Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

209results about How to "Reduce pretreatment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

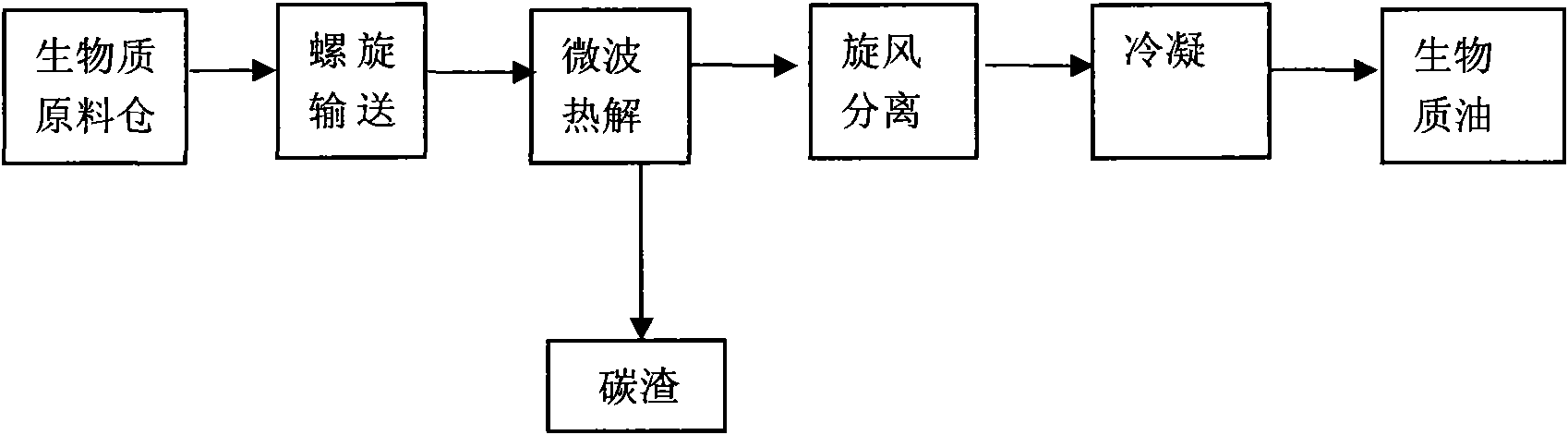

Method for preparing biomass oil in microwave thermal decomposition way

InactiveCN101560404AImprove microwave absorption performanceFast heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisScrew conveyor

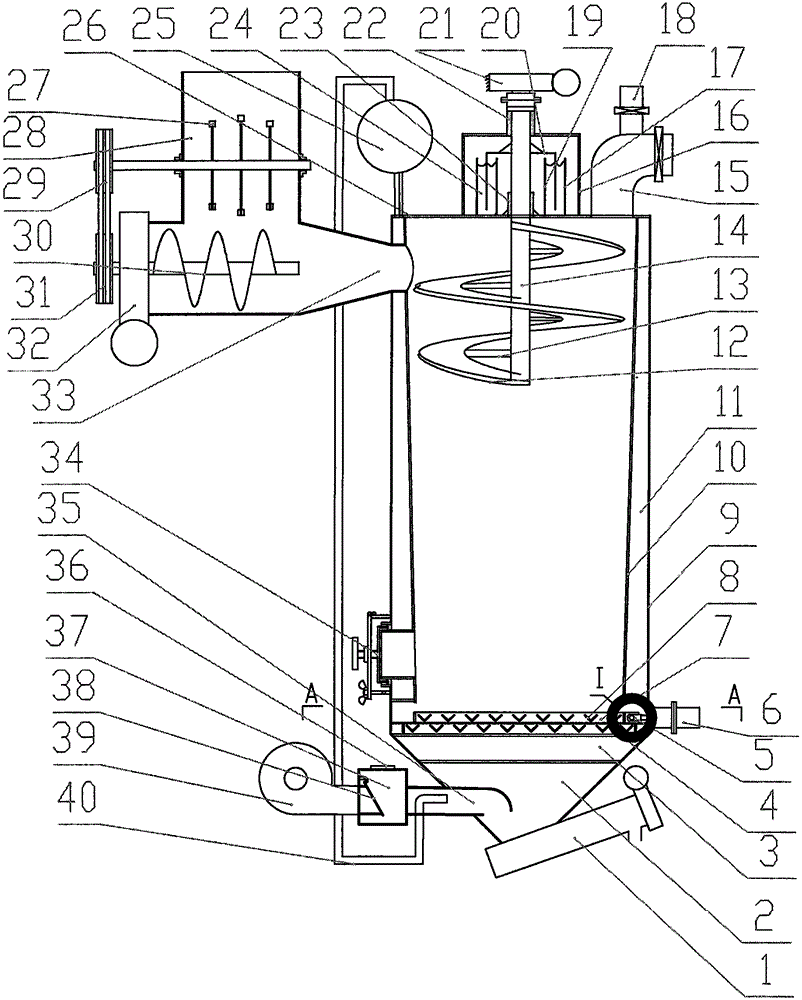

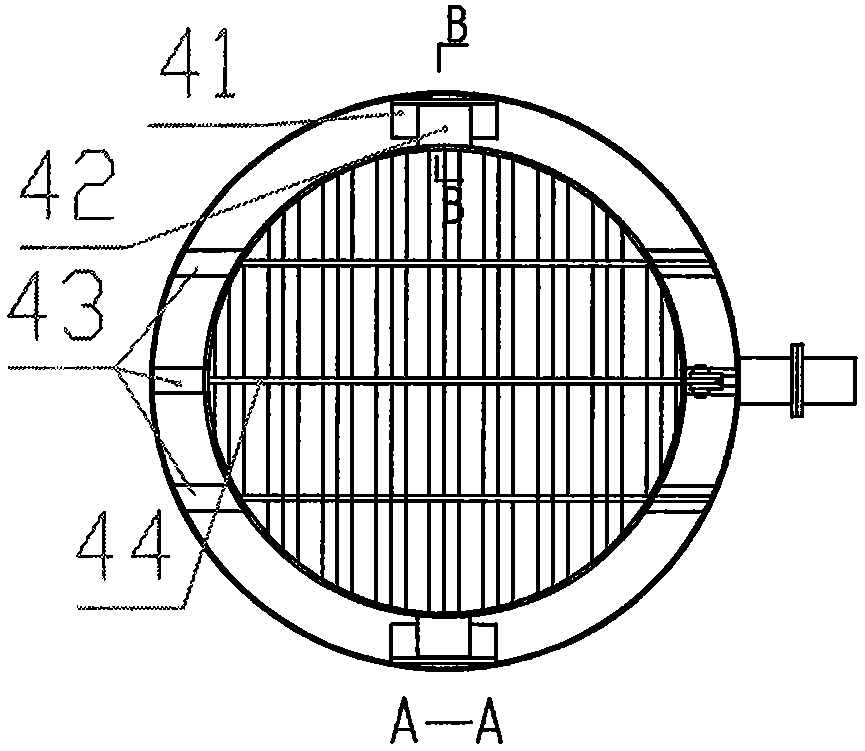

The invention discloses a method for preparing biomass oil in a microwave thermal decomposition way, which comprises the following steps: biomass enters a screw conveyer from a storage hopper, the feeding speed of the screw conveyer is 30-60 kilogram / h; the biomass enters a microwave pyrolysis reactor through the screw conveyor, the temperature of the biomass after absorbing microwave rapidly rises to 450-550 DEG C to reach the best temperature 475-500 DEG C of the biomass producing the oil; the biomass is thermally decomposed in the microwave pyrolysis reactor to produce high-temperature organic steam, the organic steam is sent to a cyclone separating device for gas and solid separation to remove carbon grains and sand; the organic steam is discharged through the cyclone separating device, the biomass is sent to a condenser for quenching, a condensable part of the biomass is changed into the biomass oil, and the biomass oil is dropped into an oil tank, thereby the biomass oil is prepared. The invention accords with the best process requirement of the biomass oil extraction without thermal conduction and has low cost, controllable and precise thermal decomposition temperature and no thermal inertia.

Owner:上海鸿泽企业发展有限公司

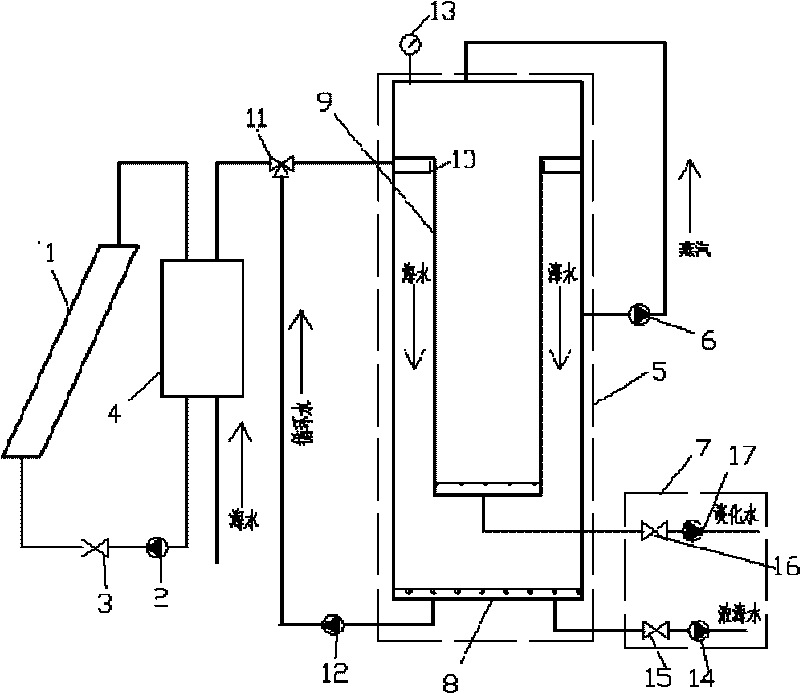

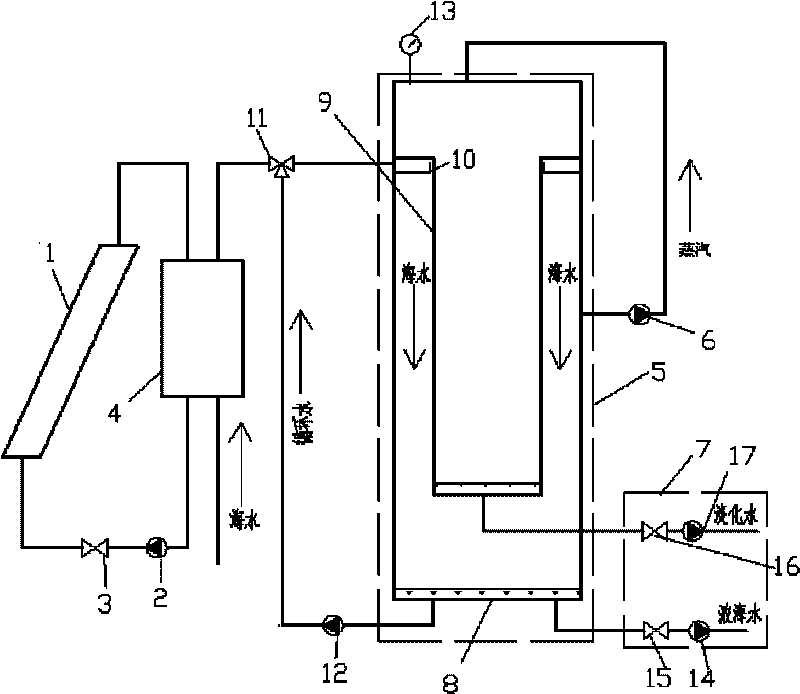

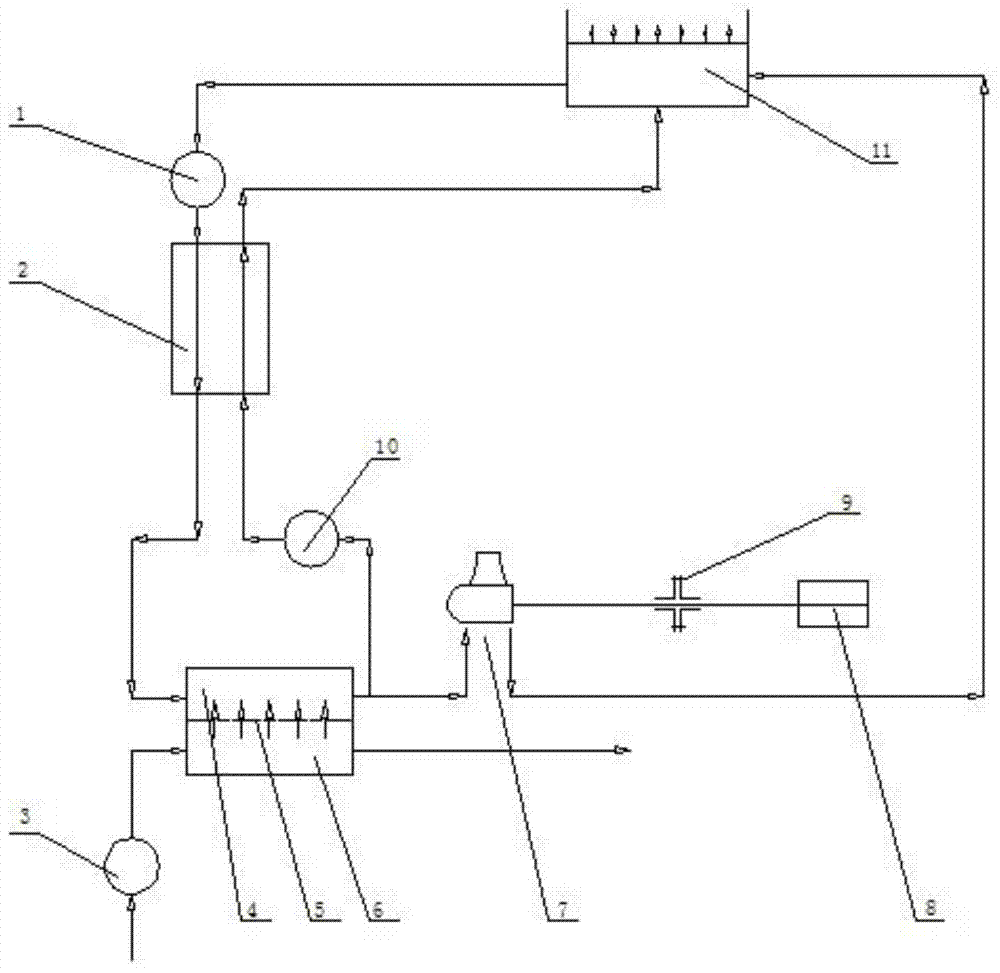

Seawater desalination device employing solar energy and vapor compressing distillation

ActiveCN101723476AEfficient use ofReduce pretreatment costsGeneral water supply conservationSeawater treatmentDistillationEngineering

The invention relates to a seawater desalination device employing solar energy and vapor compressing distillation, belonging to the technical field of solar energy. The seawater desalination device comprises a solar collector, a first circulating pump, a heat exchanger, an evaporative condenser, a blower fan and a vacuum pump mechanism, wherein the solar collector is connected with the first circulating pump; the heat exchanger is respectively connected with the solar collector and the evaporative condenser; the evaporative condenser is connected with the blower fan; the vacuum pump mechanism is connected with the evaporative condenser; the evaporative condenser comprises an evaporation chamber and a condensation chamber; the condensation chamber is embedded into the evaporation chamber; the evaporation chamber is connected with the heat exchanger; and the position where the condensation chamber is embedded into the evaporation chamber is provided with a heat exchanging wall surface. The invention desalinates seawater in the mode of combining the solar energy and a low-pressure vapor compressing distillation seawater desalination method, reduces the pretreatment cost of seawater or brackish water, simplifies the mechanism and is also conveniently realized. The whole device is operated at the low pressure, reduces the operating temperature and improves the heat efficiency by employing the evaporative condenser to recover condensation heat.

Owner:SHANGHAI JIAO TONG UNIV

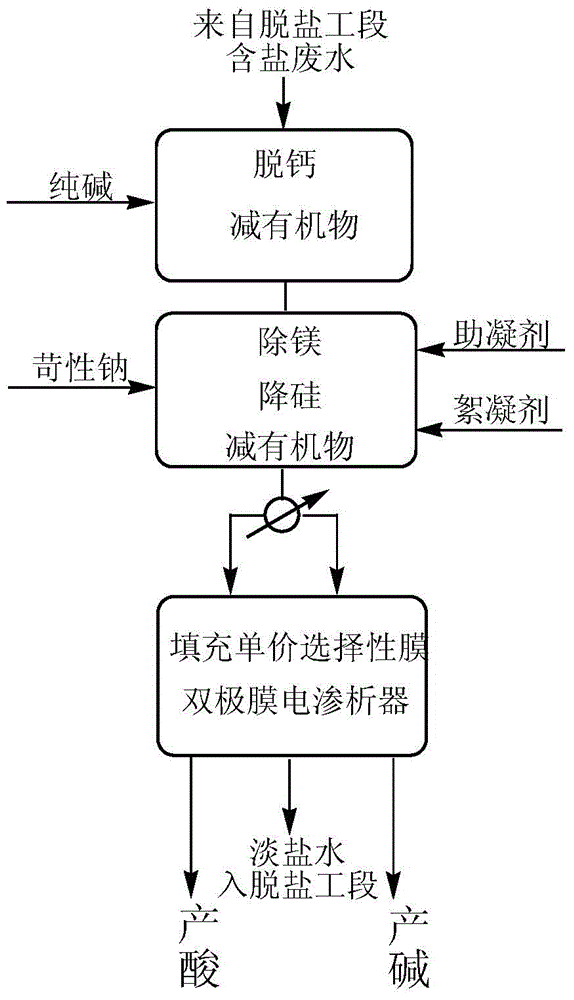

Surface water desalting apparatus by-producing saline waste water treatment method

ActiveCN104370394AReduce water consumptionReduce comprehensive water production costsGeneral water supply conservationSpecific water treatment objectivesIon-exchange membranesChemistry

The present invention provides a surface water desalting apparatus by-producing saline waste water treatment method. According to the surface water desalting apparatus by-producing saline waste water treatment method, saline waste water is pretreated by adopting a pure alkali-caustic soda-flocculation precipitation method to remove hard, reduce silicon and remove organic matters, and then a bipolar membrane electrodialysis device filled with a monovalent selective ion exchange membrane is adopted to carry out a resource treatment to convert the salt in the saline waste water into the corresponding acid and the corresponding alkali, wherein the acid and the alkali obtained from the electrodialysis can be used for the regeneration and pretreatment process of the desalting apparatus ion exchange resin, and the diluted saline water obtained from the electrodialysis can be used as the influent of the desalting apparatus. The method has characteristics of high treatment capacity, low treatment cost and significant reduction of the water consumption of the desalting apparatus, and is suitable for industrialization.

