Method for preparing microcrystalline cellulose at low temperature

A technology for microcrystalline cellulose and cellulose, which is applied in the field of microcrystalline cellulose preparation at low temperature, can solve the problems of increasing production cost, high energy consumption, low yield and the like, and achieves low energy consumption, high crystallinity and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

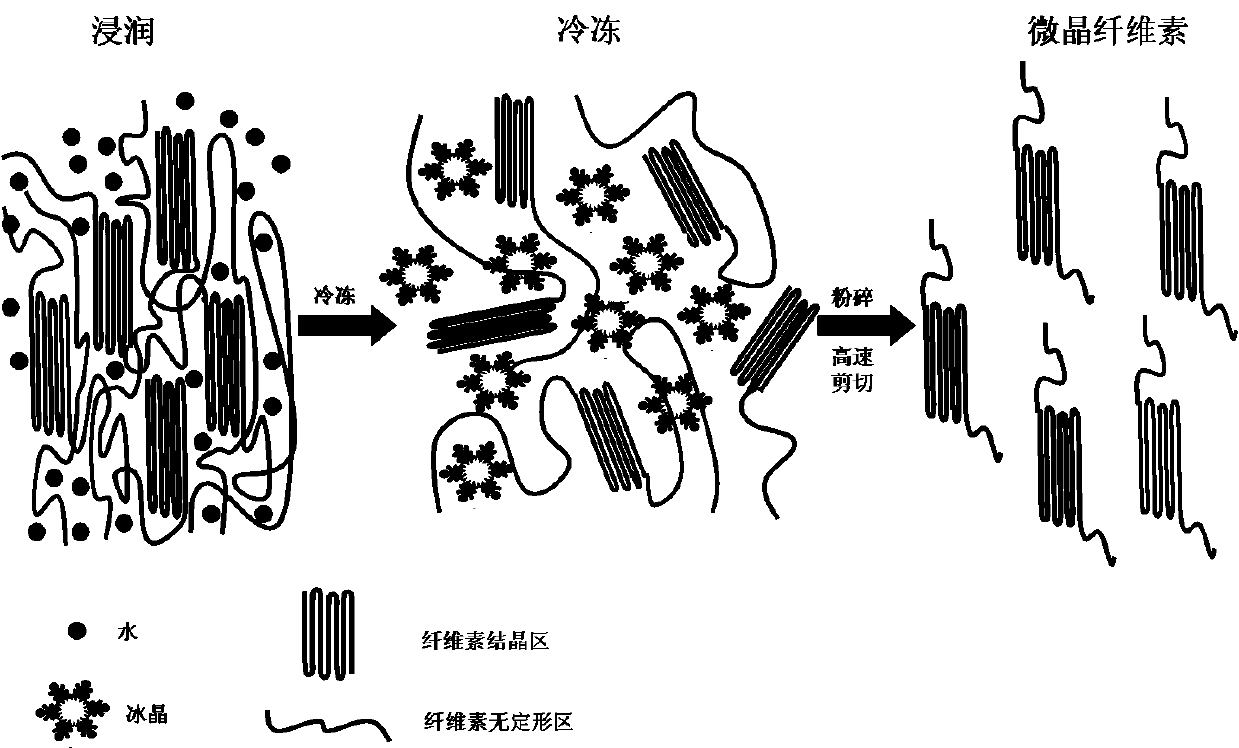

[0031] Add 20L of water to 10Kg of cotton linter pulp with high α-cellulose content after purification and removal of hemicellulose and lignin, and stir to fully swell and infiltrate the cotton linter pulp. Add liquid nitrogen to the swollen linter pulp for rapid cooling and then pulverize it fully. The pulverized cellulose raw material is processed by high-speed shearing in a 10000rpm homogenizer. The slurry after high-speed shearing treatment is dried and pulverized to obtain microcrystalline cellulose. The specific process diagram is as follows figure 1 shown.

Embodiment 2

[0033] 10L of 15wt% hydrochloric acid was added to 10Kg of the purified cotton linter pulp with high α-cellulose content after being purified by the caustic soda method to remove hemicellulose and lignin, so that the cotton linter pulp was fully swollen. The swollen pulp is rapidly cooled with liquid nitrogen until the temperature of the cellulose raw material drops to -10 o After C or below, it is fully pulverized. The pulverized cellulose raw material is processed by high-speed shearing in a 10000rpm homogenizer. The treated slurry is neutralized, washed, dried and pulverized to obtain microcrystalline cellulose.

Embodiment 3

[0035] Add 50L of water to 10Kg of bagasse with high α-cellulose content obtained by purifying and removing the hemicellulose and lignin therein, so as to fully swell the bagasse raw material. -20 o Under the low temperature storage of the swollen bagasse under low temperature, it is fully pulverized. The pulverized cellulose raw material is processed by high-speed shearing in a 10000rpm homogenizer. The treated slurry is dried and pulverized to obtain microcrystalline cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com