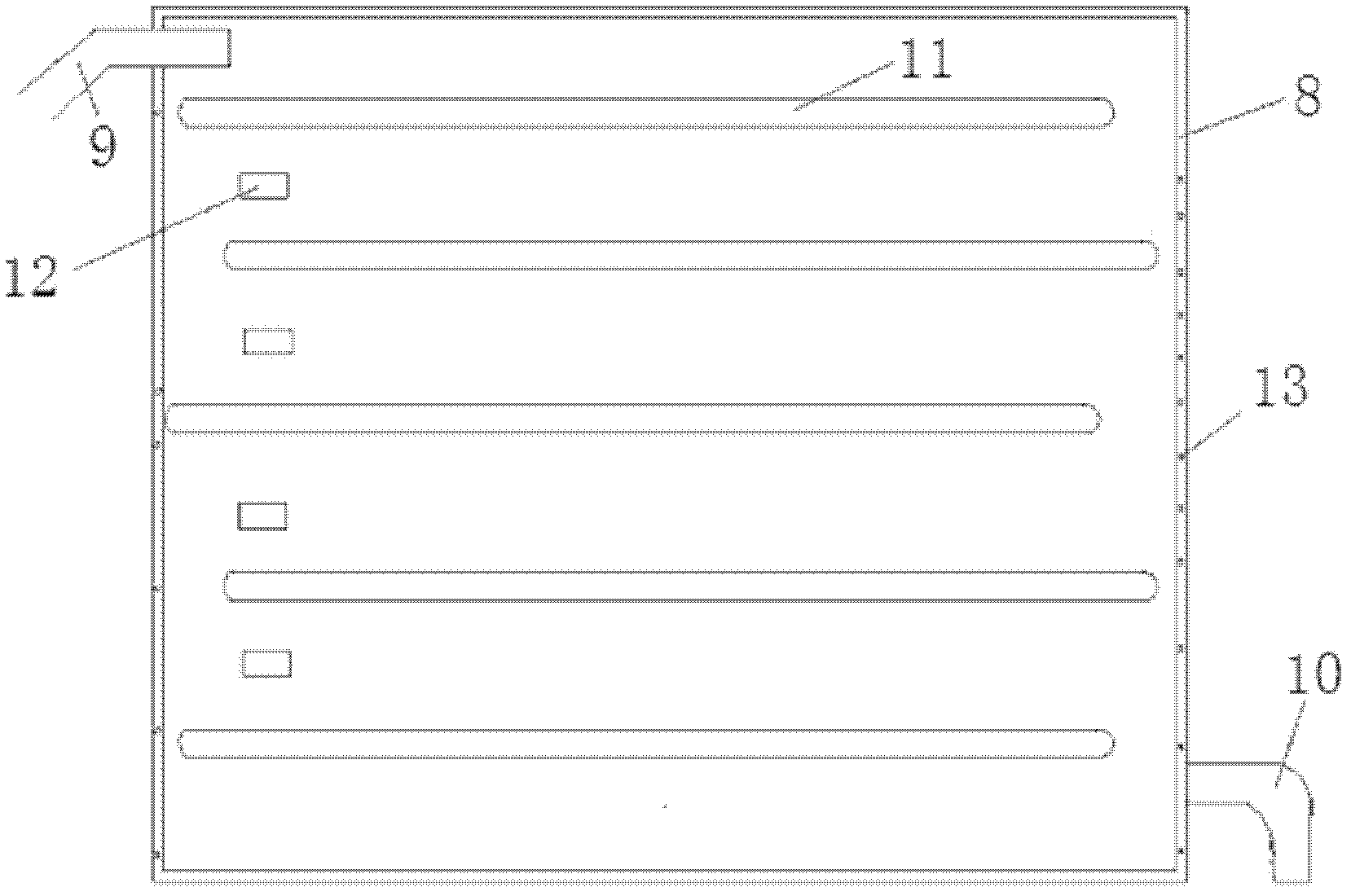

[0026] (2) Continuous progressive pressurized kneading, consisting of 6 sets of 65 automatic kneading machines, each kneading machine can automatically weigh, feed in and out leaves, take one kneading (60-70min), continuous pressurization, automatic control system According to the feedback of the volume reduction of the kneading leaves in the kneading barrel, continuous and gradual pressurization is realized.

[0027] (3) High-speed rotary deblocking is completed by a high-speed ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com