Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

213 results about "Spiral heat exchanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

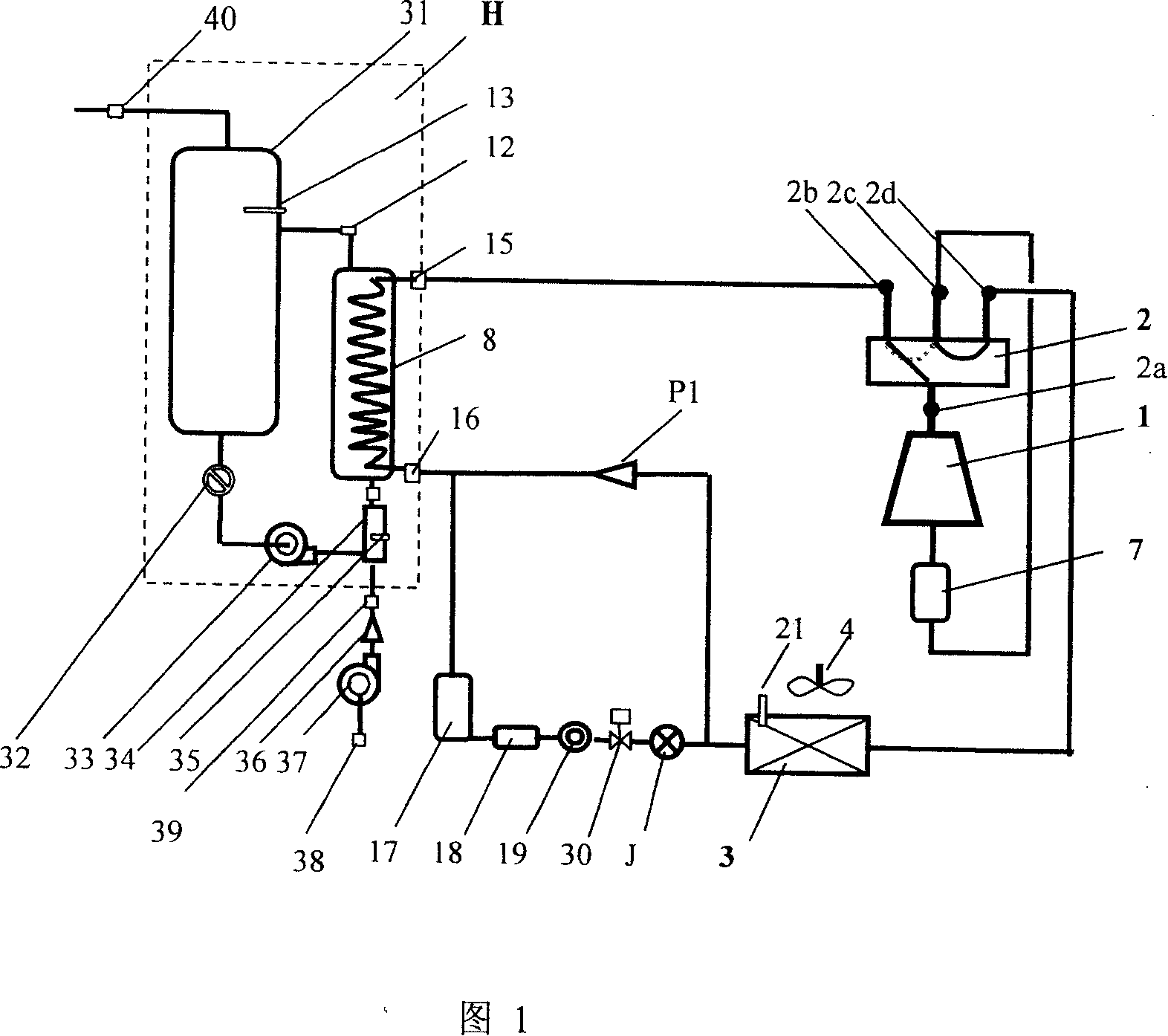

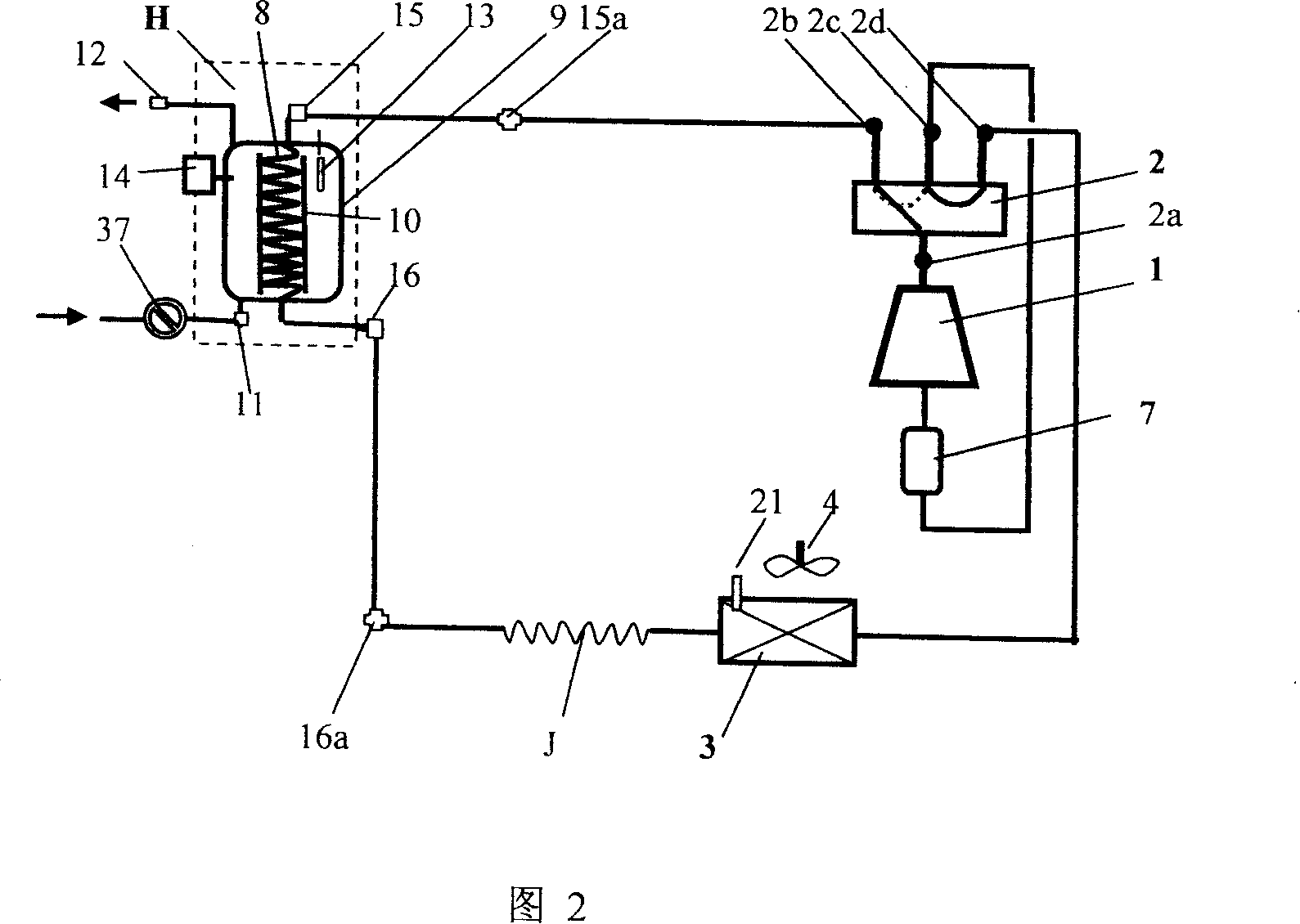

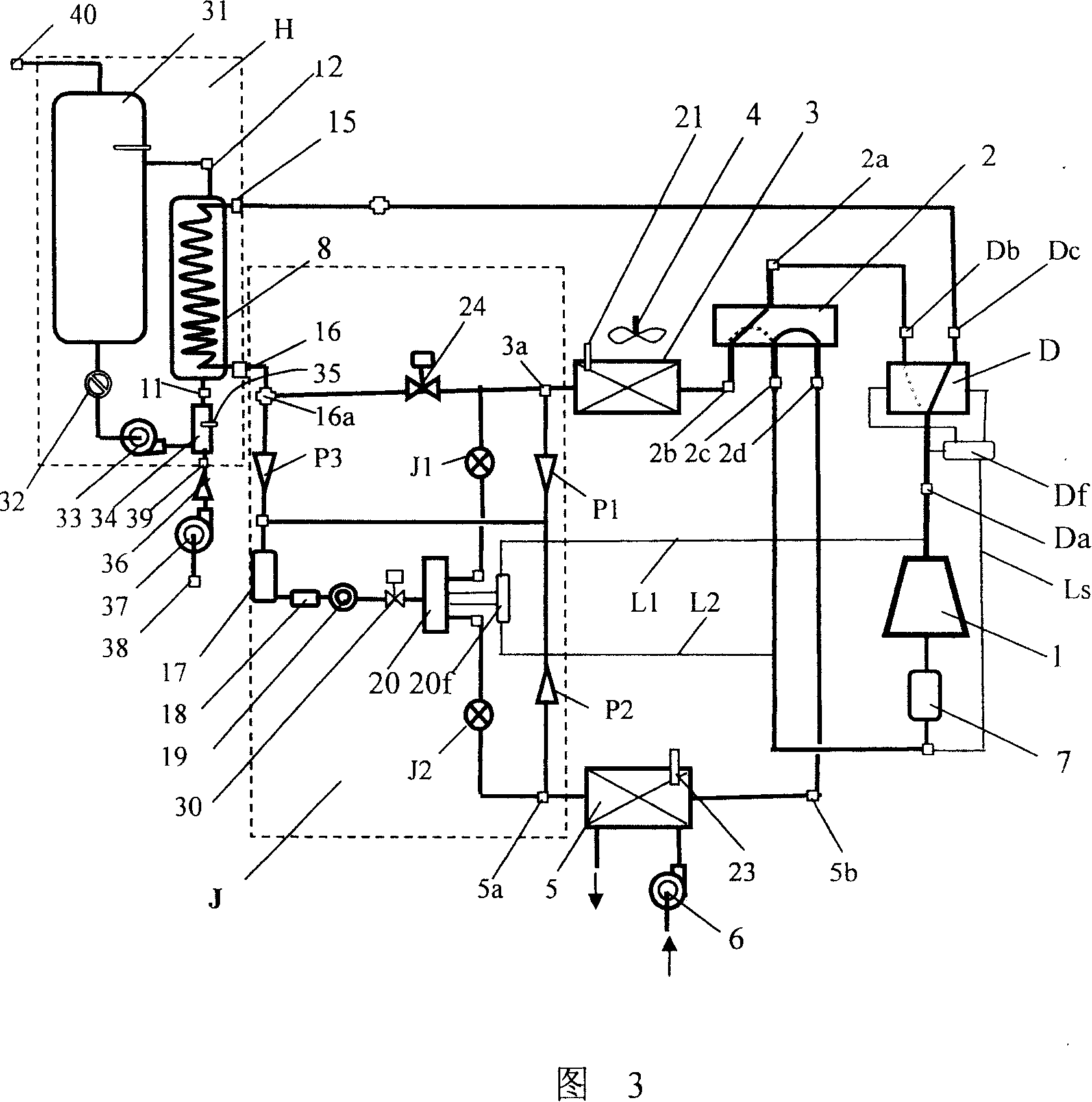

Heat pump hot water machine set of water-containing internal circulation heat-exchanging loop

ActiveCN101078580ASolve defrosting problemsHeat pumpsHeating and refrigeration combinationsFour-way valveWater cycling

The invention relates to a heat pump hot water unit with in-water cycling heat exchanging loop, comprising refrigerant loop system, water-refrigerant heat exchanging system, signal collection and circuit control system. It is characterized in that the water-refrigerant heat exchanging system adopts forced internal-cycling loop constituted by water-refrigerant heat exchanger, reflux tube and internal-cycling pump or natural internal-cycling loop which uses diversion sleeve to separate spiral heat exchanger in heat storing water tank and water pre-heating device can be collocated; the refrigerant loop system has single cycling of single air heat source, independent cycling of double heat source with four functions and adopts the structure of three-way electromagnetic valve with pneumatic valve, four-way valve and multiple-path restrictor so as to make switch of all cycles convenient; wind-cold heat exchanger also has water fin tube. The unit efficiency of invention is high and defrosting in winter is complete. Pressure can not be overloaded in summer. Hot water in 55deg.C can be supplied quickly and continuously. Waste heat can be reclaimed or solar hot water can be made use of. It can save energy by 70-85% compared with electric water heater in annual average. The independent cycling unit with double heat source has refrigeration, heating, heating water and heating water with refrigeration functions.

