Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

564results about How to "Reduce the degree of polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

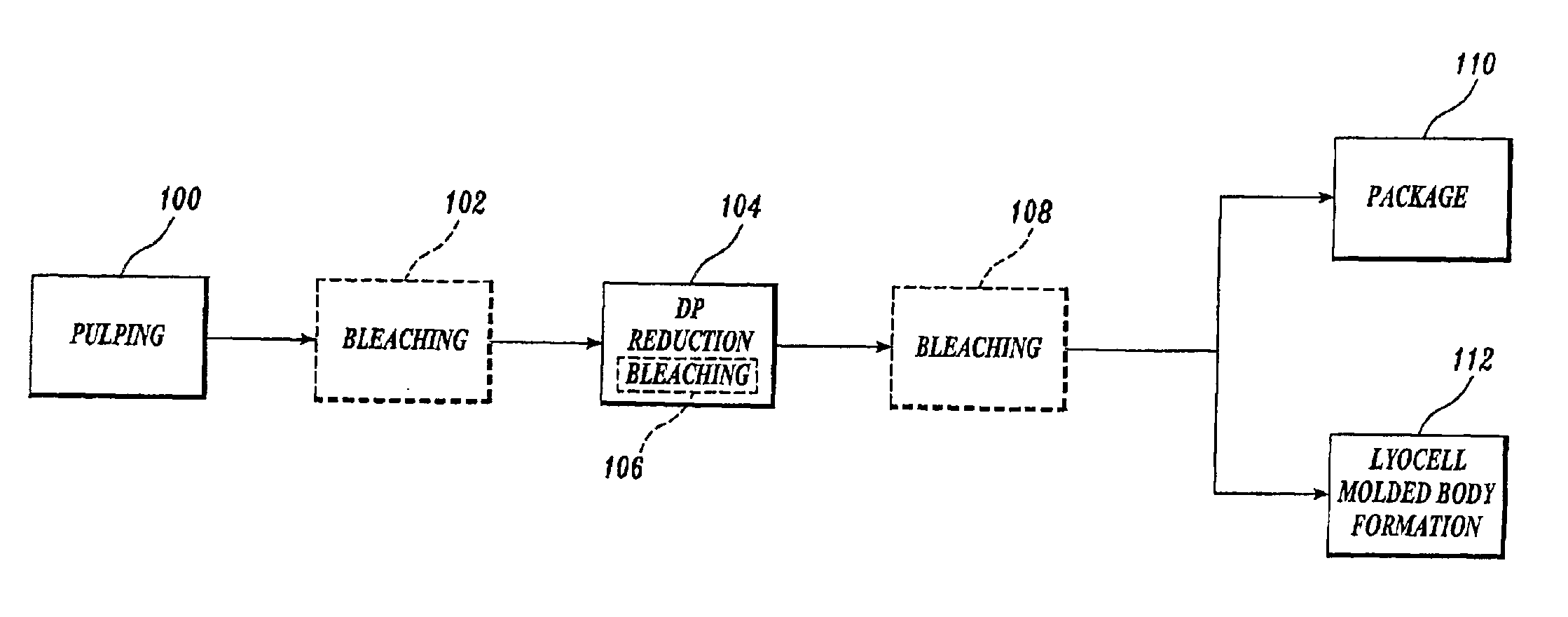

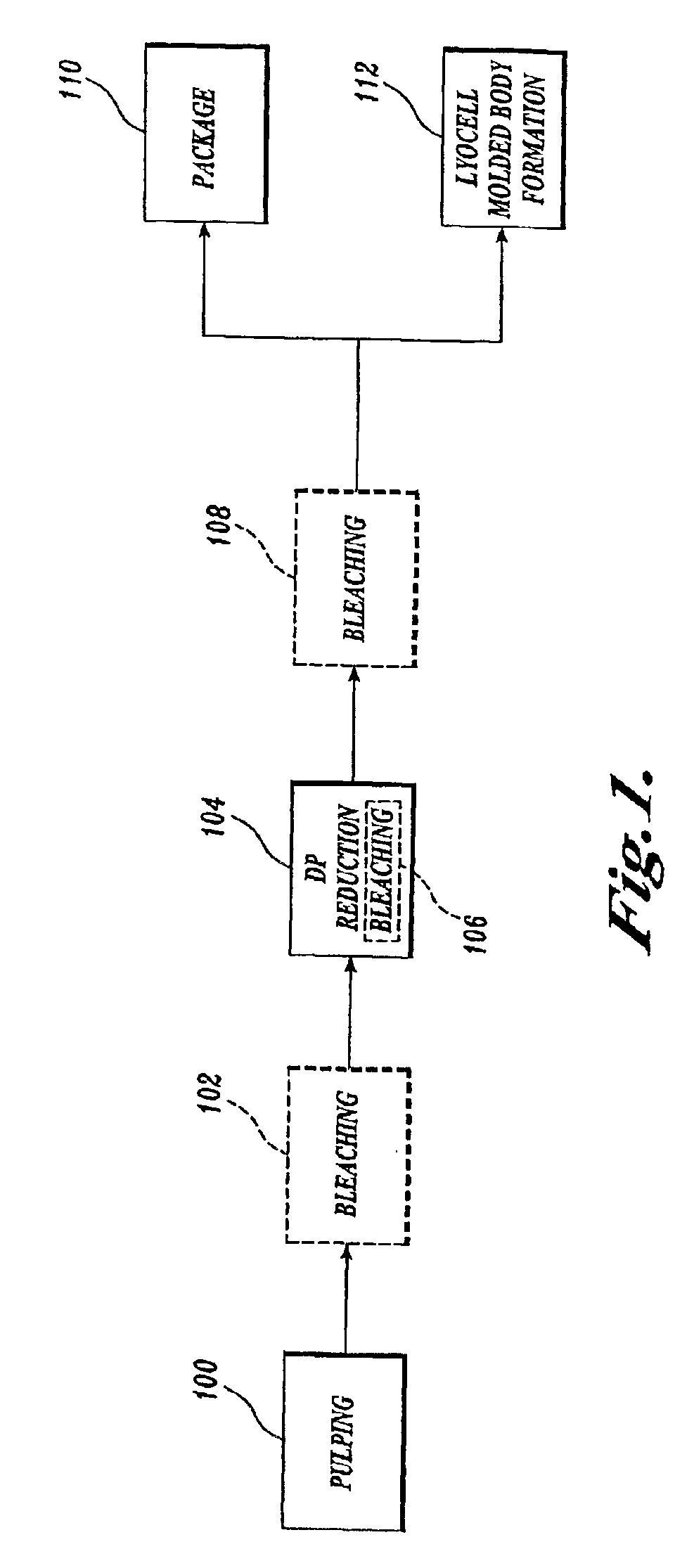

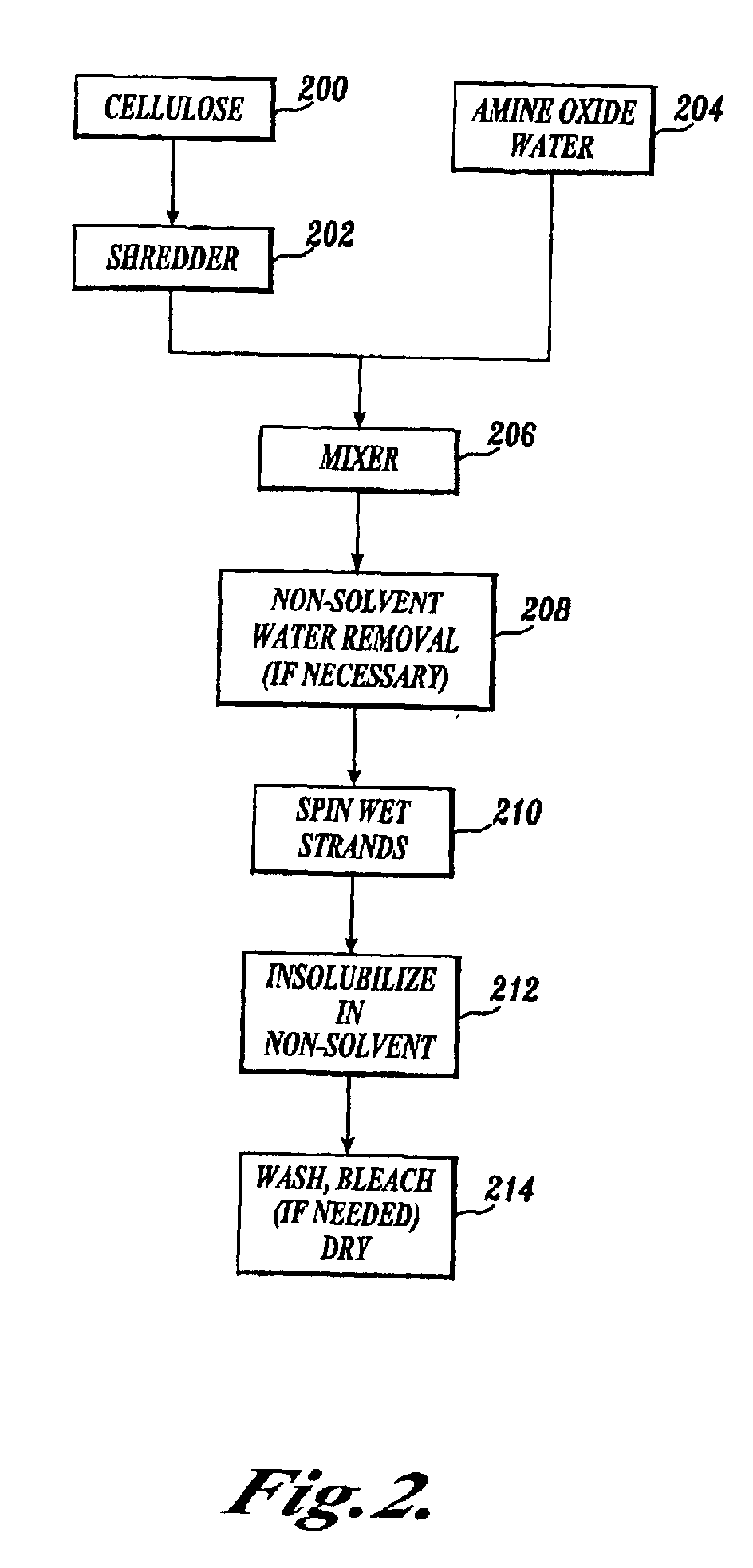

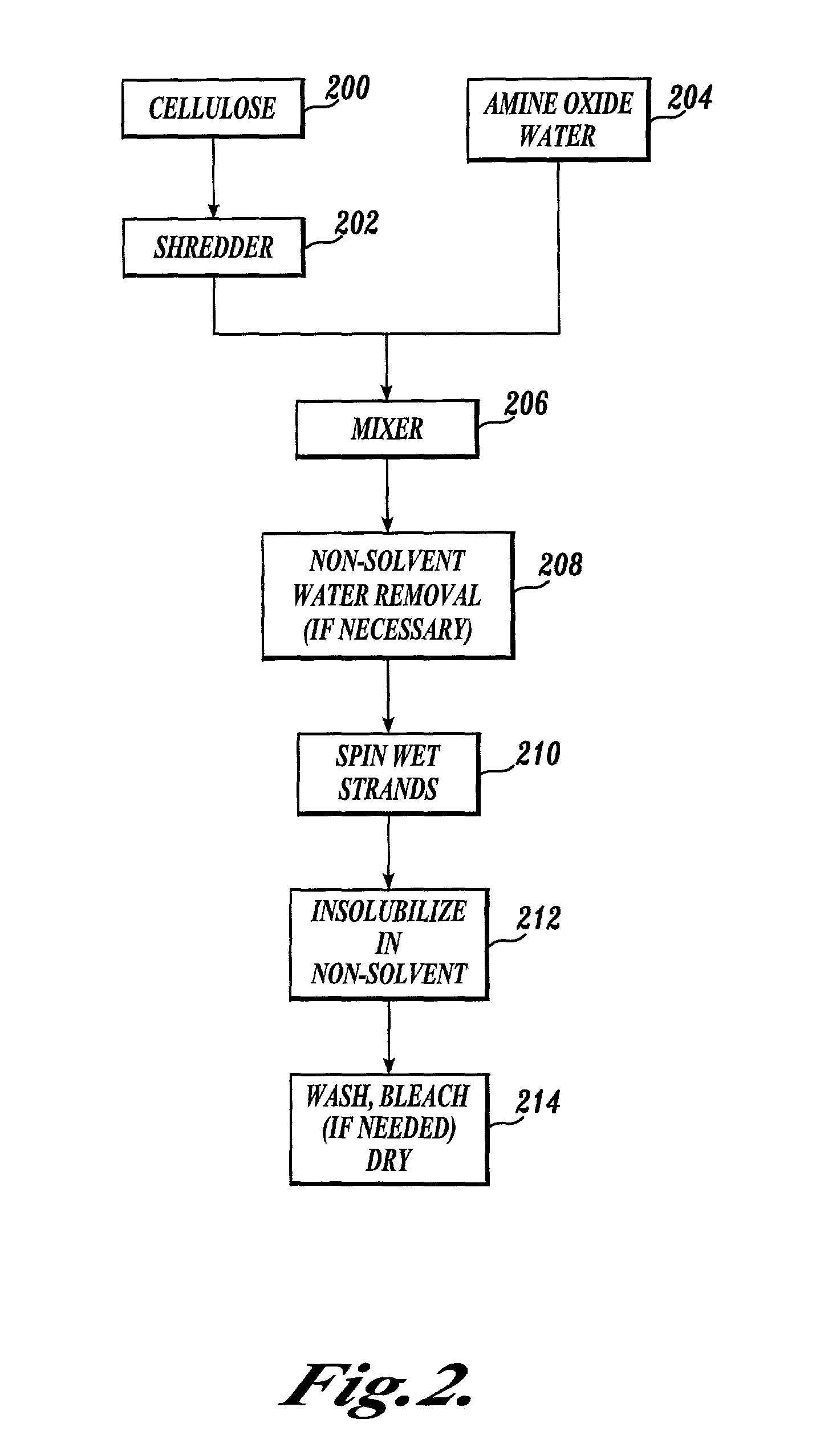

Process for making lyocell fiber from sawdust pulp

InactiveUS6861023B2Reducing average degree of polymerizationReduced hemicellulose contentPulp properties modificationArtificial filaments from cellulose solutionsCopperLyocell

A process for making lyocell fibers including the steps of pulping raw material in a digester to provide an alkaline pulp, wherein the raw material includes sawdust in an amount greater than 0% up to 100%; contacting the alkaline pulp including cellulose and at least about 7% hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to the range of from about 200 to about 1100 without substantially reducing the hemicellulose content or substantially increasing the copper number of the pulp; and forming fibers from the pulp.

