Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1319 results about "Boron containing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The most abundant minerals containing boron are kernite, borax, ulexite and colemanite. It can also be found in slate and in loam rich rock formations. Air-tight soil contains boron concentrations of between 5 and 80 ppm. Boron rich places, such as fumaroles, contain boric acid, borates and boron minerals.

Formation of boride barrier layers using chemisorption techniques

InactiveUS7208413B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBorideBoron containing

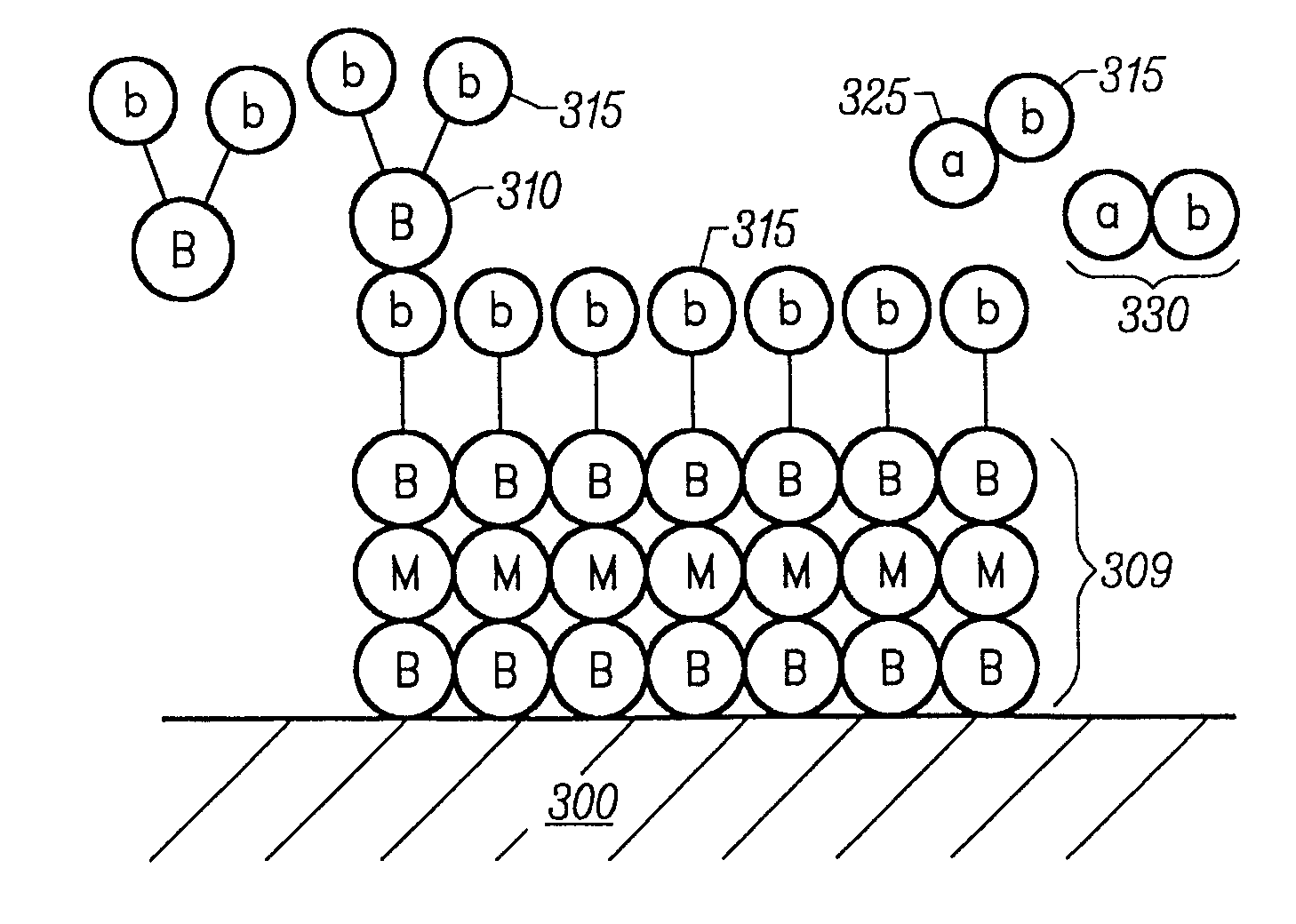

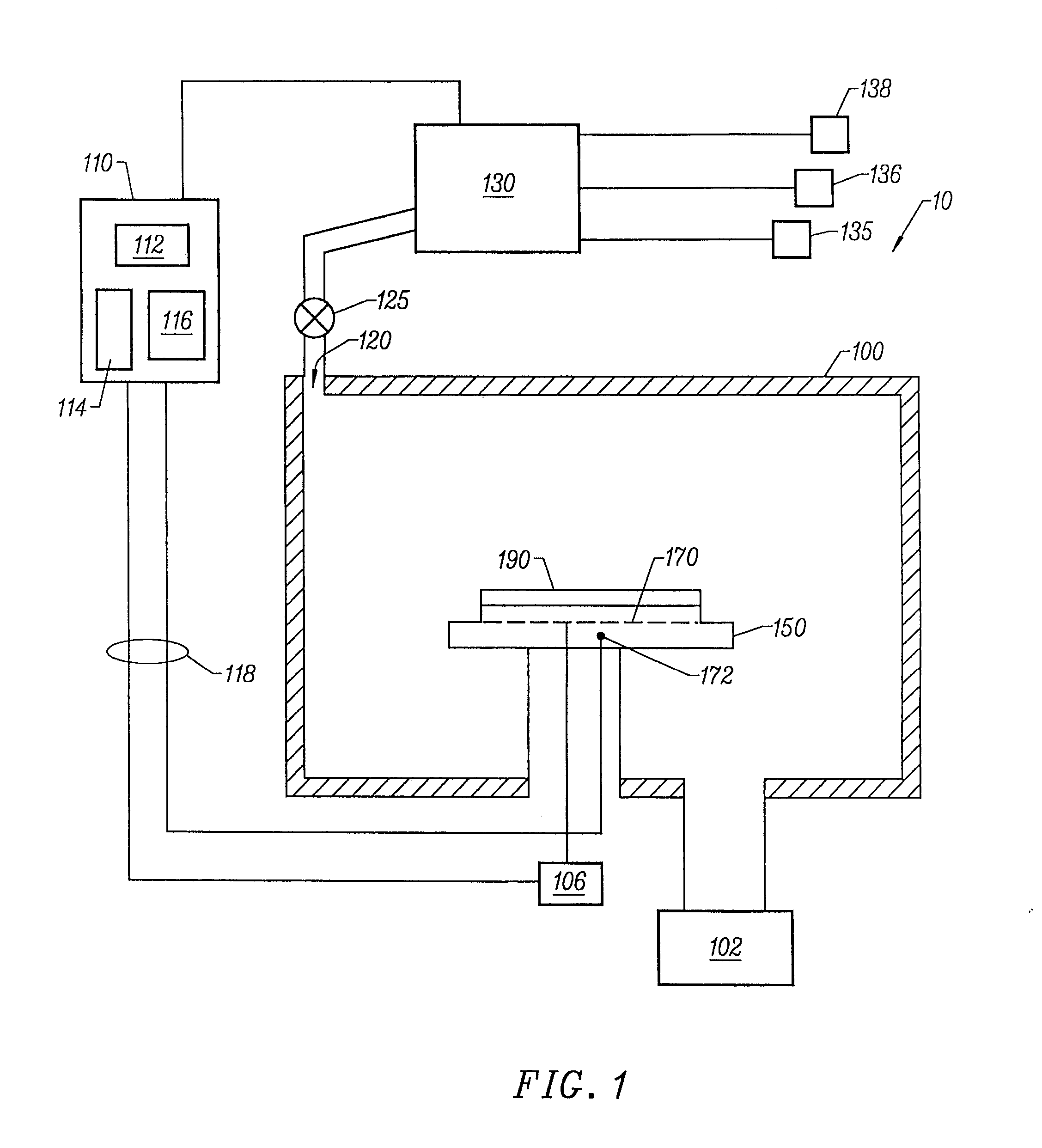

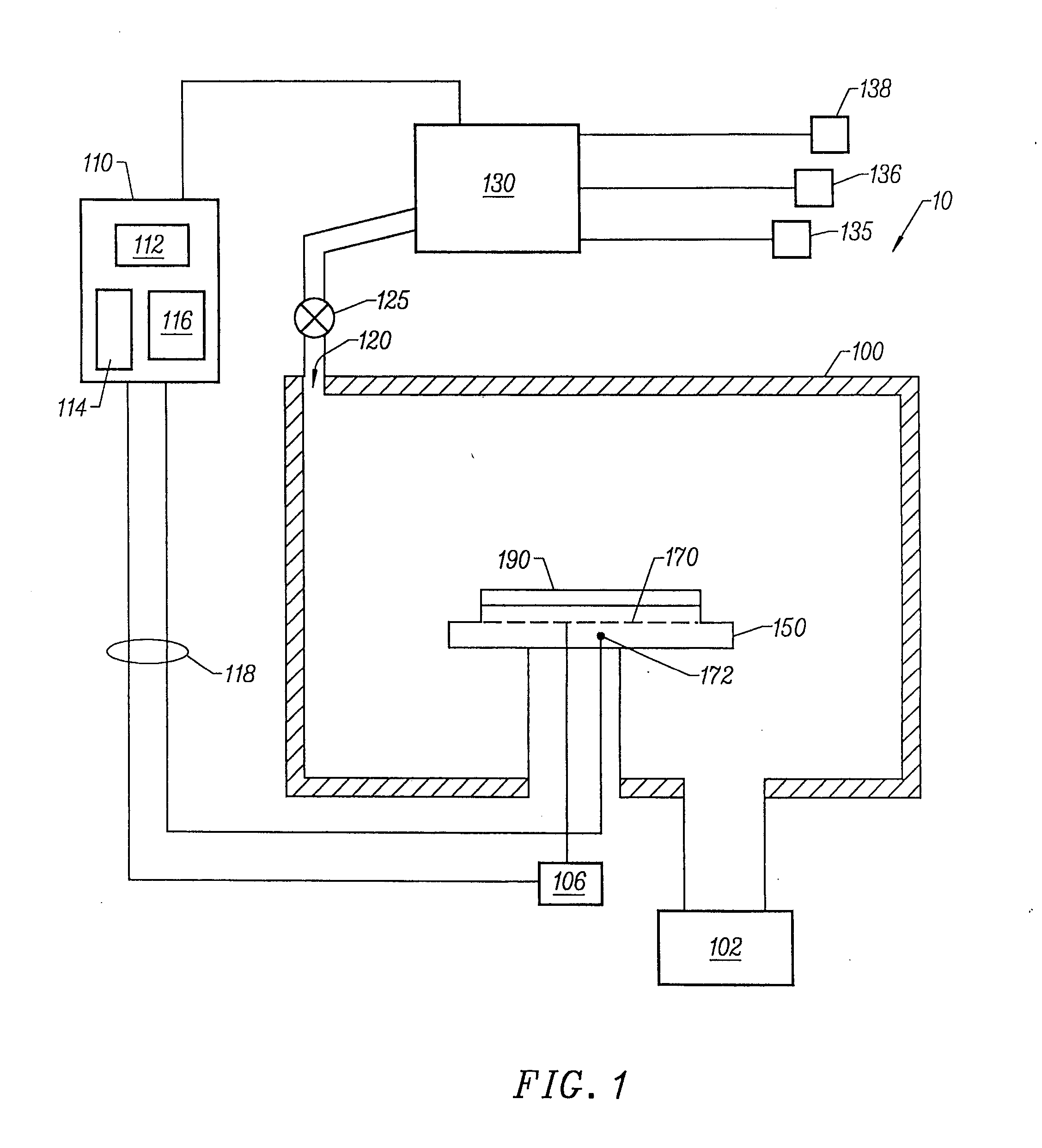

A method of forming a boride layer for integrated circuit fabrication is disclosed. In one embodiment, the boride layer is formed by chemisorbing monolayers of a boron-containing compound and one refractory metal compound onto a substrate. In an alternate embodiment, the boride layer has a composite structure. The composite boride layer structure comprises two or more refractory metals. The composite boride layer is formed by sequentially chemisorbing monolayers of a boron compound and two or more refractory metal compounds on a substrate.

Owner:APPLIED MATERIALS INC

Formation of boride barrier layers using chemisorption techniques

InactiveUS20050118804A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBorideChemisorption

A method of forming a boride layer for integrated circuit fabrication is disclosed. In one embodiment, the boride layer is formed by chemisorbing monolayers of a boron-containing compound and one refractory metal compound onto a substrate. In an alternate embodiment, the boride layer has a composite structure. The composite boride layer structure comprises two or more refractory metals. The composite boride layer is formed by sequentially chemisorbing monolayers of a boron compound and two or more refractory metal compounds on a substrate.

Owner:APPLIED MATERIALS INC

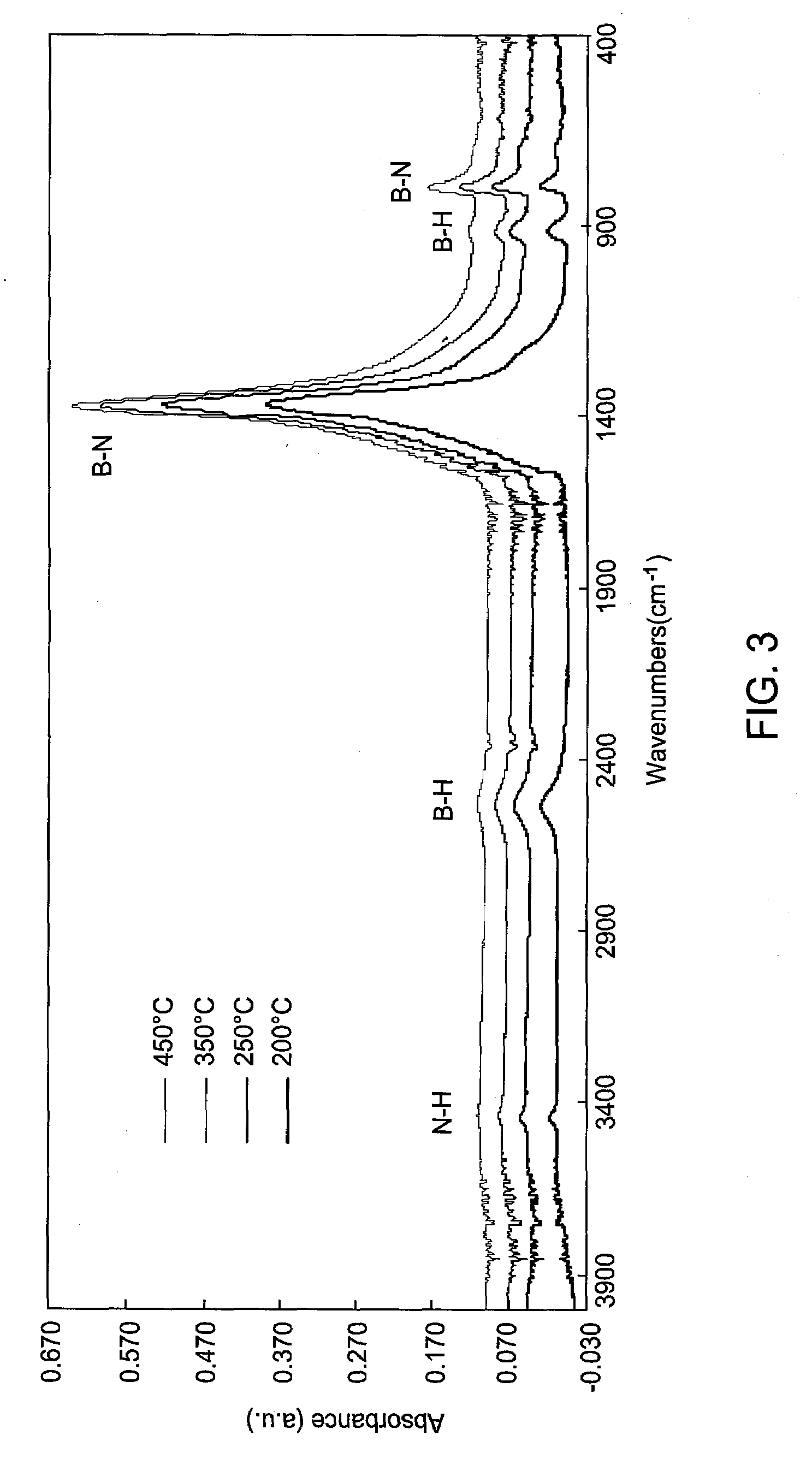

Boron nitride and boron nitride-derived materials deposition method

ActiveUS20080292798A1High nitrogen contentIncrease oxygen contentPretreated surfacesSemiconductor/solid-state device manufacturingMetallurgyBoron containing

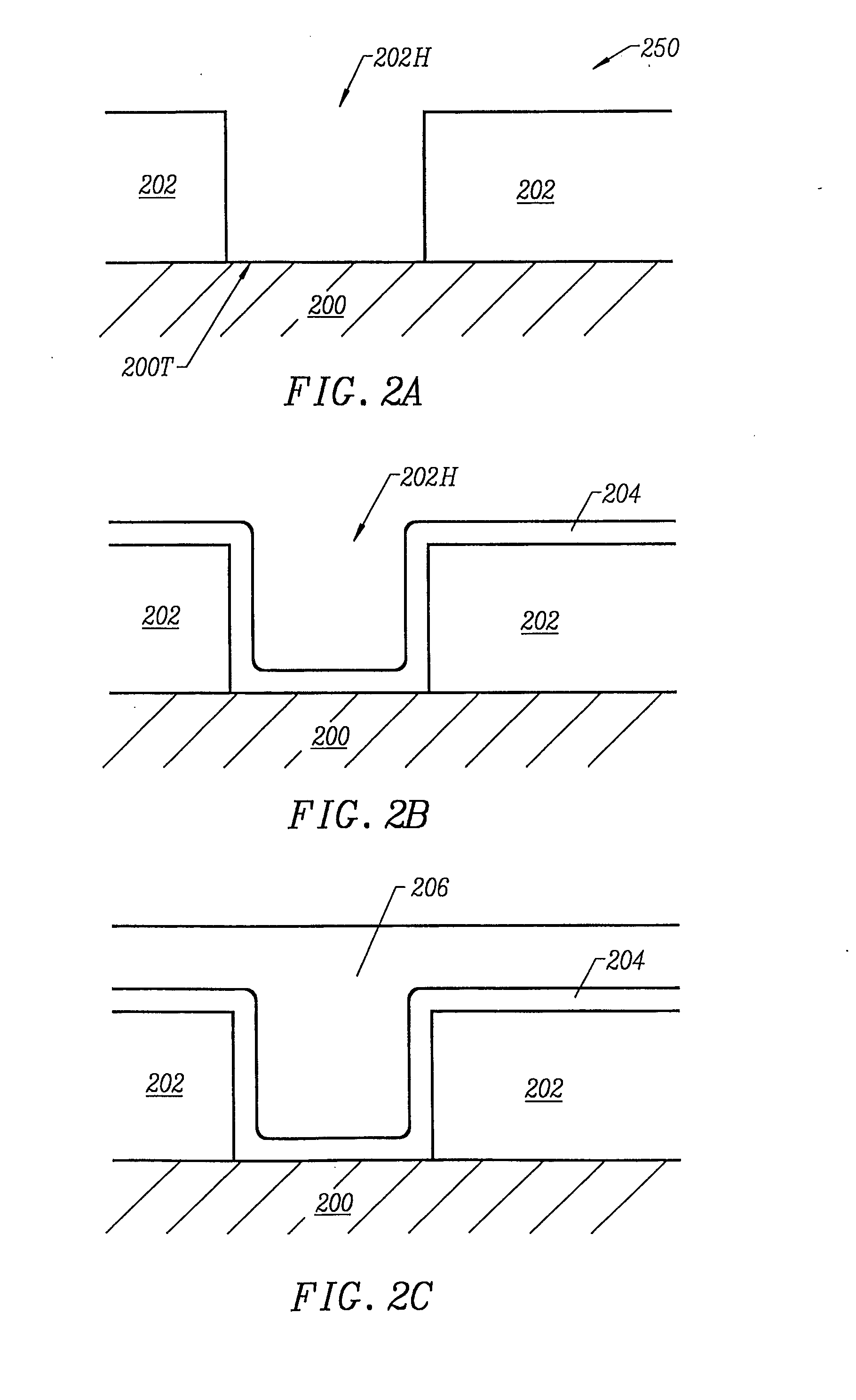

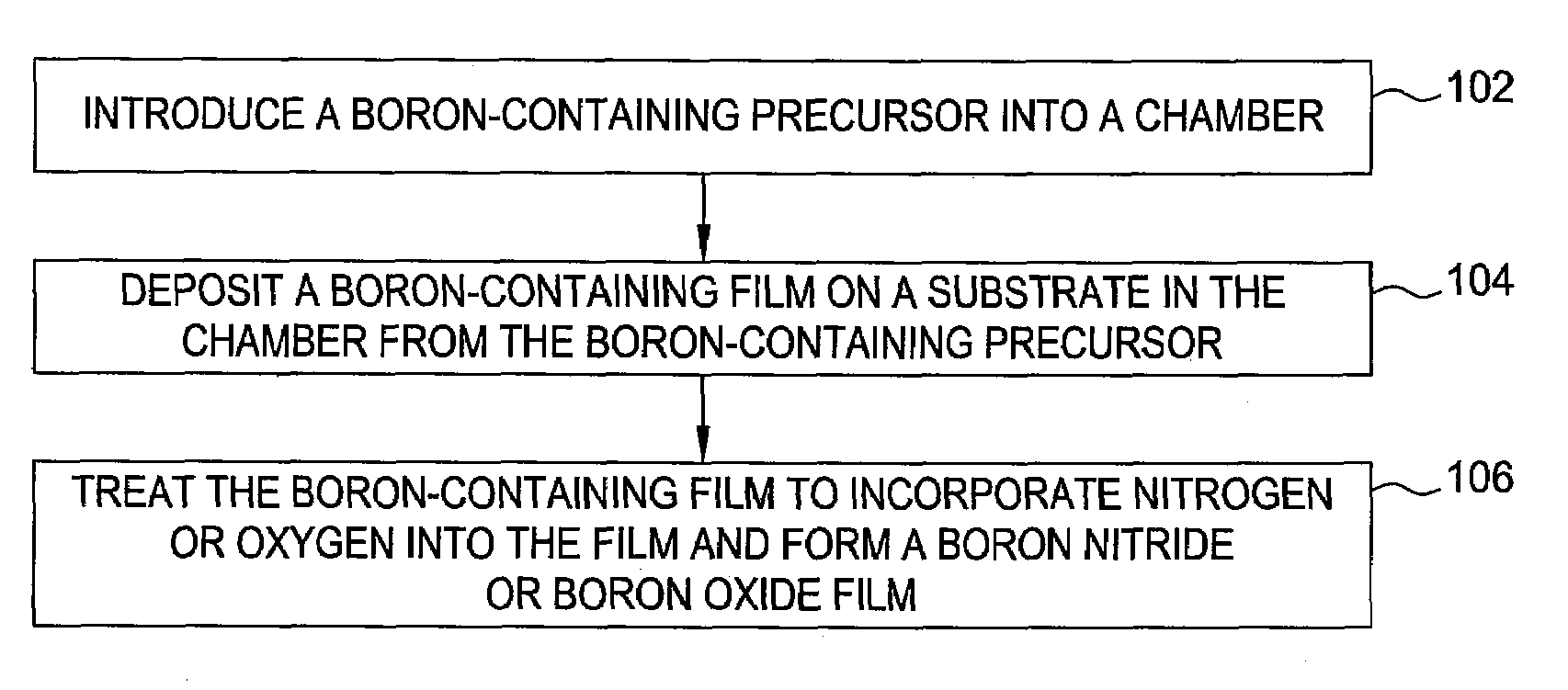

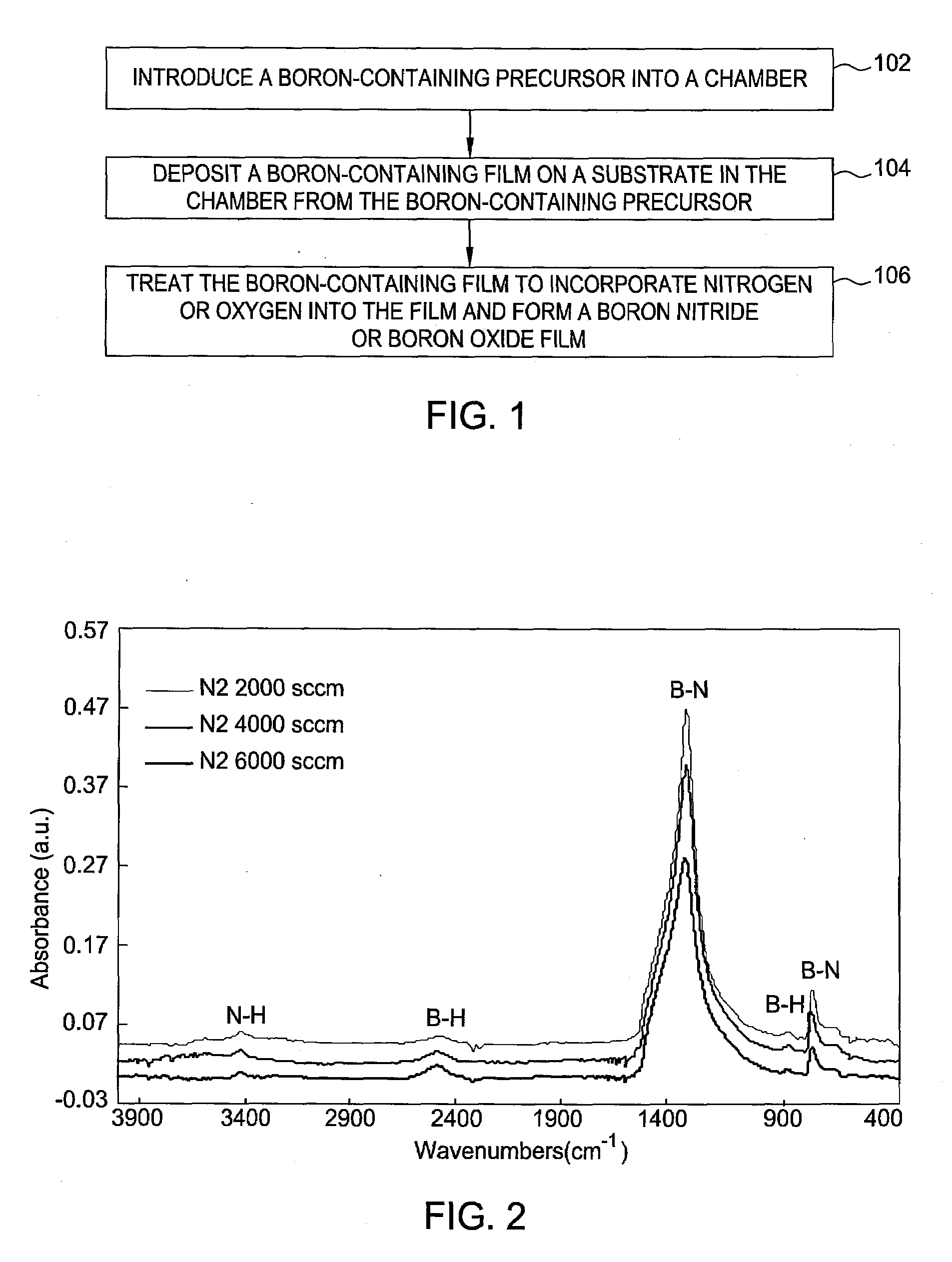

Methods for forming boron-containing films are provided. The methods include introducing a boron-containing precursor and a nitrogen or oxygen-containing precursor into a chamber and forming a boron nitride or boron oxide film on a substrate in the chamber. In one aspect, the method includes depositing a boron-containing film and then exposing the boron-containing film to the nitrogen-containing or oxygen-containing precursor to incorporate nitrogen or oxygen into the film. The deposition of the boron-containing film and exposure of the film to the precursor may be performed for multiple cycles to obtain a desired thickness of the film. In another aspect, the method includes reacting the boron-containing precursor and the nitrogen-containing or oxygen-containing precursor to chemically vapor deposit the boron nitride or boron oxide film.

