Power battery composite heat management system and method thereof

A thermal management system, power battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of not considering heat recycling, low thermal conductivity of air, poor thermal conductivity of phase change materials, etc., to avoid battery safety problems , high thermal conductivity, offset the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

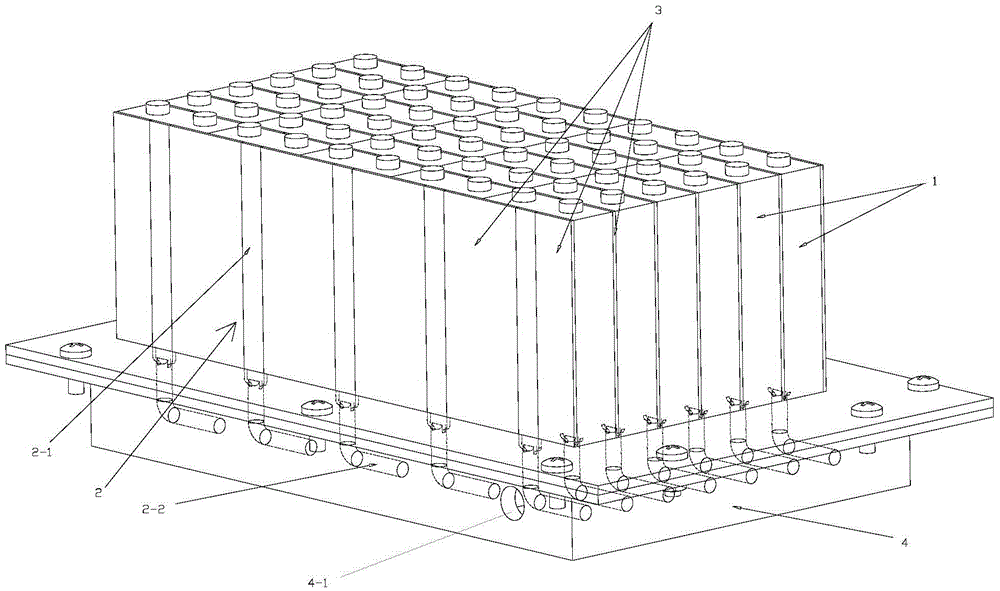

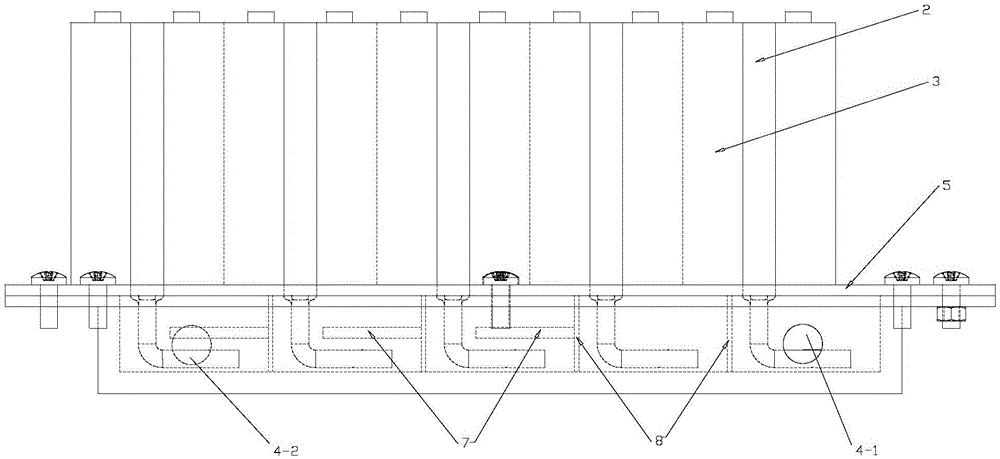

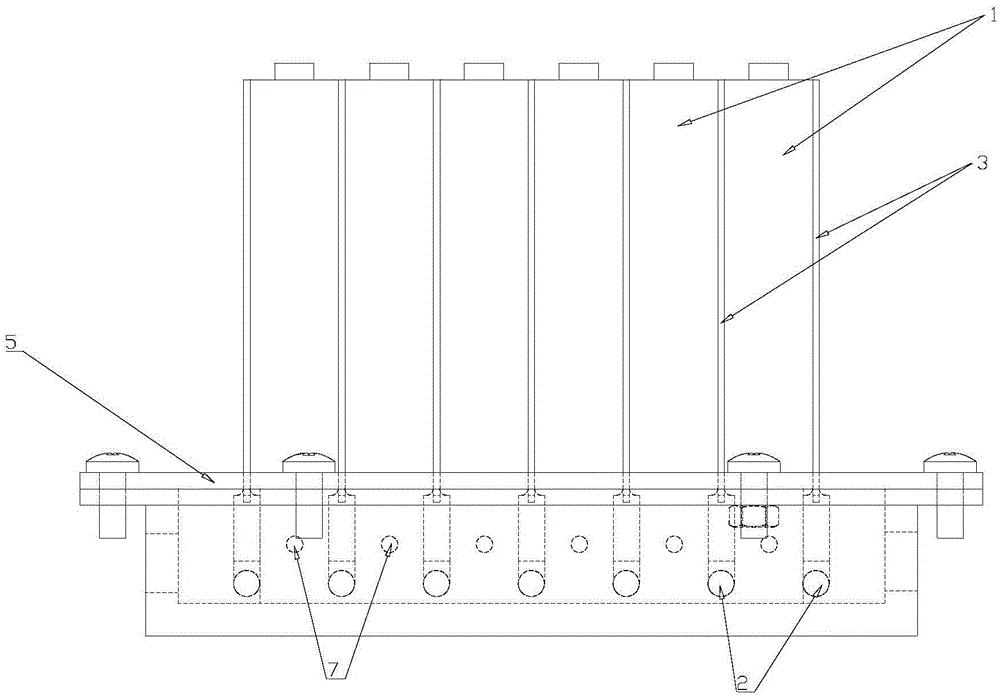

[0031] as the picture shows. The invention discloses a composite heat management system for a power battery, comprising a water tank 4 filled with a circulating fluid (the material is an aluminum alloy with light weight and low thermal conductivity), a circulating pump for driving the circulating fluid to flow, and a sealing cover plate of the water tank 4 5. A battery pack array composed of multiple single cells 1 fixedly installed on the top of the sealing cover 5; a uniform temperature plate 3 (thickness 3-5 mm) and a heat pipe 2 are pasted on the surface of each single cell 1 , there is a gap in the middle of the vapor chamber 3, the evaporation section 2-1 of the heat pipe 2 (copper powder sintered type, thickness 2-5mm) is flat, and placed in the gap, the evaporation section 2-1 passes through the The gap and the surface of the single battery 1 are attached to each other; the cooling section 2-2 of the heat pipe 2 passes through the sealing cover plate 5 and is placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com