Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

368results about "Applied substance rearrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

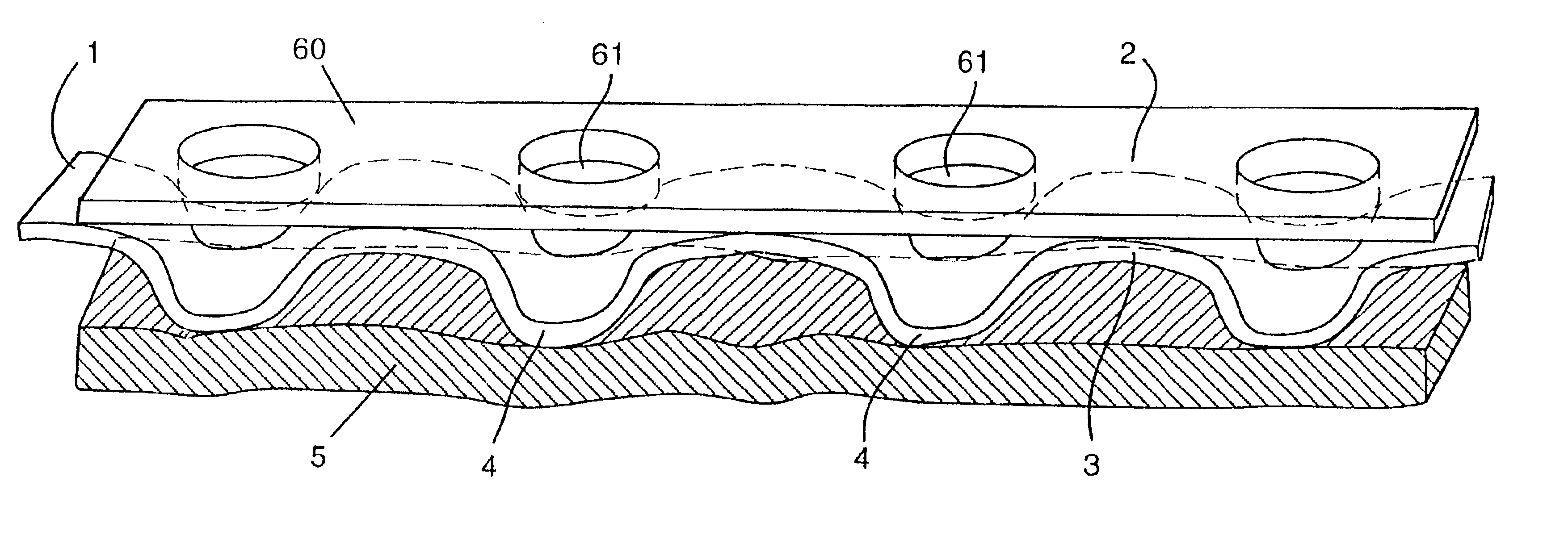

Dual-zoned absorbent webs

InactiveUS6911573B2Fast shippingImprove adaptabilityNatural cellulose pulp/paperMechanical working/deformationCelluloseEngineering

The present invention is a method for producing an absorbent article. A wet resillient, cellulosic basesheet having elevated and depressed regions with an Overall Surface Depth of at least 0.2 mm is prepared. The cellulosic basesheet has an upper surface and a lower surface. A contiguous, fibrous nonwoven web having a plurality of openings is integrally attached onto the upper surface of the cellulosic basesheet such that a portion of the openings are superposed over the depressed regions of the cellulosic basesheet. An absorbent core and an impervious web are attached to the lower surface of the cellulosic basesheet such that the absorbent core is sandwiched between the impervious web and the cellulosic basesheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