Owner:APPLIED MATERIALS INC

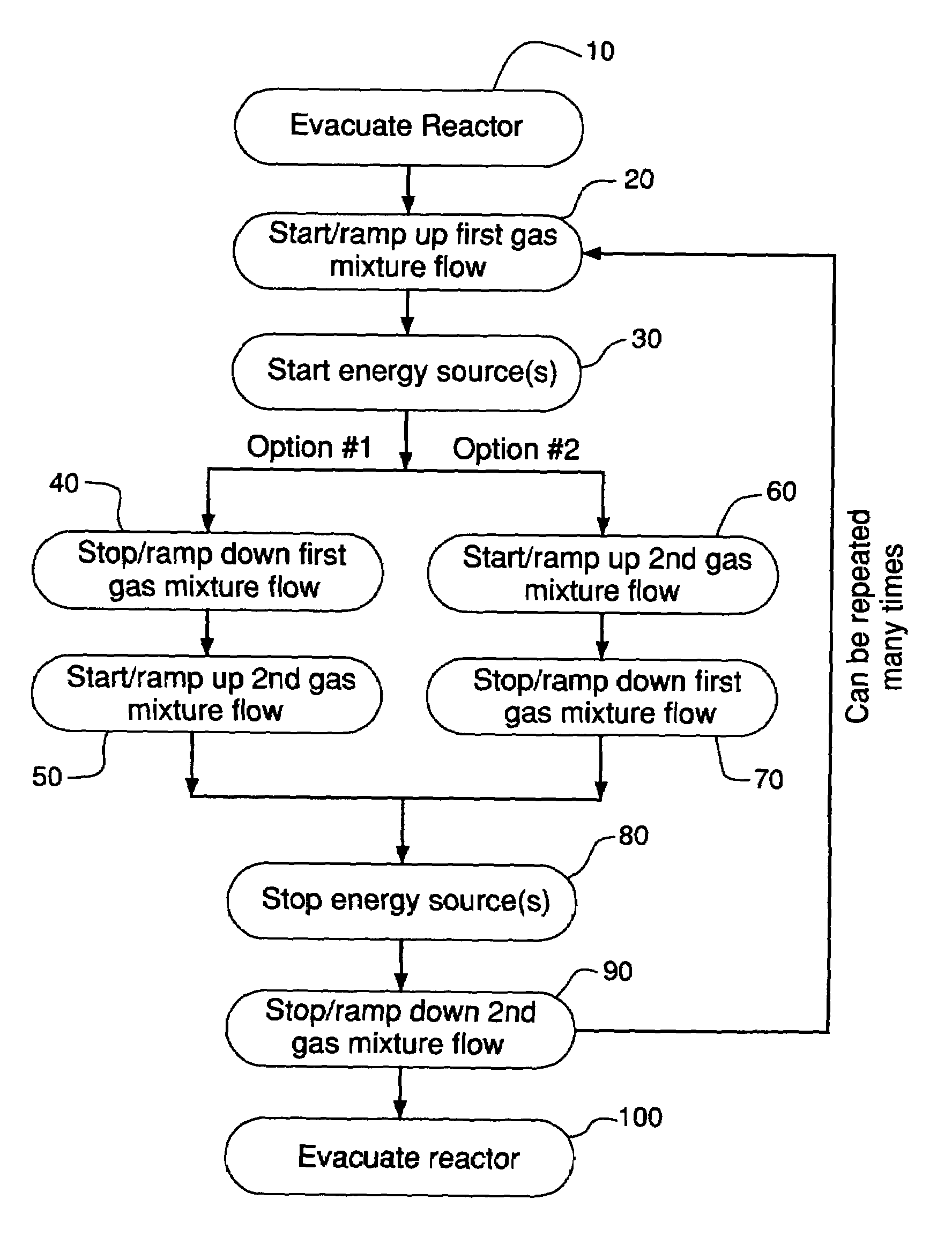

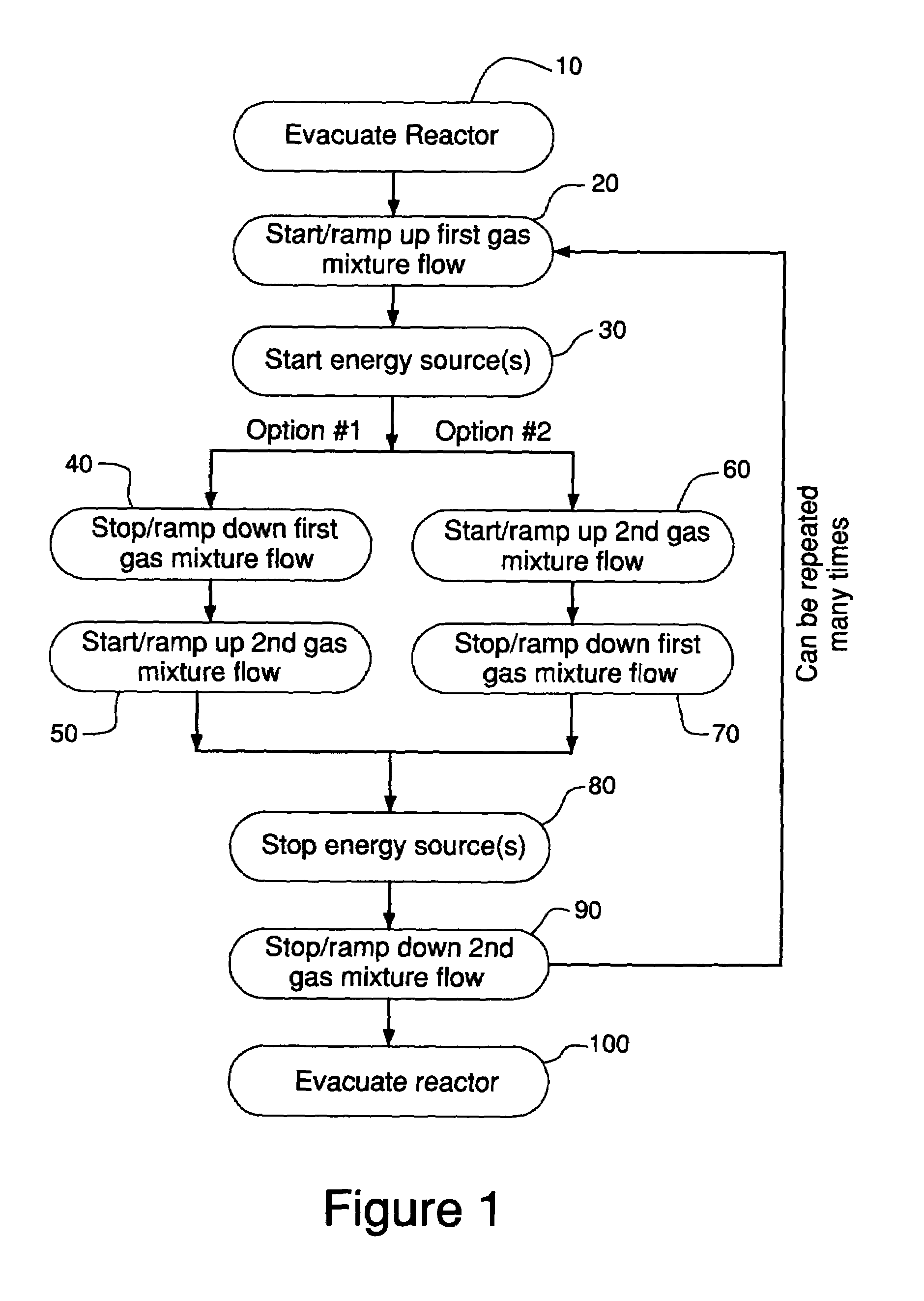

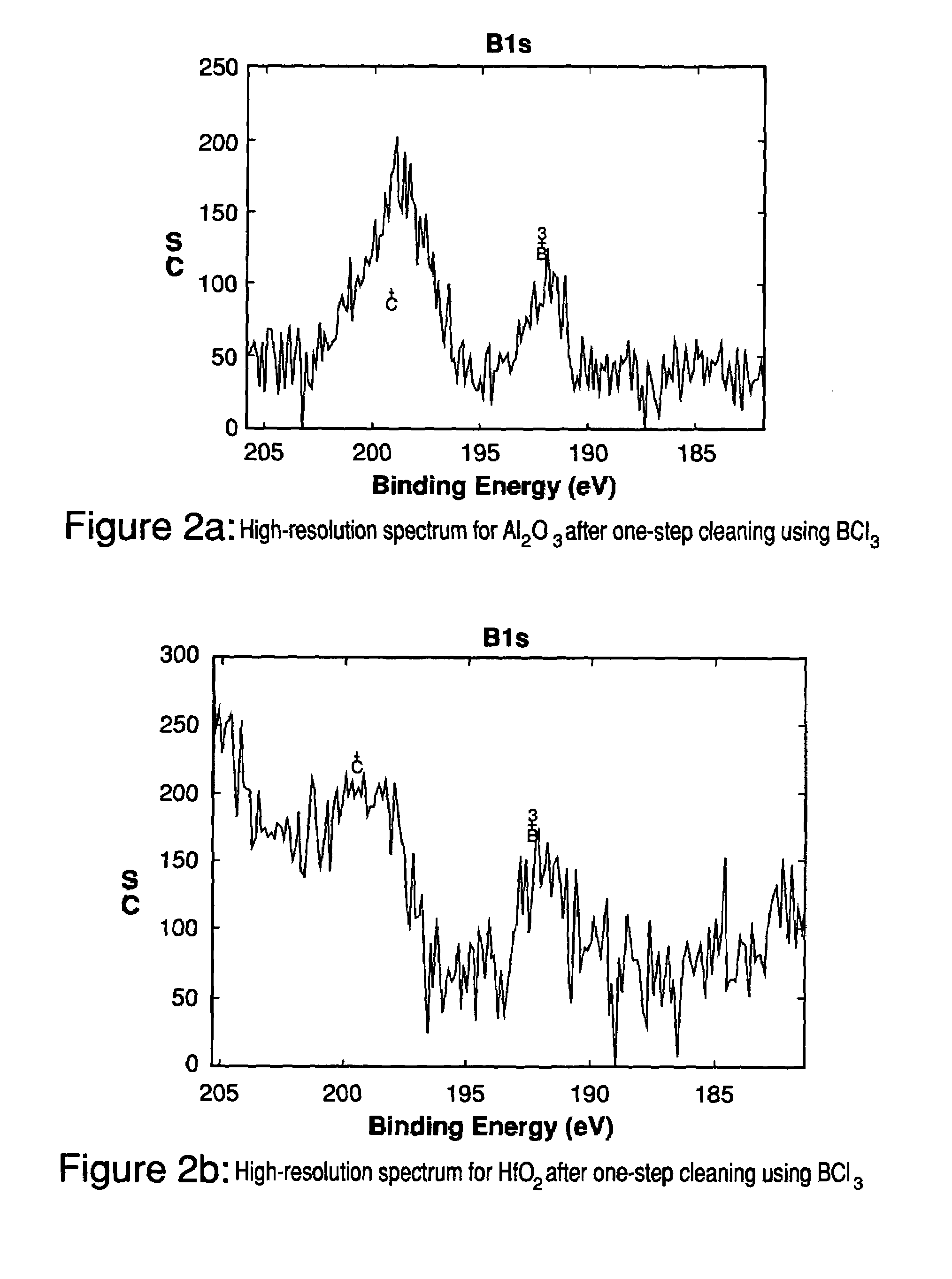

Method for cleaning deposition chambers for high dielectric constant materials

A method for dry etching and chamber cleaning high dielectric constant materials is disclosed herein. In one aspect of the present invention, there is provided a process for cleaning a substance comprising a dielectric constant greater than the dielectric constant of silicon dioxide from at least a portion of a surface of a reactor comprising: introducing a first gas mixture comprising a boron-containing reactive agent into the reactor wherein the first gas mixture reacts with the substance contained therein to provide a volatile product and a boron-containing by-product; introducing a second gas mixture comprising a fluorine-containing reactive agent into the reactor wherein the second gas mixture reacts with the boron-containing by-product contained therein to form the volatile product; and removing the volatile product from the reactor.

Owner:AIR PROD & CHEM INC

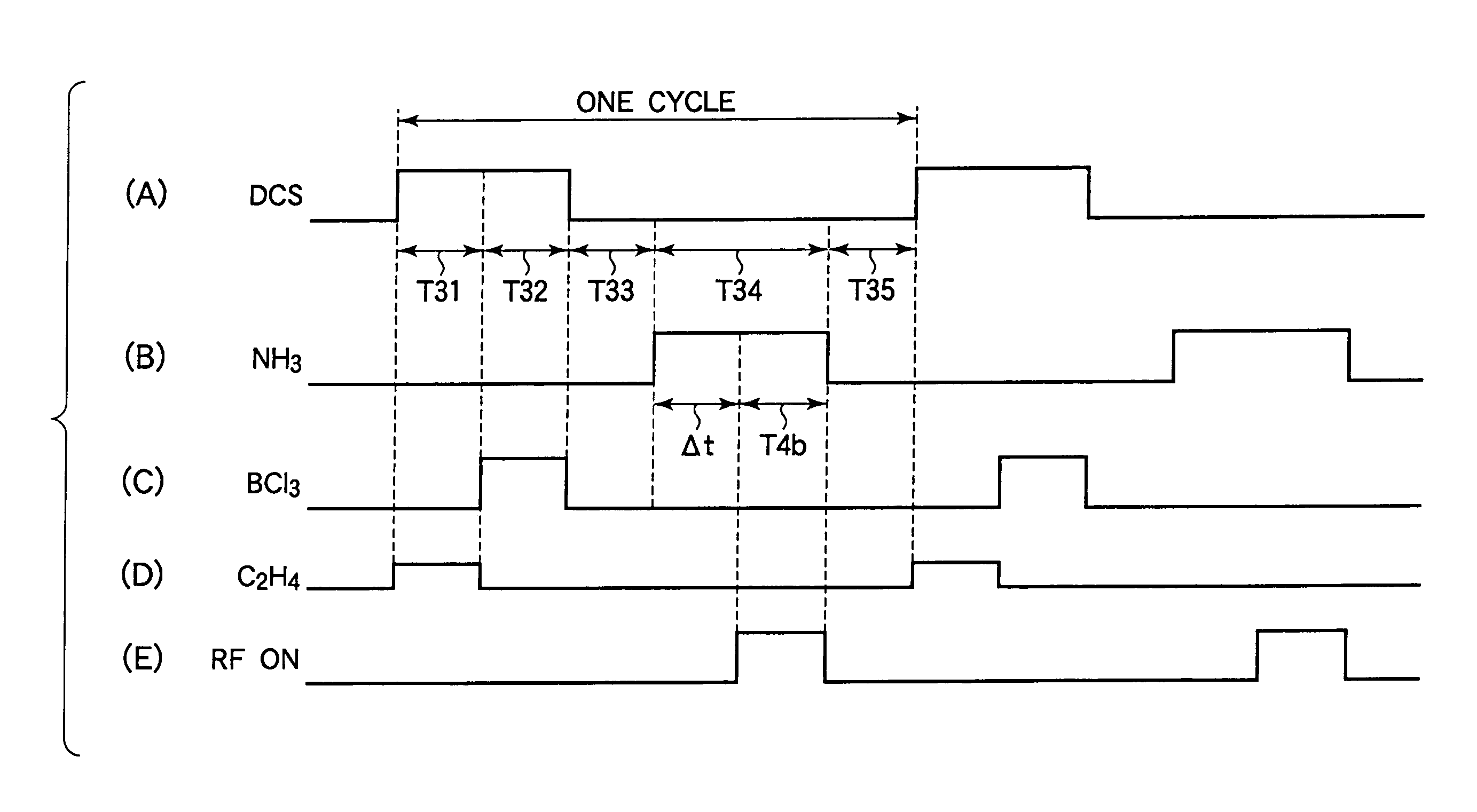

Methods to improve in-film particle performance of amorphous boron-carbon hardmask process in pecvd system

ActiveUS20170062218A1Reduce particle pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingBoron containingDelayed time

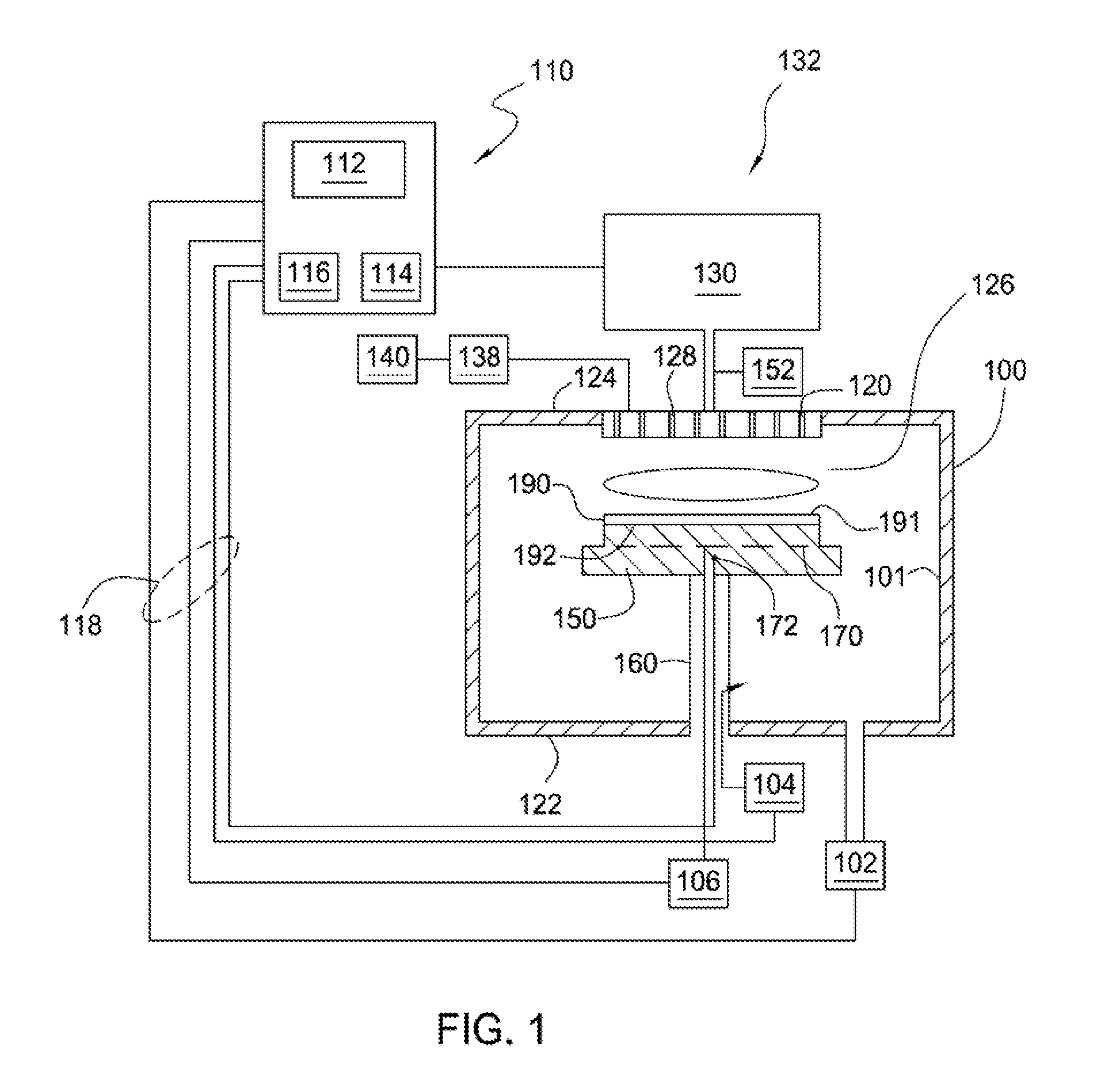

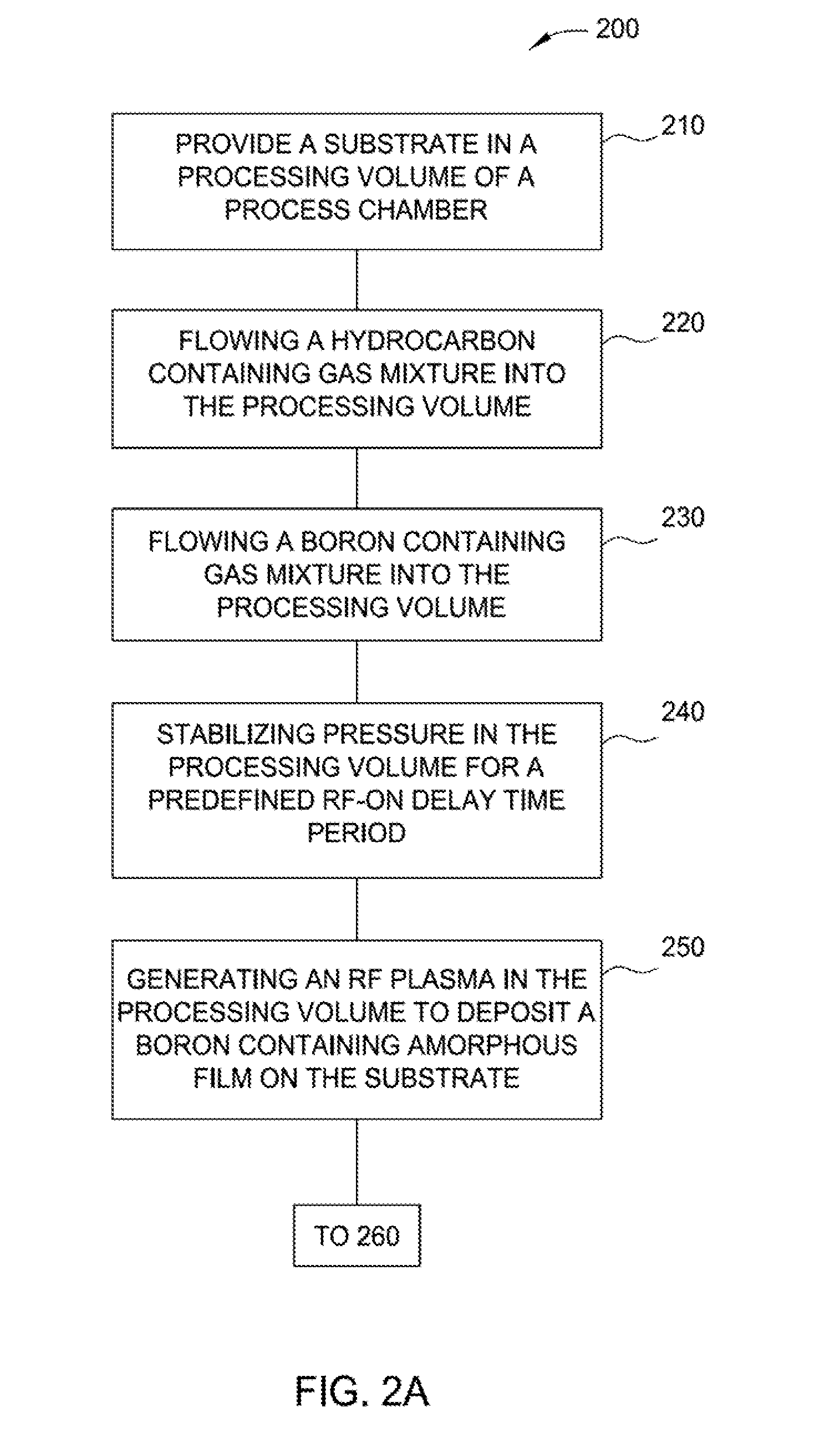

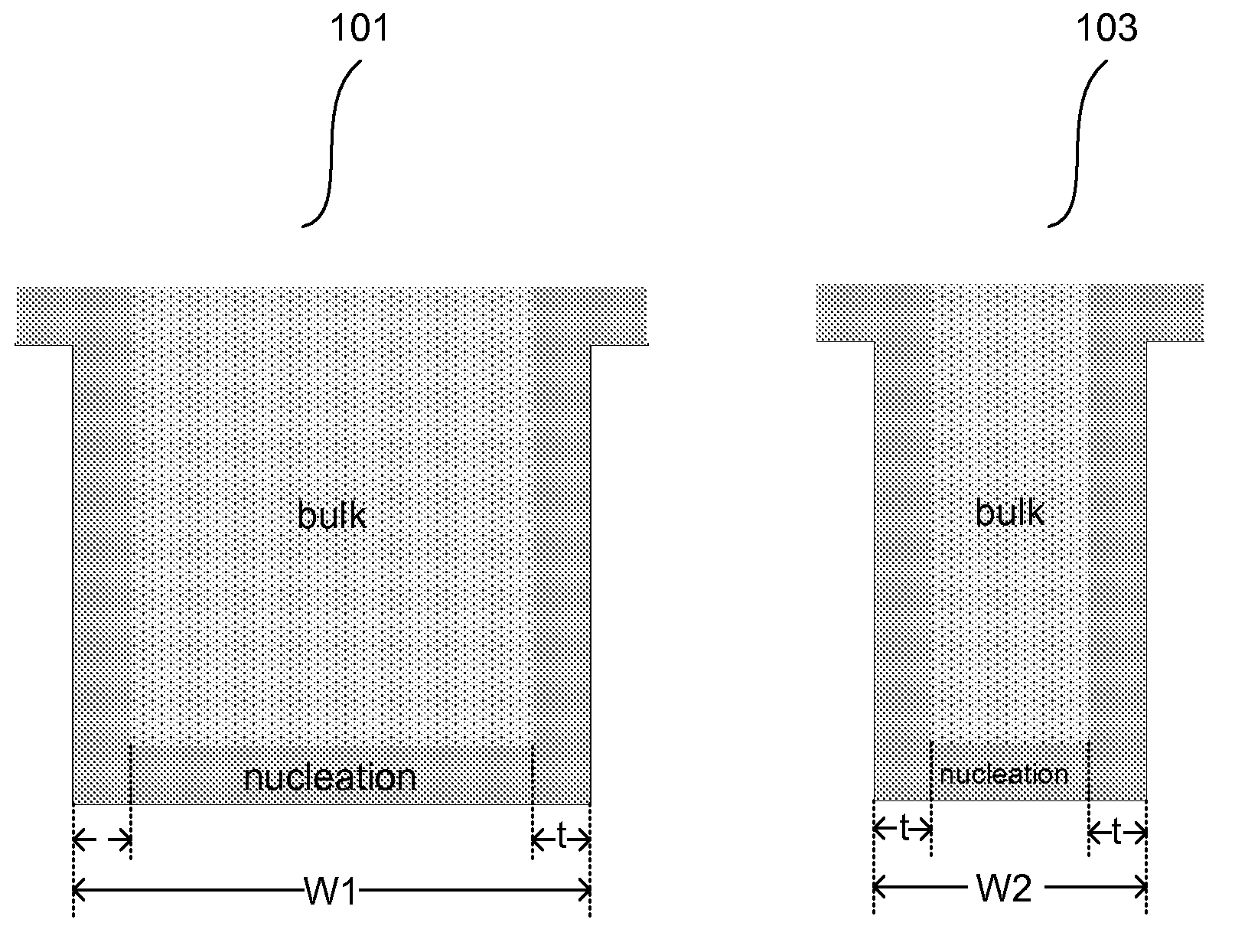

Implementations of the present disclosure generally relate to the fabrication of integrated circuits. More particularly, the implementations described herein provide techniques for deposition of boron-containing amorphous carbon films on a substrate with reduced particle contamination. In one implementation, the method comprises flowing a hydrocarbon-containing gas mixture into a processing volume having a substrate positioned therein, flowing a boron-containing gas mixture into the processing volume, stabilizing the pressure in the processing volume for a predefined RF-on delay time period, generating an RF plasma in the processing volume after the predefined RF-on delay time period expires to deposit a boron-containing amorphous film on the substrate, exposing the processing volume of the process chamber to a dry cleaning process and depositing an amorphous boron season layer over at least one surface in the processing volume of the process chamber.

