Full-automatic intelligent wine brewing machine

A brewing machine, fully automatic technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of long fermentation time, incomplete fermentation, high cost, etc., and achieve the effects of fast fermentation speed, novel structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

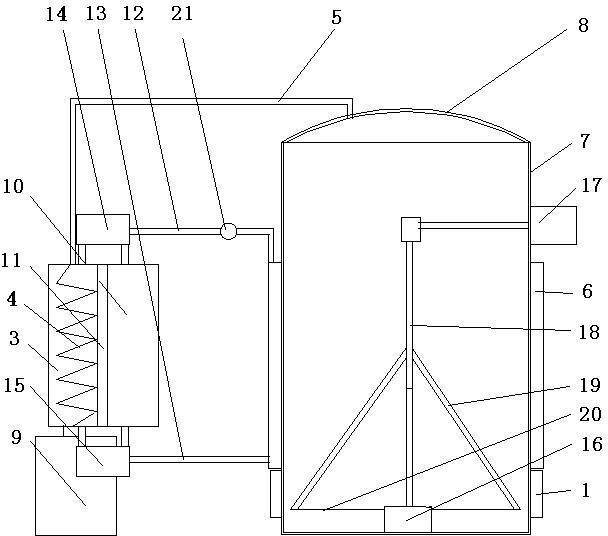

[0031] Embodiment 1: A kind of fully automatic intelligent brewing machine, comprises airtight housing, heater 1, cooling condensing device and automatic control device, the structure of described heater 1 adopts prior art respectively, this does not go into details, described cooling The condensing device includes a cooling box, a condensing pipe 4 and a steam pipeline 5. The airtight casing is formed by a cylinder body 7 and a cover body 8 at the upper end of the cylinder body 7. The upper end of the cylinder body 7 is provided with a feeding port. The side wall is provided with a temperature sensor, and the bottom of the cylinder body 7 is provided with a heater 1, and the heater 1 can be placed on the bottom of the cylinder body or on the bottom surface of the cylinder body 7, and the cover body 8 is provided with an air outlet. The feeder 2 communicates with the feeding port on the barrel 7 through the connecting pipe, the heater 1 and the temperature sensor are respective...

Embodiment 2

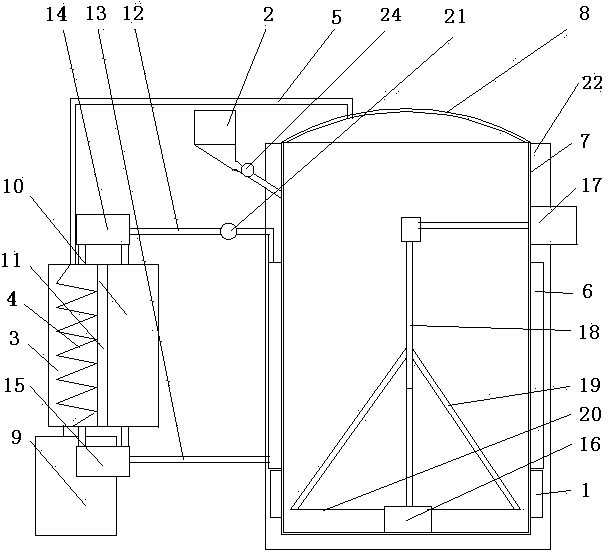

[0032]Embodiment 2: a kind of fully automatic intelligent brewing machine, comprises airtight housing, heater 1, cooling condensing device, distiller's yeast feeder 2 and automatic control device, the structure of described heater 1 adopts prior art respectively, this does not To repeat, the cooling and condensing device includes a cooling box, a condensing pipe 4 and a steam pipeline 5, and the airtight housing is formed by a cylinder 7 and a cover 8 at the upper end of the cylinder 7 which are sealed and connected, and the upper end of the cylinder 7 is provided with a There is a feeding port, the lower side wall is provided with a temperature sensor, the bottom of the cylinder 7 is provided with a heater 1, and the heater 1 can be set on the bottom of the cylinder or on the bottom of the cylinder 7, and the cover 8 is provided with an outlet Air port, the koji feeder 2 communicates with the feeding port on the barrel 7 through the connecting pipe, the heater 1 and the temper...

Embodiment 3

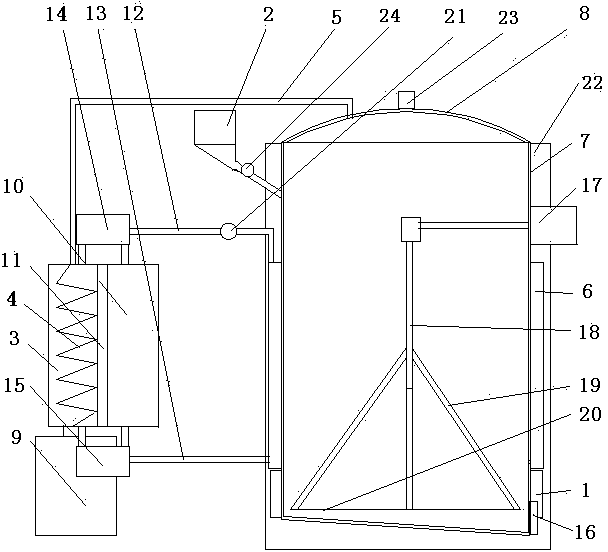

[0033] Embodiment 3: a kind of fully automatic intelligent brewing machine, comprises airtight housing, heater 1, cooling condensing device, distiller's yeast feeder 2 and automatic control device, the structure of described distiller's yeast feeder and heater 1 respectively adopts existing technology, this will not go into details. The cooling and condensing device includes a cooling box, a condensation pipe 4 and a steam pipeline 5. The airtight casing is formed by a cylinder 7 and a cover 8 on the upper end of the cylinder 7. The cylinder The upper end of the body 7 is provided with a feeding port, the lower side wall is provided with a temperature sensor, and the bottom of the cylinder 7 is provided with a heater 1, and the heater 1 can be set on the bottom of the cylinder, or can be arranged on the bottom of the cylinder 7, and the cover 8 There is an air outlet on the top, and the distiller’s yeast feeder 2 communicates with the feeding port on the cylinder body 7 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com