Device and method for hydrolyzing plant hemicellulose by fermented citric acid wastewater

A technology for fermenting citric acid and plant cellulose, which is applied in the field of enzymatically decomposing plant cellulose to obtain sugar and hydrolyzing plant hemicellulose in the next step. It can solve the problem of high cost, reduce processing cost, reduce pretreatment cost, and reduce fermentation The effect of inhibitor production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

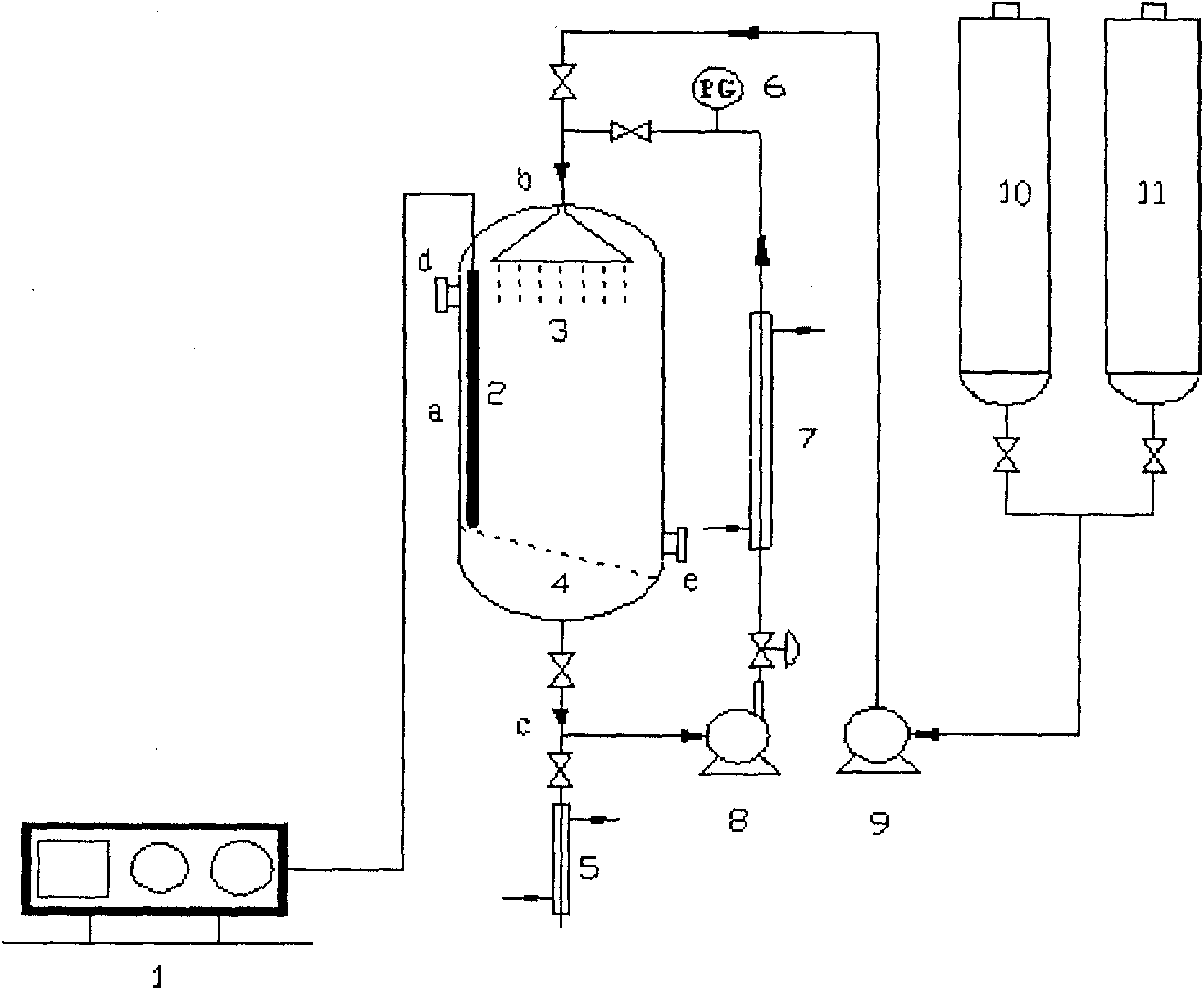

[0032] This embodiment combines figure 1 Describe the structure of the device.

[0033]The device of the present invention that can effectively utilize fermented citric acid wastewater to hydrolyze plant hemicellulose is mainly composed of a circulating spray flushing filter reactor a, an acid storage tank 11, a water storage tank 10, heat exchangers 5 and 7, wherein the circulating spray The top inlet b of the flushing reactor a is connected to the acid storage tank 11 and the water storage tank 10 through the pump 9 on the one hand, and connected to the circulating spray flushing reactor through the first heat exchanger 7 and the pressure valve 8 on the other hand. The outlet c at the bottom of a is circulated; the outlet c at the bottom of the circulating spray flushing reactor a is also connected with a second heat exchanger 5 .

[0034] Wherein, the upper side of the circulating spray flushing filter reactor a is provided with a material inlet d, and the lower side is pr...

Embodiment 2

[0037] This embodiment illustrates the detailed steps of implementing the method of the present invention by using the device of the present invention.

[0038] Wherein, the xylose detection method in the xylose hydrolyzate obtained after the hydrolysis of the hemicellulose involved in the embodiment is: HPLC (Dionex), Bio-Rad Aminex HPX-87H column, differential detector; column temperature: 65 ° C, Mobile phase 0.005mol / L sulfuric acid, flow rate: 0.6mL / min.

[0039] The detection method of glucose in the enzymolysis solution obtained after cellulose enzymolysis is: HPLC (Dionex), Bio-RadAminex HPX-87H column, differential detector. Column temperature: 65°C, mobile phase 0.005mol / L sulfuric acid, flow rate: 0.6mL / min.

[0040] (1) Pretreatment of fermented citric acid waste water: heat the fermented citric acid waste water after natural settlement to 90°C for evaporation and concentration; add concentrated sulfuric acid with a volume ratio of 0.1% and mix evenly, filter and ...

Embodiment 3

[0046] The detection method of xylose and glucose described in this embodiment is the same as that in Example 2.

[0047] (1) Pretreatment of fermented citric acid waste water: heat the fermented citric acid waste water after natural settlement to 100°C for evaporation and concentration; add concentrated sulfuric acid with a volume ratio of 0.01% and mix evenly, filter and place in acid storage tank 11 ready for use;

[0048] (2) Hydrolysis of hemicellulose: Air-dry and pulverize sorghum stalks to the last 10 mesh, add from material inlet d and place on the bottom sieve plate 4 of circulating spray flushing reactor a, ferment lemon from acid storage tank 11 The liquid-solid ratio of acid waste water and sorghum stalks is 20:1 (w / v) and injected into fermented citric acid waste water; the thermocouple 2 is controlled by the temperature controller 1 so that the temperature of the reactor a is 200°C, and the first heat exchanger 7 is controlled to maintain the same temperature. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com