Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

584results about "Pulping with acid salts/anhydrides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

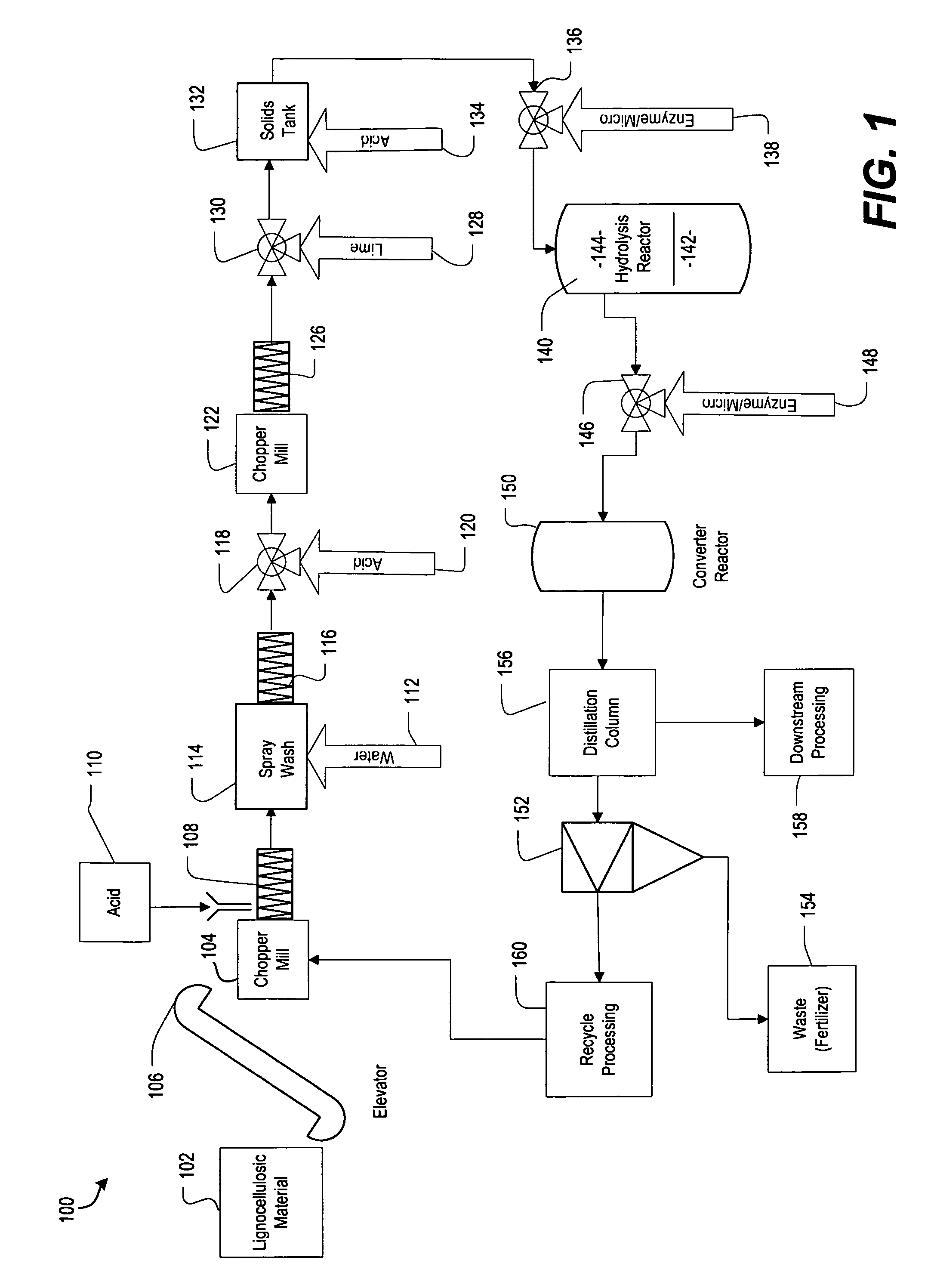

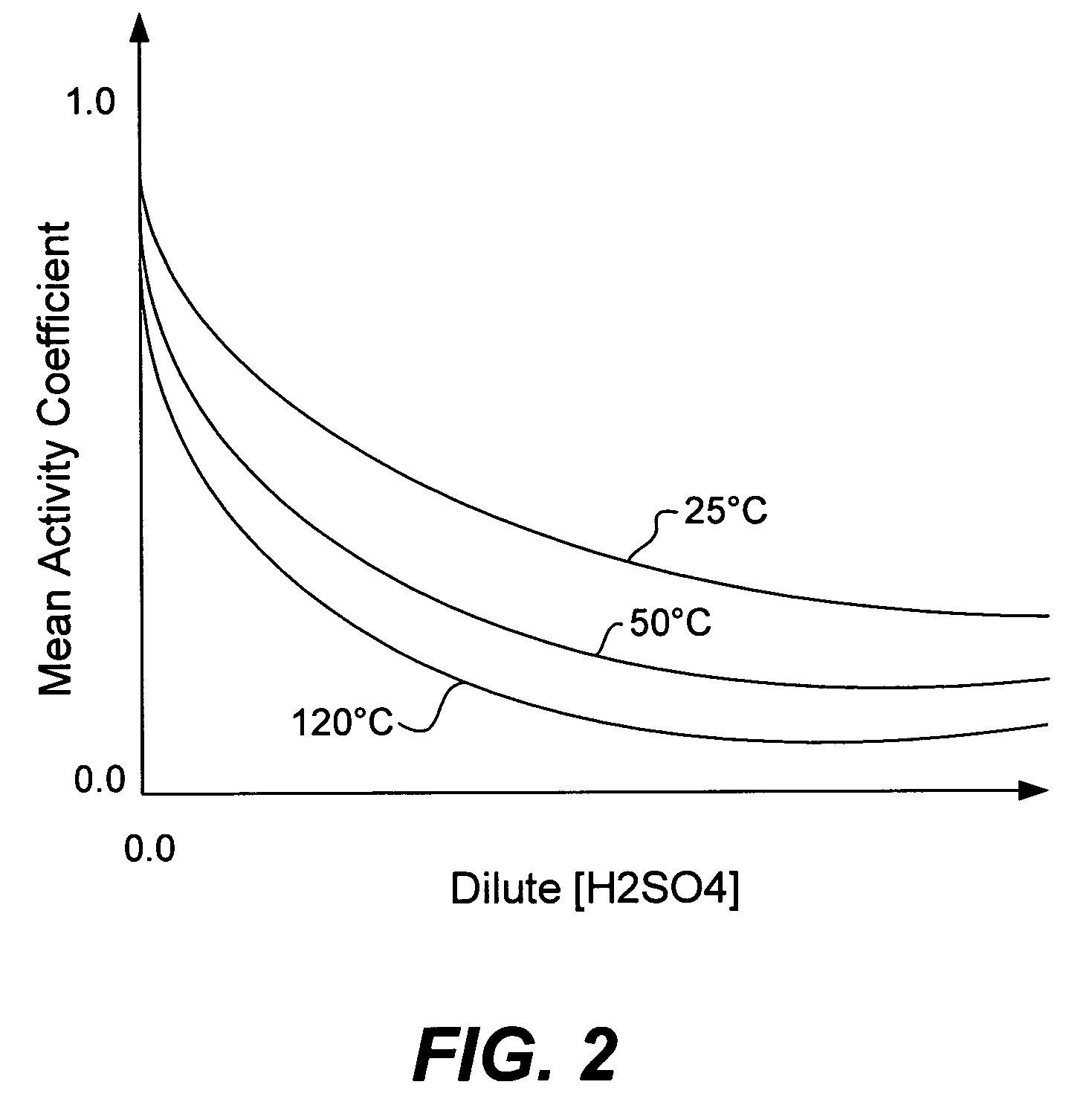

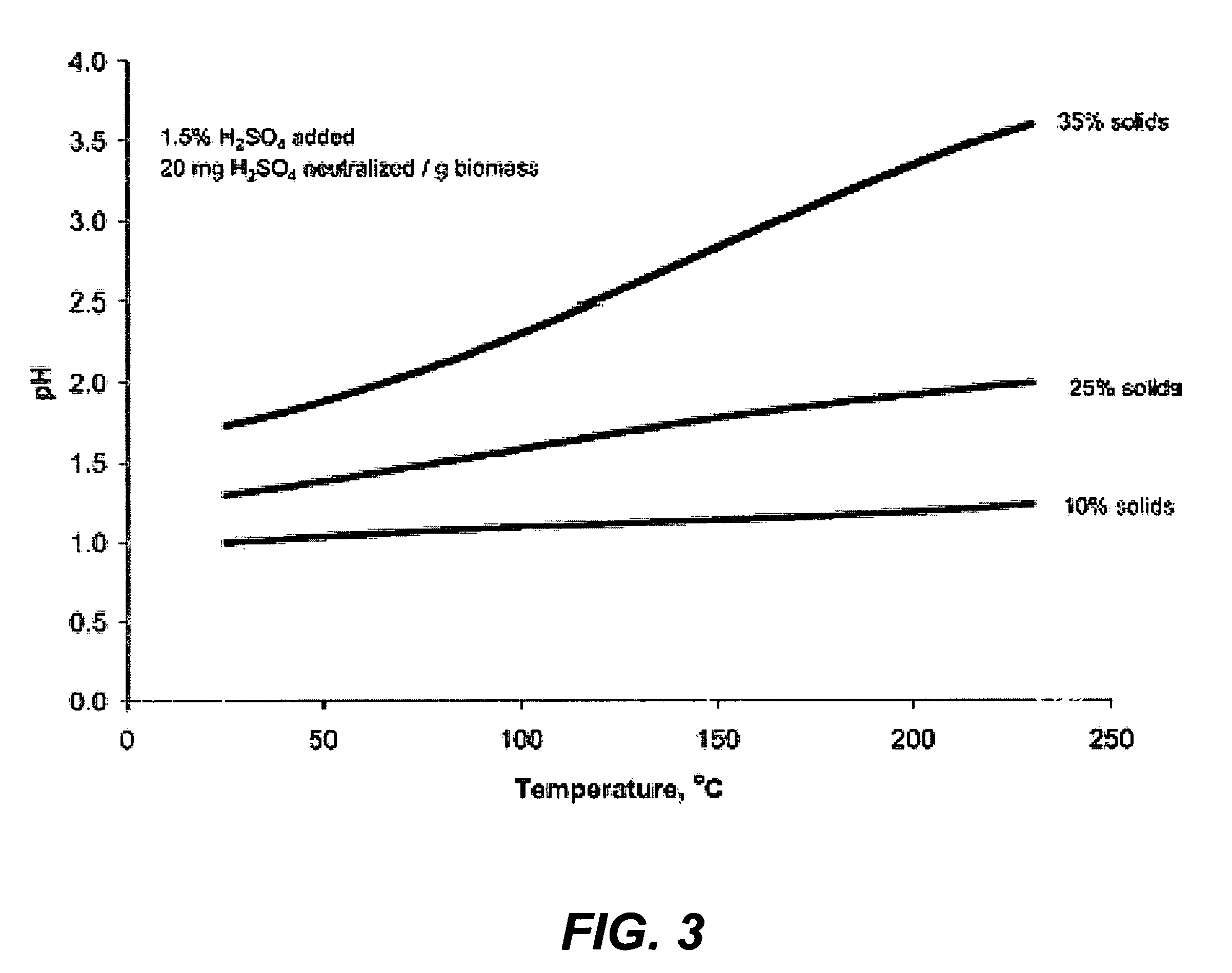

Removal of minerals from cellulosic biomass

InactiveUS7503981B2Reduce mineral contentEnhancing cellulosic saccharificationNon-fibrous pulp additionSpecial paperCellulosePre treatment

Disclosed is a method for removing minerals from a cellulosic biomass. For example, the biomass may be prewashed with an acid solution and rinsed with water to remove minerals prior to acid saccharification. The removal of minerals may reduce overall acid requirements, and decrease pretreatment costs.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

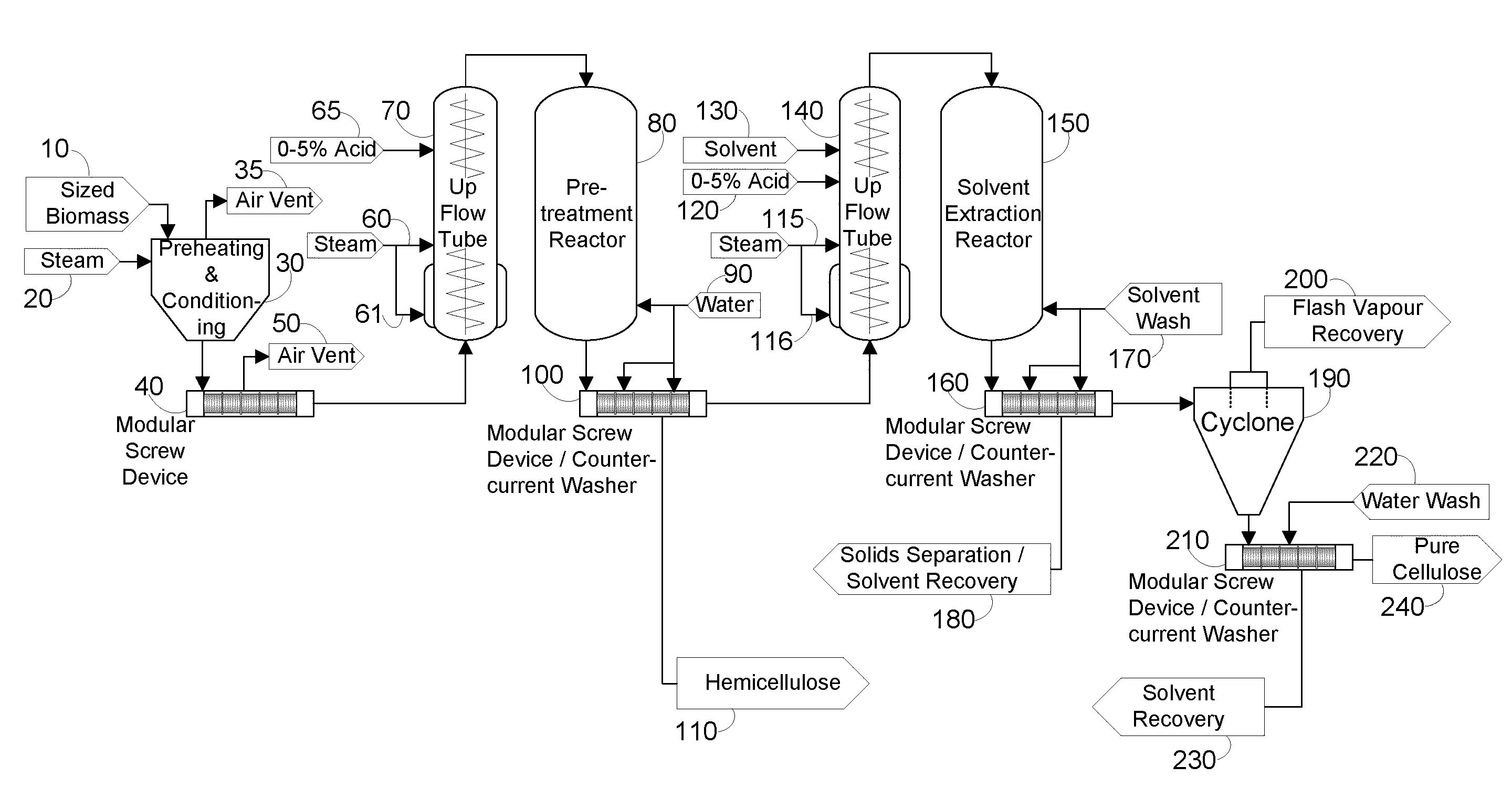

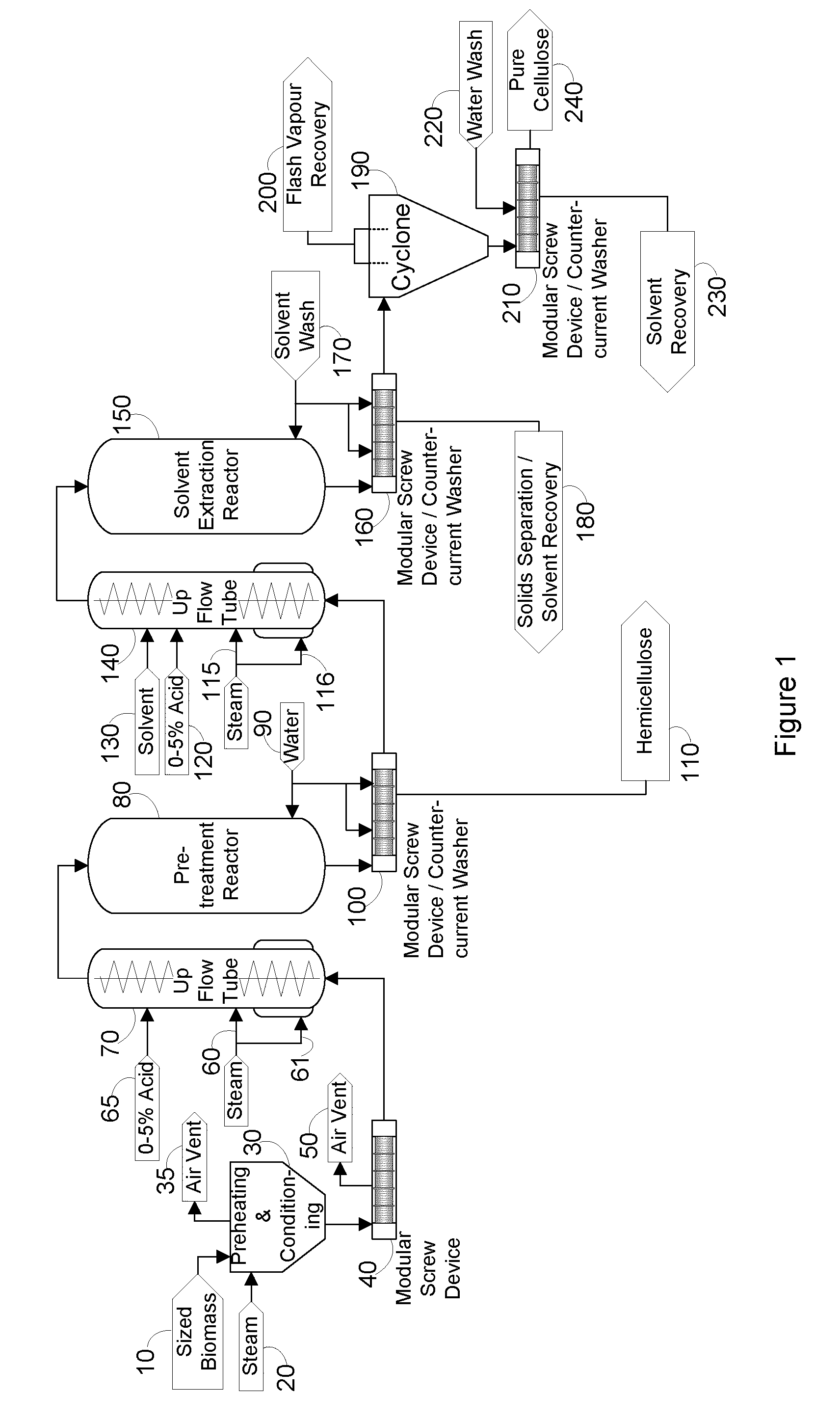

Separation of reactive cellulose from lignocellulosic biomass with high lignin content

InactiveUS20100269990A1Reduce inhibitionReduce extractionCellulosic pulp after-treatmentBiofuelsFiberLignocellulosic biomass

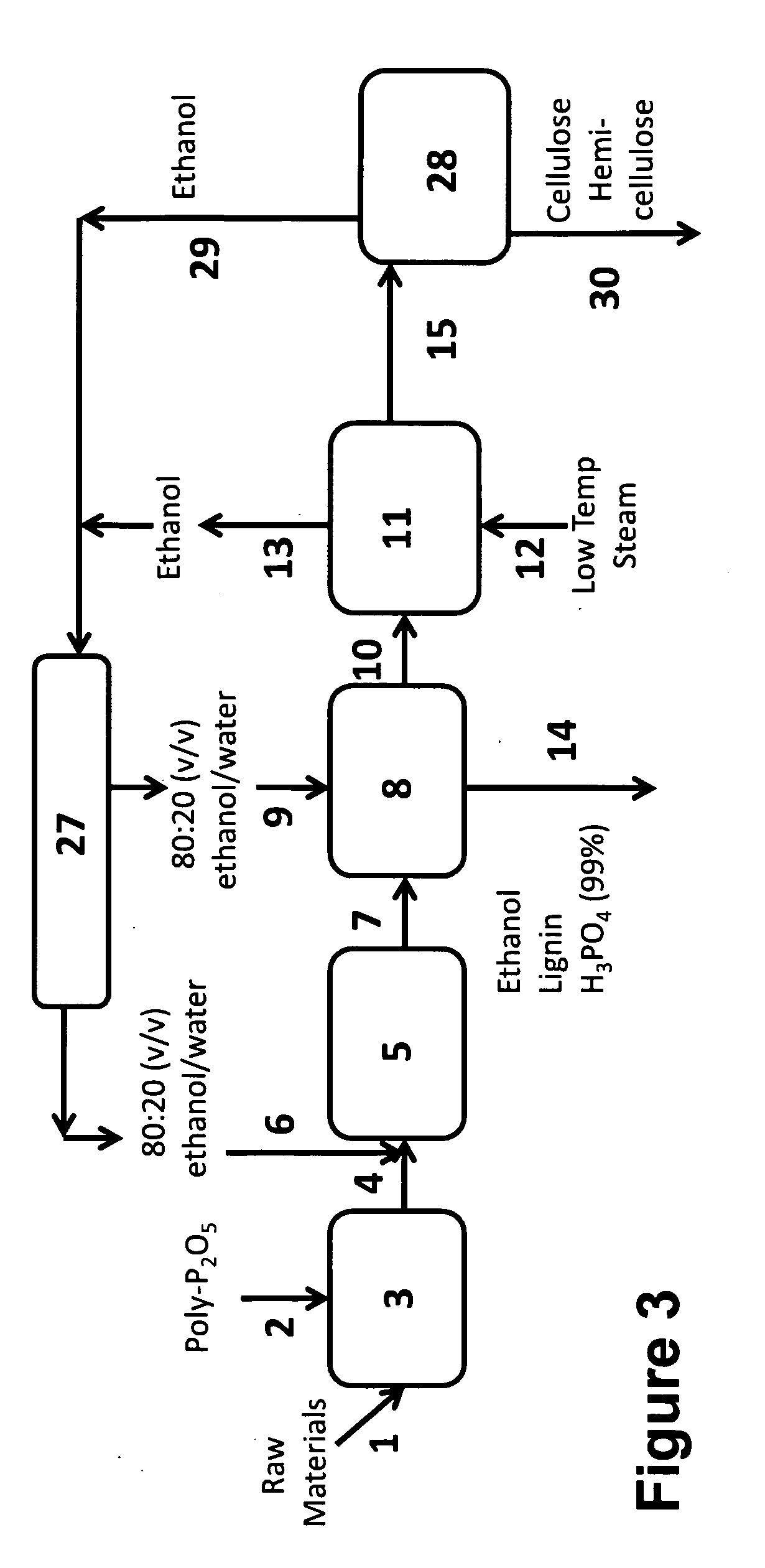

A process for separating the components of lignocellulosic biomass for the purpose of producing a pure reactive cellulose is disclosed. The process has two stages. In the first stage, the lignocellulosic biomass is pretreated with steam, with or without an acid catalyst, and then pressed, with or without the presence of an eluent, to remove hemicellulose and other impurities. In the second stage, the pretreated biomass is extracted with a solvent such as ethanol with or without acid catalysts in order to remove lignin and release a purified cellulose stream. The extracted cellulose is then rapidly decompressed to rupture the fibrous structure. The process provides a purified cellulose stream that is relatively easy to hydrolyze with enzymes and ferment to biofuels and other chemicals such as ethanol.