Owner:BEIJING LINISPLENDOUR EMPYRERL ENVIRONMENTAL ENG TECH +1

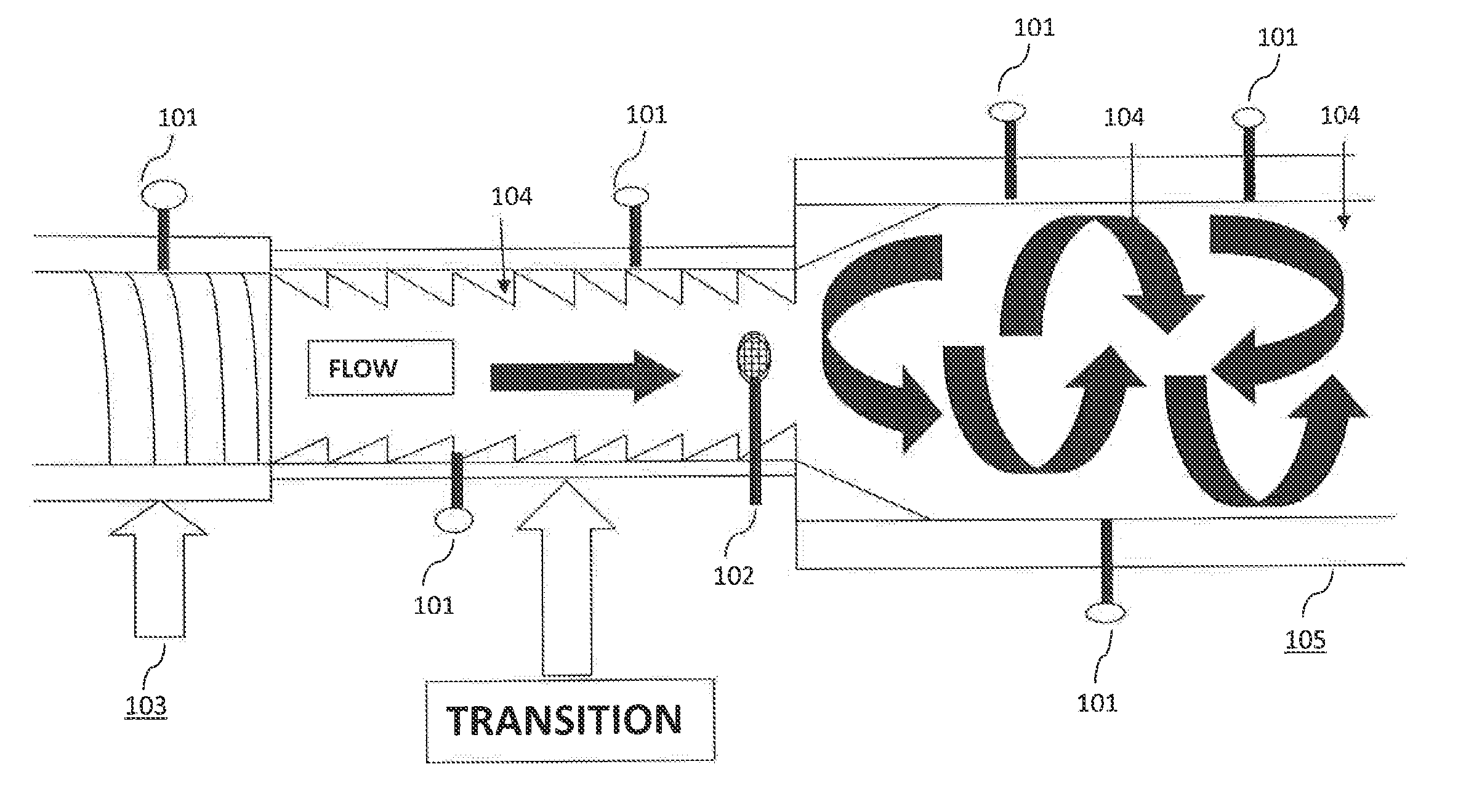

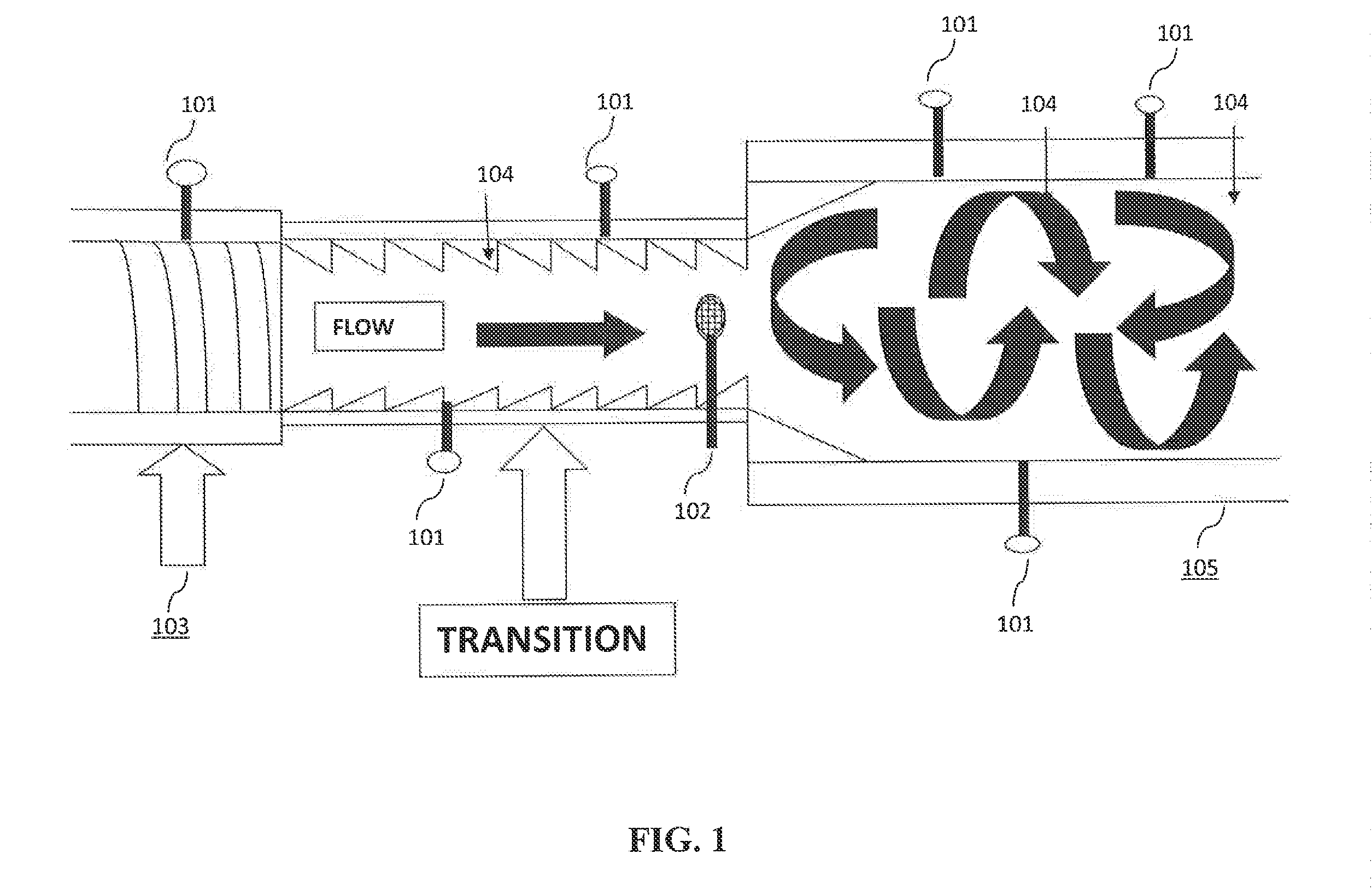

Power generation device and power generation method adopting salinity gradient power

ActiveCN103615363AReduce pretreatment costsImprove power densityMachines/enginesMechanical power devicesHigh concentrationWater turbine

The invention discloses a power generation device adopting salinity gradient power. The power generation device comprises a permeating device and water turbines. The permeating device comprises a permeating electrode formed by parallel connection of a plurality of permeable membrane elements and used for dividing strong salt water and seawater into a high-concentration side and a low-concentration side. The water turbines correspond to the high-concentration side of the permeating device and are connected with an engine through a coupler so as to drive a motor to operate. After the strong salt water and the seawater are fed into the high-concentration side and the low-concentration side of the permeating electrode, the permeating electrode can convert permeating pressure difference into hydrostatic pressure on the high-concentration side and exert back pressure in corresponding size by the aid of permeating electrode, and the water turbines can be driven to rotate to drive a generator to operate. The seawater is taken as a low-concentration water supply side and the seawater higher in concentration is used for permeating power generation, so that fresh water resources can be saved, pretreatment cost can be reduced, the permeating pressure difference can be increased, and power density can be increased; instability and difficult grid connection by the power generation mode are avoided due to the characteristics of easy storage of salt.

Owner:HUAZHONG UNIV OF SCI & TECH

Comprehensive utilizing method of sweet sorghum stalks

InactiveCN102399826AHigh in celluloseImprove accessibilityBiofuelsMicroorganism based processesChemical industryXylose

The invention discloses a comprehensive utilizing method of sweet sorghum stalks belonging to the technical field of biomass energy and chemical industry. The method comprises the following steps of: 1) fermenting sweet sorghum stalks in a solid state and distilling the sweet sorghum stalks to obtain an ethanol solution and distillers' grains; 2) hydrolyzing the distillers' grains under an acidic condition; and carrying out solid and liquid separation to obtain an xylose solution and an acidolysis slag; 3) washing the acidolysis slag by using water as an enzymatic substrate; adding an enzymolysis buffer solution; adding enzyme to carrying out enzymolysis; and then carrying out solid and liquid separation to obtain an enzymolysis mixed solution and enzymolysis xylogen; and 4) inoculating the enzymolysis mixed solution into yeast and fermenting the enzymolysis mixed solution to generate an ethanol solution. According to the invention, a new way is found for utilizing the distillers' grains; and xylose with high value added is obtained; meanwhile, the cellulose content and cellulose accessibility in the acidolysis slag are increased so that high conversion rate of cellulose enzymolysis and saccharification is realized. By using the method disclosed by the invention, the utilization rate of the lignocellulose raw material with high sugar content is increased, the ethanol yield per unit crop is increased, and the production cost of the cellulose ethanol is reduced.

Owner:TSINGHUA UNIV

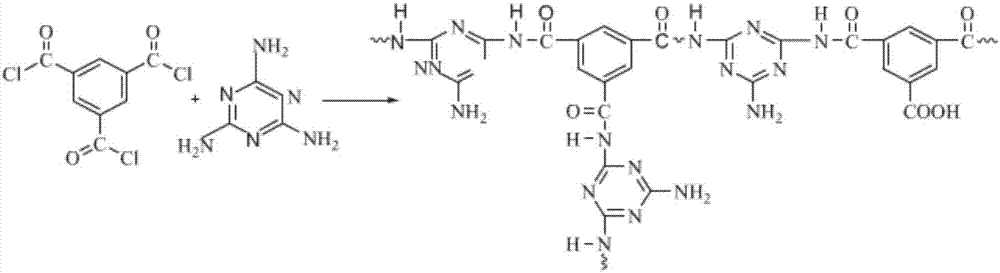

Chlorine-resistant composite nanofiltration membrane and preparation method thereof

InactiveCN107029558AImprove chlorine resistanceAddresses the limitation that it cannot be used in environments with more oxidizing mediaSemi-permeable membranesMembranesPolyamideMelamine

The invention belongs to the technical field of membrane separation, and provides a chlorine-resistant composite nanofiltration membrane and a preparation method thereof. The chlorine-resistant composite nanofiltration membrane has charge performance, and comprises a separation function layer and a support layer, wherein the support player is positioned under the separation function layer. The chlorine-resistant composite nanofiltration membrane prepared by the preparation method provided by the invention can be a flat membrane and can also be a hollow fiber membrane. The chlorine-resistant composite nanofiltration membrane monomer has melamine of a triazine ring structure and is subjected to crosslinking treatment, so that the composite membrane has significantly higher chlorine resistance than a commercial polyamide composite membrane, the limitation that the current commercial nanofiltration membrane cannot be used in the environment including residual chlorine is broken, and thus complexity of pretreatment can be greatly reduced, and the application environment is wide.

Owner:DALIAN UNIV OF TECH

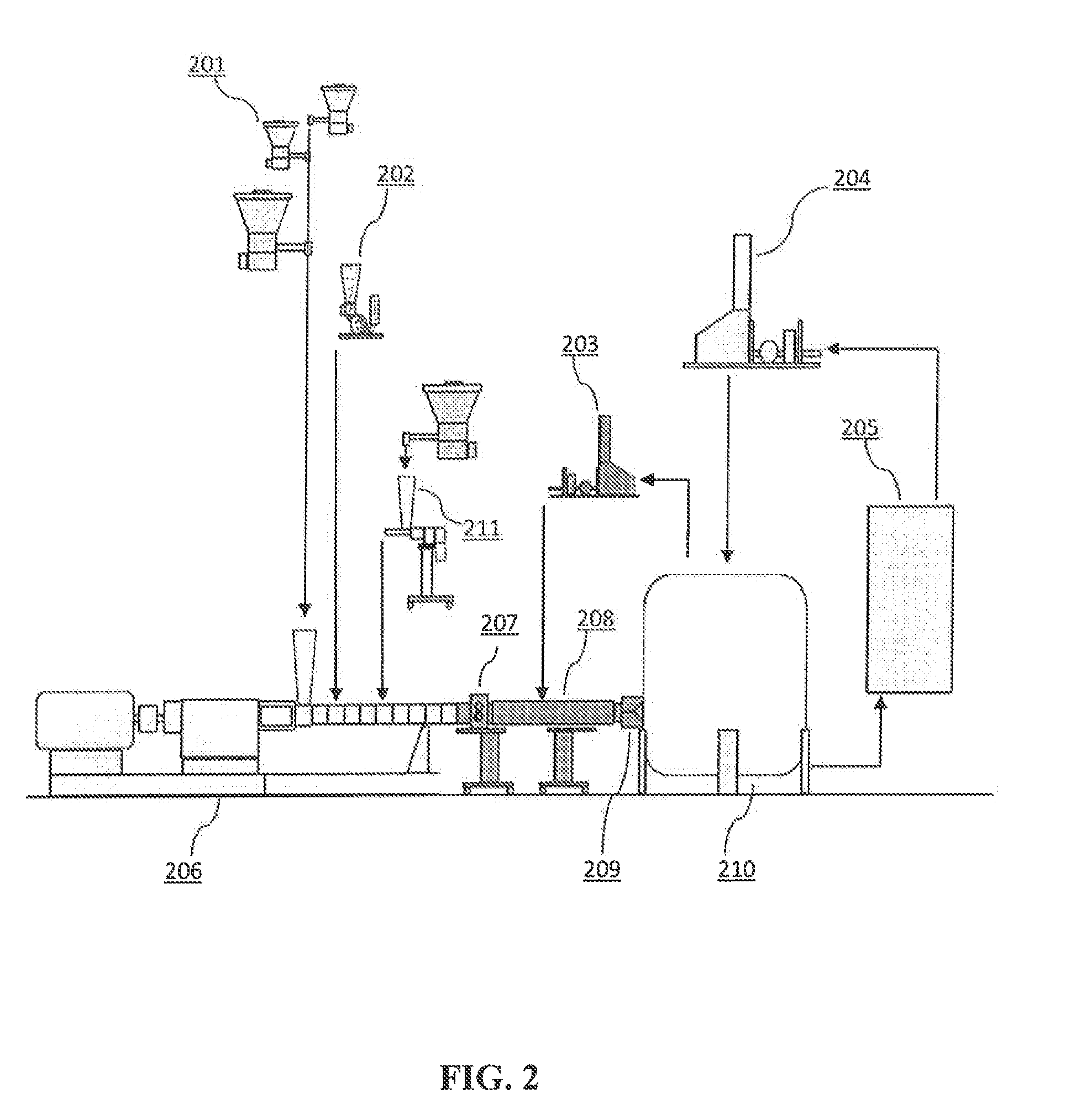

Continuous cellulostic pre-treatment and bio-mass processing by reactive extrusion

ActiveUS20120125324A1Increased ethanol productionExpand accessPressurized chemical processBiofuelsCelluloseCell wall

Cellulosic materials are treated with Supercritical Carbon Dioxide in an extruder. Machine configuration and operating parameters are strictly controlled in a manner to enhance the ability of Supercritical CO2 to enter into the cells. This results in a controlled deterioration of the ceil walls, increasing the reactivity of cellulose and also enhancing the rate and the extern of cellulose hydrolysis. This precisely controlled combination of pressure, shear & temperature accelerates the penetration of carbon dioxide molecules into the crystalline structures, thus more glucose is produced from cellulosic materials after the cell is destructurized as compared to those without the pretreatment increasing glucose yield by as much as 50%. Concurrent saccharification and fermentation tests also show the increase in the available carbon source from the cellulosic materials for fermentation to produce ethanol. As the system operates at low temperature, it will not cause degradation of sugars such as those treated with the high-temperatures involved in many systems discussed.

