Preparation method of self-repair super-hydrophobic polyurethane coating

A polyurethane coating and super-hydrophobic technology, which is applied in polyurea/polyurethane coatings, coatings, coated paper base paper, etc., can solve the problems of super-hydrophobic surface being easily damaged, resource and manpower consumption, and harsh preparation conditions. Achieve good superhydrophobic and self-cleaning properties, prolong service life, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Hydrophobic substance storage: The specific treatment steps are to add 1.8g of porous silica with a particle size of about 10μm and a pore size of 9nm to 5mL of ethanol solution containing 1.0g of stearyl alcohol, and distill it to near dryness in a constant temperature oil bath at 60°C to obtain a self-healing Functional hydrophobic porous materials.

[0026] Preparation of hydrophobic coating: Disperse 0.1g of hydrophobic porous material in 5mL of distilled water, take 1.5mL of the suspension and place it on a glass slide, air-dry at 40°C for 24 hours, then soak the obtained film in tetraethyl orthosilicate solution for 2 minutes, Then take it out and place it in an ammonia atmosphere for 3 hours for ammonolysis, and dry it for 24 hours under ventilated conditions. The resulting coating has self-healing superhydrophobic function.

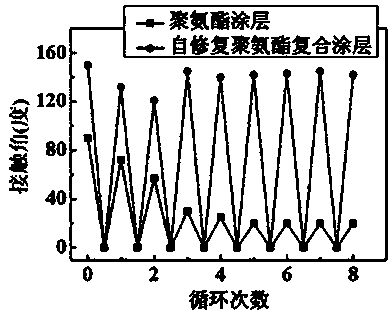

[0027] The prepared self-healing superhydrophobic coating has a static contact angle of 152°. followed by O 2 Plasma destroys the super...

Embodiment 2

[0029] The storage of hydrophobic substances, the processing steps are: add 1.8g of porous silica with a particle size of about 10μm and a pore size of 9nm to 5mL of ethanol solution containing 1.0g of octadecylamine, and distill to dryness at 60°C in a constant temperature oil bath to obtain a self-healing Functional hydrophobic porous materials.

[0030] Preparation of superhydrophobic coating: Add 1.5g of polyurethane prepolymer and 0.5g of dry hydrophobic porous material to 10mL of acetone, stir evenly, ultrasonically treat for 2min, and spray it on a glass slide with a spray gun at a pressure of 1.5 atmospheres. After standing and curing for 48 hours at room temperature, a superhydrophobic polyurethane / porous silica composite coating can be obtained.

[0031] The static contact angle of the self-healing superhydrophobic coating can be as high as 151°. After 8 times O 2 Plasma damage and self-healing at room temperature, the water contact angle is still higher than 140° ...

Embodiment 3

[0033] Hydrophobic substance storage, the processing steps are: add 1.2g of porous silica with a particle size of about 1.2μm and a pore size of about 3nm to 20mL of an ethanol solution containing 1.0g of perfluorooctanoic acid, and distill to dryness at 75°C in a constant temperature oil bath to obtain a self-healing Functional hydrophobic porous materials. Solvents can be reused.

[0034] Preparation of super-hydrophobic coating: Add 5.0 g of polyurethane prepolymer and 0.5 g of dry hydrophobic porous material to 10 mL of acetone, stir evenly, ultrasonically treat for 2 min, and spray it on a glass slide with a spray gun at a pressure of 1.5 atmospheres. After standing and curing for 48 hours at room temperature, a superhydrophobic polyurethane / porous silica composite coating can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com