Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

217results about "Coated paper substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

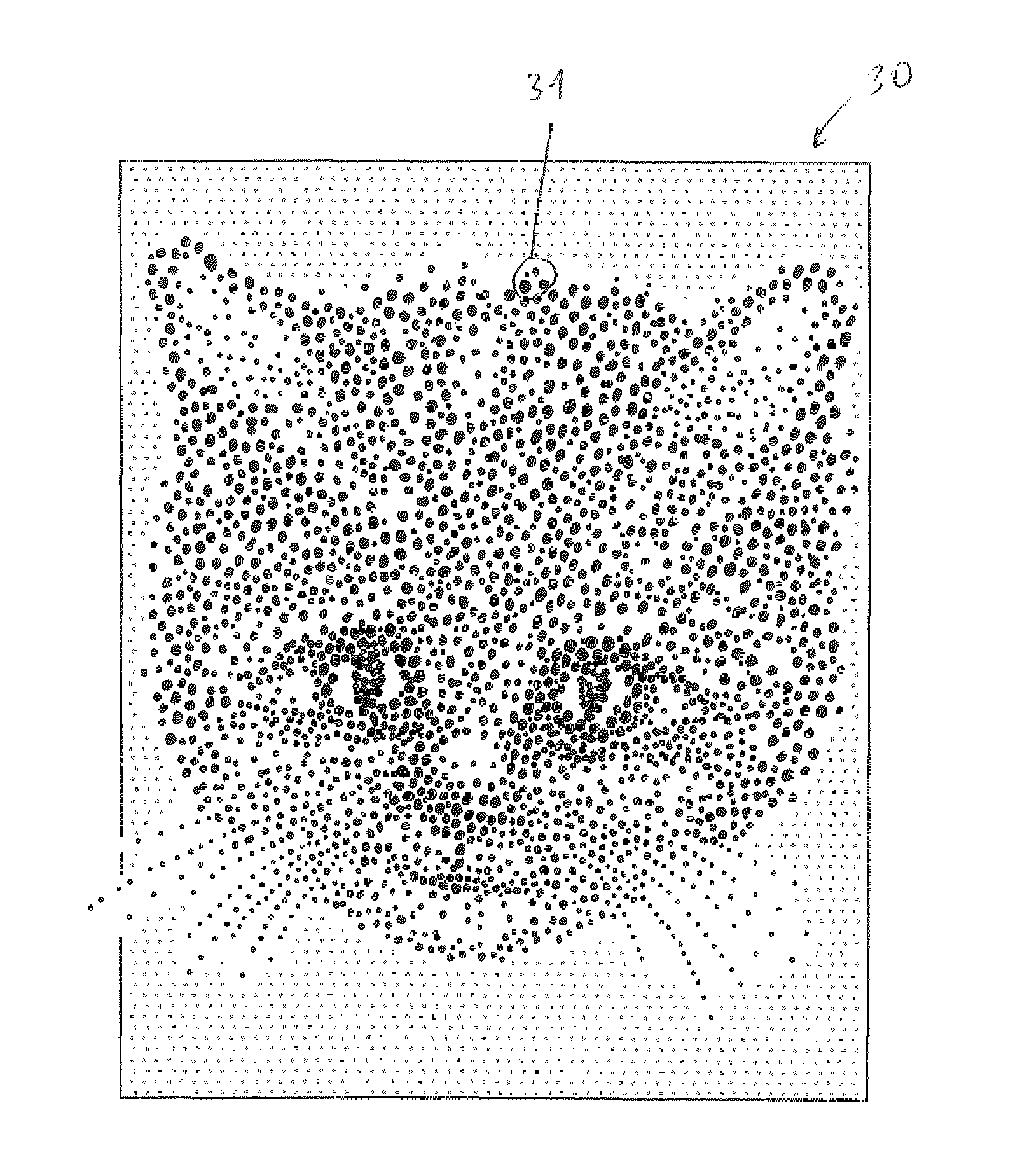

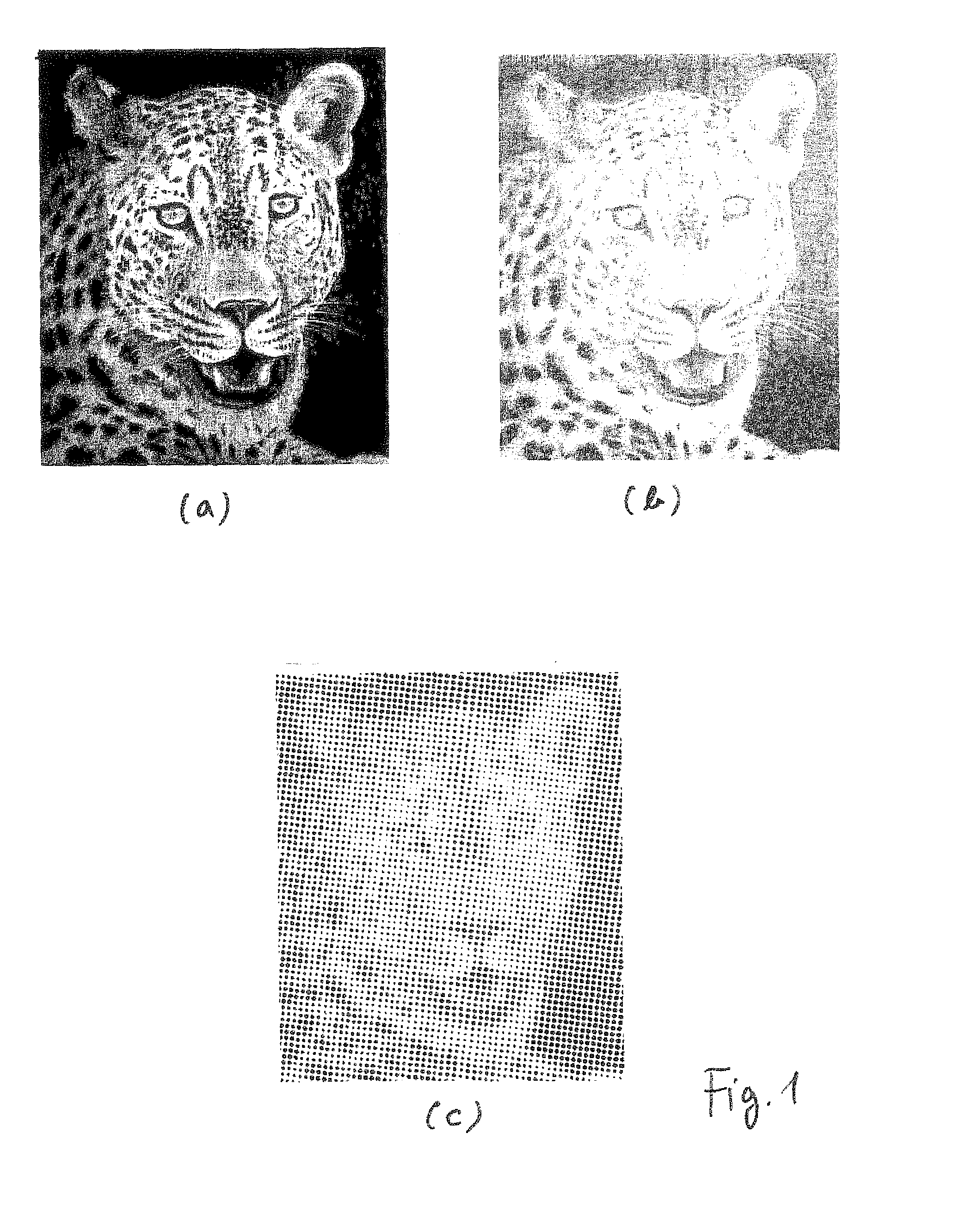

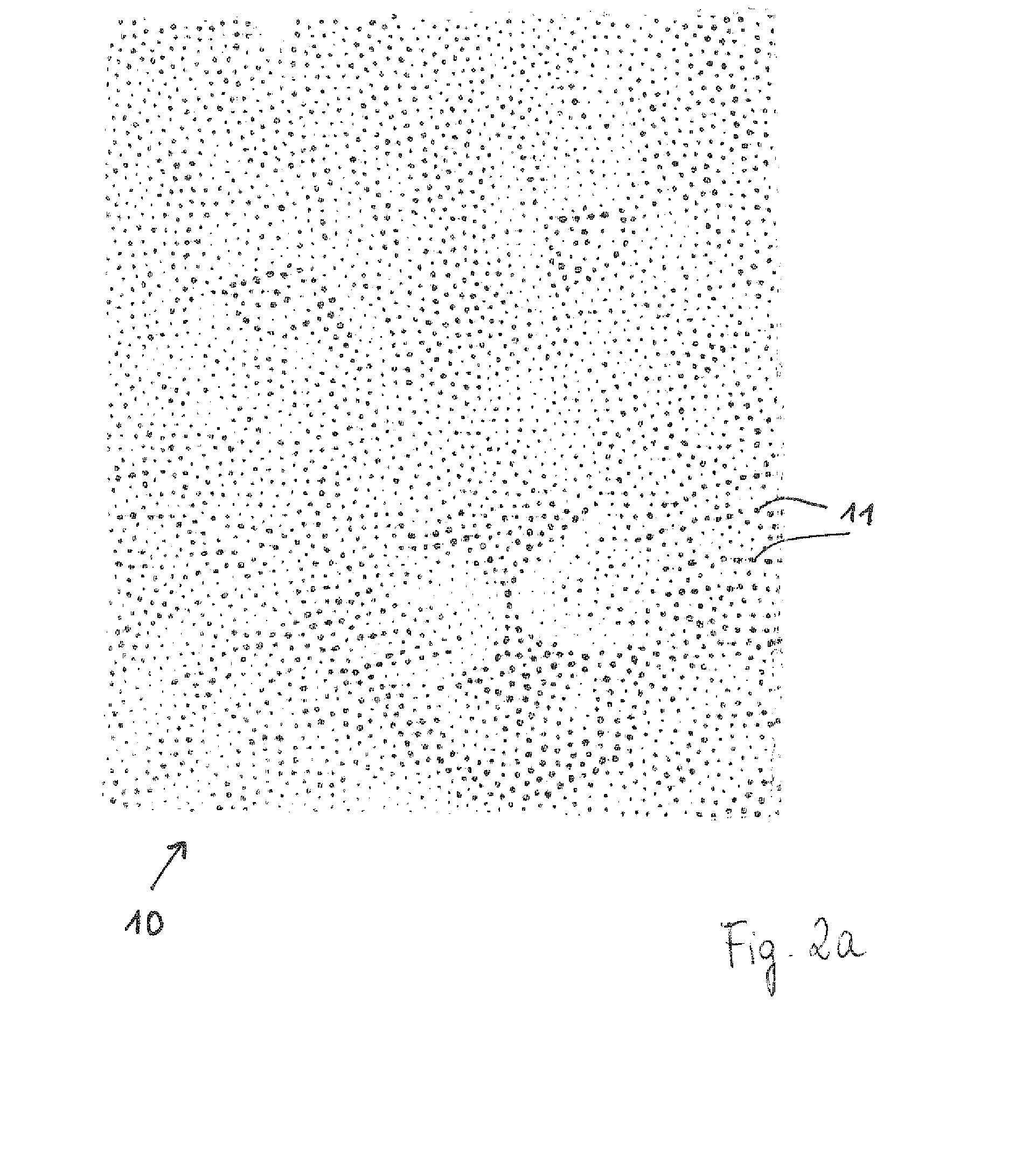

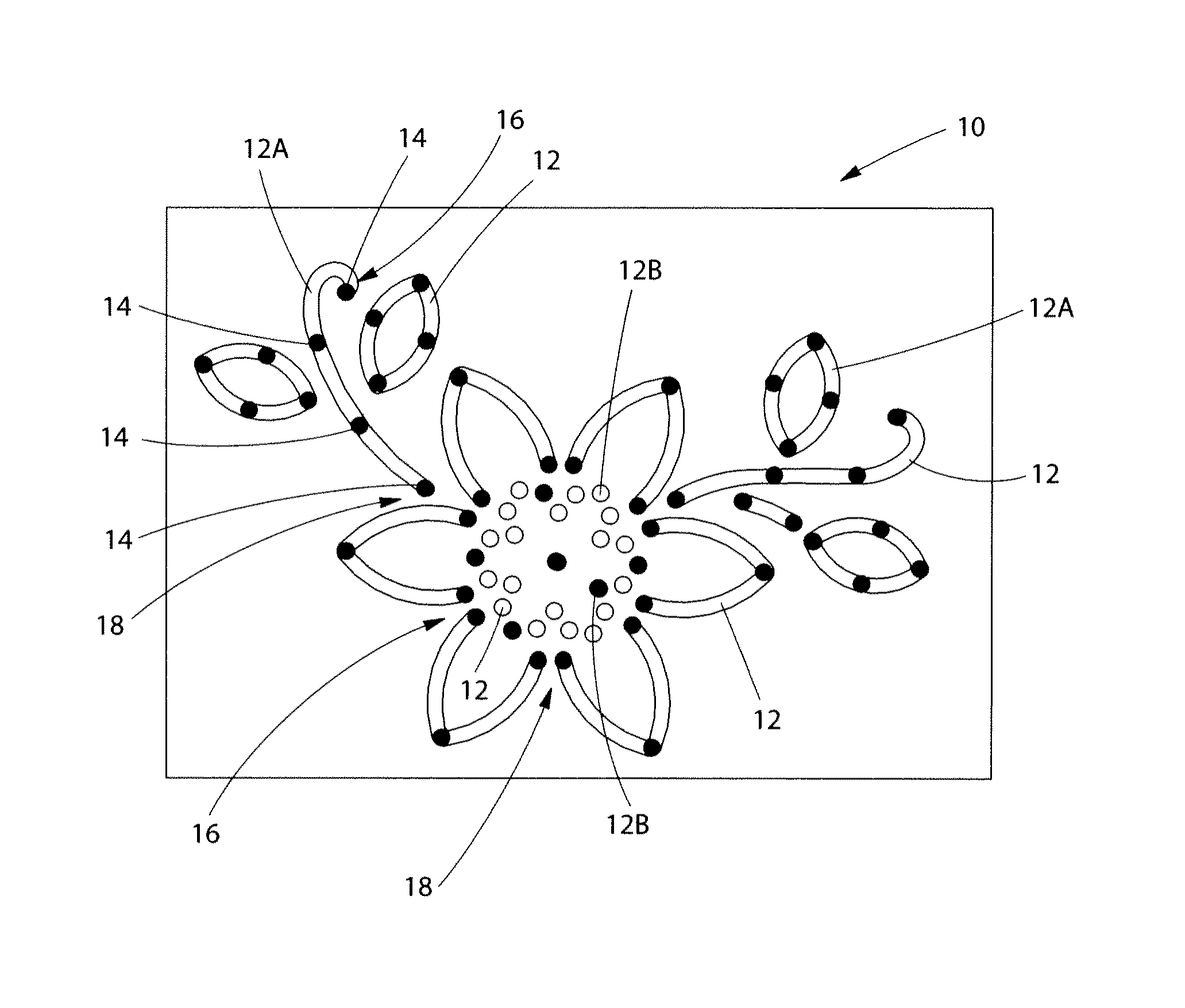

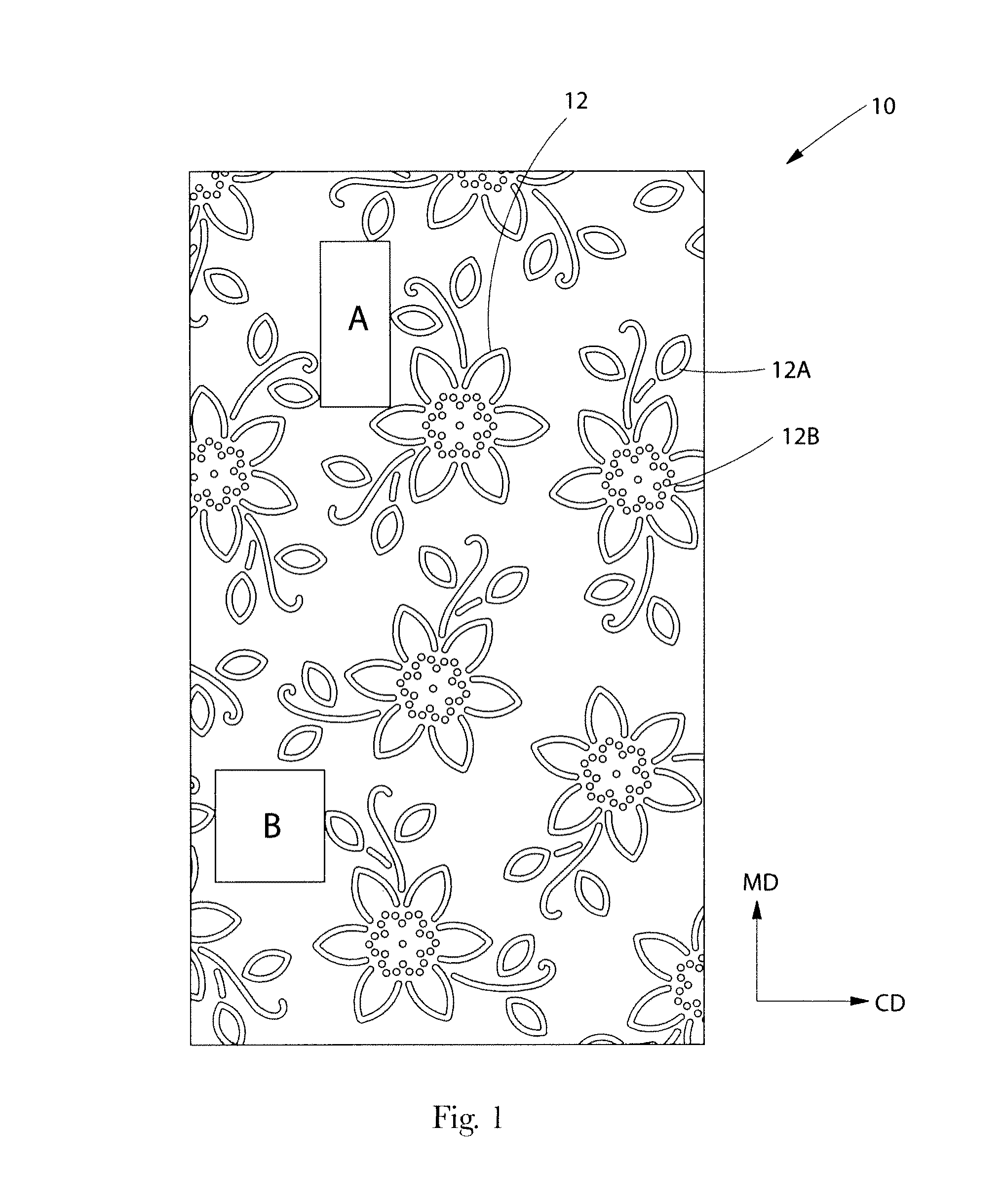

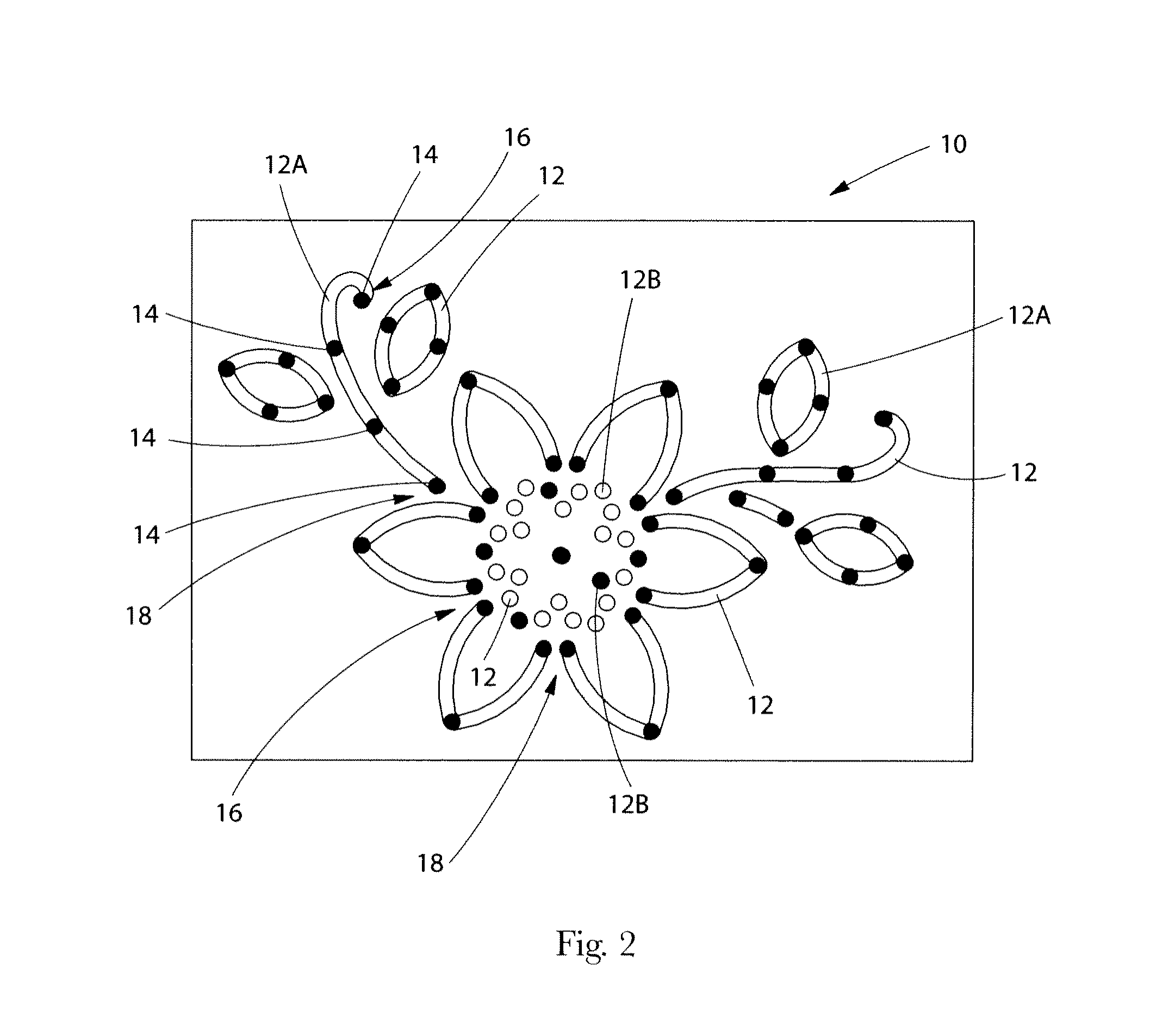

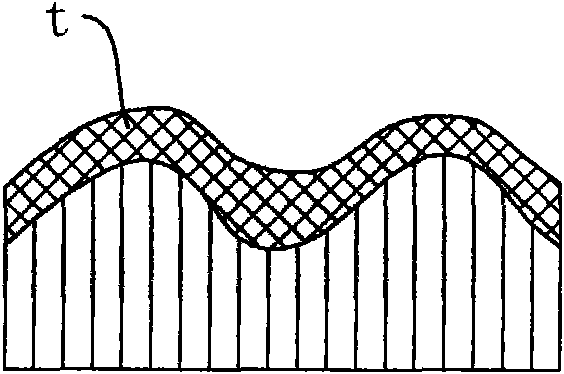

Fibrous product with a rastered embossing and method for producing same

InactiveUS20110223381A1Improve visual effectsIncrease visual appearanceSpecial visual effect coatingsMechanical working/deformationFiberGrating

A fibrous product (10, 20, 20b, 30), especially tissue paper product, non-woven products or a hybrid thereof, and preferably hygiene and cleaning product has at least one first ply (42; 62; 84; 104) with at least one embossing pattern including embossed depressions starting from a base plane of the ply; the embossed pattern being characterized by the following features: the embossing pattern has a minimum motive surface area of at least 3 cm×3 cm; the pattern includes a high number of embossed depressions which are sized and / or positioned such as to form a motive element covering the motive surface area; wherein at least some of the embossed depressions are sized and / or positioned such that minimum distances between pairs of consecutively arranged embossed depression vary. A method for producing such a fibrous product is also described.