Owner:FISK DONALD L

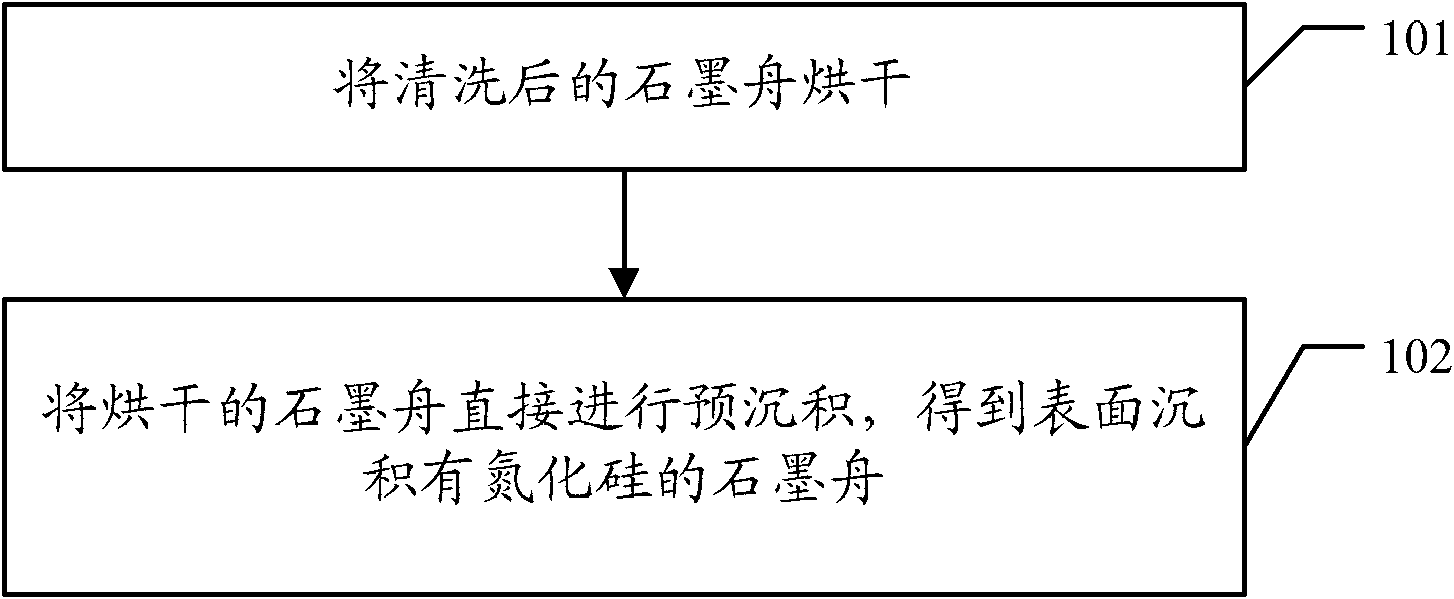

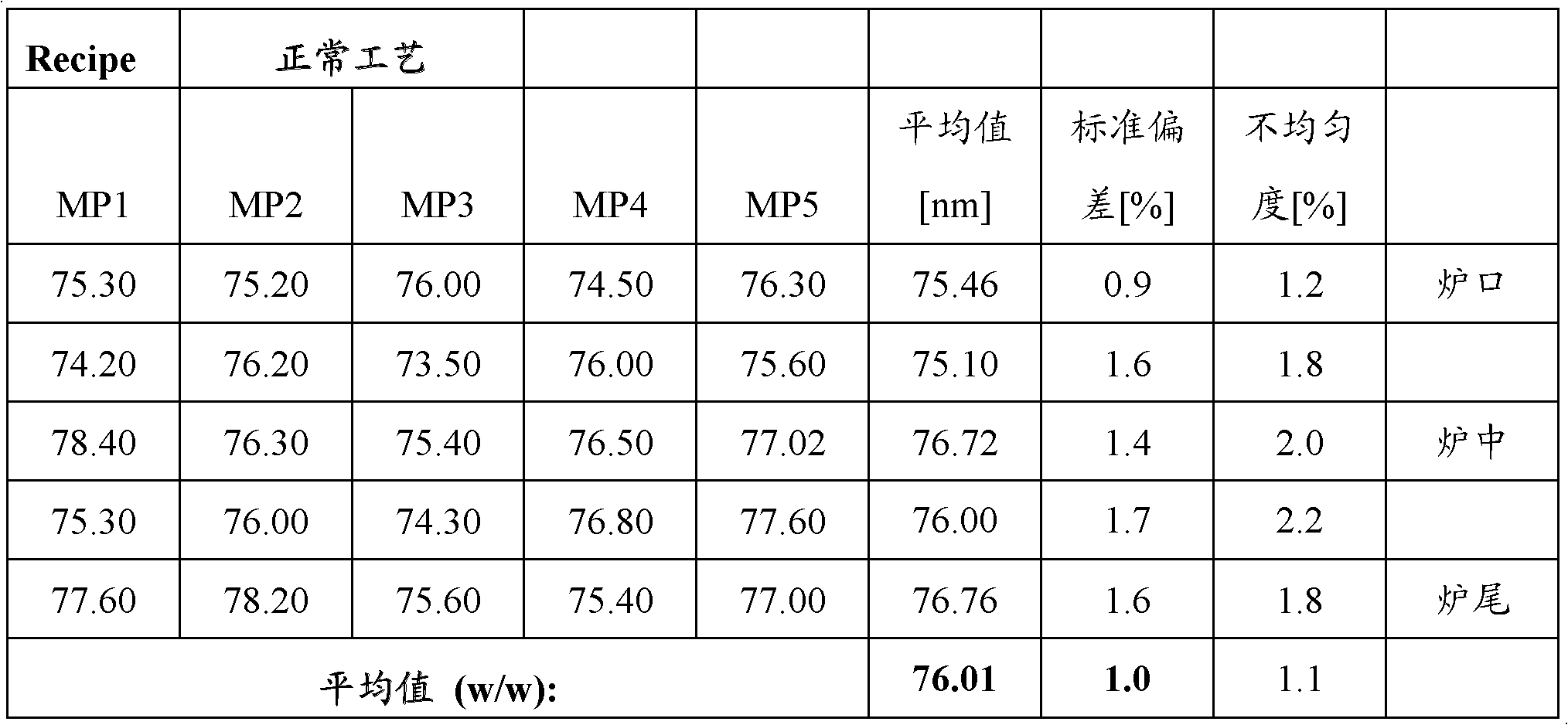

Graphite boat pretreatment method

InactiveCN103160803AReduce preprocessing timeReduce pretreatment costsFinal product manufactureChemical vapor deposition coatingPretreatment methodGraphite

The invention discloses a graphite boat pretreatment method. According to the invention, washed graphite boat is bake-dried; the dried graphite boat is directly subjected to pre-deposition, such that a graphite boat with silicon nitride deposited on the surface is obtained. According to the graphite boat pretreatment provided by the embodiment of the invention, the graphite boat is not needed to be inserted with a silicon chip before graphite boat pre-deposition, such that graphite boat pretreatment time is reduced, and graphite boat pretreatment cost is reduced.

Owner:JETION SOLAR HLDG

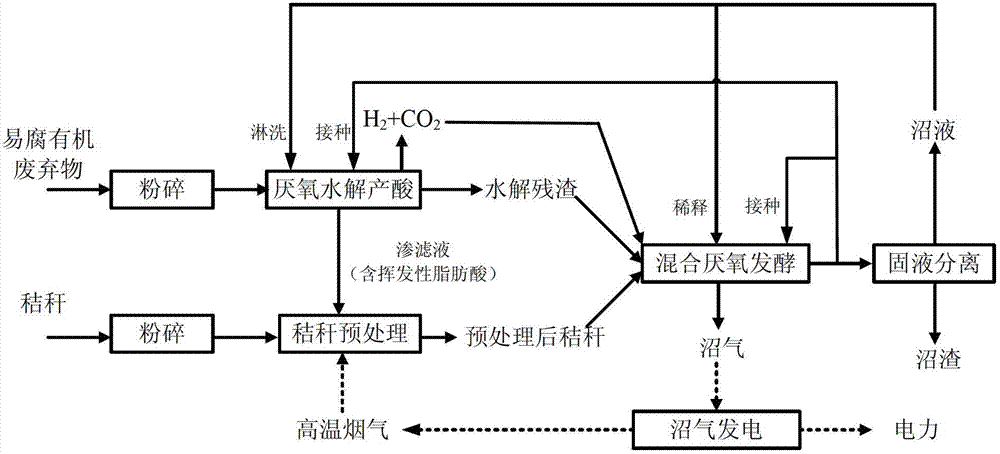

Method for producing methane through combination of perishable organic wastes and straws

ActiveCN102757980AImprove fermentation effectAvoid "acidosis"Waste based fuelFermentationStrong acidsMethane fermentation

The invention discloses a method for producing methane through combination of perishable organic wastes and straws. The method comprises the following steps: step 1, collecting the perishable organic wastes and the straws, and respectively crushing; step 2, filling the crushed perishable organic wastes on percolation fillings of a solid percolation bed, adding fermenting methane inoculants, and carrying out anaerobic hydrolysis to produce acid so as to form percolate; step 3, collecting the percolate discharged from the bottom of the solid percolation bed, adding the percolate and the crushed straws into a straw pretreatment reactor, heating, soaking and pre-treating; and step 4, collecting a mixture of hydrolysis acid production residues, and pre-treated straws and percolate, adding the mixture into a methane fermentation reactor, and carrying out hybrid anaerobic fermentation to produce the methane. According to the invention, acid poisoning of the perishable organic wastes, which is easy to happen in the conventional anaerobic fermentation process, and abrasion of equipments and pipelines in the conventional strong acid / strong alkali pretreatment can be avoided, the pretreatment cost of the straws is reduced, the method is beneficial for subsequent utilization of methane residues, and the fermentation performance of the methane is improved.

Owner:深圳市海吉星环保有限责任公司

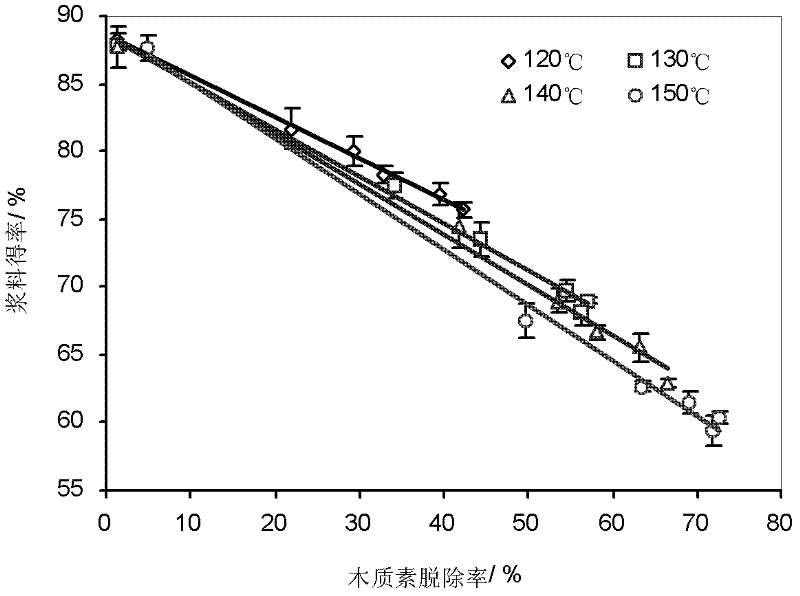

Pretreatment method for improving enzymatic hydrolysis and saccharification efficiency of non-wood fiber raw material

InactiveCN102517358ARealize industrial productionImprove hydrolysis efficiencyFermentationFiberPretreatment method

The invention discloses a pretreatment method for improving enzymatic hydrolysis and saccharification efficiency of a non-wood fiber raw material. The method comprises the following steps of: mixing an aqueous solution of sodium carbonate and the non-wood fiber raw material, pre-impregnating for 30 to 120 minutes at the temperature of between 30 and 90 DEG C, heating to the temperature of between 100 and 180 DEG C, performing heat preservation reaction for 0 to 120 minutes, washing the non-wood fiber raw material by using water, defibering the raw material into fibrous pulp by using a stuff grinder, and thus completing the pretreatment process. The yield of the pretreated non-wood fiber raw material is between 50 and 90 percent, the removal rate of lignin is between 10 and 80 percent, the loss of high glycan is between 0 and 25 percent, a little silicon dioxide is dissolved from the non-wood fiber raw material in the pretreatment solution, and most silicon dioxide is preserved in the pretreated non-wood fiber raw material.

Owner:NANJING FORESTRY UNIV

Internal pressure type fiber-reinforced filter membrane and preparation method thereof

ActiveCN103949166ASimple designEasy to operateSemi-permeable membranesInternal pressureWater production

The invention relates to an internal pressure type fiber-reinforced filter membrane and a preparation method thereof. The internal pressure type fiber-reinforced filter membrane is formed by coating the inner surface of a hollow braided tube with a layer of high-polymer membrane casting liquid and carrying out solidification and water washing under the action of internal and external coagulating bath solutions. By preparing the membrane by virtue of the hollow braided tube, the membrane casting liquid and a spinneret plate coextruded by internal coagulating core liquid, a continuous membrane preparation process is realized; the high-polymer membrane casting liquid contains a hydrophilic agent, and thus the prepared fiber-reinforced filter membrane is high in flux and strong in anti-pollution capacity. The internal pressure type fiber-reinforced filter membrane has the beneficial effects that the filter precision is high, a pore structure of the membrane can be controlled by virtue of process parameters of a membrane casting liquid preparation process and a membrane preparation process, the cross flow of inlet water is realized, the reflux ratio is low, and the water production rate is high; compared with an internal pressure type filter membrane, the internal pressure type fiber-reinforced filter membrane has the advantages that a runner is wide and is unlikely to be blocked, feed liquid with high content of suspended solids can be directly processed, and the pretreatment cost is lowered.

Owner:盐城海普润科技股份有限公司

High efficiency lime powder product and production process thereof

The invention discloses a high efficiency lime powder product and a production process thereof and particularly relates to a surface-modified lime powder product used in molten iron desulfurization pretreatment process and a production process thereof. According to the production process, silicone oil is firstly selected as surface modifier to be sprayed on crushed active lime; the adding amount of the surface modifier is 0.1-0.3% in percentage by weight. The surface-modified lime powder product disclosed by the invention has the advantages that the powder product is high in hydrophobicity and flowability and low in cost and is suitable for molten iron desulfurization pretreatment; the problems that a gun is blocked by lime powder and the lime powder is bonded on the material tank wall in the molten iron pretreatment process can be well solved, the lime powder can effectively penetrate through a gas-liquid interface and enter the interior of molten iron, so that the use ratio of calcium oxide is increased by a large margin and the molten iron pretreatment cost can be remarkably reduced; in addition, the production process of the powder product is simple, can be carried out at room temperature and is relatively simple in equipment, so that the powder product is small in investment, low in cost and high in efficiency.

Owner:TAIYUAN IRON & STEEL GROUP

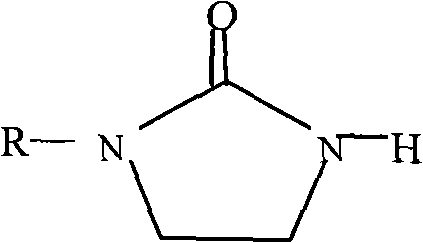

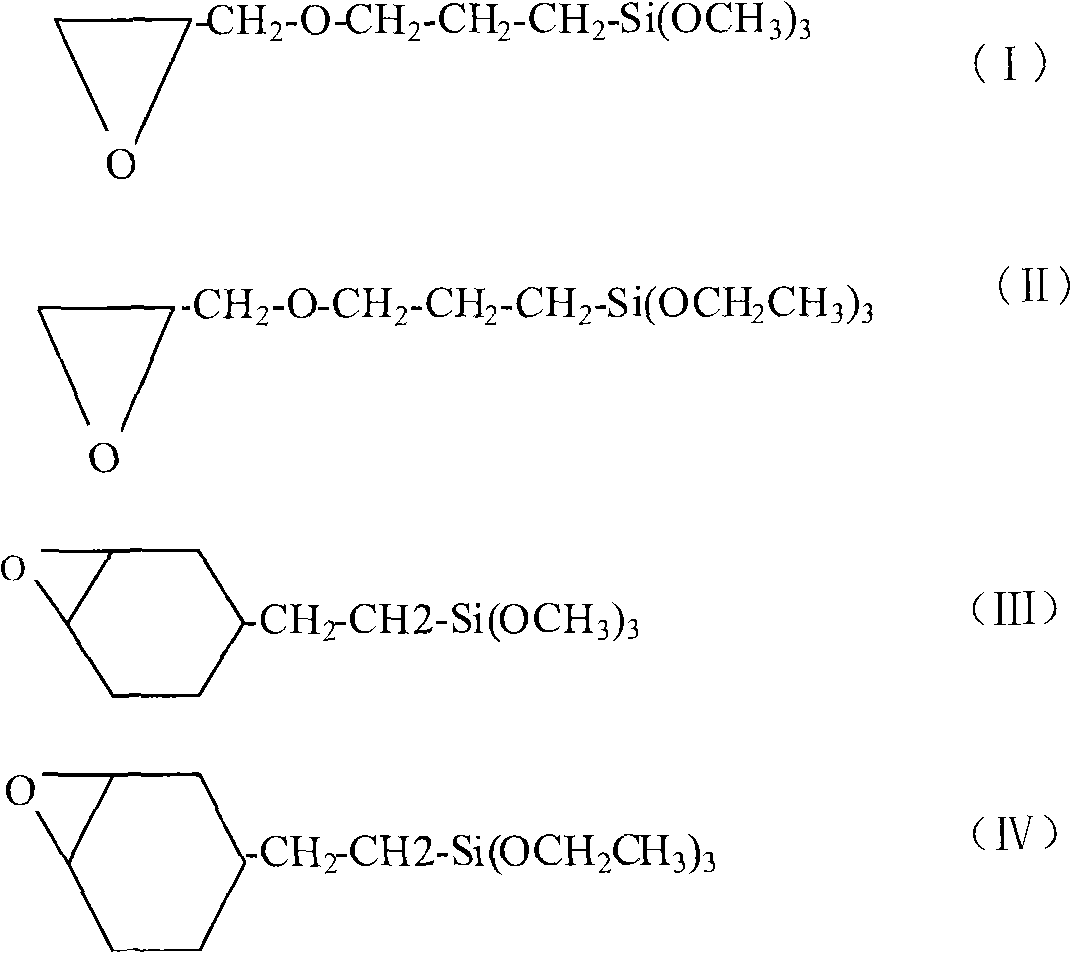

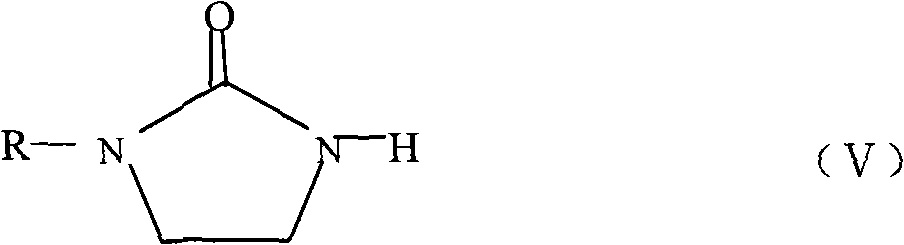

Ceramic coating film composite and preparation method thereof

ActiveCN102061126AStrong adhesionExemption from sandblasting process requirementsCoatingsMetallurgySilanes

The invention relates to a ceramic coating film composite and a preparation method thereof. The ceramic coating film composite comprises the following components: a component A and a component B, wherein the component A comprises a sol, a tinting pigment, water and an auxiliary; and the component B comprises at least one silane coupling agent with an epoxy functional group and an adhesion promoter formed by the reaction of compounds including iminazole silane ketone ring; the weight ratio of the component A to the component B is 2:1 to 1:1.5; and the total weight ratio of the sol particle in the component A and the component B is 15:40 to 40:100. The invention also provides a method for preparing the ceramic coating film composite.