Owner:INT PAPER CO

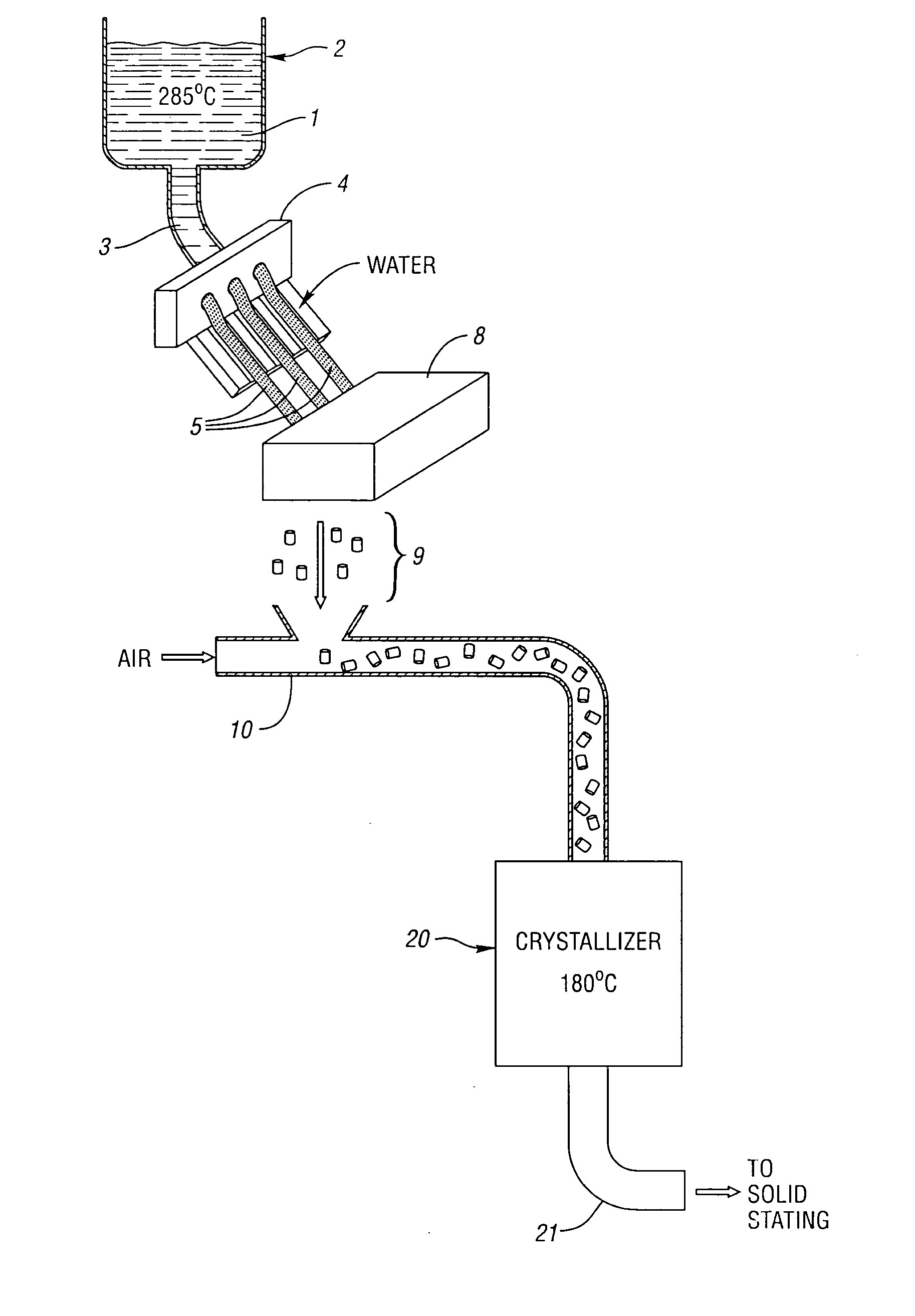

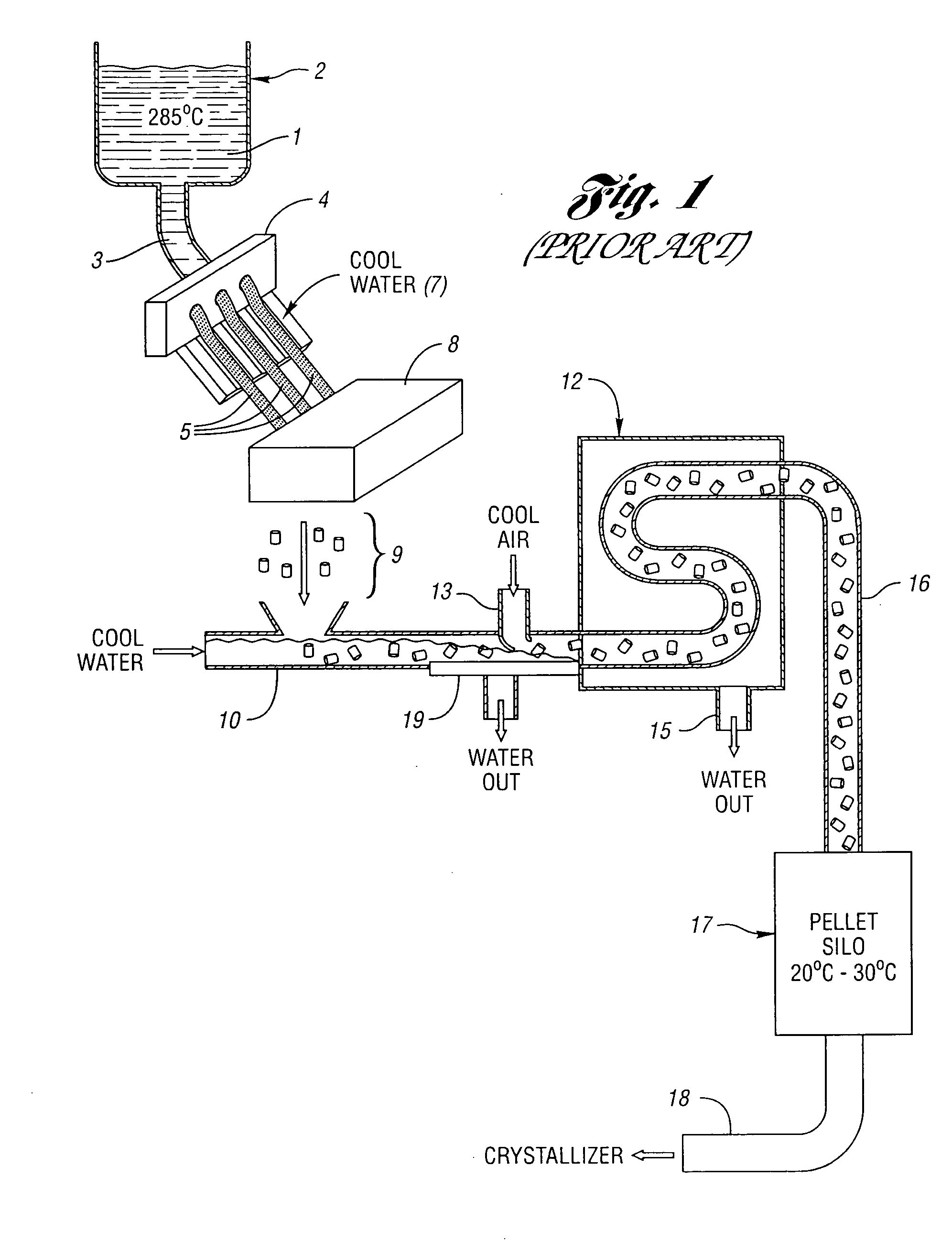

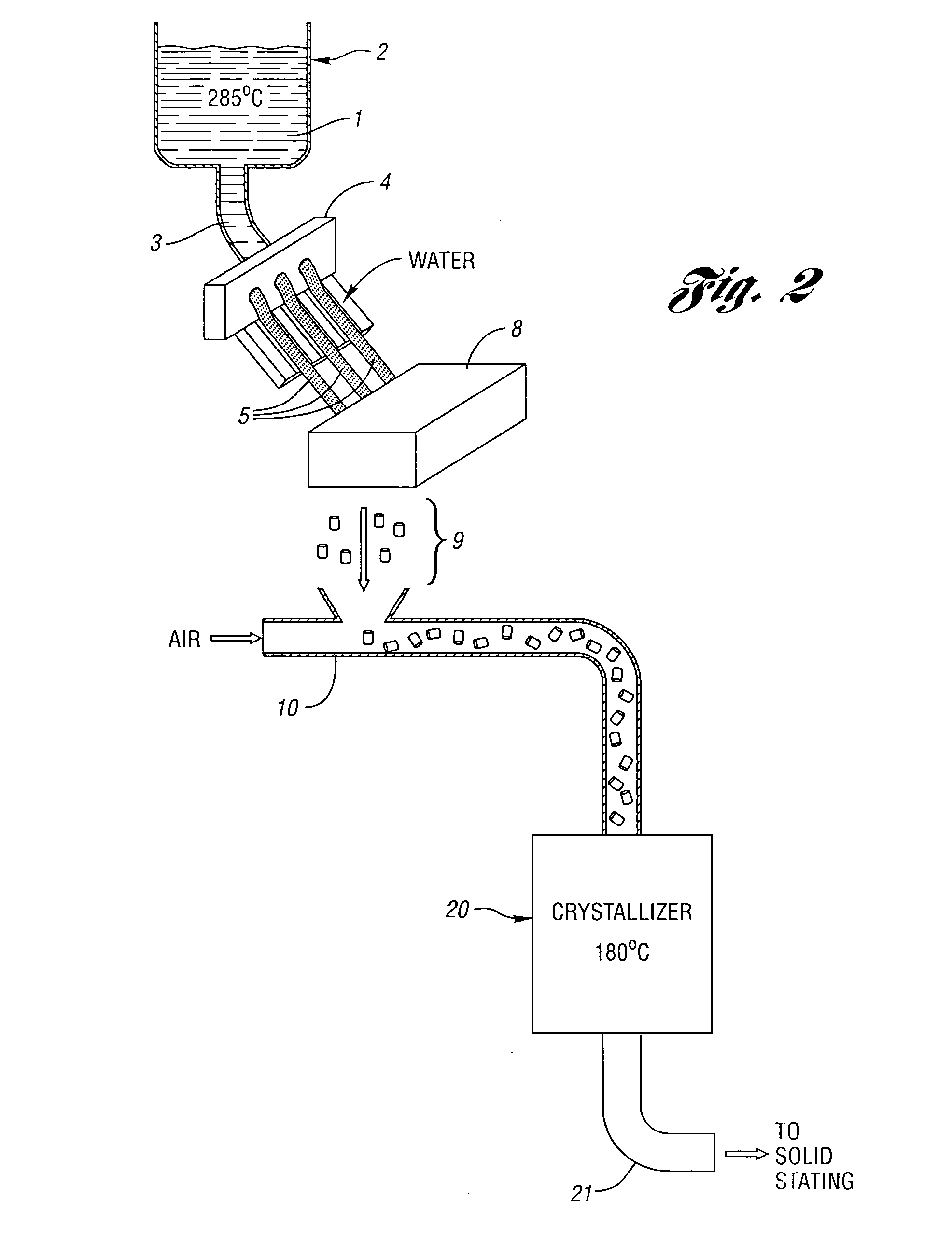

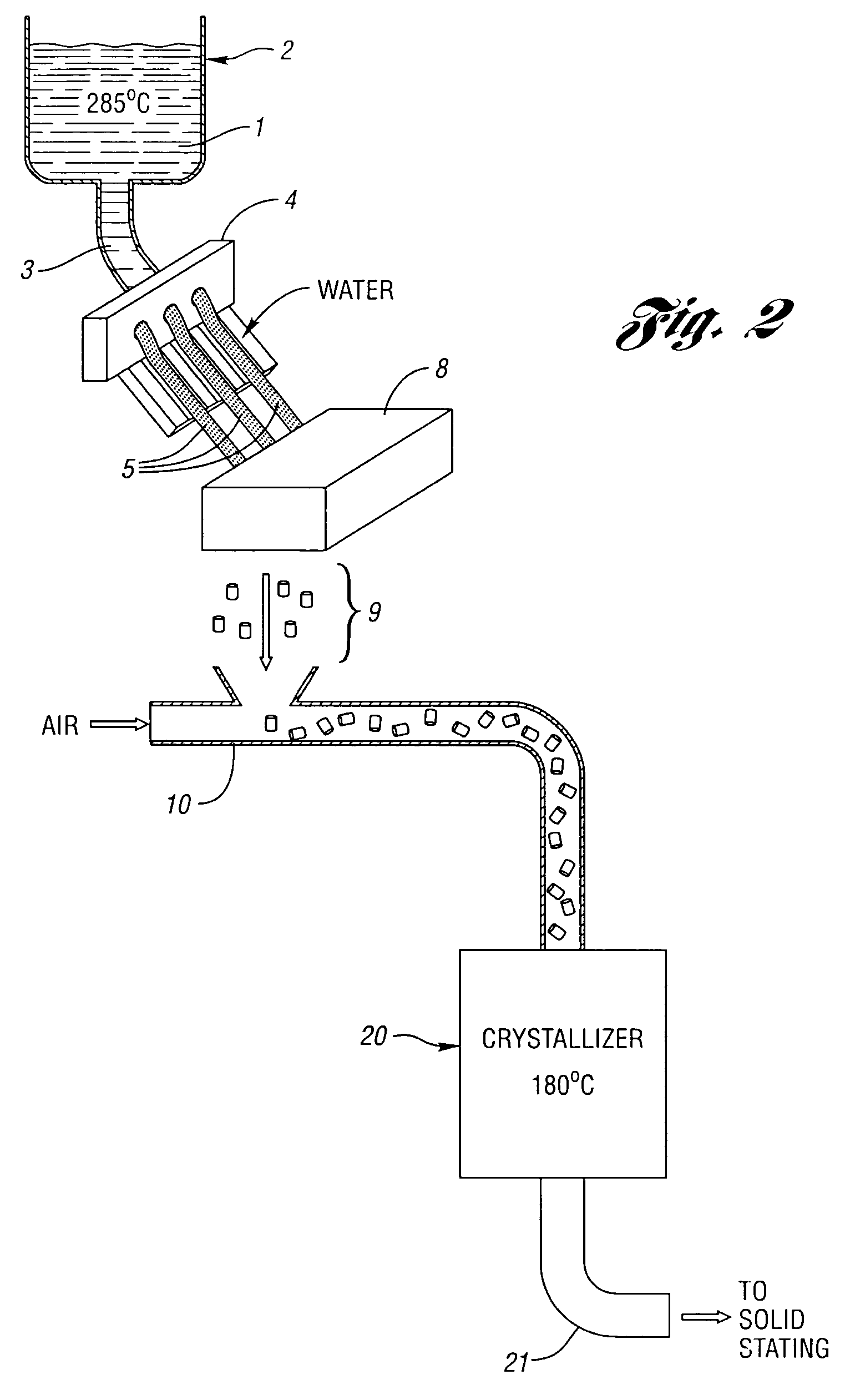

Direct coupling of melt polymerization and solid state processing for PET

ActiveUS20050056961A1Increase temperatureReduce molecular weightWood working apparatusBuilding constructionsPolyethylene terephthalate glycolPolyethylene terephthalate

Strands of molten polyethylene terephthalate (PET) from a PET polycondensation reactor are solidified, pelletized, and cooled only to a temperature in the range of 50° C. to a temperature near the polymer Tg by contact with water. The still hot pellets are conveyed, optionally followed by drying to remove water, to a PET crystallizer. By avoiding cooling the amorphous pellets to room temperature with water and cool air, significant savings of energy are realized.

Owner:ALPEK POLYESTER SA DE CV

Direct coupling of melt polymerization and solid state processing for PET

InactiveUS7204945B2Reduce molecular weightReduce the degree of polymerizationWood working apparatusDomestic articlesPolyethylene terephthalatePolyethylene terephthalate glycol

Strands of molten polyethylene terephthalate (PET) from a PET polycondensation reactor are solidified, pelletized, and cooled only to a temperature in the range of 50° C. to a temperature near the polymer Tg by contact with water. The still hot pellets are conveyed, optionally followed by drying to remove water, to a PET crystallizer. By avoiding cooling the amorphous pellets to room temperature with water and cool air, significant savings of energy are realized.

Owner:ALPEK POLYESTER SA DE CV

Process for the production of articles covered with silica-base coats

InactiveUS6465108B1Reduce the degree of polymerizationImprove responsePretreated surfacesLiquid/solution decomposition chemical coatingCooking & bakingAlcohol

Coating liquid prepared by dissolving an acid and a silicon alkoxide into alcohol, containing at least one of either a silicon alkoxide or a hydrolyzate thereof (including a partial hydrolyzate) in an amount of 0.010 to 3% by weight (in terms of silica), an acid in terms of 0.0010 to 1.0 normality, and water in terms of 0 to 10% by weight is coated on a substrate to produce an article coated with a silica-based film. By this method for producing a silica-based film coated article, an excellent silica-based film coated article can be obtained without requiring baking and pretreatment. Furthermore, a functional film coated article excellent in durability can be produced in a short period of time and safely by using the abovementioned silica-based film as a primer film and applying thereon an organosilane having a hydrolyzable group and a functional group having a specific function or a hydrolyzate thereof.

