Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

742 results about "Conditioning equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In telecommunication, the term conditioning equipment has the following meanings: At junctions of circuits, equipment used to obtain desired circuit characteristics, such as matched transmission levels, matched impedances, and equalization between facilities. Corrective networks used to improve data transmission, such as equalization of the insertion loss-vs.-frequency characteristic and the envelope delay distortion over a desired frequency range.

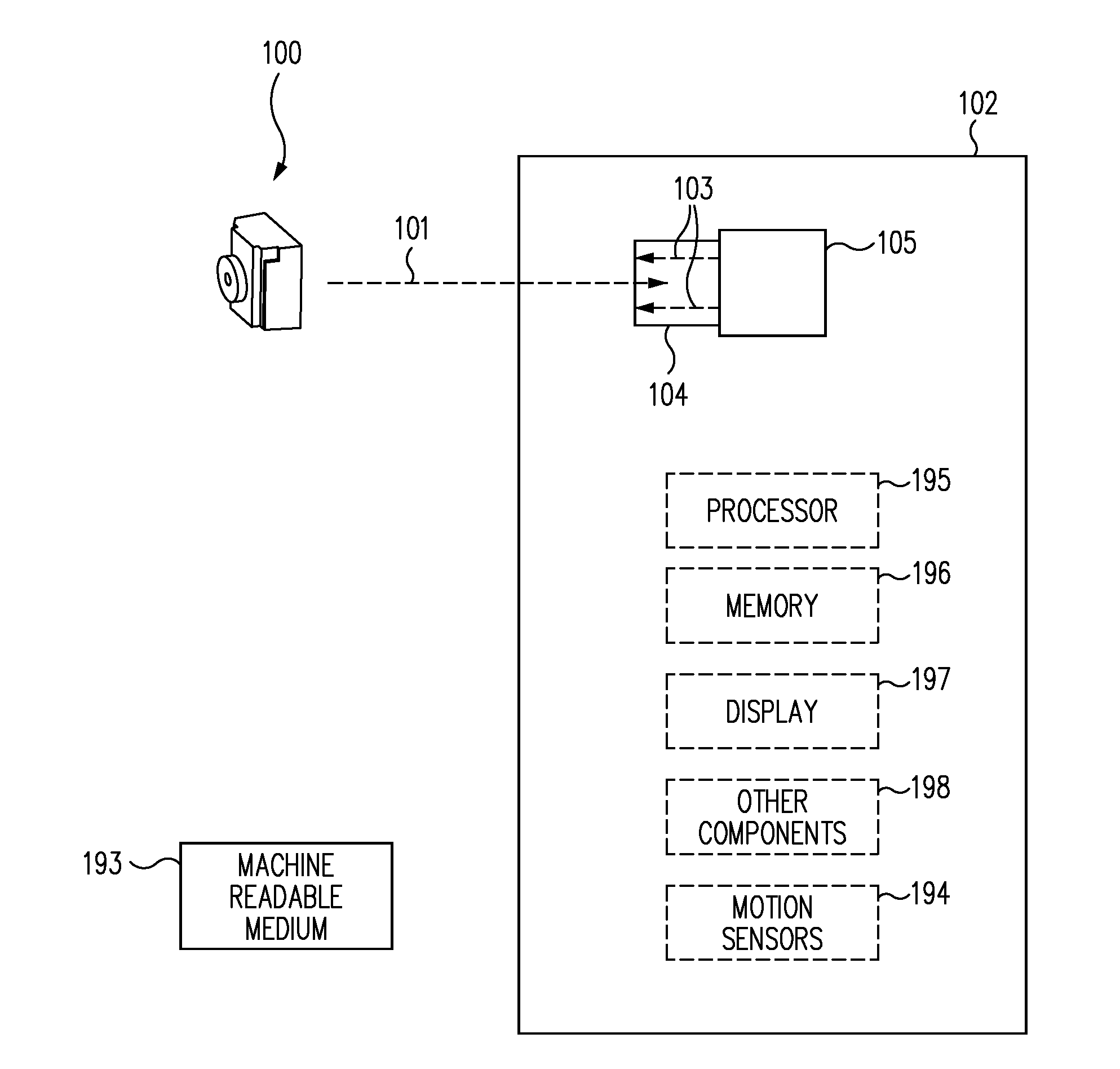

Systems and methods for intelligent monitoring of thoroughfares using thermal imaging

InactiveUS20140112537A1Television system detailsOptical detectionIntelligent lightingThermal image processing

Various techniques are disclosed for systems and methods using thermal imaging to intelligently monitor thoroughfares. For example, an intelligent monitoring system may include an infrared imaging module, a processor, a communication module, a memory, and an adjustable component. The system may be mounted, installed, or otherwise disposed at various locations along thoroughfares, and capture thermal images of a scene that includes at least a portion of the thoroughfares. Various thermal image processing and analysis operations may be performed on the thermal images to generate comprehensive monitoring information including an indication of detected objects in the scene and at least one attribute associated with the objects. Various actions may be taken, such as generating various alarms and intelligently adjusting operation of various adjustable devices on thoroughfares, based on the monitoring information. The monitoring information may be shared among multiple instances of the system, and may be communicated to external devices.

Owner:FLIR SYST INC

Home network frequency conditioning device

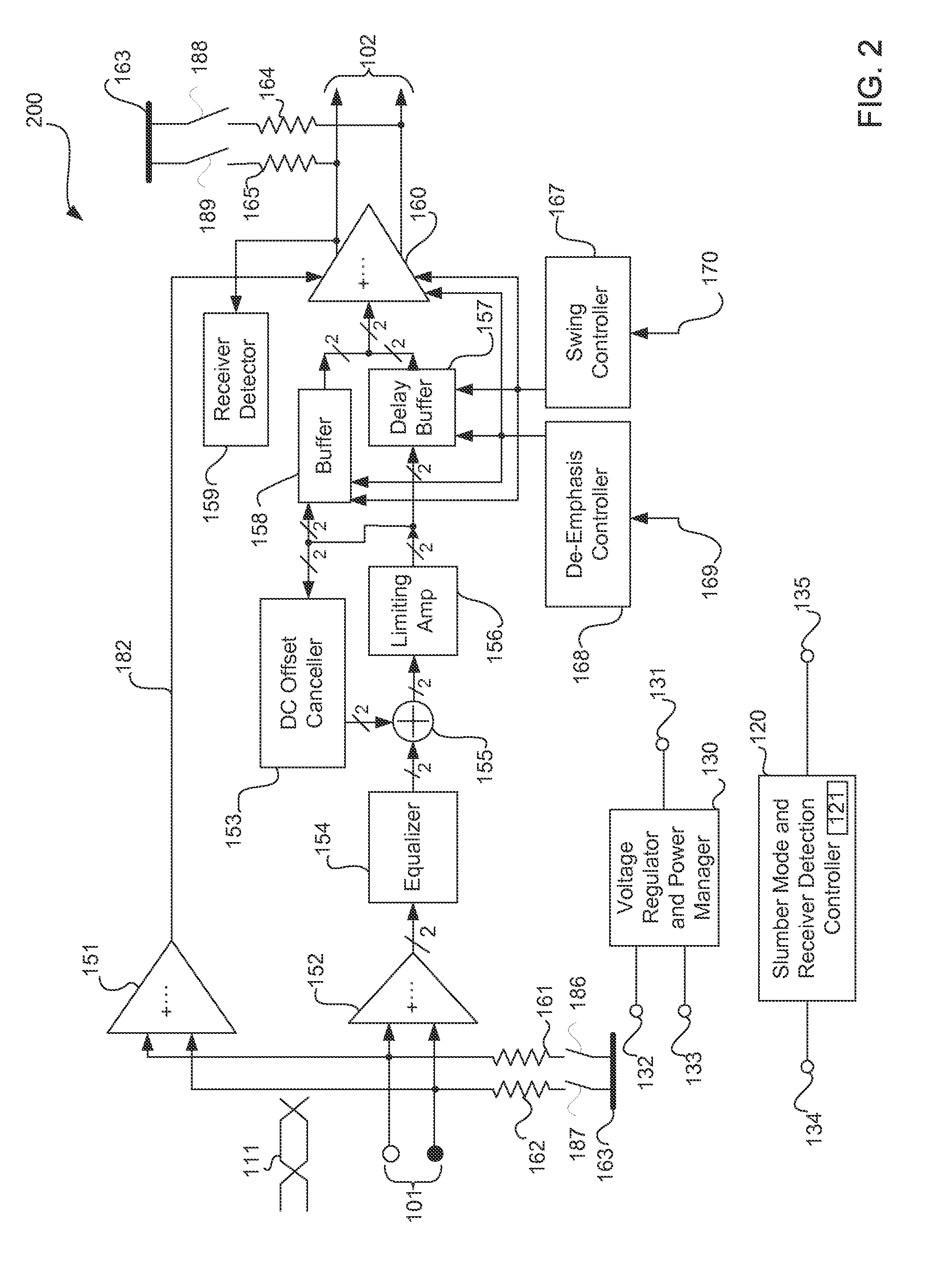

InactiveUS20120054805A1High frequency responseBroadband local area networksClosed circuit television systemsSignal conditioning circuitsEngineering

This invention disclosure relates to a conditioning device for improving the frequency response of signals conducted within an in-home cable infrastructure that includes both CATV bandwidth and in-home entertainment bandwidth. Disclosed is a CATV network device which includes a CATV signal transmission path and an in-home entertainment signal transmission path. Also disclosed is a signal conditioning circuit that is placed along the in-home entertainment signal transmission path. The signal conditioning circuit includes at least one LC resonant shunt circuit and at least one LC resonant tank circuit. In a particular embodiment two signal conditioning circuits are used. The CATV network device attenuates and equalizes the in-home entertainment signals transmitted along the in-home entertainment signal path so that the in-home entertainment signals don't interfere with the CATV signals.

Owner:PPC BROADBAND INC

Temperature control of electronic devices using power following feedback

InactiveUS20030001605A1Temperatue controlSemiconductor/solid-state device detailsTemperature controlEquipment temperature

A system and method for controlling a temperature of a device during testing with a thermal controller and a heat exchanger includes measuring an instantaneous power consumption of the device during testing. The heat exchanger is controlled with the thermal controller using the measured instantaneous power consumption by the device to regulate the temperature of the device during testing, wherein the heat exchanger is in conductive contact with the device.

Owner:DELTA DESIGN

Home network frequency conditioning device and method

ActiveUS20120054819A1Broadband local area networksAnalogue secracy/subscription systemsSignal conditioning circuitsNetwork conditions

An in-home entertainment network conditioning device for use with a coaxial device in a CATV network includes an input node adapted to conduct CATV signals in a first and second frequency range, and in-home entertainment signals in a third frequency range that is different from the first frequency range and the second frequency range. The device includes a first signal path branched from the input node that includes a low-pass filter adapted to conduct the CATV signals and reject the in-home entertainment signals. A second signal path in parallel electrical communication with the first signal path includes a high-pass filter in series electrical connection with a signal conditioning circuit. The high-pass filter is adapted to conduct the in-home entertainment signals and reject the CATV signals. The signal conditioning circuit attenuates and equalizes the in-home entertainment signals when coupled to the coaxial device.

Owner:PPC BROADBAND INC

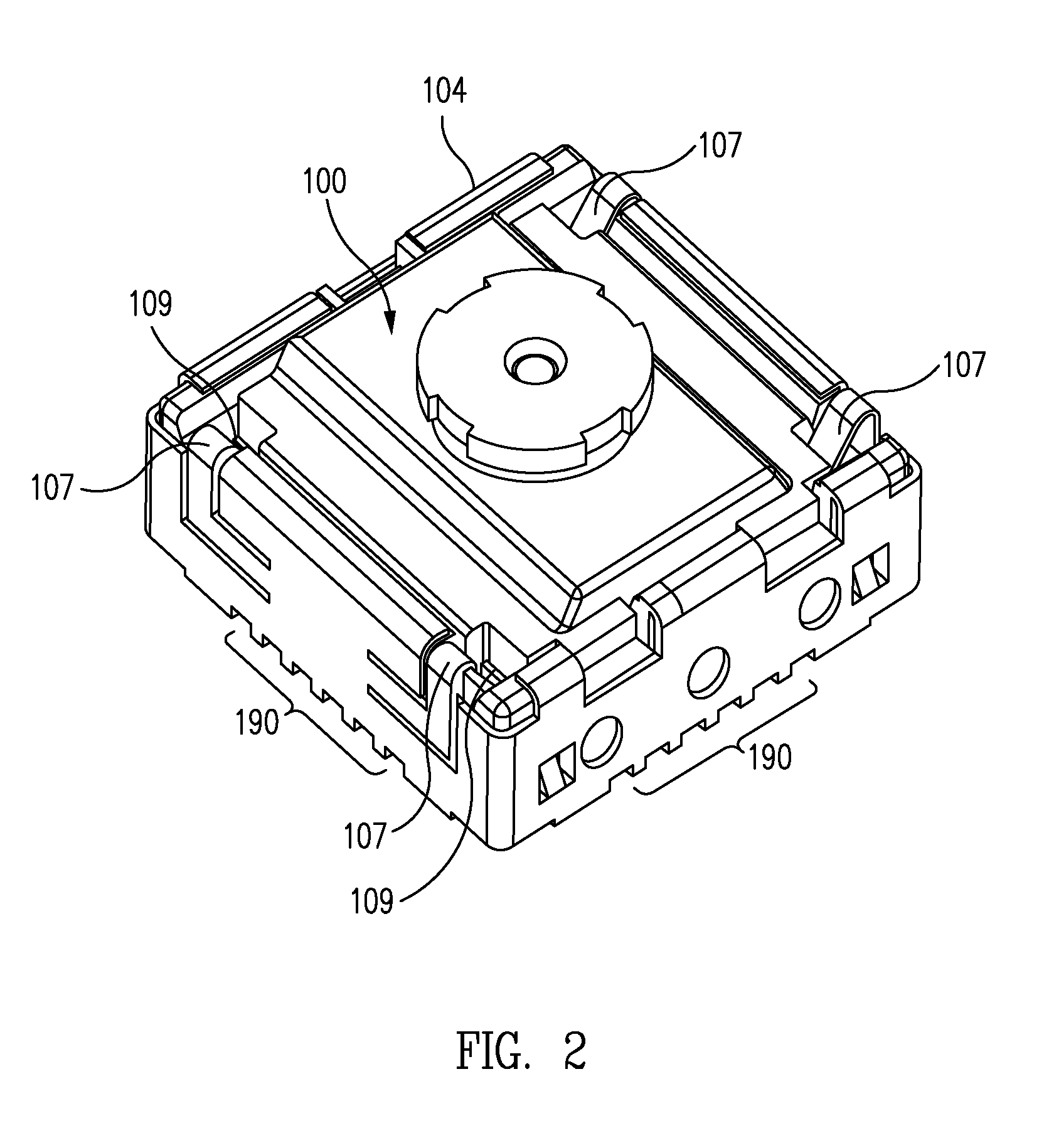

Voltage regulator with bypass mode

ActiveUS20060164054A1Not to damageParticular applicabilityRead-only memoriesEmergency protective arrangements for limiting excess voltage/currentOutput deviceP channel

A step down voltage regulator with bypass comprised of devices designed to operate over a maximum rated voltage lower than a supply voltage. The regulator includes an output regulation device coupled to the supply voltage and an output. An output device protection circuit is provided which is responsive to the supply voltage and the output to ensure that the maximum rated voltage of the output regulation device is not exceeded. A bypass circuit having a bypass output device and being coupled to the supply voltage is provided with a protection circuit. The output regulation devices comprise p-channel transistors, and may have an operating maximum rated voltage in a range of 2.7-3.6 volts with the supply voltage is in a range of 4.4-5.25 volts, or 2.9-3.5 volts.