Owner:上海金力泰化工股份有限公司

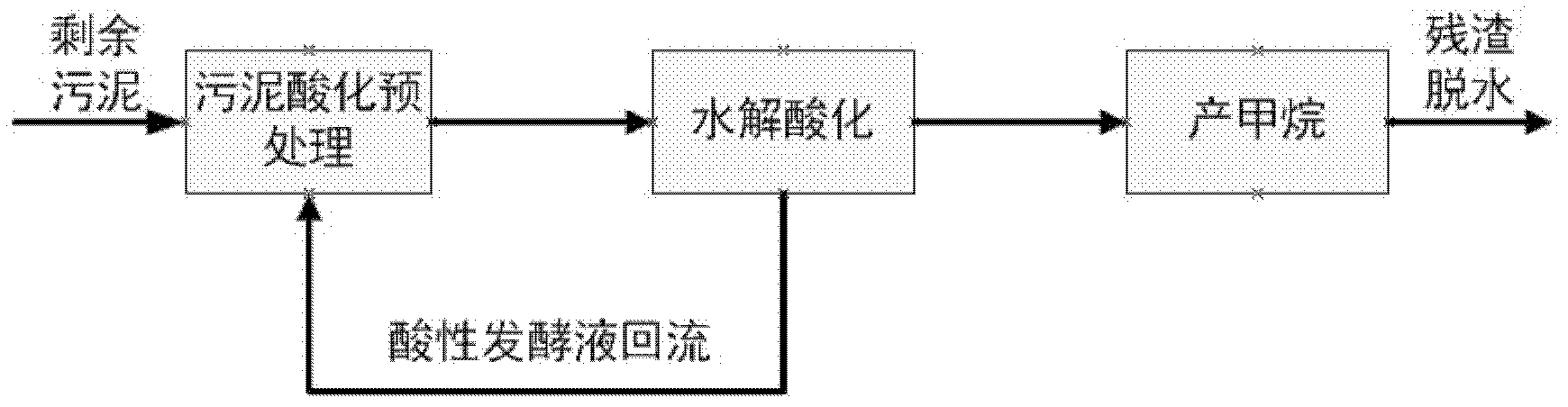

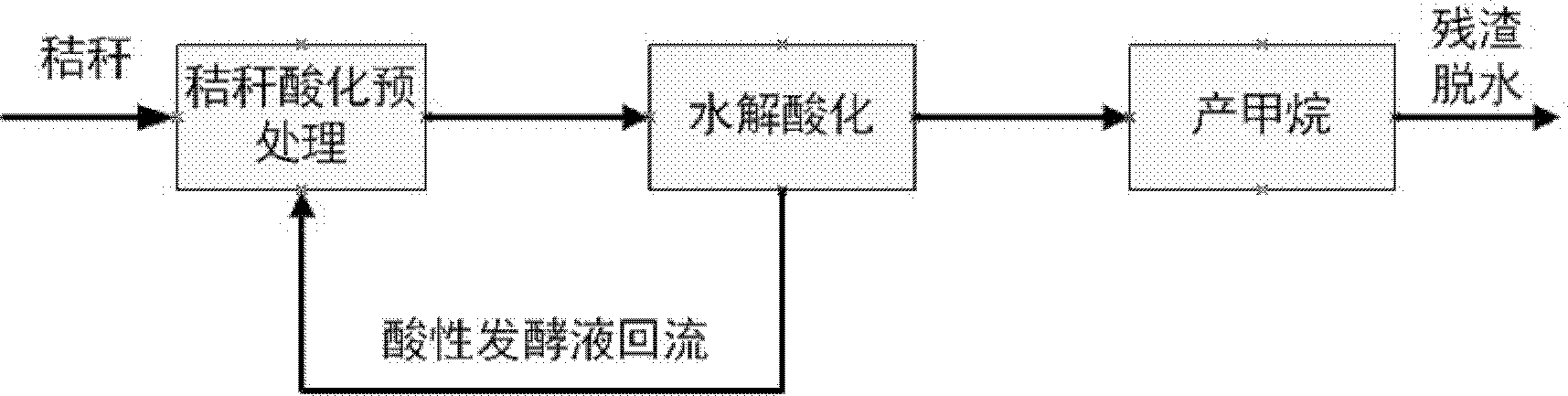

Method for treating sludge through refluxing of acidified fermentation liquor and application of method

InactiveCN102531311AIncrease productionReduce pretreatment costsWaste based fuelBiological sludge treatmentMethane productionPre treatment

The invention discloses a method for treating sludge through the refluxing of acidified fermentation liquor and application of the method. The method comprises the following steps of: performing hydrolytic acidification on the sludge, refluxing the acidified fermentation liquor of the sludge, performing acidification pretreatment on the sludge, and performing hydrolytic acidification fermentation on the pretreated sludge and producing methane by using a product. The sludge is subjected to acidification pretreatment by using the fermentation liquor of the sludge, so that the time required by anaerobic digestion is shortened, the gas yield is improved, and the operating cost is reduced.

Owner:TIANJIN UNIV

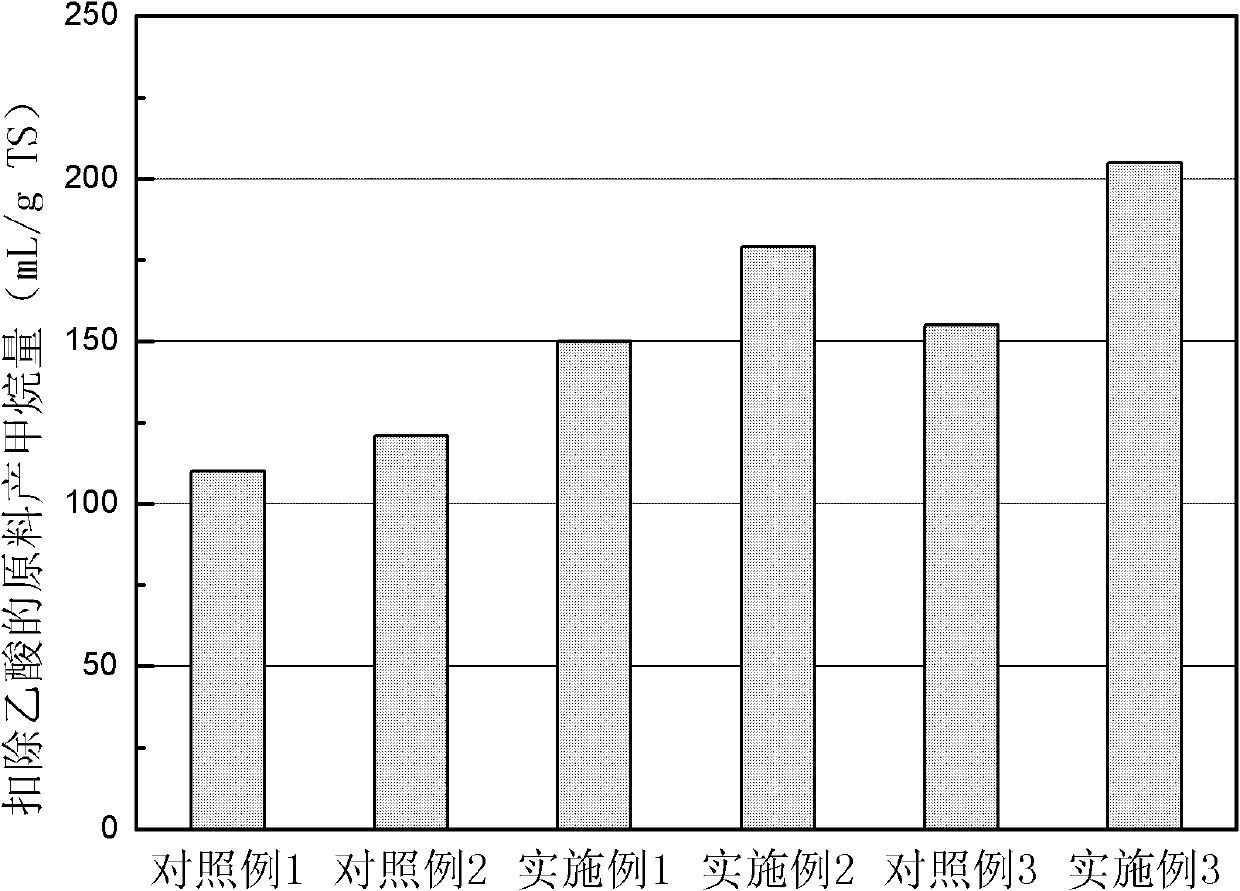

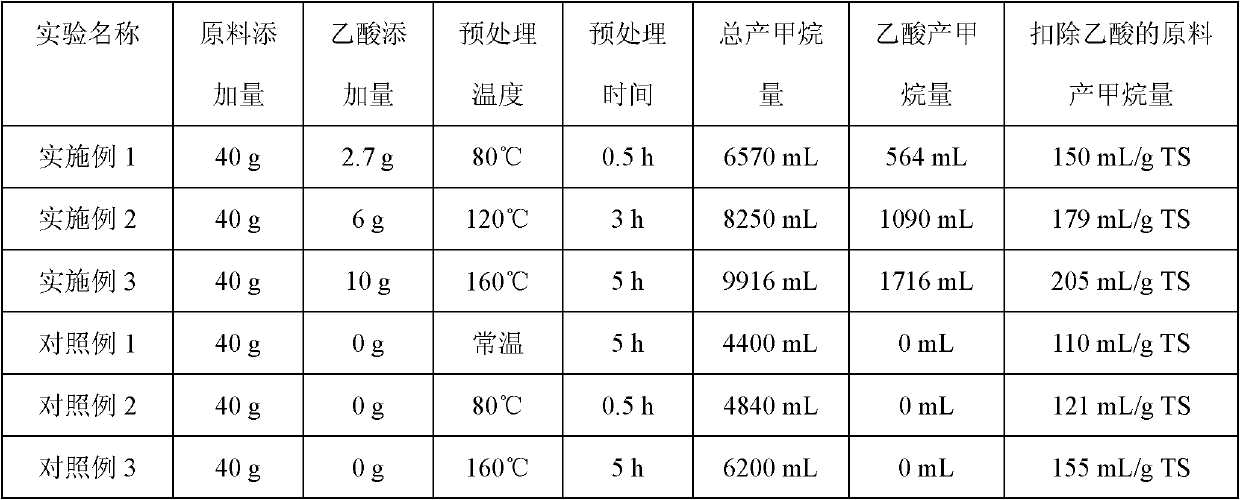

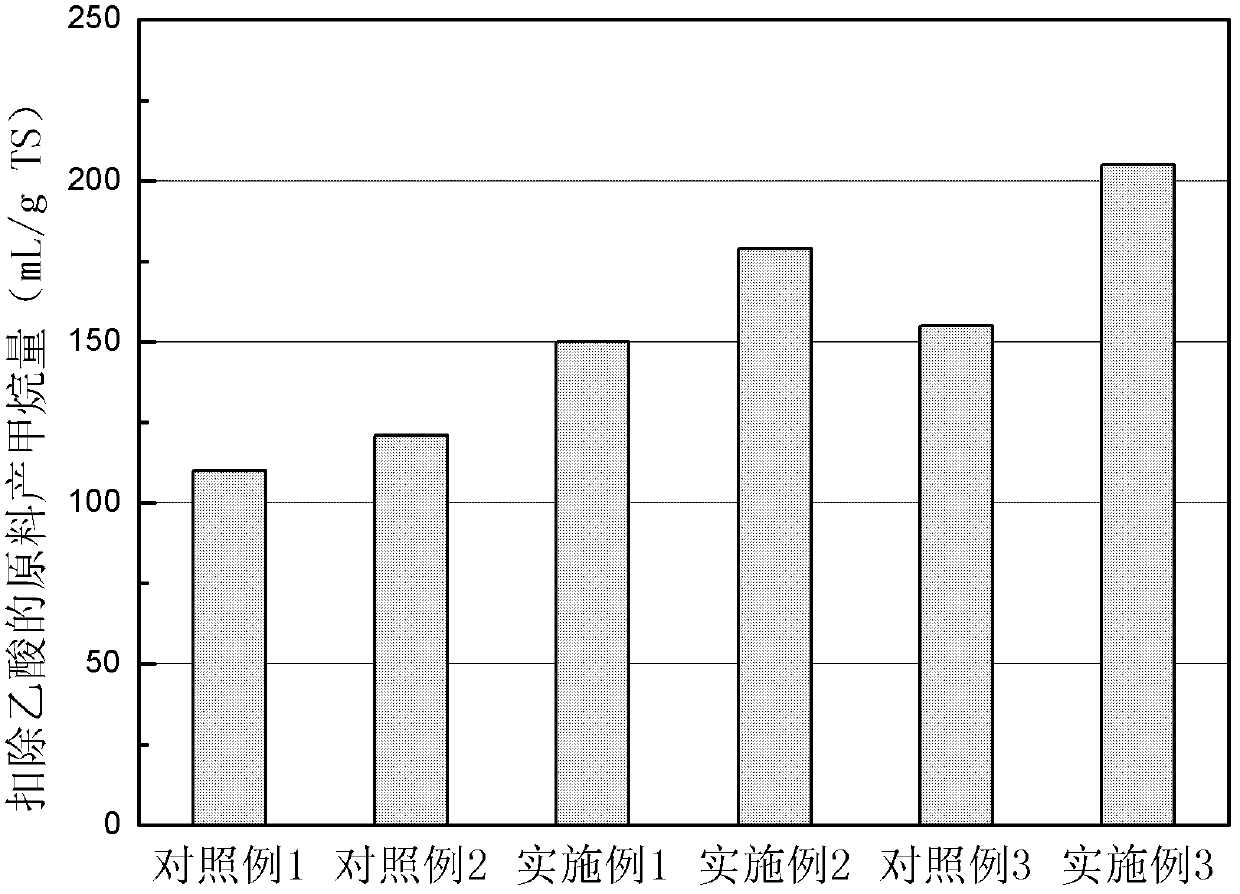

New method for pre-treating raw materials for fermenting wheat straw biogas

InactiveCN102604999AAvoid corrosionIncrease productionWaste based fuelFermentationVolatile fatty acidsMixed materials

The invention discloses a new method for pre-treating raw materials for fermenting wheat straw biogas. The method comprises the following steps of: crushing a wheat straw raw material; adding the crushed wheat straw raw material into a pre-treating reactor; adding a volatile fatty acid or organic waste water which contains the volatile fatty acid into the reactor in the mass ratio of the volatile fatty acid to dry wheat straws being 1:(4-15); adding water into the pre-treating reactor to adjust the mass concentration of the dry wheat straws to 8 to 15 percent; uniformly stirring the mixed materials; and after sealing the pre-treating reactor, pre-treating the materials for 0.5 to 5 hours by heating and soaking the materials, and controlling the temperature of the pre-treatment to be between 80 and 160 DEG C, thus obtaining the pre-treated raw materials. Corrosion to equipment and pipes can be avoided, the loss caused when organics are dissolved is avoided, the accumulation of alkali-metal ions which are introduced in a large amount is reduced, anaerobic fermentation inhabitation and environmental pollution are avoided, the subsequent utilization of biogas residues is facilitated, and the pretreatment cost for unit biogas yield can be reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