Owner:SCA HYGIENE PROD AB

Soft tissue paper having a polyhydroxy compound applied onto a surface thereof

A tissue paper product having at least one ply, wherein only one outer surface of said tissue paper product has a polyhydroxy compound applied thereto by slot extrusion, said polyhydroxy compound providing said tissue paper product with a Wet Burst greater than about 90 g, a Dynamic Coefficient of Friction less than about 0.9, and a Bending Flexibility less than about 0.1 gf cm2 / cm.

Owner:PROCTER & GAMBLE CO

Process for making coated paper or paperboard

InactiveUS20050039871A1Increase shear viscosityEfficient use ofNon-fibrous pulp additionLiquid surface applicatorsPaperboardEngineering

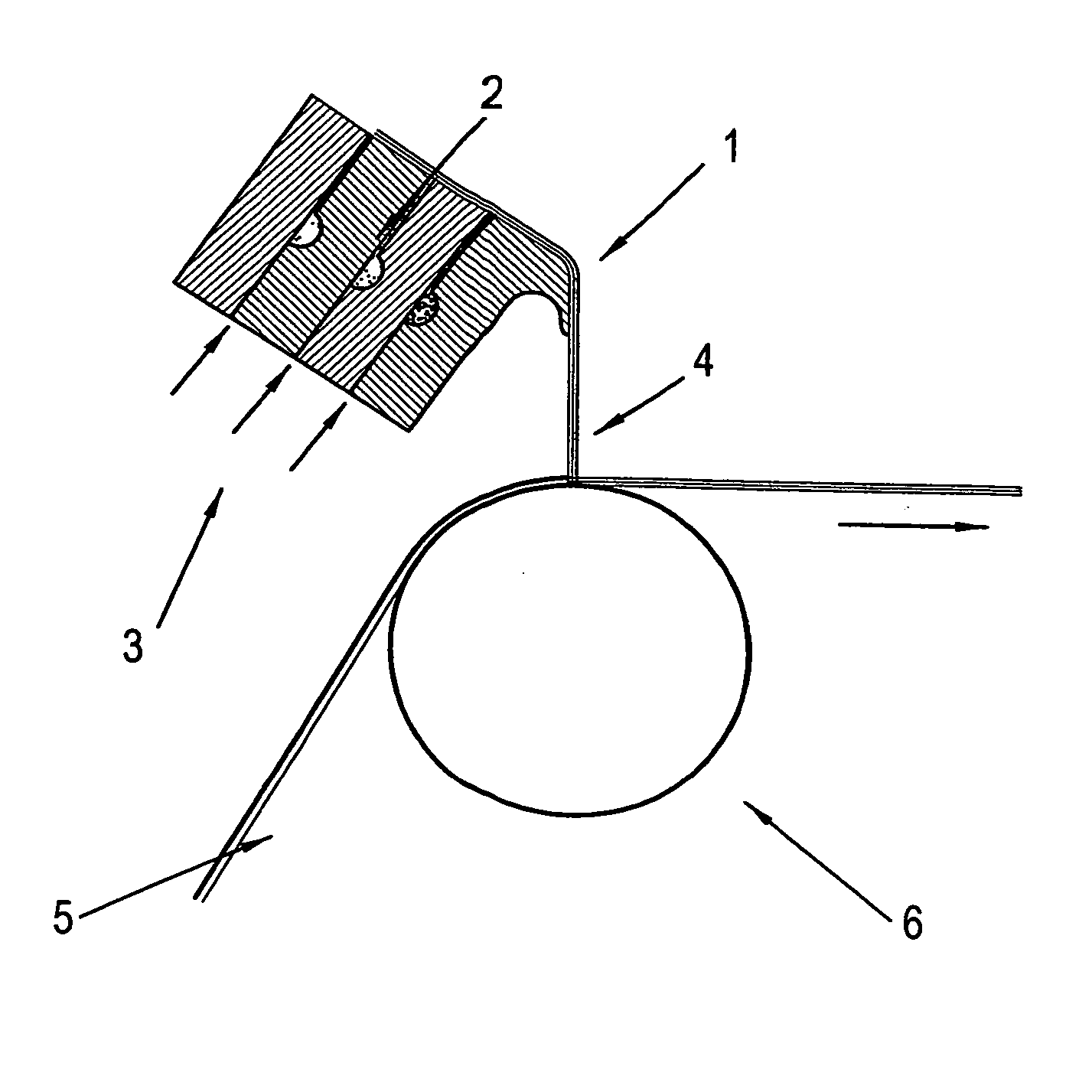

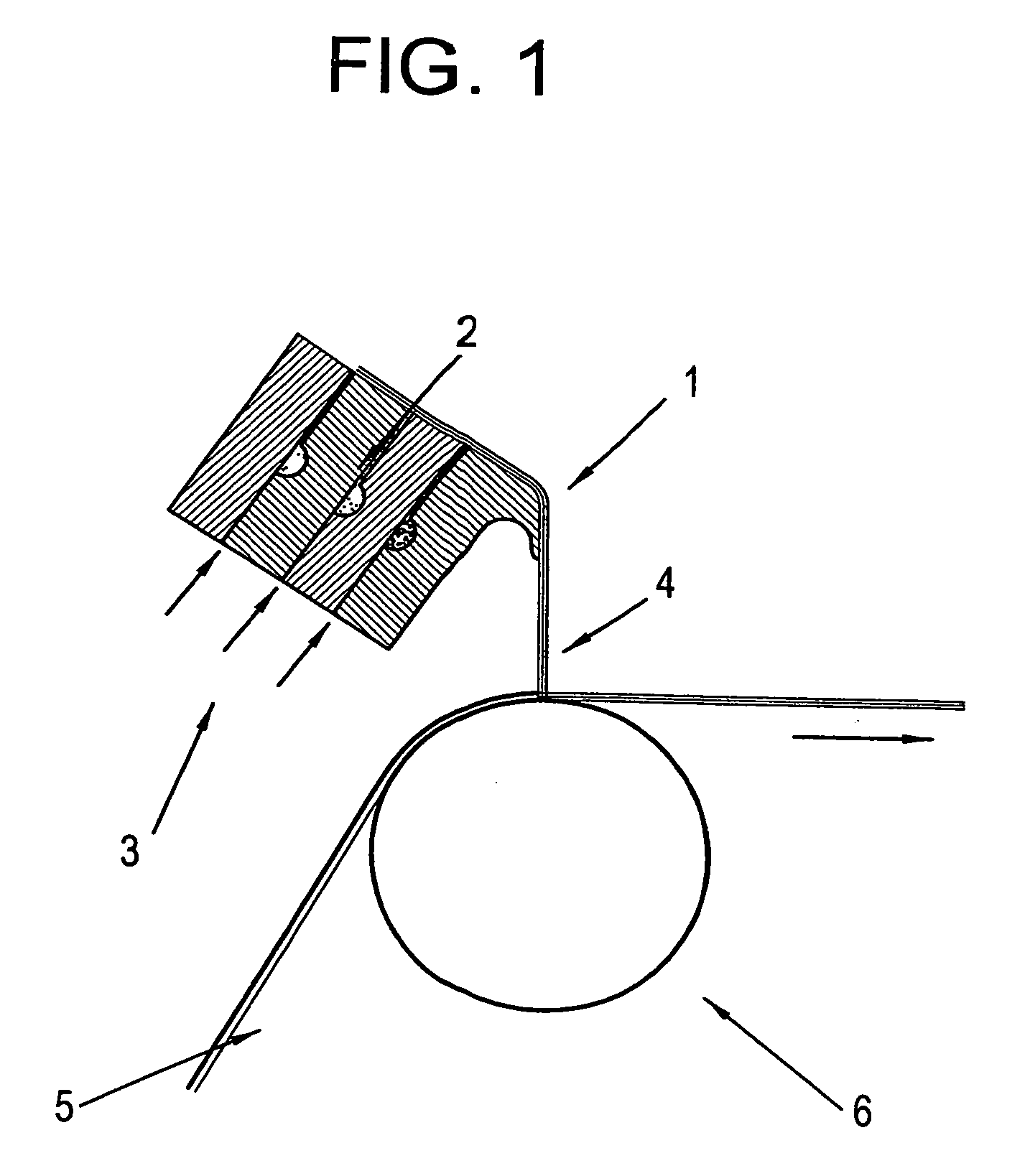

The present invention refers to a method of producing a coated paper or paperboard, but excluding photographic papers, comprising the steps of: (a) forming a free flowing curtain comprising at least one layer, whereby the composition forming at least one layer of the free flowing curtain has a high shear viscosity of at least about 50 mPa.s, and (b) contacting the curtain with a continuous web substrate of basepaper and paperboard.