Owner:江苏恒信诺金科技股份有限公司

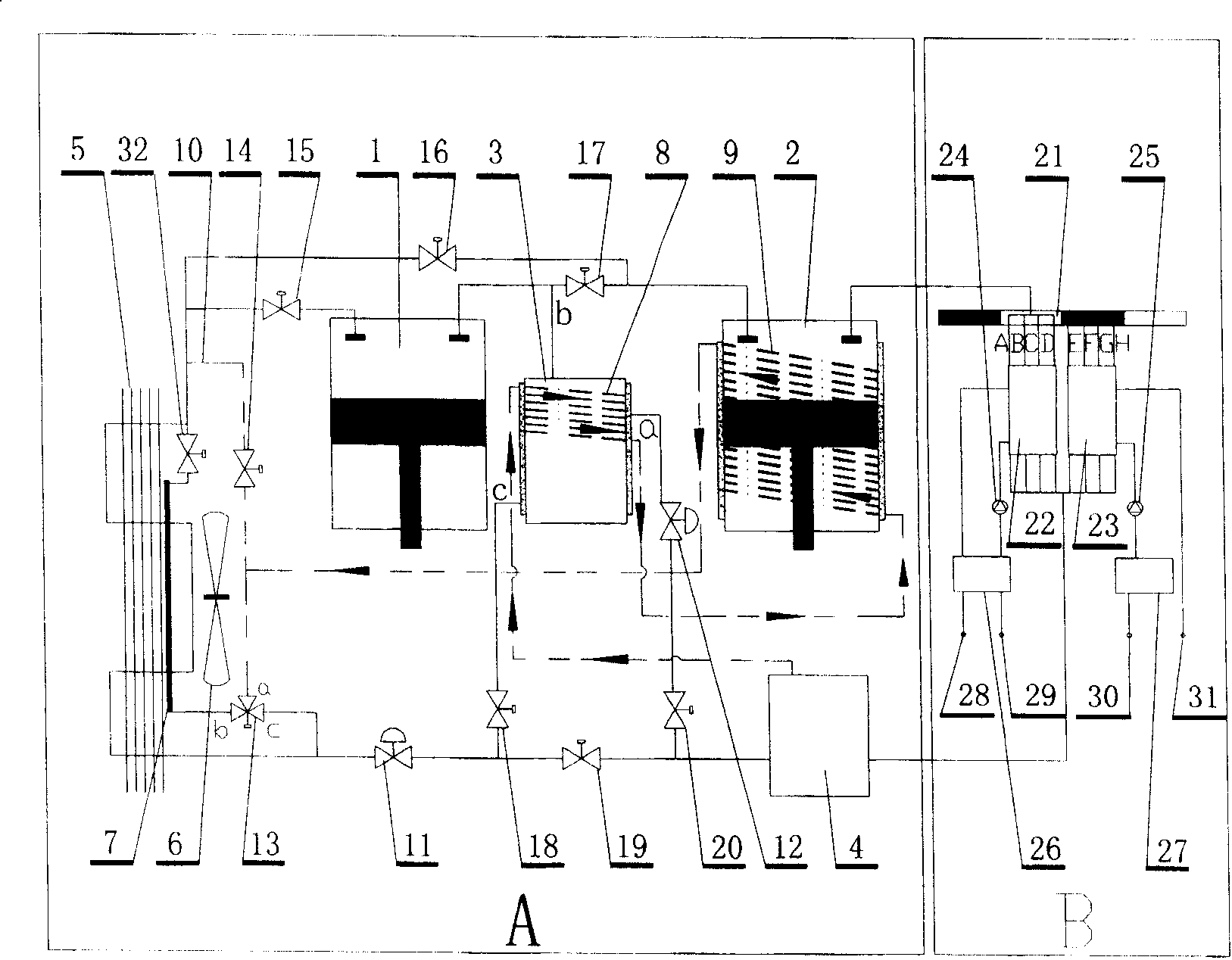

Domestic air source heat pump heating system and apparatus for coldness area

InactiveCN101457949ALower oil temperatureReduce exhaust temperatureHeat pumpsEnergy efficient heating/coolingBusiness efficiencyFlash-gas

The invention discloses a household air source heat pump heating system in cold area and a device thereof, and relates to a heat pump system which uses the air source for running steadily under the low-temperature environment and supplying the interior with the needed heat and healthy hot water and a device thereof. The device comprises parts such as a low pressure frequency compressor, a high pressure compressor, an outdoor heat exchanger, a flash evaporator, a reservoir, a defrosting coil, a flash gas overheating coil, a compressor heat radiating recovery coil, a low pressure air supply pressurization line, a sub-thermal converter, a multi-head efficient spiral heat exchanger, a thermal expansion valve, and the like, which are connected by a pipeline. The invention is characterized in that the system comprises a flash evaporator component, a flash gas overheating coil, a compressor heat radiating recovery coil, and a low pressure air supply pressurization line. When in heat operation under low-temperature working condition, based on the two-stage compression cycle which is incompletely cooled between two stages of throttles, the invention uses the flash gas overheating coil, the compressor heat radiating recovery coil, and the low pressure air supply pressurization line for recovering the heat radiating capacity of a compressor, realizes the overheating of the flash gaseous working substance, enhances the gas transmission capacity of the compressor, and further improves the heat and the energy efficiency ratio of a heat pump system. Meanwhile, the defrosting coil is added to the bottom part of the heat exchanger device, so the frosting problem of the outdoor heat exchanger of the heat pump is solved. The invention can realize the mutual switch among a single heating operating mode in winter, a heating and healthy hot water united operating mode in winter, and a healthy hot water single operating mode during a non-heating period.

Owner:DALIAN ZHONGXING TECH DEV

Collecting pipe structure for heat exchanger

ActiveCN101943539AHigh compressive strengthGive full play to the cooling effectHeat exchanger casingsEngineeringMechanical engineering

The invention discloses a collecting pipe structure for a heat exchanger. A positioning liner is arranged on an opposite side of an interface in an inner cavity of a collecting pipe; an inner end face of a radiating flat pipe is pressed against a positioning surface of the positioning liner; a plurality of ribs are arranged outside the positioning liner; the positioning liner is brazed and fixed on an inner surface of the collecting pipe through the external side faces of the ribs; the space between adjacent ribs forms a medium distribution microchannel; a plurality of medium distribution through holes are formed on the side wall of the positioning liner and are communicated with the medium distribution microchannel; and the number of the medium distribution through holes is reasonably designed so as to uniformly distribute the medium to flow through each flat pipe. The collecting pipe structure for the heat exchanger has the advantages of high positioning consistency of the flat pipe, contribution to uniformly distributing the medium to flow through each flat pipe, achieving the radiating effect of all flat pipes, improving the heat exchange efficiency of the heat exchanger, reducing the possibility that redundant melted solder corrodes products, and contributing to prolonging the service life of the products.

Owner:浙江新金宸机械有限公司

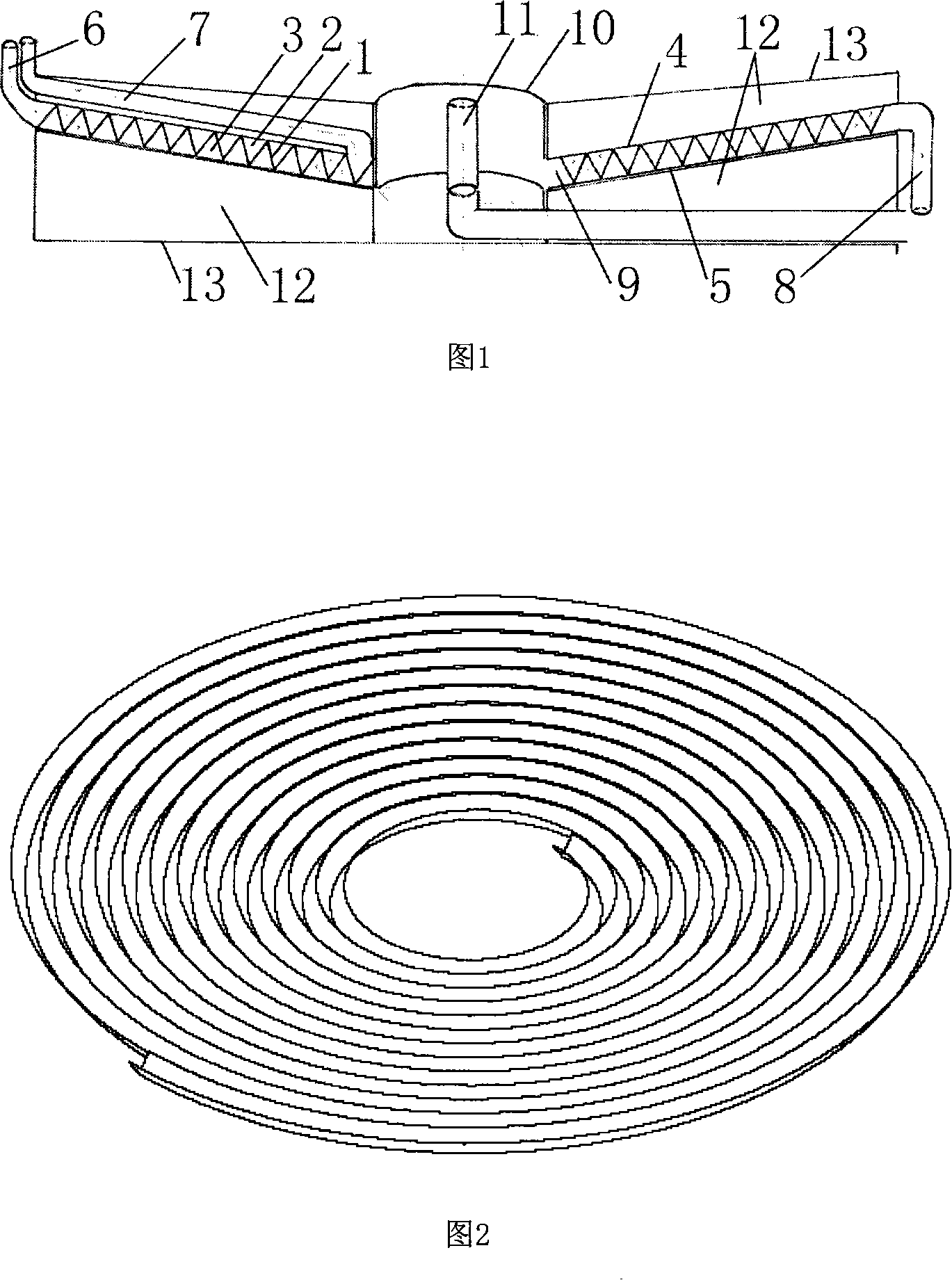

Multi-tube in spiral heat exchanger

InactiveUS20050103482A1Increase surface areaCompact designSafety devices for heat exchange apparatusStationary tubular conduit assembliesEngineeringSpiral heat exchanger

A heat exchanger has a first thermally conductive tube for conducting a fluid and a second thermal conductive tube for conducting a fluid. The first thermally conductive tube forms a first loop while the second thermally conductive tube forms a second loop. The first loop neighbors the second loop.