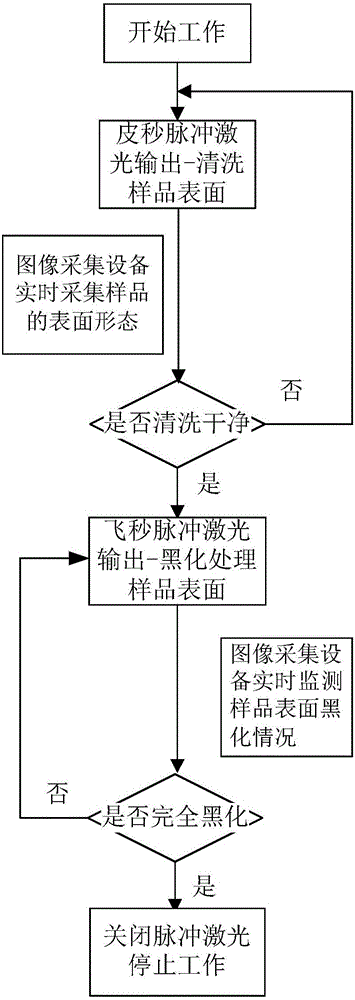

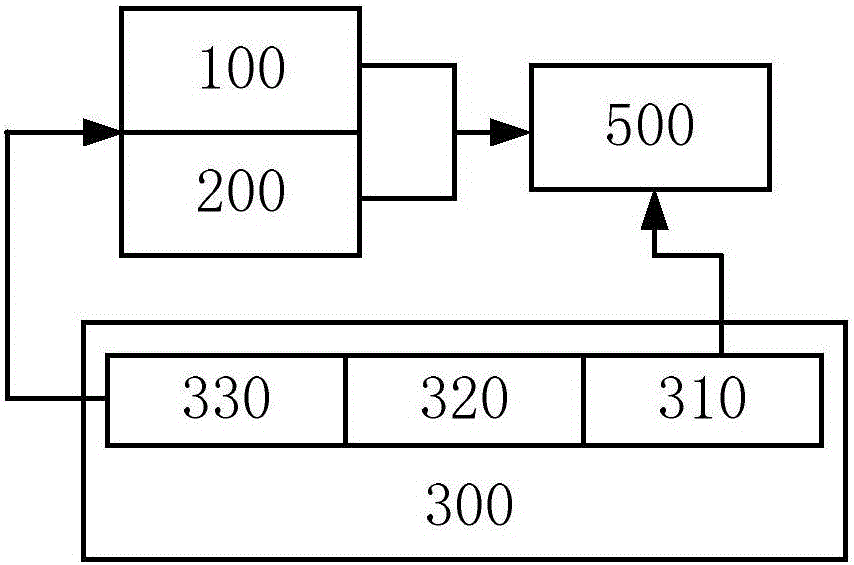

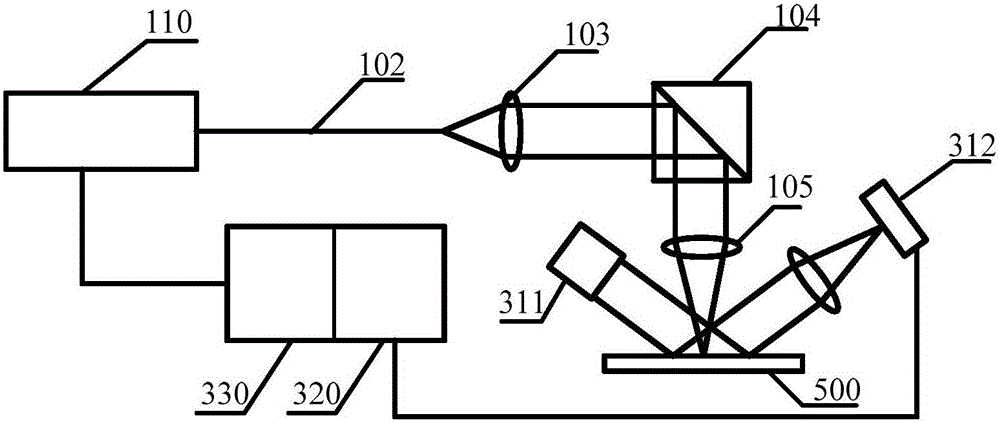

Pretreatment method and system for material surface before laser welding

ActiveCN106624367AImprove welding qualityImprove welding efficiencyLaser beam welding apparatusMicro nanoPretreatment method

The invention relates to a pretreatment method and system for a material surface before laser welding. The method comprises the following steps: firstly cleaning the surface of a sample by picosecond pulse laser, acquiring surface morphology of the sample in real time by image acquisition equipment while the surface of the sample is cleaned by virtue of the picosecond pulse laser, and judging whether the surface of the sample is clean or not according to the surface morphology of the sample, if the surface of the sample is not clean, continuing to clean the surface of the sample by virtue of the picoseconds pulse laser; if the surface of the sample is clean, turning off the picoseconds pulse laser, and carrying out blackening treatment on the surface of the sample by virtue of femtosecond laser; during the blackening treatment, monitoring the blackening condition of the surface of the sample in real time by the image acquisition equipment, when the surface of the sample is completely blackened, turning off the femtosecond laser, thus completing pretreatment on the material surface before welding. The method provided by the invention has the advantages that strong reflection action of the sample on lights can disappear, a micro-nano structure is formed on the surface, absorption efficiency of a material on laser in a laser welding process is greatly improved, and laser welding efficiency and quality are effectively improved.

Owner:美戈利浙江轨道交通研究院有限公司

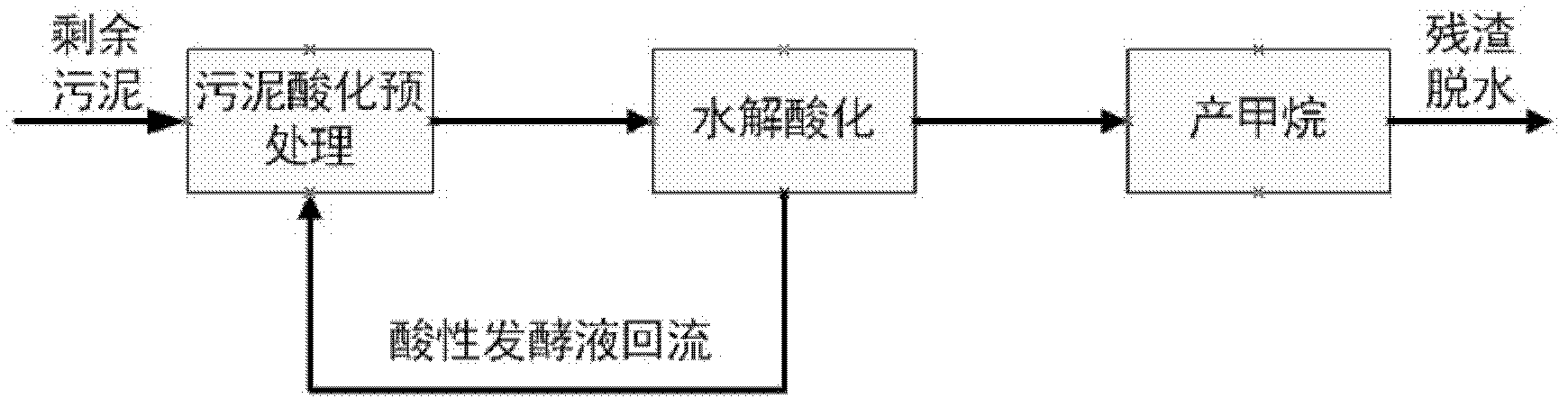

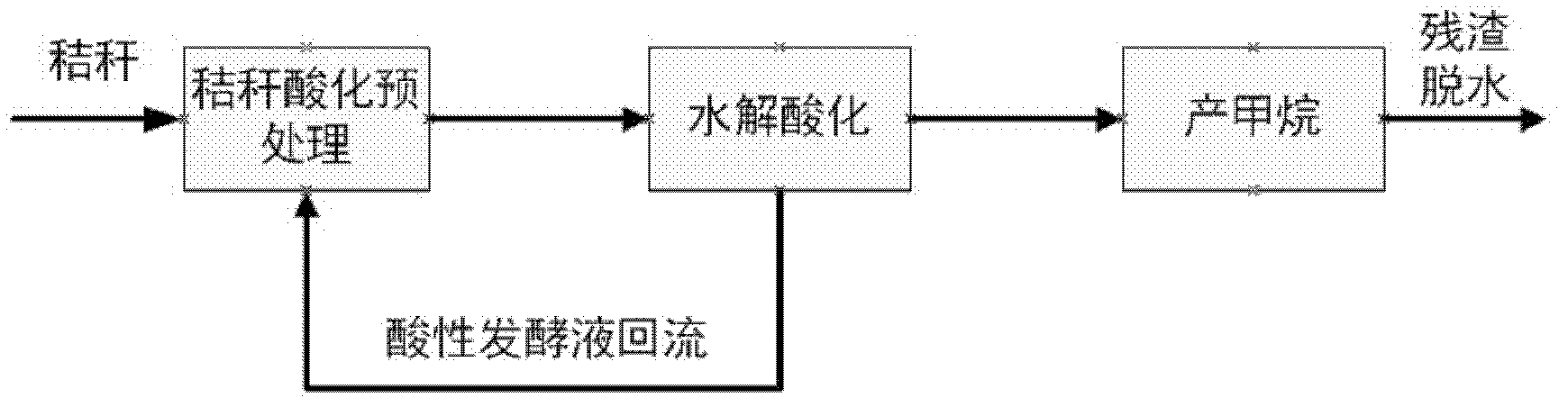

Method for treating crop straws by utilizing acidizing fermentation liquor backflow and applications thereof

InactiveCN102533871AIncrease productionReduce pretreatment costsWaste based fuelFermentationAgricultural scienceAgricultural engineering

The invention discloses a method for treating crop straws by utilizing acidizing fermentation liquor backflow and applications thereof. The method for treating the crop straws by utilizing the acidizing fermentation liquor backflow comprises the following steps: performing hydrolytic acidification on the crop straws; then, enabling the acidizing fermentation liquor of the crop straws to flow back to perform acidolysis pretreatment on the crop straws; then, performing hydrolytic acidification fermentation on the pretreated crop straws; and finally, producing methane by utilizing the crop straws. According to the method for treating the crop straws by utilizing the acidizing fermentation liquor backflow, the acidolysis pretreatment is performed on the crop straws by utilizing the fermentation liquor of the crop straws, thereby, the time required by anaerobic digestion is shortened, the gas production rate is increased, and the operating cost is reduced. The invention provides a method for increasing the two-phase anaerobic digestion efficiency through pretreating the crop straws by utilizing the fermentation liquor backflow of the crop straws.

Owner:TIANJIN UNIV

Pretreatment process for combed polyester cotton bleached cloth

InactiveCN103437140AStrong damageHigh whitenessMercerising of indefinite length fabricsBiochemical fibre treatmentPolyesterEthylene diamine

The invention relates to a pretreatment process for combed polyester cotton bleached cloth. The pretreatment process comprises the procedures of singeing, desizing, bleaching, mercerizing and heat-shaping, wherein during desizing, the enzyme-desizing cold-dwelling process that desizing anzyme and a penetrant are added into the desizing procedure is adopted; in the bleaching procedure, the following materials are adopted: 0.2-0.4 part of potassium borate serves as the bleaching liquor, 0.8-1.2 part(s) of diethylenetriaminepenta acid (DTPMP), 0.8-2 part(s) of acrylic acid maleic acid copolymer, 0.5-1 part of 1, 5-anhydrous glucitol, 1-2 part(s) of caprolactam activator, 0.4-0.7 part of tetraacetylethylenediamine (TAED), 3-8 parts of sodium hydroxide, 3-7 parts of hydrogen peroxide and 900-1000 parts of water. When the pretreatment process is used for processing fabrics, prominent damage to the fabrics is small; as enzyme desizing is adopted, the desizing ration is improved; the bleaching liquor adopted in the bleaching procedure can effectively improve the whitenness of the fabrics; meanwhile, the pretreatment cost is lowered.