Owner:DOW GLOBAL TECH LLC

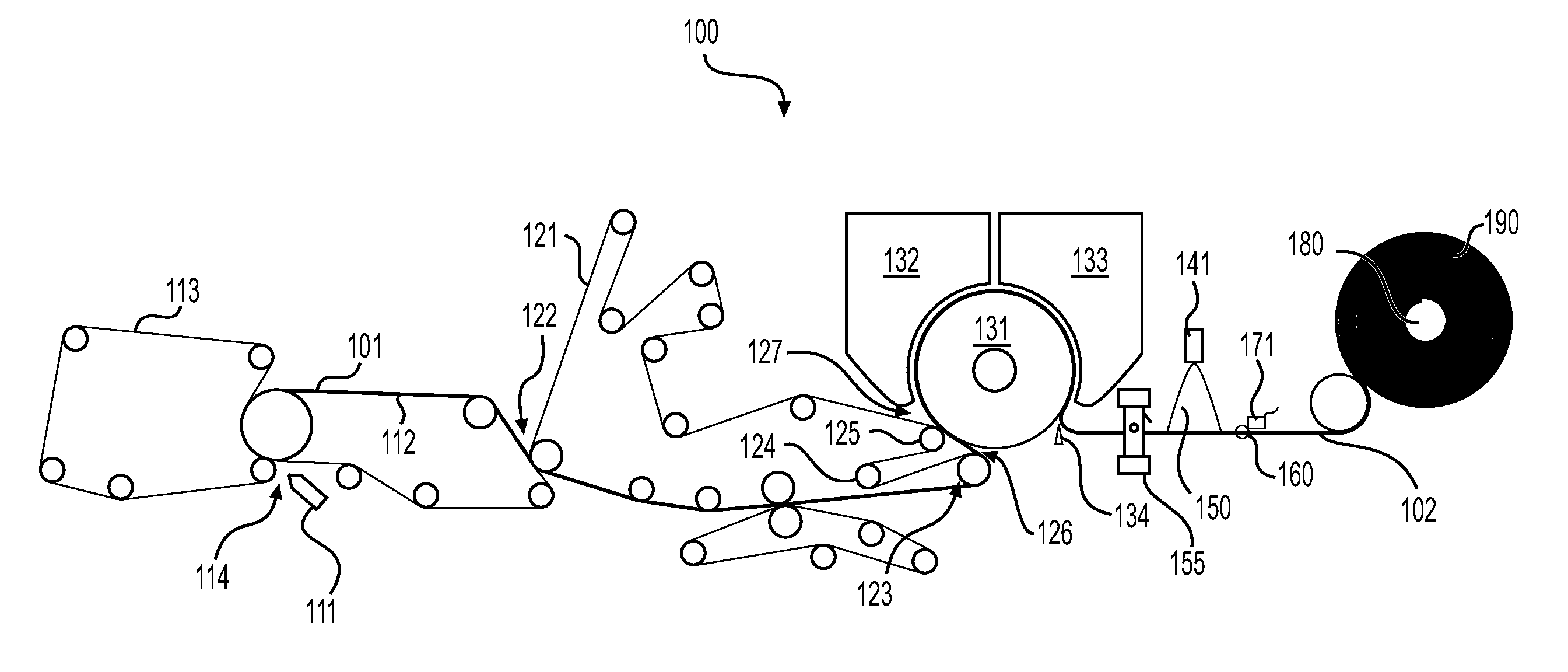

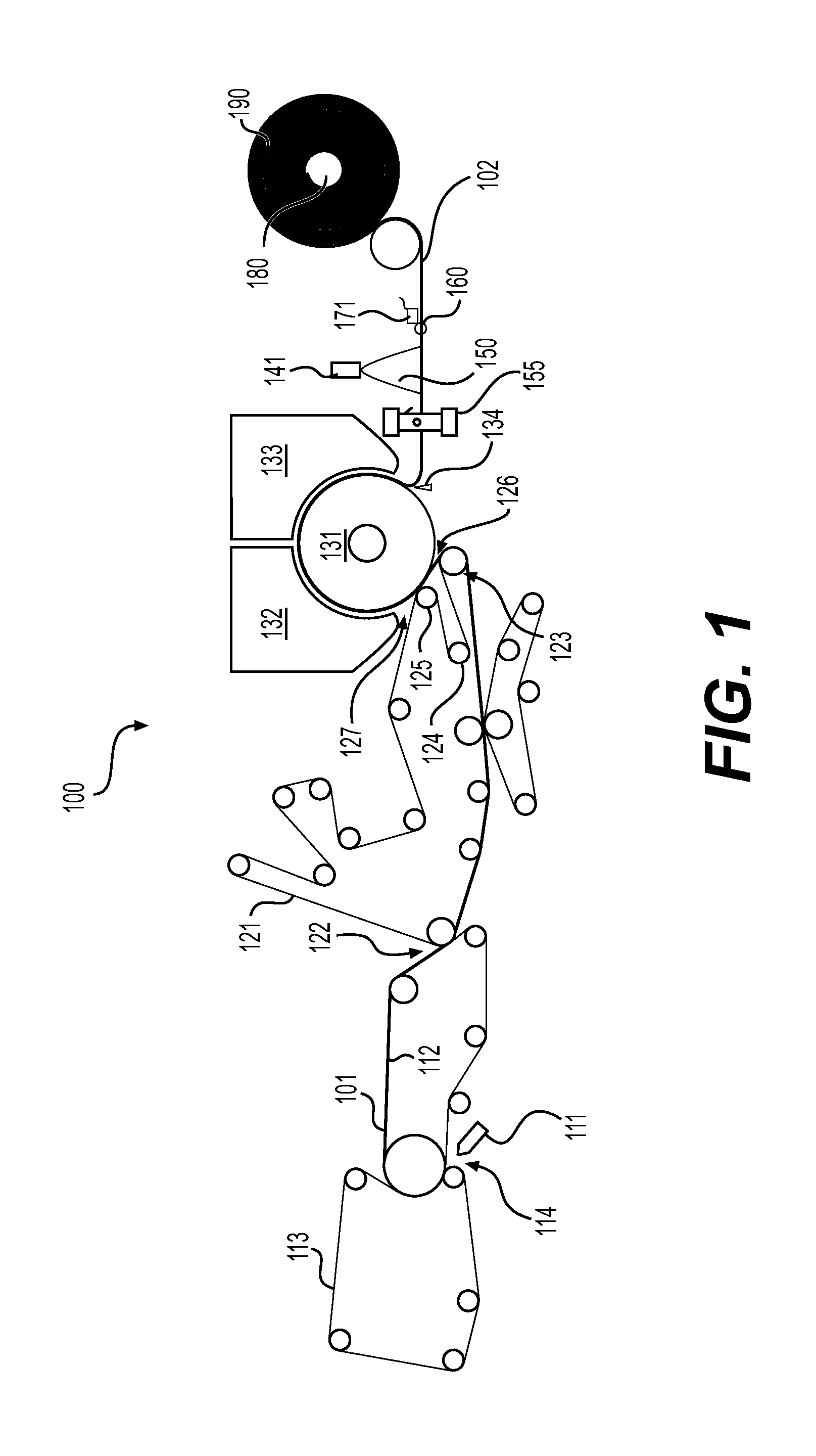

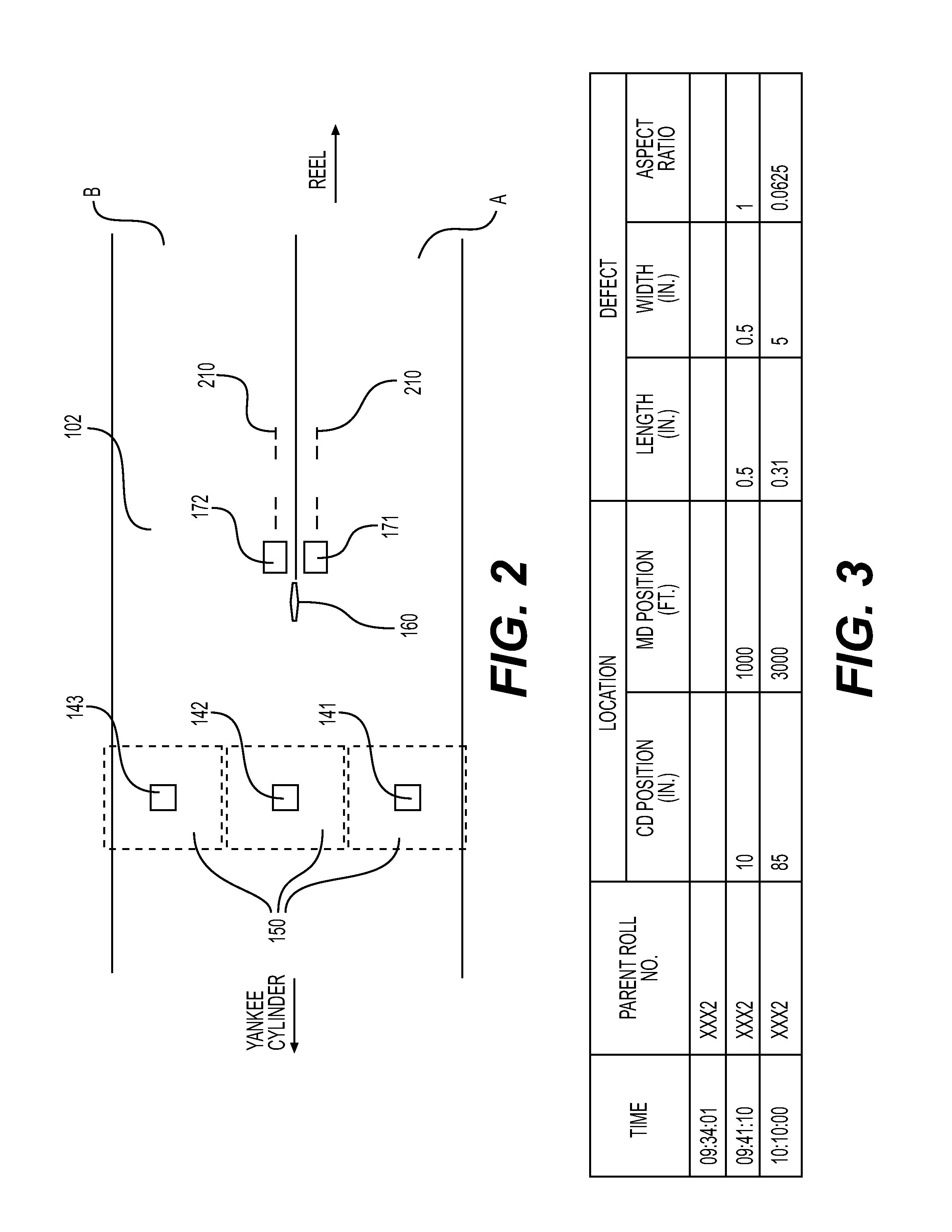

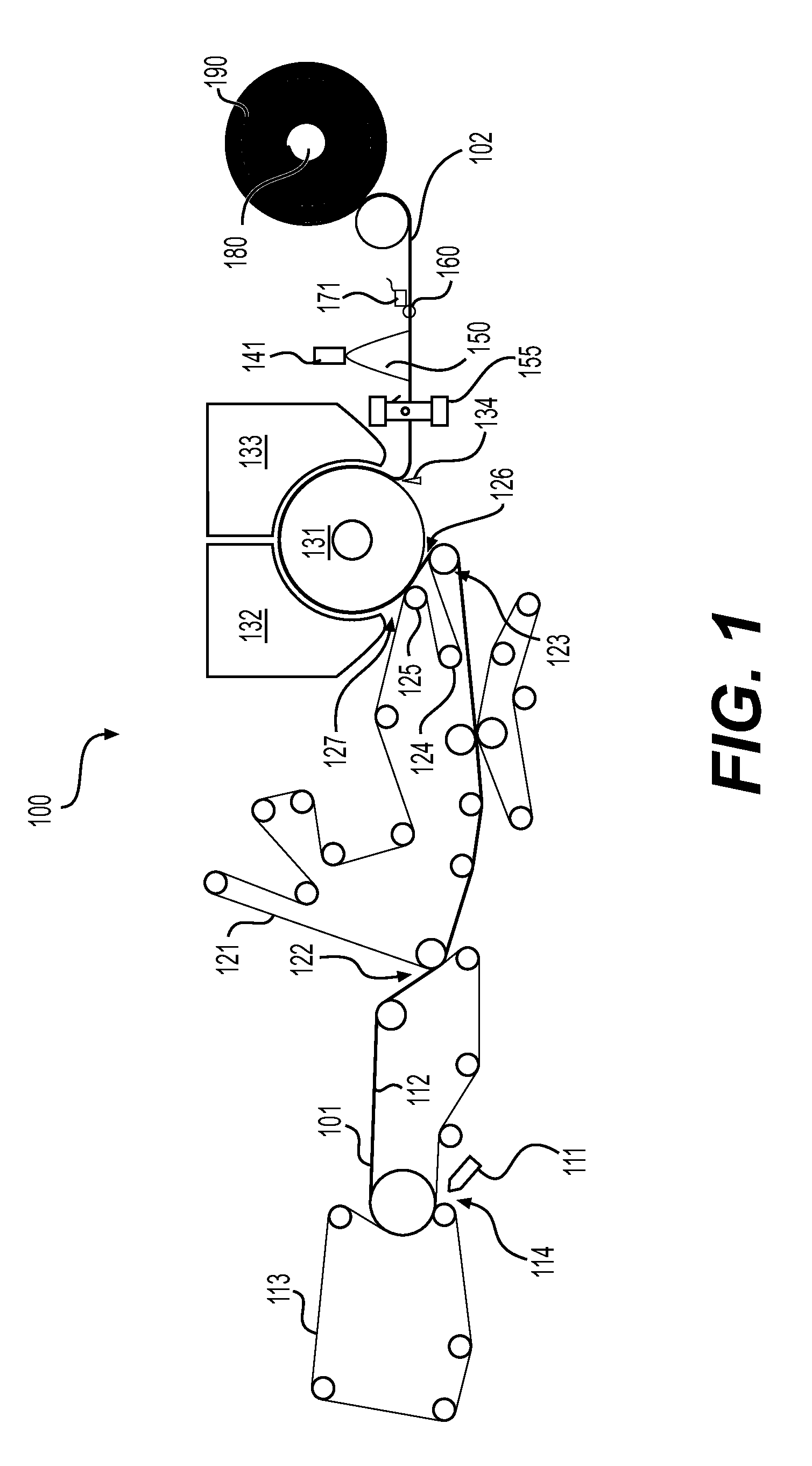

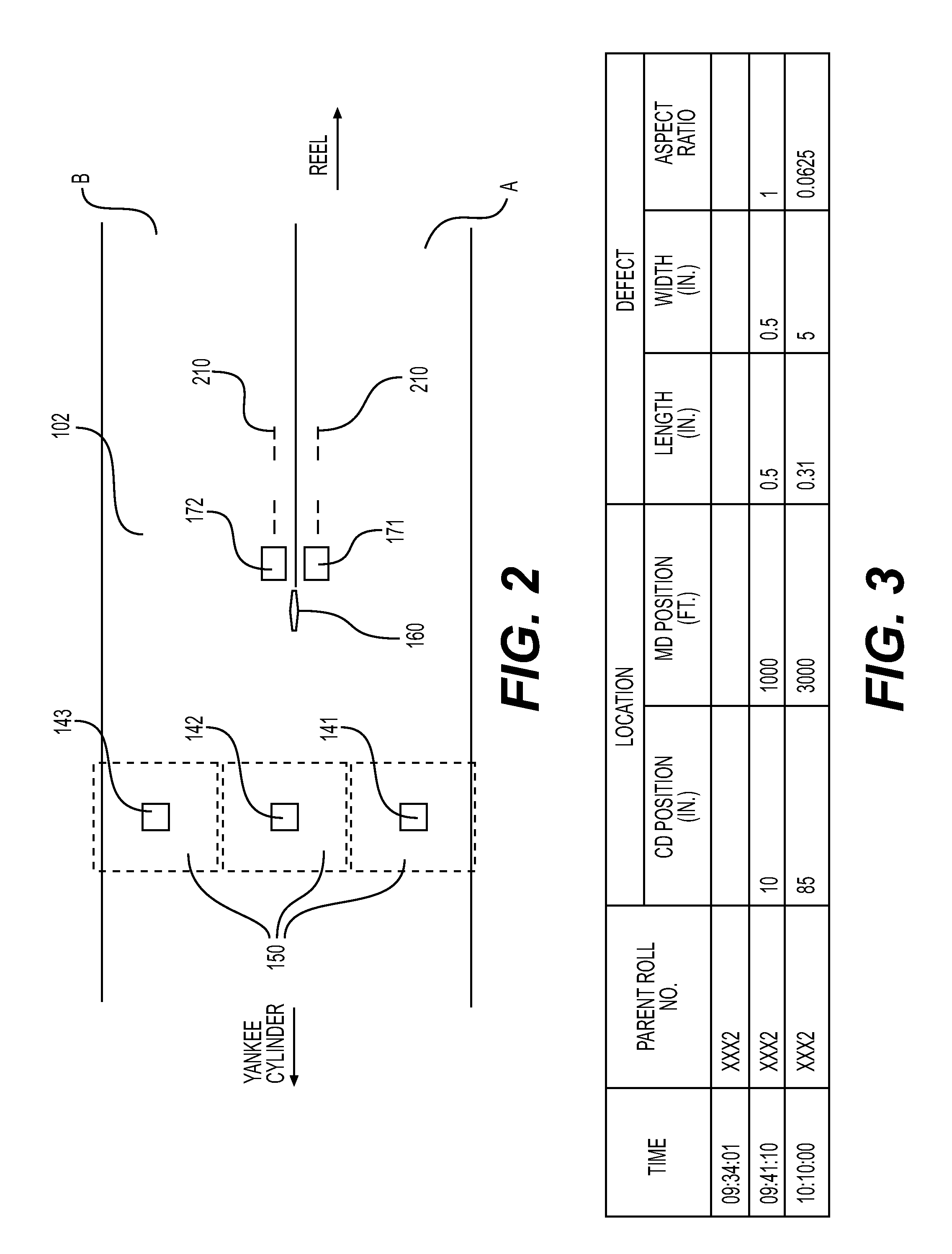

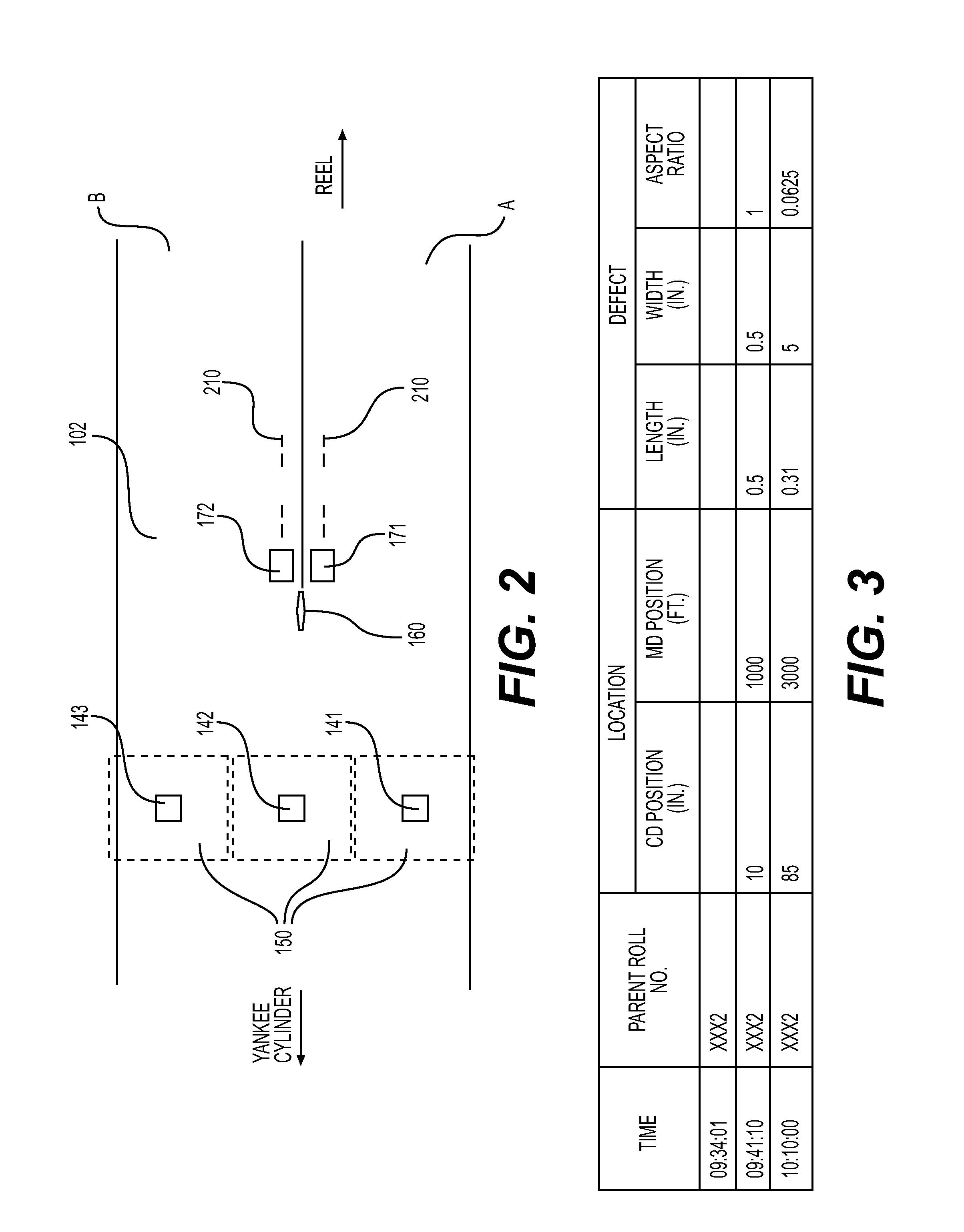

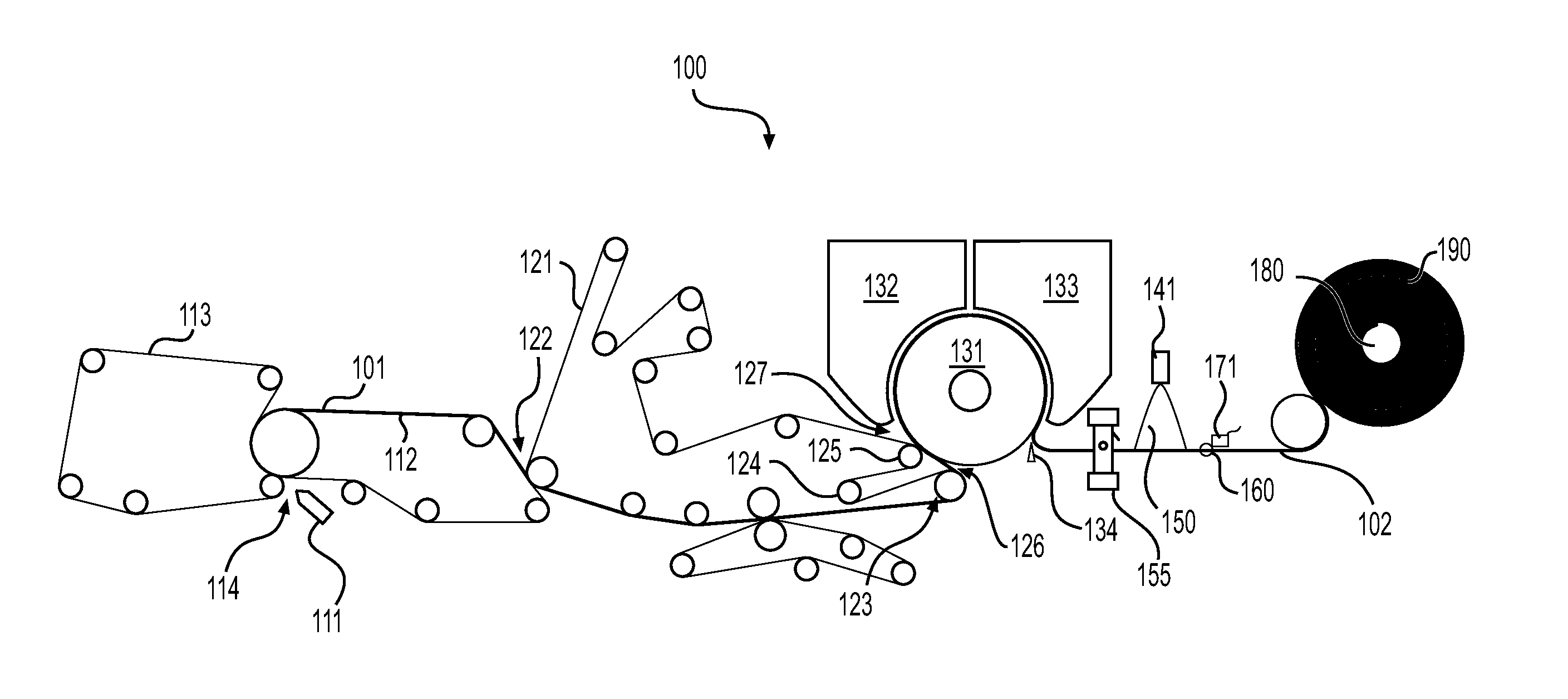

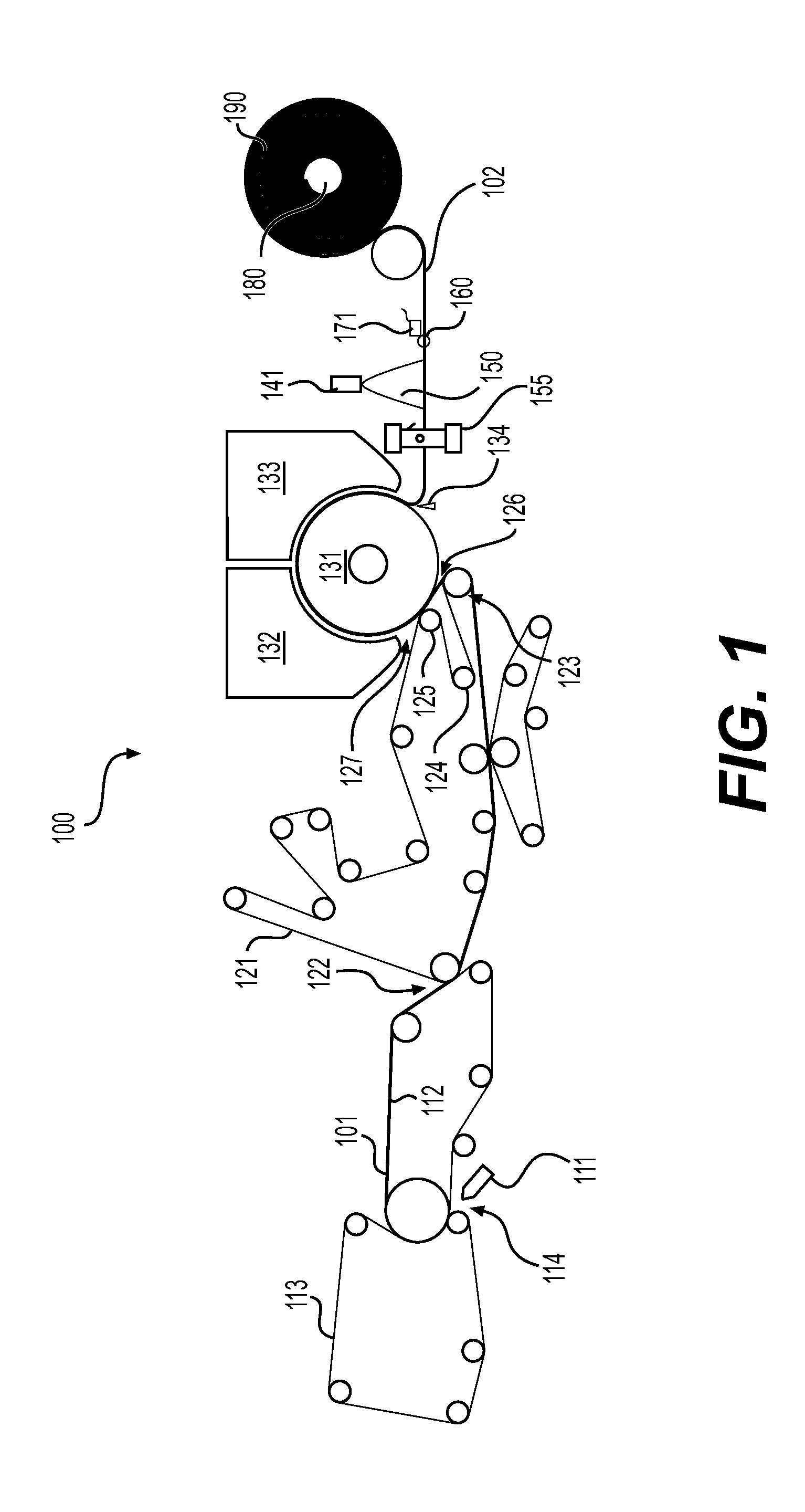

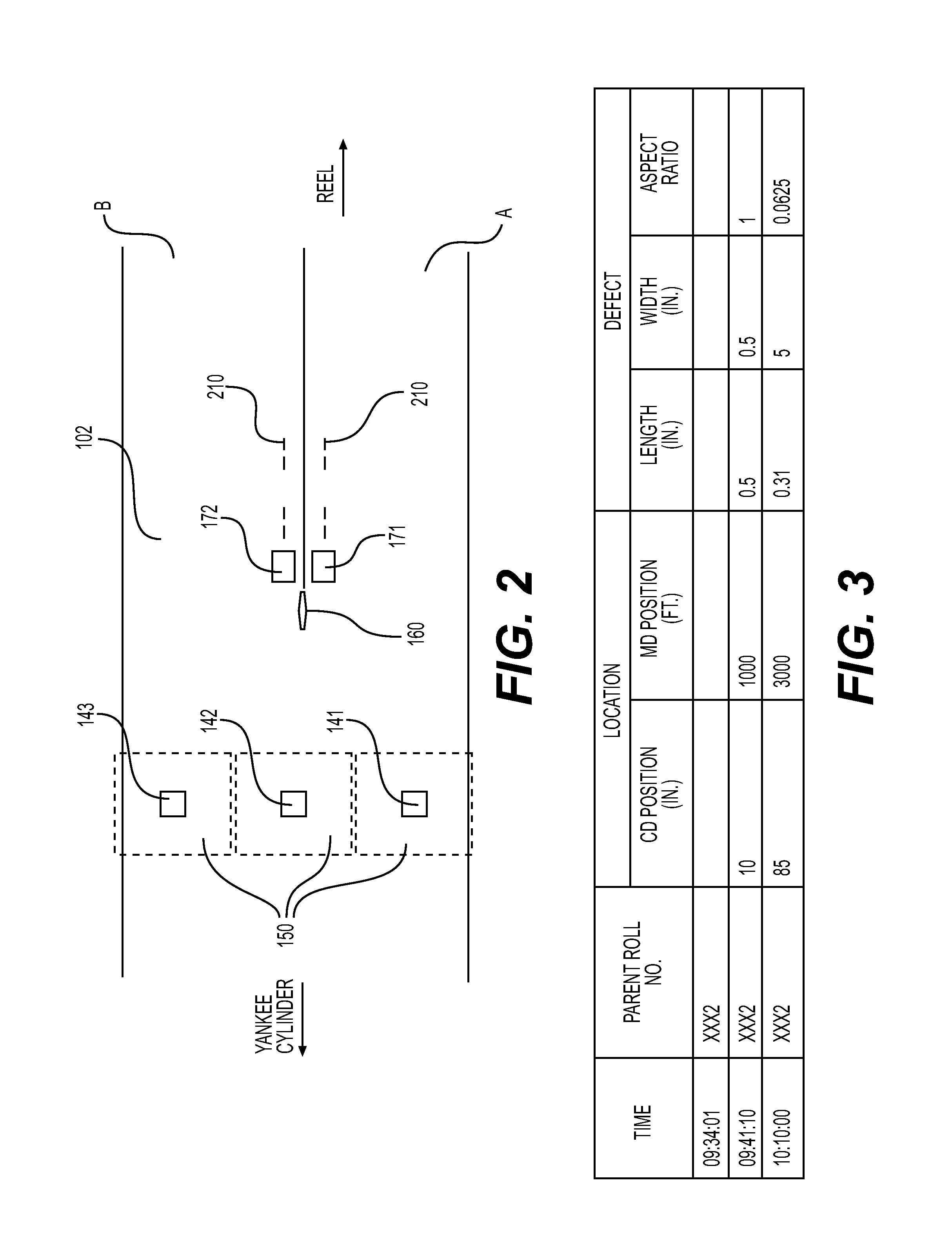

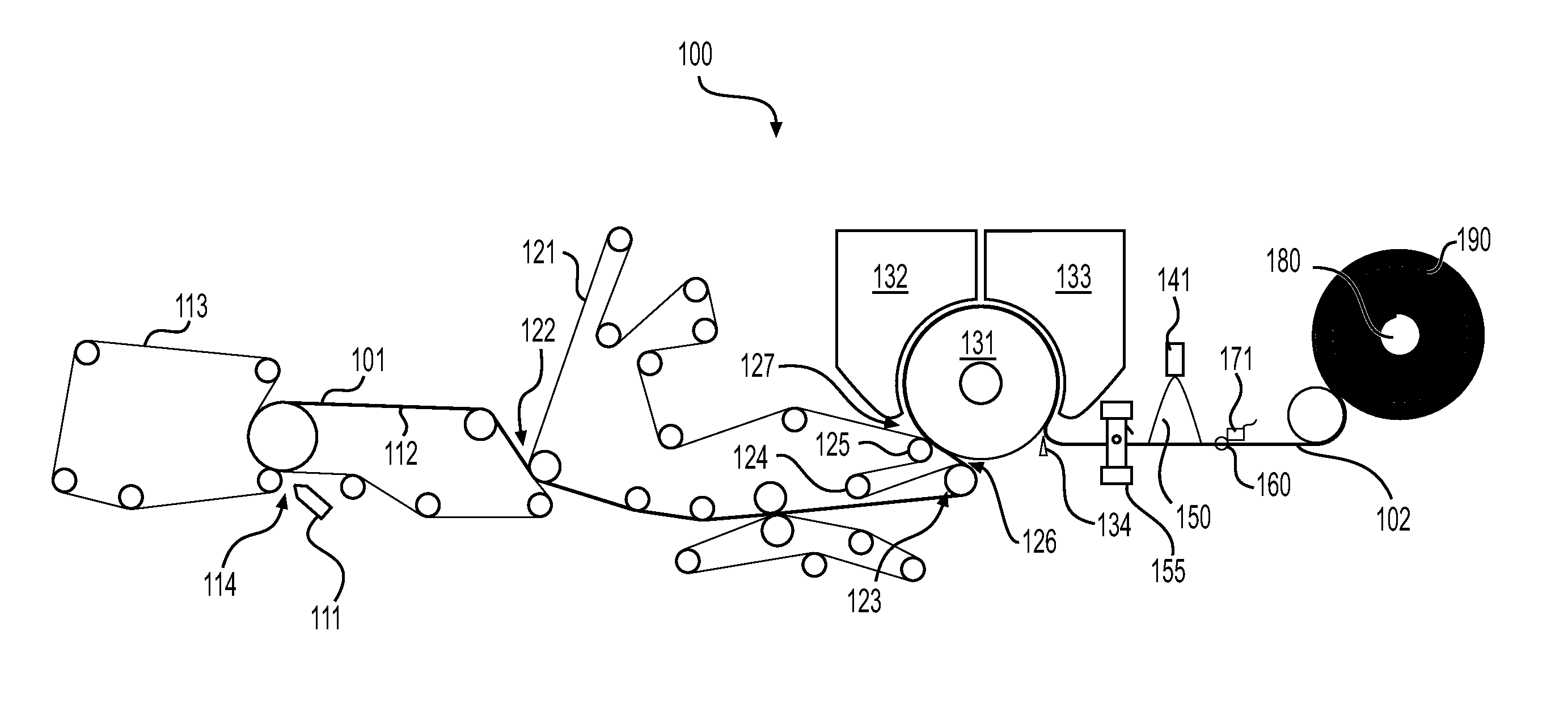

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS20150292155A1Special visual effect coatingsLiquid surface applicatorsPulp and paper industryManufacturing line

Owner:GPCP IP HLDG LLC

Coated paper and process for producing same

InactiveUS20040180184A1Less smoothnessHigher proportion of mechanical fiberLayered productsCoated paper substrateChemical pulpFiber

In the conventional process of producing a coated paper, the use of a furnish that is characterized by a base sheet fiber content made of about 60 to 85 weight percent of a bleached thermomechanical pulp (TMP), about 10 to 35 weight percent of a bleached chemical pulp and 0 to about 15 weight percent of a deinked pulp, and also comprising about 12 to 20 weight percent of an inorganic filler, with a freeness below 50 ml Csf and a brightness over 75° ISO, gives a coated paper of the same or superior quality and at a much lower cost than the usual coated paper obtained through a conventional process.

Owner:BPR

Soft tissue paper having a polyhydroxy compound and lotion applied onto a surface thereof

The present invention provides a paper product having at least one ply, wherein only one outer surface of said tissue paper has a polyhydroxy compound and a lotion applied thereto.

Owner:THE PROCTER & GAMBLE COMPANY

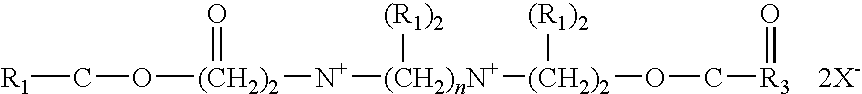

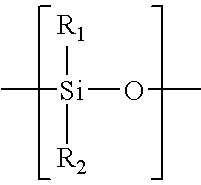

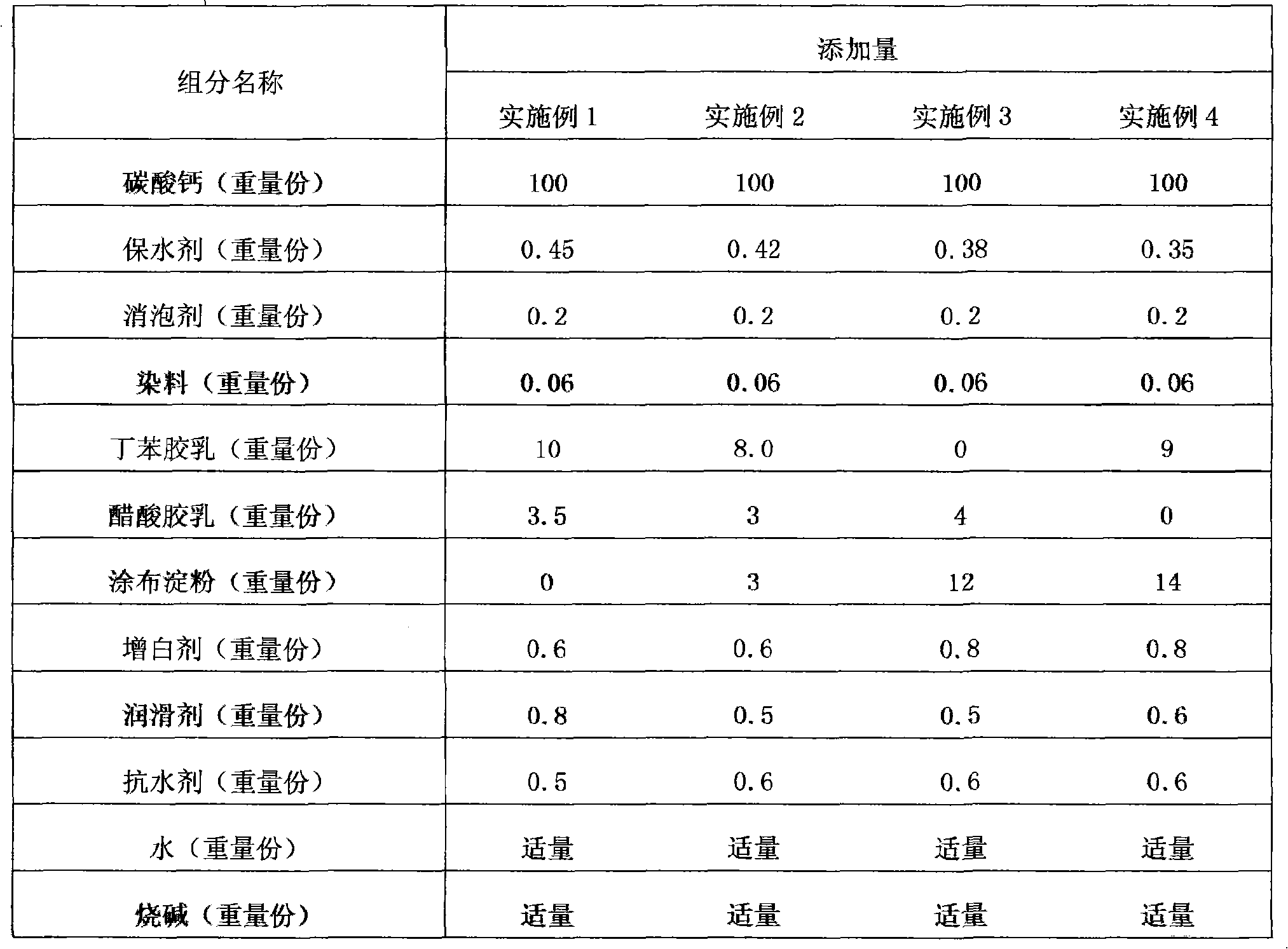

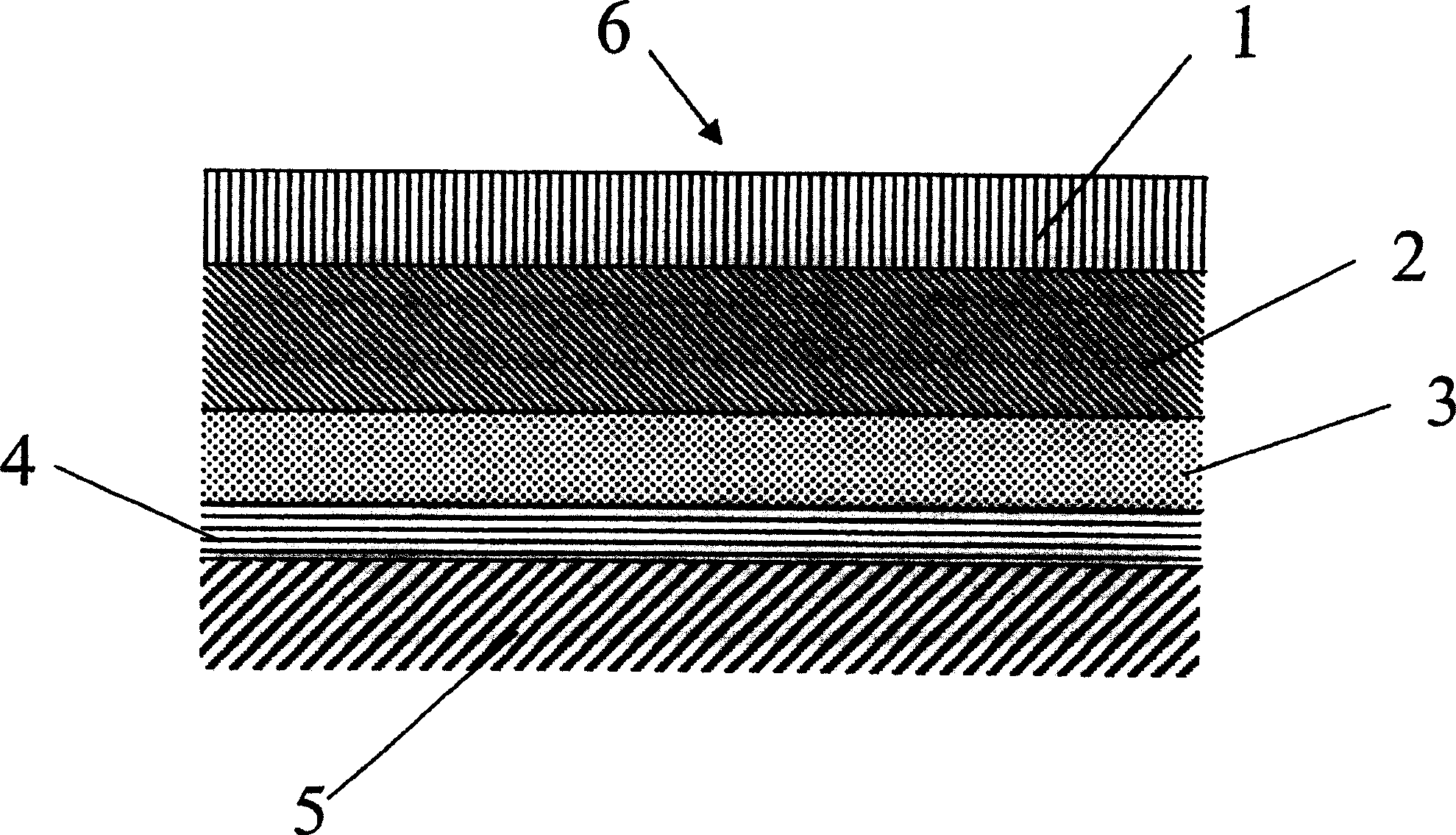

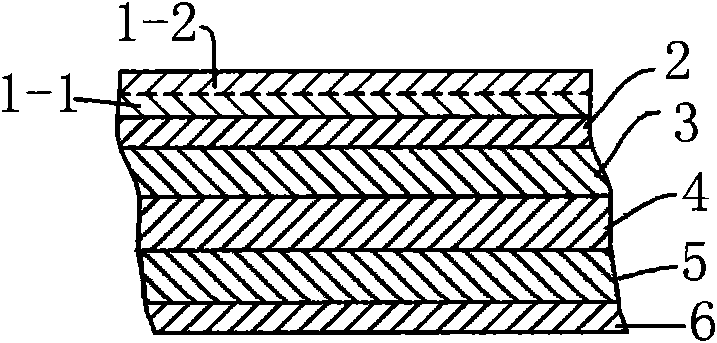

Coated white-top kraft liner board and manufacturing method thereof

ActiveCN101586317ARetention strengthIncrease productionNon-fibrous pulp additionCoatings with pigmentsSurface layerPaper sheet

The invention discloses a coated white-top kraft liner board, which comprises a coating layer, a surface layer, a lining, a bottom layer and a glue application layer, wherein the coating layer at least comprises two coating separated layers orderly arranged on the surface layer, and the coating separated layer positioned on the topmost has a level and smooth surface; the glue application layer is arranged on the surface of the bottom layer; and the ration of the coated white-top kraft liner board is between 120 and 220g / m, and the coating weight of the coating layer is between 12 and 40g / m. The invention also discloses a manufacturing method for the coated white-top kraft liner board. The invention adopts a compound coating method of film transfer coating and scraper coating, and the produced coated white-top kraft liner board well combines the advantages of a white-top kraft liner board and a high weight coated paper, has strong strength and good performance of indexes of lustrousness, smoothness and printability of the paper surface in the condition of low ration, and completely meets the requirement of advanced printing and packaging.

Owner:SHANDONG CENTURY SUNSHINE PAPER GROUP +1

A kind of production method of tobacco sheet cigarette paper

ActiveCN102277780AImprove taste qualityReduce woodinessNon-fibrous pulp additionCoated paper substrateFiberIrritation