Owner:NIPPON SHEET GLASS CO LTD

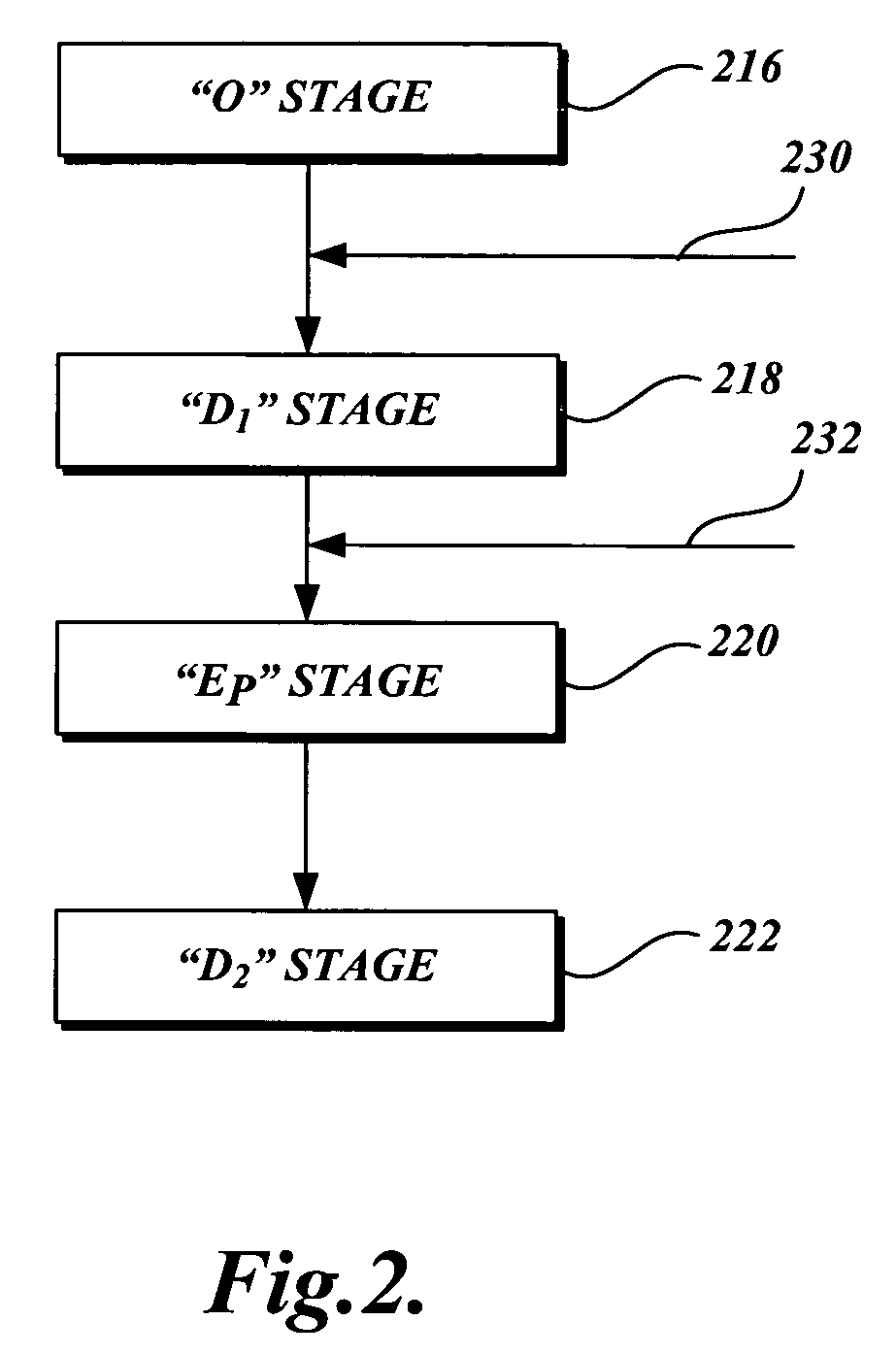

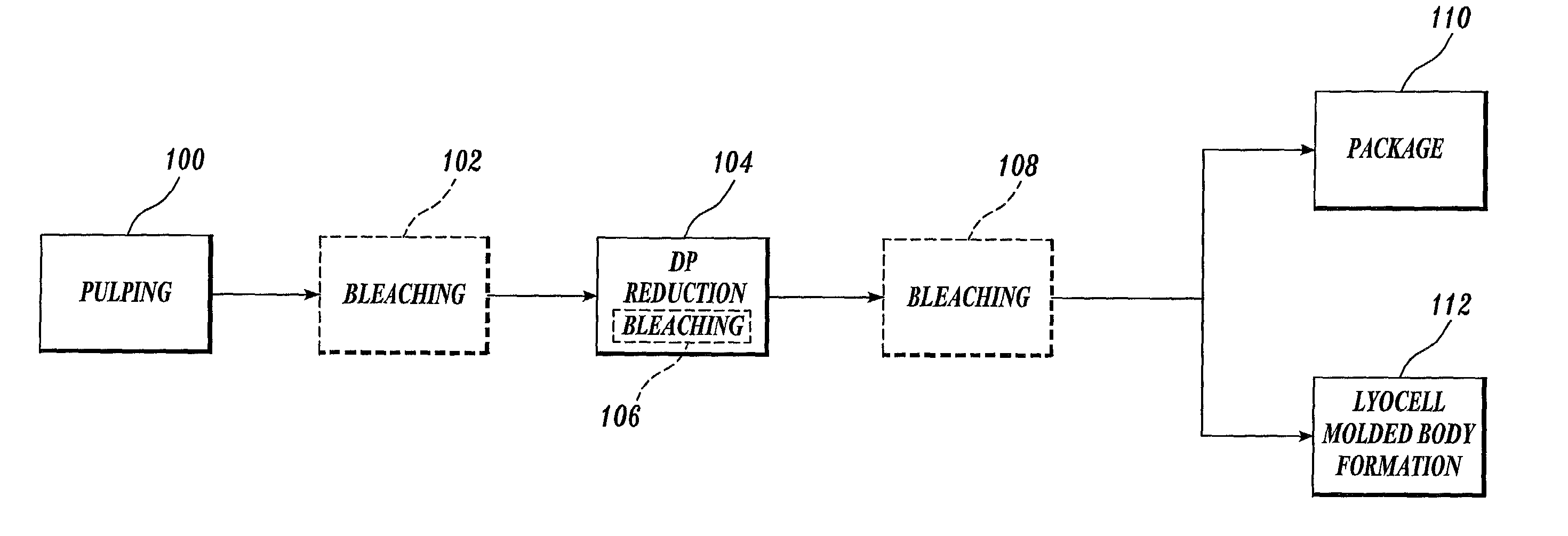

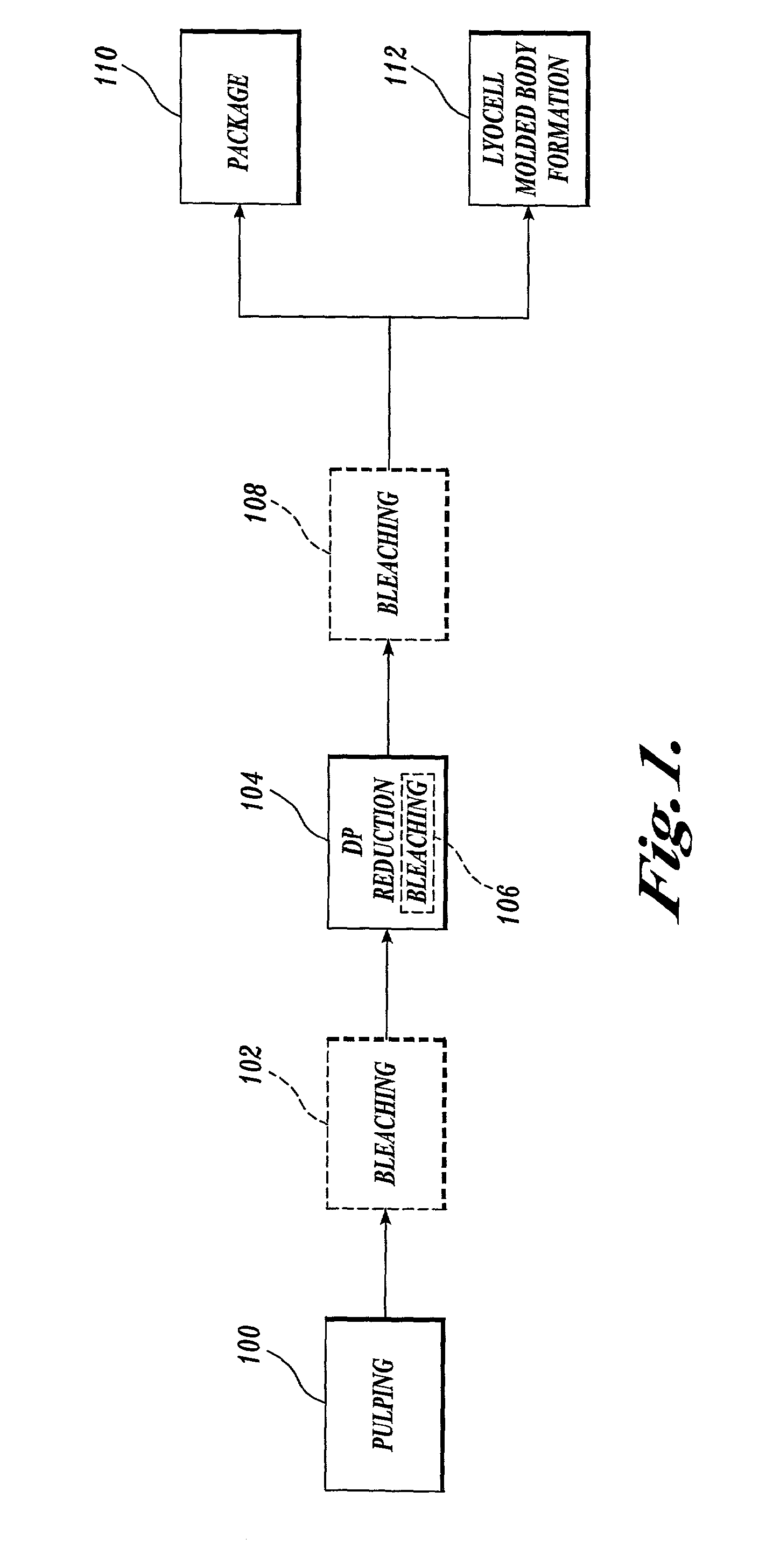

Low pH treatment of pulp in a bleach sequence to produce pulp having low D.P. and low copper number for use in lyocell manufacture

InactiveUS20060070711A1Reduce the degree of polymerizationIncreasing copper numberPulp properties modificationLayered productsBleachPulp mill

A high pH and a low pH process for reducing the degree of polymerization of a pulp having a hemicellulose content of at least 7%. The high pH is greater than 8, and the low pH process is 2 to 8. The high pH process reduces the degree of polymerization without substantially increasing the copper number. The low pH process requires a subsequent treatment with alkali to reduce the copper number of the pulp to less than 2. The process can be practiced in pulp mills with a bleaching sequence having one or more E or D stages. At the end of the bleach sequence, a pulp having a degree of polymerization of 200 to 1100, a copper number of less than 2, and a hemicellulose content of at least 7% is provided. The pulp can be used to make lyocell fibers.

Owner:WEYERHAEUSER NR CO

Method for producing dissolving pulp by oxygen continuous digesting method

InactiveCN101333778AReduce the degree of polymerizationAchieve continuous cookingPaper material treatmentCyclonic separationCooking methods

The invention relates to a production method for preparing a dissolving pulp by an oxygen-dissolving and continuous-cooking method, which applies the preparation of cotton linters in the production of viscose fibers in the textile industry, and the method comprises the following steps of: I. cotton linter pretreatments: including cotton linter loosening, cyclone separation and dust removal, feeding, two-roll grinding treatment, etc. to the cotton linters by a two-roll pulping machine; and II. oxygen dissolving and continuous cooking: a horizontal continuous cooking digester is adopted to realize the continuous, fast and low-pollution preparation of dissolving cotton pulp through the actions of high temperature, alkali, oxygen or hydrogen peroxide. The horizontal continuous cooking digester includes a pre-reaction bin, a two-roll gauge, a feeding screw, a T-shaped tube, a continuous-cooking tube and a cold discharge device. The method can effectively solve the problems of: cutting, tearing and cell primary wall breakage to the cotton linters by dry method after feed preparation, physical and chemical stripping to mass impurities in the cotton linters, fast accumulation reduction of the cotton linters in a continuous-cooking device and the purification of alpha cellulose under fast accumulation reduction, recycling of waste heat in the production link, and reduction of total amount of COD in a black liquor, and the method has advantages of even cooking and short cooking cycle.

Owner:宜宾长毅浆粕有限责任公司

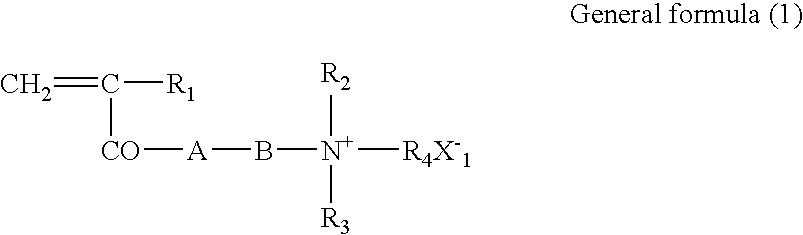

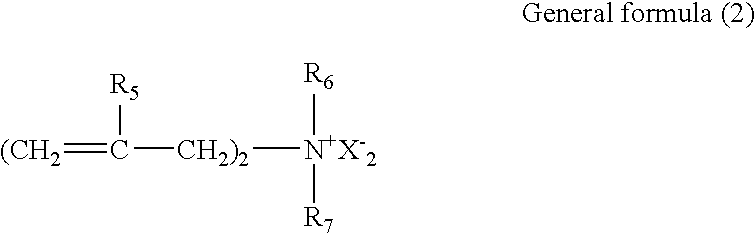

Water-soluble polymer dispersion, process for producing the same and method of use therefor

InactiveUS20060162882A1Marked effectImproved yieldNatural cellulose pulp/paperSpecial paperWater soluble polymersIon

A water-solible polymer dispersion, p process for producing the same and a method of use therefor. In particular, the water-soluble polymer dispersion is one comprising water-soluble polymer fine particles of 100 μm or less diameter having at least one ionic property selected from among cationic, amphoteric, nonionic and anionic properties together with a polyalkyleneimine and / or a product of polyalkyleneimine modification wherein according to necessity an appropriate amount of water-soluble inorganic salt is incorporated. The provided process enables easily performing the production in dispersed form by means of production facilities of low cost. The obtained water-soluble polymer dispersion is excellent in storage stability and exhibits satisfactory fluidity and solubility so as to enable use in papermaking raw material pretreatments added to papermaking raw materials prior to machine operation and also for enhancement of freeness, increase of sizing degree and enhancement yield. Further use can be found in incorporation in an organic sludge or paper mill sludge for flocculation and ensuing drainage.

Owner:HYMO CORPORATION

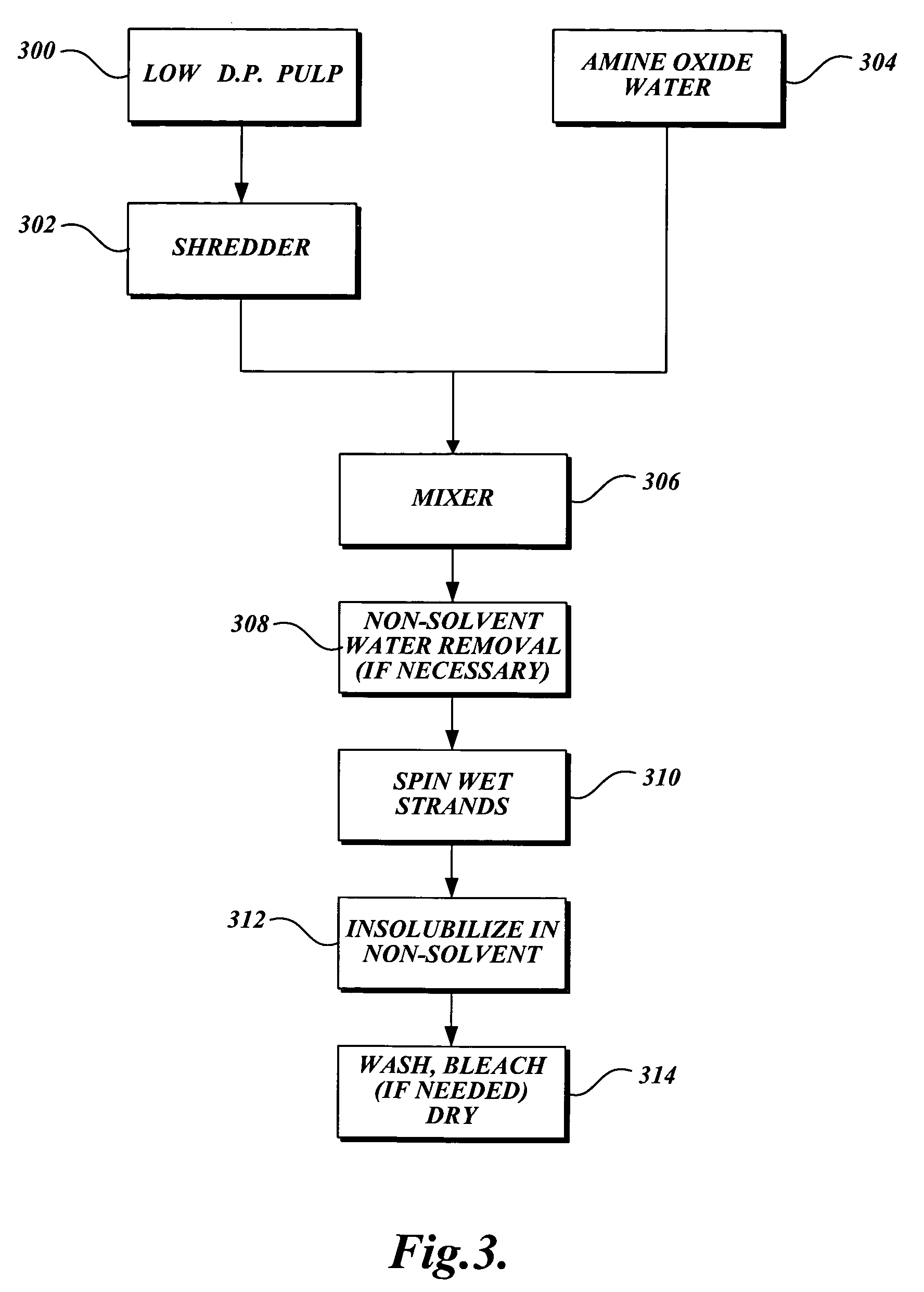

Process for making composition for conversion to lyocell fiber from sawdust

InactiveUS7090744B2Reduce the degree of polymerizationReduce contentPulp properties modificationMonocomponent cellulose artificial filamentCopperHemicellulose

A process for making a composition for conversion to lyocell fiber where the process comprises pulping a raw material in a digester to provide an alkaline pulp, wherein the raw material comprises sawdust in an amount greater than 0 % up to 100 %; and contacting the alkaline pulp comprising cellulose and at least about 7 % hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to within the range of from about 200 to about 1100, without substantially reducing the hemicellulose content of the pulp or substantially increasing the copper number.

