Composite-construction treatment equipment

a technology for treating equipment and composite materials, applied in the direction of vehicle maintenance, manufacturing tools, vehicle cleaning, etc., can solve the problems of reducing durability, taking time, and requiring work, and achieves the effects of simple manner, quick and easy installation and replacement of blade holders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

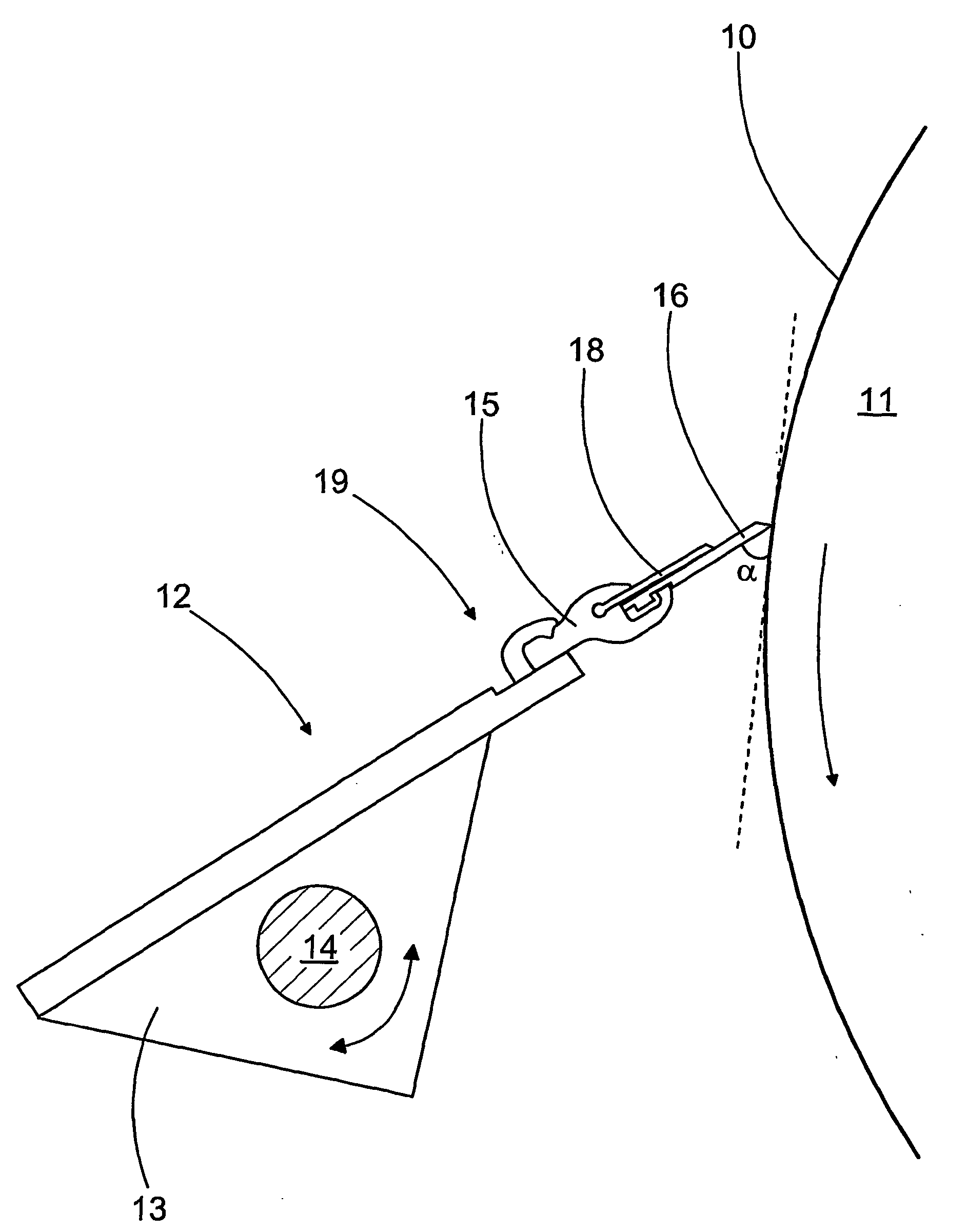

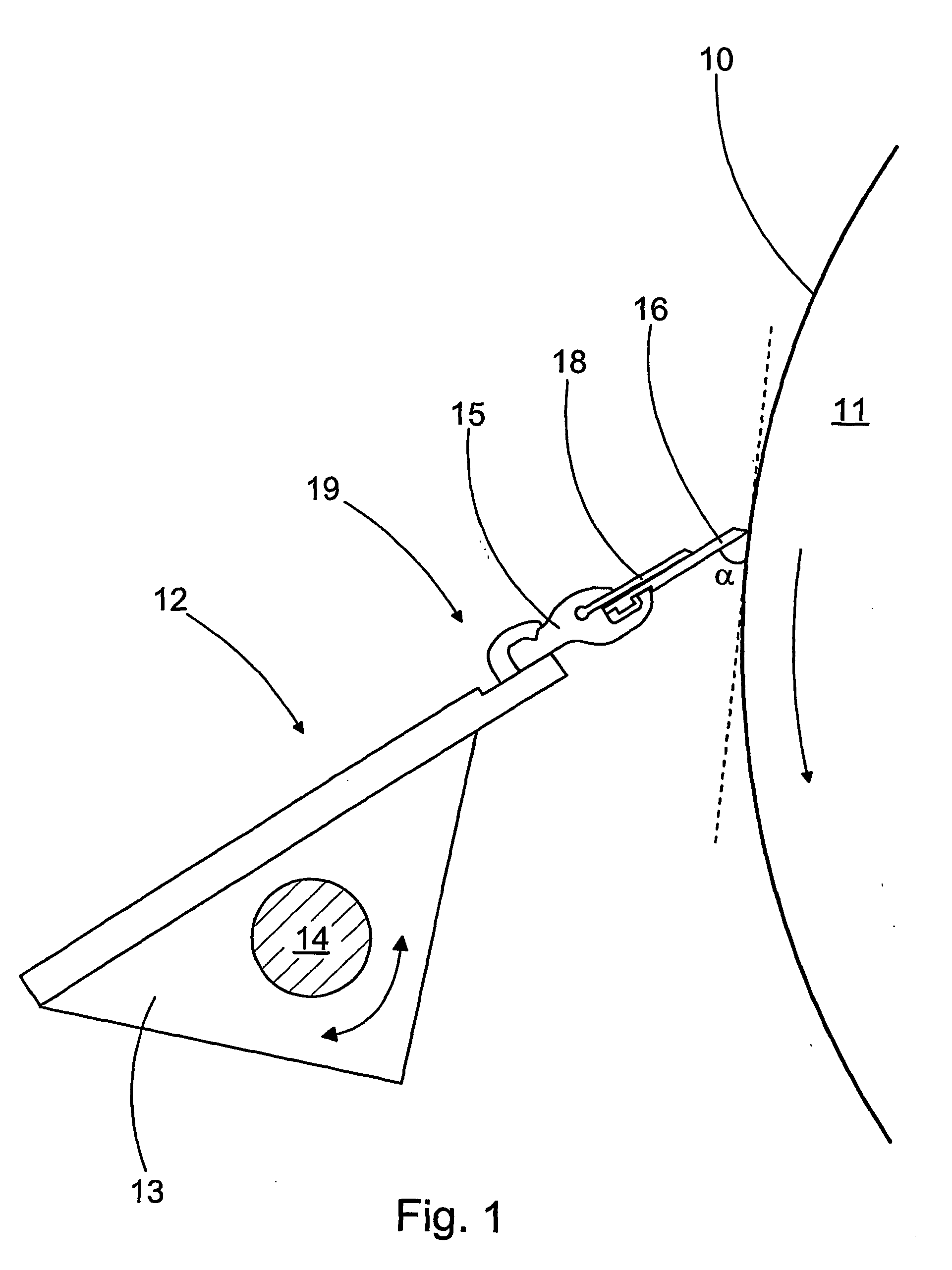

