Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Fine paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fine papers are printing and writing paper grades based mainly on chemical pulps. Normally the content of mechanical pulps are below 10% and the amount of fillers in the range 5–25%.

Process for producing pulp with a mixture of formic acid and acetic acid as cooking chemical

InactiveCN1170031CPulping with organic compoundsPulping with acid salts/anhydridesAcetic acidHemicellulose

The invention relates to a process based on formic acid cooking for producing pulp from herbaceous plants and deciduous trees by using acetic acid as an additional cooking chemical. The obtained pulp can be used in fine paper and board production as short-fibred material, for instance. The invention also relates to a process for adjusting the hemicellulose content of the pulp in connection with the formic acid cooking by using acetic acid as an additional cooking chemical.

Owner:CHEMPOLIS OY

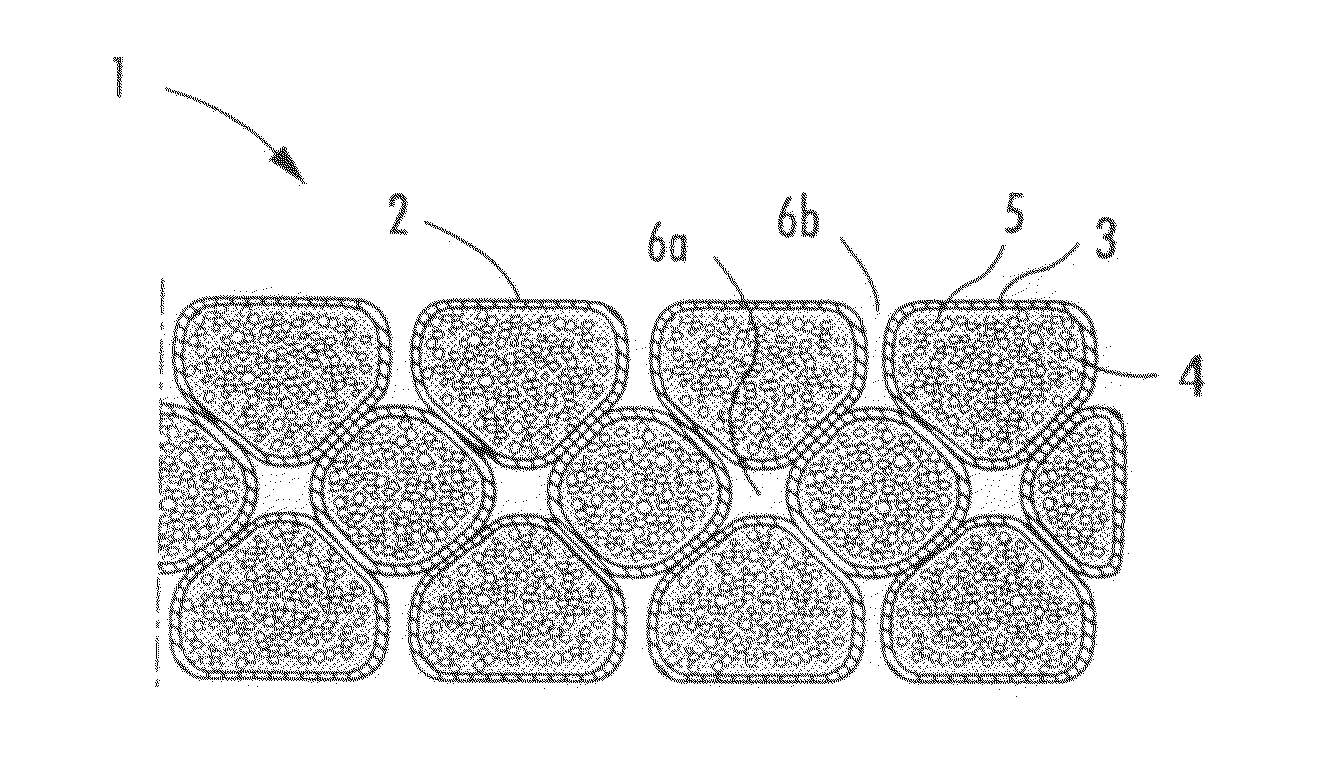

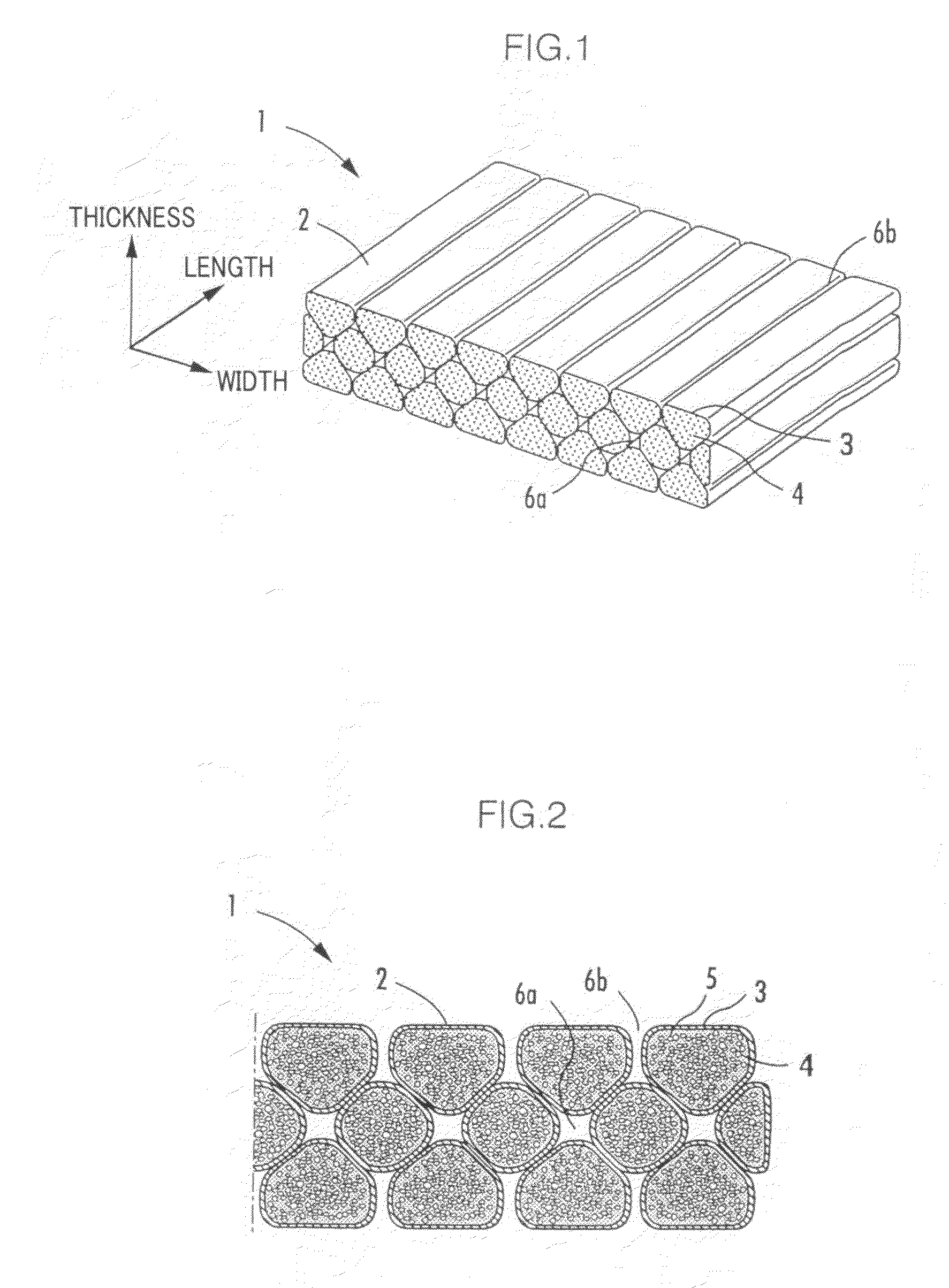

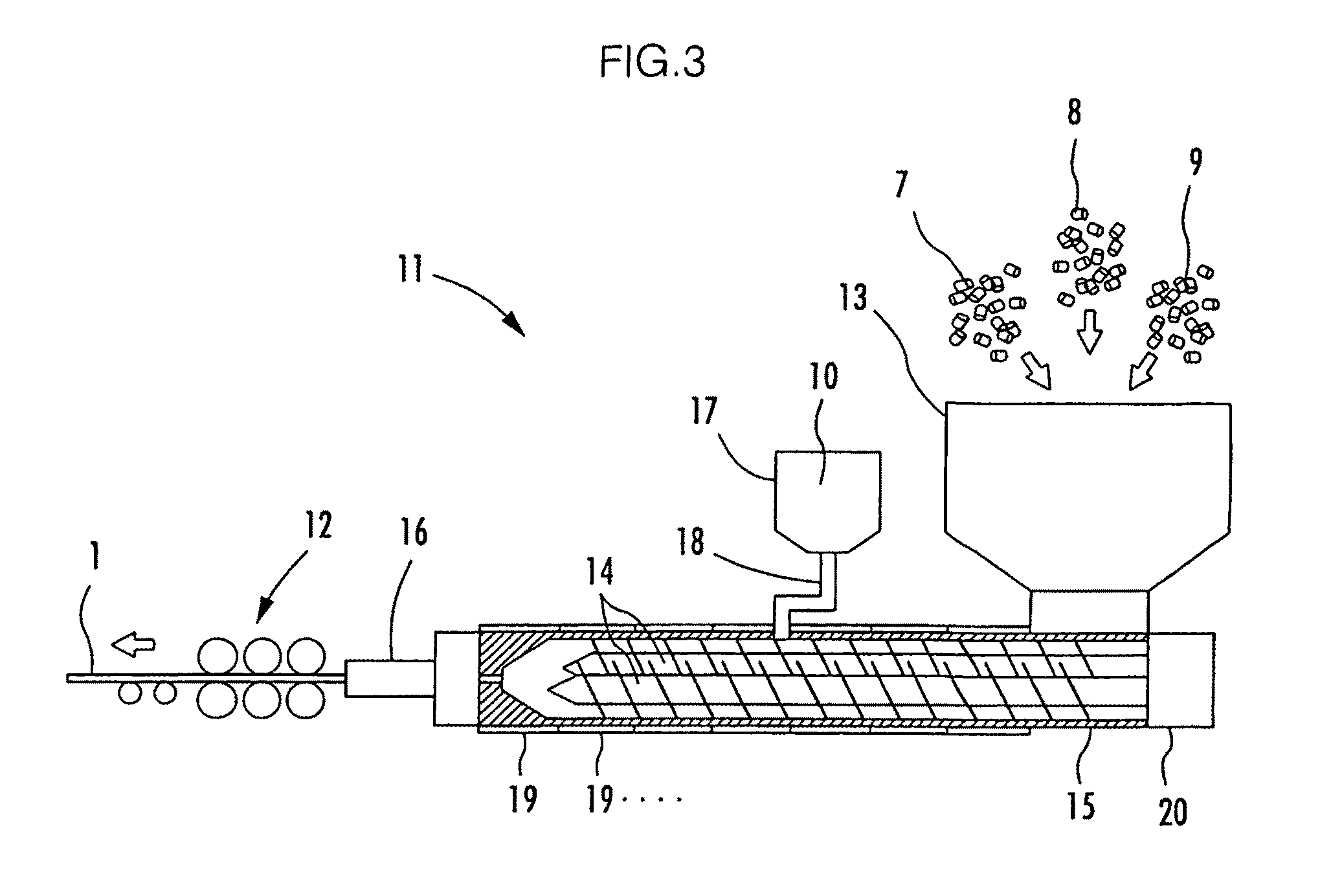

Foamed product and manufacturing method of the same

ActiveUS8227075B2Low calorific valueGenerates no smokeLaminationLamination apparatusThermal insulationPolystyrene

