Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

473results about How to "Improve hydrolysis efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Detoxifying and Recylcing of Washing Solution Used In Pretreatment Of Lignocellulose-Containing Materials

ActiveUS20090056889A1Improve hydrolysis efficiencyImprove filtering effectWashing/displacing pulp-treating liquorsBiofuelsPre treatmentOrganic chemistry

The invention relates to a process of detoxifying pretreated lignocellulose-containing material comprising washing the pretreated lignocellulose-containing material in a washing solution and treating the used washing solution to remove an enzyme inhibitor and / or an inhibitor of a fermenting organism before recycling the used washing solution.

Owner:COFCO GROUP

Method for hydrolyzing lignocellulose

The invention discloses a method for hydrolyzing lignocellulose. Lignocellulose is pulverized into particles, and the particles are mixed with water to form even seriflux; the seriflux is preheated to60-150 DEG C by using ultrasonic waves or microwaves; the preheated even seriflux is quickly heated to 120-300 DEG C, solid acid is added and used as a catalyst, and stirring and catalytic reaction are simultaneously carried out for 15-300 minutes. The use of the ultrasonic waves or microwaves radiation in synergism with solid alkali for catalyzing and hydrolyzing the lignocellulose can greatly reduce the reaction time as well as energy consumption. The solid acid catalyst can be repeatedly used, is easily separated, and has the advantages of high mechanical strength, high durability, certainselectivity, relative singularity of catalytic hydrolyzate, high hydrolyzing efficiency and good market application prospect.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

Process for efficiently preprocessing lignocellulose

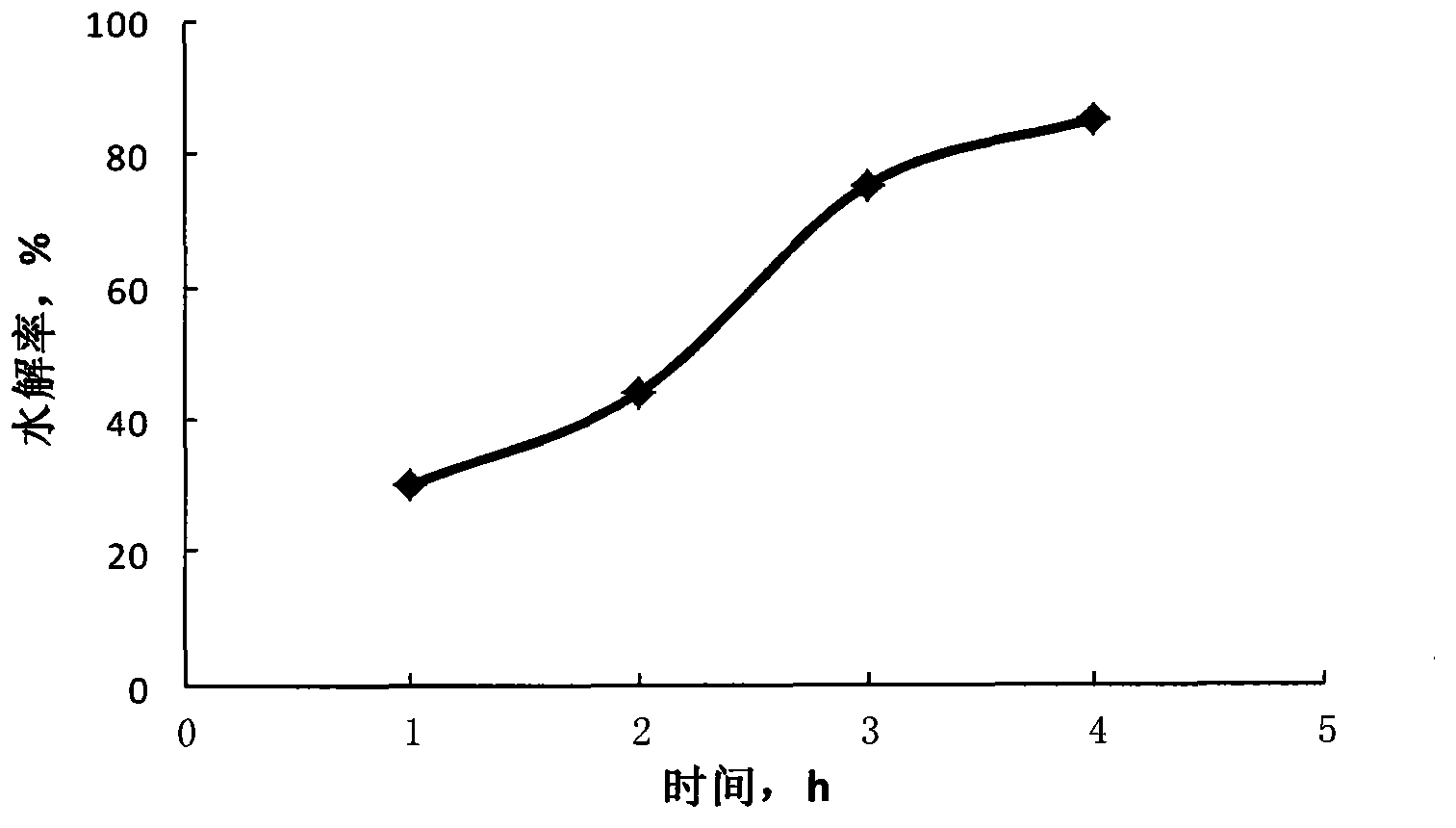

InactiveCN101736631ALess side effectsReduce usageFermentationPaper material treatmentDecompositionReaction temperature

The invention relates to a process for efficiently preprocessing lignocellulose. The process adopts the following procedures of stepwise optimizing and hydrolyzing: firstly, boiling the lignocellulose in overheated water to ensure that most hemicellulose is dissolved into oligosaccharide; continuously reacting the boiled mixture in a special flash evaporation reactor; and gradually changing reaction temperatures in the process of reaction to slow down xylose decomposition as far as possible and ensure that the hemicellulose is more completely transformed into xylose. The process has the advantages of simpleness, low cost, reasonable energy utilization, no solid-liquid separation in stepwise process, direct hydrolysis on the hot mixture, energy saving and high hydrolysis efficiency of processed cellulose on enzyme.

Owner:熊鹏

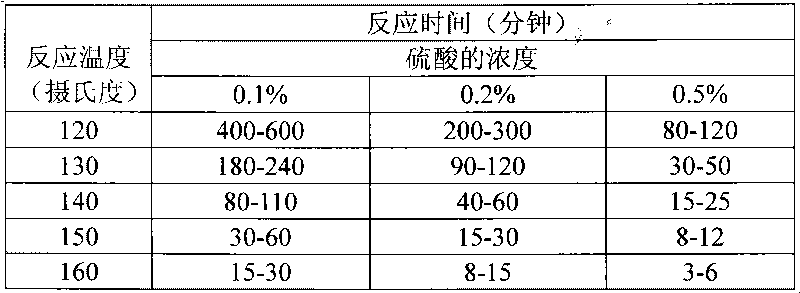

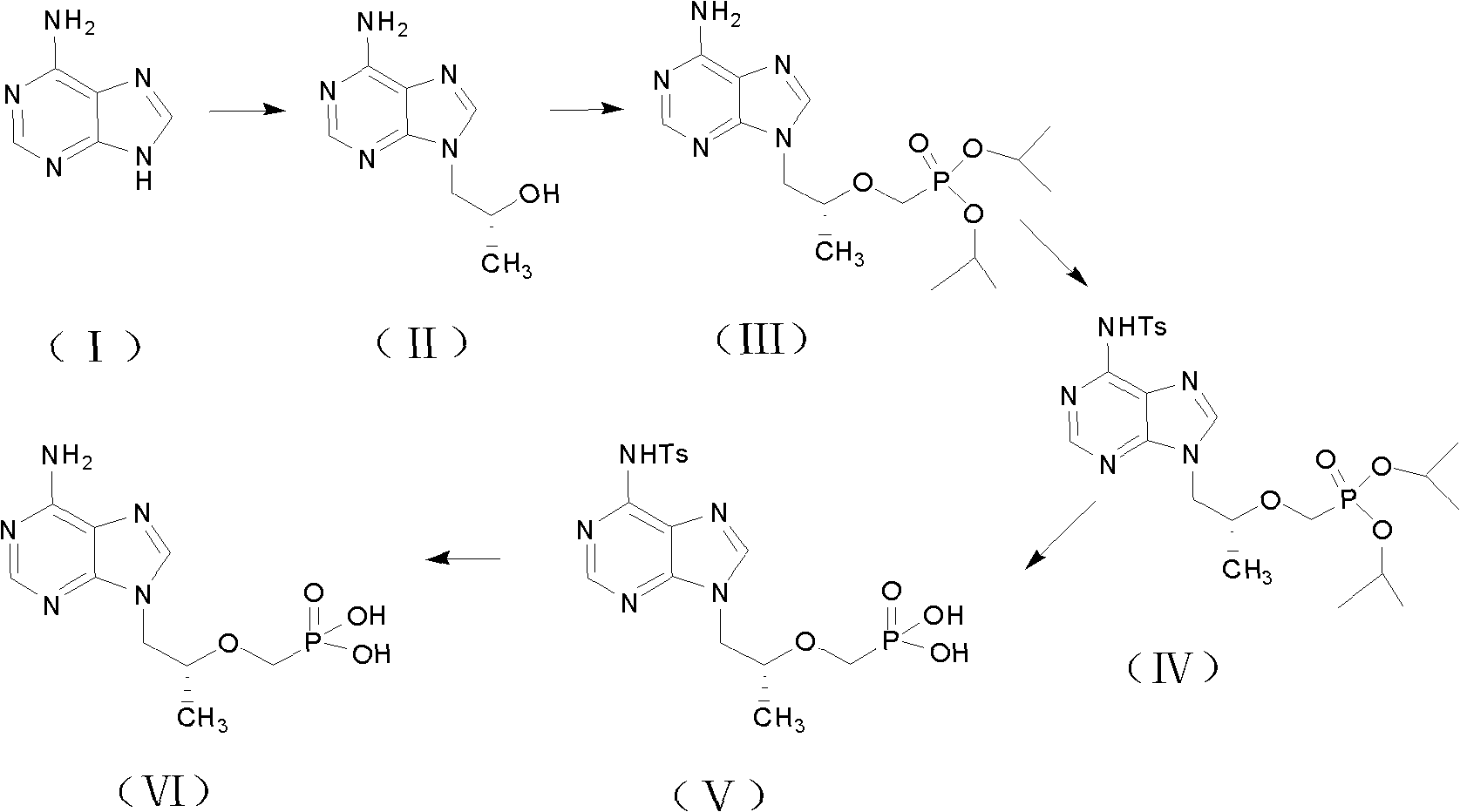

Preparation method for tenofovir

ActiveCN102060876AReduce energy consumptionImprove securityGroup 5/15 element organic compoundsBenzeneAlcohol

The invention discloses a preparation method for tenofovir disoproxil fumarate, which comprises the following steps of: A, performing condensation reaction adenine and (R)-propylene carbonate which serve as raw materials to generate (R)-9-(2-hydroxypropyl) adenine; B, performing condensation reaction on the (R)-9-(2-hydroxypropyl) adenine and p-methylphenyl mesyloxy diethyl phosphonate under the catalysis of potassium alcoholate to prepare (R)-9-[2-(diethyl phosphonyl methoxy) propyl] adenine; C, reacting the (R)-9-[2-(diethyl phosphonyl methoxy) propyl] adenine obtained by the step B with para-toluenesulfonate acyl chloride to protect an amino group at bit four to prepare (R)-4-(p-toluenesulfonyl)-9-[2-(diethyl phosphonyl methoxy) propyl] adenine; D, hydrolyzing the (R)-4-(p-toluenesulfonyl)-9-[2-(diethyl phosphonyl methoxy) propyl] adenine obtained by the step C under a strong acid condition to obtain (R)-4-(p-toluenesulfonyl)-9-[2-(dihydroxy phosphonyl methoxy) propyl] adenine; and E, reacting the (R)-4-(p-toluenesulfonyl)-9-[2-(dihydroxy phosphonyl methoxy) propyl] adenine obtained by the step D with mercapto-benzene under a weak alkaline condition to remove a para-toluenesulfonate group to obtain the tenofovir. The invention aims to provide the preparation method for the tenofovir, which is low in cost, safe in process and good in product quality, and is suitable for industrialization.

