Method for preparing lignocellulosic nanofibrils

A technology of lignocellulose and nanofibrils, which is applied in the direction of pulping with inorganic alkali and pulping with acid/acid anhydride, etc. It can solve the problems of low yield of cellulose fibrils and poor strengthening and toughening effect of cellulose fibers. , achieve high yield, good reinforcement and toughening effect, and improve elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

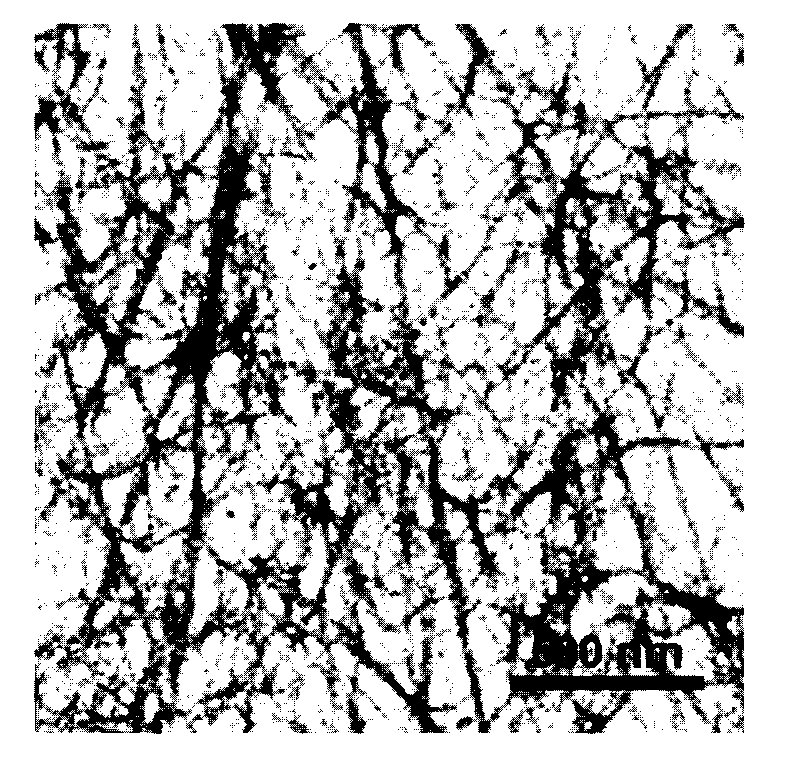

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the preparation method of lignocellulose nano-fibril of the present embodiment is carried out according to the following steps: one, wood powder is put into phenylethanol solution and extracts, and extraction temperature is 85~90 ℃, and extraction time is 5-7h, the phenylethanol solution is composed of benzene and ethanol according to the volume ratio of 2:1; 2. Take 1.8-2.2g of the wood powder treated in step 1, 63-67mL of distilled water, and 0.4-0.6mL of glacial acetic acid Mix with 0.5-0.7g of sodium chlorite in a conical flask, then seal the conical flask and heat it in a water bath at 72-77°C for 0.8-1.2h; Add 0.4-0.6mL of glacial acetic acid and 0.5-0.7g of sodium chlorite into the shaped bottle and mix evenly, heat treatment in a water bath at 72-77°C for 0.8-1.2h; 4. Repeat step 3 for 3-5 times Remove lignin; 5. Add 35 to 37 mL of KOH solution with a mass concentration of 1.5% to 2.5% to the material treated in step 4, mix evenly, and k...

specific Embodiment approach 2

[0015] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the wood powder is poplar wood powder with a particle size of 50-70 mesh, fir powder with a particle size of 50-70 mesh or 50-70 mesh particle size Pine flour. Other steps and parameters are the same as those in Embodiment 1.

[0016] When the wood flour in this embodiment is a mixture, various wood flours can be mixed in any ratio.

specific Embodiment approach 3

[0017] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the extraction temperature in step 1 is 90° C., and the extraction time is 6 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com