Owner:SANDISK TECH LLC

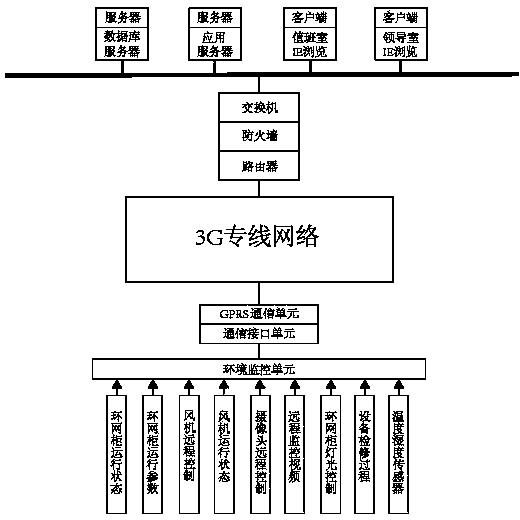

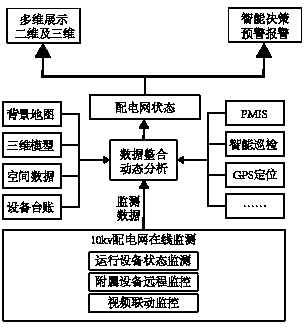

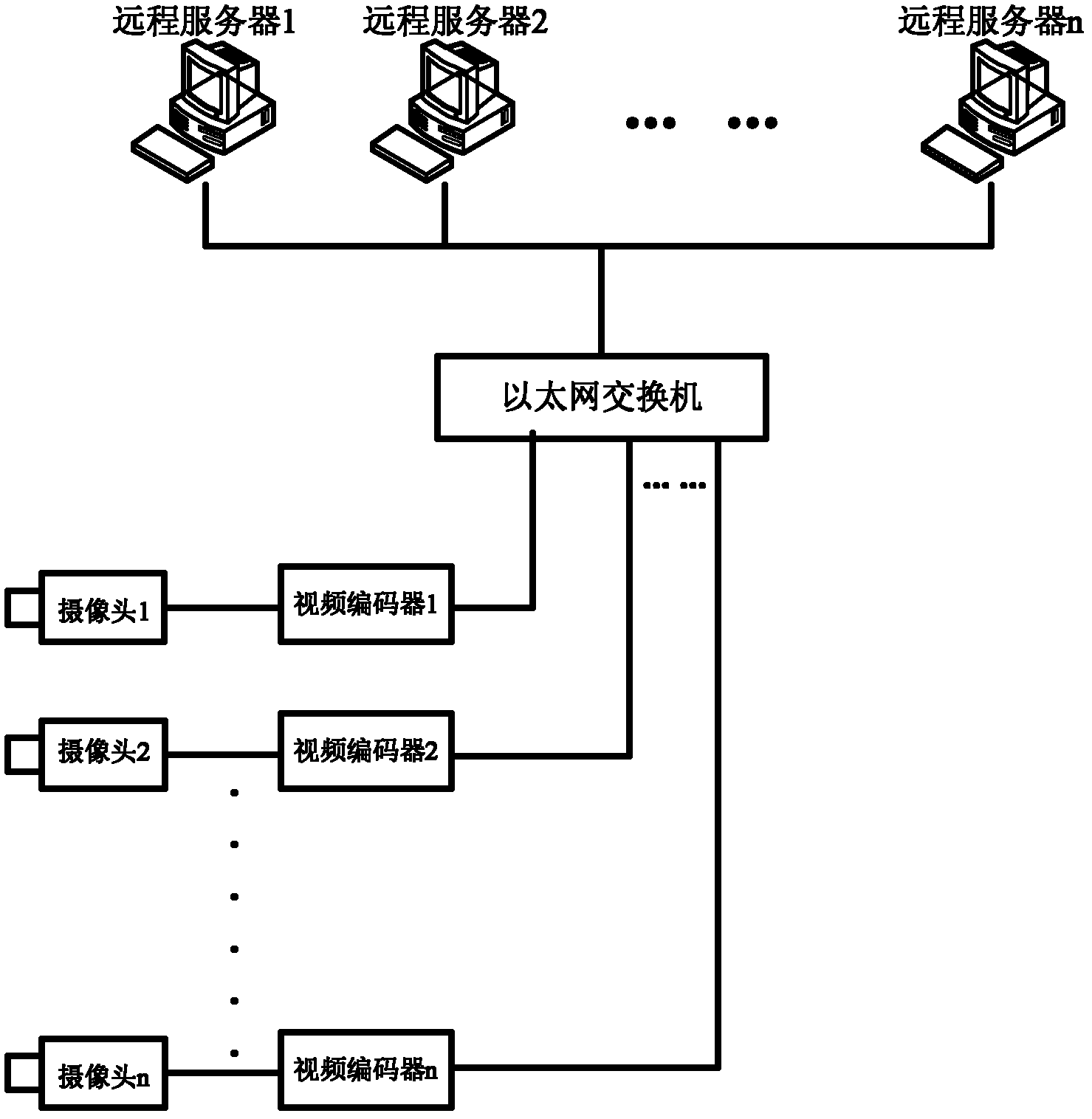

Cable 10kV high voltage ring main unit remote monitoring and control system

ActiveCN103558818ATimely processingGuaranteed safe operationProgramme total factory controlElectric power systemSurveillance camera

The invention relates to the field of electric power system monitoring, in particular to a cable 10kV high voltage ring main unit remote monitoring and control system which is used for conducting real-time monitoring of operation conditions of power distribution facilities and distribution cable lines, realizing early warning and alarming of abnormal and failure states and postmortem analysis after accidents, and controlling and regulating the operating environment of equipment through remote operation. According to the cable 10kV high voltage ring main unit remote monitoring and control system, grid smart operation management serves as the target, various on-line monitoring techniques are integrated, and monitoring cameras, a fan and solar equipment are installed in a switching station; the system can be used for checking the information of the monitoring cameras in the switching station in real time, monitoring the operating state of the fan, realizing the early warning and alarming of the abnormal and failure states and the postmortem analysis after the accidents, realizing dynamic evaluation of health conditions of the equipment, and realizing remote operation control over monitoring of the equipment; a multi-dimensional display technology is combined, safe and reliable operation capacity of a distribution network is enhanced, trouble shooting efficiency and maintenance efficiency are improved, and therefore a complete set of grid visual monitoring system is formed.

Owner:STATE GRID CORP OF CHINA +1

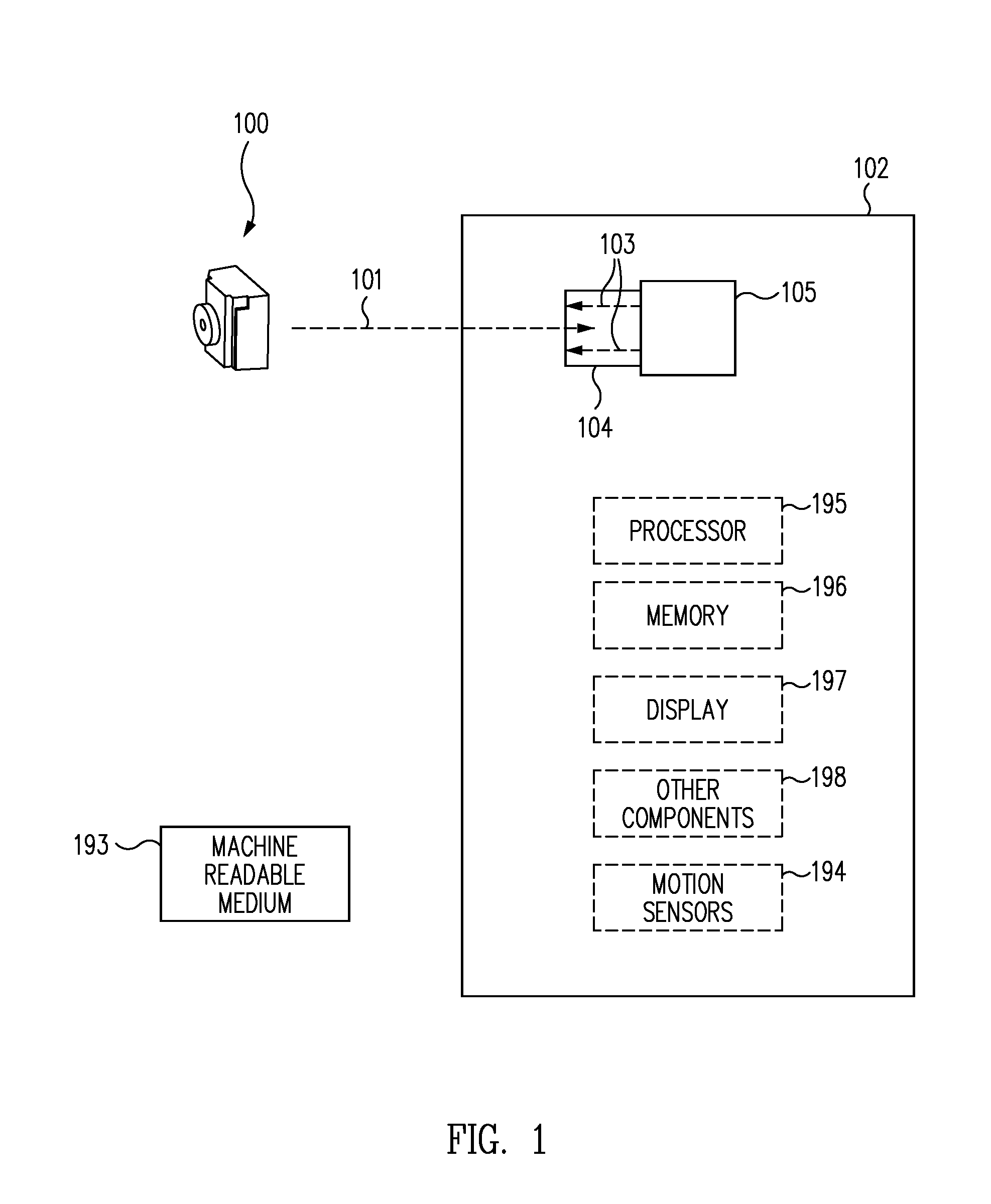

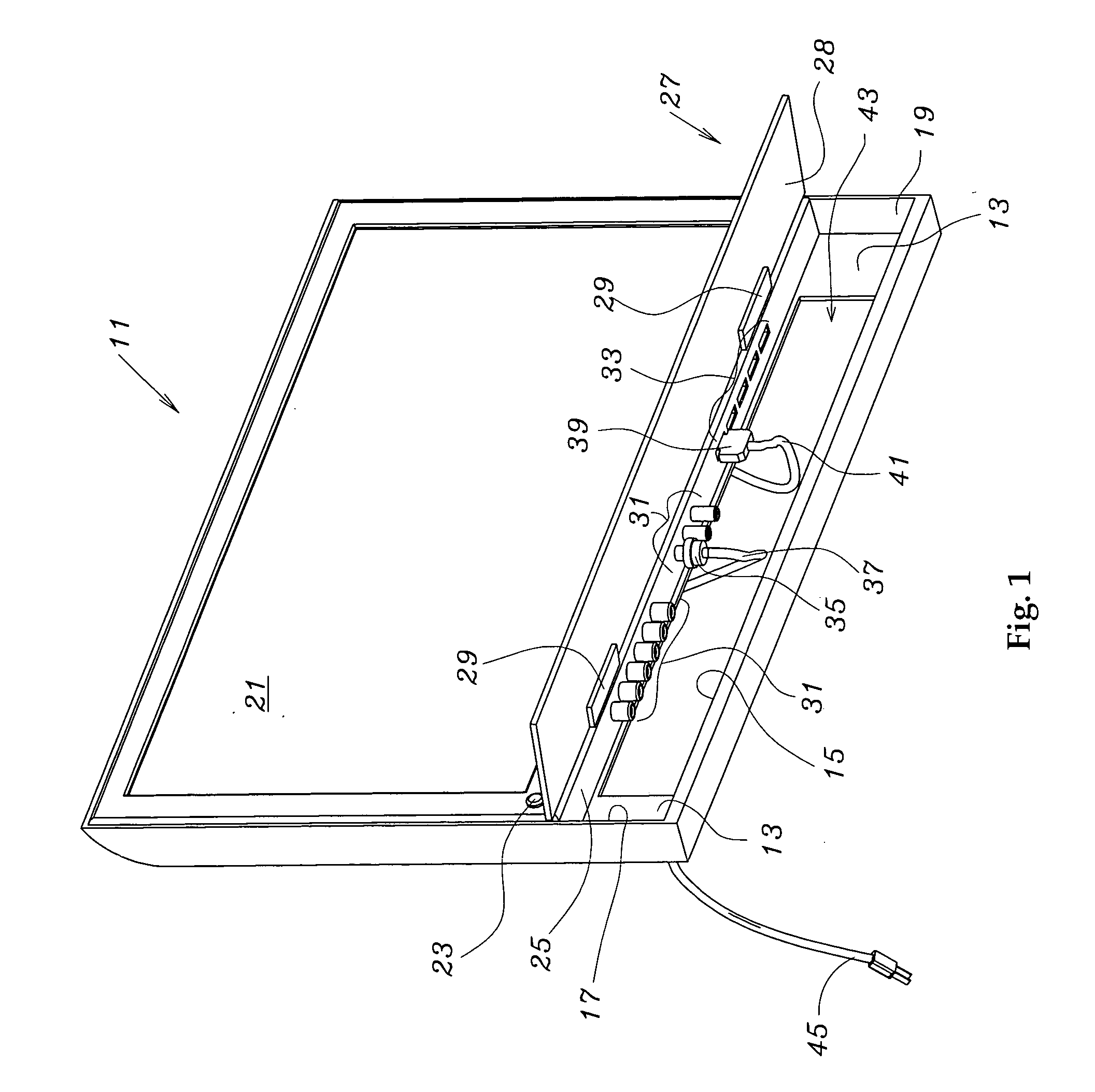

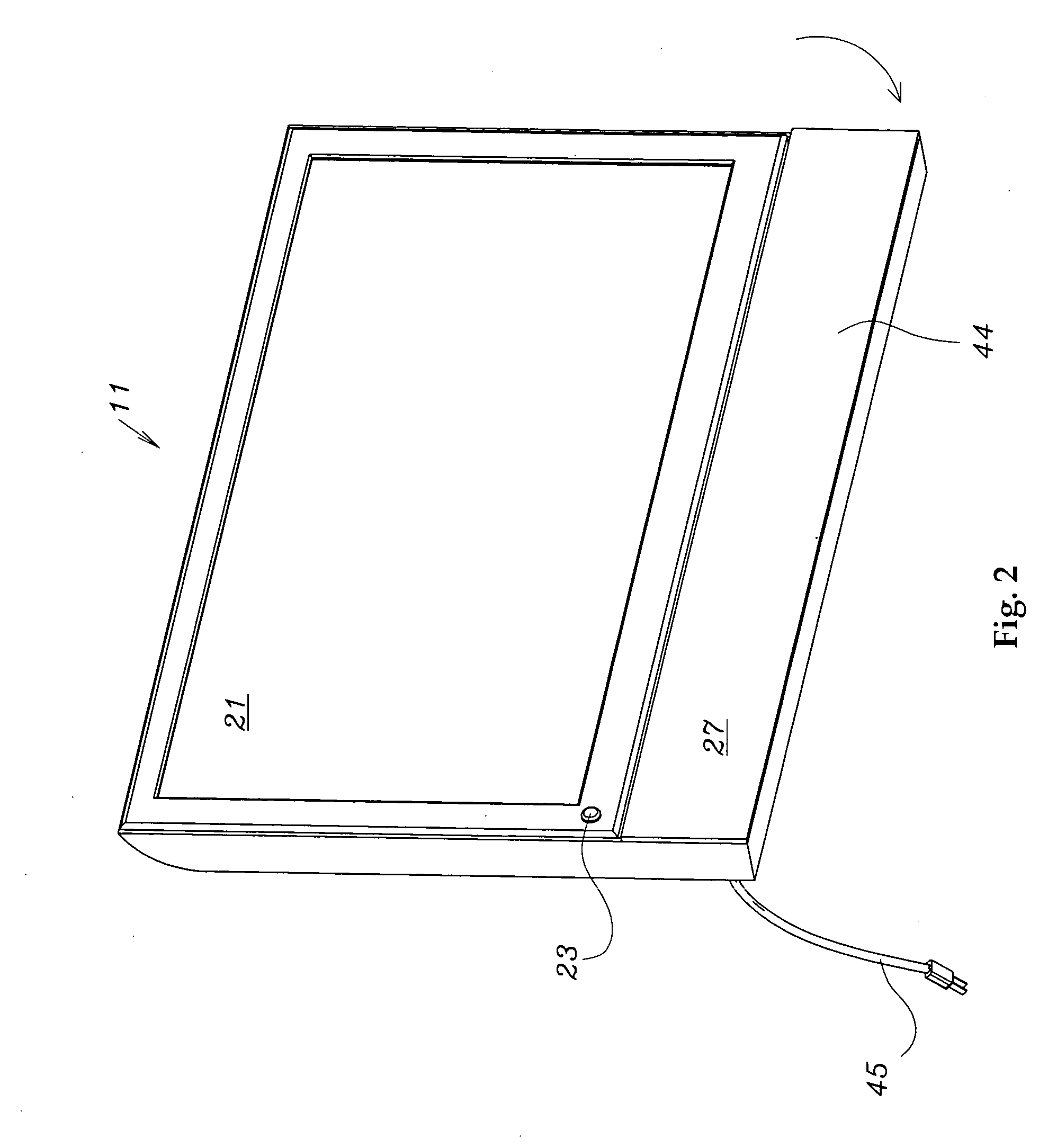

Adjustable device holder

ActiveUS20150196140A1Prevent disengagementShow cabinetsLocks for portable objectsEngineeringMechanical engineering

Owner:CHEN-SOURCE INC

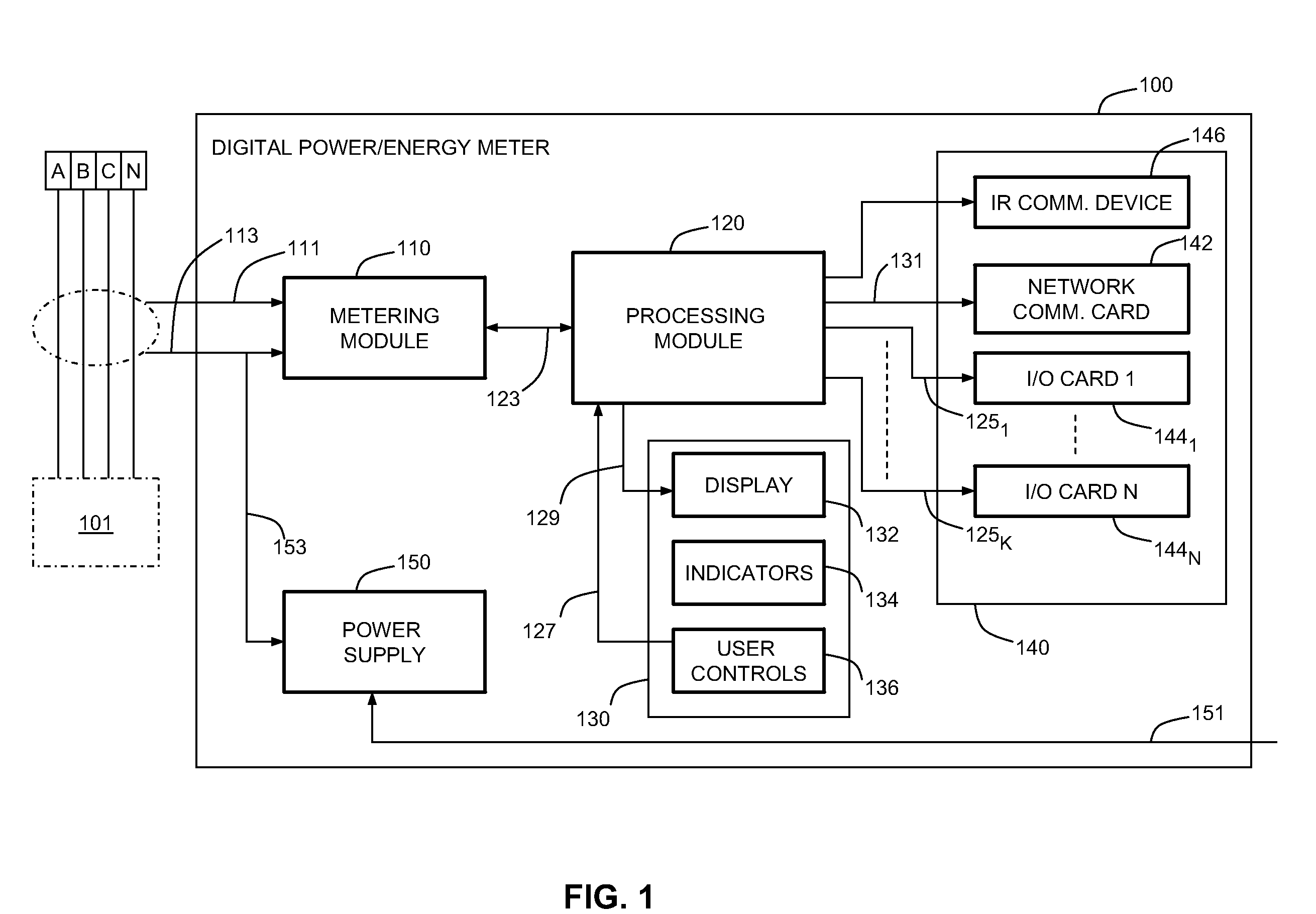

Intelligent Electronic Device and Method Thereof

ActiveUS20120078555A1Easy to implementTariff metering apparatusCurrent/voltage measurementPower flowData acquisition

An intelligent electronic device (IED) having a gain control unit adapted to selectively regulate operating ranges of output signals of a sensing circuit of the device is described. In one embodiment, the IED is a digital electric power and energy meter, which operating ranges for supply voltages and supply currents of electrical services may be adjusted to match pre-determined ranges for input signals of a data acquisition system or a data processing module of the meter.

