Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

354 results about "Cotton linters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cotton linters are in sheet form and sold by the pound. Each sheet measures 30" x 27" and weighs almost 1 pound. However we may cut sheets to fit more easily into boxes. Cotton linters can be processed very easily in a kitchen blender or other form of mixer if a Hollander beater is unavailable.

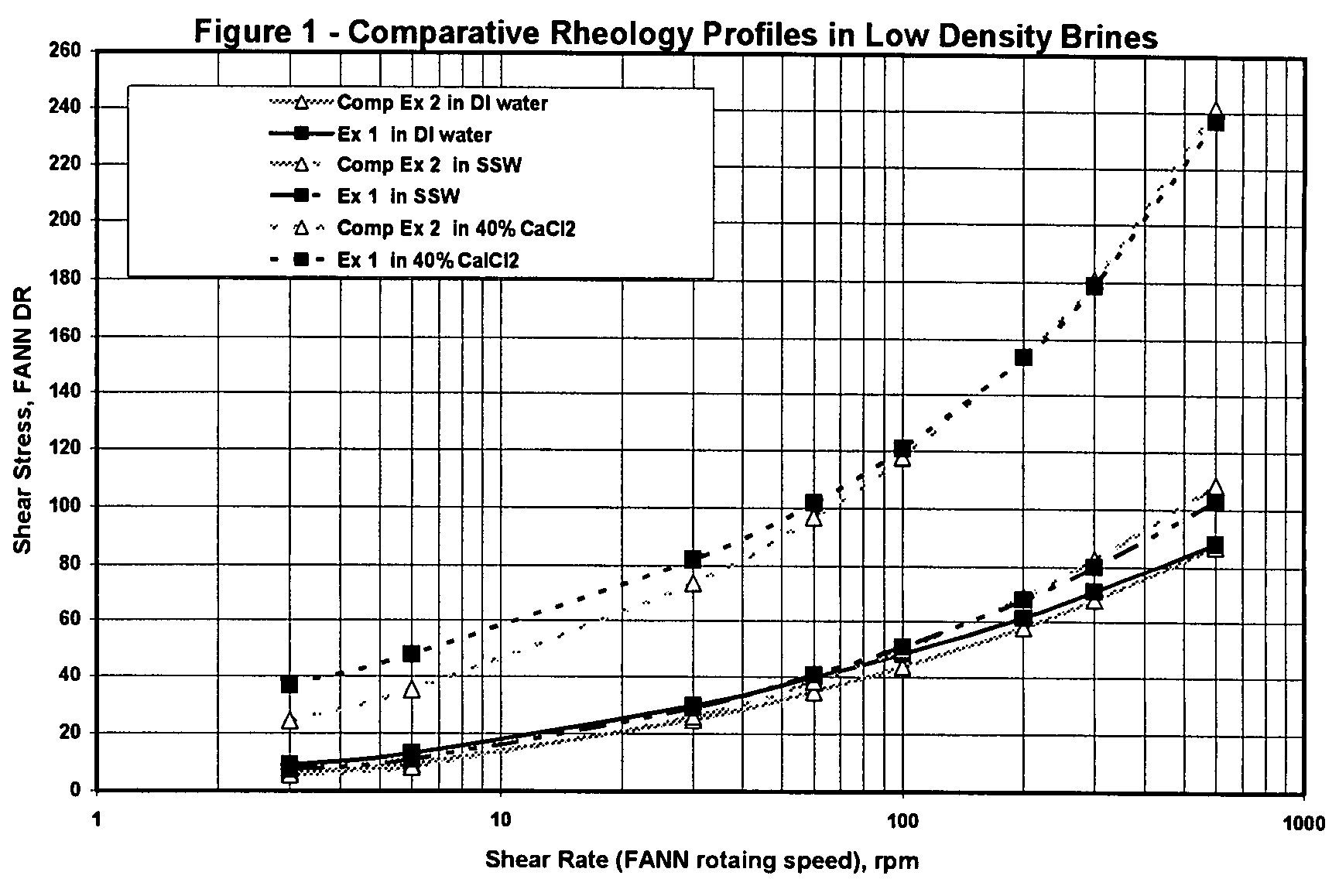

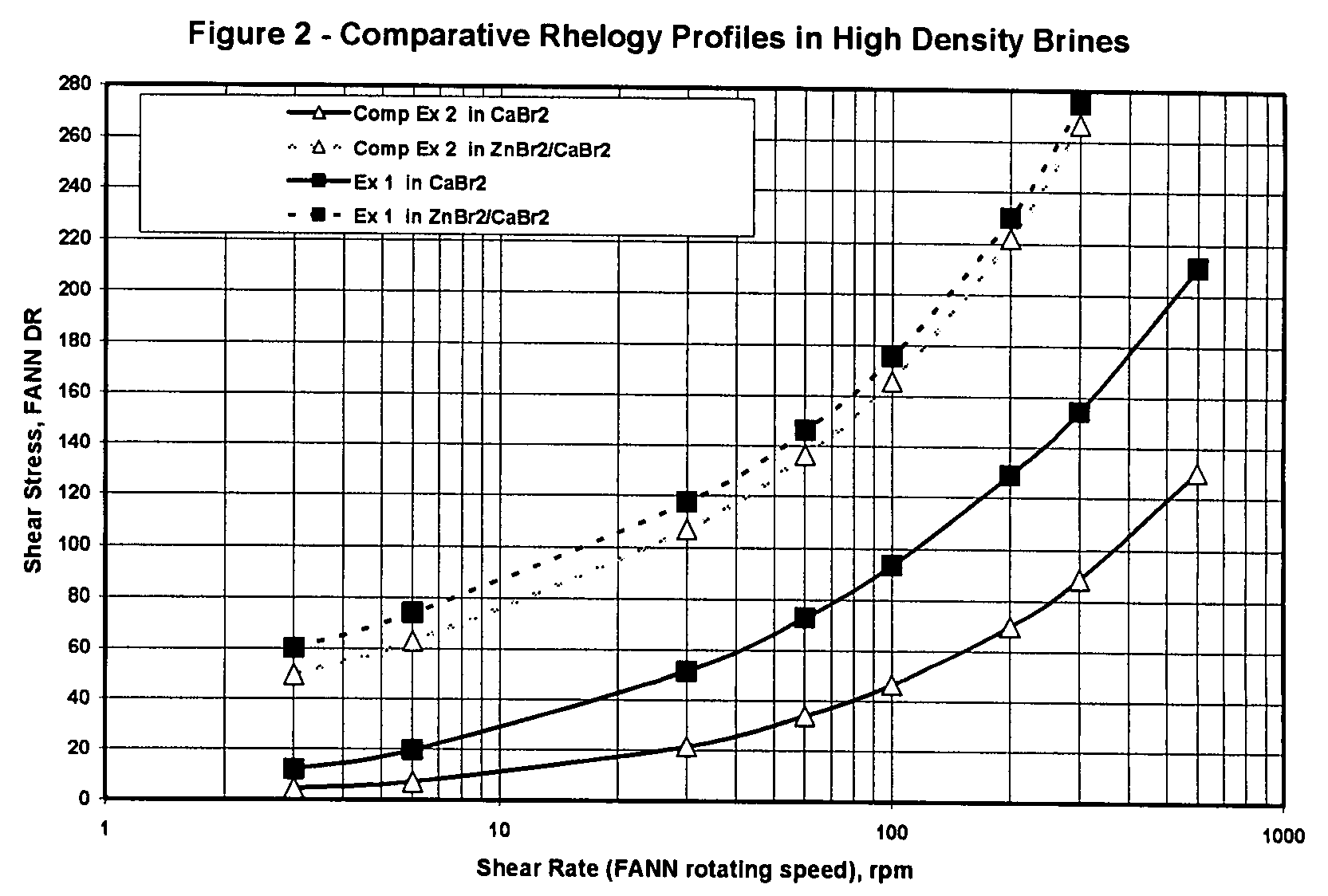

Water-based drilling fluids

InactiveUS20060019834A1Reduce molecular weightFlushingDrilling compositionWater basedInorganic salts

A water-based drilling fluid composition includes water and at least one rheology modifier and / or fluid loss control agent, and at least one other ingredient of polymeric additive, inorganic salts, dispersants, shale stabilizers, weighting agents, or finely divided clay particles, depending upon the desired attributes, wherein the rheology modifier and / or the fluid loss control agent comprises carboxymethylated raw cotton linters (CM-RCL) made from the baled raw cotton linters or comminuted raw cotton linters with increased bulk density.