Owner:ZHONGSHAN BAILING BIOTECHNOLOGY CO LTD

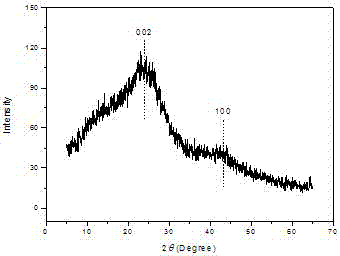

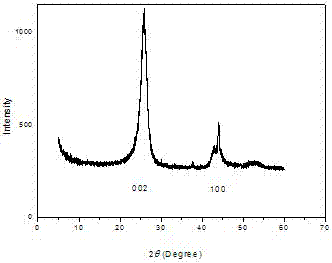

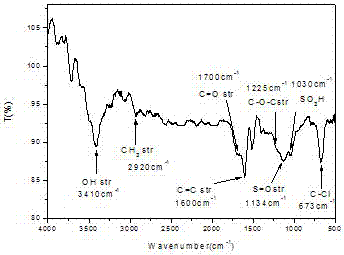

Carbon-based solid acid catalyst and preparation method thereof

InactiveCN103691483AHigh catalytic activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCarbon layerReactive site

The invention discloses a carbon-based solid acid catalyst and a preparation method thereof. The preparation method comprises the following steps: proportionally mixing carbon-containing raw materials and a chlorine-containing organic high-molecular compound, and carbonizing a mixture to obtain a black solid product; cooling and grinding the black solid product, and adding a sulfonating agent to perform sulfonating; performing cooling, filtering, washing and drying to obtain a black granular material, wherein the sulfonic group density of the black granular material is 0.1 to 5mmol / g, the chlorine content of the black granular material is 0.2 to 70mg / g, and the molar ratio of C to H to O is 1:(0.05-1.3):(0.1-1). The black granular material comprises a carbon framework and active sites, wherein aromatic carbon layer sheets which are in bridge bond connection so as to form a basic unit; the active sites are connected to the carbon layer sheets and comprise -Cl, -SO3H, -OH and -COOH. The carbon-based solid acid catalyst prepared by using the method is stable in structure, high in acidity, low in cost, good in catalytic effect, easy to recycle and wide in application prospect.

Owner:TAIYUAN UNIV OF TECH

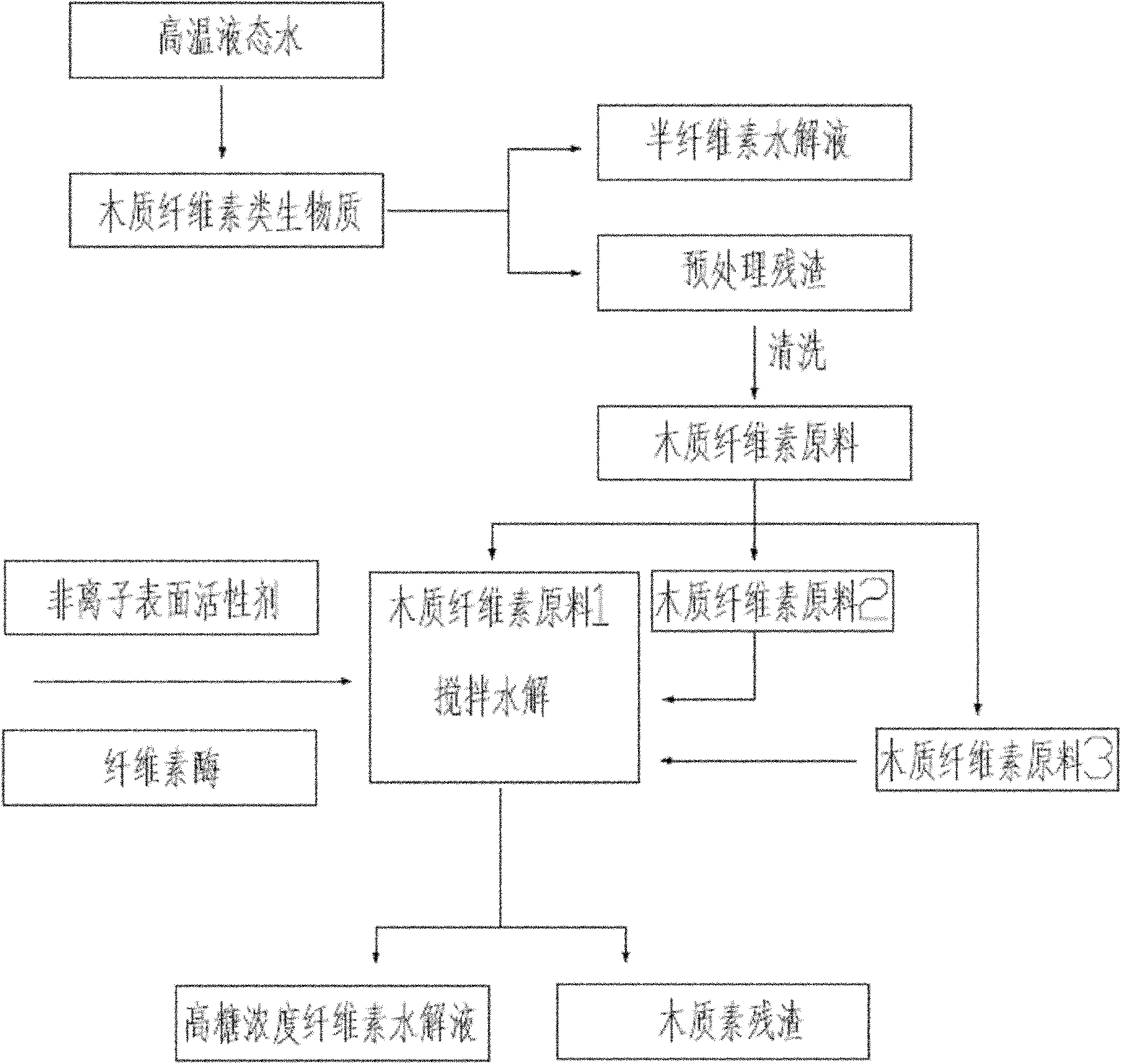

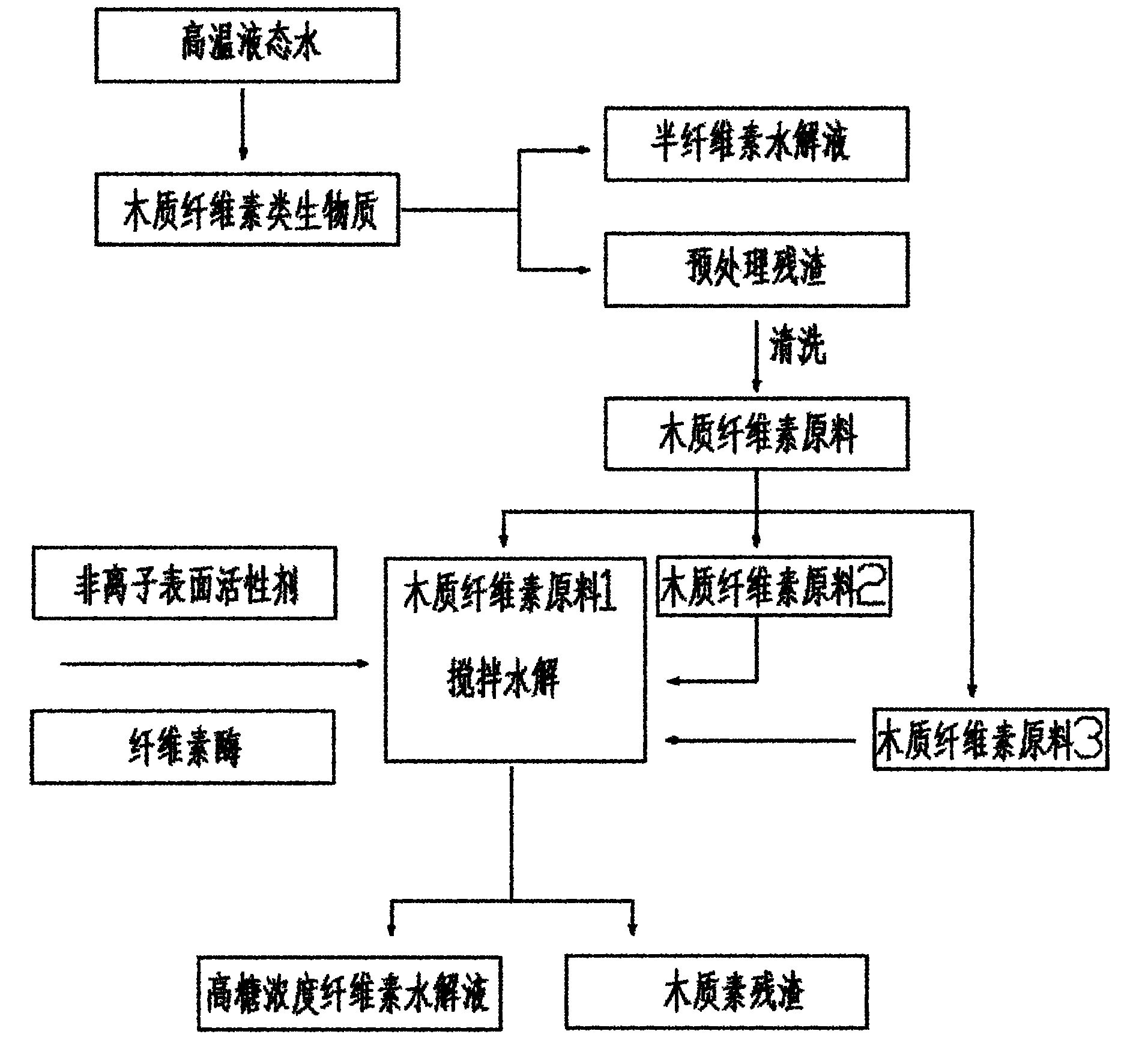

Efficient enzyme hydrolysis method of lignocellulose biomass

InactiveCN102174594AEasy to operatePromote the process of hydrolysis reactionBiofuelsFermentationSodium acetateHigh concentration

