Printable matt fine paper and method of preparing same

A printing paper, advanced technology, applied in the direction of duplication/marking method, printing, papermaking, etc., can solve the problems of increased gloss of high-grade paper, increase ink drying time, etc., and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0057] Experimental examples 1 and 2 involve fine paper, Rives Tradition Used in Experiment 1, Conqueror Velin For Experimental Example 2, they were all untreated, ie not covered with a treatment coating.

[0058] The other experimental examples (3 to 12) relate to treated fine papers, ie comprising a pigment and binder based treatment coating on at least one surface of the fine paper.

[0059] In Experimental Example 3, the treatment coating contained 60% of kaolin with a particle size of less than 2 μm as the sole pigment. Therefore, the treatment coating has no silica. The binder in the coating is styrene-acrylic, and the coating also includes a synthetic thickener. 8g / m by air knife technology 2 The rate per side deposits the treatment coat on fine paper.

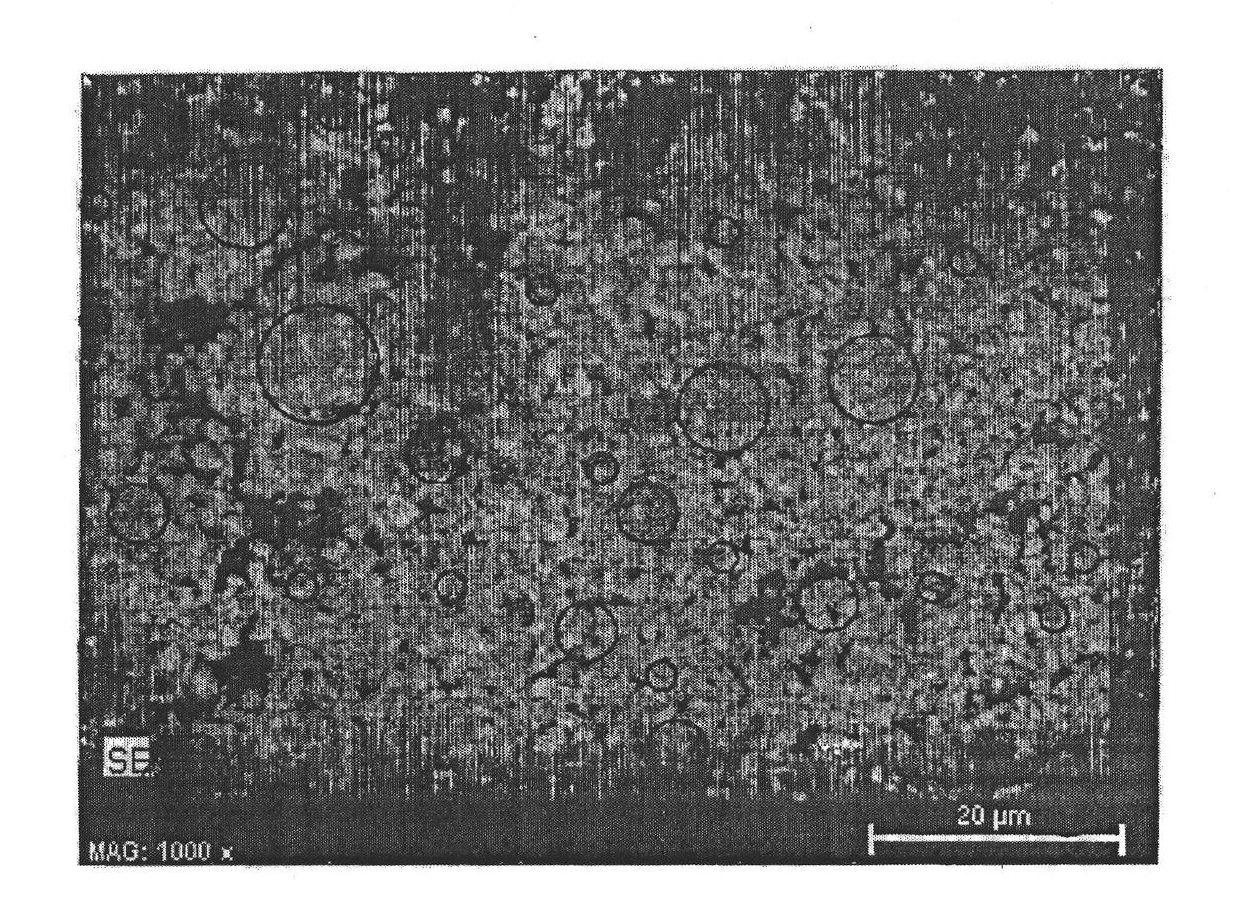

[0060] The fine papers in Experimental Examples 4 to 12 were all covered with a treatment coating comprising silica under the trademark Syloid ED5 by the supplier Grace. Products on sale. It comprises porous a...