Owner:HERCULES LLC

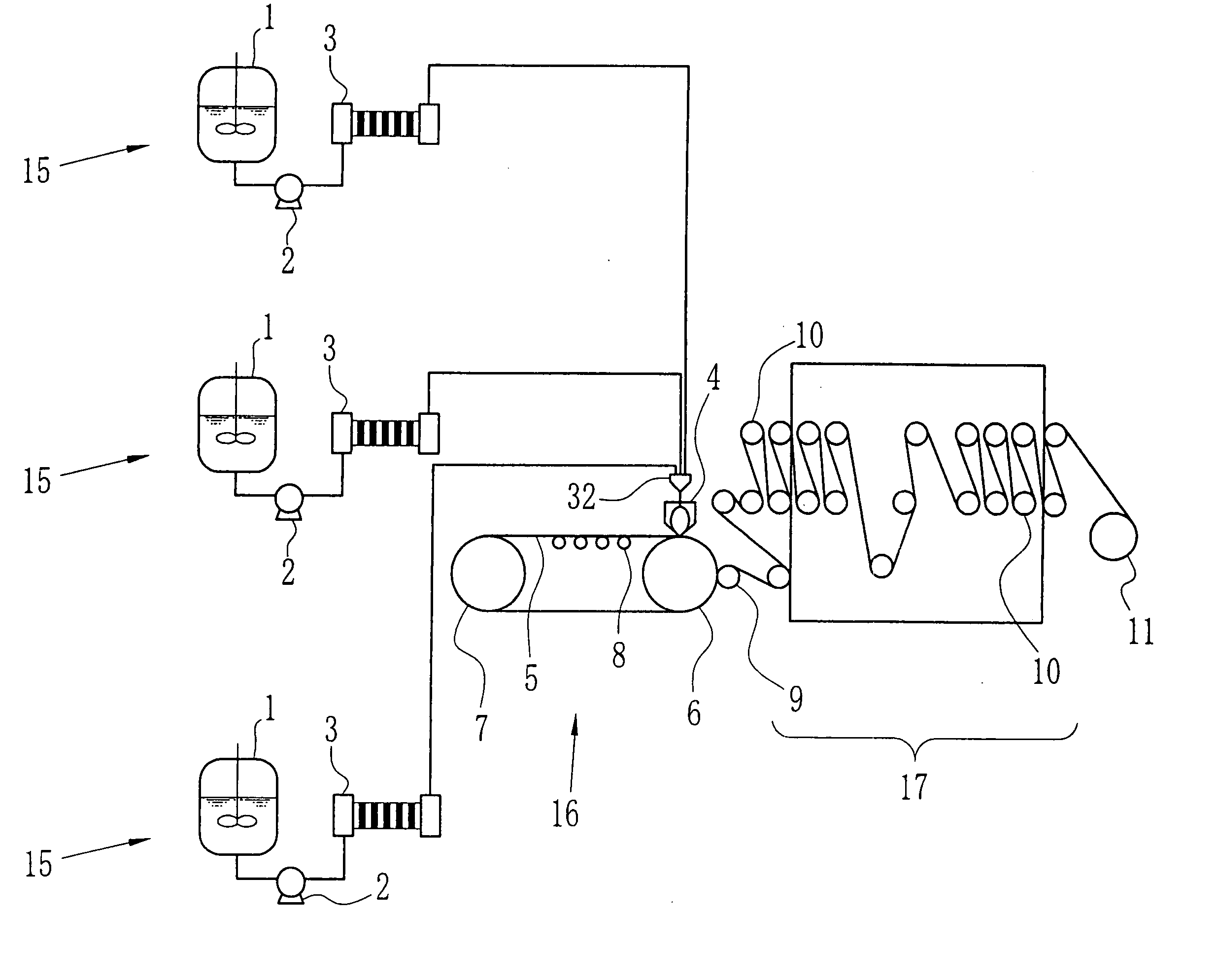

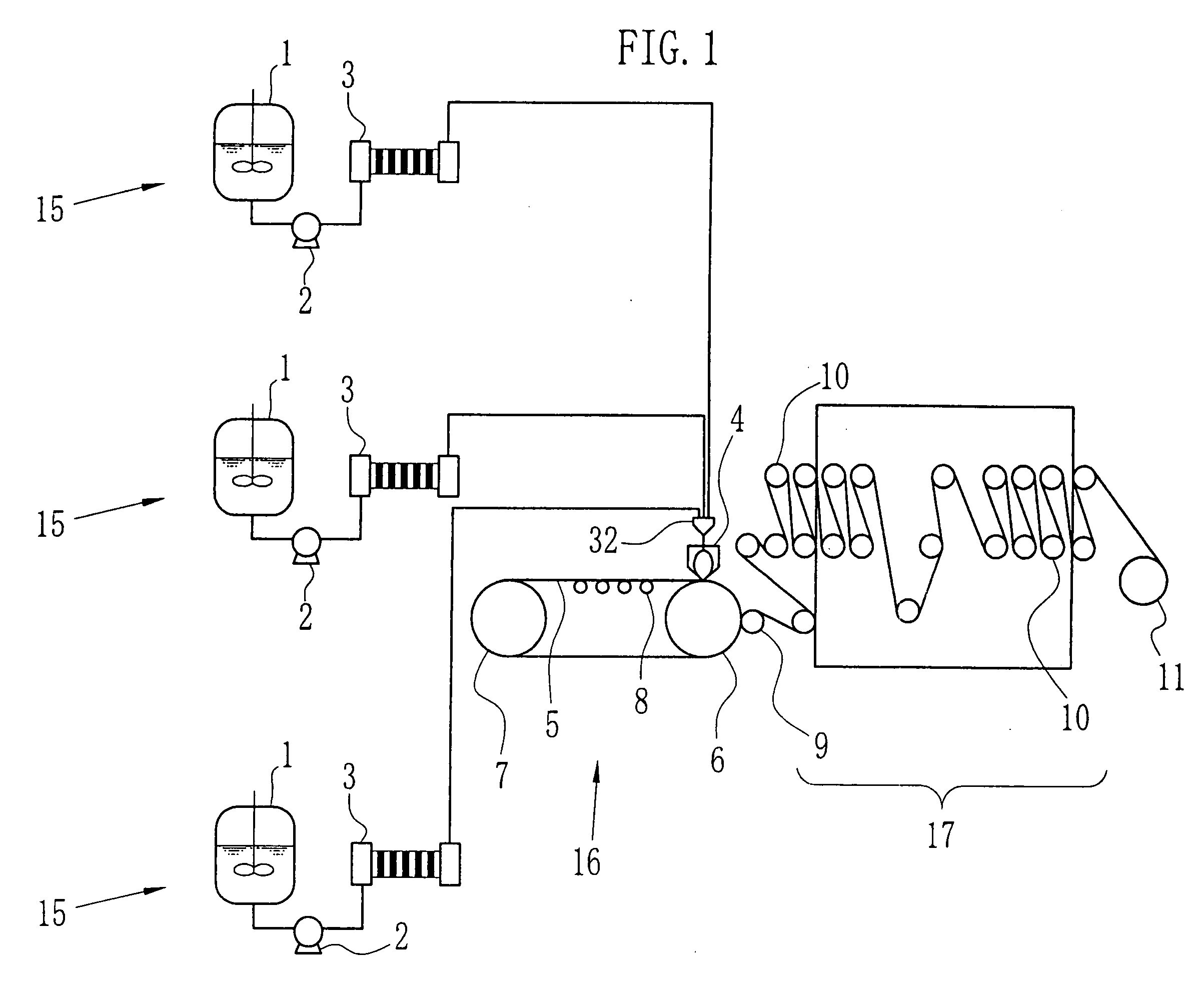

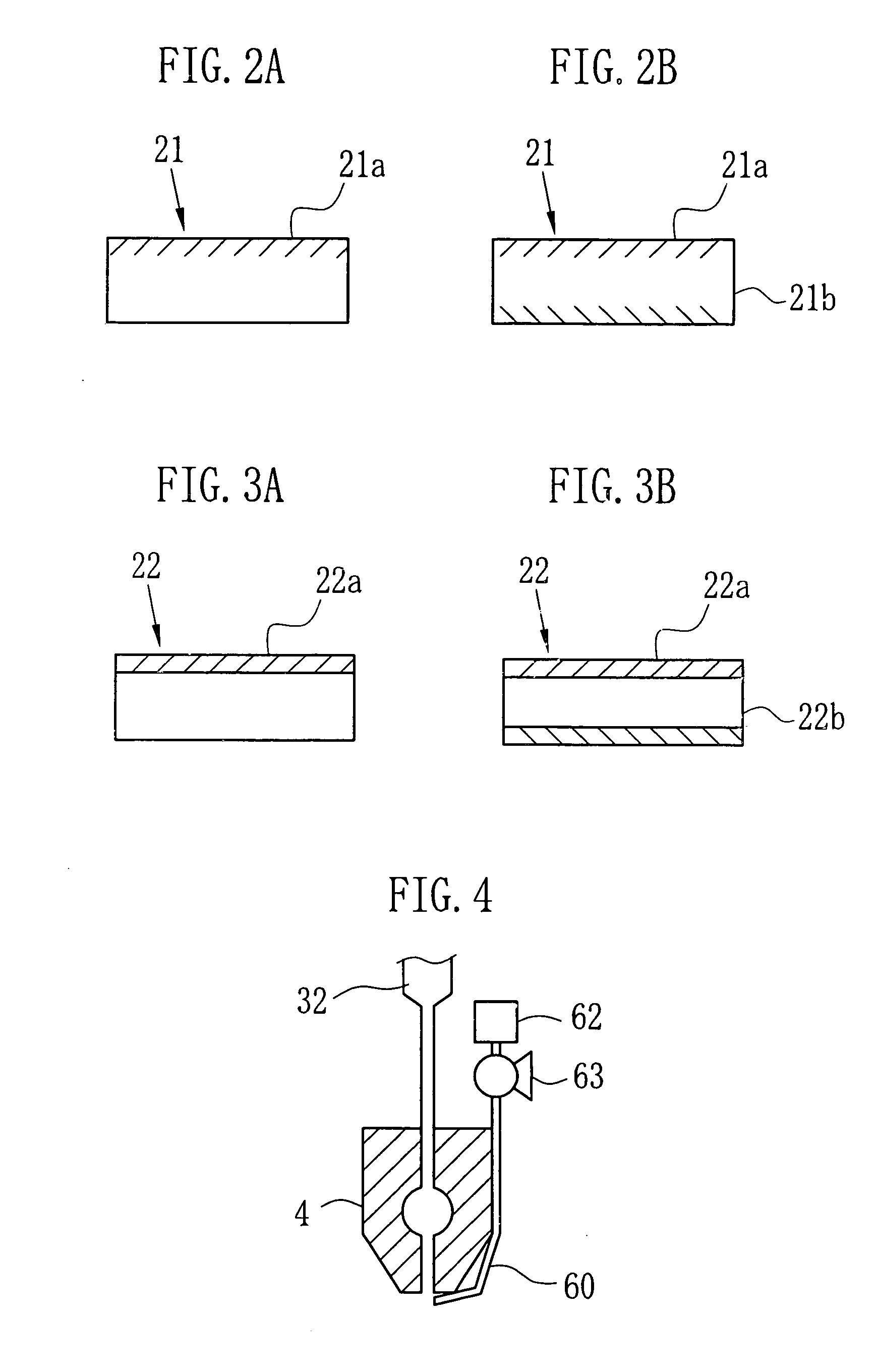

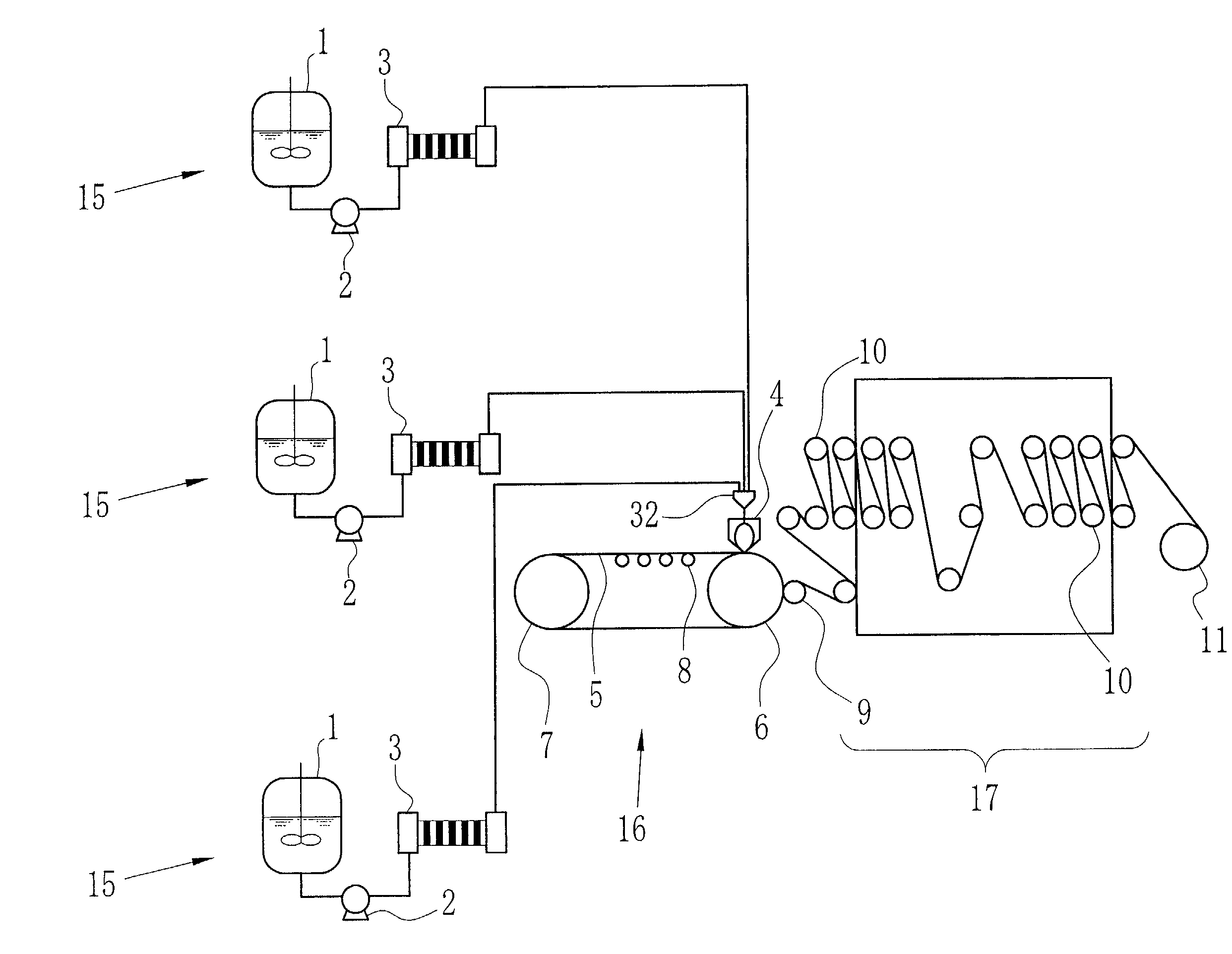

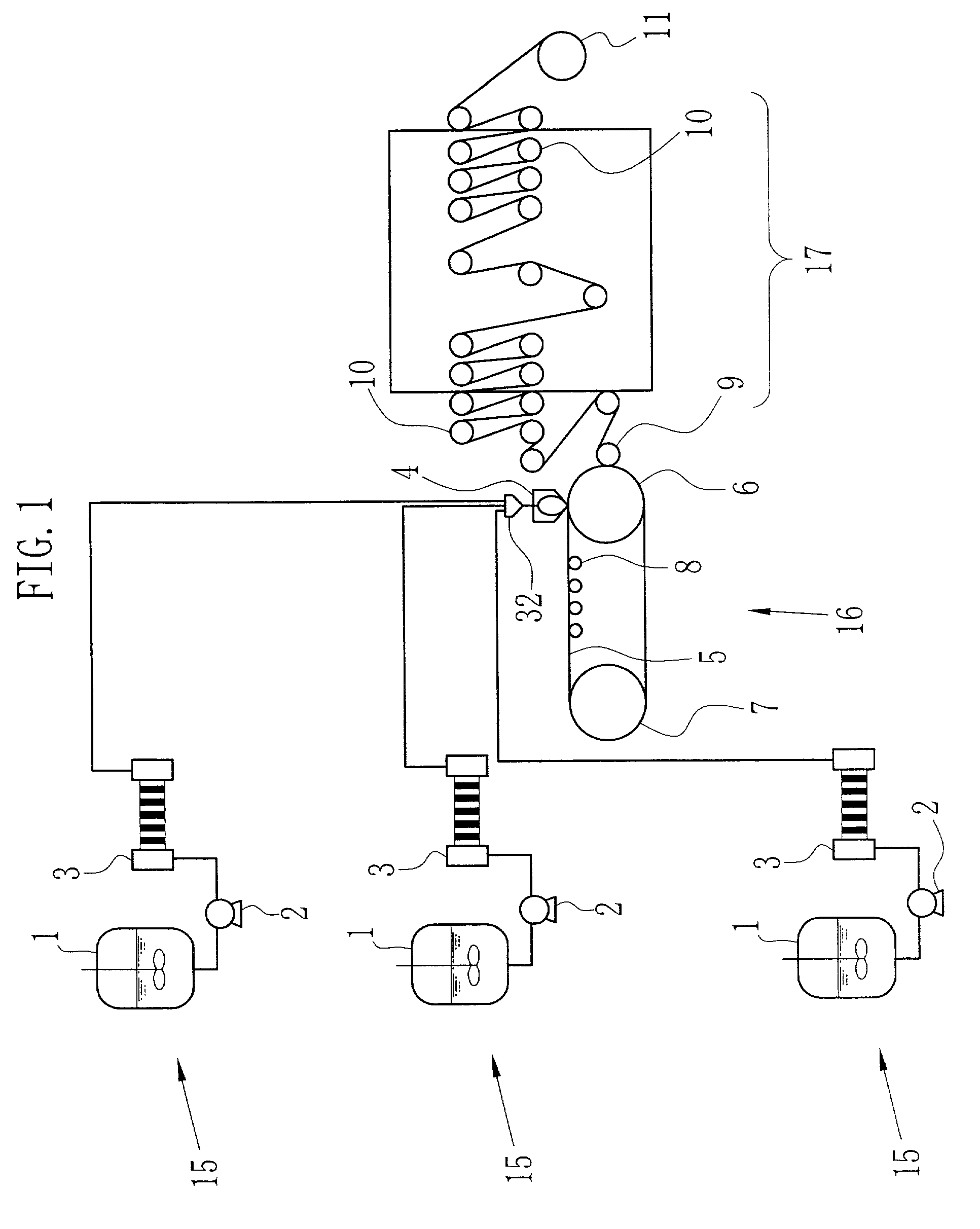

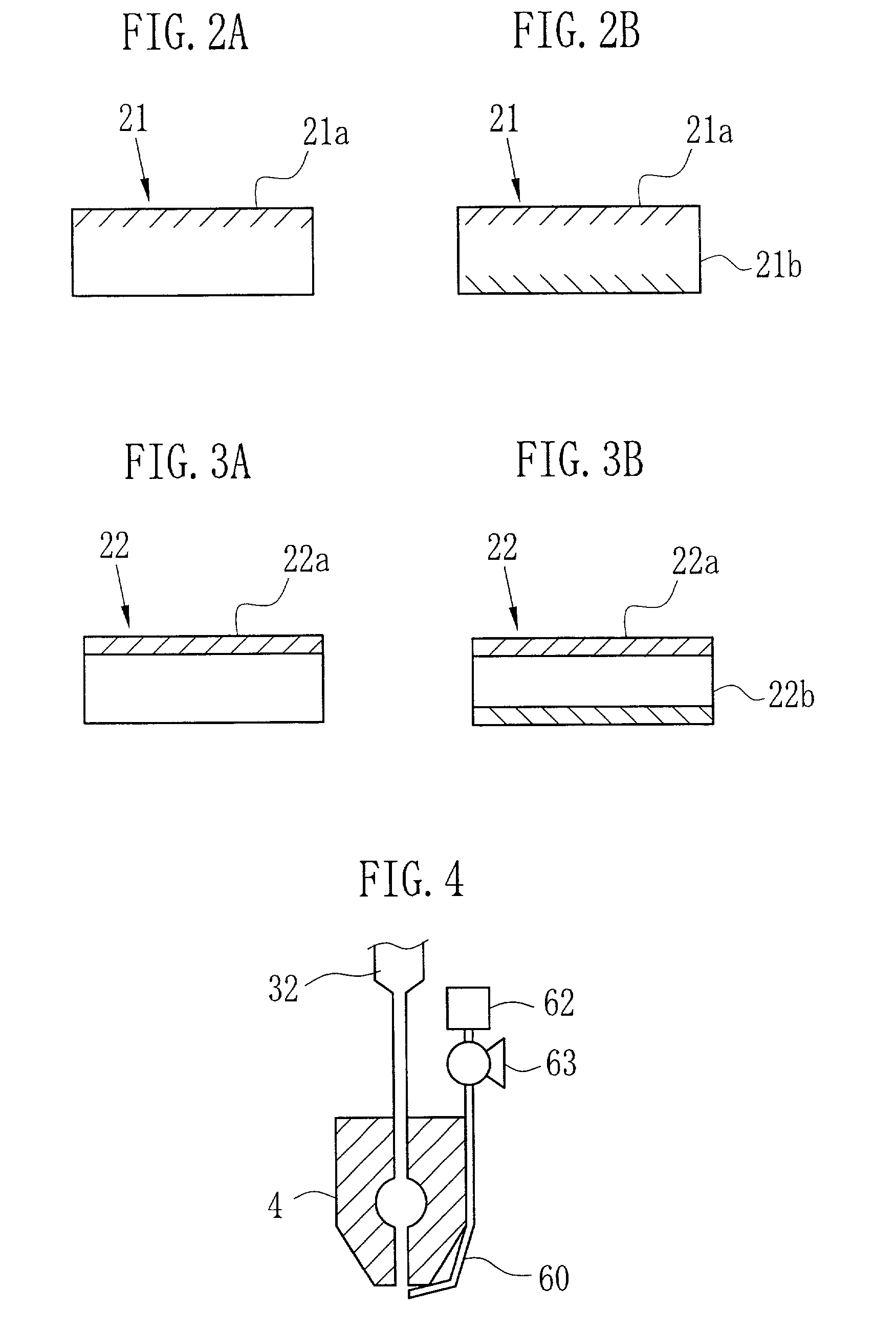

Method for producing of cellulose ester film

InactiveUS20050133953A1Prevent skinAvoid it happening againFlat articlesCoatingsCarbon numberCellulose ester membrane

In order to produce a cellulose ester film constructed of a front layer, an intermittent layer and a rear layer, a dope solution is doped on a supporter. In at least one of the front layer and the rear layer, a mass ratio of a cotton linter to a wood pulp (cotton