Owner:ELECTRO INDUSTRIES GAUGE TECH

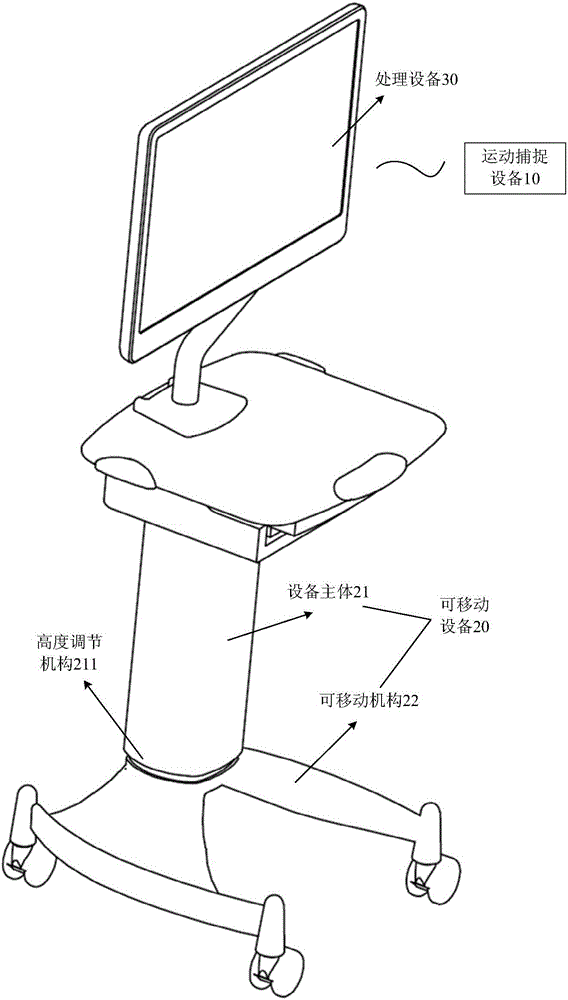

Virtual reality rehabilitation training system and method

InactiveCN104991639AIncrease interest in trainingReduce dependencyInput/output for user-computer interactionData processing applicationsComputer moduleSmall footprint

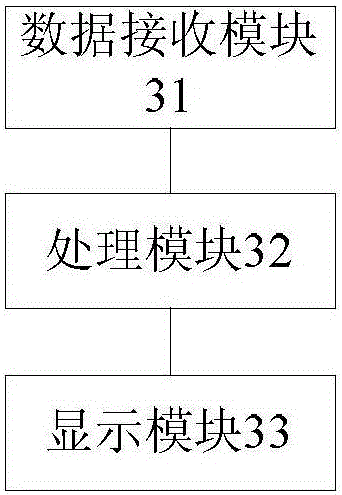

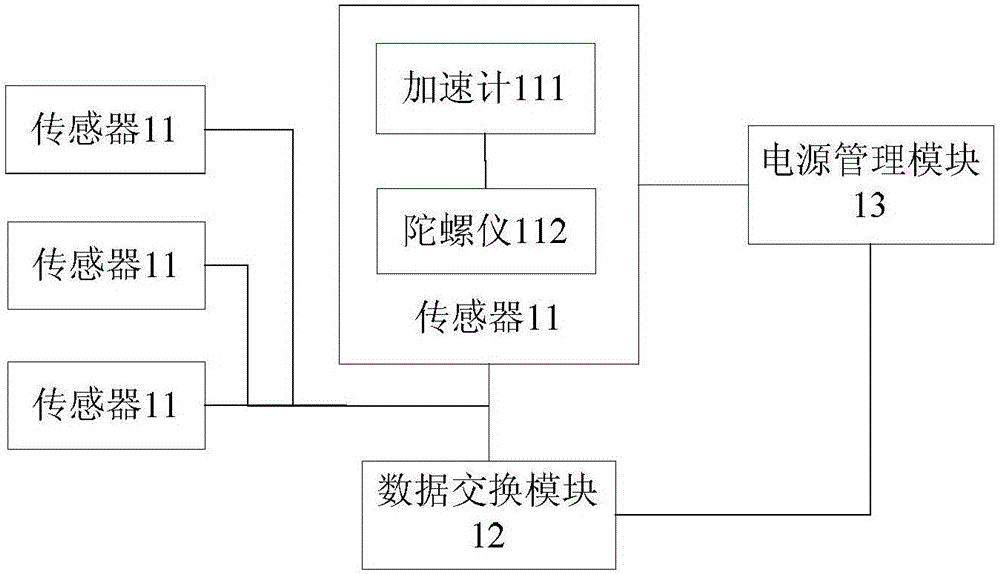

The invention discloses a virtual reality rehabilitation training system and method. The system comprises a motion capture device, a mobile device and a processor. The processor is installed in the mobile device to form an integrated bedside device, and the processor is connected with the motion capture device. The motion capture device is used for acquiring patient's limb motion data in real time. The processor comprises a data receiving module, a processing module and a displaying module. The data receiving module is used for receiving the limb motion data. The processing module is used for emitting a driving signal, and assessing training on a patient according to the limb motion data to obtain an assessment result. The display module is used for displaying changes of three-dimensional human model's actions in real time according to the driving signal, and the assessment result. The mobile device comprises a device main body and a mobile mechanism connected at the lower end of the device main body, the device main body is provided with a height adjusting mechanism used for adjusting the height of the device main body. The virtual reality rehabilitation training system is low in cost, small in land occupation and convenient to move, so the system can be disposed beside a patient's bed.

Owner:CHINA REHABILITATION RES CENT

Method and device for automatically regulating device voice volume

InactiveCN101005588AEliminates the effects of output volume changesTelevision system detailsColor television detailsEngineeringConditioning equipment

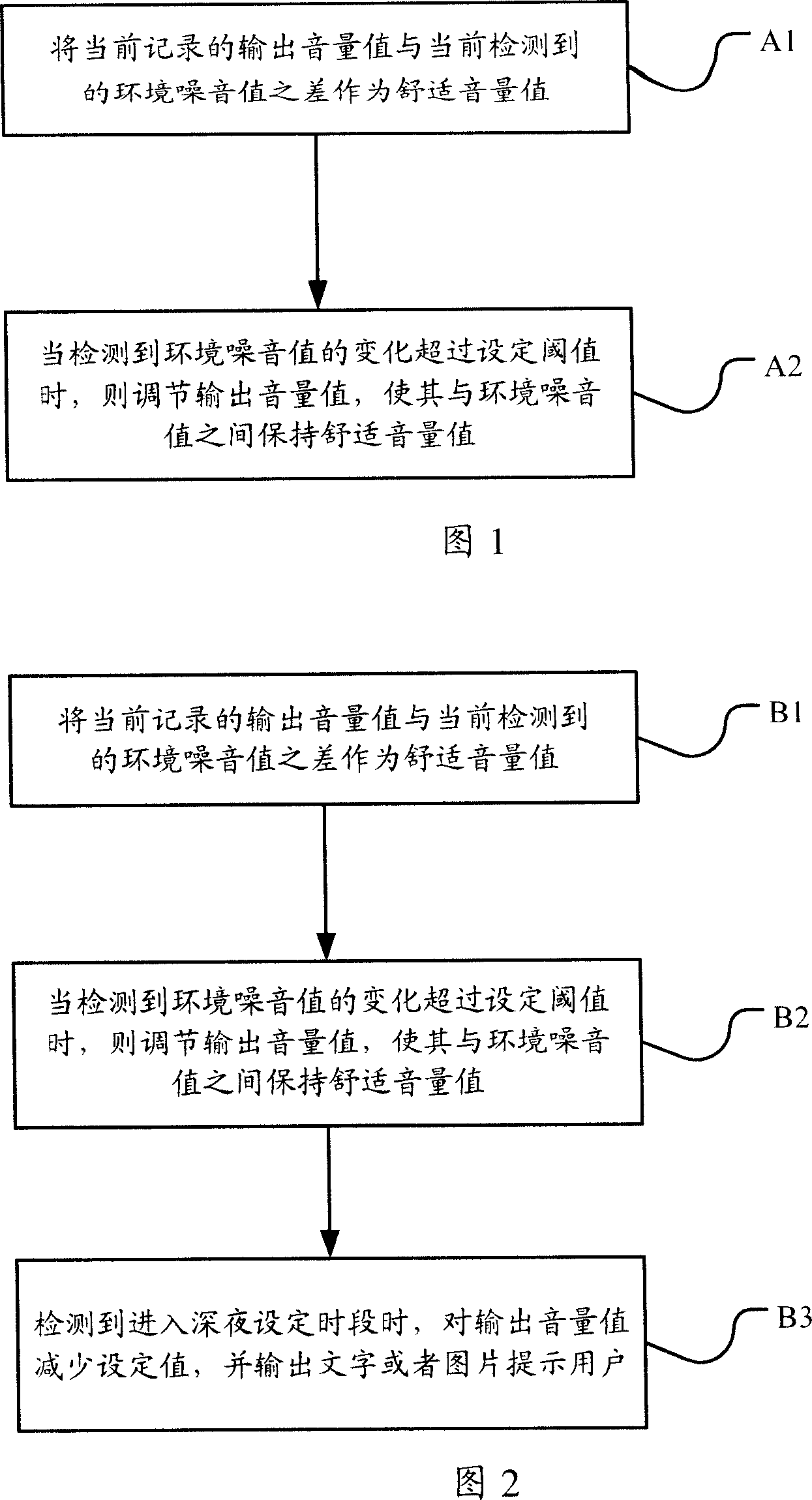

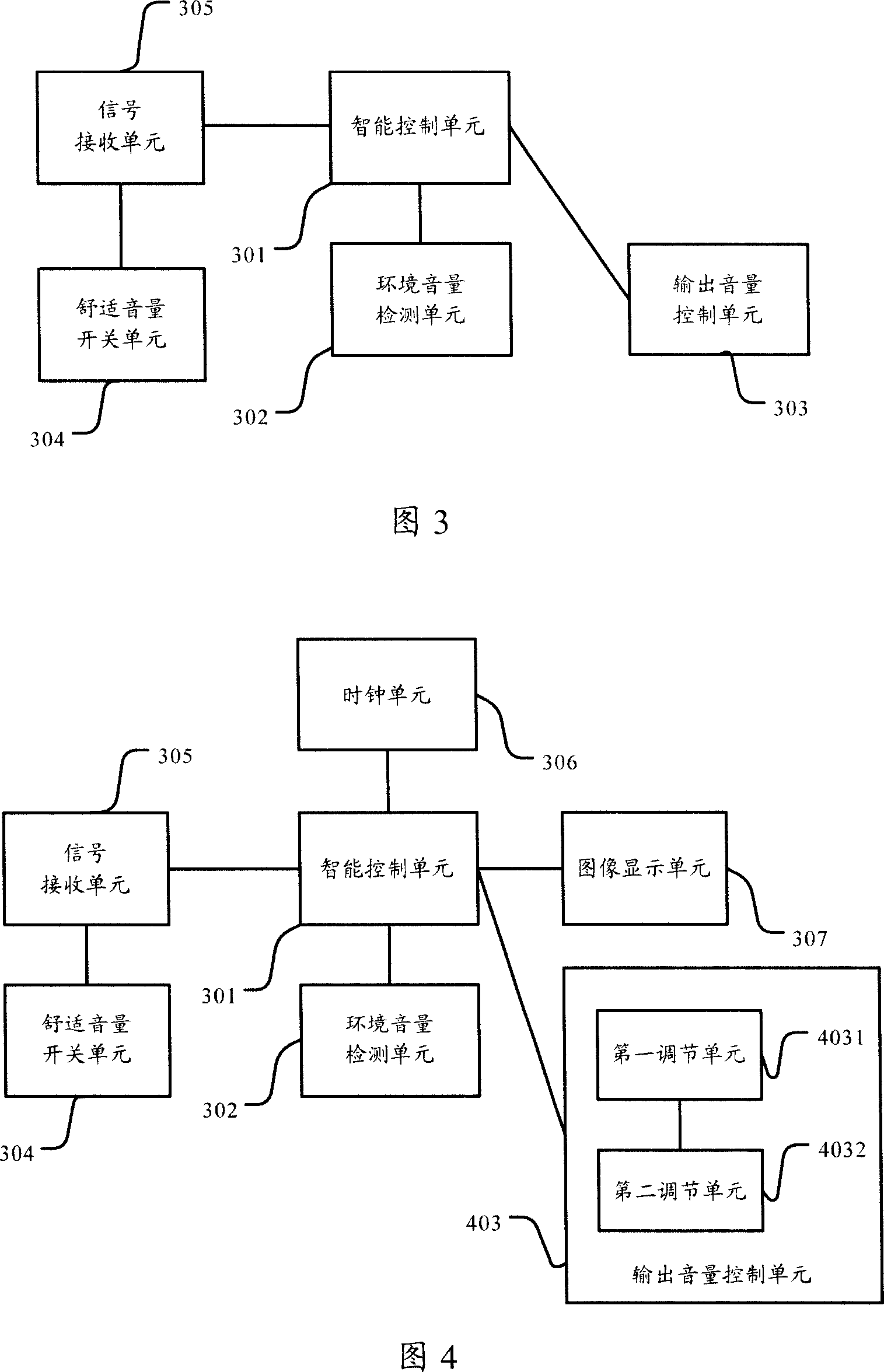

The method comprises: detecting noise value, and recording the output volume value of the device; according to the noise value and the output volume value of device, getting a comfortably-listening sound value; when detecting that the variation of noise value is over a preset threshold, the output sound value of device is tuned in order to keep a balanced sound value between the outputted volume value and the nose value to make user comfortable.