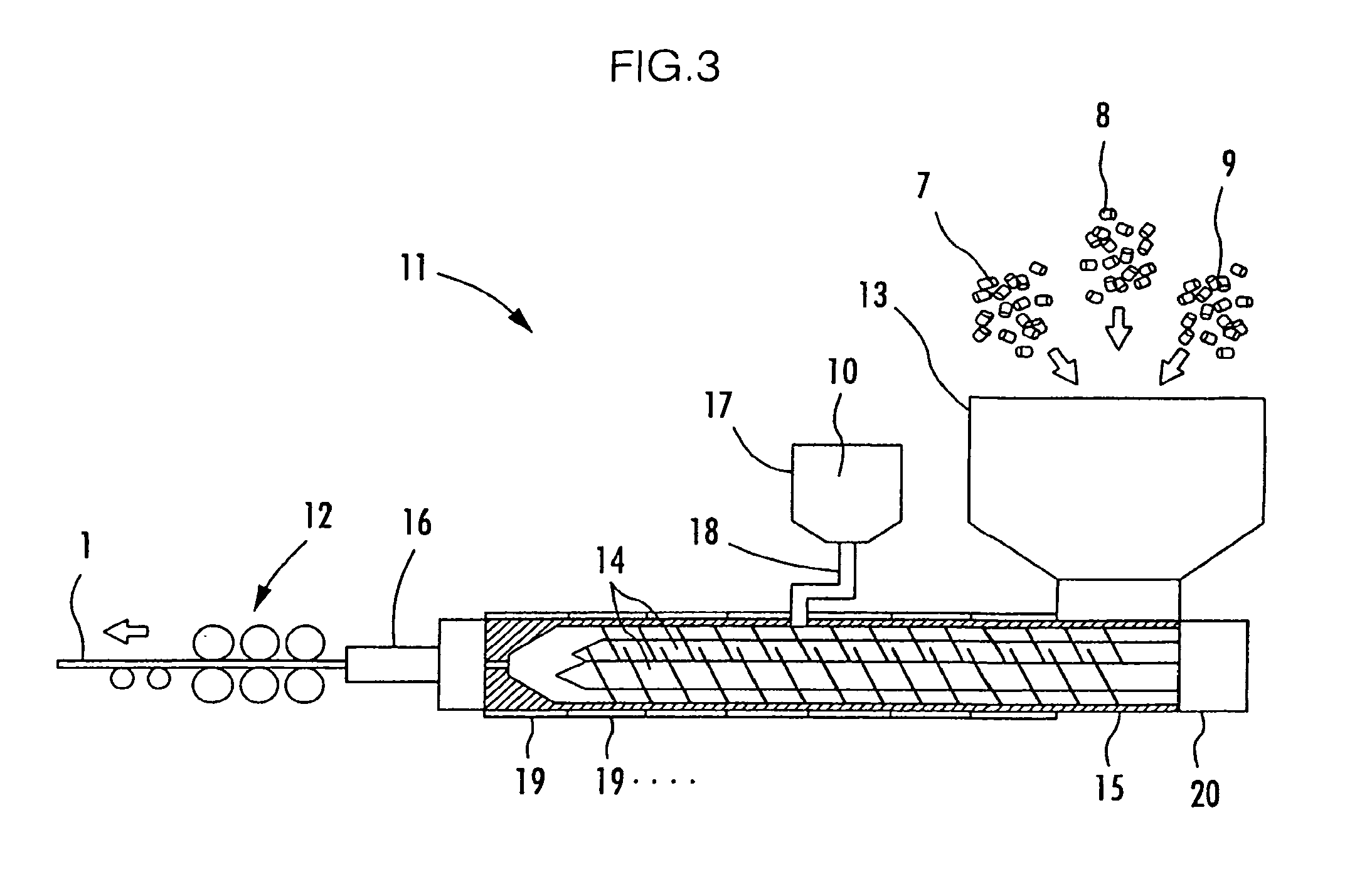

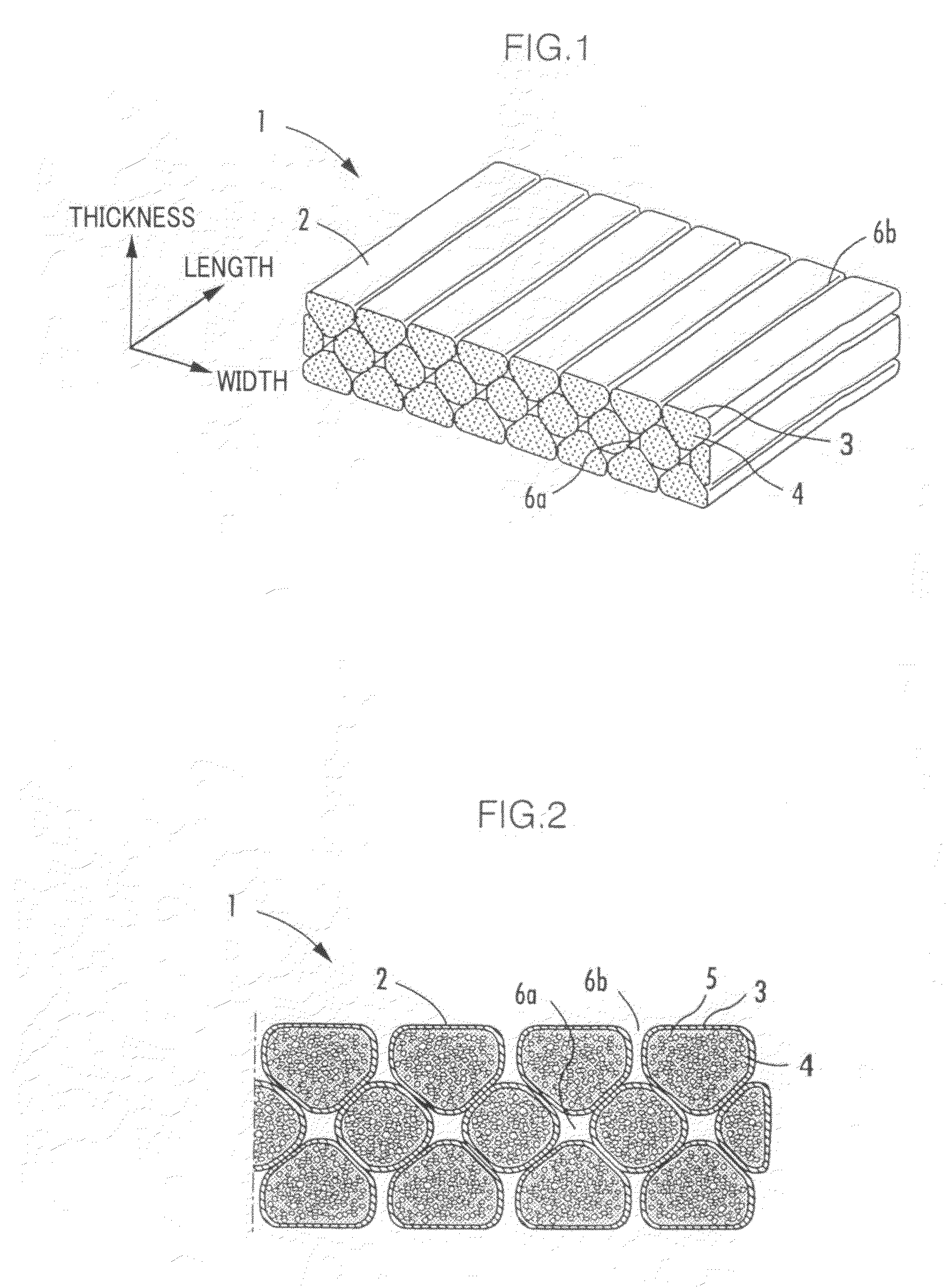

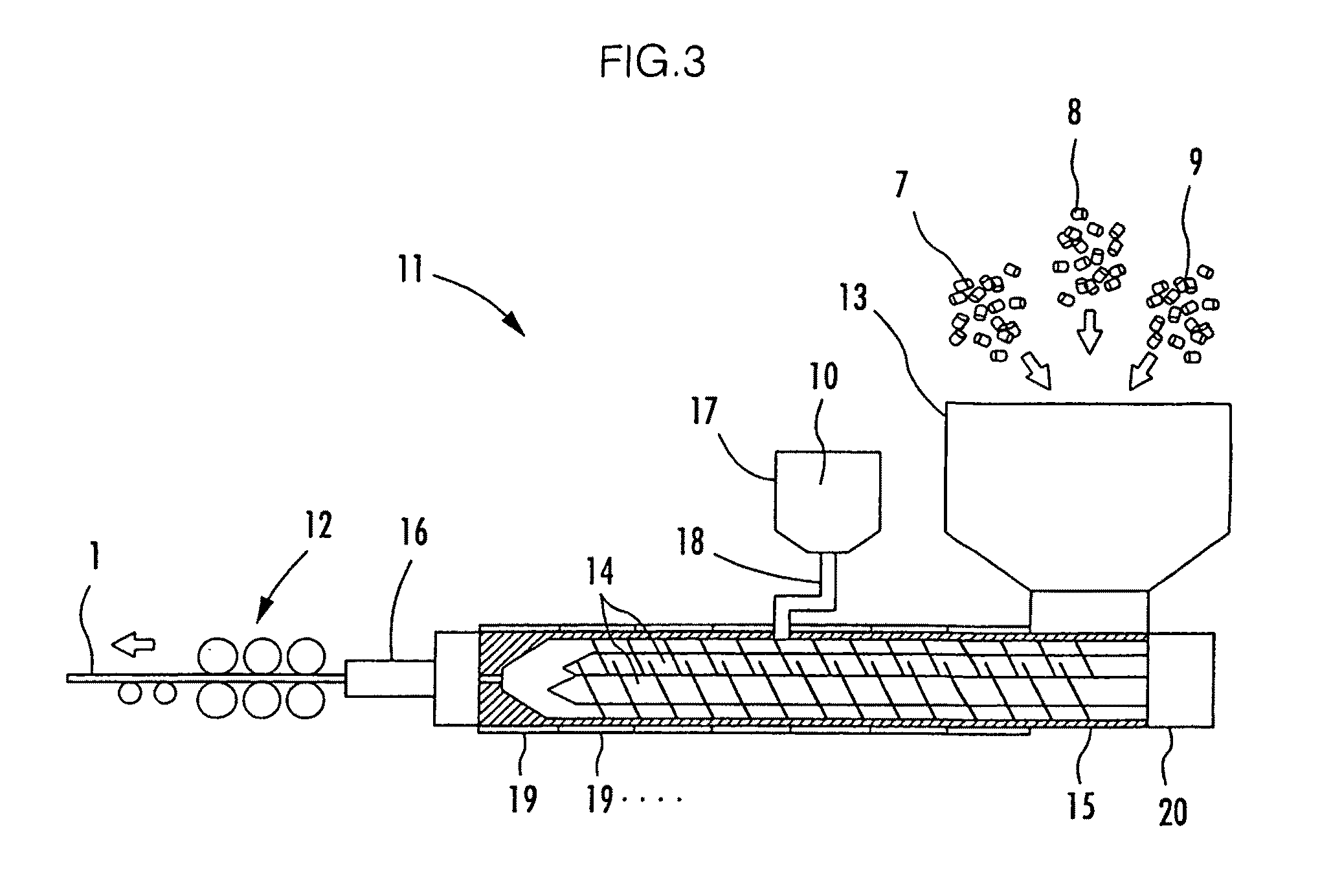

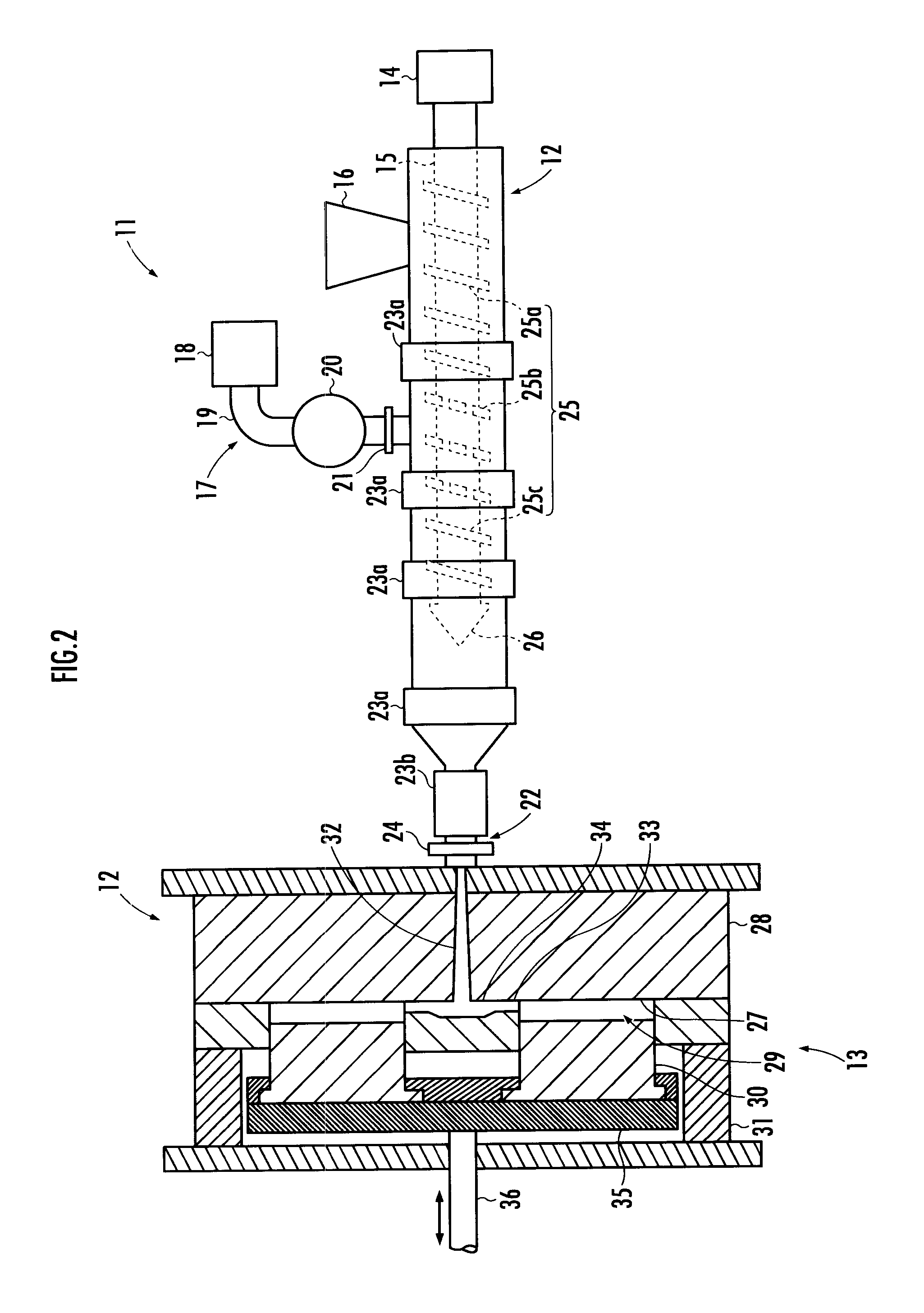

A foamed product that generates no smoke when incinerated, has a low calorific value, and achieves a desired dimension and thermal insulation performance is provided. A foamed product 1 is formed by heat-mixing, in an extruder 11, a paper pellet 7 that is a mixture of a fine paper powder having a particle diameter of 30 to 200 μm and starch, a container recycle pellet 8 that is a mixture of polypropylene, polyethylene, and polystyrene, foamable polypropylene 9, and water 10. A weight distribution is set so that the paper pellet 7 is 50 to 65% by weight, the container recycle pellet 8 is 15 to 25% by weight, the foamable polypropylene 9 is 10 to 30% by weight, and the water 10 is 10 to 20% by weight to these resins and other materials.

Owner:KANKYOKEIEISOGOKENKYUSHO CO INC

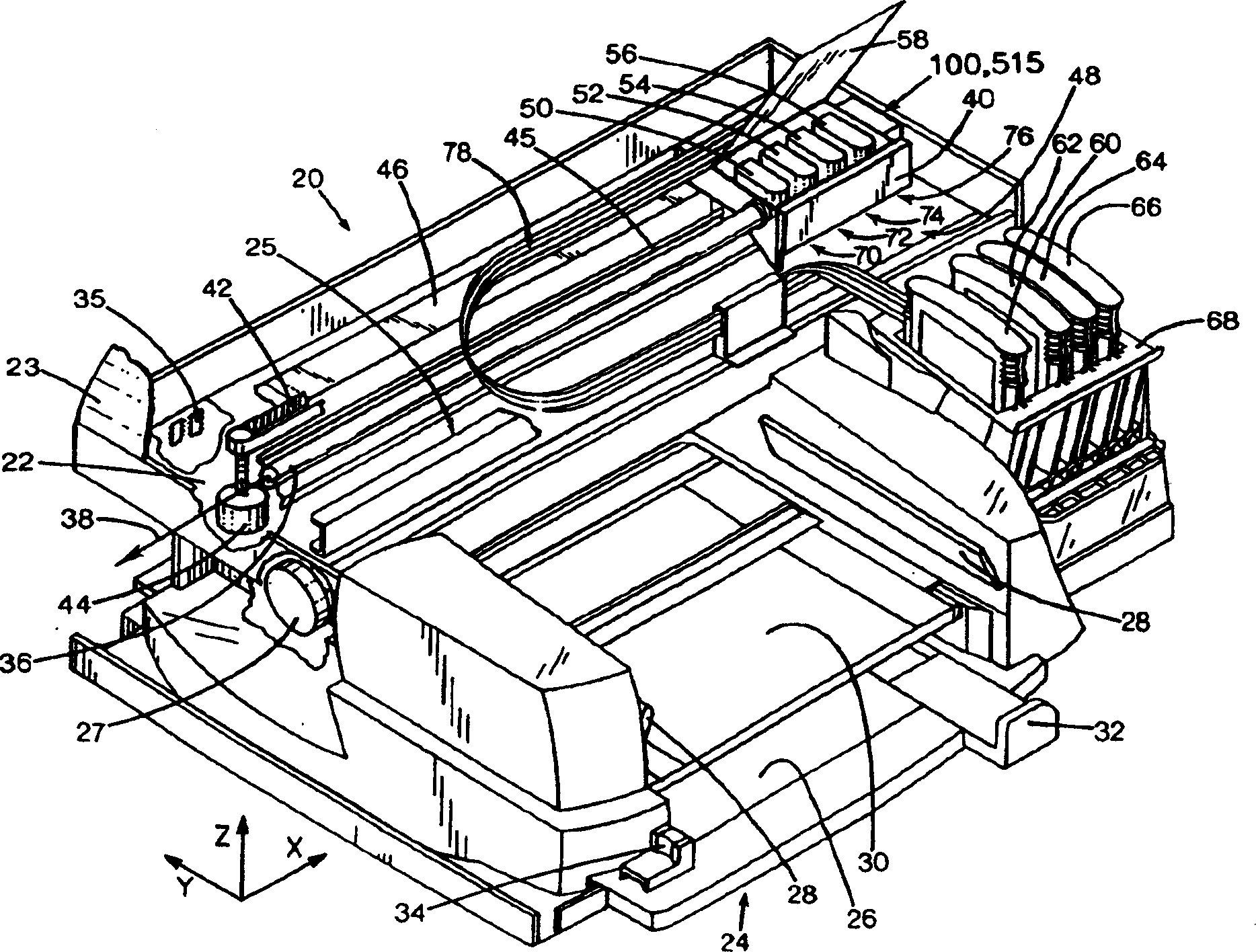

Advanced media determination system for ink jet printing

The present invention provides a system for classifying the type of input media entering an inkjet or other printing machine without requiring any special manufacturer markings to identify the media. The leading edge of the input media (170) is optically scanned with a violet light (520) to obtain diffuse reflectance (200) and specular reflectance (200') values. These reflectance values are Fourier transformed to produce a spatial frequency signal for the input medium. Compare this spatial frequency with known values for different media types, in terms of major categories such as transparencies, glossy photo media, fine paper, plain paper, and within these categories such as matte photo premium media and very glossy photo media and other specific media types to classify input media. Select the optimal print mode for a given media type, producing outstanding images without user intervention. A printing machine for implementing the method is also provided.

Owner:HEWLETT PACKARD CO

Manufacturing method of Pinfeng base paper

ActiveCN105586802AEasy to shapeImprove uniformityCoated paper substrateNon-macromolecular organic additionLogistics managementSlurry

The invention discloses a manufacturing method of Pinfeng base paper. The method comprises the following processing steps: pulping and preparing softwood pulp and hardwood pulp respectively; adding auxiliary materials; making wet paper sheets; carrying out pre-drying and surface sizing treatment; and carrying out post-drying, calendaring and finishing. Through research on slurry selection, slurry proportioning, a beating technology, a functional chemical additive added to the slurry and a digital printing assistant, measures of calendaring and the like are carried out by film-transfer surface sizing treatment by soft calendaring equipment; and the qualified Pinfeng base paper is manufactured by referring to related paper machine parameters. Compared with ordinary logistics label middle paper, the Pinfeng base paper has the advantages of low gram weight, high tensile strength, good internal bonding strength, high smoothness, low hygroscopic property, good surface strength, good digital printing effect, fine paper surface and good hand feeling, and is capable of completely replacing the ordinary logistics label middle paper and reducing the production cost for customers.

Owner:YUEYANG FOREST & PAPER CO LTD

Twisted paper yarn and the fabric therewith

The present invention is twisted paper yarn produced through twisting fine paper tape with yarn silk, hemp fiber or cotton fiber. The present invention also discloses fabric of the said twisted paper yarn and other fiber yarn. The paper is Chinese Xuanzhou paper, Korean paper or Japanese paper. The fabric with the twisted paper yarn is light, thin, easy to dye, permeable, easy to water, easy to dry and environment friendly, and may be used in fashionable dress, common clothing, towel, etc.

Owner:金承华

Foamed Product and Manufacturing Method of the Same

ActiveUS20110244223A1Improve insulation effectLow calorific valueLaminationLamination apparatusAmyrisThermal insulation

A foamed product that generates no smoke when incinerated, has a low calorific value, and achieves a desired dimension and thermal insulation performance is provided. A foamed product 1 is formed by heat-mixing, in an extruder 11, a paper pellet 7 that is a mixture of a fine paper powder having a particle diameter of 30 to 200 μm and starch, a container recycle pellet 8 that is a mixture of polypropylene, polyethylene, and polystyrene, foamable polypropylene 9, and water 10. A weight distribution is set so that the paper pellet 7 is 50 to 65% by weight, the container recycle pellet 8 is 13 to 25% by weight, the foamable polypropylene 9 is 10 to 30% by weight, and the water 10 is 10 to 20% by weight to these resins and other materials.

Owner:KANKYOKEIEISOGOKENKYUSHO CO INC

Latex-treated filler slurries for use in papermaking

InactiveUS20080302496A1High retention rateTrend downPigmenting treatmentNatural cellulose pulp/paperPapermakingPaperboard

A continuous filler treatment process has been developed to enhance the fixation of anionic latex on filler in a short time. In this process anionic polymer dispersions (latex) are added to common papermaking filler slurries at ambient temperature and then mixed with water of temperature higher than the glass transition temperature (Tg) of the latex used. To efficiently fix the latex the temperature of the filler / latex mixture must be 30-60° C. higher than the Tg of the latex used. The chemical composition of the resin and the type of surfactant used during the emulsion polymerisation process of the polymer latex dispersions are important factors for efficiently fixing the latex onto the filler by adding hot water and improving the properties of paper made with the treated filler. The enhanced fixation of anionic latex onto filler using hot water is done in mixing vessels that can control shear and mixing time. The anionic latexes applied by this process are totally and irreversibly fixed or bound onto the filler particles and the aggregated filler slurry is stable over time. The latex-treated filler slurry can be added to papermaking furnishes at any point prior to the headbox of the paper machine or stored for later use. It can be added to wood-free or wood-containing furnishes commonly used for making fine papers, mechanical pulp papers, and multi-ply paperboards. The latex-treated filler slurry improves filler retention, only slightly reduces sheet strength and improves sizing performance. Furthermore, latex-treated calcium carbonate filler, such as precipitated calcium carbonate (PCC), is more acid-resistant and, when used in manufacturing mechanical pulp paper under neutral conditions, less acid is needed to control the pH.

Owner:FPINNOVATIONS INC

Foamed product and manufacturing method of the same

ActiveUS20110244217A1Improve insulation effectLow calorific valueLaminationLamination apparatusAmyrisThermal insulation

A foamed product that generates no smoke when incinerated, has a low calorific value, and achieves a desired dimension and thermal insulation performance is provided. A foamed product 1 is formed by heat-mixing, in an extruder 11, a paper pellet 7 that is a mixture of a fine paper powder having a particle diameter of 30 to 200 μm and starch, a container recycle pellet 8 that is a mixture of polypropylene, polyethylene, and polystyrene, foamable polypropylene 9, and water 10. A weight distribution is set so that the paper pellet 7 is 50 to 65% by weight, the container recycle pellet 8 is 15 to 25% by weight, the foamable polypropylene 9 is 10 to 30% by weight, and the water 10 is 10 to 20% by weight to these resins and other materials.

Owner:KANKYOKEIEISOGOKENKYUSHO CO INC

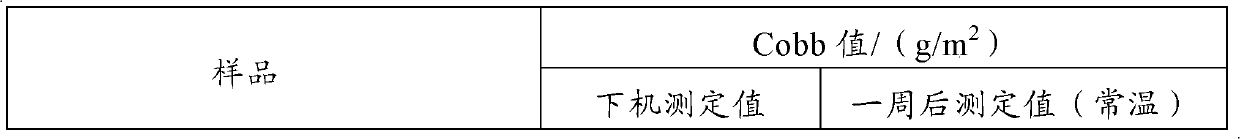

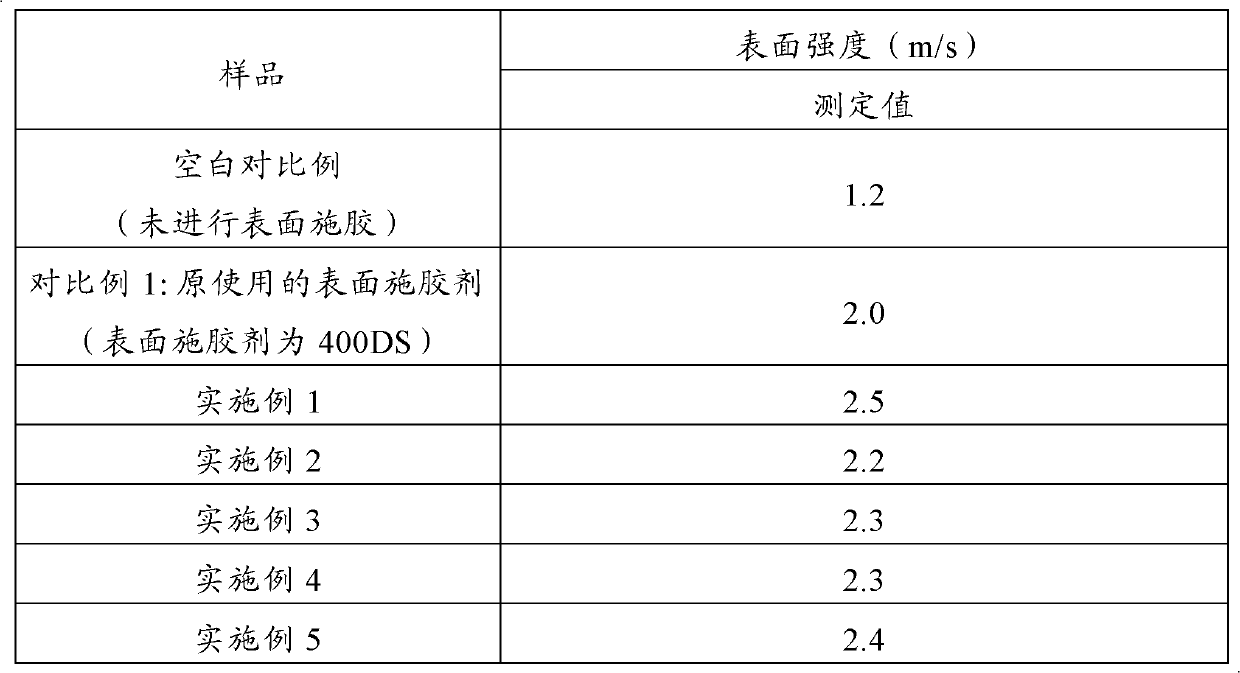

Styrene-acrylic emulsion, preparation method thereof, and application thereof

ActiveCN102775542AGood film formingImprove hydrophobicityWater-repelling agents additionPaper coating(Hydroxyethyl)methacrylateEmulsion

The invention relates to a styrene-acrylic emulsion, a preparation method thereof, and an application thereof. The styrene-acrylic emulsion provided by the invention comprises the components of: starch, amylases, a cationic monomer, an acrylate monomer, a crosslinking monomer, styrene, a dispersing agent, hydroxyethyl methacrylate, an initiator aqueous solution with a concentration of 20wt%, and deionized water. A surface sizing emulsion prepared by using the styrene-acrylic emulsion provided by the invention and biological latex has better film-forming performance and good hydrophobicity. With the surface sizing emulsion, paper can be provided with better surface strength, better printing performance, and certain water resistance. The styrene-acrylic emulsion is environment-friendly. When in use, the surface sizing emulsion prepared by using the styrene-acrylic emulsion provided by the invention is directly coated on the surface of paper, and surface sizing starch is no longer used during the surface sizing process. Therefore, a fine paper surface sizing operation process is simplified, and surface sizing process stability in fine paper production is improved.