Owner:APPLIED MATERIALS INC

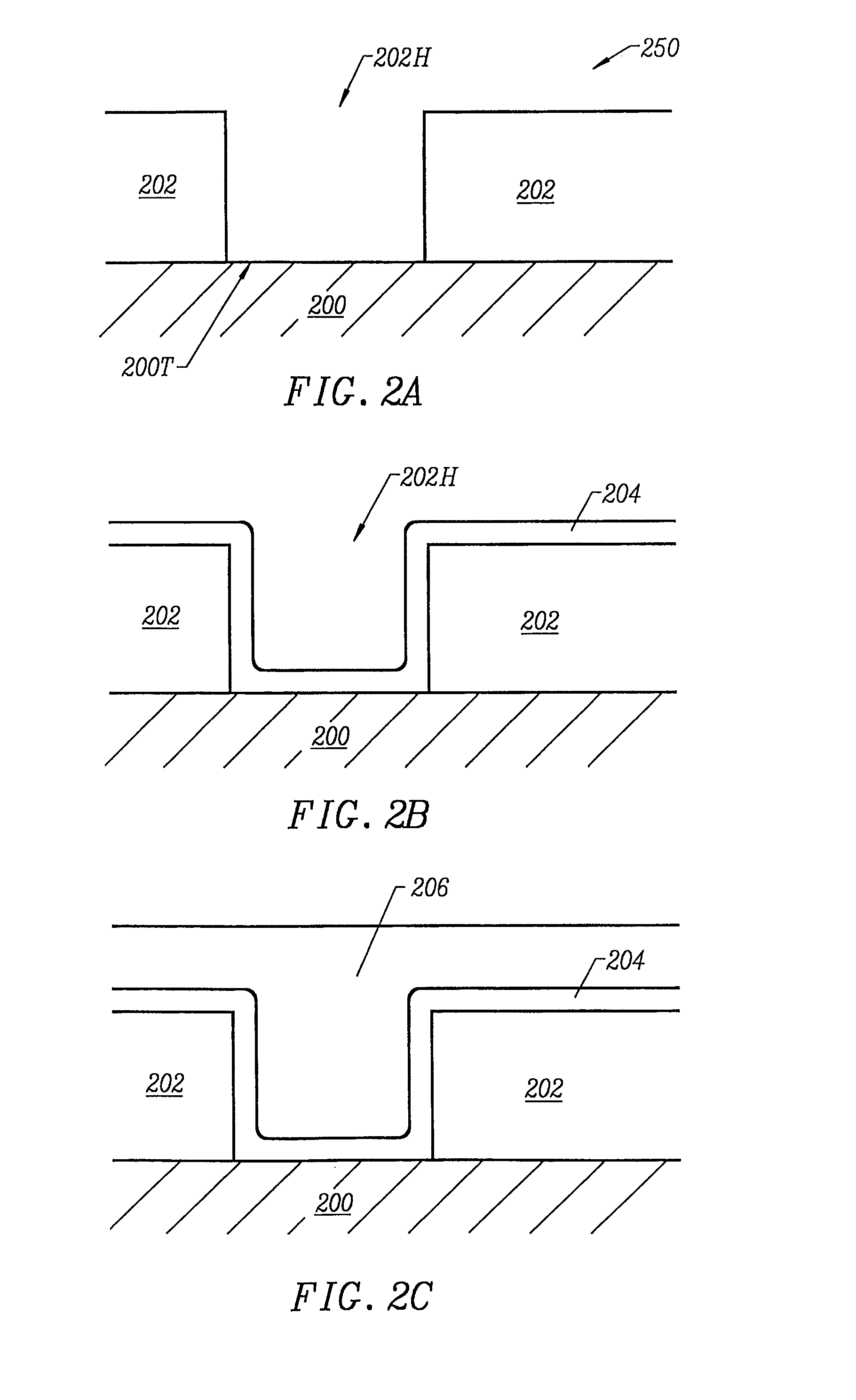

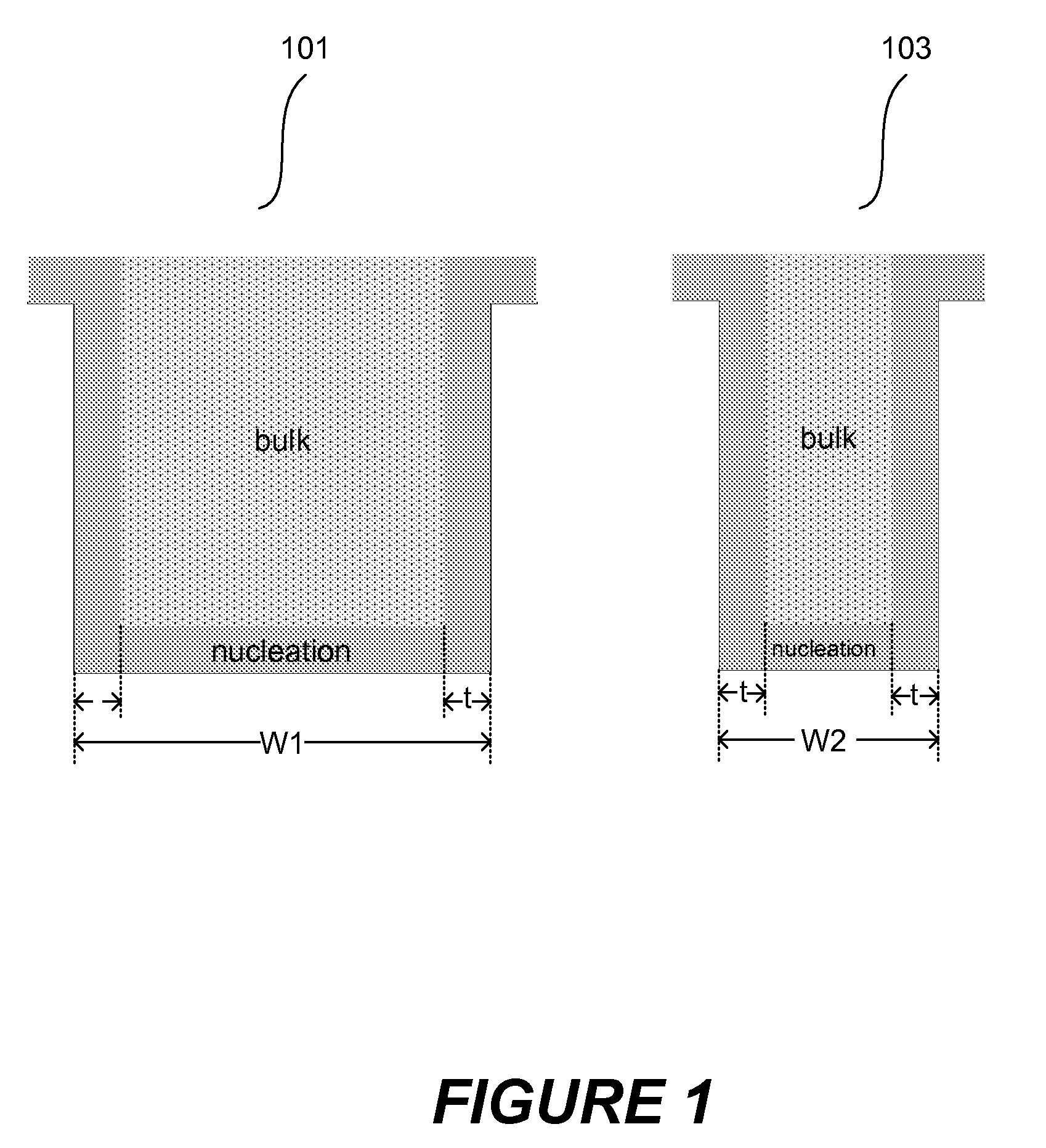

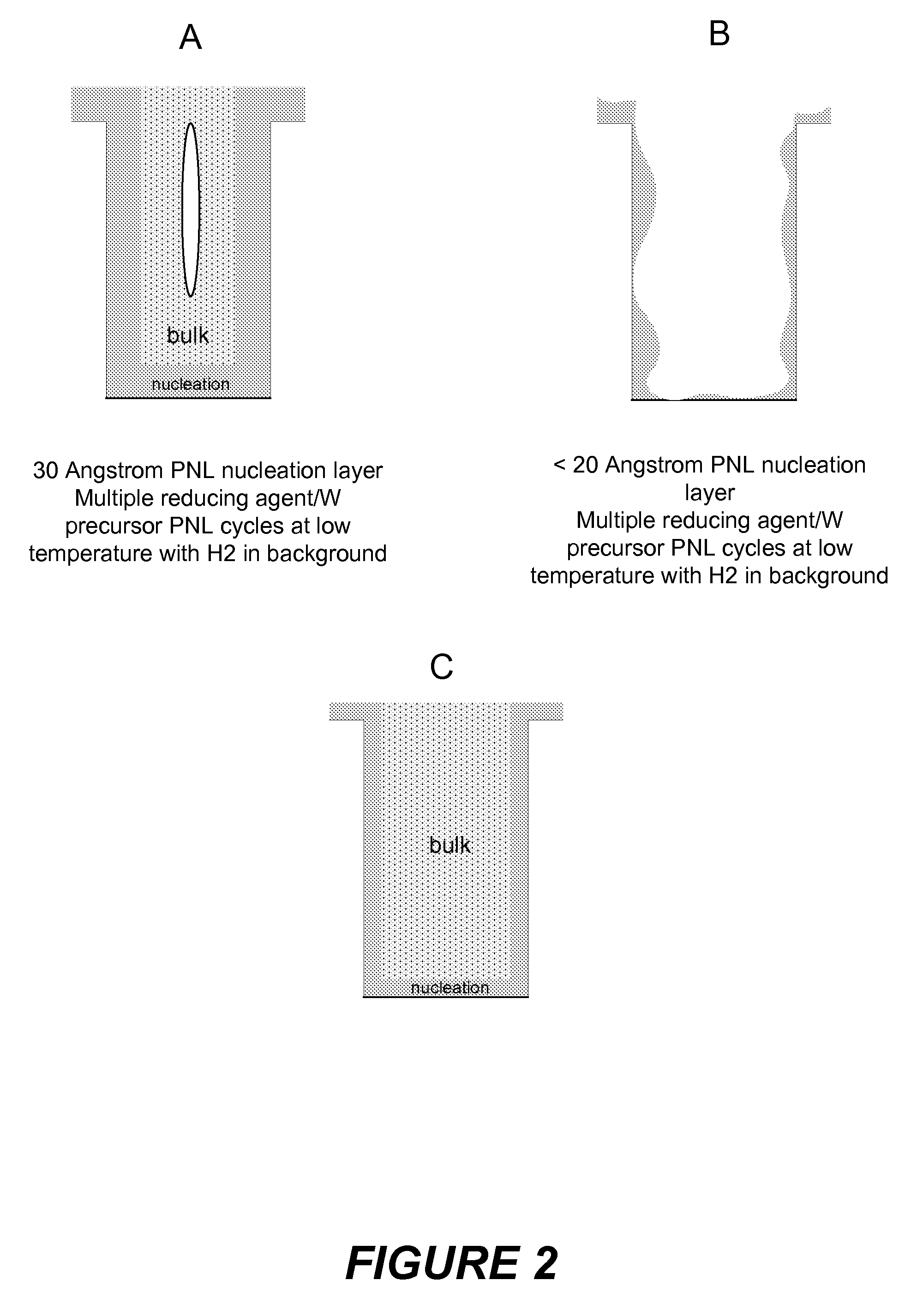

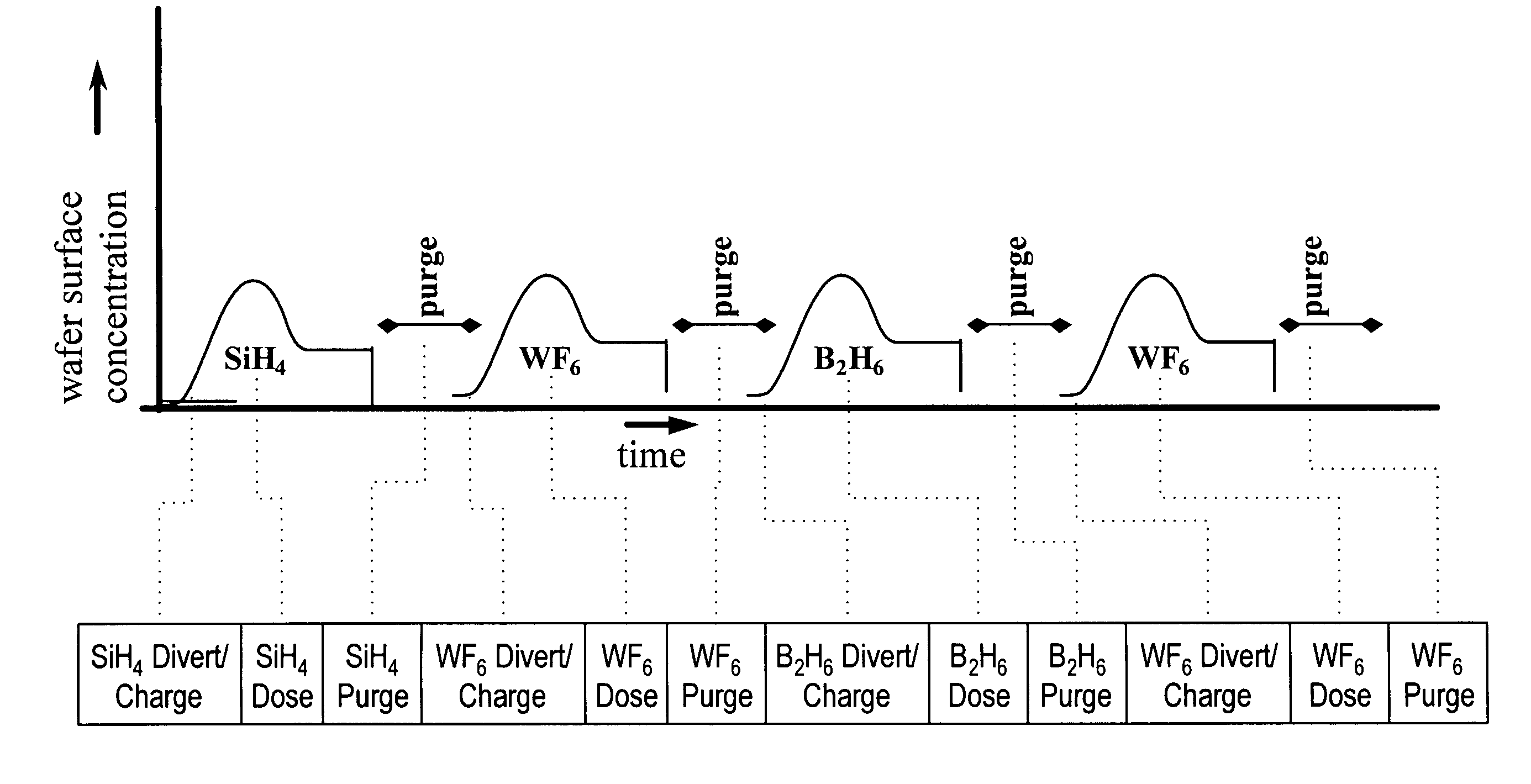

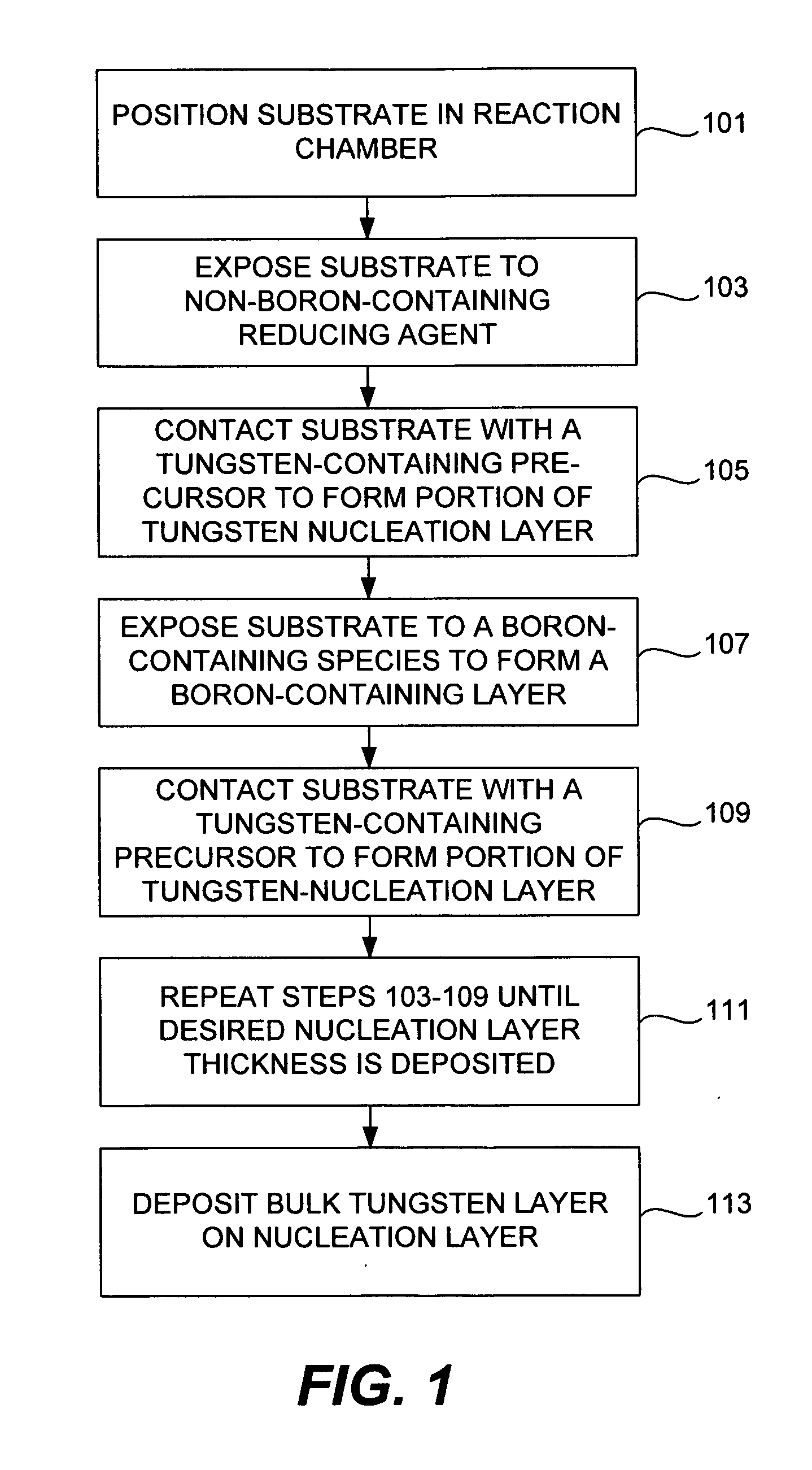

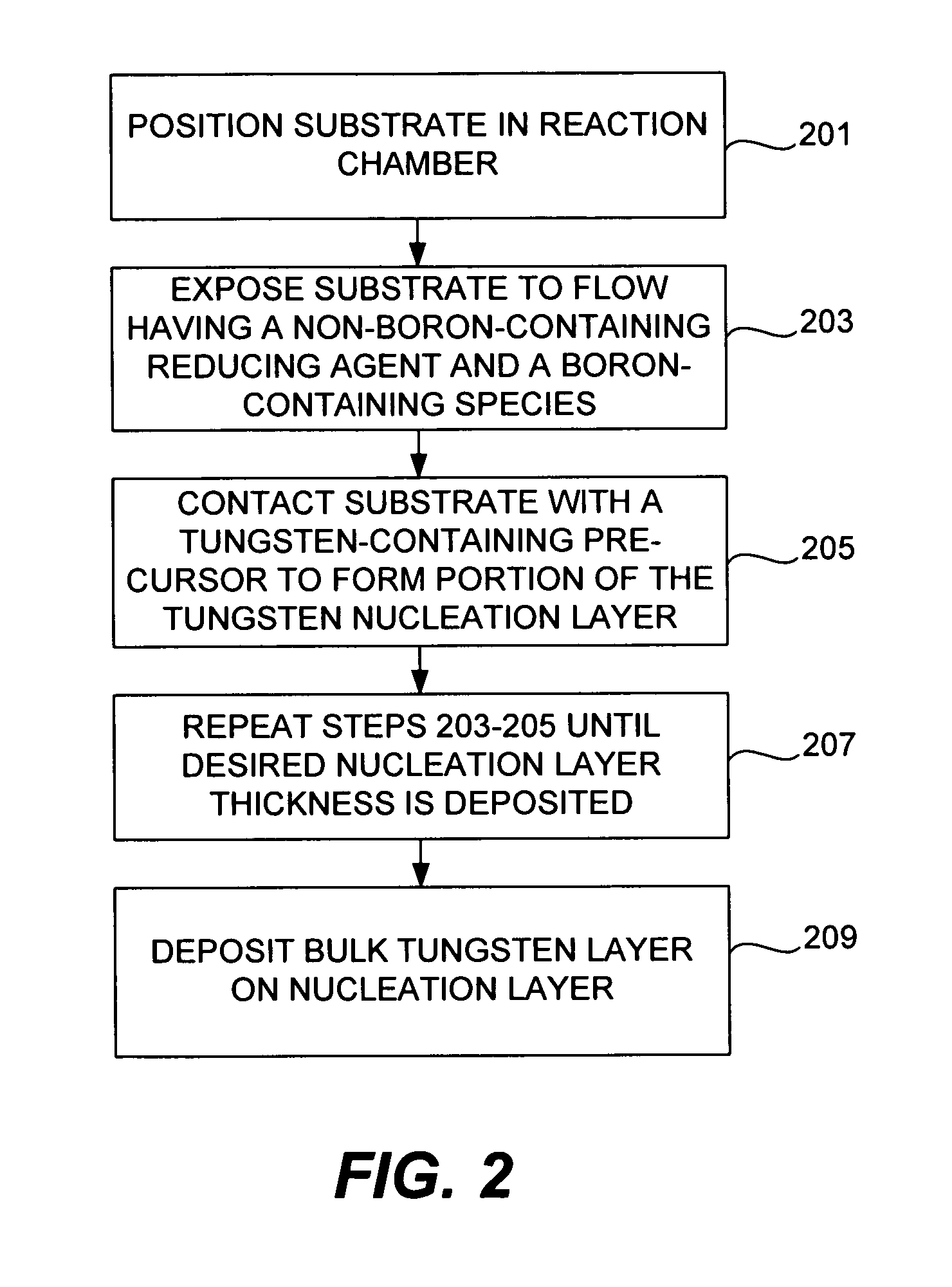

Methods for growing low-resistivity tungsten for high aspect ratio and small features

InactiveUS20080254623A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenGas phase

The present invention addresses this need by providing methods for depositing low resistivity tungsten films in small features and features having high aspect ratios. The methods involve depositing very thin tungsten nucleation layers by pulsed nucleation layer (PNL) processes and then using chemical vapor deposition (CVD) to deposit a tungsten layer to fill the feature. Depositing the tungsten nucleation layer involves exposing the substrate to alternating pulses of a boron-containing reducing agent and a tungsten-containing precursor without using any hydrogen gas, e.g., as a carrier or background gas. Using this process, a conformal tungsten nucleation layer can be deposited to a thickness as small as about 10 Angstroms. The feature may then be wholly or partially filled with tungsten by a hydrogen reduction chemical vapor deposition process. Resistivities of about 14 μΩ-cm for a 500 Angstrom film may be obtained.