Owner:HUAWEI TECH CO LTD

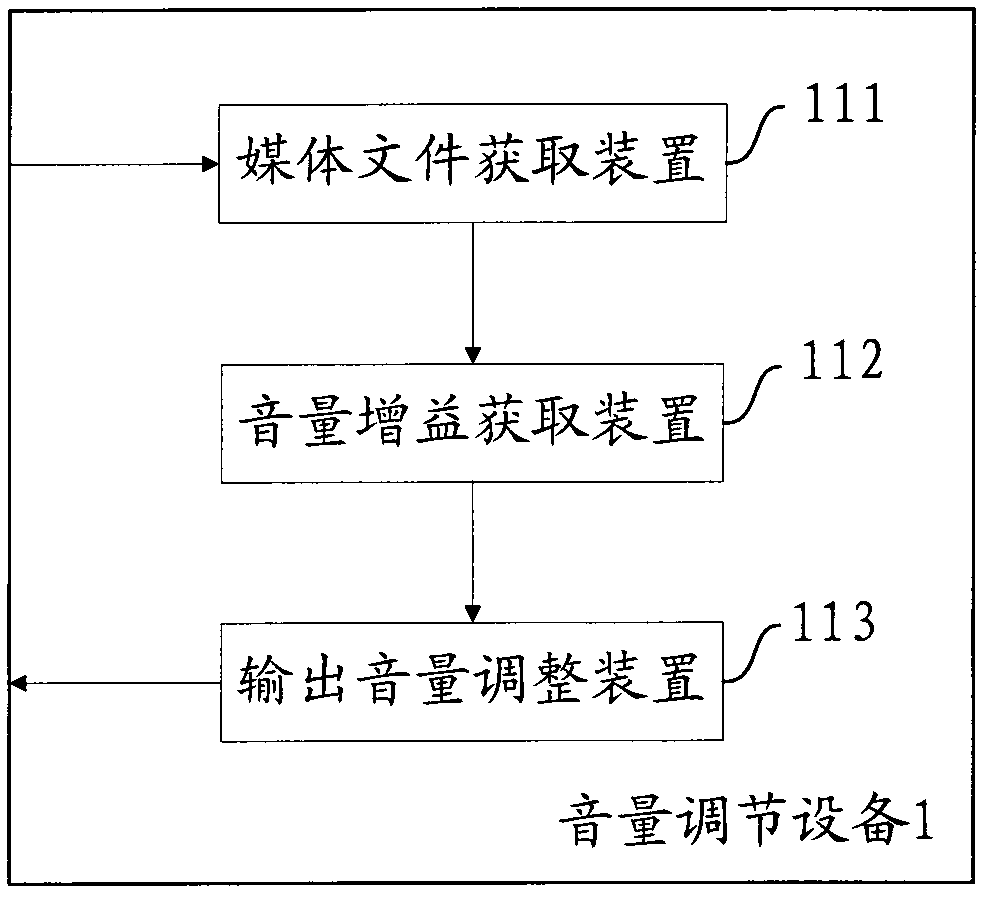

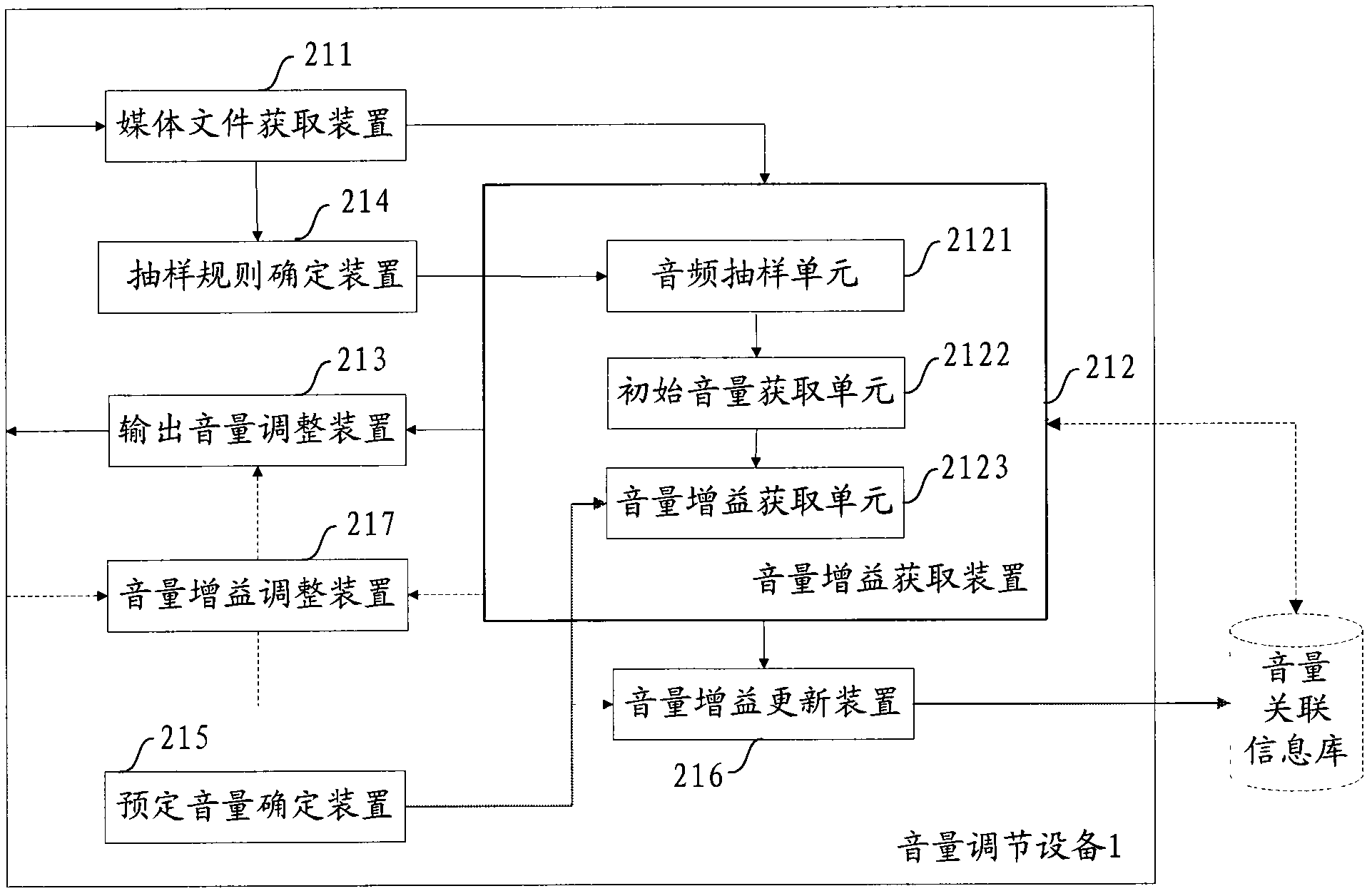

Method and device for adjusting volume of media file

InactiveCN102999492AConsistent output volumeImprove playback experienceSound input/outputSpecial data processing applicationsComputer scienceConditioning equipment

The invention provides a method and a device for adjusting the volume of a media file. The method includes the volume adjusting device obtaining the media file to be played, obtaining volume gain information corresponding to the media file according to the media file, and adjusting and playing the media file according to the volume gain information. Compared with the prior art, the corresponding volume gain information is obtained according to the media file to be played, the media file is adjusted and played according to the volume gain information, so that a user can obtain a clear volume when playing the media file; and additionally, the output volume of the media file can be maintained to be accordant through the method and the device, therefore the user can obtain the playing volume accordant with the prior media file after switching the media file, and user playing experience is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

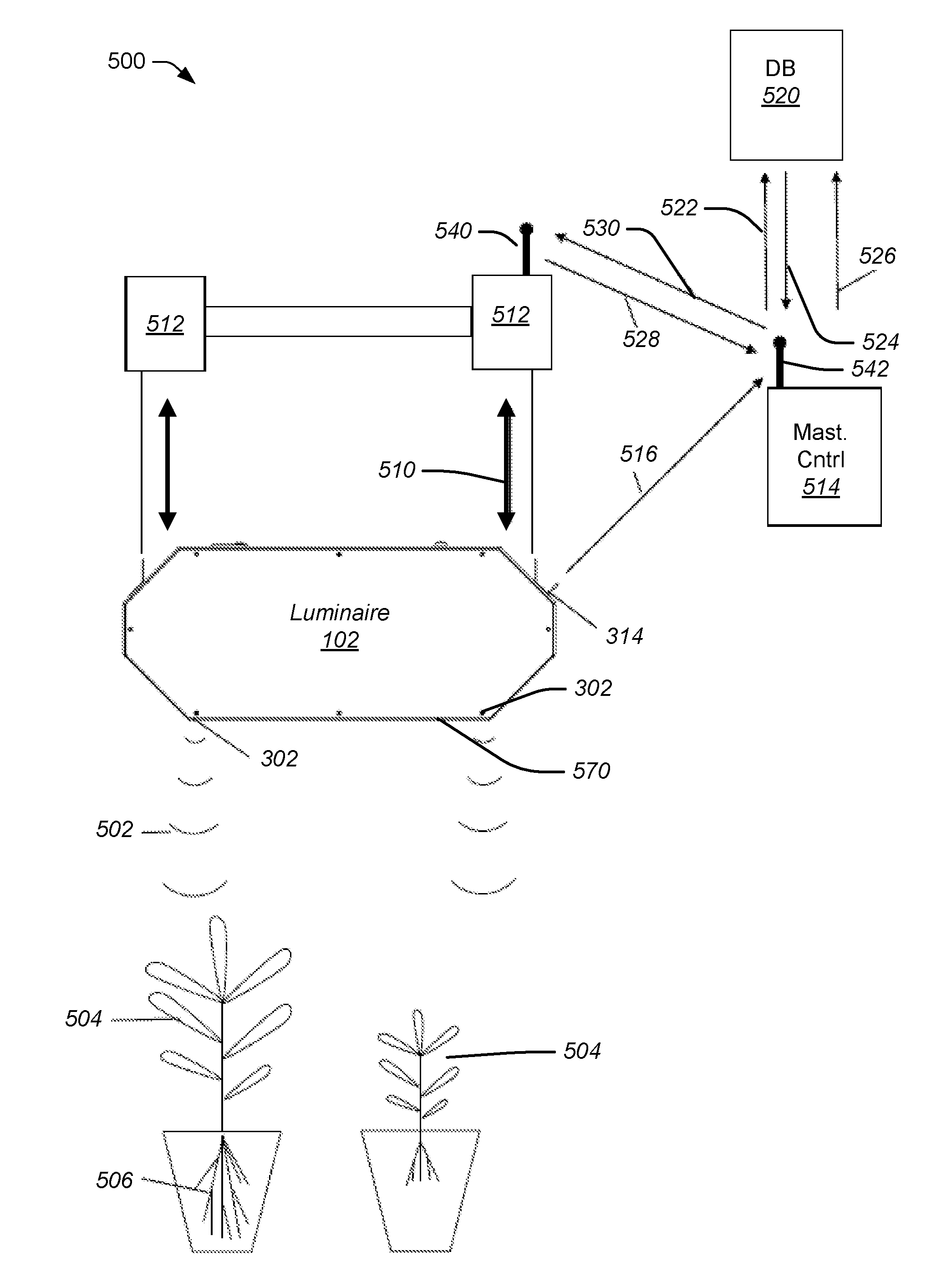

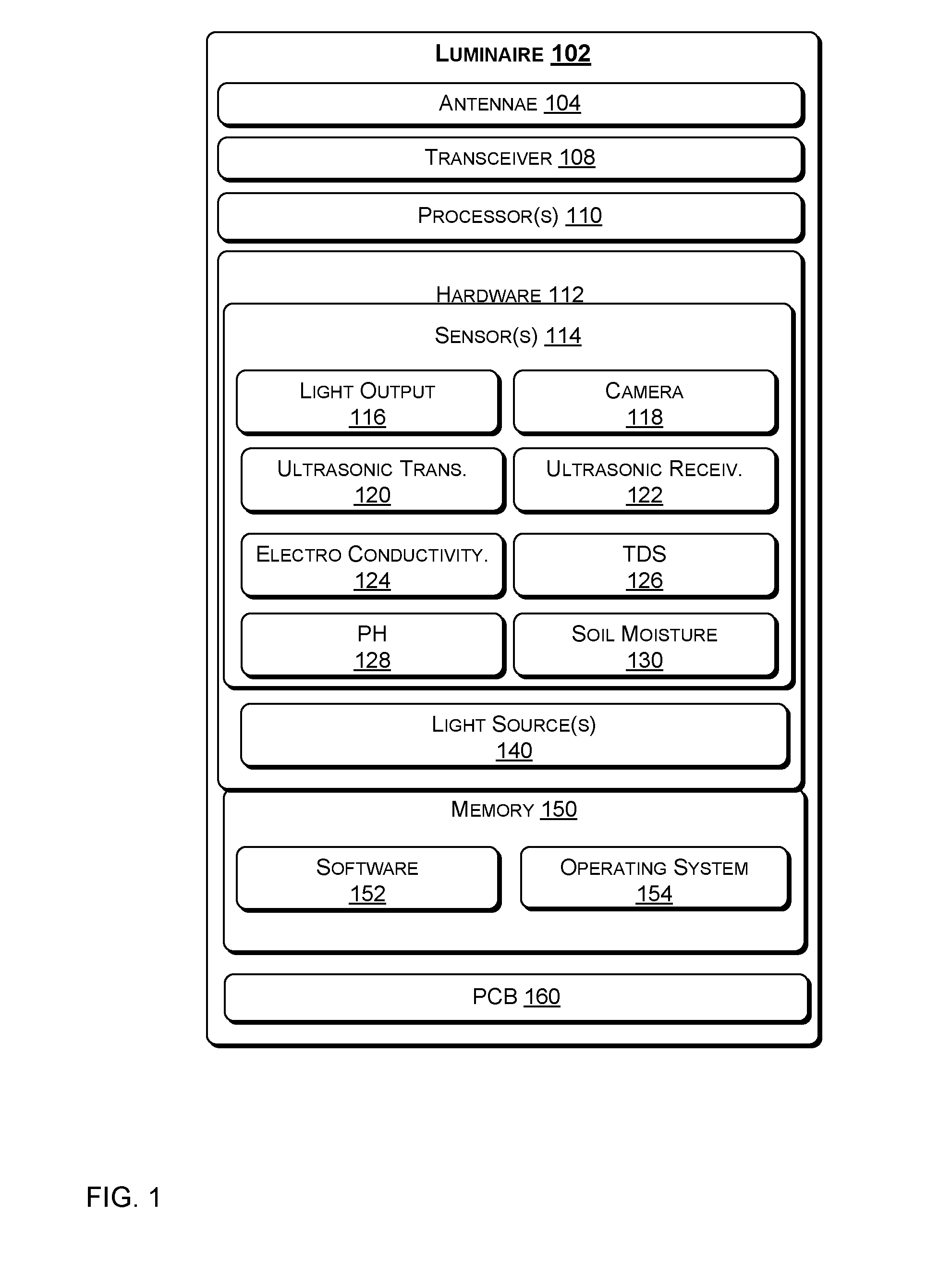

Radio-controlled lighting fixture with integrated sensors

Horticultural lighting may be provided by radio-controlled luminaires with integrated sensors. A distance from a bottom of the luminaire to a plant canopy is determined via the ultrasonic sensor at a predetermined interval. Upon determining that the distance from the bottom of the luminaire to the plant canopy is not at a predetermined distance, the distance is adjusted to the predetermined distance. The light spectrum over time on the plant is adjusted by varying a wavelength of the luminaire over a predetermined time period based on wireless instructions received from a master controller.

