Paper based composite light absorption material for efficient photothermal conversion and preparation method thereof

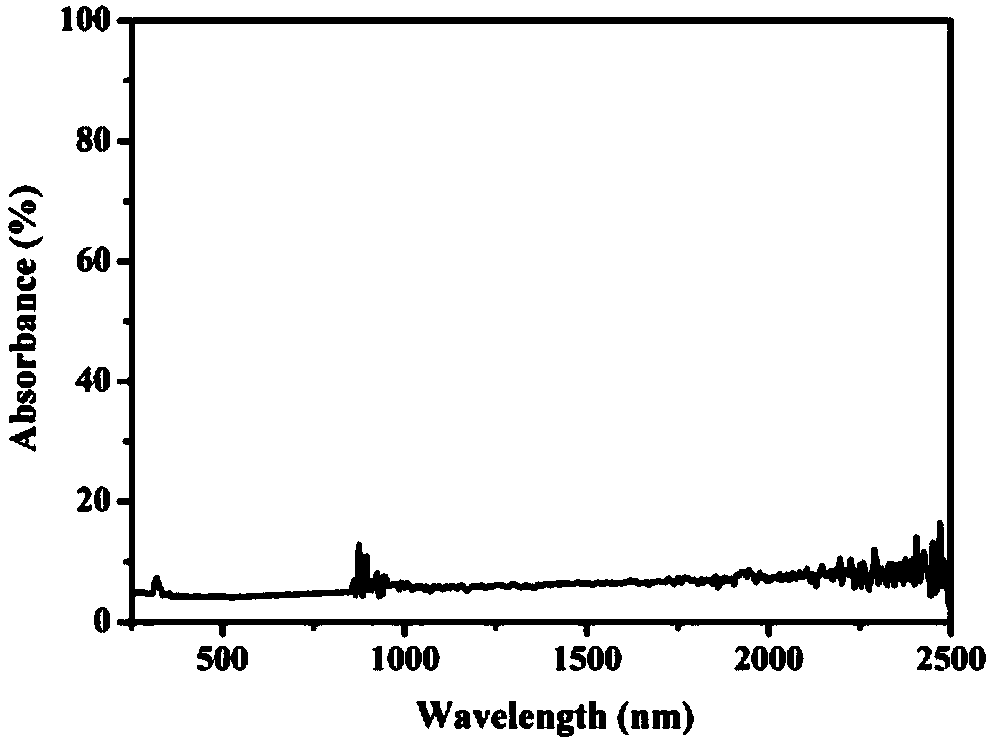

A light-absorbing material, photothermal conversion technology, applied in coated paper base paper, lighting and heating equipment, pulp raw material addition process, etc., can solve problems such as high cost and complex preparation process, achieve low cost and wide spectral response range , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Synthesis of ink-paper-based composite light-absorbing material based on fast filter paper

[0033] 1) Put 25×25×0.2mm 3 The filter paper has a pore size of 80–120μm. The fast qualitative filter paper is placed in 20ml of black carbon ink solution, and then placed in an ultrasonic cleaning machine. Under the action of 70% ultrasonic power, ultrasonic deposition is performed for 5 minutes, repeated three times, and the ink is Carbon black particles are deposited on the surface of the filter paper fiber;

[0034] 2) Vacuum drying the filter paper loaded with carbon black particles obtained in step 1) at 60° C., so that the ink carbon black particles can be firmly attached to the surface of the filter paper fiber to obtain a dried material;

[0035] 3) Put the dried material obtained in step 2) into a beaker, add 20ml of deionized water, and sonicate it for 5 minutes under the action of ultrasound with a power of 70% until the color of the deionized water does not chan...

Embodiment 2

[0038] Example 2: Synthesis of ink-paper-based composite light-absorbing material based on medium-speed filter paper

[0039] 1) Put 25×25×0.2mm 3 The medium-speed qualitative filter paper with a pore size of 20-60μm is placed in 20ml black carbon ink solution, and then placed in an ultrasonic cleaning machine. Under the action of 100% ultrasonic power, ultrasonic deposition is performed for 3 minutes. Repeat three times to remove the carbon in the ink. Black particles are deposited on the surface of the filter paper fiber;

[0040] 2) Vacuum drying the filter paper loaded with carbon black particles obtained in step 1) at 70° C., so that the ink carbon black particles can be firmly attached to the surface of the filter paper fibers to obtain a dried material;

[0041] 3) Put the dried material obtained in step 2) into a beaker, add 20ml of deionized water, under the action of 100% ultrasonic power, until there is no change in the color of the deionized water, so as to attach the exc...

Embodiment 3

[0044] Example 3: Synthesis of ink-paper-based composite light-absorbing material based on slow filter paper

[0045] 1) Put 25×25×0.2mm 3 The filter paper with a pore size of 1–3μm is placed in 40ml of black carbon ink solution, and then placed in an ultrasonic cleaning machine. Under the action of ultrasound with a power of 70%, ultrasonic deposition is performed for 5 minutes. Repeat three times to put the ink in Carbon black particles are deposited on the surface of the filter paper fiber;

[0046] 2) Vacuum drying the filter paper loaded with carbon black particles obtained in step 1) at 60° C., so that the ink carbon black particles can be firmly attached to the surface of the filter paper fiber to obtain a dried material;

[0047] 3) Put the dried material obtained in step 2) into a beaker, add 40ml of deionized water, under the action of 70% ultrasonic power, until there is no change in the color of the deionized water, so as to attach the excess to the filter paper fiber Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com