Owner:广州市迪笙生物科技有限公司

Red sludge superfine fibre pulp from solid wastes and manufacturing method thereof

InactiveCN101514532AReduce "white pollution"Low costInorganic fibres/flakesNon-macromolecular organic additionPlant fibreSludge

A method for manufacturing red sludge superfine fibre pulp from solid wastes comprises the following steps: feeding the red sludge superfine fibres into the water, sequentially adding the following additives: adding fibre surface modifier, mixing and stirring the mixture for 10-20 minutes, adding fibre dispersant, mixing and stirring for 10-20 minutes, adding fibre miscible agent, mixing and stirring for 10-20 minutes, adding plant fibre slurry, mixing and stirring the mixture for 20-30 minutes, adding fibre intensifier, mixing and stirring the mixture for 30-40 minutes; and removing partial water to obtain the red sludge superfine fibre pulp. In the inventive manufacturing method, all the processes are carried out at the normal temperature with low industrial production cost. The invention endows the red sludge superfine fibre pulp from solid wastes with highly valuable usage, and the prepared pulp is capable of producing fine paper, package paper, functional paper and paper apparatus and appliances. The project is significant in meaning and value for the recycle and reuse of resources.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Latex-treated filler slurries for use in papermaking

InactiveUS20110308753A1Trend downReduce amountPigmenting treatmentNatural cellulose pulp/paperPrillPaperboard

A continuous filler treatment process has been developed to enhance the fixation of anionic latex on filler in a short time. In this process anionic polymer dispersions (latex) are added to common papermaking filler slurries at ambient temperature and then mixed with water of temperature higher than the glass transition temperature (Tg) of the latex used. To efficiently fix the latex the temperature of the filler / latex mixture must be 30-60° C. higher than the Tg of the latex used. The chemical composition of the resin and the type of surfactant used during the emulsion polymerisation process of the polymer latex dispersions are important factors for efficiently fixing the latex onto the filler by adding hot water and improving the properties of paper made with the treated filler. The enhanced fixation of anionic latex onto filler using hot water is done in mixing vessels that can control shear and mixing time. The anionic latexes applied by this process are totally and irreversibly fixed or bound onto the filler particles and the aggregated filler slurry is stable over time. The latex-treated filler slurry can be added to papermaking furnishes at any point prior to the headbox of the paper machine or stored for later use. It can be added to wood-free or wood-containing furnishes commonly used for making fine papers, mechanical pulp papers, and multi-ply paperboards. The latex-treated filler slurry improves filler retention, only slightly reduces sheet strength and improves sizing performance. Furthermore, latex-treated calcium carbonate filler, such as precipitated calcium carbonate (PCC), is more acid-resistant and, when used in manufacturing mechanical pulp paper under neutral conditions, less acid is needed to control the pH.

Owner:FPINNOVATIONS INC

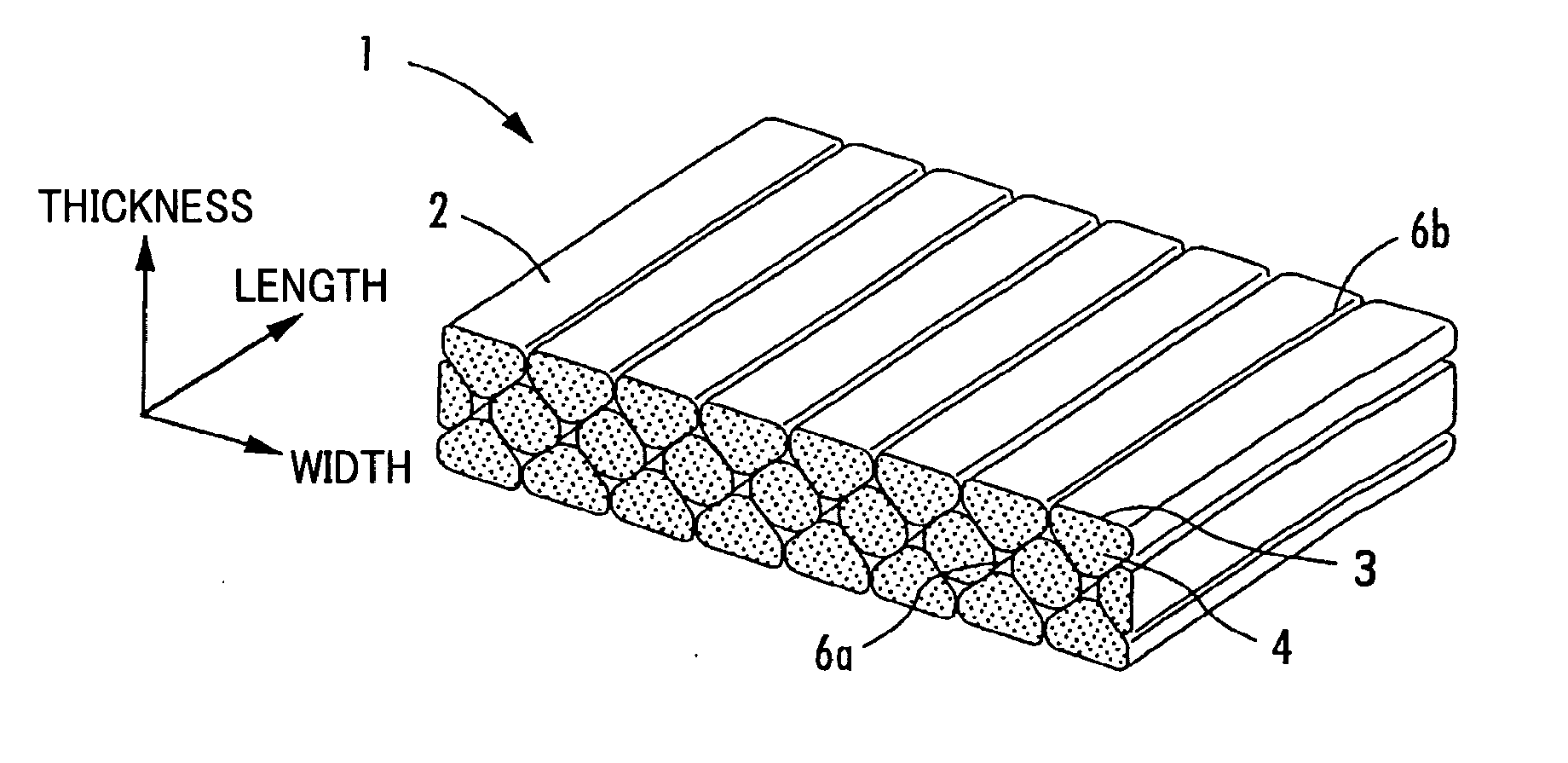

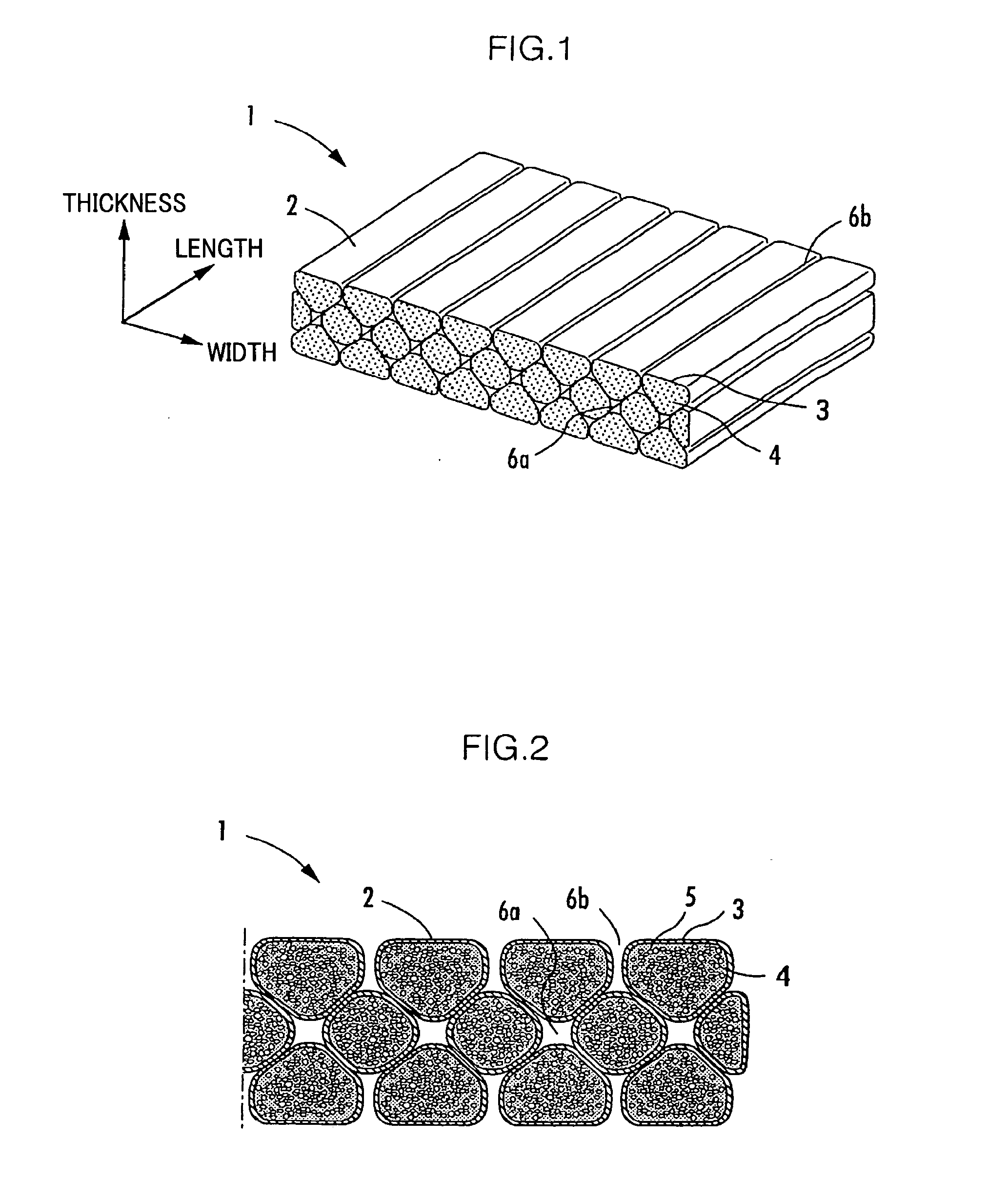

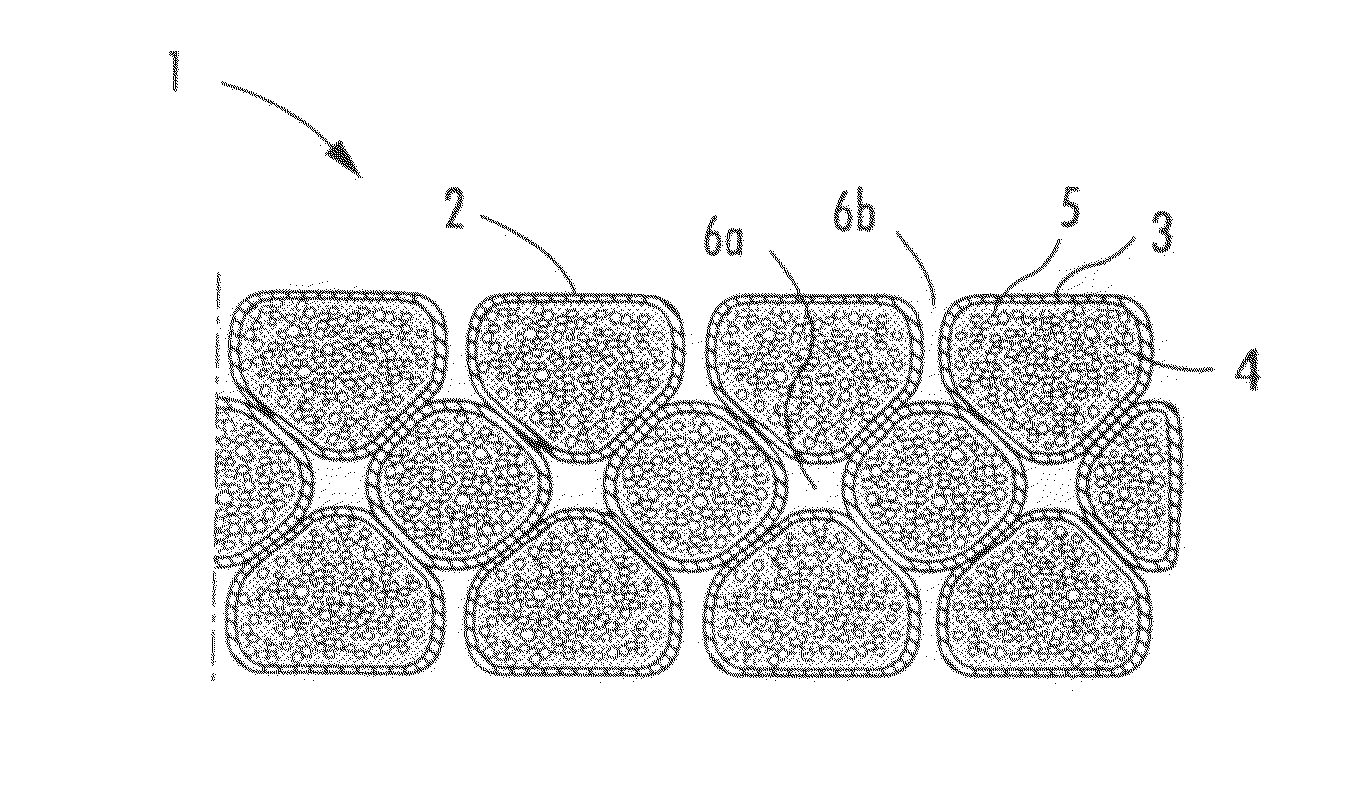

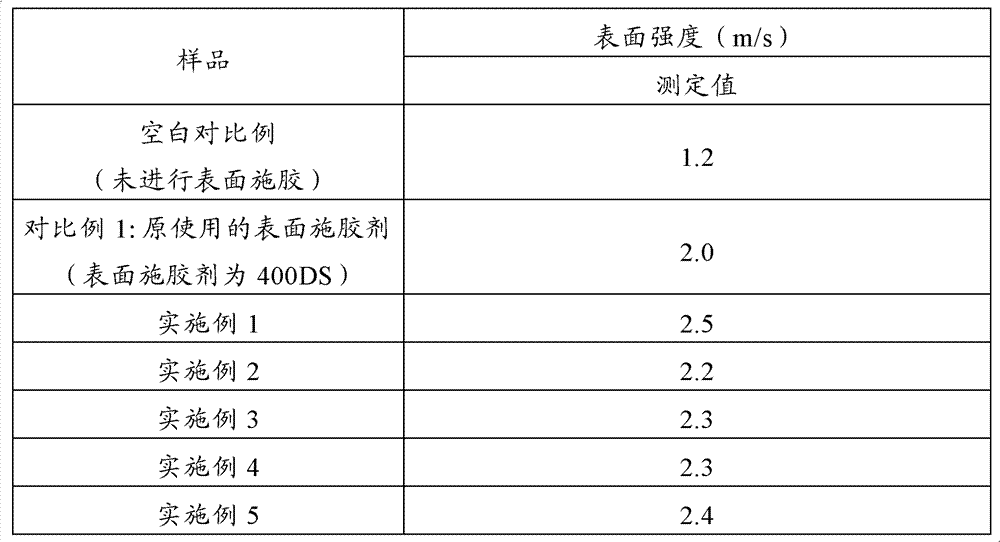

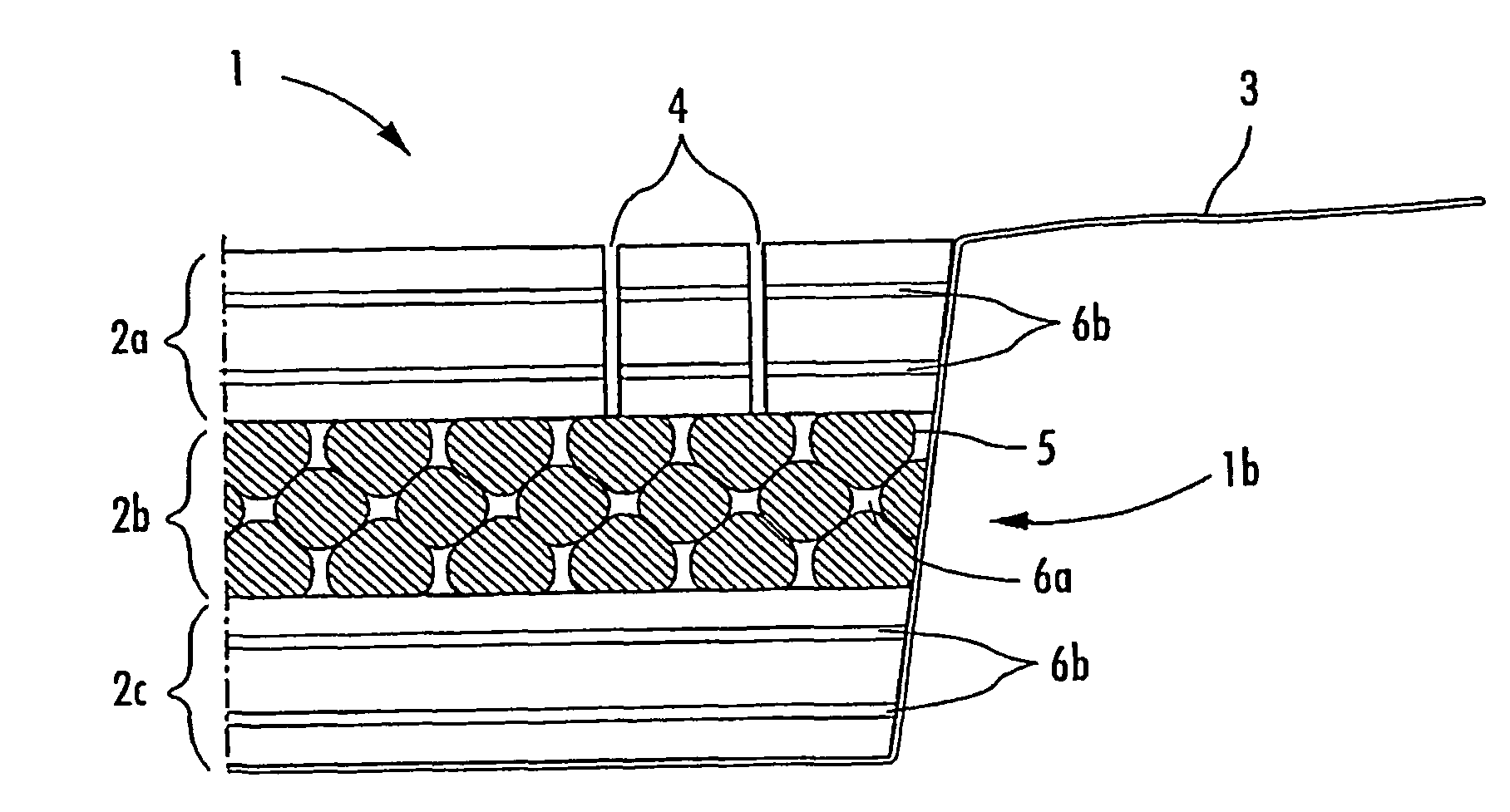

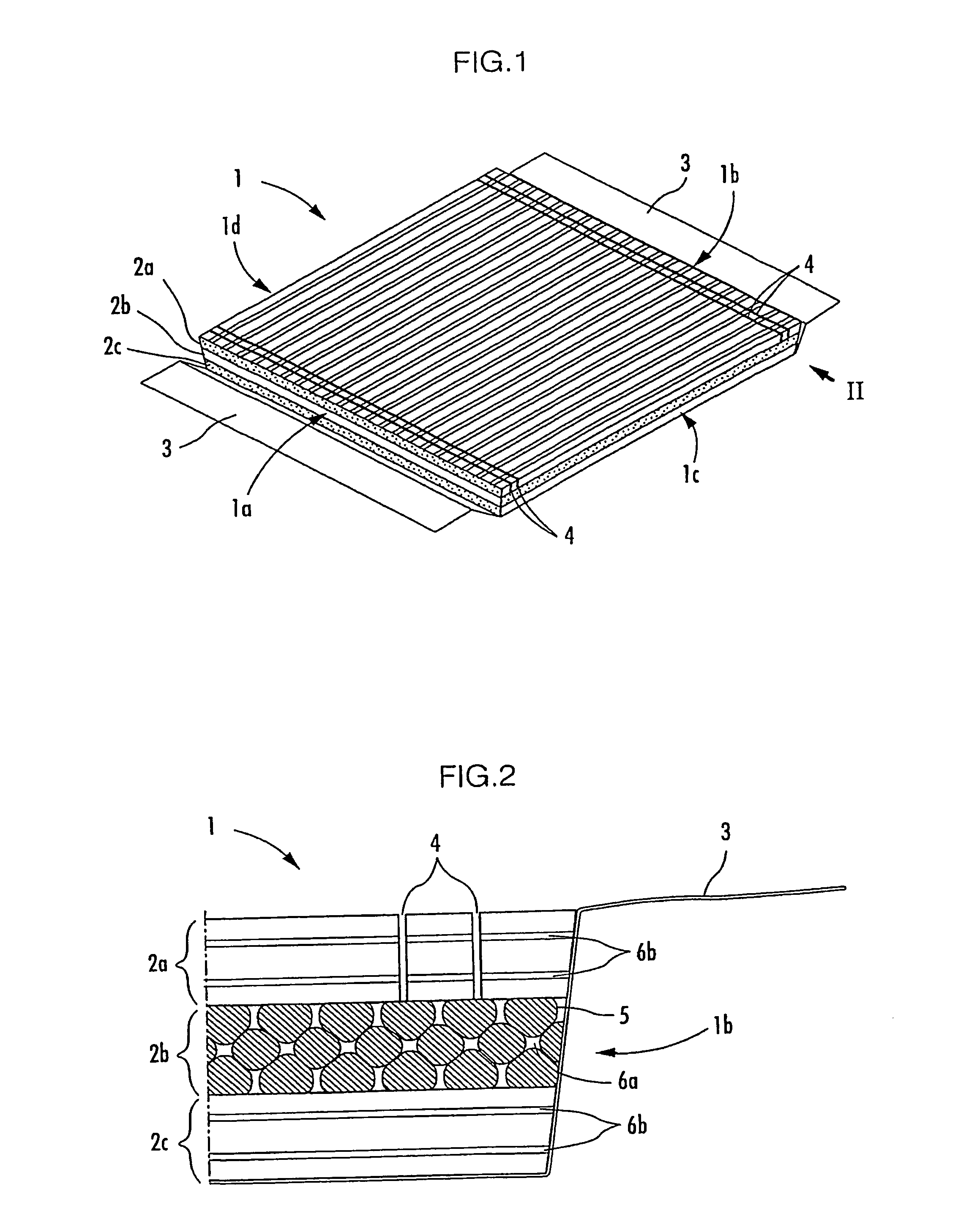

Fine paper powder-containing resin molded object and manufacturing method thereof