Owner:GREENFIELD SPECIALTY ALCOHOLS

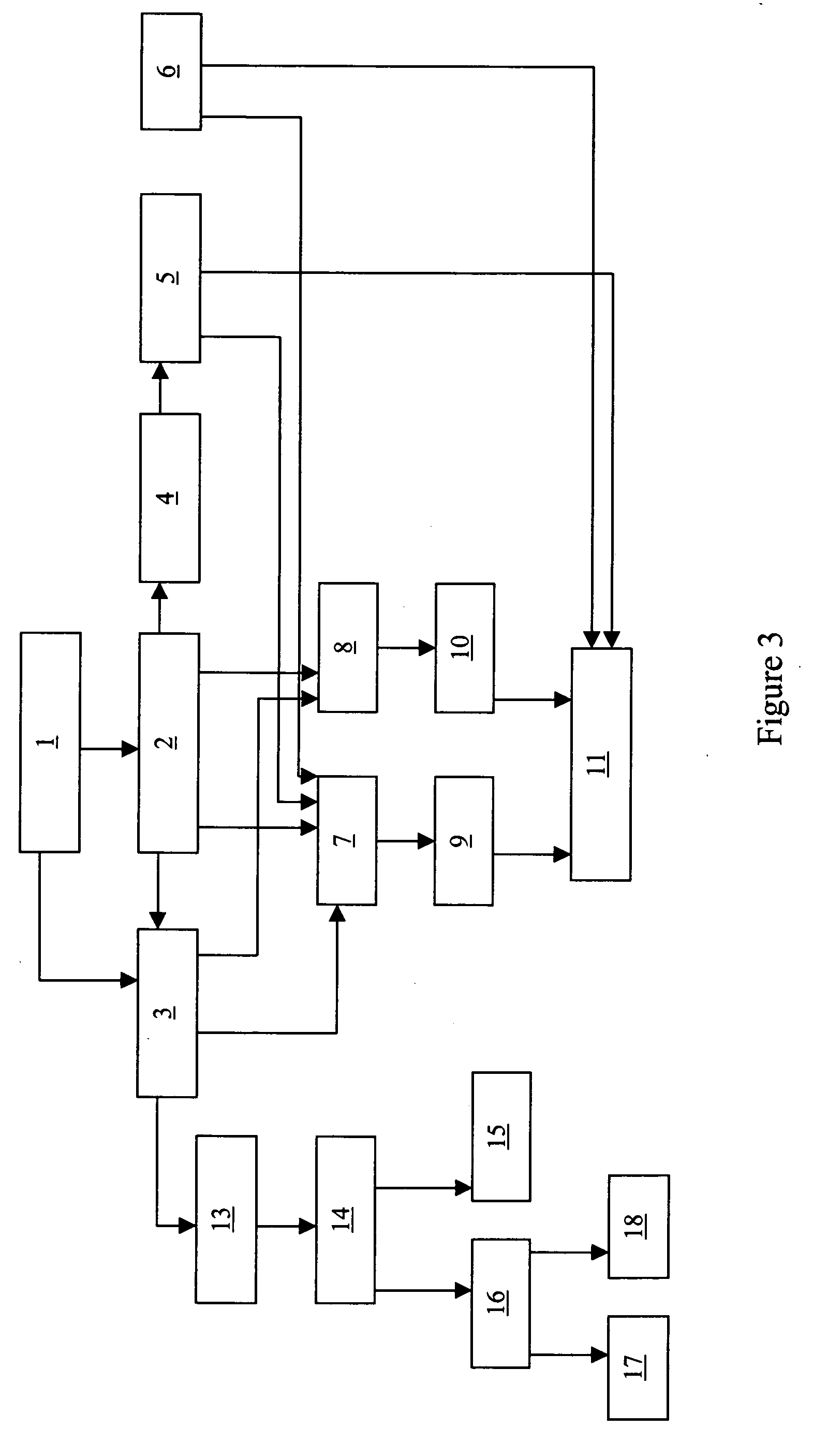

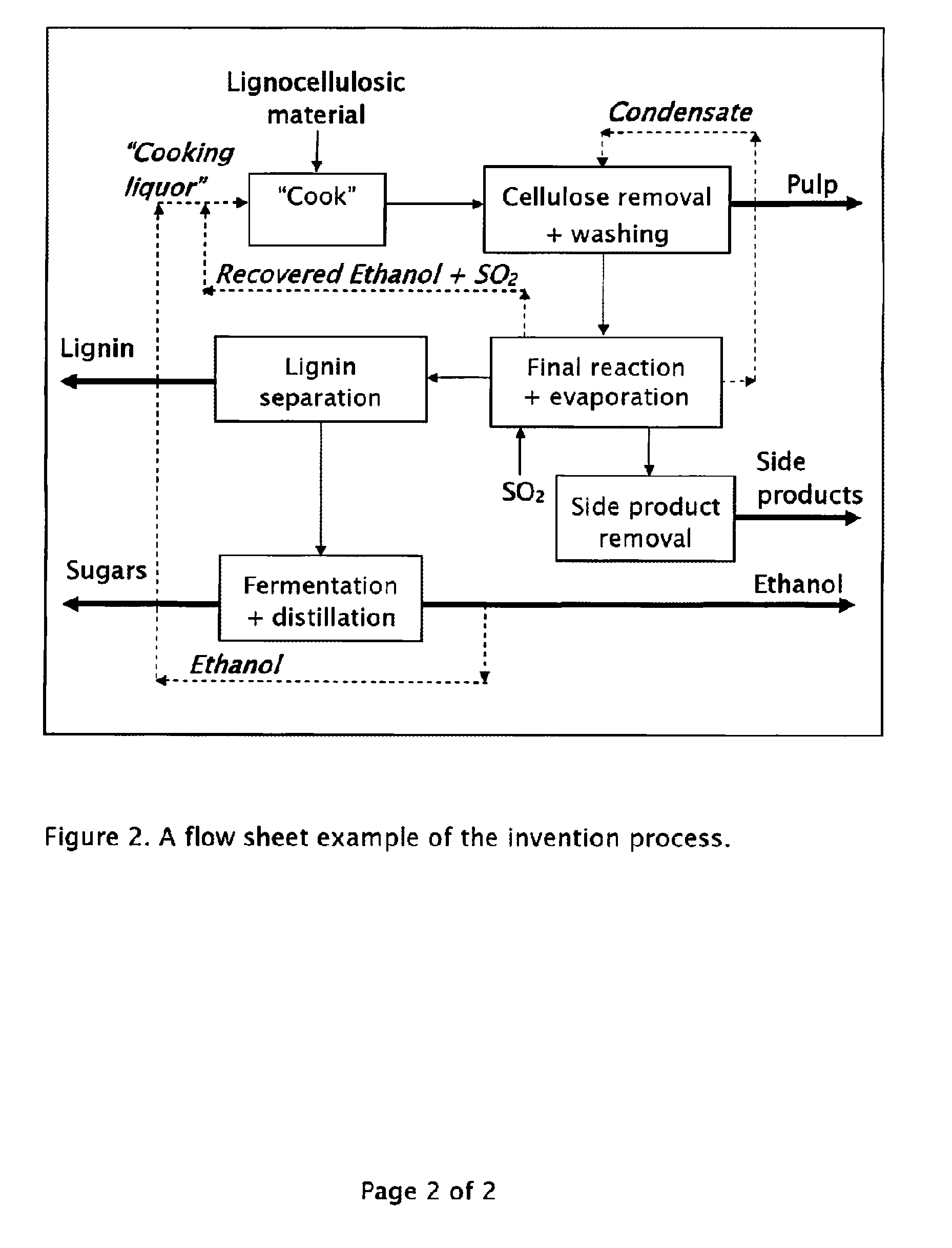

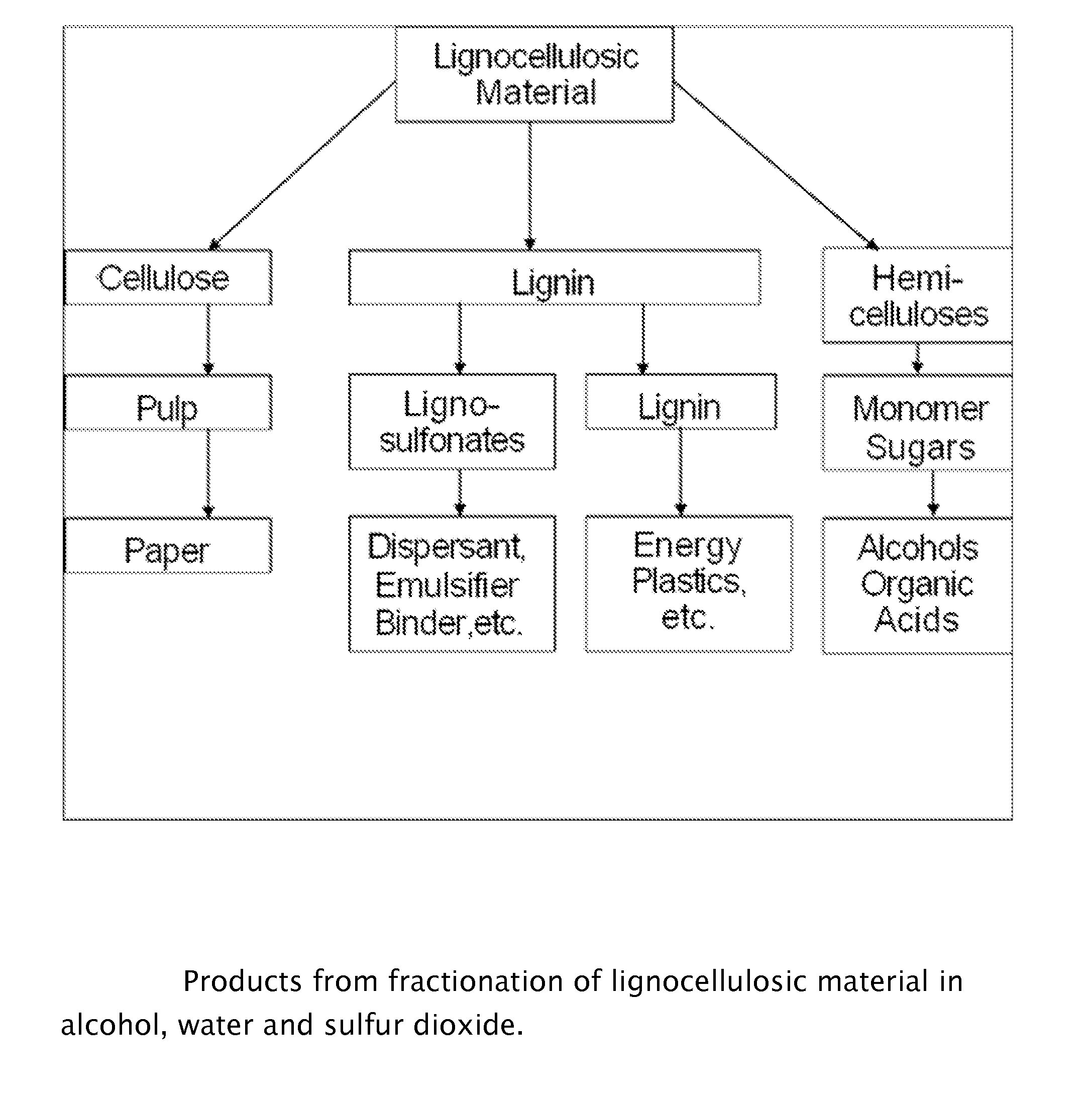

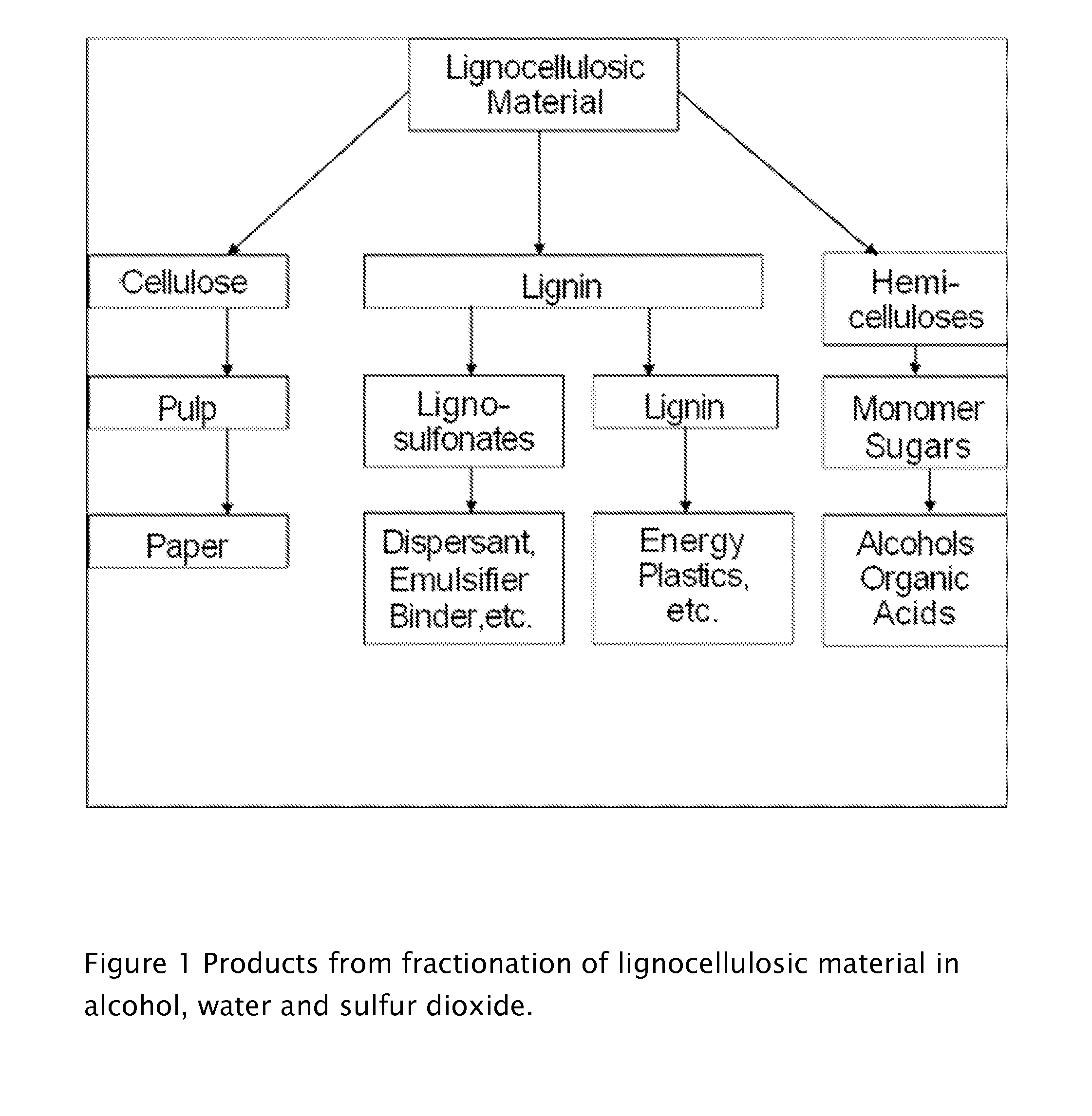

Product and processes from an integrated forest biorefinery

ActiveUS20070079944A1Easy to optimizePretreatment with water/steamPulping with acid salts/anhydridesPulp and paper industrySugar