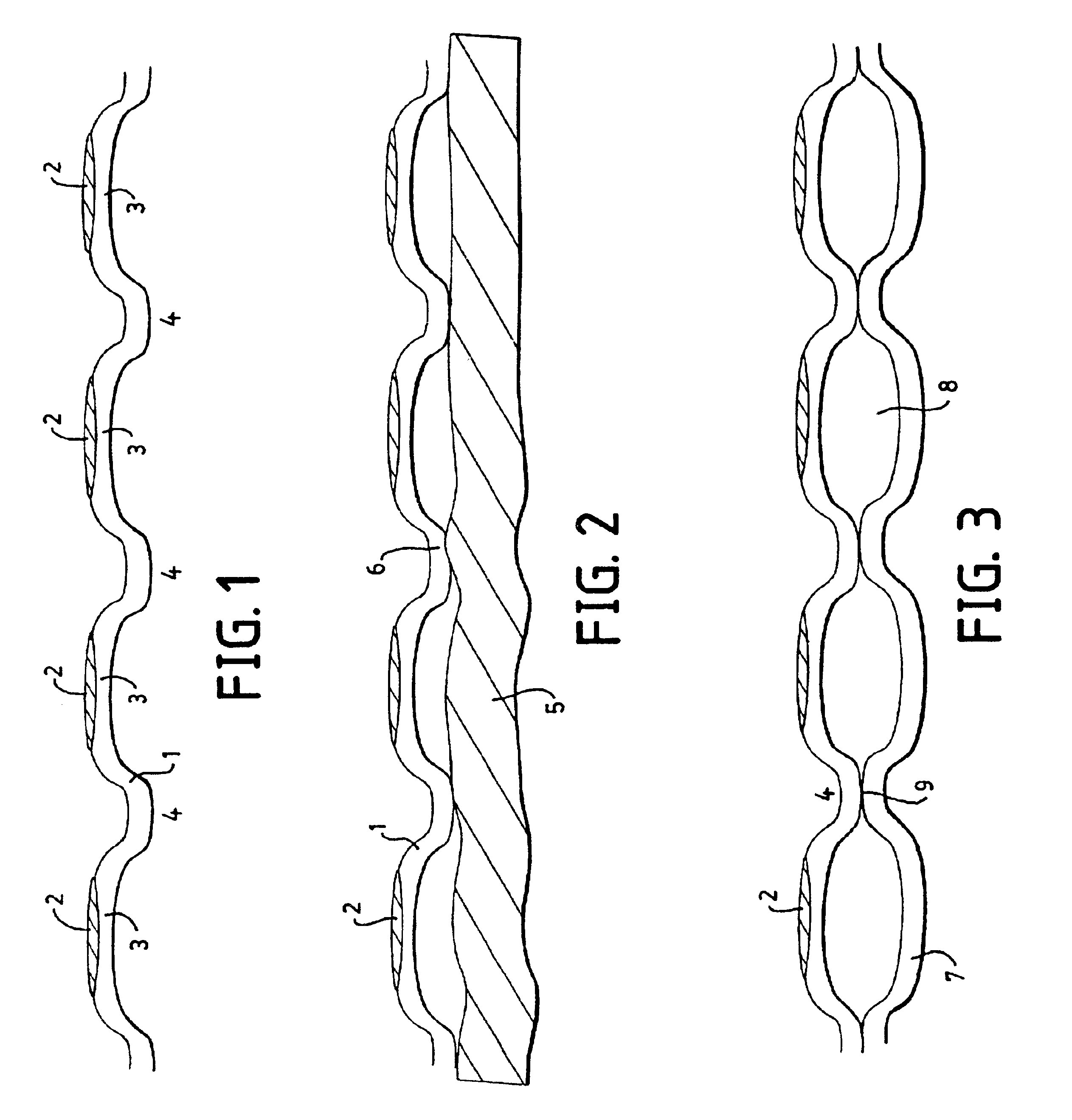

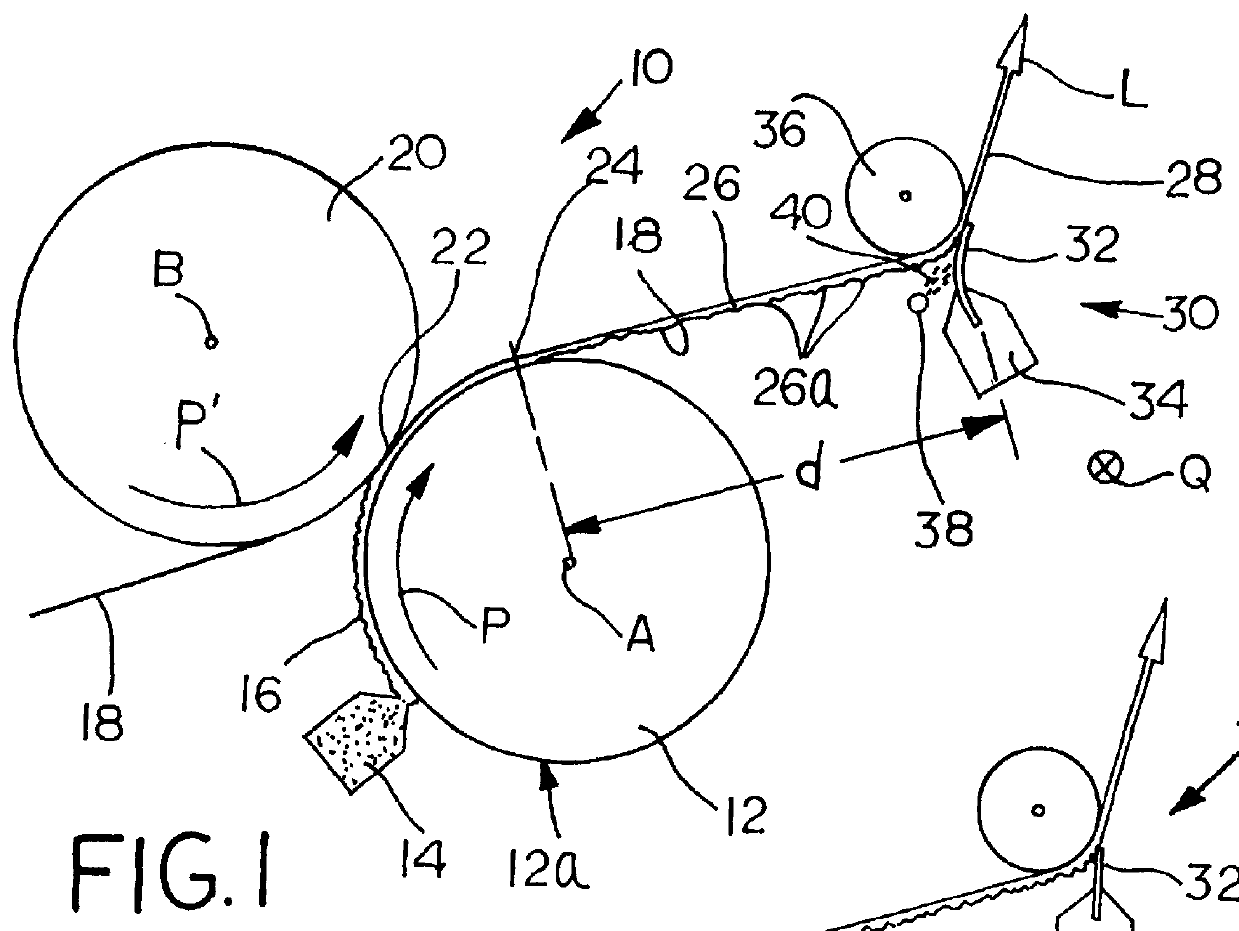

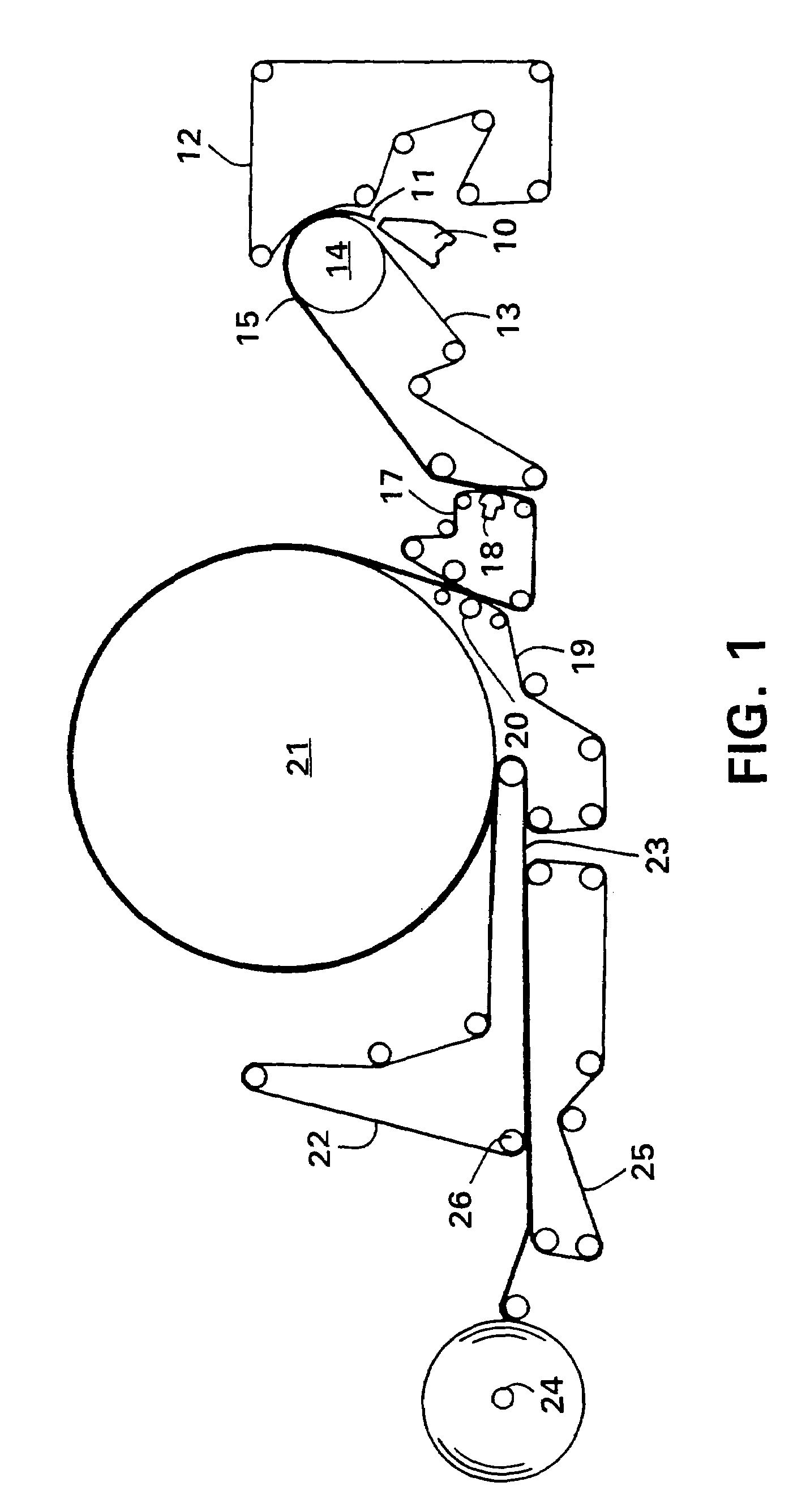

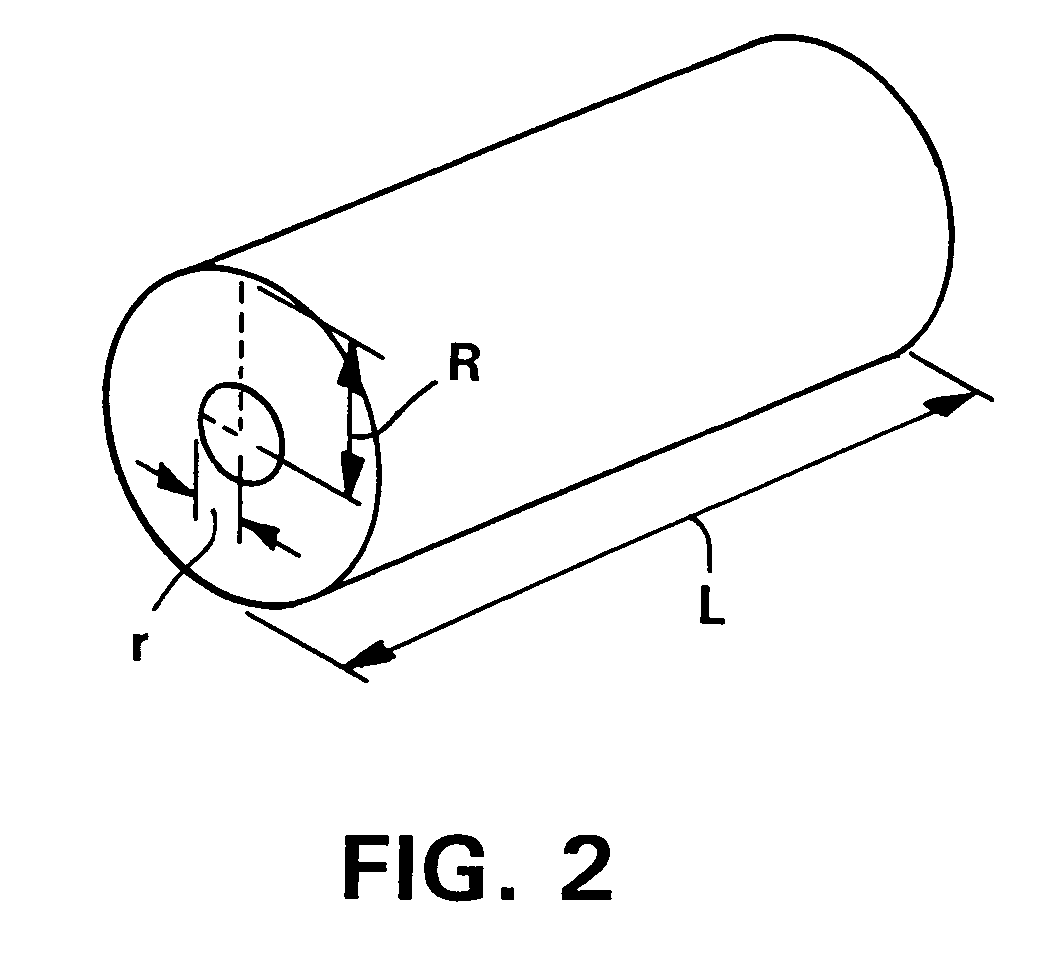

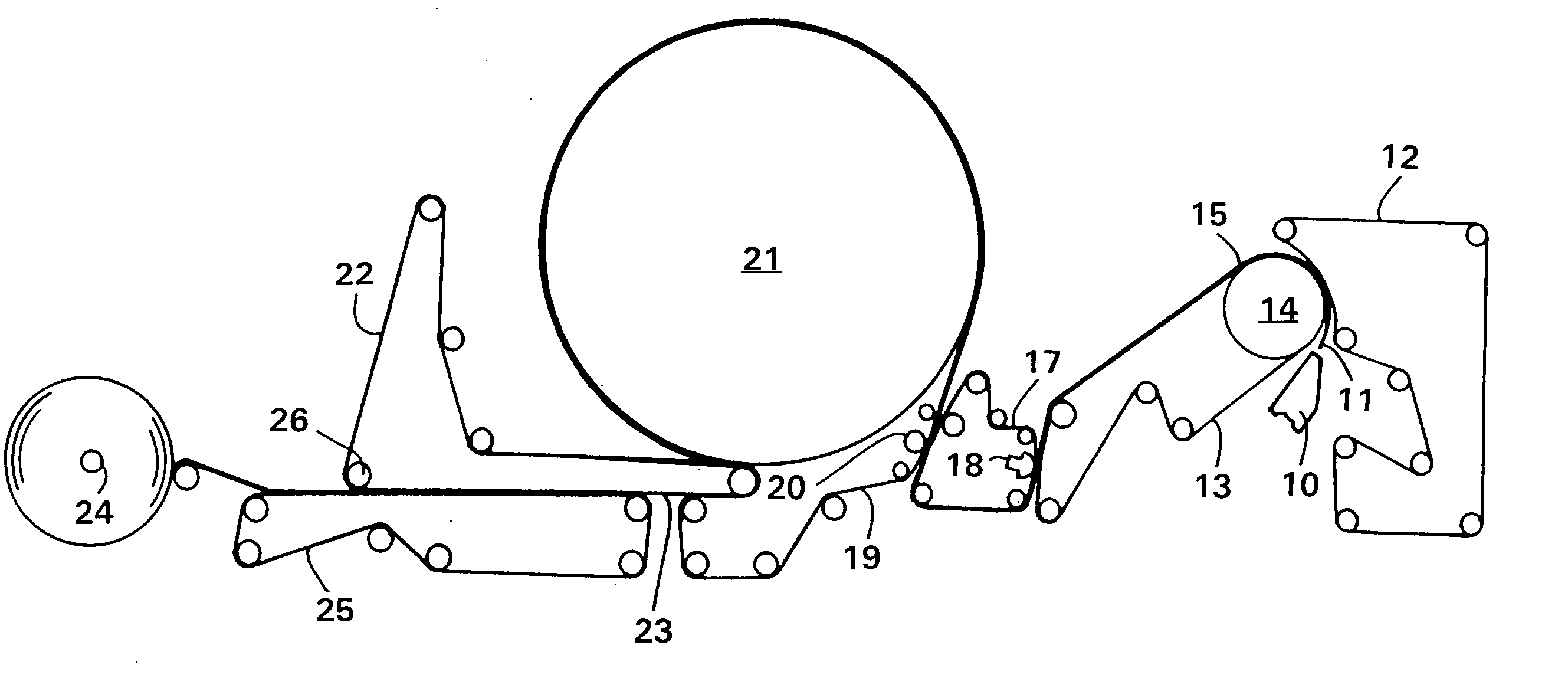

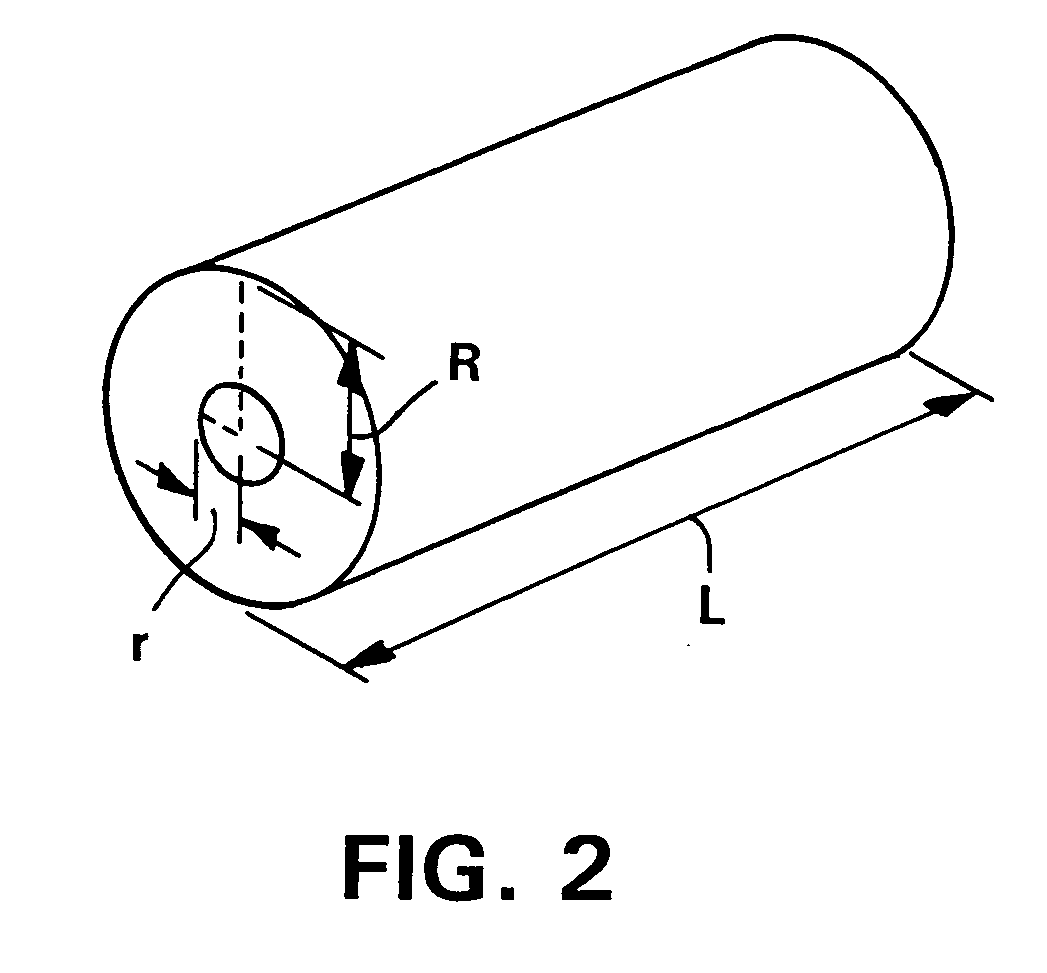

Wet crepe throughdry process for making absorbent sheet and novel fibrous products

InactiveUS20020148584A1Big cost advantageReduce air permeabilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

An improved process for making sheet from a fibrous furnish includes: depositing the furnish on a foraminous support; compactively dewatering the furnish to form a nascent web; drying the web on a heated cylinder; creping the web therefrom and throughdrying the web to a finished product. The microstructure of the web is controlled so as to facilitate throughdrying. The product exhibits a characteristic throughdrying coefficient of from 4 to 10 when the airflow through the sheet is characterized by a Reynolds Number of less than about 1. The novel products of the invention are characterized by wet springback ratio, hydraulic diameter and an internal bond strength parameter.

Owner:GPCP IP HLDG LLC

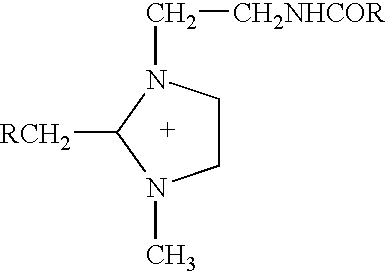

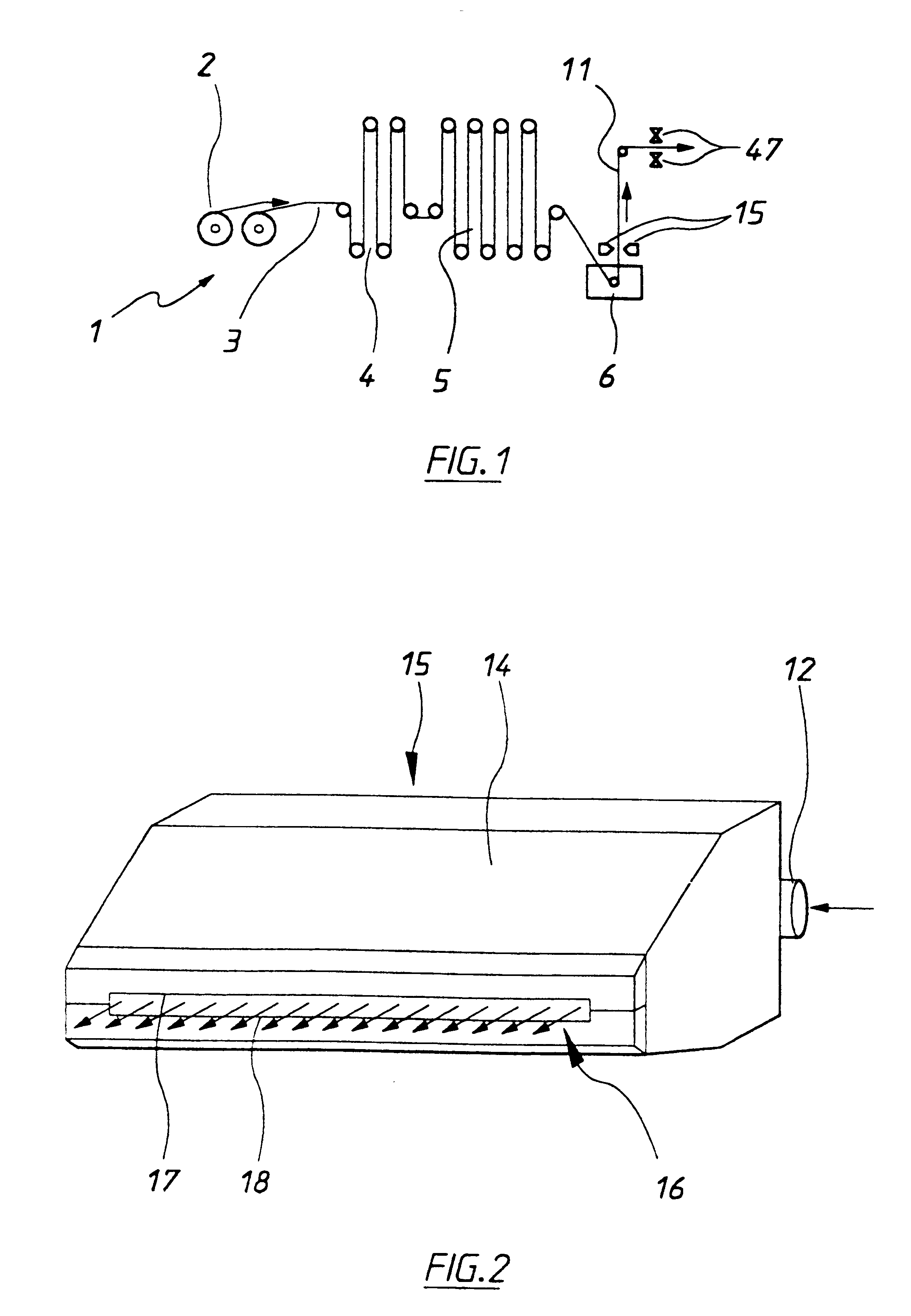

Coating thickness control

An air knife mouth arrangement for use in an air knife assembly having a laterally extending mouth through which pressurized fluid passes to operate on a coating applied to a surface of a sheet material passing the mouth in a longitudinal direction to control the thickness of the coating. In