Owner:NOVELLUS SYSTEMS

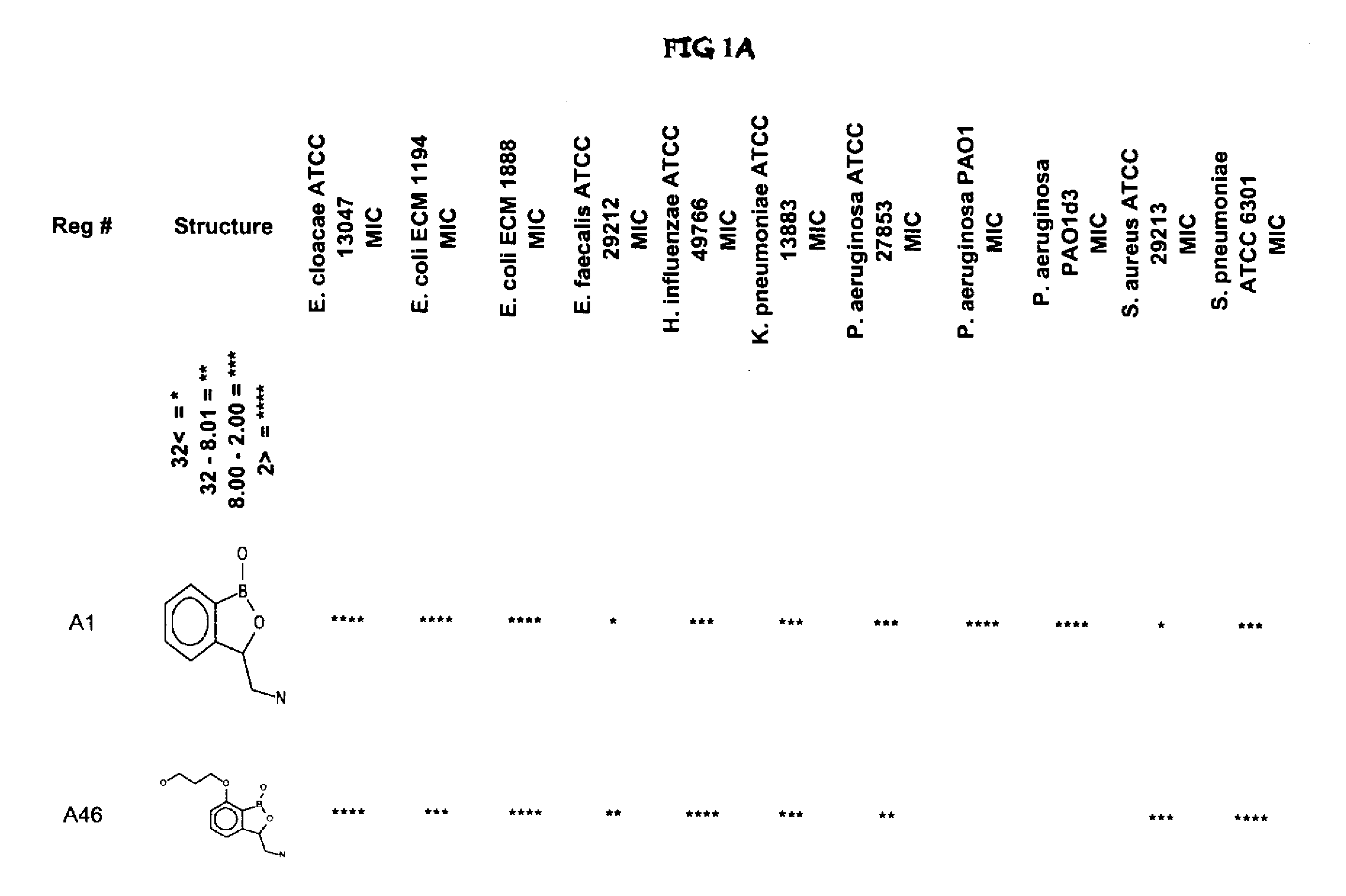

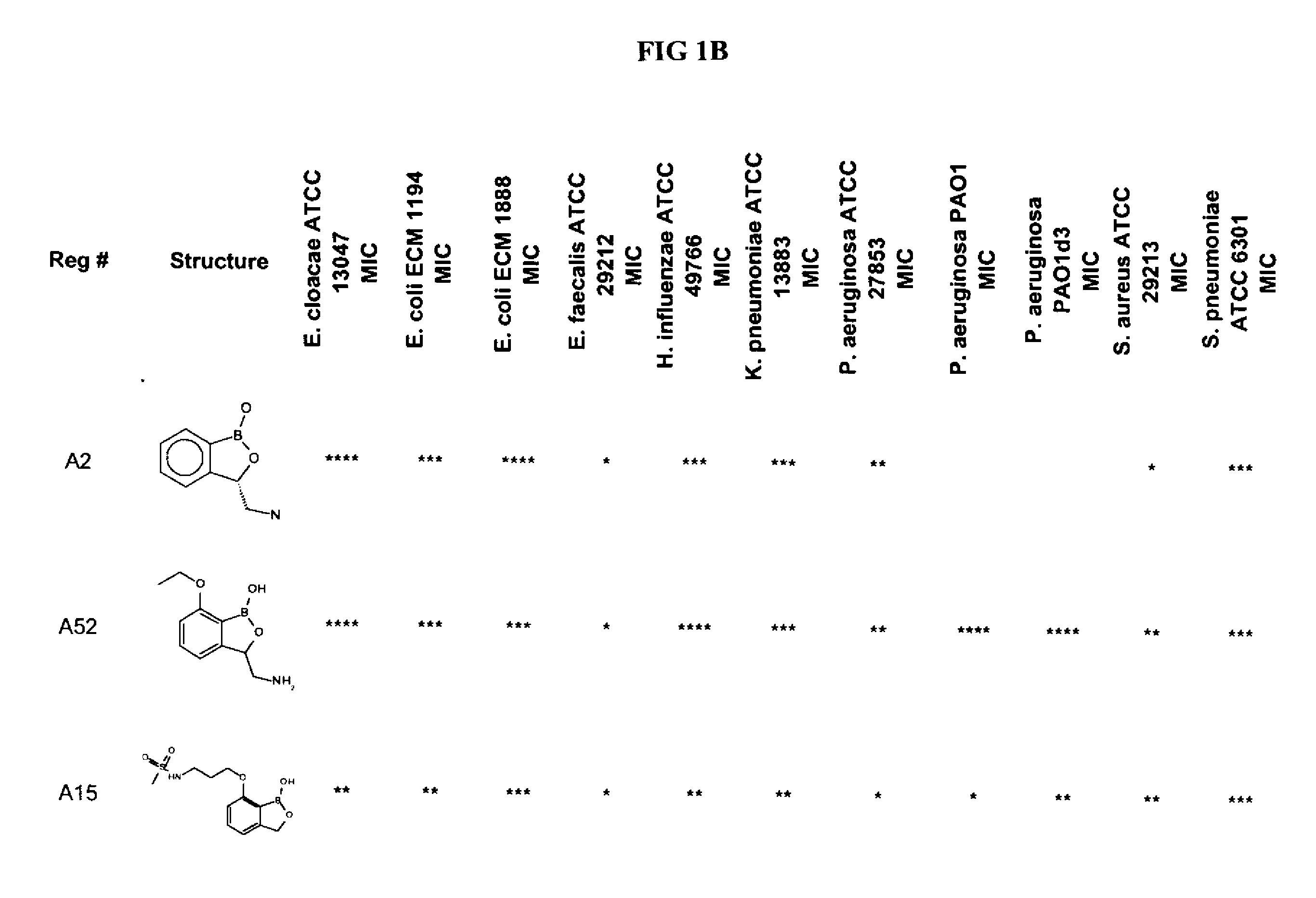

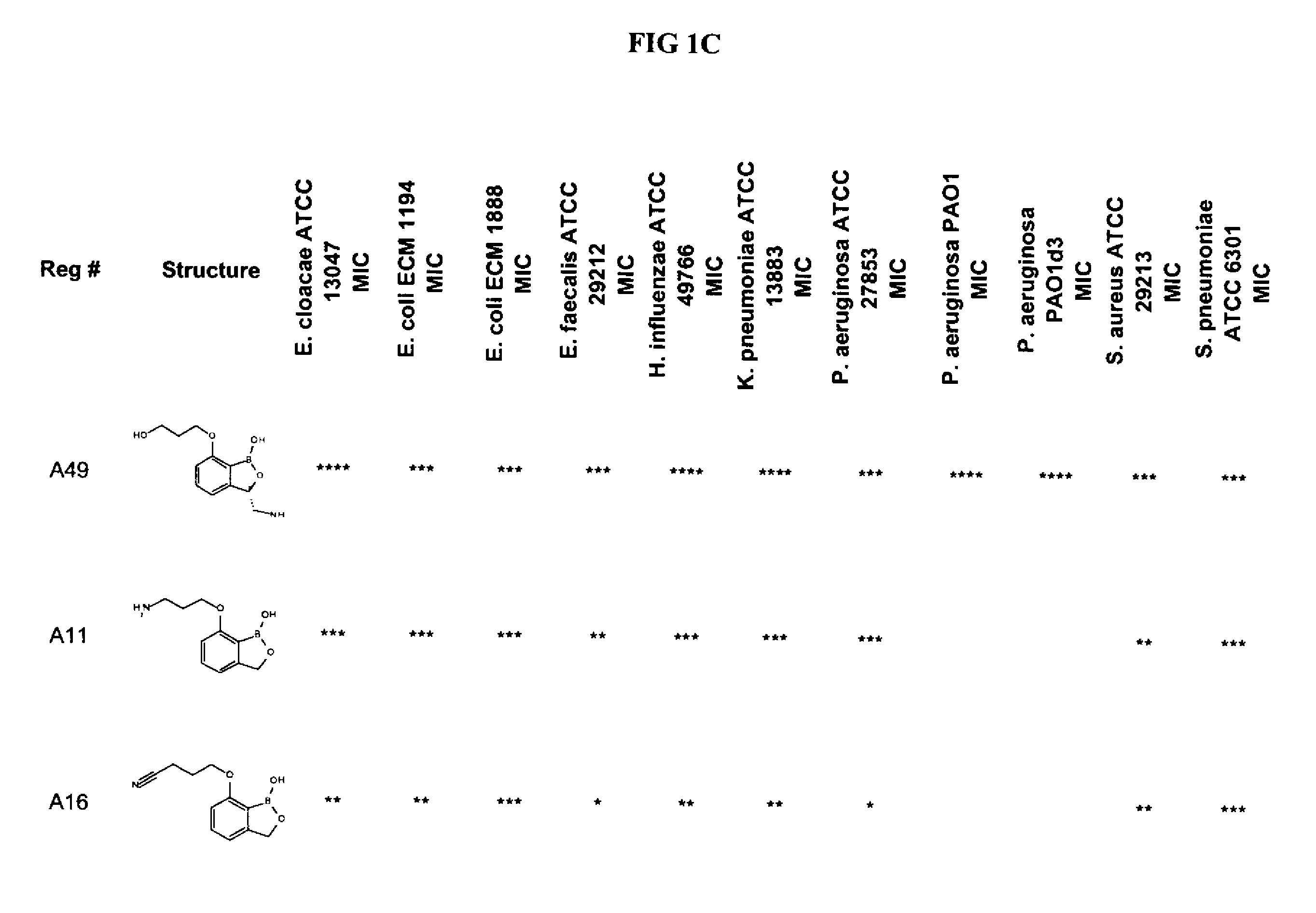

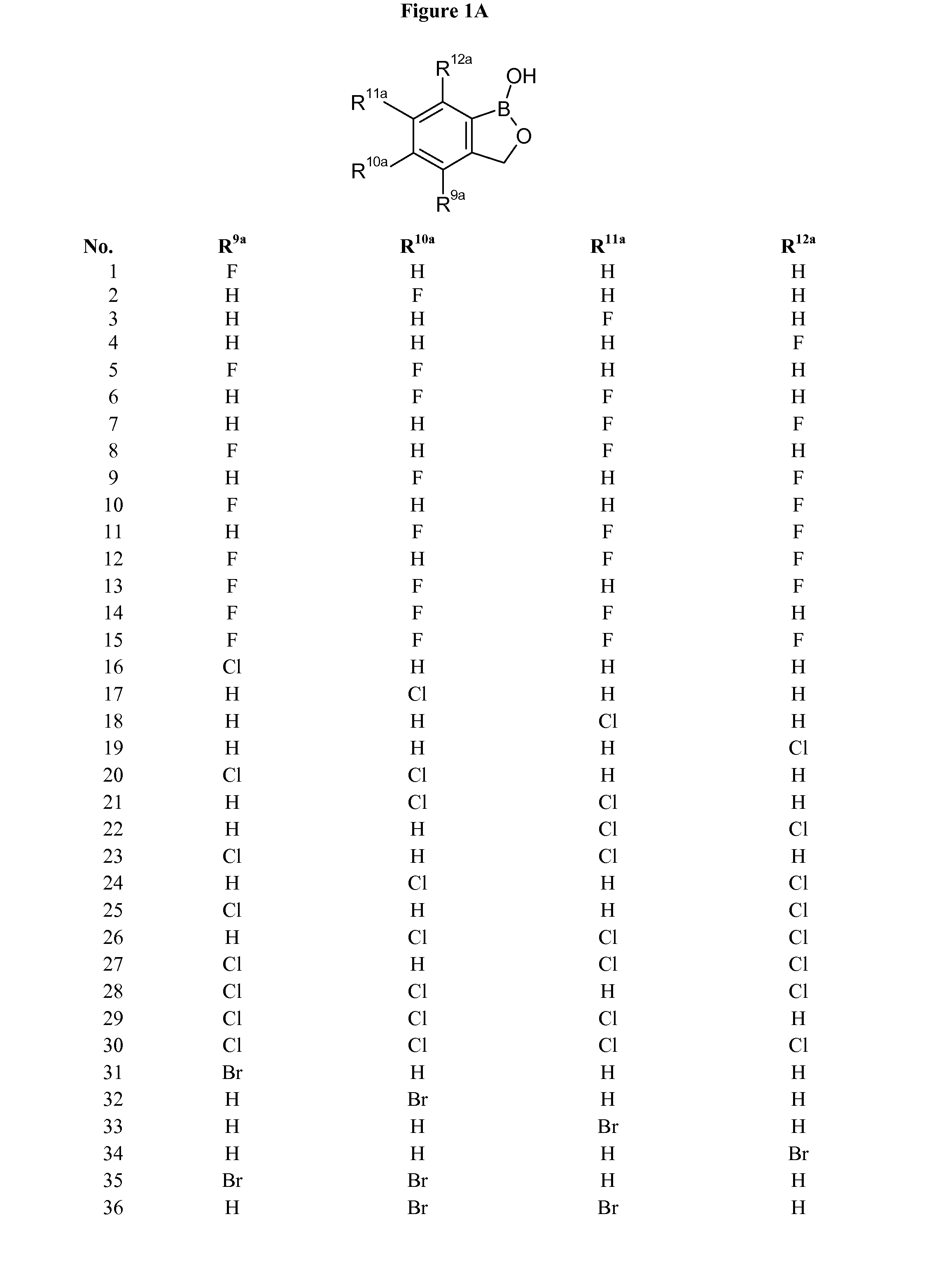

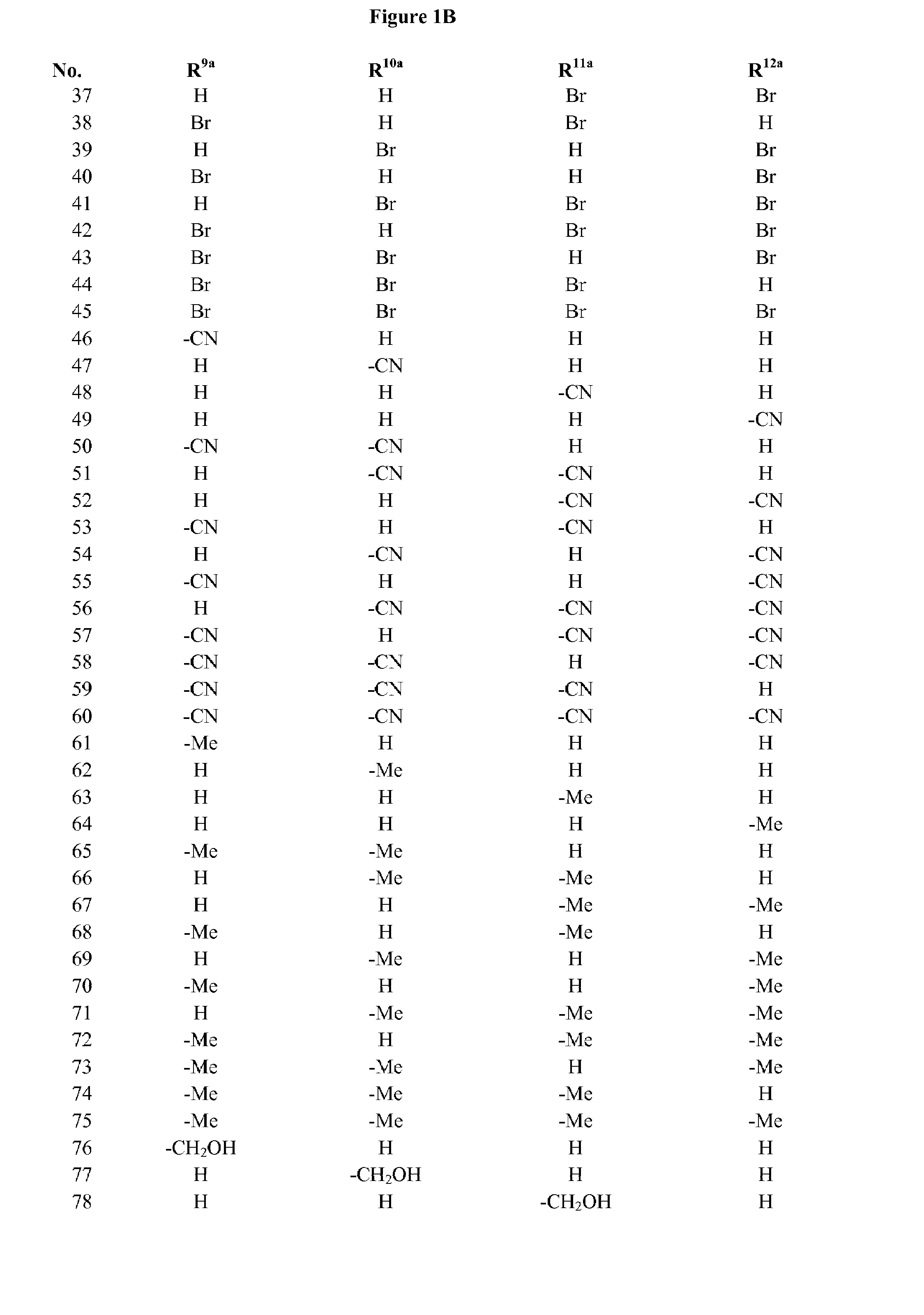

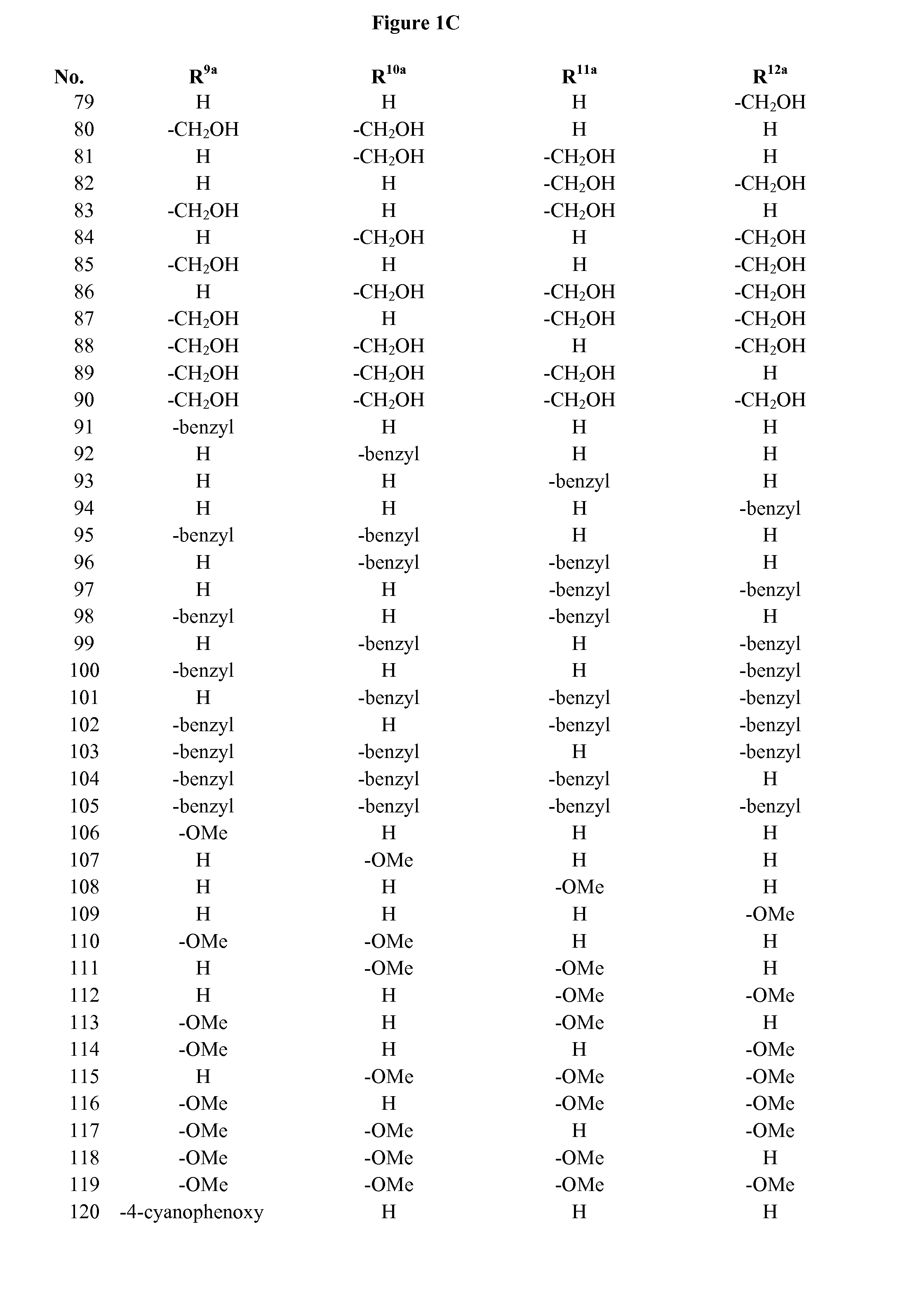

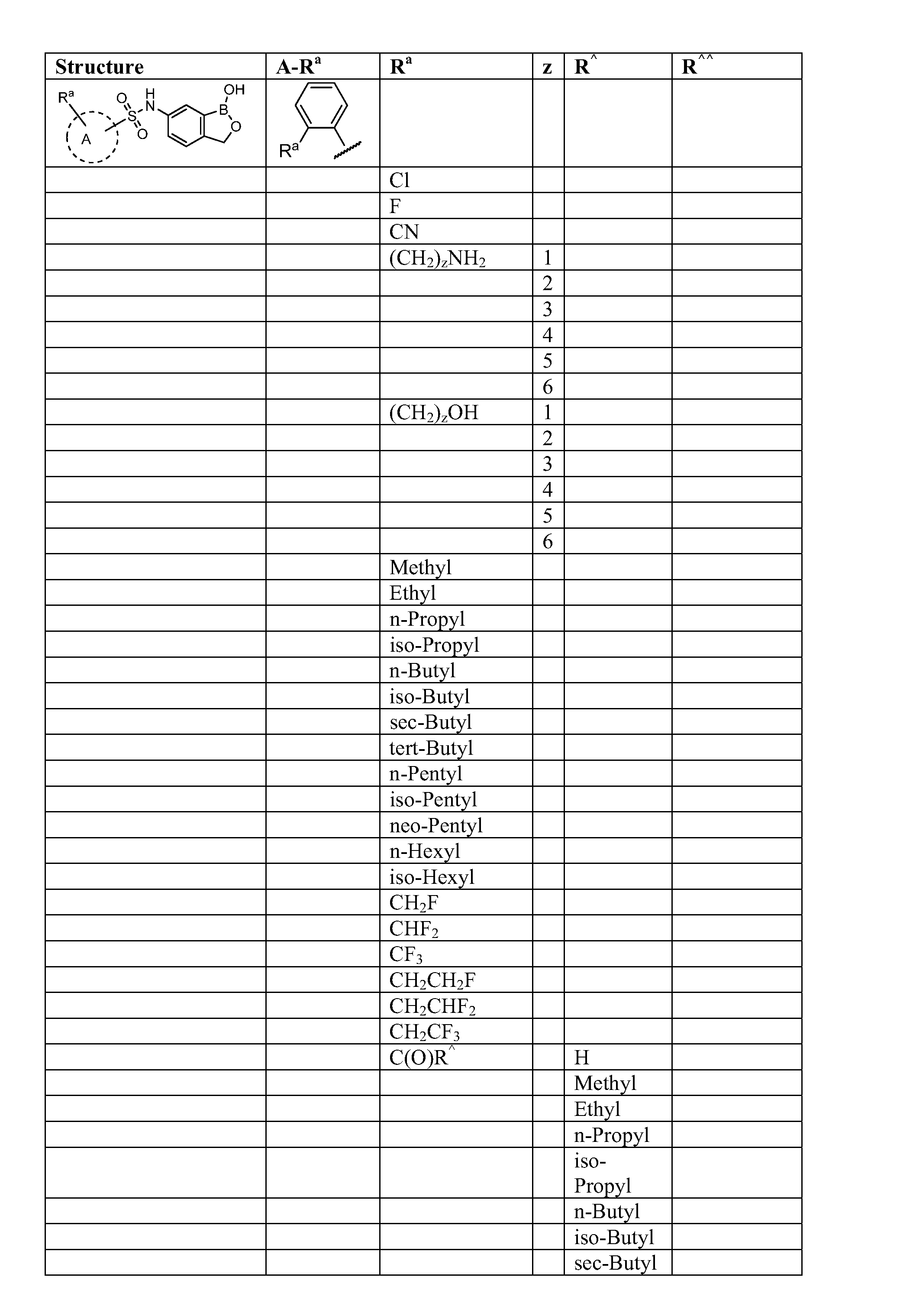

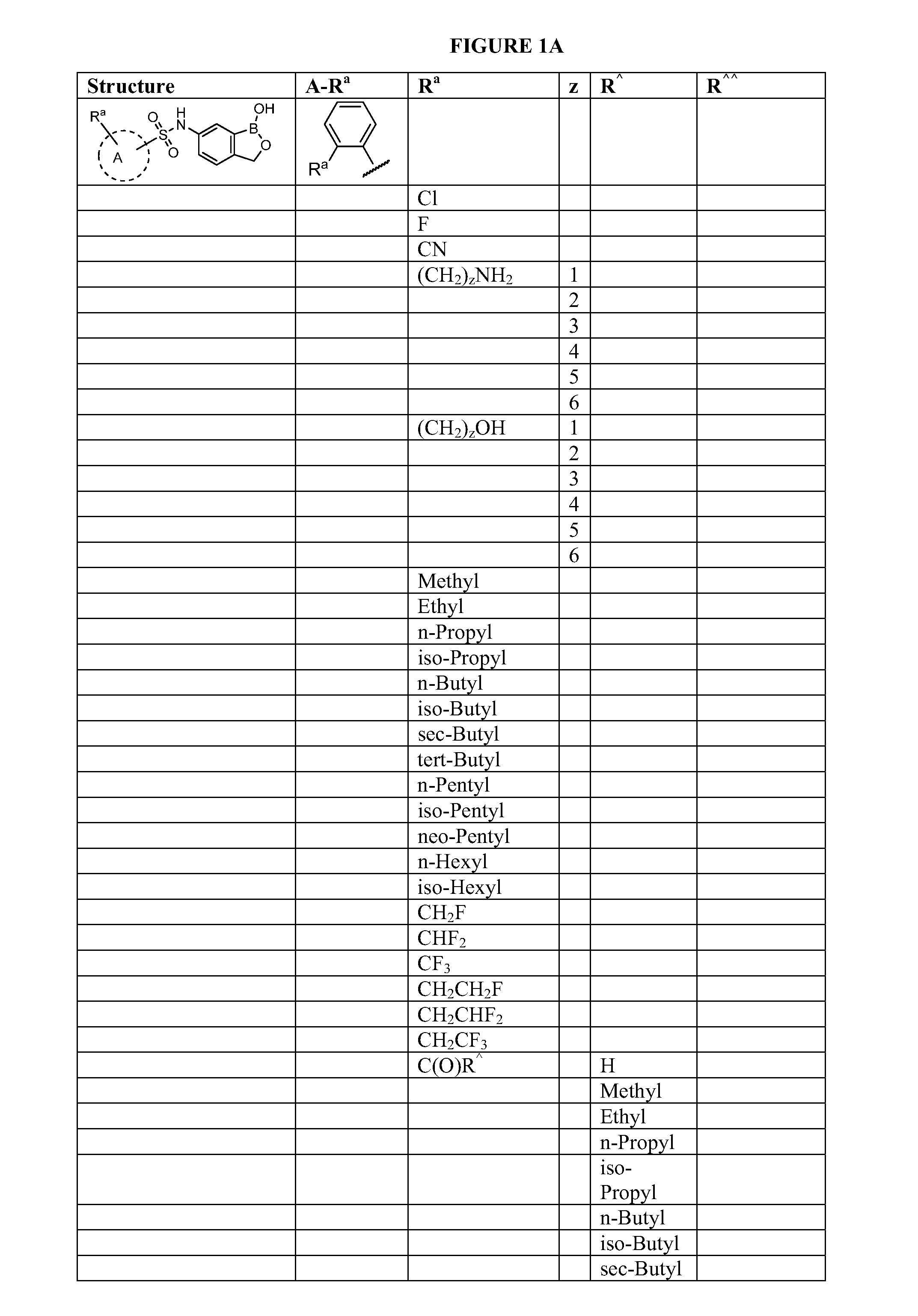

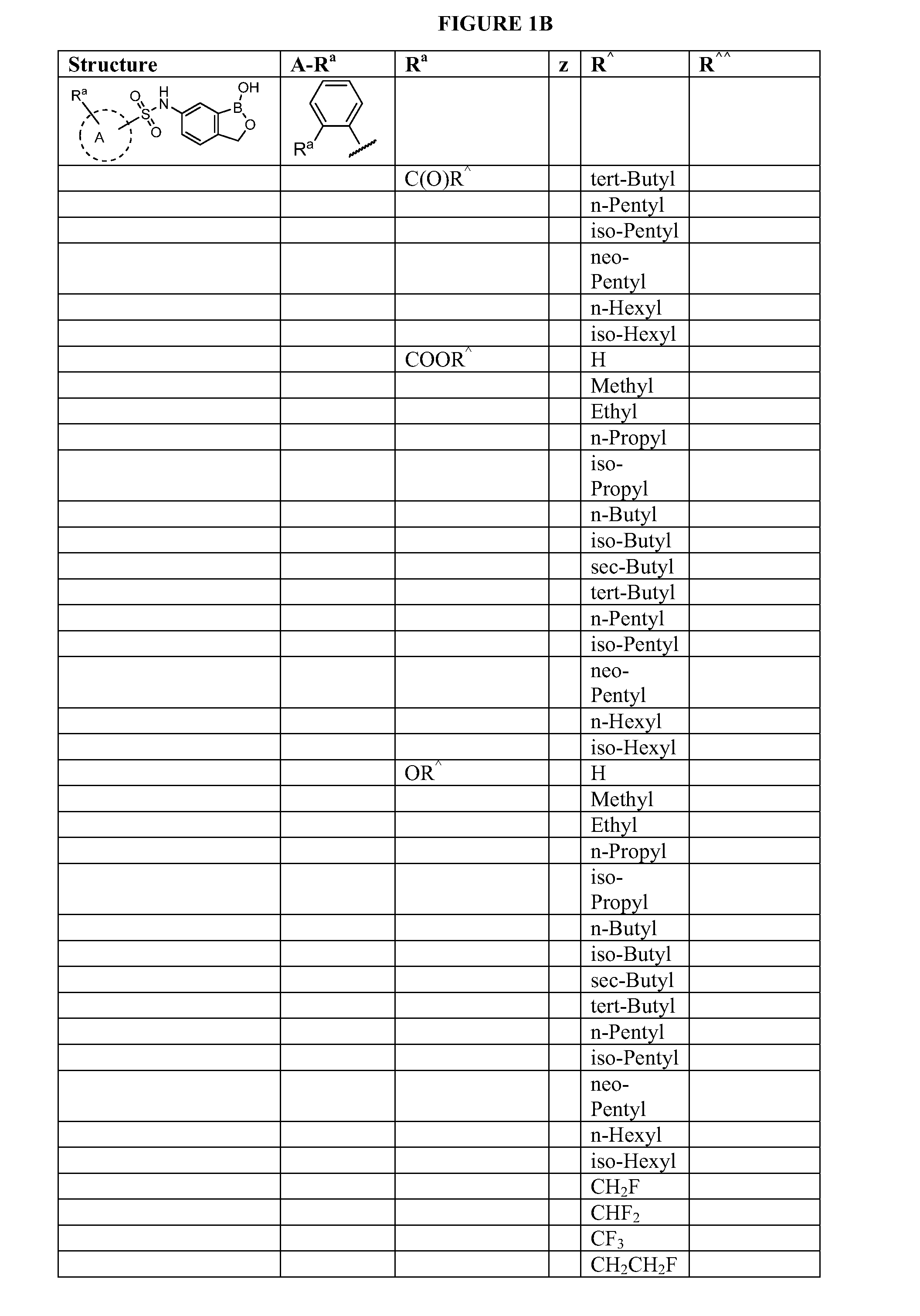

Boron-containing small molecules

Owner:ANACOR PHARMA INC

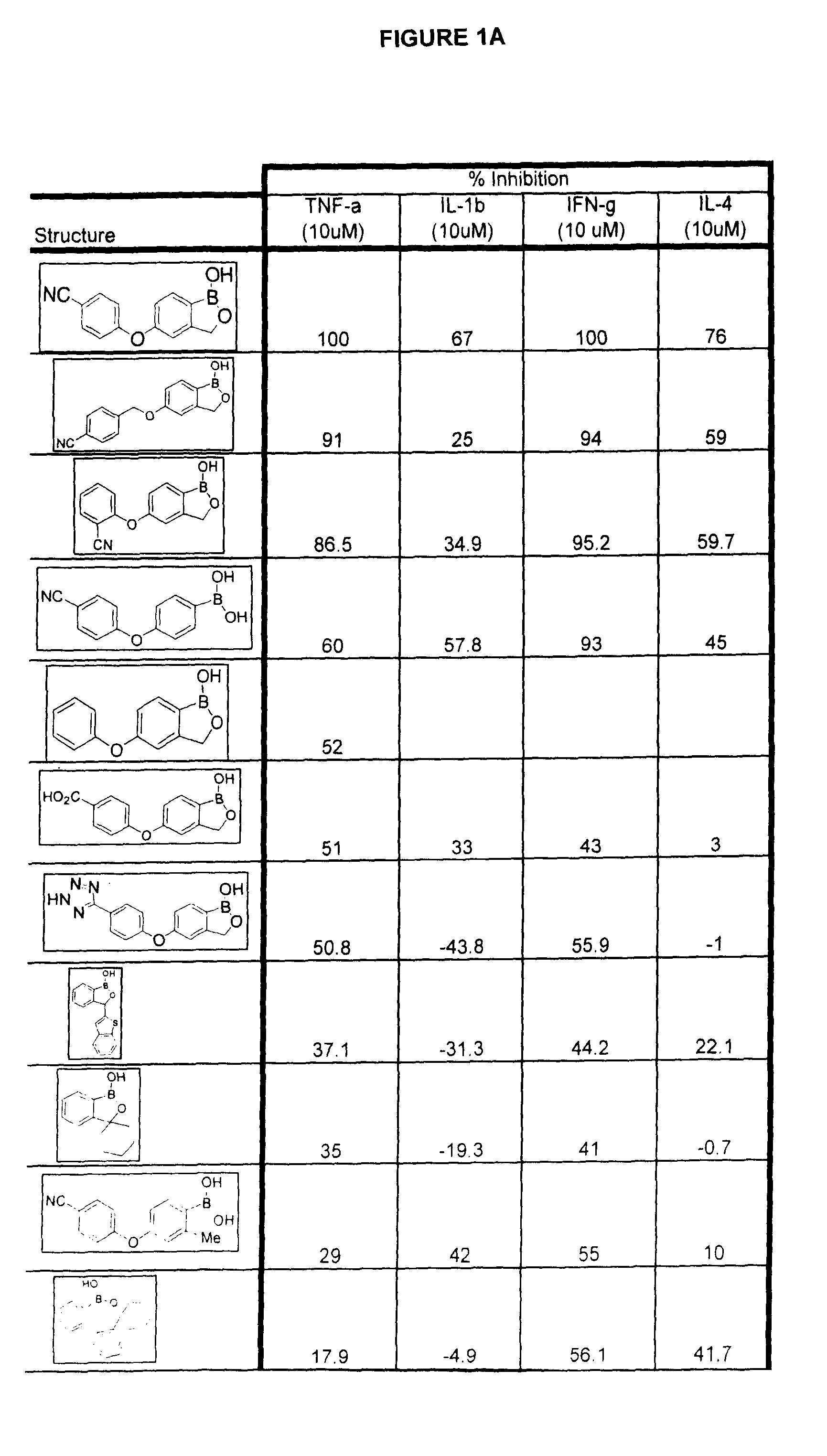

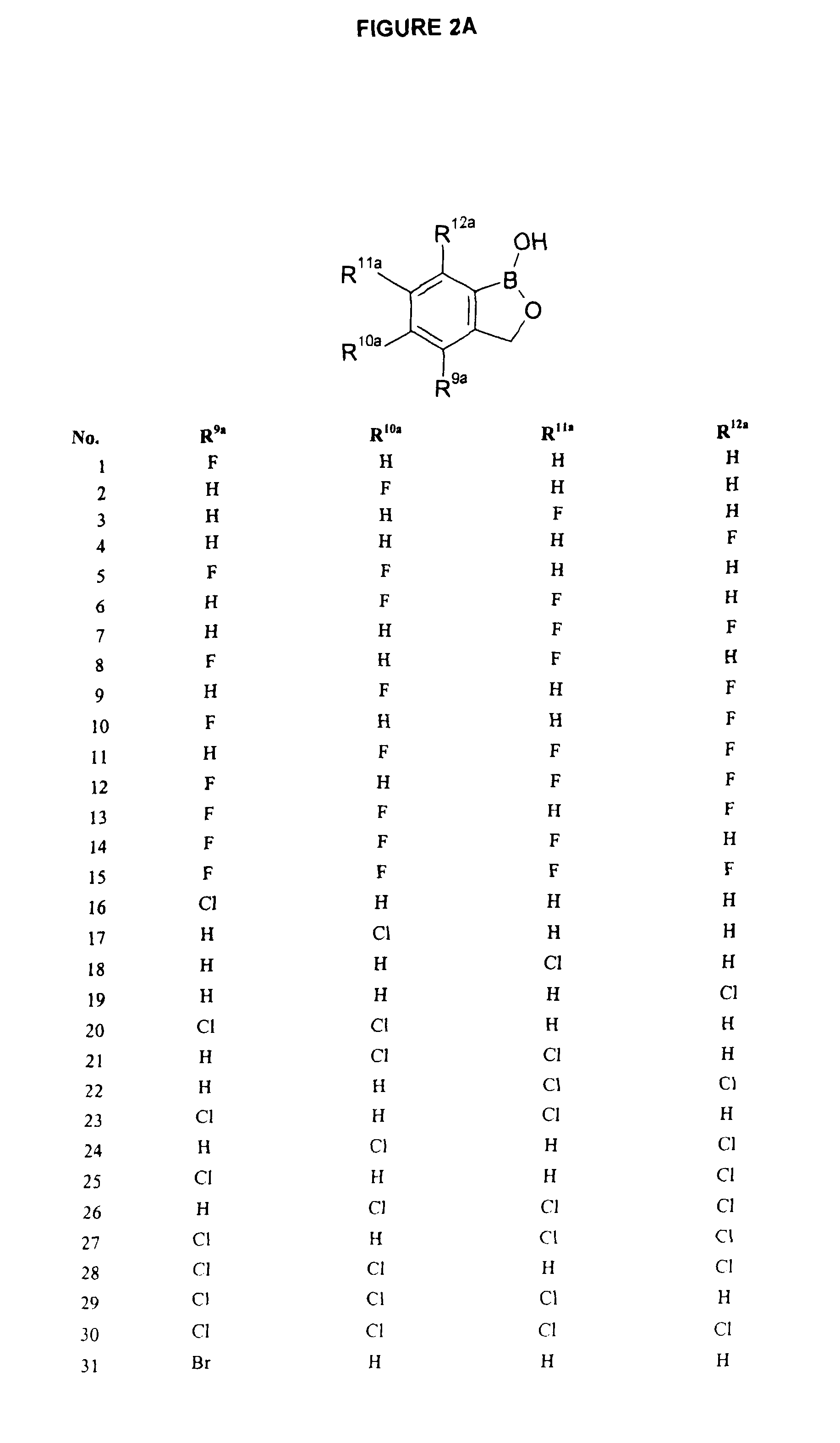

Boron-Containing Small Molecules as Anti-Inflammatory Agents

Owner:ANACOR PHARMA INC

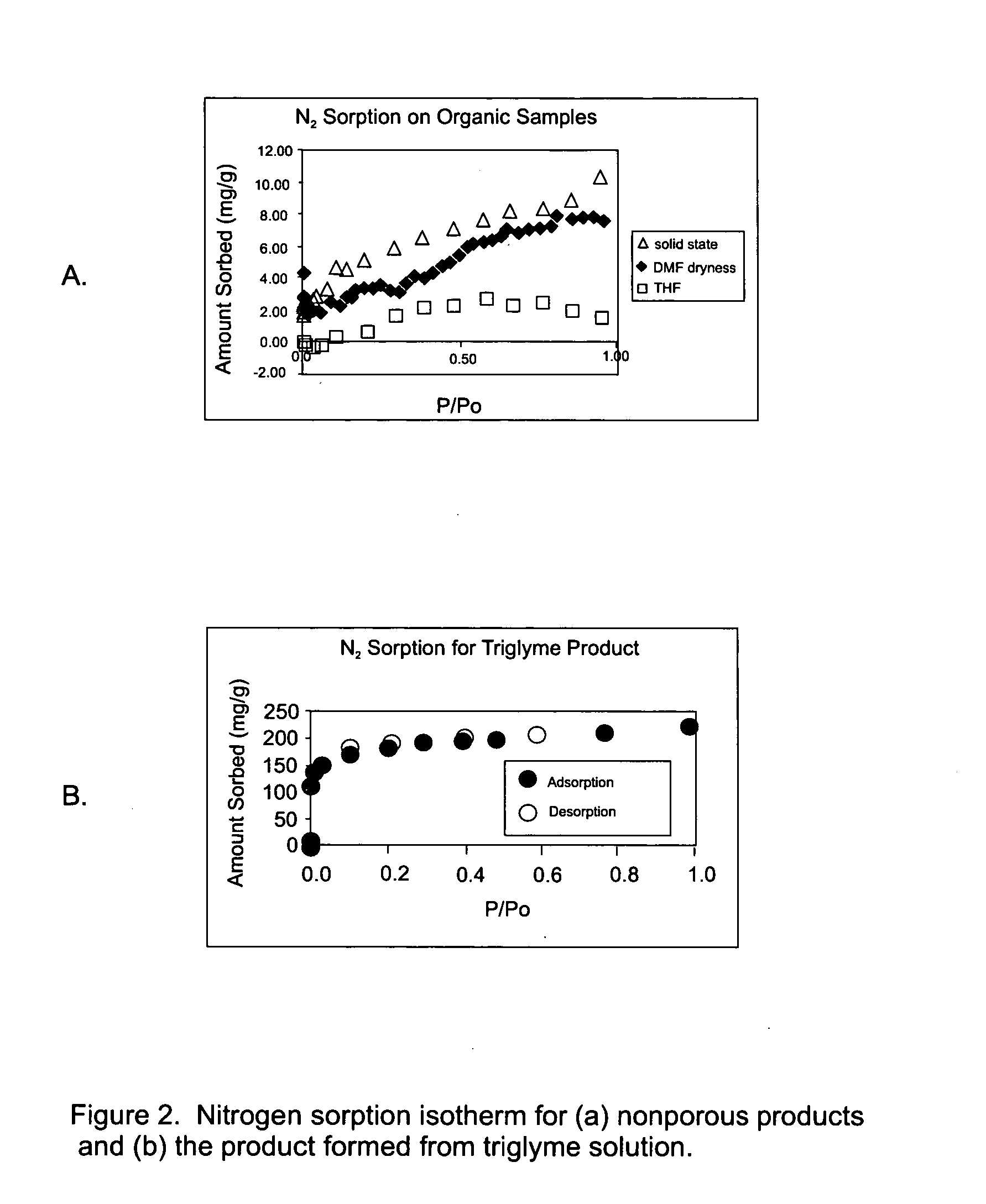

Covalently linked organic frameworks and polyhedra

InactiveUS20060154807A1Silicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsBoron containingLink group