The invention discloses an efficient enzyme hydrolysis method of lignocellulose biomass, comprising the following steps: pretreating the lignocellulose biomass through high-temperature aqueous water to obtain a lignocellulose raw material to be used as a substrate; dispersing the substrate into an acetic acid-sodium acetate buffer solution in a certain concentration; adding a nonionic surfactant and cellulose; stirring the materials; hydrolyzing for some time; adding a certain amount of materials twice; and simultaneously adding the nonionic surfactant and the cellulose; and continuously hydrolyzing to obtain a saccharide compound and lignocellulose residues. In the method provided by the invention, high-temperature aqueous water pretreatment, batch charging, nonionic surfactant adding and stirring and an enzyme hydrolysis process are coupled, thus the hydrolysis efficiency is high, the concentration of the enzymolysized lignocellulose raw material can be greatly improved; the concentration reaches 30%; the sugar generation concentration and the hydrolysis efficiency are high under the condition of high-concentration lignocellulose raw materials; the enzymolysized raw material concentration is improved; and simultaneously the high-concentration sugar is produced, thus improving the hydrolysis efficiency, and realizing the efficient enzyme hydrolysis of the lignocellulose biomass.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for improving anaerobic digestion performance of sludge by utilizing microwave alkaline thermal hydrolysis

InactiveCN101524699AImproved Anaerobic Digestion PerformanceShortened hydrolysis efficiencySolid waste disposalBiological sludge treatmentMicrowaveRoom temperature

The invention relates to a method for improving anaerobic digestion performance of sludge by utilizing microwave alkaline thermal hydrolysis, and the method belongs to the technical field of solid waste treatment. Alkaline solution is firstly added in the sludge with the solid concentration of 7 percent-10 percent for controlling the pH value of the sludge, the mixing is carried out after adding the alkaline solution, the alkalified sludge is placed in a pressure-bearing reactor, the heating is carried out in a microwave field with the frequency of 2450MHz, the sludge heated by microwave is cooled to the room temperature, and the anaerobic digestion treatment is carried out on the sludge after the cooling. More than 60 percent of organic matters in the sludge which is treated by the method are converted to liquid phase; during anaerobic digestion, the conversion efficiency of the organic matters of the sludge is improved, thereby being an effective means for realizing the whole process pollution control, the energy conservation and the emission reduction of sewage treatment.