the preferred form of the invention shown the air knife mouth arrangement comprises a mouth defined by a pair of facing lips, each lip having in front elevation a curved shape along its length. The curved shapes of the two lips face each other. The lips of the air knife mouth arrangement are selectively laterally displaceable relative to each other by a moving means so as to thereby vary the separation of the lips and hence the width of the mouth along the length of the mouth. It is to be noted that the term "length" refers to the dimension of the mouth in the lateral direction (indicated by the X axis), while the term "width" refers to the dimension of the mouth in the longitudinal direction (indicated by the Y axis).

Owner:HATCH LTD

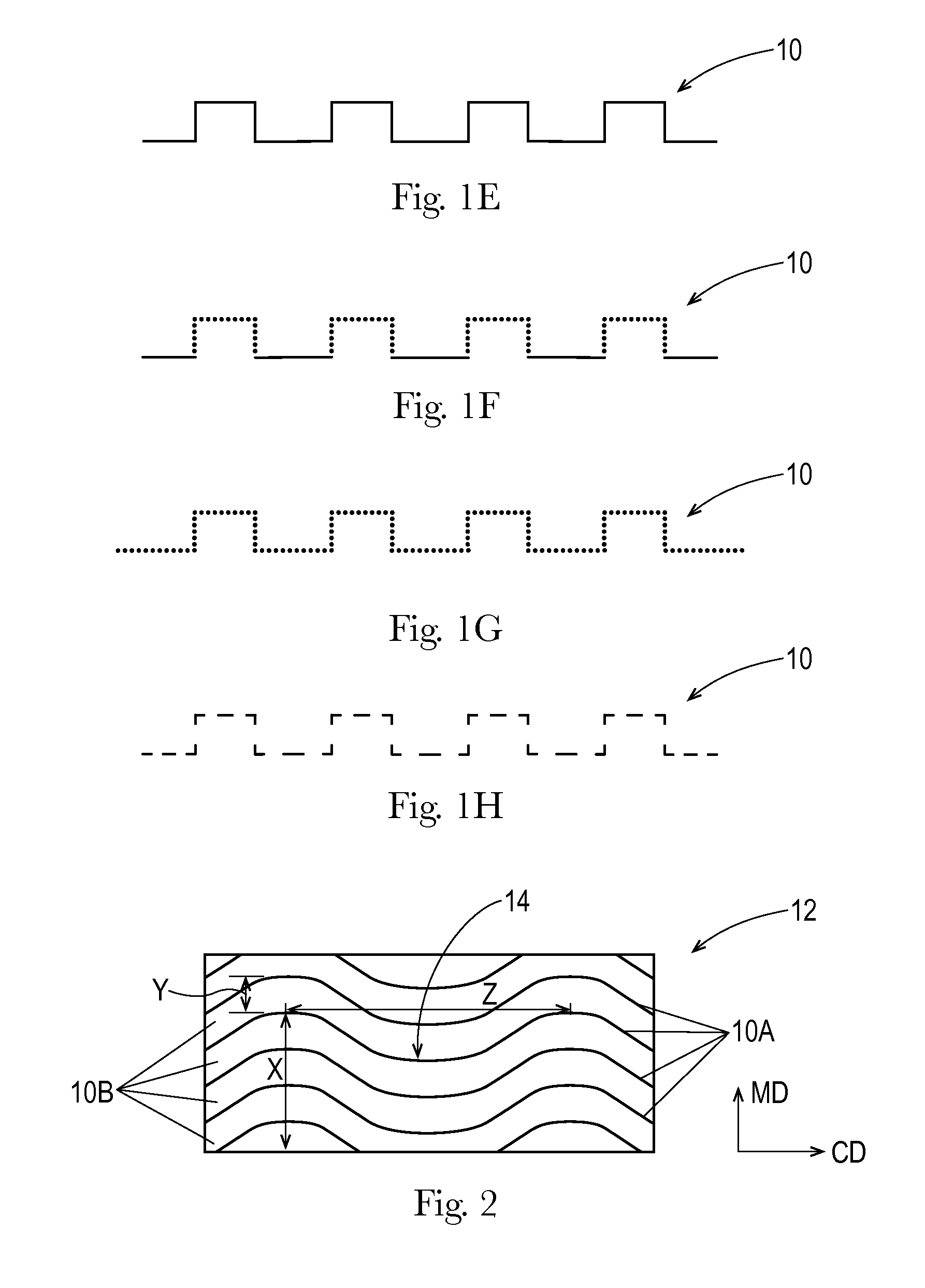

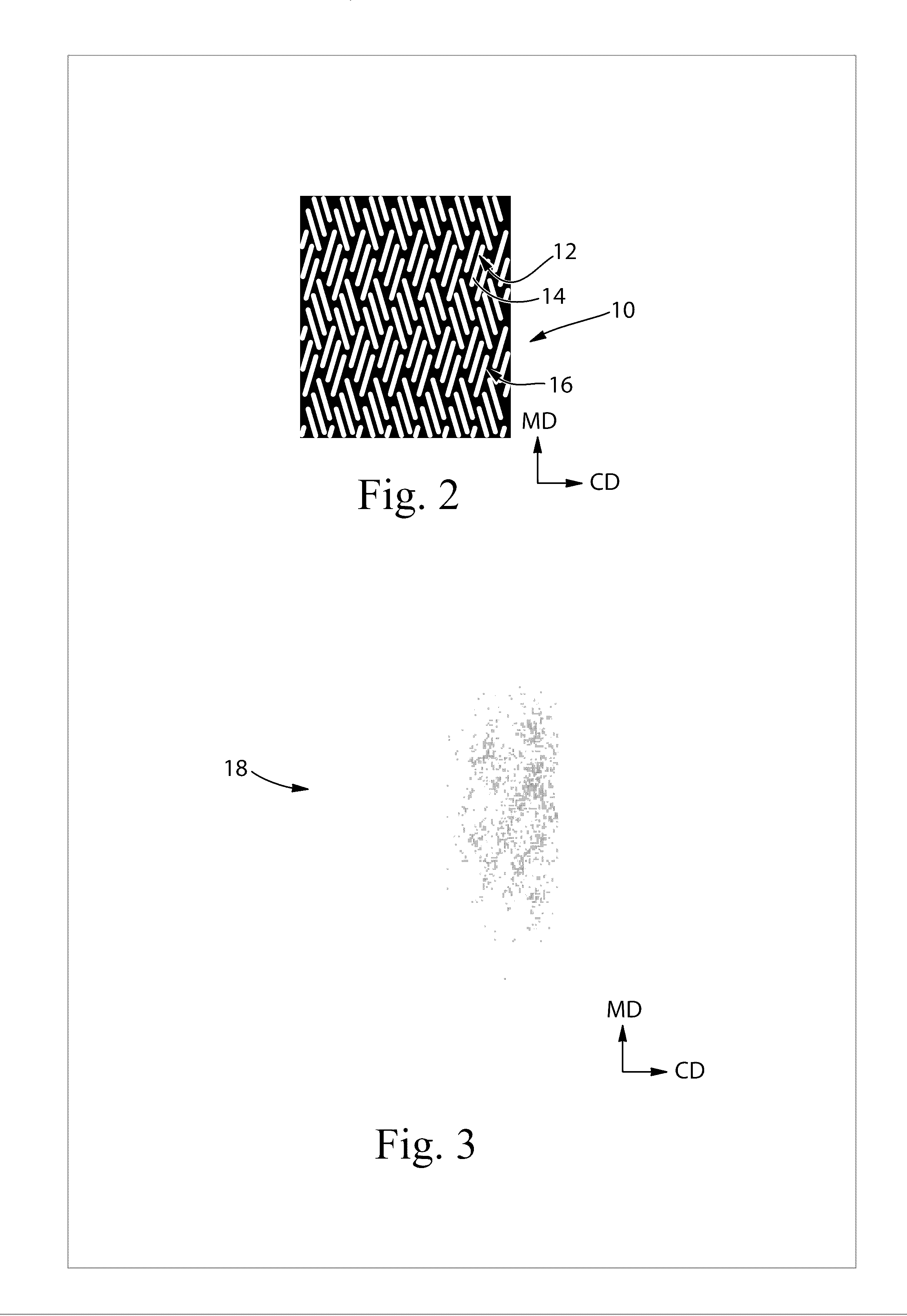

Tissue sheets having improved properties

InactiveUS20060083899A1Improve firmnessImprove propertiesNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringBiomedical engineering

The roll properties of tissue sheets are improved either by imparting cross-machine direction dominant bar-like protrusions to the air side of the tissue by using specially woven transfer fabrics and / or by offsetting recurring surface features of the sheet relative to the surface features of adjacent sheets within the roll, such as by providing a throughdryer fabric with an offset seam. Both techniques provide the resulting tissue sheets with improved capabilities for providing an improved combination of roll bulk and roll firmness.