Owner:RGT UNIV OF MICHIGAN

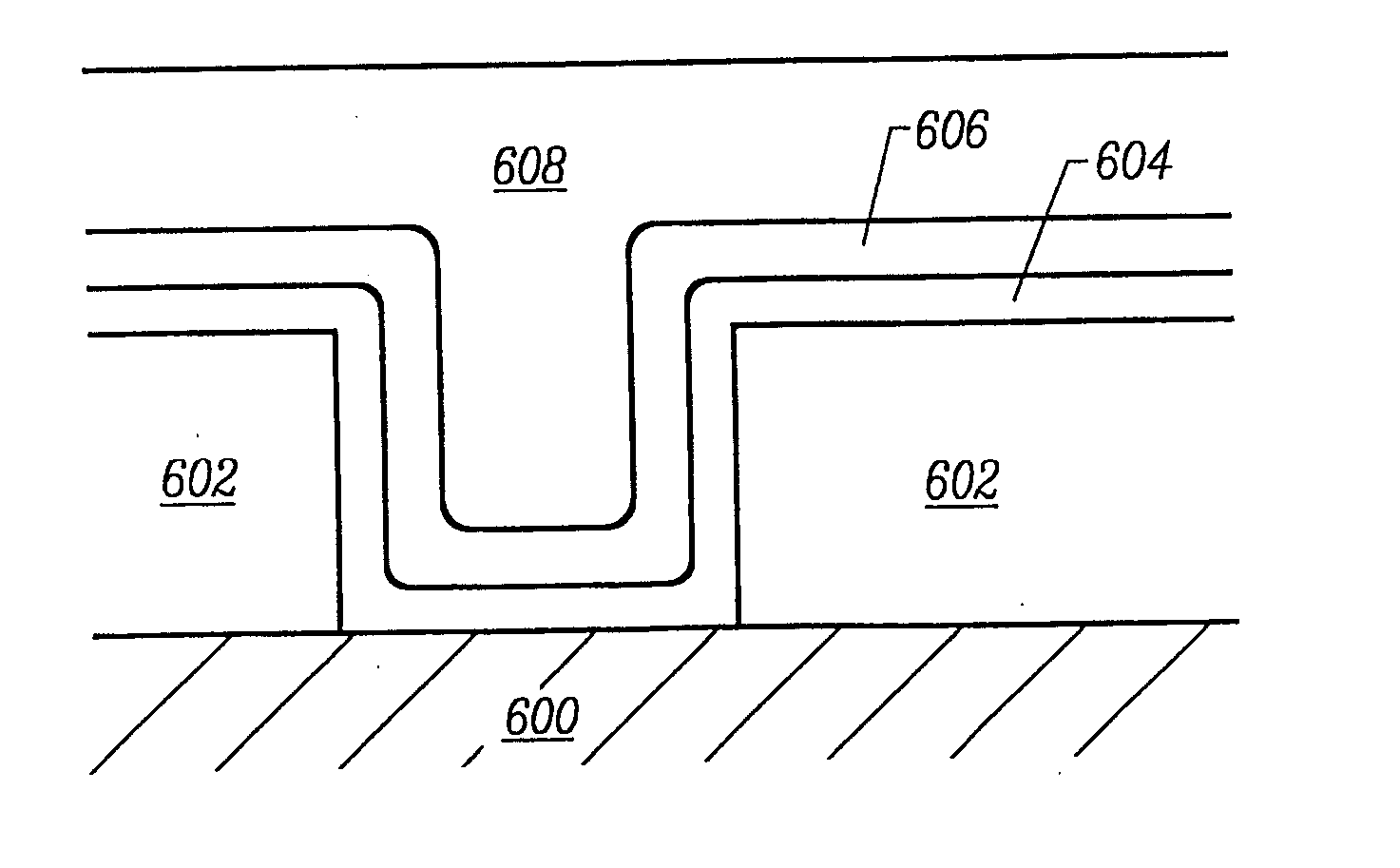

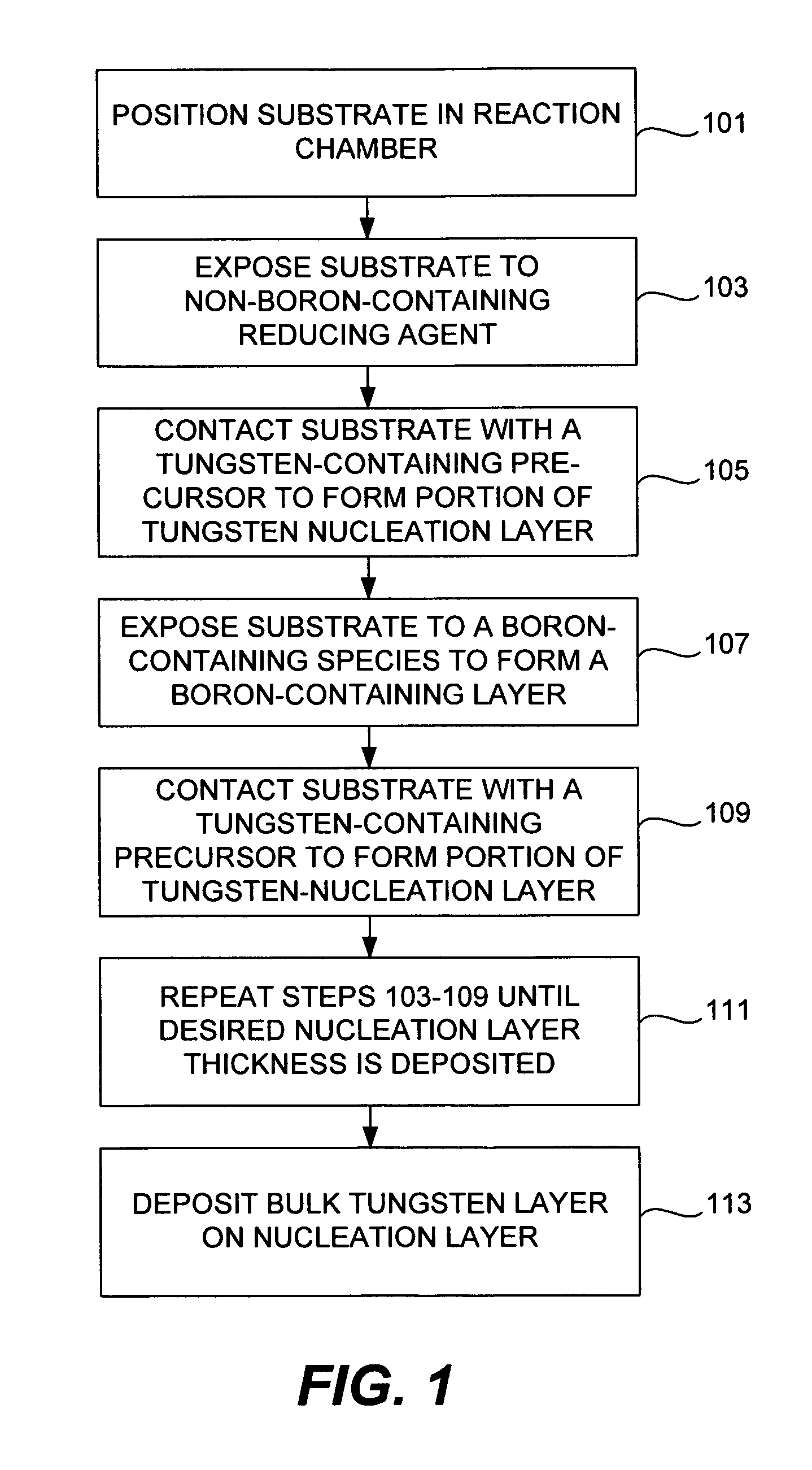

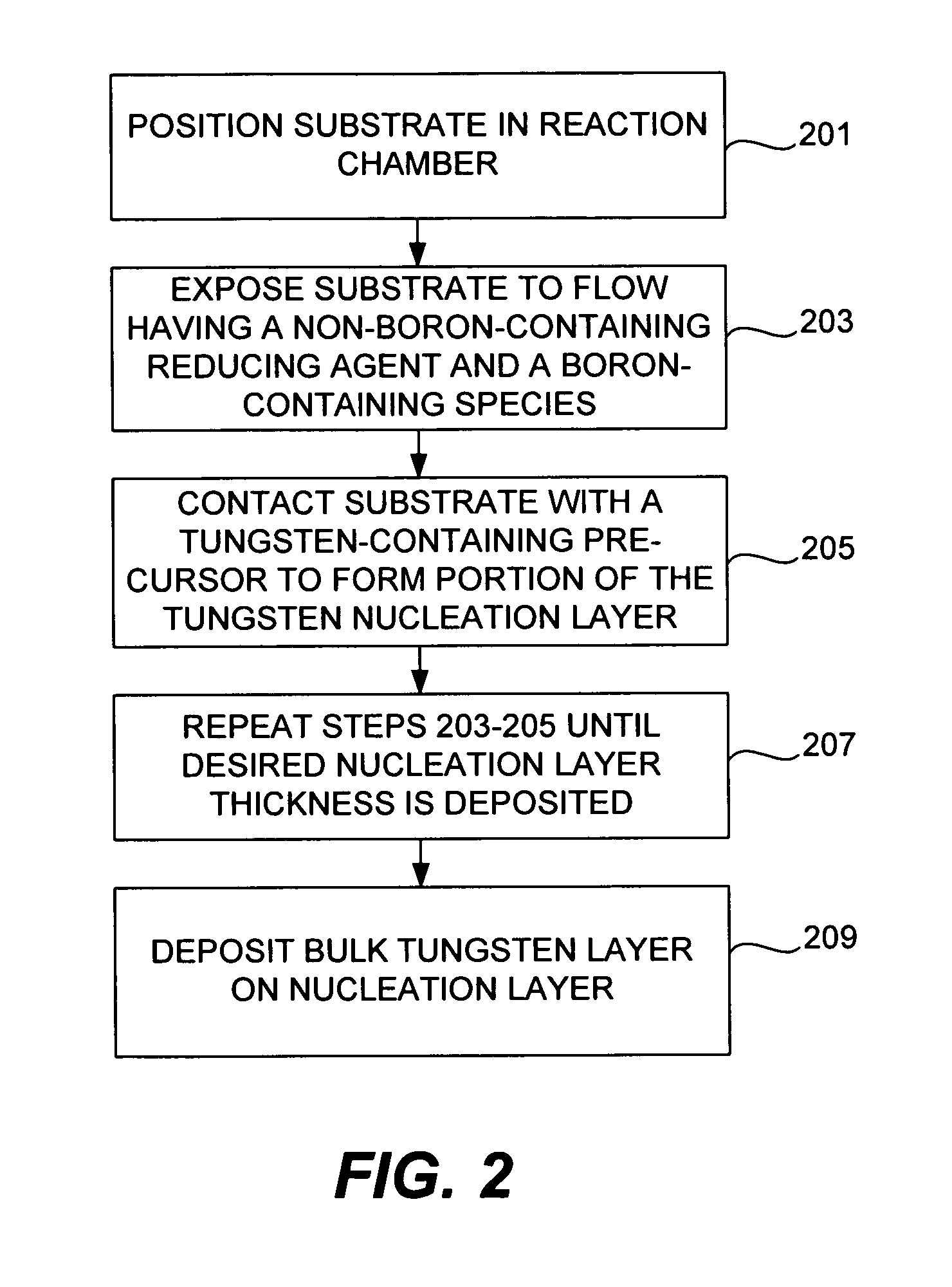

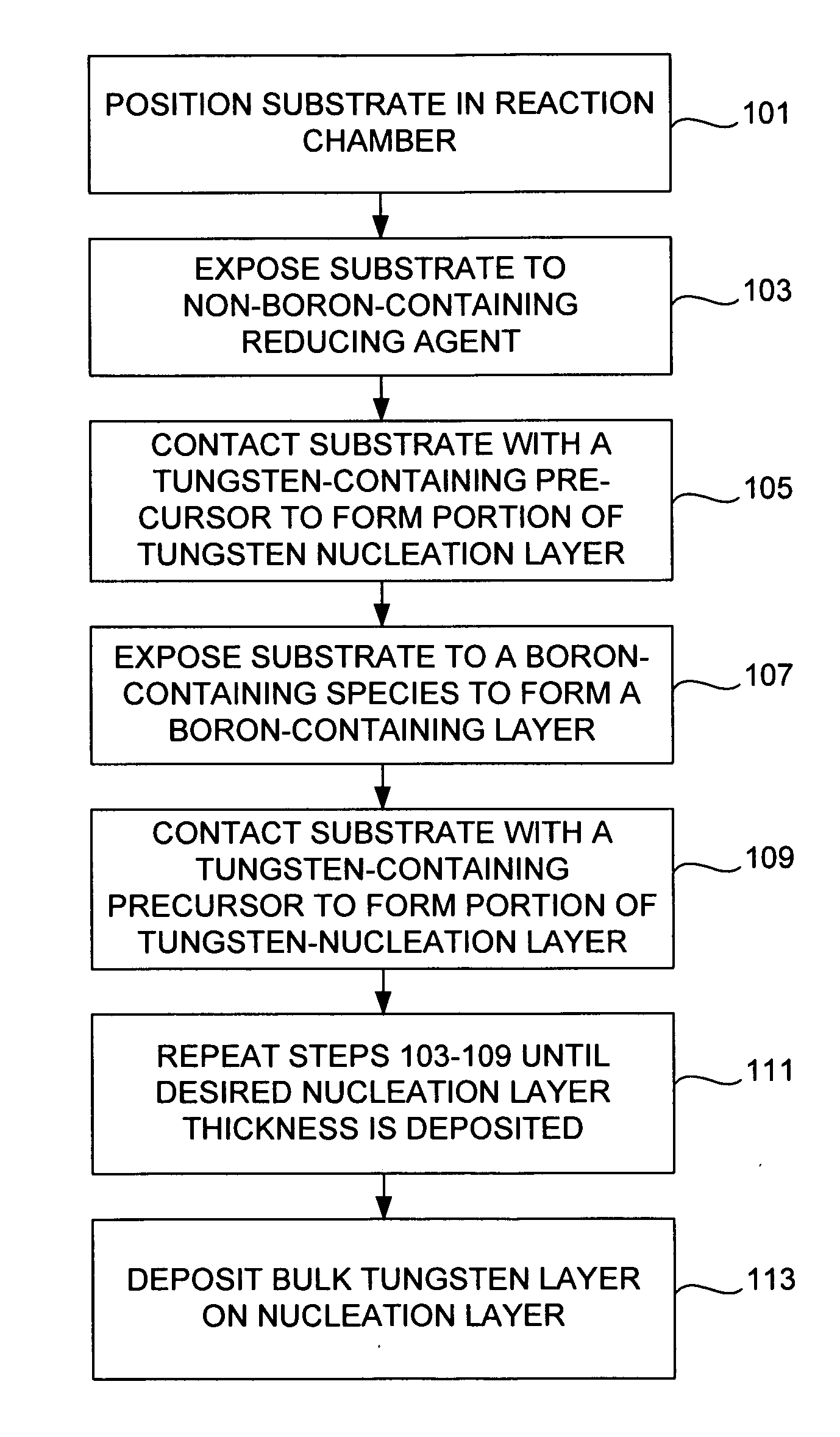

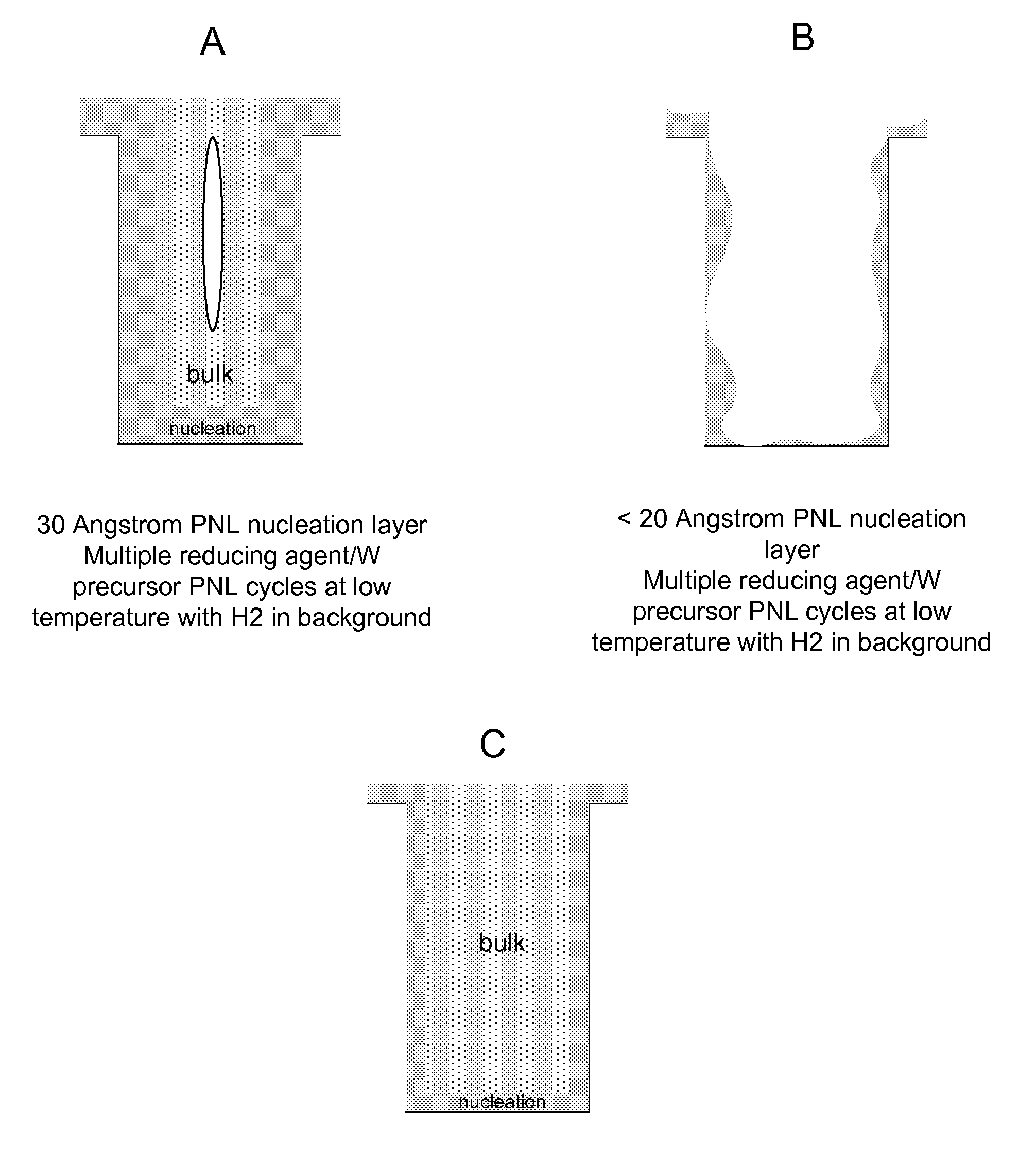

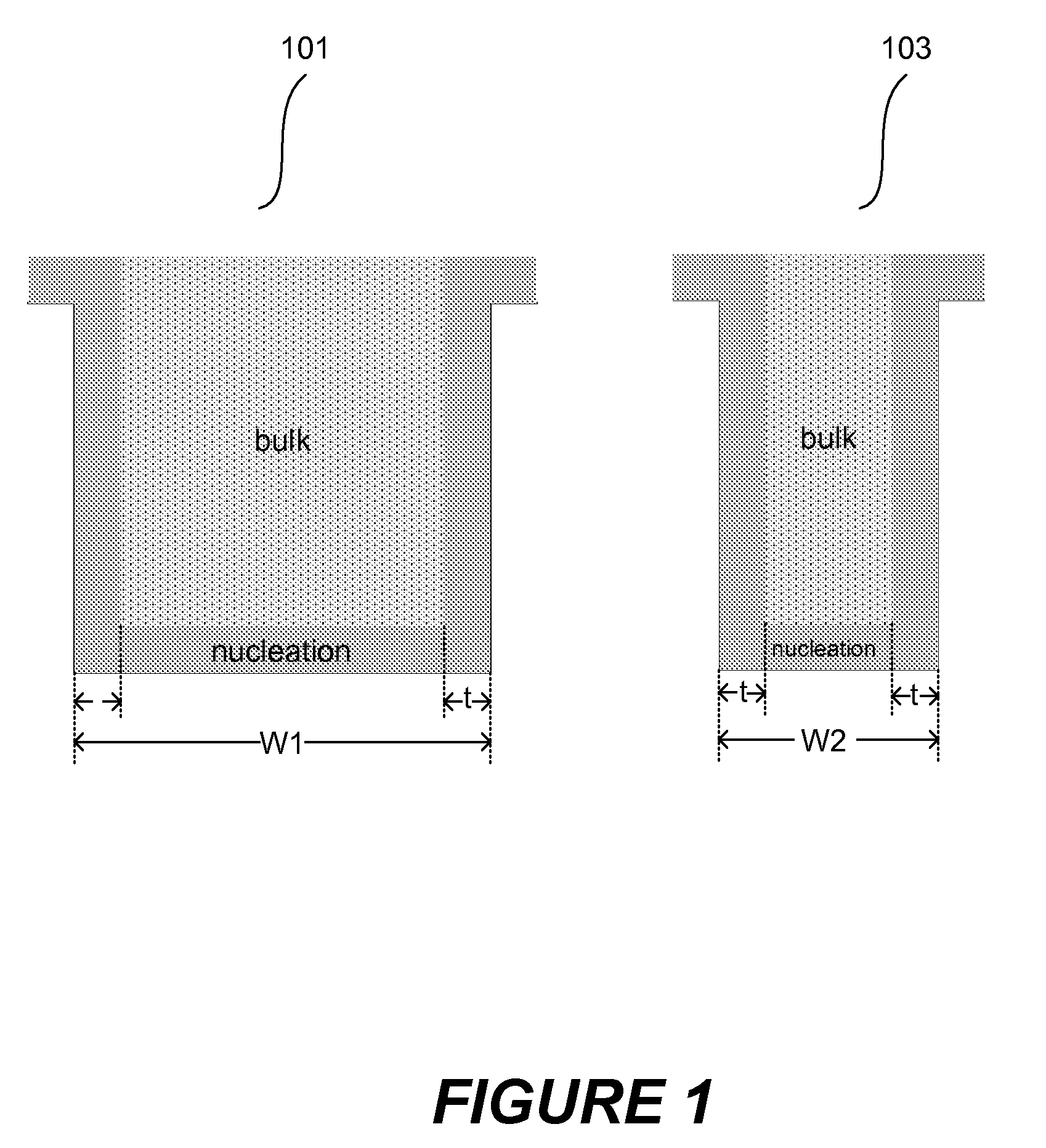

Methods for growing low-resistivity tungsten film

InactiveUS7589017B2Low resistivityGood step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingBoron containingLayer thickness

Improved methods for depositing low resistivity tungsten films are provided. The methods involve depositing a tungsten nucleation layer on a substrate and then depositing a tungsten bulk layer over the tungsten nucleation layer to form the tungsten film. The methods provide precise control of the nucleation layer thickness and improved step coverage. According to various embodiments, the methods involve controlling thickness and / or improving step coverage by exposing the substrate to pulse nucleation layer (PNL) cycles at low temperature. Also in some embodiments, the methods may improve resistivity by using a high temperature PNL cycle of a boron-containing species and a tungsten-containing precursor to finish forming the tungsten nucleation layer.

Owner:NOVELLUS SYSTEMS

Boron-containing small molecules

InactiveUS20100256092A1Prevent bacterial growthInhibiting β-lactamaseAntibacterial agentsBiocideBoron containingSmall molecule

Owner:ANACOR PHARMA INC +1

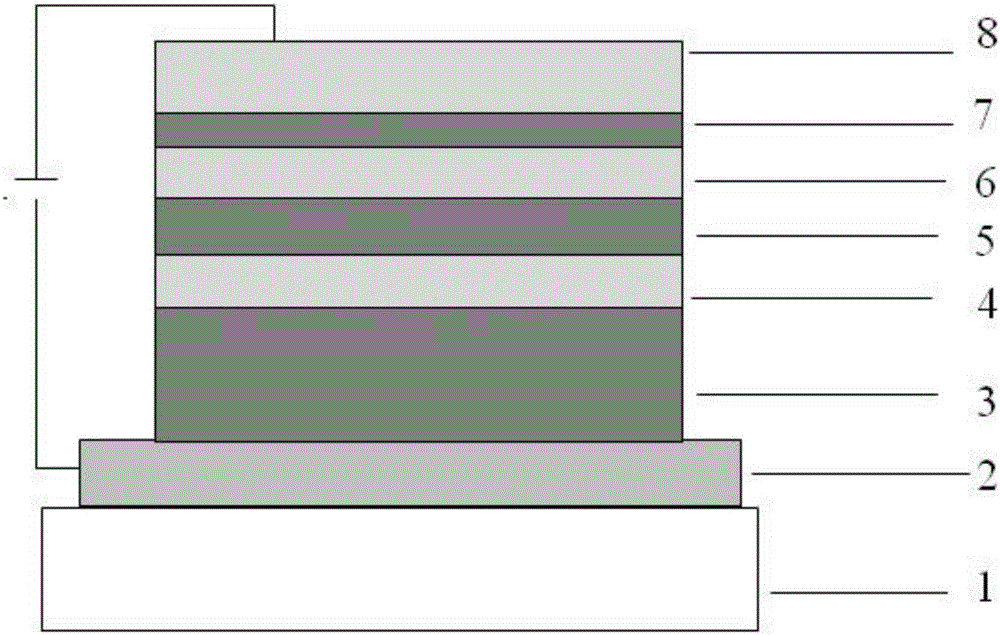

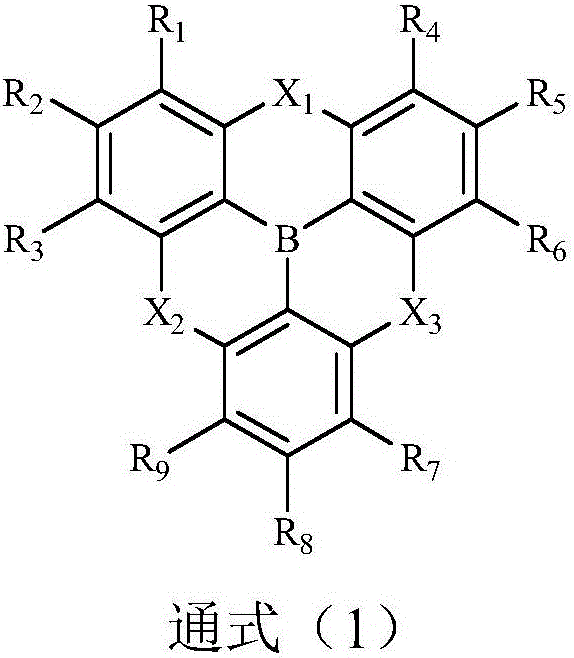

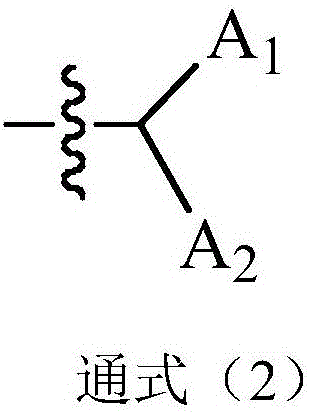

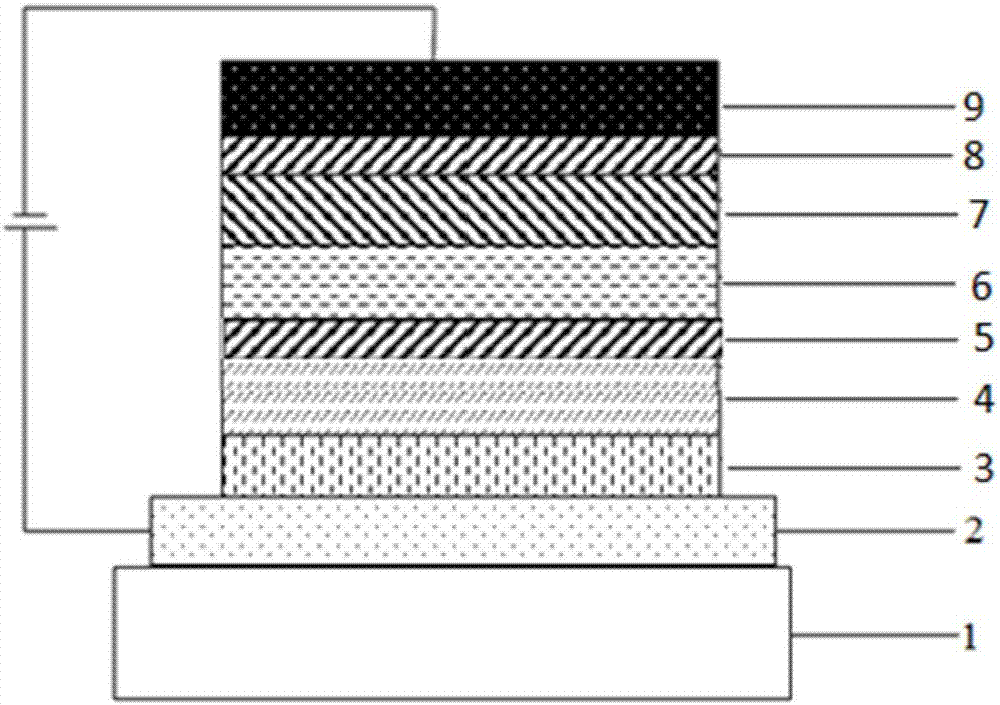

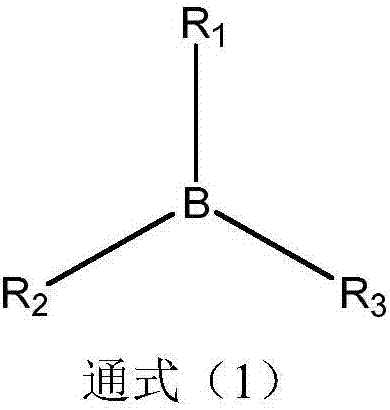

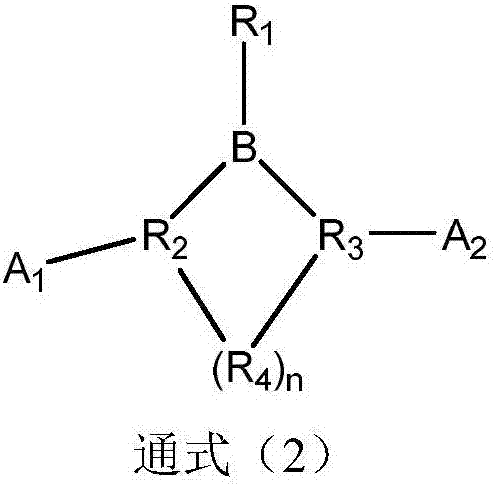

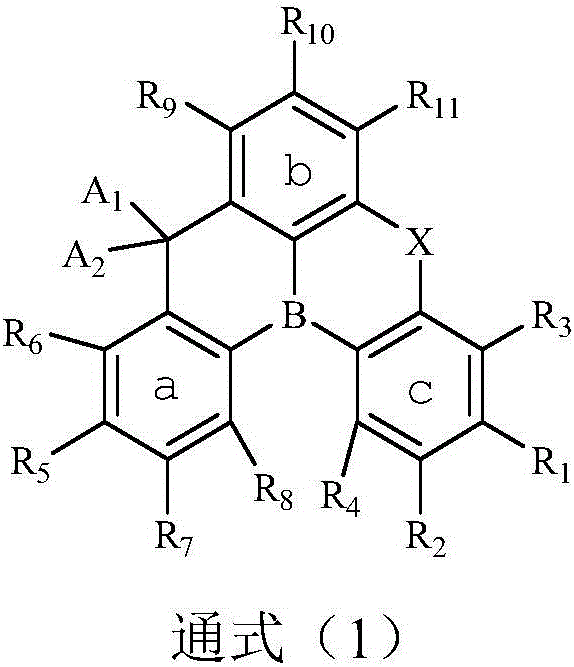

Boron-containing organic electroluminescent compound and application to OLED device

ActiveCN106467553AImprove applicabilityImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceStructural formula

The invention discloses a boron-containing efficient organic electroluminescent compound and application of the compound to an OLED device. The structural formula of the compound is as shown in the general formula (1). Boron atom as the core extends outward three six-membered rings composed of carbon-carbon single bonds, wherein the carbon-carbon single bonds also can be replaced with carbon-oxygen and carbon-nitrogen bonds; a benzene ring is sandwiched between each two six-membered rings; and each phenyl ring is respectively externally connected to hydrogen, aryl group, heteroaryl group, alkyl group, alkyloxy group, or arylamine group. The material has good fluorescence quantum efficiency and electroluminescent efficiency, is easy to form an amorphous film, and has good heat stability. Thus, the material can be used as a luminescent layer material in an organic electroluminescent device.