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

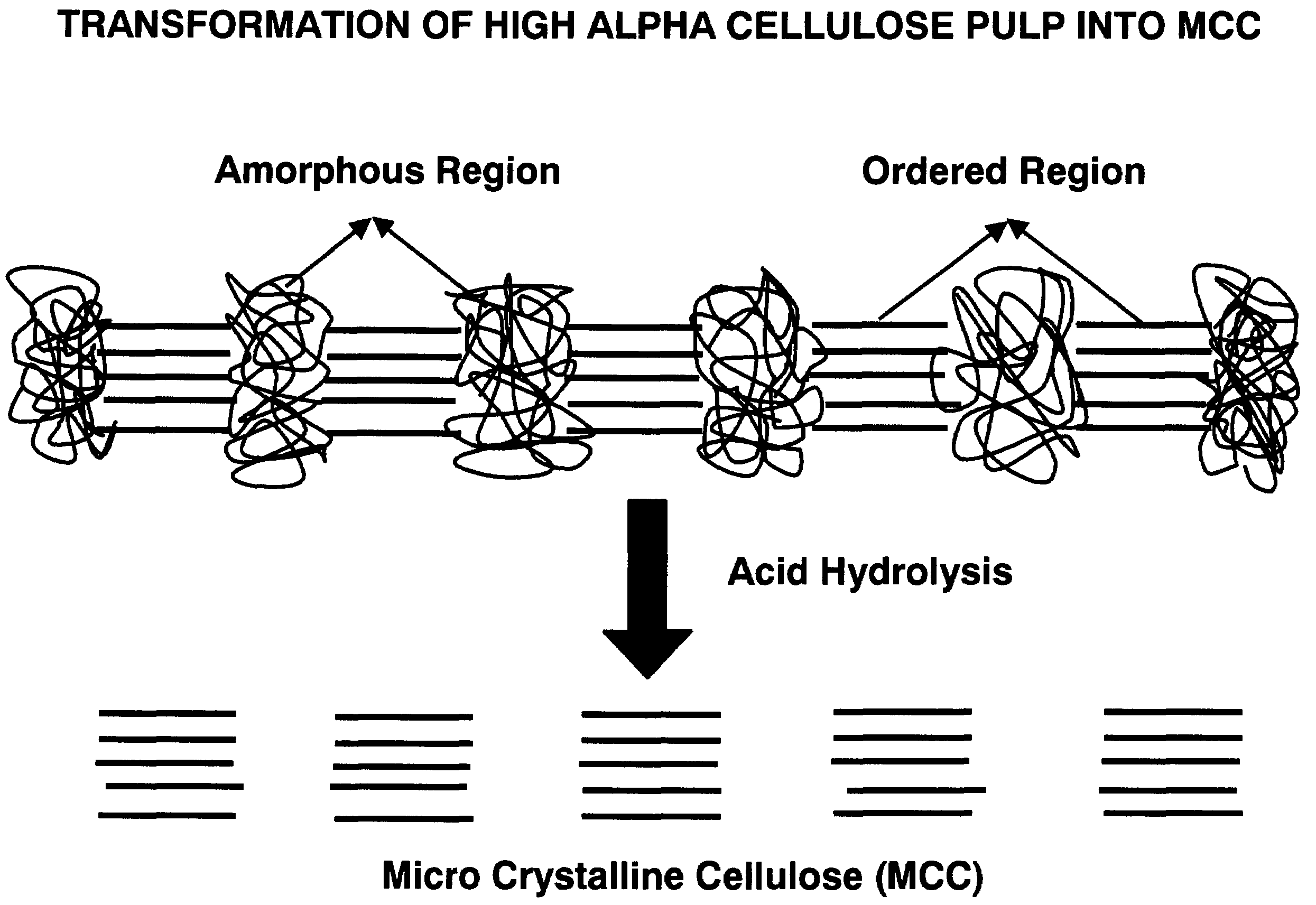

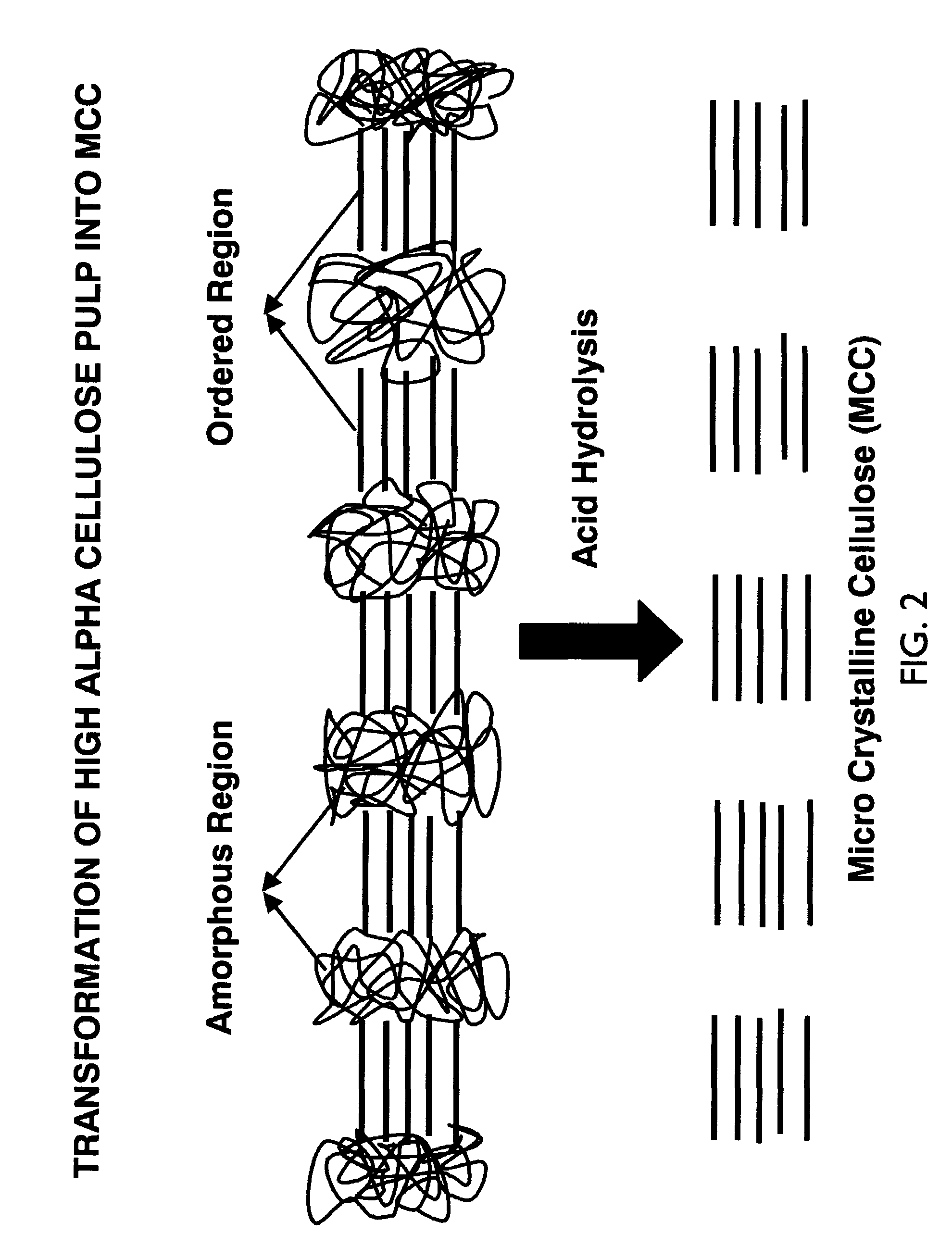

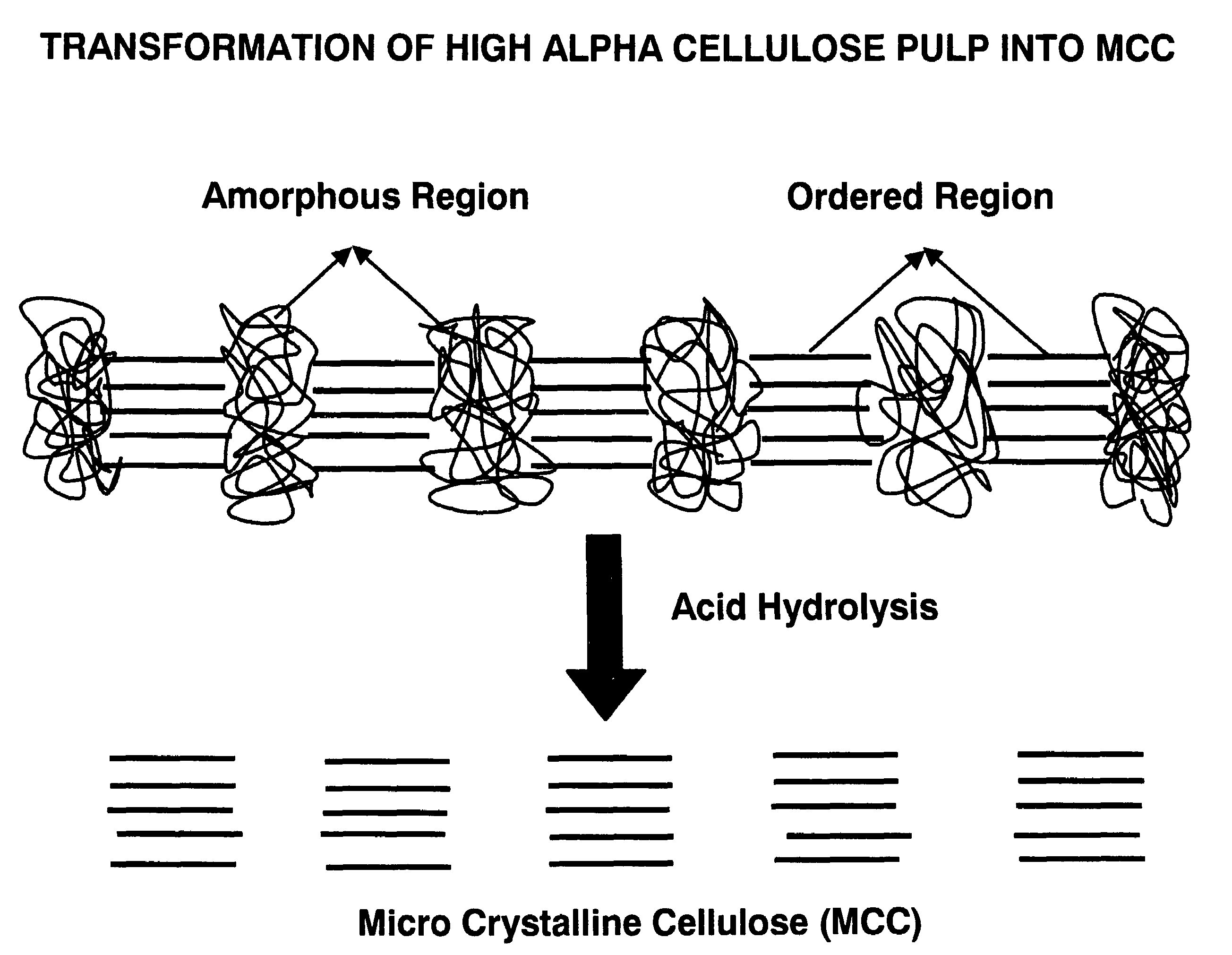

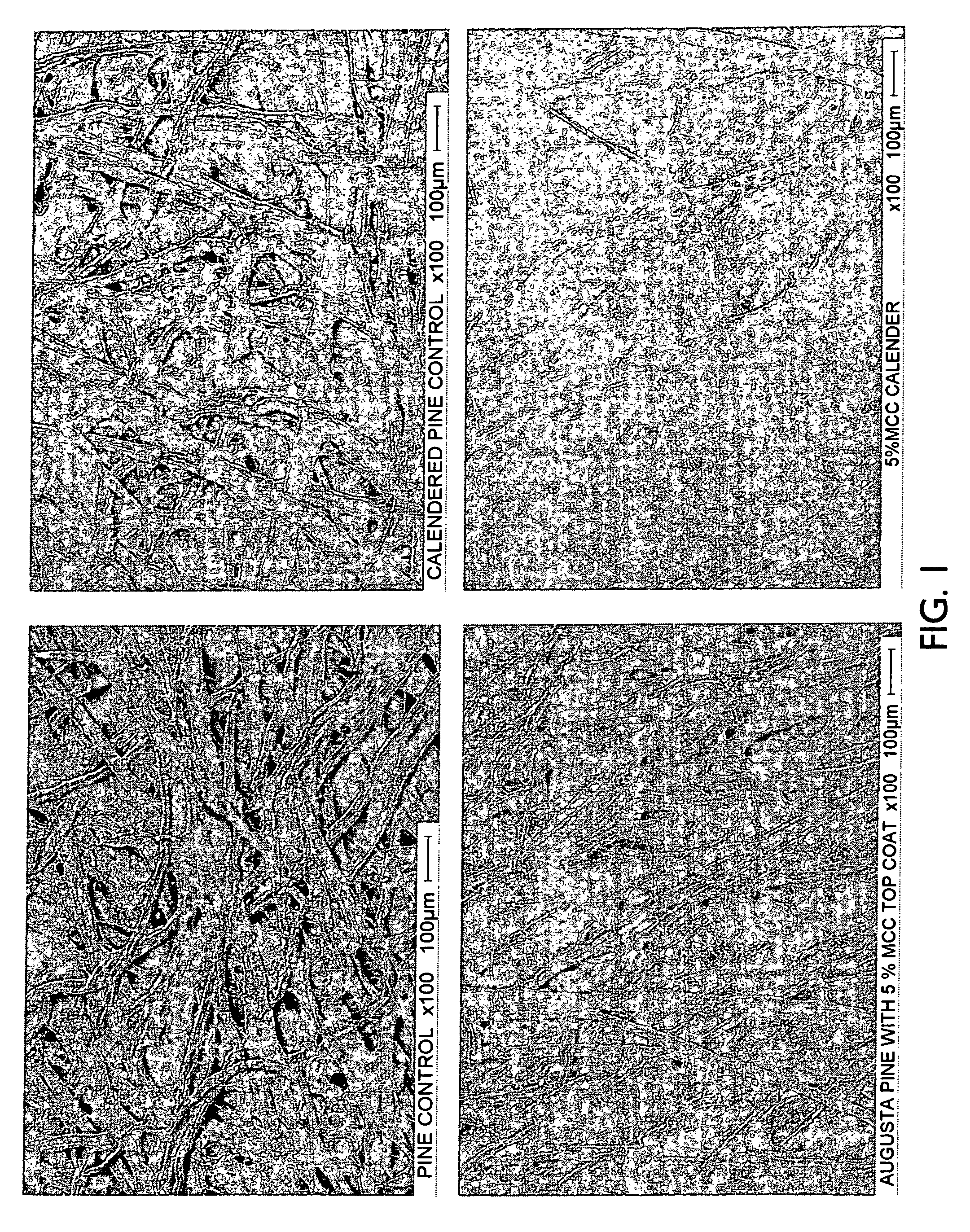

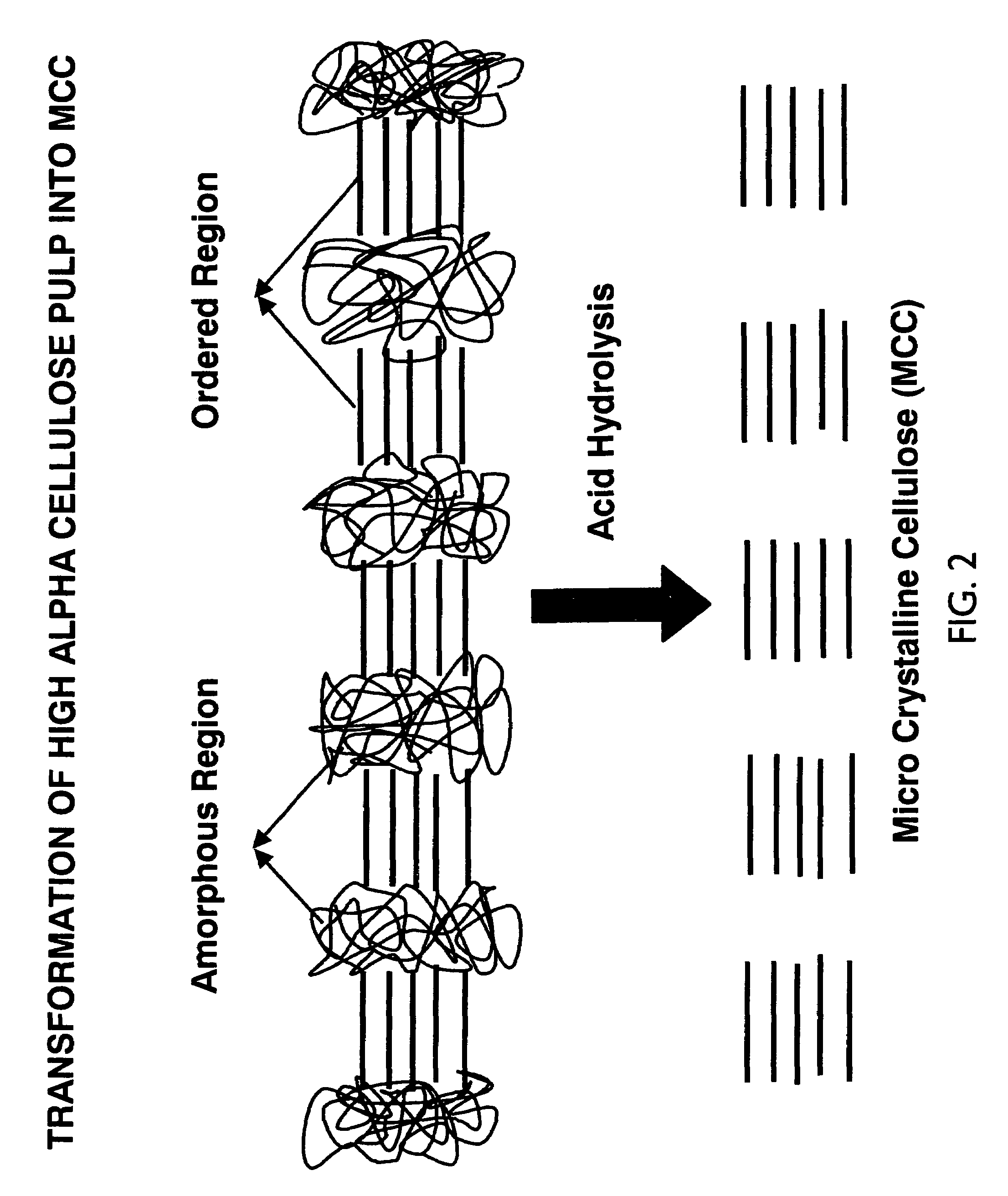

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

InactiveUS7037405B2High binding capacityImprove abilitiesNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaperboard

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

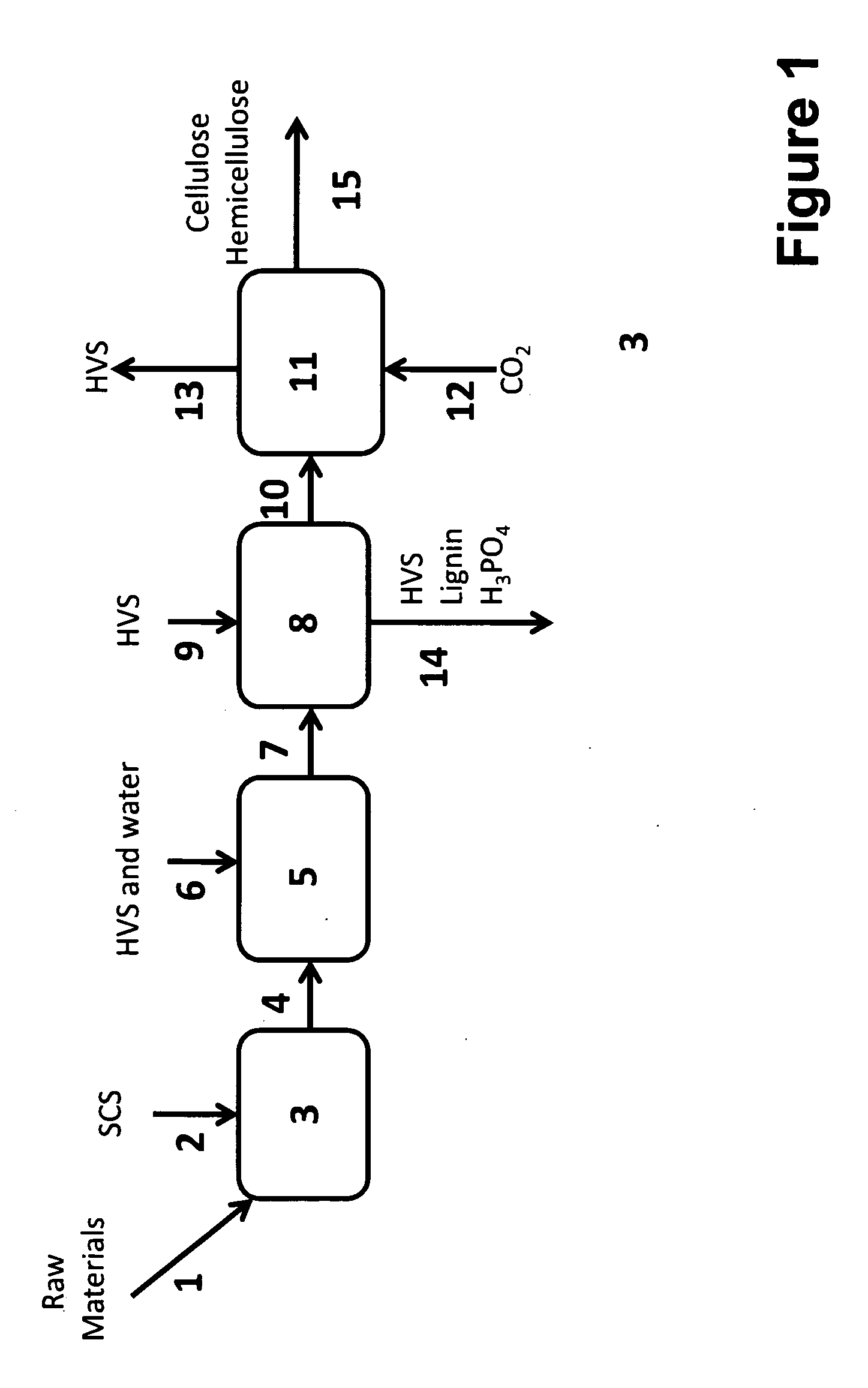

Method and apparatus for lignocellulose pretreatment using a super-cellulose-solvent and highly volatile solvents

InactiveUS20090229599A1Overcome shortcomingReduce solvent usagePressurized chemical processBiofuelsAlcoholGram