Owner:CARRIER CORP

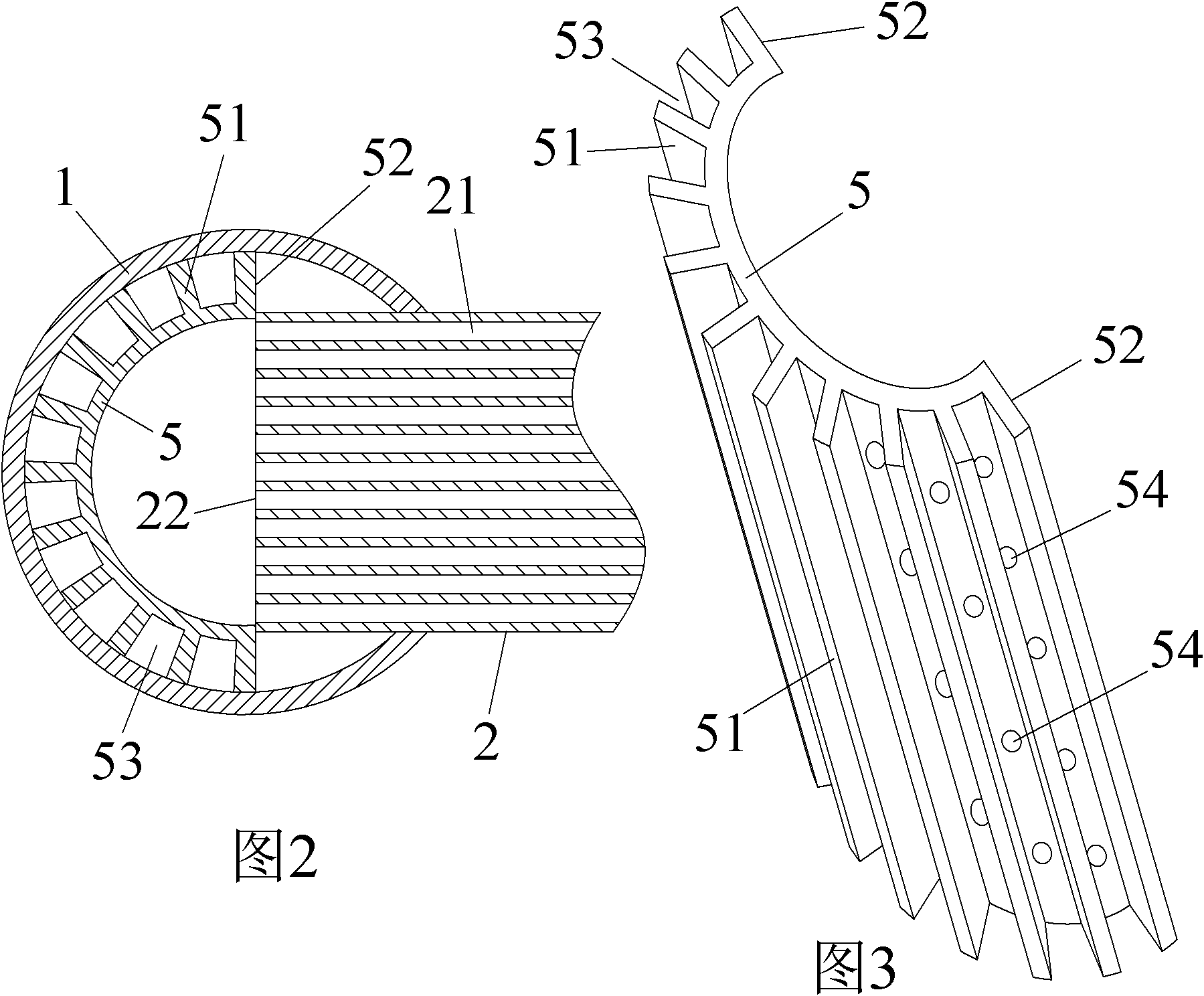

Helical heat exchanger for electric motors

An electric motor has a stator, a rotor, and a helical heat exchanger disposed outboard of the stator. The helical heat exchanger includes: an inner sleeve; an outer sleeve coaxially disposed with and outboard of the inner sleeve with a void therebetween; at least one helical wall disposed in the void between the inner and outer sleeves extending from one end to an opposite end of the inner and outer sleeves; the at least one helical wall forming a fluid tight seal along its helical path to define at least one helical fluid flow path in the void between the inner and outer sleeves; and the at least one helical fluid flow path configured to permit at least one heat transfer medium to helically travel within the void between the inner and outer sleeves.