Owner:TSINGHUA UNIV

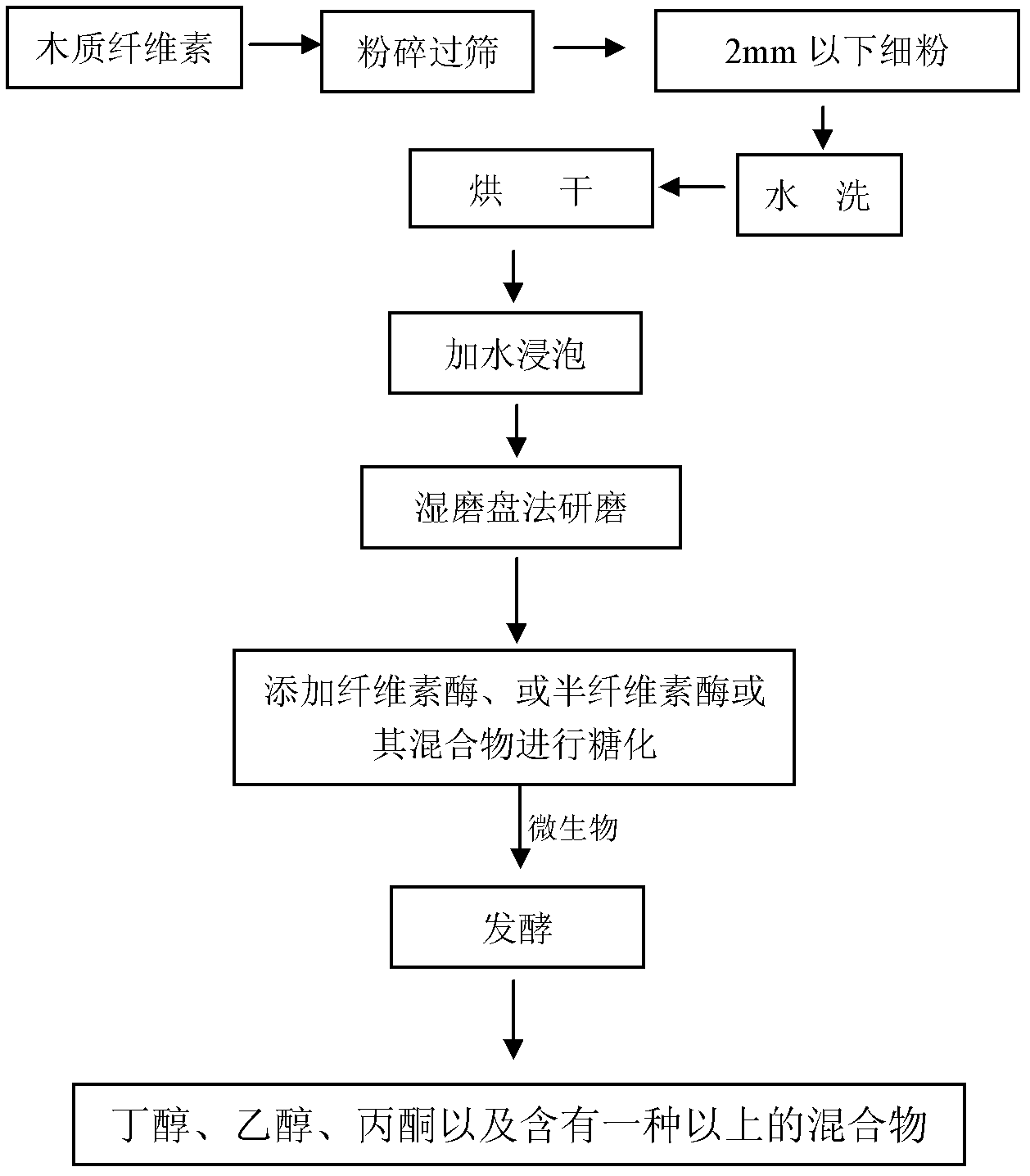

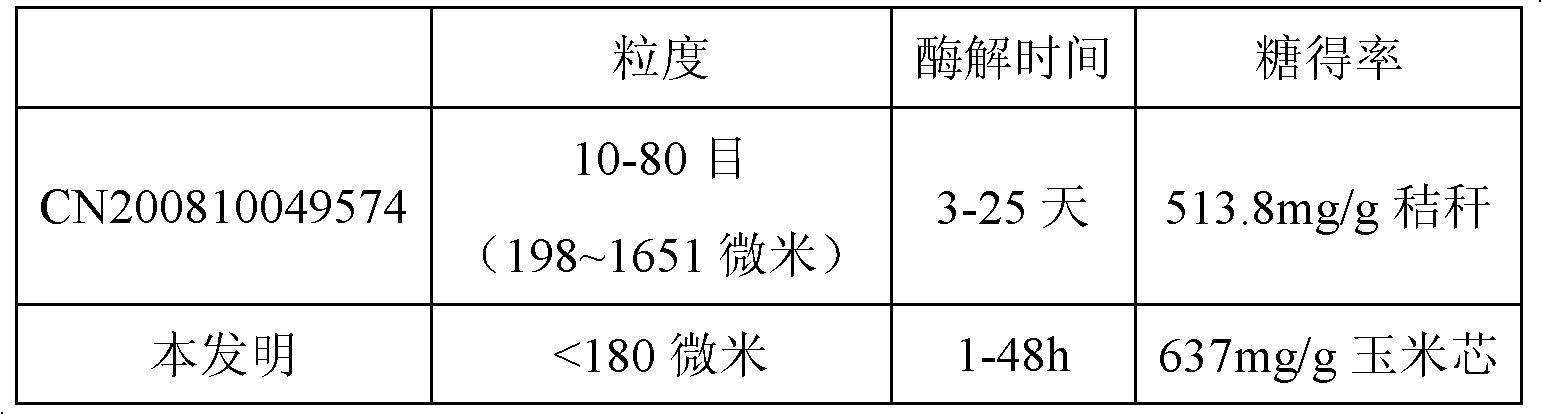

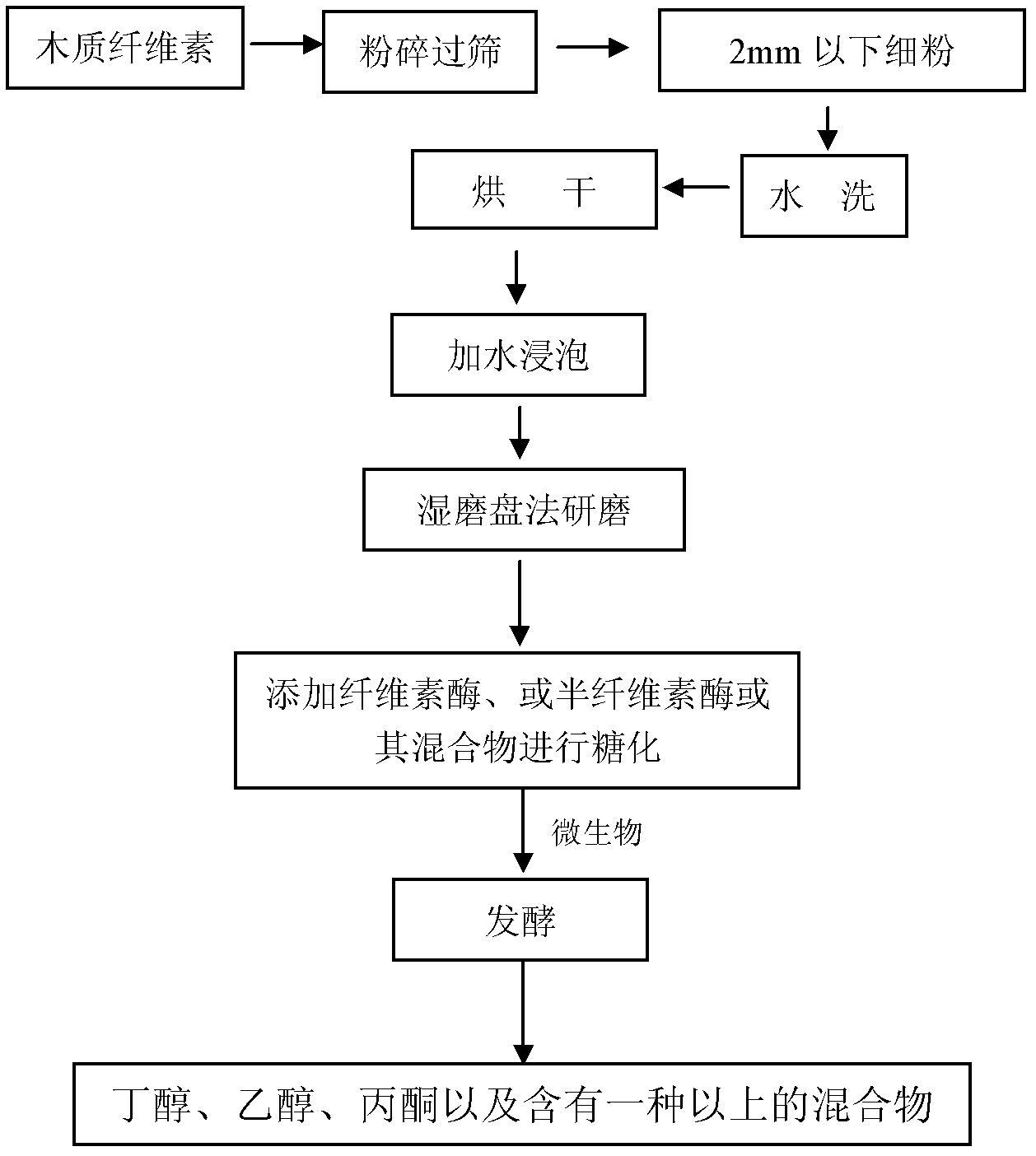

Method for producing ethanol or acetone and butanol by taking lignocellulose as raw material

ActiveCN102304550AReduce energy consumptionImprove hydrolysis efficiencyBiofuelsMicroorganism based processesGas explosionMetal

The invention relates to a method for producing ethanol or acetone and butanol by taking lignocellulose as a raw material. According to the invention, a wet disc grinding machine-ultrafine grain melting and crushing machine physical method is adopted for pretreating the lignocellulose raw material, so that a cellulose structure wrapped by hemicellulose is opened and a cellulose crystalline structure is simultaneously opened, the method can be used for replacing all acid, alkali and gas explosion treatment methods, the conditions of high temperature and high pressure are not required, no external metal or organic matter such as sulfur is added, the pollution is avoided and the hydrolysis efficiency is high. By adopting the method, no secondary substance inhibiting the growth and the fermentation of yeast, bacteria and anaerobic bacteria is generated, and cellulose, the hemicellulose and lignin are not damaged.

Owner:SHANDONG UNIV +1

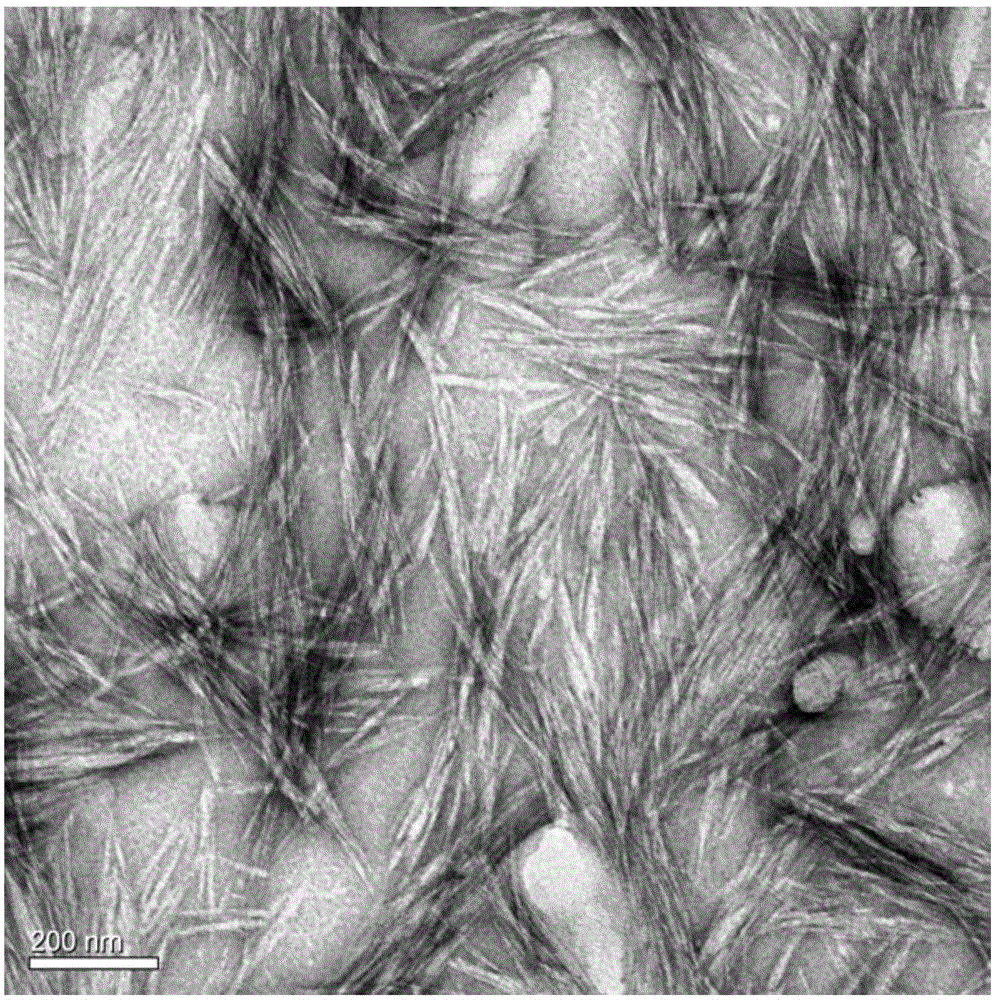

Method for preparing nano cellulose by formic acid hydrolysis by using metal salt catalyst

ActiveCN105153316AImprove hydrolysis efficiencyReduce formic acid concentrationAcid hydrolysisFormic acid

The invention relates to a novel method for preparing nano cellulose by hydrolyzing a cellulose raw material with formic acid by using a metal salt catalyst. In the method, the metal salt is utilized to catalyze the formic acid to hydrolyze the cellulose raw material, so that the hydrolysis efficiency is greatly enhanced, thereby lowering the formic acid concentration and further saving the cost. Besides, the method has the advantages of milder reaction conditions and controllable reaction, and is simple to operate.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

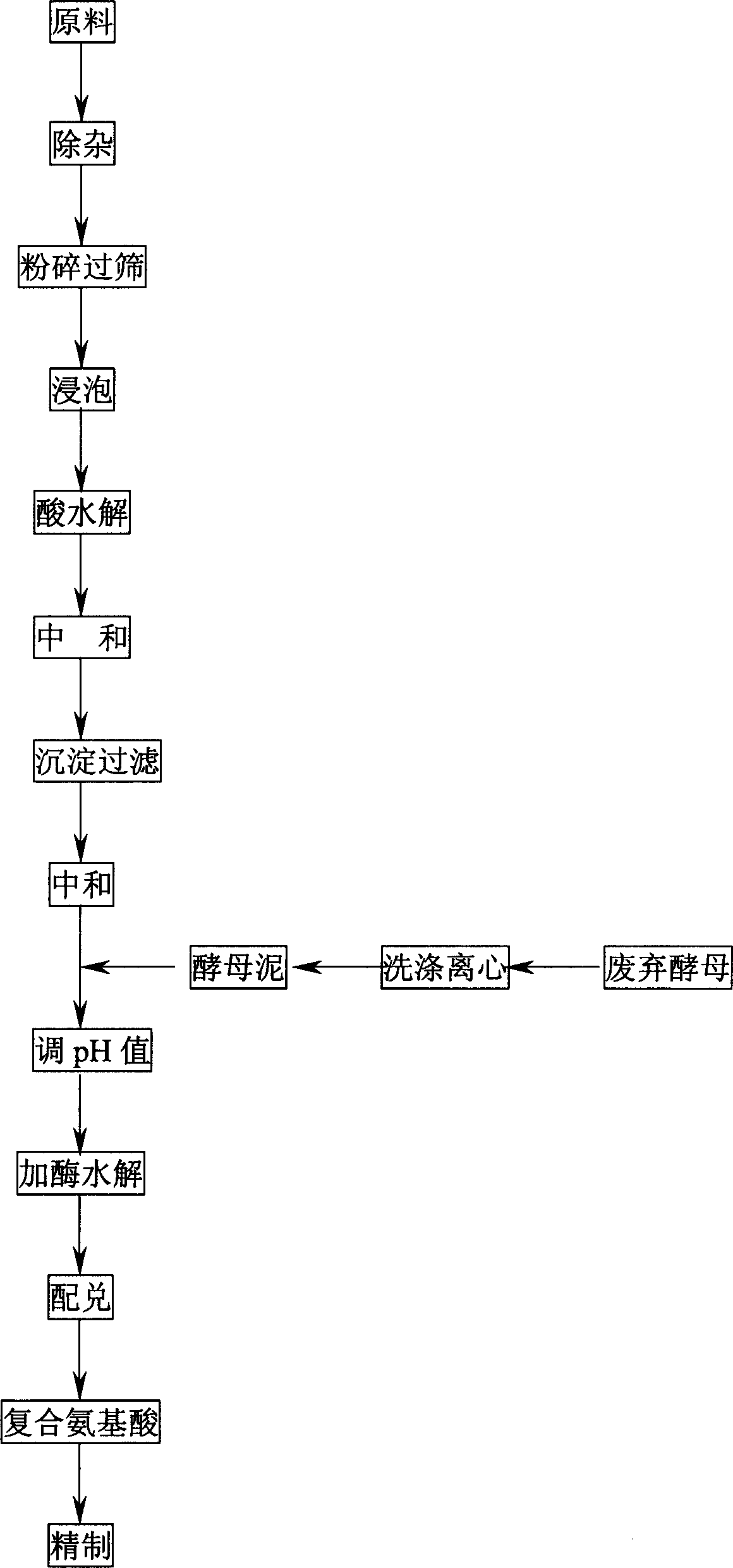

Method for preparing composite amino acid liquid using waste protein

InactiveCN1733925AEasy to operateSimple preparation processFermentationBacterial neutral proteaseImpurity

The invention discloses a method to prepare composite amino acid liquid by abandoned protein, which comprises steps: a. pretreating the material, smashing and removing impurity to soya bean waste, rape seed cake and cotton cake; sieving, dipping with dilute sulphuric acid or muriatic acid; filtering supernatant and cooking; b. mixing material; c. hydrolyzing with neutral proteased at thermostatic condition; d. hydrolyzing with edible pure muriatic acid on condition of thermostatic and pressure; e. neutralizing with edible caustic soda, filtering, and adjusting with caustic soda solution pH value to 4.5~5.0; f. matching and mixing. This method is simple and high efficient.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