ActiveUS9174370B2Improve liquidityIncrease contentSynthetic resin layered productsCeramic shaping apparatusAdditive ingredientEngineering

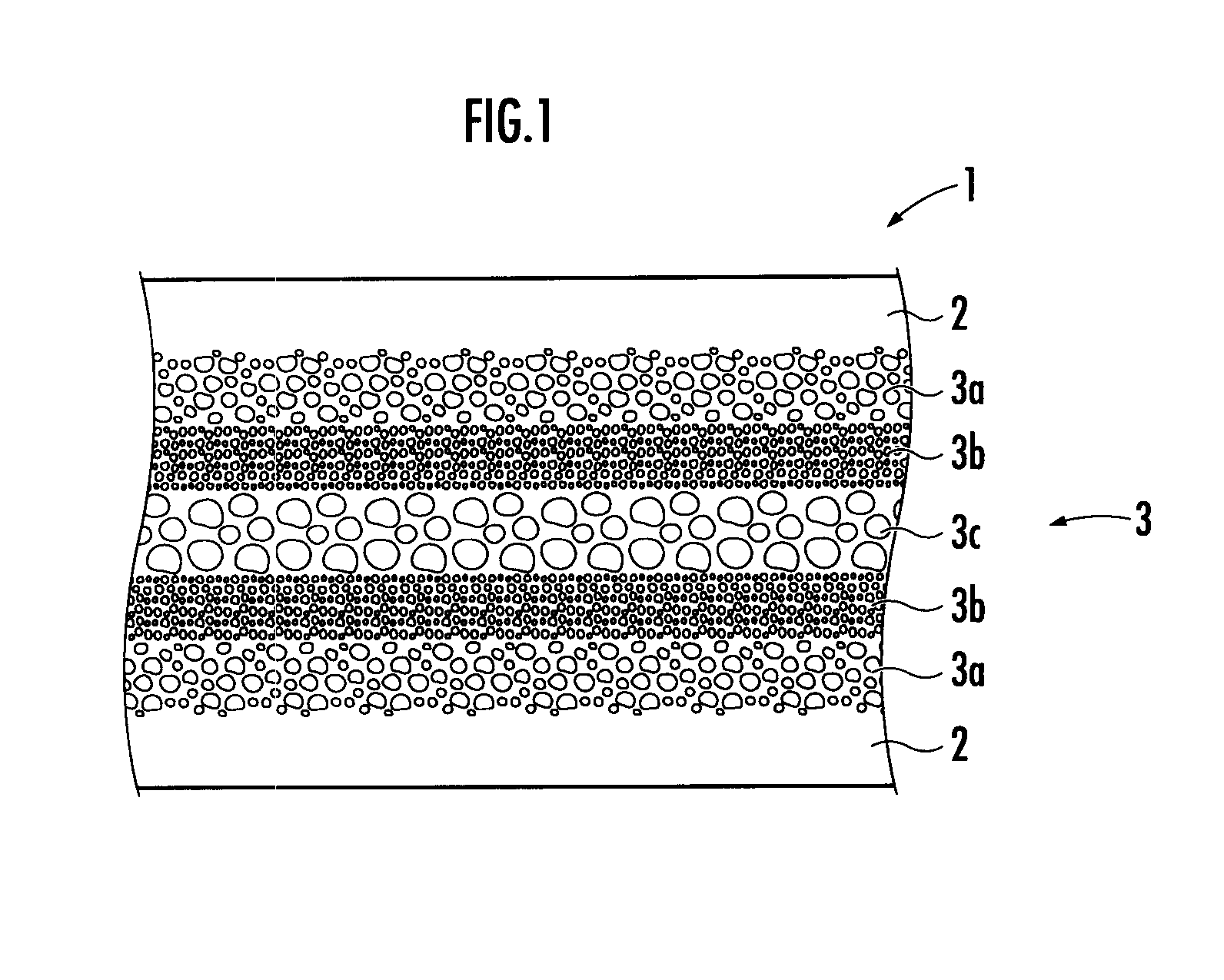

Provided is a fine paper powder-containing resin molded object with a content of a thermoplastic resin being reduced to offer a lighter weight and a superior mechanical strength, and a manufacturing method thereof. The fine paper powder-containing resin molded object (1) is made from a thermoplastic resin containing fine paper powder and is composed of a non-foam layer (2) formed on the surface and a foam layer (3) formed in the inner side. The foam layer (3) has, in the order from the surface side, a first foam layer (3a) containing cells having an average cell diameter ranging from 10 to 100 μm, a second foam layer (3b) containing cells having an average cell diameter from 5 to 50 μm, and a third foam layer (3c) containing cells having an average cell diameter from 20 to 500 μm. The molded object (1) contains an aromatizing ingredient.

Owner:KANKYOKEIEISOGOKENKYUSHO CO INC

Overcoating base paper used for outdoor highly-strengthened plate and preparation method of overcoating base paper

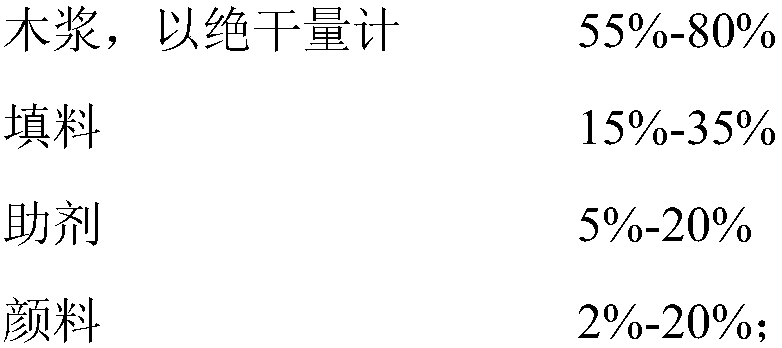

ActiveCN108130815AIncrease coverageImprove breathabilitySpecial paperReinforcing agents additionFiberPapermaking

The invention belongs to the technical field of papermaking, and in particular relates to overcoating base paper used for an outdoor highly-strengthened plate and a preparation method of the overcoating base paper. The base paper is prepared from the following raw materials: wood pulp, a filler, an auxiliary agent and a pigment, wherein the auxiliary agent is composed of sodium hydroxide, sulphuric acid, aluminium sulphate and a wet strength agent; and the filler is composed of titanium dioxide, magnesium silicate and kaolin. The prepared overcoating base paper used for the outdoor highly-strengthened plate provided by the invention has a good covering property, fiber distribution uniformity, fine paper surfaces, strong corrosion resistance, a high sun-proof grade, and high water washing color fastness; and after the base paper is impregnated with melamine for veneering, the base paper is impregnated into a solution with the pH of 3.5-10, and no phenomena such as blistering and deformation of the paper happen; and the sun-proof grade is 6 grade or more, and the water washing color fastness is high. The invention also provides a preparation method of the overcoating base paper usedfor the outdoor highly-strengthened plate, and the base paper has high practicability and scientific and reasonable operation, and is simple and practicable.