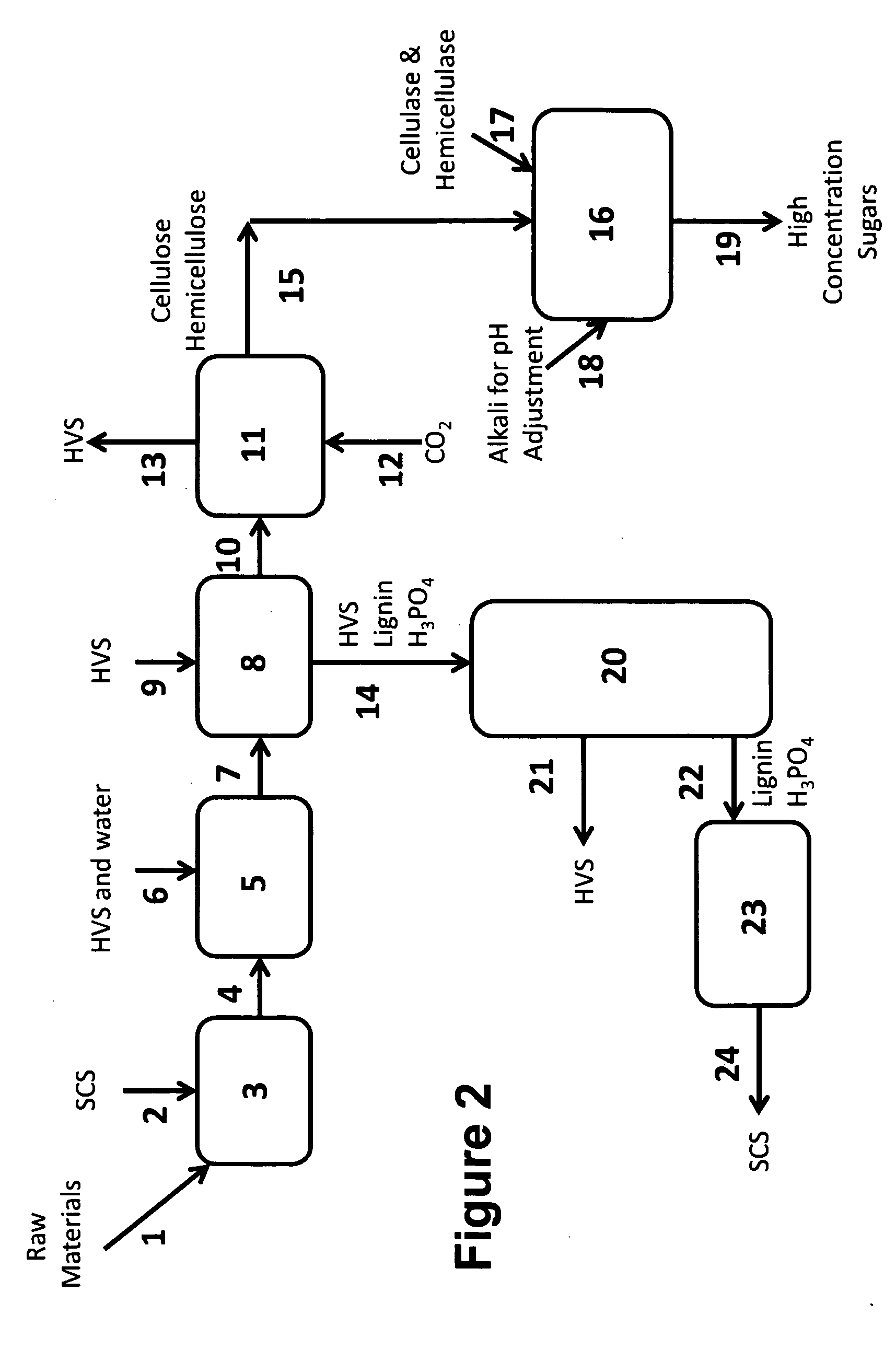

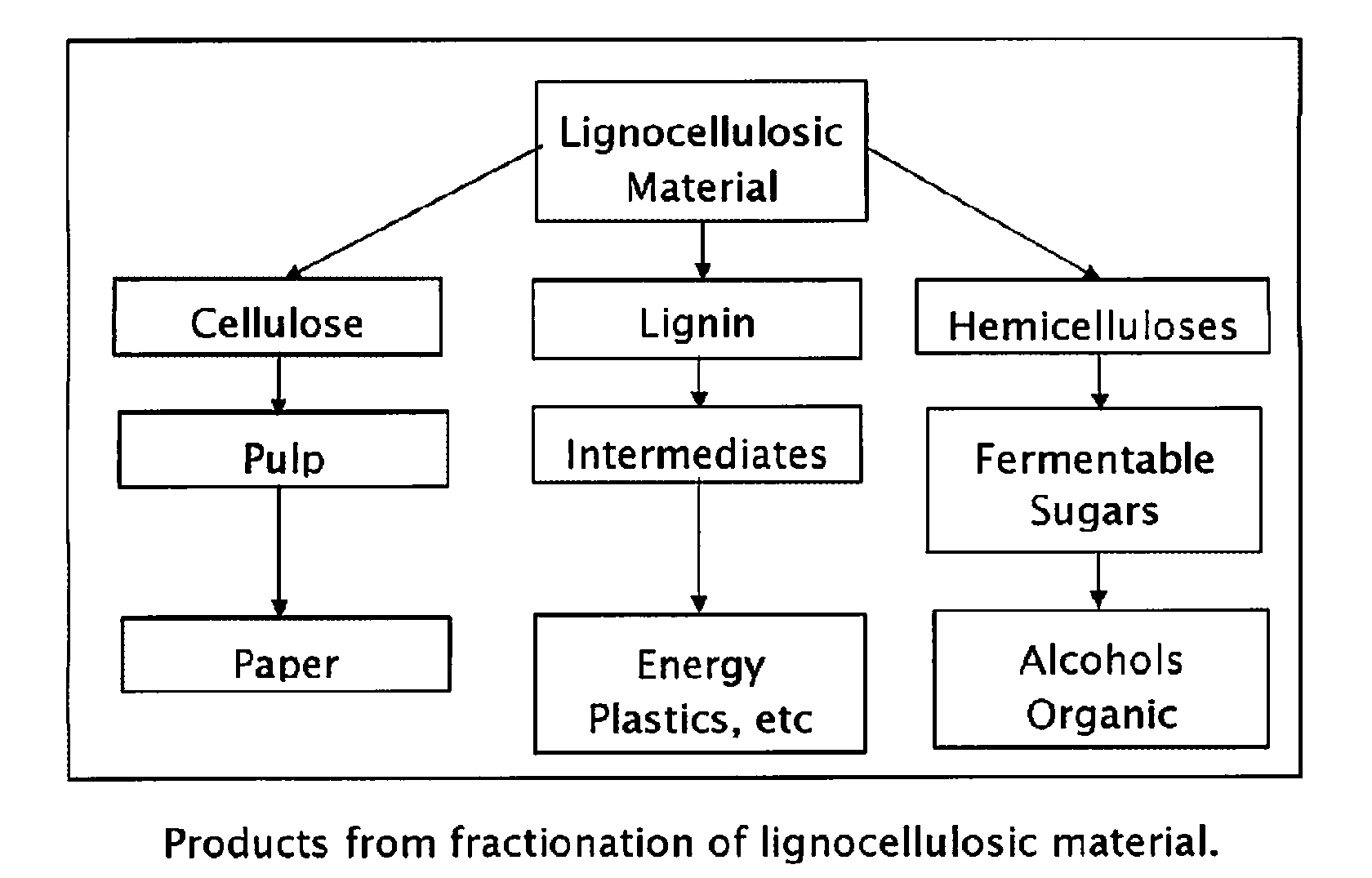

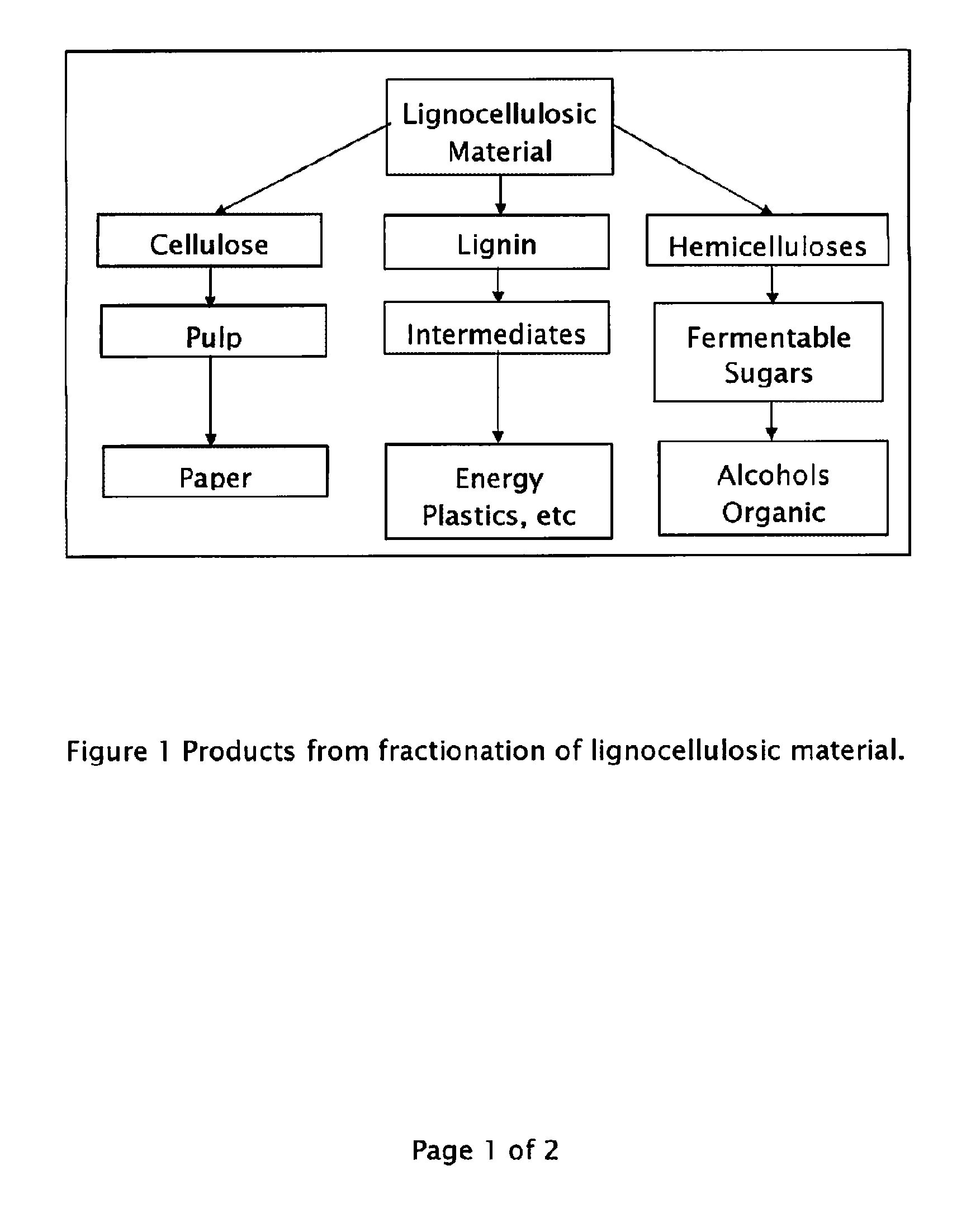

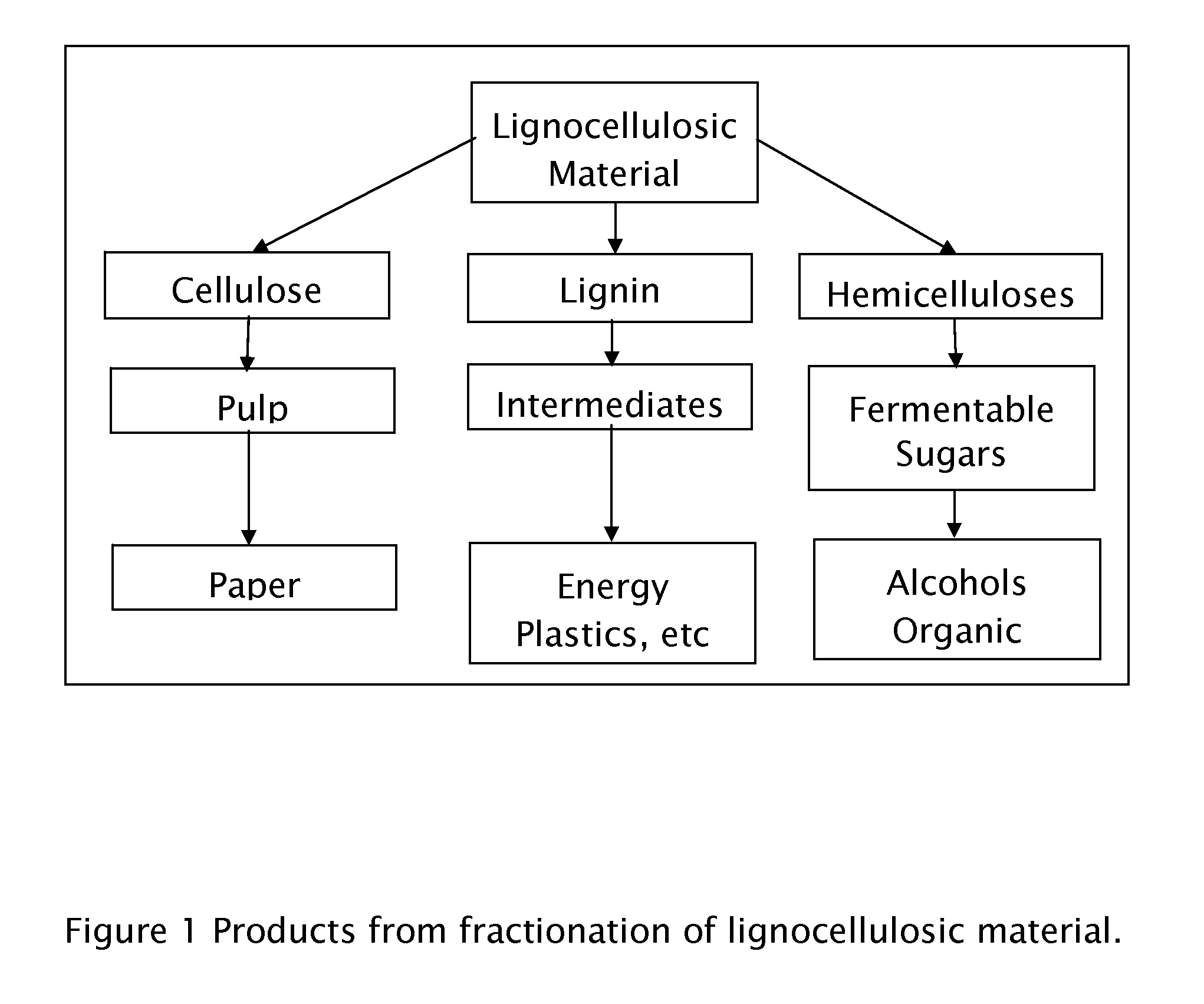

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and a system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose, and lignin. The cellulose and hemicellulose thus obtained are highly amorphous and can be readily converted into highly concentrated mixtures of five and six carbon sugars using known methods. Typical yields of sugars exceed 100 grams of sugars per liter of sugar solution. Other products, such as alcohols, can easily be prepared according to methods of the invention. The modest process conditions and low solvent / solid ratios of some embodiments of the invention require relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

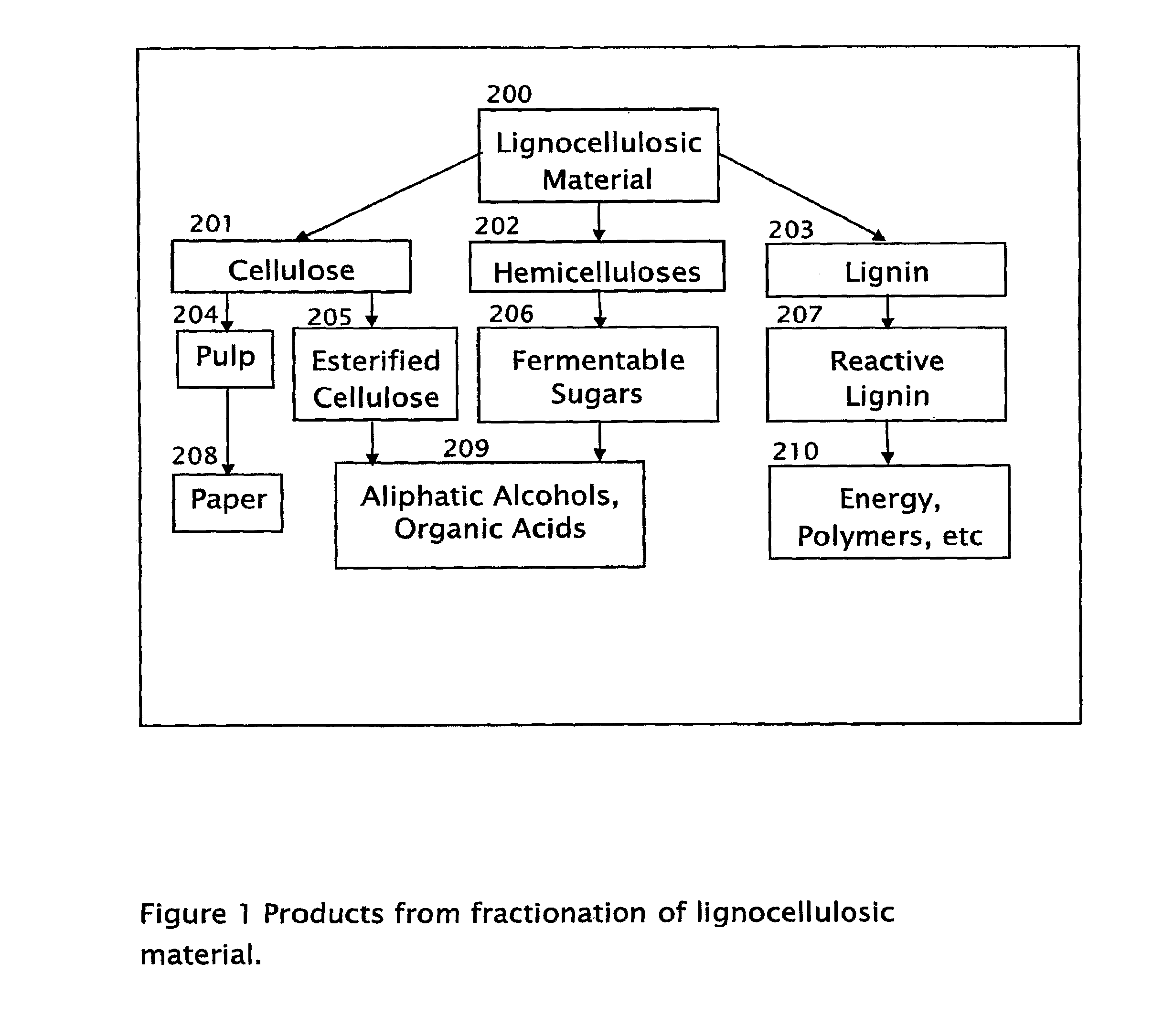

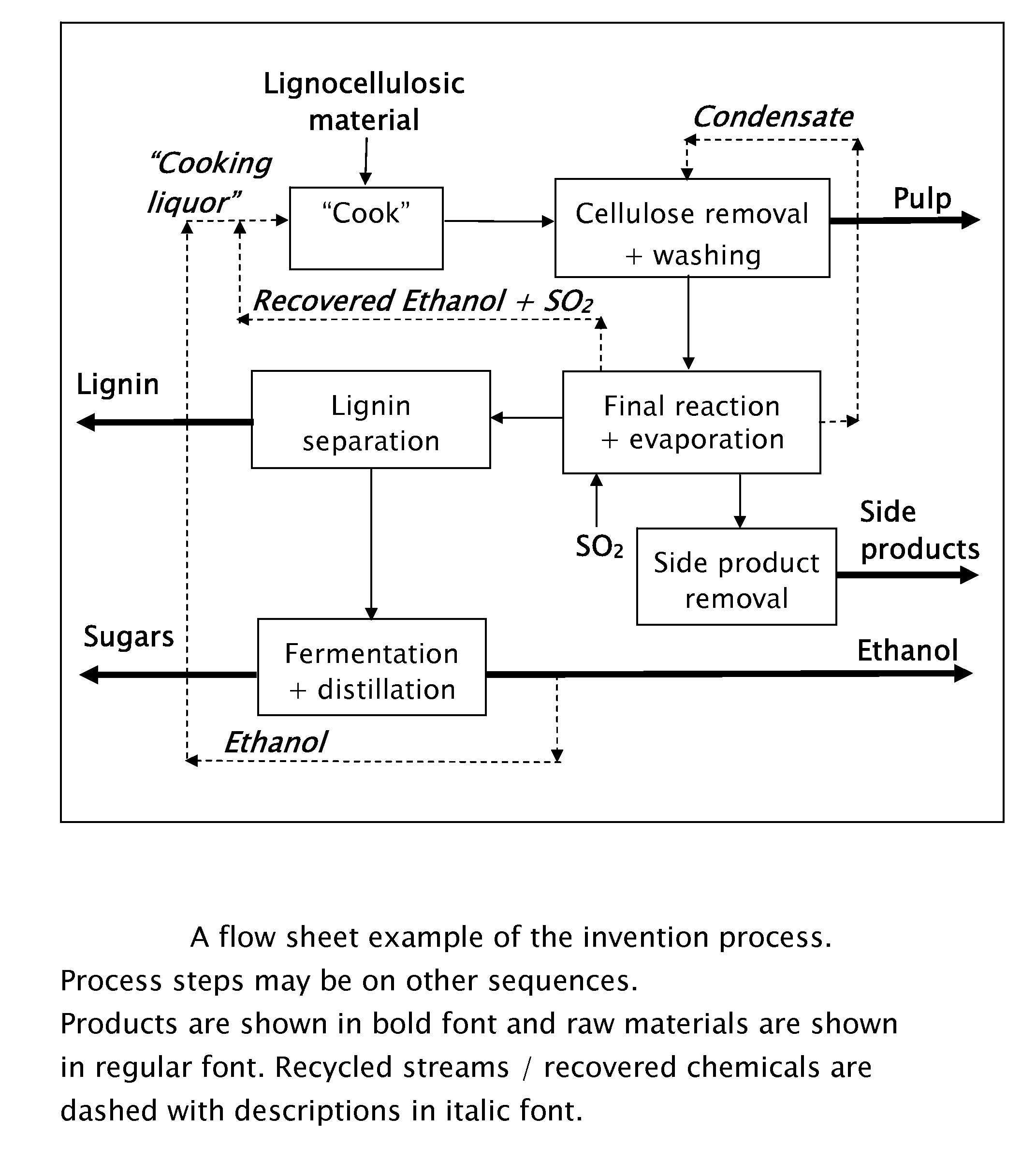

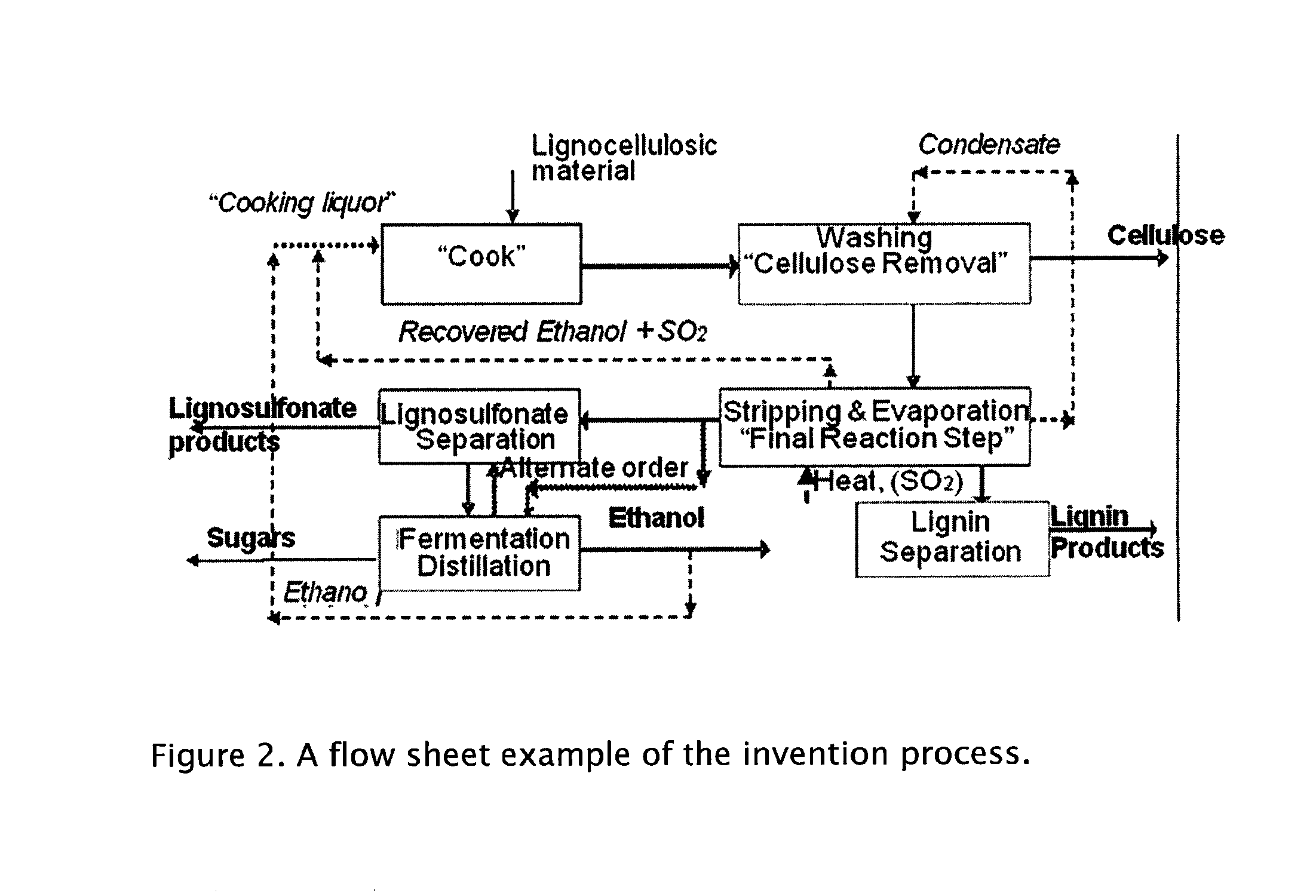

Method for the production of fermentable sugars and cellulose from lignocellulosic material

ActiveUS8030039B1High yieldIncreased ethanol yieldFats/resins/pitch/waxes removal in pulpPulping with organic compoundsOrganic acidAlcohol

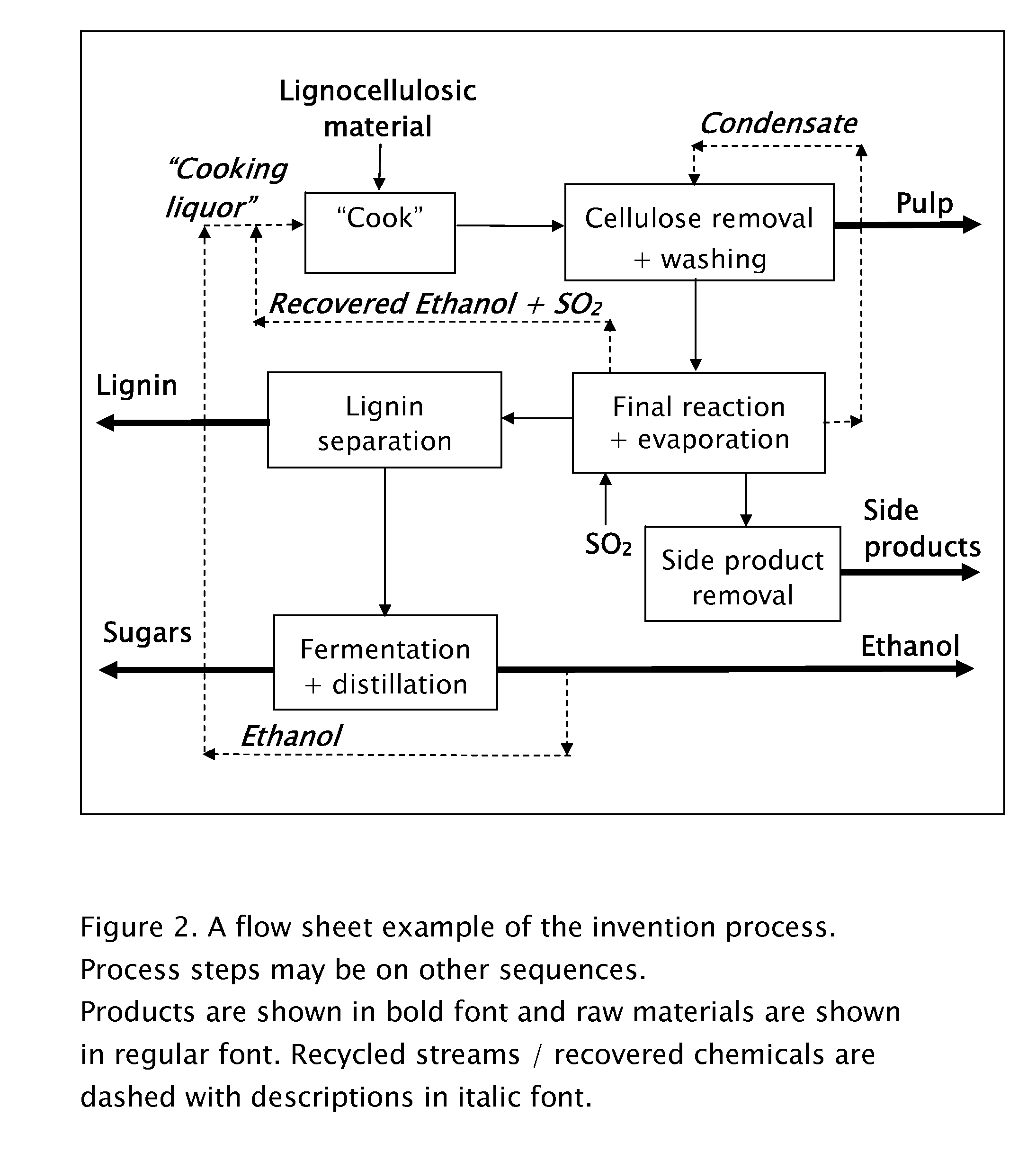

A method for the production of fermentable sugars and high viscosity cellulose from lignocellulosic material in a batch or continuous process is provided. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, cooking chemicals can be reused, lignin is separated for the production of process energy, and hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. High yield production of alcohols or organic acids can be obtained from this method using the final reaction step.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

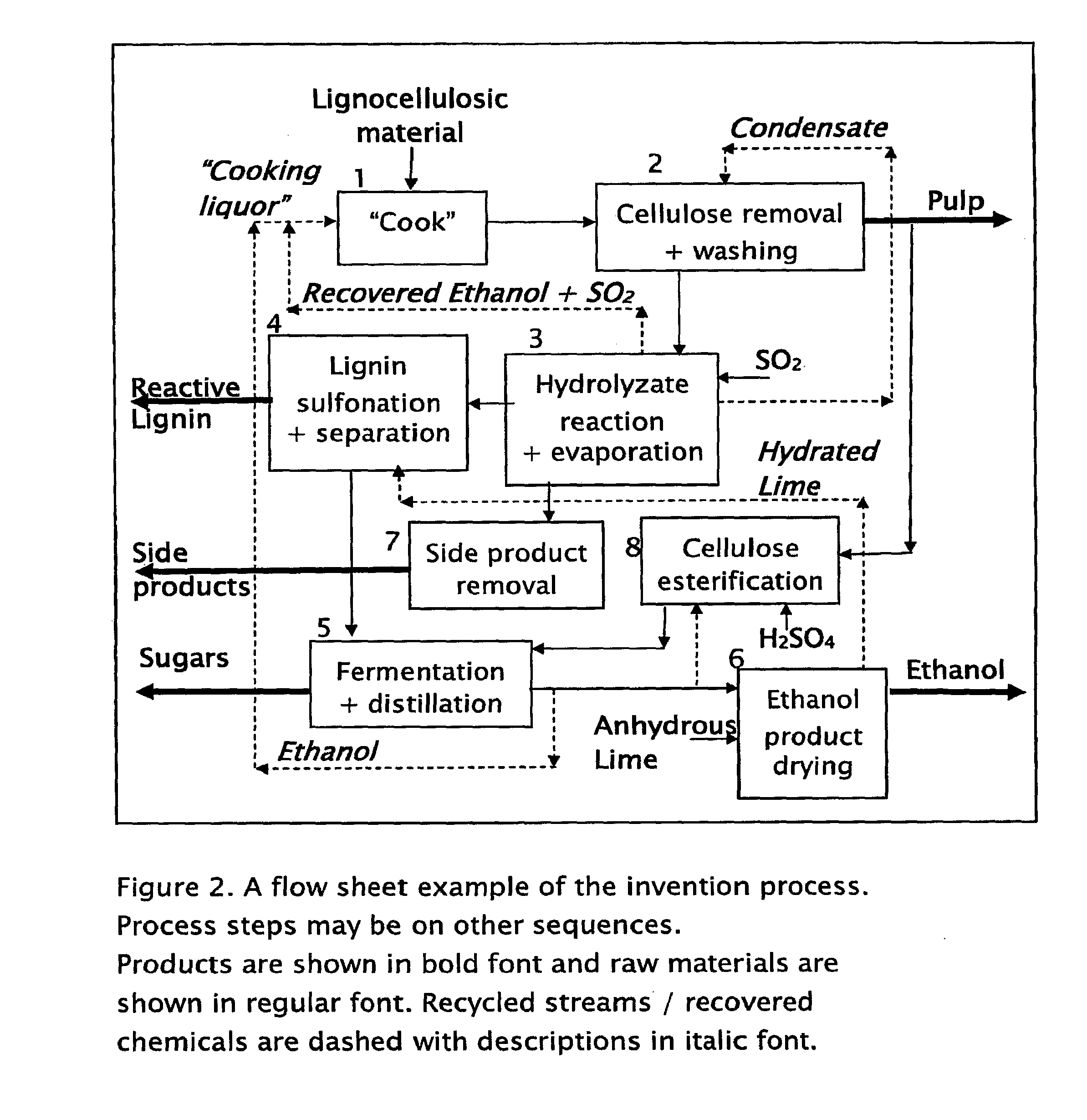

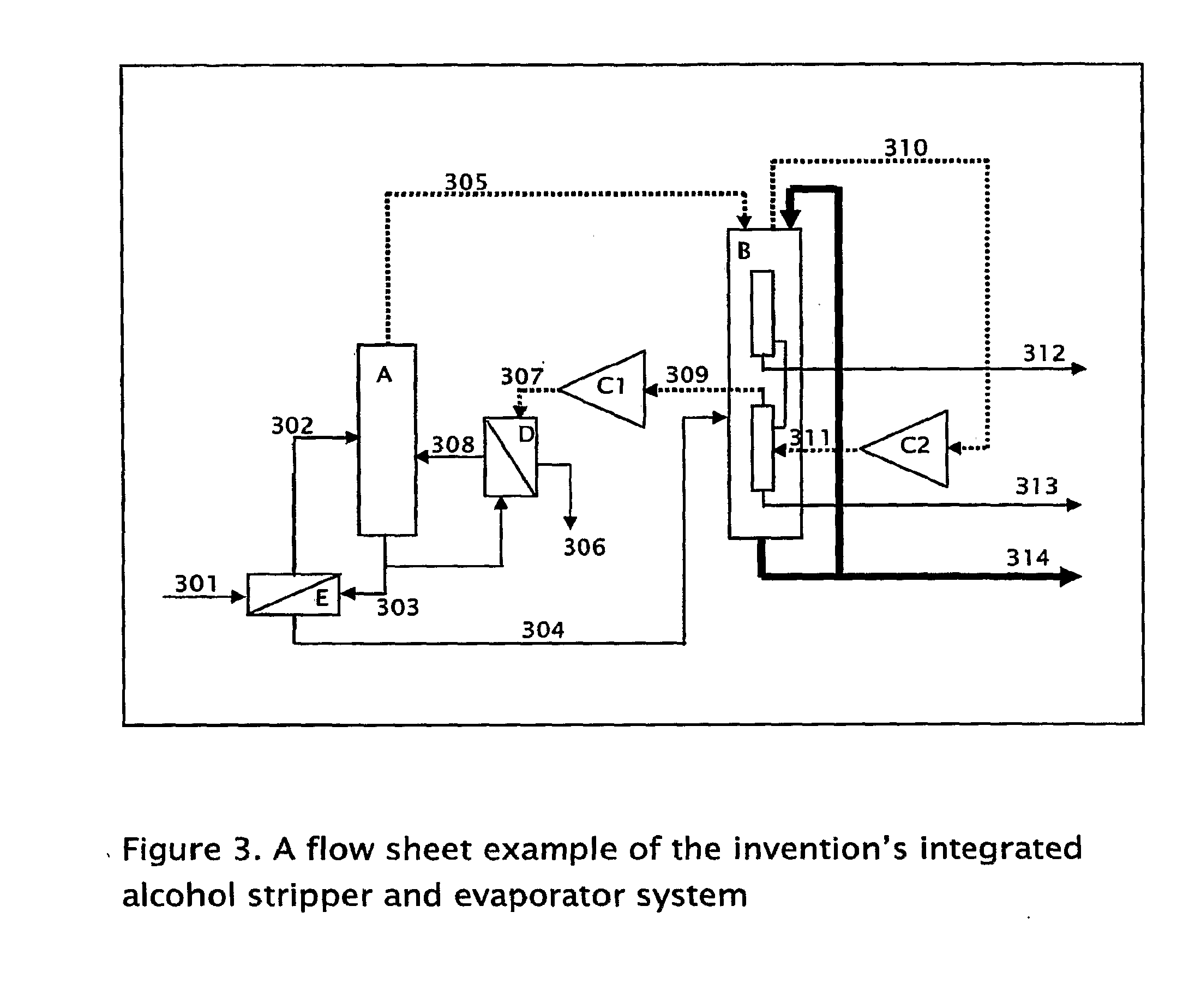

Process for the stepwise treatment of lignocellulosic material to produce reactive chemical feedstocks