Owner:ARNOLD MAGNETIC TECH

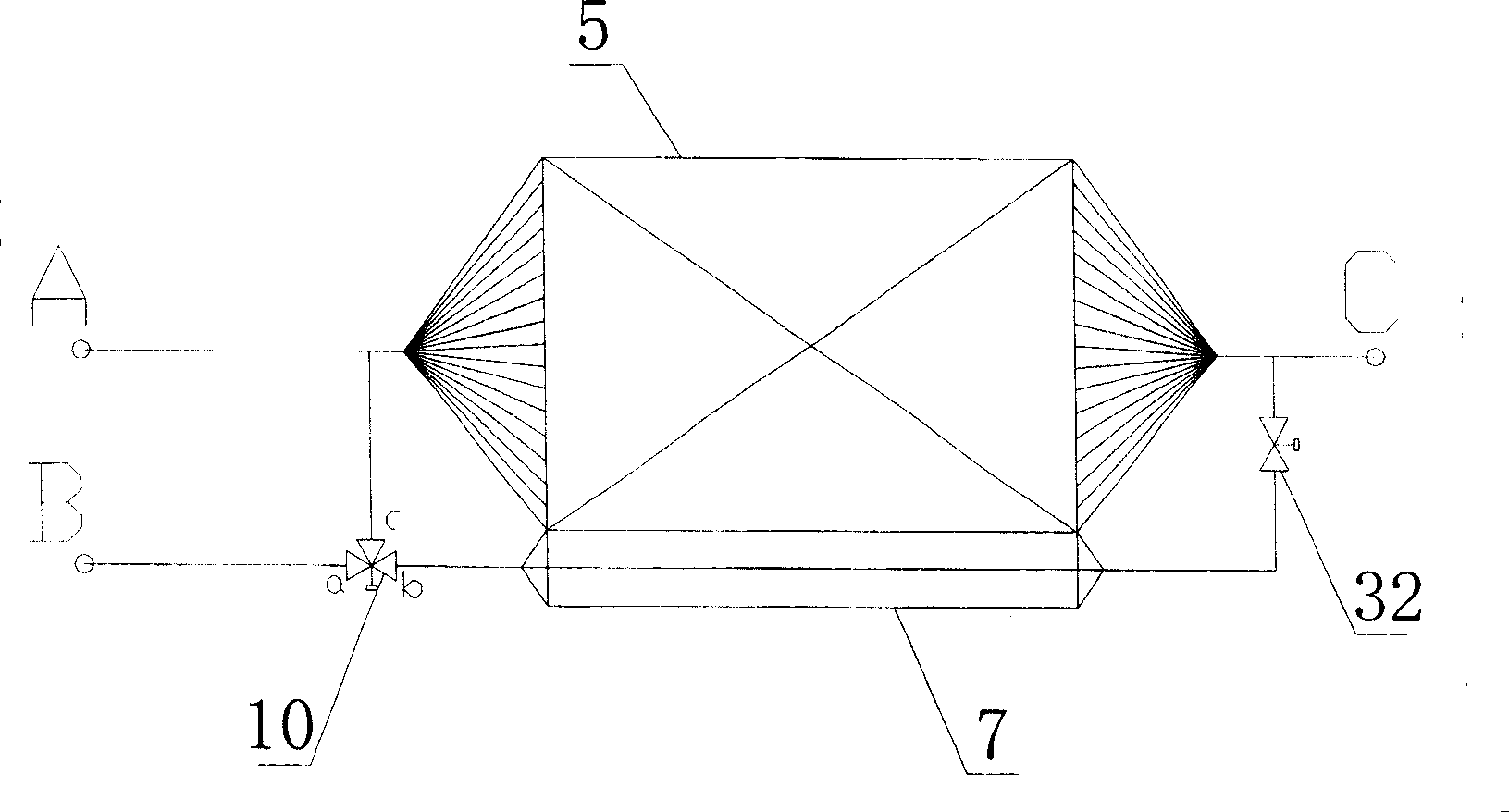

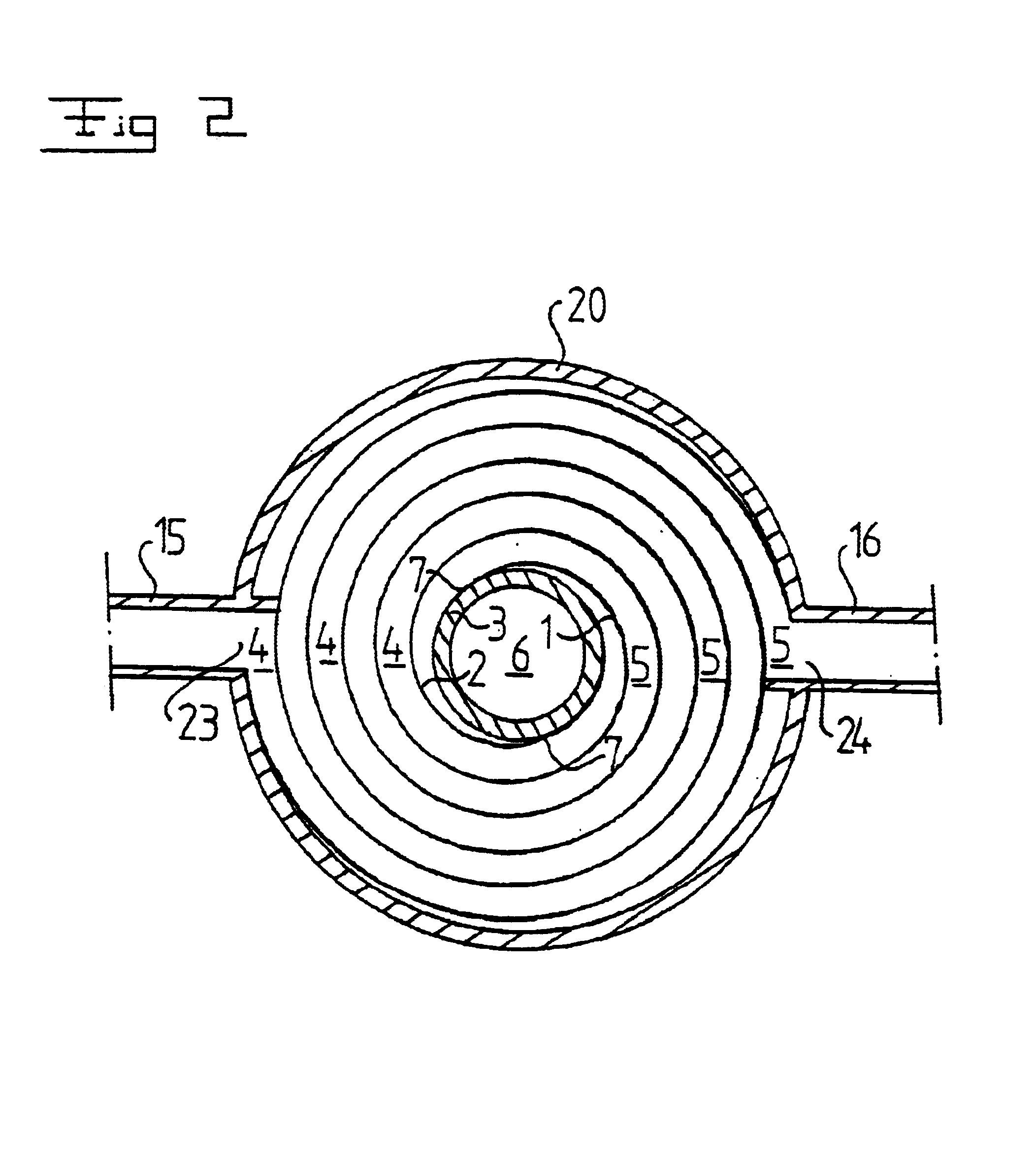

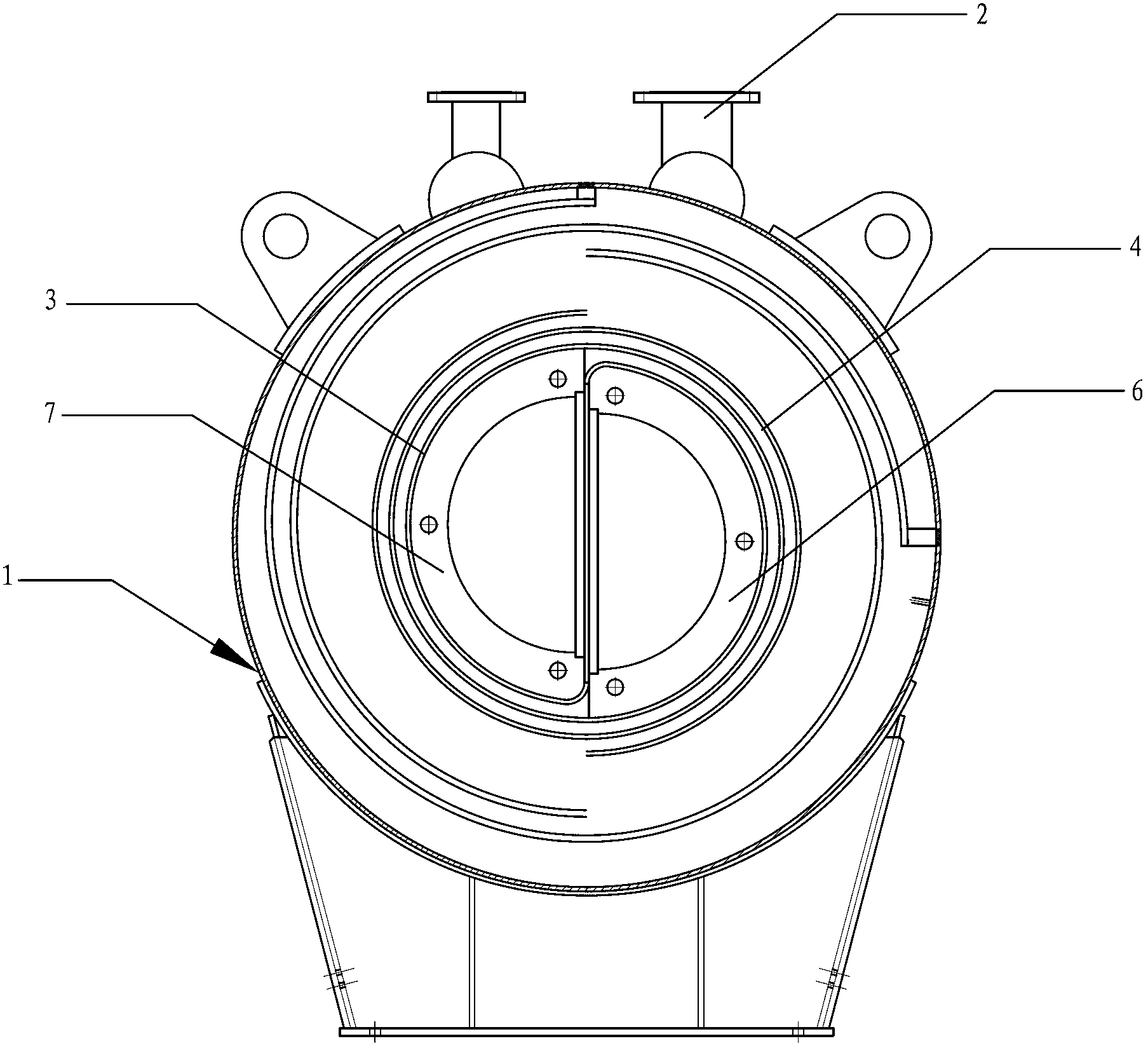

Spiral heat exchanger

InactiveUS6644391B1High strengthImprove rigidityStationary tubular conduit assembliesStationary plate conduit assembliesEngineeringSpiral heat exchanger

The invention relates to a spiral heat exchanger including at least two spiral sheets (1, 2) extending along a respective spiral-shaped path about a common center axis (x) and forming at least two spiral-shaped, substantially parallel flow channels (4, 5). Each flow channel (4, 5) permits a heat exchange fluid to flow in a substantially tangential direction with respect to the center axis (x). Each flow channel includes a radially outer orifice, which forms an outlet or an inlet of the respective flow channel and which is located at a radially outer part of the respective flow channel and a radially inner orifice, which enables communication between the respective flow channel and a respective inlet / outlet chamber (13, 14). The center axis (x) extends through the inlet / outlet chamber of the radially inner orifice. The spiral heat exchanger includes a center body (3) extending around the center axis (x) and being closed with respect to the flow channels (4, 5).

Owner:ALFA LAVAL AB

Heat exchanger of the plate type

InactiveUS20120125582A1Improve efficiencyReduce heat lossSolar heating energyThermal insulationPlate heat exchangerEngineering

A heat exchanger of a structurally self-supporting plate type and provided with an internal flow passage constrained between a first and a second plate and extending between an inlet and an outlet; The flow passage is subdivided in multiple generally parallelly directed longitudinally extending channels with the longitudinally extending channels having continuous joints formed by the two plates; The longitudinally extending channels have an arch-shaped cross-section and the arch-shape of the plates of the channels is in the same face direction orthogonal to the plates; The parallel running longitudinally extending channels include several laterally directed arches relative to their main axis in their longitudinal extension.

Owner:HIFORM +1

Shell-and-tube heat exchanger

InactiveCN101650138AAvoid short circuit shunt phenomenonImprove heat transfer efficiencyEvaporators/condensersHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

A shell-and-tube heat exchanger comprises a tubular shell, tube sheets arranged along two ends of the tubular shell and an end cover which is fixedly connected to the end of the tubular shell on the outer side of the tube sheets. A cavity of the shell and the tube sheet are provided with a whirl plate, a hollow coil heat exchanger bundle, a pull rod and a pipe spacer. Pores are uniformly arrangedon the whirl plate and periphery of the whirl plate is provided with a soft edge. The hollow coil heat exchanger bundle passes through the pore on the whirl plate and is fixed between two tube sheets.The hollow heat exchanger is the hollow coil heat exchanger bundle, tube wall of which has a continuous spiral slot shape and the external surface of which also has a spiral slot shape. The inventionavoids short circuit and split stream of flow media formed in the shell, and water is forced to spirally flow from a flowing pore gap, which is formed between the pore on the whirl plate and the spiral heat exchanger bundle, through the heat exchanger bundle. The invention improves heat-exchanging efficiency, enables shell side fluid to flow through a reasonable passage, reduces local scour, andeffectively prevents corrosion of the whirl plate, with clean and pollution-free water.

Owner:广州联合冷热设备有限公司

Spiral heat exchanger

InactiveUS8573290B2Improve heat transfer characteristicsHigh mechanical strengthStationary tubular conduit assembliesLaminated elementsPlate heat exchangerEngineering

A spiral heat exchanger includes a spiral body formed by at least one spiral sheet wound to form the spiral body forming at least a first spiral-shaped flow channel for a first medium and a second spiral-shaped flow channel for a second medium, wherein the spiral body is enclosed by a substantially cylindrical shell being provided with connecting elements communicating with the first flow channel and the second flow channel, where the at least one spiral sheet comprises a corrugated heat transfer surface with corrugations for increasing the heat transfer and supports for spacing the wounds of the at least one spiral sheet in the spiral body.

