Waste heat recovery system of phase change heat exchanger in thermal power generation enterprise

A technology of waste heat recovery system and phase change heat exchanger, which is applied in indirect heat exchangers, lighting and heating equipment, combustion product treatment, etc. Emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples.

[0017] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

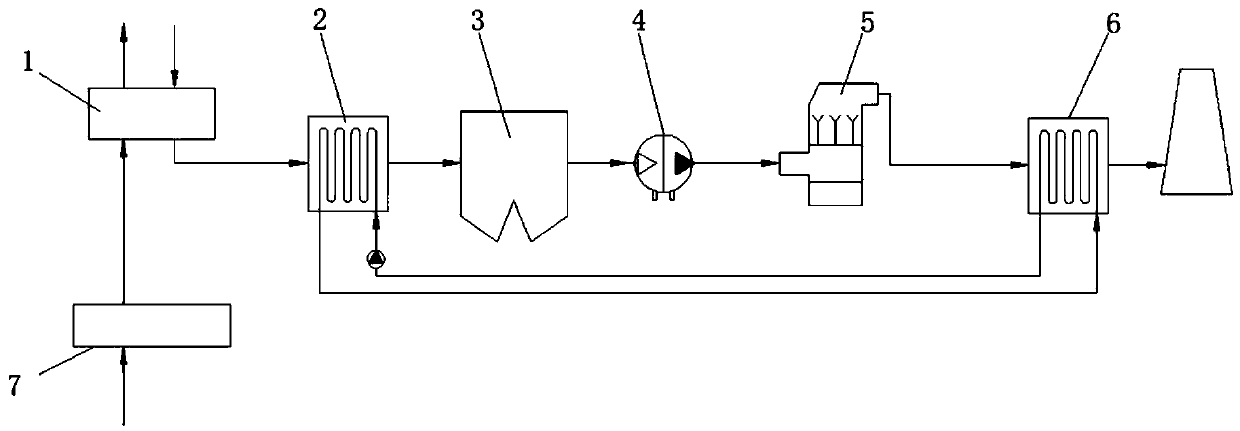

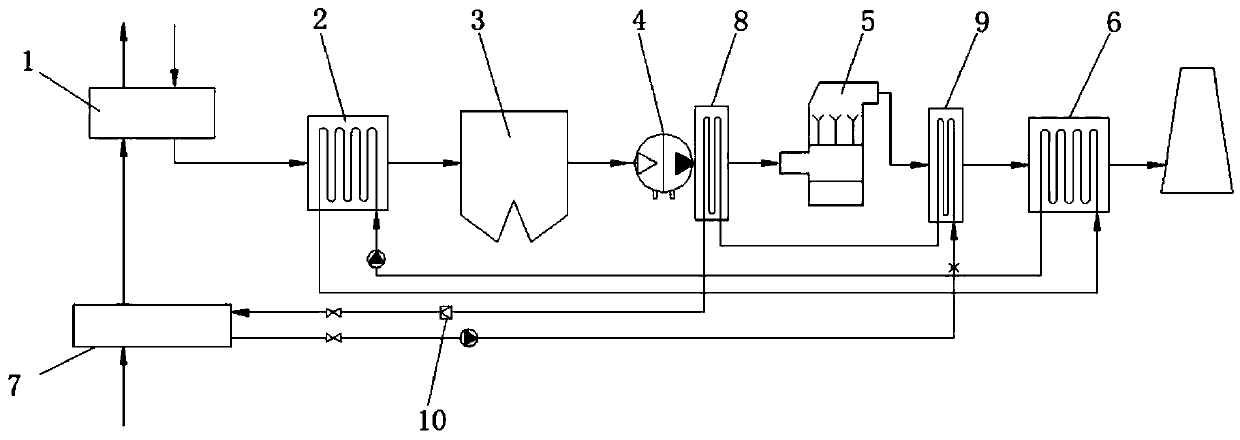

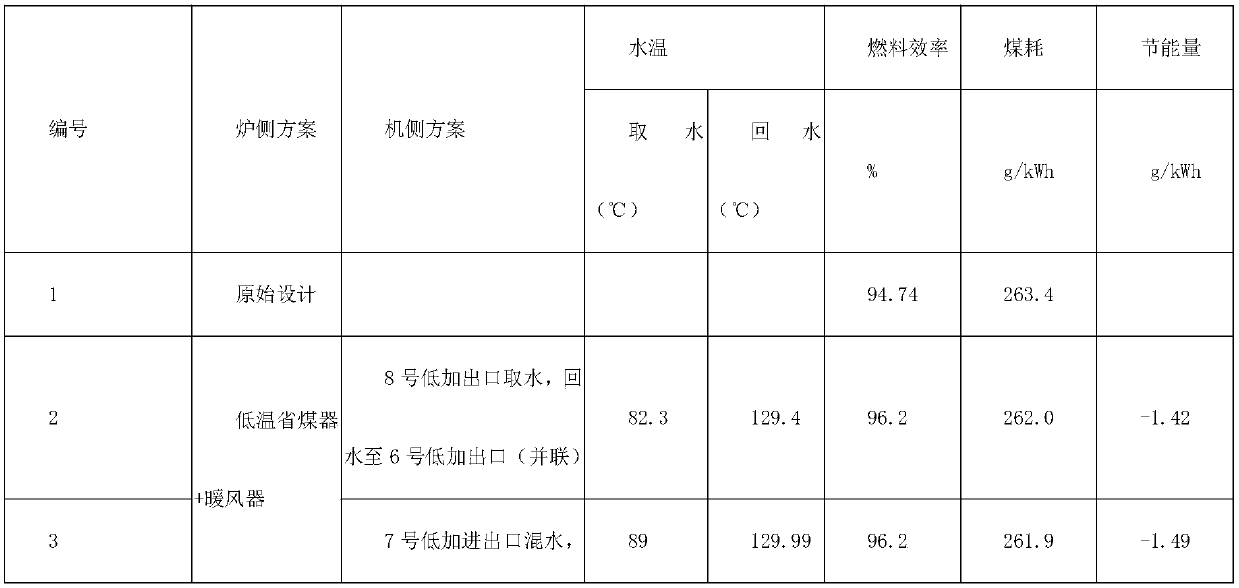

[0018] see Figure 1-2 , the present invention provides a technical solution: a waste heat recovery system of a phase change heat exchanger in a thermal power generation enterprise, the waste heat recovery system includes an air preheater 1, a dust collector 3, an induced draft fan 4, a desulfurization tower 5 and a heater 7, Air preheater 1, dust collector 3, induced draft fan 4 and desulfurization tower 5 are connected through pipelines in sequence, the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com