Owner:IUNU INC

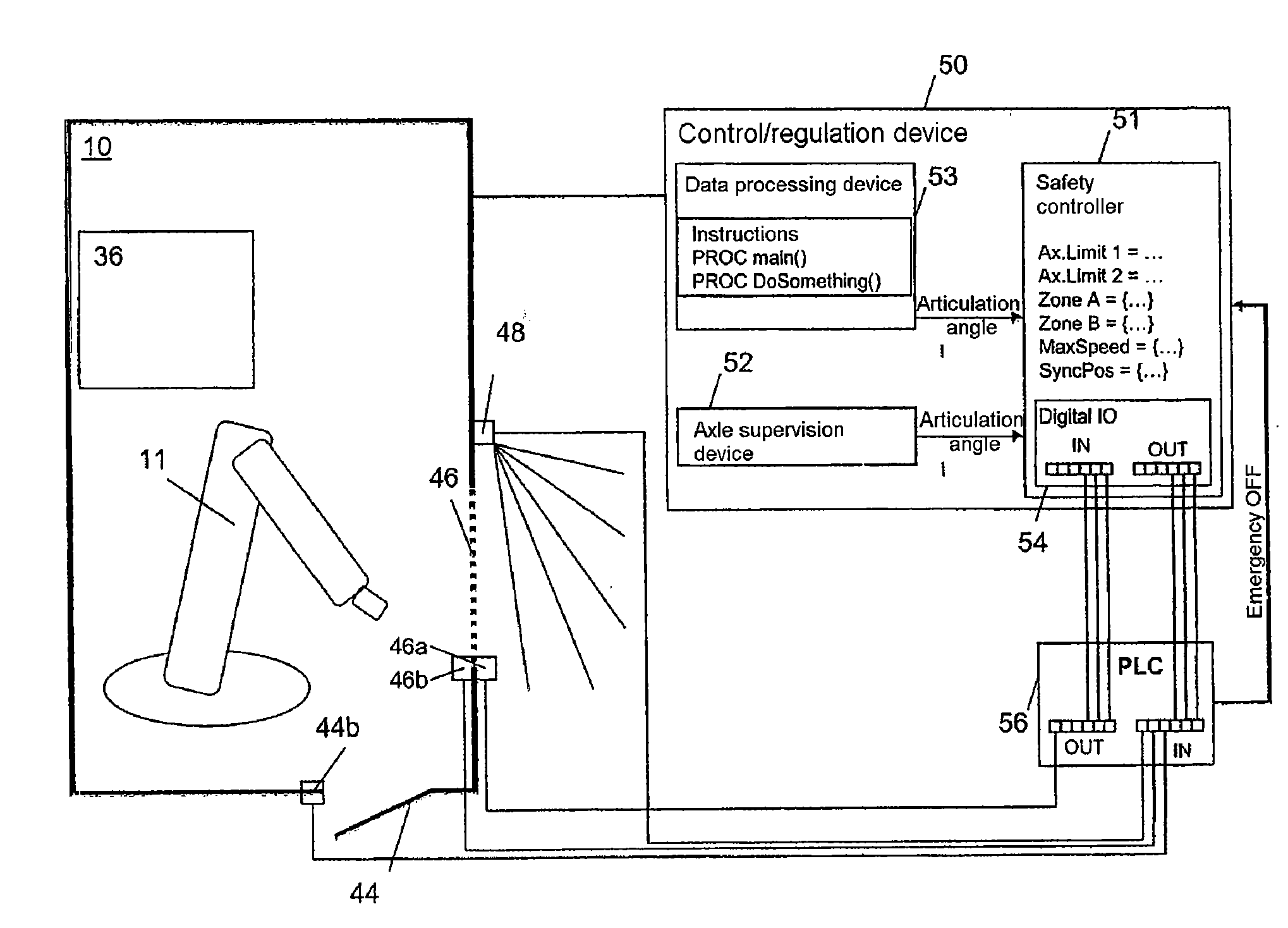

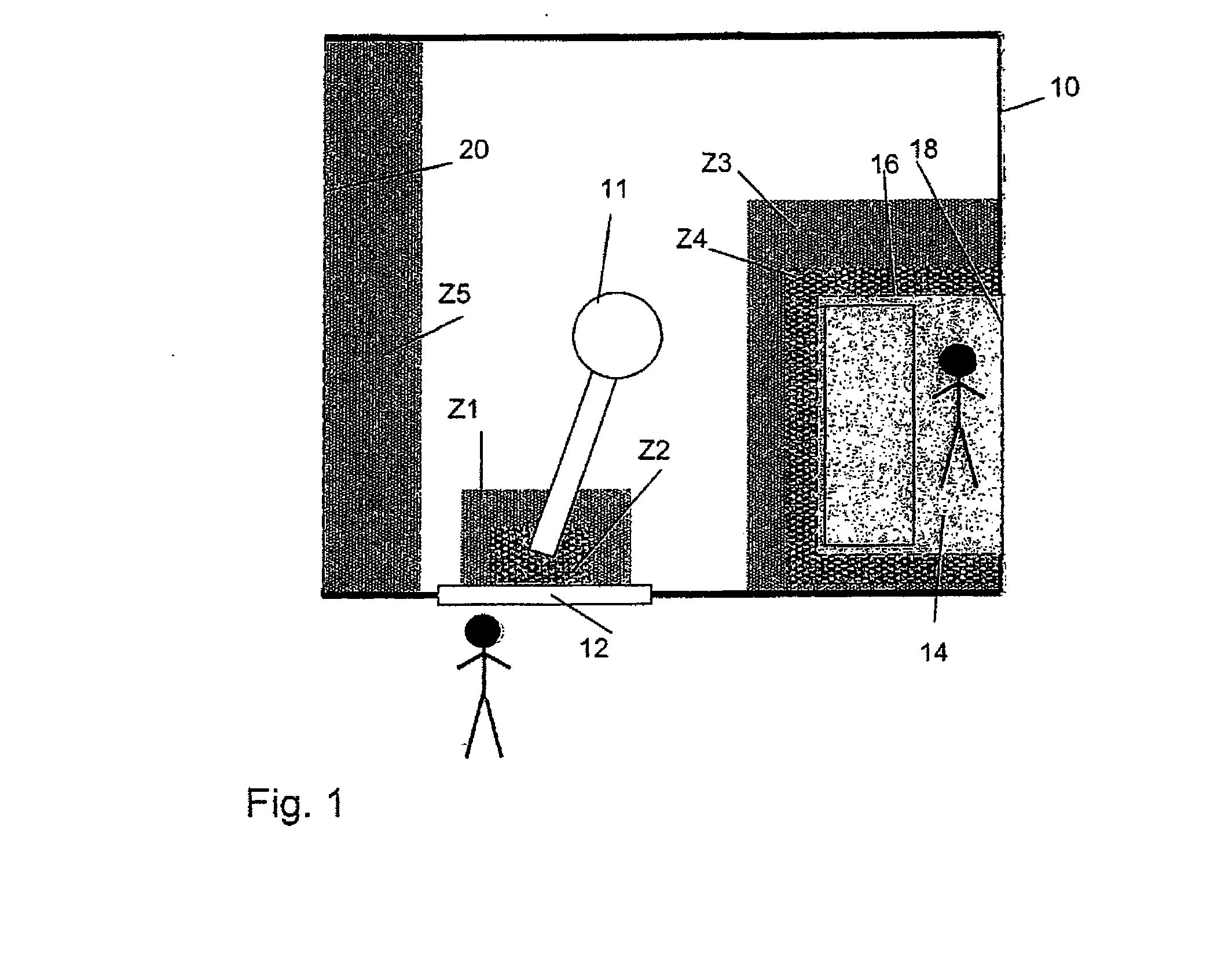

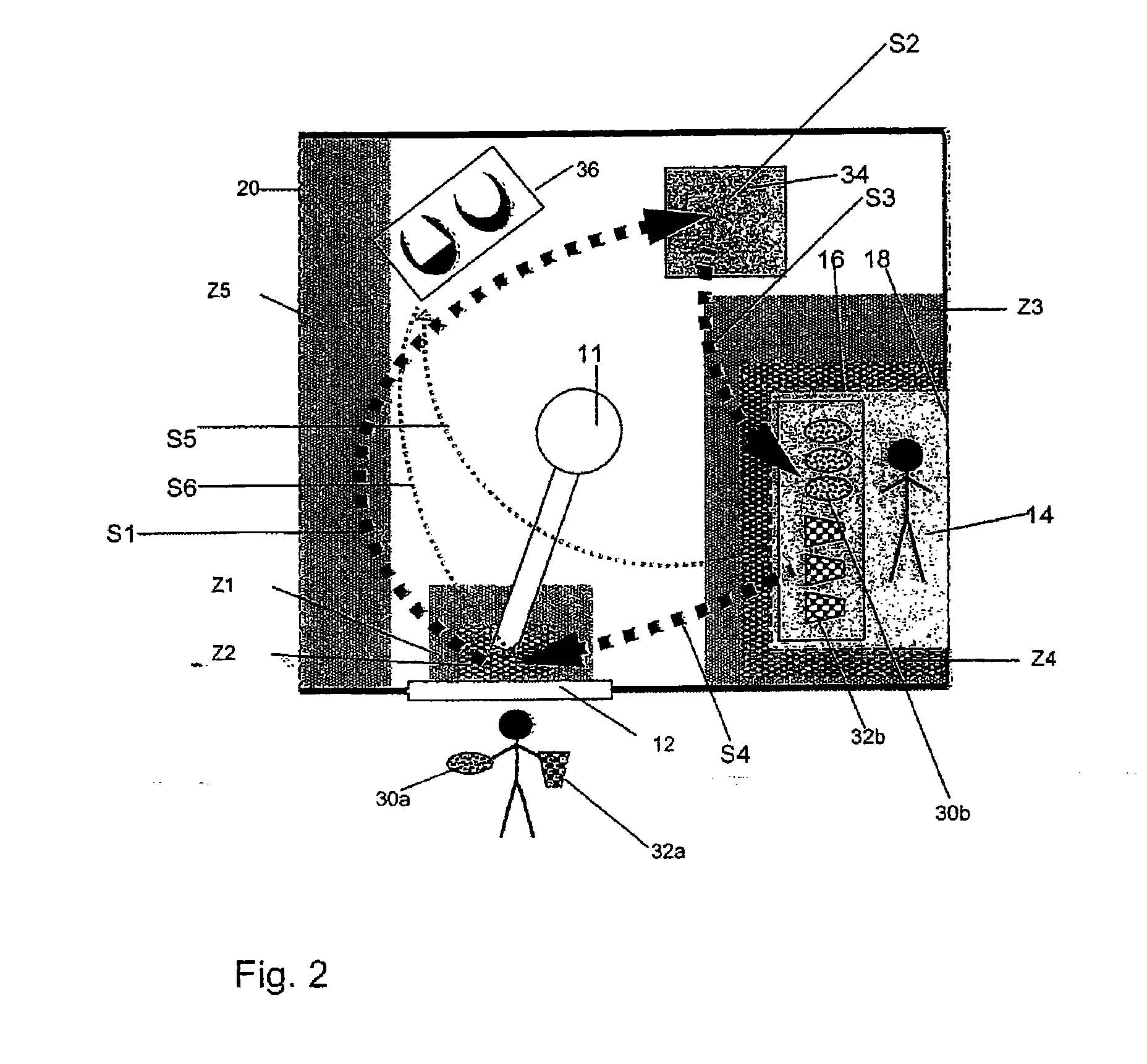

Process control, system, and method for the automated adaptation of process parameters of at least one handling device

InactiveUS20100179690A1Improved and simplifiedSimplified and improved possibilityProgramme-controlled manipulatorSafety arrangmentsControl systemEngineering

A system for automated adaption of a process parameter of a handling device includes a supervision device configured to selectively monitor at least one process parameter and / or to adapt the at least one process parameter of the handling device in an automated manner based on specifications and / or the environment and / or in a rule-based manner in interaction with a control / regulation device, wherein environment / safety-specific specifications and / or regulations are complied with and / or implemented irrespective of the type of a respective working process, wherein the system is configured to interact with the control / regulation device configured to monitor, control and / or regulate the handling device.

Owner:ABB RES LTD

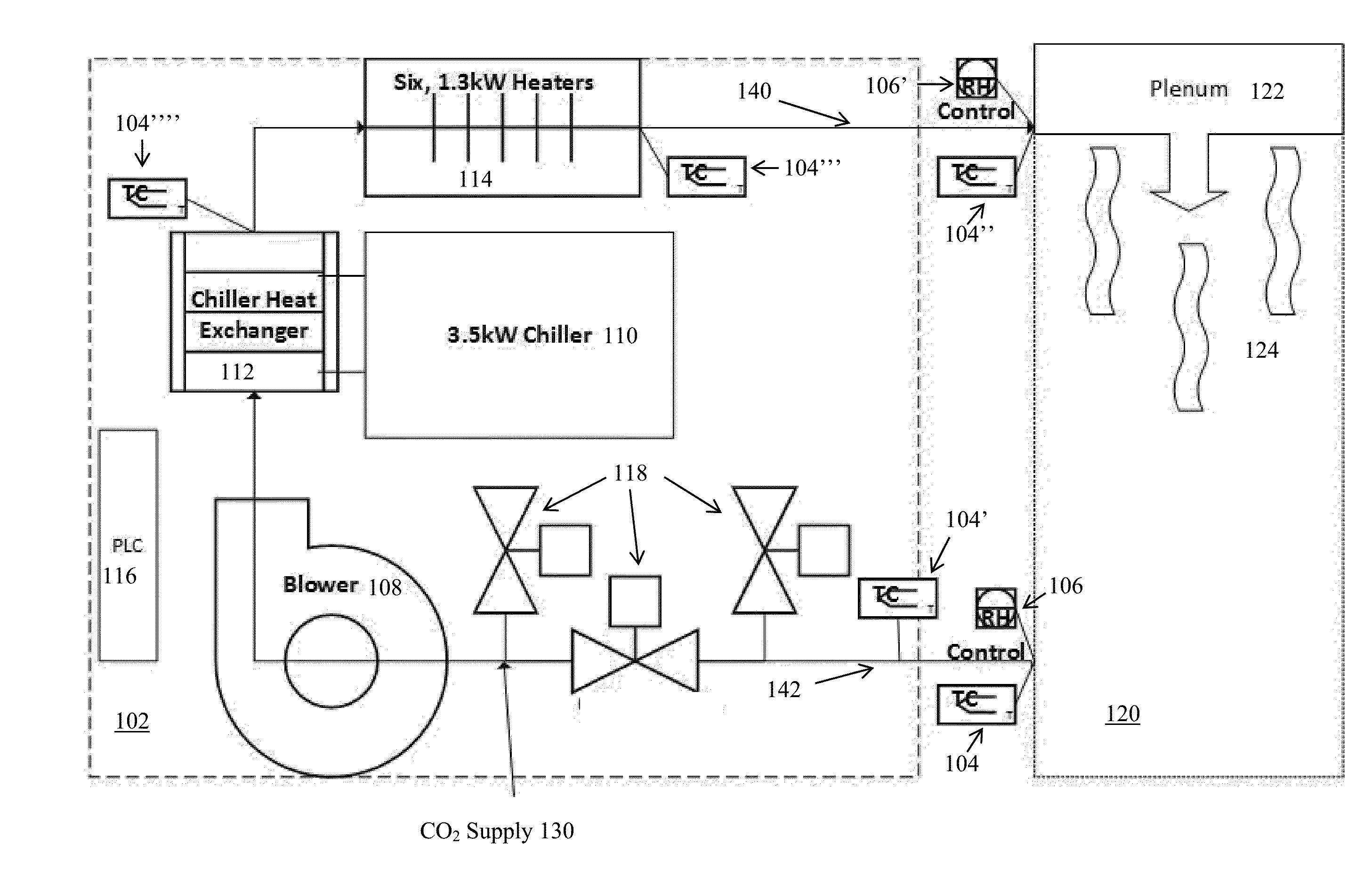

Method and apparatus for the curing of composite material by control over rate limiting steps in water removal

ActiveUS20150336852A1Long period of timeProcess control/regulationGaseous chemical processesRate limitingControl system

The invention encompasses equipment used to condition a recirculating gas stream in order to cure a CO2 Composite Material (CCM) and processes that use such equipment to cure the CCM. The gas conditioning equipment allows for a process that controls, reduces or eliminates the rate-limiting steps associated with water removal during the curing of a composite material. The equipment may include, but will not be limited to, control over the temperature, relative humidity, flow rate, pressure, and carbon dioxide concentration within the system; which includes the conditioning equipment, any vessel containing the CCM, and the material itself. Flow rate control can be used as a means to achieve uniformity in both gas velocity and composition.

Owner:SOLIDIA TECH

Detection and Use of Acoustic Signal Quality Indicators

A computer-driven device assists a user in self-regulating speech control of the device. The device processes an input signal representing human speech to compute acoustic signal quality indicators indicating conditions likely to be problematic to speech recognition, and advises the user of those conditions.

Owner:PROMPTU SYST CORP

Method and system for controlling superheat degree of air-conditioning equipment

ActiveCN103438544APrevent liquid shockImplement superheat control methodSpace heating and ventilation safety systemsLighting and heating apparatusThermodynamicsControl system

The invention discloses a method for controlling superheat degree of air-conditioning equipment, which comprises the following steps: detecting compressor suction pressure P1, compressor suction temperature T1, compressor bottom temperature Td and outdoor environment temperature Th; calculating Tb, DeltaTx and DeltaTd; judging whether Th is smaller than or equal to 0 DEG C, and if so, setting the target suction superheat degree DeltaTm as a first target value, wherein the first target value is -1 DEG C to 1 DEG C; and judging whether DeltaTd is smaller than 10 DEG C, if so, giving an alarm, and if not, adjusting the opening of the electronic expansion valve according the magnitudes of DeltaTx and DeltaTm. The practice proves that the suction superheat degree of the invention is 0-1 DEG C when the outdoor environment temperature is smaller than or equal to 0 DEG C, thereby avoiding the phenomenon of carbon deposition due to overhigh exhaust temperature; only when the compressor bottom superheat degree is greater than or equal to 10 DEG C, the invention adjusts the opening of the electronic expansion valve, thereby still preventing the compressor from liquid slugging in practice when the suction superheat degree is 0-1 DEG C. The invention also discloses a system for controlling superheat degree of air-conditioning equipment.

Owner:SHENZHEN MCQUAY AIR CONDITIONING

Method and system for managing central air-conditioning end equipment of teaching building based on schedule

ActiveCN102679493AReduce wasteReduce energy burdenMechanical apparatusSpace heating and ventilation safety systemsCentral air conditioningAuthorization

The invention discloses a method and a system for managing central air-conditioning end equipment of a teaching building based on a schedule. The method comprises a step of performing classification management on the central air-conditioning end equipment of classrooms through arrangement of the schedule, namely turning on air-conditioning end equipment in classrooms where students have classes in advance and removing the control authority of the air-conditioning end equipment; and counting the number of students in classrooms where students do not have classes by a video identification technology, and scientifically and reasonably planning and arranging the central air-conditioning end equipment in all classrooms where students do not have classes in the whole building. The system for managing the central air-conditioning end equipment can be applied to the teaching building, so that the phenomenon of energy wastage of the air-conditioning equipment of the teaching building can be effectively avoided, energy burden of schools is lightened, and the construction of green campuses is facilitated; and meanwhile, authorization management departments at different levels can remotely monitor the air-conditioning equipment in different areas on network nodes through a network and remotely regulate and control the areas where the air-conditioning equipment is unreasonably used, so that the aim of saving energy can be fulfilled.

Owner:GUANGZHOU YUANZHENG INTELLIGENCE TECH

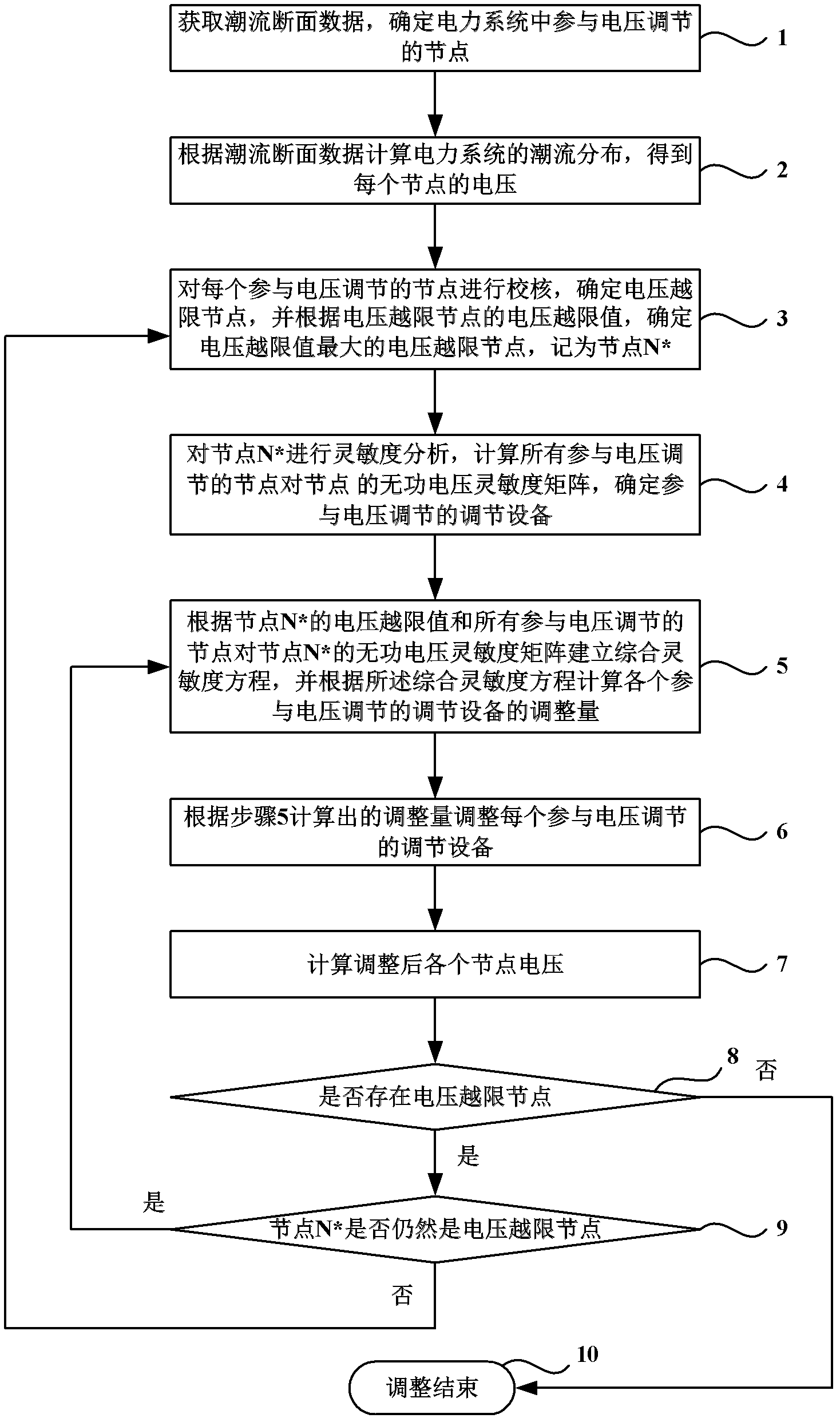

Voltage out-of-limit adjusting method

InactiveCN102545230AQuick calculationAccurate calculationAc network voltage adjustmentReactive power compensationPower flowVoltage regulation

The invention discloses a voltage out-of-limit adjusting method in the technical field of power supply system control. The voltage out-of-limit adjusting method comprises the following steps of: obtaining power flow interface data and determining nodes which take part in voltage adjustment; calculating power flow distribution of a power supply system according to the power flow interface data, so as to obtain voltage of each node; correcting and checking each node which takes part in the voltage adjustment, determining a voltage out-of-limit node and the voltage out-of-limit node with a maximum voltage out-of-limit value, and recording the node with the maximum voltage out-of-limit value as a node N*; carrying out sensitivity analysis on the node N*, calculating a reactive voltage sensitivity matrix of all the nodes which take part in the voltage adjustment to the node N*, and determining adjustment equipment taking part in the voltage adjustment; establishing a comprehensive sensitivity equation and calculating an adjustment amount of each adjustment equipment taking part in the voltage adjustment; adjusting each adjustment equipment taking part in the voltage adjustment according to the adjustment amount; calculating the adjusted voltage of each node; and if no voltage out-of-limit node exists, stopping adjusting. According to the voltage out-of-limit adjusting method disclosed by the invention, the adjustment capacity of the adjustable equipment can be rapidly and accurately calculated, and the security and the reliability of the power supply system are improved.

