Process for producing super high bulk, light weight coated papers

a coating paper and super high bulk technology, applied in papermaking, non-fibrous pulp addition, press section, etc., can solve the problems of poor gloss paper quality, poor quality of coated paper,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

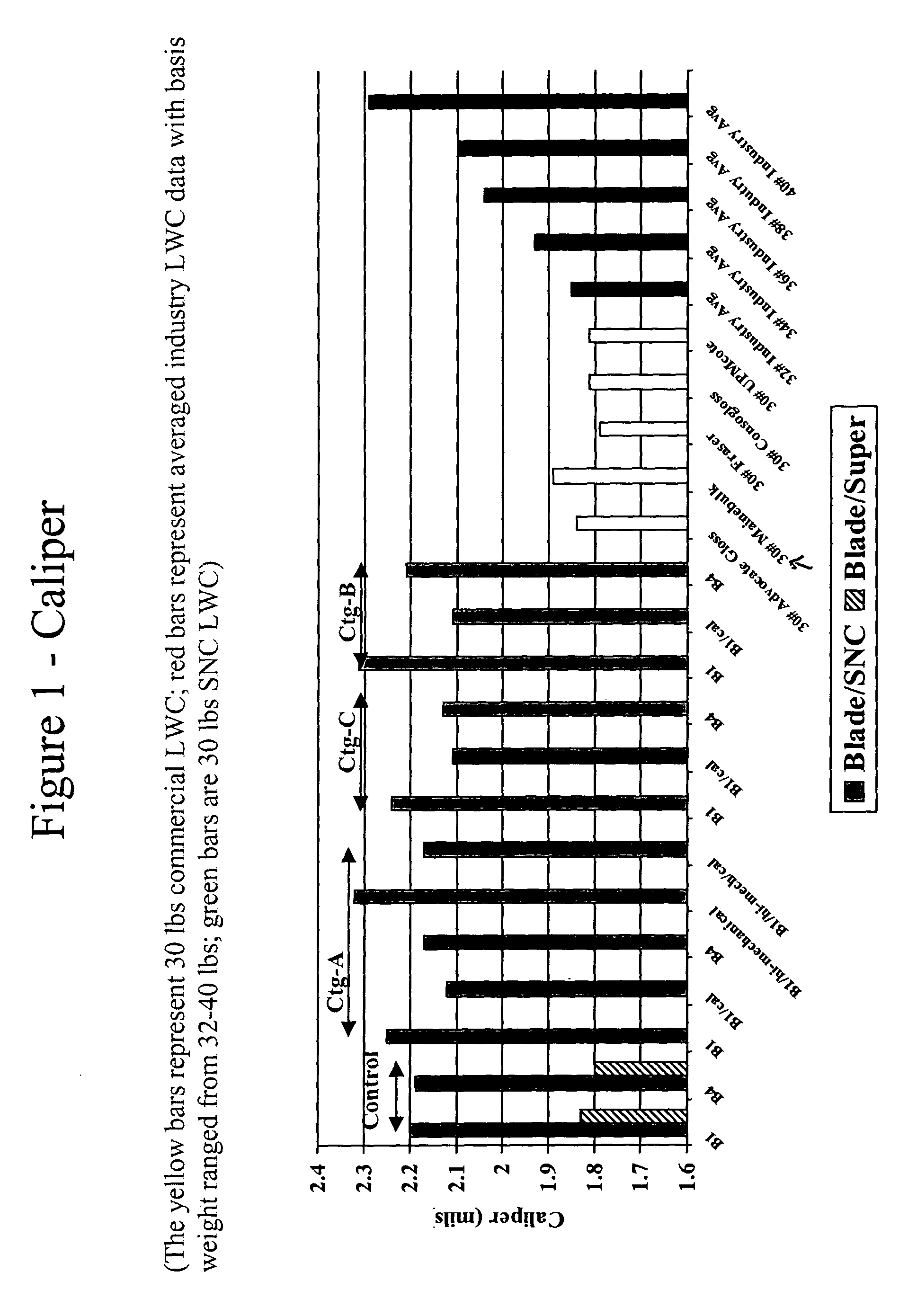

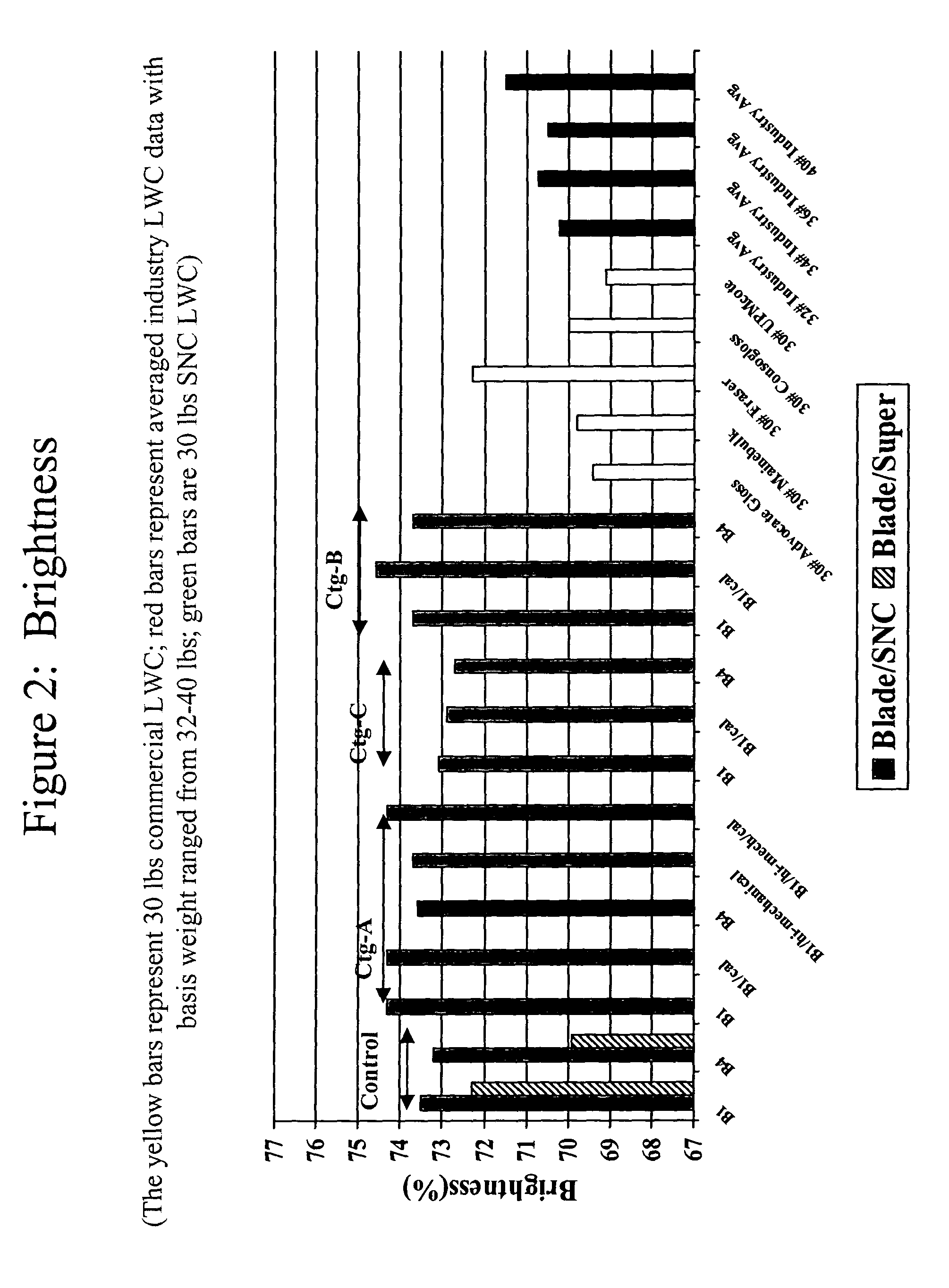

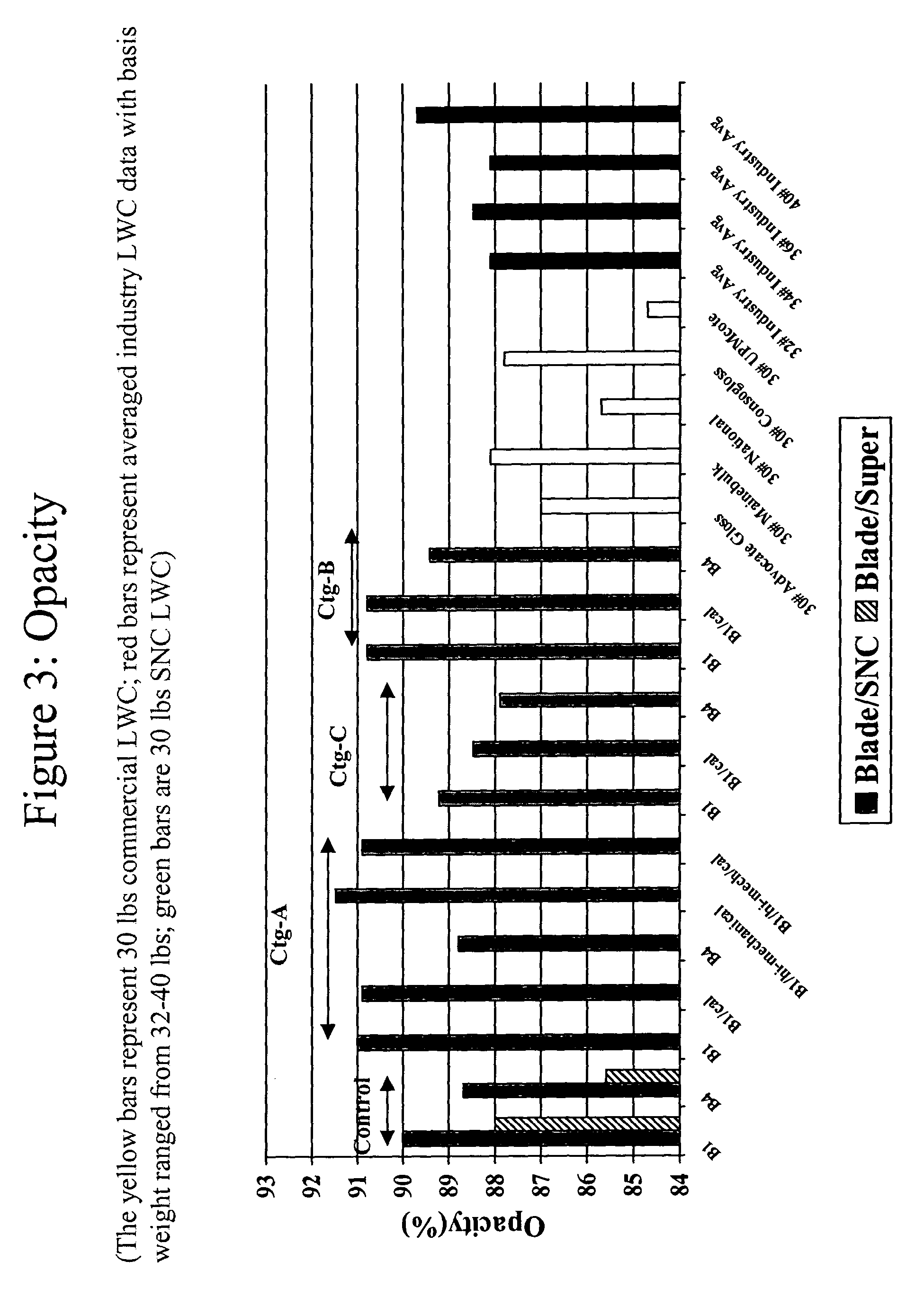

[0062] Basepaper

[0063] The effect of five 32 g / m.sup.2 basepaper was examined using the following types of basepaper: B1, B1 / hi-mechanical, B4 and two hot soft pre-calendered basepaper (B1 / precalendering and B1 / hi-mechanical / precalen-dering). The properties of the B1 and B1 / hi-mechanical basepaper are shown in Table 1. B4 basepaper is similar to B1 basepaper, except that the B4 has less addition of wet-end starch in the sheet. Precalendering basepaper has smoother surfaces than non-precalendered basepaper, but its caliper is reduced. Table 1 shows that by increasing TMP content from 30% to 60% the total mechanical pulp content increases from 60% to 70%, while still maintaining good paper machine runnability. Table 2 shows that by increasing the amount of mechanical pulp from 60% to 70% the caliper increases from 2.85 to 3.03, while roughness and porosity are slightly increased.

[0064] Coating Formulations

[0065] The "control" coating is a typical No.5 lightweight coating, consisting o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com