InactiveUS20110003352A1Using liquid separation agentCalcium/strontium/barium sulfatesSulfonateLignosulfonates

A method for the fractionation of lignocellulosic materials into reactive chemical feedstock in a batch or semi continuous process by the stepwise treatment with aqueous aliphatic alcohols in the presence of sulfur dioxide or acid. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, or converted to esterified cellulose, cooking chemicals are reused, lignin is separated in the forms of reactive native lignin and reactive lignosulfonates and hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. In an integrated vapor compression stripper and evaporator system, aliphatic alcohol is removed from a liquid stream and the resulting stream is concentrated for further processing.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC +1

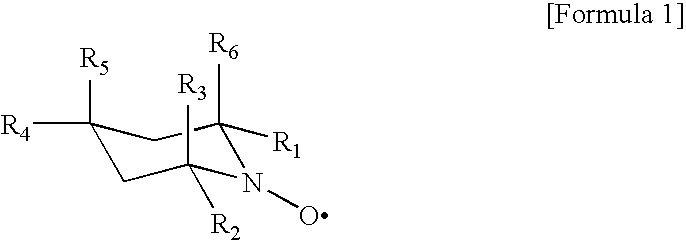

Processes for producing cellulose nanofibers, cellulose oxidation catalysts and methods for oxidizing cellulose

The present invention aims to provide a process for producing cellulose nanofibers using a 4-hydroxy TEMPO derivative less expensive than TEMPO and a process capable of rapidly producing homogeneous cellulose nanofibers. Wood cellulose can be efficiently converted into nanofibers by a process for producing cellulose nanofibers comprising treating a cellulosic material with an oxidizing agent in water in the presence of a cellulose oxidation catalyst comprising an N-oxyl compound represented by formula 1 below:wherein R1 and R2 are each independently hydrogen or a C1-C6 straight or branched alkyl group; and(i) one of R4 or R5 is —OR, —OCOR or —OSO2R wherein R is a straight or branched carbon chain having 4 or less carbon atoms, and the other of R4 or R5 is hydrogen, and R3 and R6 are methyl, or(ii) R4 is hydrogen, and R5, R3 and R6 are taken together with a piperidine ring to form an aza-adamantane compound having formula 2 below:or a mixture thereof, and a compound selected from the group consisting of bromides, iodides and mixtures thereof to prepare oxidized cellulose, and microfibrillating the oxidized cellulose to convert it into nanofibers.

Owner:NIPPON PAPER IND CO LTD

Organic biomass fractionation process

InactiveUS20030041982A1Economical and efficientLow costPretreatment with acid reacting compoundsWaste based fuelFractionationNitration

A method for fractionating fibrous biomass comprising cellulose, hemicellulose and lignin components to separate said lignin, cellulose and hemicellulose from one another comprises: (a) shredding said fibrous biomass; (b) concurrently with or subsequent to said shredding, contacting said biomass with an aqueous solution of a nitrate ion source at a concentration of about 0.1-0.3% at a temperature in the range of about 60° to about 80° C. to initiate nitration of the lignin component of said biomass; (c) submerging said partially nitrated biomass in an aqueous solution of a nitrate ion source in the presence of an aluminum compound at a temperature within the range of about 75-100° C. for a time sufficient to complete the nitration of said lignin component; (d) contacting the nitrated biomass produced in step (c) with an alkaline extraction liquor comprising NH4OH at an initial concentration sufficient to solubilize said nitrated lignin component and said hemicellulose component from said cellulose component of said biomass; e) recovering said cellulose from said extraction liquor containing said solubilized nitrated lignin and hemicellulose components, wherein said cellulose comprises at least about 88% alpha cellulose; (f) treating said extraction liquor with an acid to precipitate lignin contained therein, and (g) separating said lignin from soluble hemicellulose in said extraction liquor. The recovered cellulose component comprises at least 88% alpha cellulose and is useful as a starting material for the production of ethanol.

Owner:PRIOR ERIC S

Method for the production of fermentable sugars and cellulose from lignocellulosic material

InactiveUS20070254348A1Pulping with acid salts/anhydridesPulp by-products recoveryOrganic acidAlcohol

A method for the production of fermentable sugars and cellulose from lignocellulosic material in a batch or continuous process. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, cooking chemicals reused, lignin is separated for the production of process energy, hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. High yield production of alcohols or organic acids can be obtained from this method using the final reaction step.

Owner:RETABINA THEODORA +1

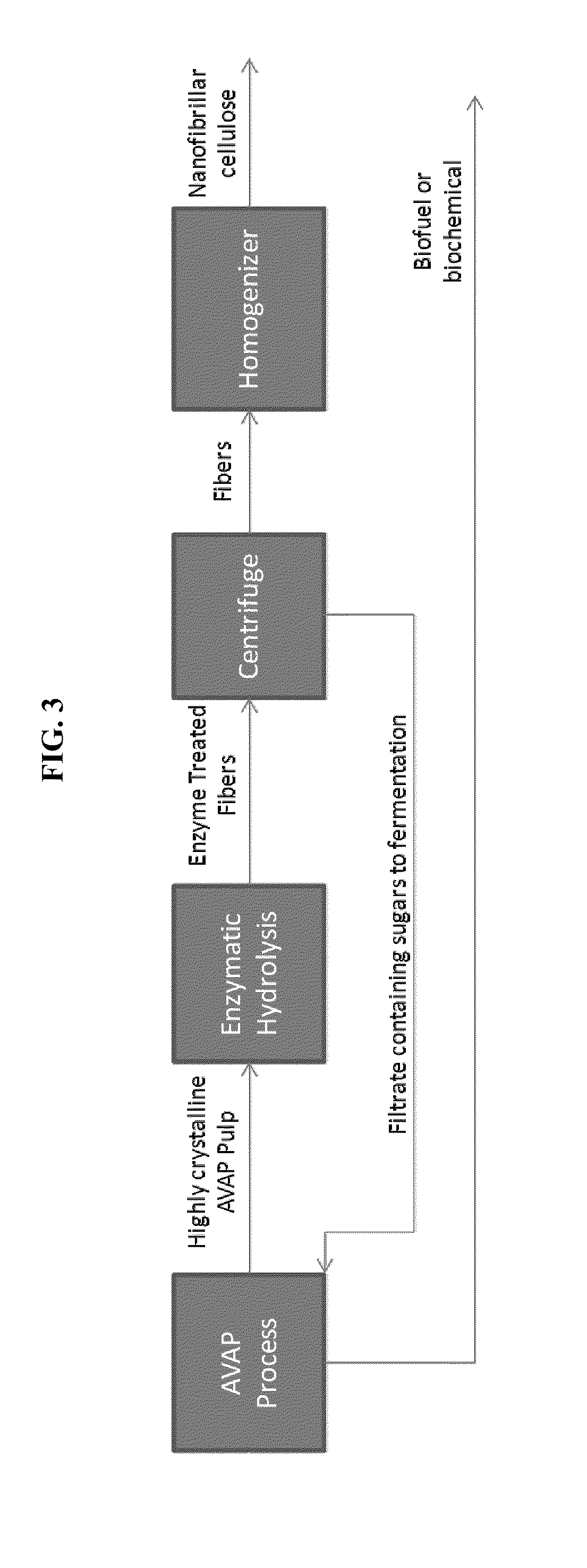

Processes and apparatus for producing nanocellulose, and compositions and products produced therefrom

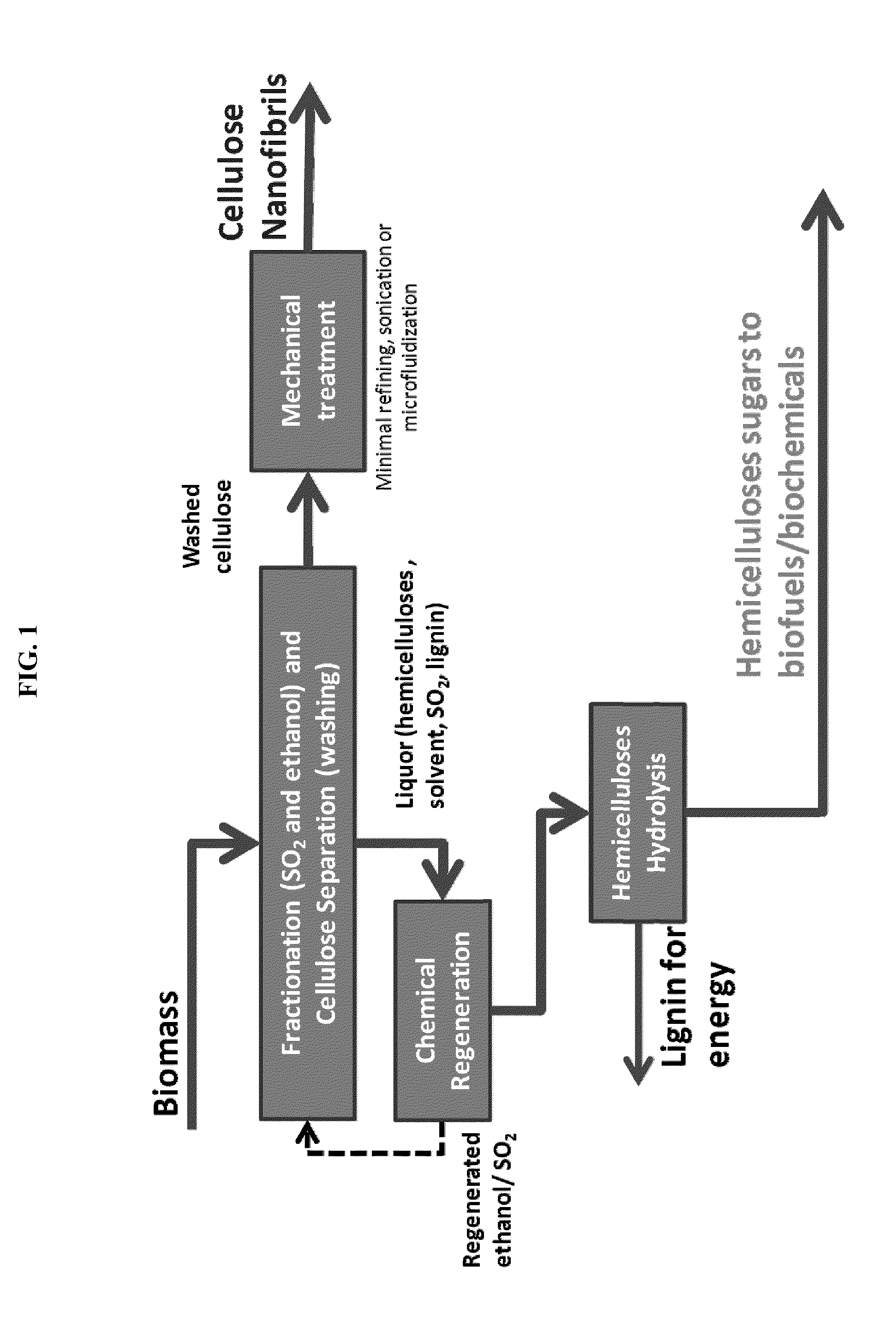

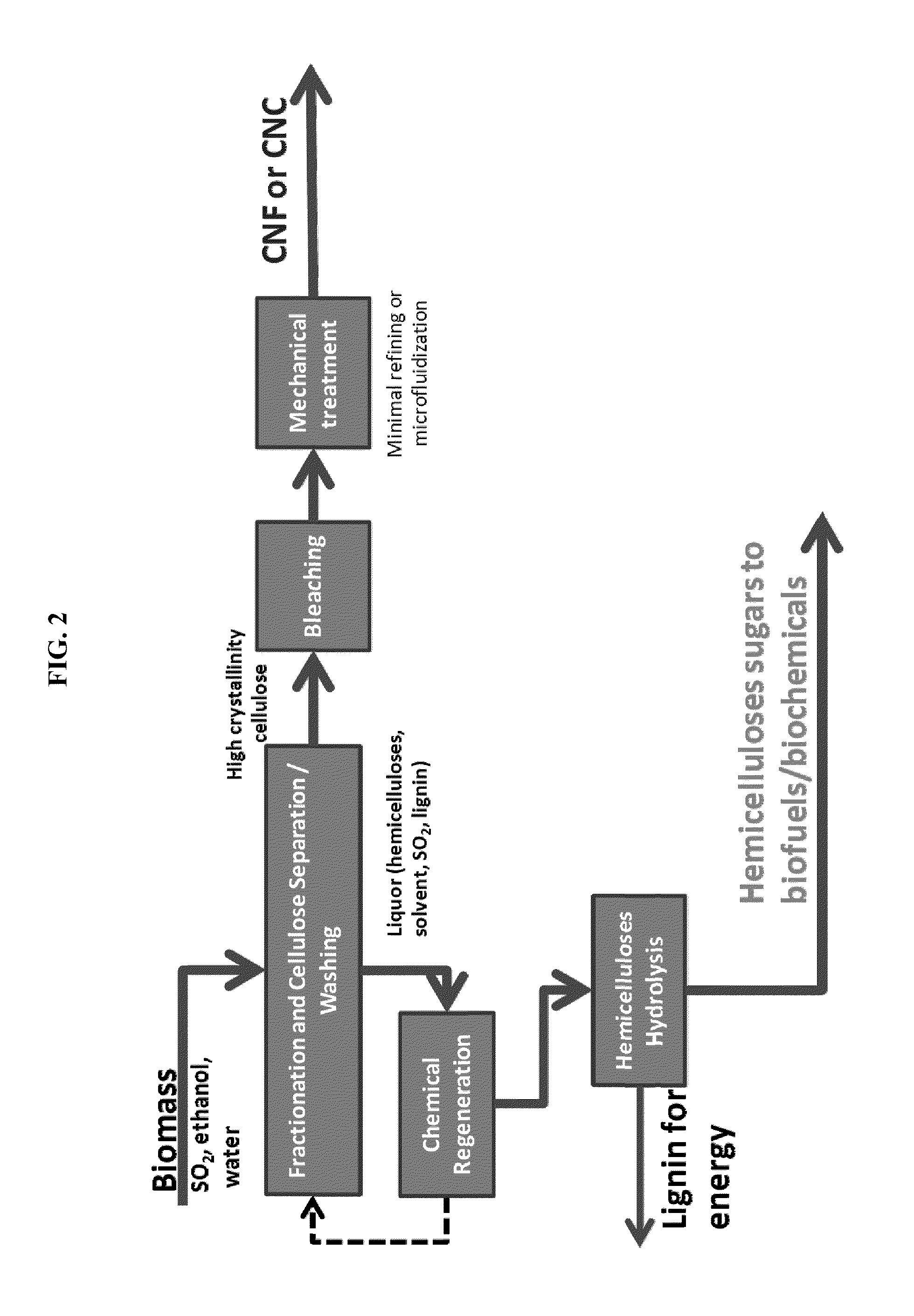

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with surprisingly low mechanical energy input. In some variations, the process includes fractionating biomass with an acid (such as sulfur dioxide), a solvent (such as ethanol), and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

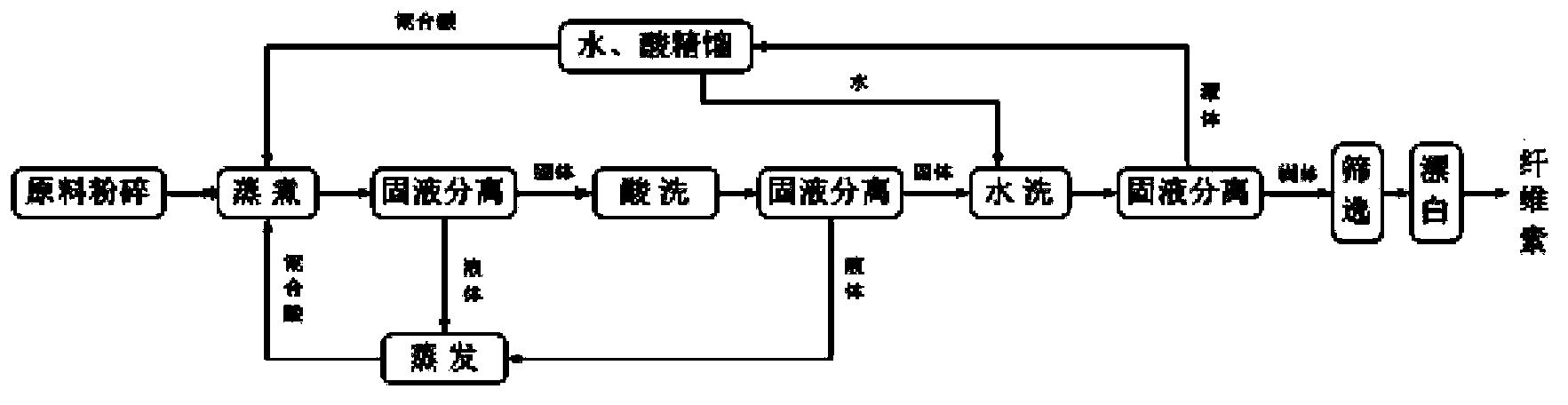

Technology for extracting cellulose from biomass raw materials

ActiveCN103898782AHigh purityReduce cooking timePulp bleachingPulping with acid salts/anhydridesAcetic acidOrganic acid

The invention relates to a cellulose extracting technology, and specifically relates to a technology that utilizes organic acids to extract cellulose from biomass raw materials in the presence of a hydrogen peroxide catalyst. The technology comprises the following steps: in the presence of a hydrogen peroxide catalyst, utilizing an organic acid to cook biomass raw materials, wherein the organic acid is composed of formic acid with a concentration of 70 to 95 wt% and acetic acid with a concentration of 70 to 95 wt%; extracting and screening so as to obtain screened cellulose pulp; and further bleaching the screened pulp so as to obtain the target cellulose; wherein the cellulose is dissolving pulp or industrial cellulose. The alpha-cellulose content of the cellulose obtained by the method provided by the invention is more than 90 wt%. The technology has the advantages of simple route and low energy consumption.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

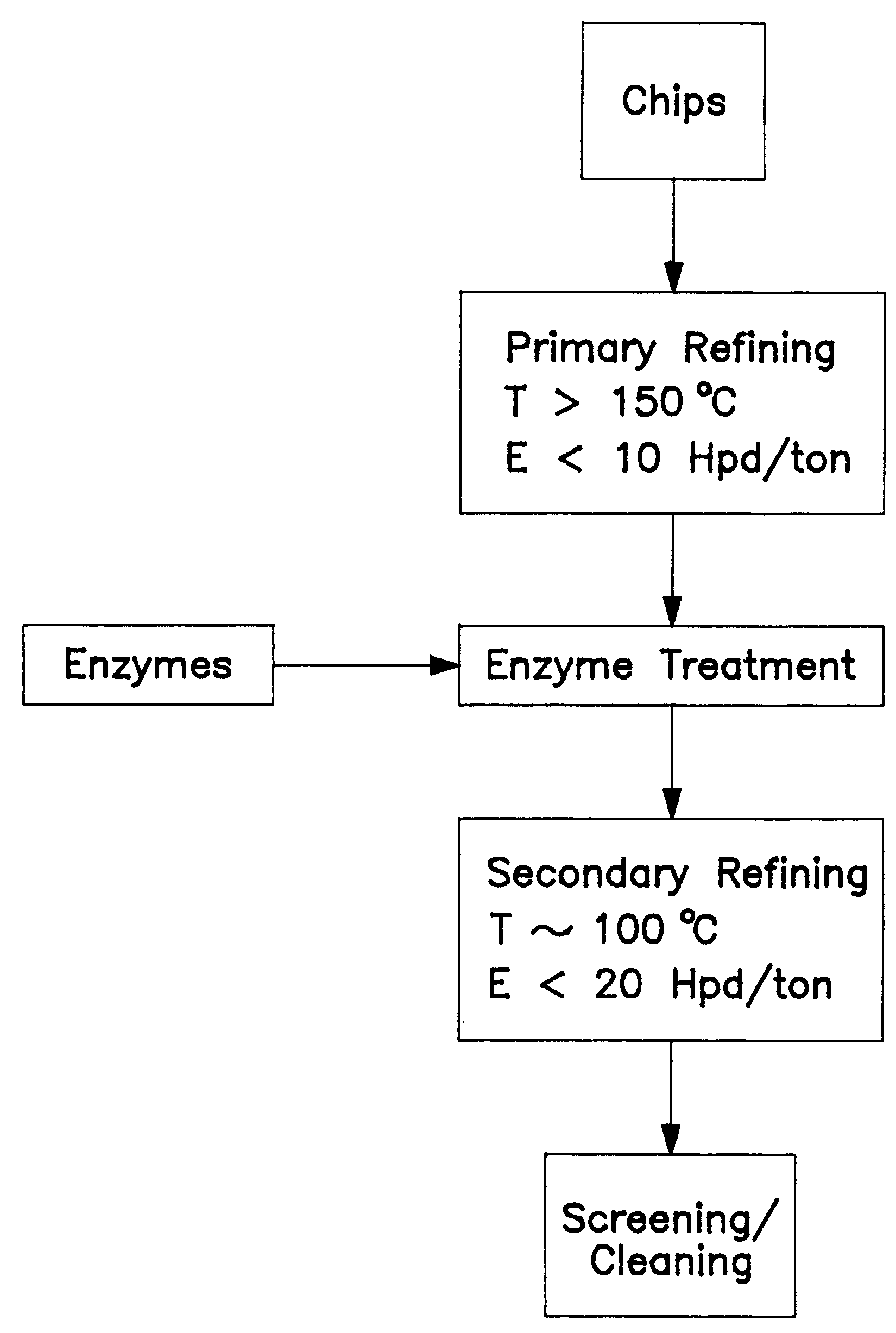

Low energy thermomechanical pulping process using an enzyme treatment between refining zones

InactiveUS6267841B1Pulping with acid salts/anhydridesPulping with inorganic basesPulp and paper industryEnzyme

A low energy thermomechanical pulping process which employs an enzyme treatment stage between two low energy thermomechanical stages.

