Biomass crushed aggregate dense gasification device and method

A gasification device and biomass technology, applied in the details of the gasification device, gasification device feeding tools, gasification process, etc., can solve the problems of not being suitable for a large amount of straw, low gasification efficiency, and inability to scale up. Achieve the effect of saving straw pretreatment cost, safe and reliable operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

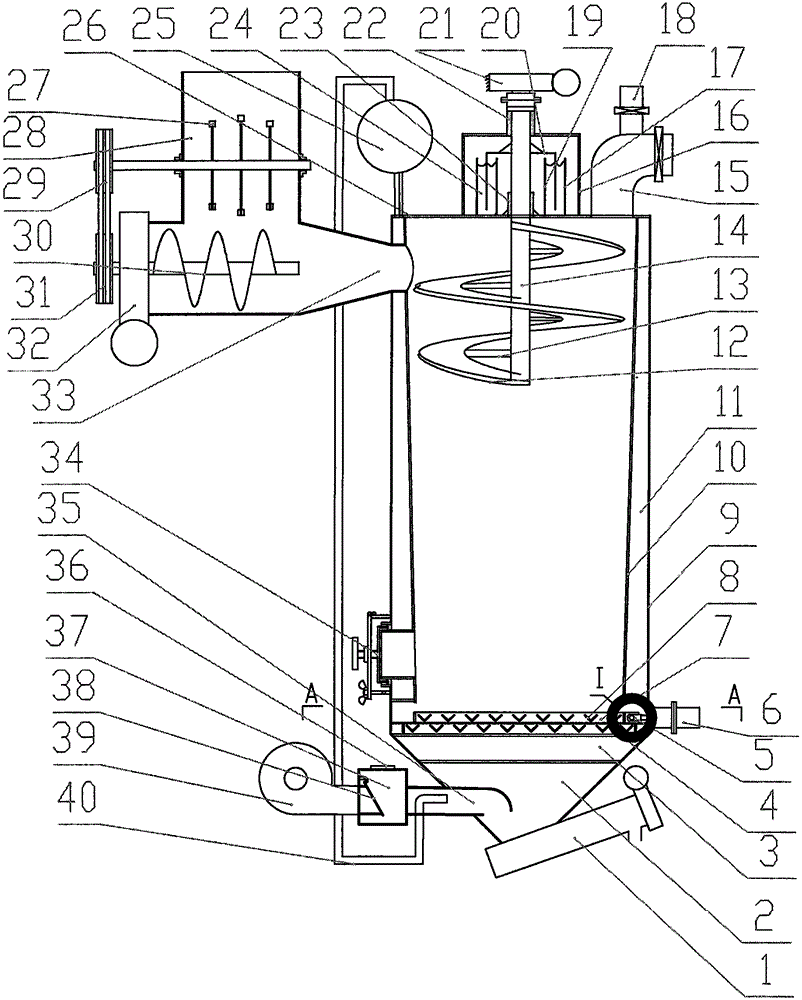

[0024] The straw is cut into 30-50 mm sections or crushed, directly enters the silo 28, is pushed into the furnace by the screw feeder 30, passes through the sealing cone inlet 33, and the straw scraps are compressed to seal the gas in the furnace. The function of venting, the screw feeding rod 30 runs continuously, and sends the compressed straw scraps into the main body. In order to prevent the silo from swelling, the other end of the feeding reducer 32 shaft is provided with a driving pulley 31, which drives the driven pulley 29 and dial material slurry 27 rotations, and the material in the feed bin is continuously dropped.

[0025] The dense screw reducer assembly 21 is positioned through the upper bushing fixed on the bracket 16 and the lower bushing 23 fixed on the main body upper cover 26 to drive the dense screw shaft 14 to rotate, and the screw blade 12 is welded on the dense screw shaft through the screw blade support plate 13. The screw shaft 14 rotates together as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com