Owner:JIANGSU SUNERA TECH CO LTD

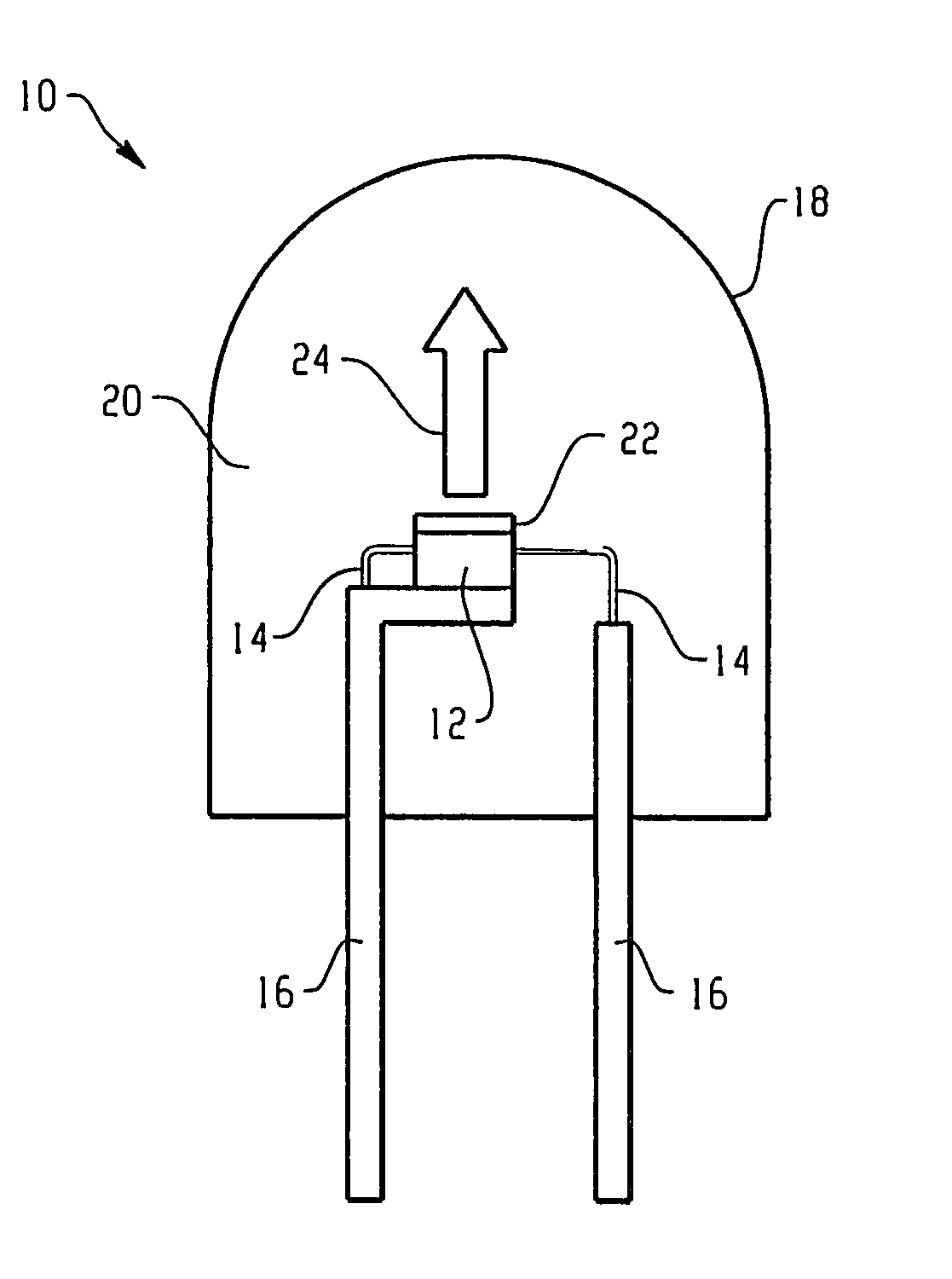

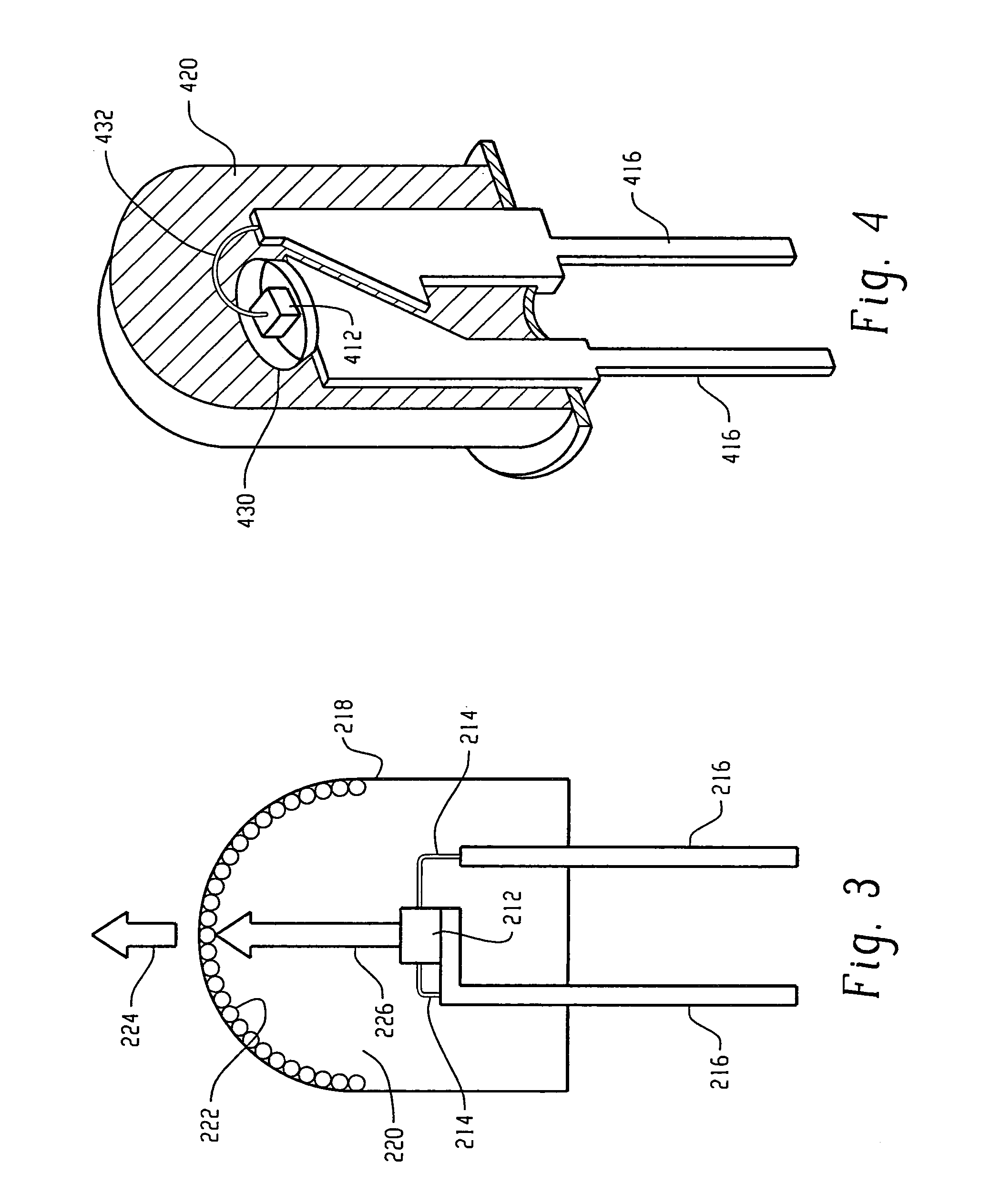

Borate phosphor materials for use in lighting applications

Boron containing phosphor compositions having the formulas (1) M3Ln2(BO3)4 doped with at least one activator selected from the group of Eu2+, Mn2+, Pb2+, Ce3+, Eu3+, Tb3+, and Bi3+ where M is at least one of Mg, Ca, Sr, Ba, or Zn, and Ln is at least one of Sc, Y, La, Gd, or Lu; (2) M2−xM′x(Al, Ga)2−y(Si, Ge)yB2O7−zNz:Eu2+, Mn2+, Pb2+ where M′ is one or more of alkali metals Na and / or K, M″ is one or more of alkaline earth Mg, Ca, Sr, Ba or Zn, 0≦x≦2, 0≦y≦2, 0≦z≦4; and z=x+y; (3) M′2−x+y′M″x−y′(Al, Ga)2−y(Si, Ge)yB2O7−z−y′NzXy:Eu2+, Mn2+, Pb2+, where M′ is one or more of alkali metals Na and / or K, M″ is one or more of alkaline earth metals Mg, Ca, Sr, Ba and / or Zn, 0≦x≦2, 0≦y≦2, 0≦z≦4; z=x+y, X═F and / or Cl, and 0≦y′≦2; (4) M′2−xM″xAl2−y+y′Siy−y′B2O7−z−y′NzXy:Eu2+, Mn2+, Pb2+, where M′ and M″ are defined above, 0≦x≦2, 0≦y≦2, 0≦z≦4; z=x+y, X═F and / or Cl, and 0≦y′≦2; (5) M′2−x+x′M″x−x″Al2−y+y′Siy−y′B2O7−z−x′−y′NzX(x′+y′):Eu2+, Mn2+, Pb2+, where M′ and M″ are defined above, 0≦x≦2, 0≦y≦2, 0≦z≦4; z=x+y, X═F and / or Cl, and 0≦y′≦2; (6) MAl2B2O7:Eu2+, Mn2+, Pb2+; where M═Mg, Ca, Sr, Ba or Zn; (7) MAl2−xSixB2O7−xNx:Eu2+, Mn2+, Pb2+, where M═Mg, Ca, Sr, Ba and / or Zn, and 0≦x≦2; and (8) MAl2B2−xSixO7−xNx:Eu2+, Mn2+, Pb2+, where M═Mg, Ca, Sr, Ba and / or Zn, and 0≦x≦2. Also disclosed are light emitting devices including a light source and at least one of the above phosphor compositions.

Owner:GELCORE LLC (US)

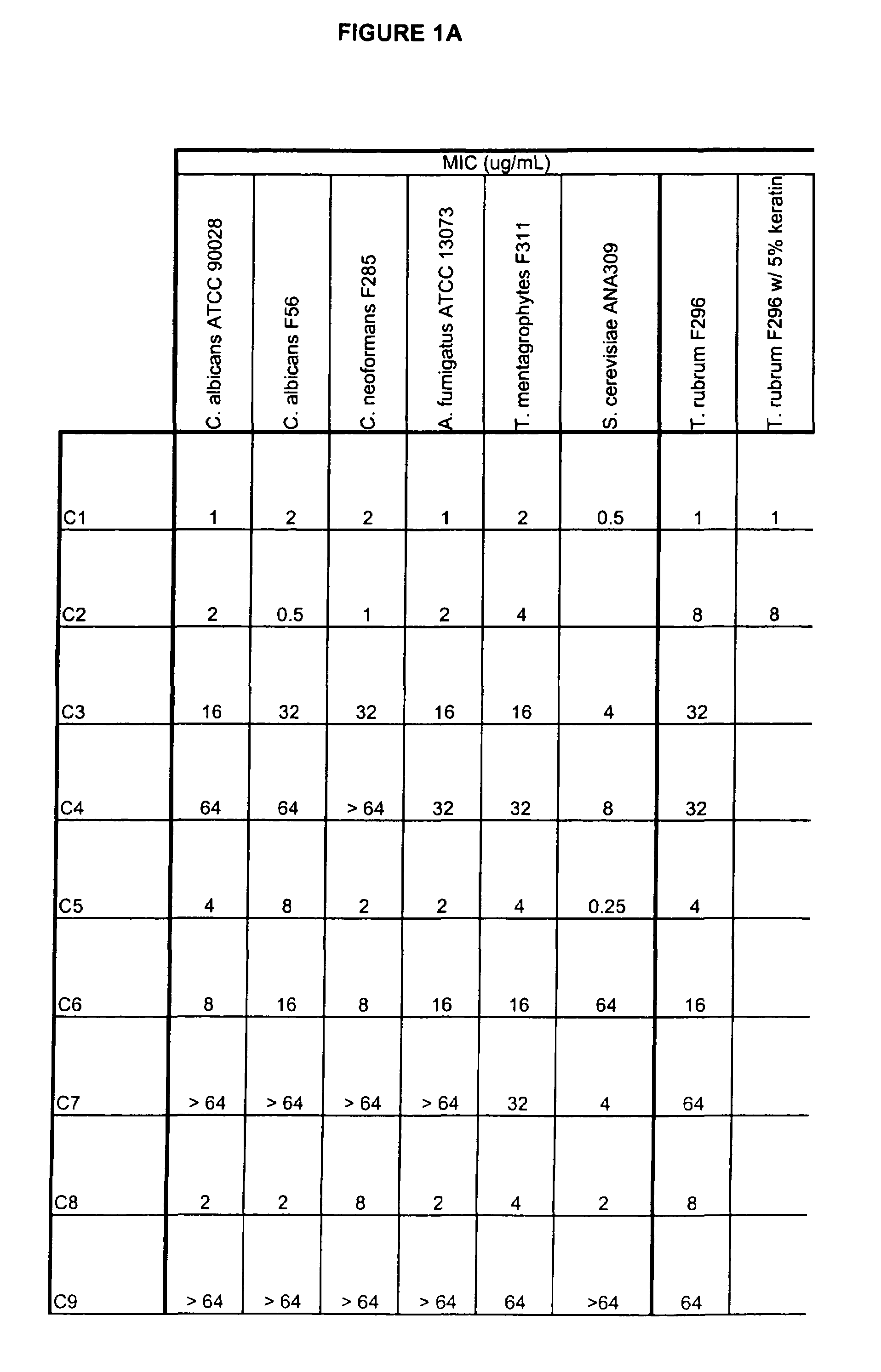

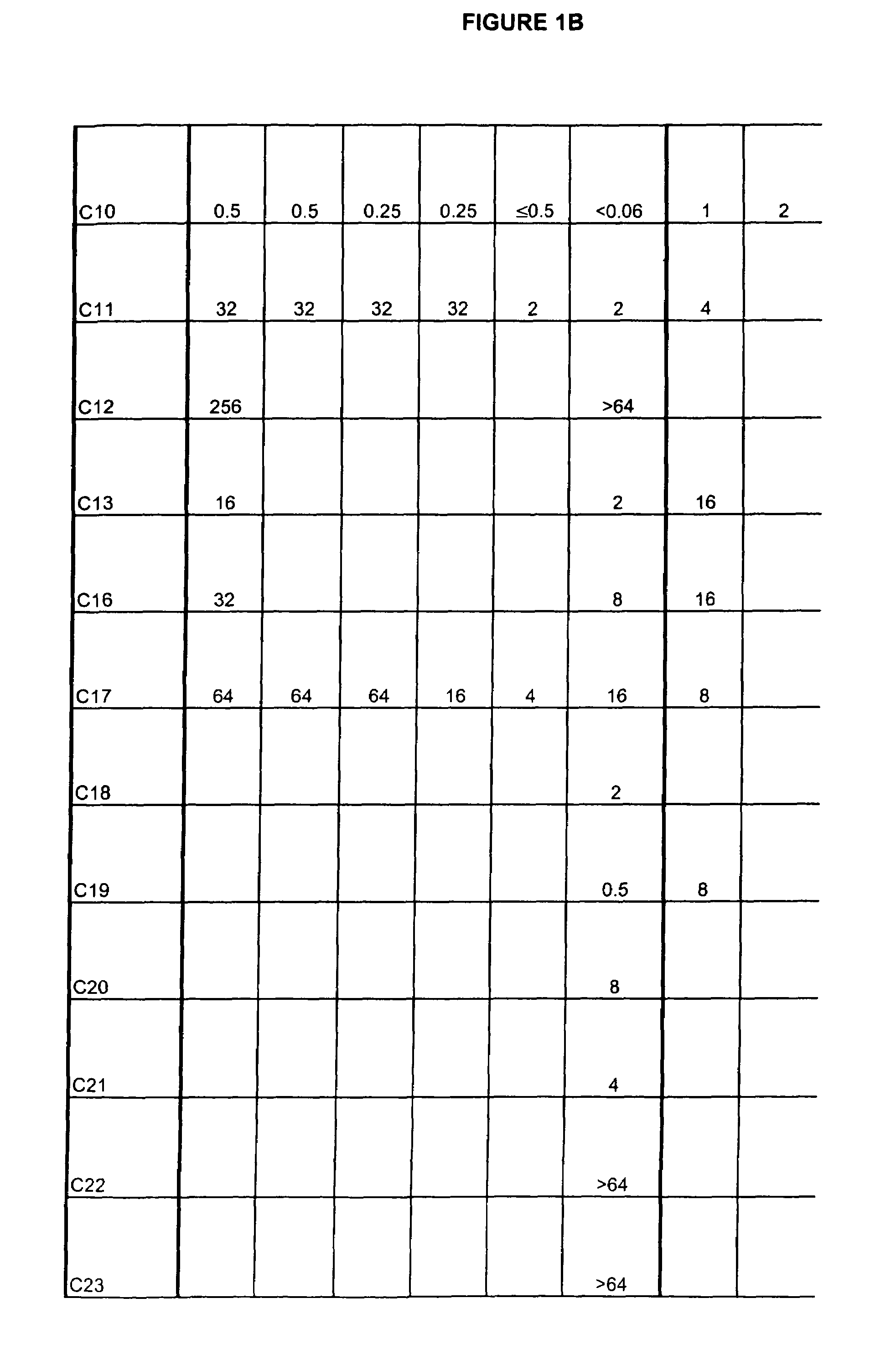

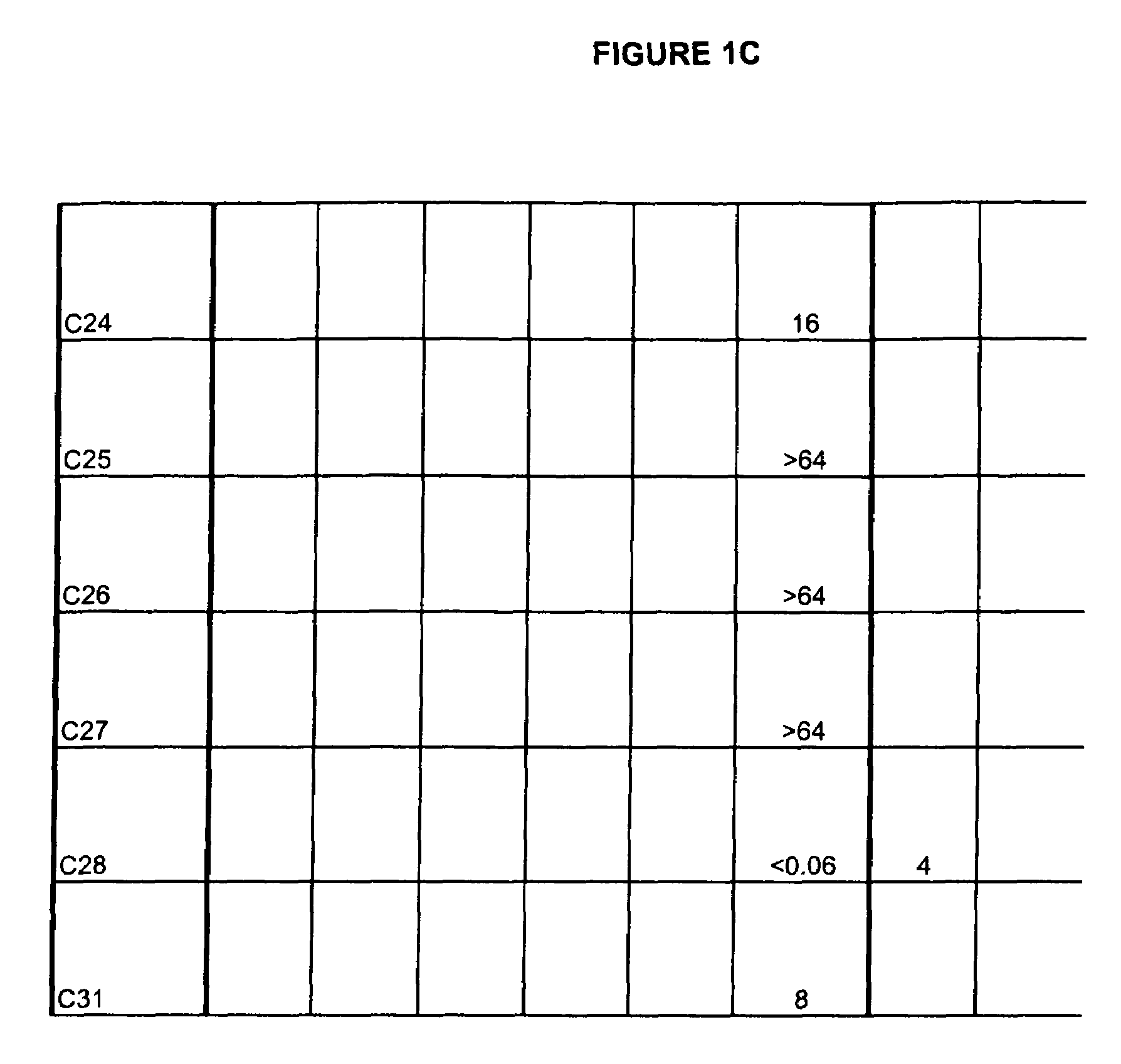

Boron-containing small molecules

This invention relates to compounds useful for treating fungal infections, more specifically topical treatment of onychomycosis and / or cutaneous fungal infections. This invention is directed to compounds that are active against fungi and have properties that allow the compound, when placed in contact with a patient, to reach the particular part of the skin, nail, hair, claw or hoof infected by the fungus. In particular the present compounds have physiochemical properties that facilitate penetration of the nail plate.

Owner:ANACOR PHARMACEUTICALS LLC

Methods for growing low-resistivity tungsten film

InactiveUS20080124926A1Control thicknessGood step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingBoron containingImproved method

Improved methods for depositing low resistivity tungsten films are provided. The methods involve depositing a tungsten nucleation layer on a substrate and then depositing a tungsten bulk layer over the tungsten nucleation layer to form the tungsten film. The methods provide precise control of the nucleation layer thickness and improved step coverage. According to various embodiments, the methods involve controlling thickness and / or improving step coverage by exposing the substrate to pulse nucleation layer (PNL) cycles at low temperature. Also in some embodiments, the methods may improve resistivity by using a high temperature PNL cycle of a boron-containing species and a tungsten-containing precursor to finish forming the tungsten nucleation layer.

Owner:NOVELLUS SYSTEMS

Methods for growing low-resistivity tungsten for high aspect ratio and small features

InactiveUS7955972B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenGas phase

The present invention addresses this need by providing methods for depositing low resistivity tungsten films in small features and features having high aspect ratios. The methods involve depositing very thin tungsten nucleation layers by pulsed nucleation layer (PNL) processes and then using chemical vapor deposition (CVD) to deposit a tungsten layer to fill the feature. Depositing the tungsten nucleation layer involves exposing the substrate to alternating pulses of a boron-containing reducing agent and a tungsten-containing precursor without using any hydrogen gas, e.g., as a carrier or background gas. Using this process, a conformal tungsten nucleation layer can be deposited to a thickness as small as about 10 Angstroms. The feature may then be wholly or partially filled with tungsten by a hydrogen reduction chemical vapor deposition process. Resistivities of about 14 μΩ-cm for a 500 Angstrom film may be obtained.

Owner:NOVELLUS SYSTEMS

Lithium ion battery composite cathode material and preparation method

InactiveCN101604743APromote circulationImprove cycle performanceElectrode manufacturing processesActive material electrodesFuranEpoxy

The invention relates to a lithium ion battery composite cathode material and a preparation method. The cathode material comprises a hard carbon precursor material containing hetero atoms, and natural spherical graphite, wherein the hard carbon precursor material selects one or more than two of phenolic resin, polyfurfural, furan resin, polyvinyl alcohol, epoxide resin or polyacrylonitrile as raw materials, and accounts for 5 to 45 percent of the natural spherical graphite by mass; modifier of the hetero atoms is boron-containing modifier including boric acid and diboron trioxide, phosphor-containing modifier including phosphoric acid and phosphorus pentoxide, and nitrogen-containing modifier HNO3; and one of the modifiers accounts for 5 to 35 percent of the hard carbon precursor by mass. An analog battery formed by the cathode material which is prepared by the method has the capacity over 350 mAH / g and first coulomb efficiency up to 95.8 percent, and has good circulation performance. The preparation method has the advantages of low cost and simple process.

Owner:珠海华丽新能源科技有限公司

Boron-containing small molecules as anti-inflammatory agents

Owner:ANACOR PHARMACEUTICALS LLC

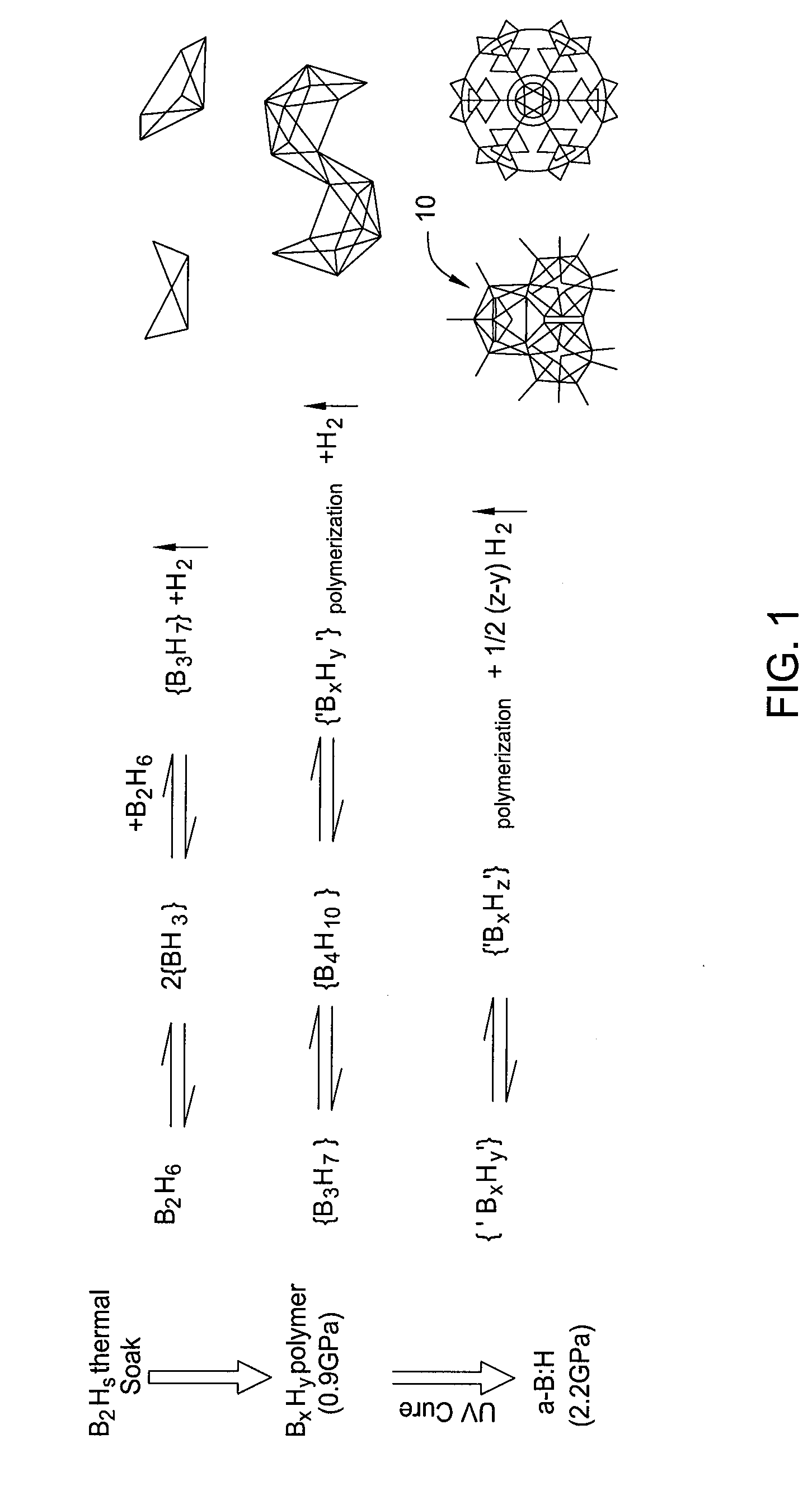

Boron derived materials deposition method

Methods of forming boron-containing films are provided. The methods include introducing a boron-containing precursor into a chamber and depositing a network comprising boron-boron bonds on a substrate by thermal decomposition or a plasma process. The network may be post-treated to remove hydrogen from the network and increase the stress of the resulting boron-containing film. The boron-containing films have a stress between about −10 GPa and 10 GPa and may be used as boron source layers or as strain-inducing layers.