experiment example 5

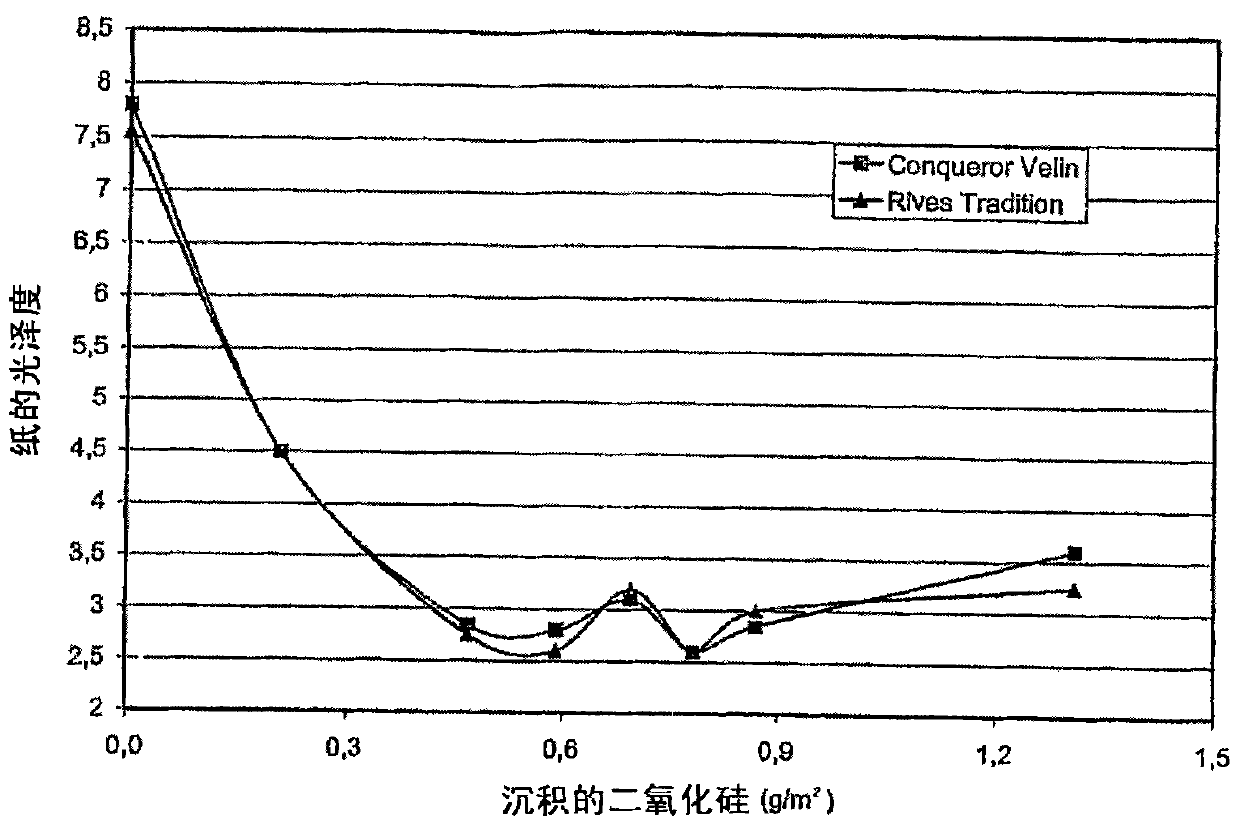

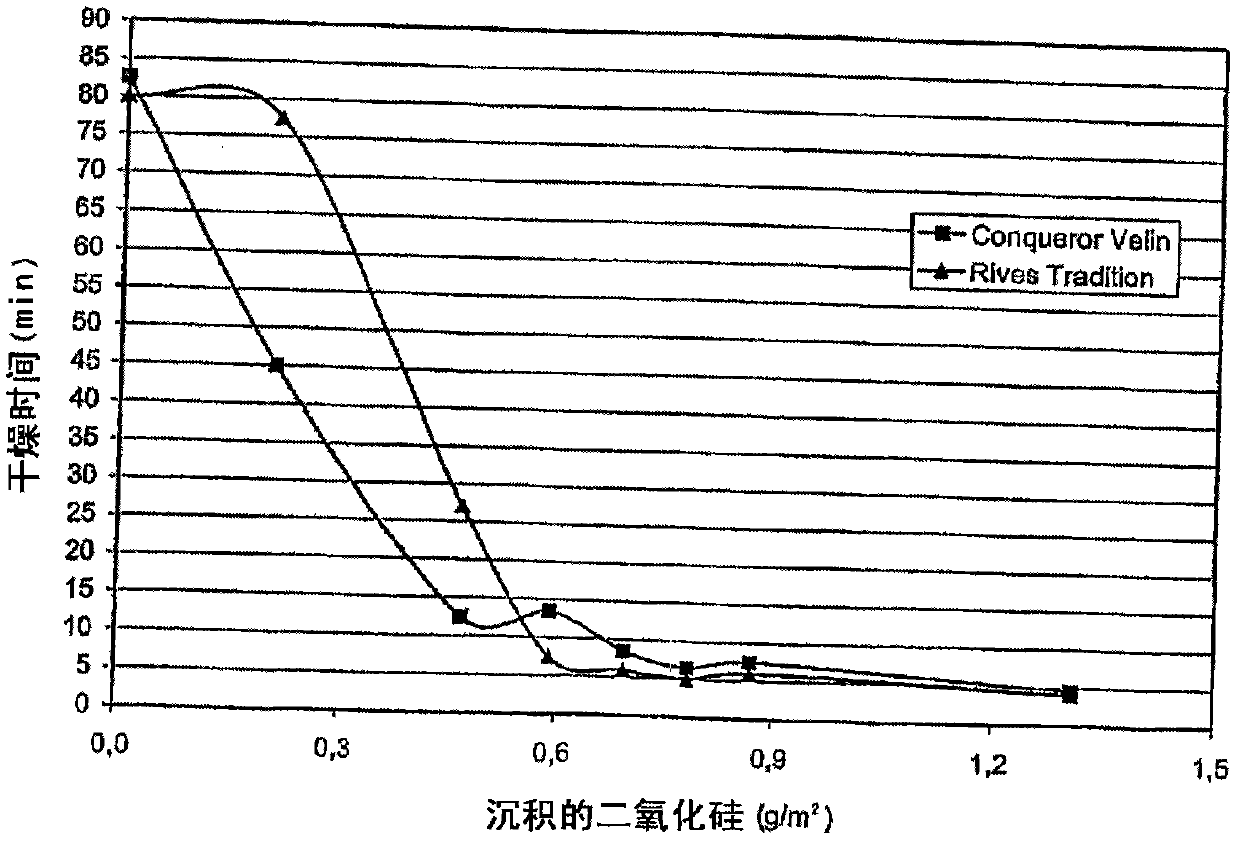

[0084] The high-grade paper in Experimental Example 5 is a textured paper, so it should be compared with figure 1 and 2 Applies to Rives Tradition in Compare the curves of the paper. The fine paper is covered with a treatment coating such that the amount of deposited silica is 0.47 g / m 2 . like figure 1 As shown, this amount of silicon dioxide helps to make the glossiness of high-grade paper lower than 6% after printing, that is, the glossiness before printing is lower than 3.5%, which is basically the same as the result of Experimental Example 5 (the high-grade paper before printing The gloss is 2.8%, and its gloss after printing is 4.6%) corresponds. Although the amount of silicon dioxide deposited per unit area in Experimental Example 5 (0.47g / m 2 ) is within the range of values suitable for the present invention, but it cannot sufficiently reduce the drying time of the ink, which is 27 minutes.

[0085] figure 2 It clearly shows that, for paper of this quality,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com