Owner:KIMBERLY-CLARK WORLDWIDE INC

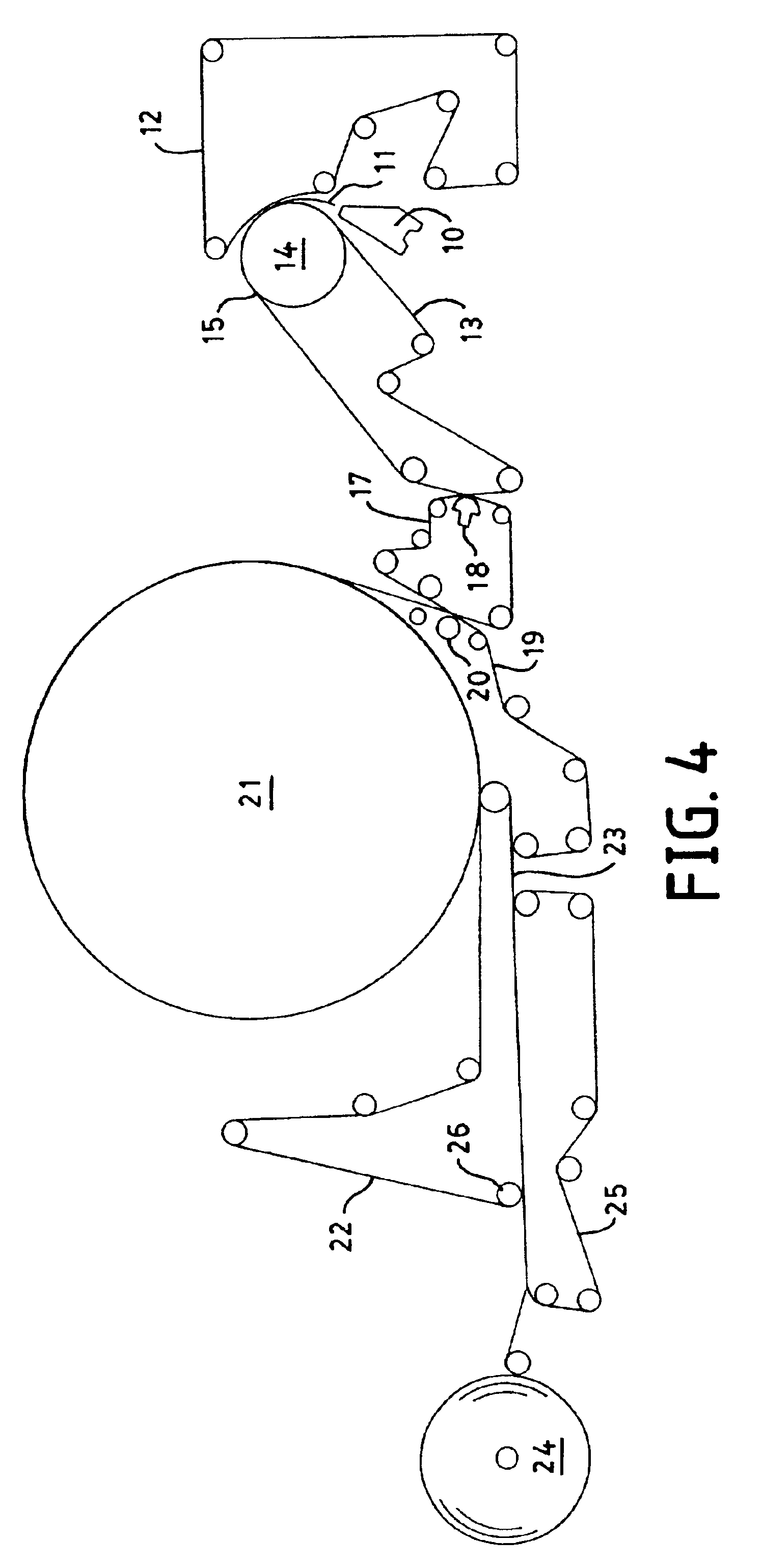

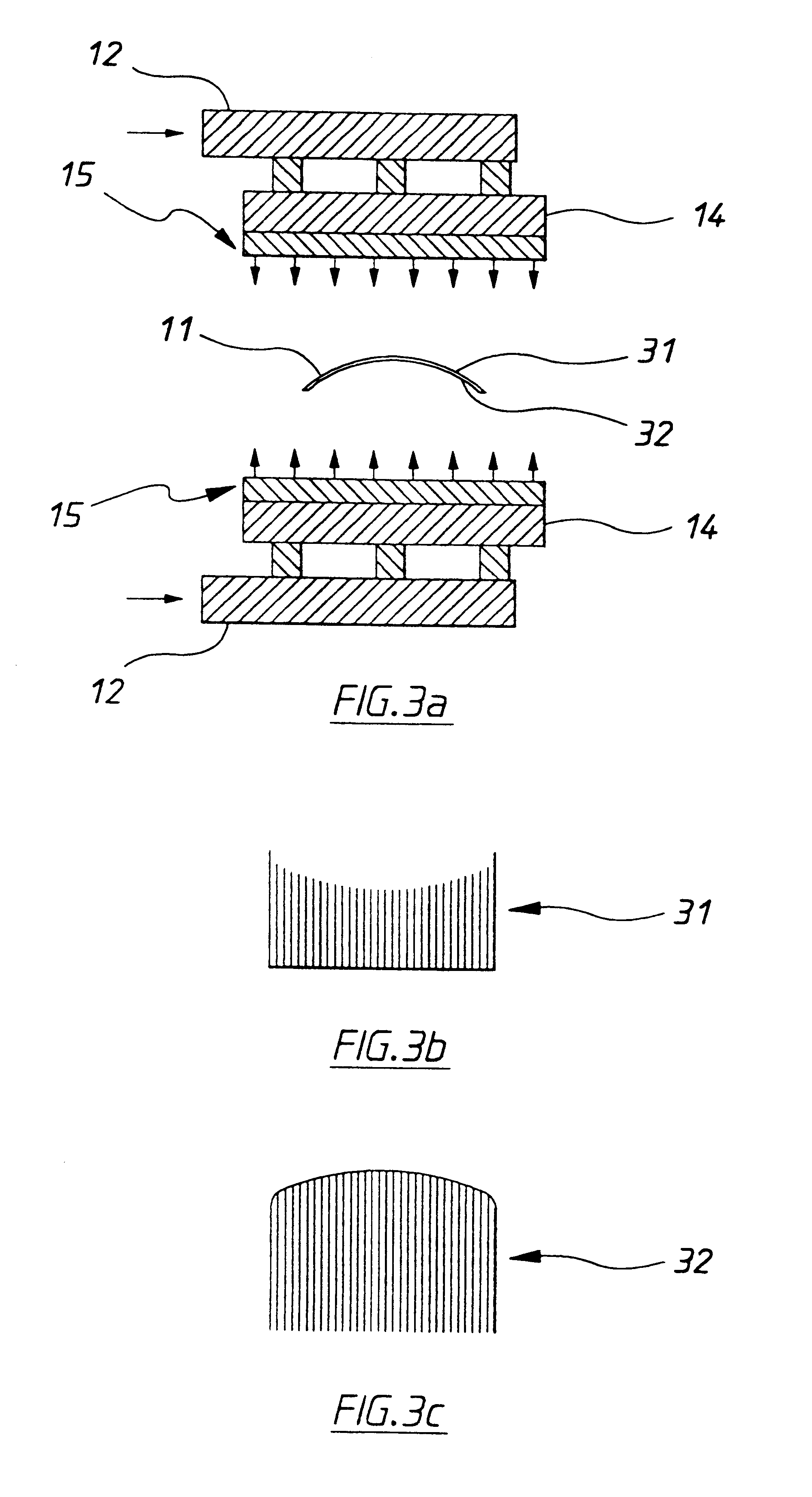

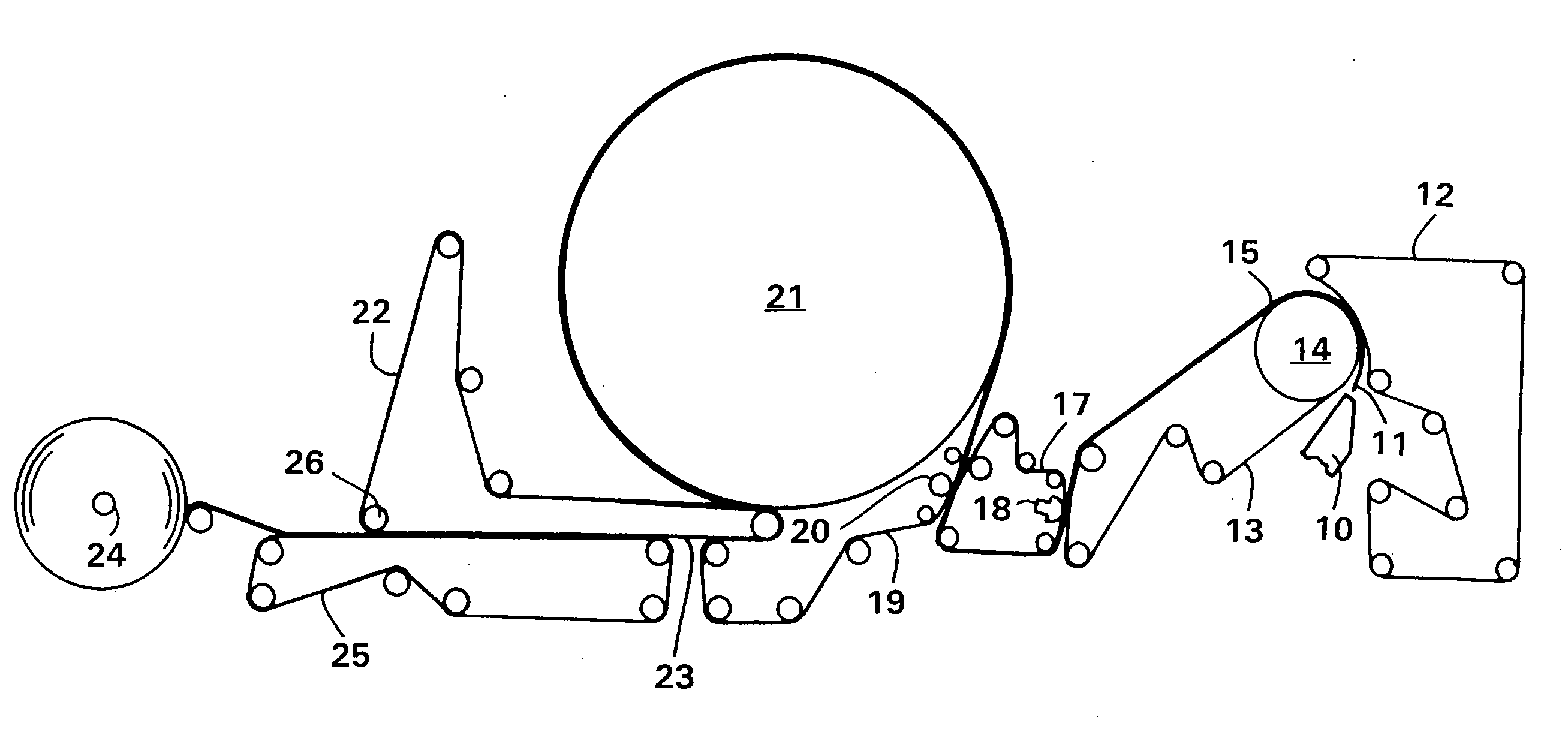

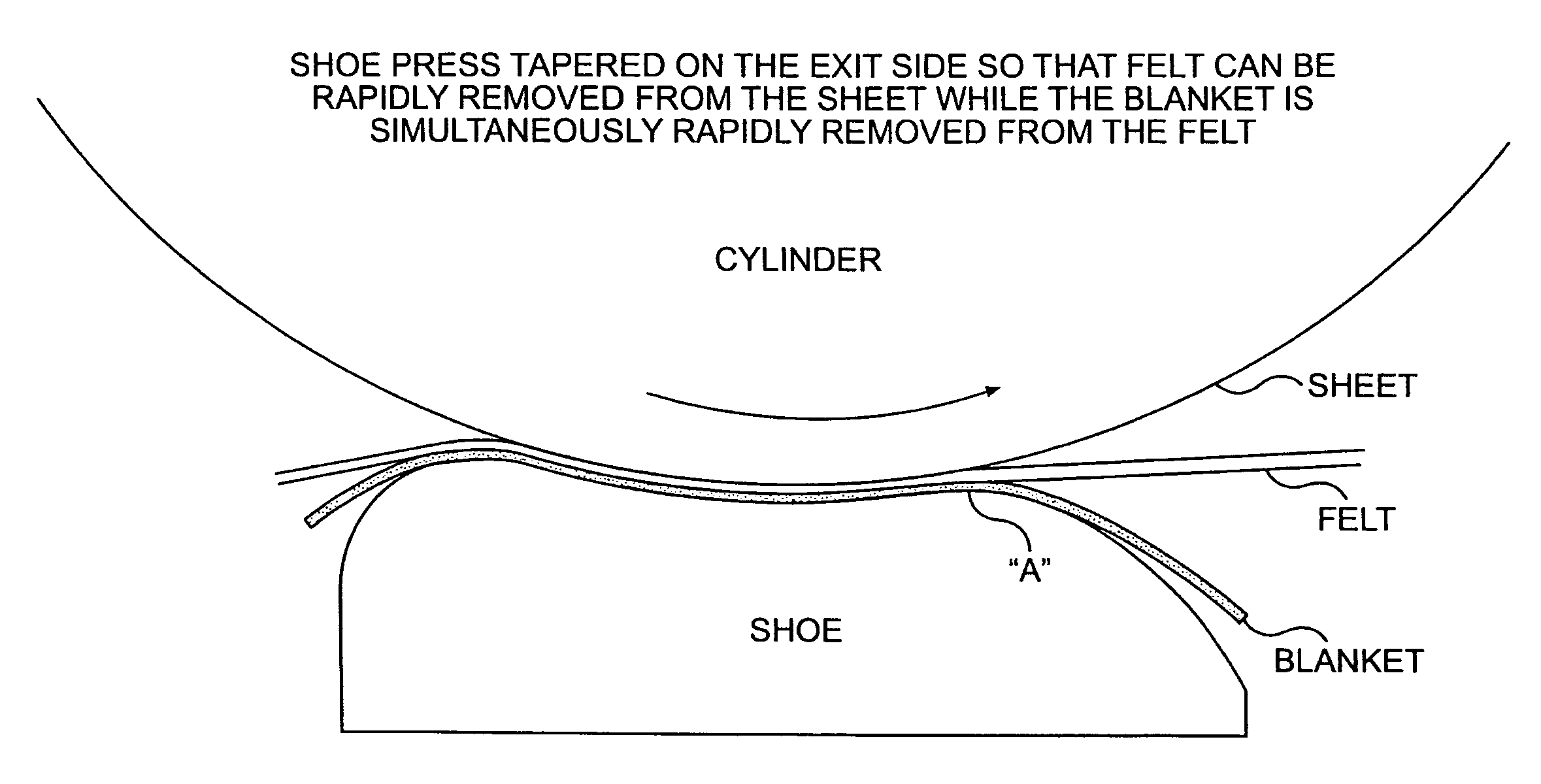

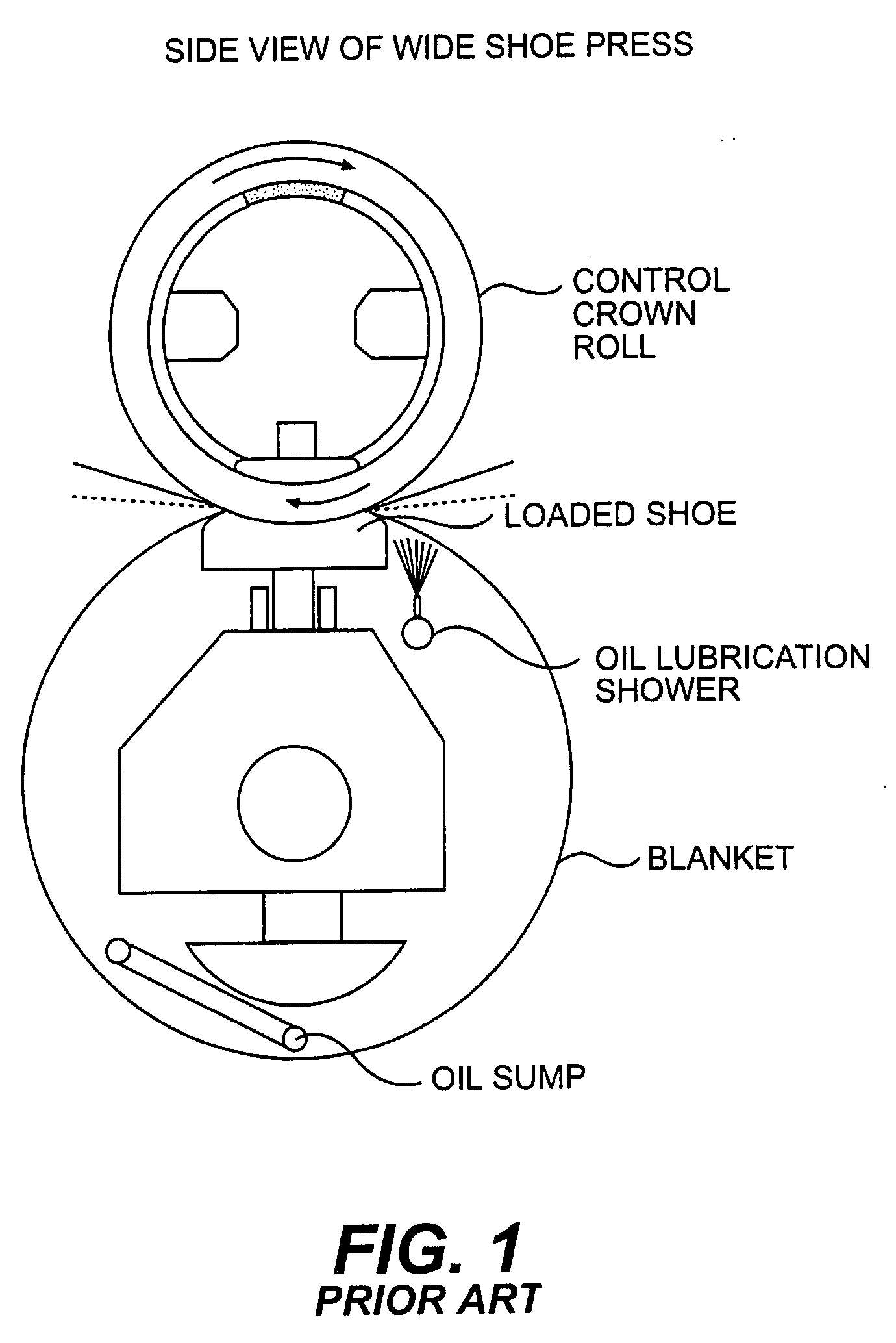

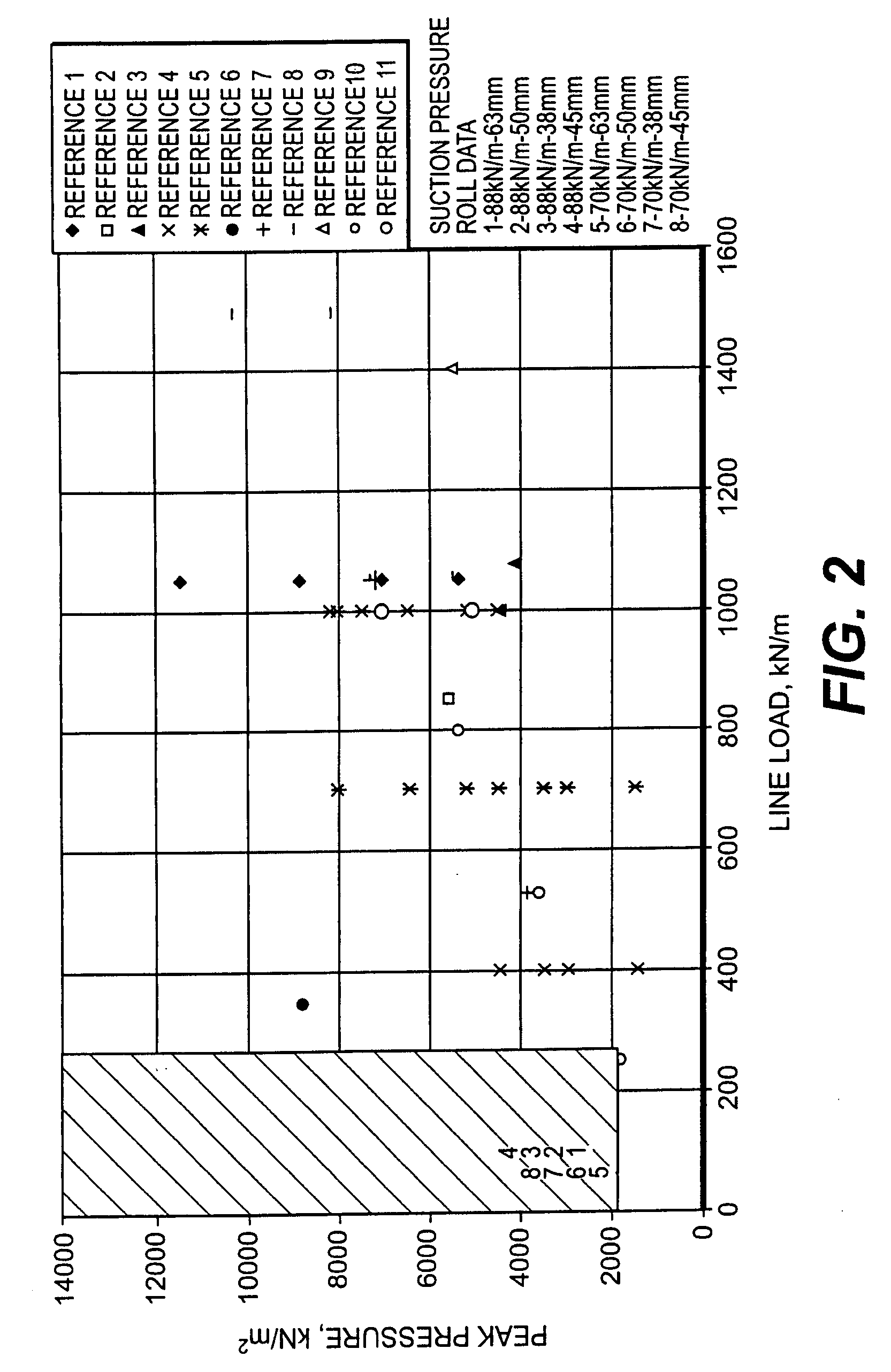

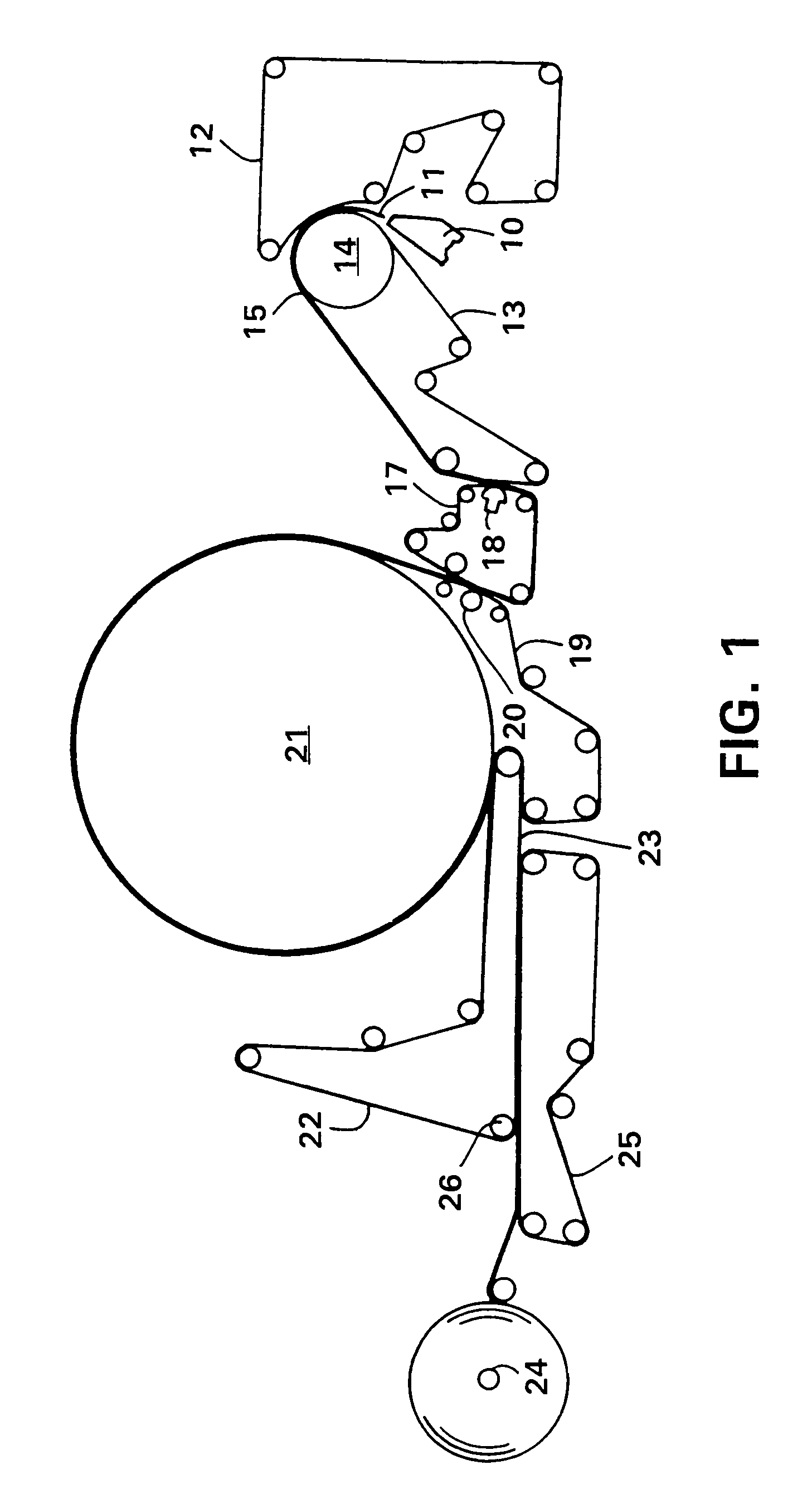

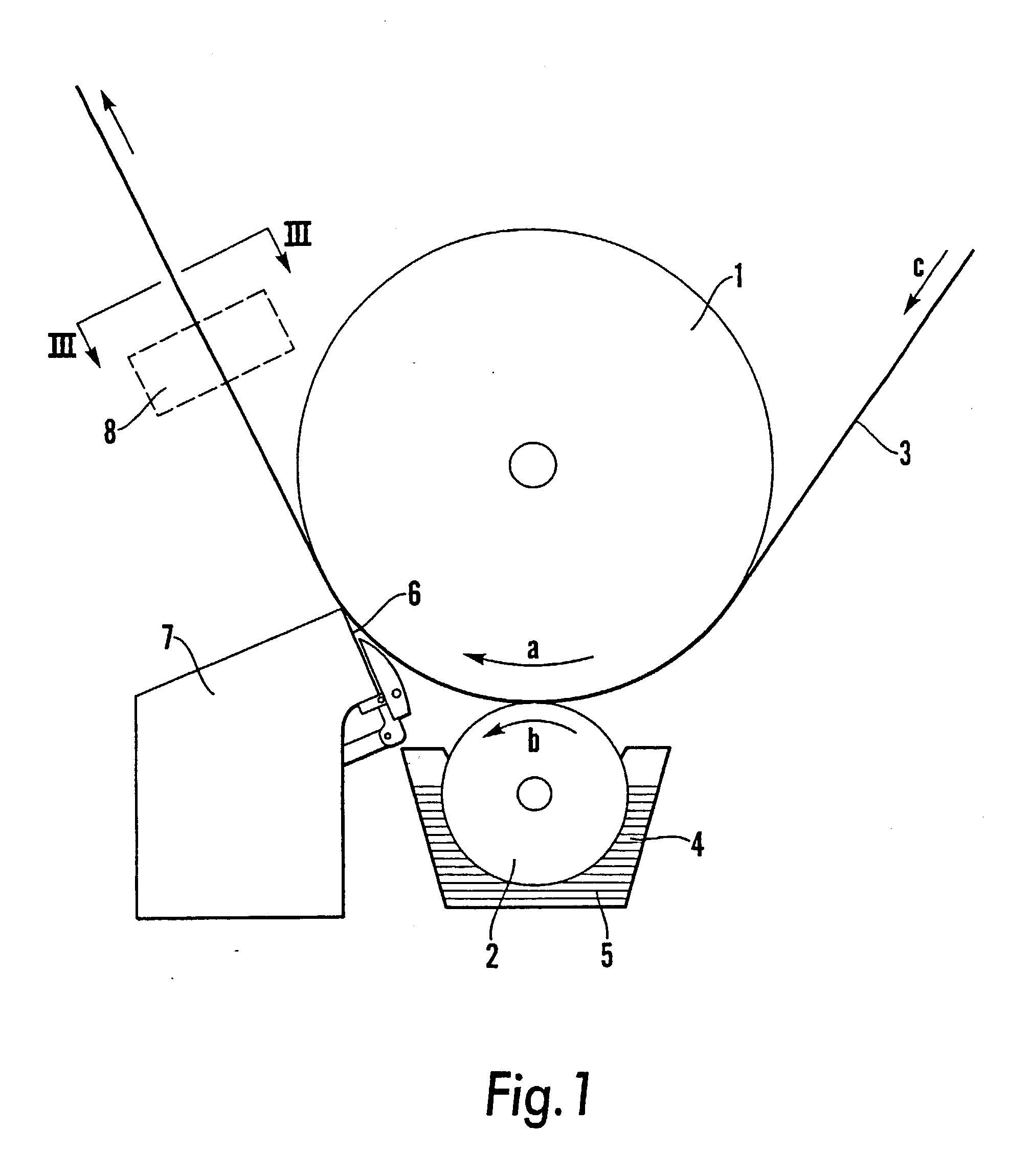

Method for Maximizing Water Removal in a Press Nip

InactiveUS20080035289A1Non-fibrous pulp additionNatural cellulose pulp/paperProduction lineEngineering

The present invention is a method for maximizing water removal from an absorbent web in a press nip. The present invention uses a pressing unit having a blanket with a void volume and with a pressure profile that maximizes water removal in the press section or on the Yankee dryer of a paper machine. The pressure profile of the pressing unit according to the present invention has a very steep pressure drop at and / or following the exit of a pressure distribution curve in order to maximize water removal by minimizing rewet of the web. The improved pressure profile according to the present invention results in increased water removal and / or improved line speed. The void volume further increases water removal and / or improves line speed.

Owner:GPCP IP HLDG LLC

Process for making coated paper or paperboard

InactiveUS20050039871A1Increase shear viscosityEfficient use ofNon-fibrous pulp additionLiquid surface applicatorsPaperboardEngineering

The present invention refers to a method of producing a coated paper or paperboard, but excluding photographic papers, comprising the steps of: (a) forming a free flowing curtain comprising at least one layer, whereby the composition forming at least one layer of the free flowing curtain has a high shear viscosity of at least about 50 mPa.s, and (b) contacting the curtain with a continuous web substrate of basepaper and paperboard.

Owner:DOW GLOBAL TECH LLC

Gloss-coated paper with enhanced runnability and print quality

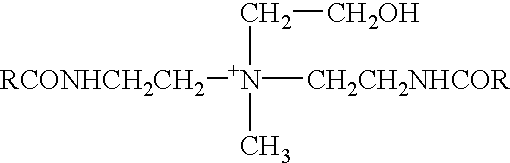

InactiveUS7018708B2Increase foam resistanceGuaranteed uptimeCoatings with pigmentsSynthetic resin layered productsMedicineOptical brightener

This invention provides a gloss-coated electrophotographic paper with superior runnability and print quality in colour and monochrome copiers and printers. The coated paper product comprises a paper substrate coated on at least one side with a pigmented coating. The pigment coating consists of a mixture of at least three different pigments and a binder. The coating may further include a lubricant. Optionally, the coating formulation may contain an optical brightening agent, a defoamer and a thickener. In addition, the gloss coated electrophotographic paper of this invention provides a superior toner adhesion in colour and monochrome electrophotographic imaging applications.