The invention relates to a production method of tobacco sheet cigarette paper. The method comprises the following steps of: (1) adding tobacco leaf pieces or tobacco stems into hot water, and extracting at 40-70 DEG C for 20-40 minutes, wherein the adding amount of the hot water is 3-5 times of the weight of the tobacco pieces; (2) primarily extruding the extracted tobacco leaf pieces or tobacco stems with a pulp extrusion machine, then adding hot water of which the amount is 1-3 times of the total weight of the tobacco leaf pieces or tobacco stems, extracting at 45+ / -5 DEG C for 20 minutes, extruding again, and then pulping with a pulping machine until the SR (Schopper-Riegler) degree reaches 25-40; (3) pulping applied fibers with the pulping machine until the SR degree reaches 40-75, mixing with the tobacco pulp, and making cigarette paper, wherein the adding amount of the applied fibers is 0.25-0.5 time of the total weight of the tobacco leaf pieces or tobacco stems; and (4) mixingthe two extraction liquids, then concentrating until the relative density reaches 1.02-1.2 g / cm<3>, adding potassium salts, food pigments and spices, mixing to obtain a coating liquid, and spreading the coating liquid on the cigarette paper. The method provided by the invention can improve the cigarette quality, can reduce the woody smoke of cigarettes and reduce the irritation, and makes naturalsweet taste of tobaccos more predominant.

Owner:HUBEI CHINA TOBACCO IND +1

Fruit fresh-keeping paperboard and preparation method thereof

InactiveCN101806016AControl metabolic rateImprove securityNon-fibrous pulp additionCoated paper substrateSlagPaperboard

The invention provides a fruit fresh-keeping paperboard and a preparation method thereof. The fruit fresh-keeping paperboard consists of paperboard base paper and fresh-keeping coat which is spread on the surface of the paperboard base paper. The paperboard base paper is mainly made from the waste paper, and the base weight is 90 to 100 g / m2. The fresh-keeping coat mainly comprises the following components in part by weight: 1 part of cristobalite, 0.25 to 1.5 parts of kaolin, 0.005 to 0.01 part of sodium polyacrylate, 0.0003 to 0.0005 part of nisin, 0.0001 to 0.0003 part of natamycin, 0.2 to 0.5 part of oxidized starch and 1.0 to 2.0 parts of water, and the base weight is 5 to 30 g / m2. The waste paper is made into the paperboard base paper through, disintegration, high-consistency slag removal, defibering, low-consistency slag emoval and screening, the cristobalite, kaolin, the sodium polyacrylate, the nisin, the natamycin and water are added into a high-speed dispersion machine to be made into pigment dispersion liquid after being adequately dispersed and filtered, and the oxidized starch and the water are heated to be dissolved to obtain the oxidized starch liquid. The pigment dispersion liquid is mixed with the oxidized starch liquid to obtain the fresh-keeping paint liquid, after being filtered by 180 to 200-mesh sieve, the fresh-keeping paint liquid is spread onto the surface of the paperboard base paper through a spreading machine, and the paperboard base paper with the surface being coated with the fresh-keeping paint is secondarily dried, press finished and decorated to obtain the finished product. The fruit fresh-keeping paperboard has the advantages that the fresh-keeping effect is good, the environment compatibility is good, the fresh-keeping package and the storage and transportation package are integrated, and the continuous mass production can be realized on the papermaking machine.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