Owner:ZIBO OU MU SPECIAL PAPER

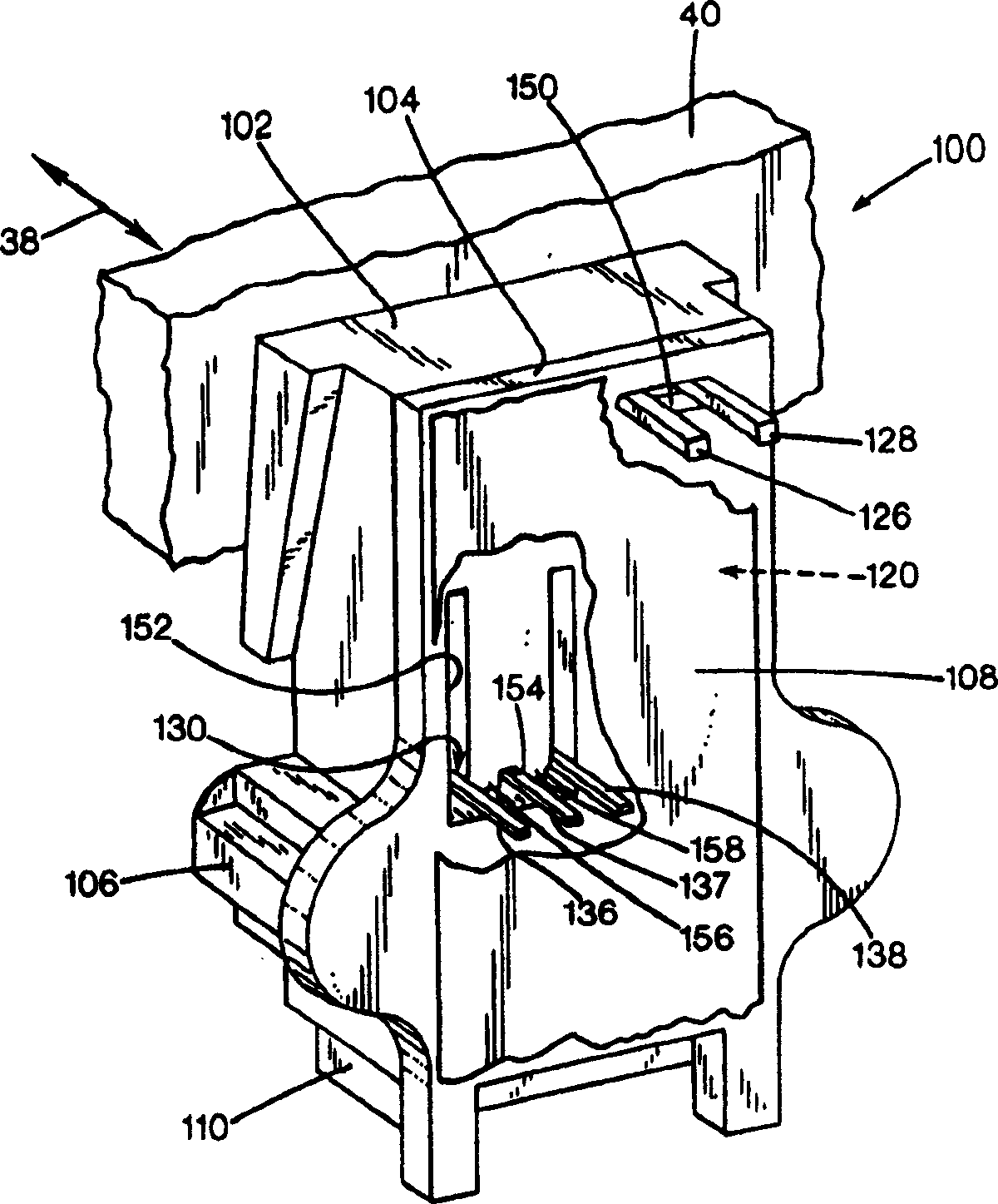

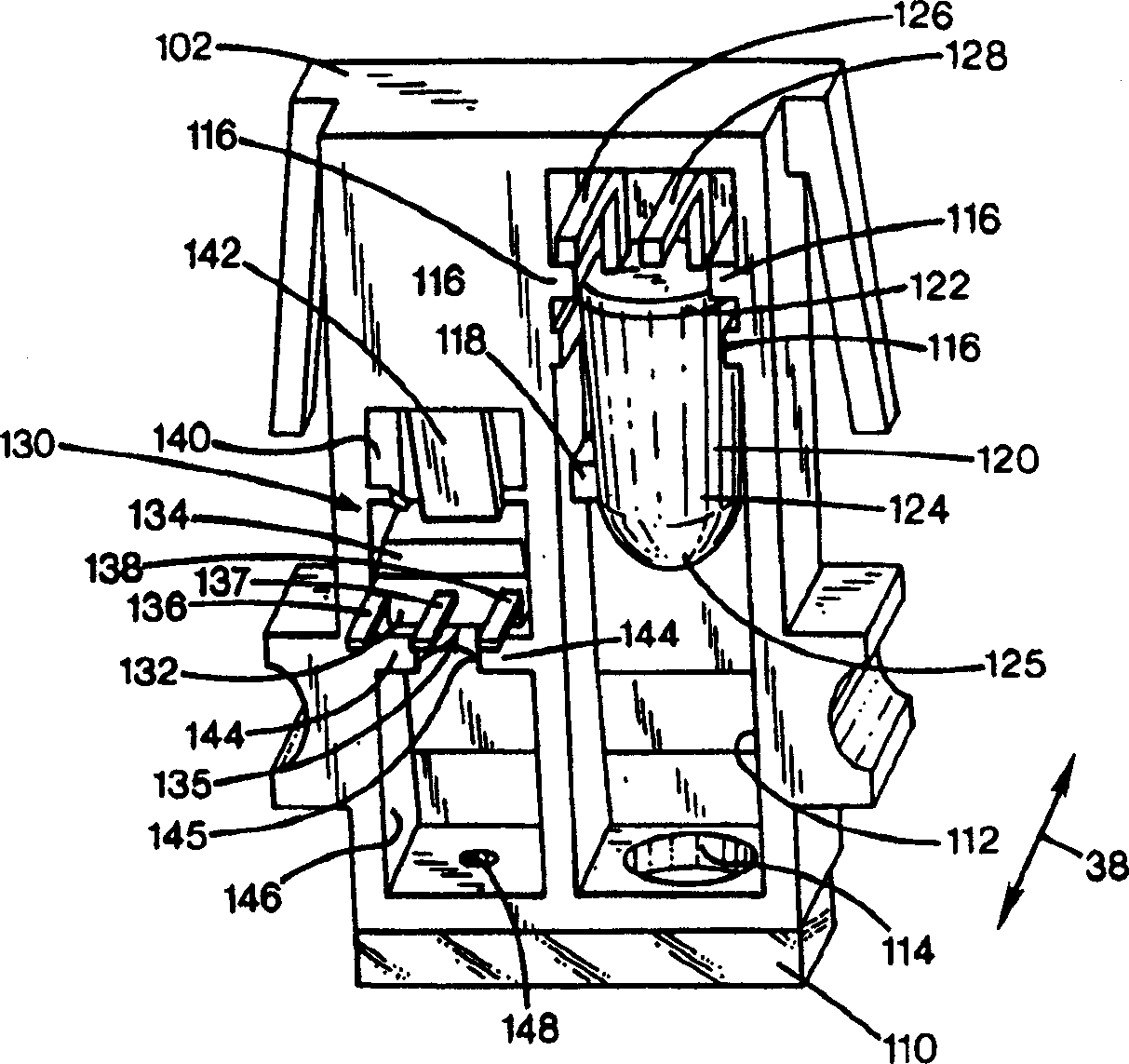

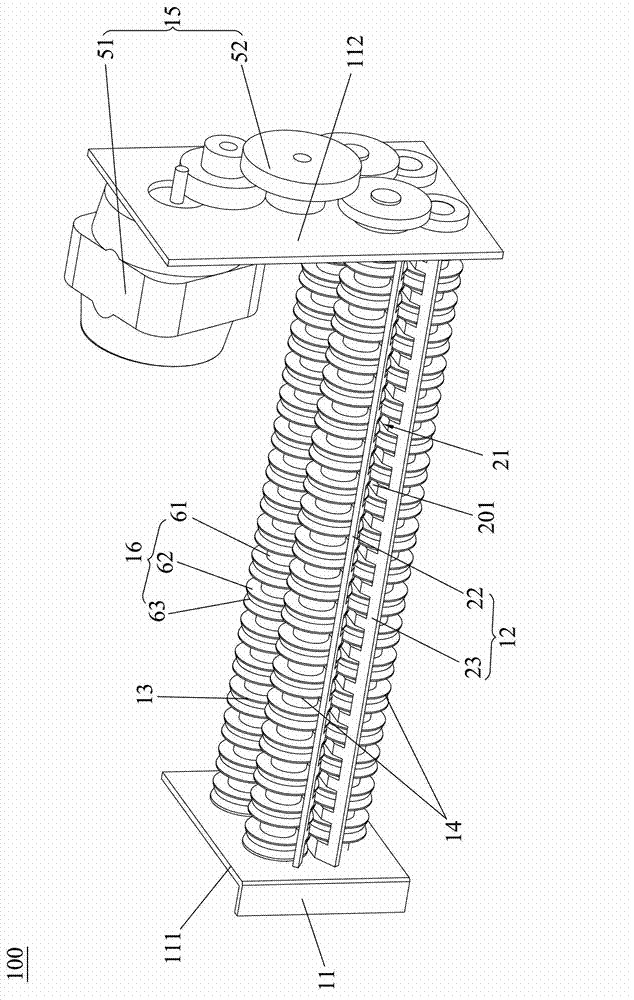

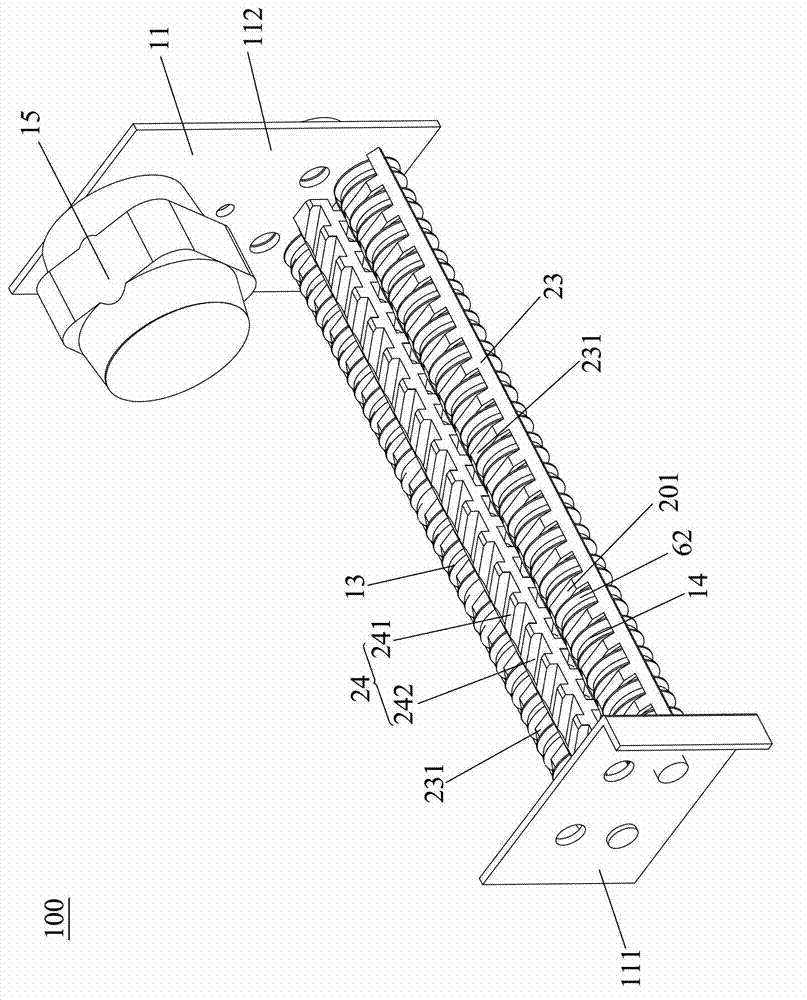

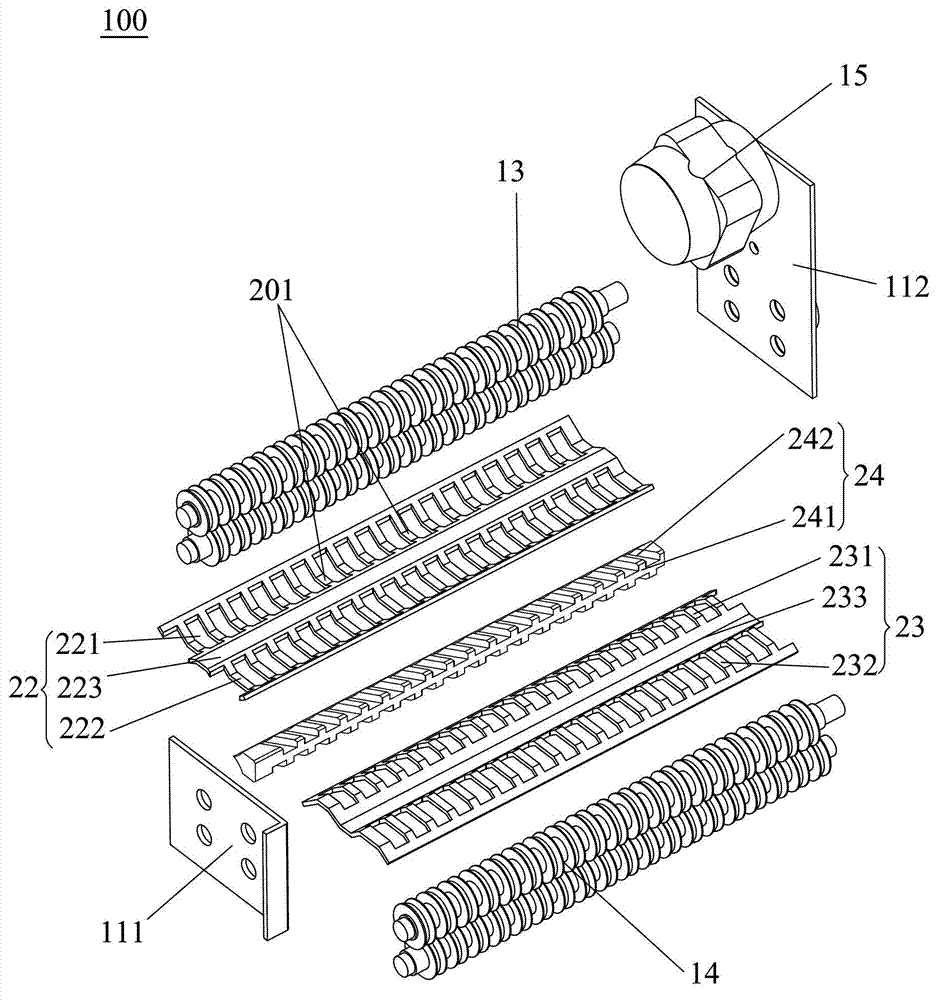

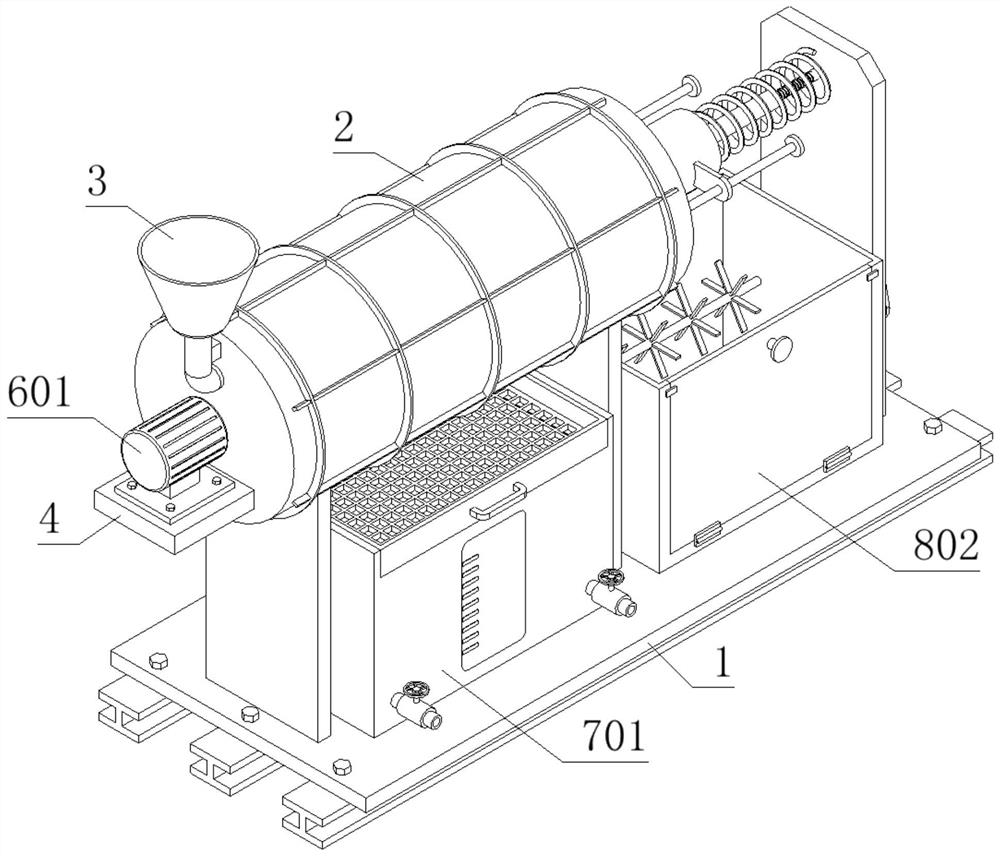

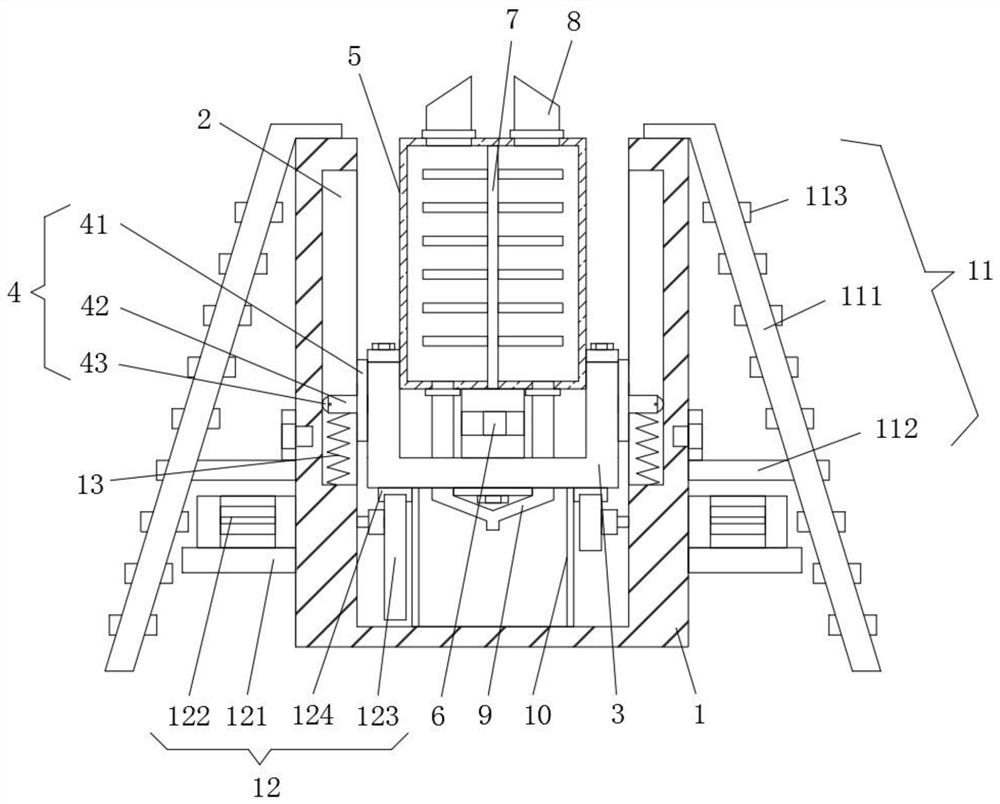

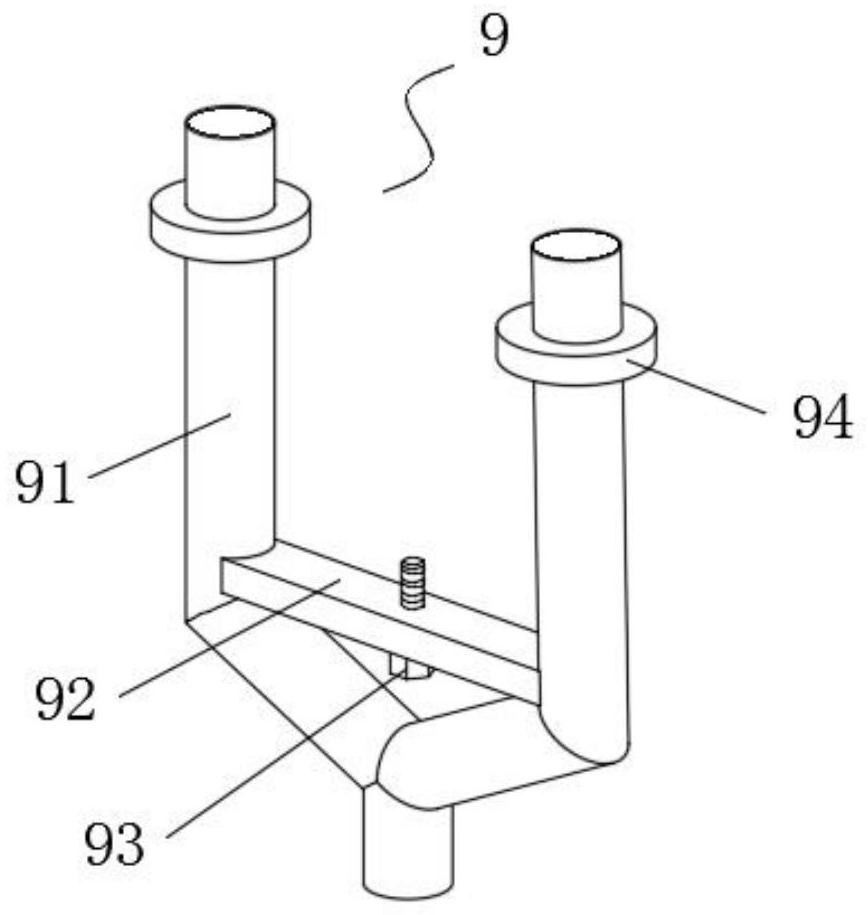

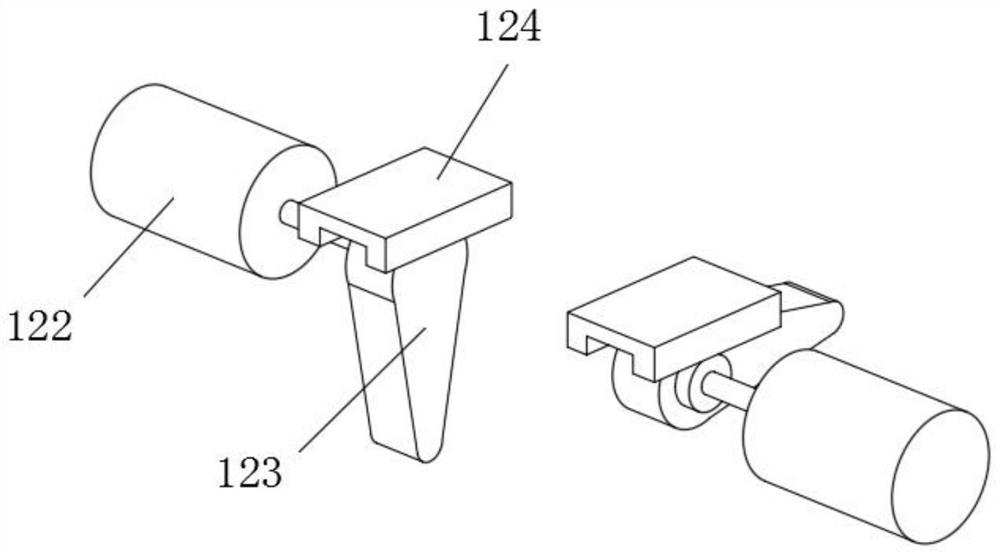

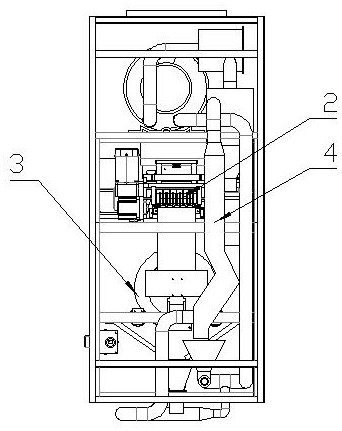

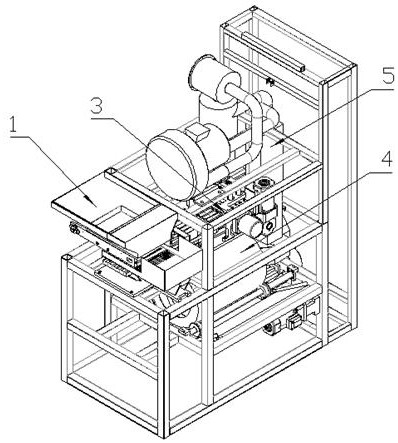

Connecting ring cutter paper shredder and paper shredding method of paper shredder

ActiveCN103041900AImprove efficiencySimple structureGrain treatmentsAcute anglePulp and paper industry

The invention provides a connecting ring cutter paper shredder which comprises a rack, and a first paper shredding mechanism, a second paper shredding mechanism and a driving mechanism which are arranged on the rack, wherein the driving mechanism is respectively connected with the first paper shredding mechanism and the second paper shredding mechanism and drives the first paper shredding mechanism and the second paper shredding mechanism to shred a paper; the first paper shredding mechanism and the second paper shredding mechanism are strip-shaped paper shredding mechanisms; a paper outlet of the first paper shredding mechanism is communicated with a paper inlet of the second paper shredding mechanism; and an acute angle is available between a paper transmitting direction of the paper inlet of the second paper shredding mechanism and the axial direction of a cutter shaft of the second paper shredding mechanism. When the paper is shredded, the first paper shredding mechanism is used for cutting the paper into a plurality of fine paper tapes at the same time, and a second paper shredding cutter is used for inwards and slantwise cutting off the plurality of fine paper tapes into shredded paper particles along one side of the second paper shredding mechanism at the acute angle, so that the paper is labor-saving and high-efficiency to shred. Furthermore, the invention further provides a paper shredding method of the paper shredder.