Owner:INT PAPER CO

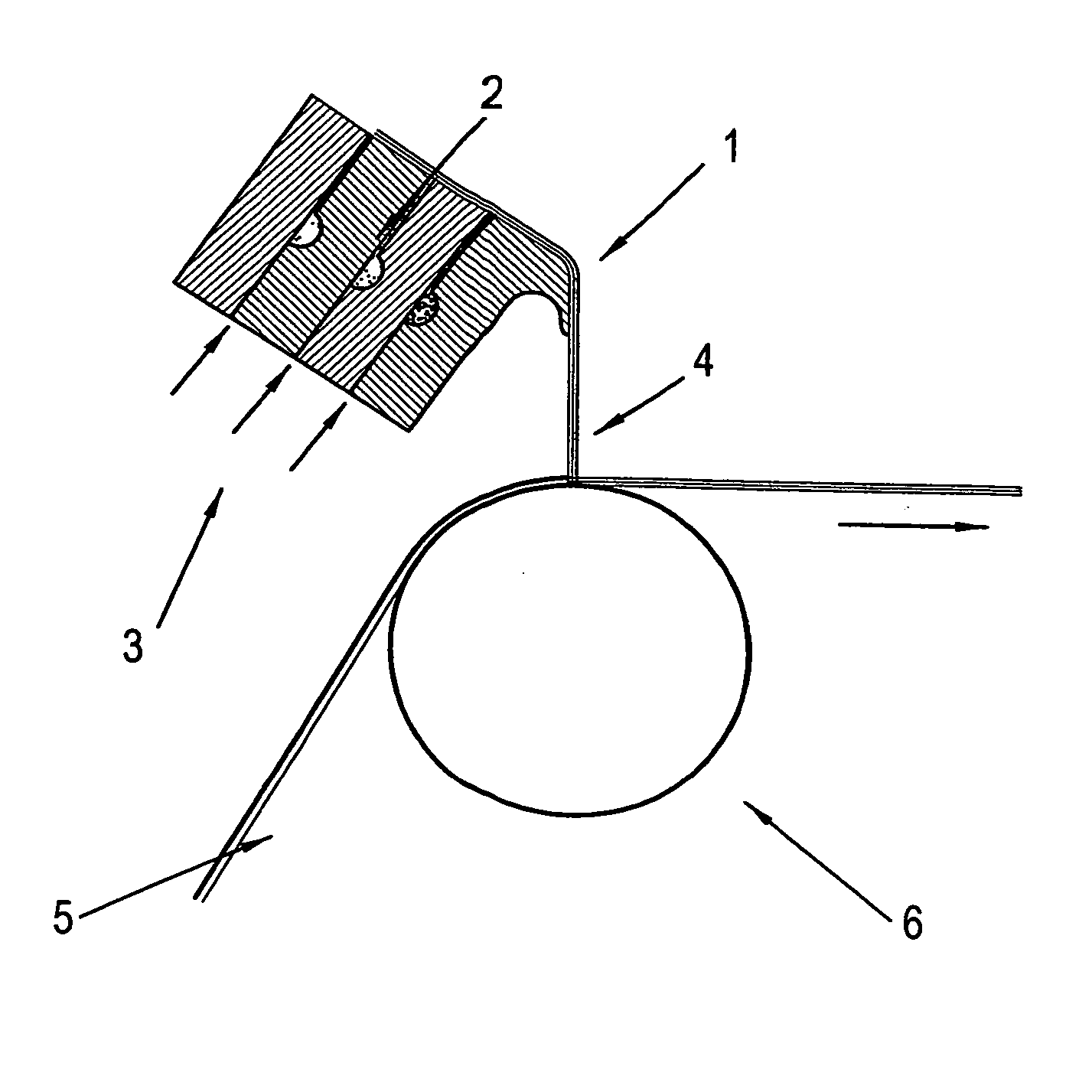

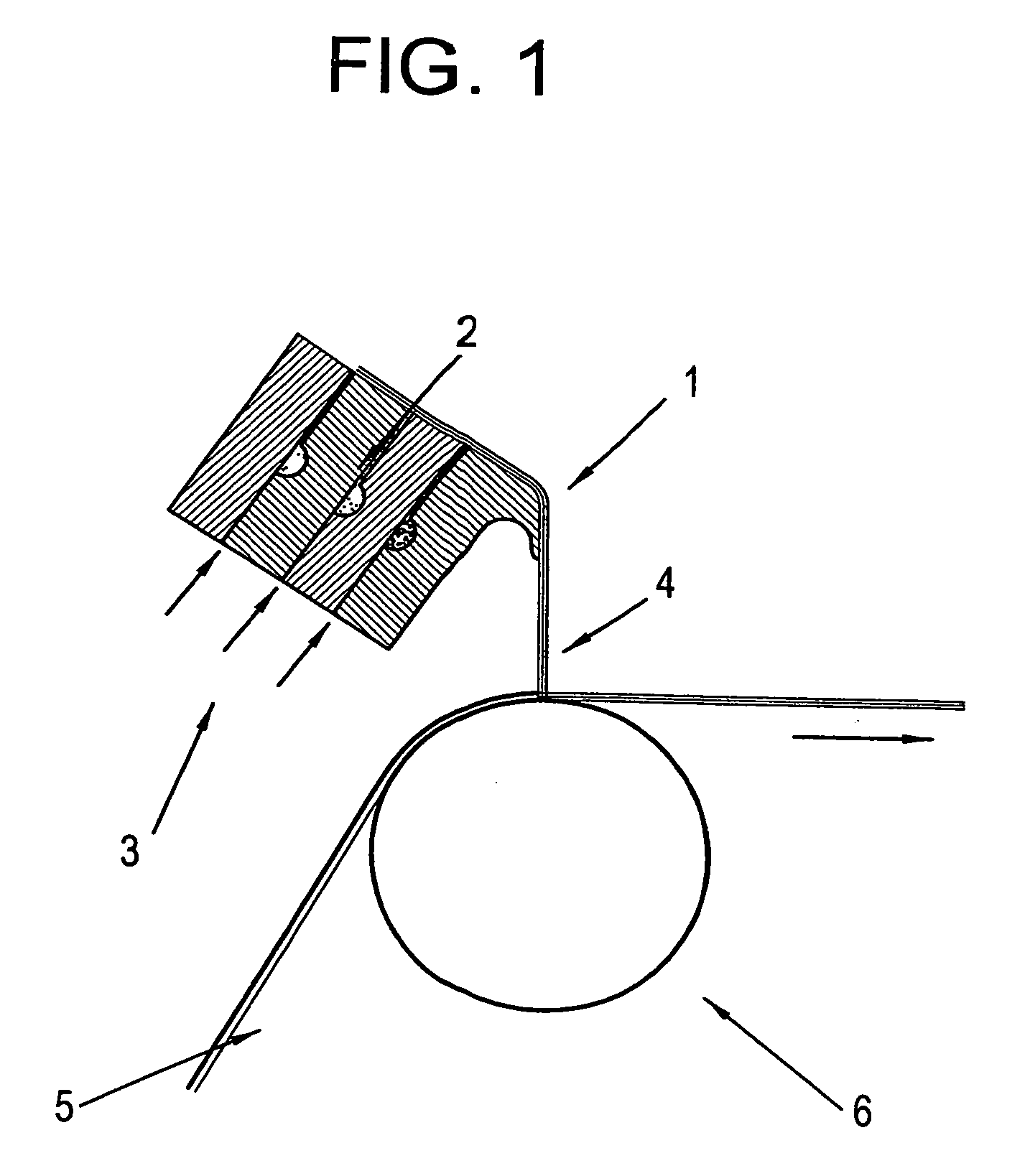

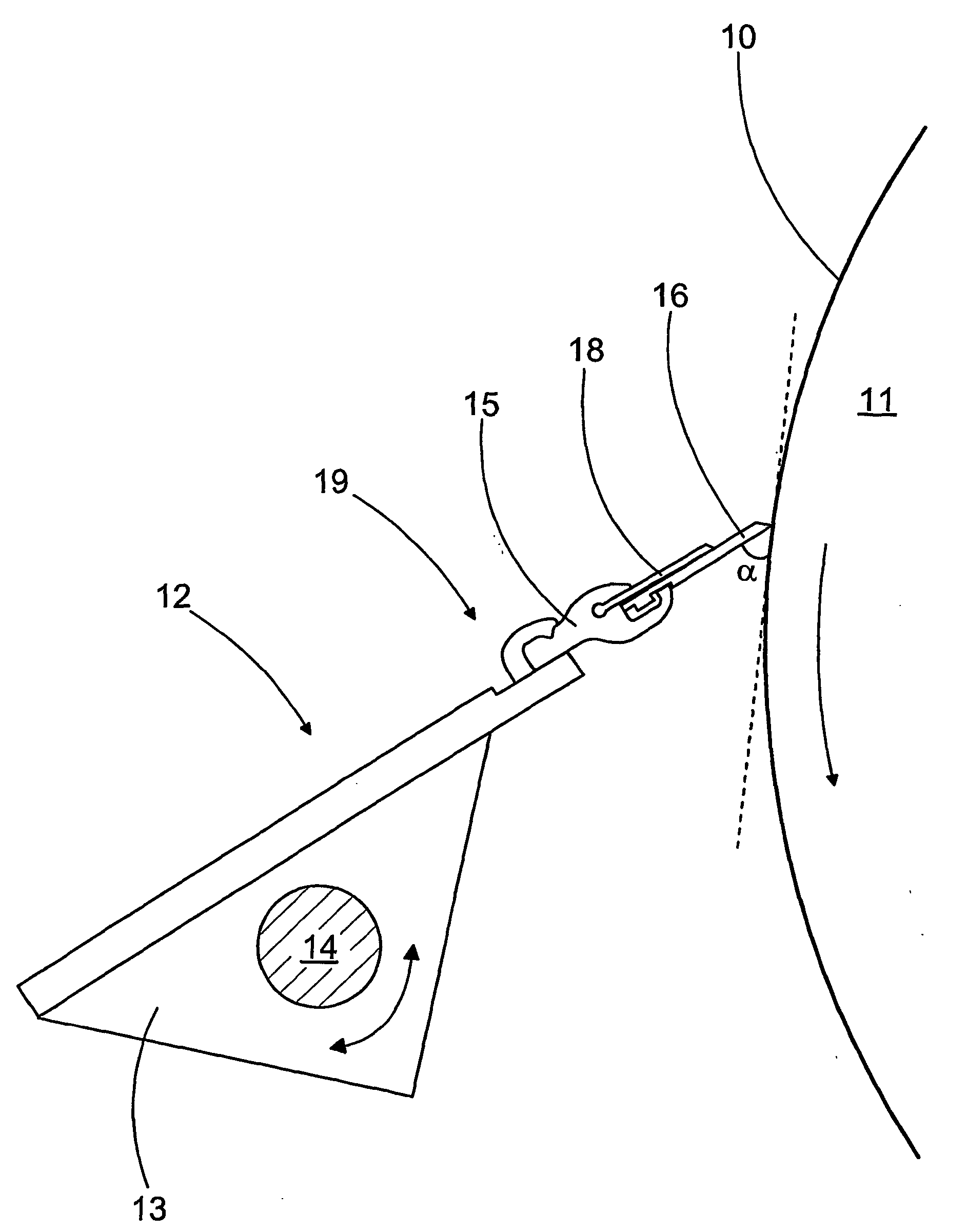

Composite-construction treatment equipment

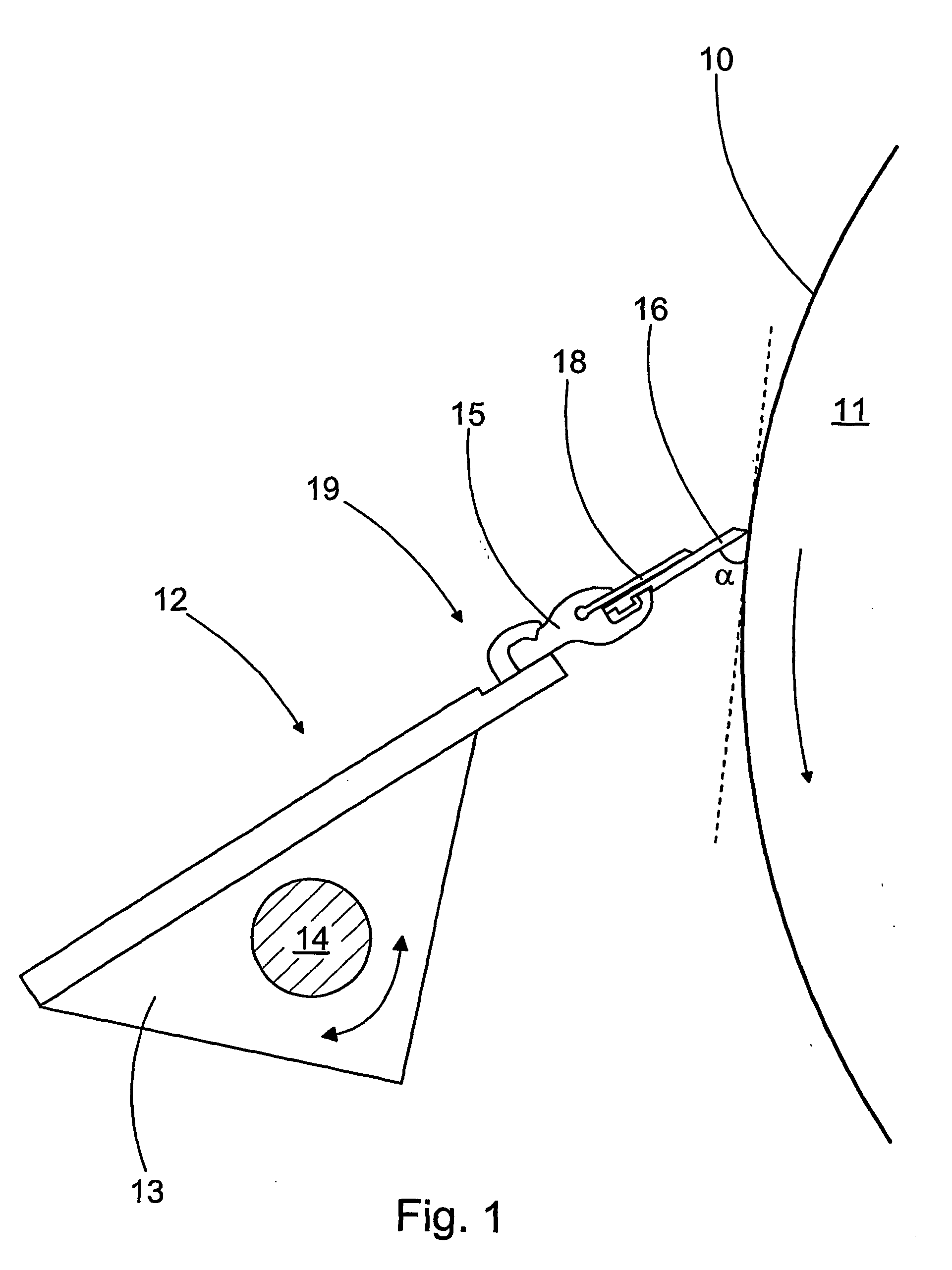

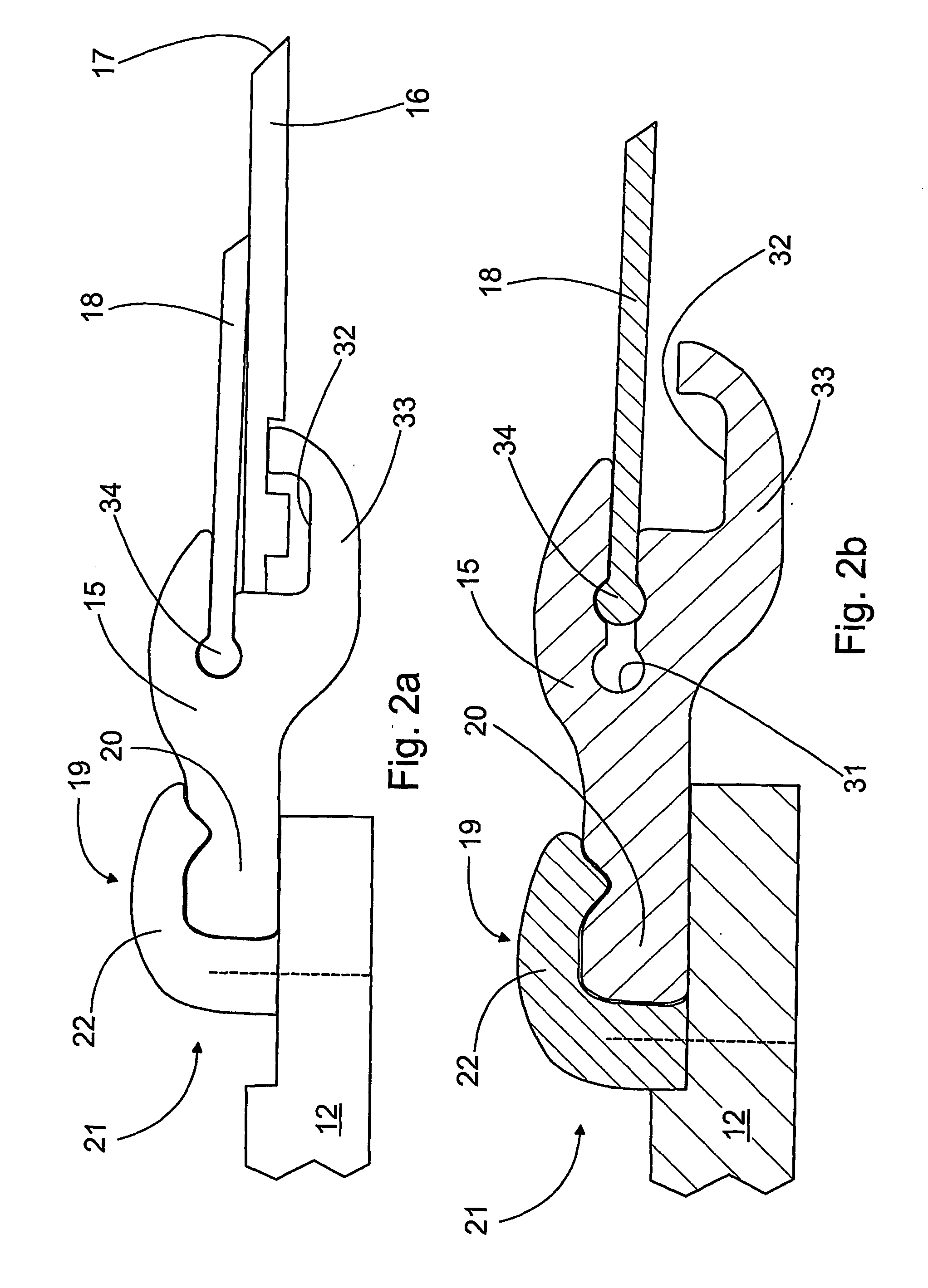

InactiveUS20060180291A1Easy to serviceEasy to useLiquid surface applicatorsMechanical working/deformationComposite constructionEngineering

A composite-construction treatment equipment has a frame (12) with a connected blade holder (15) made of a composite material. The blade holder (15) has a blade (16) and a separate backing blade (18). The blade holder (15) is removably adapted to the frame (12) using a pair of form-locking counter clamps (19). The form-lock is arranged tight in the lateral direction of the blade (16) and essentially free in the axial direction of the blade (16).