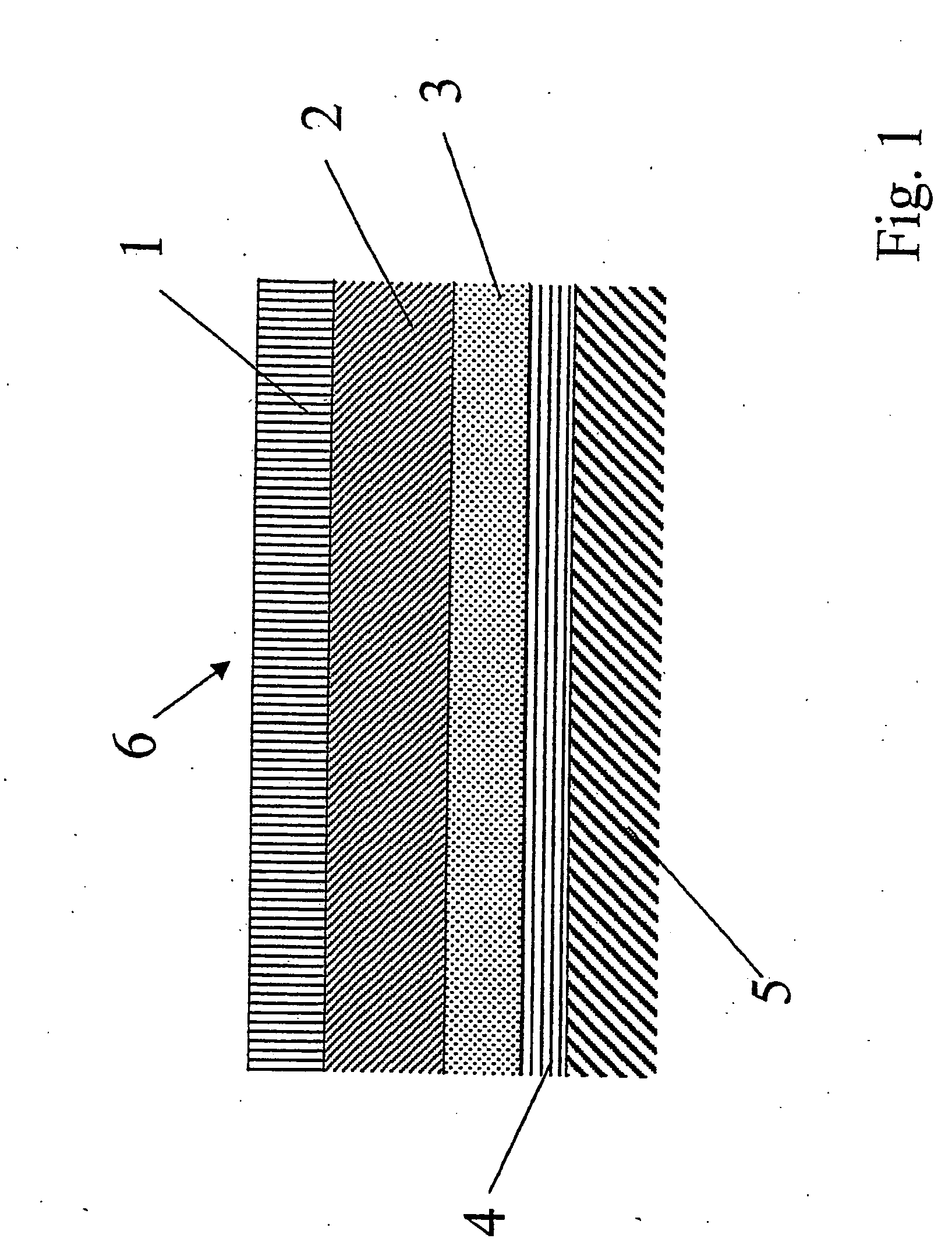

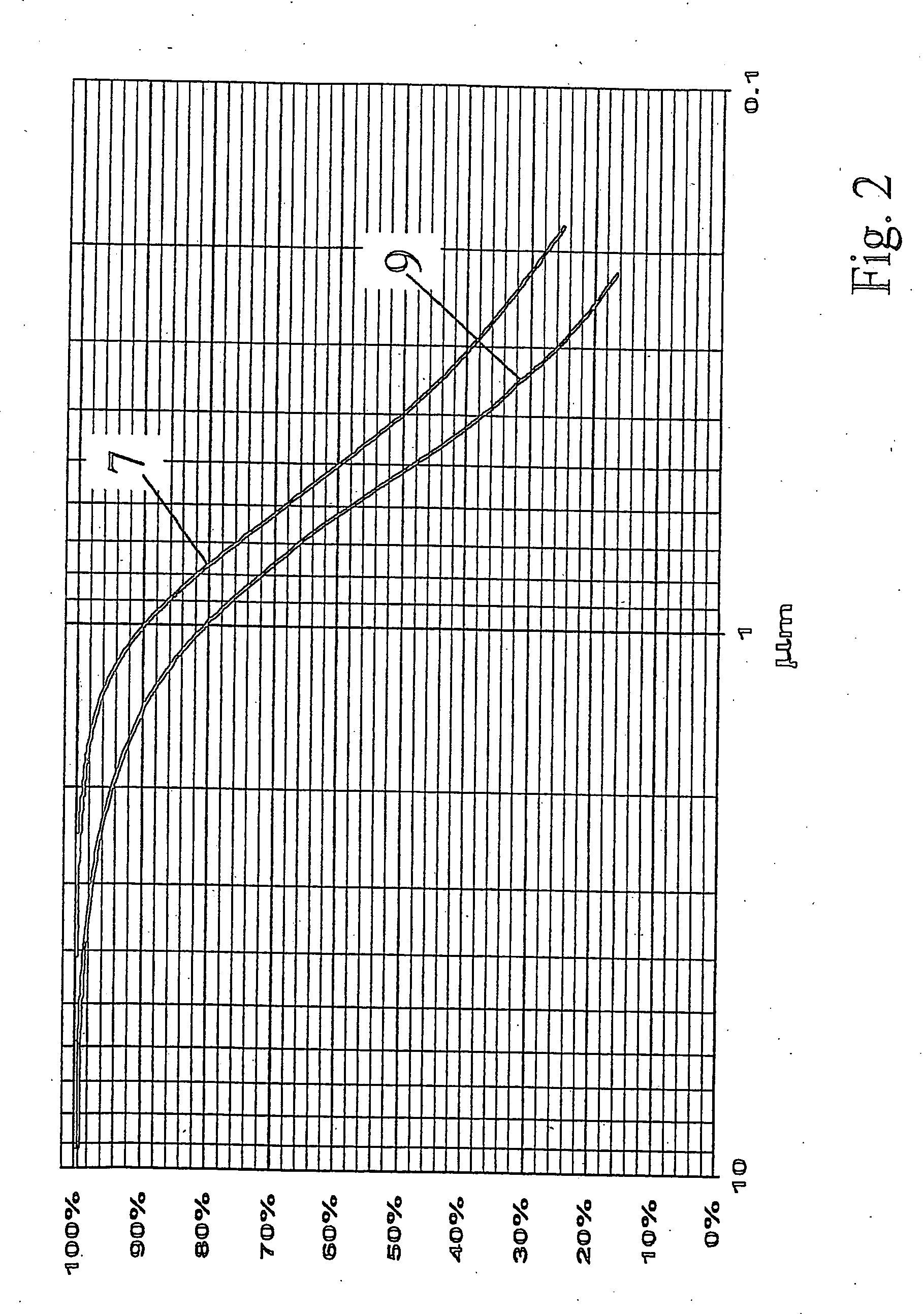

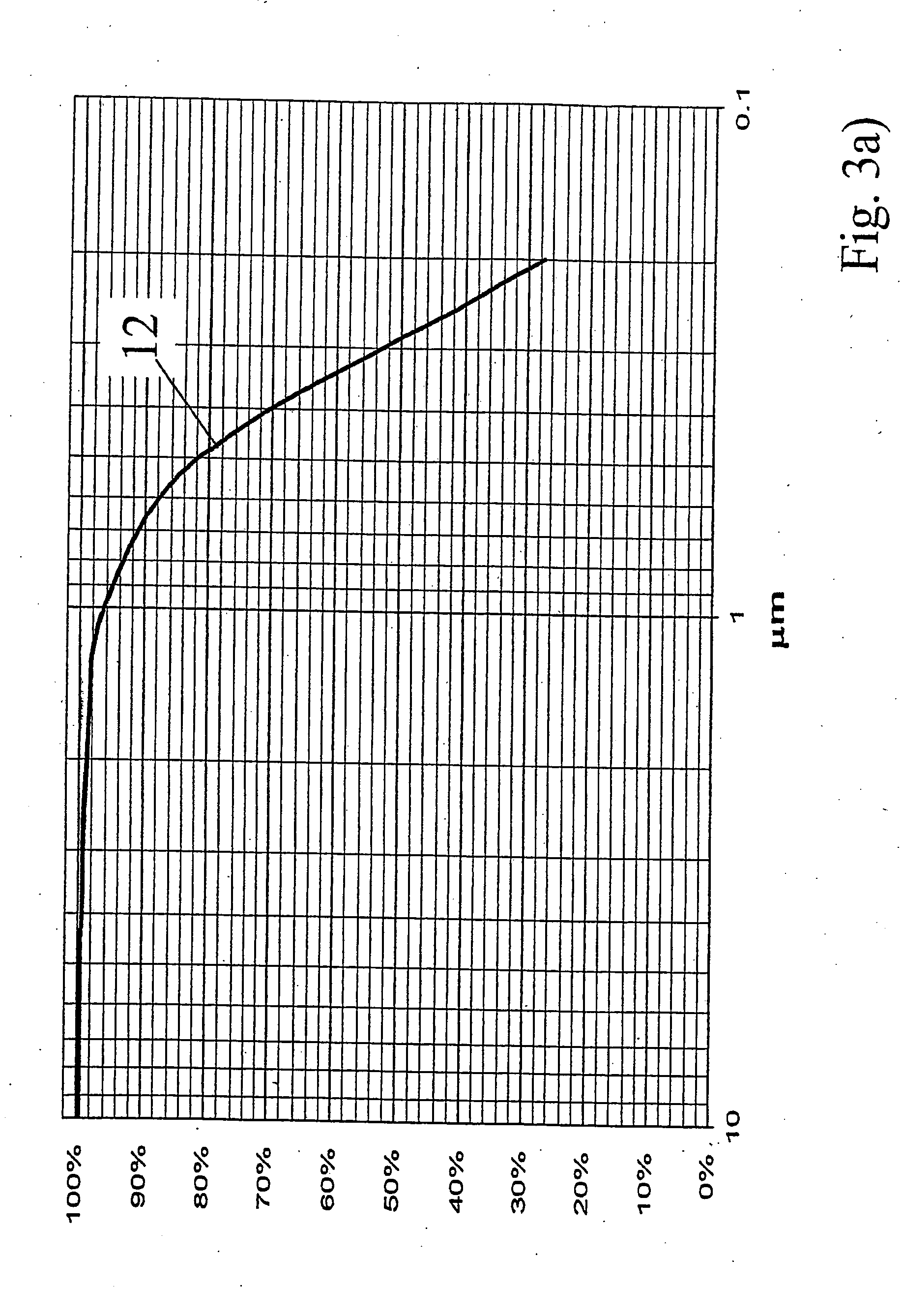

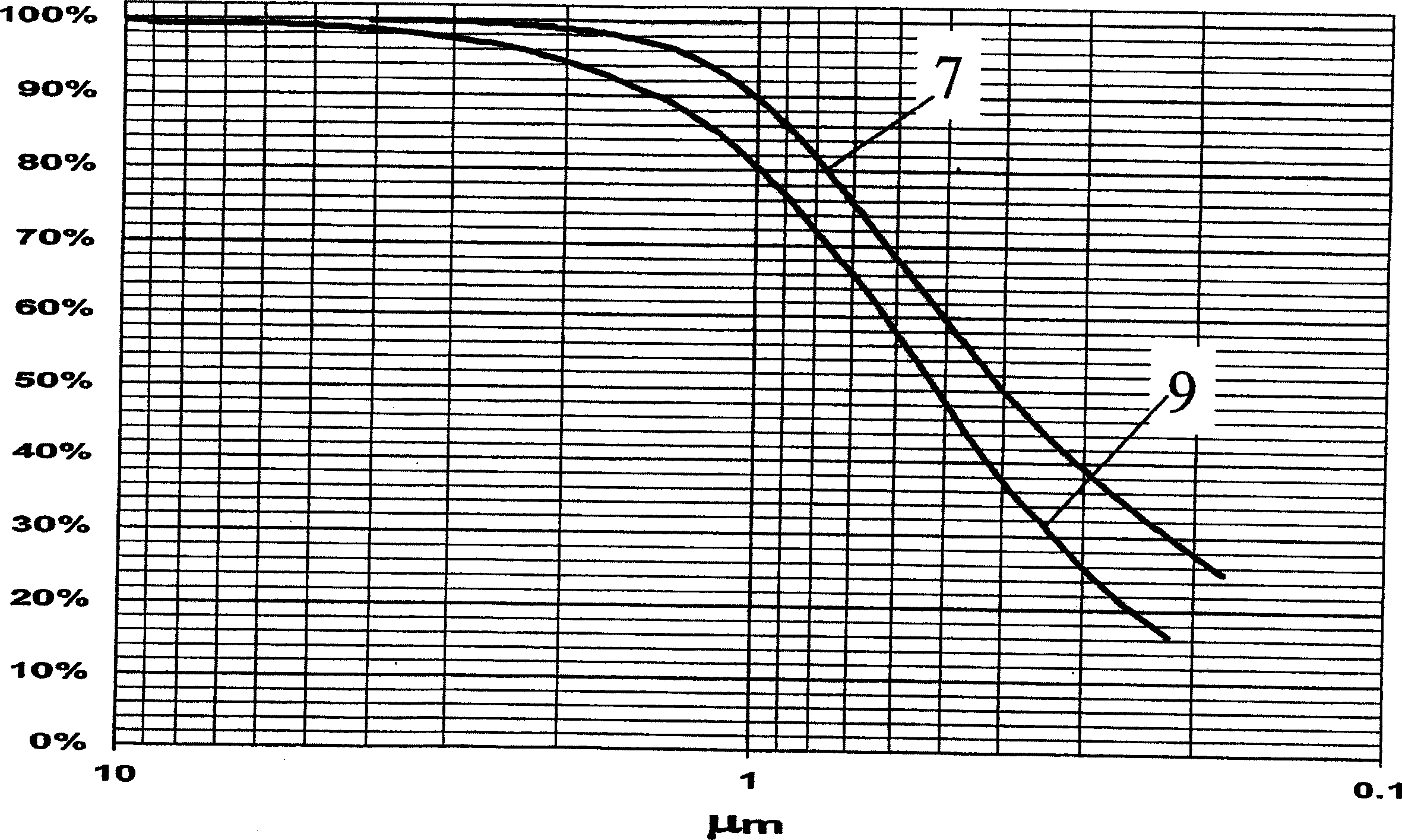

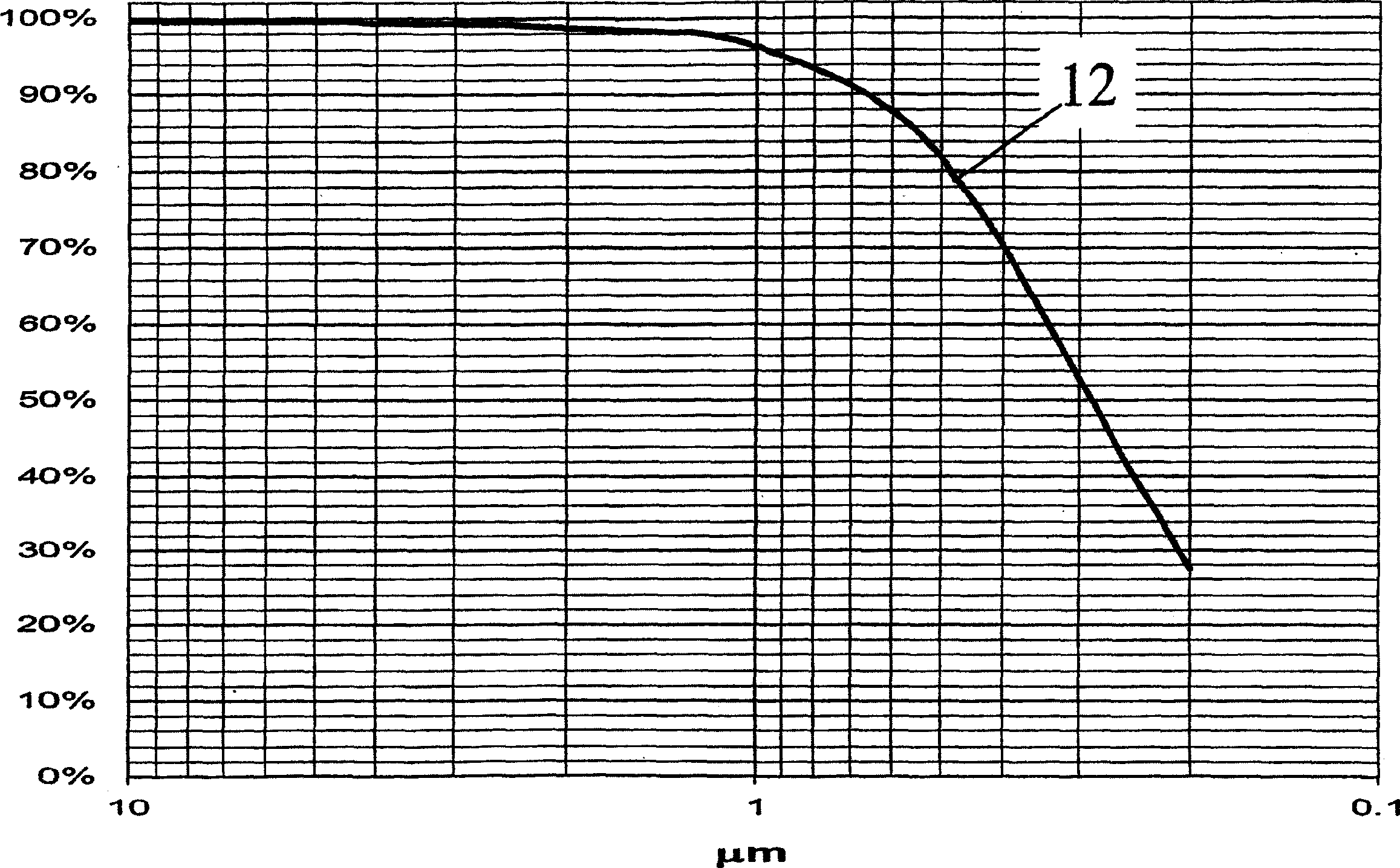

Coated printing sheet and process for making same

InactiveUS20060257593A1Efficient settingsGood dispersionNon-fibrous pulp additionCoatings with pigmentsParticulatesPorosity

A printing sheet is described comprising a substrate and, on at least one side of the substrate, an image receptive coating layer with a cumulative porosity volume of pore widths below 200 nm as measured using nitrogen intrusion methods of more than 0.006 cm3 per gram paper. In particular in the context of printing sheets with high-gloss this particular porosity distribution leads to a quick and easily adjustable ink setting behaviour. Additionally a method for manufacturing such a printing sheet is described using organic, i.e. polymer and inorganic particulate pigments of fine particle characteristics.