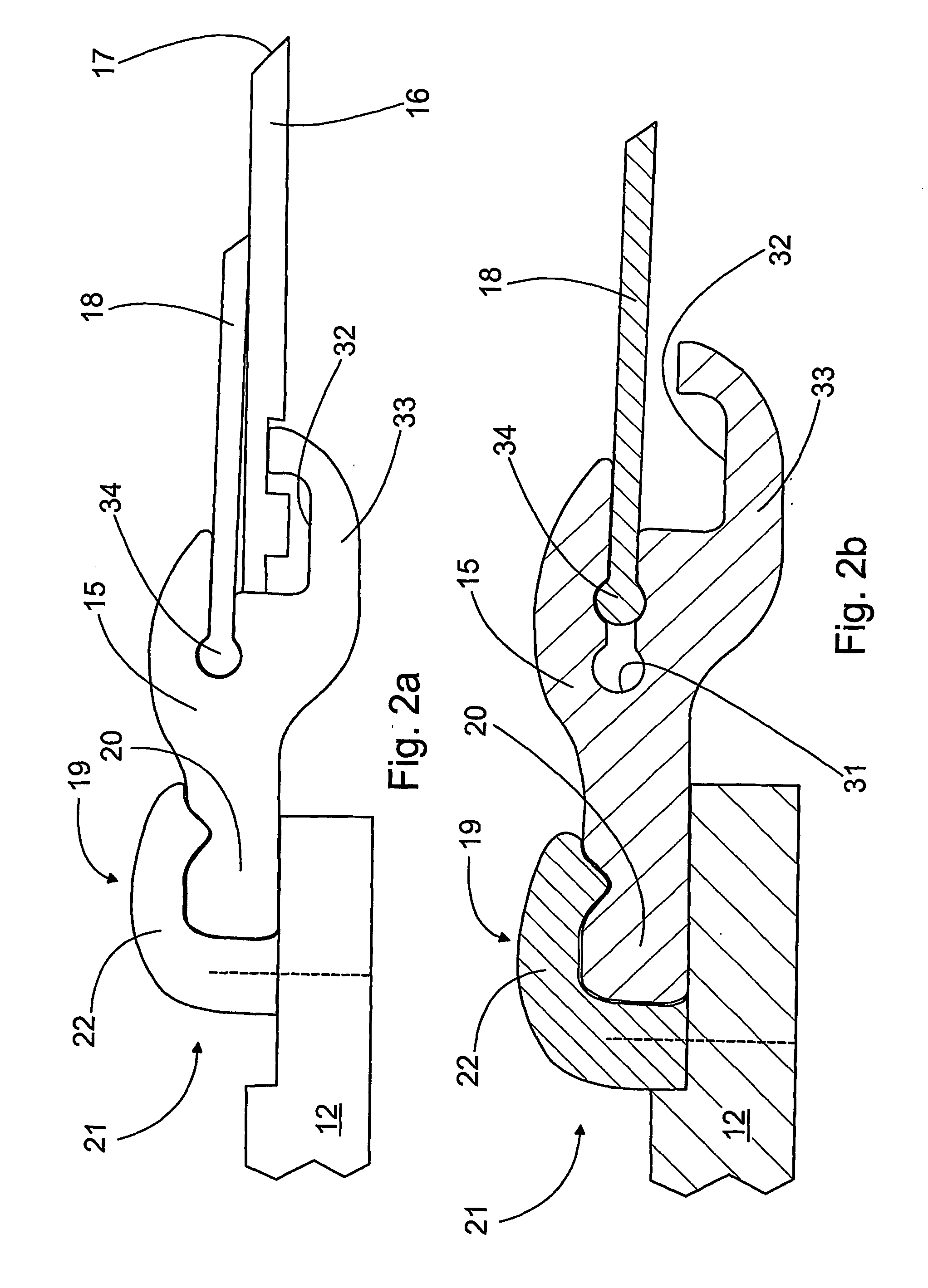

[0019]FIG. 1 shows the treatment equipment according to the invention adapted in connection with a moving surface 10. Here the moving surface 10 is a paper machine roll 11, of which only a part is shown. Generally the purpose of the treatment equipment is to treat a moving surface. In the doctoring example, the purpose of doctoring is to remove impurities from the surface or, for example, the web itself in some paper machine positions. In paper and board machines and in other forming machines, moving surfaces also comprise the surfaces of various cylinders and fabrics. The treatment equipment is used for example for web coating, in which a coating paste is applied to the surface of a moving web. This is illustrated in FIG. 5a. Furthermore, the treatment equipment comprises a frame 12, arranged in the vicinity of the surface 10 to be treated. In FIG. 1 the frame 12 is a beam 13, which is supported by a shaft 14 in a way that allows pivoting in relation to the paper machine constructi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com