linter / wood pulp) is between 5 / 95 and 0 / 100, and a solvent of the dope contains more than 15 wt. % alcohols and hydrocarbons whose carbon number each is 1-10. Further, a ratio of a solid content density of a solution for forming the front layer and the rear layer to a solid density of a solution for forming the intermittent layer is less than 0.9 wt. %, and a total thickness of the solutions for front and rear layers is more than 5% of the dope ribbon.

Owner:FUJIFILM CORP

Method of producing of cellulose ester film

InactiveUS20030015820A1Quality improvementAvoid it happening againLayered productsFlat articlesCarbon numberCellulose ester membrane

In order to produce a cellulose ester film constructed of a front layer, an intermittent layer and a rear layer, a dope solution is doped on a supporter. In at least one of the front layer and the rear layer, a mass ratio of a cotton linter to a wood pulp (cotton linter / wood pulp) is between 5 / 95 and 0 / 100, and a solvent of the dope contains more than 15 wt. % alcohols and hydrocarbons whose carbon number each is 1-10. Further, a ratio of a solid content density of a solution for forming the front layer and the rear layer to a solid density of a solution for forming the intermittent layer is less than 0.9 wt. %, and a total thickness of the solutions for front and rear layers is more than 5% of the dope ribbon.

Owner:FUJIFILM CORP

Joint compounds using thickeners prepared from raw cotton linters

InactiveUS20050235878A1Reduce the amount requiredWorkability of wetPropellersSolid waste managementJoint compoundEther

A mixture composition of a cellulose ether made from raw cotton linters and at least one additive is used in a ready mixed joint compound composition wherein the amount of the cellulose ether in the joint compound composition is significantly reduced. When this joint compound composition is mixed with water and applied to a substrate, the water retention, sag resistance, and workability of the wet joint compound are comparable or improved as compared to when using conventional similar cellulose ethers.

