Method for preparing composite coating by using preset piece method to conduct laser multi-layer cladding

A multi-layer cladding and composite coating technology, which is applied in the coating, metal material coating process, etc., can solve the problem that the cladding layer cannot be prepared continuously, the cladding defects of the previous layer cannot be solved, and the pre-coating process cannot be controlled. Solve problems such as powder thickness to achieve the effect of low cost, high efficiency and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

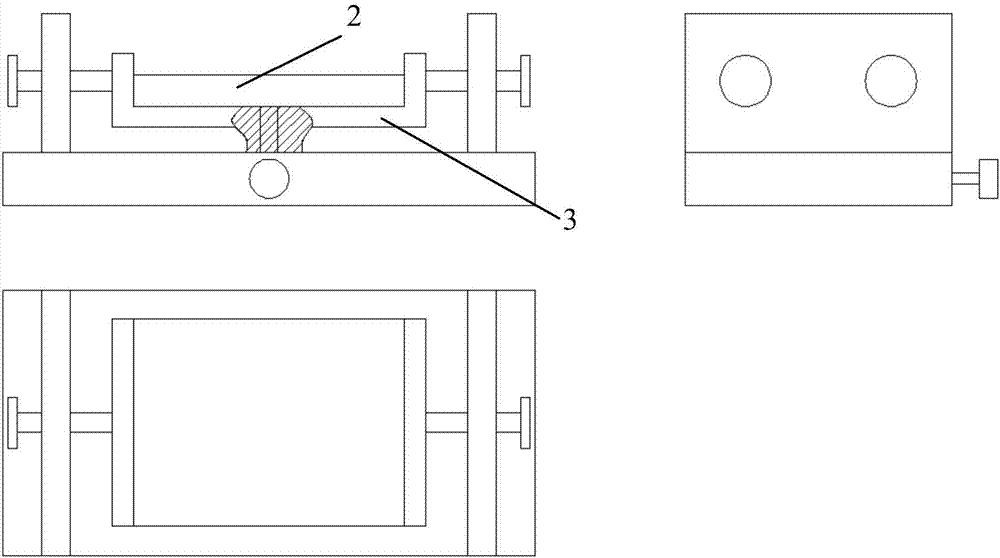

[0038] The schematic diagram of the jig for making the preset sheet in the embodiment is as follows figure 1 shown.