Owner:VALMET TECH INC

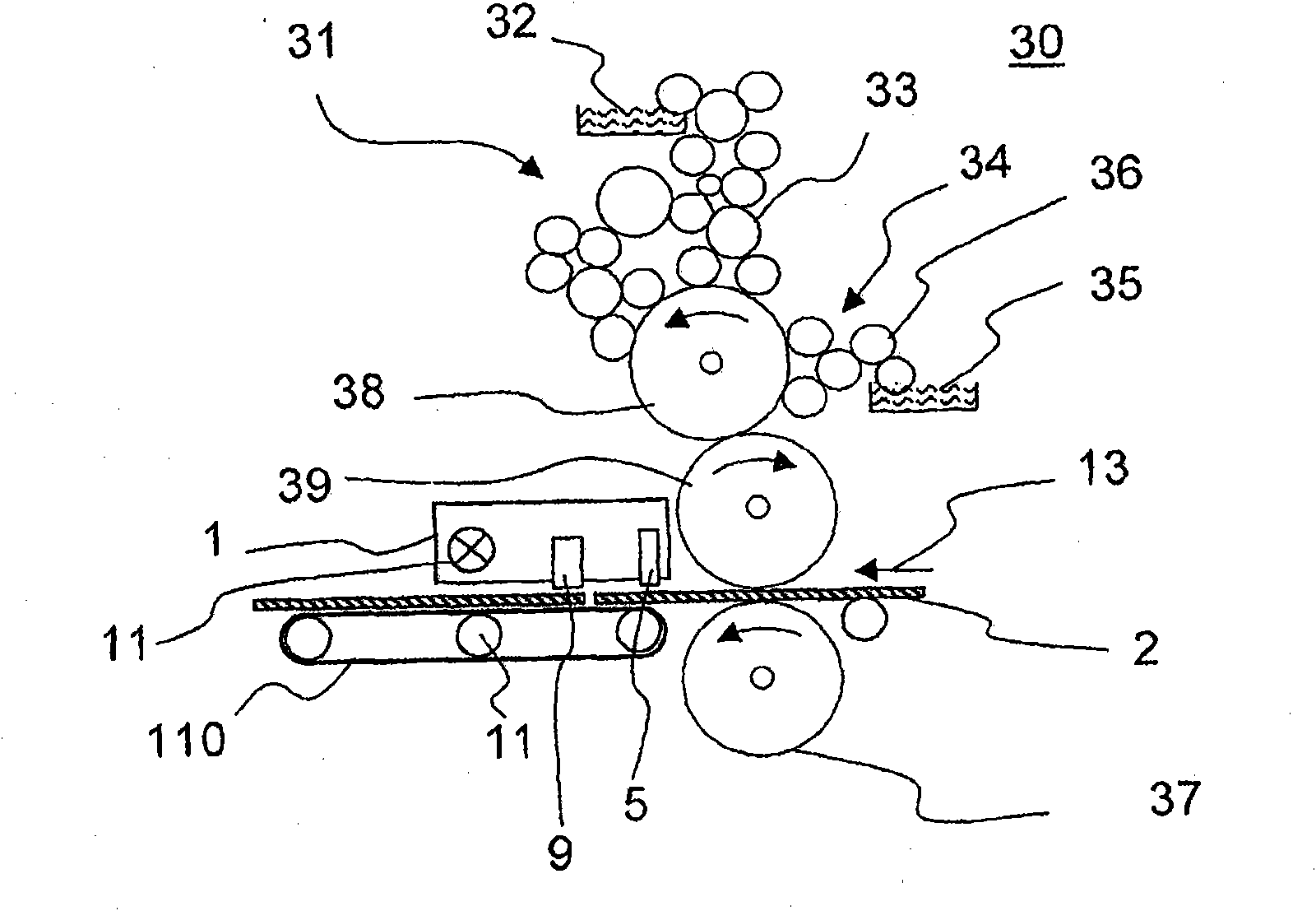

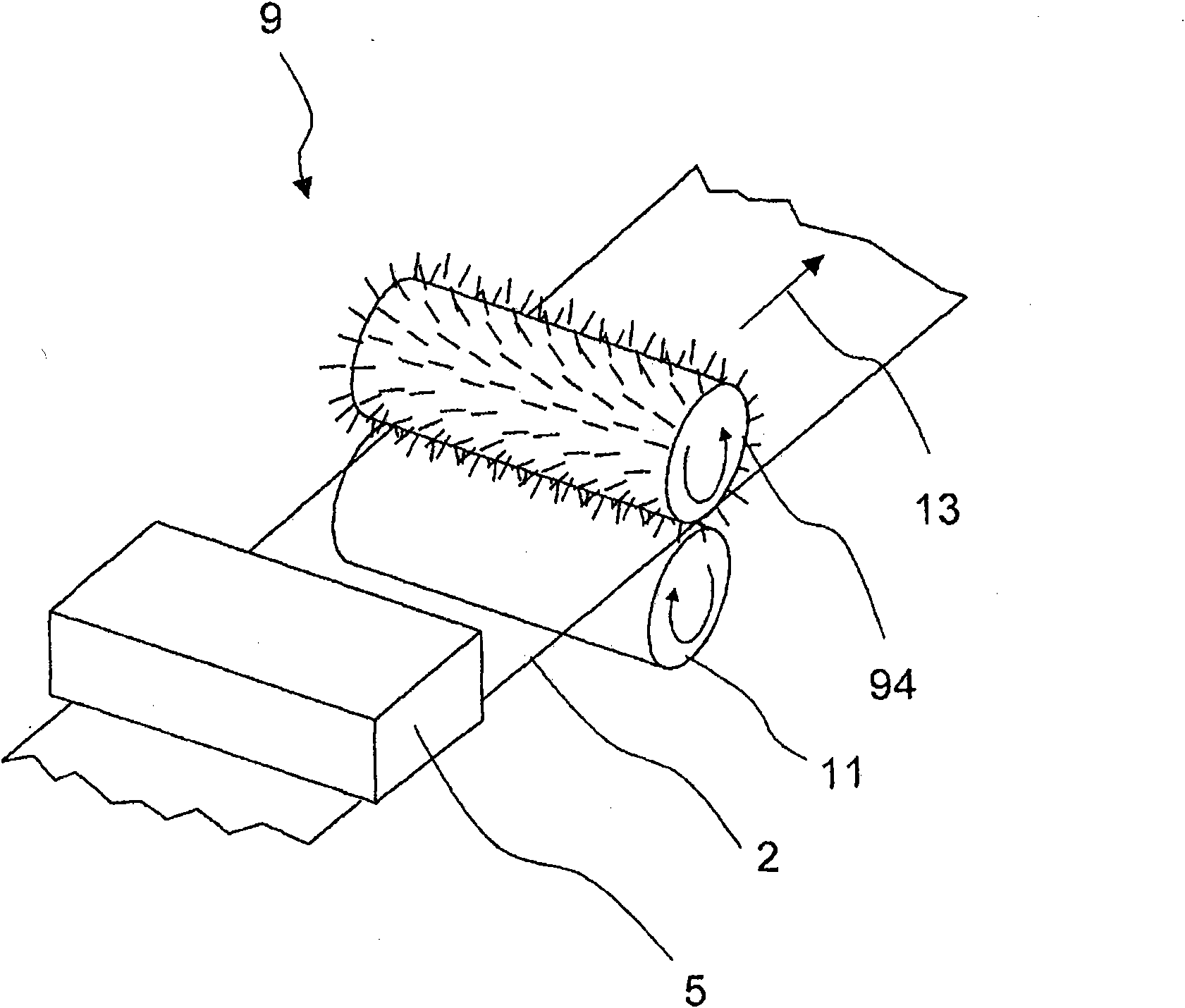

Device used to indirectly apply a liquid or viscous medium onto a material web, specifically a paper or cardboard web

InactiveUS6126750AEvenly layeredAvoid pollutionLiquid surface applicatorsMachine wet endCardboardEngineering

A device for indirect application of a liquid or viscous medium onto a traveling material web, specifically a paper or cardboard web, includes an applicator device for the application of a layer of liquid or viscous medium onto a surface of a transfer element. The transfer element is in contact with the moving material web and transfers the coating onto the web. A leveling unit is equipped with a leveling element positioned against the material web for smoothing of the coating layer on the material web. The leveling element is mounted rigidly in cross direction to the material web, that is, in a direction substantially orthogonal and in a local material web progression to the direction of travel of the material web.

Owner:VOITH PATENT GMBH

Soft and strong fibrous structures

Fibrous structures, especially fibrous structures that exhibit softness and strength, sanitary tissue products employing such fibrous structures and methods for making such fibrous structures are provided. More particularly, fibrous structures that have a long fiber furnish that comprises less than 10% by weight of fibers having a coarseness of less than 20 mg / 100 m, sanitary tissue products employing such fibrous structures and methods for making such fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Papers for liquid electrophotographic printing and method for making same

InactiveUS7828935B2Low viscosityImprove performanceNatural cellulose pulp/paperSpecial paperCellulose fiberCalipers

The specification discloses papers suitable for liquid electrophotographic printing (“LEP”) and a method for making such papers. According to the method, a papermaking furnish containing cellulosic fibers is formed into a fibrous web on a papermaking machine and at least partially dried. The web is then treated with a sizing composition comprising starch, an acrylic acid polymer, an organic material having an HLB value of from about 2 to about 14 such as a polyglycerol ester, and water. The treated web is dried and calendered to a final desired caliper. Since the sizing composition is an aqueous mixture, it may be applied to the web on-line during production of the paper on the papermaking machine, thereby avoiding the expense and inconvenience of conventional off-line methods used to make existing LEP papers. The resulting paper exhibits at least 80% and preferably above 90% toner adhesion as measured by the tape pull tests used for the assessment of papers printed by LEP.

Owner:GLOBAL HLDG II INC

Tissue sheets having improved properties

InactiveUS7935409B2High degree of bulk and firmnessImprove propertiesNon-fibrous pulp additionNatural cellulose pulp/paperBiomedical engineeringPaper sheet

Owner:KIMBERLY-CLARK WORLDWIDE INC

Producing process for preparing lubricant of papermaking coating with polyvinyl wax oxide as main materials

A lubricant with oxidized polyvinyl wax as main material is manufactured by non-ionizing oxidized polyvinyl wax, negative ionizing surfactant OP-10 or TX-10 or NP-10, then composing modified surfactant said above and non-ionized oxidized polyvinyl wax and silicone, emulsifying to prepare solids content 25% products which is oil-in-water type emulsified products. The lubricant is used as special coating for papermaking and has viscosity<30Mpa.s, and its performance / price rate exceeds imported products.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

Method for making rolls of tissue sheets having improved properties

InactiveUS7166189B2High degree of bulk and firmnessImprove propertiesNon-fibrous pulp additionNatural cellulose pulp/paperPaper towelEngineering

The roll properties of tissue sheets are improved either by imparting cross-machine direction dominant bar-like protrusions to the air side of the tissue by using specially woven transfer fabrics and / or by offsetting recurring surface features of the sheet relative to the surface features of adjacent sheets within the roll, such as by providing a throughdryer fabric with an offset seam. Both techniques provide the resulting tissue sheets with improved capabilities for providing an improved combination of roll bulk and roll firmness.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Sanitary Tissue Products and Methods for Making Same

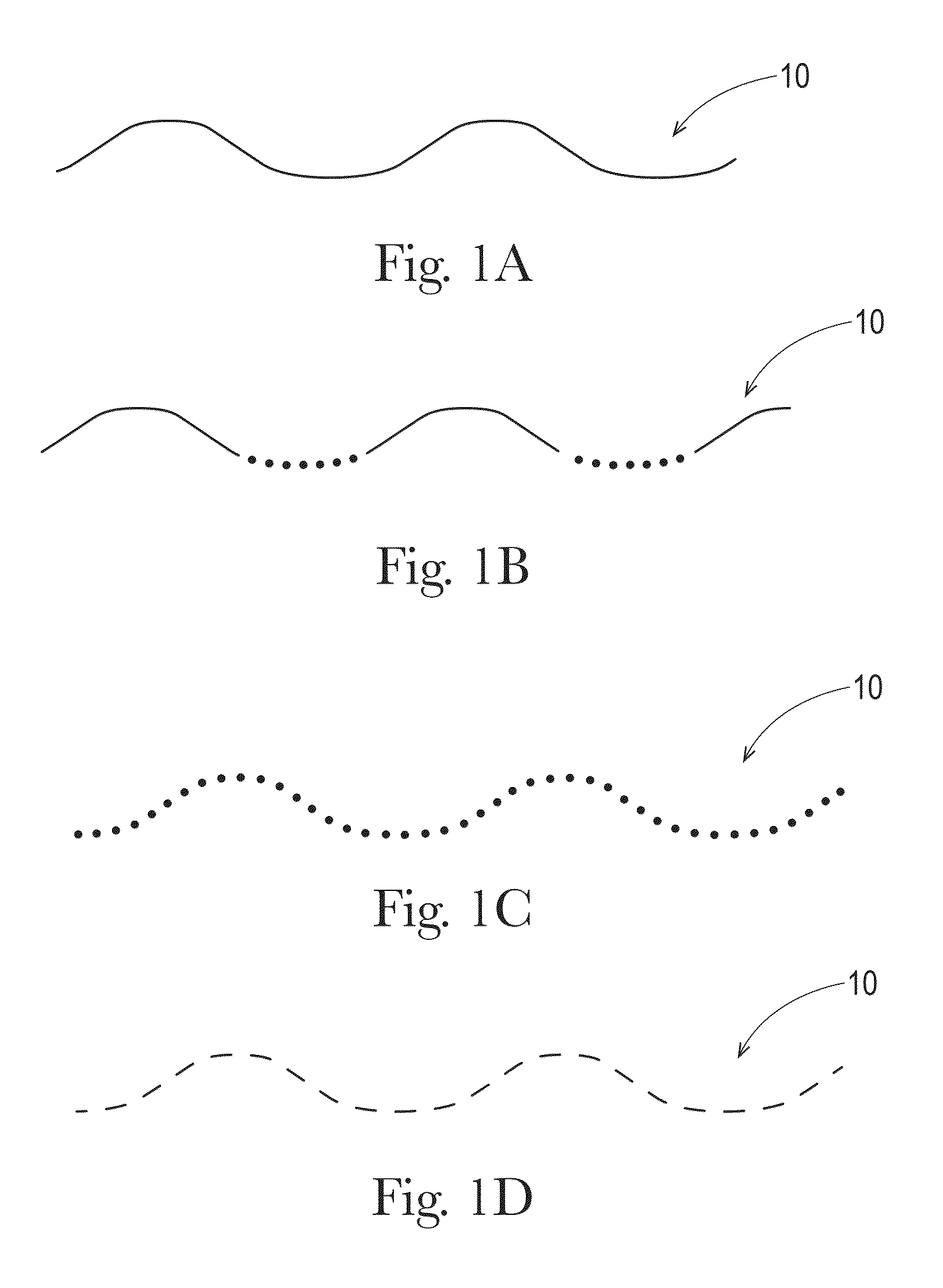

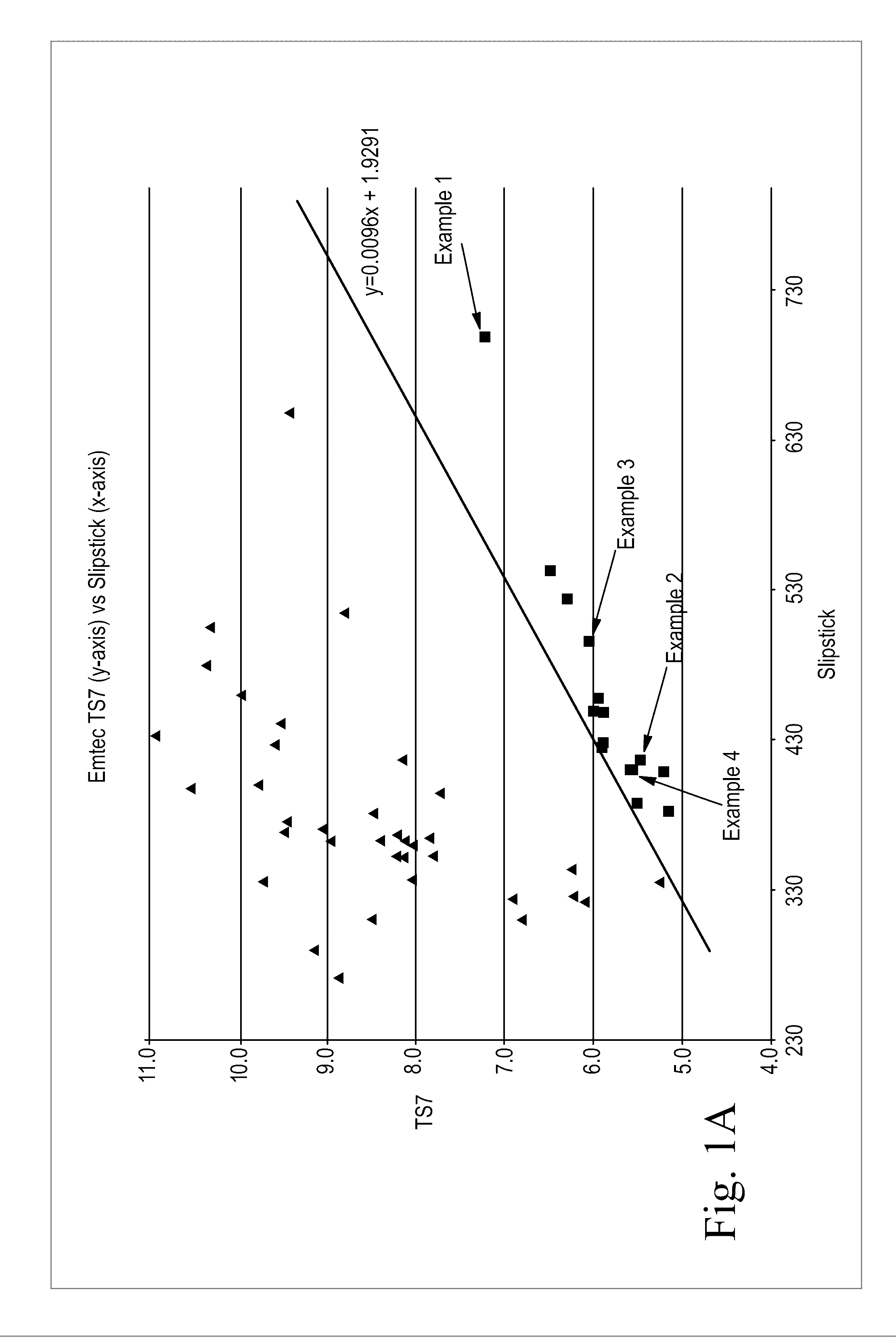

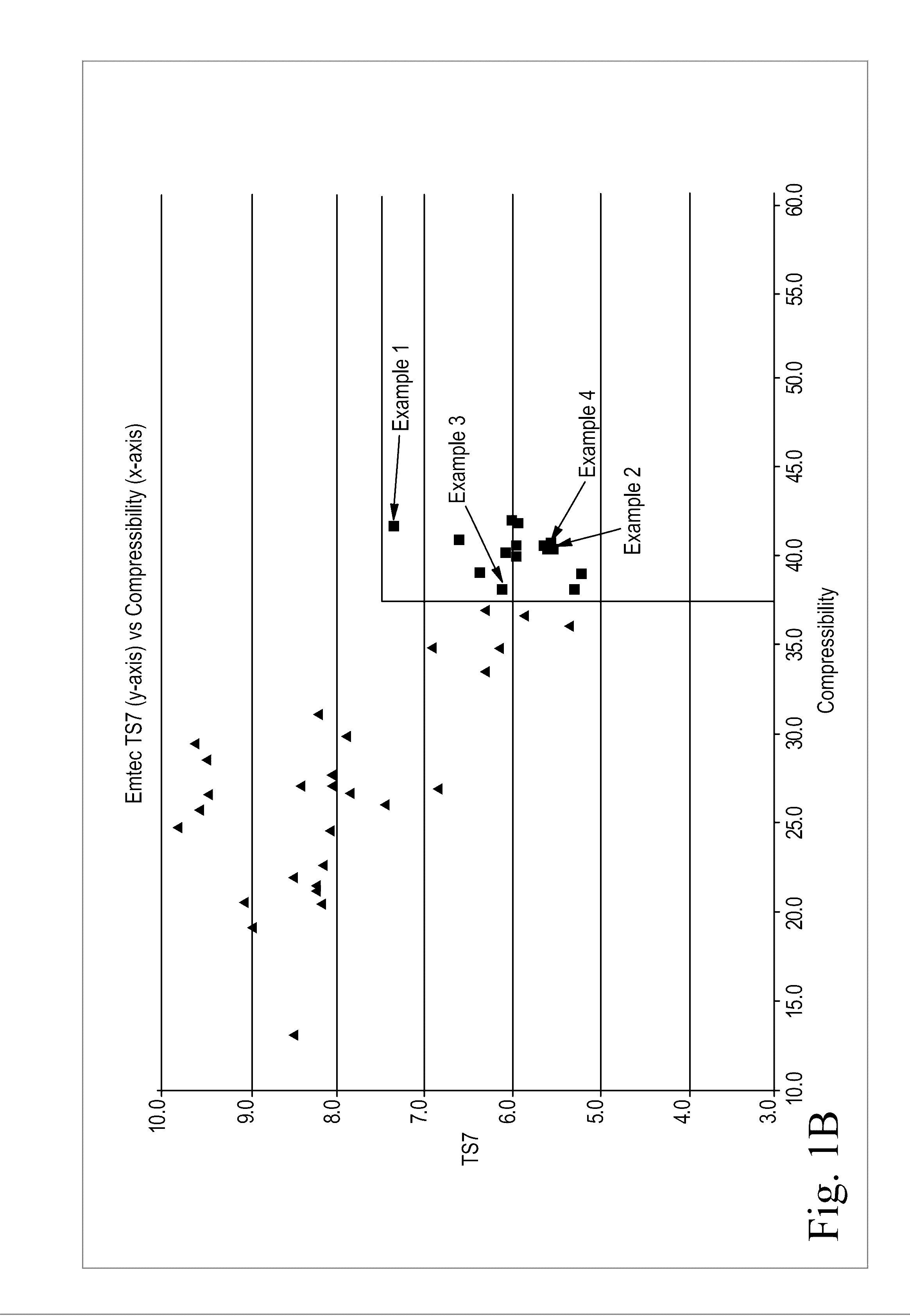

ActiveUS20150176218A1Improve compression performanceIncrease stiffnessNon-fibrous pulp additionNatural cellulose pulp/paperFiber3d patterning

Sanitary tissue products employing 3D patterned fibrous structure plies having a surface comprising a novel three-dimensional (3D) pattern such that the 3D patterned fibrous structures and / or sanitary tissue products employing the fibrous structures exhibit novel cushiness as evidenced by compressibility of the fibrous structures and / or sanitary tissue products, novel flexibility as evidenced by plate stiffness of the fibrous structures and / or sanitary tissue products, and / or surface smoothness as evidenced by slip stick coefficient of friction of the fibrous structures and / or sanitary tissue products, and methods for making same, are provided.