Owner:ALFA LAVAL CORP AB

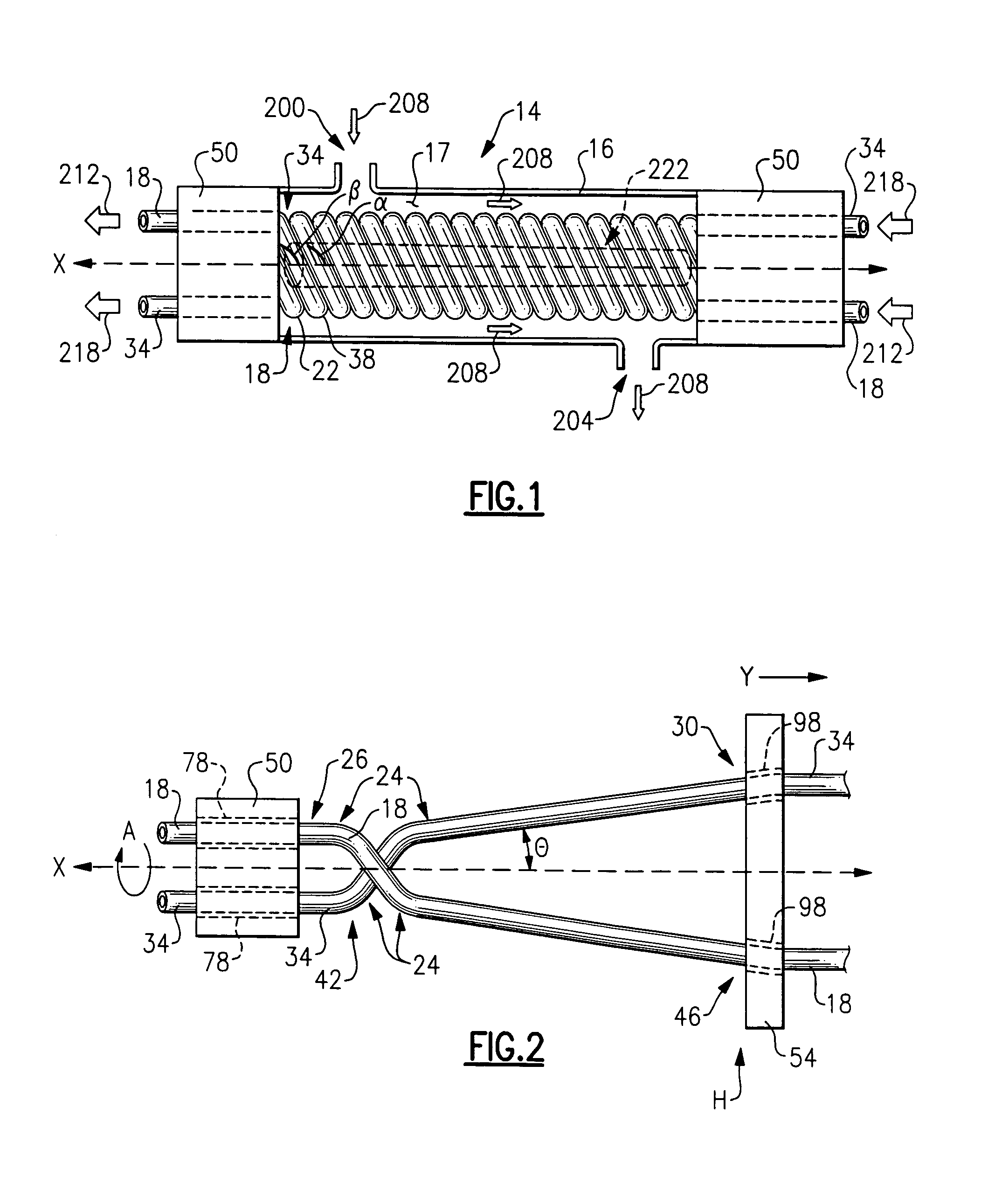

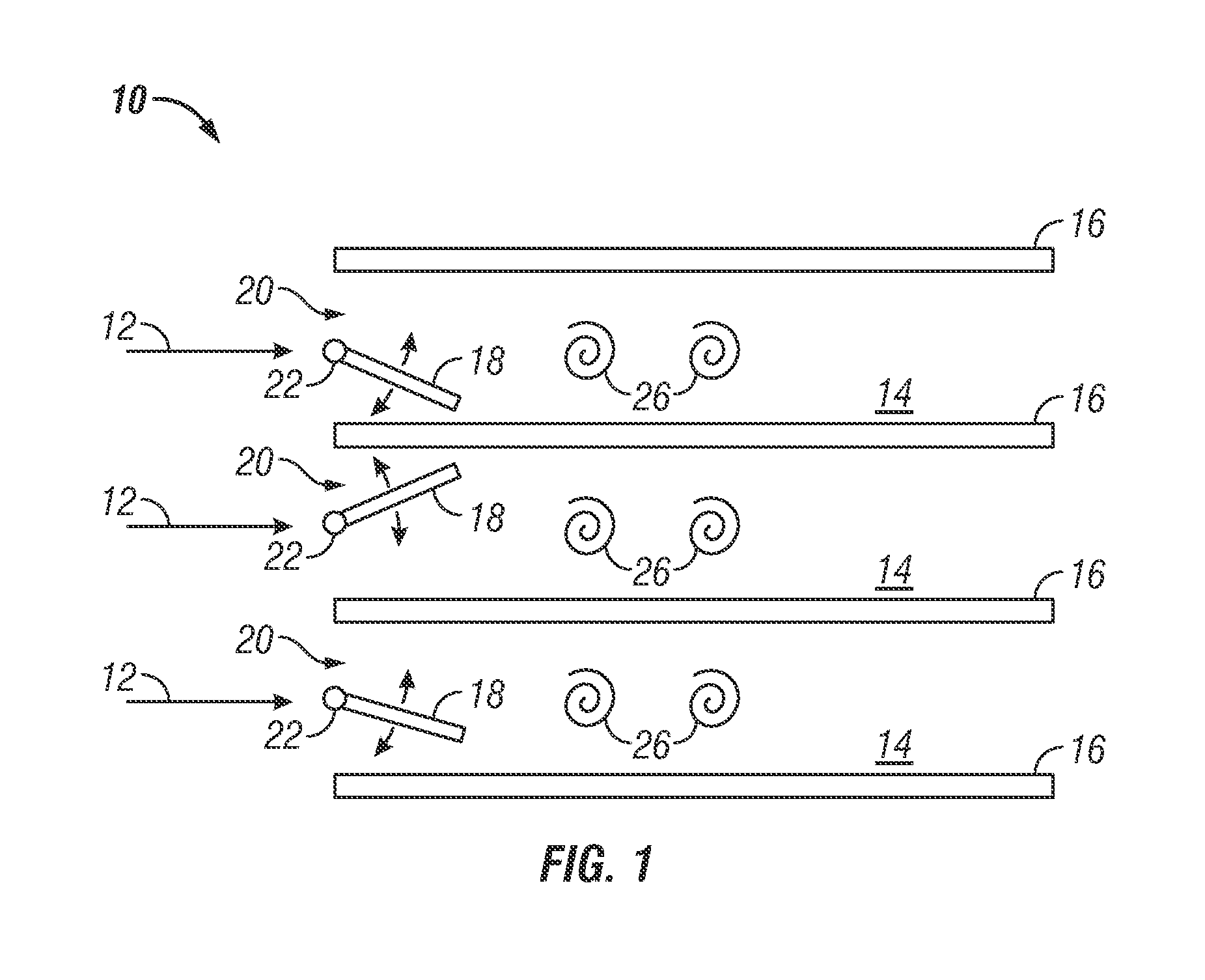

Fluid routing methods for a spiral heat exchanger with lattice cross section made via additive manufacturing

ActiveUS20190063842A1Additive manufacturing apparatusStationary tubular conduit assembliesEngineeringInlet manifold

A spiral heat exchanger features: a cold fluid inlet manifold, a hot fluid inlet manifold and at least one spiral fluid pathway. The cold fluid inlet manifold receives cold fluid and provide cold inlet manifold fluid. The hot fluid inlet manifold receives hot fluid and provide hot inlet manifold fluid. The at least one spiral fluid pathway includes cold spiral pathways configured to receive the cold inlet manifold fluid and provide cold spiral fluid pathway fluid, and hot spiral pathways configured to receive the hot inlet manifold fluid and provide hot spiral fluid pathway fluid. The cold spiral pathways and the hot spiral pathways are configured in relation to one another to exchange heat between the cold spiral pathway fluid and the hot spiral pathway fluid so that the hot spiral fluid pathway fluid warms the cold spiral fluid pathway fluid, and vice versa.

Owner:FLUID HANDLING

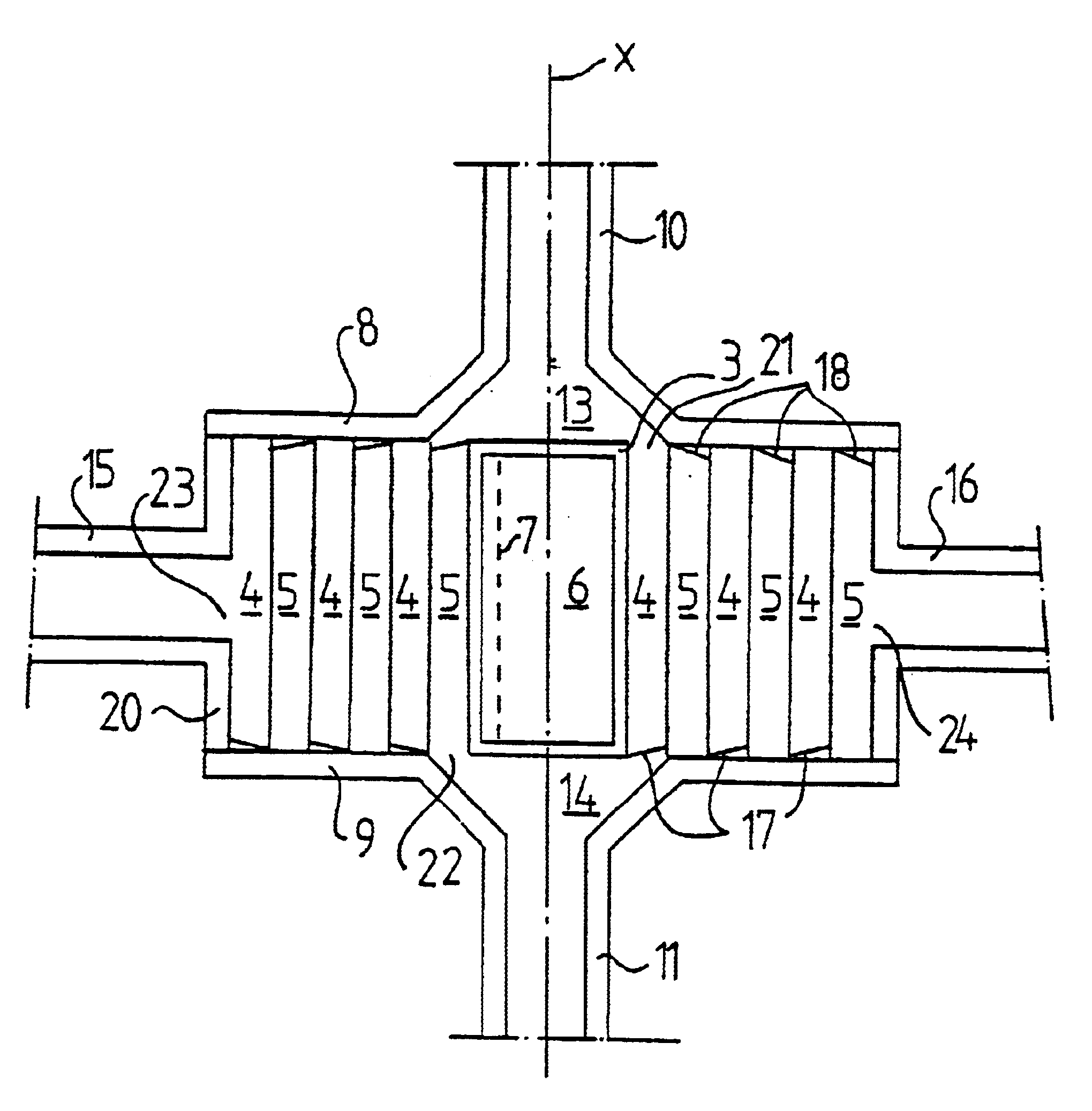

Spiral heat exchanger

InactiveUS7640972B2Simple waySimple designHeat exchanger casingsStationary tubular conduit assembliesInterior spaceEngineering

The invention relates to a spiral heat exchanger including a central cylinder (5) and at least two spiral sheets (6, 7). The sheets extend from the cylinder to form a first spiral-shaped flow channel (8) for a first medium and a second spiral-shaped flow channel (9) for a second medium. The cylinder forms an inner space within the cylinder. The cylinder includes a first opening (11) communicating with the first flow channel and a second opening (12) communicating with the second flow channel. A pipe (14) extends into the inner space of the cylinder. A first communication channel, communicating with the first flow channel via the first opening, is formed within the pipe. A second communication channel, communicating with the second flow channel via the second opening, is formed in the inner space outside the pipe.

Owner:ALFA LAVAL CORP AB

Spiral heat exchanger

InactiveUS20110174470A1Improve heat transfer performanceImprove heat transfer efficiencyStationary tubular conduit assembliesMoving conduit heat exchangersEngineeringCentrifugal force

A spiral heat exchanger includes two assembled covers defining a chamber therebetween for receiving a spiral unit therein. The spiral unit includes a first and a second spiral member separately spirally extending from a central outlet to a peripheral outlet on the two covers to respectively form a first and a second flow passage. A driving unit is assembled to and drives the assembled covers to rotate at the same time, so that cold and hot airflows respectively enter and flow through the first and second spiral members from the central outlet to the peripheral outlet under a centrifugal force to exchange heat at the spiral unit. The spiral unit provides extended flow passages and increased heat exchange area, giving the spiral heat exchanger increased heat transfer capacity and heat exchange efficiency and allowing omission of fans and radiating fin assembly to eliminate operating noise and accumulated dust.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Multi-tube in spiral heat exchanger

InactiveUS7165605B2Increase surface areaCompact designSafety devices for heat exchange apparatusStationary tubular conduit assembliesPlate heat exchangerEngineering

A heat exchanger has a first thermally conductive tube for conducting a fluid and a second thermal conductive tube for conducting a fluid. The first thermally conductive tube forms a first loop while the second thermally conductive tube forms a second loop. The first loop neighbors the second loop.