Owner:如皋市五山漂染有限责任公司

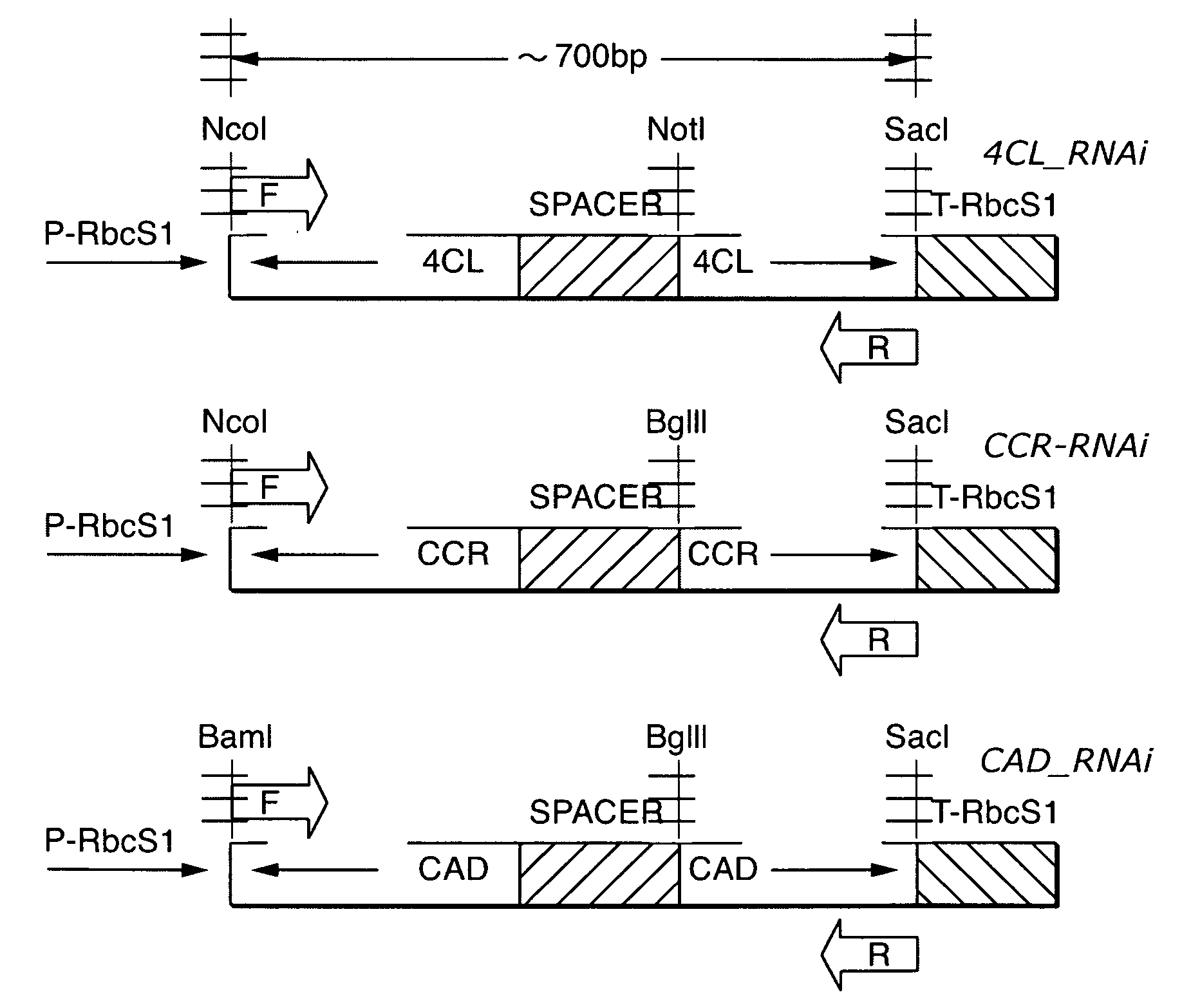

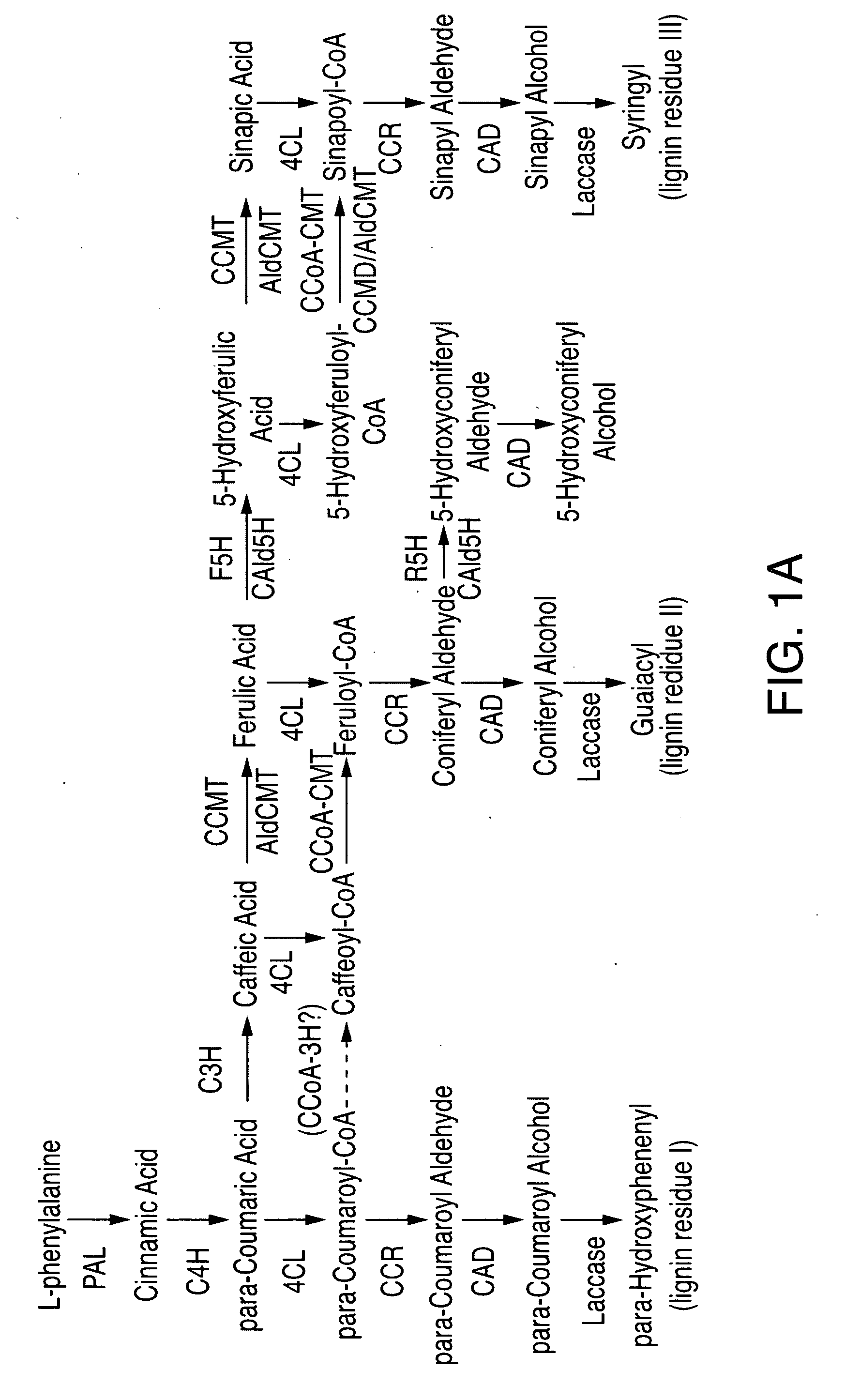

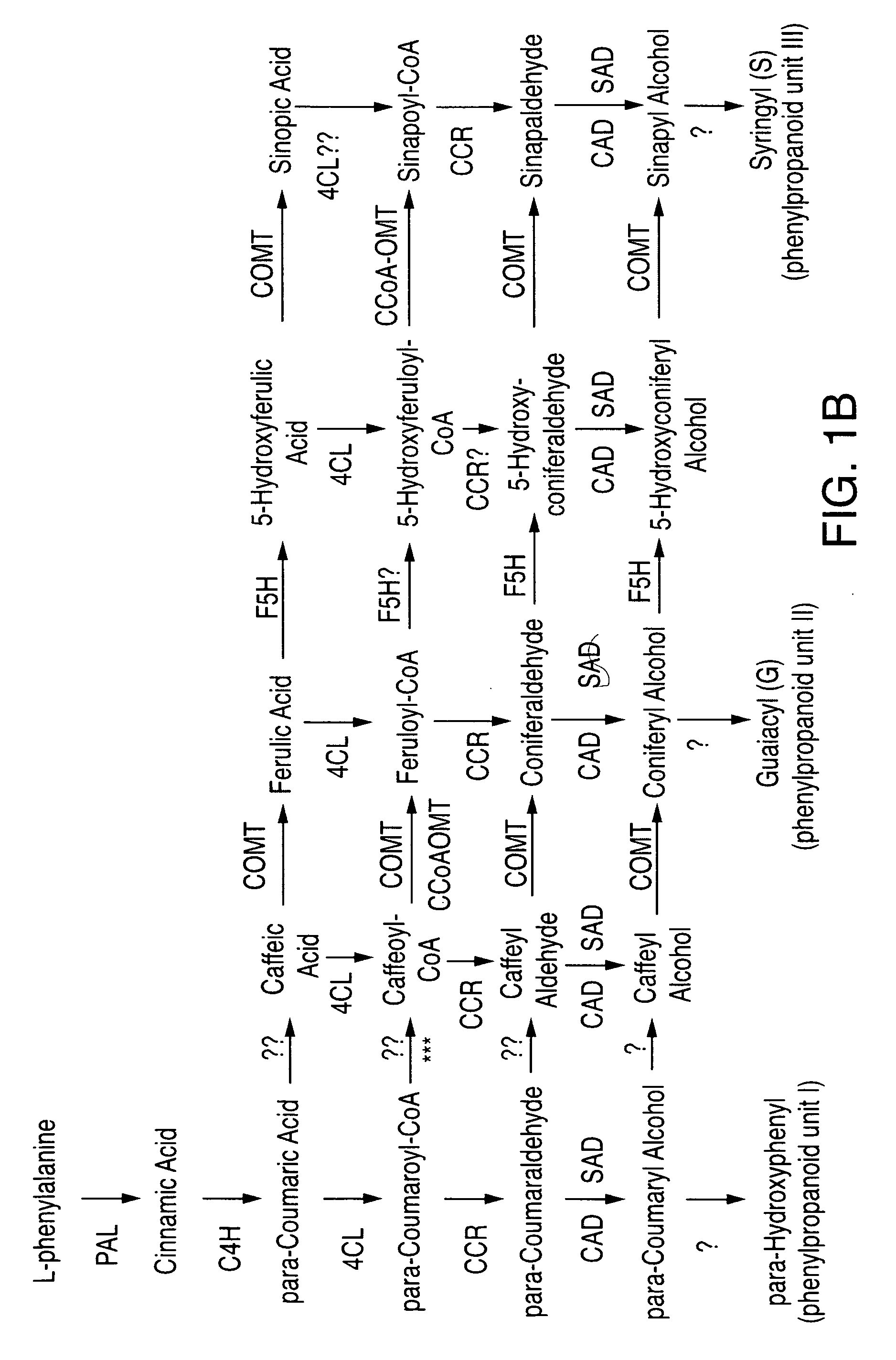

Altering regulation of maize lignin biosynthesis enzymes via RNAi technology

InactiveUS20080213871A1Increase in celluloseIncrease in amountBiofuelsOther foreign material introduction processesLignin biosynthesisCellulose

The present invention relates to compositions and methods for providing RNA Interference (RNAi) vectors comprising maize lignin biosynthesis enzymes for altering lignin content of plants. Specifically, plants comprising RNAi maize lignin vectors for reducing or altering lignin content are provided for reducing pretreatment costs of biofuel production. Additionally, RNAi maize lignin vectors are provided for altering cellulose production in plants for reducing pretreatment costs of plant biomass processing by increasing amounts of fermentable sugars.

Owner:MICHIGAN STATE UNIV

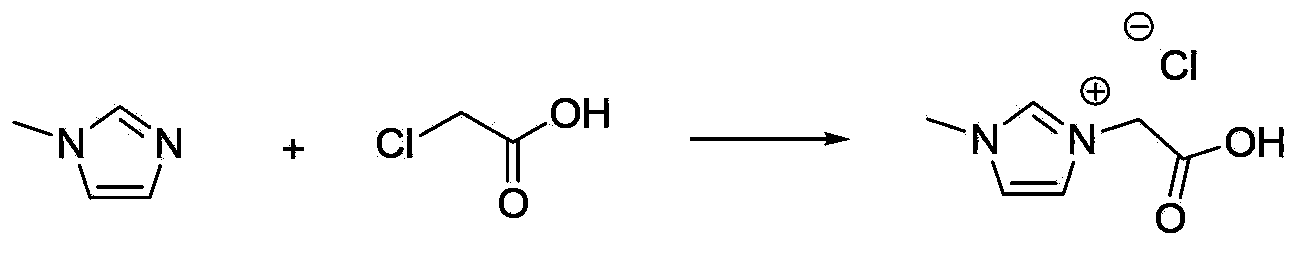

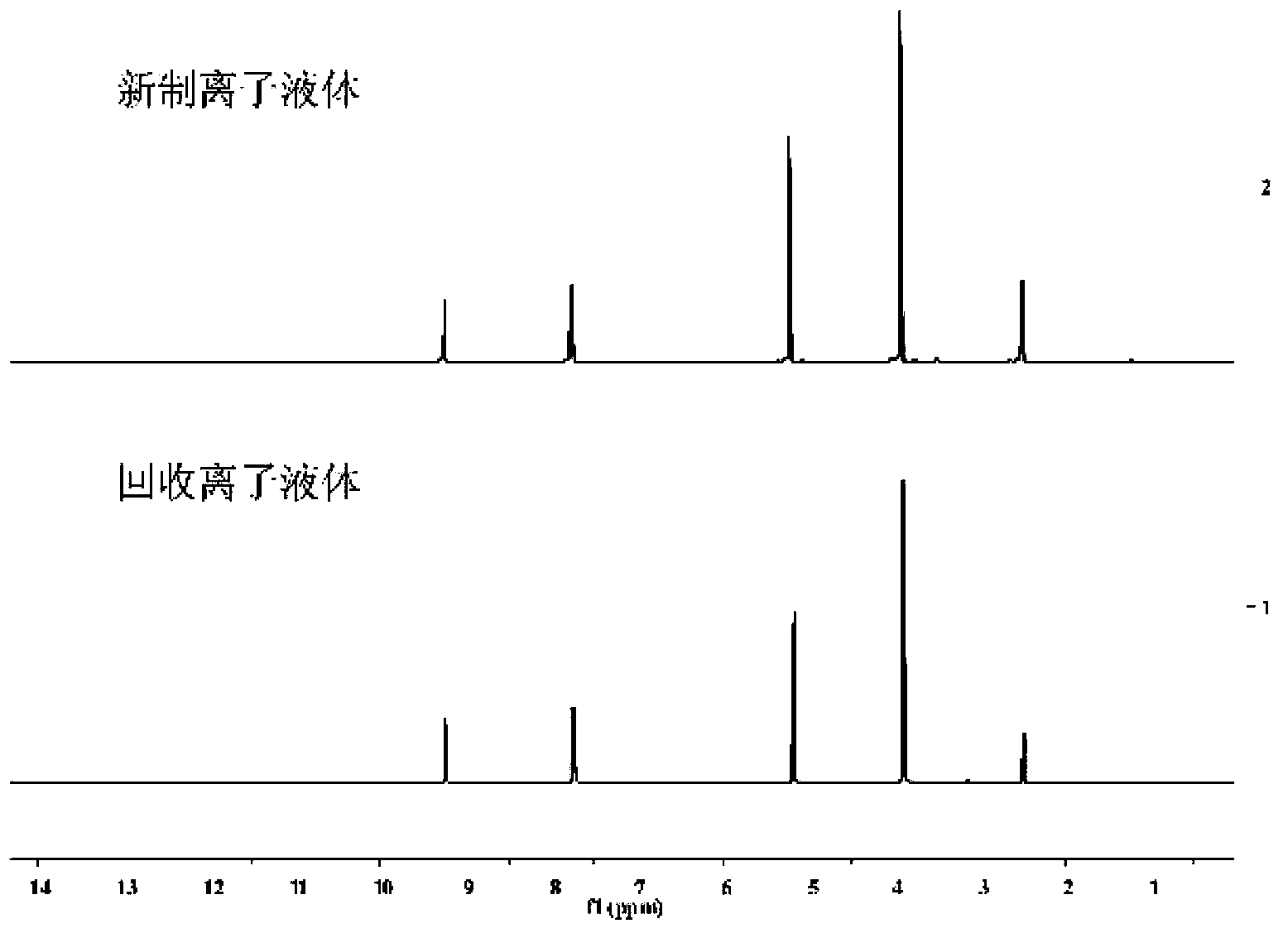

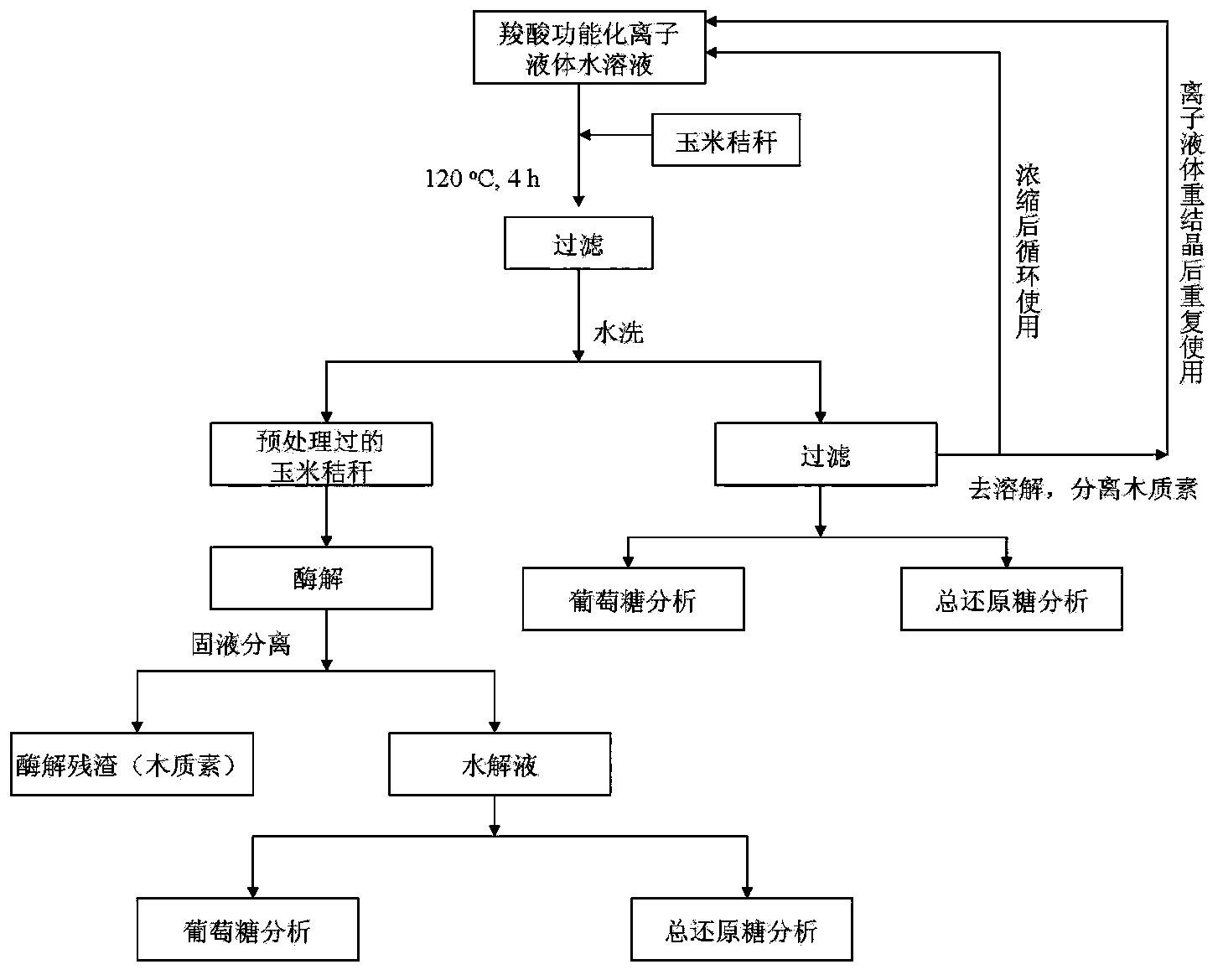

Method for pretreating lignocellulose by using carboxyl functionalized ionic liquid solution

ActiveCN103849665AReduce usageReduce pretreatment costsFermentationBulk chemical productionSolid phasesIon

The invention provides a method for performing green efficient hydrolysis pretreatment on lignocellulose biomasses. The method comprises the steps of performing pretreatment on a lignocellulose biomass in a reaction kettle at a certain temperature by adopting a mixed solution containing carboxyl functionalized ionic liquid and a solvent; selectively hydrolyzing hemicellulose in a raw material to realize separation of cellulose, hemicellulose and lignin in the lignocellulose raw material to finish the pretreatment process and improve the enzymolysis efficiency. A solid phase separated and cleaned to obtain a component rich in cellulose and lignin; the ionic liquid can be recycled. According to the method disclosed by the invention, a solution of the carboxyl functionalized ionic liquid is used as a pretreatment medium, the selective hydrolysis efficiency of the hemicellulose in the lignocellulose biomass is high, the separation of the cellulose and the lignin is relatively thorough, the enzymatic saccharification efficiency of a sample rich in cellulose is high, and the aims of environmental protection, efficient separation of components of lignocellulose and efficient preparation of low-cost fermentable sugar solution from a lignocellulose material are achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Textile continuous cold-batch pretreatment method, auxiliary used for method and preparation method of auxiliary

ActiveCN103147276ARealize the pre-treatment processReduce consumptionVegetal fibresPolyesterPretreatment method

The invention relates to a textile continuous cold-batch auxiliary, a preparation method of the auxiliary and a method of textile pretreatment. The continuous cold-batch auxiliary is composed of two parts including LYM-A and LYM-B, wherein the LYM-A and the LYM-B are produced and stored in an independent auxiliary mode, when application of mass production is conducted, the two parts, hydrogen peroxide and sodium hydroxide are configured to form working solution according to different proportions and prescription requirements, continuous desizing, scouring and bleaching pretreatment is conducted on woven fabrics such as cotton and polyester cotton on a long vehicle device under the conditions of temperature of 35-45 DEG C and time of 50-90 minutes, the two parts of the auxiliary are both environment-friendly and do not contain banned chemicals. The method can replace a conventional high-temperature steaming pretreatment process.

Owner:YANTAI YUANMING CHEM

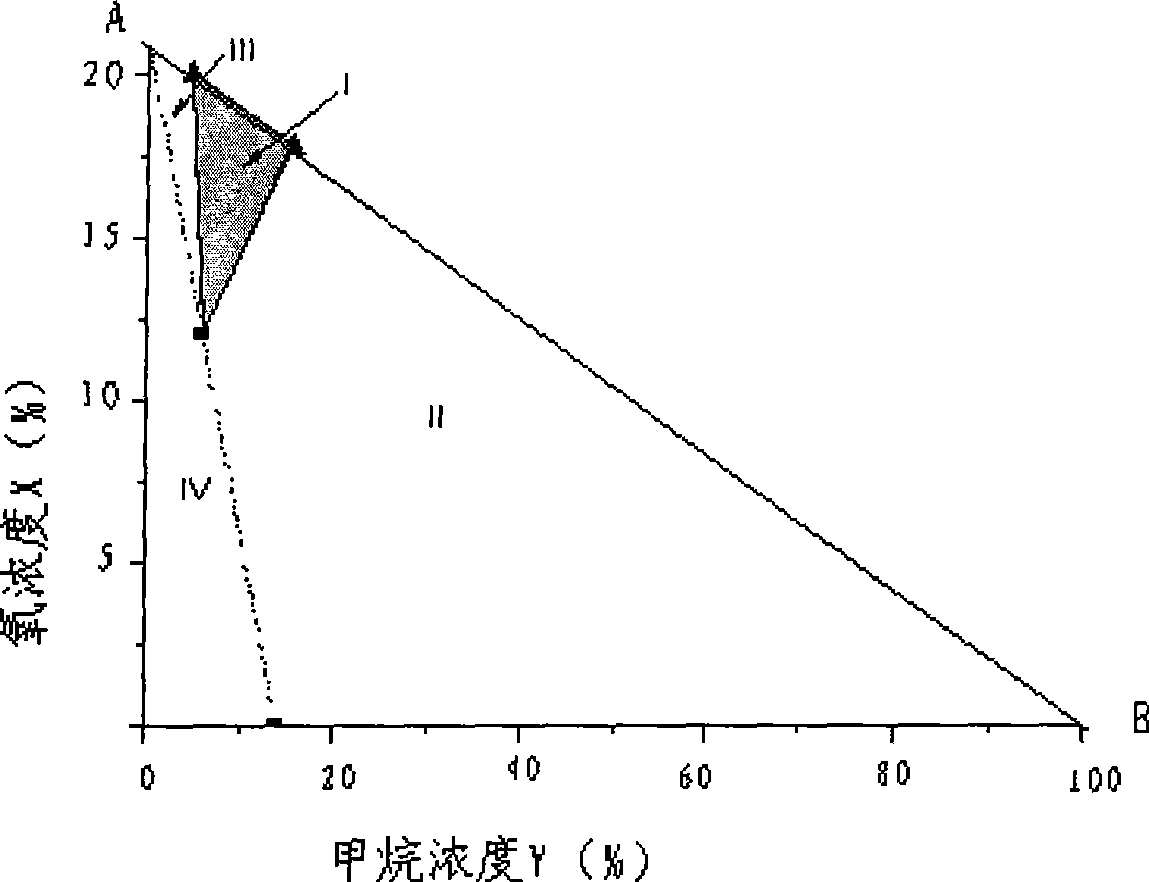

Method for purifying and separating methane from oxygen-containing coal bed gas

InactiveCN101531559AEnsure safetyReduce pretreatment costsDistillation purification/separationHydrocarbonsVolume concentrationCoal