Owner:INT PAPER CO

Process for controlled polymerization of a mixed polymer

InactiveUS7297721B2Reduce the degree of polymerizationReduce usageProductsReagentsPolymer scienceMonoethylene Glycol

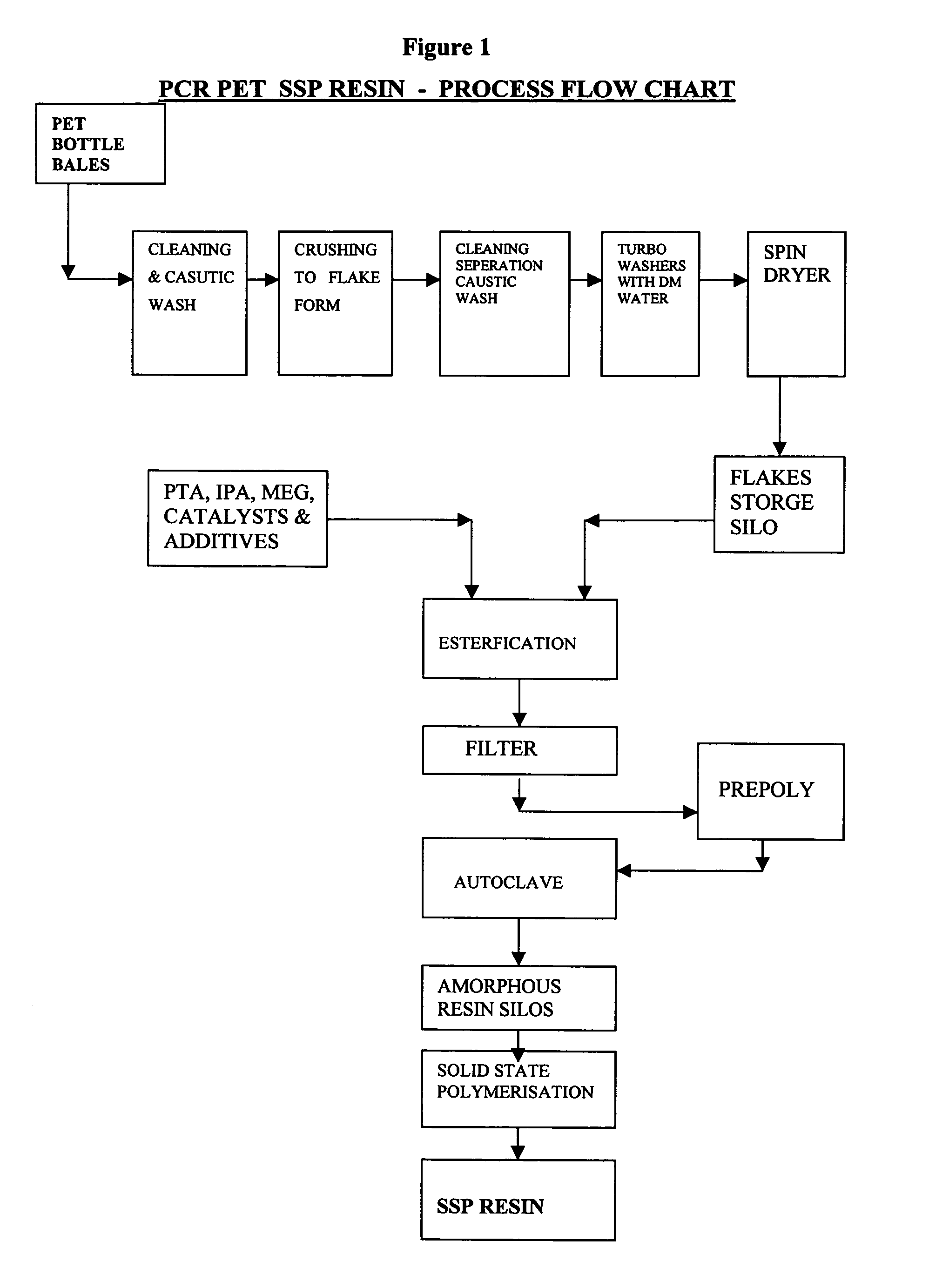

The present invention provides a process for the preparation of high molecular weight crystalline Polyethyleneterephthalate (PET) using up to 50% of Post consumer recycled PET flakes along with Pure Terephthalic Acid (PTA), Isophthalic Acid (IPA) and Mono Ethylene Glycol (MEG) as a virgin raw material, in the presence of a combination of catalysts and additives to obtain an intermediate prepolymer heel having a low degree of polymerization further subjecting to autoclaving to yield an amorphous melt and followed by solid state polymerization.

Owner:FUTURA POLYESTERS LTD

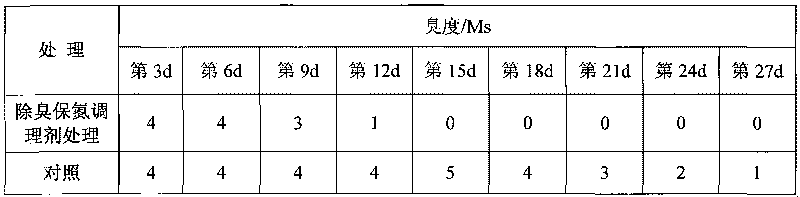

Deodorant nitrogen-conserving conditioner of livestock manure compost and using method

InactiveCN101696137AReduce the degree of polymerizationSolve the difficulty of degradationBio-organic fraction processingClimate change adaptationLivestock manureAnimal feces

The invention relates to a deodorant nitrogen-conserving conditioner. The using method comprises the following steps: evenly mixing pig manure and crushed straw or other crop straw in a ratio of 2-8:1, wherein the moisture content is between 60 and 65 percent; carrying out simple high-temperature composting by adding 25 to 40kg deodorant nitrogen-conserving conditioner in each 1,000kg compost rawmaterial; and adopting a pile-turning or a forced ventilation mode, wherein the temperature is not more than 70 DEG C during high-temperature composting. The deodorant nitrogen-conserving conditionercomprises 15 to 20kg calcium chloride, 10 to 15kg calcium superphosphate and 3 to 8kg zeolite. The compost becomes thoroughly decomposed after 30-day composting. The deodorant nitrogen-conserving conditioner is characterized in that: the conditioner can reduce odorous substances in the pig manure compost and ammonia volatilization and eliminates odour more than 10 days earlier; moreover, the conditioner increases the content of nitrogen nutrients in a compost product by over 20 percent and reduces nitrogen loss by over 70 percent in the composting process; and at the same time, the conditioner has the advantage of simple and easy operation and is suitable to be used in organic fertilizer factories and vast rural areas.

Owner:HUNAN AGRICULTURAL UNIV

Method for preparing water-soluble solid styrene/acrylic resin and application thereof

InactiveCN101575397AAvoid it happening againAvoid cloggingInksCoatingsAcrylic resinUnsaturated monomer

The invention discloses a method for preparing water-soluble solid styrene / acrylic resin and application thereof. The method prepares the required resin by simultaneously performing free radical polymerization reaction and esterification reaction on an aromatic vinyl unsaturated monomer, an aliphatic vinyl unsaturated monomer, an unsaturated carboxylic acid monomer, fat alkanol, an initiating agent and an alpha-methyl styrene dimer in a reactor. In the method, the alpha-methyl styrene dimer is added as a chain transfer agent to reduce the branching degree and avoid the generation of gel and the blockage of the reactor; and simultaneously, the added fat alkanol performs esterification reaction with acroleic acid to inhibit the esterification reaction between an alcohol ether solvent and the acroleic acid, thus the viscosity of the reaction mixture is controlled effectively, and the finally prepared resin has narrow molecular weight distribution (Mw / Mn is less than 2.0), low molecular weight (Mw is less than 10,000), few organic volatile matters, and good wetting dispersion of pigment, and can be applied to preparing water color ink, coating or oil polish.

Owner:SUN YAT SEN UNIV

Catalytic system for cellulose acylation process for producing said catalytic system, and for its practical application

InactiveUS6407224B1Reduce the degree of polymerizationExtended durationSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidCellulose

A catalytic system for cellulose acylation includes an adduct of sulfuric acid with N,N-dimethylacetamide, free sulfuric acid or free N,N-dimethylacetamide with the following mole ratio of the components: adduct:1.0; free sulfuric acid, max:0.49; or free N,N-dimethylacetamide, max:0.4. A process for producing such a catalytic system is based upon reacting sulfuric acid with N,N-dimethylacetamide in an anhydrous medium at a temperature of 0° C.-25° C. with the following mole weight ratio of the components: sulfuric acid:1.0; N,N-dimethylacetamide, max:1.4. A process for cellulose acylation in the presence of this catalytic system incorporates cellulose treatment with acetic acid followed by treatment of the resultant activated cellulose with a lower fatty acid anhydride at a temperature of 10° C.-90° C. in the presence of this catalytic system taken in an amount of 1.5-30.0 wt. % of the cellulose weight in terms of sulfuric acid, a weight ratio of the liquid phase and cellulose being 3-7:1, respectively.