Owner:CARRIER CORP

Polymerization using a spiral heat exchanger

ActiveUS9708428B2Compression machines with reversible cycleStationary tubular conduit assembliesPolymer scienceReaction zone

This invention relates to a polymerization process for forming polymer comprising: contacting (typically in a solution or slurry phase), a monomer and a catalyst system in a reaction zone comprising at least one spiral heat exchanger and recovering polymer, wherein the monomer, the catalyst system and the polymer flow through the at least one spiral heat exchanger in a cross-flow direction relative to spirals of the at least one spiral heat exchanger.

Owner:EXXONMOBIL CHEM PAT INC

Novel slab type spiral heat exchanger

InactiveCN101118133AEnhanced convectionIncreased turbulenceStationary plate conduit assembliesWastewaterProcess engineering

The present invention relates to a novel plate type spiral heat exchanger, which has the characteristics of a plate heat exchanger, a spiral plate heat exchanger, and a spiral shell tube heat exchanger, and is characterized in that the size is small, the heat exchanging efficiency is high, the countercurrent heat exchange can be operated, the requirement of heat exchange in low temperature difference is met, a modular structure filter is provided, and a novel heat exchanger is easy to disassemble and clean, the present invention is easy for modularization process and assembly production, and the production cost is low. The present invention is particularly suitable for recycling of the after heat of bathing waste water and pre heating clean tap water in the process of household bathing, and more than 60 percent of waste heat can be effectively recycled, and the water heater power can be doubled in the condition of using lower cost and no energy consumption is added.

Owner:杨杰

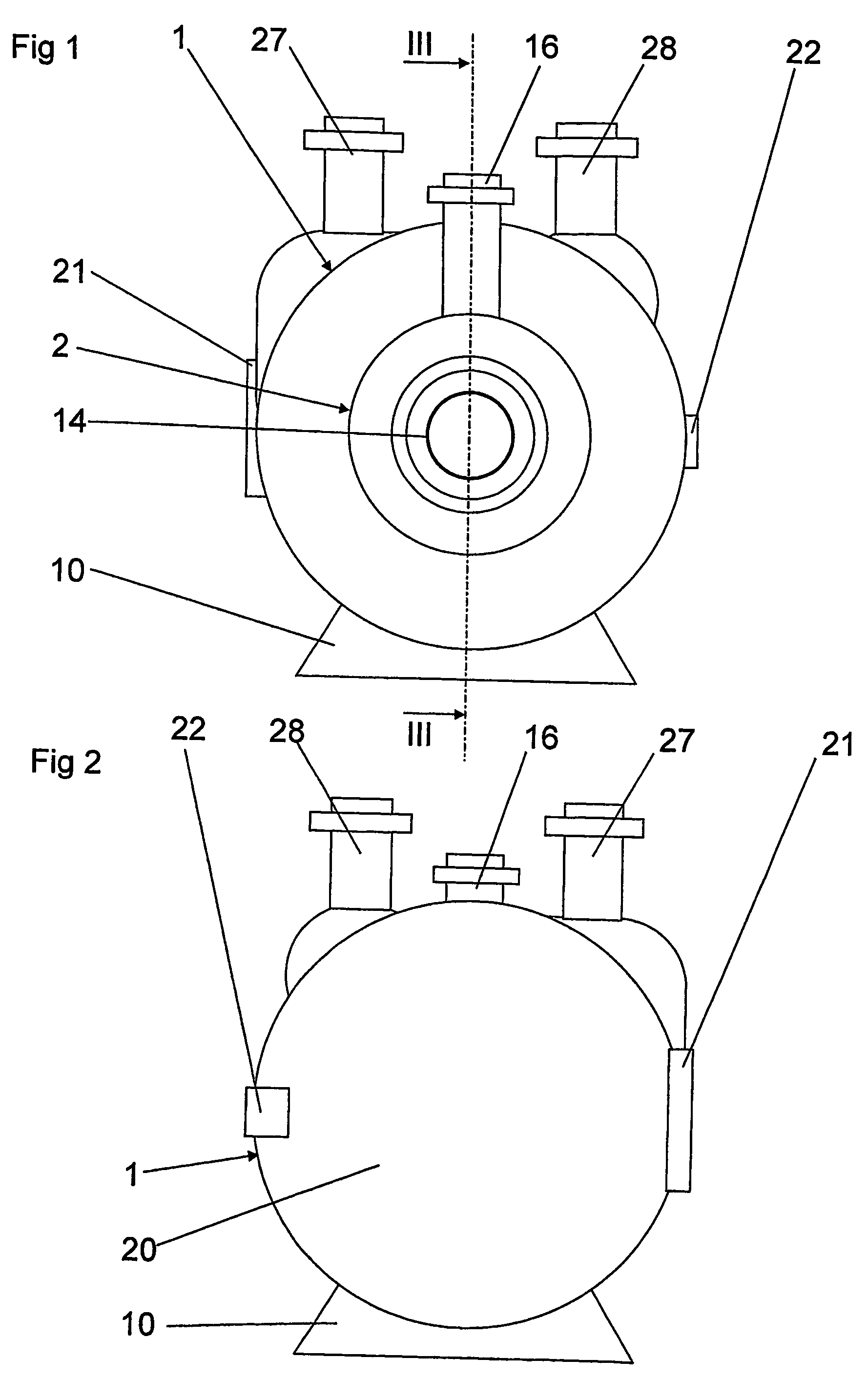

Vertical heat exchanger

InactiveUS7377307B1Improve heat transfer efficiencyImproved in in resistance to corrosionRing springsSafety devices for heat exchange apparatusPlate heat exchangerSludge

A vertical heat exchanger is described, which allows efficient elimination of the gas generated therein and efficient removal of the sludge accumulated therein. The vertical heat exchanger has at least part of one end of a vent pipe formed of an upper tube sheet part (an upper cover part in the case of a spiral heat exchanger) and the other end thereof connected outside the heat exchanger to an immediately adjacent fluid passing port passing the same fluid as the vent and / or at least part of one end of a drain pipe formed of a lower tube sheet part (a lower cover part in the case of a spiral heat exchanger) and the other end thereof connected outside the heat exchanger to an immediately adjacent fluid passing port passing the same fluid as the drain.

Owner:NIPPON SHOKUBAI CO LTD

Spiral heat exchanger with Anti-fouling properties

InactiveUS20140318748A1Reduce dirtHigh resistance against formation of crackCorrosion preventionCoatingsSilicon oxideMechanical engineering

The invention relates to a spiral heat exchanger comprising a spiral body formed by at least one spiral sheet wound to form the spiral body forming at least a first spiral-shaped flow channel for a first medium and a second spiral-shaped flow channel for a second medium, wherein the spiral body is enclosed by a substantially cylindrical shell being provided with connecting elements communicating with the first flow channel and the second flow channel. At least a part of the spiral heat exchanger is provided with a coating comprising silicon oxide, SiOx.

Owner:ALFA LAVAL CORP AB

Plate fin heat exchanger

ActiveUS8985192B2Lower performance requirementsSmall sizeLiquefactionAir-treating devicesEngineeringPlate fin heat exchanger

A plate fin heat exchanger of the present invention includes a heat exchange part including a heat exchange part main body including layers of plural flow passages, and heat transfer members each of which is disposed within each flow passage of the heat exchange part main body to transfer the heat of fluid flowing in each of the flow passages to each partition walls opposed across the flow passage; and sensing parts connected to both the outsides of the heat exchange part respectively. Each of the sensing parts includes plural sealed spaces, and a sensor wall disposed to separate the outermost sealed space from the sealed space on the inner side thereof. The plate fin heat exchanger further includes a detection means for detecting damage of the sensor wall of the sensing part. According to such a structure, external leak of the fluid performing the heat exchange can be prevented while suppressing deterioration of performance or increase in size or weight.

Owner:KOBE STEEL LTD

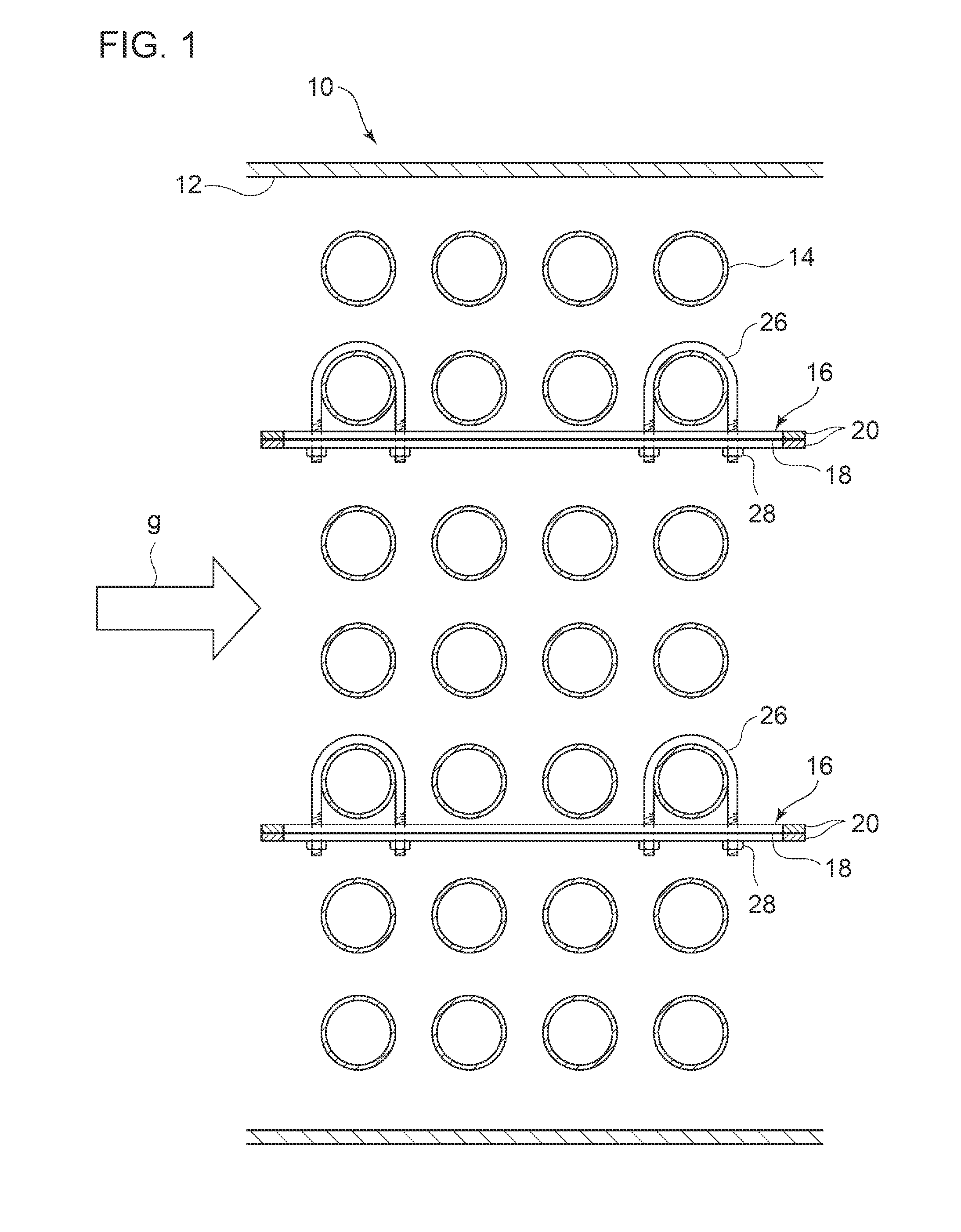

Heat-exchanger header and heat exchanger provided therewith

ActiveCN104285121AReduce heat transferSimple structureHeat exchanger casingsStationary tubular conduit assembliesEngineeringRefrigerant

Provided are: a heat-exchanger header that can reduce pressure losses, can distribute a refrigerant evenly without causing the heat-transfer performance of the heat exchanger to decrease, and has a simple structure; and a heat exchanger provided with said heat-exchanger header. This heat-exchanger header (10, 20) is used in a heat exchanger in which a refrigerant is run in parallel through a plurality of heat-transfer tubes (30) laid out in parallel. A plurality of through-holes (12) to which one end of each of the plurality of heat-transfer tubes is attached are lined up in the header in the lengthwise direction thereof. At least one chamber (10A) that connects to the plurality of through-holes, forming a refrigerant channel, is formed in the header. Each of the plurality of through-holes is either an entrance-side through-hole or an exit-side through-hole to which either the refrigerant-entrance-side end or the refrigerant-exit-side end of one of the plurality of heat-transfer tubes is attached. A plurality of grooves (14) that extend in the lengthwise direction of the header are formed, in the widthwise direction perpendicular to said lengthwise direction, in the parts of the abovementioned chamber facing the entrance-side through-holes.