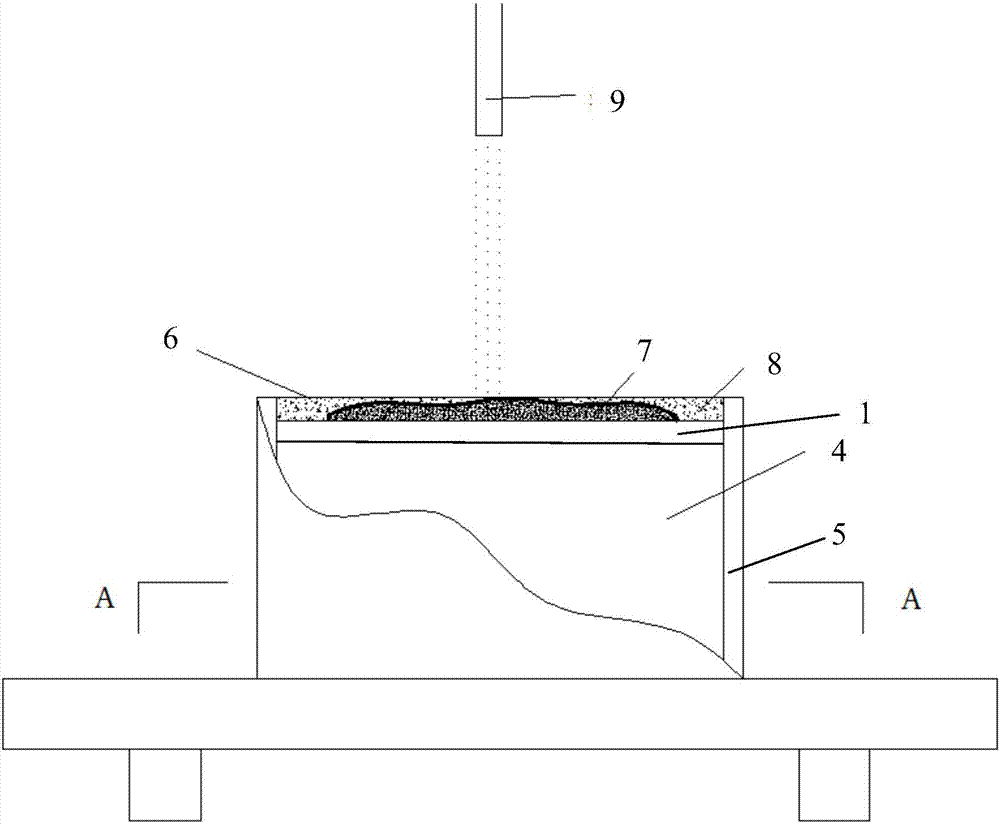

[0039] The schematic diagram of replenishing powder in the embodiment is as figure 2 , image 3 shown.

[0040] A method for preparing a composite coating by laser multi-layer cladding with a preset chip method, comprising the steps of:

[0041] A. Pretreat the surface of the base material 1, clean off the rust, grease and dust on the surface of the workpiece, and dry it; first, use sandpaper to polish the surface of the base material 1 to remove oxidation or rust spots on the surface of the base material 1; then, use alcohol Clean the surface of the substrate 1 to remove surface dust. After the above two pretreatments, a clean and clean surface of the substrate 1 can be obtained.

[0042] B. Powder treatment: put the powder to be made into a pre-set in a vacuum drying oven, dry it at 80°C for 24 hours, spread it flat on the fixture groove plate 3 covered...

Embodiment 2

[0070] A method for preparing a composite coating by laser multi-layer cladding with a preset chip method, comprising the steps of:

[0071] A total of 100g of tin bronze powder with a volume fraction of 85% and 400 meshes and a total of 100g of spherical graphite powder with a volume fraction of 15% and 200 meshes were evenly mixed to prepare a 2mm thick preset sheet; then, the surface of the cladding substrate 1 was pretreated to obtain a clean and a clean surface; finally, place the preset sheet 2 on the substrate 1 for laser cladding, and keep the vertical distance between the cladding layer 7 and the laser head 9 unchanged for each cladding, and if a certain layer of cladding layer is uneven , make powder replenishment to make it flat before proceeding to the next layer of cladding. The laser head is a semiconductor laser head, 8 layers of cladding for each layer, 12 layers of cladding, laser power of 1100W, spot diameter of 2.2mm, overlapping rate of 50%, and scanning sp...

Embodiment 3

[0073] A method for preparing a composite coating by laser multi-layer cladding with a preset chip method, comprising the steps of:

[0074] 5g of carbon fiber, 20g of silicon carbide powder of 200 mesh, and 80g of nickel powder of 200 mesh are used to prepare a 1mm thick preset sheet; then, the surface of the cladding substrate 1 is pretreated to obtain a clean and clean surface; finally, the preset sheet 2. Place it on the base material 1 for laser cladding. Keep the vertical distance between the cladding layer 7 and the laser head 9 unchanged for each cladding. If a certain layer of cladding layer 7 is uneven, add powder to make it smooth Then proceed to the next layer of cladding. The laser head is a semiconductor laser head, 8 layers of cladding for each layer, 10 layers of cladding, laser power of 1000W, spot diameter of 2.2mm, overlapping rate of 50%, and scanning speed of 500mm / min. The surface of the obtained coating is smooth, the thickness of the coating is 8.5 mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com