Owner:THE PROCTER & GAMBLE COMPANY

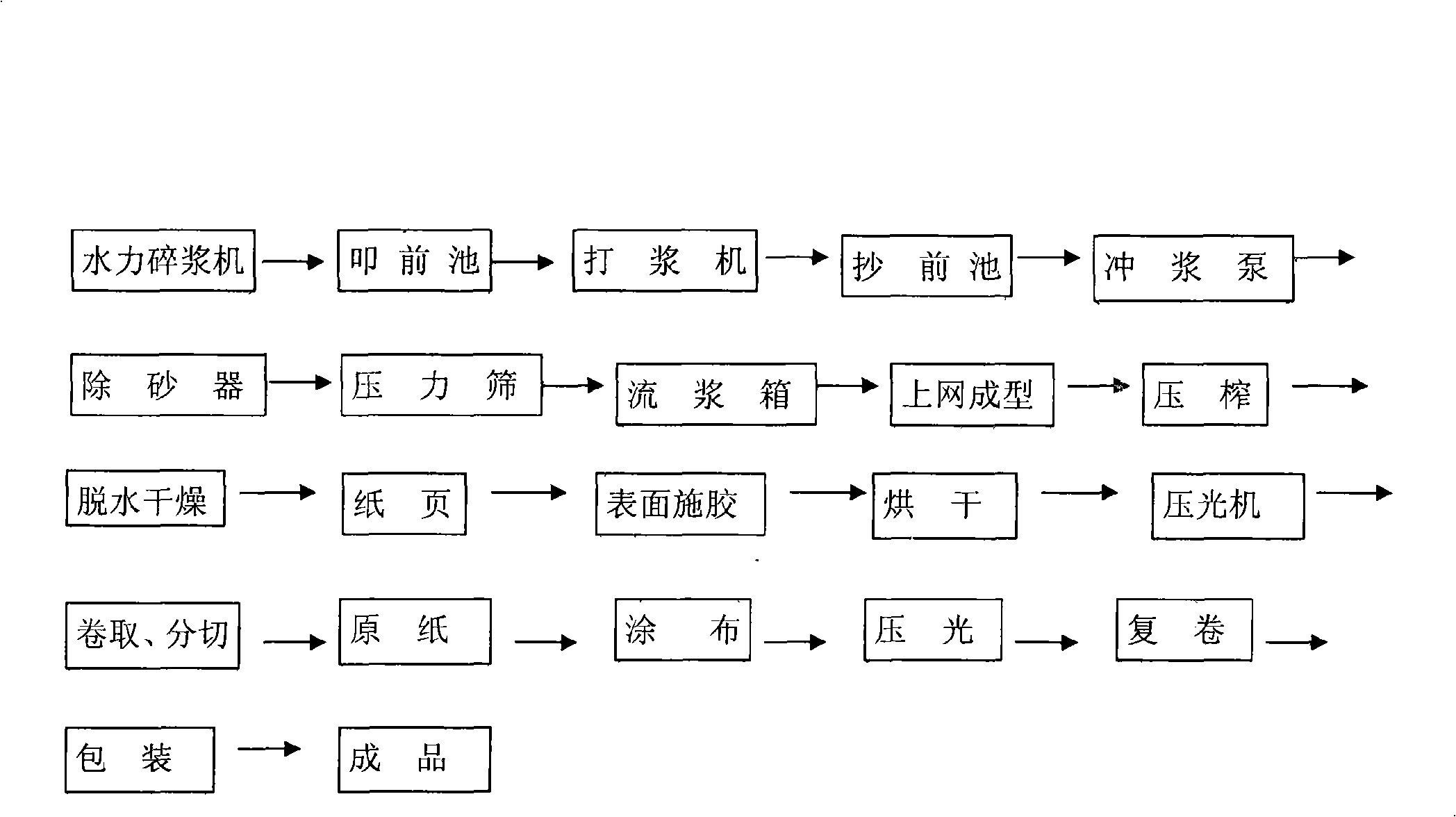

Paper making process for precoating water transfer printing base paper

ActiveCN101289824AHigh mechanical strengthImprove surface propertiesCoatings with pigmentsWater-repelling agents additionPulp and paper industryWater transfer

The invention relates to paper and a process for making the same, in particular to a process for making precoated water transfer printing paper base paper. The process comprises the following steps that: after steps of crushing, pulp beating, pulp mixing, screening and purification, on-screen forming, dewatering and drying, surface glue blending and winding and parting cut, materials are turned into base paper; after steps of base paper coating, press finishing and rewinding, the base paper is turned into the precoated water transfer printing paper base paper. The process of the invention has the advantages of simple technological flow, smooth paper surface, good stiffness, stable printing dimension, big differences of both paper surfaces on water absorption, good tensile strength, short decoating time and even decoating.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

Sanitary tissue products and methods for making same

ActiveUS9315945B2Cushier, more flexibleImprove compression performanceMechanical working/deformationPaper/cardboardFiber3d patterning

Sanitary tissue products employing 3D patterned fibrous structure plies having a surface comprising a novel three-dimensional (3D) pattern such that the 3D patterned fibrous structures and / or sanitary tissue products employing the fibrous structures exhibit novel cushiness as evidenced by compressibility of the fibrous structures and / or sanitary tissue products, novel flexibility as evidenced by plate stiffness of the fibrous structures and / or sanitary tissue products, and / or surface smoothness as evidenced by slip stick coefficient of friction of the fibrous structures and / or sanitary tissue products, and methods for making same, are provided.

Owner:PROCTER & GAMBLE CO

Method and apparatus for the application of plastics coatings

The invention relates to an apparatus for the application of coatings to surfaces of substrates in the form of paper, paperboard, or plastics foils, preferably for the finishing of print products. The apparatus encompasses a coating unit for the application of coating material in fluid form to the substrate surface, and equipment for smoothing of the film while it is still fluid after it has been applied by means of the coating unit to the substrate surface, where the equipment encompasses equipment for generating a gas stream orientated onto the substrate surface coated with the film, where the gas stream smooths the film with at least partial elimination of undesired structures in the film surface, e.g. depressions, elevations and craters, prior to the hardening of the coating material.

Owner:ACTEGA SCHMID RHYNER AG

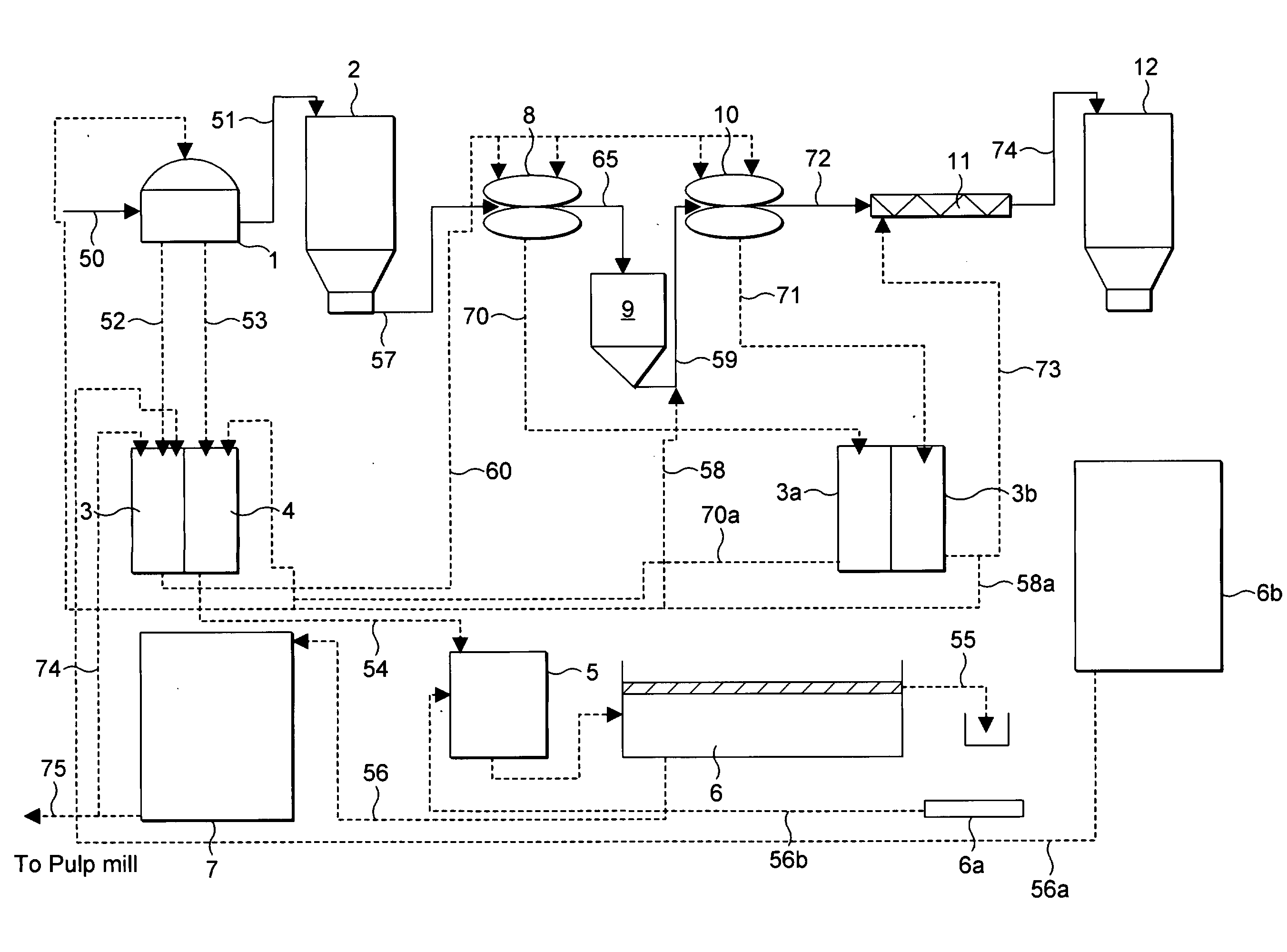

Treatment of Pulp

InactiveUS20080264586A1Minimizes waste streamMaintain balanceNatural cellulose pulp/paperSpecial paperFiberAlkaline earth metal

A method of treating a fibre pulp mixture comprises: (a) separating the fibre pulp mixture into at least two fractions to form a coarse fraction and a fine fraction; (b) bleaching the coarse fraction from (a); and (c) precipitating an alkaline earth metal carbonate in the fine fraction from (a). The products from steps (b) and (c) may combined in an integrated paper making process.

Owner:IMERYS MINERALS

Sanitary Tissue Products

ActiveUS20170022670A1Increase valueImprove surface mobilityApplied substance rearrangementPaper/cardboardFiberCompressibility

Sanitary tissue products employing fibrous structures that exhibit novel combination of average TS7 values and slip stick coefficient of friction and / or compressibility properties and methods for making same.

Owner:THE PROCTER & GAMBLE COMPANY

Method of producing coated paper with reduced gloss mottle

ActiveUS20070169902A1Reduced gloss mottleImprove smoothnessNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringHigh pressure

A method of producing a coated paper having reduced gloss mottle and excellent smoothness includes the steps of calendering a base stock at a relatively high pressure in a first calendering step, coating at least one side of the calendered base stock and calendering the coated base stock at a relatively low pressure in a second calendering step.

Owner:VERSO PAPER HLDG LLC

Gloss-coated paper with enhanced runnability and print quality

InactiveUS20060159910A1Guaranteed uptimeImprove image qualityCoatings with pigmentsDuplicating/marking methodsMedicineOptical brightener

This invention provides a gloss-coated electrophotographic paper with superior runnability and print quality in colour and monochrome copiers and printers. The coated paper product comprises a paper substrate coated on at least one side with a pigmented coating. The pigment coating consists of a mixture of at least three different pigments and a binder. The coating may further include a lubricant. Optionally, the coating formulation may contain an optical brightening agent, a defoamer and a thickener. In addition, the gloss coated electrophotographic paper of this invention provides a superior toner adhesion in colour and monochrome electrophotographic imaging applications.

Owner:INT PAPER CO

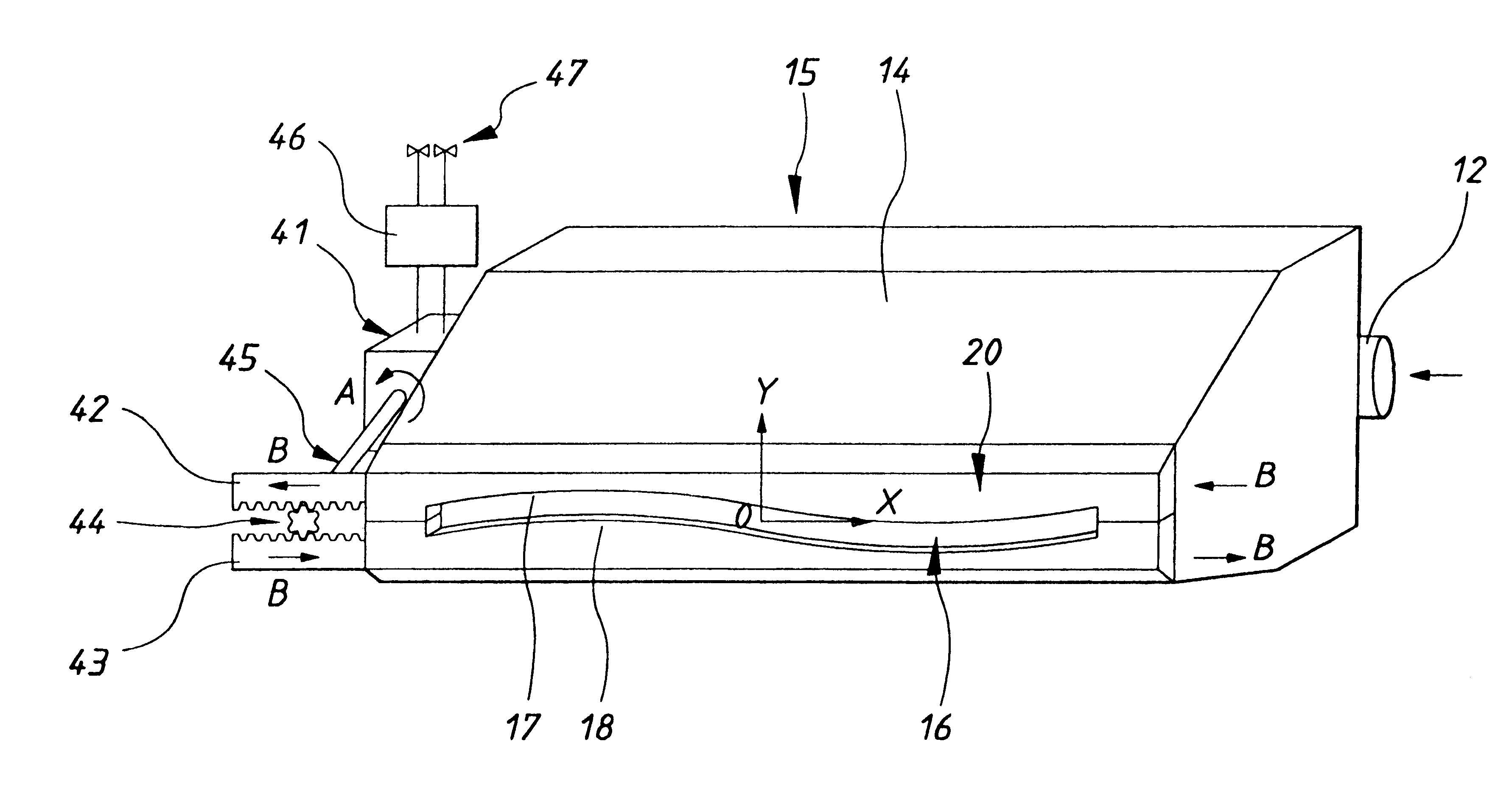

Method and device relating to coating a running web

InactiveUS20030104130A1Counteract tacking problemReduce noise levelPretreated surfacesApplied substance rearrangementFiberEngineering

When a running web (3) is coated with a liquid coating mixture, at least one side of the web is provided with a coating (40, 40') of coating mixture. Existing excess (33) of coating mixture in or adjacent to the regions of the edge portions of the web is removed by being blown off downstreams of where the coating operation is performed.