Owner:MITSUBISHI ELECTRIC CORP

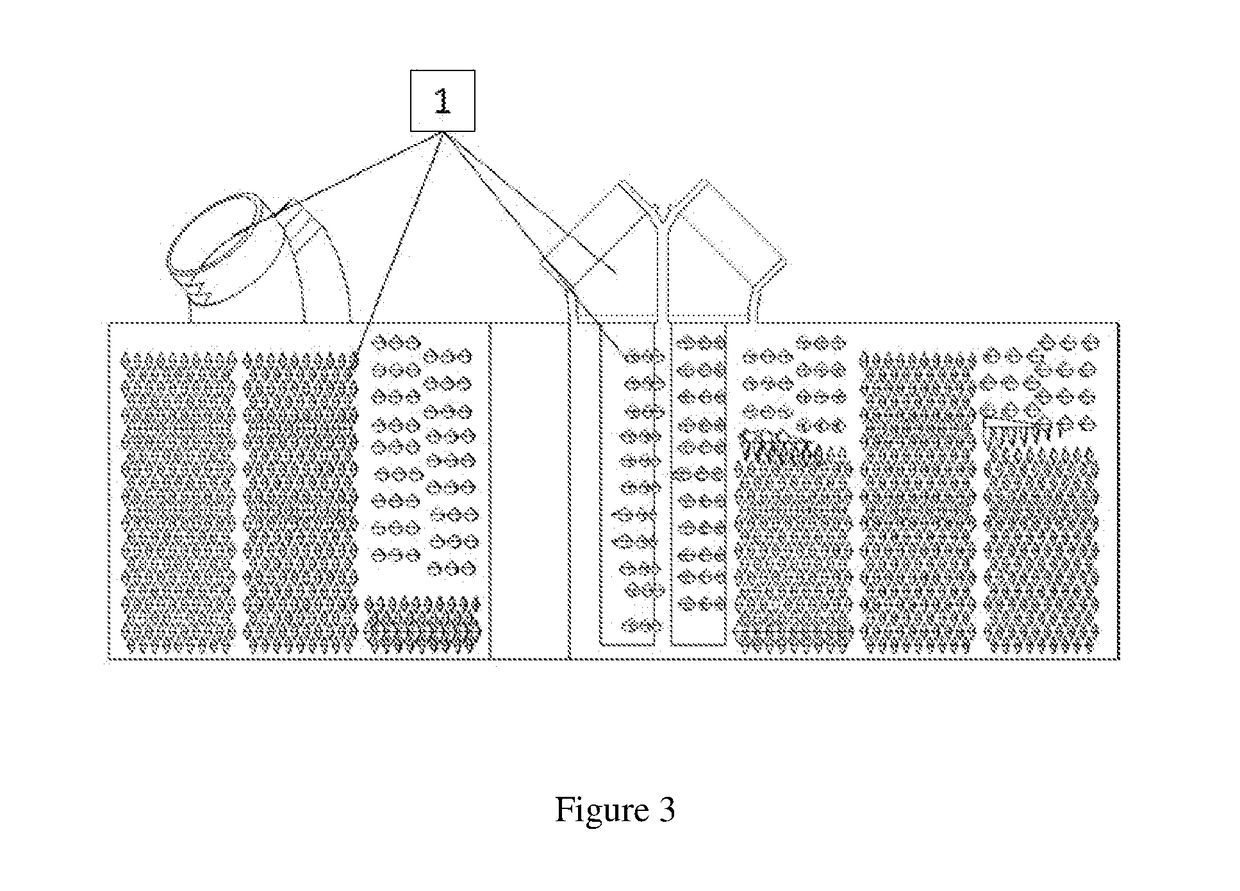

3D spiral heat exchanger

ActiveUS20170370652A1Additive manufacturing apparatusIncreasing energy efficiencyPlate heat exchangerEngineering

A spiral heat exchanger features first spiral channels configured to form rows and columns of coiled hot fluid pathways to receive hot fluid; and second spiral channels configured to form corresponding rows and columns of coiled cold fluid pathways to receive cold fluid having a temperature less than the hot fluid. The first spiral channels and the second spiral channels are configured to alternate every other row and column so as to form a matrix of alternating rows and columns of coiled hot and cold fluid pathways separated by alternating coiled walls that act as both fluid separators and conduits through which heat is transferred between the hot fluid and cold fluid.

Owner:FLUID HANDLING

Tube case heat exchange system and heat exchanger

ActiveCN104101245AHigh densityImprove compactnessEvaporators/condensersStationary tubular conduit assembliesPlate heat exchangerStraight tube

A tube case heat exchanger comprises a drum body and a sealing cover positioned at one end of the drum body, wherein a liner is arranged in the drum body; a cooling liquid inlet and a cooling liquid outlet are formed in upper and lower sides of the liner; the liner and the drum are sealed by a liner cover plate; the sealing cover and the cover plate are arranged at the same side; the liner is internally provided with a heat exchange tube bundle structure comprising at least one irregular W-shaped heat exchange tube; each irregular W-shaped heat exchange tube is formed by bending the same straight tube and comprises a first U-shaped tube and a second U-shaped tube which are positioned at different planes and provided with openings in the same direction; respective straight tubes of each first U-shaped tube and the corresponding second U-shaped tube are connected by a bent tube to form a third U-shaped tube with the opening in the opposite direction; the irregular W-shaped heat exchange tubes are uniformly arrayed and arranged along the radial direction of the heat exchanger in a staggering mode; the other straight tubes of the first U-shaped tubes and the second U-shaped tubes penetrate through the cover plate of the liner of the heat exchanger as opening tubes; the opening tubes among different irregular W-shaped heat exchange tubes are serially connected by tube fittings. The tube case heat exchanger is compact in structure, and safe and efficient in use.

Owner:TONGJI UNIV

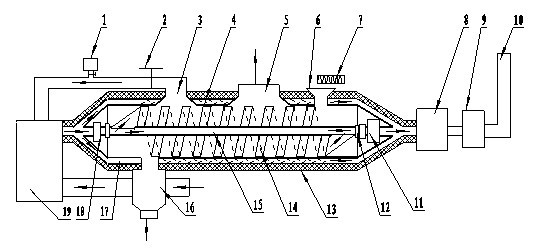

Large spiral low-order lignite quality improving system

InactiveCN102627991ADoes not affect movementLow particle size requirementSolid fuelsCombustion chamberPlate heat exchanger

A large spiral low-order lignite quality improving system comprises a spiral heat exchanger, a combustion chamber, a lignite feeding device, a quenching box and a dedusting device. The spiral heat exchanger is horizontally placed and composed of an outer sleeve, a rotating shaft and a motor, wherein the rotating shaft and the motor are sleeved in the outer sleeve, and the rotating shaft is in transmission connection with the motor. A spiral blade is axially arranged along the rotating shaft, the wall of the outer sleeve, the rotating shaft and the spiral blade are all of hollow structures, tow ends of the spiral blade are communicated with a hollow cavity of the rotating shaft, the inlet end of a hollow cavity of the wall of the outer sleeve and the inlet end of the hollow cavity of the rotating shaft are communicated with the combustion chamber, and the outlet end of the hollow cavity of the wall of the outer sleeve and the outlet end of the hollow cavity of the rotating shaft are communicated with the dedusting device. The lignite feeding device is arranged on the upper portion of the spiral heat exchanger and close to the side of the dedusting device, and the quenching box is arranged on the lower portion of the spiral heat exchanger and close to the side of the combustion chamber. The large spiral low-order lignite quality improving system requires no pre-drying process, is strong in adaptability of coal types and particularly suitable for improving quality of sticky lignite, only needs to pre-break raw coal, is safe in operation, simple in structure and high in heat exchange efficiency, can perform large-scale continuous production easily and can obtain semi-coke, tar and coal gas with high quality.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Collecting main and heat exchanger with same

ActiveCN103148729ALow costImprove reliabilityEvaporators/condensersStationary conduit assembliesRefrigerant distributionEngineering

The invention discloses a collecting main comprising an axially extending inner cavity and a plurality of axially extending and single components, wherein the inner cavity comprises a refrigerant charging cavity and a refrigerant distributing cavity; the refrigerant charging cavity is separated from and is in fluid communication with the refrigerant distributing cavity, and a refrigerant enters the refrigerant charging cavity and is distributed to heat exchange tubes from the refrigerant distributing cavity; and the refrigerant charging cavity and the refrigerant distributing cavity is formed by sequentially arranging and connecting the axially extending and single components in an assembly direction vertical to the axial direction. According to the structure of the collecting main disclosed by the invention, the collecting main is formed by connecting the single components together so that a problem of two-phase flow distribution of a heat exchanger is improved, and the heat exchange performance is improved; moreover, the problem of instable quality of a product is improved due to the simple assembly technology; and in addition, a problem of high cost of the existing radio-frequency welded tube is solved.

