A flue gas purification system

A flue gas purification system and flue gas technology are applied in air quality improvement, chemical instruments and methods, dispersed particle separation, etc., and can solve the problems of large demand for ammonia water, large amount of fly ash, visual pollution of white smoke, etc. Simple, remove water vapor visual pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

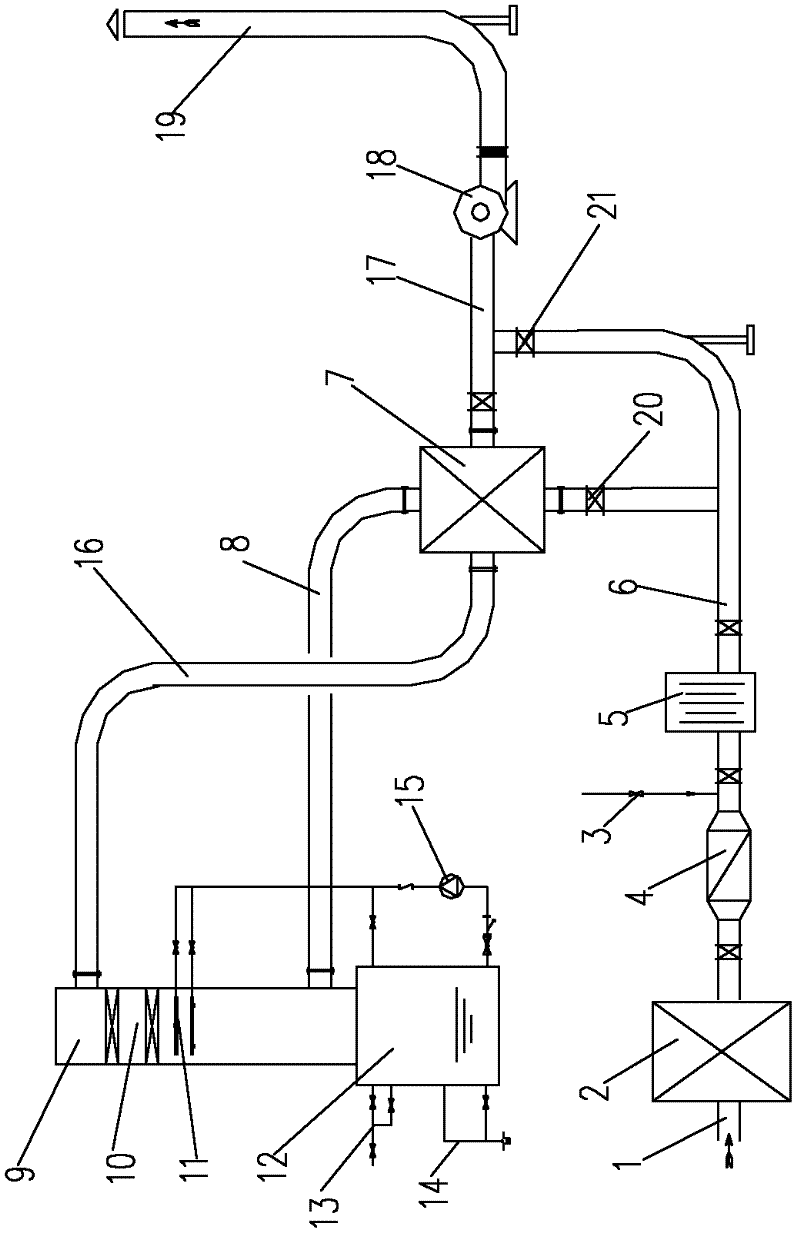

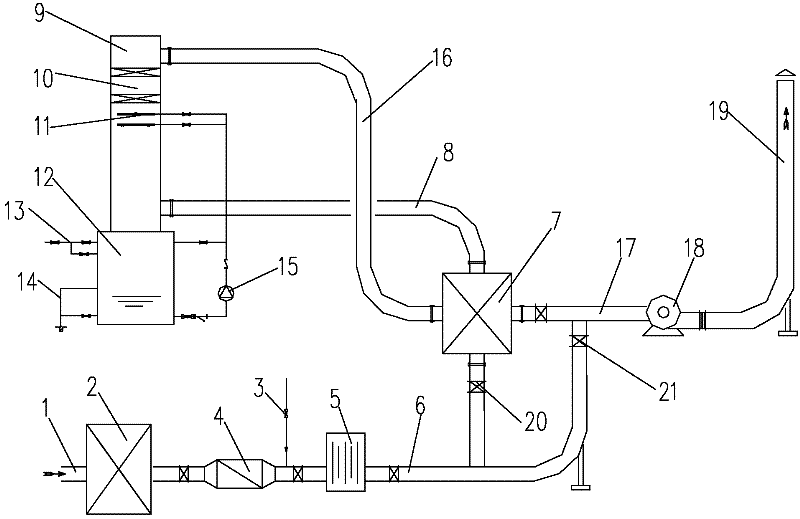

[0029] Example 1, such as figure 1 As shown, a flue gas purification system includes a dust collector 2 installed at the inlet of flue gas 1 after dry and semi-dry deacidification, an induced draft fan 18 and a smoke exhaust chimney 19 . Between the described deduster 2 and the induced draft fan 18, the ammonia injection device 3 for denitrification is set in sequence through the flue, the catalytic reactor 5 for removing dioxin and nitrogen oxides, the reaction of deacidification and white smoke elimination Tower 9; the reaction tower 9 is a washing tower, including a water tank 12 arranged at the bottom of the tower body, a secondary side low-temperature flue 16 for entering flue gas on the tower body, and a secondary side high-temperature flue gas outlet for flue gas at the upper part of the tower body. A flue 17; at least one set of spraying device 11 is arranged on the upper part of the tower body; a filler 10 (such as stone) that absorbs heat and blocks water smoke is al...

Embodiment 2

[0031] Embodiment 2, on the basis of the technical solution of Embodiment 1, in order to increase the exhaust gas temperature and facilitate the catalytic reaction of the flue gas, a heater 4 for flue gas is also arranged between the dust collector 2 and the ammonia injection device 3 . All the other are with embodiment 1. A particularly preferred flue gas heater is an electric heater.

Embodiment 3

[0032] Embodiment 3, on the basis of the technical scheme of embodiment 1 or 2, in order to reduce the temperature of the flue gas entering the reaction tower 9, an isolated double-smoke-smoke heat exchange is set between the catalytic reactor 5 and the reaction tower 9 device 7; the primary high-temperature flue 6 at the outlet of the catalytic reactor 5 is connected to the primary low-temperature flue 8 connected to the reaction tower 9 through the first valve 20 and the isolated double-smoke-smoke heat exchanger 7 . Further, the low-temperature flue 18 on the secondary side connected to the reaction tower is connected to the high-temperature flue 17 on the secondary side through the isolated double-smoke-smoke heat exchanger 7 . All the other are with embodiment 1 or 2. The inner wall of the smoke-smoke heat exchanger is treated with anti-corrosion treatment (such as setting ceramic materials) to prevent low-temperature corrosion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com