On-line analysing-monitoring system for heat-engine plant pipeline heat-efficiency

A monitoring system and thermal efficiency technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as blanks, and achieve the effect of high calculation speed and accuracy, novel technical route, simple and fast heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

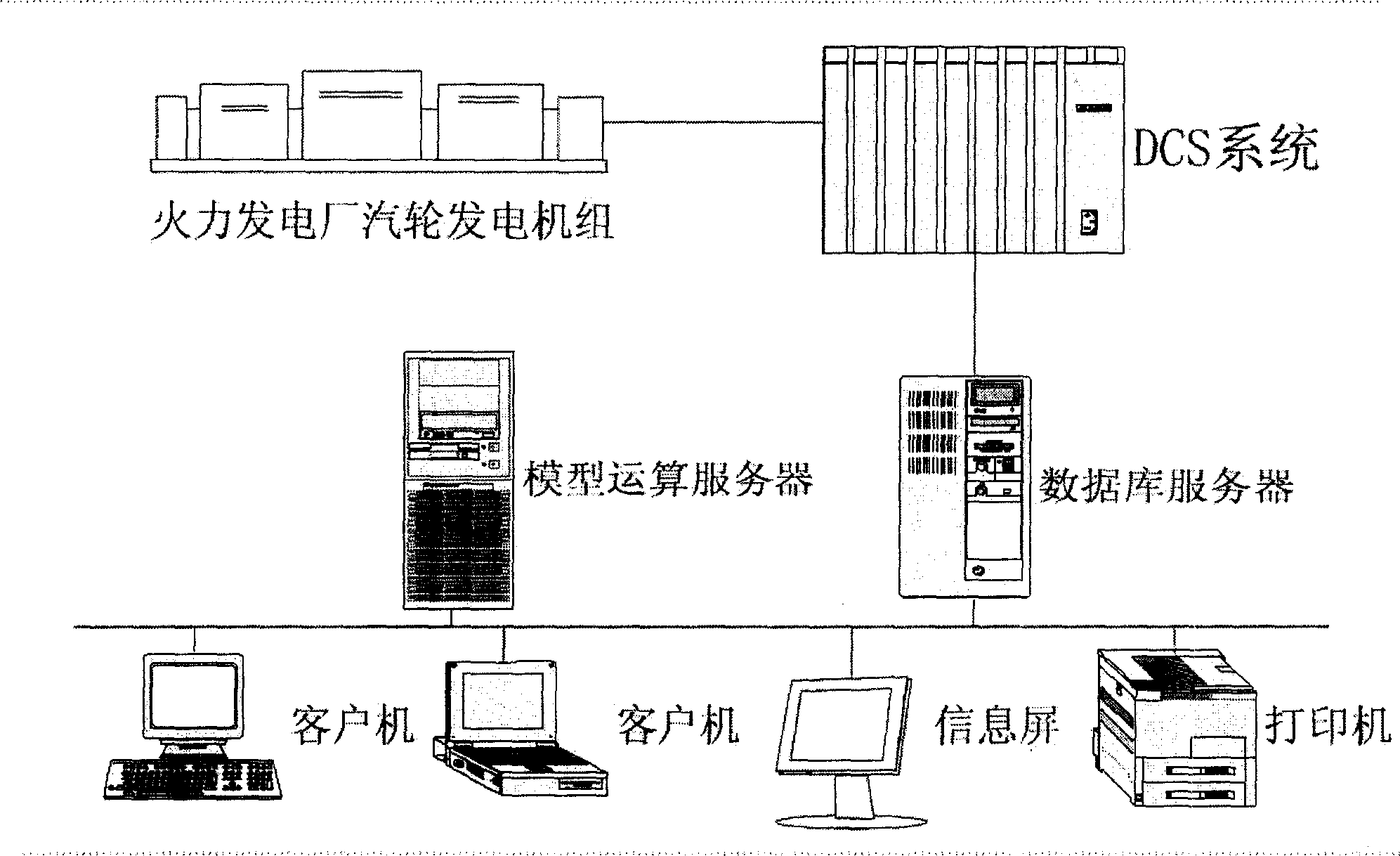

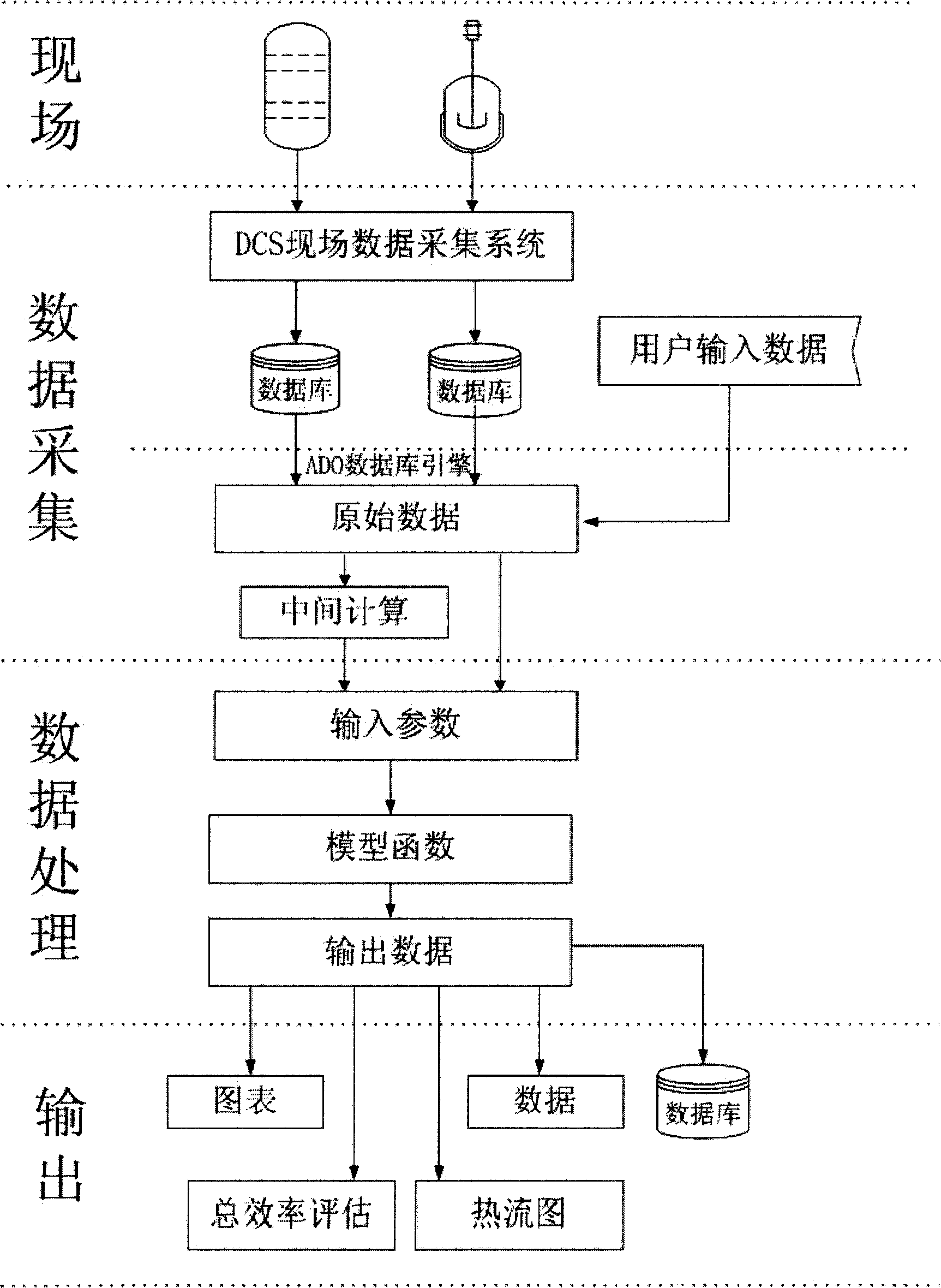

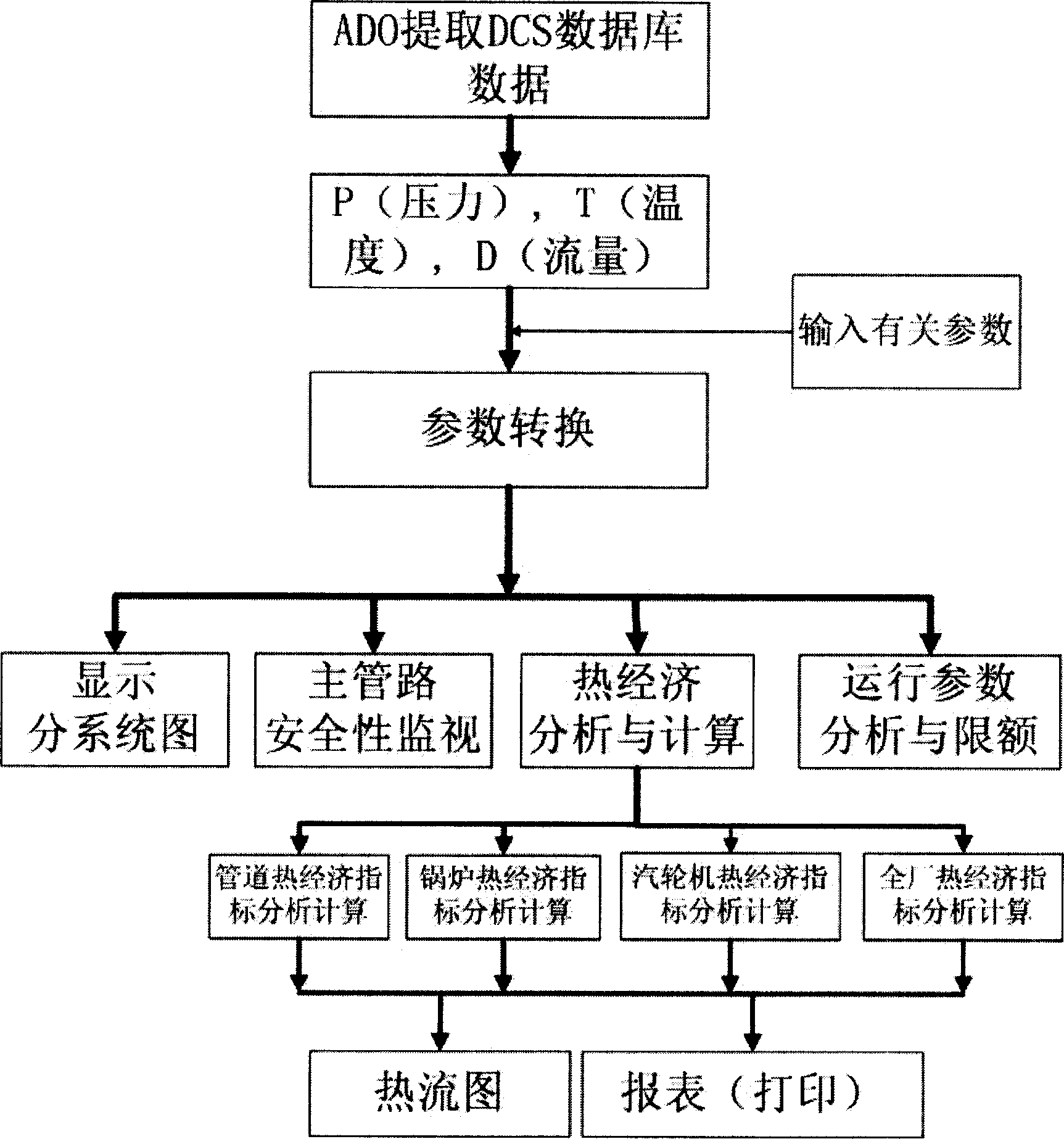

[0027] A best embodiment of the present invention, the on-line analysis and monitoring system for thermal efficiency of pipelines in thermal power plants consists of a hardware system and a software system. System operation process description:

[0028] On-site data acquisition system (DCS system, collecting physical parameters related to soda water parameters) --> stored in the DCS database server or a dedicated database server (raw data storage database) --> extracted by the model computing server through the ADO database engine (output Relevant data) --> carry out necessary conversion and intermediate calculation (conversion of measurable parameters and calculation parameters, necessary unit conversion) --> obtain input data required by the model (conversion of calculation parameters and its sequence) --> Substituting into the model for calculation and analysis (through (1) ~ (8) to calculate the heat loss of the pipeline and related thermal economic indicators, etc.) --> o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com