Owner:SAPPI NETHERLANDS SERVICES

Release Paper and Method of Manufacture

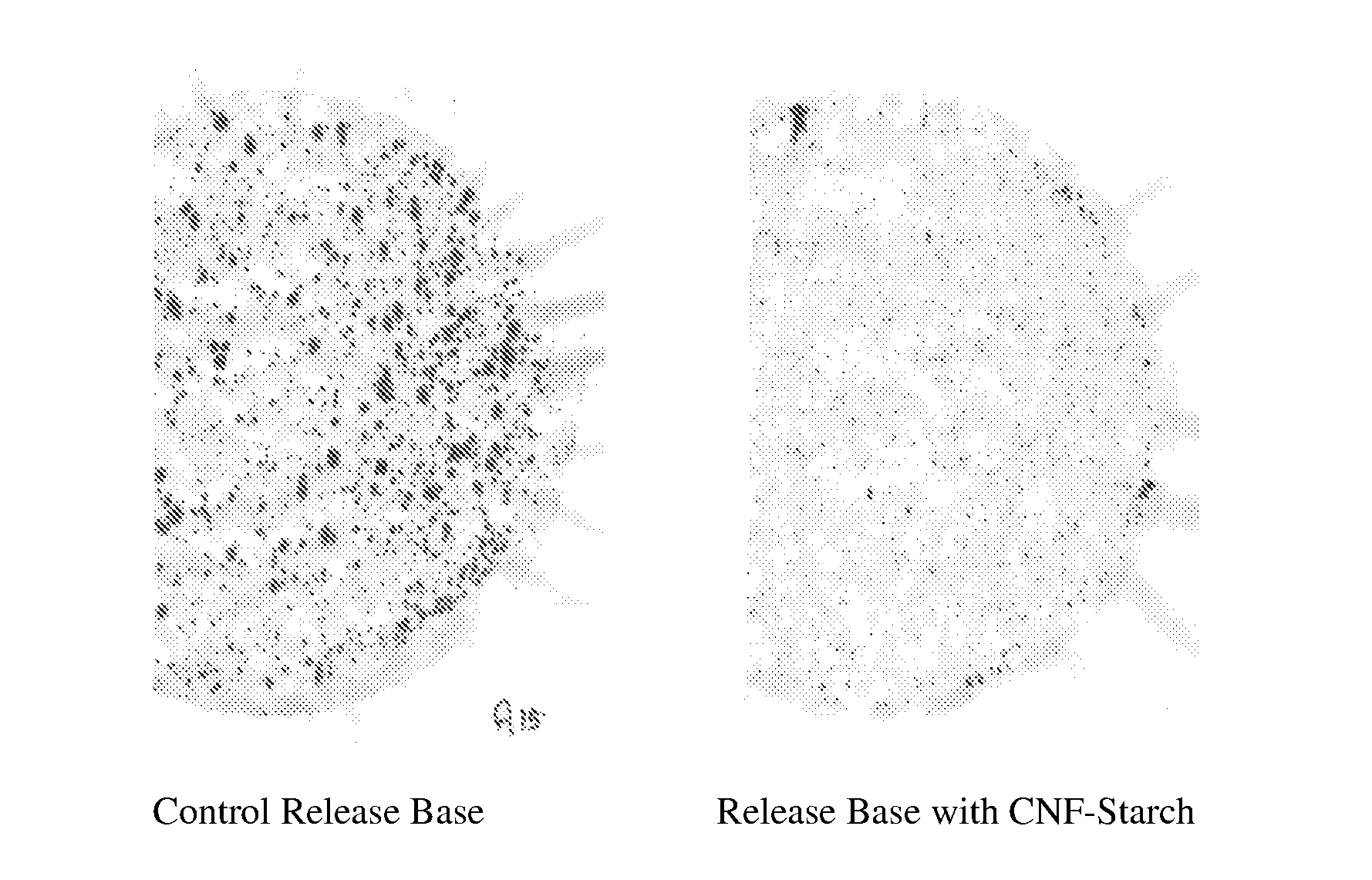

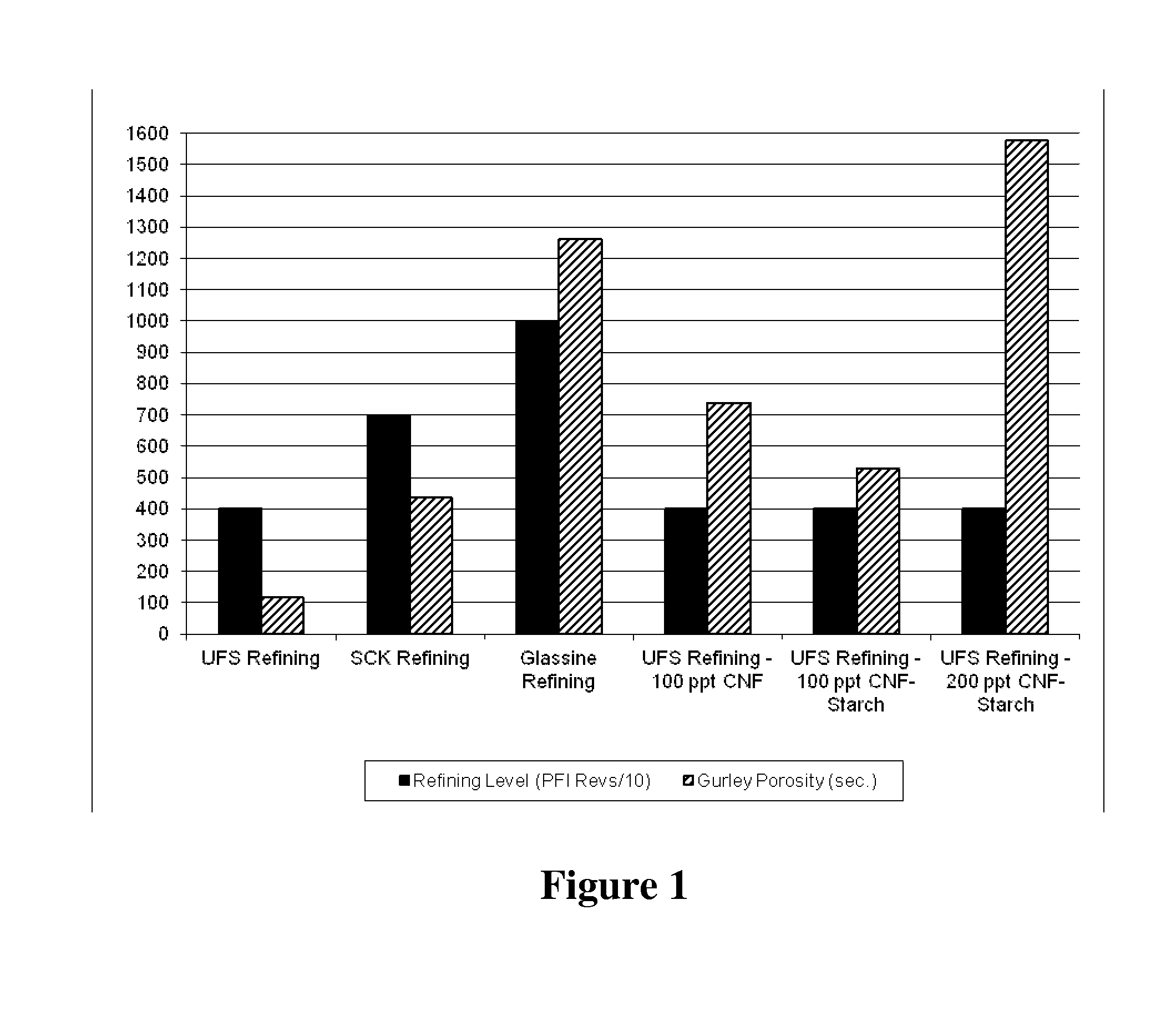

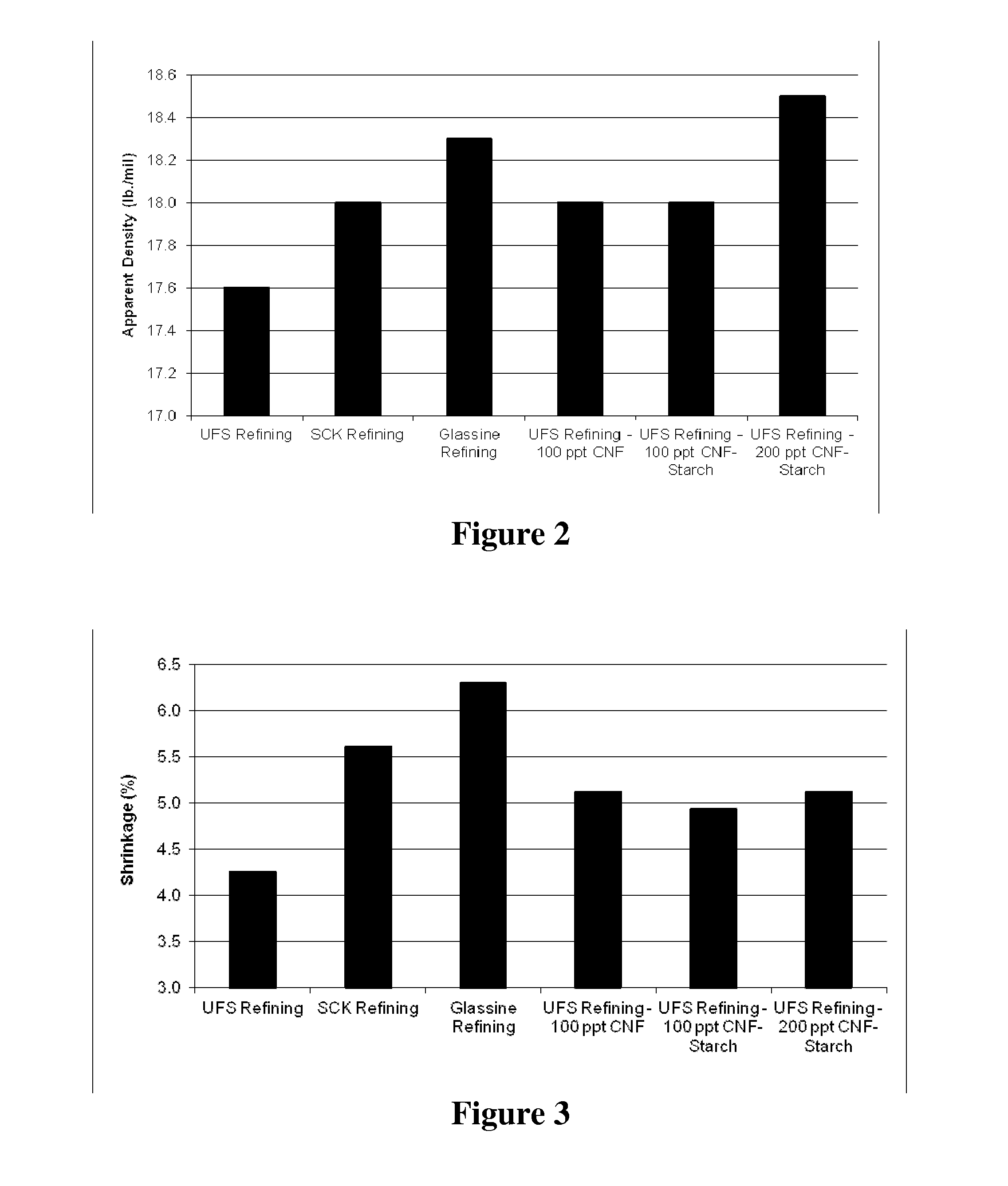

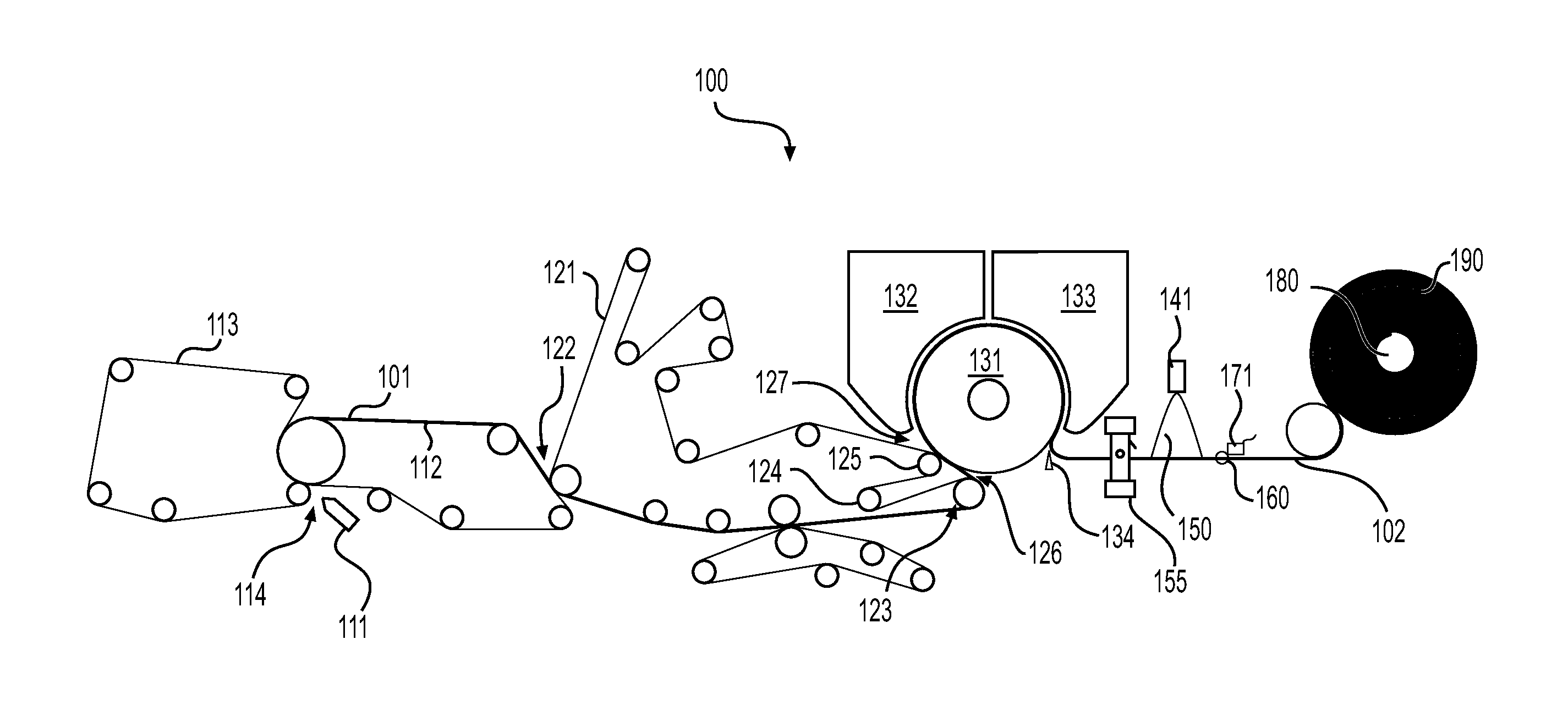

ActiveUS20150125658A1Increase speedLower requirementNon-fibrous pulp additionRecord information storageCellulosePolymer science

Release base papers with improved surface properties and more efficient manufacturing potential are made using cellulose nanofibrils (CNF) along with high freeness, less refined pulp. Release papers serve as the backing for common adhesive labels, for industrial film coatings, and also for certain food processing uses. The CNF may be added to the furnish and processed to paper, or the CNF may be added as a coating onto a partially dried web of paper. The CNF may optionally be combined with a starch and a starch crosslinker.