Owner:INT PAPER CO

Method for producing pulp and lignin

InactiveUS20040244925A1Pretreatment with acid reacting compoundsPulp bleachingCellulosePtru catalyst

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

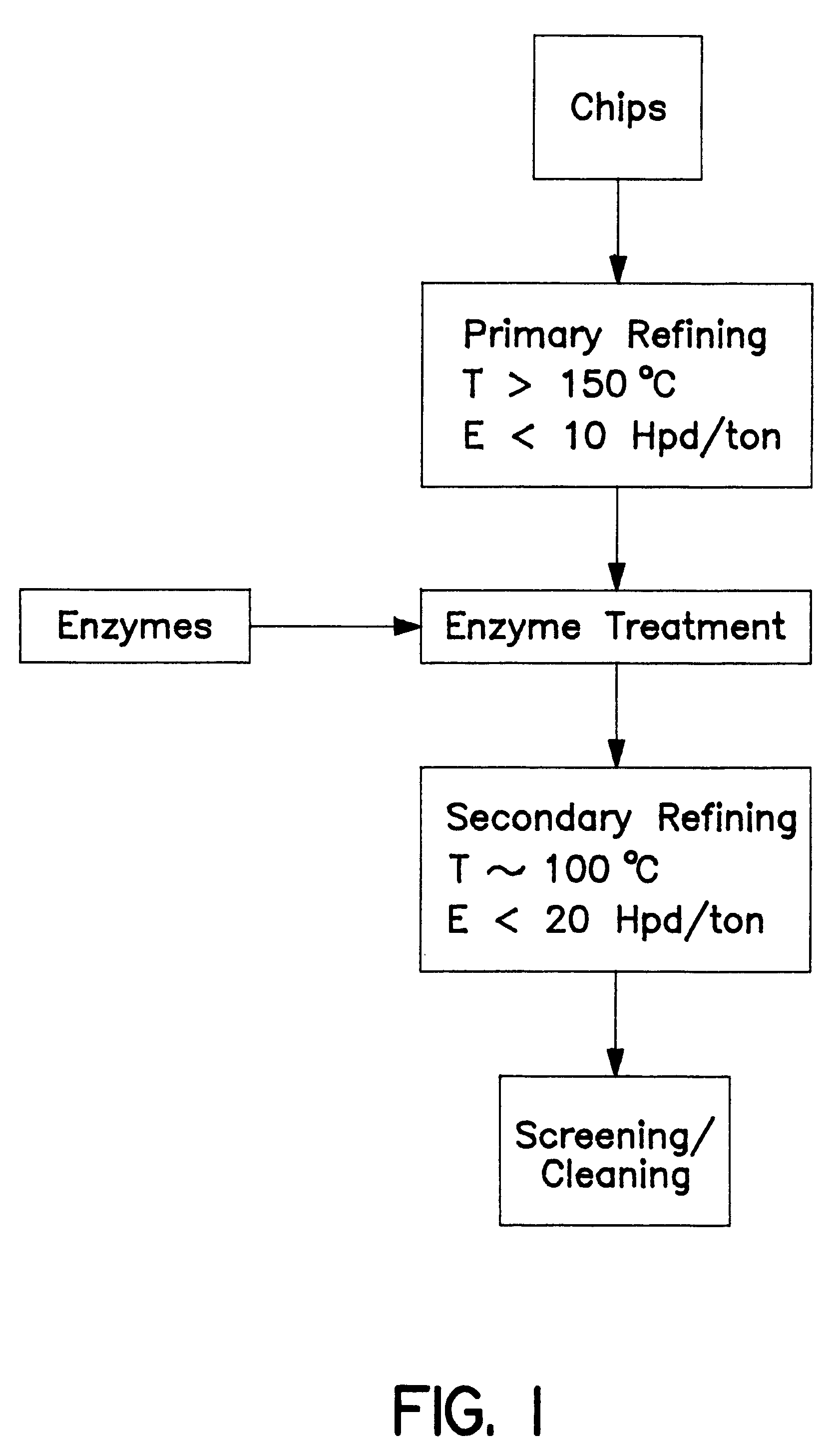

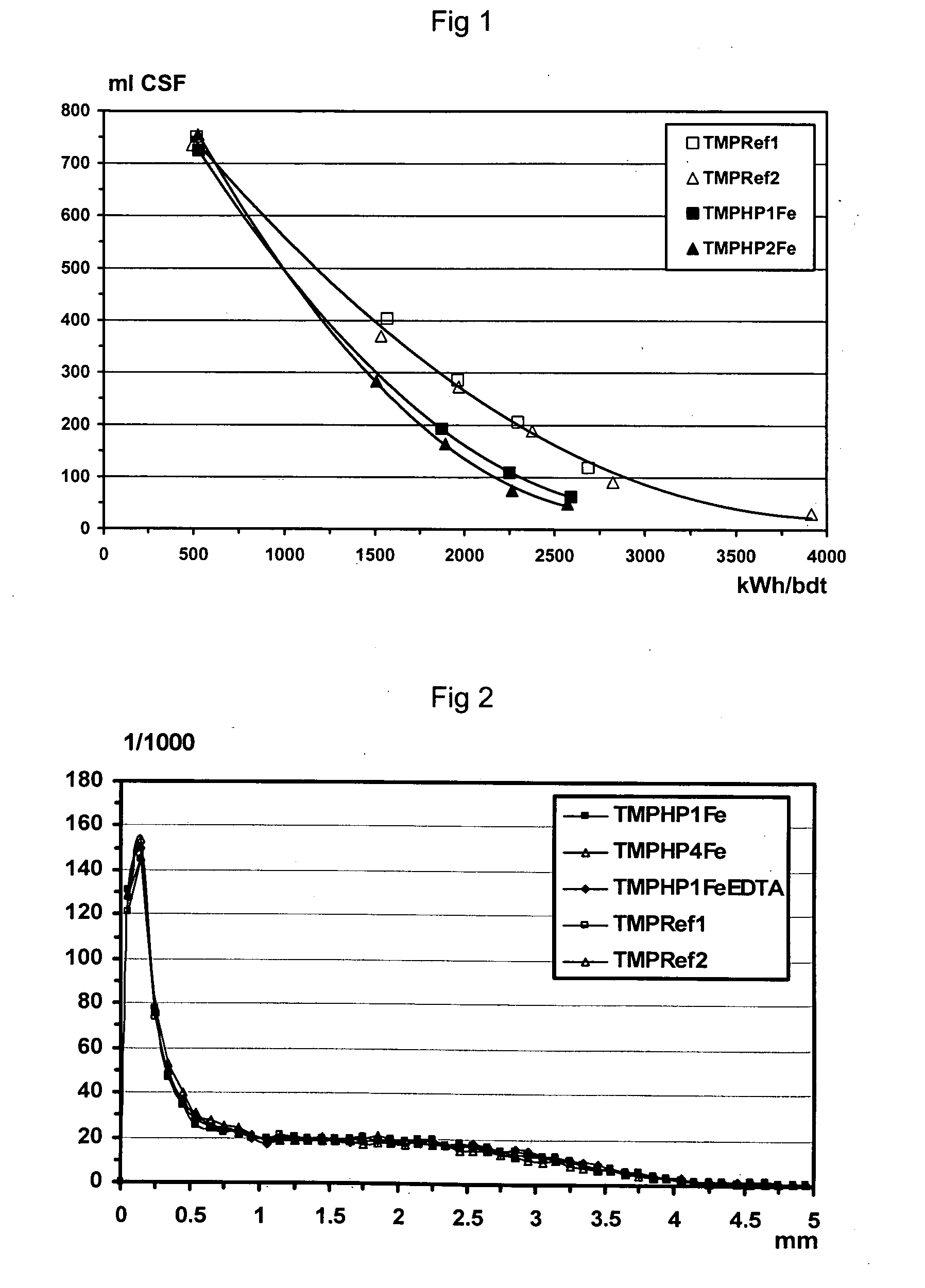

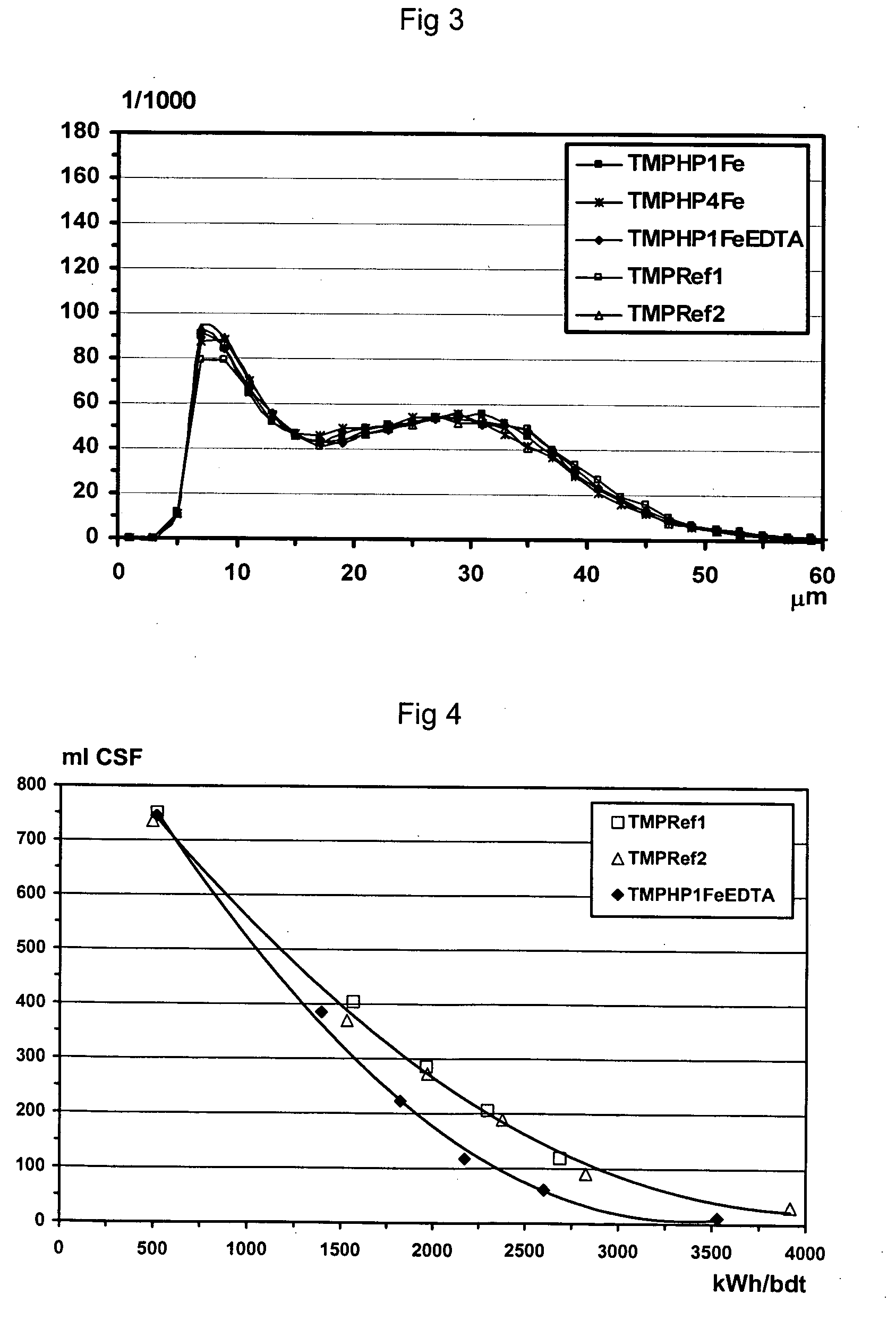

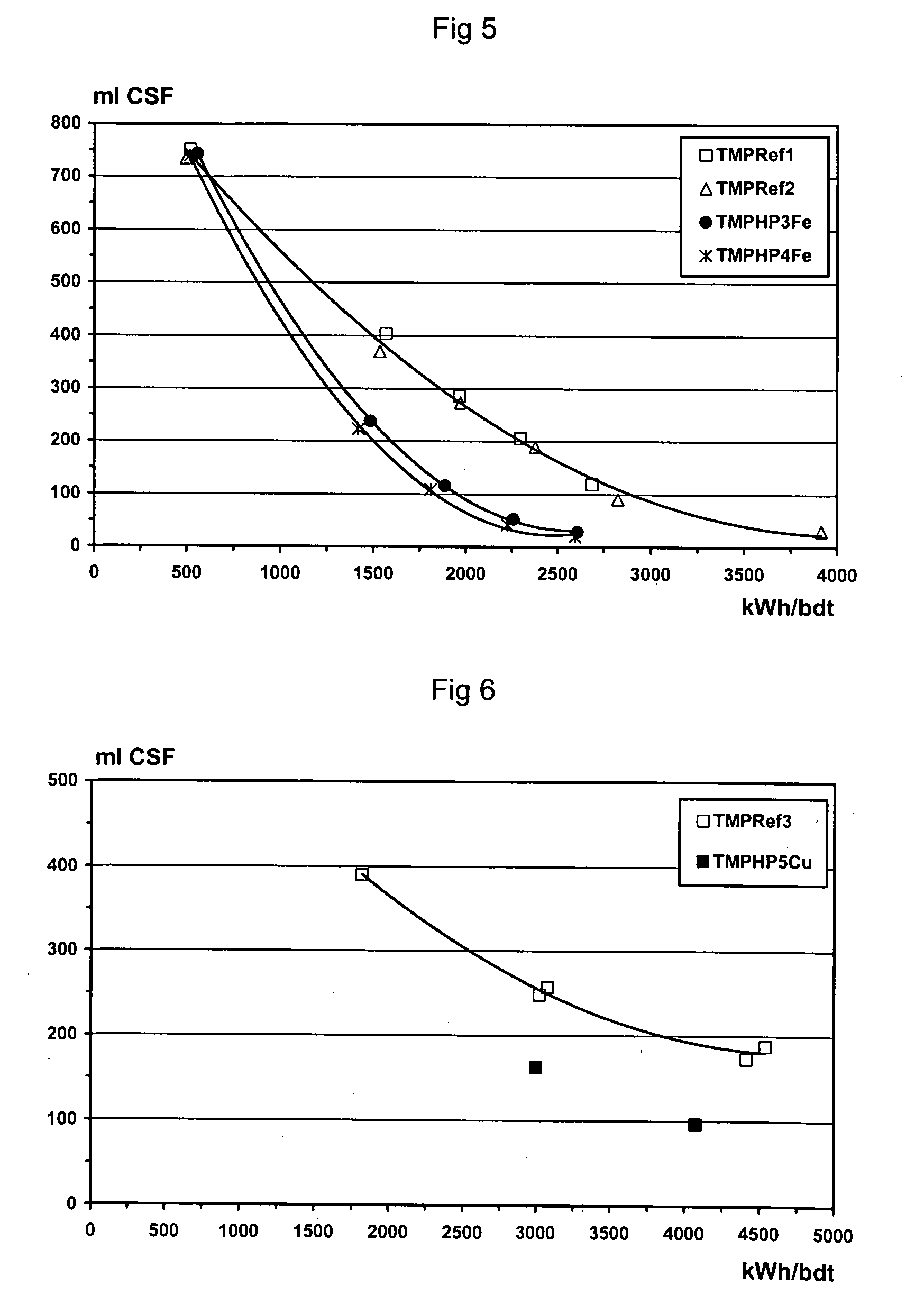

Process of producing high-yield pulp

The present invention relates to a process for preparing a high-yield pulp comprising a) treating a lignocellulose containing material chemically by means of an oxidising system comprising at least one non-enzymatic oxidant substantially free from ozone and chlorine dioxide and an activator at a pH from about 2 to about 6.5; and b) treating the lignocellulose containing material mechanically for a time sufficient to produce a high-yield pulp, wherein the lignocellulose containing material is chemically treated prior to and / or during any mechanical treatment stage, and wherein the lignocellulose containing material is not chemically treated at a pH from about 11.5 to about 14 between stages a) and b).

Owner:AKZO NOBEL CHEM INT BV

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

Process of producing xylose and dissolving pulp

ActiveUS20110192560A1High yieldReduce the amount requiredPretreatment with water/steamWashing/displacing pulp-treating liquorsChromatographic separationXylan

The present invention relates to a process for the production of xylose and dissolving pulp from xylan-containing biomass, such as hardwood. The invention is based on prehydrolysis of the xylan-containing biomass with SO2 in specified conditions, followed by chromatographic fractionation, nanofiltration or precipitation crystallization of the xylose-containing prehydrolyzate to obtain a xylose product having a xylose content of at least 55% on DS. The dissolving pulp obtained from the process can be used for example for the production of viscose.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Separation of Lignin From Hydrolyzate

ActiveUS20110165643A1Pulp liquor regenerationPulping with acid salts/anhydridesWater insolubleLignosulfonates

A method for the production water insoluble reactive lignin having low sulfur content and lignosulfonates from lignocellulosic material in a batch or continuous process. Lignocellulosic material is fractionated to produce water insoluble native lignin and lignosulfonates in various ratios, while preserving the cellulose and hydrolyzed hemicelluloses using water, ethanol and sulfur dioxide.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Process for producing pulp with a mixture of formic acid and acetic acid as cooking chemical

InactiveCN1170031CPulping with organic compoundsPulping with acid salts/anhydridesAcetic acidHemicellulose

The invention relates to a process based on formic acid cooking for producing pulp from herbaceous plants and deciduous trees by using acetic acid as an additional cooking chemical. The obtained pulp can be used in fine paper and board production as short-fibred material, for instance. The invention also relates to a process for adjusting the hemicellulose content of the pulp in connection with the formic acid cooking by using acetic acid as an additional cooking chemical.

Owner:CHEMPOLIS OY

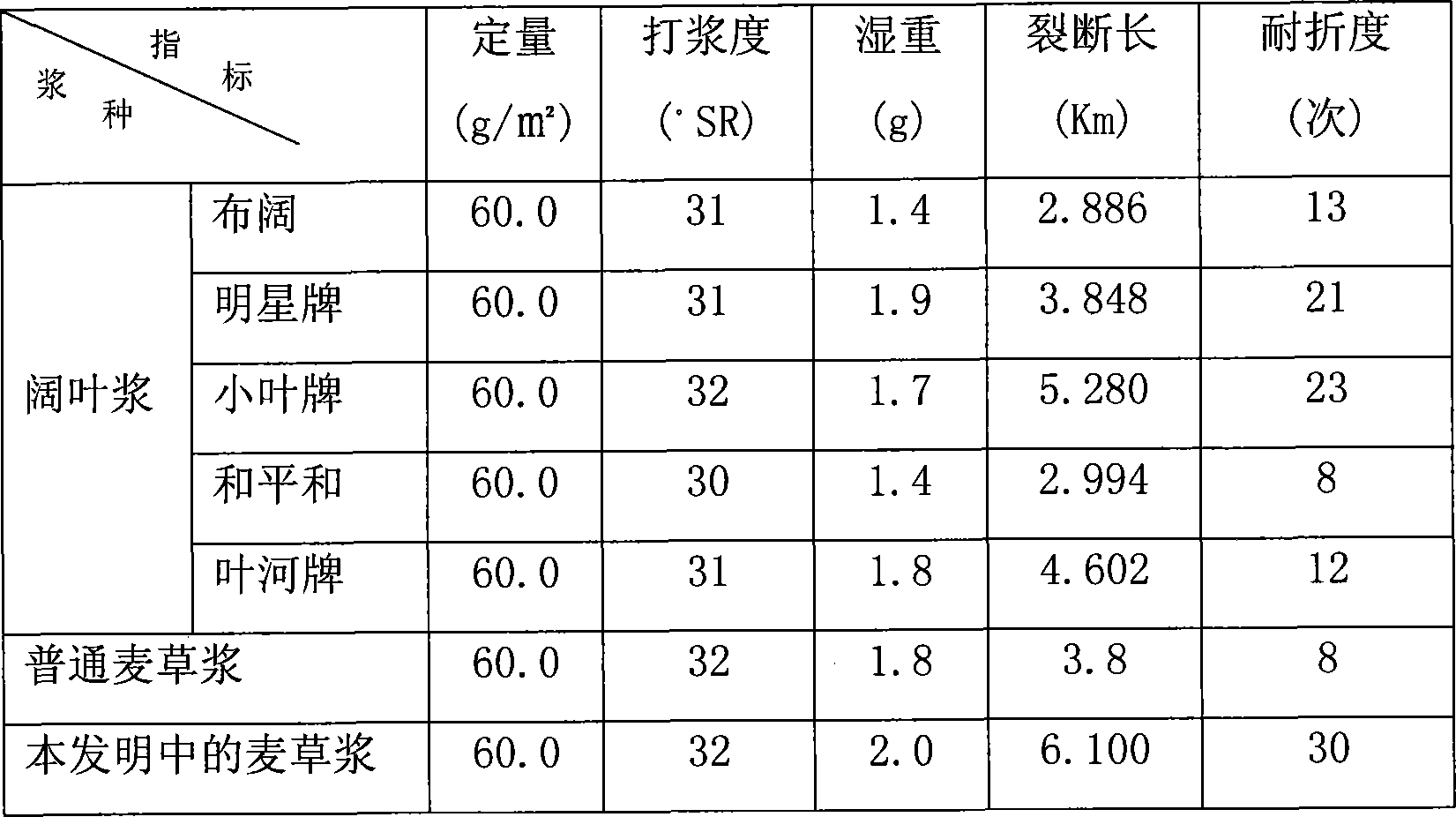

Prepared high hardness pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089290AReduce dosageReduce manufacturing costDigestersPulping with acid salts/anhydridesKappa numberHardness

The present invention discloses a method for preparing high-hardness pulp by using graminoid plant as raw material and its cooking process. The hardness of said high-hardness pulp is equal to Kappa number 24-50. The described cooking method includes the following steps: preparing graminoid plant raw material, soaking said raw material, feeding said raw material into a cooker, adding cooking liquor into said cooker, introducing steam to make heating operation to attain the requird pressure, then heat-insulating to the required time.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

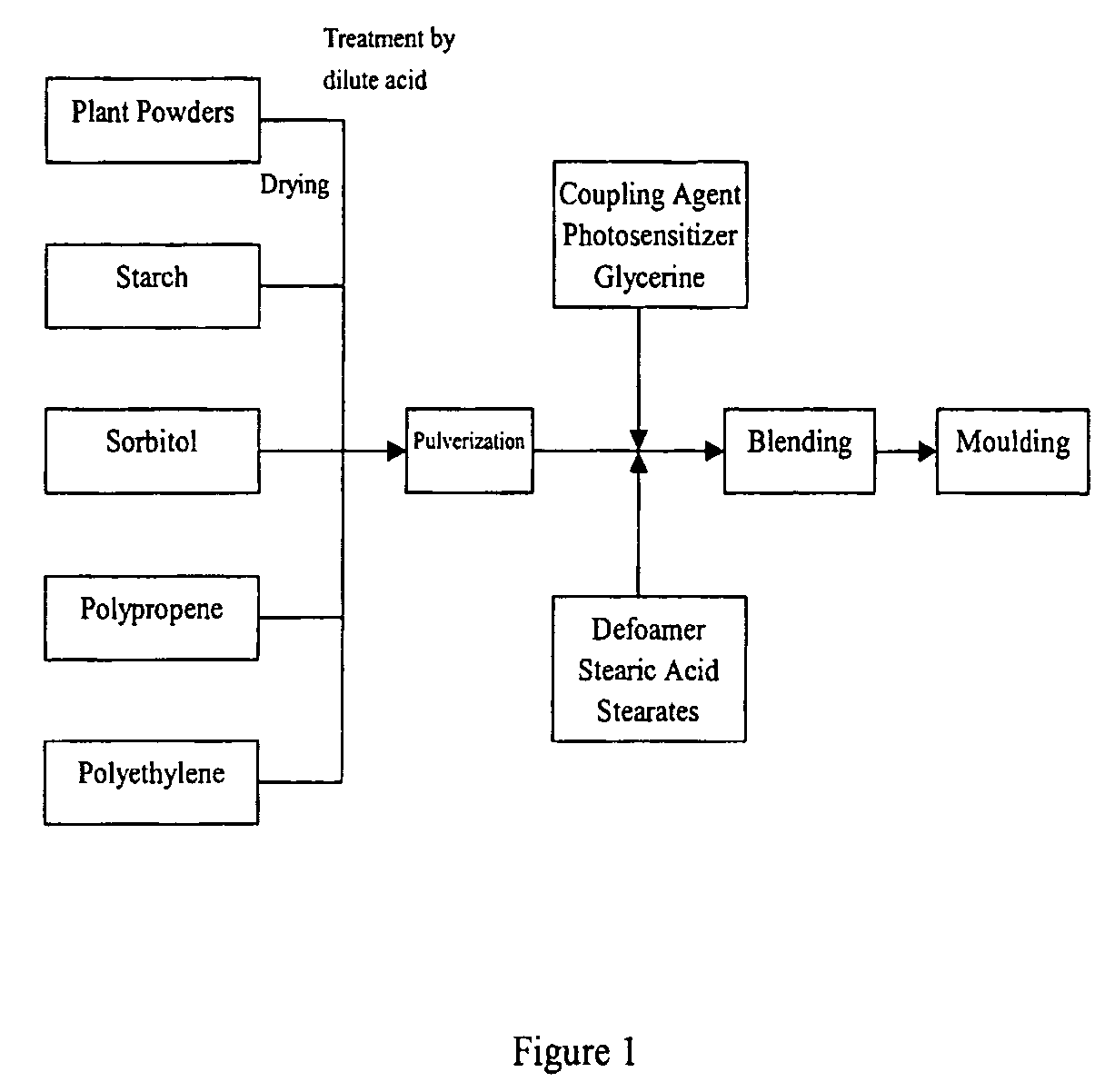

Biodegradable composition for the preparation of tableware, drink container, mulching film and package and method for preparing the same

The present invention relates to a biodegradable composition for the preparation of table-ware, mulching film and package, which comprises: 2-6% by weight of starch; 35-45% by weight of plant powders; 20-30% by weight of calcium carbonate; 2-7% by weight of sorbitol; 7-13% by weight of polypropylene; 2-5% by weight of polyethylene; 2-6% by weight of coupling agent; 1-2% by weight of defoamer; 2-5% by weight of stearic acid; 2-6% by weight of stearate; 3-6% by weight of glycerine or epoxidized soybean oil; and 60-100 ppm photosensitizer. The present invention also relates to a method for preparing the composition, which comprises: treating a plant waste with a diluent acid, drying and pulverizing, then mixing it with starch, polypropylene, and polyethylene, sorbitol, defoamer, coupling agent, stearic acid, stearate, glycerine and photosensitizer homogeneously; and blending the mixture obtained in a double-screw extruder at a temperature of 160-180° C. to obtain the composition of the present invention.