Owner:APPLIED MATERIALS INC

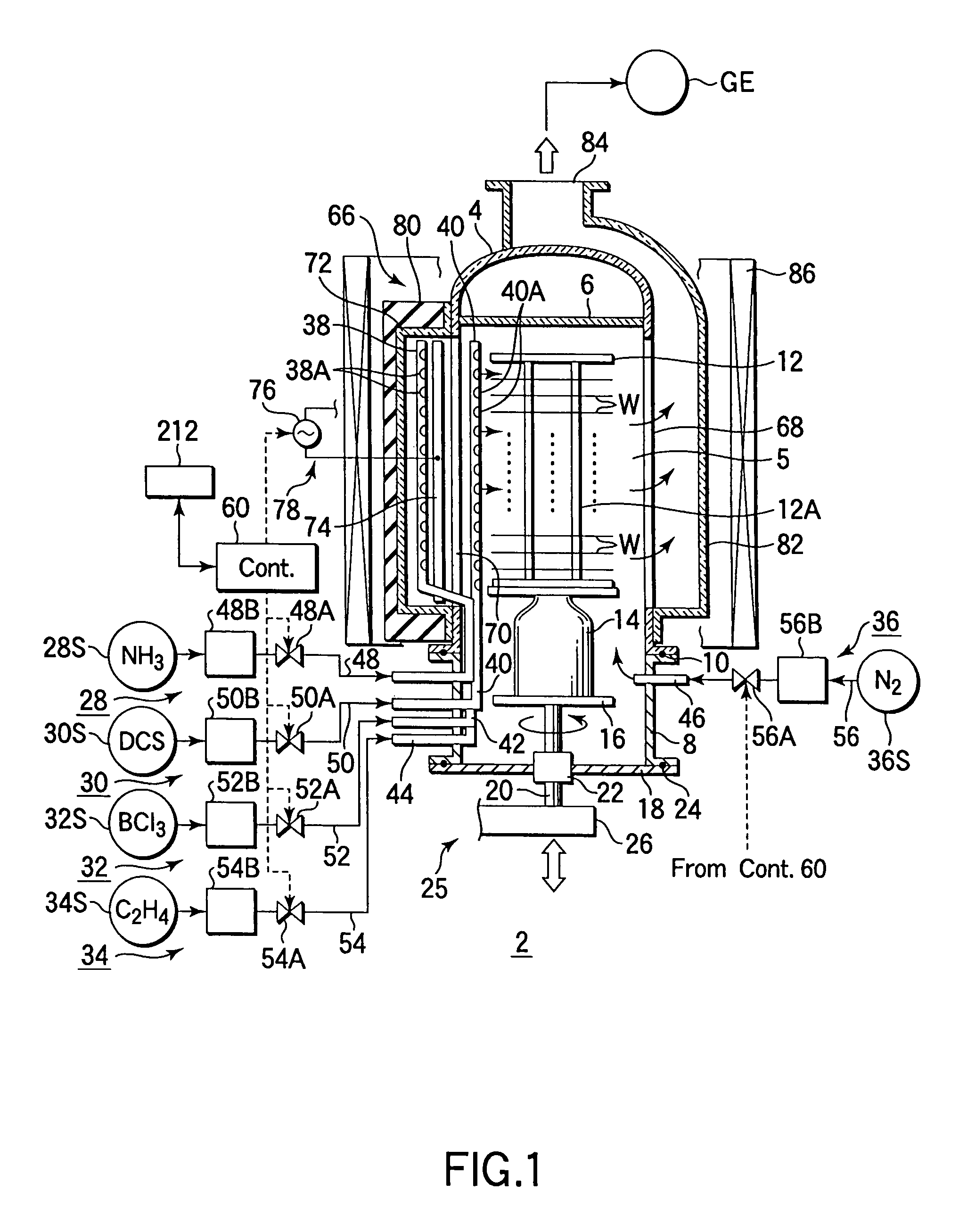

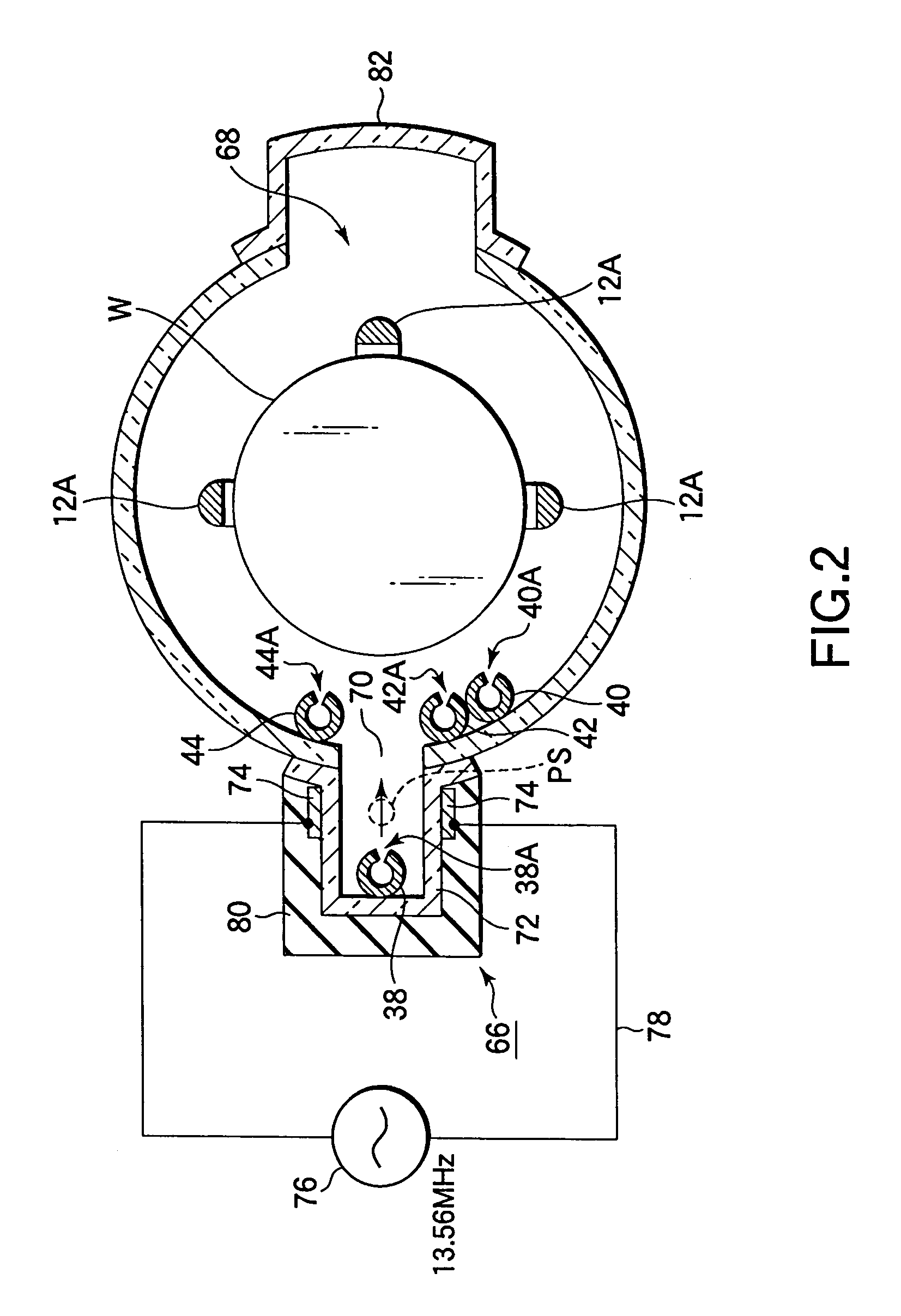

Film formation method and apparatus for semiconductor process

ActiveUS7964241B2Low process temperatureImprove controllabilityChemical vapor deposition coatingSilanesBoron containing

An insulating film is formed on a target substrate by CVD, in a process field to be selectively supplied with a first process gas containing a silane family gas, a second process gas containing a nitriding gas or oxynitriding gas, a third process gas containing a boron-containing gas, and a fourth process gas containing a carbon hydride gas. A first step performs supply of the first process gas and a preceding gas, which is one of the third and fourth process gases, while stopping supply of the second process gas and a succeeding gas, which is the other of the third and fourth process gases. A second step performs supply of the succeeding gas, while stopping supply of the second process gas and the preceding gas. A third step performs supply of the second process gas while stopping supply of the first process gas.

Owner:TOKYO ELECTRON LTD

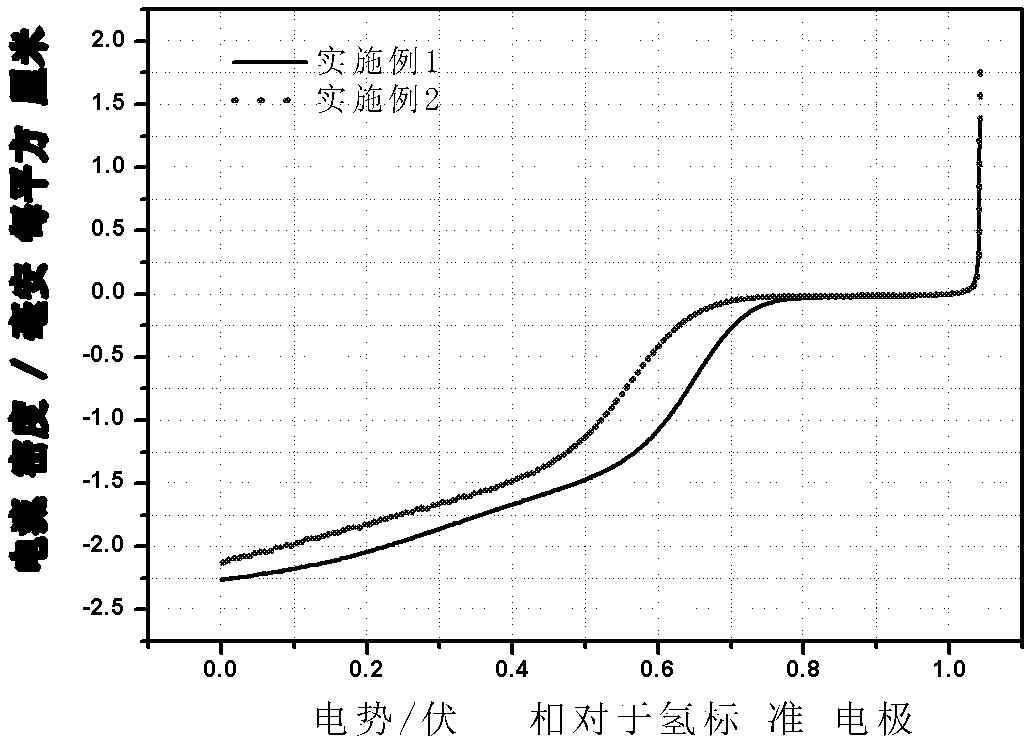

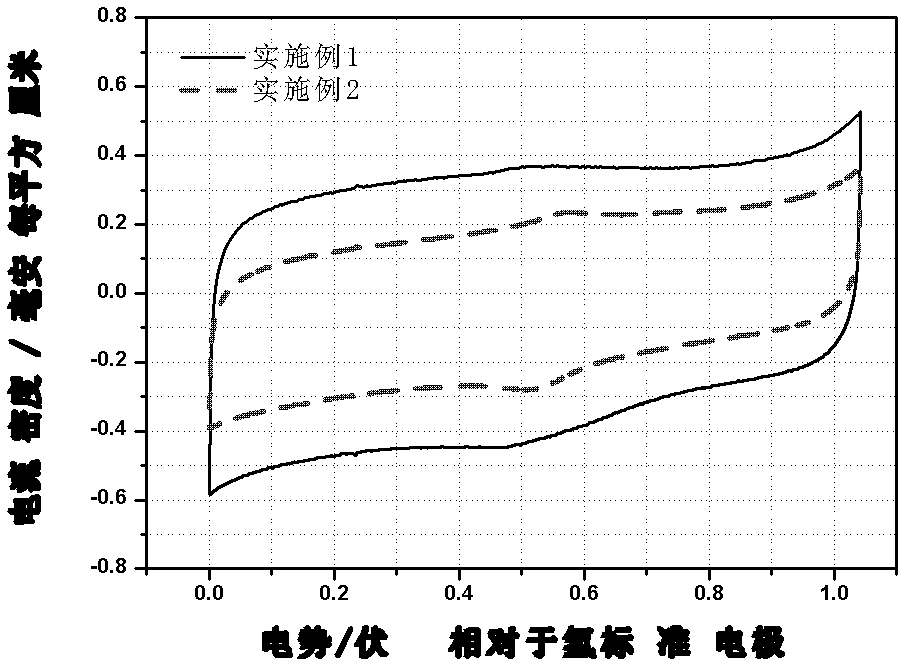

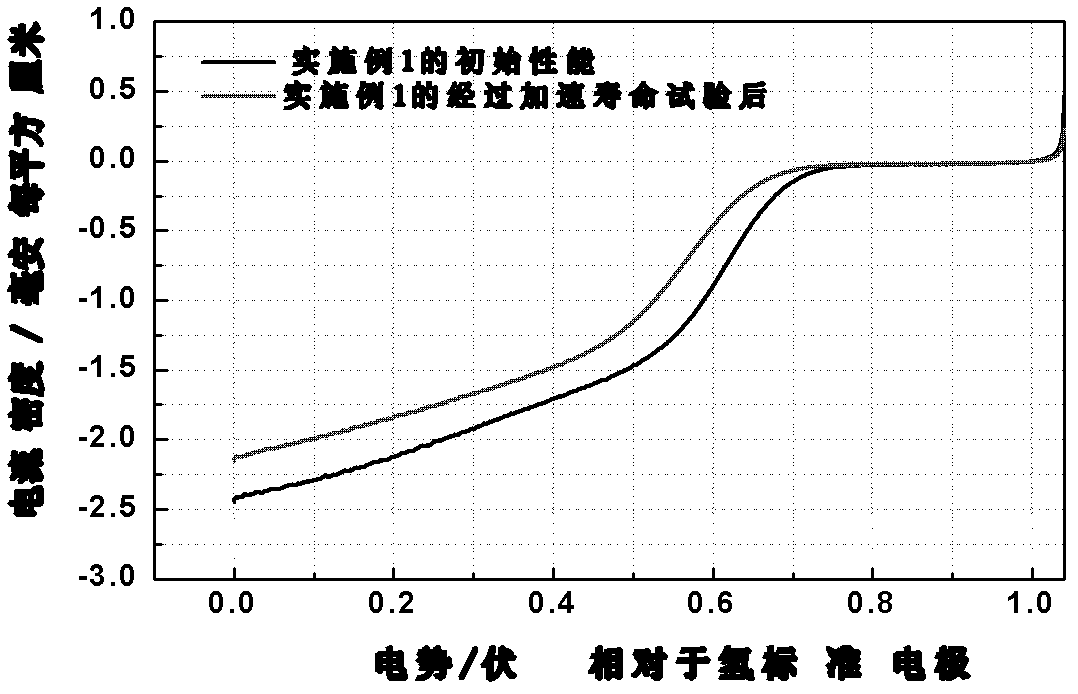

Nano carbon doped electrocatalyst for fuel cell, and application of nano carbon doped electrocatalyst

InactiveCN103050714AChange the microstructureChange Edge Face DefectsPhysical/chemical process catalystsCell electrodesMicrowave radiometryHigh heat

The invention relates to a nano carbon doped electrocatalyst for a fuel cell, and application of the nano carbon doped electrocatalyst. The electrocatalyst is prepared by adopting the steps of: complexing a nitrogen-containing and / or boron-containing organic precursor and a transition metal salt to form a composite; adding nano carbon as a carrier, and heating and reacting a mixture by adopting a microwave radiation method; and after the reaction is complete, filtering and drying, placing a product obtained after the reaction in an inert atmosphere and / or reducing atmosphere, and treating at a high temperature of 500-1500 DEG C to obtain the nano carbon doped electrocatalyst. The nano carbon doped electrocatalyst is very low in cost, high in activity and stability and excellent in anti-poisoning capacity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

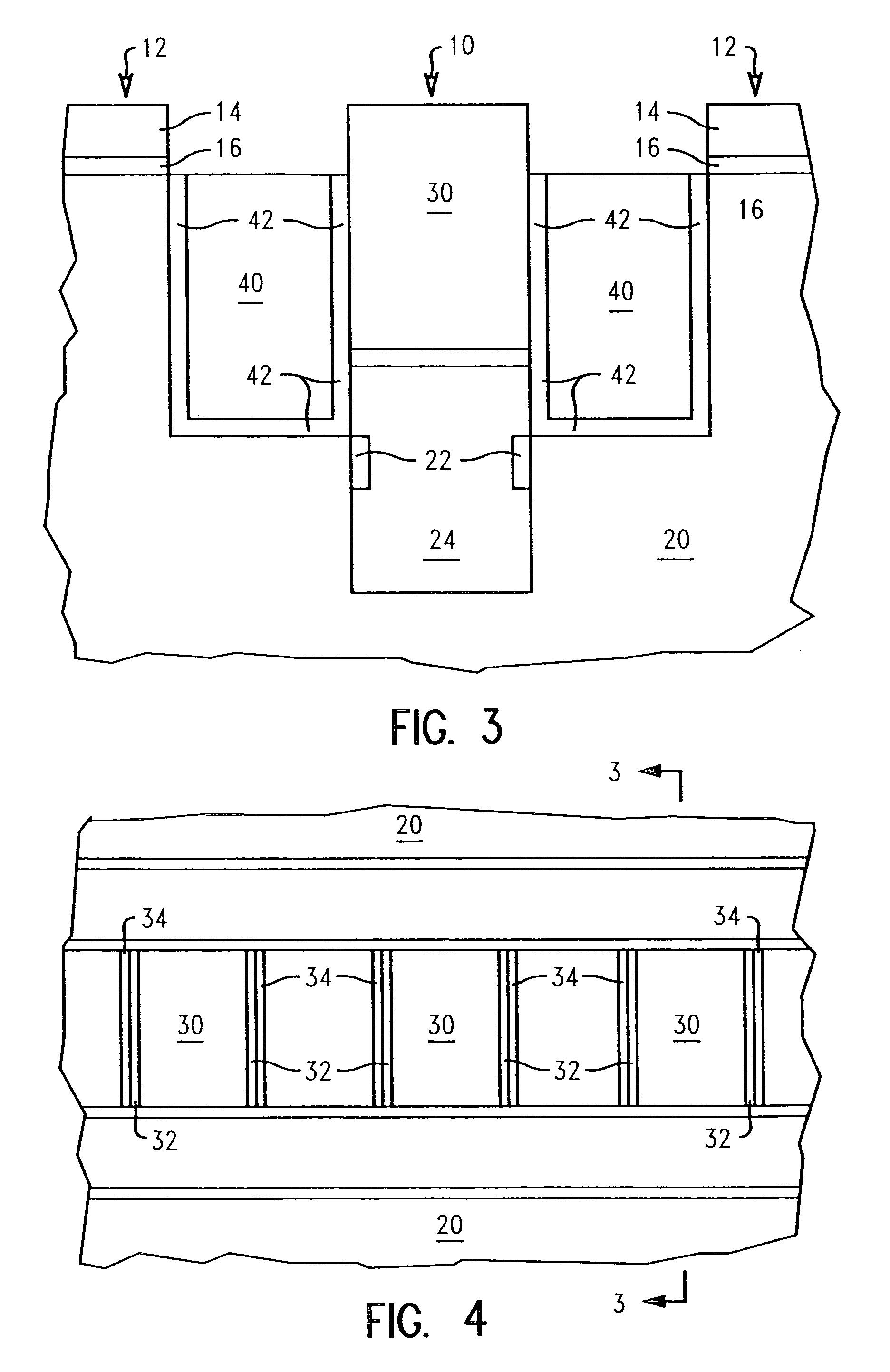

Nitrided sti liner oxide for reduced corner device impact on vertical device performance

ActiveUS20050151181A1Reduces dopant depletionReduced isolationTransistorSolid-state devicesMOSFETElectrical conductor

A method of fabricating an integrated circuit device comprises etching a trench in a substrate and forming a dynamic random access memory (DRAM) cell having a storage capacitor at a lower end and an overlying vertical metal oxide semiconductor field effect transistor (MOSFET) comprising a gate conductor and a boron-doped channel. The method includes forming trenches adjacent the DRAM cell and a silicon-oxy-nitride isolation liner on either side of the DRAM cell, adjacent the gate conductor. Isolation regions are then formed in the trenches on either side of the DRAM cell. Thereafter, the DRAM cell, including the boron-containing channel region adjacent the gate conductor, is subjected to elevated temperatures by thermal processing, for example, forming a support device on the substrate adjacent the isolation regions. The nitride-containing isolation liner reduces segregation of the boron in the channel region, as compared to an essentially nitrogen-free oxide-containing isolation liner.

Owner:INFINEON TECH AG +1

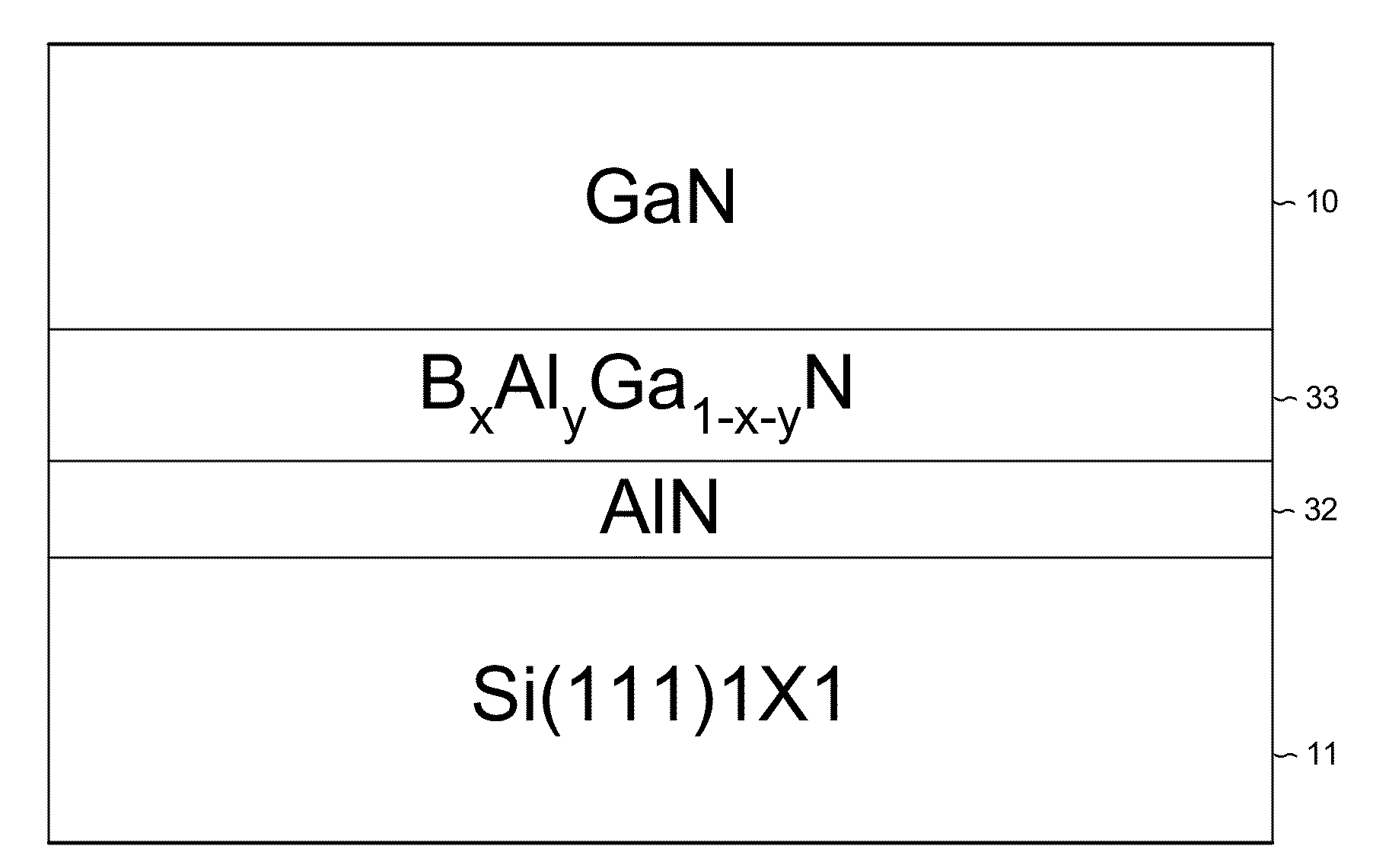

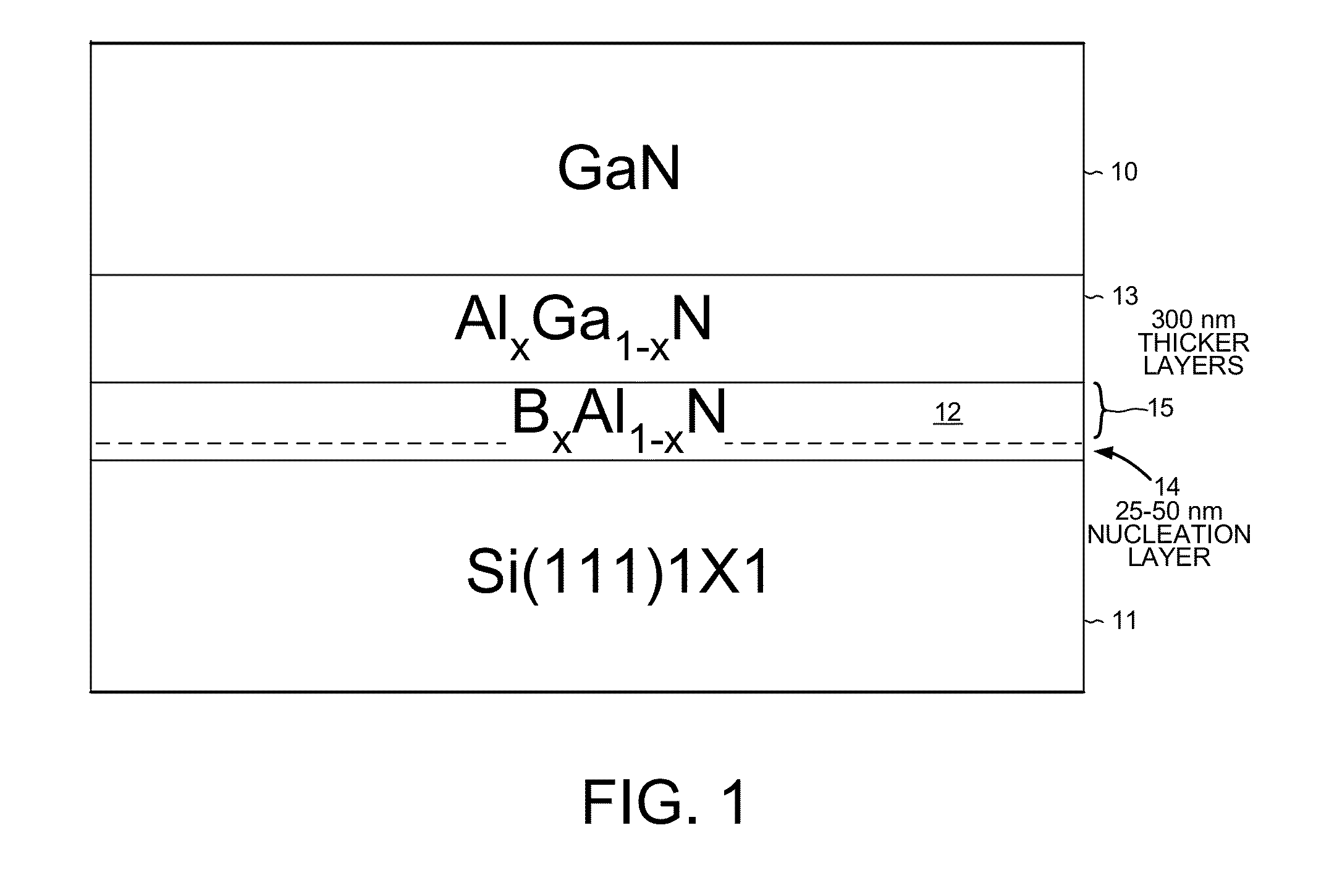

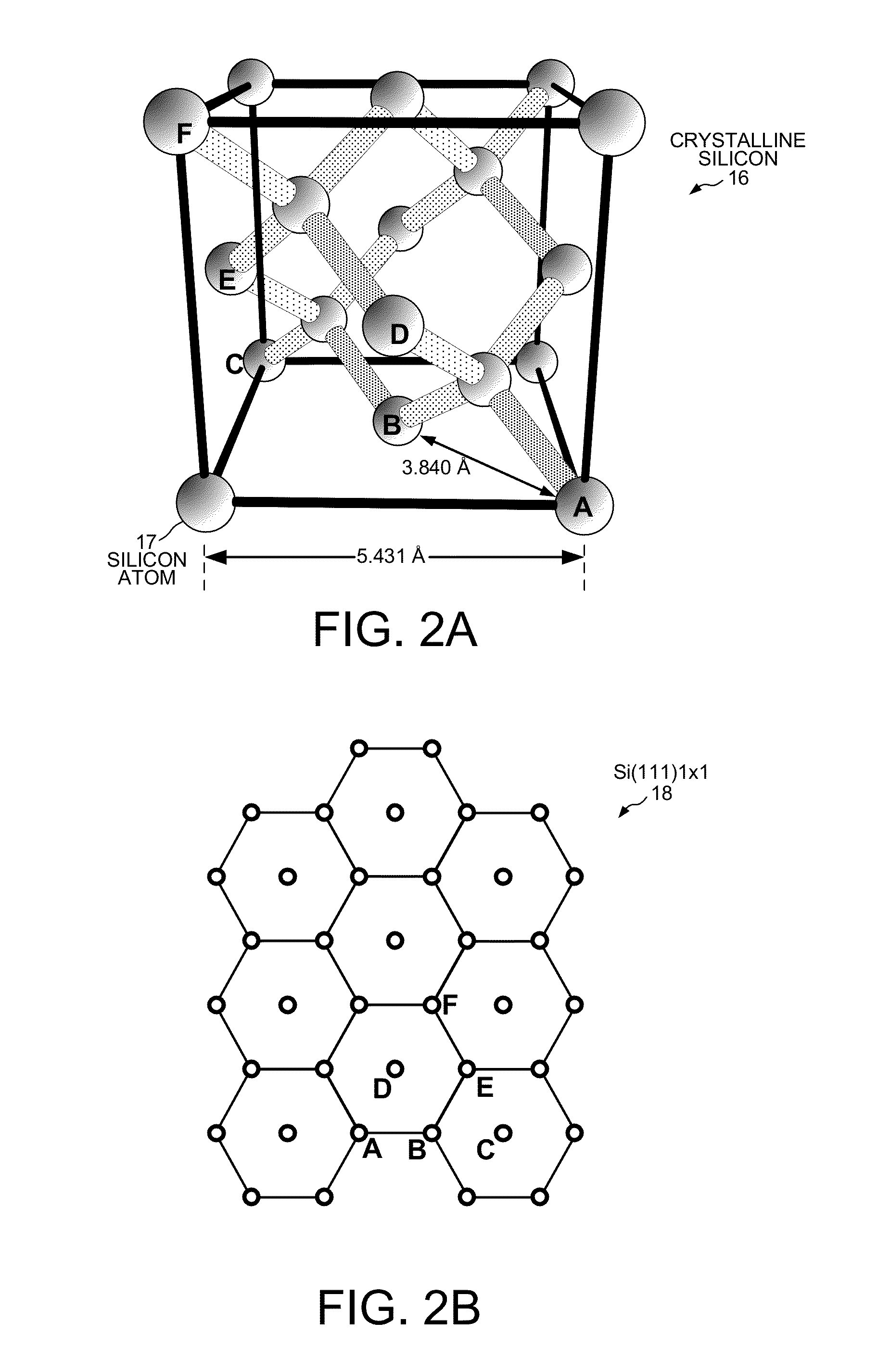

Boron-Containing Buffer Layer for Growing Gallium Nitride on Silicon

InactiveUS20130026482A1Small sizeMore stressSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogenBoron containing

A silicon wafer used in manufacturing GaN for LEDs includes a silicon substrate, a buffer layer of boron aluminum nitride (BxAl1-xN) and an upper layer of GaN, for which 0.35≦x≦0.45. The BAlN forms a wurtzite-type crystal with a cell unit length about two-thirds of a silicon cell unit length on a Si(111) surface. The C-plane of the BAlN crystal has approximately one atom of boron for each two atoms of aluminum. Across the entire wafer substantially only nitrogen atoms of BAlN form bonds to the Si(111) surface, and substantially no aluminum or boron atoms of the BAlN are present in a bottom-most plane of atoms of the BAlN. A method of making the BAlN buffer layer includes preflowing a first amount of ammonia equaling less than 0.01% by volume of hydrogen flowing through a chamber before flowing trimethylaluminum and triethylboron and then a subsequent amount of ammonia through the chamber.