Owner:STATE GRID SICHUAN ELECTRIC POWER +1

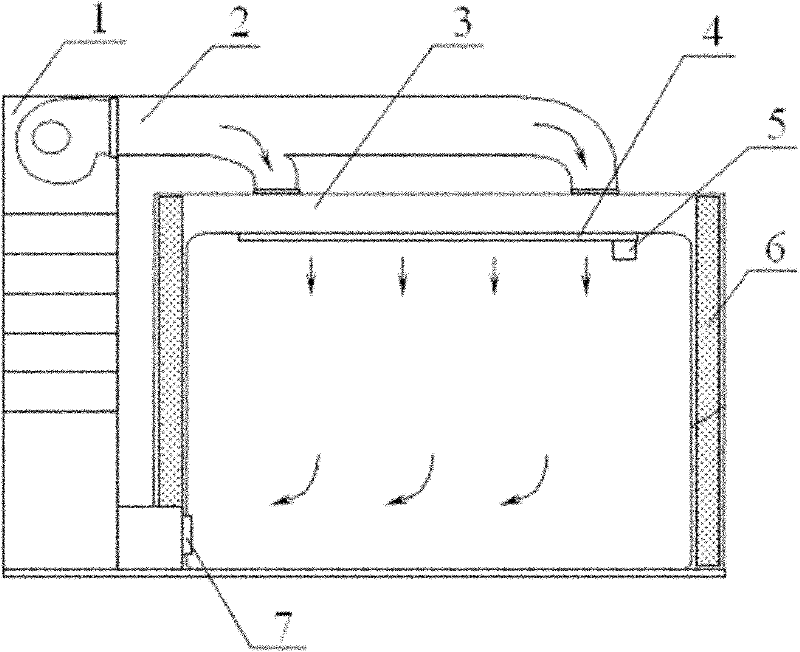

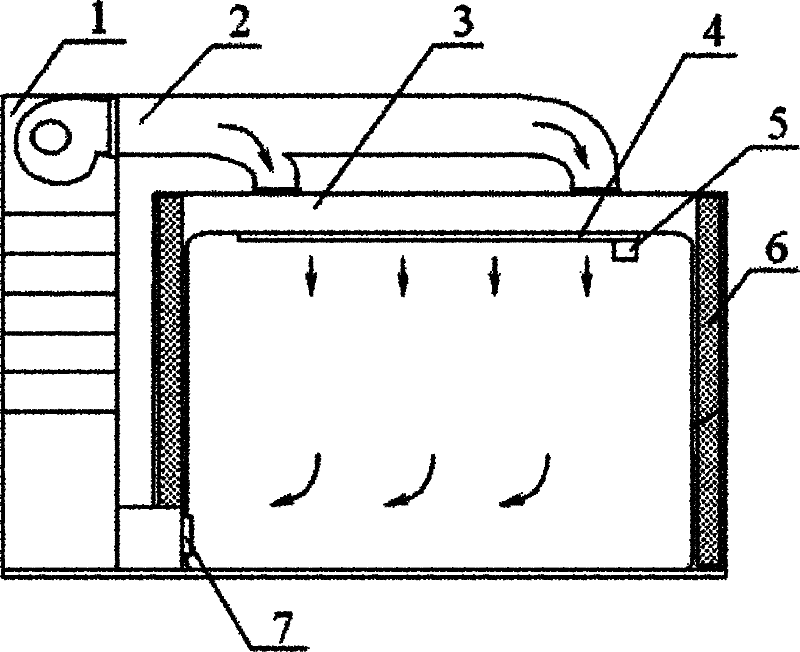

Environment control system

ActiveCN102679472AImprove efficiencyNoise isolationLighting and heating apparatusNoise suppressionAir velocityIndoor air quality

The invention relates to an environment control system which comprises an air purification device, a controllable gas delivery device and an environment regulation device. The air purification device is disposed inside a building. The controllable gas delivery device and the environment regulation device are disposed inside the air purification device. Compared with the prior art, the environment control system creates a 'house-in-house' environment beneficial to human physiological and mental health to achieve health caring. The indoor environment created by the environment control system includes factors such as temperature, humidity, cleanliness, freshness, oxygen concentration, anion concentration, luminance, air velocity, air uniformity, noise, color, music, fragrance, air pressure and electromagnetic wave, and accordingly the problems of indoor air pollution and low indoor air quality are solved substantially. The environment control system cares human health.

Owner:上海三因环保科技有限公司

Liquid antenna for controlling transmitting-receiving wave beam directions by gravity

PendingCN108281771ARealize beam automatic steering functionCost advantageRadiating elements structural formsElongated active element feedJet aeroplaneBeam direction

The invention discloses a liquid antenna for controlling transmitting-receiving wave beam directions by gravity, and belongs to the field of communication equipment design and application. The liquidantenna comprises a container with an inner cavity and fluids placed in the inner cavity, the container is fixedly connected with a feed structure of the antenna, the inner cavity is closed, the fluids have spatial steady-state fixed structures formed by constraint of the gravity and the inner cavity, and the wave beam definite direction of the antenna is set by the spatial steady-state fixed structures. The liquid antenna can realize an automatic wave beam turning function without active regulating equipment such as a water pump. When the liquid antenna is used for satellite communication, the liquid antenna has the advantages of capability of covering the broad communication bandwidth of most satellite communication bands (such as GPS), low profile, small size, light weight, conformal property and the like. The liquid antenna is universally applicable to various application scenes such as airplanes, vehicles, body local area networks and IoT (internet of things) requiring suitabilityof the antenna for bearing capacity.

Owner:太行通信股份有限公司

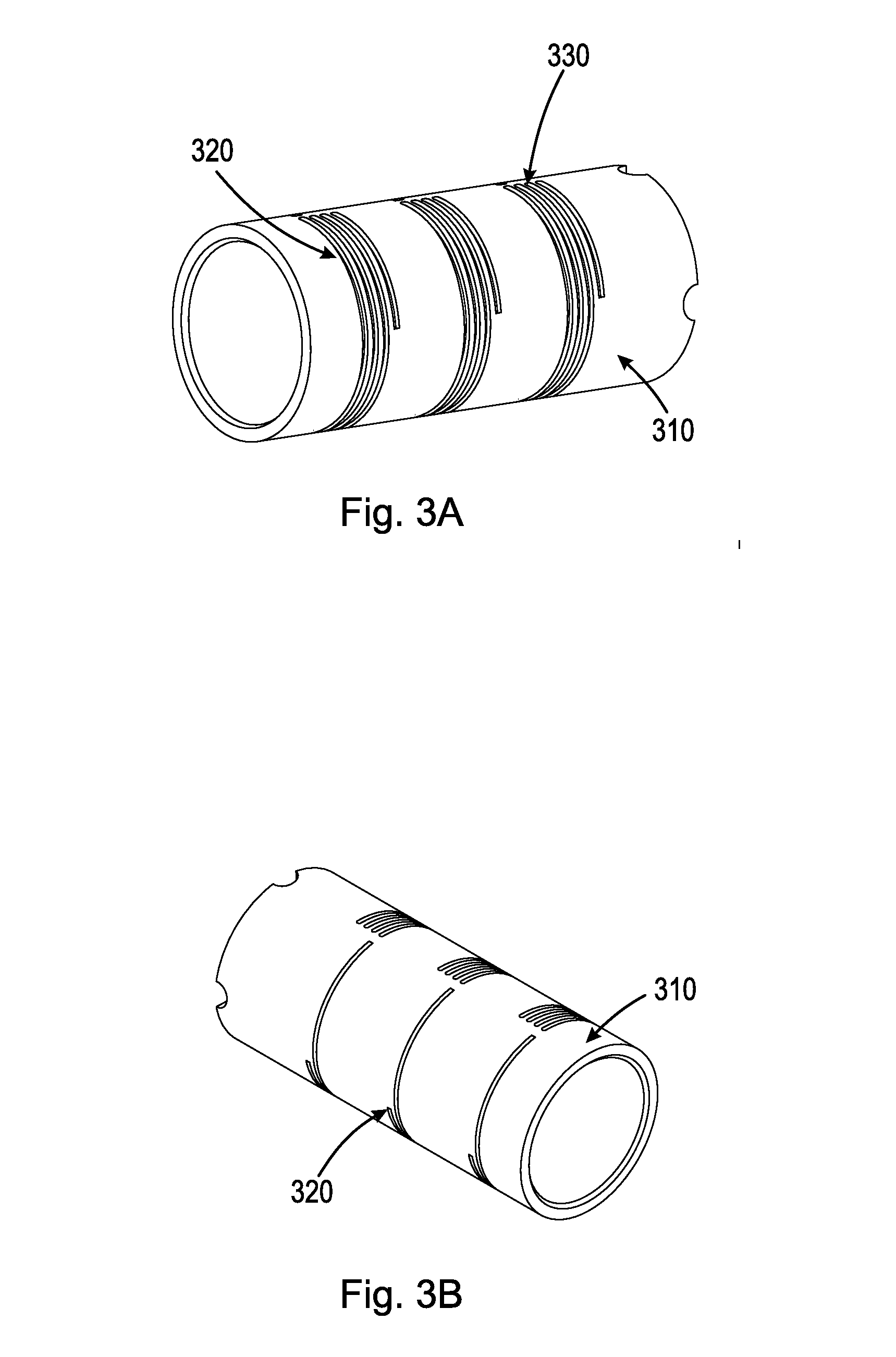

Shock absorber with variable damping profile

Disclosed herein in an energy absorption device that incorporates a diverse range of uses within a single shock absorber. The disclosed energy absorption device is a novel combination of interaction between various components (e.g., piston head, shock tube, cylinder end, external cylinder, and adjustment mechanism) within a single shock absorber. When the components disclosed herein are considered together and designed as an interrelated assembly, the ability to incorporate such a diverse range of uses within a single device emerges. The ability to combine dashpot, square wave, progressive wave, and self-compensating damping in a single device is unprecedented, as is the ability to deliver sublinear damping force vs. input velocity performance in an adjustable device. The disclosed device allows a user to make simpler sizing calculations and decisions, and provides the user with the ability to adjust the shock absorber to a specific application, for example, with the turn of an adjustment knob.

Owner:KYNTEC

Self-adaptive load balance scheduling mechanism for internet-of-things device access processing platform

ActiveCN104270322AReduce the impact of "noise"Overcome limitationsData switching networksIot gatewayComputer network technology

The invention relates to the technical field of computer networks, in particular to a self-adaptive load balance scheduling mechanism for an internet-of-things device access processing platform. The invention provides a novel scheduling algorithm framework in which a routing policy and a routing algorithm are independently separated, the routing policy can be replaced, the evaluation indicator is expandable, the routing algorithm is open-ended, and three routing policies including a single algorithm policy, a combined algorithm policy and an adaptive algorithm policy, are also provided to deal with the abruptness and the randomness of a device connection request in a real application environment. With the adoption of the self-adaptive load balance scheduling mechanism, an internet-of-things device access system effectively adjusts the distribution condition of the device connection request according to the performance difference and the load conditions of various nodes in a cluster, so that the overall performance of a cluster system is improved. Compared with the prior art, the self-adaptive load balance scheduling mechanism for the internet-of-things device access processing platform has the advantages of novel thought, flexibility in use, and good convenience for expansion, fully meets the scheduling requirements of the connection request of an internet-of-things gateway, and effectively breaks the limitations that the single router is not applicable to all scenes.

Owner:CETHIK GRP

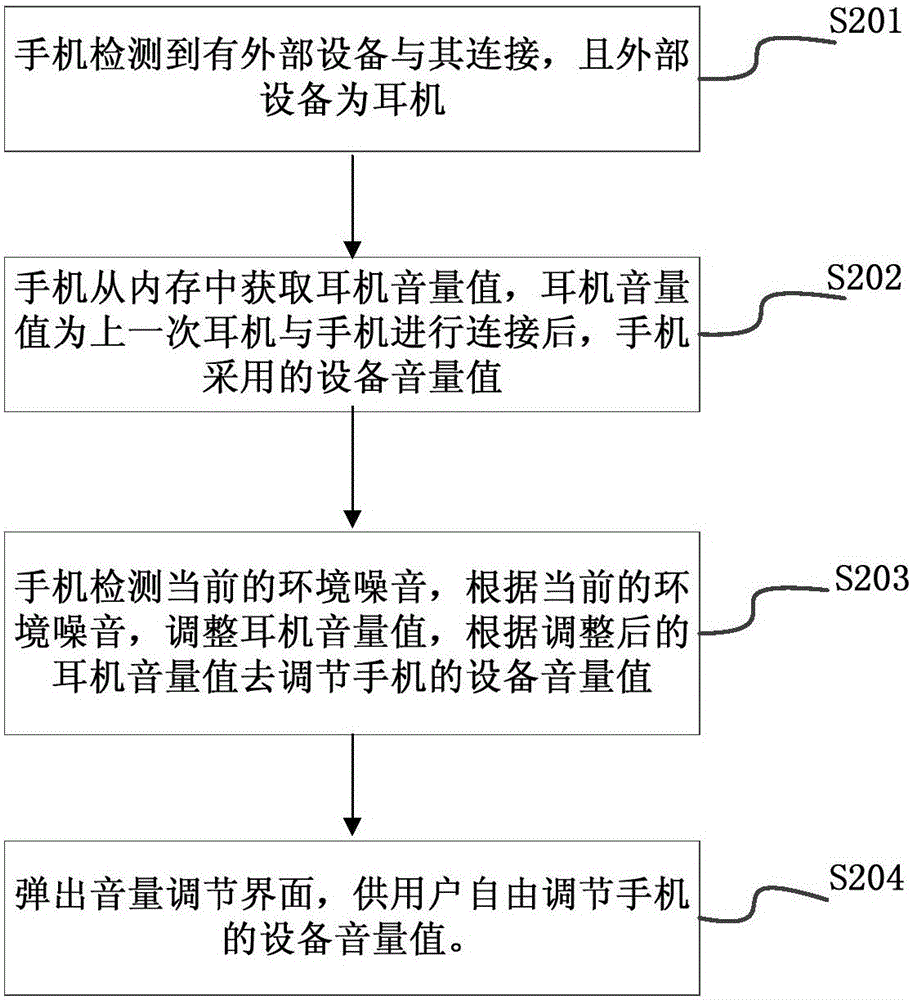

Method and device for adjusting volume of terminal device

The embodiment of the invention discloses a method and a device for adjusting volume of a terminal device. The method comprises the following steps: a detecting step: if detecting a peripheral device is established a connection with the terminal device, detecting whether the peripheral device is an earphone or a sound box; if the peripheral device is the earphone, obtaining an earphone volume value, pre-stored in the terminal device, of the earphone; if the peripheral device is the sound box, obtaining a sound box volume value, pre-stored in the terminal device, of the sound box; and an adjusting step: adjusting a device volume value of the terminal device according to the earphone volume value or the sound box volume value. According to the method and the device disclosed by the invention, when a user uses the peripheral device such as the earphone, the sound box and the like, the earphone volume value or the sound box volume value pre-stored in the terminal device can be directly employed to take as the device volume value of the current terminal device, and the device volume value does not need to be adjusted manually by the user.