Owner:STIRLING CONSULTING +1

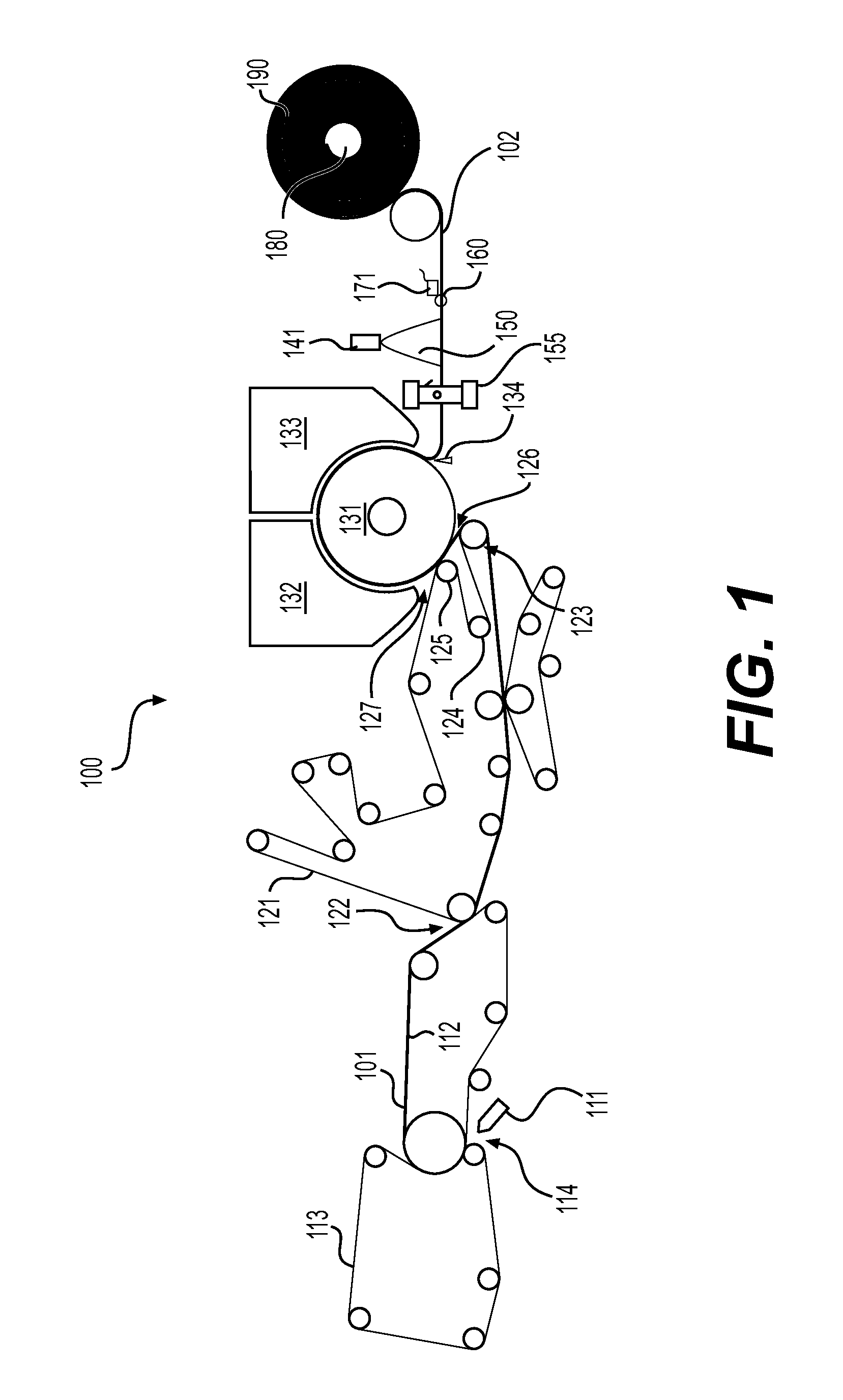

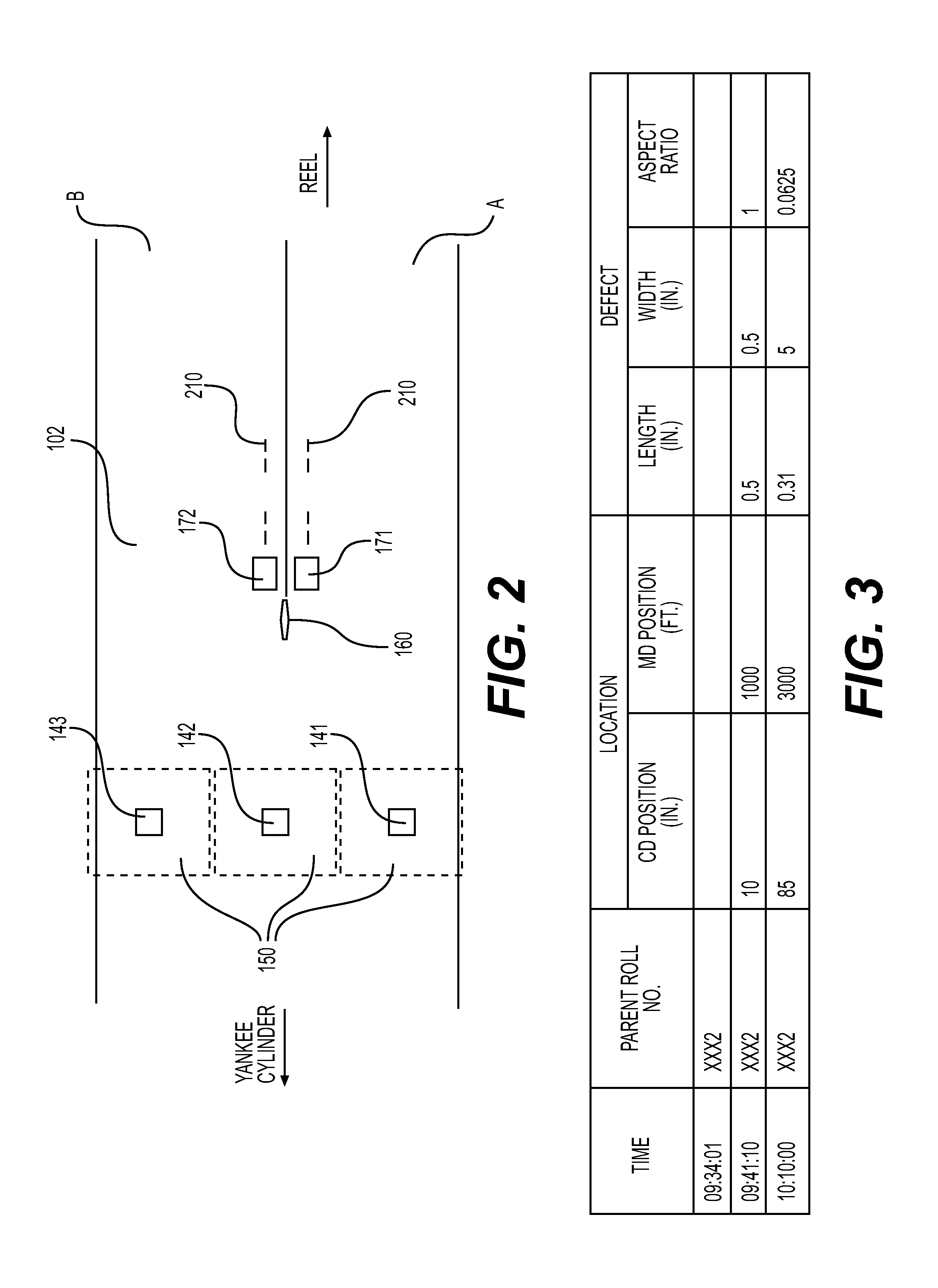

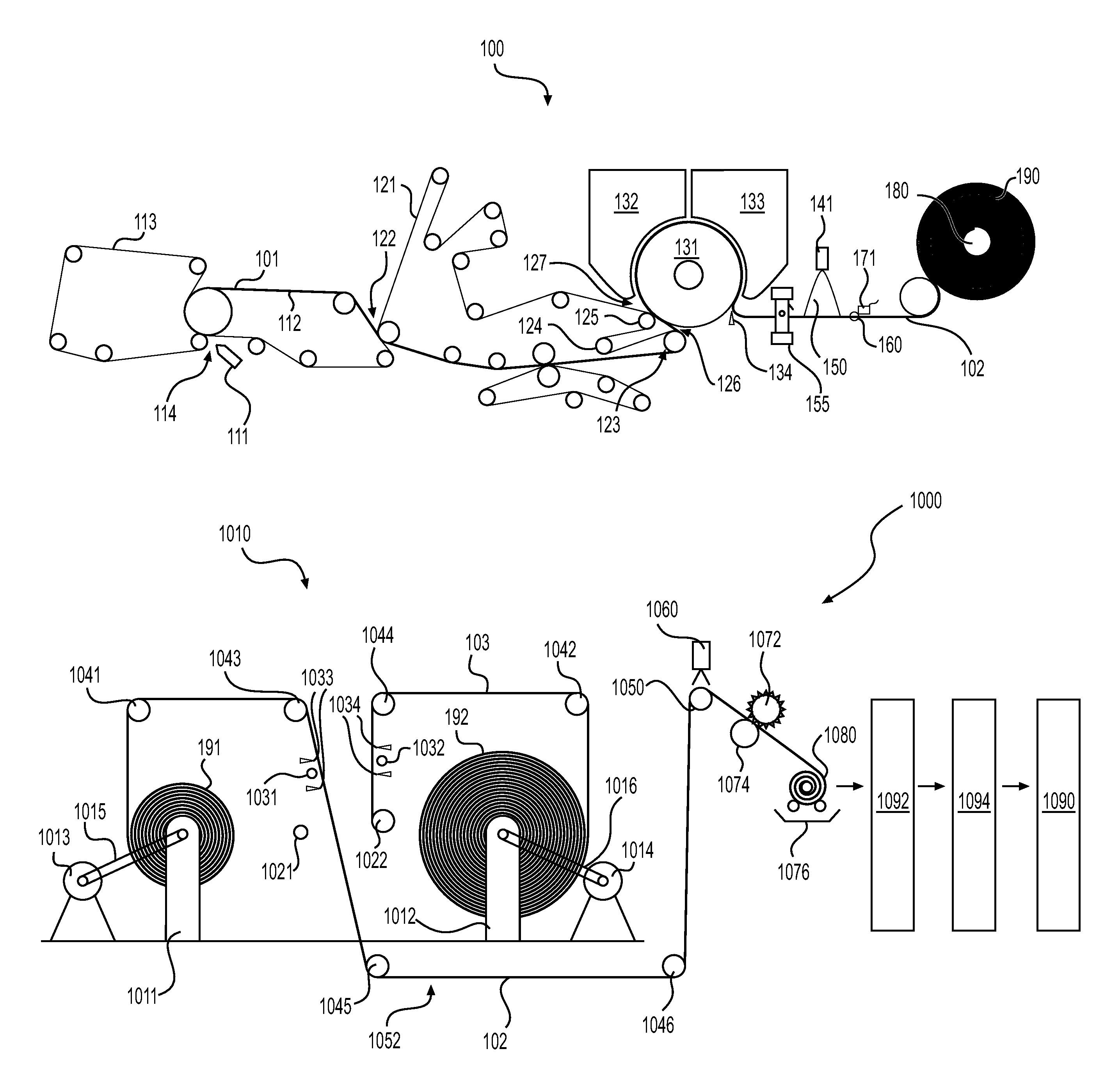

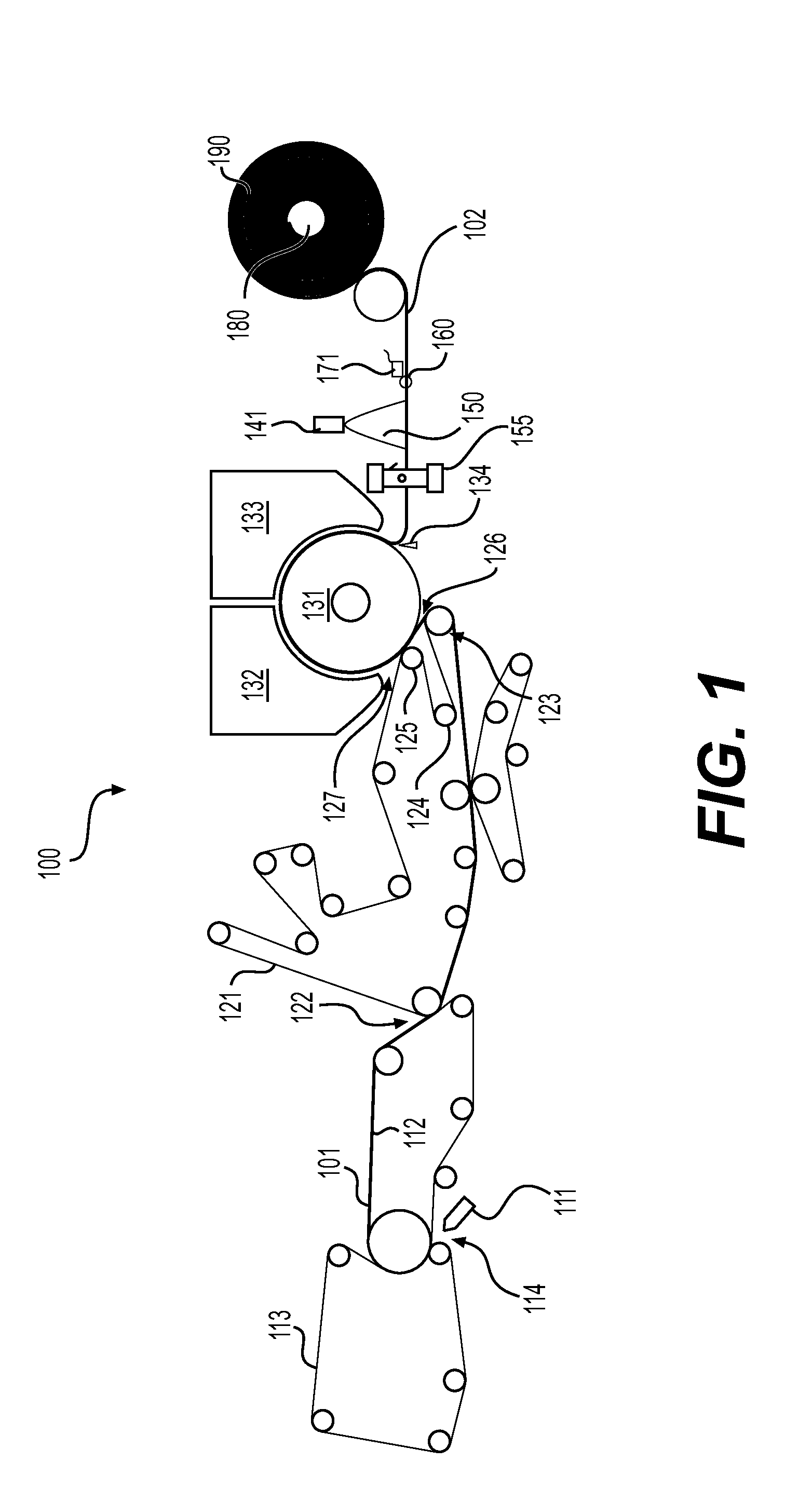

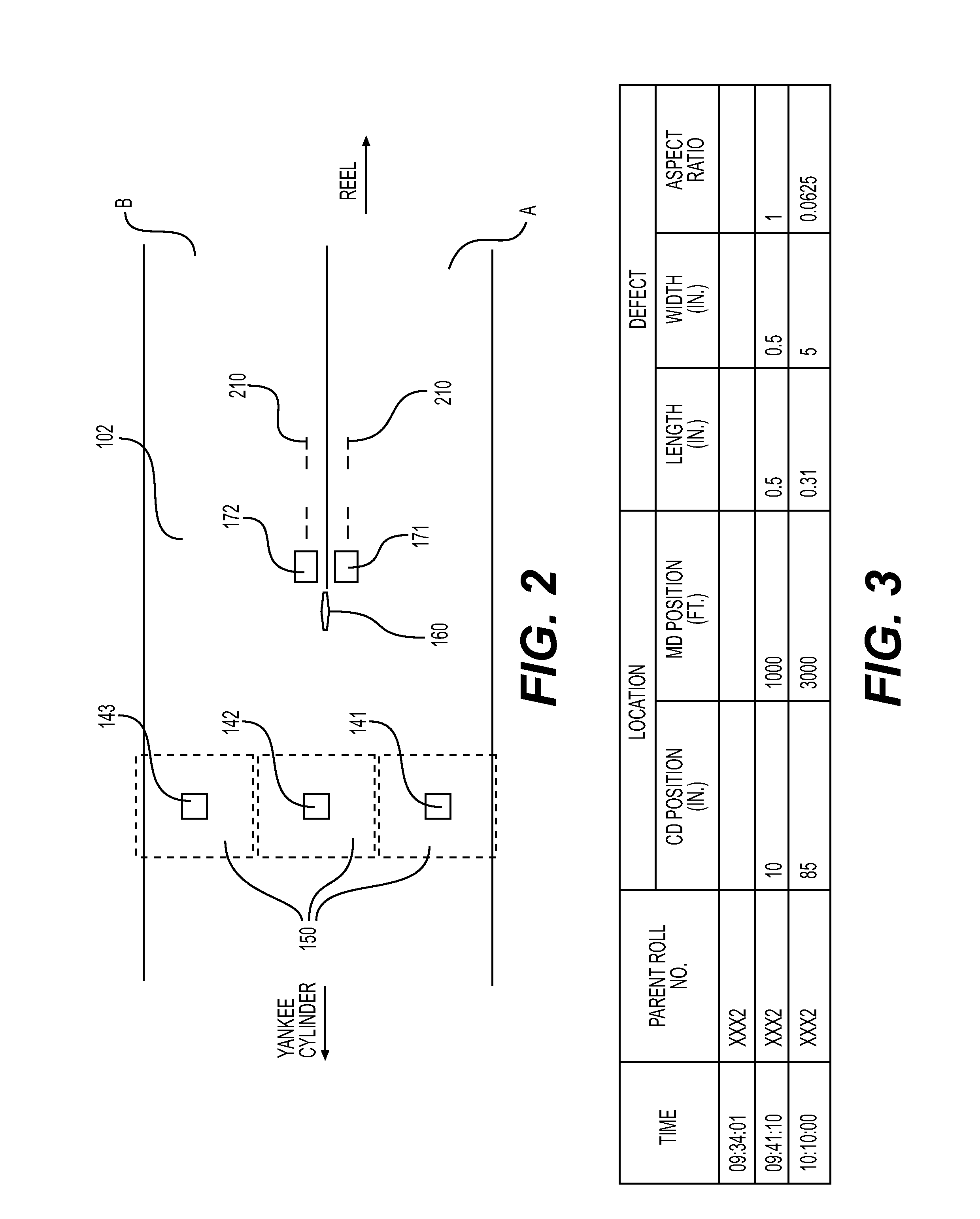

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS20150292163A1Special visual effect coatingsLiquid surface applicatorsMarking outProcess engineering

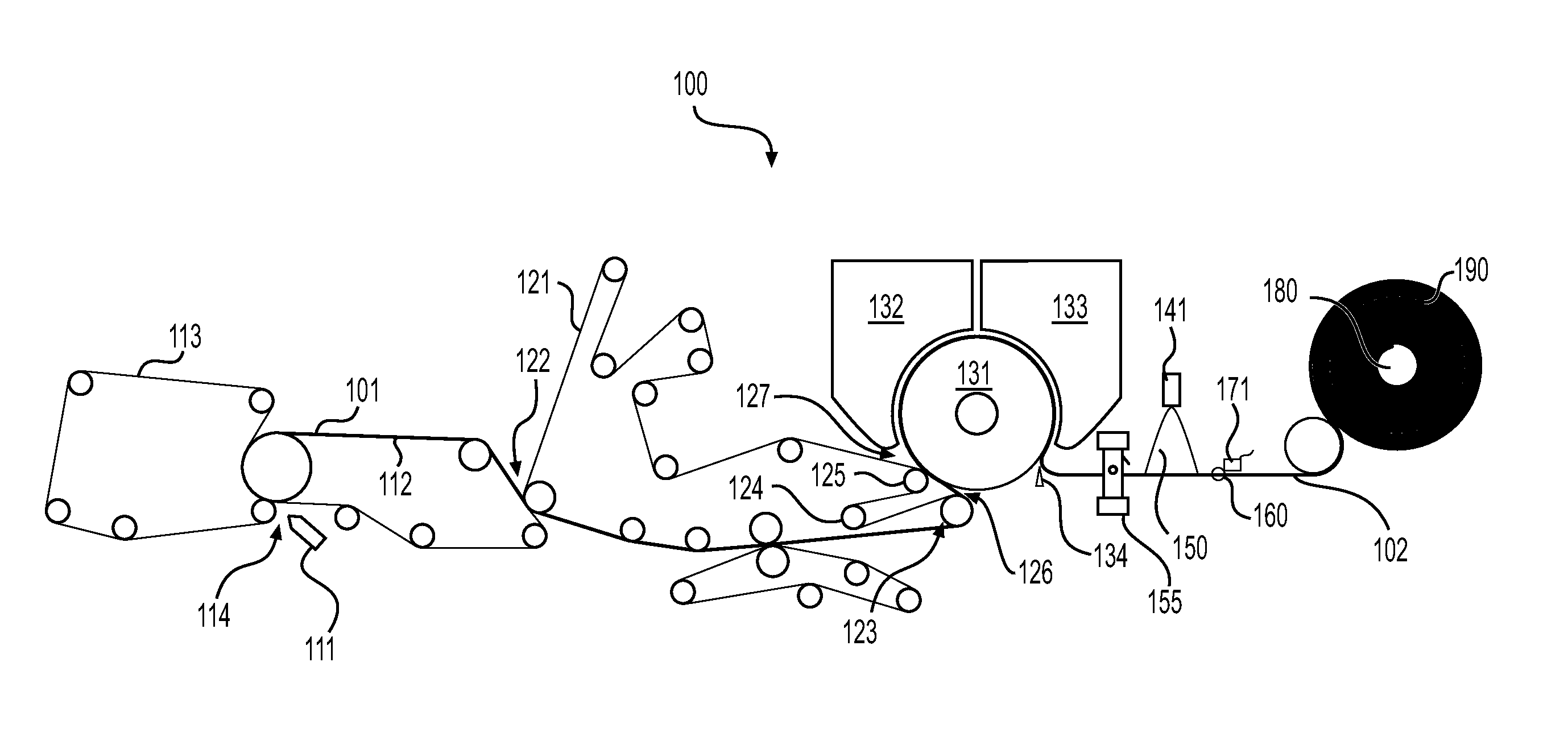

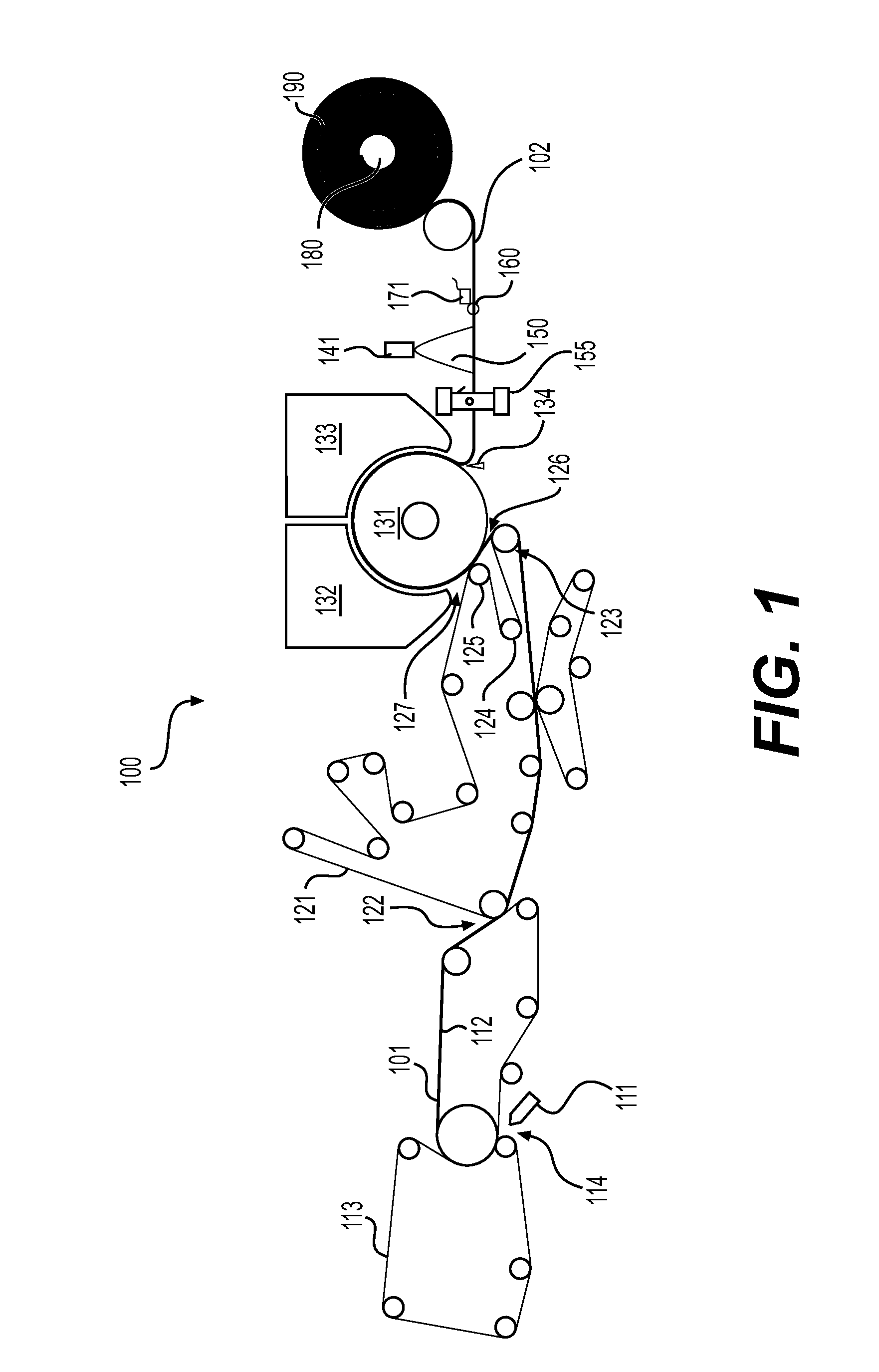

A system for producing a paper product. The system includes a paper machine, an analysis tool, and a converting line. The paper machine forms a paper web having a plurality of sections, inspects the paper web to identify web properties, and marks the paper web with a plurality of marks. The analysis tool assigns action scores to each section of the paper web based upon the identified properties that section of the paper web. The converting line reads at least one of the plurality of marks on the paper web, obtains the action score associated with a second one of the plurality of marks, calculates a distance between the at least one mark read by the reading unit and the second one of the plurality of marks, and changes at least one operational parameter of the converting line when the calculated distance is less than a threshold.

Owner:GPCP IP HLDG LLC

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS9518362B2Special visual effect coatingsLiquid surface applicatorsMarking outProcess engineering

A system for producing a paper product. The system includes a paper machine, an analysis tool, and a converting line. The paper machine forms a paper web having a plurality of sections, inspects the paper web to identify properties, and marks the paper web with a plurality of marks, at least one mark being assigned to each of the plurality of sections. The analysis tool assigns a paper rating to each section of the paper web based upon the identified properties in that section of the paper web. The converting line has a plurality of operational parameters and converts the paper web into the paper product. The converting line reads at least one of the plurality of marks on the paper web, obtains the paper rating associated with the mark read, and changes at least one operational parameter of the converting line based upon the paper rating.

Owner:GPCP IP HLDG LLC

Dullish coated paper for printing

InactiveUS20050016701A1Good flexibilityImprove surface smoothnessNatural cellulose pulp/paperSpecial paperFiberAdhesive

A dull coated printing paper that is bulky (low in density) having a density of 0.90 to 1.15 g / cm3 and yet offers excellent pliability, superior surface smoothness, high degree of print gloss and minimal small-scale gloss variations in the image area are obtained by forming a coating layer comprising a pigment and an adhesive on a base paper which contains an organic compound having an action to inhibit binding between pulp fibers and then carrying out calender treatment at a line pressure for the treatment of 50 to 150 kg / cm.

Owner:NIPPON PAPER IND CO LTD

Multi-ply fibrous structures and methods for making same

Owner:THE PROCTER & GAMBLE COMPANY

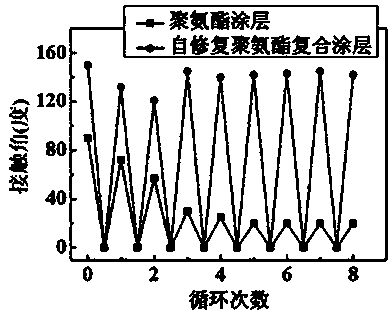

Preparation method of self-repair super-hydrophobic polyurethane coating

ActiveCN103449736ARealize self-healing functionExtended service lifeCoated paper substratePolyurea/polyurethane coatingsOrganic solventPolyurethane coating

The invention discloses a preparation method of a self-repair super-hydrophobic polyurethane coating. According to the preparation method, first a porous material is added to a saturated solution of a low-surface-energy matter, and is distilled to dry in a constant temperature oil bath to obtain a hydrophobic porous material with a self-repair function, then the hydrophobic porous material and ethyl orthosilicate or a polyurethane prepolymer are dispersed in an organic solvent, a dipping or spraying method is used, after curing a coating with super hydrophobic function is obtained, and the super hydrophobic property of the coating can be self-repaired. The preparation method has the advantages of simple process, mild condition and low cost.

Owner:YANTAI ZHONGKE RES INST OF ADVANCED MATERIALS & GREEN CHEM ENG

Coated printing sheet and process for making same

A printing sheet is described comprising a substrate and, on at least one side of the substrate, an image receptive coating layer with a cumulative porosity volume of pore widths below 200nm as measured using nitrogen intrusion methods of more than 0.006 cm<3> per gram paper. In particular in the context of printing sheets with high-gloss this particular porosity distribution leads to a quick and easily adjustable ink setting behaviour. Additionally a method for manufacturing such a printing sheet is described using organic, i.e. polymer and inorganic particulate pigments of fine particle characteristics.

Owner:SAPPI NETHERLANDS SERVICES

Dullish coated paper for printing

A dull coated printing paper that is bulky (low in density) having a density of 0.90 to 1.15 g / cm3 and yet offers excellent pliability, superior surface smoothness, high degree of print gloss and minimal small-scale gloss variations in the image area are obtained by forming a coating layer comprising a pigment and an adhesive on a base paper which contains an organic compound having an action to inhibit binding between pulp fibers and then carrying out calender treatment at a line pressure for the treatment of 50 to 150 kg / cm.

