Dye sensitized solar cell and preparation method thereof

A solar cell and dye sensitization technology, applied in the field of solar cells and their preparation, can solve problems affecting installation, use, and hindering the industrialization of DSC, and achieve the effects of reducing self-weight, reducing the risk of short circuit, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1, liquid single substrate dye-sensitized solar cell

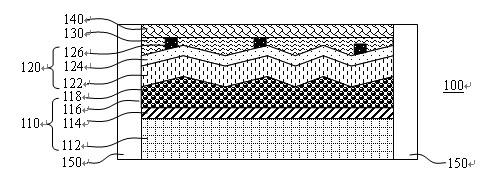

[0030] figure 1 is a schematic cross-sectional structure diagram of a liquid single-substrate dye-sensitized solar cell 100 . refer to figure 1 , the liquid single-substrate dye-sensitized solar cell 100 includes a photoanode 110 , a counter electrode 120 , a liquid electrolyte 130 , and an encapsulation shell. The photoanode 110, the counter electrode 120 and the liquid electrolyte 130 are all packaged in the encapsulation shell. The encapsulation shell includes a cover glass 140 and an encapsulation material 150 , wherein the cover glass 140 is placed on the counter electrode 120 , and the encapsulation material 150 encapsulates the photoanode 110 and the counter electrode 120 in its entirety.

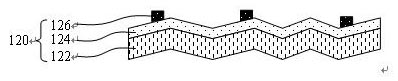

[0031] refer to figure 2 , the photoanode 110 includes a transparent conductive substrate 112, a transparent conductive film 114 deposited on the surface of the transparent conductive substrate 112, and a poro...

Embodiment 2

[0045] Example 2, quasi-solid-state single-substrate dye-sensitized solar cell

[0046] Figure 5 is a schematic cross-sectional structure diagram of a quasi-solid-state single-substrate dye-sensitized solar cell 200 . The same content as in Example 1 will not be repeated here. The quasi-solid single-substrate dye-sensitized solar cell 200 is composed of a photoanode 110 , a counter electrode 120 , a quasi-solid electrolyte 230 , and an encapsulation shell 150 .

[0047] refer to Figure 5 and Figure 8 , the quasi-solid electrolyte 230 shown in the figure actually does not just exist above the counter electrode 120, but completely wets the entire counter electrode 120, and completely fills the entire space between the photoanode 110 and the encapsulation material 150. space.

[0048] The quasi-solid electrolyte 230 is a quasi-solid redox electrolyte. In this embodiment, the preferred composition of the quasi-solid electrolyte 230 is 0.6M 1-propyl-3 methylimidazolium iodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com