Owner:NAUCHNO PROIZVODSTVENNAYA FA EFIRY TSELLJULOSY

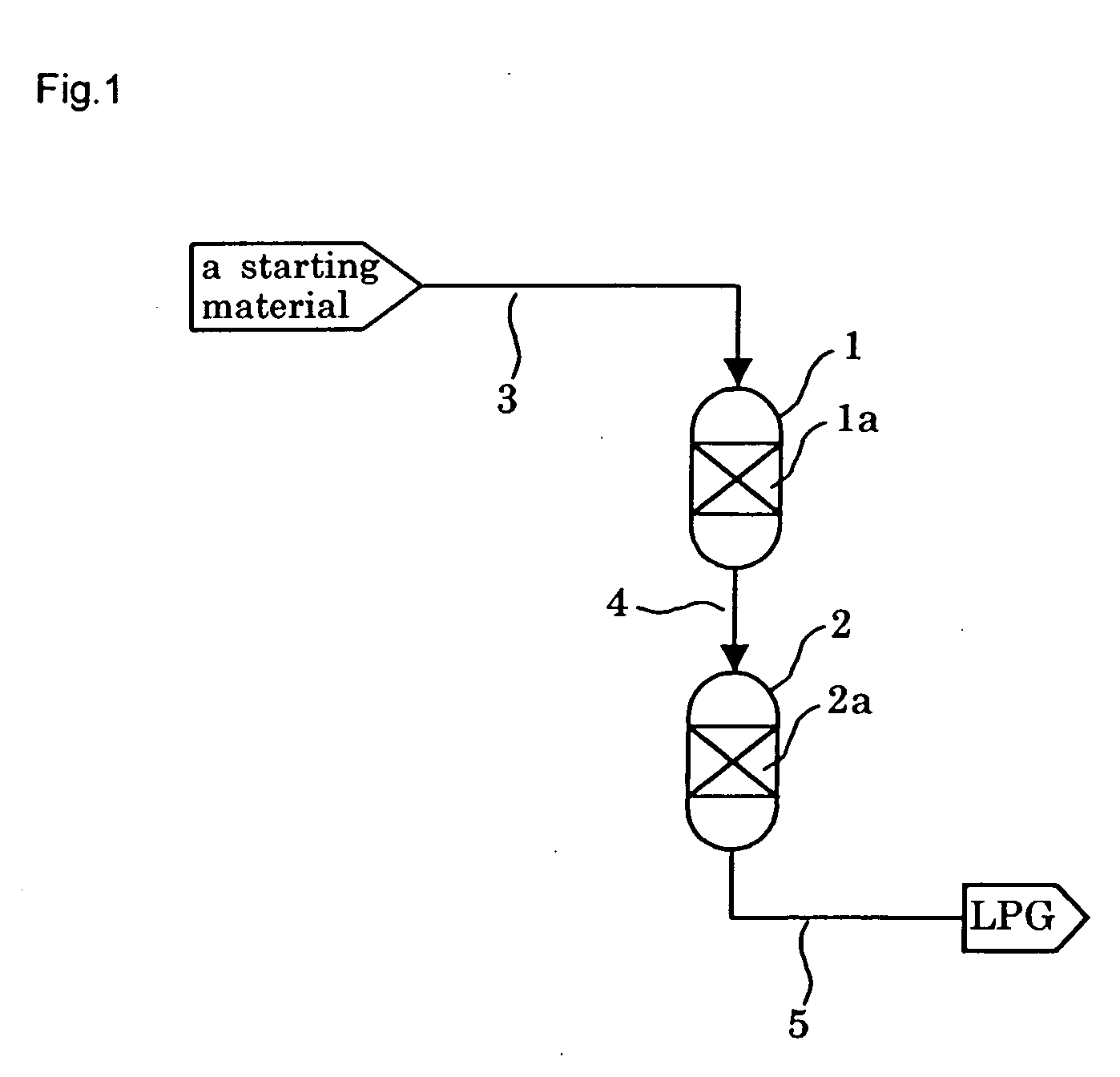

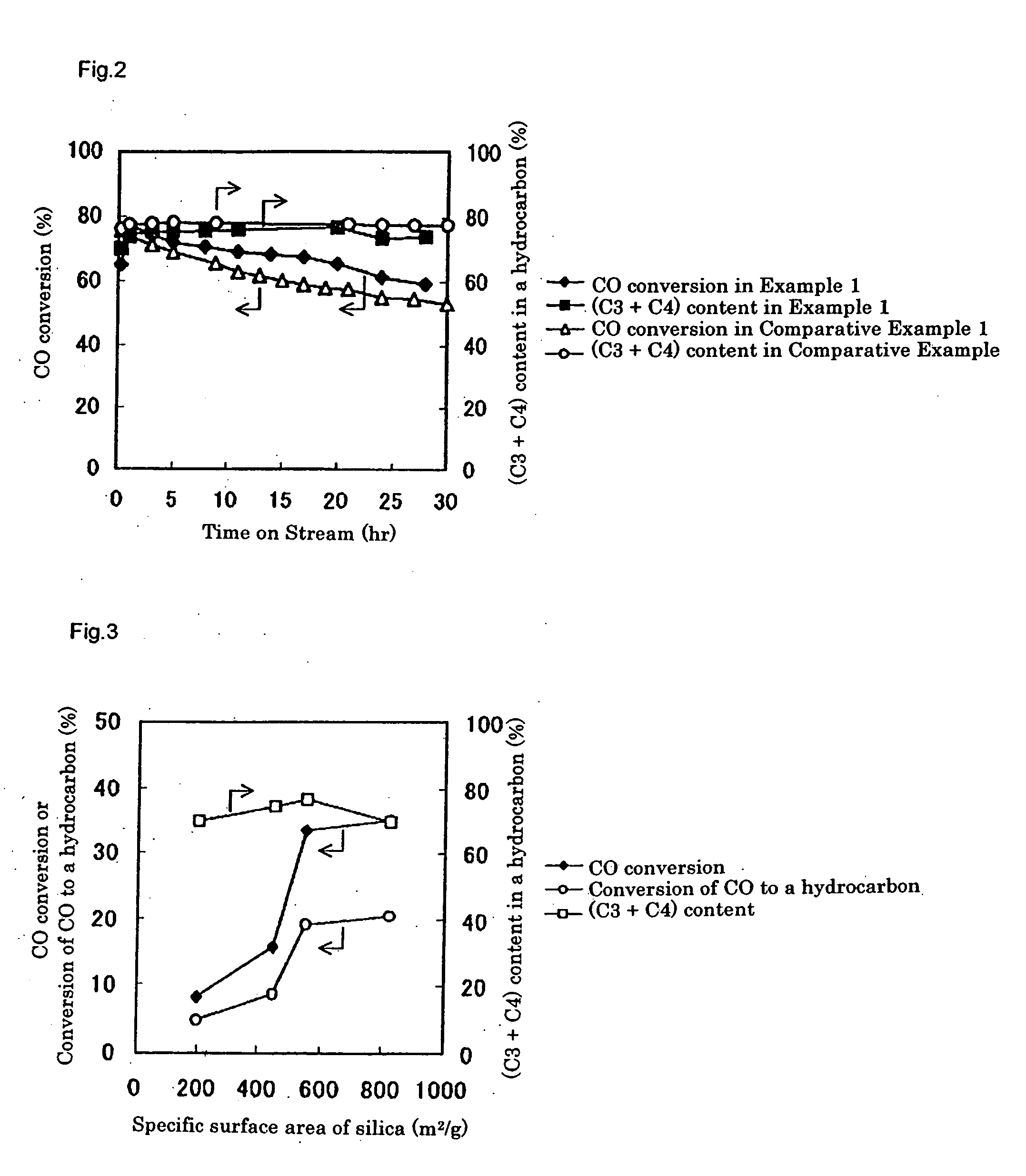

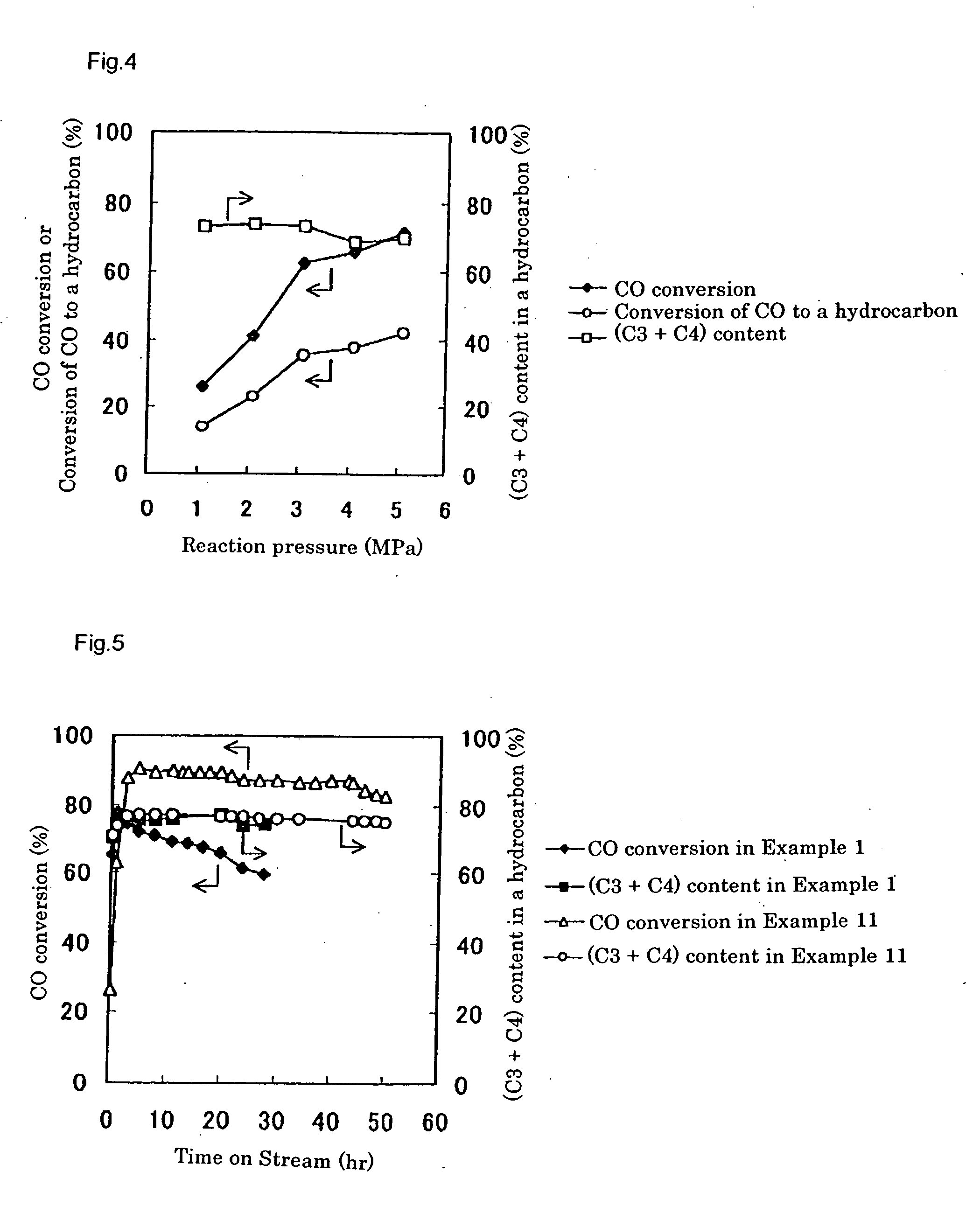

Catalyst and process for LPG production

InactiveUS20060009349A1Less deteriorationHigh activityMolecular sieve catalystsOrganic compound preparationHydrogenHigh activity

A catalyst for producing a liquefied petroleum gas according to the present invention comprises a Pd-based methanol synthesis catalyst component and a β-zeolite catalyst component. It can be used in a reaction of carbon monoxide and hydrogen to give a hydrocarbon containing propane or butane as a main component, i.e., a liquefied petroleum gas, with high activity, high selectivity and high yield. Furthermore, the catalyst has a longer catalyst life with less deterioration.

Owner:JAPAN GAS SYNTHESIZE

Composite material for pultrusion polyurethane resin and preparation method thereof

The invention discloses a composite material for pultrusion polyurethane resin and a preparation method thereof. The composite material is prepared from continuous fiber and polyurethane resin; the continuous fiber is selected from glass fiber or carbon fiber and is 60-85% of the total volume of the composite material in percentage by weight; and the polyurethane resin is 15-40% of the total volume of the composite material in percentage by weight. The resin disclosed by the invention has fast speed during curing, high degree of cross-linking, excellent mechanical property and good wettability to fiber reinforced materials.

Owner:南京聚发新材料有限公司

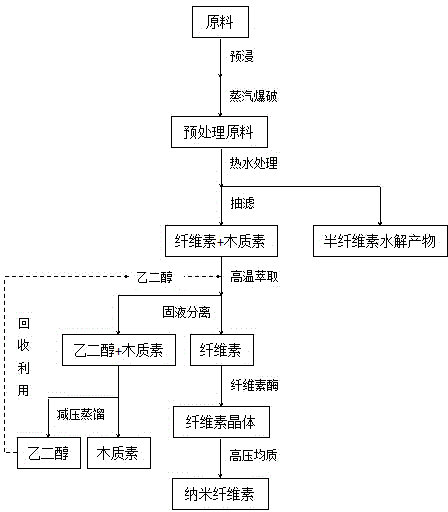

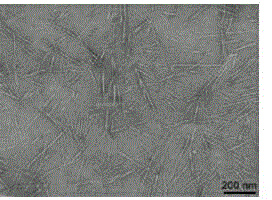

Preparation method of cellulose nanofiber

InactiveCN104651964ALarge specific surface areaHigh activityMonocomponent cellulose artificial filamentFermentationFiberHydrolysate

The invention relates to a preparation method of a cellulose nanofiber. The method comprises the following steps: with wood fiber biomass as a raw material, presoaking, and carrying out steam explosion pretreatment; carrying out high-temperature hydro-thermal treatment on pretreated materials; hydrolyzing hemicellulose, and carrying out washing suction filtration to obtain hemicellulose hydrolysate and filter residues rich in lignin; putting the filter residues into a high-pressure reaction kettle, adding an ethylene glycol solution, heating and extracting the lignin from the residues with ethylene glycol; extracting and carrying out solid-liquid separation to obtain a lignin extract liquid and cellulose solid; carrying out enzymolysis on the cellulose solid with cellulase and removing an amorphous region of the cellulose to obtain cellulose crystal; and carrying out high-pressure homogenizing on the cellulose crystal to obtain a cellulose nanofiber product. The cellulose nanofiber prepared by the method has the advantages of nanoscale, large specific surface area, high activity and high security.

Owner:NANTONG LIANHAIWEIJING BIOLOGY

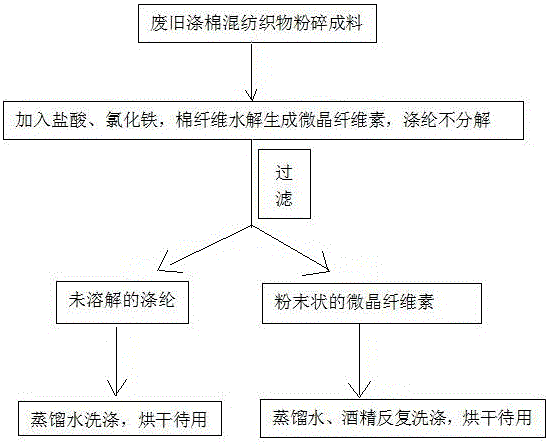

Method for separating and recovering waste cotton-polyester blended fabric under subcritical water condition

ActiveCN106674588AReduce crystallinityReduce the degree of polymerizationPlastic recyclingFiberPolyester

The invention discloses a method for separating and recovering waste cotton-polyester blended fabric under a subcritical water condition, and belongs to the field of resource recycling and reuse of waste fabric. Under the conditions that the mass fraction of hydrochloric acid is 0.5-2% and reaction temperature is 130-160DEG C, reaction is carried out for 3-5h, cotton fibers in the waste cotton-polyester blended fabric are decomposed into microcrystalline celluloses, but polyester fibers are not changed, and therefore, the polyester fibers and the microcrystalline celluloses are separated and recovered. The method is suitable for the cotton-polyester blended fabric formed at any ratio and has the advantages of simpleness in operation, short technological process, low energy consumption, light environment pollution and the like.

Owner:TAIYUAN UNIV OF TECH

PVC (Polyvinyl Chloride) paste resin and preparation method thereof

The invention discloses PVC (Polyvinyl Chloride) paste resin and a preparation method thereof, belonging to the technical field of polymer chemical industry. Weighted in 100 parts by weight of vinyl chloride, the PVC paste resin with the average grain diameter of 0.5-2mum, the average degree of polymerization of 1600-1900 and the paste viscosity of 1500-3500mPa.s is prepared from the following components: 70-120 parts of deionized water, 0.5-5 parts of mixed emulsifier, 0.005-0.02 part of oil-soluble compound initiating agent, 0.05-0.5 part of pH value regulator and 0-0.1 part of chain extender through microsuspension polymerization. The paste resin prepared according to the invention has the advantages of high degree of polymerization, low paste viscosity, rapidness in plasticization, good transparency and favorable defoaming performance.

Owner:SHENYANG CHEM IND CO LTD

Bacterial cellulose concentrate and method for the treatment of the concentrate

InactiveUS6069136AHigh degree of polymerizationIncrease elasticityBiocideSugar derivativesViscosityBacterial cellulose

PCT No. PCT / JP97 / 01785 Sec. 371 Date Mar. 16, 1998 Sec. 102(e) Date Mar. 16, 1998 PCT Filed May 26, 1997 PCT Pub. No. WO97 / 45452 PCT Pub. Date Dec. 4, 1997The purpose of the present invention is to provide a simple and economical method for the production of BC having improved properties such as dispesibility, suspensibility and viscosity. The present invention relates to a method for the improvement of dispersibility and suspensibility of bacterial cellulose, comprising concentrating an aqueous suspension of bacterial cellulose to a final concentration of the bacterial cellulose of between 10% by weight or more and less than 75% by weight, dispersing it again into an aqueous solution and homogenizing the bacterial cellulose in the resulting dispersion, to a method for the improvement of paper properties of bacterial cellulose, comprising concentrating an aqueous suspension of homogenized bacterial cellulose to a final concentration of the bacterial cellulose of between 4% by weight or more and less than 75% by weight, dispersing it again into an aqueous solution and homogenizing the bacterial cellulose in the resulting dispersion, and to the BC concentrate thus prepared.

Owner:AJINOMOTO CO INC

Method for recovering sulfuric acid from concentrated acid hydrolysate of plant cellulose material

ActiveUS8052953B2Reduce solubilityEasier the sugars precipitateSugar derivativesSugar crystallisationCelluloseOrganic solvent

Owner:CHEN PEIHAO

Water soluble polyvinyl alcohol fiber and its prepn and use

InactiveCN1403641ADimensionally stableShorten the dissolution timeFibre treatmentMonocomponent synthetic polymer artificial filamentSolventChemistry

The present invention features that PVA of polymerization degree 500-2000 and alcoholysis degree 75-99 mol% in 100 portions is mixed with solvent mixture of dimethyl sulfoxide and water in 200-400 portions, the mixture is stirred and heated to 80-120 deg.c at -0.01--0.08 MPa pressure in a stainless steel reactor for 3-4 hr to compound the spinning solution, and the spinning solution is filtered and defoamed and used in spinning to obtain water soluble PVA fiber after post-treatment. The PVA fiber has a water solving temperature of 10-90 deg.c, strength greater than 3.5 cN / dtex, monofilament length of 1.5-10 dtex, fracture elongation of 15-30%. It may be processed into top, which may further blended with wool top, cotton, top, etc. to produce fine yarn or hollow yarn, or cut into staple fiber for producing non-woven fabric, etc.