Owner:LETV HLDG BEIJING CO LTD +1

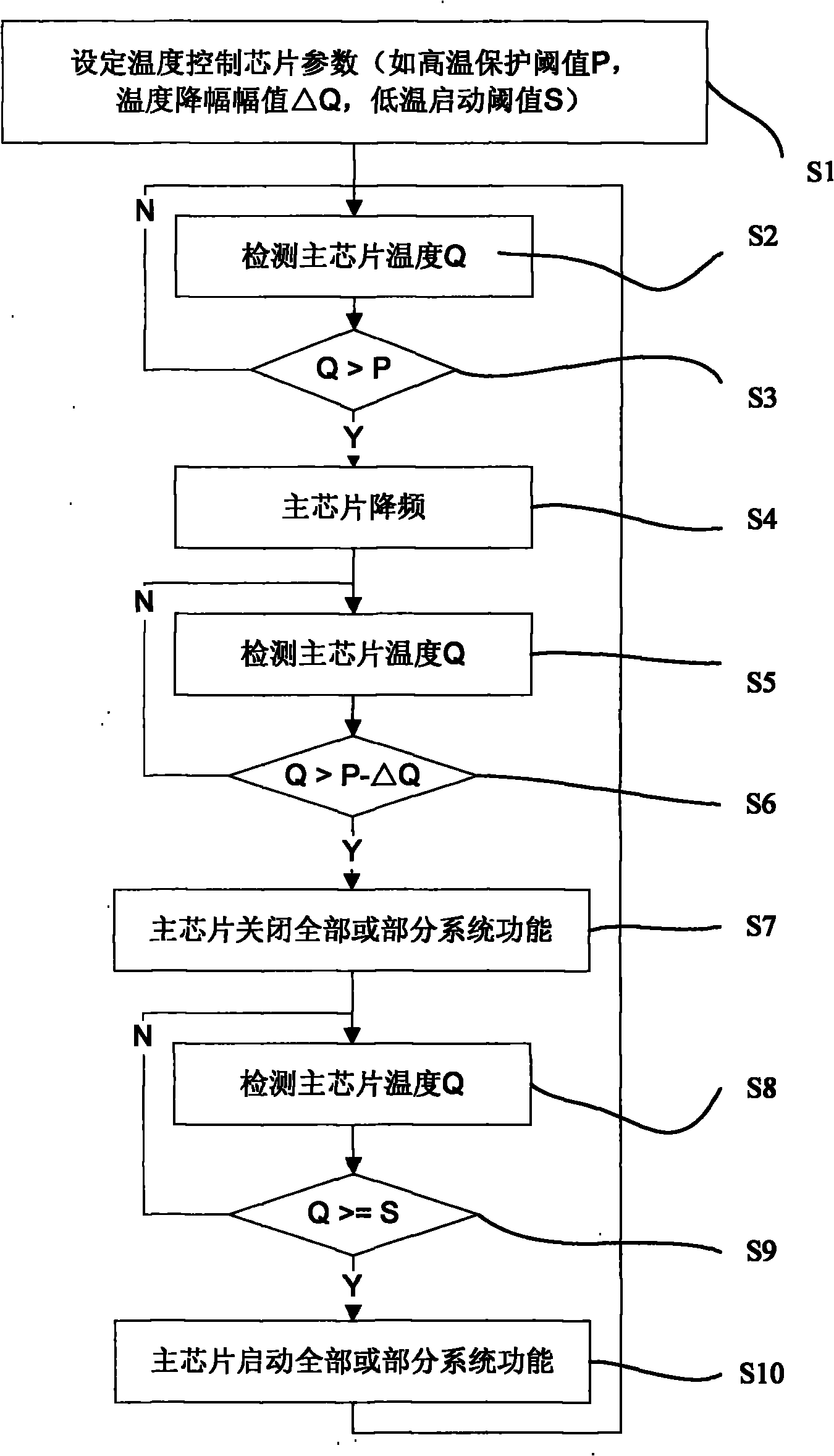

Power equipment and high-temperature self-protection method thereof

InactiveCN102055166AEffective self-regulationExtended service lifeThermometer detailsElectric signal transmission systemsGeneral Packet Radio ServiceEngineering

The invention provides power equipment and a high-temperature self-protection method thereof. The power equipment comprises a completely-sealed housing, a plurality of functional modules arranged in a cavity enclosed by the housing and a main chip for controlling the all functional modules to operate. The main chip has a function of automatically regulating the working frequency per se and coordinating the work of the functional modules. Each functional module comprises a temperature control module and a plurality of communication modules, such as a WiFi (Wireless Fidelity), an LAN (Local Area Network), a GSM / GPRS (Global System For Mobile Communications / General Packet Radio Service), a PLC (Programmable Logic Controller), an RS485 (Radio Station), and the like. The temperature control module is in charge of detecting the temperature in the cavity of the equipment, comparing the temperature with the threshold preset inside the temperature and informing the compared result to the main chip in an electric signal manner; and the main chip regulates the working frequency per se and the working mode of each functional module according to the received signal and further regulates the internal power consumption and the heating quantity of the equipment. The service life of the power equipment can be greatly prolonged without an air window and a fan.

Owner:SHENZHEN GREAT WALL KEMEI TECH CO LTD

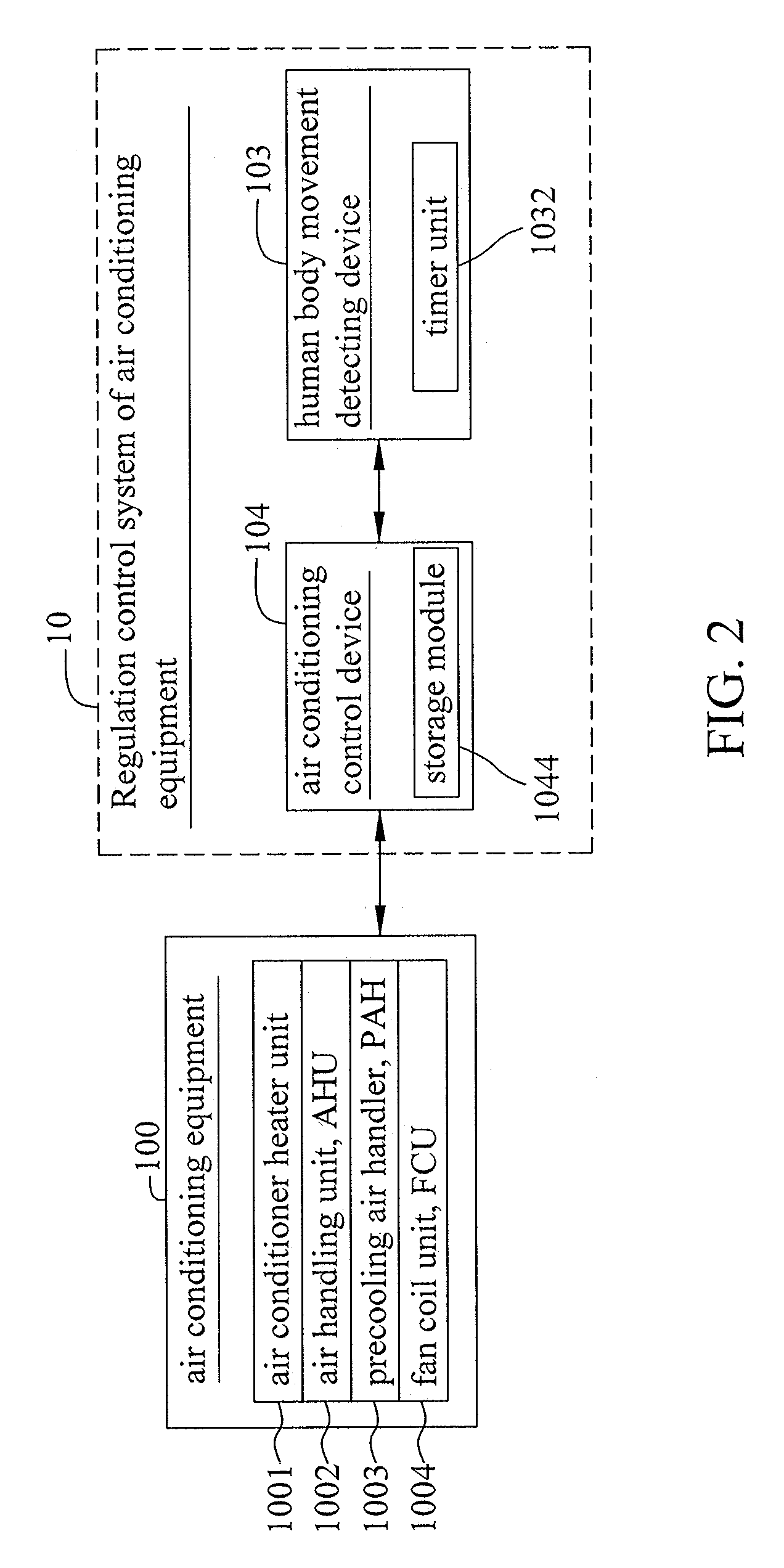

Regulation control system of air conditioning equipment

InactiveUS20090026280A1Sampled-variable control systemsMechanical apparatusControl systemEngineering

A regulation control system of air conditioning equipment is provided according to the present invention; the regulation control system mainly interconnects an entrance guarding device and / or a human body movement detecting device with an air conditioning control device, by this way, data of air conditioning usage surroundings condition are generated by the entrance guarding device and / or the human body movement detecting device, and then an air conditioning control device executes regulation and control over the air conditioning equipment based on the data of air conditioning usage surroundings condition with referring to a set of preset regulation parameters; thereby providing the air conditioning equipment with proper regulation and control to operate in preset conditions, and further achieving objective of energy management of the air conditioning equipment.

Owner:CHUNGHWA TELECOM CO LTD

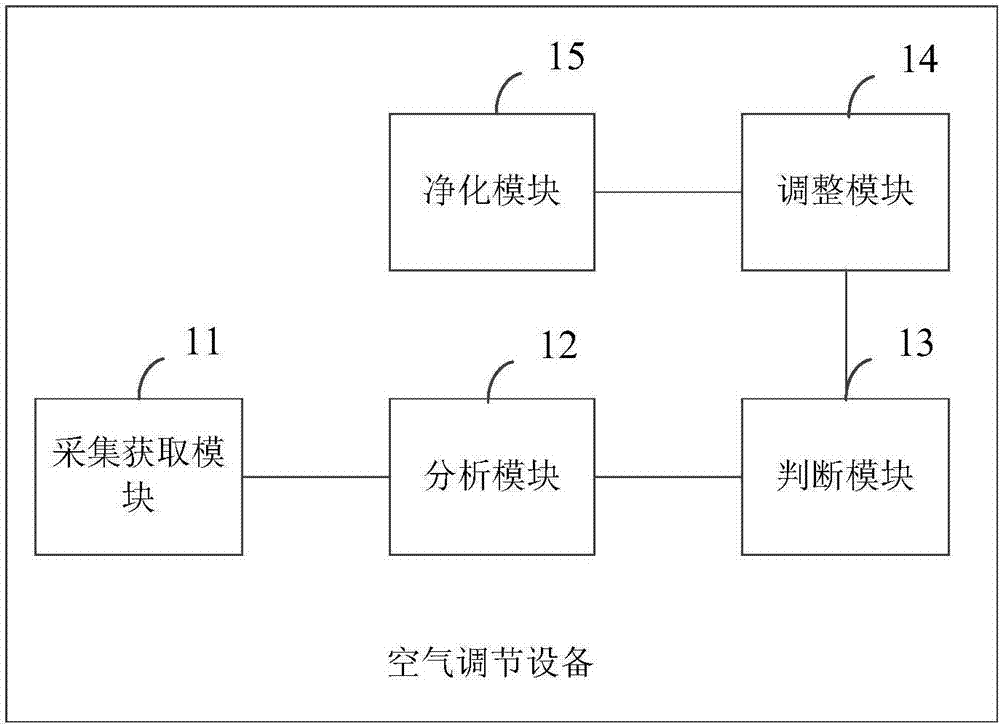

Controlling method for air conditioning equipment, air conditioning equipment and air conditioner device

InactiveCN107355940ASpace heating and ventilation safety systemsLighting and heating apparatusCrowdsEngineering

The invention provides a controlling method for air conditioning equipment, air conditioning equipment and an air conditioner device. The controlling method for the air conditioning equipment comprises the steps that air data of current environment is acquired through a plurality of sensors which are arranged on the air conditioning equipment; pollutant composition and the concentration of each pollutant in the air data are analyzed; whether the concentration of various pollutants exceeds the set threshold or not is judged; if one or more pollutant concentrations exceeds the set threshold, the condition that the current air quality is harmful to a crowd is judged; and adjusting parameters of the air conditioning equipment are adjusted to purify the air according to the adjusted parameters. Therefore, according to the controlling method for the air conditioning equipment, the air quality of the current environment can be improved when the air quality of the current environment is harmful to the crowd, using is convenient for a user, and user experience is enhanced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

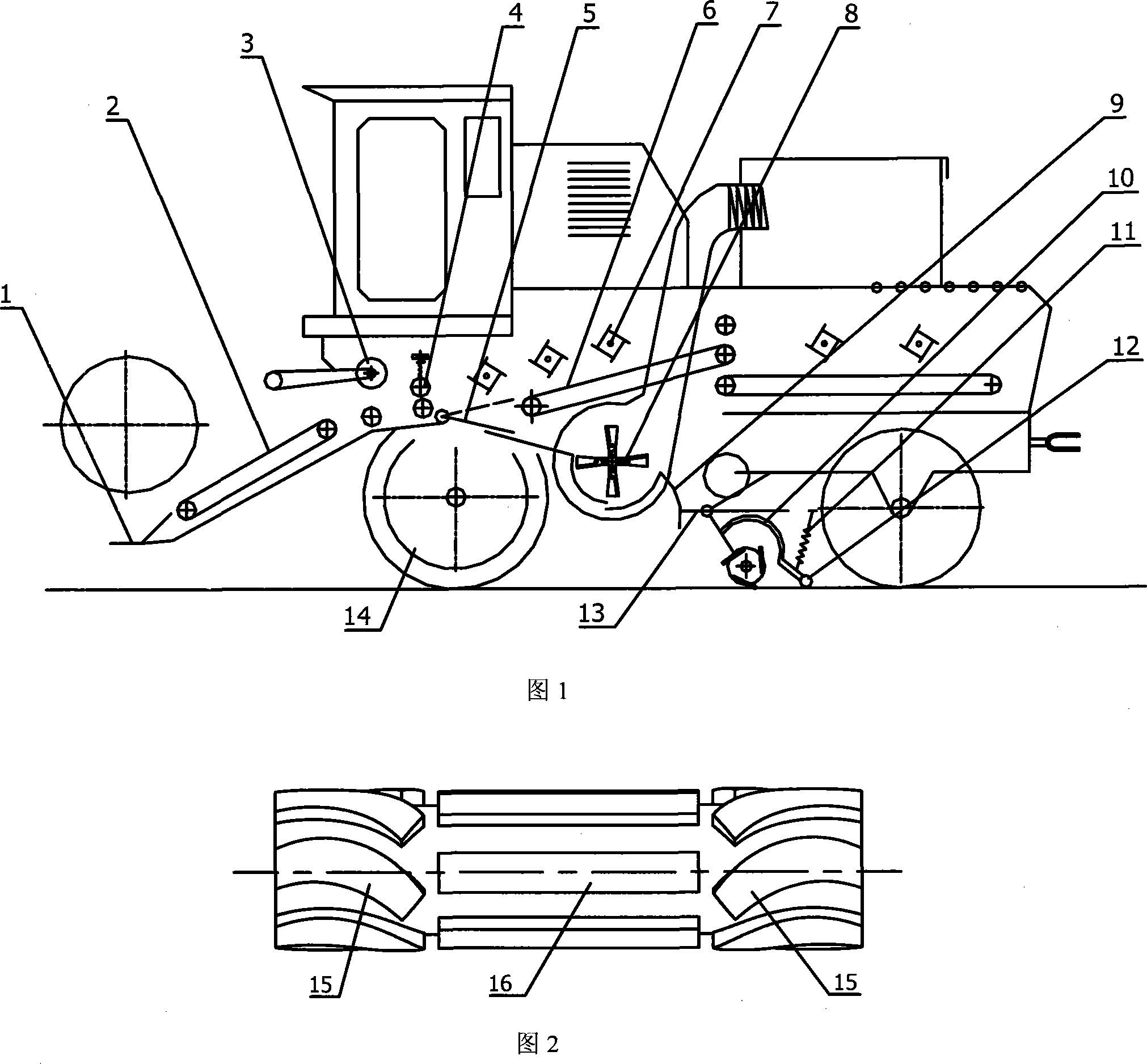

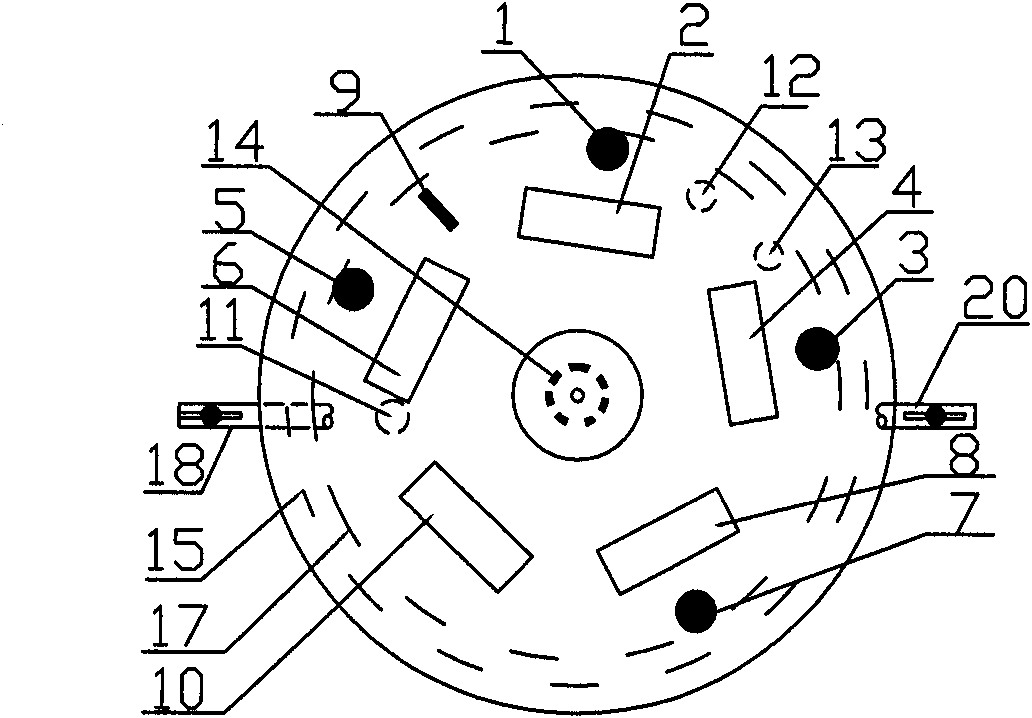

Conditioning equipment for selectively harvesting corn stalk

The invention provides a dedicated maize straw selecting and harvesting conditioner. The whole machine comprises a header, a flattening device, a shredding device, a flattening straw conveying device, a root stubble breaking device, a flattening straw guide valve, a shredded straw flow valve and a self-propelled chassis. The header is connected with the inclined conveying device, and the upper shaft of the inclined conveying device is hinged to a frame. The header can swing around the upper shaft of the inclined conveying device so as to harvest different parts of the straw. The upper roller of a feeding roller and the upper rollers of flattening rollers are limited to float up and down by a guide slot spring, so that flattening rollers rotate oppositely to mill the straw. The front end of the flattening straw guide valve is hinged to the frame and can be swung to be regulated in position so as to guide the straw. When the flattening straw guide valve is shifted to an upper position, the flattening straw conveying device is revolved and an elastic plate type compressing wheel performs the rotating compression so as to deliver the flattened straw out of the machine to be dried in a strip shape for the preparation of briquetted compressed dry feed or briquetted fuel. When the flattening straw guide valve is shifted to a lower position, the shredding device is rotated at a high speed for shredding and polishing the straw. Shredded stalks flow toward a shell hinged to the upper end of the shredding device. The shredded straw flow valve opens or closes to send the crushed straw to be ensiled or returned. The front end of the support of the root stubble breaking device is hinged to the frame. A toddy roller arranged at the tail end of the support is contacted with the ground to cope the ground. A pressure spring is arranged between the tail part of the support and the frame and is used for realizing the adjustment of the downward pressure of a root system breaking knife roller.