Owner:KK TOSHIBA

Modified natural graphite material used in lithium ion battery negative electrodes, and preparation method thereof

InactiveCN102231434AReduce crystallinityLarge interplanar distanceCell electrodesPower batteryCarbon layer

The invention discloses a modified natural graphite material used in lithium ion battery negative electrodes. With a core-shell structure, the material comprises an inner core and a shell coated on the inner-core. The inner-core is composed of natural graphite, and the shell coated on the core is composed of an inner shell and an outer shell. The inner shell is a boron-containing hard carbon layer, and the outer shell is a soft carbon layer. The boron-containing hard carbon layer is coated on natural graphite, and the soft carbon layer is coated on the boron-containing hard layer. The method has advantages of simple technology, suitability for mass production, low graphitization processing temperature, and low cost. With advantages of small specific surface area, high tap density, high first efficiency, high specific capacity, excellent cycling performance, and good rate performance, the modified natural graphite material can be applied in power batteries.

Owner:HENAN THINKER ENERGY MATERIALS

Boron containing hydrodesulphurization catalyst and preparation method thereof

ActiveCN101314130AHigh desulfurization activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationBoron containing

The invention discloses a boron-bearing hydrodesulfurization catalyst and a preparation method thereof. The boron-bearing hydrodesulfurization catalyst contains a carrier, at least one VIB hydrogenative reactive metal composition and at least one VIII hydrogenative reactive metal composition and boron; the catalyst is calculated by oxide and a catalyst is taken as a reference, the content of the VIB metal composition is between 0.5 and 35 weight percent, the content of the VIII metal composition is between 0.1 and 10 weight percent, the content of the boron is between 0.2 and 6 weight percent, and the content of the carrier is between 49 and 99.2 weight percent, wherein, the carrier contains alumina provided with a delta and / or theta structure. Compared with the prior catalyst, the catalyst has higher hydrodesulfurization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

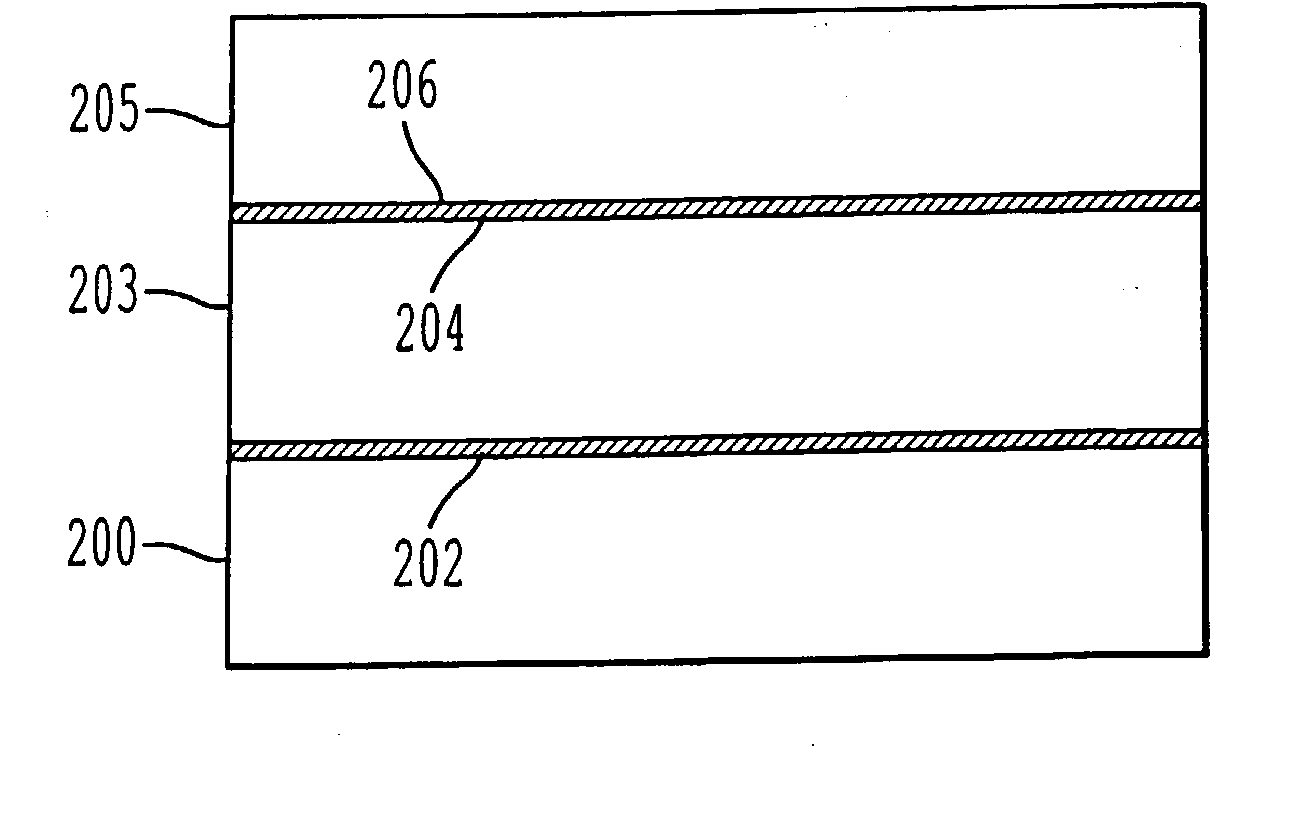

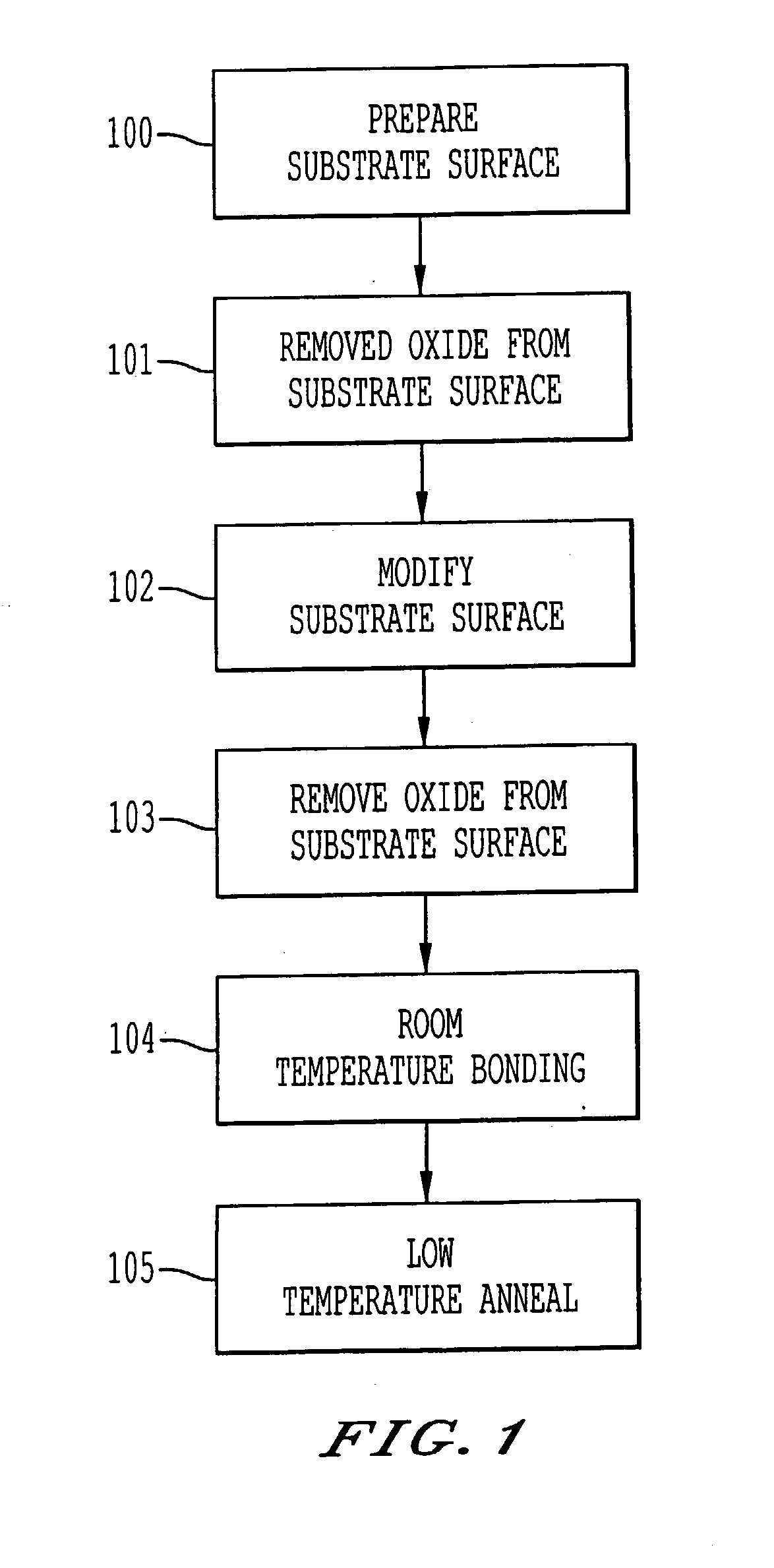

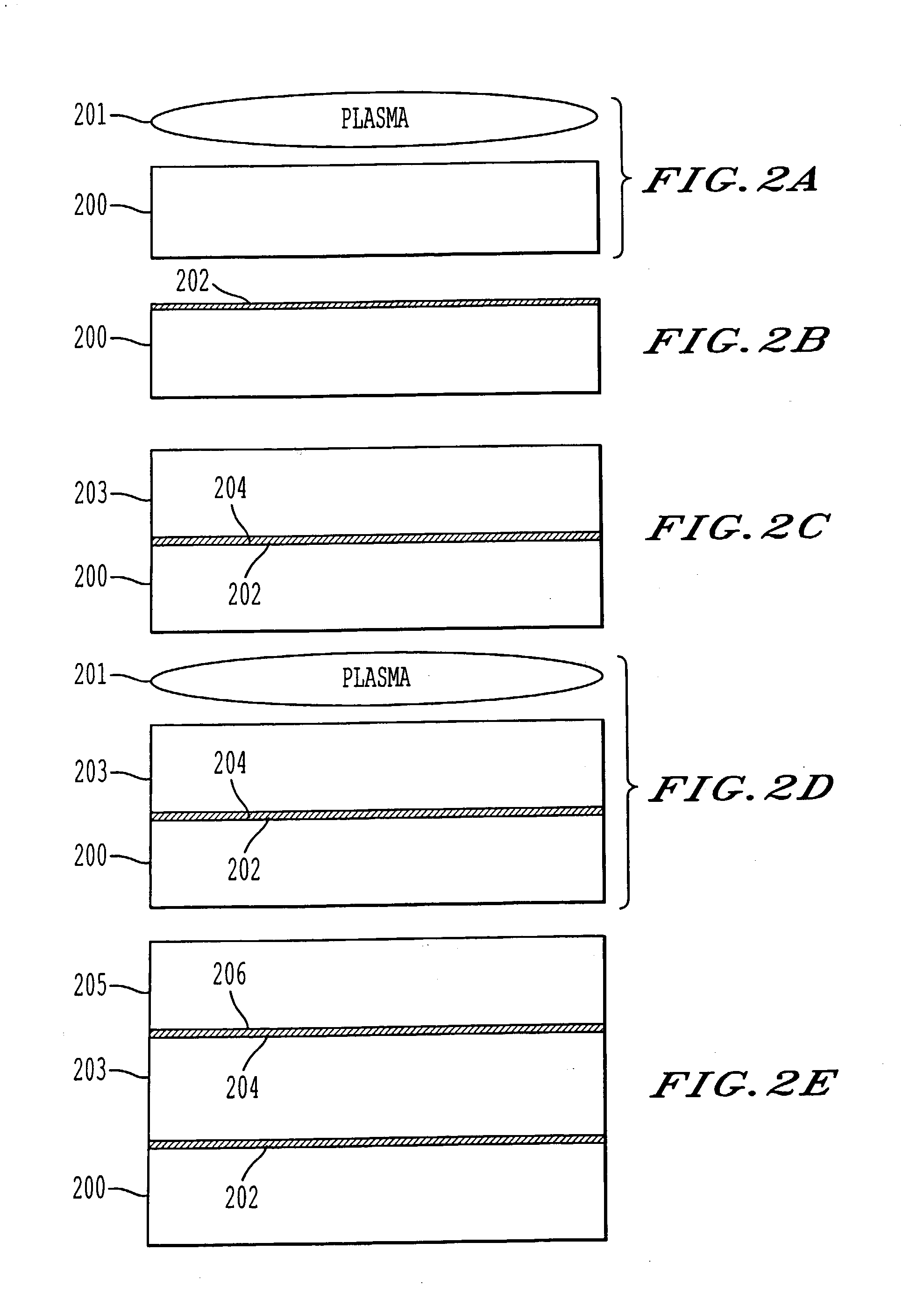

Method of epitaxial-like wafer bonding at low temperature and bonded structure

InactiveUS20030141502A1Semiconductor/solid-state device detailsSolid-state devicesBond energyHydrogen

A process for bonding oxide-free silicon substrate pairs and other substrates at low temperature. This process involves modifying the surface of the silicon wafers to create defect regions, for example by plasma-treating the surface to be bonded with a or boron-containing plasmas such as a B2H6 plasma. The surface defect regions may also be created by ion implantation, preferably using boron. The surfaces may also be amorphized. The treated surfaces are placed together, thus forming an attached pair at room temperature in ambient air. The bonding energy reaches approximately 400 mJ / m2 at room temperature, 900 mJ / m2 at 150° C., and 1800 mJ / m2 at 250° C. The bulk silicon fracture energy of 2500 mJ / m2 was achieved after annealing at 350-400° C. The release of hydrogen from B-H complexes and the subsequent absorption of the hydrogen by the plasma induced modified layers on the bonding surfaces at low temperature is most likely responsible for the enhanced bonding energy.

Owner:INVENSAS BONDING TECH INC

Boron-containing organic light emission diode device and preparation method thereof

ActiveCN107507921AReduced singlet-triplet energy level differenceDelayed fluorescenceSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionTriplet state

Owner:JIANGSU SUNERA TECH CO LTD

Boron-containing organic electroluminescent compound and use thereof

InactiveCN106467554AImprove applicabilityImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyFluorescence

The invention discloses a boron-containing organic electroluminescent compound and a use thereof. The compound has a general structural formula (1). The compound has good fluorescence quantum efficiency and electroluminescent efficiency, easily forms an amorphous film and has good thermal stability. Therefore, the compound can be used as a luminescent layer doping material or a main body material in an organic electroluminescent device.

Owner:VALIANT CO LTD

Low boron containing microfiberglass filtration media

InactiveUS6933252B2Enhanced filtration performance characteristicSmall toleranceFibre treatmentSynthetic resin layered productsAir filtrationFiber

The present invention provides nonwoven glass composites formed from an essentially boron free glass wool and an essentially boron free chopped glass fiber, used as a reinforcing material. The nonwoven glass composites are suitable for air filtration apparatus and can be used in the semiconductor industry where the elimination of boron from clean rooms is of importance.

Owner:HOLLINGSWORTH VOSE

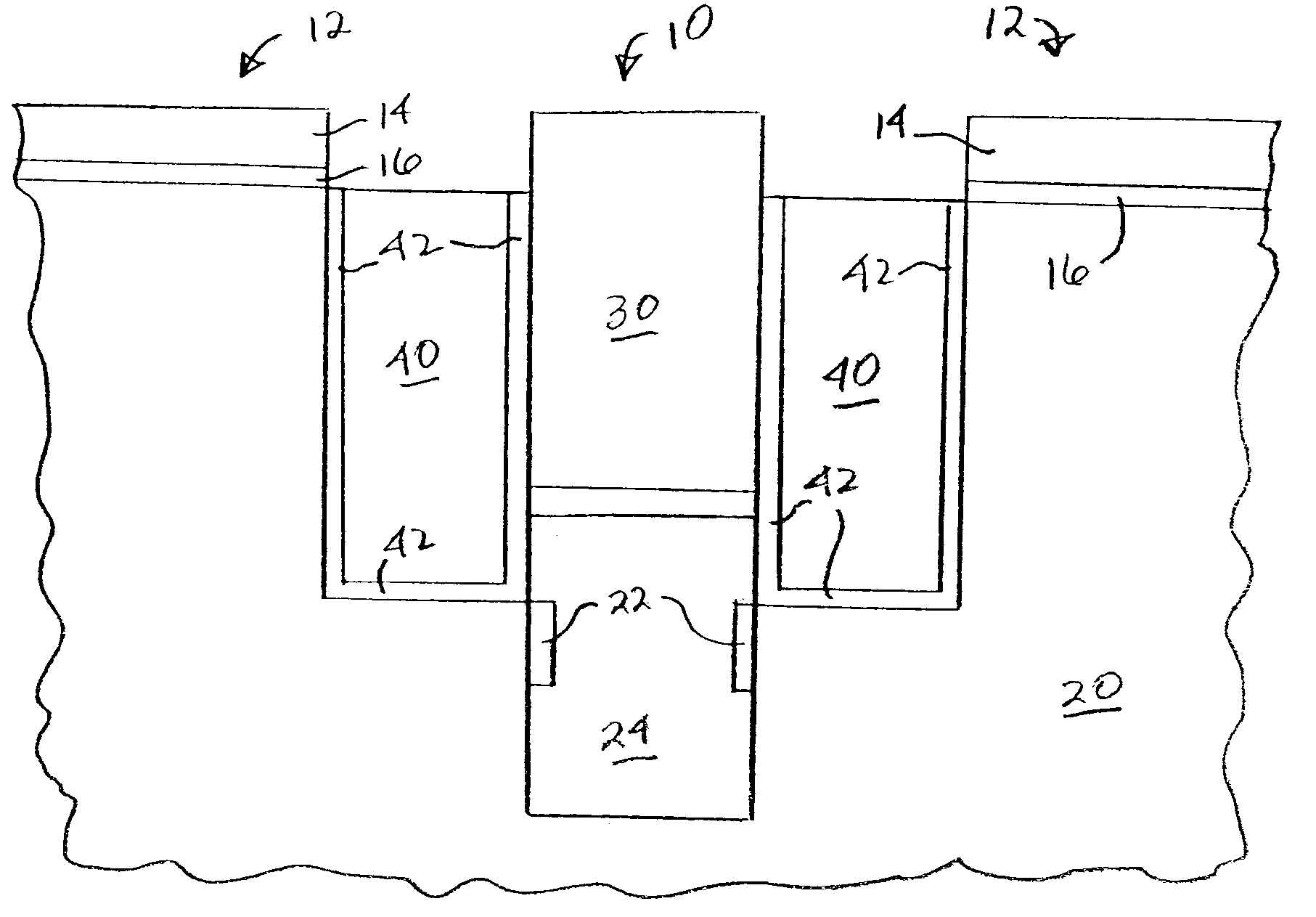

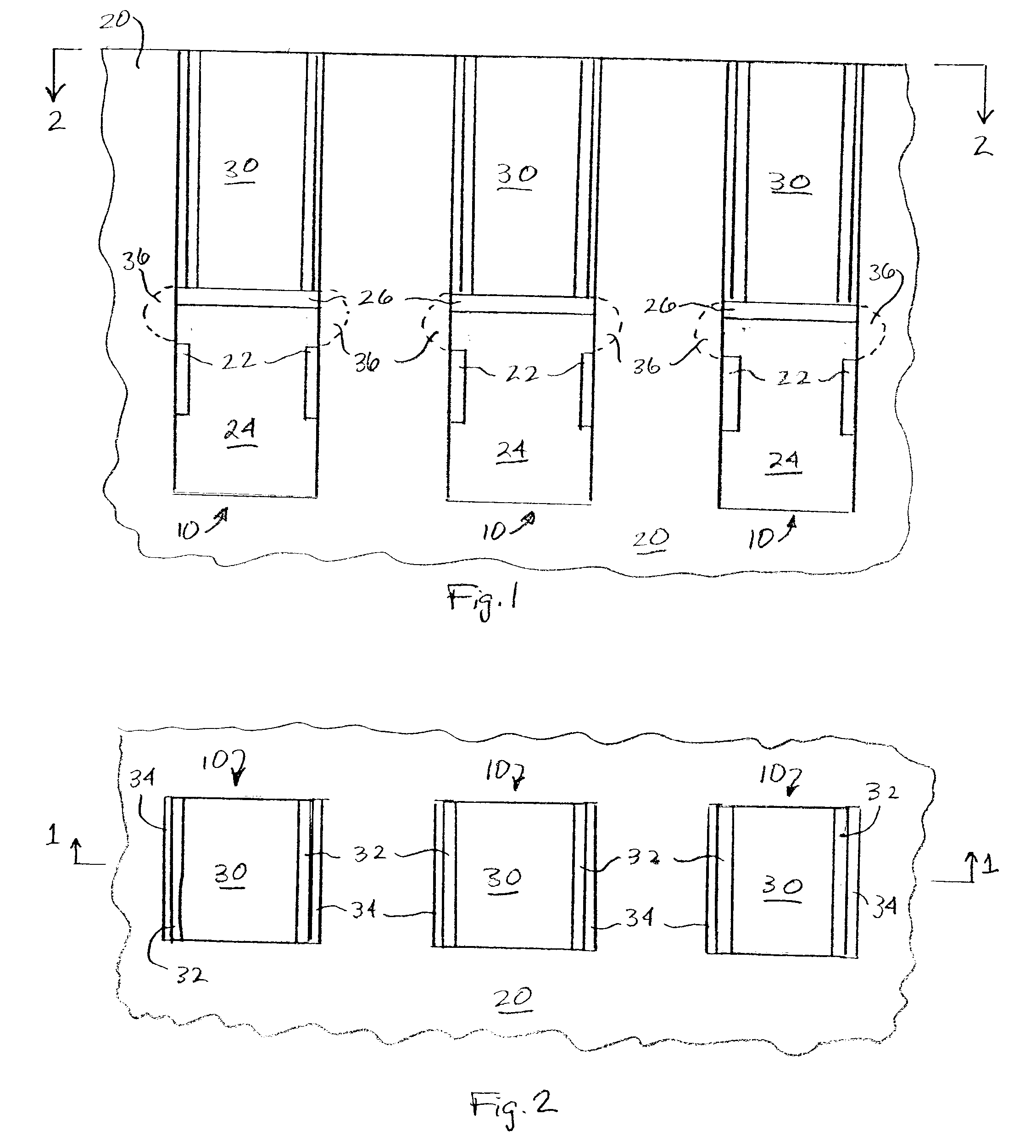

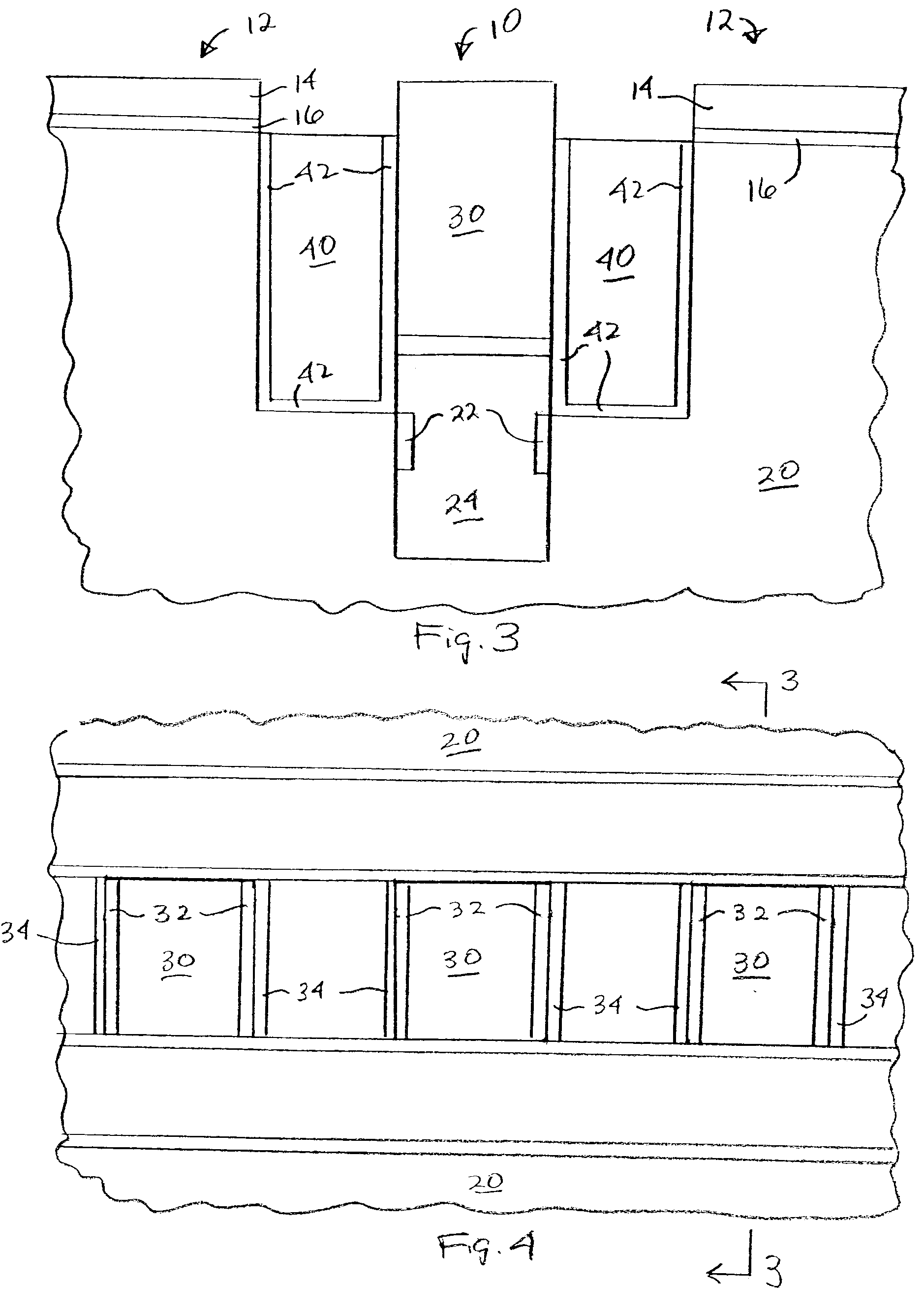

Nitrided STI liner oxide for reduced corner device impact on vertical device performance

ActiveUS6998666B2Reduces corner effectReduces dopant depletionTransistorSolid-state devicesMOSFETElectrical conductor

A method of fabricating an integrated circuit device comprises etching a trench in a substrate and forming a dynamic random access memory (DRAM) cell having a storage capacitor at a lower end and an overlying vertical metal oxide semiconductor field effect transistor (MOSFET) comprising a gate conductor and a boron-doped channel. The method includes forming trenches adjacent the DRAM cell and a silicon-oxy-nitride isolation liner on either side of the DRAM cell, adjacent the gate conductor. Isolation regions are then formed in the trenches on either side of the DRAM cell. Thereafter, the DRAM cell, including the boron-containing channel region adjacent the gate conductor, is subjected to elevated temperatures by thermal processing, for example, forming a support device on the substrate adjacent the isolation regions. The nitride-containing isolation liner reduces segregation of the boron in the channel region, as compared to an essentially nitrogen-free oxide-containing isolation liner.

Owner:INFINEON TECH AG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com