Owner:CHINA PETROCHEMICAL CORP +2

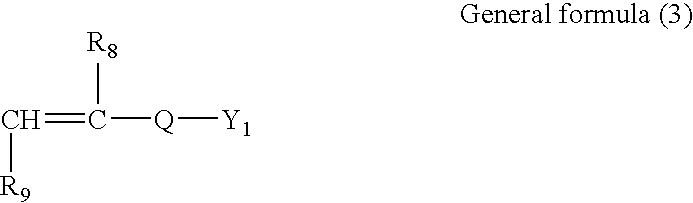

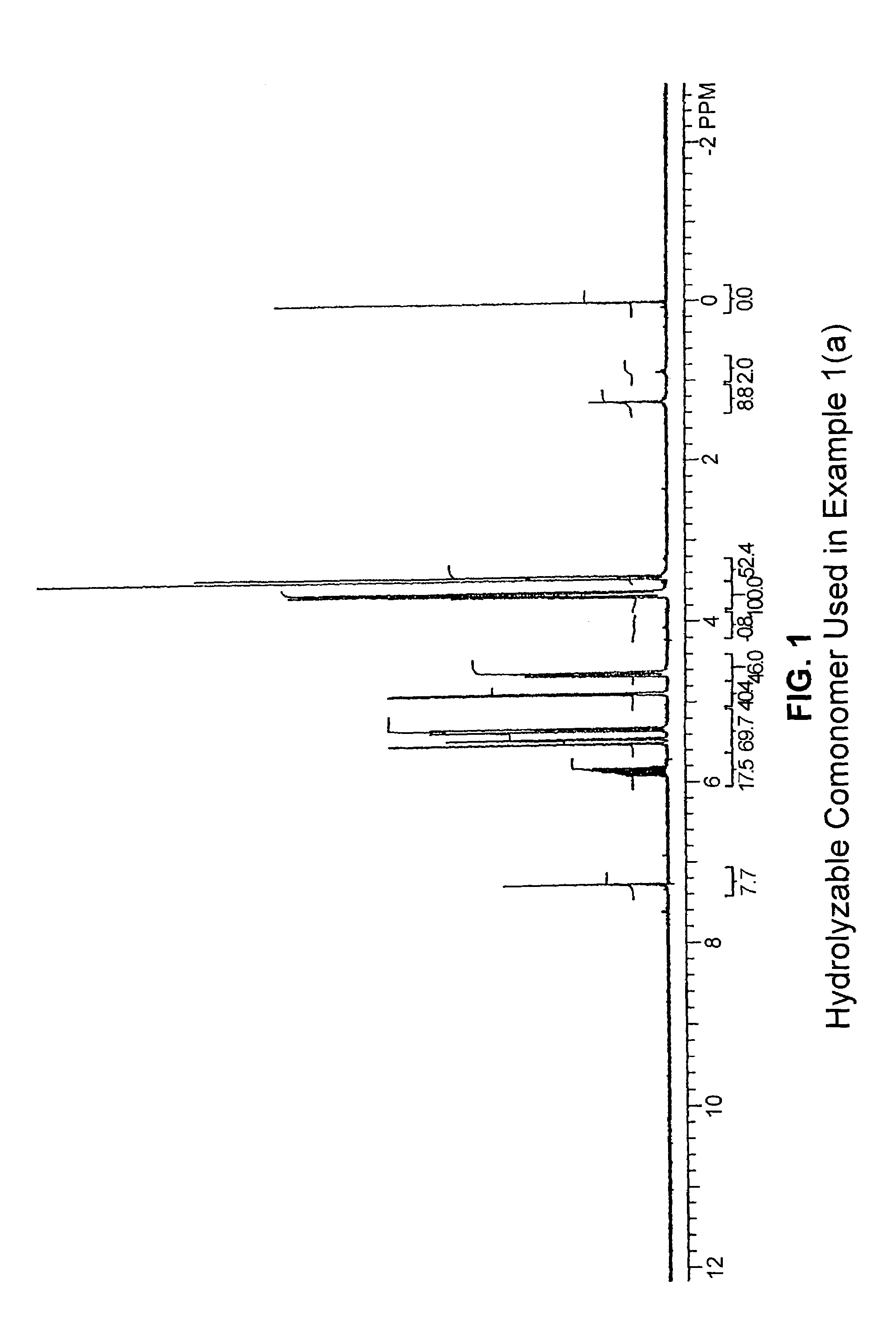

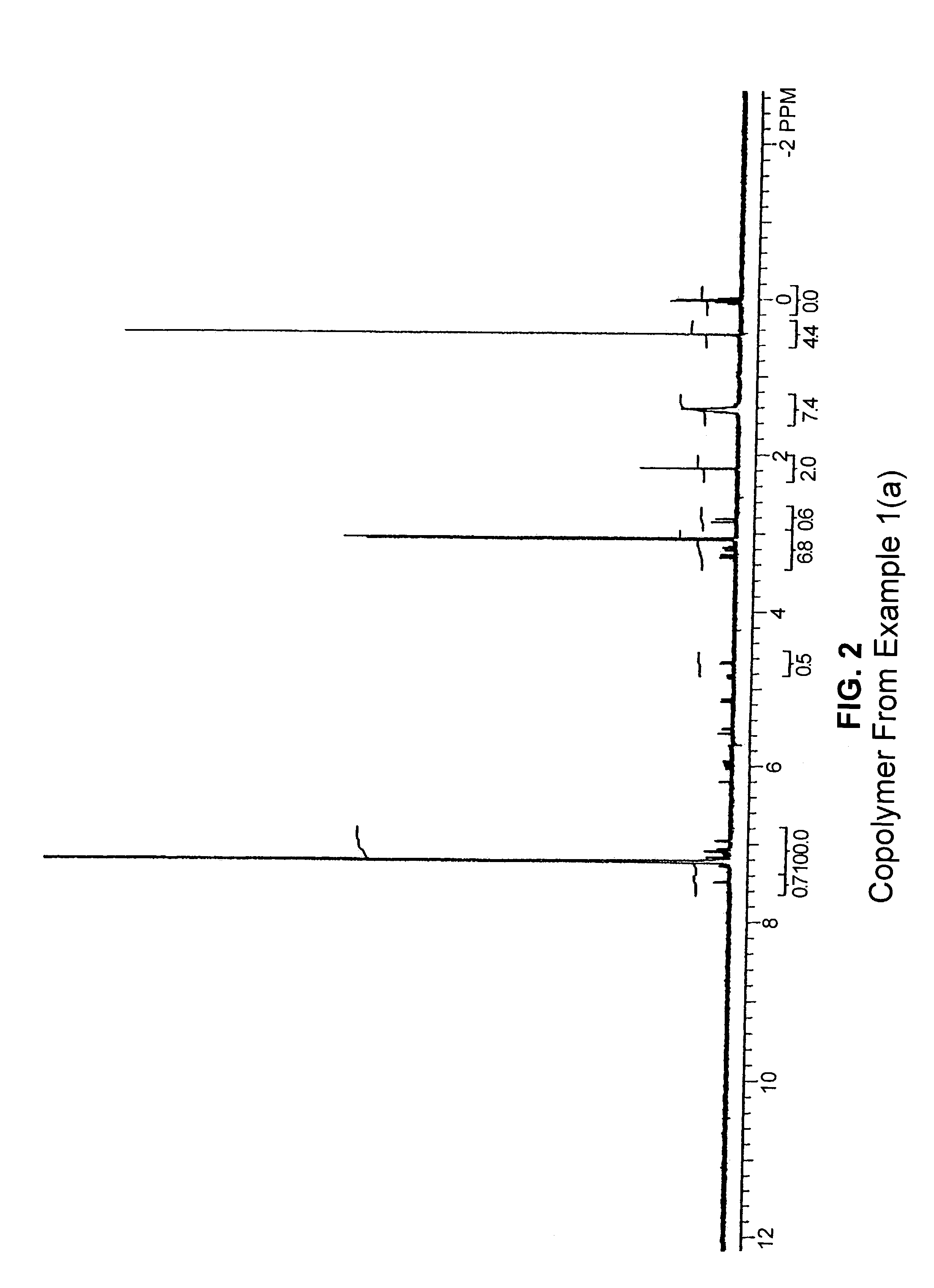

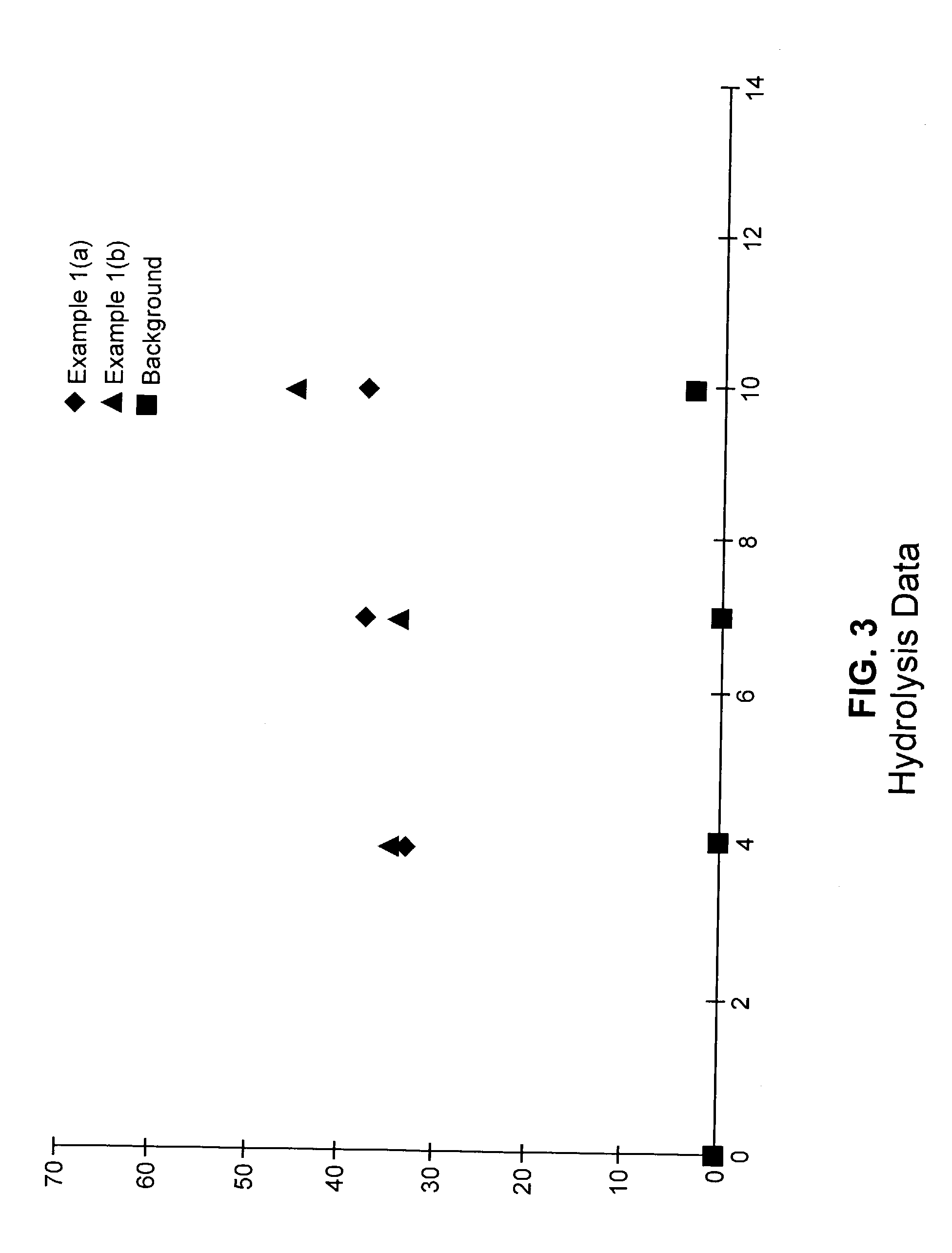

Olefin copolymers containing hydrolytically cleavable linkages and use thereof in degradable products

The invention is directed to olefin copolymers composed of nonhydrolyzable monomer units and hydrolyzable monomer units, the latter resulting from copolymerization of monomers containing a linkage that is hydrolytically cleavable in the presence of aqueous base or aqueous acid. Generally, the hydrolyzable monomer units represent a significant fraction of the copolymer, such that upon hydrolysis, a substantial portion of the copolymer is degraded into low molecular weight fragments. Also provided are degradable articles that are at least partially composed of a degradable copolymer in which hydrolyzable monomer units represent at least 20 mole % of the copolymer. These degradable articles include agricultural film products, adhesive tape substrates, bed linens, containers, disposable absorbent articles, packaging materials, bags, labels, pillow cases, protective clothing, surgical drapes, sponges, tampon applicators, disposable syringes, temporary enclosures and temporary siding, toys, wipes, foamed plastic products, and controlled release pellets, strips and tabs.

Owner:SRI INTERNATIONAL

Process for controlled polymerization of a mixed polymer

InactiveUS20050187306A1Reduce the degree of polymerizationReduce usageProductsReagentsPolymer scienceHigh pressure

The present invention provides a process for the preparation of high molecular weight crystalline Polyethyleneterephthalate (PET) using up to 50% of Post consumer recycled PET flakes along with Pure Terephthalic Acid (PTA), Isophthalic Acid (IPA) and Mono Ethylene Glycol (MEG) as a virgin raw material, in the presence of a combination of catalysts and additives to obtain an intermediate prepolymer heel having a low degree of polymerization further subjecting to autoclaving to yield an amorphous melt and followed by solid state polymerization.

Owner:FUTURA POLYESTERS LTD

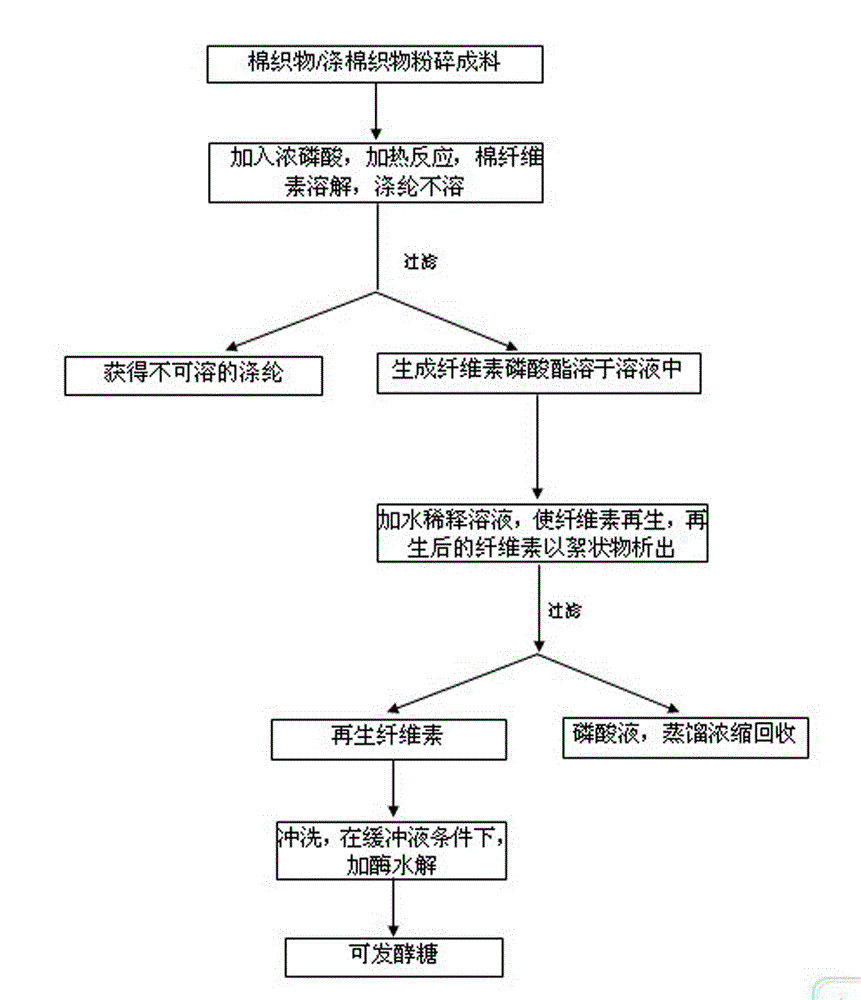

Resourced recovering and utilizing method for waste cotton fabric

InactiveCN102911395AReduce crystallinityReduce the degree of polymerizationProductsReagentsPolyesterPhosphoric acid

The invention relates to a resourced recovering and utilizing method for waste cotton fabric, in particular to a technology for recovering polyester and cotton fiber from waste polyester cotton blended fabric and using the polyester and the cotton fiber during the production of fermentable sugar, and belongs to the field of resourced cycling and reutilizing of solid waste. According to the resourced recovering and utilizing method, concentrated phosphoric acid is used as a solvent, a reaction is conducted under the conditions that the mass fraction of the phosphoric acid is 82 to 86 percent, the solid-liquid ratio is 1:10 to 1:30, the reaction temperature is 45 to 60 DEG C, and the reaction time is 2 to 18 hours; the cotton fiber in the polyester cotton blended fabric is completely dissolved, so as to enable the polyester to be isolated and recovered by one hundred percent; then water is added to a solution to dilute the solution, so as to enable cellulose to be regenerated and obtain regenerative cellulose with a low cleanliness degree and a low polymerization degree, which is applicable to enzymatic hydrolysis; and after the regenerative cellulose is subjected to the enzymatic hydrolysis, the fermentable sugar is generated to be used as a carbon source for fermenting and producing bio-based products. Waste liquid is distilled and the concentrated phosphoric acid is recovered to be circularly used. The resourced recovering and utilizing method is applicable to the polyester cotton blended fabric formed in any proportion, has the advantage of relatively low energy consumption and is simple to operate; and the polyester can be recovered by one hundred percent, the concentrated phosphoric acid can be simultaneously recovered to reduce costs, and the cotton fiber component is utilized to produce bio-based sources or bio-based products.