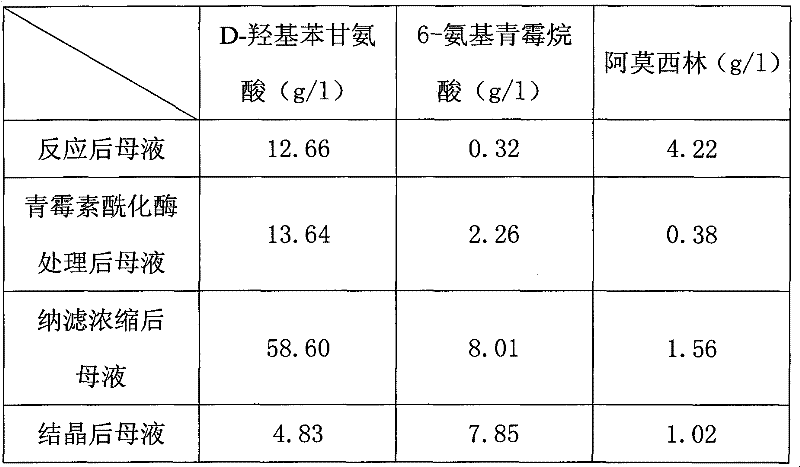

Recovering method of effective components in amoxicillin enzymatic synthesis mother liquor by utilizing nanofiltration

ActiveCN102392060AAvoid destructionImprove hydrolysis efficiencyOrganic compound preparationAmino-carboxyl compound preparationEnzymatic synthesisIsoelectric point

The invention discloses a recovering method of effective components in amoxicillin enzymatic synthesis mother liquor by utilizing nanofiltration. The method comprises the following steps: (1) regulating pH of the mother liquor; (2) hydrolyzing amoxicillin in the mother liquor by utilizing penicillin acylase, thus only D-hydroxyphenylglycine and 6-amino-penicillanic acid (6-amino-penicillanic acid) exist in the other liquor; (3) preparing concentrated mother liquor by nanofiltration; and (4) separating and recovering the D-hydroxyphenylglycine and the 6-amino-penicillanic acid (6-amino-penicillanic acid) by isoelectric point crystallization. The method has the advantages that: the recycling rate of an inactive lateral chain can be improved regarding certain amoxicillin synthetase with highhydrolysis activity, so that the enzymatic synthesis of amoxicillin is more economical.

Owner:INNER MONGOLIA CHANGSHENG PHARMA

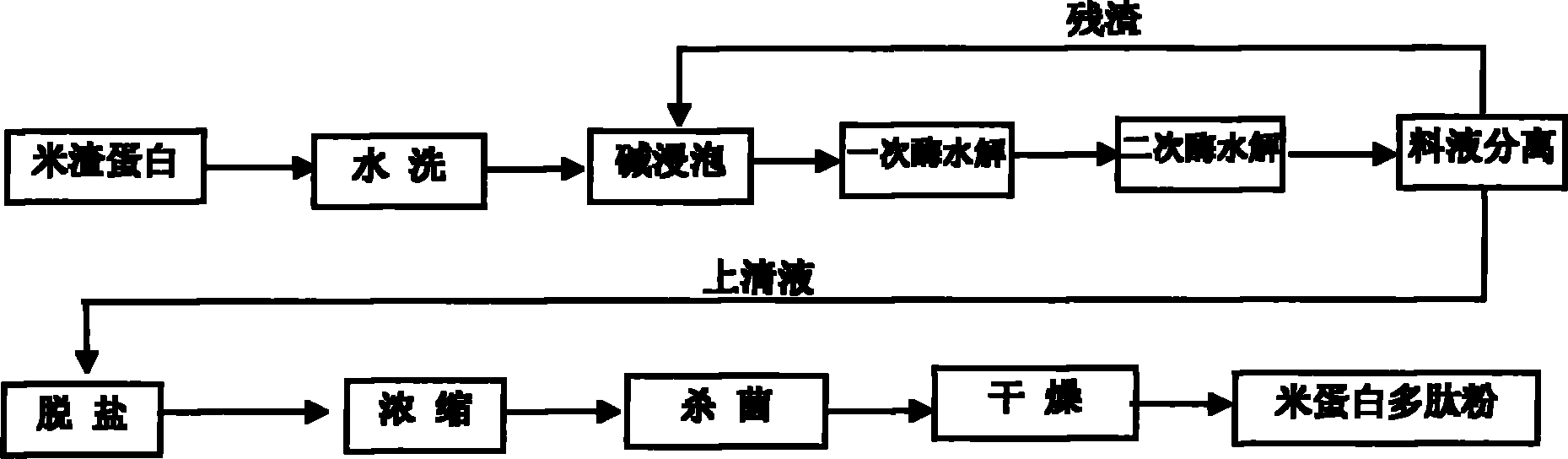

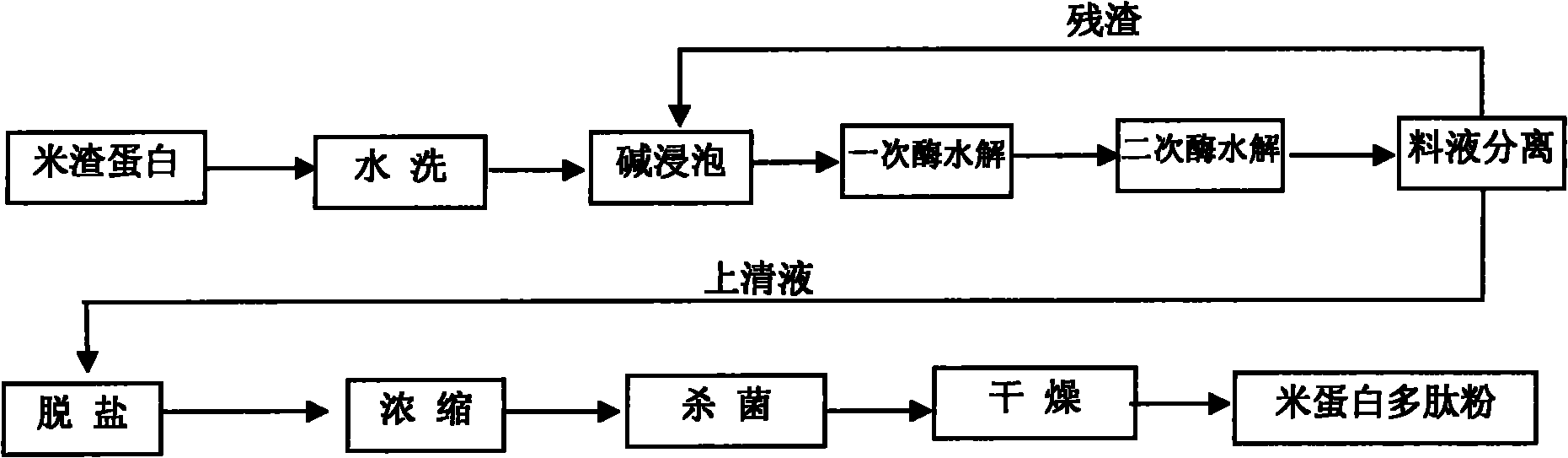

Method for preparing rice protein polypeptide powder from rice residue protein

InactiveCN101766253AEdibleHigh protein and peptide contentProtein composition from vegetable seedsFood preparationProtein contentSmall peptide

The invention provides a method for preparing rice protein polypeptide powder from rice residue protein. The method comprises the following steps: using the byproduct rice residue protein in starch sugar plants as the raw material, washing, hydrolyzing, desalting, drying and the like to obtain the food-level rice protein polypeptide powder. The protein content in the rice protein polypeptide powder is more than or equal to 77%, and small peptides, the molecular weight of which is about 1,000, account for 67% of the total protein. The rice protein polypeptide powder not only keeps the advantages of low irritability, high biological value and the like of the rice protein, but also has obvious functions in the aspects of digestive absorption and health care because that the powder contains alarge amount of small peptides.

Owner:ZHEJIANG XINHE ENVIRONMENT SCI & TECH

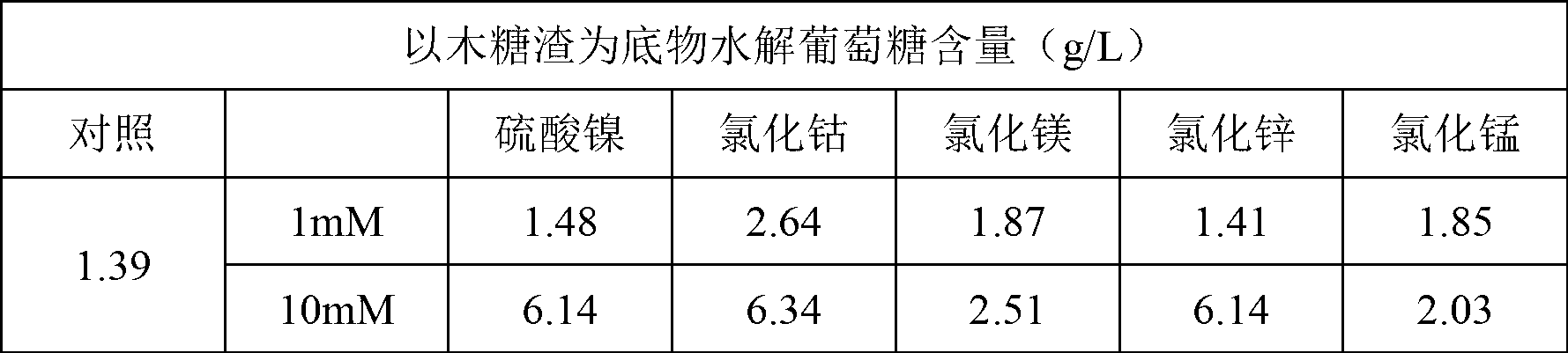

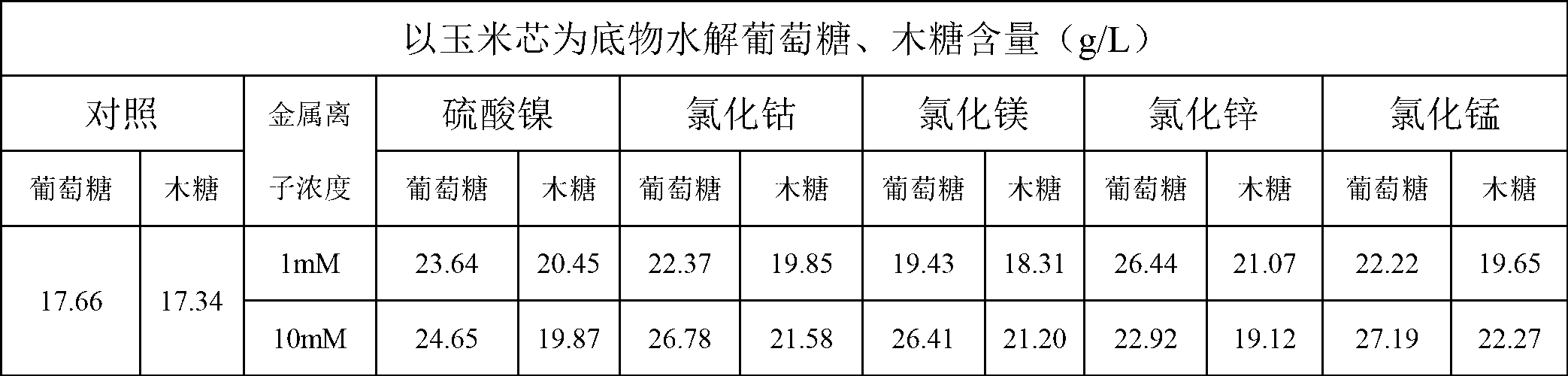

Method for promoting hydrolysis of lignocellulose

The invention discloses a method for promoting hydrolysis of lignocelluloses. According to the method, metal ions such as nickel, cobalt, magnesium, zinc, manganese and the like are added in the processes of saccharifying and hydrolyzing the lignocelluloses so as to improve the enzyme activity of the ligno-cellulase and hemicellulase, thereby further improving the hydrolysis efficiency of the ligno-cellulase. Proved by experiments, the hydrolysis efficiency of glucan can be improved by 4.5 times by adding the metal ions. According to the method, the operation is simple, the metal ions can be recycled, the investment cost is low, the usage range is wide, the pollution does not exist, the hydrolysis efficiency of the cellulose is obviously improved, and the method can be widely applied in the process of hydrolyzing the lignocelluloses and in the fields of manufacturing and developing biomass energy.