Owner:UMV COATING

Soft and strong fibrous structures

Fibrous structures, especially fibrous structures that exhibit softness and strength, sanitary tissue products employing such fibrous structures and methods for making such fibrous structures are provided. More particularly, fibrous structures that have a long fiber furnish that comprises less than 10% by weight of fibers having a coarseness of less than 20 mg / 100 m, sanitary tissue products employing such fibrous structures and methods for making such fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

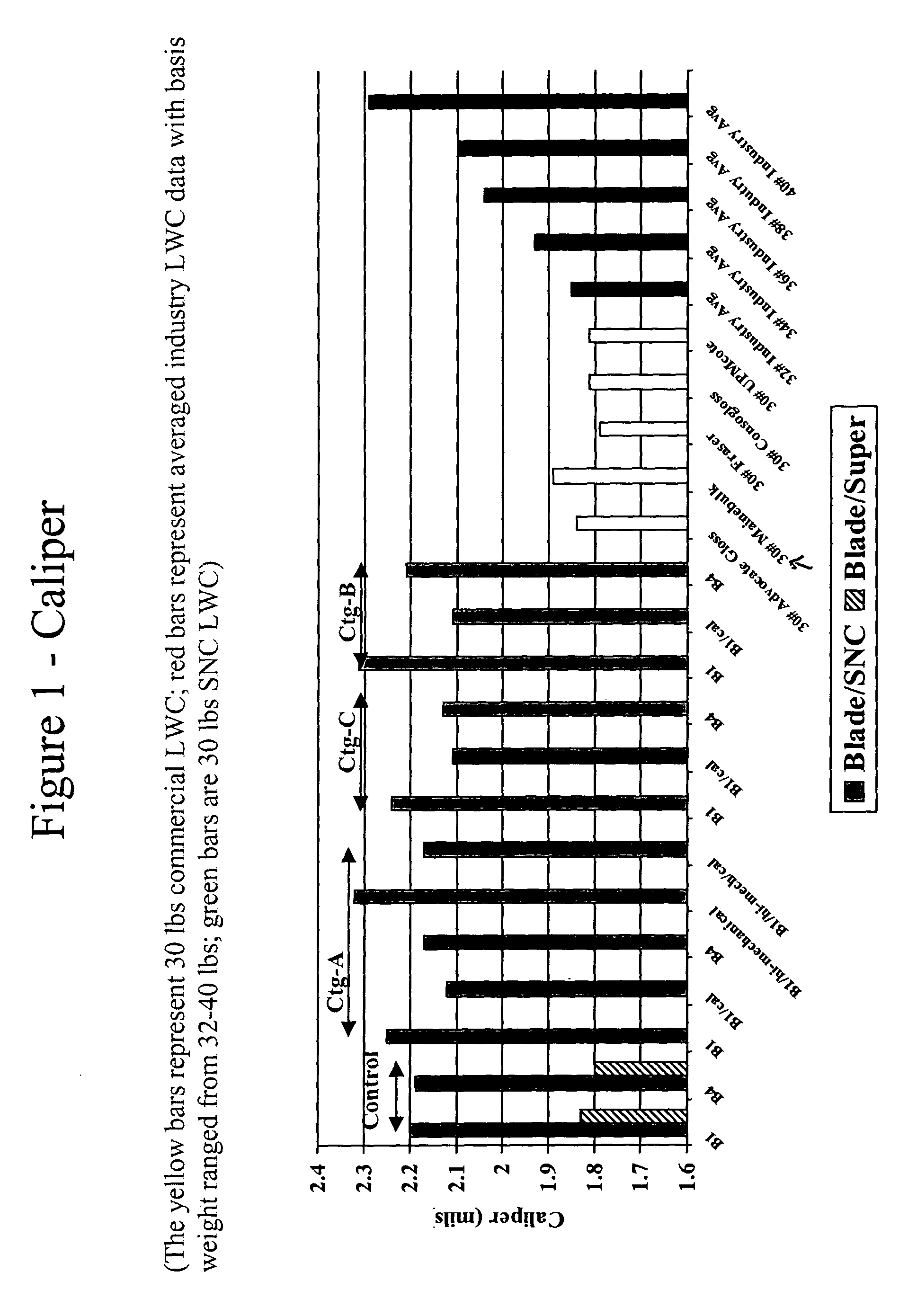

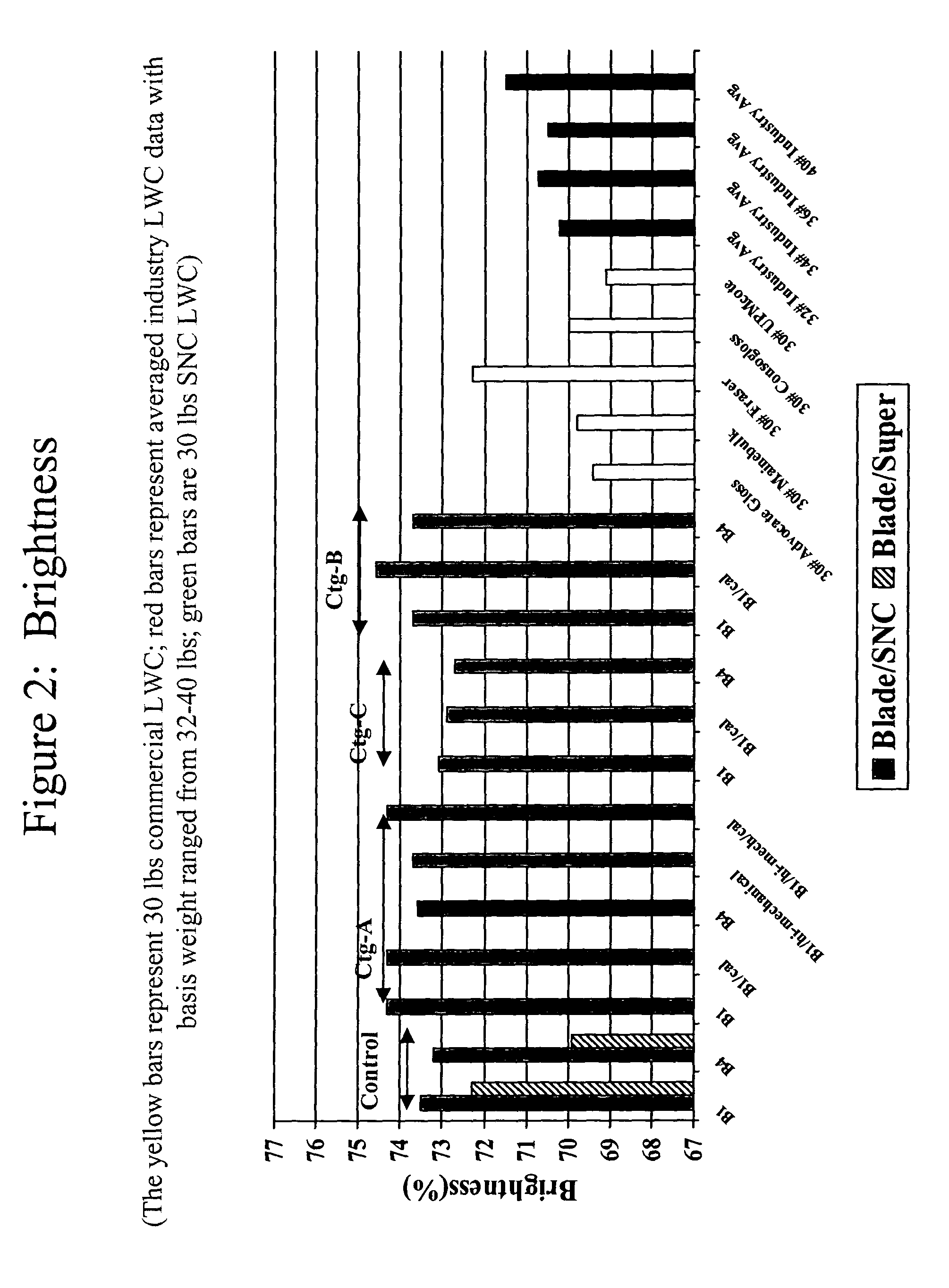

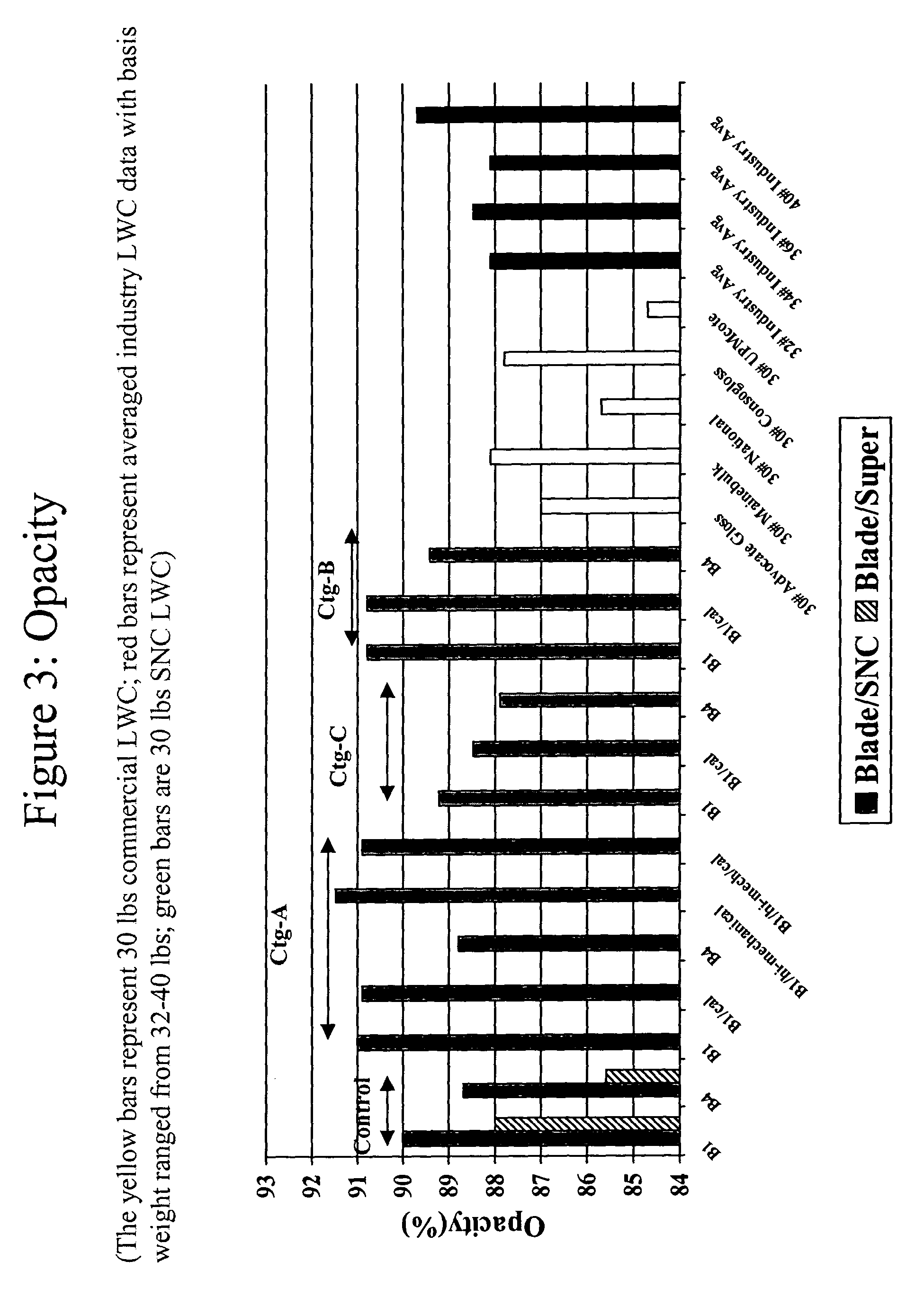

Process for producing super high bulk, light weight coated papers

InactiveUS20040099391A1Non-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industryHardness

The present invention relates to a process of manufacturing a high bulk, low weight paper product produced by using a high level of groundwood containing sheet, blade coating with specifically formulated coatings then passing the paper web between two extended-nip calenders, one calender for each side of paper. As a result, densification of the resulting coated paper product is reduced, while maintaining stiffness and opacity comparable to heavier weight sheets.

Owner:VERSO PAPER

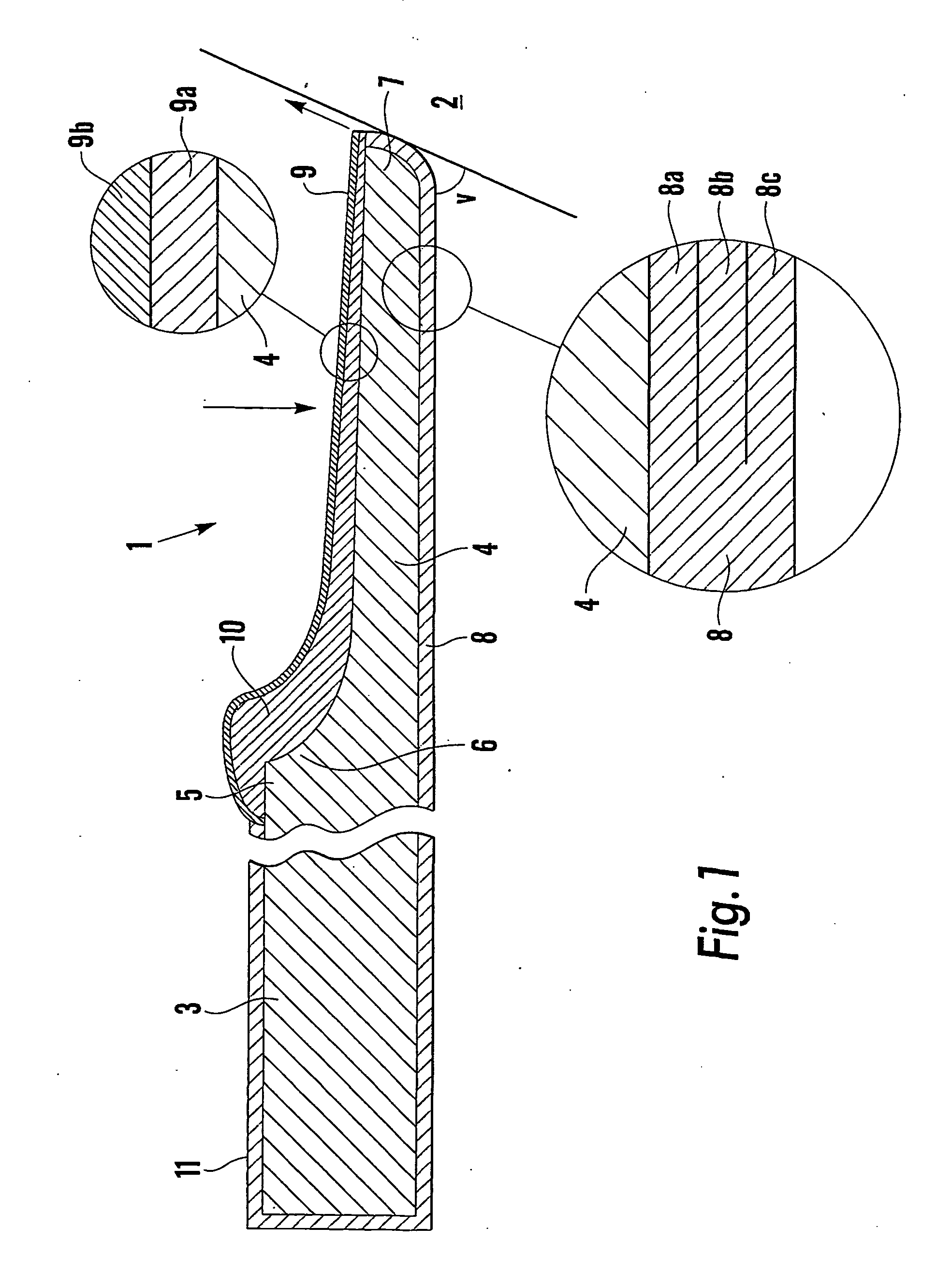

Doctor or coater blade and method in connection with its manufacturing

InactiveUS20040137261A1Improve wear resistanceEasy to wearLiquid surface applicatorsMechanical working/deformationNickel saltElectrolyte

The invention relates to a doctor or coater blade (1) of steel, having a nickel coating comprising abrasion resistant particles, said coating being constituted by an electrolytic nickel layer comprising abrasion resistant particles. The coating preferably comprises at least two electrolytic nickel layers having different composition, and may be formed differently in different sections of the blade. The invention also relates to a continuous process for electrolytic nickel coating in at least one electrolytic cell holding an electrolyte liquid comprising at least one nickel salt, and in at least one of these cells also comprising abrasion resistant particles.

Owner:SWEDEV

Dullish coated paper for printing

InactiveUS20050016701A1Good flexibilityImprove surface smoothnessNatural cellulose pulp/paperSpecial paperFiberAdhesive

A dull coated printing paper that is bulky (low in density) having a density of 0.90 to 1.15 g / cm3 and yet offers excellent pliability, superior surface smoothness, high degree of print gloss and minimal small-scale gloss variations in the image area are obtained by forming a coating layer comprising a pigment and an adhesive on a base paper which contains an organic compound having an action to inhibit binding between pulp fibers and then carrying out calender treatment at a line pressure for the treatment of 50 to 150 kg / cm.

Owner:NIPPON PAPER IND CO LTD

Liquid wear resistant paper and production process thereof

InactiveCN105421154AImprove clarityHigh glossSurface covering paperPaper/cardboardSolid woodWear resistant

The present invention relates to paper and a production method thereof, in particular to decorative paper which is processed and produced by domestic surface paper and has decorative and wear-resistant effects and a production process thereof. Liquid wear resistant paper disclosed by the present invention comprises raw paper and a wear resistant coating, the raw paper is domestic surface paper, and the quantity is 18-35 g / m<2>; and the wear resistant coating is a glue layer formed on the surface of the surface paper, the glue layer is formed by adding white corundum particles, a suspending agent, a dispersant and a curing agent into glue and uniformly stirring. The liquid wear resistant paper and the production process thereof have the advantages that definition is high, the number of wear resistant revolutions has a low correlation with the definition, the definition is seldom affected, and the effect is similar to that of real woods; the number of the wear resistant revolutions can be adjusted according to requirements of clients and can reach up to AC 5 without changing the raw paper; and the glossiness is high and can reach up to 90-105 Gs.

Owner:JIANGSU JIANFENG DECORATION PAPER CO LTD

Method for making rolls of tissue sheets having improved properties

InactiveUS20060065382A1Improve firmnessImprove propertiesNon-fibrous pulp additionNatural cellulose pulp/paperBiomedical engineeringSheet material

The roll properties of tissue sheets are improved either by imparting cross-machine direction dominant bar-like protrusions to the air side of the tissue by using specially woven transfer fabrics and / or by offsetting recurring surface features of the sheet relative to the surface features of adjacent sheets within the roll, such as by providing a throughdryer fabric with an offset seam. Both techniques provide the resulting tissue sheets with improved capabilities for providing an improved combination of roll bulk and roll firmness.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com