Owner:SICHUAN AGRI UNIV

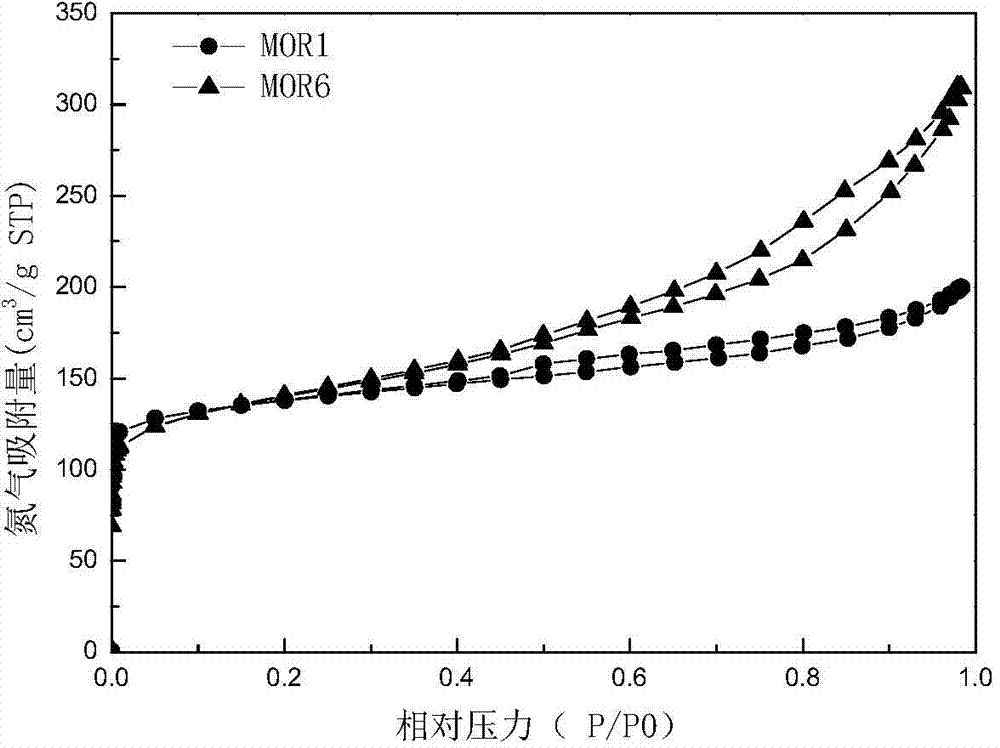

Preparation method of nanometer stepped hole mordenite molecular sieve

ActiveCN104843731ASmall grain sizeImproved hydrodealkylation performanceCrystalline aluminosilicate zeolitesMolecular sieveSeed crystal

The invention discloses a preparation method of a nanometer stepped hole mordenite molecular sieve. The method comprises the following steps: dissolving sodium hydroxide in water and then adding a silicon source at room temperature to stir for 0.5-1.5 h to obtain alkaline silicon source solution; adding an aluminum source dissolved by using the water into the alkaline silicon source solution, stirring for 1 h at the room temperature to form uniform silicon and aluminum mixed solution, adding a mesoporous soft template (R) for 1 h, then adding a seed crystal (M) and stirring for 1 h to form a gel mixture, and then dynamically crystallizing at 100-180 DEG C for 12-96 h; cooling, performing extraction filtration and washing the product after crystallization until pH is about 7, drying at 100 DEG C for 12 h, roasting at the constant temperature of 110 DEG C for 3 h and then rising temperature to 500 DEG C to roast for 3 h to obtain a nanometer stepped hole mordenite product. The mordenite molecular sieve prepared by the invention has the typical nanometer stepped hole characteristic, and the hydrodealkylation performance of the Pt / MOR catalyst loaded with the sieve as a carrier is obviously improved.

Owner:HEBEI UNIV OF TECH

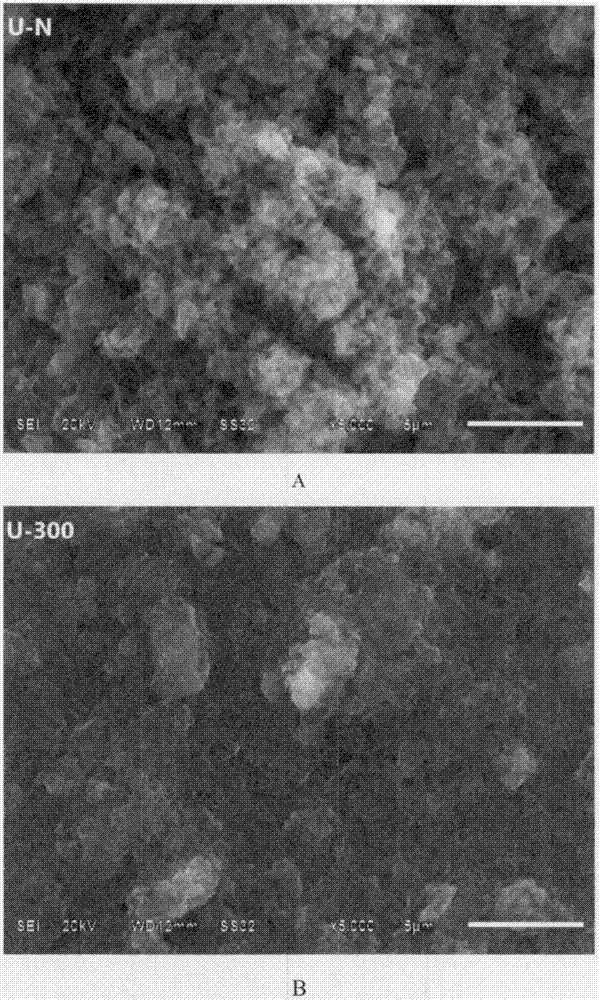

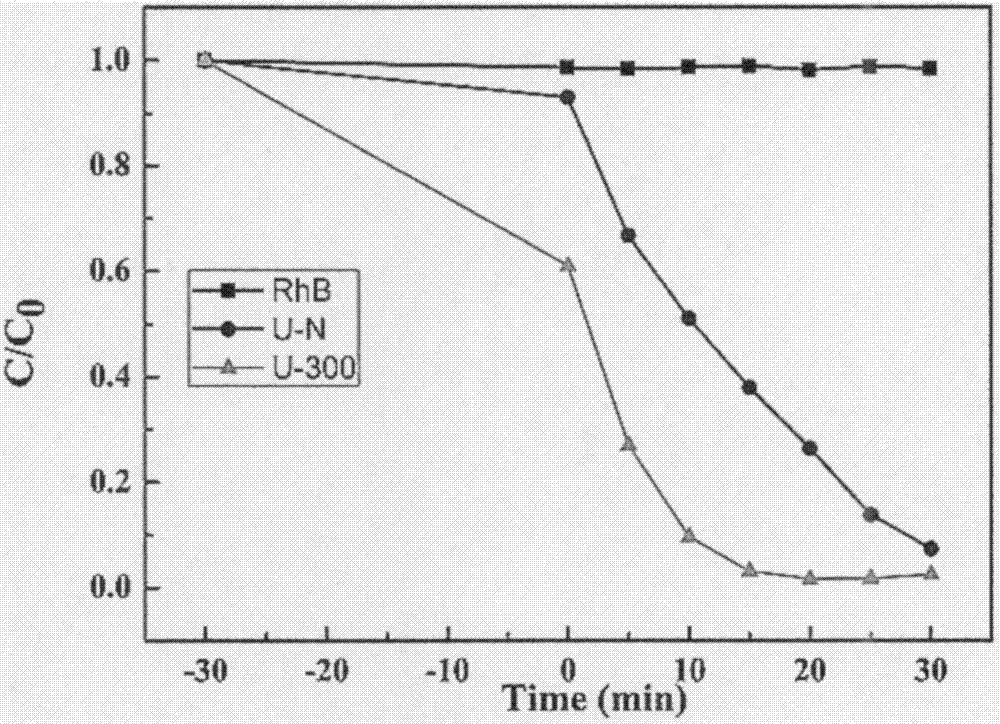

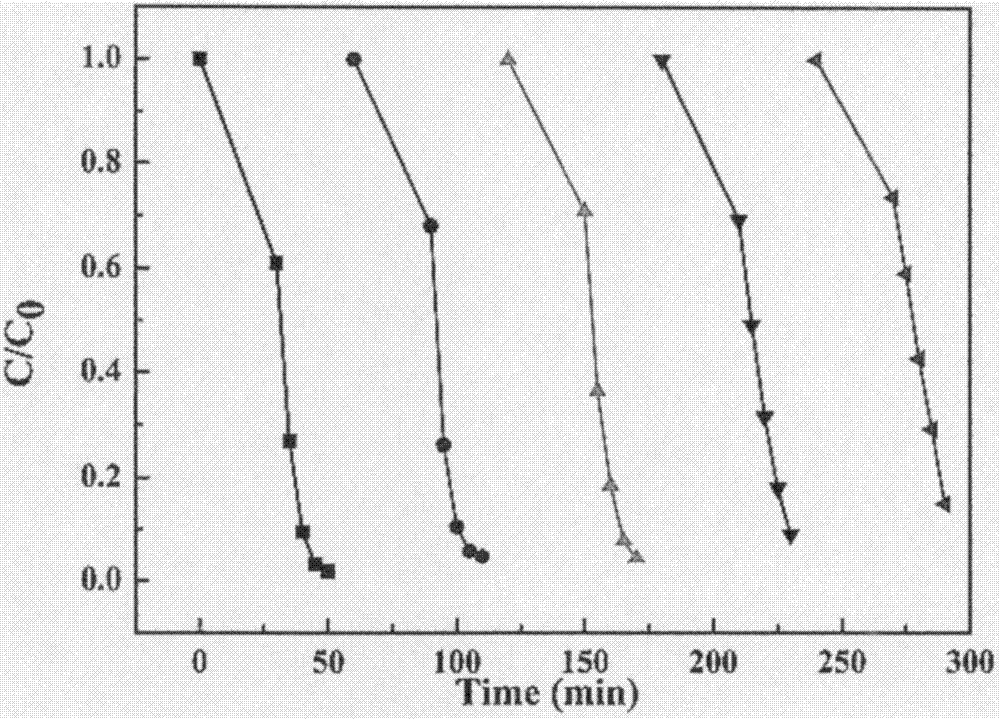

High-activity graphite-phase carbon nitride material and preparation method thereof

InactiveCN107252701AReduce compoundingImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationMaterials preparationReactive site

The invention belongs to the technical field of material preparation and photocatalysis, and discloses a high-activity graphite-phase carbon nitride material and a preparation method thereof. The preparation method comprises the following steps: forming a self-generated gas atmosphere a gas generated from a precursor by pyrolysis in the high-temperature calcining process under the control on an inert gas, and guiding synthesis of a carbon nitride material, thereby obtaining a flaky porous graphite-phase carbon nitride material. According to the preparation method, after the inert gas is not introduced any longer, a self-generated gas generated from the precursor is relatively uniform at different parts, and the carbon nitride material prepared with the preparation method is uniform in morphology and relatively good in crystal form; due to the escape of the self-generated gas, the material is effectively pored, and thus the specific surface area and the active sites of the material are increased; due to the self-generated gas atmosphere, the polymerization degree of the precursor is reduced, and the obtained carbon nitride material has a relatively large amount of unpolymerized amino or imino groups. The preparation method disclosed by the invention is simple, efficient and low in cost, and the carbon nitride material prepared with the preparation method is excellent in photocatalysis activity and very good in practicability.

Owner:CHINA WEST NORMAL UNIVERSITY

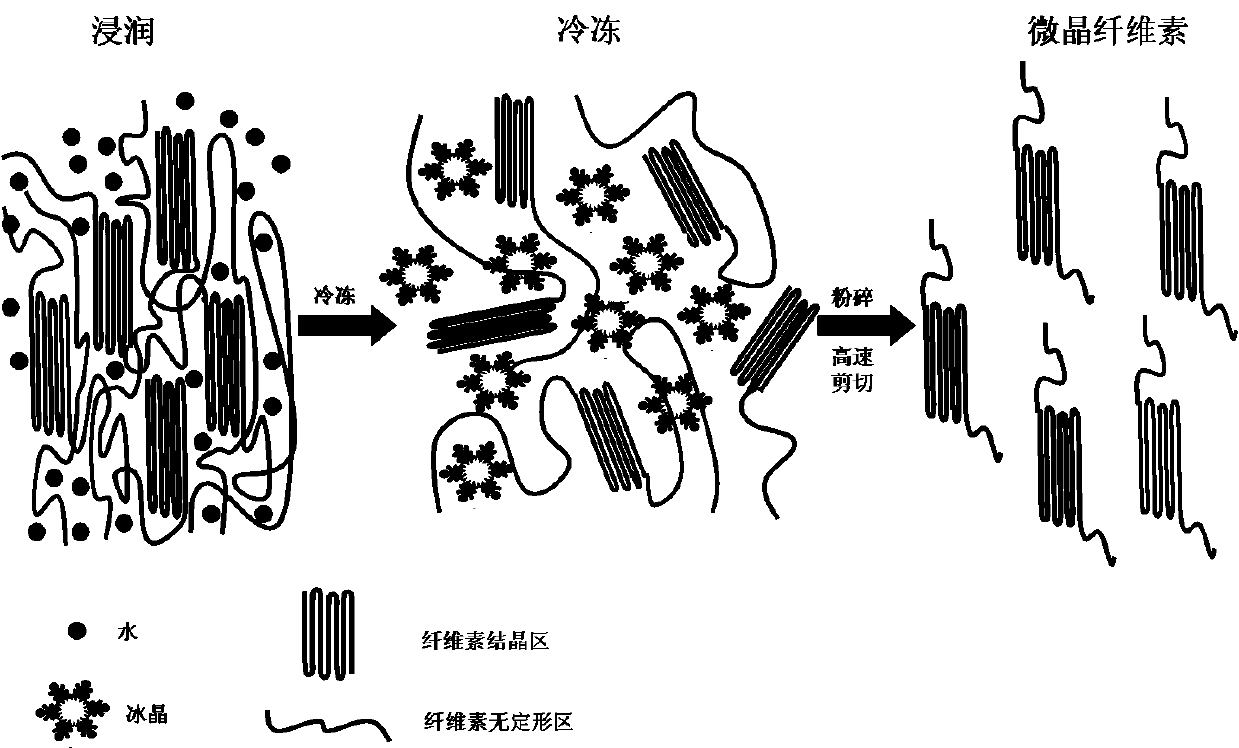

Method for preparing microcrystalline cellulose at low temperature

ActiveCN103726378AReduce the degree of polymerizationHigh crystallinityPulping with acid salts/anhydridesSolventHot Temperature

The invention relates to a method for preparing microcrystalline cellulose at low temperature. The method is characterized by comprising the following steps: (1) completely soaking the cellulose raw material in a soaking solvent, wherein the soaking solvent is water or an acid solution with mass percent concentration not over 15wt% or an oxide solution with mass percent concentration not over 5wt%; (2) freezing the cellulose raw material after the soaking treatment in the step (1), and grinding; (3) performing high-speed shear treatment on the cellulose powder obtained by the grinding in the step (2), and performing aftertreatment on the product after the high-speed shear treatment to obtain the microcrystalline cellulose. The method for preparing microcrystalline cellulose at low temperature provided by the invention can obtain microcrystalline cellulose with different polymerization degrees lower than 350 and relatively high crystallization degree; high-temperature treatment process can be avoided, the energy consumption is low, and the process is simple and green and environment-friendly.

Owner:HUBEI GEDIAN HUMANWELL PHARMA EXCIPENTS

Energy-saving and high-efficiency method for dying crude wood

InactiveCN102241039AAvoid the disadvantages of needing glueImprove use valueWood treatment detailsGranularityEnergy consumption

The invention discloses an energy-saving and high-efficiency method for dying crude wood, comprising the following steps of: (1) selecting crude wood; (2) preparing a dye solution for dying; (3) dyeing the crude wood; and (4) drying the dyed crude wood and preparing dyed wood. The invention has the advantages that: firstly, in the process, fresh crude wood is used in the dyeing process so as to avoid energy source consumption due to dried dyeing and secondary drying; secondly, the granularity and the polymerization degree of dye molecules subjected to ultrasonic treatment are greatly reduced so as to be conductive for the dye molecules to enter inside the wood for deeply dyeing; thirdly, the dyed crude wood can be sawn into boards in different thicknesses according to requirements; fourthly, the wood subjected to dyeing treatment by using the process is uniform in colors inside and outside and retains natural structures and grains of the crude wood; and fifthly, the dyeing process is simple and easy to operate.