Owner:XU HAO

Prepared bleach chemical pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089291AReduce manufacturing costQuality improvementDigestersPulp de-wateringKappa numberFolding endurance

The present invention discloses a bleached chemical pulp prepared by using graminoid plant as raw material and its preparation method. Said invention is characterized by that it utilizes a high-hardness pulp which is obtained by using cooking process and whose permanganate number is 16-28 and equal to Kappa number 26-50 and makes said high-hardness pulp undergo the processes of pulp-washing and bleaching treatment so as to obtain the invented bleached chemical pulp whose breaking length is 4500-8000 m and folding endurance is 20-70 times.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

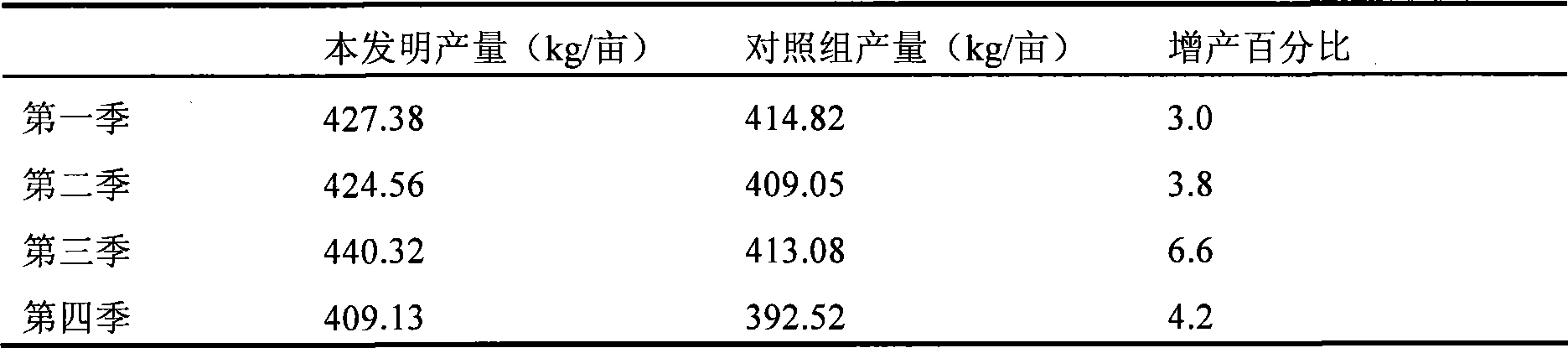

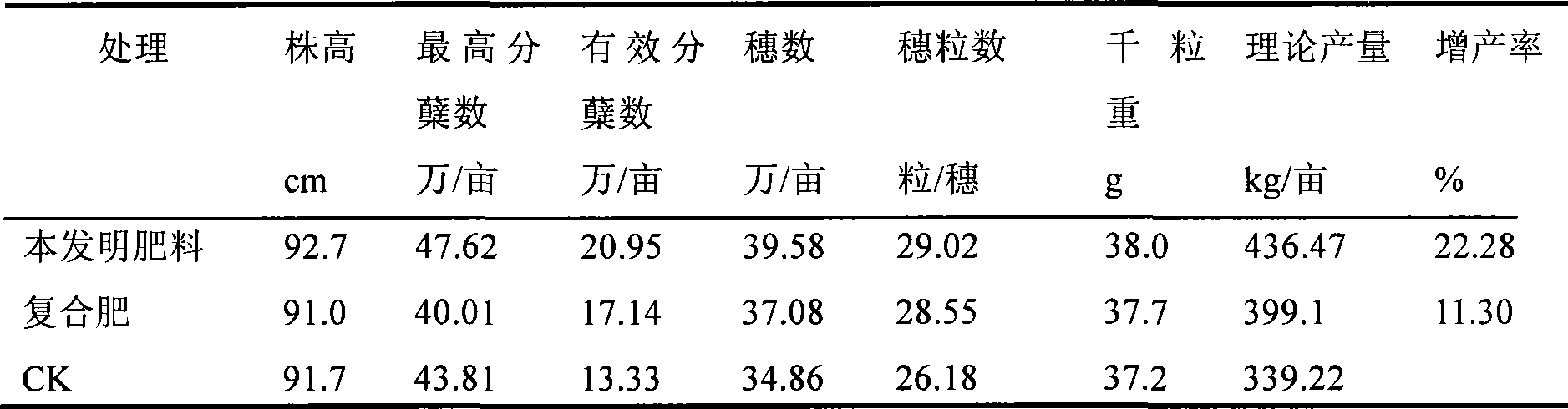

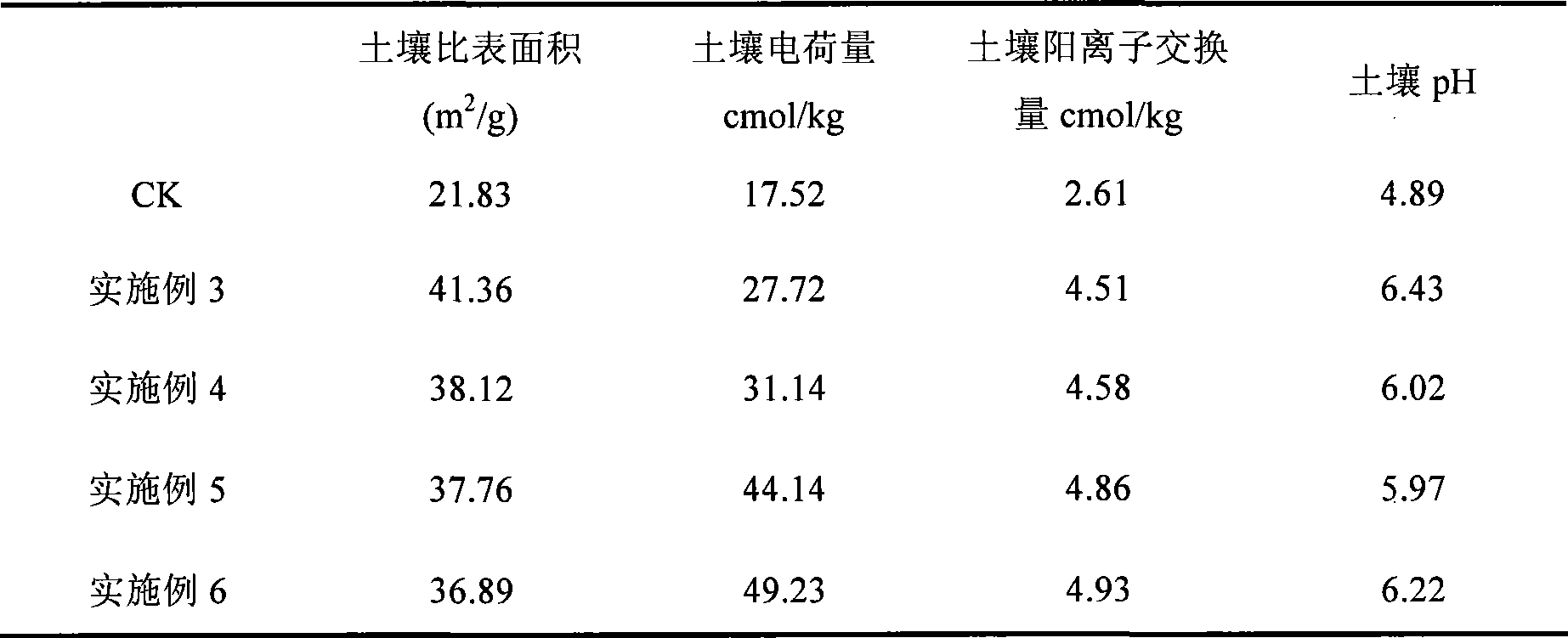

Method for comprehensive utilization of grass type stalk

ActiveCN101451315AHigh in Fulvic AcidSmall molecular weightPulp liquor regenerationDigestersCelluloseBlack liquor

The invention relates to a comprehensive utilization method for grass straws. Firstly, cellulose in the straws is utilized to pulp to serve as a raw material of paper pulp; during the pulping, lignin is dissolved in a stewing liquor to become a main constituent of a solid in a black liquor; the lignin is fully refined through the stewing and has easy degradation, and crops are easy to absorb, so the black liquor becomes a good organic fertilizer; at the same time, a fulvic acid with considerable quantity can be formed under conditions of high temperature and high pressure during the pulping, so the black liquor can be prepared into a high-quality fulvic acid fertilizer; the aim of comprehensive utilization of the grass straws is achieved through the steps, and the good economic benefit can be obtained thanks to the fact that the paper pulp and the fulvic acid fertilizer are expensive.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

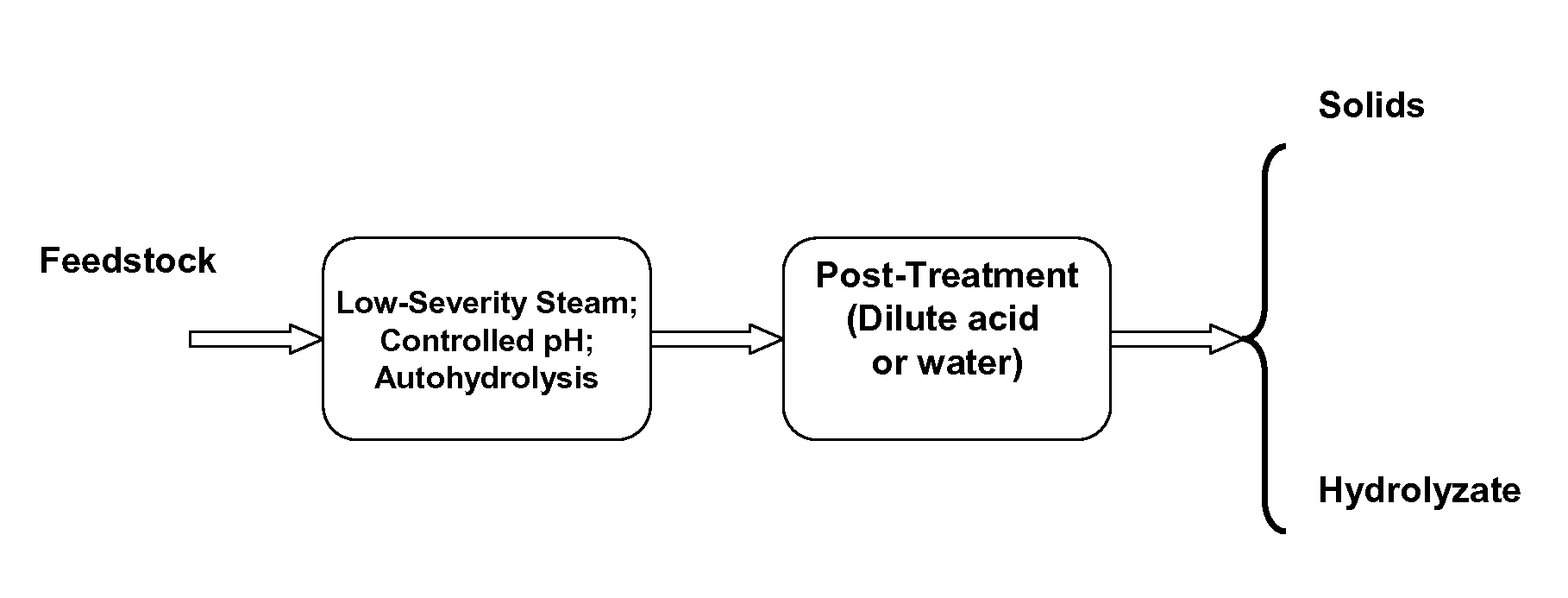

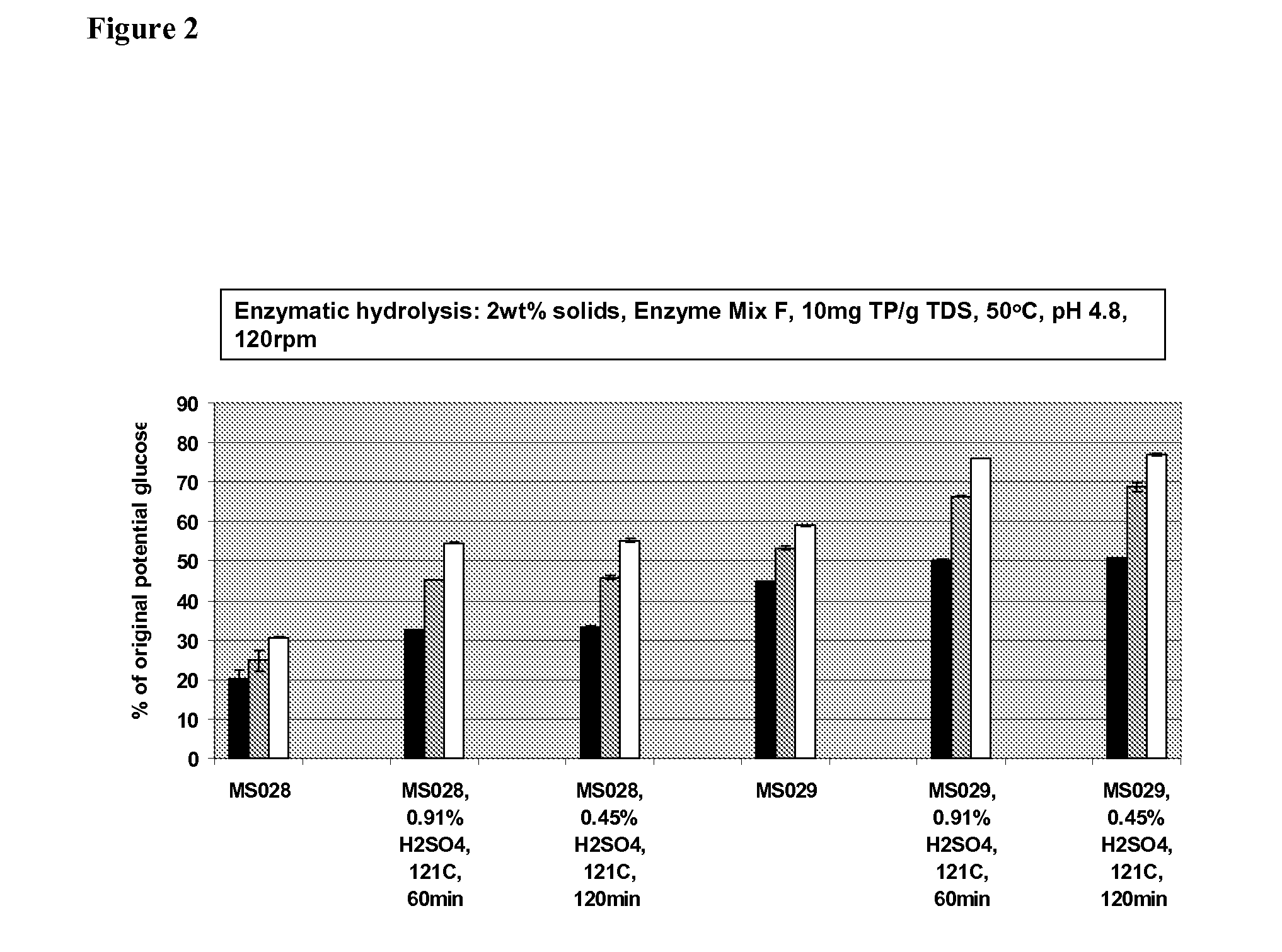

Two-Stage Process for Biomass Pretreatment

InactiveUS20110300586A1Increase rangeImprove digestibilityBiofuelsPulping with acid salts/anhydridesAcid hydrolysisLignocellulosic biomass

Described herein are improved methods of pretreating lignocellulosic biomass. One aspect of the invention relates to a two-stage pretreatment process comprising a relatively low severity steam treatment, a controlled pH pretreatment, or autohydrolysis, followed by hydrolysis with dilute acid or hot water at a relatively low temperature. In certain embodiments, the methods increase hemicellulose sugar yields, substrate digestibility, and suitability for fermentation as compared to steam explosion or acid hydrolysis alone. The two-stage pretreatment processes also employ few chemicals, minimizing the costs associated with pretreatment of lignocellulosic biomass. Moreover, the two-stage pretreatment process may expand the range of suitable feedstocks for bioethanol production.

Owner:MASCOMA CORPORATION

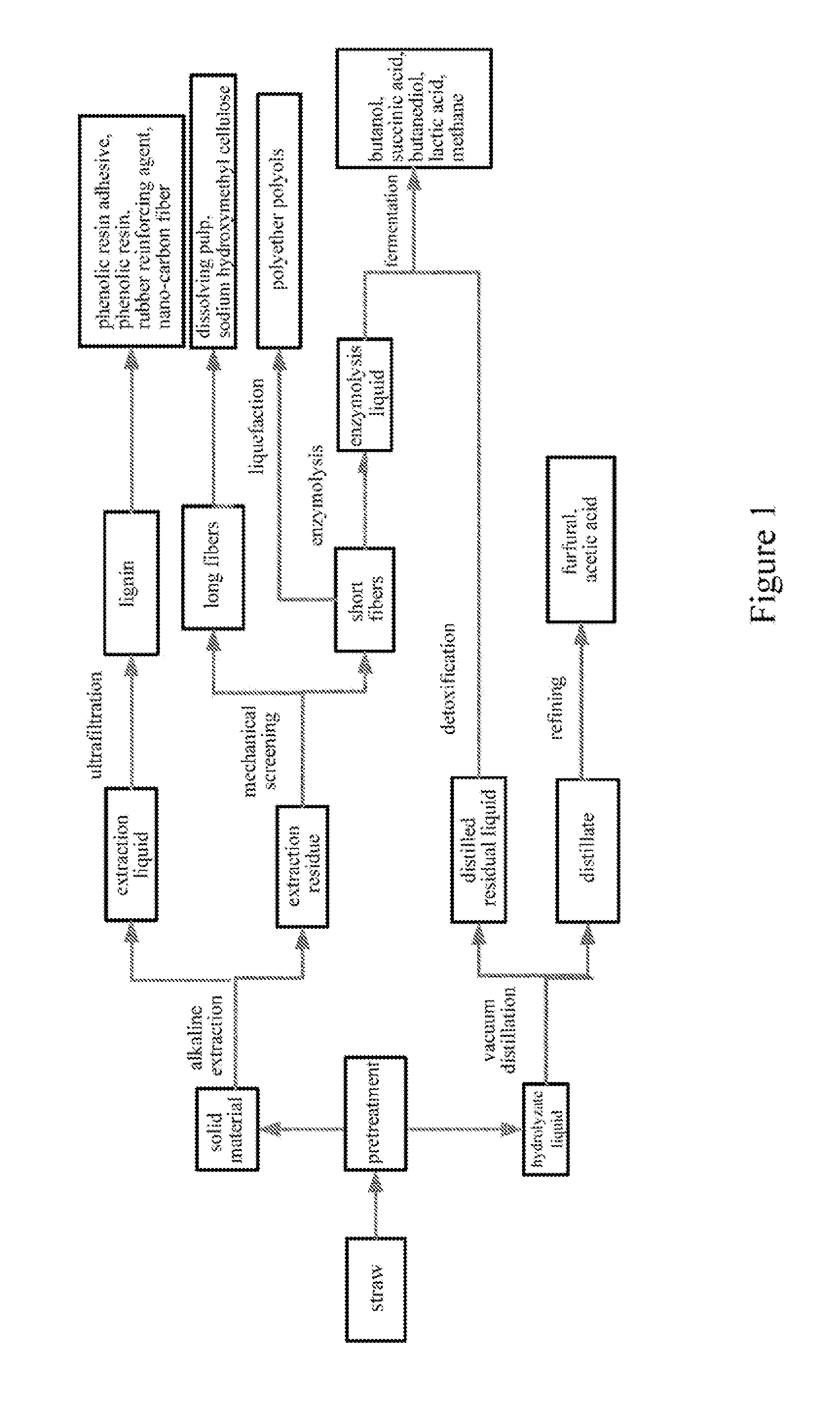

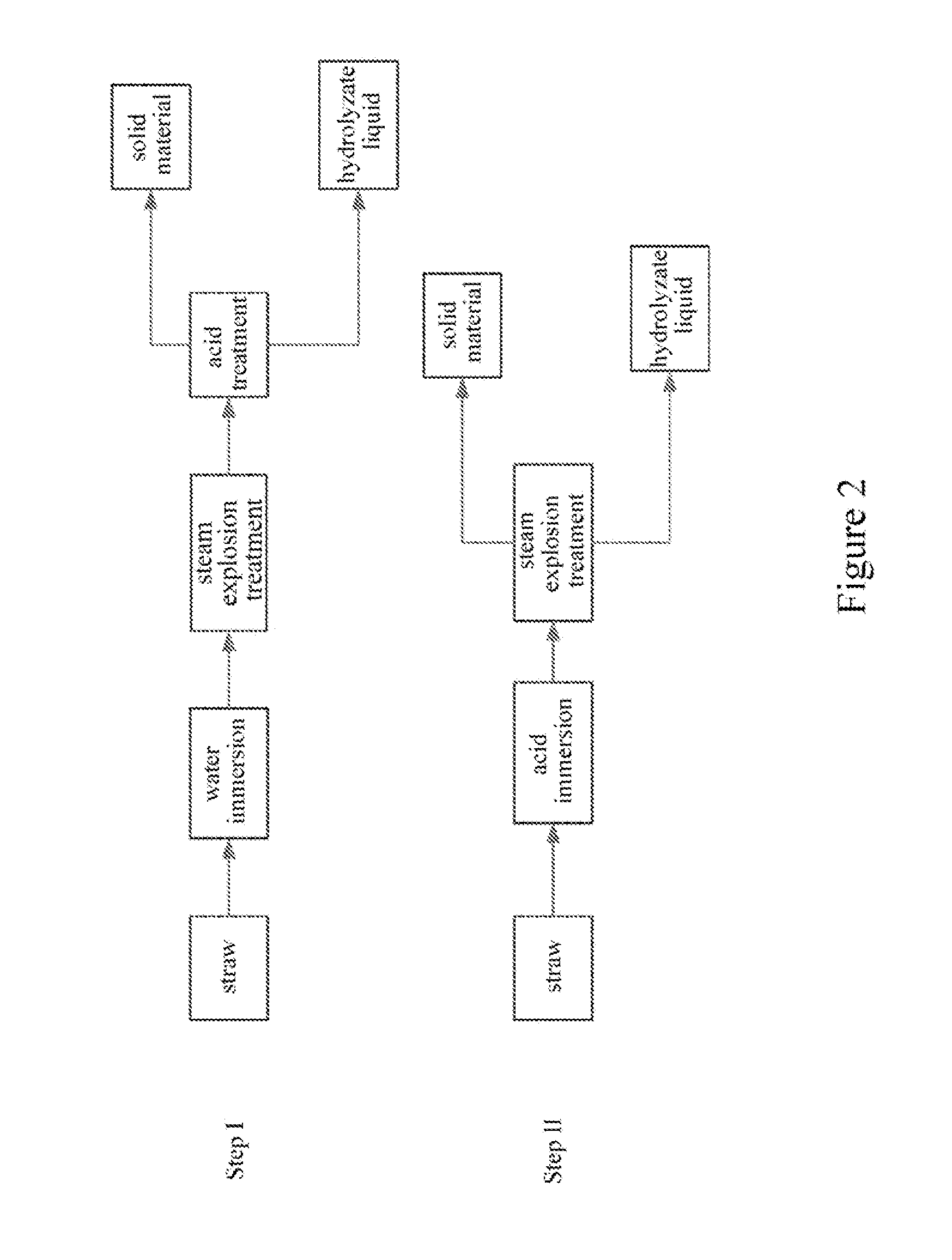

Process for producing bio-based product from straw hemicellulose and fully utilizing the components thereof

