Styrene-acrylic emulsion, preparation method thereof, and application thereof

A styrene-acrylic emulsion and emulsion technology, which is applied in the papermaking field to achieve the effects of good surface strength, simplified operation process, and improved surface strength and sizing degree of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

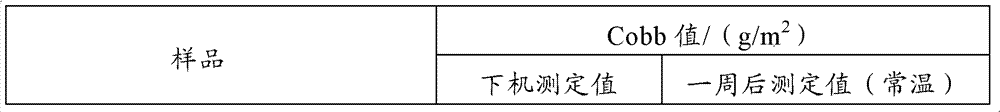

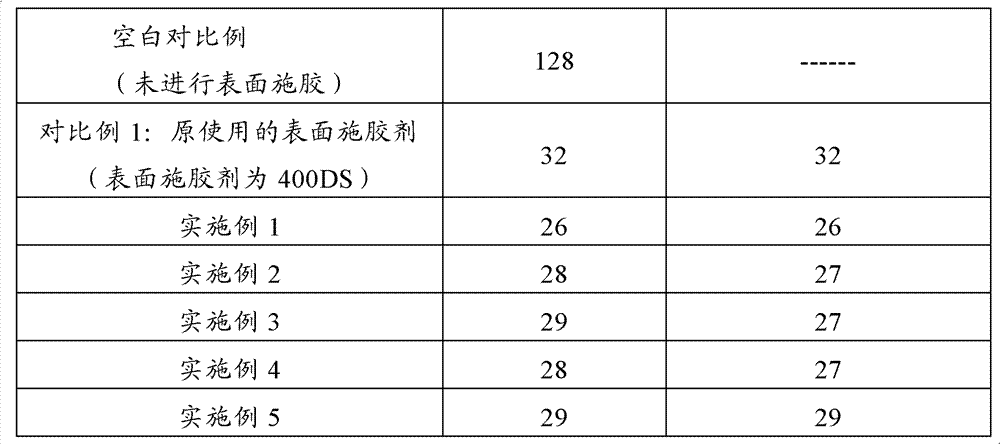

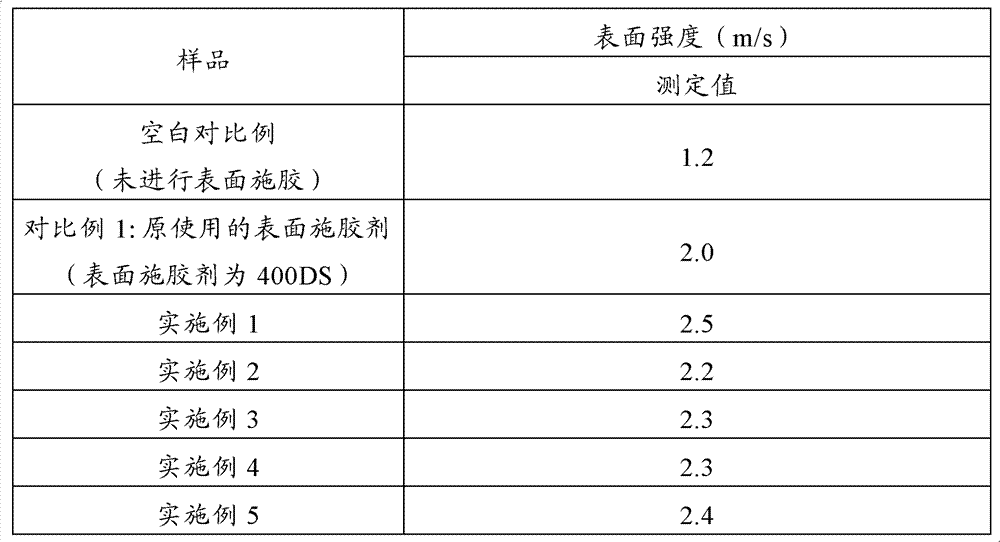

Examples

Embodiment 1

[0037] 1. Preparation of styrene-acrylic emulsion: raw materials: 690kg of deionized water, 100kg of CS-08 starch, 0.6kg of amylase (sizing enzyme KDNzymeS60, Shanghai Kangdien Biological Group), 15kg of gelatin with a molecular weight of 20000g / mol, 30kg of hydroxyethyl acrylate Grease, 1kg cationic monomer acryloyloxyethyltrimethylammonium chloride, 0.5kg concentration of ammonium persulfate aqueous solution of 20% by weight as initiator, styrene 100kg, N, N`-methylene acrylamide 3kg, 60kg of propyl methacrylate.

[0038] Add 300kg of deionized water into the reaction tank, add 100kg of CS-08 starch, add 0.6kg of amylase, heat up to 65°C, heat up to 85°C with steam after 0.5 hours of reaction time, add 15kg of gelatin, and then add 200kg of deionized water, Until the gelatin dissolves in deionized water, keep it warm for 0.5 hours, then add 190kg of deionized water, cool down to 45°C, add 30kg of hydroxyethyl acrylate, add 1kg of cationic monomer acryloyloxyethyltrimethylamm...

Embodiment 2

[0042] 1. Preparation of styrene-acrylic emulsion: raw materials: 630kg deionized water, 100kg CS-08 starch, 0.6kg amylase (LPK-CS01S amylase, Shenzhen Lvweikang Biological Engineering Co., Ltd.), 12kg gelatin with a molecular weight of 100000g / kg, 30kg Hydroxyethyl methacrylate, 2kg cationic monomer dimethylaminoethyl methacrylate chloride, 0.6kg concentration are 20% ammonium persulfate aqueous solution by weight as initiator, styrene 95kg, N, N`- Methylene acrylamide 3kg, propyl methacrylate 65kg.

[0043]Add 300kg of deionized water into the reaction tank, add 100kg of CS-08 starch, add 0.6kg of amylase, heat up to 65°C, heat up to 85°C with steam after 0.5 hours of reaction time, add 12kg of gelatin, and then add 200kg of deionized water, Until the gelatin is dissolved in deionized water, keep it warm for 0.5 hours, then add 130kg of deionized water, cool down to 45°C, add 30kg of hydroxyethyl methacrylate, and add 1.5kg of cationic monomer dimethyl diallyl ammonium chlor...

Embodiment 3

[0047] 1. Preparation of styrene-acrylic emulsion: raw materials: 690kg of deionized water, 100kg of CS-08 starch, 0.6kg of amylase (Au-PEA550S amylase, Su Kehan (Weifang) Biological Engineering Co., Ltd.), 10kg of gelatin with a molecular weight of 100,000g / mol , 30kg hydroxyethyl methacrylate, 1.5kg cationic monomer dimethyl diallyl ammonium chloride, 0.6kg concentration is the ammonium persulfate aqueous solution of 20% by weight as initiator, styrene 100kg, acrylate aminopropyl 4kg ester, 60kg butyl methacrylate.

[0048] Add 300kg of deionized water to the reaction tank, add 100kg of CS-08 starch, add 0.6kg of amylase, heat up to 65°C, heat up to 85°C with steam after 0.5 hours of reaction time, add 10kg of gelatin, and then add 200kg of deionized water, Until the gelatin dissolves in deionized water, keep it warm for 0.5 hours, then add 190kg of deionized water, cool down to 45°C, add 30kg of hydroxyethyl methacrylate, and add 1.5kg of cationic monomer dimethyl diallyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com