Owner:SHANDONG UNIV +1

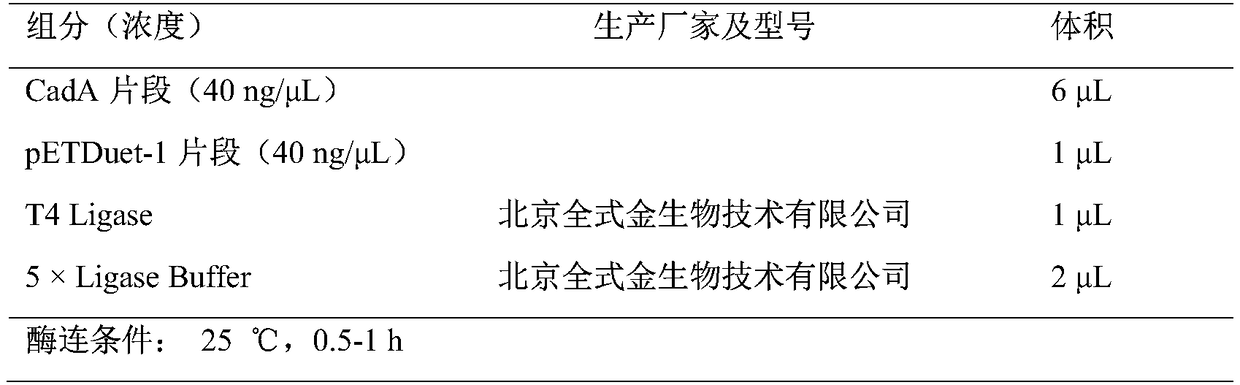

Method for producing 1,5-pentanediamine by fermenting soybean residue hydrolysate

InactiveCN109055449ASolve processing problemsReduce manufacturing costMicroorganism based processesFermentationPectinaseEscherichia coli

The invention discloses a method for producing 1,5-pentanediamine by fermenting a soybean residue hydrolysate. The method comprises the following steps: (1) enzymatically hydrolyzing soybean residuesby use of a composite enzyme to prepare the soybean residue hydrolysate, the composite enzyme comprising protease, cellulase, pectinase and amylase, and preparing a fermentation medium by use of the soybean residue hydrolysate, inorganic nitrogen and an inorganic salt; (2) activating escherichia coli and inoculating the fermentation medium prepared in step (1) with the activated escherichia coli to produce the 1,5-pentanediamine by fermentation. According to the method, the cheap and abundant soybean residues are enzymatically treated to obtain the hydrolysate containing components such as amino acid, peptides and glucose as a raw material for fermentation production of the 1,5-pentanediamine, so that not only are problems about waste treatment of the processing industry solved, but also the production cost of the 1,5-pentanediamine is reduced; the method has a broad development prospect.

Owner:NANJING UNIV OF TECH

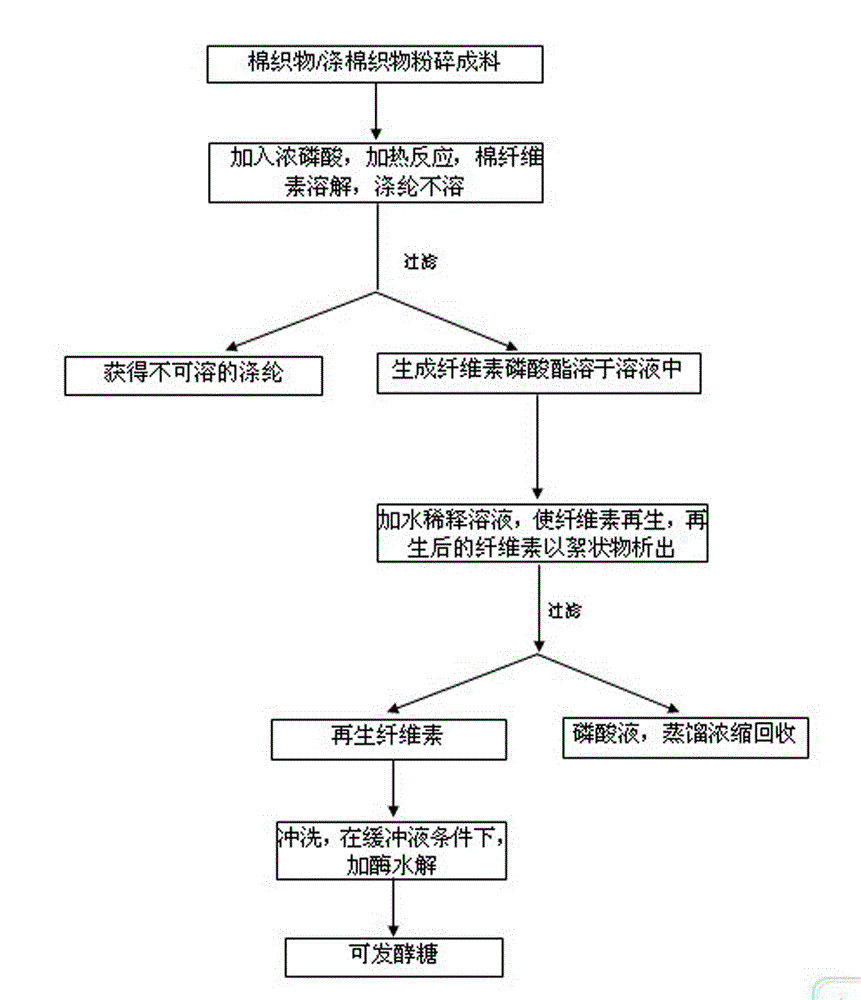

Resourced recovering and utilizing method for waste cotton fabric

InactiveCN102911395AReduce crystallinityReduce the degree of polymerizationProductsReagentsPolyesterPhosphoric acid

The invention relates to a resourced recovering and utilizing method for waste cotton fabric, in particular to a technology for recovering polyester and cotton fiber from waste polyester cotton blended fabric and using the polyester and the cotton fiber during the production of fermentable sugar, and belongs to the field of resourced cycling and reutilizing of solid waste. According to the resourced recovering and utilizing method, concentrated phosphoric acid is used as a solvent, a reaction is conducted under the conditions that the mass fraction of the phosphoric acid is 82 to 86 percent, the solid-liquid ratio is 1:10 to 1:30, the reaction temperature is 45 to 60 DEG C, and the reaction time is 2 to 18 hours; the cotton fiber in the polyester cotton blended fabric is completely dissolved, so as to enable the polyester to be isolated and recovered by one hundred percent; then water is added to a solution to dilute the solution, so as to enable cellulose to be regenerated and obtain regenerative cellulose with a low cleanliness degree and a low polymerization degree, which is applicable to enzymatic hydrolysis; and after the regenerative cellulose is subjected to the enzymatic hydrolysis, the fermentable sugar is generated to be used as a carbon source for fermenting and producing bio-based products. Waste liquid is distilled and the concentrated phosphoric acid is recovered to be circularly used. The resourced recovering and utilizing method is applicable to the polyester cotton blended fabric formed in any proportion, has the advantage of relatively low energy consumption and is simple to operate; and the polyester can be recovered by one hundred percent, the concentrated phosphoric acid can be simultaneously recovered to reduce costs, and the cotton fiber component is utilized to produce bio-based sources or bio-based products.

Owner:SICHUAN AGRI UNIV

Phosphotungstic acid-metal organic skeleton used for catalyzing hydrolysis of cellulose, and preparation method and application thereof

InactiveCN105344378AEnsure loading efficiencyEvenly distributedOrganic-compounds/hydrides/coordination-complexes catalystsGlucose productionCellulosePolymer science

The invention discloses a phosphotungstic acid-metal organic skeleton used for catalyzing hydrolysis of cellulose, and a preparation method and application thereof. According to the invention, organic ligand with strongly electronegative groups and basic groups is screened out and participates in coordination reaction of a metal organic skeletal material so as to realize functionalization, phospho-tungstic acid is directly added into a synthesis system, and immobilization is realized in the process of synthesis. The prepared phosphotungstic acid-metal organic skeleton reduces the frequency of contact with glucose through formation of a hydrogen bond with cellulose so as to reduce side reaction of glucose under the catalysis of acid, high glucose selectivity is obtained, and oriented conversion of cellulose to glucose can be realized; meanwhile, the effect of the hydrogen bond can weaken the effect of a hydrogen bond in cellulose, reduces the crystallization degree of cellulose, enables cellulose to be easier to hydrolyze and improves hydrolysis efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Biomass Hydrolysis Process

InactiveUS20110020873A1Reduce water consumptionImprove hydrolysis efficiencyBiofuelsWaste based fuelHydrolysisEnzyme inhibitor

Owner:NOVOZYMES AS +1

Method for preparing bacterial cellulose by using wheat straw

ActiveCN101985641AImprove hydrolysis efficiencyEasy to produceMicroorganism based processesFermentationEconomic benefitsCellulase

The invention relates to a method for preparing bacterial cellulose by using wheat straw, which comprises: pretreating the wheat straw in ionic liquid at 90 to 120 DEG C for 15 minutes to 21 hours; adding deionized water; stirring for regeneration; adding cellulose for enzymolysis, and obtaining enzymolysis solution; detoxifying the enzymolysis solution to obtain the culture medium for culturing the bacterial cellulose; adding yeast extract and tryptone to prepare the culture medium; adding seed liquid of bacterial cellulose producing bacteria; and culturing the bacteria at 20 to 30 DEG C for 8 to 28 days and obtaining the bacterial cellulose. In the invention, usually waste or burnt crop straw byproducts are used as raw materials, a cheap carbon source is developed, environmental pollution is reduced, and the bacterial cellulose can be used for producing products with high added values and can create good economic benefit for the related industry.