Owner:HERCULES INC

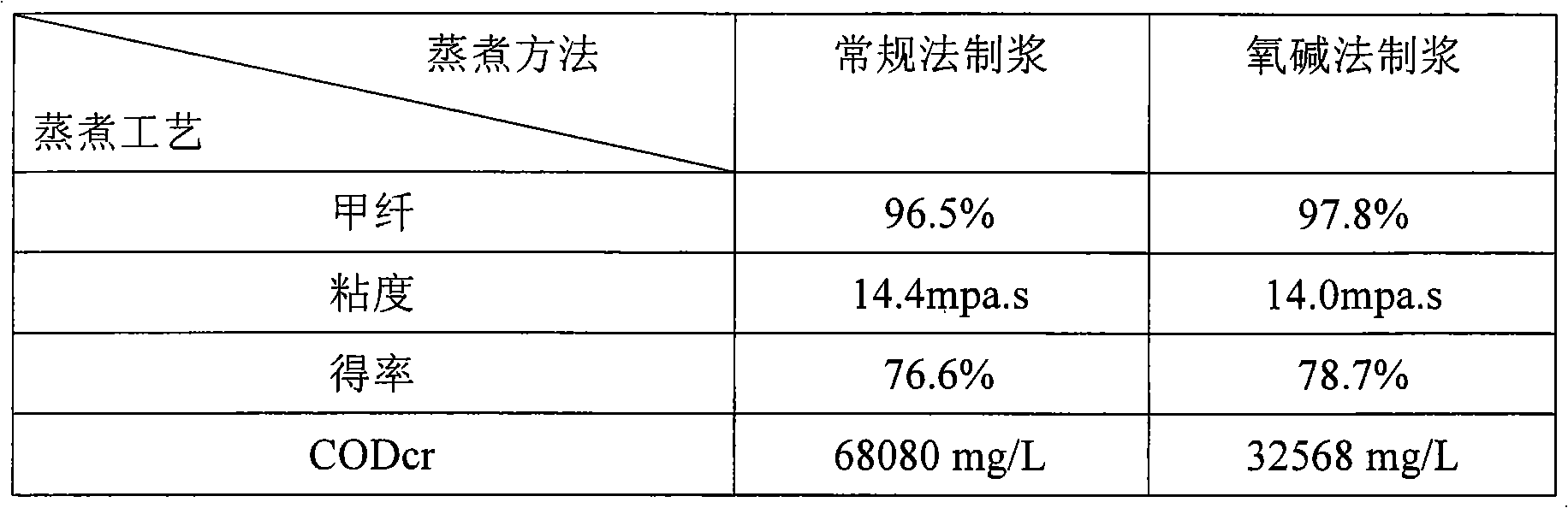

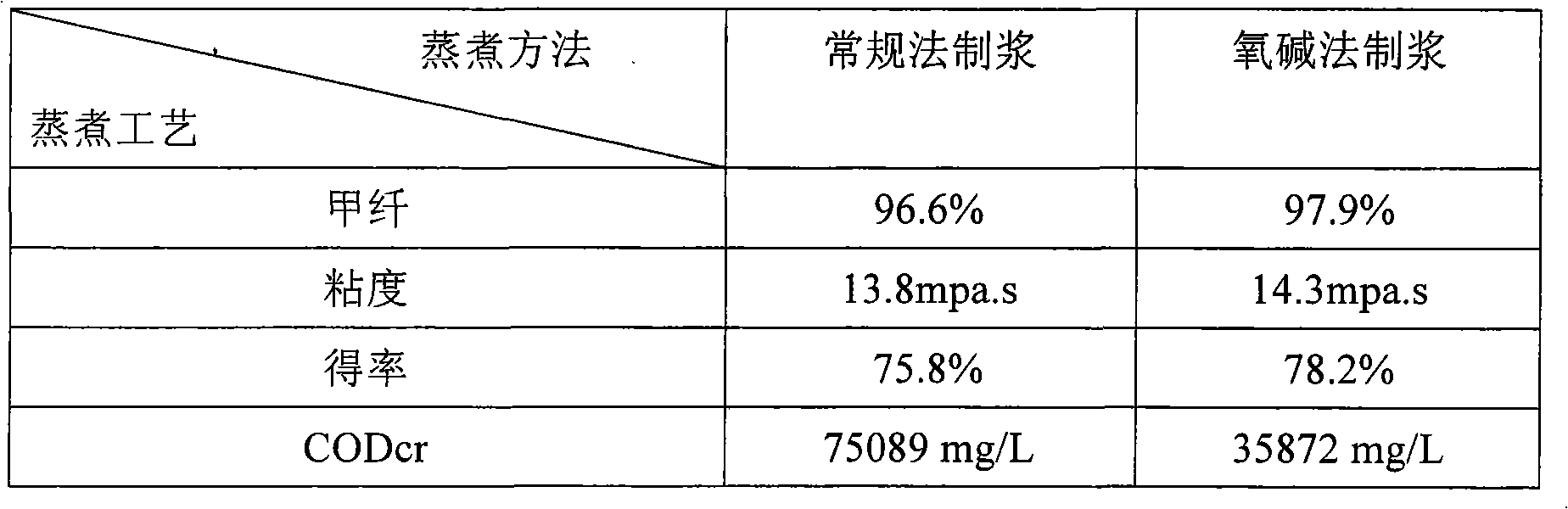

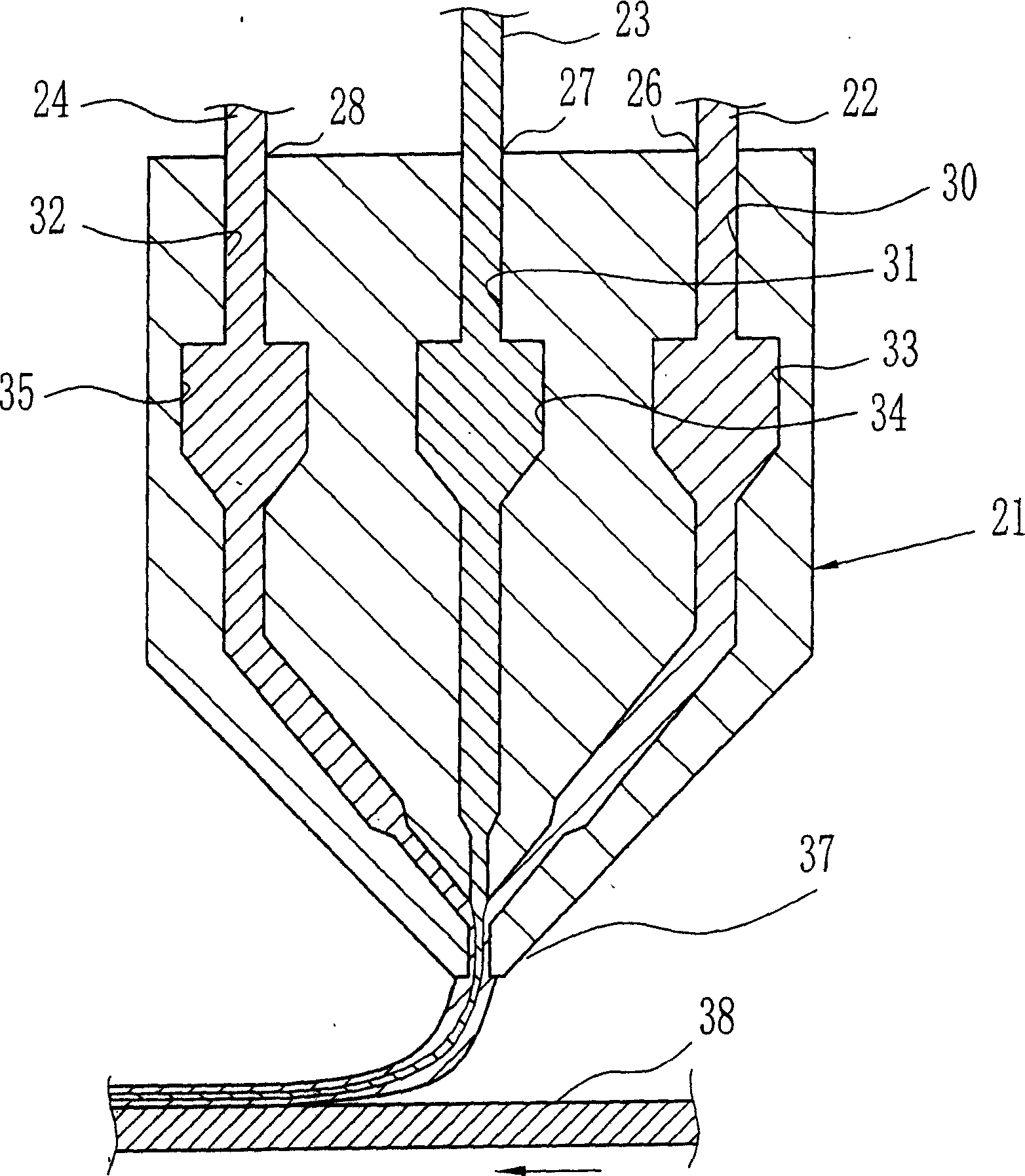

Method for producing dissolving pulp by oxygen continuous digesting method

InactiveCN101333778AReduce the degree of polymerizationAchieve continuous cookingPaper material treatmentCyclonic separationCooking methods

The invention relates to a production method for preparing a dissolving pulp by an oxygen-dissolving and continuous-cooking method, which applies the preparation of cotton linters in the production of viscose fibers in the textile industry, and the method comprises the following steps of: I. cotton linter pretreatments: including cotton linter loosening, cyclone separation and dust removal, feeding, two-roll grinding treatment, etc. to the cotton linters by a two-roll pulping machine; and II. oxygen dissolving and continuous cooking: a horizontal continuous cooking digester is adopted to realize the continuous, fast and low-pollution preparation of dissolving cotton pulp through the actions of high temperature, alkali, oxygen or hydrogen peroxide. The horizontal continuous cooking digester includes a pre-reaction bin, a two-roll gauge, a feeding screw, a T-shaped tube, a continuous-cooking tube and a cold discharge device. The method can effectively solve the problems of: cutting, tearing and cell primary wall breakage to the cotton linters by dry method after feed preparation, physical and chemical stripping to mass impurities in the cotton linters, fast accumulation reduction of the