Owner:DONGGUAN ELITE ELECTRIC HARDWARE PRODUCT CO LTD

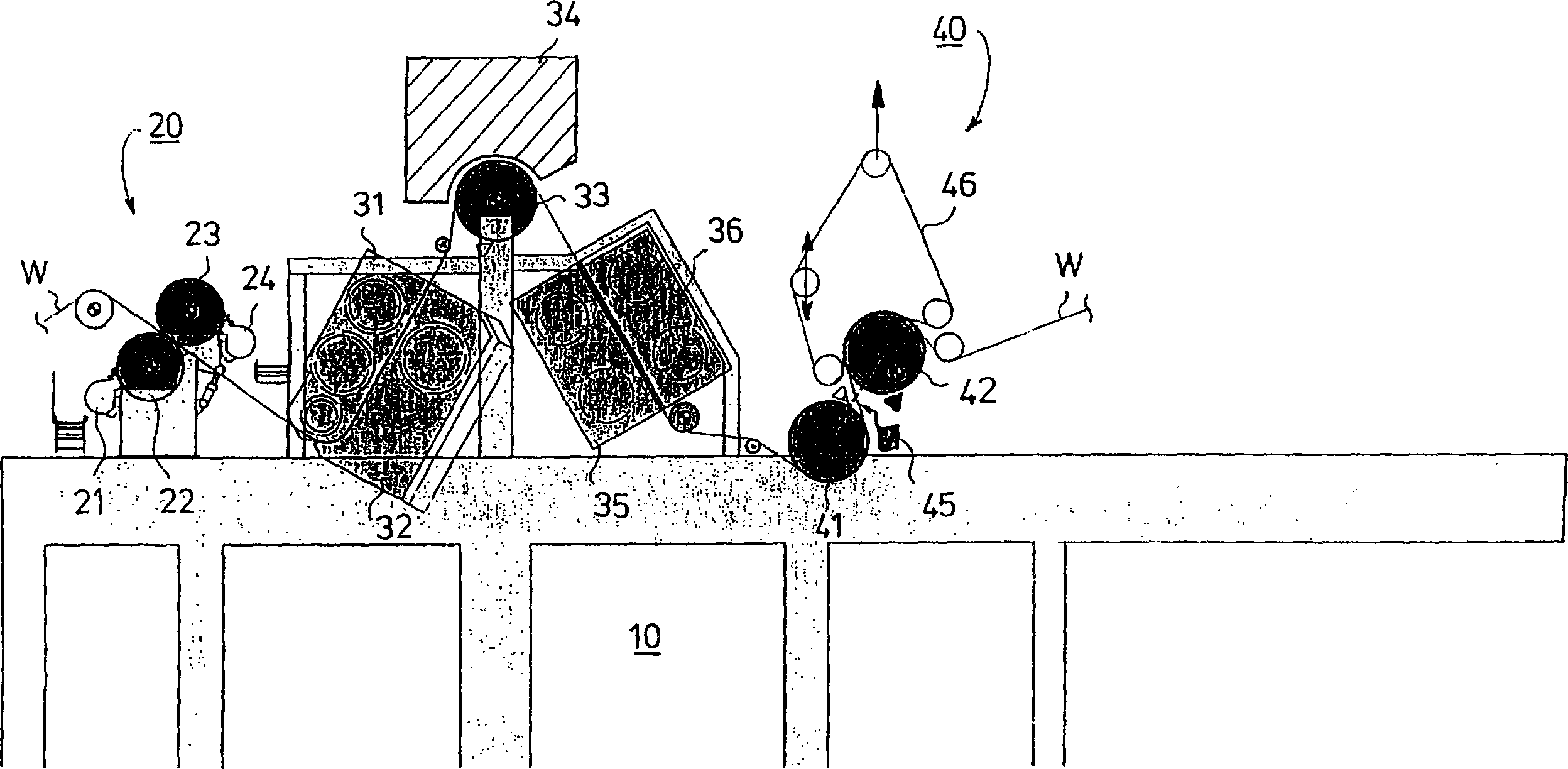

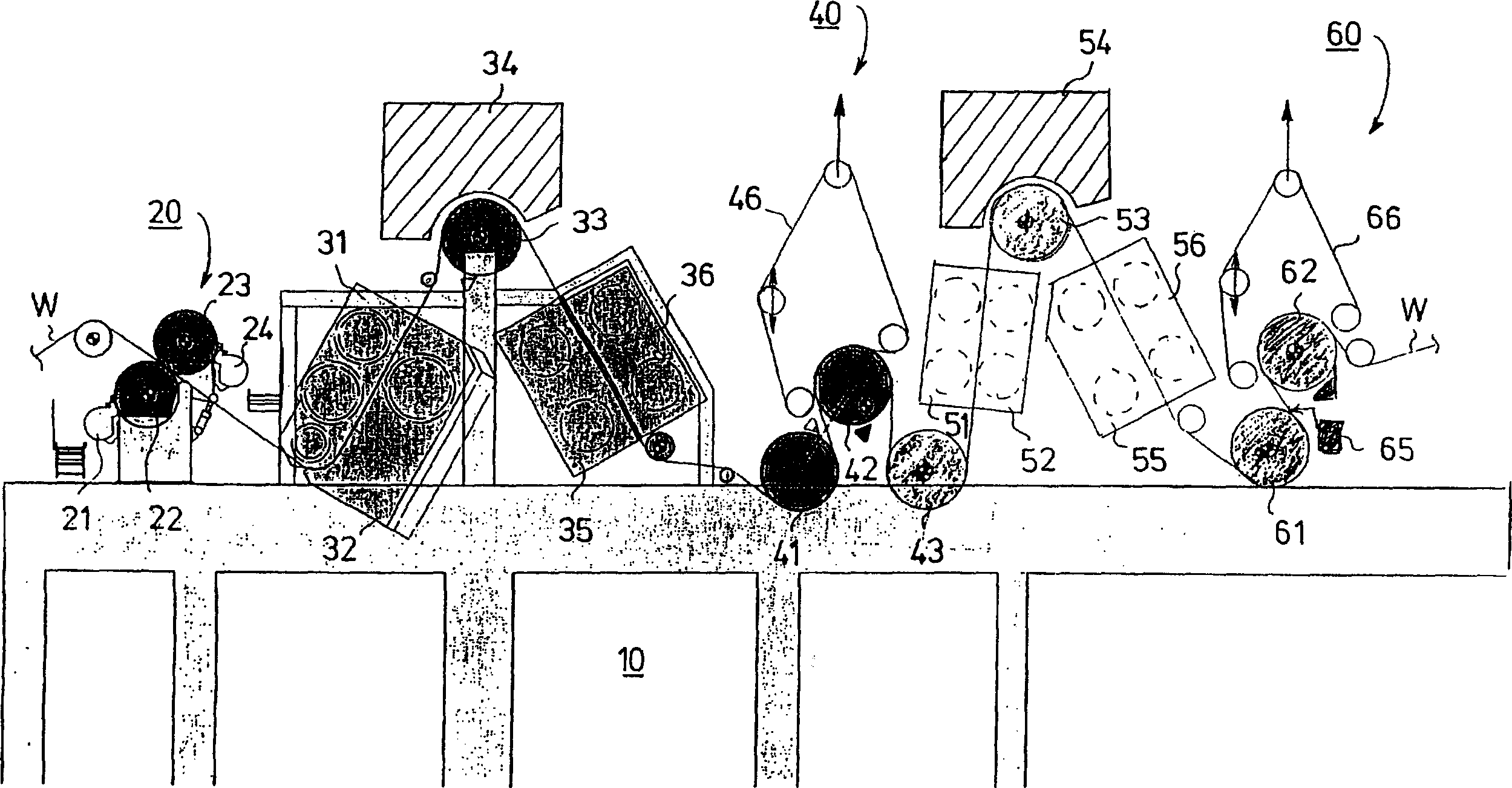

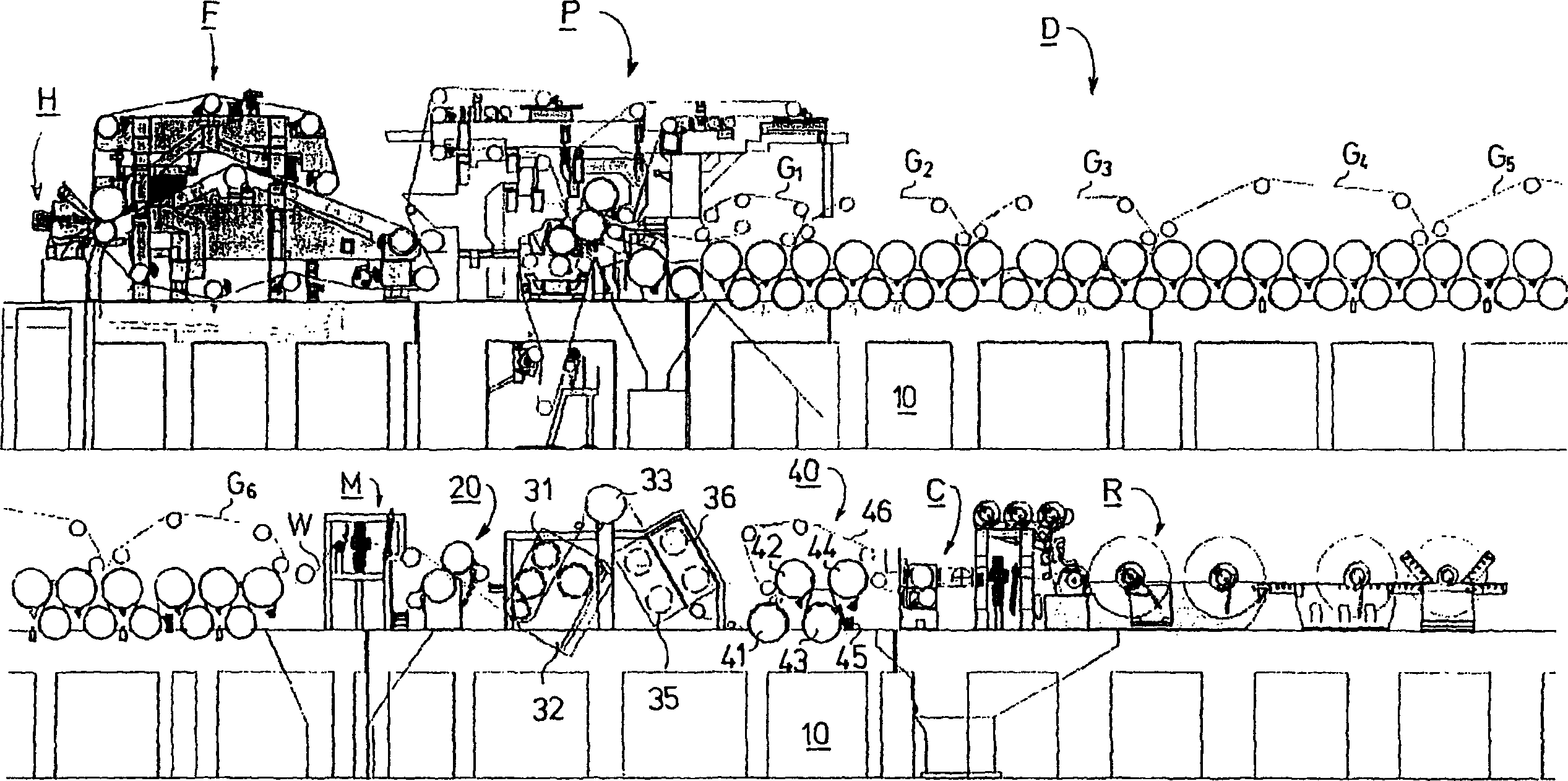

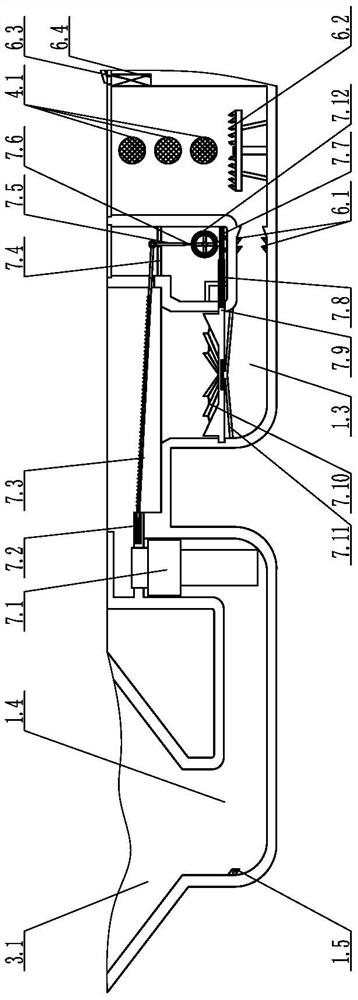

Method for control of the curl of paper in the treatment of surface-sized paper, and finishing section of a paper machine

InactiveCN1802468AEliminates the frizz tendencySmall curls control power runsDryer sectionContact freeFine paper

The invention relates to a method in the treatment of suface-sized paper, in particular fine paper, in a finishing section of a paper machine. In the method a paper web (W) is first dried in a forward dryer section (D) of the paper machine in several successive downward open drying groups (G1...g6) that apply single-wire draw, after which the paper web (W) is finished in the finishing section. In the finishing section the web (W) is surface-sized in a surface-sizing unit (20) and dried. According to the invention, in the method, the surface-sized paper web (W) is mainly dried by means of contact-free drying. The web (W) is dried at least partly by means of airbone web-dryers (31, 32, 34, 36) or by means of impingement drying. In the method, the power of the airbone web-drying / impingement drying is regulated on both sides of the web (W) such that the tendency of curling created in the web (W) in the forward dryer section (D) can be controlled. In addition, the invention relates to a finishing section of a paper machine in the treatment of surface-sized paper, in particular fine paper, in the paper finishing section. Before the finishing section, the paper machine comprises a forward dryer section (D) in which there are several successive downward open drying groups (G1...G6) that apply single-wire draw. The finishing section comprises surface-sizing devices (20) and drying means. According to the invention, the drying means of the finishing section are mainly based on contact-free drying. At least one of the means are airborne web-dryers / impingement dryers (31, 32, 35, 36), whose power can be regulated such that the tendency of curling of the web can be controlled by the effect of drying applied on the different sides of the web (W).

Owner:VALMET CHINA CO LTD

Method for producing tree pit cover plate from paper mill sludge

InactiveCN107663003AReduce moisture contentReduce manufacturing costSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPresent methodEconomic benefits

The invention discloses a method for manufacturing a tree hole cover plate by using papermaking sludge. In the method, a mineralizer, a flocculant, a coupling agent, a retarder and an expansion agent are respectively added to the papermaking sludge for treatment, so that the papermaking sludge is treated with The moisture content of the mud is reduced from more than 60% to less than 10%, so that the papermaking sludge can meet the requirements of stabilization, harmlessness, reduction and resource utilization, and then the papermaking sludge is crushed and homogenized to form Fine powder, papermaking sludge fine powder is added with corresponding materials and stirred by a high-speed mixer. After stirring, the material is injected into the tree hole cover shaping die from the extruder, and the melt in the shaping die is cooled to obtain the tree hole cover plate. The method effectively treats the papermaking sludge to make the tree hole cover, which reduces the production cost of the tree hole cover, saves beneficial resources, reduces the pollution of the papermaking sludge to the environment, and has greater social and economic benefits.

Owner:上海永玺环境科技有限公司

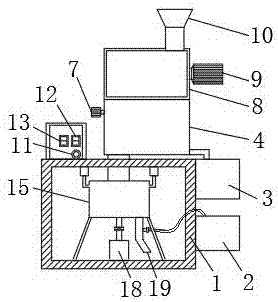

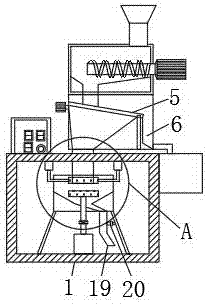

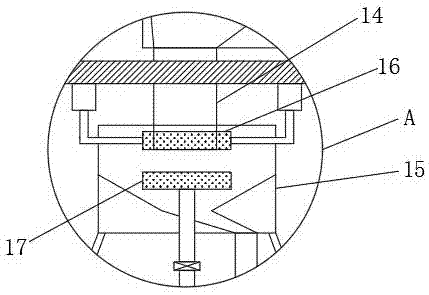

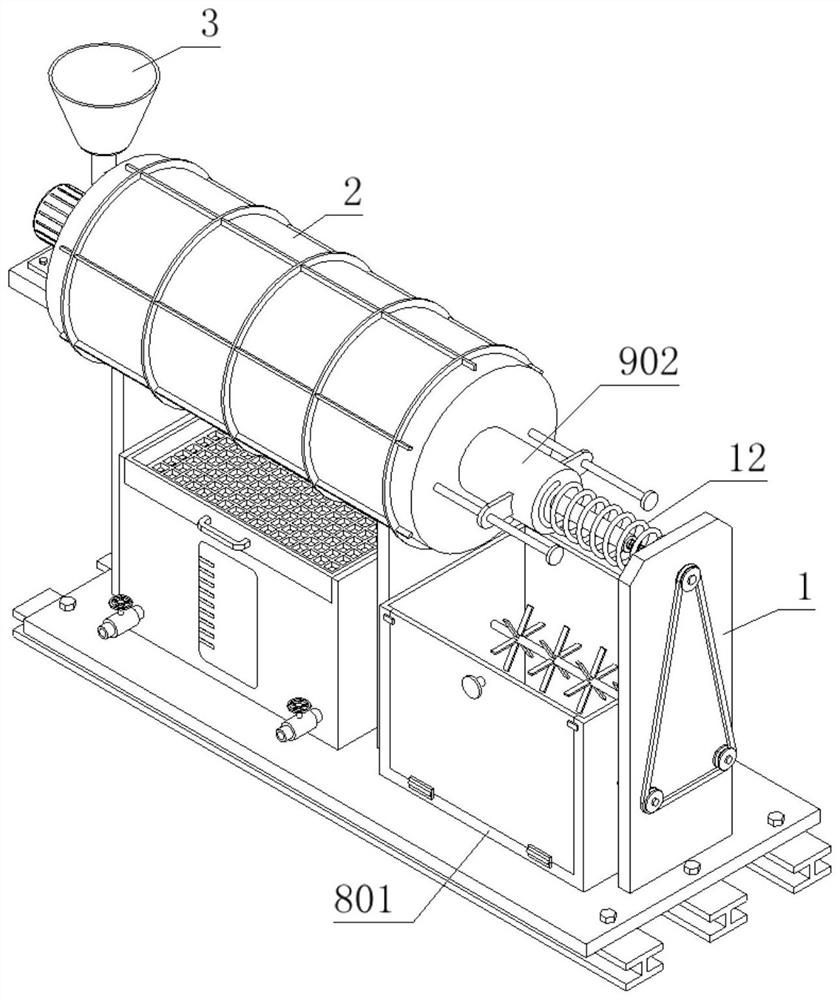

Pulping machine for papermaking

PendingCN107476107AEnergy savingImprove discharge efficiencyPulp beating/refining methodsElectric machineryPapermaking

The invention discloses a pulping machine for papermaking. The pulping machine comprises a machine frame, a large paper pulp recycling box, a filtering box, a cutting box, a grinding machine and an air hammer, wherein the large paper pulp recycling box is arranged on one side of an air compressor, one side of the large paper pulp recycling box is provided with the filtering box, one side of the filtering box is provided with a vibrating screen, one side of a vibration motor is provided with the cutting box, the top of a fine paper pulp outlet is provided with the grinding machine, an upper grinding wheel is arranged on one side of the grinding machine, and a lower grinding wheel is arranged on one side of the upper grinding wheel; a grinding motor is arranged on one side of the lower grinding wheel, one side of the grinding motor is provided with a discharge port, and one side of the discharge port is provided with the air hammer. Paper pulp obtained after cutting can be filtered, so that the size of the filtered paper pulp is uniform, the large paper pulp can be recycled and reused, and energy is saved; meanwhile, the pulp discharging rate is high, the paper pulp cannot adhere to the inner wall of the outlet, and the pulping machine is convenient to use.

Owner:枣庄市恒宇纸业有限公司

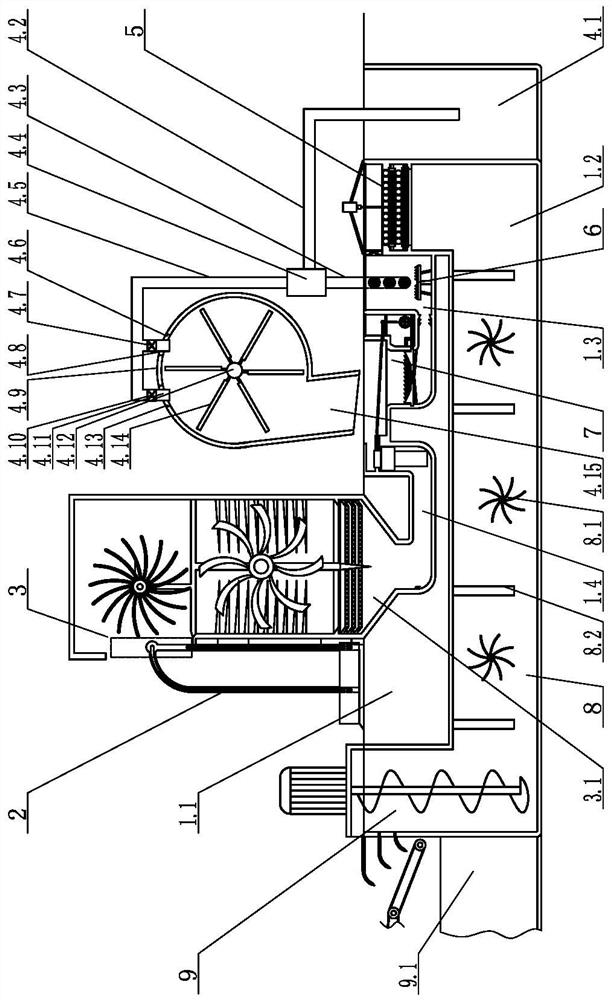

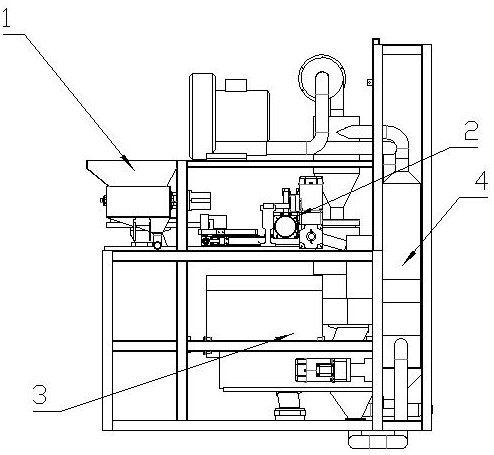

Efficient environment-friendly papermaking production line

ActiveCN112342811AQuality improvementReduce labor intensityWashing/displacing pulp-treating liquorsPaper recyclingPaper dustPapermaking

The invention relates to an efficient environment-friendly papermaking production line, belonging to the technical field of papermaking mechanical equipment. The efficient environment-friendly papermaking production line is characterized by comprising pulping equipment, wherein a feeding device of the pulping equipment can feed waste paper raw materials into a coarse crushing device; the coarse crushing device can crush the waste paper raw materials into coarse paper pulp; the coarse paper pulp is conveyed into a screening device through water flow assistance; the coarse paper pulp enters a pulp washing device after being screened and filtered by the screening device; and the pulp enters a fine grinding device after being cleaned by the pulp washing device, and enters a storage device after being finely ground by the fine grinding device. According to the invention, fine paper pulp can be finally obtained through automatic feeding, coarse crushing, paper material circulating and infiltrating, screening and paper scrap grinding and refining, and is stored for papermaking operation.

Owner:山东海天造纸机械有限公司

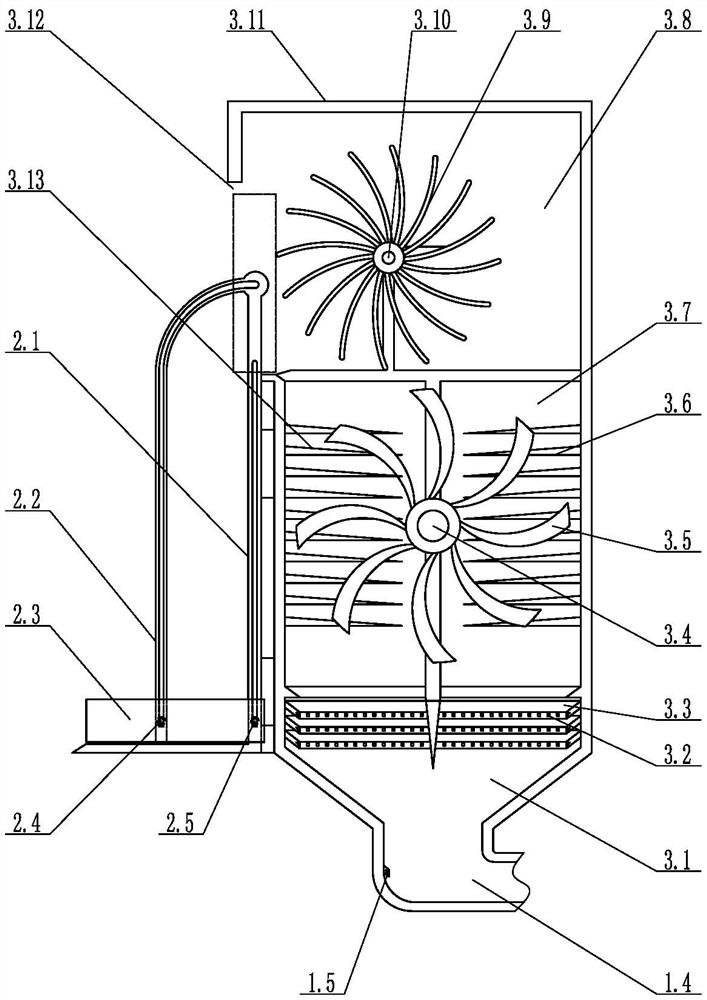

Multi-disc concentration equipment of papermaking system

The invention provides multi-disc concentration equipment for a papermaking system. The multi-disc concentration equipment comprises a base; a cylinder is fixedly mounted at the top of the base, and a mounting plate is fixedly mounted on the left side of the base; a feeding hole is fixedly formed in the left side of the base, and the feeding hole is positioned above the mounting plate; a flow guide device is mounted at the top of the mounting plate, and the right side of the flow guide device is located in a concentration device; a collecting device is installed on the left side of the top of the base, and a receiving device is installed on the right side of the top of the base; and a material baffling device is installed on the right side of the cylinder, and an elastic piece is arranged between the material baffling device and the base. When a motor works, a connecting shaft drives a first belt wheel to rotate, so that a gear drives a gear ring to rotate, a filtering cover slowly rotates, meanwhile, filtered water washes filtering holes in the bottom, self-cleaning of the filtering holes is achieved, and the filtering holes are of a conical structure, so that fine paper pulp blocked in the filtering holes can flow out conveniently, and the filtering holes are prevented from being blocked.

Owner:LONGYOU COUNTY JINLONG PAPER

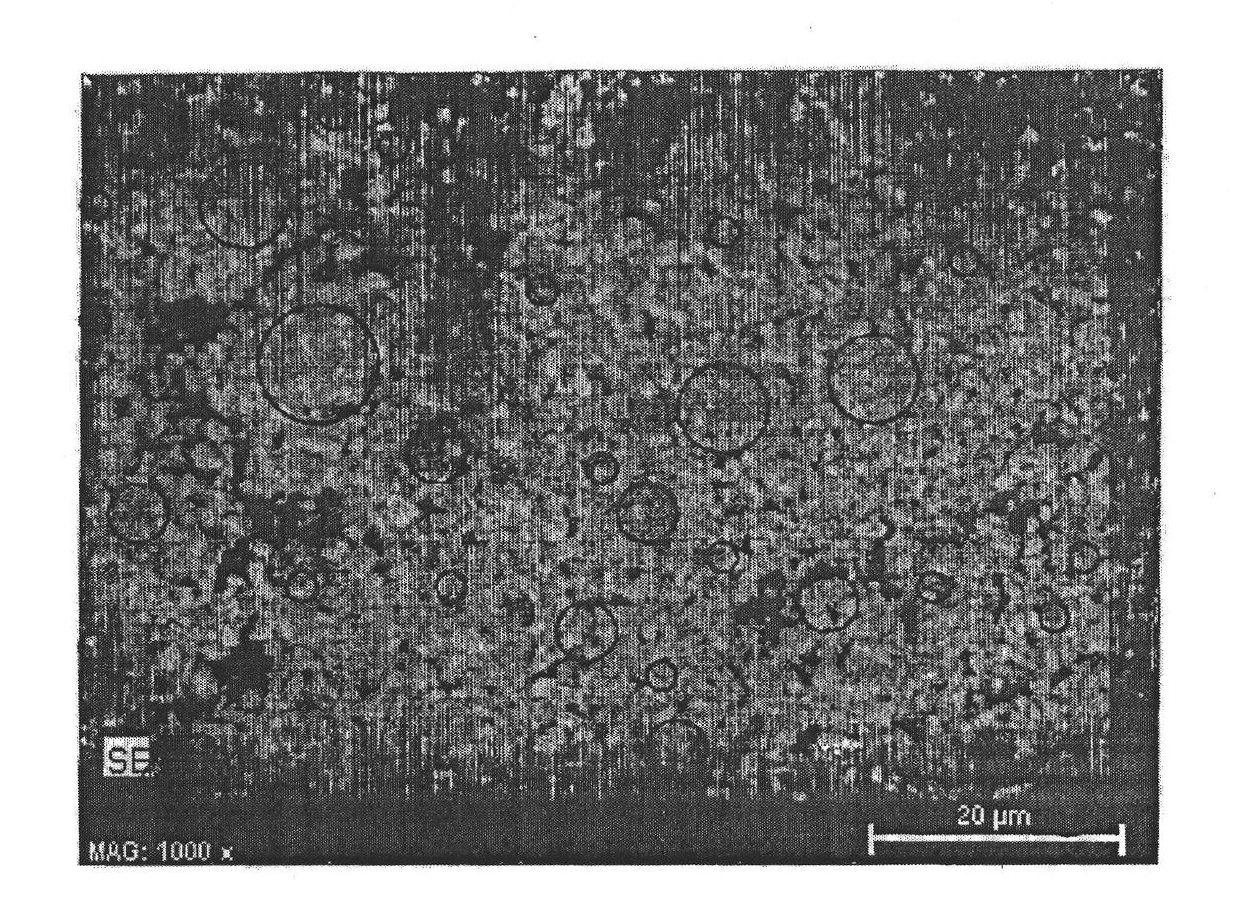

Coated fine paper having a soft touch

InactiveUS20130157021A1Improve the immunityGood printabilityNon-fibrous pulp additionCoatings with pigmentsPolyurethane dispersionEngineering

Fine paper for writing, packaging and / or printing, in particular offset printing, comprising a fibrous layer having a bulk greater than or equal to 1.10 cm3 / g and at least one coating, said coating having a dry deposition on one or each face of the fibrous layer that is between 3 and 10 g / m2 and comprising at least one mineral pigment, at least one latex acting as a binder, and at least one aqueous polyurethane dispersion at a rate of 0.5 to 8% dry weight with respect to the dry weight of pigment(s) of the coating, such that the coated paper has a similar texture to that of the fibrous layer.