Owner:DONGHUA UNIV

Method for extracting bioactive substances from eggshell membrane

InactiveCN104292364AImprove hydrolysis efficiencyNutritional value fully preservedPeptide preparation methodsFermentationIonChemistry

The invention discloses a method for extracting bioactive substances from an eggshell membrane. The method for extracting the bioactive substances from the eggshell membrane comprises the following steps: separating an eggshell membrane, smashing, carrying out enzymolysis, and extracting the bioactive substances, wherein eggshell membrane powder is treated by adopting ionic liquid before enzymolysis is carried out, and the ionic liquid is 1-hydroxyethyl-3-methylimidazole tetrafluoroborate. The method for extracting the bioactive substances from the eggshell membrane has the advantages that enzymolysis efficiency is improved, combined separation and extraction of keratin, hyaluronic acid and chondroitin sulphate is realized, and bioactive substance extraction also can be simplified, and environmental requirement is met.

Owner:ZHEJIANG UNIV

Preparation process of fish scale collagen protein

ActiveCN103540635ASmall molecular weightTake advantage ofPeptide preparation methodsFermentationWaste materialImpurity

The invention provides a preparation process of a fish scale collagen protein. With the preparation process, the collagen protein can be extracted from fish scales, so that the fish scales are changed into things of value from waste material and thorough utilization of resources is realized. The preparation process comprises the following steps of pretreating, decalcifying, neutralizing and removing impurity, washing by using water, sol, solid-liquid separating and filtering, hydrolyzing, filtering and separating the collagen protein, filtering and separating the macromolecular protein, desalting, dehydrating, drying and the like to obtain collagen protein powder. The collagen protein powder prepared by the preparation process has the molecular weight of less than 5000 Daltons and can be absorbed by the human body easily.

Owner:SHISHI HAIXING FOOD +1

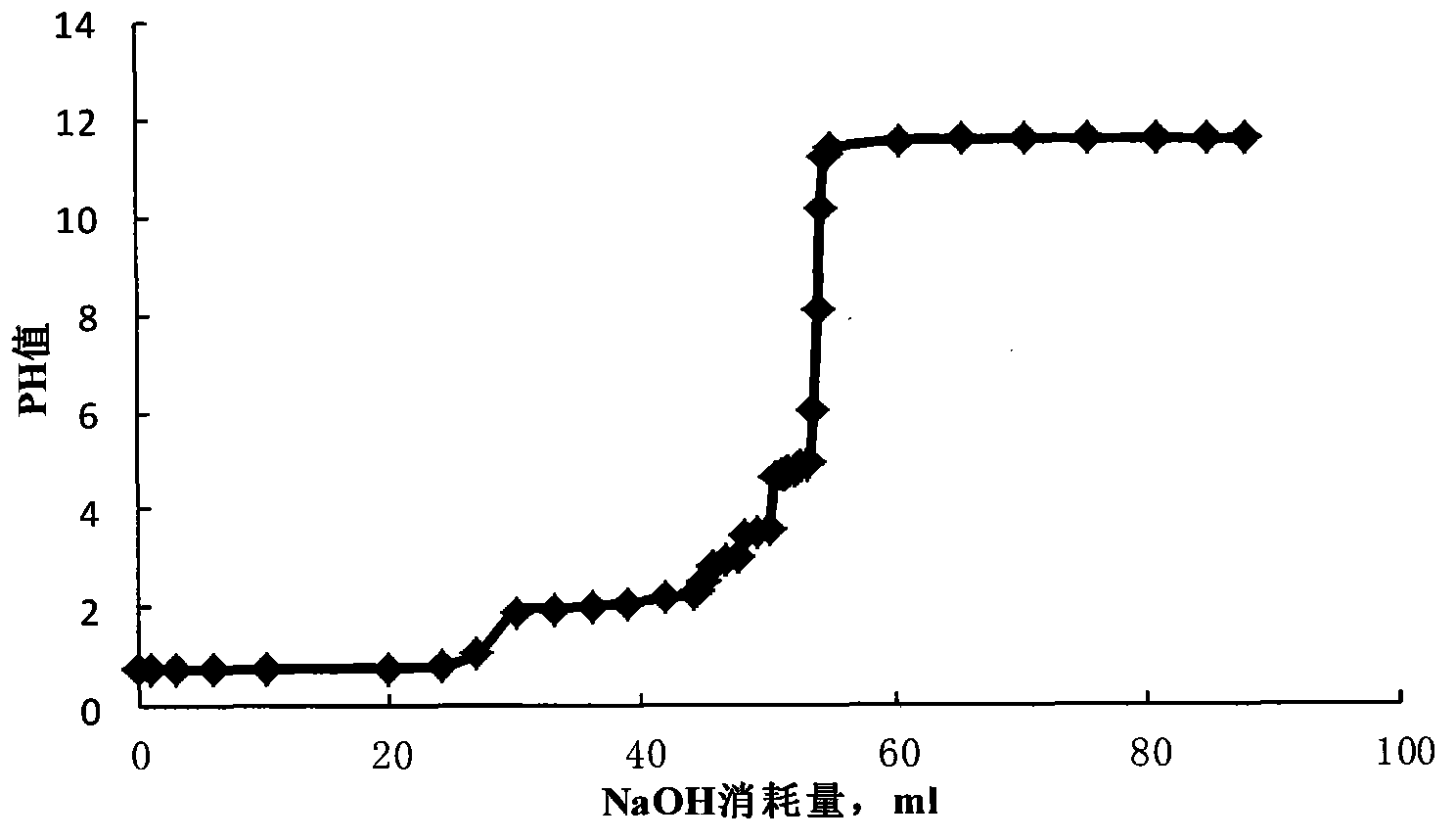

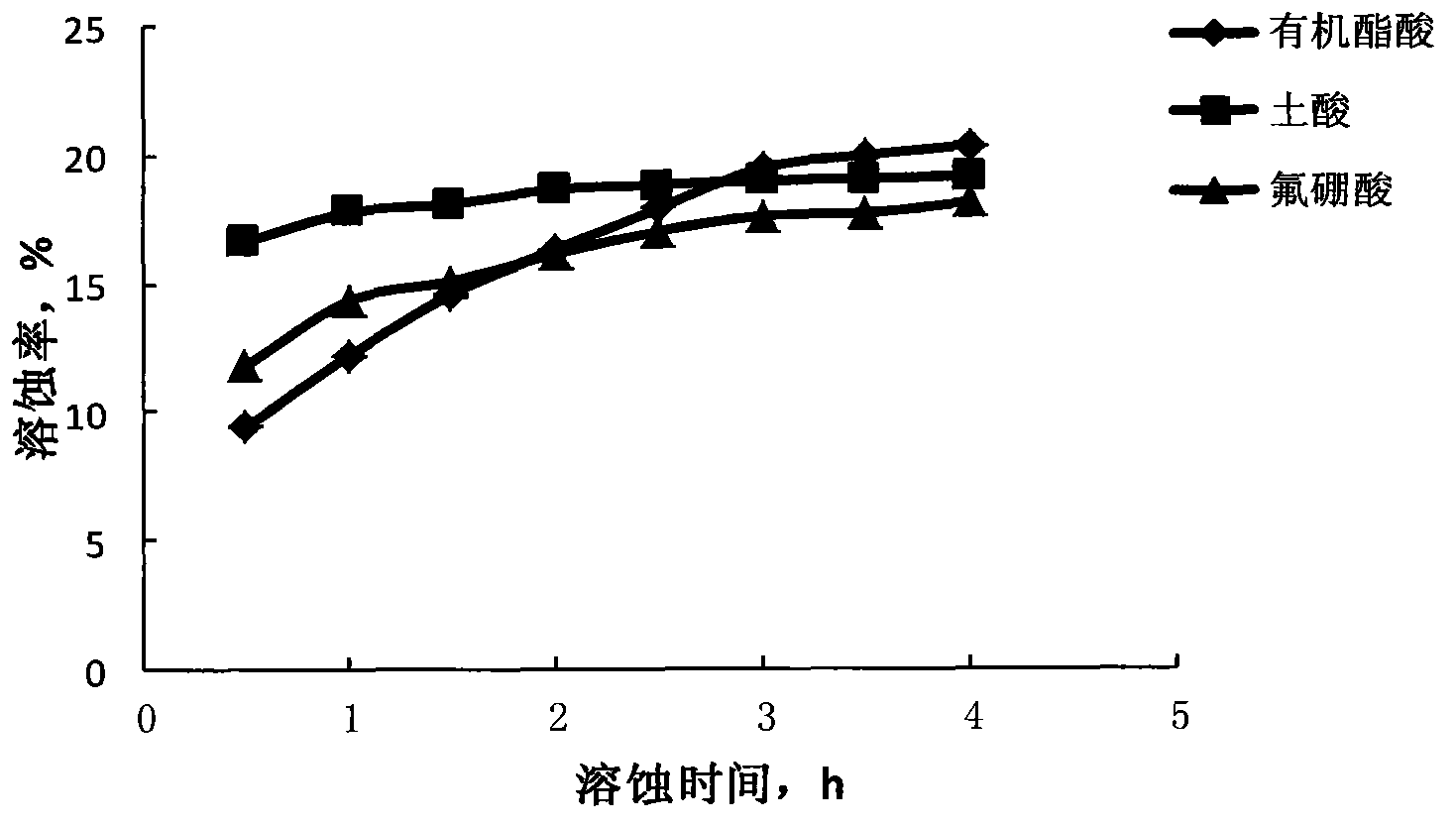

Retardance and low damage acid solution system for high temperature condensate oil gas reservoir acidification

The present invention discloses a retardance and low damage acid solution system for high temperature condensate oil gas reservoir acidification. The acid solution system is suitable for acidification modification of high temperature deep well, particularly condensate gas reservoir, and comprises the following components, by weight, 0.5-3 parts of hydrofluoric acid or 6-12 parts of fluoroboric acid, 8-10 parts of an organic ester, 0.01-0.05 part of a catalyst, 0.1-1 part of a corrosion inhibitor, 0.1-1 part of an iron ion stabilizer, 0.1-1 part of a clay stabilizer, 1-2 parts of a cleanup additive, and 80-100 parts of water. According to the present invention, effects of retardance and corrosion inhibition of the acid solution system can be well achieved at a high temperature, and water blocking can be released and acid solution backflow can be easily achieved with the finally produced methanol and the carbon dioxide.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing hairtail polypeptides

InactiveCN101200751AAid in diffusionGood nutrition and health effectProtein composition from fishCosmetic preparationsNisinHydrolysis