Owner:DANFOSS MICRO CHANNEL HEAT EXCHANGER JIAXING

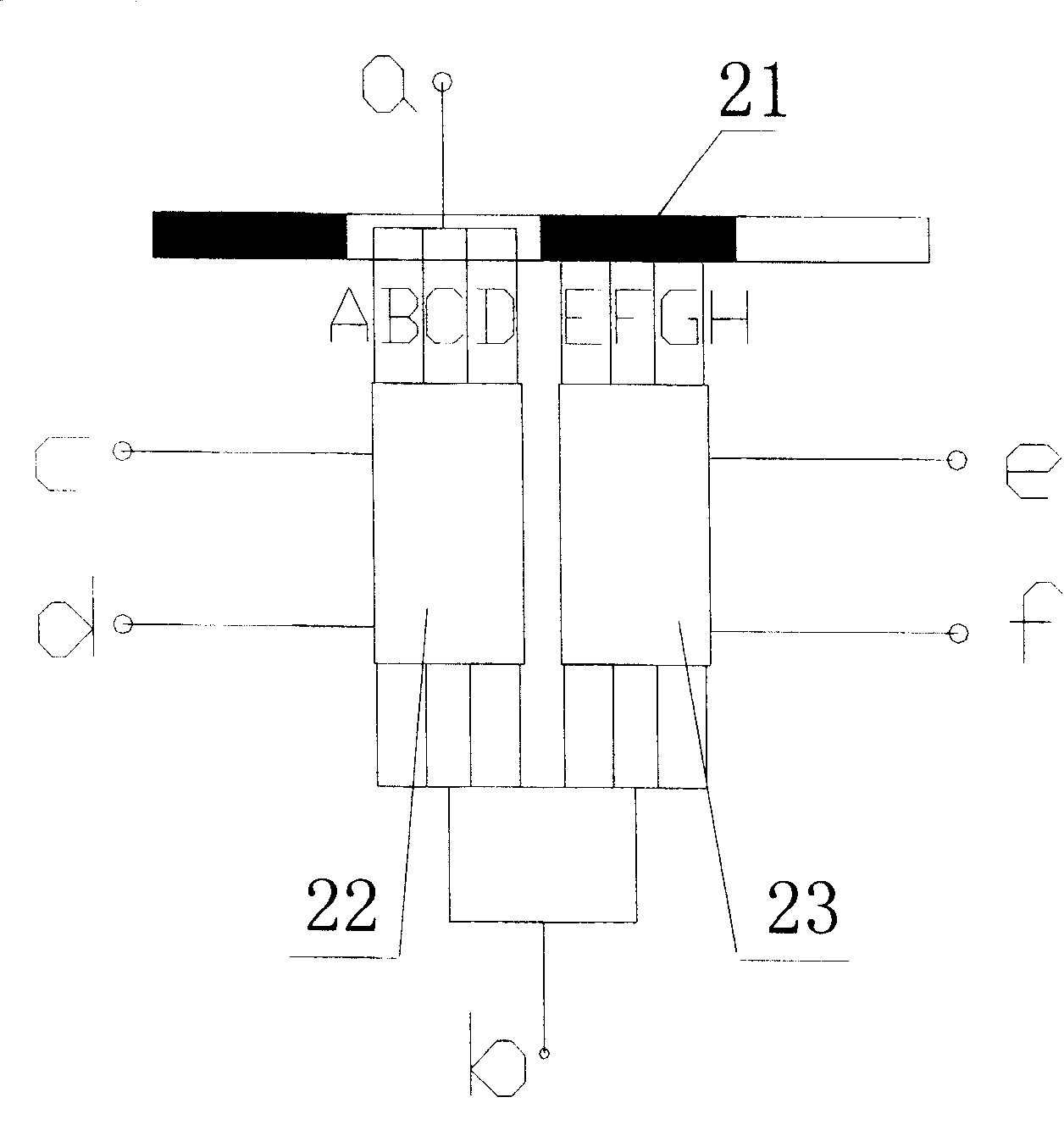

A spiral heat exchanger

InactiveCN1802547AOptimize layoutHeat exchange apparatusStationary plate conduit assembliesInterior spaceThin sheet

The invention relates to a spiral heat exchanger including a central cylinder (5) and at least two spiral sheets (6, 7). The sheets extend from the cylinder to form a first spiral-shaped flow channel (8) for a first medium and a second spiral-shaped flow channel (9) for a second medium. The cylinder forms an inner space within the cylinder. The cylinder includes a first opening (11) communicating with the first flow channel and a second opening (12) communicating with the second flow channel. A pipe (14) extends into the inner space of the cylinder. A first communication channel, communicating with the first flow channel via the first opening, is formed within the pipe. A second communication channel, communicating with the second flow channel via the second opening, is formed in the inner space outside the pipe.

Owner:ALFA LAVAL CORP AB

Stacking type heat exchanger

ActiveCN104911878AEasy to shapeIncrease the number ofCorrosion preventionHeat exchanger casingsPlastic materialsEngineering

Owner:QINGDAO HAIER DRUM WASHING MACHINE

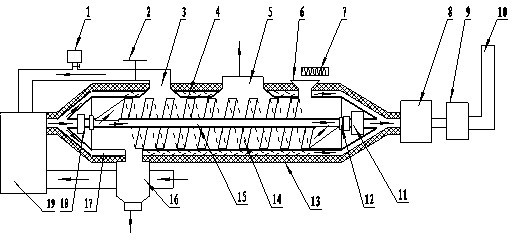

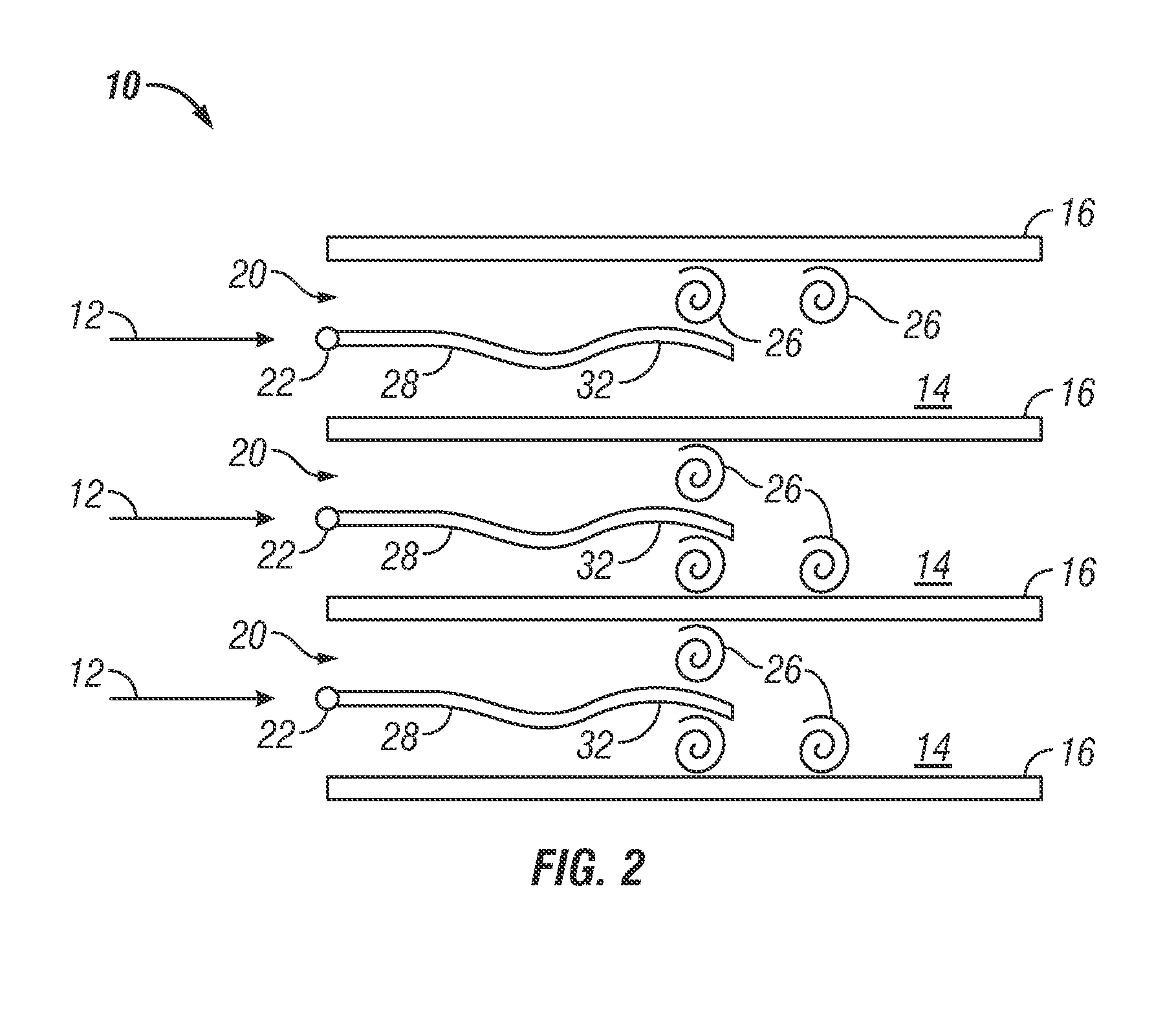

Active structures for heat exchanger

ActiveUS20120006511A1Raise transfer toSpeed up heat transferHeat transfer modificationThermal energyFlow disruption

A heat exchanger includes a plurality of channels and one or more active flow disruption members disposed at an entrance to the plurality of channels. The active flow disruption members are configured to induce unsteadiness in a flow through the plurality of channels to increase thermal energy transfer in the plurality of channels. A method for transferring thermal energy from a heat exchanger includes locating one or more active flow disruption members at an entrance to a plurality of channels of the heat exchanger. A flow is directed across the one or more active flow disruption members into the plurality of channels and an unsteadiness is produced in the flow via the one or more active flow disruption members. The unsteadiness in the flow increases the transfer of thermal energy between the heat exchanger and the flow.

Owner:HAMILTON SUNDSTRAND CORP

Heat exchanger

InactiveUS20160290742A1Lose weightMounting workBoiler water tubesSafety devices for heat exchange apparatusCombustionResonance

An object is to provide a heat exchanger including a resonance-prevention baffle plate disposed between a plurality of heat transfer tubes, the resonance-prevention baffle plate being obtainable and mountable readily and at lower cost. A heat exchanger 10 disposed in a flow passage of combustion gas of a boiler or the like includes: a plurality of heat transfer tubes 14 disposed in parallel and spaced from one another, an axial direction of each heat transfer tube intersecting with the combustion gas g, inside a duct wall 12 forming the flow passage of the combustion gas g; and a resonance-prevention baffle 16 having a plate shape and disposed along the combustion gas g and between the heat transfer tubes 14, the resonance-prevention baffle including a metal foil sheet 18.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Spiral heat exchanger and manufacturing method thereof and air conditioner

InactiveCN104006577AIncrease the windward areaImprove heat transfer efficiencyEvaporators/condensersEngineeringMicro heat exchanger

The invention provides a spiral heat exchanger and a manufacturing method thereof and an air conditioner. The spiral heat exchanger comprises a heat exchange pipe and a plurality of fins, the heat exchange pipe is spirally wound to be cylindrical, the centers of the fins are provided with mounting holes matched with the heat exchange pipe, and the outer portion of the heat exchange pipe is sleeved with the fins at intervals through the mounting holes. Air can be sucked around the spiral heat exchanger; compared with a mode that a traditional plane-shaped heat exchanger can only suck air with one side, the windward area of the spiral heat exchanger is increased by 2-3 times, and integral heat exchange efficiency of the spiral heat exchanger is greatly improved; in addition, according to the spiral heat exchanger, a semicircular connecting pipe does not need to be welded to the heat exchange pipe, the bending process and cost of the semicircular pipe are reduced, the technical risk of refrigerant leakage caused by poor pipe opening welding is avoided, the manufacturing of the spiral heat exchanger becomes simple and convenient, product quality is effectively guaranteed, and product production efficiency is improved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP

A heat exchanger plate, a plate heat exchanger, and a method of making a plate heat exchanger

A heat exchanger plate (1), a plate heat exchanger for evaporation of a first fluid, and a method of making a plate heat exchanger are disclosed. The heat exchanger plate comprises a heat exchanger area extending in parallel with an extension plane (p) of the heat exchanger plate, an edge area extending around the heat exchanger area, a number of portholes (11-14) extending through the heat exchanger area, and a peripheral rim (15) surrounding a first porthole of said number of portholes and extending transversely to the extension plane from a root end (16) to a top end (17) with a rim height(H) perpendicular to the extension plane. The heat exchanger plate comprises at least one restriction hole (20) extending through the peripheral rim and having a hole height (h) perpendicular to the extension plane.

Owner:ALFA LAVAL CORP AB

Detachable spiral heat exchanger and manufacturing method thereof

InactiveCN103322839AUniform deformationAvoid deformationHeat exchanger casingsStationary plate conduit assembliesMechanical engineeringIndustrial engineering

The invention discloses a detachable spiral heat exchanger and a manufacturing method thereof. The detachable spiral heat exchanger comprises a shell, two pairs of outlets and inlets, a supporting framework, a first heat exchange plate and a second heat exchange plate, the outlets and the inlets are arranged on the shell, and the first heat exchange plate and the second heat exchange plate are arranged in the shell and are spirally alternately wound by taking the supporting framework as a center. As the supporting framework is firstly arranged and then the first heat exchange plate and the second heat exchange plate are wound by taking the supporting framework as the center, uneven deformation of the first heat exchange plate and the second heat exchange plate can be effectively prevented in winding.

Owner:SUZHOU CITY JINXIANG PRESSURE CONTAINER MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com