Owner:ARJO WIGGINS FINE PAPERS LTD

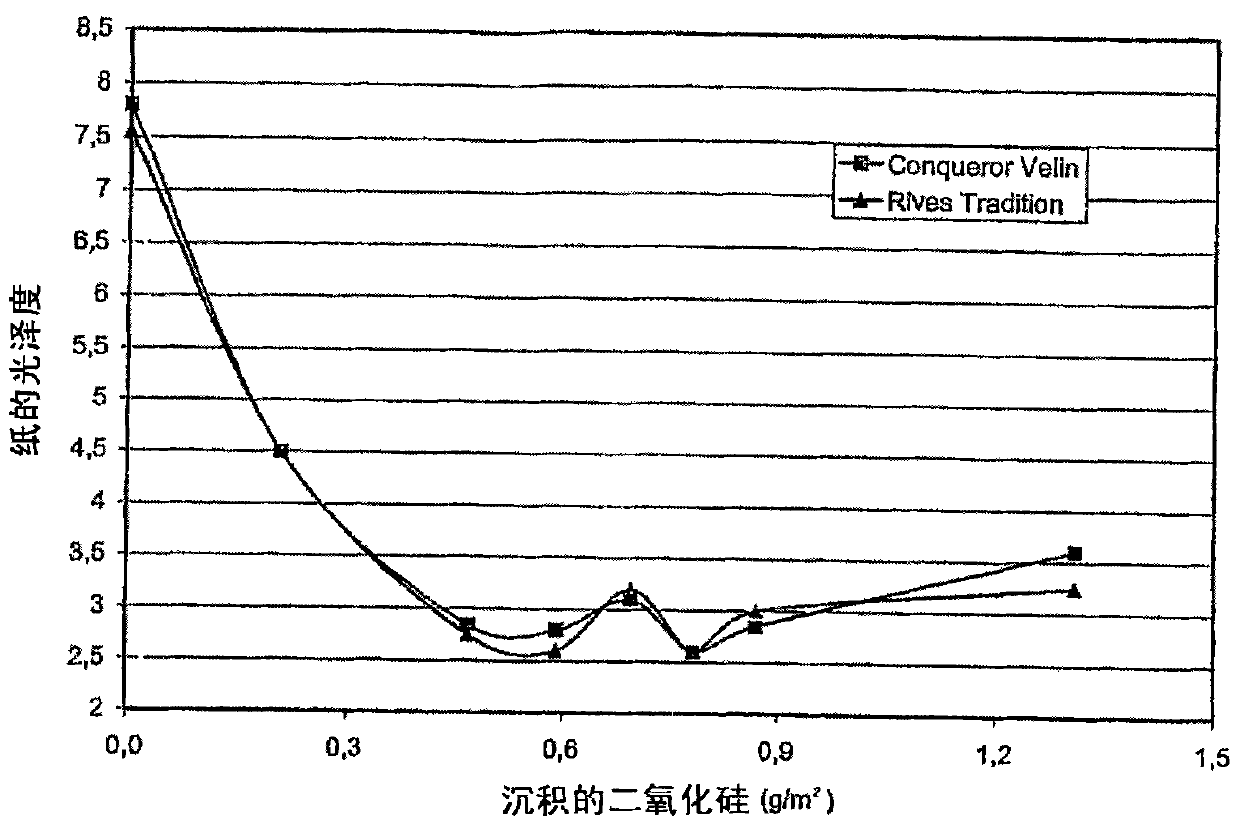

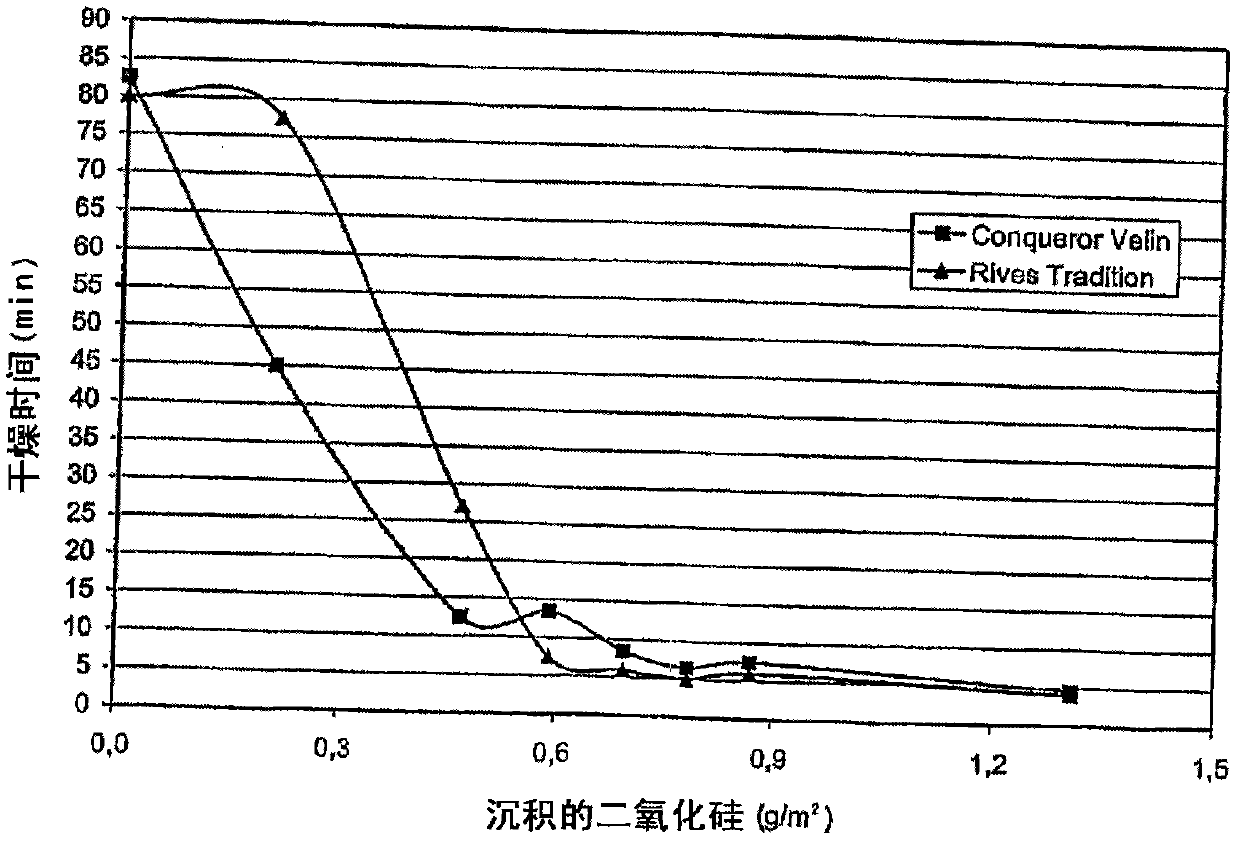

Printable matt fine paper and method of preparing same

InactiveCN102378841AUniform thicknessSmooth outer surfaceNon-fibrous pulp additionCoatings with pigmentsFine paperSilicon dioxide

Matt fine paper for writing and / or that can be printed, in particular by offset printing, having, on at least one of its faces, a layer comprising pigments and a binder, the pigments comprising silica, the average particle diameter of which is greater than or equal to 3 [mu]m, and the amount of which deposited per unit of surface area of the layer is greater than 0.4 g / m2 and less than 1.5 g / m2 or the amount of silica of which is alternatively or in combination greater than 6% and less than 15%, in particular less than 10% by dry weight relative to the total dry weight of the layer, the paper having on said face a degree of gloss before printing of less than 3.5%, measured at 75 DEG according to the Tappi TM T480 standard.