Owner:BEIJING FORESTRY UNIVERSITY

Apparatus for continuous stirring and process for continuous polycondensation of polymer resin

InactiveUS6846103B2Quality improvementLow viscosityRotary stirring mixersTransportation and packagingPolymer resinEngineering

Owner:HITACHI LTD

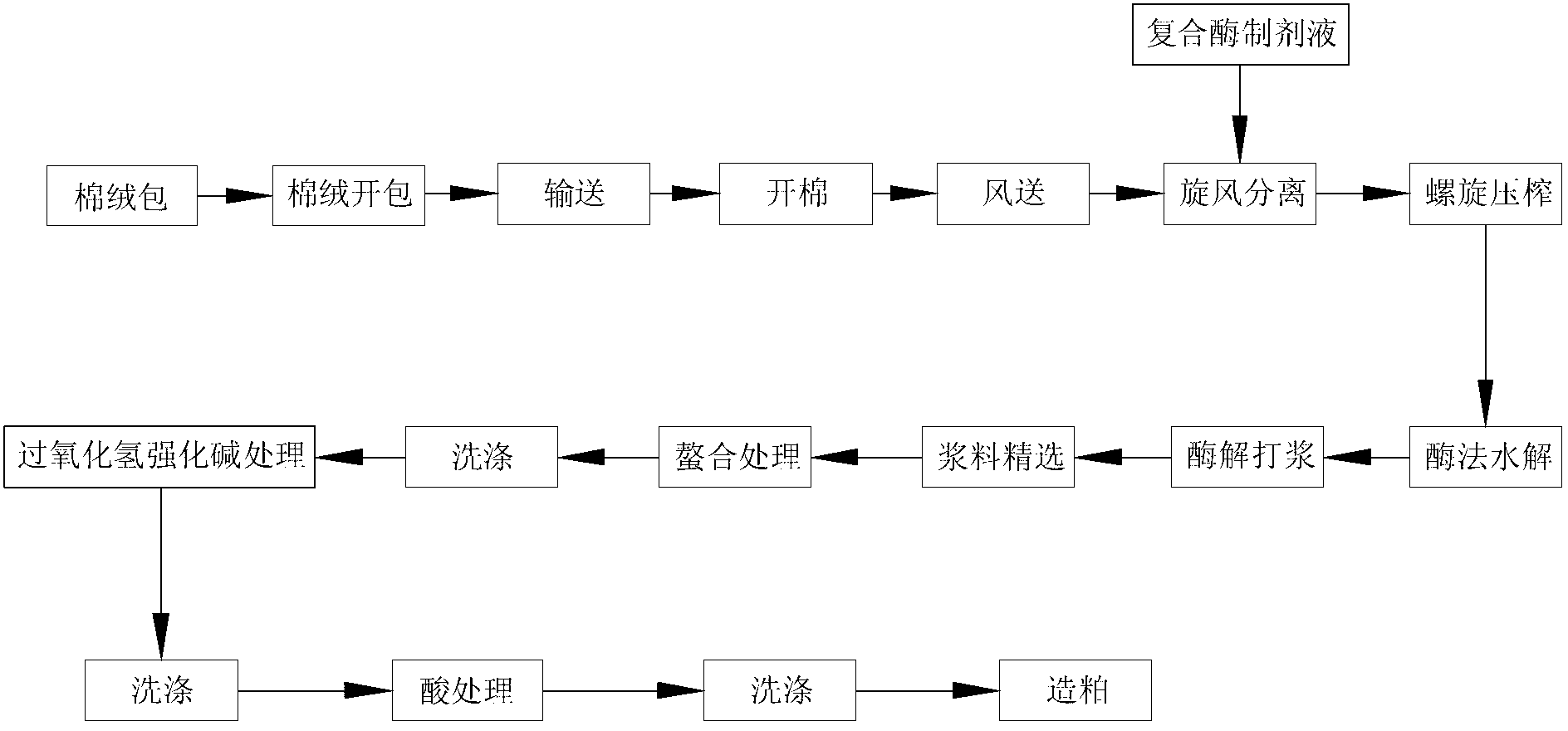

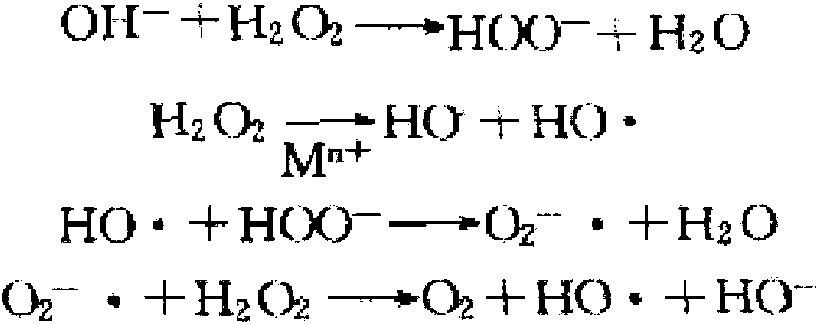

Complex enzyme preparation and technique for preparing dissolving pulp by using same

ActiveCN103061181ALoose structureEnhancement and effectPaper material treatmentChemical oxygen demandCellulose fiber

The invention relates to the technical field of production of regenerated cellulose fiber, in particular discloses a complex enzyme preparation applied in the preparation of dissolving pulp and a technique for preparing the dissolving pulp by using the enzyme preparation. The complex enzyme preparation is divided into a complex enzyme preparation I and a complex enzyme preparation II, wherein the complex enzyme preparation I mainly consists of feruloyl esterase, lipase and the like; and the complex enzyme preparation II mainly consists of xylanase, cellulase and the like. The complex enzyme preparation is applied in the technique for purifying alpha-cellulose and preparing the dissolving pulp; and the technique comprises the following steps of impurity removal for raw materials, enzyme method pretreatment, enzymolysis pulping, chelation treatment, alkali hydroxyl active oxygen cooking, acid treatment, washing, sand removal and pulp mixing. The method has the simple preparation technique, and adopts the complex enzyme preparation to treat the raw material pulp so as to effectively remove lignin, hemicellulose, pectin substance and waxiness and to reduce the degree of polymerization of the alpha-cellulose; the energy consumption is low under the normal pressure condition; the COD (Chemical Oxygen Demand) value of the pulping waste water is low; the yield of the dissolving pulp is high; the alpha-cellulose has high content and uniform degree of polymerization; and the production requirements of viscose can be satisfied.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

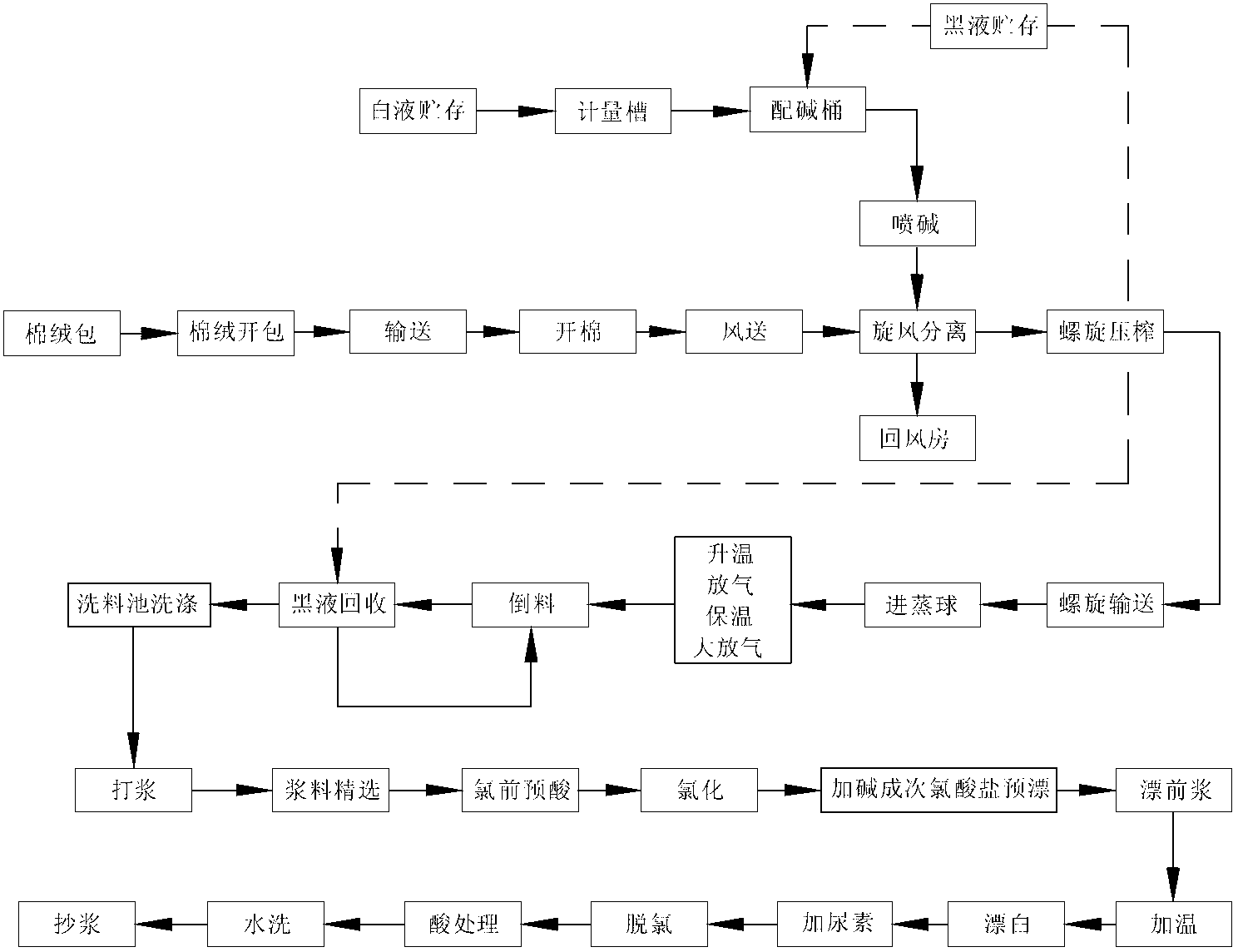

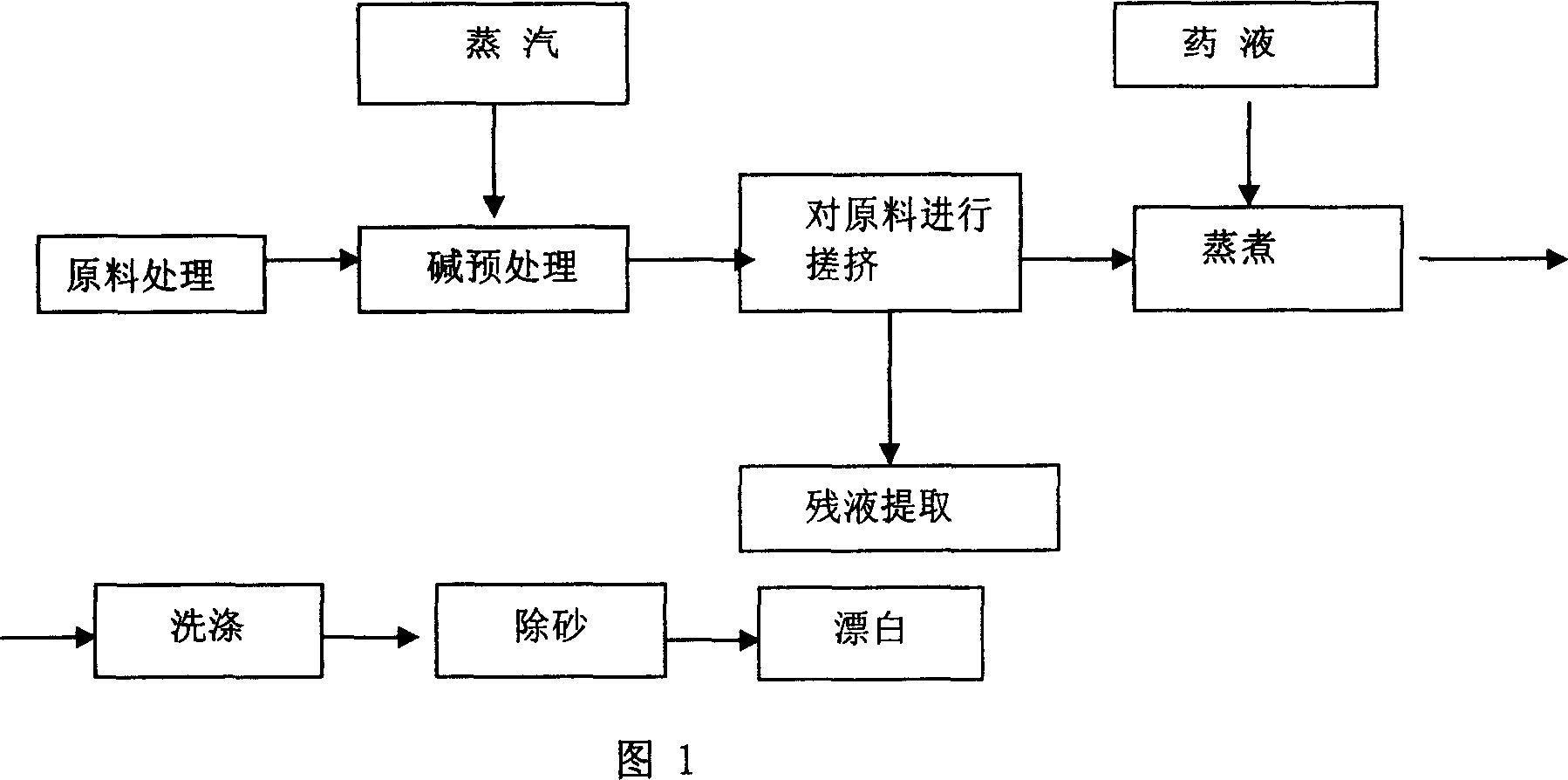

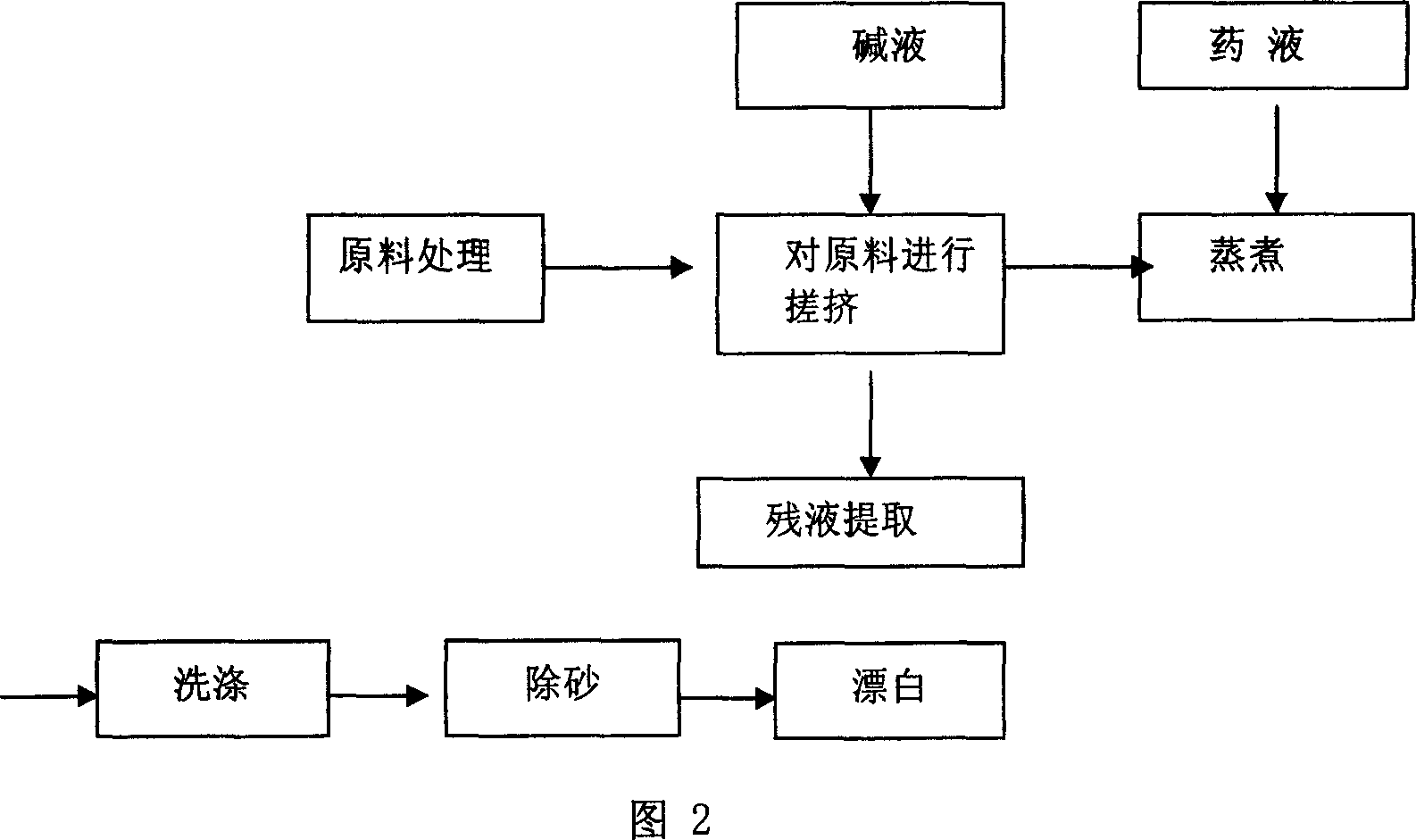

Method for producing chemical fiber pomace with fiber as raw material

InactiveCN1974922APerformance activationImprove impregnation effectCellulosic pulp after-treatmentDigestersBlack liquorPlant fibre

The present invention relates to a method for producing chemical fibre pulp by using plant fibre as raw material. Said method includes the following several steps: raw material treatment, making the treated raw material undergo the processes of rubbing and extruding, cooking, washing, removing sand and bleaching treatment. It is characterized by that in the preparation process of said chemical fibre pulp a screw extruding machine and a rubbing-extruding machine are adopted.

Owner:湖南吉湘生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com