The invention provides a method for purifying and separating methane from oxygen-containing coal bed gas, the method comprises the following steps of firstly cooling raw material gas of the oxygen-containing coal bed gas and then carrying out rectification treatment on the oxygen-containing coal bed gas; exhaust gas flows out from the top part of a rectification system, pure methane flows out from the bottom part of the rectification system, a) the initial volume concentration y<0> of the methane in the raw material gas is detected; b) the volume concentration Y of the methane is taken as an x-coordinate and the volume concentration X of oxygen is taken as a y-coordinate for establishing the coordinate region against the oxygen-containing coal bed gas in the separation process flow and determining an explosion triangle in the corresponding coordinate region of the oxygen-containing coal bed gas in the initial state; c) when the y<0> is positioned in the oxygen deficiency region of the coordinate region of the oxygen-containing coal bed gas at the position, the oxygen in the raw material gas to be cooled is removed; and d) the volume concentration of the methane is maintained, and the methane is separated from the raw material gas. The coarse oxygen removal according to the technical proposal of the invention can reduce the pretreatment cost of the raw material gas under the premise of more accurately ensuring no explosion.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

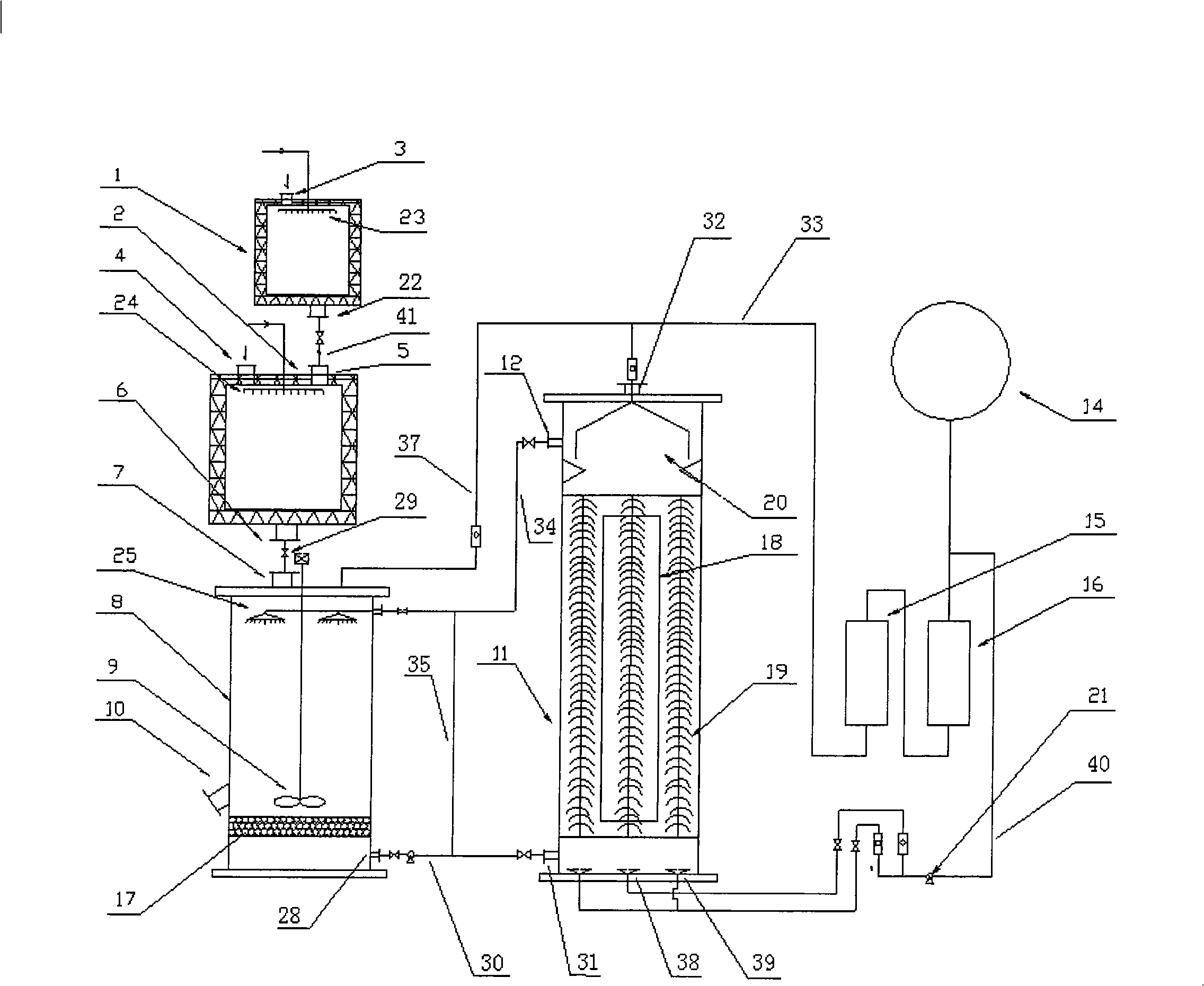

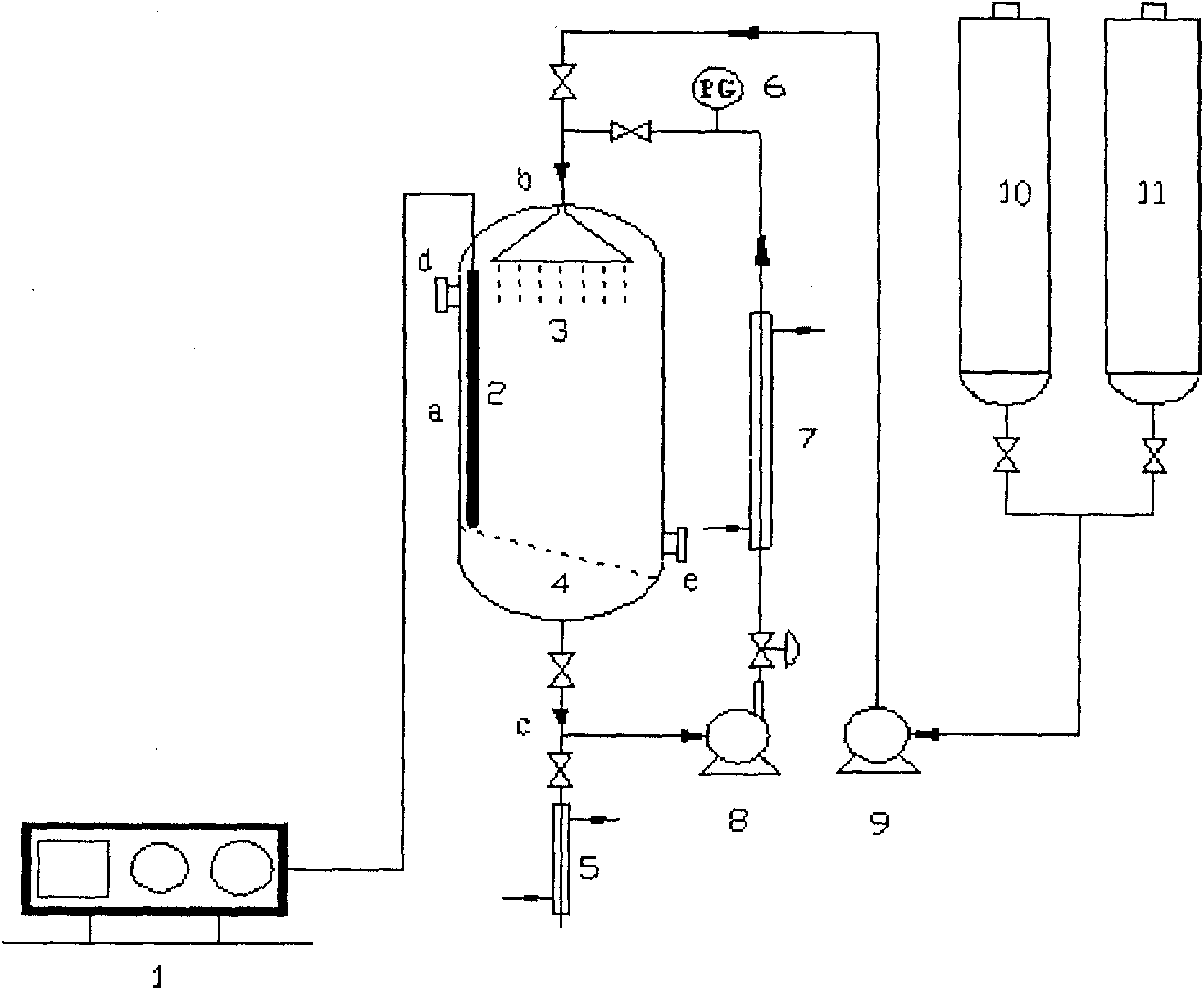

Apparatus and method for producing sludge gas with organic castoff

InactiveCN101314551ASolve pollutionRenewable energyBio-organic fraction processingWaste based fuelSludgeMethane production

The invention provides a device for preparing biogas by utilization of organic waste, comprising a biogas collector (14) used for storing the biogas and a methane production reactor (11) used for preparing the biogas through fermentation. The device is characterized in that: the device also comprises an acid treater (1) used for acid treatment of the organic waste, a caustic treater (2) used for alkaline treatment of the organic waste, and an acid production reactor (8), wherein, the acid treater (1) is communicated with the caustic treater (2) by means of fluid; the caustic treater (2) is communicated with the acid production reactor (8) by means of fluid; the acid production reactor (8) is communicated with the methane production reactor (11) by means of fluid; and the methane production reactor (11) is communicated with the biogas collector (14) by means of fluid. The device for preparing the biogas by utilization of the organic waste provided by the invention can improve the gas production efficiency by 50 to 120 percent, can simultaneously obtain potassium-enriched organic fertilizer if KOH is used, and has the excellent advantages of simple and high-efficiency technique, energy conservation, low cost and so on.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for coproduction of xylose, lignin and ethanol from corncobs

The invention discloses a method for the coproduction of xylose, lignin and ethanol from corncobs in the technical field of biochemical industry, comprising the following steps of: 1) hydrolyzing the corncobs under an acidic condition to obtain xylose solution and acidolysis residues; 2) performing alkaline liquor / alcohol extraction on the acidolysis residues to obtain lignin and lignin-free residues; 3) taking the lignin-free residues as an enzymolysis zymolyte, adding enzymolysis buffer solution, and performing enzymolysis using cellulase, thereby obtaining enzymolysis mixed solution; and 4) fermenting the enzymolysis mixed solution to produce ethanol solution. The method of coproduction of the invention comprehensively utilizes three components of the corncobs to obtain high value-added xylose and lignin products; and the cellulose content in the enzymolysis substrate is increased and the accessibility of the cellulase is improved, so that high transformation ratio of cellulose enzymolysis is realized. The method causes the utilization ratio of the lignocellulose raw material to be increased and the production cost of the cellulose ethanol to be reduced.

Owner:TSINGHUA UNIV

Pre-treatment method for micro-disseminated type refractory primary gold ore

ActiveCN104911372AImprove leaching rateReduce the impact of subsequent gold leachingProcess efficiency improvementPretreatment methodBiological oxidation

The invention discloses a pre-treatment method for micro-disseminated type refractory primary gold ore. According to the pre-treatment method for the micro-disseminated type refractory primary gold ore, mashed gold ore is performed with oxidation pre-treatment, alkaline leaching pre-treatment and leaching in sequence; the method can reduce the influence of the organic carbon in the gold ore on the subsequent gold leaching, the alkaline leaching process can enable quartz packaging gold to expose, and the gold leaching efficiency is improved. Compared with a traditional hot-pressing technology, the pre-treatment method for the micro-disseminated type refractory primary gold ore is capable of finishing the reaction under normal temperature and normal pressure conditions, and the pre-treatment cost is greatly lowered; compared with roasting oxidation pre-treatment, the pre-treatment method for the micro-disseminated type refractory primary gold ore has advantages of low energy consumption and environment friendliness; compared with a biological oxidation method, the period is short. The pre-treatment method for the micro-disseminated type refractory primary gold ore is easy to operate, low in cost and ideal in use effect.

Owner:GUIZHOU UNIV

Novel high-temperature steel slag modifier and modification pretreatment process

ActiveCN110055370AAchieve high temperature modificationAchieve recyclingManufacturing convertersSlagNitrogen

The invention discloses a novel high-temperature steel slag modifier and a modification pretreatment process, and belongs to the technical field of steel slag modification. The novel high-temperaturesteel slag modifier comprises a substance containing elemental silicon and a substance containing elemental carbon, the content of the elemental silicon in the substance containing the elemental silicon is more than or equal to 60%, and the content of the elemental carbon in the substance containing the elemental carbon is more than or equal to 80%. The invention further discloses the novel high-temperature steel slag modification pretreatment process which comprises the following steps 1) adding the substance containing the elemental carbon and the substance containing the elemental silicon into a slag tank in advance; 2) when a converter is deslagging, adding the substance containing the elemental silicon into the slag tank at the same time; 3) blowing nitrogen into a material after deslagging, and collecting generated dust at the same time; and 4) carrying out hot stuffy treatment on steel slag subjected to nitrogen blowing treatment in the step 3). The novel high-temperature steelslag modifier and the modification pretreatment process can effectively improve the stability and grindability of the steel slag and improve the recovery rate of the slag and steel.