Owner:ARJO WIGGINS FINE PAPERS LTD

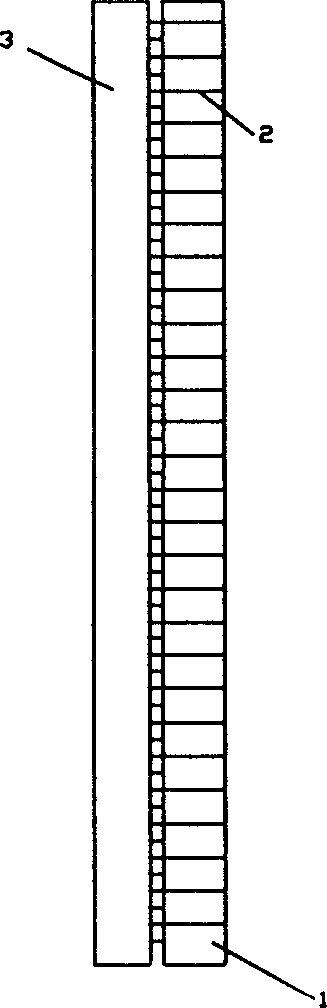

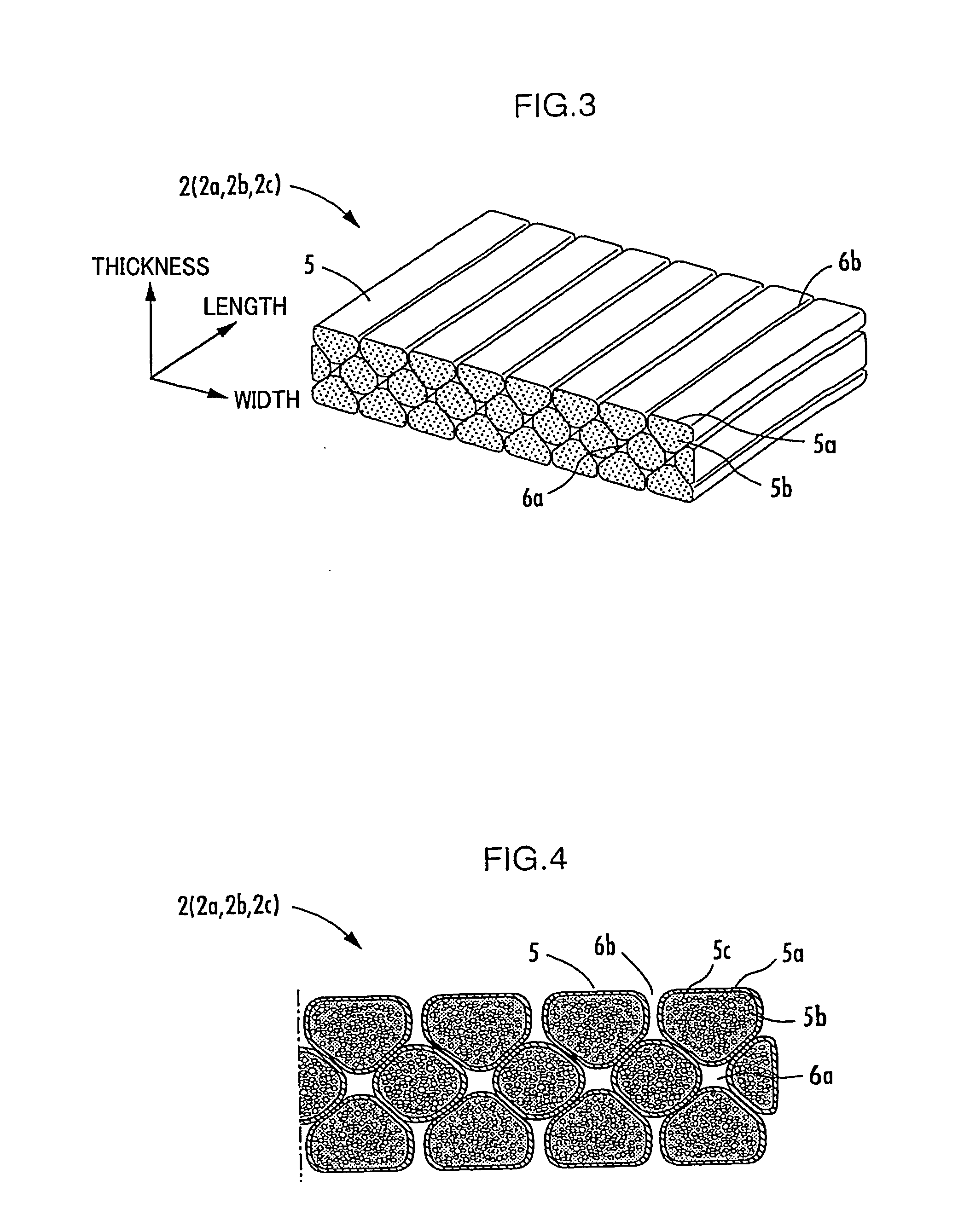

Heat insulator

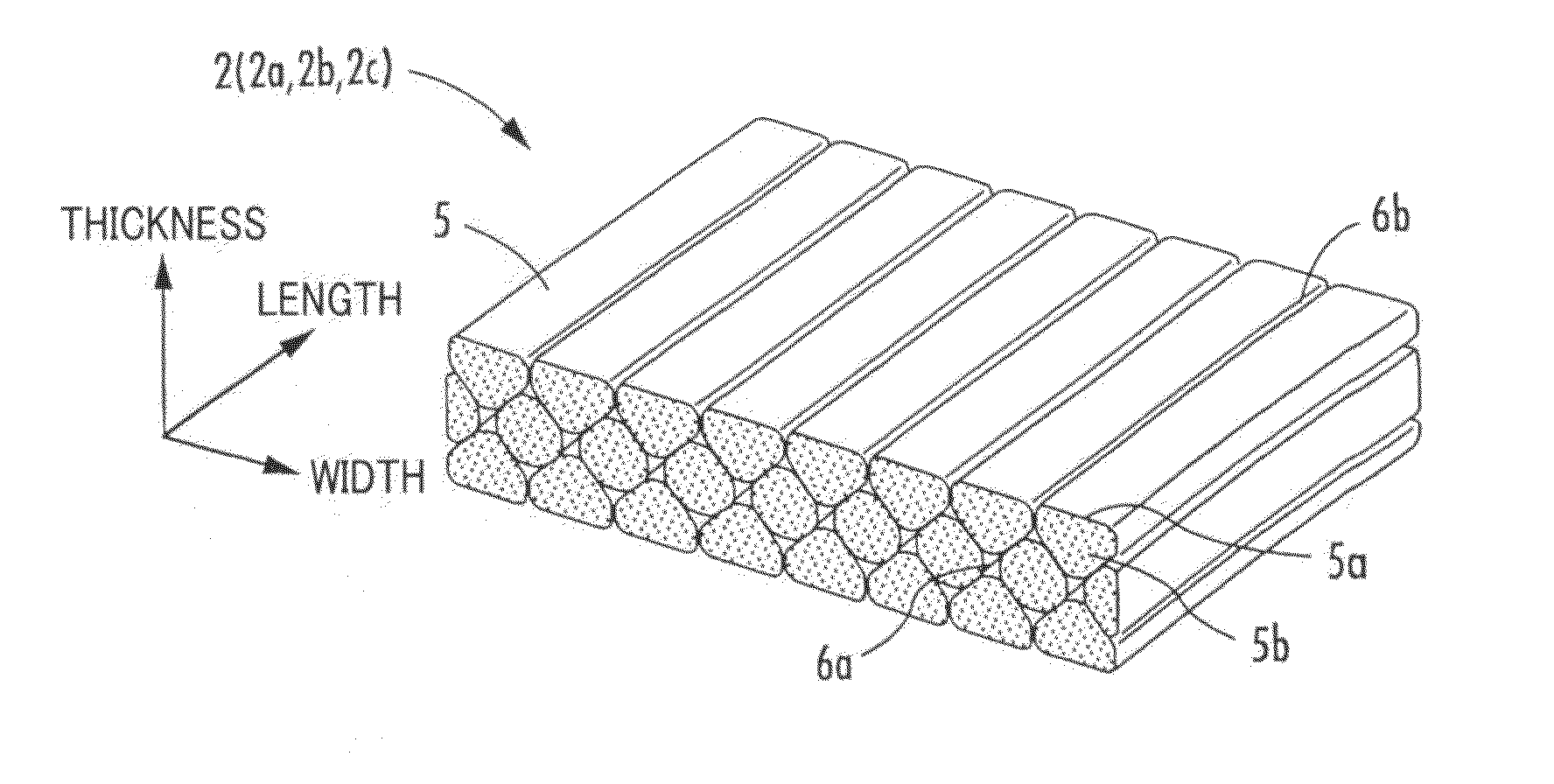

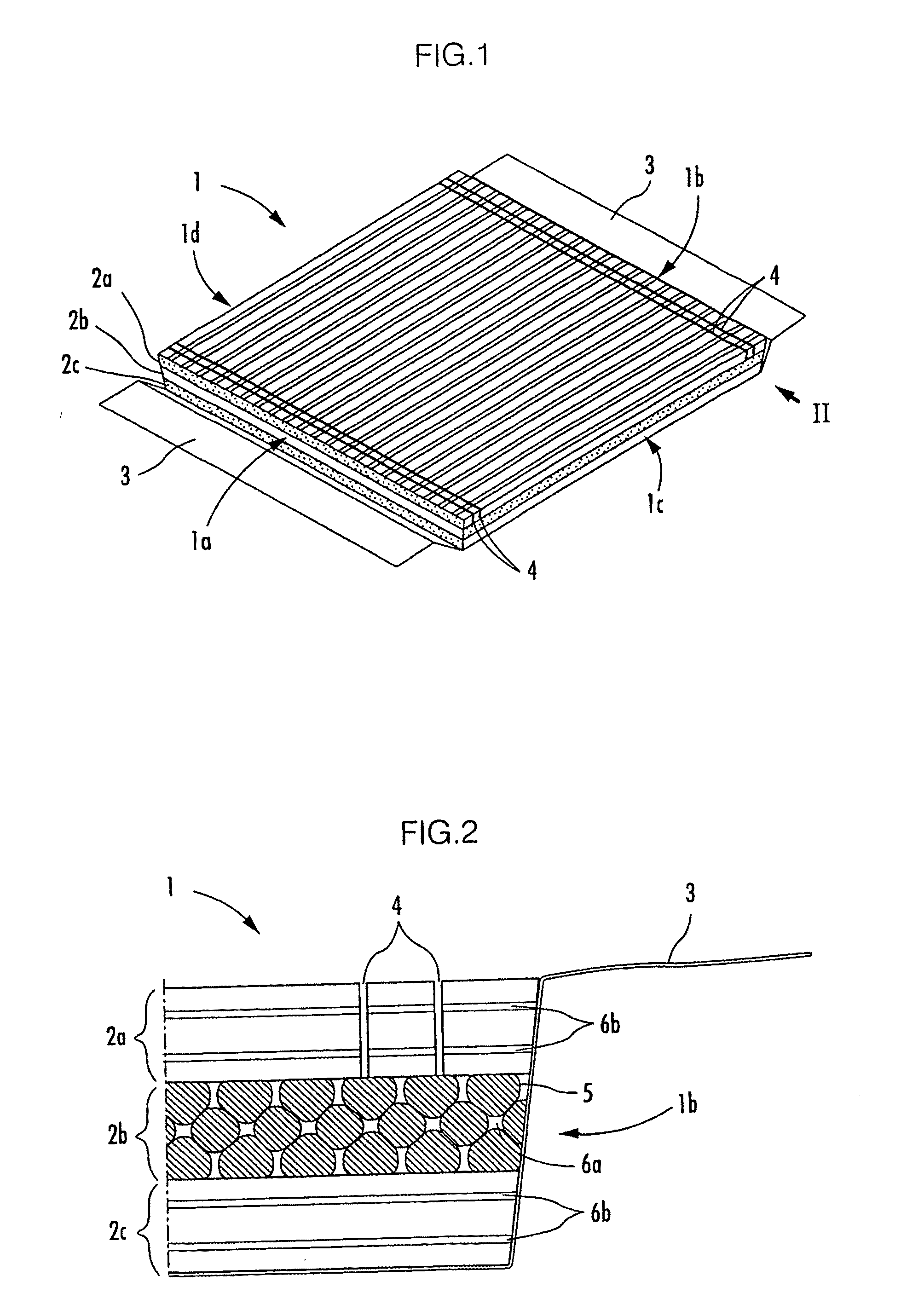

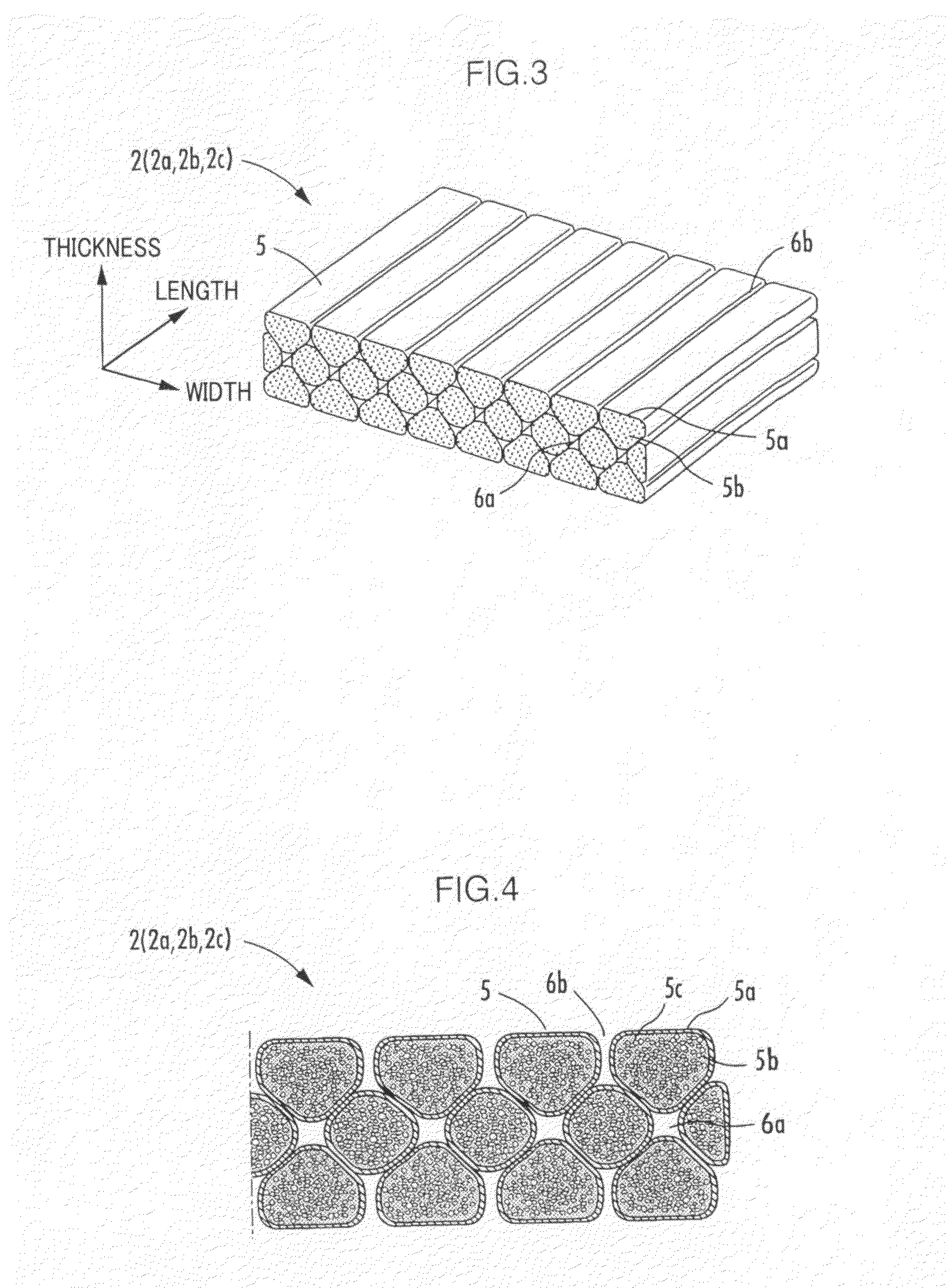

InactiveUS20110244195A1Easy to installGenerates no smokeLayered productsPlastic recyclingPolystyreneEngineering

A heat insulator that generates no smoke when incinerated, has a low calorific value, and achieves a desired dimension and heat insulation performance is provided. A heat insulator 1 is formed by heat-mixing, in an extruder 11, a paper pellet 7 that is a mixture of a fine paper powder having a particle diameter of 30 to 200 μm and starch, a container recycle pellet 8 that is a mixture of polypropylene, polyethylene, and polystyrene, foamable polypropylene 9, and water 10 to obtain a plate-like foamed product 2, and orthogonally overlaying a plurality of plate-like foamed products 2. A weight distribution is set so that the paper pellet 7 is 50 to 65% by weight, the container recycle pellet 8 is 15 to 25% by weight, the foamable polypropylene 9 is 10 to 30% by weight, and the water 10 is 10 to 20% by weight to these resins and other materials.

Owner:KANKYOKEIEISOGOKENKYUSHO CO INC

Papermaking method by oxidizing banana stemfiber

InactiveCN102733251ASolve the problems of papermakingImprove qualityCellulosic pulp after-treatmentNon-woody plant/crop pulpPapermakingFine paper

The invention provides a papermaking method by oxidizing banana stemfiber, comprising the following steps of: cutting banana stem into sheets, and coarsely grinding into fiber sizing agent; washing the fiber sizing agent to remove hemicellulose, lignin, pectin and the like in a washing way; extruding to be fiber sizing agent which has 50%-60% of moisture after washing; adding quick lime and sodium hypochlorite after extruding, charging CO2 gas to oxidize the fiber sizing agent, separating impurity by a centrifugal pulp screen after oxidizing, and carrying out medium-consistency grinding on the pulp to be 32-36 beating degree in the process of separating; and mixing the sizing agent as required, so that the sizing agent is applicable to the sizing agent quality requirement of various papers. According to the invention, the papermaking method which oxidizes the banana stemfiber, and is free from stewing, pollution-free to environment, low-carbon, and energy-saving is adopted, so that the banana fiber papermaking difficulty can be effectively solved, the banana stemfiber can be softened within 40min, and the integrants which can not be used for papermaking in the hemicellulose, the lignin and the banana stem can be separated; and therefore, the banana fiber paper pulp which is suitable for making the fine paper can be obtained.

Owner:云南柏昇生物科技有限公司

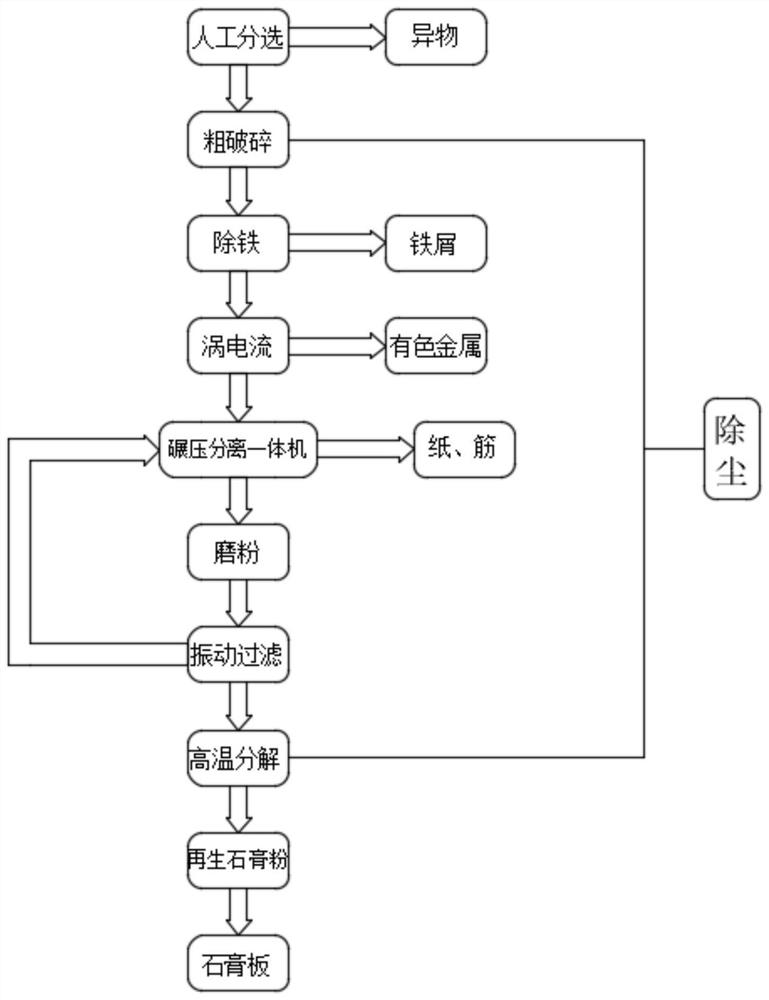

Production method for fully separating, regenerating and recycling old gypsum boards

The invention relates to a production method for fully separating, regenerating and recycling old gypsum boards. The production method comprises the following steps of S1, manual sorting; S2, coarse crushing; S3, iron removal; S4, nonferrous metal removal; S5, rolling and screening; S6, pulverizing; S7, vibration filtering; S8, high-temperature decomposition; and S9, gypsum board manufacturing. According to the method, nonferrous metal and fine paper, ribs and other impurities in gypsum raw materials can be effectively removed, the purity of the gypsum board is improved, and high color difference of the gypsum boards manufactured by recycling materials is avoided.

Owner:TAICANG GOLDENMA METAL STRUCTURE

Bamboo wallpaper weaving method

InactiveCN1631627ALow costEasy to get materialsCane mechanical workingWood layered productsNatural substanceEngineering

The invention discloses a bamboo wallpaper weaving method and relates to indoor decorative wallpaper made of natural bamboo with natural tint. The technique procedure involves bamboo fins, thin rope and back lining layer, includes lengthwise arrangement of bamboo fins each column of which is lined up lengthwise by thin rope. Back lining layer is attached to the back of the bamboo fins. Above back lining layer is capable of paper, cloth and fine paper. The clearance between the bamboo fins is 0 to 5 centimeters and between the ropes 0 to 5 centimeters. The weaving method introduced in this invention is adopted with natural bamboo which is harmless to human body preventing the sicknesses caused by the decorative material harmful smells; moreover the bamboo wallpaper is absorbing carbon dioxide in the room facilitating the indoor air refreshment which can be called as natural oxygen cylinder.

Owner:陈玉强

Heat insulator

ActiveUS8414998B2Generates no smokeLow calorific valueLayered productsDecorative surface effectsPolystyreneEngineering

Owner:KANKYOKEIEISOGOKENKYUSHO CO INC

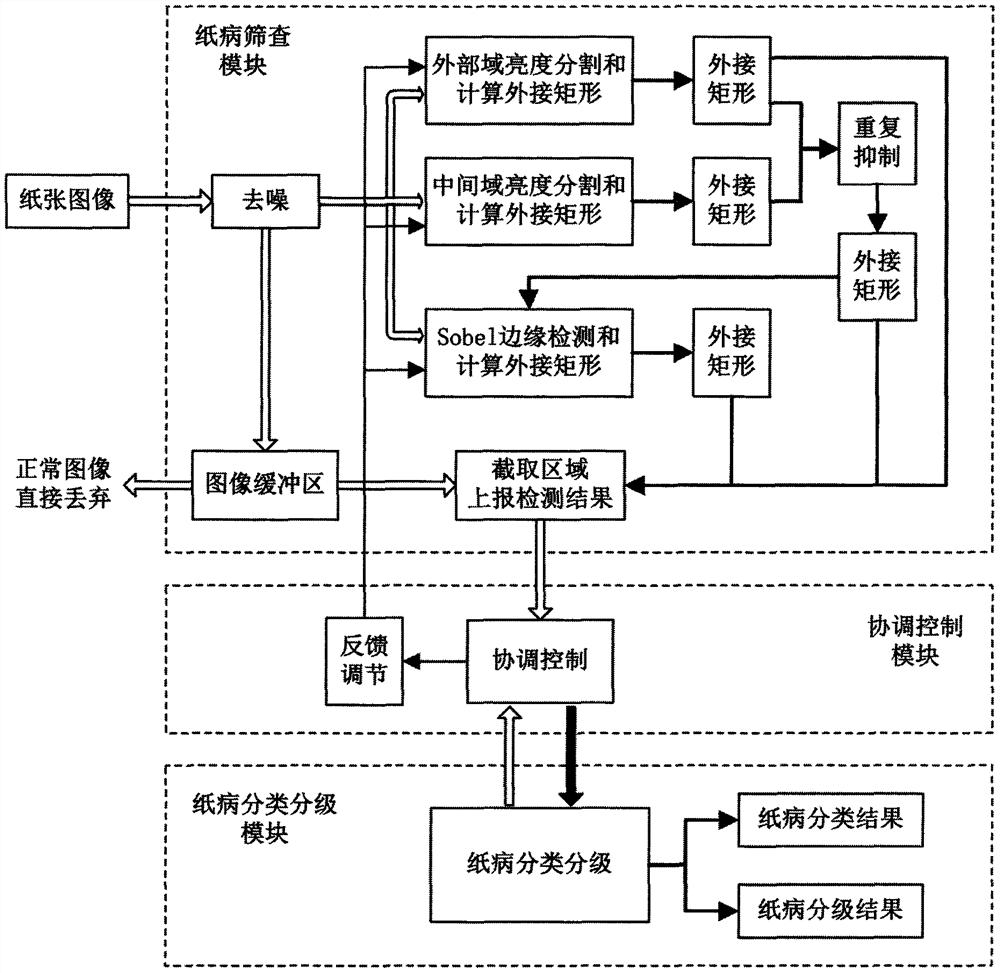

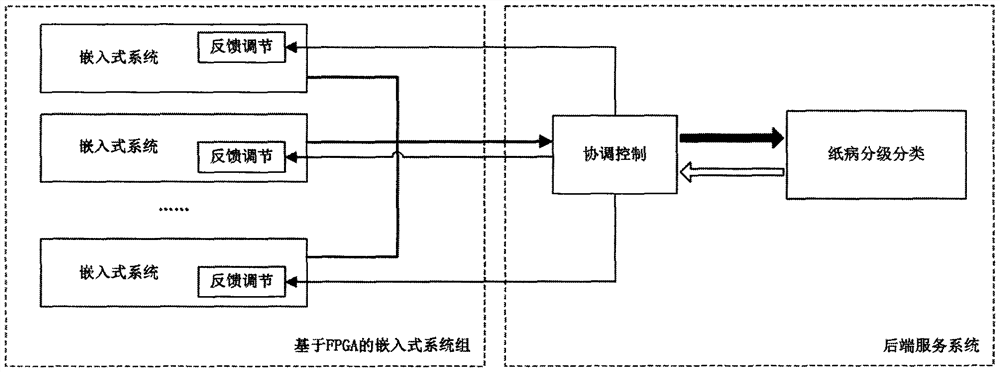

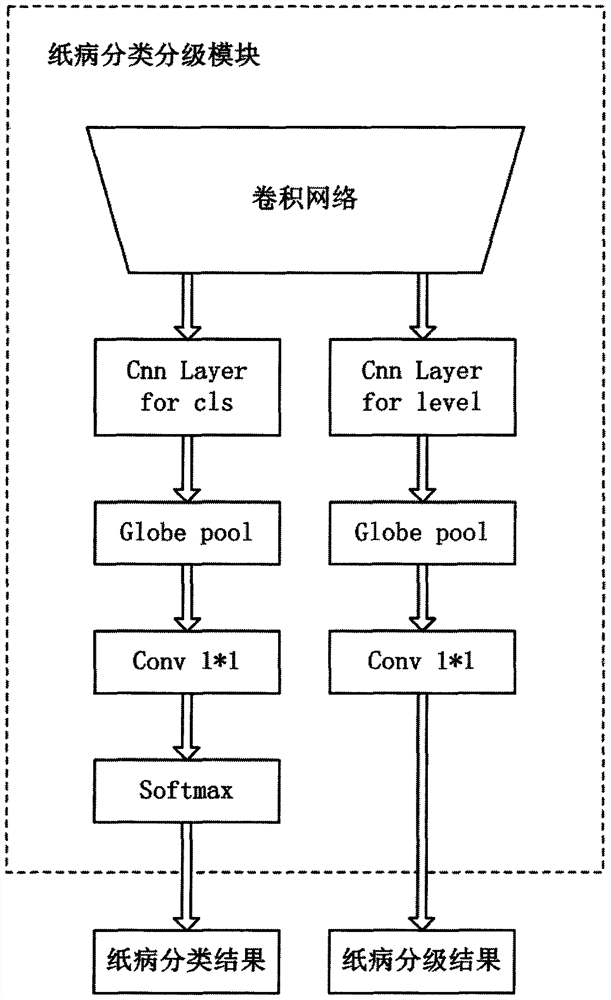

Coarse-to-fine paper defect detection method

ActiveCN111709932AImprove resource utilizationImage enhancementImage analysisImaging processingAlgorithm

The invention relates to the technical field of image processing and paper defect detection, in particular to a coarse-to-fine paper defect detection method which mainly comprises three modules and processes, namely a paper defect screening module, a coordination control module and a paper defect classification module. The method comprises the following steps that: 1, a paper defect screening module runs in an FPGA-based embedded system to ensure that a high-speed high-resolution paper image can be processed in real time, thus screening out an image possibly having a defect after the sampled paper image is primarily processed, directly discarding a normal image after the paper defect is screened, and transmitting an image with a suspected paper defect to the next step; secondly, the coordination control module mainly completes the functions of function calling, feedback control and the like between the paper defect screening module and the paper defect classification and grading module; thirdly, the paper defect classification and grading module builds a classification and grading network through a convolutional network, the classification network can complete the function of classifying paper defects, and the grading network can complete the function of grading the severity degree of the paper defects.

Owner:广州麦仑信息科技有限公司

Pulping equipment and method for toilet paper machine

ActiveCN112144310AFully integratedImprove beating efficiencyPulp beating methodsPaper recyclingElectric machineryProcess engineering

The invention discloses pulping equipment for the toilet paper machine. The pulping equipment comprises a gantry framework, sliding grooves are formed in the two sides of an inner cavity of the gantryframework, a shaking frame is arranged in the inner cavity of the gantry framework, sliding auxiliary mechanisms are slidably connected to the inner cavities of the sliding grooves, and the oppositesides of the two sliding auxiliary mechanisms are welded to the shaking frame; and a first motor is installed at the bottom of an inner cavity of the shaking frame, a pulping tank is fixedly installedat the top of the shaking frame, and an output shaft of the first motor penetrates into the inner cavity of the pulping tank and is fixedly connected with a pulping rod. The first motor is started todrive the pulping rod to rotate to pulp a paper raw material in the pulping tank, and the shaking mechanism is started to shake the pulping tank up and down, so that the paper raw material and watercan be fully mixed to obtain fine paper pulp, and the pulping efficiency of the pulping equipment is improved; and the quality of the toilet paper can be improved.

Owner:山东凯信重机有限公司

A waste cigarette shredded tobacco recovery device

ActiveCN109330019BReduce lossFully automatedCigarette manufactureVortex flow apparatusPaper dustEnvironmental engineering

The invention relates to a recovery device for waste cigarettes and shredded tobacco, which comprises a cigarette straightening device, a tobacco cutting device, a shredded tobacco-dirty separation device and a shredded tobacco purification device. Incoming waste cigarettes are separated from shredded tobacco debris in the straightening device, and the cigarettes are straightened and then sent to a cutting device for cigarettes. In the cutting device, they are positioned, rolled, and completely cut, and then shredded tobacco, filter tips, and tobacco paper are sent to the shredded tobacco-dirty separation device for preliminary separation of shredded tobacco and large-sized sundries. Then the separated shredded tobacco is sent to the shredded tobacco purification device again to further separate fine paper scraps and other sundries in the shredded tobacco. The device for recovering waste cigarettes and shredded tobacco in the present invention has the advantages of high degree of mechanization, high efficiency of shredded tobacco recycling, complete separation, applicable to various kinds of cigarettes, and small occupied space.

Owner:郑州格兰高环境工程有限公司

Styrene-acrylic emulsion, preparation method thereof, and application thereof

ActiveCN102775542BGood film formingImprove hydrophobicityWater-repelling agents additionPaper coating(Hydroxyethyl)methacrylateEmulsion

The invention relates to a styrene-acrylic emulsion, a preparation method thereof, and an application thereof. The styrene-acrylic emulsion provided by the invention comprises the components of: starch, amylases, a cationic monomer, an acrylate monomer, a crosslinking monomer, styrene, a dispersing agent, hydroxyethyl methacrylate, an initiator aqueous solution with a concentration of 20wt%, and deionized water. A surface sizing emulsion prepared by using the styrene-acrylic emulsion provided by the invention and biological latex has better film-forming performance and good hydrophobicity. With the surface sizing emulsion, paper can be provided with better surface strength, better printing performance, and certain water resistance. The styrene-acrylic emulsion is environment-friendly. When in use, the surface sizing emulsion prepared by using the styrene-acrylic emulsion provided by the invention is directly coated on the surface of paper, and surface sizing starch is no longer used during the surface sizing process. Therefore, a fine paper surface sizing operation process is simplified, and surface sizing process stability in fine paper production is improved.

Owner:广州市迪笙生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com