Owner:HEBEI AGRICULTURAL UNIV.

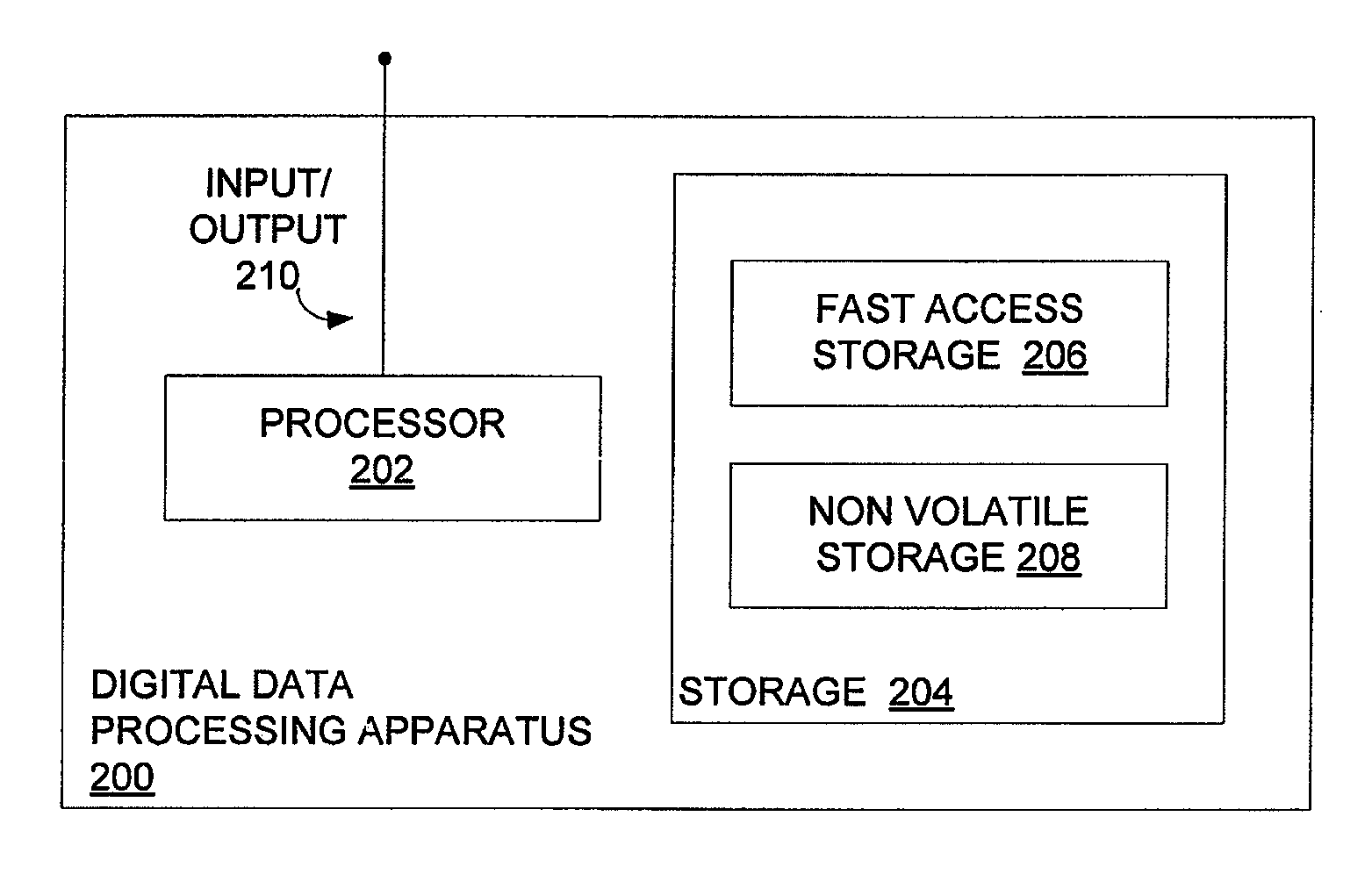

Front access enclosure

InactiveUS20090161322A1Improve concealmentQuickly and efficiently neatenDigital data processing detailsElectrical apparatus contructional detailsEngineeringAmplifier

An enclosure and method of construction for use with electronic devices such as computers, amplifiers, switching systems, receivers, video monitors, and televisions, allows a user to access virtually all connector ports on a given piece of equipment from the front of the equipment by displacing a moveable front accessible control panel which supports control mechanisms by which to regulate the equipment. The ideal enclosure may be elevated on adjustable feet such that connector cables from connected peripheral devices may be routed beneath the enclosure to corresponding connector ports at the front of the enclosure. Alternatively, the enclosure may include one or more channels through which connector cables may be passed for greater concealment. Channels may be fixed, may include moveable panels for greater access, or may be completely removable for more easily accessing internal components of the enclosure.

Owner:HUGHES ROBERT M

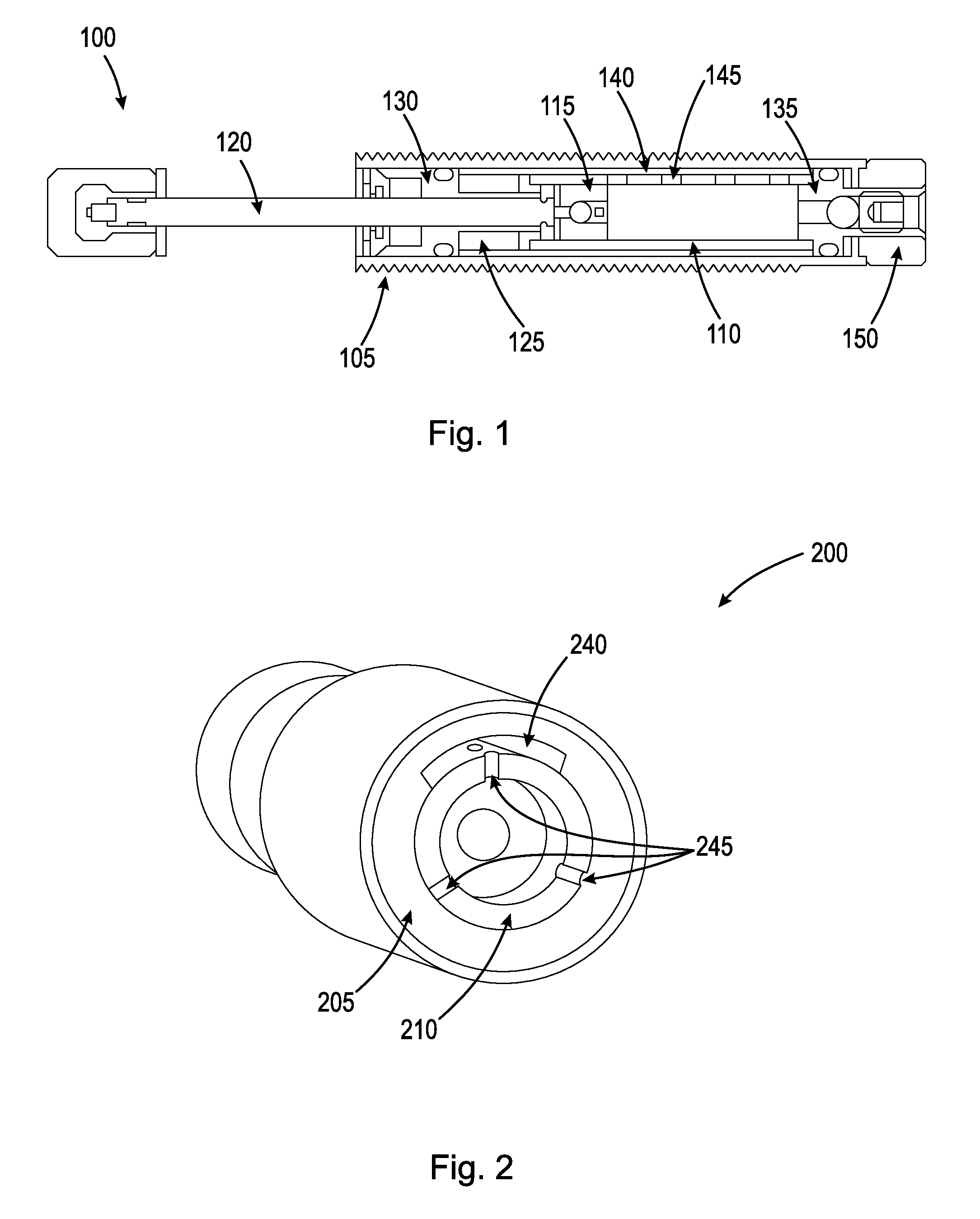

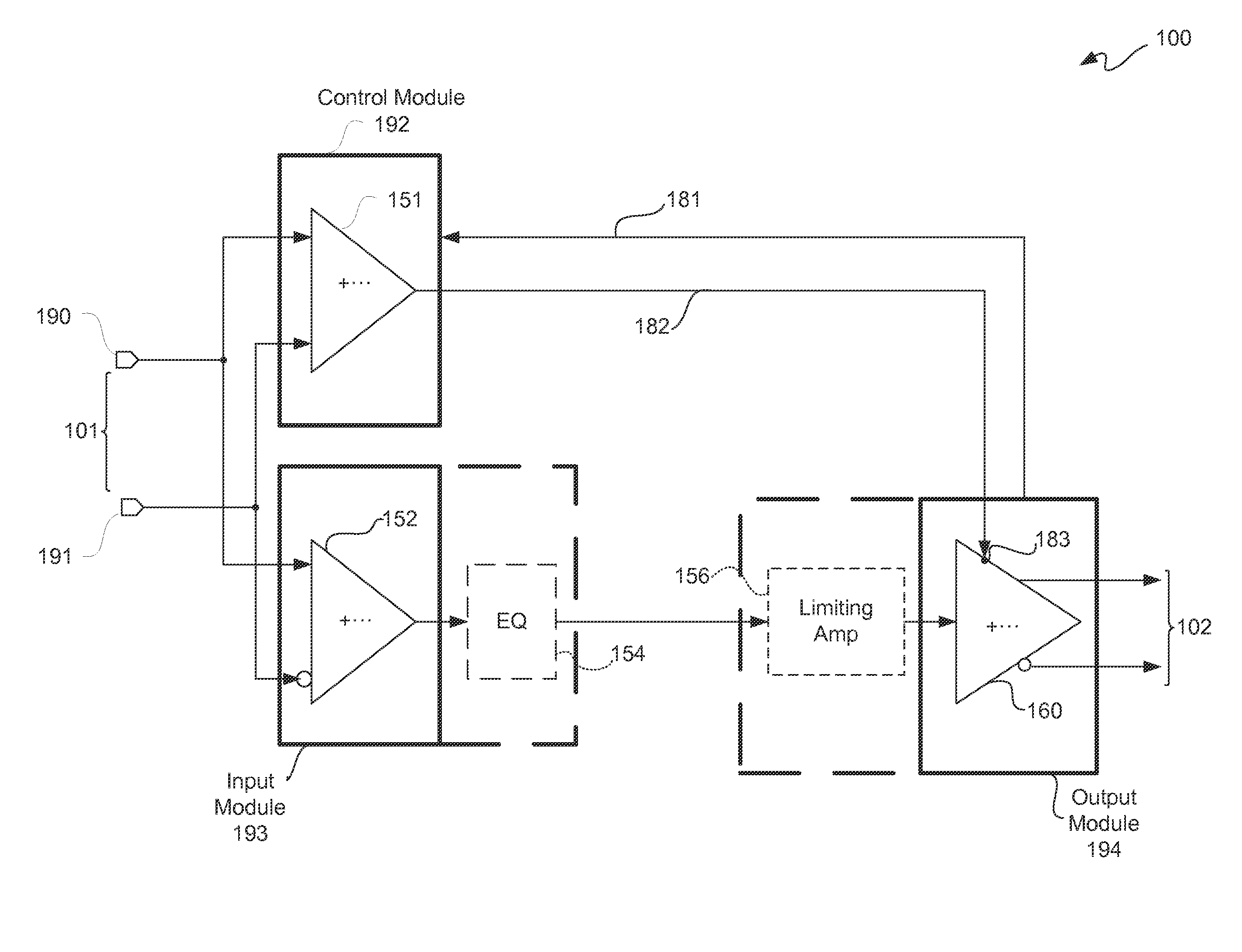

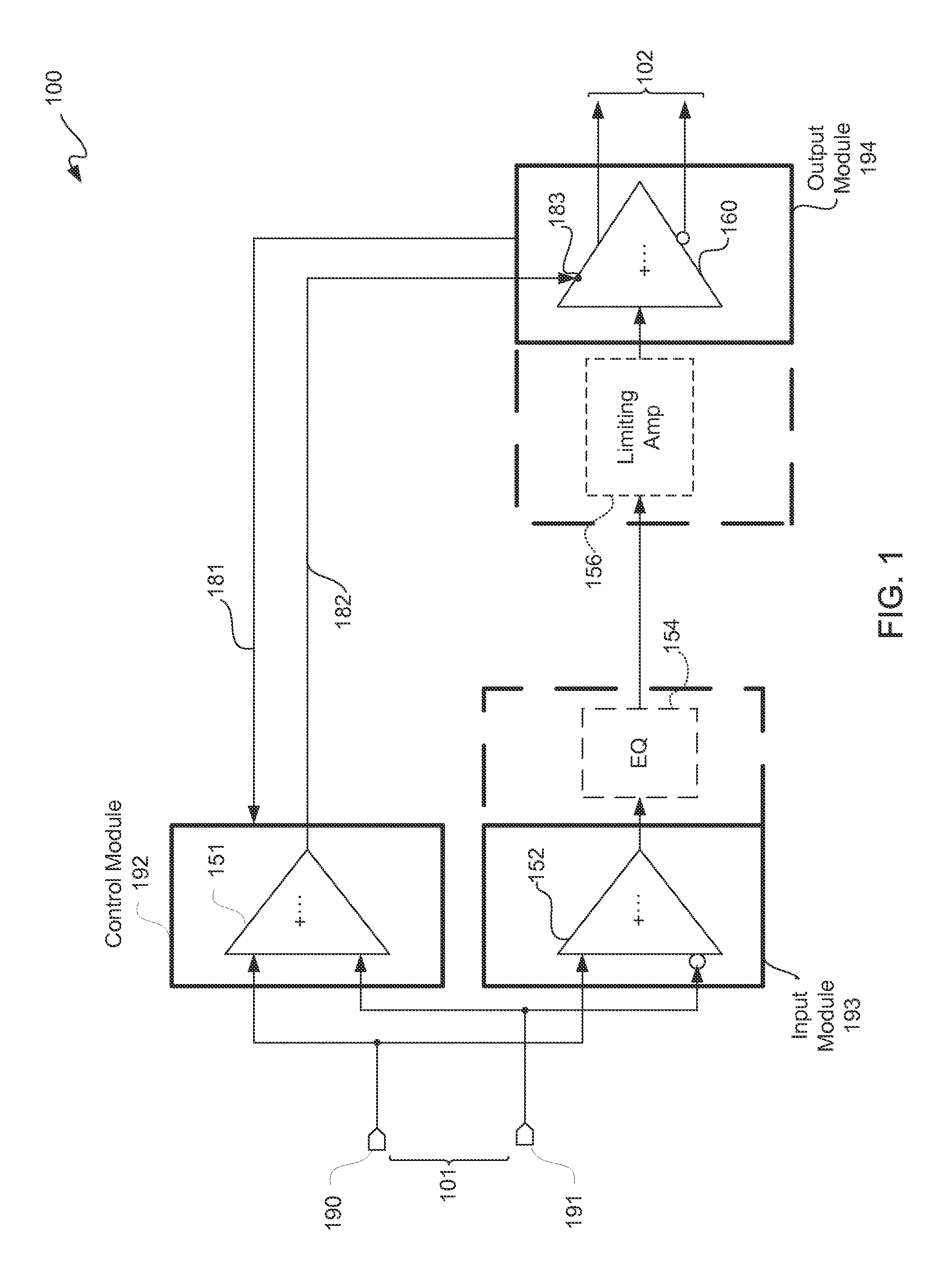

Intermediary signal conditioning device with interruptible detection mode

Disclosed are embodiments for an intermediary signal conditioning device with an input adaptable detection mode. In one embodiment, an intermediary signal conditioning device has a control module, an input module, and an output module. The input module and the control module are for receiving an input signal. The control module is configured to interrupt the output module within a duration of time to allow at least a minimum pulse length of the input signal to be output as an output signal from the output module. The intermediary signal conditioning device is configured to condition the input signal for retransmission as the output signal.

Owner:DIODES INC

Three-dimensional electrode/ electro-Fenton reactor

InactiveCN101844822AWell mixedNo dead endsWater/sewage treatment by oxidationWastewaterThree dimensional electrode

The invention discloses a three-dimensional electrode / electro-Fenton reactor, relating to a water treatment reactor. The reactor comprises a main reaction tank and a footstock. The whole reactor is round, and the footstock is provided with a DC voltage-stabilized power supply, mixing equipment, an indicating meter, an aerator, pH conditioning equipment and a pH detector; an water inlet, a pH probe, an acid adding tube and an alkali adding tube are arranged on the upper part of the main reaction tank; the main reaction tank is provided with an anode and a cathode; the mixing equipment passes through the inside of cathode; a water outlet, a round aeration disk and a mud disposal port are arranged on the lower of the main reaction tank; the aeration disk is arranged on the lower part of the water outlet; and the mud disposal port is arranged at the bottom of the reactor. The reactor is provided with a net-like annular anode and a hollow columnar cathode, and adopts round design to cause material in the reactor to be evenly mixed without the blind angle; in addition, the reactor has high electrolytic efficiency and can treat organic waste water which is hard to be degraded.

Owner:SHENYANG JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com