Owner:MAANSHAN IRON & STEEL CO LTD

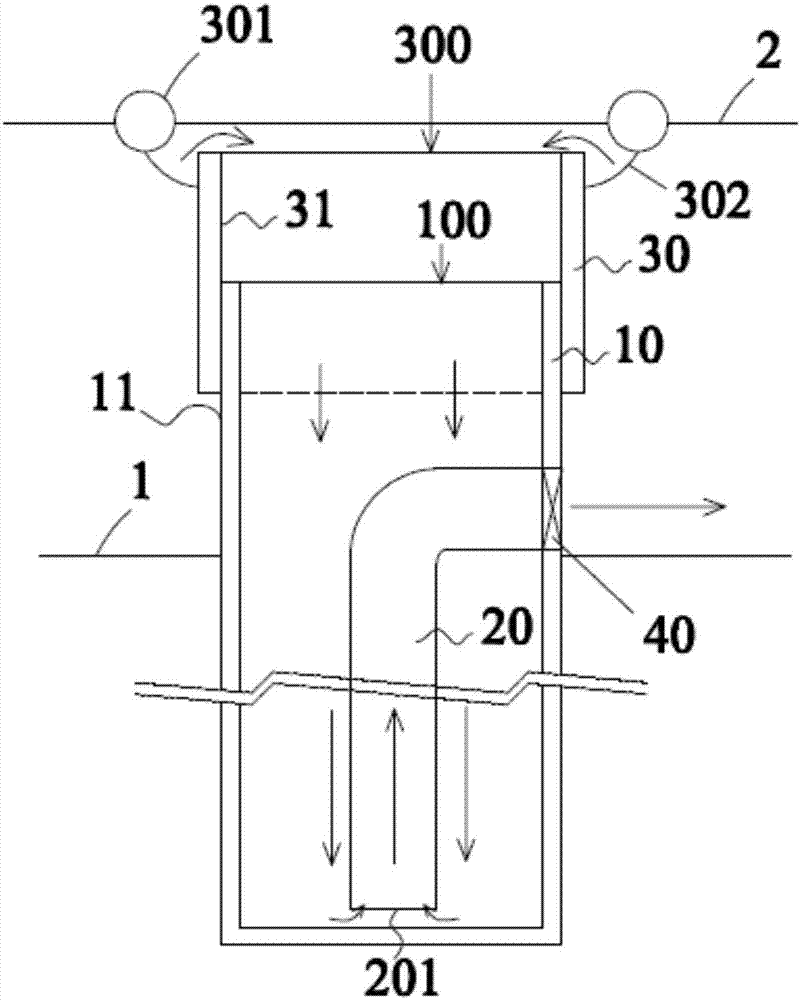

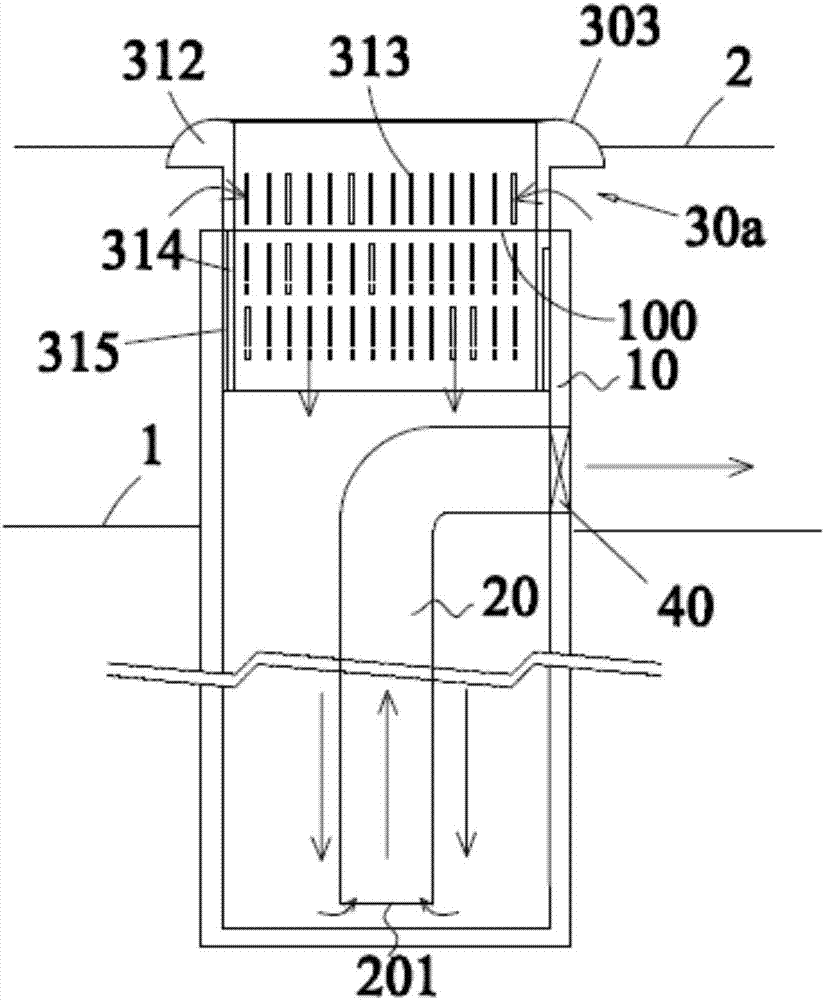

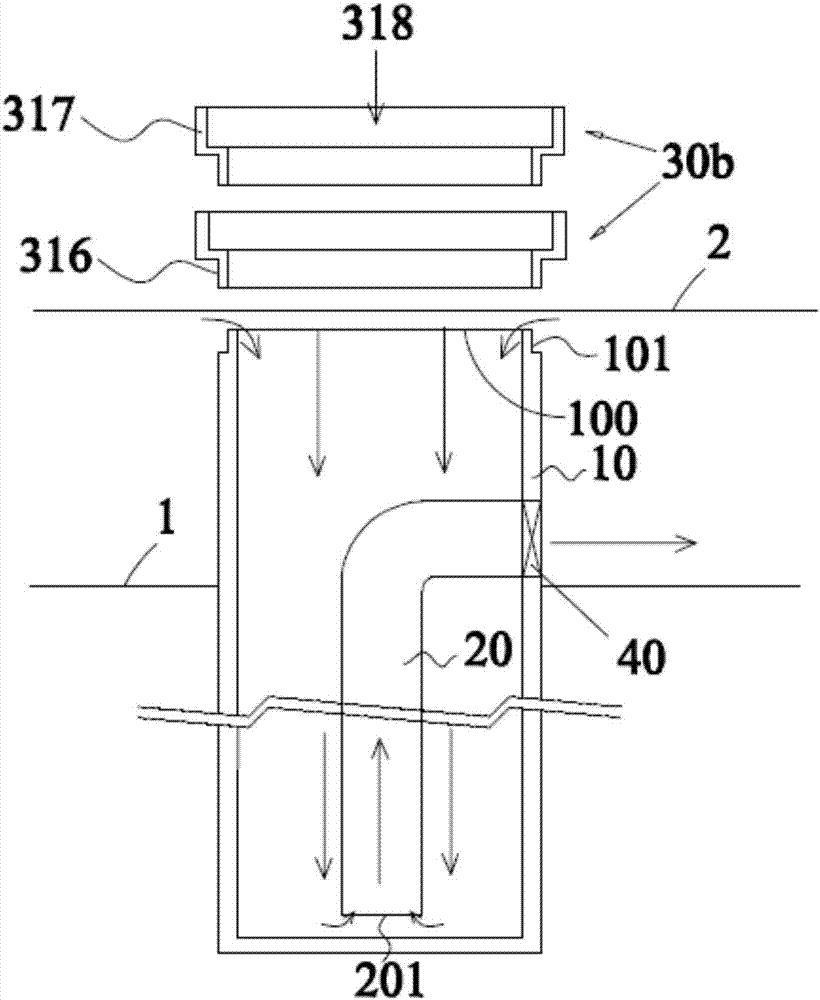

Blue alga deep well treatment device and blue alga treatment method

PendingCN107265526AEfficient ecological treatmentSuppress outbreakSpecific water treatment objectivesWater/sewage treatmentAlgaeEnvironmental geology

The invention provides a blue alga deep well treatment device and a blue alga treatment method. The blue alga deep well treatment device comprises a deep well and a water draining device, the top of the deep well is provided with a water inlet and is inserted to the bottom of water, the water draining device is arranged at the side part of the deep well and is higher than the water bottom, the water draining device is connected with one end of a water draining tube, and the other end of the water draining tube extends to the bottom of the deep well. A hydrostatic pressure formed at the bottom of the deep water by the water guided into the deep well is used to break blue algae in order to form blue alga fragments, and a negative pressure formed by the water draining device guides the blue algae to the bottom of the deep wall and discharges the blue algae from the deep well in order to make the blue algae directly preyed by fish, zooplanktons and benthonic animals in the water, so the high-efficiency ecologic treatment of the blue algae is realized, the blooming of the blue algae is effectively prevented, and the water quality is effectively improved, thereby the blooming of the blue algae is fundamentally prevented, the blue alga pretreatment cost is reduced, and stink is prevented.

Owner:WUXI DELINHAI ENVIRONMENTAL PROTECTION TECH CO LTD

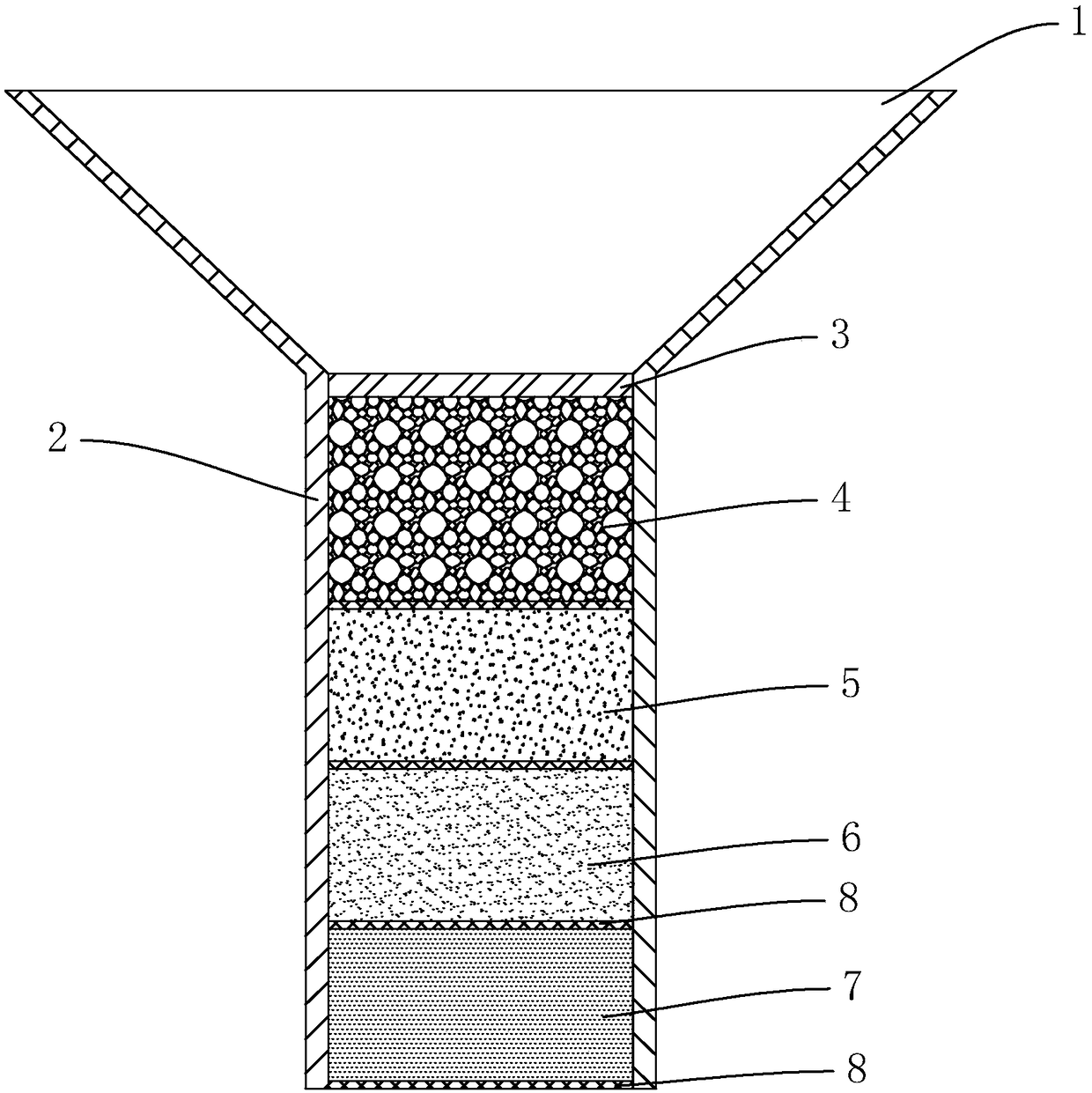

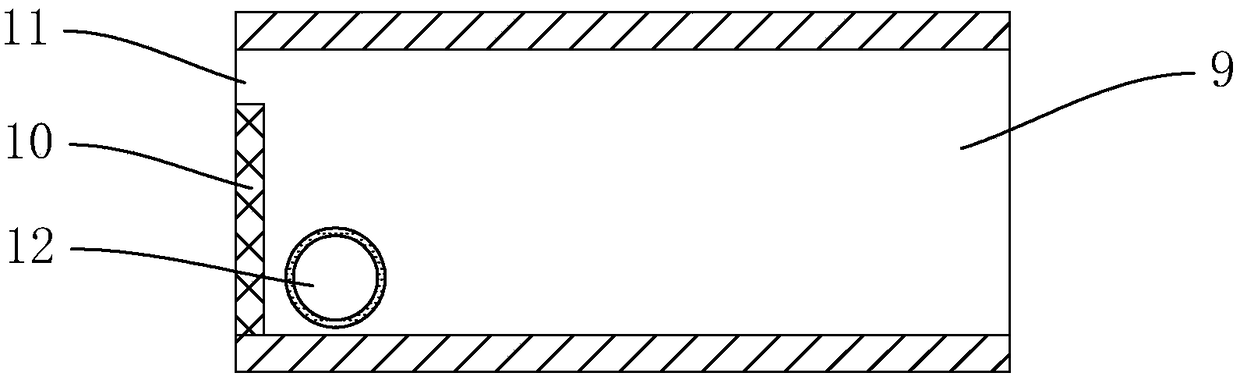

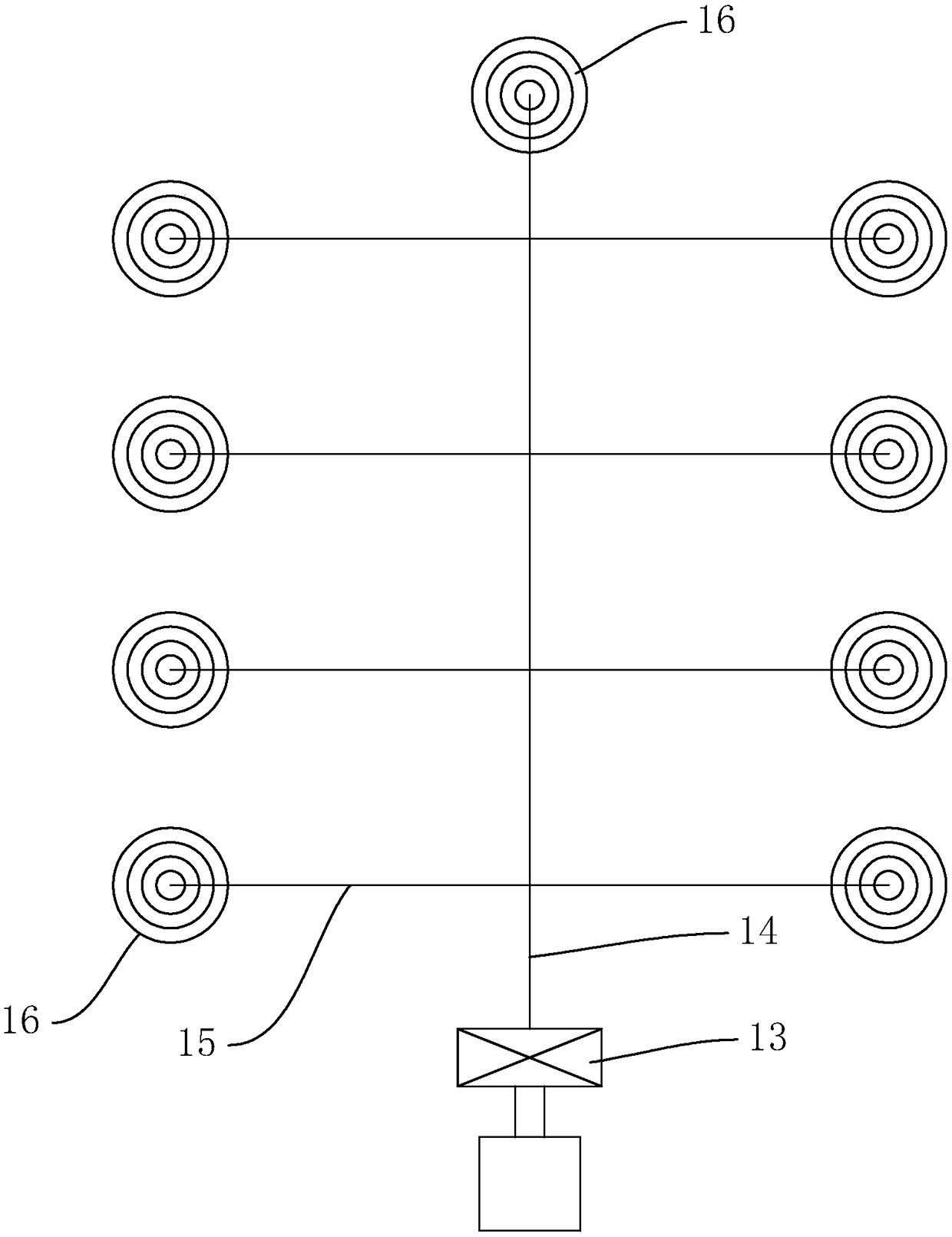

Device and method for hydrolyzing plant hemicellulose by fermented citric acid wastewater

InactiveCN101787086AReduce processing costsSolve the sourceFermentationHigh concentrationWater storage tank

The invention relates to a device capable of effectively utilizing fermented citric acid wastewater to hydrolyze plant hemicellulose. The device is mainly composed of a circulating spray flushing and filtering reactor, an acid storage tank, a water storage tank and a heat exchanger; the method is characterized by comprising the steps: at first, mixing the citric acid wastewater with raw material of the plant hemicellulose for hydrolysis reaction at 100 to 200 DEG C to obtain hydrolyzate mainly containing pentose, and then adding cellulase into hydrolyzed residues for batch enzyme hydrolysis to obtain high-concentration dextrose for the fermentation of ethanol. The method for preparing fermentable sugar for ethanol by pretreating the raw material of the plant hemicellulose by using the fermented citric acid wastewater can not only sufficiently utilize the fermented citric acid wastewater to save water resource, but can also lower the cost for treating wastewater from fermented citric factory and the production cost of the fermentable sugar for cellulose ethanol.

Owner:NANJING UNIV OF TECH

Ecological restoration method for black and odorous water

InactiveCN109020064AReduce pollutionPromote recoveryWater treatment parameter controlWater treatment compoundsProtozoaRestoration method

The invention discloses an ecological restoration method for black and odorous water, and relates to the field of ecological restoration of water in order to solve the technical problems that inadaptation to different black and odorous waters, short restoration effect keeping time and easy pollution rebounding in the prior art. The method comprises the following steps: 1, salvaging floating matters in water; 2, intercepting dirt; 3, rebuilding a water ecosystem: adding protozoa and native plants, then planting aquatic plants, and adding spiral shells, fish and shrimps to promote the restoration and balance of the water ecosystem and restore self-purification capability; 4, maintaining the water ecosystem: timely cleaning away water garbage and decaying plants, and regularly harvesting planted plants; 5, regulating the environment surrounding the water body: greening or protecting the waterfront of the water according to the construction situation around the water; and 6, carrying out inspection and maintenance. The method can adapt to different black and odorous waters, makes the water stable for a long time after being restored, and achieves three-dimensional ecological restoration of the black and odorous water.

Owner:浙江泰诚环境科技有限公司

Biomass crushed aggregate dense gasification device and method

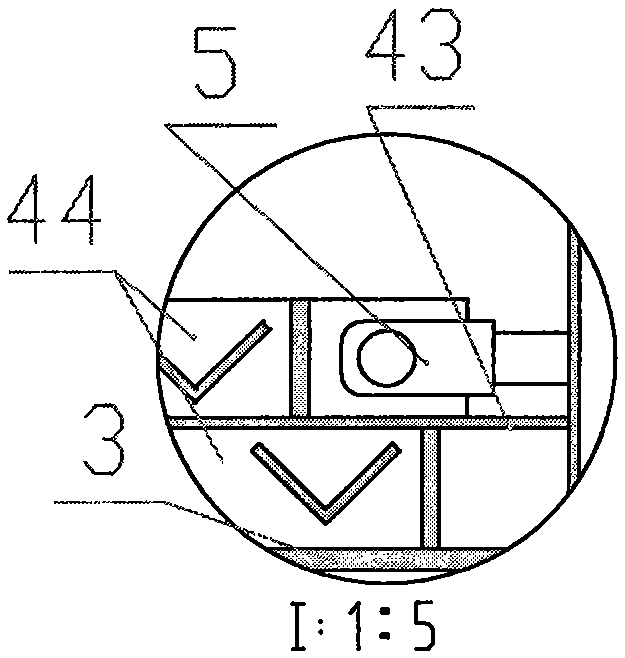

InactiveCN105542864AReduce pretreatment costsReduce energy consumptionGasifier feeding meansGasification processes detailsEngineeringBiomass

The invention discloses a biomass crushed aggregate dense gasification device and method. Straw is cut into segments with the length of 30-50 mm and directly enters a feed bin, the straw segments are pushed into a furnace through a spiral feeding rod and compressed by a sealing cone inlet, and the function of making gas in the sealed furnace not leak outwards is achieved while feeding is achieved. A dense spiral assembly conveys straw crushed aggregates downwards, the straw crushed aggregates form an inverted cone at the bottom of a body inner shell and are compacted with fire grates as supports, and a material layer meeting the gasification technological requirement is formed. The fire grates on the lower portion of a body comprises the movable fire grate and the fixed fire grate, it is guaranteed that a gasification agent is smoothly supplied, the movable fire grate is pulled by an oil cylinder and a transmission assembly to move in a reciprocating mode, and straw ash is scraped, falls at the bottom of an air box and is discharged through an ash remover. Generated gas is conveyed to a user from a gas outlet from bottom to top in the gasification device.

Owner:舒瑞 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com