ActiveUS20130252293A1Low costHigh value utilizationPretreatment with water/steamBacteriaHigh concentrationSuccinic acid

Provided is a process for producing biomass-based product from straw hemicellulose and utilizing the components thereof thoroughly. Steam-explosion and acid-hydrolysis are combined in the pre-treatment of straw in the process, thus a higher concentration of a sugar liquid can be obtained, and furfural and acetic acid can be recovered. The hemicellulose obtained by the pre-treatment can be used directly as ferment materials for producing butanol, succinic acid, butylene glycol, lactic acid, hydrogen and firedamp, which reduces the cost of these biomass-based products. The cellulose and lignin obtained by extracting the straw with an alkaline solution can produce products, such as sodium hydroxymethyl cellulose etc. In the process, all components in the straw can be utilized thoroughly and waste and pollutant will not be produced.

Owner:HAINAN SUPER HEALTHY GRAIN CO

Method of producing a pulp from cellulosic material using formic acid and hydrogen peroxide

InactiveUS6183597B1Facilitate lignin breakdownIncrease brightnessPulp liquor regenerationPulping with organic compoundsCardboardCellulose

A process for producing a pulp from cellulose-containing material, wherein the material is reacted with formic acid as the solvent, and cooked at approximately the boiling temperature of the solvent, whereby return condensation is used. Annual plants, deciduous or coniferous wood can be used as the cellulose-containing material. In one variant of the process, the cellulose-containing material is only slightly warmed, whereby backflow cooling is used, and then a precisely predetermined quantity of hydrogen peroxide is slowly added to the liquid at a constant rate. This process variant can be repeated at a lower cooking temperature. The pulp thus obtained is preferably utilized in the production of cellulose, and in particular in the production of paper or cardboard. It is proposed that the lignin, which is isolated from the cellulose-containing material, have further applications, whereby such lignin is, after the pulp has been separated from the solvent, itself precipitated out in water. The lignin thus obtained can be used as a new building material, as a filler material or as an output substance to be used in the manufacture of aromatic products.

Owner:NATURAL PULPING

Method for preparing lignocellulosic nanofibrils

ActiveCN101691698AHigh yieldReduce forcePulping with acid salts/anhydridesPulping with inorganic basesAcetic acidFibril

The invention discloses a method for preparing lignocellulosic nanofibrils, which relates to a method for preparing nanofibrils. The method solves the problems that the traditional cellulose fiber manufactured by taking timber as a raw material has poor strengthening and toughening effects and cellulose fibrils obtained through the preparation have low yield. The method comprises the steps of: 1, extracting wood meal; 2, mixing raw materials and performing heating treatment on the mixture; 3, then adding glacial acetic acid and sodium chlorite into the mixture, and performing heating treatment after the mixing; 4, removing lignin; 5, removing hemicellulose; 6, re-removing the lignin; 7 re-removing the hemicellulose; and 8, performing ultrasonic crushing treatment to obtain the lignocellulosic nanofibrils. The yield of the manufacturing method is between 80 and 90 percent and is high; and the lignocellulosic nanofibrils prepared by the method have good strengthening and toughening effects.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for extruding black liquor from high-hardness plasm obtained by boiling grass plant raw material

ActiveCN101082189AAvoid damageImprove performanceNon-macromolecular organic additionPulp de-wateringBlack liquorHardness

The invention provides a method to remove black liquor by a presser from the high rigidity pulp prepared by cooling the grass materials. Send the cooked pulp which has the rigidity of potassium permanganate value 16-28 (equals to karber value 24-50) into the inlet of the presser for pressing. The pulp discharges from the outlet after removing the black liquor. The invention aims at pressing the low concentration and high rigidity pulp prepared by cooling the grass materials to remove the black liquor. It prepares for the necessary washing and bleaching steps during the processing, advances the bleaching effect and saves the necessary chemicals for bleaching, which is an economic and environmental protection method.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

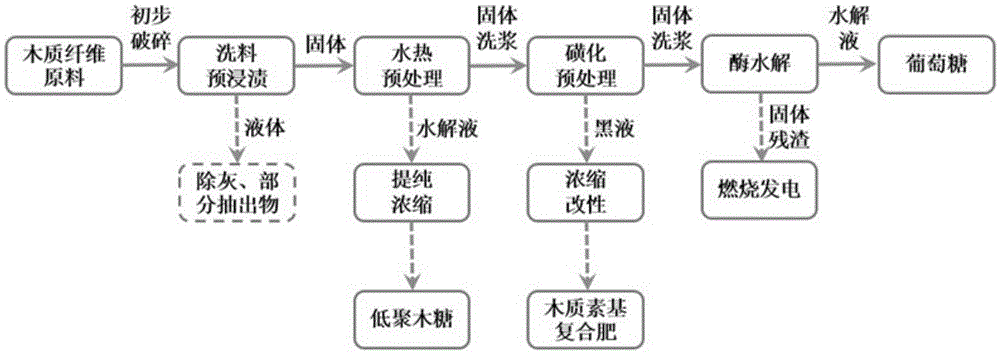

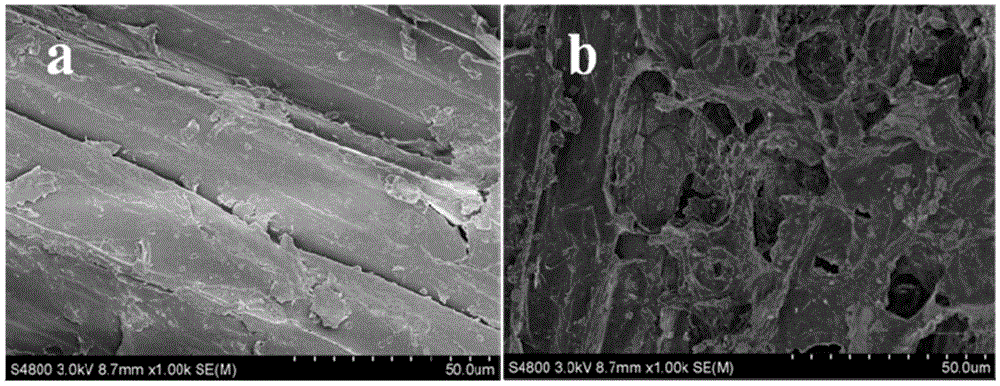

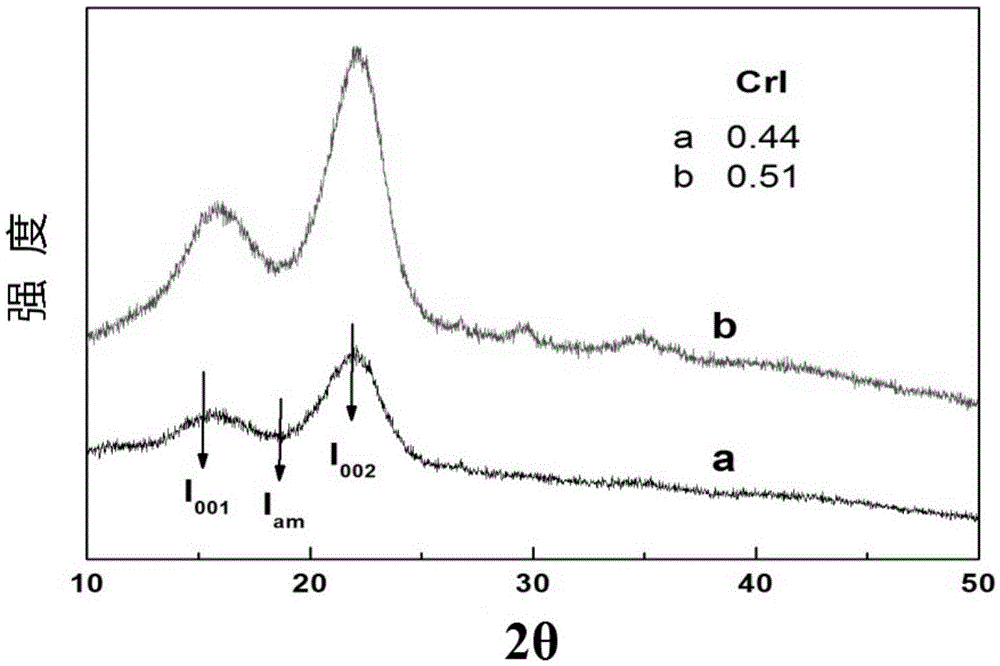

Method for pretreatment and separation of lignocellulose biomass

ActiveCN105625075AEfficient removalIncrease contentPretreatment with water/steamPulping with acid salts/anhydridesWater vaporCombined method

The invention provides a hydrothermal and sulfonating combined method for pretreatment and separation of lignocellulose biomass. The method comprises the steps of 1, mechanically crushing the lignocellulose biomass into a proper particle size, and then conducting preimpregnation; 2, mixing solid obtained from the step 1 with water or vapor for hydrothermal pretreatment; 3, mixing a hydrothermally pretreated and cleaned solid material obtained from the step 2 with sulfonating pretreatment liquor medicine for sulfonating pretreatment. According to the method, hydrothermal pretreatment and sulfonating pretreatment are combined, hemicelluloses can be effectively removed, lignin can be effectively removed, and then the content of substrate cellulose is increased remarkably and enzyme hydrolysis efficiency is improved greatly.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

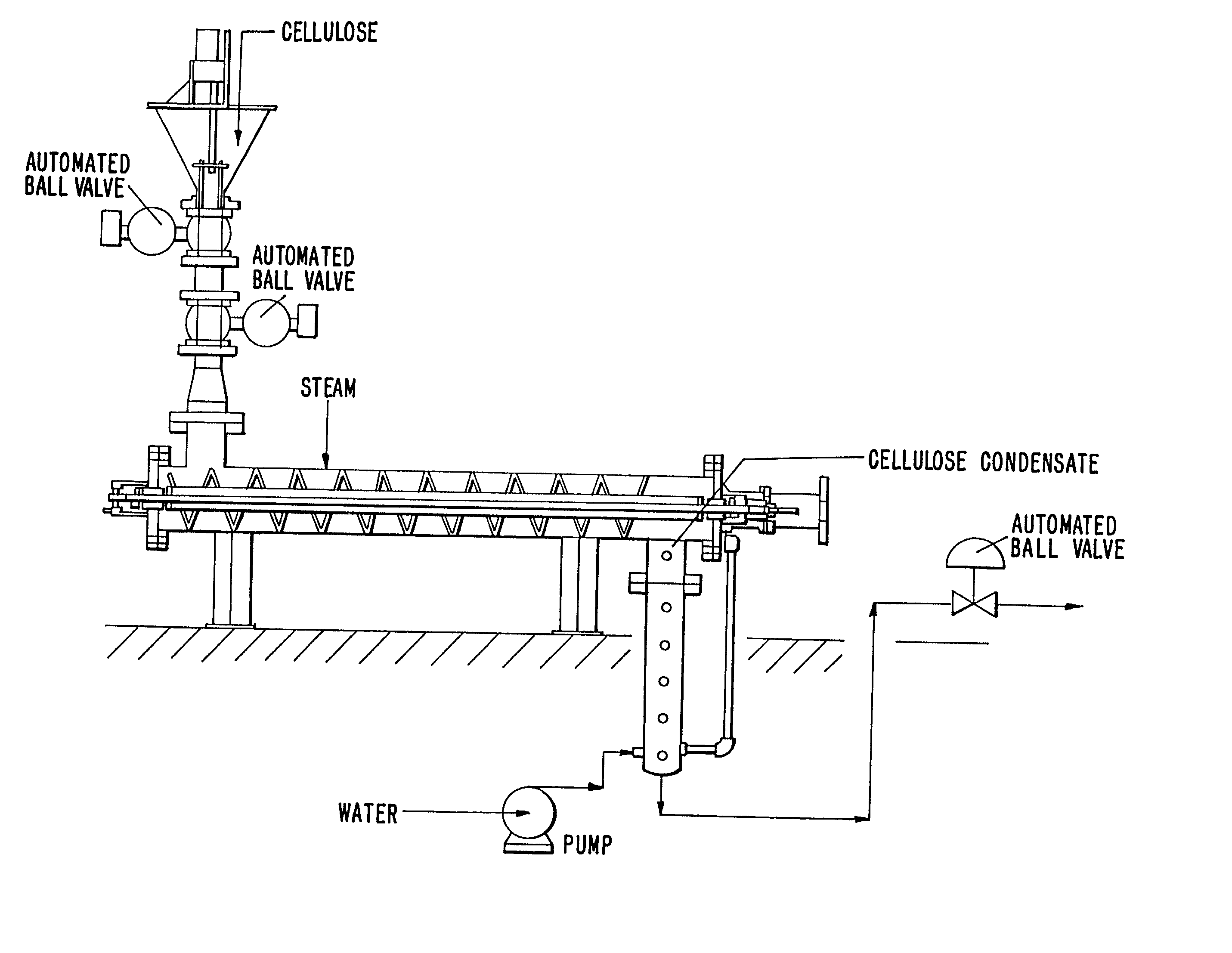

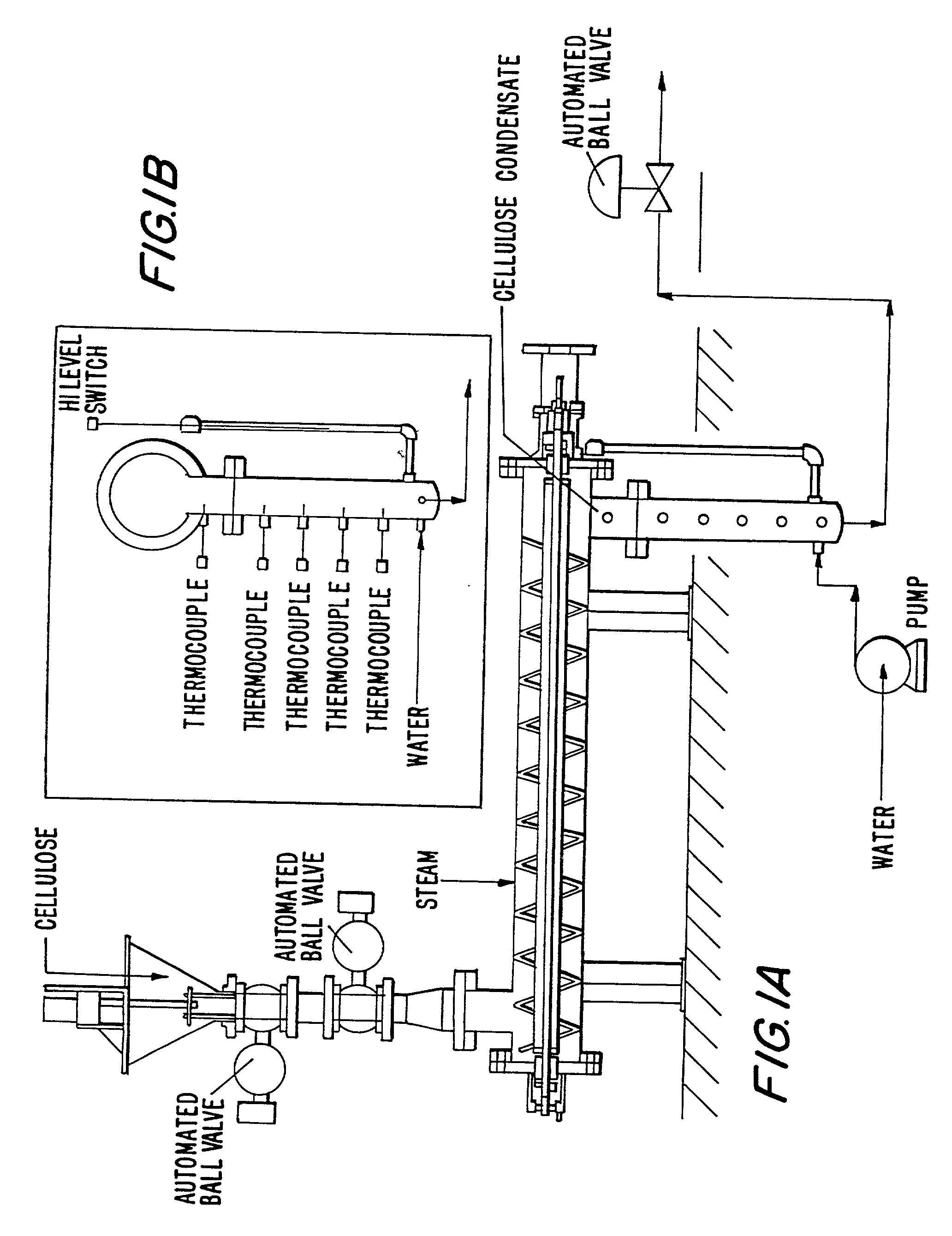

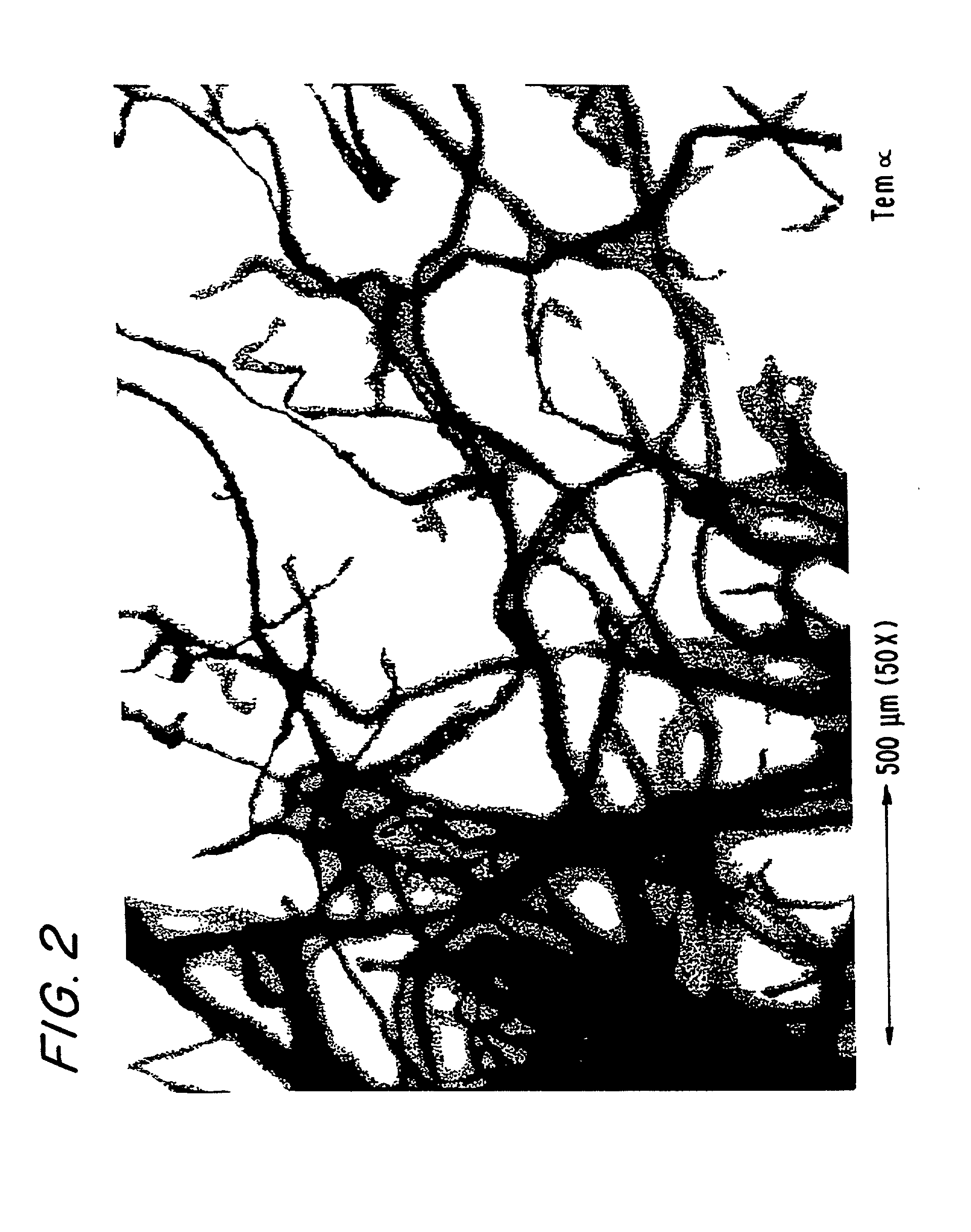

Process for producing microcrystalline cellulose

InactiveUS20030089465A1High yieldProduction is limitedPulp properties modificationSugar derivativesEngineeringPulp and paper industry

A process is provided for preparing a commercially acceptable pharmaceutical grade microcrystalline cellulose which comprises: a) repulping a pulp, the pulp having a composition, b) pressing the pulp obtained in a; c) decompacting of the pulp obtained in b; d) feeding the pulp obtained in c) into a pre-heated reactor; e) cooking the pulp in the reactor until the pulp obtains a desired degree of polymerization, said cooking being performed at a temperature, a time, and a pressure which is a function of the desired degree of polymerization and the composition of the pulp, the cooked pulp being hydrolyzed cellulose; f) partially depressurizing the reactor; g) injecting water into the reactor; h) discharging the hydrolyzed cellulose from the reactor, i) filtrating the hydrolyzed cellulose; j) deaggregating the hydrolyzed cellulose of step i; and k) drying the hydrolyzed cellulose to form microcrystalline cellulose.

Owner:PENWEST PHARMA CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com