The invention relates to a preparation method of hairtail polypeptide, including the following steps: (1) putting hairtail in water which is 1 to 3 times of the weight of the hairtail and wringing the hairtail and the water evenly into fish meat pulp; (2) putting the fish meat pulp in an enzymatic vessel, raising the temperature to 45 DEG C-65 DEG C and regulating the pH value to 5.5-8.5; in the weight of the hairtail, adding endoprotease of 1.0-3.0 percent and nisin which is 0.02-0.1 percent of the weight of the fish meat pulp weight at the same time; implementing the agitation hydrolysis on the mixed fish meat pulp for 16-24h; adding the endoprotease of 1.0-5.0 percent, regulating the temperature to 45 DEG C-60 DEG C, regulating the pH value to 5.0-8.0 and keeping on the agitation hydrolysis for 3-6h; (3) killing enzyme; (4) centrifuging to fetch supernatant; (5) decompressing, concentrating, vacuuming and drying the supernatant to obtain a hairtail polypeptide product. The molecular weight range of the hairtail polypeptide obtained through the method is kept within 250Da-6000Da; the content of the polypeptide, the molecular weight of which is smaller than 1000Da, is higher than 50 percent.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Sludge treatment method

InactiveCN108423961AImprove sludge hydrolysis efficiencyAchieve recyclingSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisTarChemistry

The invention discloses a sludge treatment method. The method comprises steps as follows: sludge is injected into a reaction kettle, saturated steam is introduced into the reaction kettle, so that thesludge is subjected to a thermal hydrolysis reaction, and mud subjected to thermal hydrolysis is obtained; the obtained mud is injected into a filter press for mechanical filter-pressing dewatering,and a mud cake and filtrate are obtained; the obtained mud cake is put in a carbonization furnace to be carbonized, and biochar, pyrolysis gas and tar are obtained; a part of the obtained biochar is taken as a catalyst for the thermal hydrolysis reaction and back-mixed in the reaction kettle; the obtained pyrolysis gas and tar are subjected to dust removal and introduced into a pyrolysis gas steamboiler, and produced high-temperature steam is returned to the reaction kettle. By means of the method, the bio-char is taken as a raw material for the catalytic thermal hydrolysis reaction, the sludge hydrolysis efficiency can be improved, no chemical addition in the high-dryness dewatering process of sludge can be realized, and a new thought for sludge treatment is further expanded.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

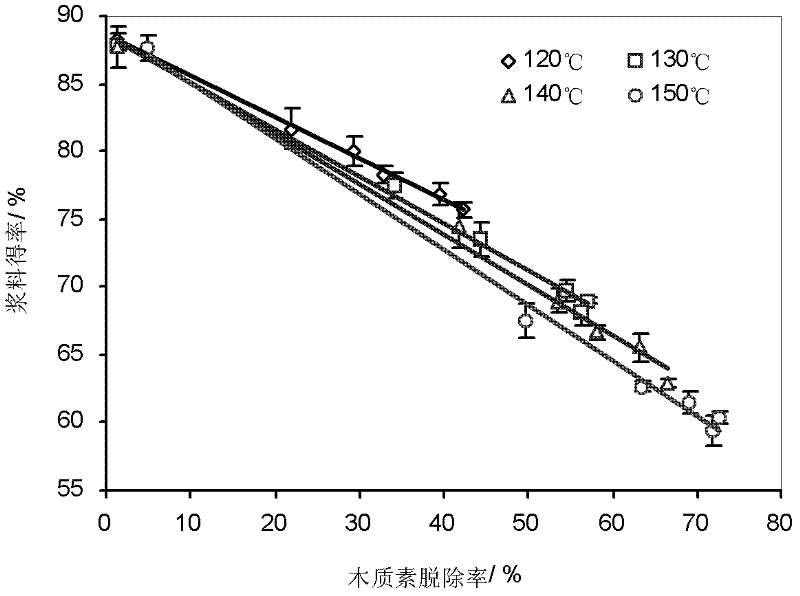

Pretreatment method for improving enzymatic hydrolysis and saccharification efficiency of non-wood fiber raw material

InactiveCN102517358ARealize industrial productionImprove hydrolysis efficiencyFermentationFiberPretreatment method

The invention discloses a pretreatment method for improving enzymatic hydrolysis and saccharification efficiency of a non-wood fiber raw material. The method comprises the following steps of: mixing an aqueous solution of sodium carbonate and the non-wood fiber raw material, pre-impregnating for 30 to 120 minutes at the temperature of between 30 and 90 DEG C, heating to the temperature of between 100 and 180 DEG C, performing heat preservation reaction for 0 to 120 minutes, washing the non-wood fiber raw material by using water, defibering the raw material into fibrous pulp by using a stuff grinder, and thus completing the pretreatment process. The yield of the pretreated non-wood fiber raw material is between 50 and 90 percent, the removal rate of lignin is between 10 and 80 percent, the loss of high glycan is between 0 and 25 percent, a little silicon dioxide is dissolved from the non-wood fiber raw material in the pretreatment solution, and most silicon dioxide is preserved in the pretreated non-wood fiber raw material.

Owner:NANJING FORESTRY UNIV

Bacterial cellulose fermentation medium made from apple pomace and method for producing bacterial cellulose by utilizing medium

ActiveCN104031956AImprove solubilityReduce degradationMicroorganism based processesFermentationHydrolysateSugar

The invention discloses a bacterial cellulose fermentation medium made from apple pomace and a method for producing the bacterial cellulose by utilizing the medium, and belongs to the field of biotechnology. The bacterial cellulose fermentation medium comprises cane sugar, beef extract, disodium hydrogen phosphate, citric acid, ethanol and apple pomace hydrolysate. The method comprises the following steps: (1) activating and propagating gluconacetobacter xylinum to obtain gluconacetobacter xylinum seed solution, incubating the gluconacetobacter xylinum seed solution into a bacterial cellulose fermenting medium for fermenting to obtain bacterial cellulose fermenting solution; and (2) treating a bacterial cellulose in the bacterial medium fermenting solution to obtain bacterial cellulose. The method has the advantages of low cost, simple process and the like, is convenient for industrial production, is good in stability and reproducibility, and is suitable for large-scale production, wherein the yield of the fermented bacterial cellulose is more than 15g / L.

Owner:SHAANXI UNIV OF SCI & TECH

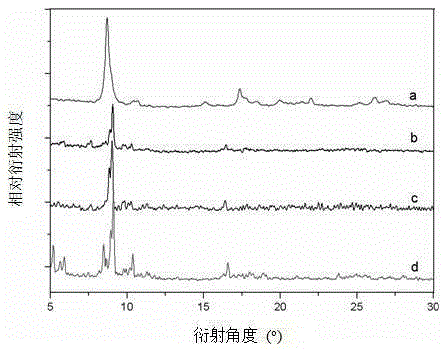

A method for pretreating lignocellulosic raw materials with concentrated phosphoric acid and hydrogen peroxide for enzymatic hydrolysis

ActiveCN103555774BReduce crystallinityEfficient removalBiofuelsFermentationStrong acidsPhosphoric acid

The invention discloses a method for pre-treating a lignocelluloses raw material for enzyme hydrolysis in combination of strong phosphoric acid and hydrogen peroxide. The method comprises the following steps: using strong phosphoric acid as a solvent and hydrogen peroxide as a catalyst to remove lignin and hemicellulose in the lignocelluloses raw material, adding water in the solution to regenerate cellulose in the solution so as to obtain regenerated cellulose which is low in crystalline and polymerization degree and suitable for enzyme hydrolysis, using the regenerated cellulose after filtering and separating for the enzyme hydrolysis to produce fermentable carbohydrate, wherein the hydrolysis efficiency is 75-100%. The method is suitable for lignocelluloses raw materials in different types such as crop stalks, woods and bamboos, wild herbs or woody and the like, the method is simple in operation, low in energy consumption, clean and non-pollution, low in requirement on grain size of raw materials, and strong in raw material adaptability, and the pre-treatment effect is perfect.

Owner:SICHUAN AGRI UNIV

Preparation method of high-purity arctigenin

InactiveCN103145655AAvoid thermal changesAvoid interferenceOrganic chemistryFluid phaseEthyl acetate

The invention discloses a preparation method of high-purity arctigenin. The preparation method of the high-purity arctigenin does not need a heating return flow method to extract arctigenin constituents, does not need an enzymolysis method and a column chromatography, and directly uses ethyl acetate diacolation to extract arctiin in burdock, the potential of hydrogen (PH) value of a diacolation concentrated solution is adjusted to be 3.0-4.0, the arctiin is directly hydrolyzed to become an arctigenin crude product, and an opposite phase preparative liquid chromatography optimized by a large number of experiments is adopted to obtain the high-purity arctigenin. The preparation method of the high-purity arctigenin is reasonable and in the entire preparation process design, high in preparation efficiency, strong in operability, and suitable for industrialized mass production.

Owner:NANJING HAIYUAN CHINESE HERBAL PIECES CO LTD

Preparation method of narrow-distribution medium-molecular-weight hydroxyethyl starch

The invention relates to the field of medical chemistry, in particular to a preparation method of narrow-distribution medium-molecular-weight hydroxyethyl starch. The method comprises the following steps of: dispersing wax corn starch with purified water, and hydrolyzing with an inorganic acid; performing gradient temperature change control and controlling the hydrolyzing degree by using dynamic viscosity; and performing hydroxyethylation, carbon removing filtration, ultrafiltration and spray drying on a hydrolysate to obtain a narrow-distribution medium-molecular-weight hydroxyethyl starch raw material. According to the method, the weight average molecular weight of the medium-molecular-weight hydroxyethyl starch is controlled more accurately, and the molecular weight distribution is more concentrated.

Owner:SHANDONG QIDU PHARMA

Method for preparing nourishing instant solid beverage of crab

InactiveCN101313769AAdd flavorImprove hydrolysis effectFood preparationNeutral proteaseAdditive ingredient

The invention discloses a method for making a crab nutritional instant solid beverage, which is characterized by comprising the following steps of grinding portunid leftovers, drying, degreasing, carrying out composite enzymolysis, centrifuging, concentrating clear liquid, seasoning, homogenizing, spraying, drying, etc., wherein composite enzymolysis adopts neutral protease and flavored protease. The method effectively extracts nutritional components in the portunid leftover to product the solid beverage, which changes waste into valuables, produces considerable economic benefit, can satisfy the consuming needs of people, and can promote human health.

Owner:HEFEI UNIV OF TECH

Sulfonated carbonaceous solid acid catalyst as well as preparation method and application thereof

InactiveCN108273526AGood contactImprove hydrolysis efficiencyPhysical/chemical process catalystsGlucose productionDensity ratioSolid acid

The invention discloses a sulfonated carbonaceous solid acid catalyst as well as a preparation method and application thereof to a microcrystalline cellulose hydrolysis process. The density of a sulfonic acid group on the surface of the catalyst is 0.30 to 0.80mmol / g and the density of an oxygen-containing group is 1.00 to 2.50mmol / g; the density ratio of the sulfonic acid group to the oxygen-containing group is controlled to be from (1 to 1.25) to (1 to 8.33). The catalyst has high hydrolysis efficiency and a preparation technology is simple and is suitable for large-scale production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com