Owner:NIPPON PAPER IND CO LTD

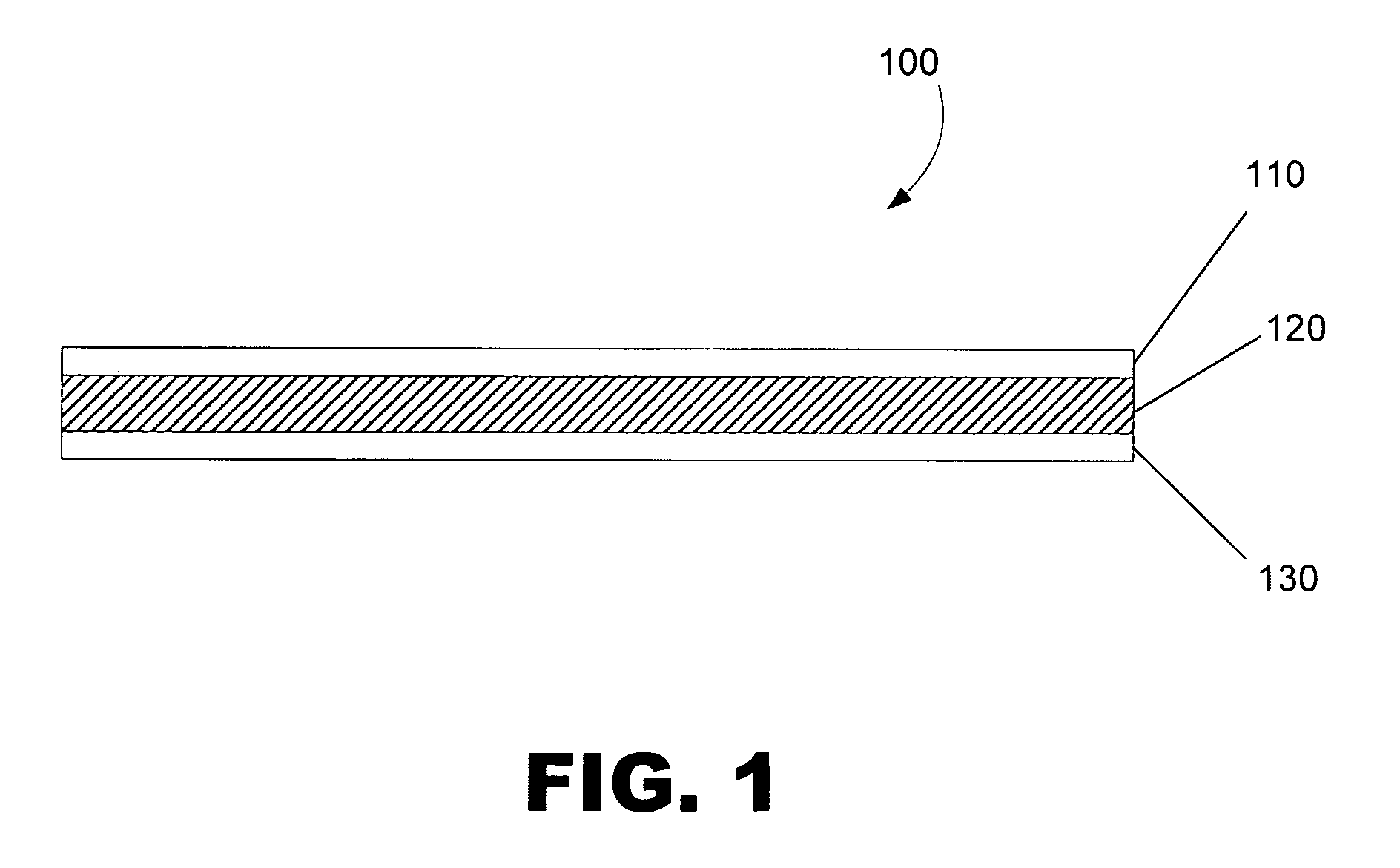

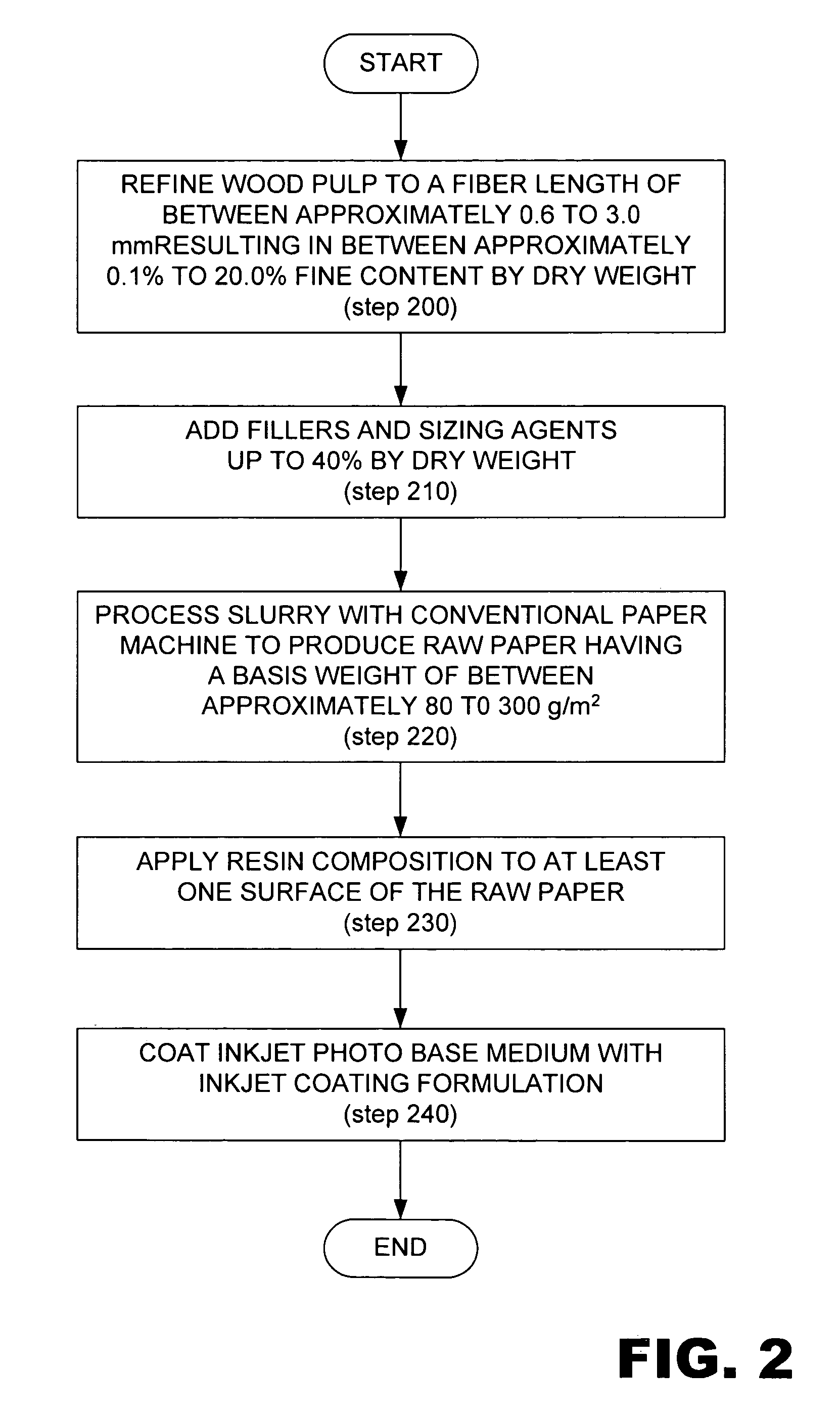

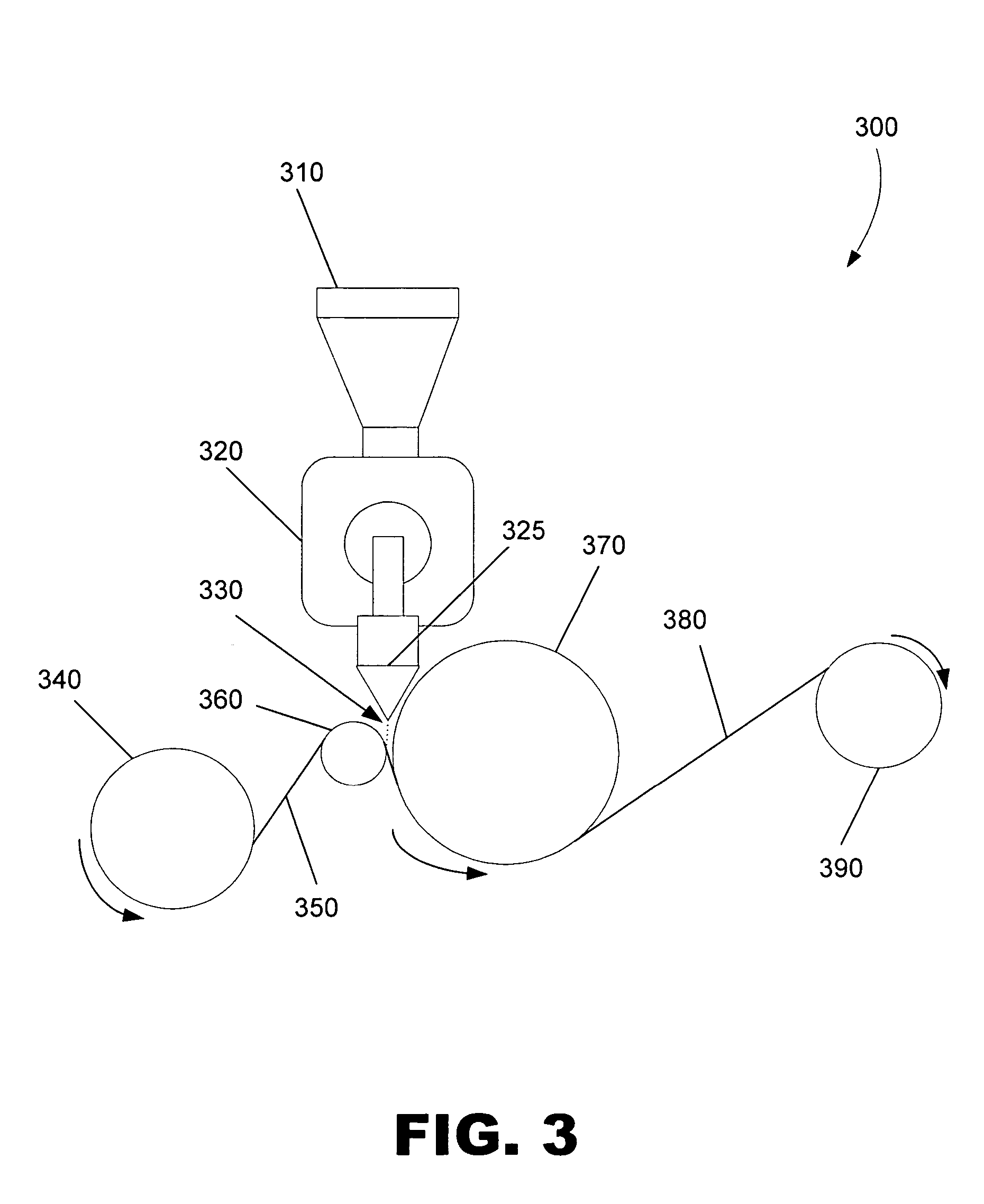

System and a method for inkjet image supporting medium

Owner:HEWLETT PACKARD DEV CO LP

Method of coating cellulosic and lignocellulosic webs

InactiveUS6413591B1High strengthIncrease the number ofNon-fibrous pulp additionNatural cellulose pulp/paperPaperboardEngineering

A method for coating paper, wherein a coating composition containing coating particles is applied to the surface of a paper web containing lignocellulosic fibers to produce a coated paper web having coating particles bound to the paper web, and the coated web is dried. According to the method the surface area of the interface between the paper web and the coating particles is increased in order to enhance hydrogen bonding between the coating particles and the fibers of the web. The surface area can be increased by using a coating composition comprising fine fibrous material or by abrading the surface of the paper or paperboard web or both. The invention will improve the smoothness of the surface without addition of foreign polymer binding agents to the web.

Owner:IDI HEAD

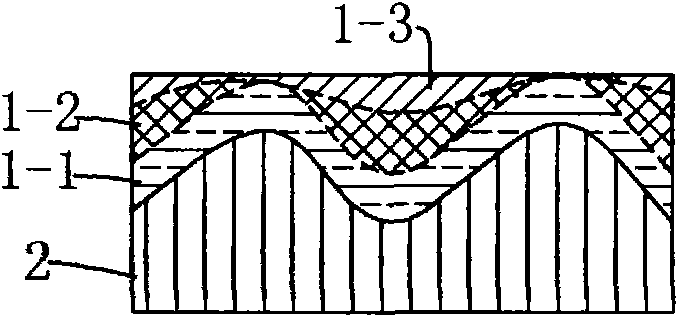

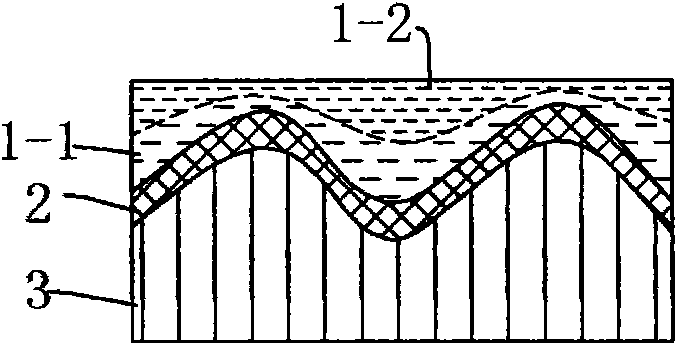

Light coated white craft paper and method for manufacturing same

ActiveCN101581055AUniform thicknessEliminate slightly rough imperfectionsNon-fibrous pulp additionCoatings with pigmentsMaterials scienceCoated paper

The invention discloses a light coated white craft paper, which comprises a top layer, a core layer, a bottom layer and a coating layer, wherein the coating layer is arranged on the top layer, has a relatively uniform thickness and goes up and down with the surface of the top layer; and the fixed weight of the light coated white craft paper is 120 to 220 g / m and the coating weight of the coating layer is 6 to 15 g / m. The invention also discloses a method for manufacturing the light coated white craft paper. With the combined advantages of the conventional white craft paper and heavy coated paper, the light coated white craft paper has a thin coating layer and retains the strength of base paper, thereby realizing an extremely low fixed weight that can greatly improve the paper yield of unit weight and reduce production costs for users. At the same time, less coating content reduces the difficulties in the recovery of the light coated white craft paper, reduces water pollution and brings the light coated white craft paper a promising development prospect.

Owner:昌乐新迈纸业有限公司

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS20150292162A1Special visual effect coatingsLiquid surface applicatorsProduction linePulp and paper industry

A converting line for producing a paper product. The converting line includes a paper web being unwound from a parent roll. The paper web has a plurality of sections with at least one mark, associated with an action score, assigned to each of the plurality of sections. The converting line also includes a mark reading unit, which reads one of the plurality of marks on the paper web. The converting line further includes a controller configured to obtain the action score associated with a second one of the plurality of marks; to calculate a distance between the one mark read by the reading unit and the second one of the plurality of marks; and to change at least one operational parameter of the converting line based upon the action score of the second one of the plurality of marks when the calculated distance is less than a threshold.

Owner:GPCP IP HLDG LLC

Porous coating compositions for printing applications

Improved coating compositions for flexographic and other printing applications can comprise calcined clay, a binder and optionally one or more additional pigments. In some embodiments, the binder can comprise a natural composition and a synthetic composition. In addition, the coating composition can further comprise additives such as, for example, dispersants, defoamers, plastic pigments, rheology modifies, biocides, optical brighteners, cross-linkers, functional chemicals and combinations thereof. Due to the presence of the calcined clay, the improved coatings can have sufficient porosity to absorb water located in ink layers without employing significant amounts of expensive additives such as silicates and other porous compounds.

Owner:LIBERTY PAPER

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS20150292161A1Non-fibrous pulp additionLayered productsPulp and paper industryManufacturing line

Owner:GPCP IP HLDG LLC

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS20150292156A1Non-fibrous pulp additionNatural cellulose pulp/paperMarking outProcess engineering

A system for producing a paper product. The system includes a paper machine, an analysis tool, and a converting line. The paper machine forms a paper web having a plurality of sections, inspects the paper web to identify properties, and marks the paper web with a plurality of marks, at least one mark being assigned to each of the plurality of sections. The analysis tool assigns a paper rating to each section of the paper web based upon the identified properties in that section of the paper web. The converting line has a plurality of operational parameters and converts the paper web into the paper product. The converting line reads at least one of the plurality of marks on the paper web, obtains the paper rating associated with the mark read, and changes at least one operational parameter of the converting line based upon the paper rating.

Owner:GPCP IP HLDG LLC

Hollow polymer particle and its preparing method, paper coating composition, coating paper and mfg. method

InactiveCN1477134AImprove the hollow rateGood spreadabilityCoated paper substrateCoatingsPolymer scienceEmulsion polymerization

The present invention provides a kind of hollow polymer granules with good balancing property, for example gloss and coating strength and production method of said granules, paper coating composite by using said granules and coated paper. The hollow polymer granules can be obtained by using the following raw materials and processes: emulsion polymerization containing unsaturated carboxylic acid and free radical polymerizable monomer which can be copolymerized with unsaturated carboxylic acid, preparation of polymer granules, preparing core-shell polymer granules, regulating pH value of dispersion containing said core-shell polymer granules to above 7 and polymerizing unreacted monomer.

Owner:JSR CORPORATIOON

Low-specific-gravity stone paper

ActiveCN102154932AIncrease coverageReduce weightCoatings with pigmentsCoated paper substrateManufacturing cost reductionGlass ball

The invention discloses low-specific-gravity stone paper relating to synthetic paper. The low-specific-gravity stone paper comprises a base paper layer and a coating layer, wherein the coating layer is coated on the base paper layer; the base paper layer comprises 15-30 parts by weight of synthetic resin and 70-85 parts by weight of mixing material, wherein the synthetic resin is polylactic acid, EVA (ethylene vinyl acetate copolymer), PP (polypropylene), PE (poly ehtylene) or a mixture of any two of the polylactic acid, the EVA, the PP and the PE; the mixing material is a hollow glass ball, coal ash or the mixture of the hollow glass ball and the coal ash; and the coating layer comprises 20-40 parts by weight of acrylic resin, 20-40 parts by weight of lithopone and 30-50 parts by weight of deionized water. The low-specific-gravity stone paper has the following benefits: the mixing material is the hollow glass ball or coal ash so that the mixing material has low specific gravity and good dispersity; the lithopone has good covering power, thus the weight of the paper is convenient to reduce, the paper quality is improved, and the manufacturing cost is reduced.

Owner:大正新型材料(肇庆)有限公司

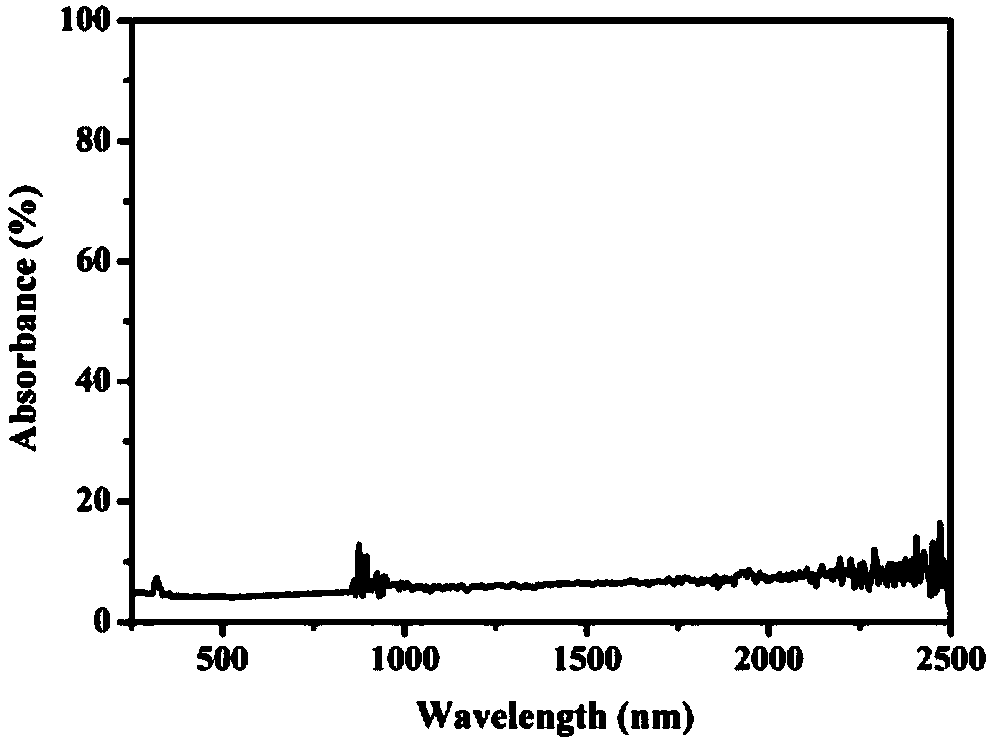

Paper based composite light absorption material for efficient photothermal conversion and preparation method thereof

InactiveCN107604756ALow costEasy to operateSolar heating energyCoatings with pigmentsSpectral responsePhotothermal conversion

The invention discloses a paper based composite light absorption material for efficient photothermal conversion and a preparation method thereof. Carbon black particles in commercial carbon black inkare deposited on a filter paper surface by ultrasonic loading, the preparation method is simple, low in cost, and green and environment-friendly, and a composite light absorption material characterized by broad spectral response range, high photothermal conversion efficiency and strong hydrophilcity can be obtained, is easy for mass production and wide application, enriches the existing photothermal material field, and fills the blank of the technical field. At the same time, by utilizing the efficient photothermal conversion characteristic, the paper based composite light absorption materialprovided by the invention can be applied to seawater desalination, can meet the social requirement for rapid acquisition of purified water, and also provides a new way for photothermal utilization ofsolar energy.

Owner:GUILIN UNIV OF ELECTRONIC TECH

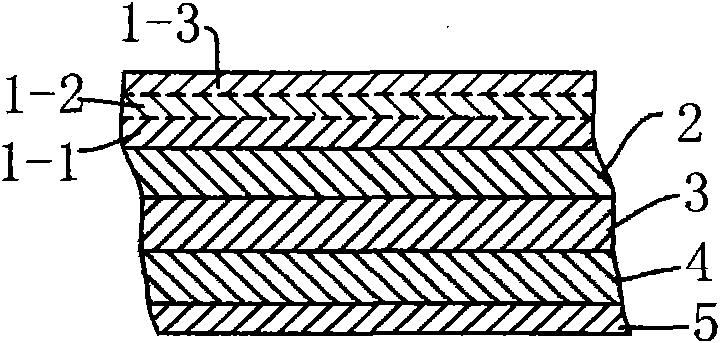

Coated white-top kraft liner board and manufacturing method thereof

ActiveCN101586318AImprove hair sheddingImproves paint adhesive migrationNon-fibrous pulp additionCoatings with pigmentsCardboardSurface layer

The invention discloses a coated white-top kraft liner board, which comprises a surface layer, a lining and a bottom layer, and also comprises two glue application layers and a coating layer; the two glue application layers are respectively arranged on the surface of the bottom layer and the surface of the surface layer; the coating layer at least comprises a coating separated layer orderly arranged on the surface layer, and the coating separated layer positioned on the surface has a level and smooth surface; and the ration of the coated white-top kraft liner board is between 120 and 220g / m, and the coating weight of the coating layer is between 12 and 28g / m. The invention also discloses a manufacturing method for the coated white-top kraft liner board. The invention adopts a coating method that a film transfer machine performs double-sided glue application on a base paper board and then scraper coating is performed; and the produced coated white-top kraft liner board has good strength index, and good performance of lustrousness, smoothness and printability of the paper surface on the premises of low coating weight and low ration, and can completely meet the requirement of advanced printing and packaging.

Owner:SHANDONG CENTURY SUNSHINE PAPER GROUP +1

Manufacturing method of Pinfeng base paper

ActiveCN105586802AEasy to shapeImprove uniformityCoated paper substrateNon-macromolecular organic additionLogistics managementSlurry

The invention discloses a manufacturing method of Pinfeng base paper. The method comprises the following processing steps: pulping and preparing softwood pulp and hardwood pulp respectively; adding auxiliary materials; making wet paper sheets; carrying out pre-drying and surface sizing treatment; and carrying out post-drying, calendaring and finishing. Through research on slurry selection, slurry proportioning, a beating technology, a functional chemical additive added to the slurry and a digital printing assistant, measures of calendaring and the like are carried out by film-transfer surface sizing treatment by soft calendaring equipment; and the qualified Pinfeng base paper is manufactured by referring to related paper machine parameters. Compared with ordinary logistics label middle paper, the Pinfeng base paper has the advantages of low gram weight, high tensile strength, good internal bonding strength, high smoothness, low hygroscopic property, good surface strength, good digital printing effect, fine paper surface and good hand feeling, and is capable of completely replacing the ordinary logistics label middle paper and reducing the production cost for customers.

Owner:YUEYANG FOREST & PAPER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com