cotton linters in a continuous-cooking device and the purification of alpha cellulose under fast accumulation reduction, recycling of waste heat in the production link, and reduction of total amount of COD in a black liquor, and the method has advantages of even cooking and short cooking cycle.

Owner:宜宾长毅浆粕有限责任公司

Raw cotton linters composition, method of making, and uses thereof

A composition of a loose mass of comminuted raw cotton linter fibers has a bulk density of at least 8 g / 100 ml and at least 50% of the fibers in the mass passes through a US standard sieve size #10 (2 mm opening). This composition is made by obtaining a loose mass of first cut, second cut, third cut, or mill runs raw cotton linters or mixtures thereof and comminuting the loose mass of raw cotton linters to a size wherein at least 50% pass through a US standard sieve size #10 (2 mm opening). This composition is used to make cellulose ether derivatives.

Owner:HERCULES LLC

High polymerization degree cotton pulp and method for making the same

InactiveCN101130886AHigh fiber contentHigh whiteness valueVegetable materialCotton fibreDegree of polymerization

The present invention discloses a cotton pulp with high degree of polymerization and method for preparing said cotton pulp with high degree of polymerization by using cotton linters as raw material. Said preparation method includes the following steps: preparing raw material, digesting, washing material, pulping, removing sand, bleaching, acid treatment, water-washing, filtering and pulp-making, etc.

Owner:CHTC HELON

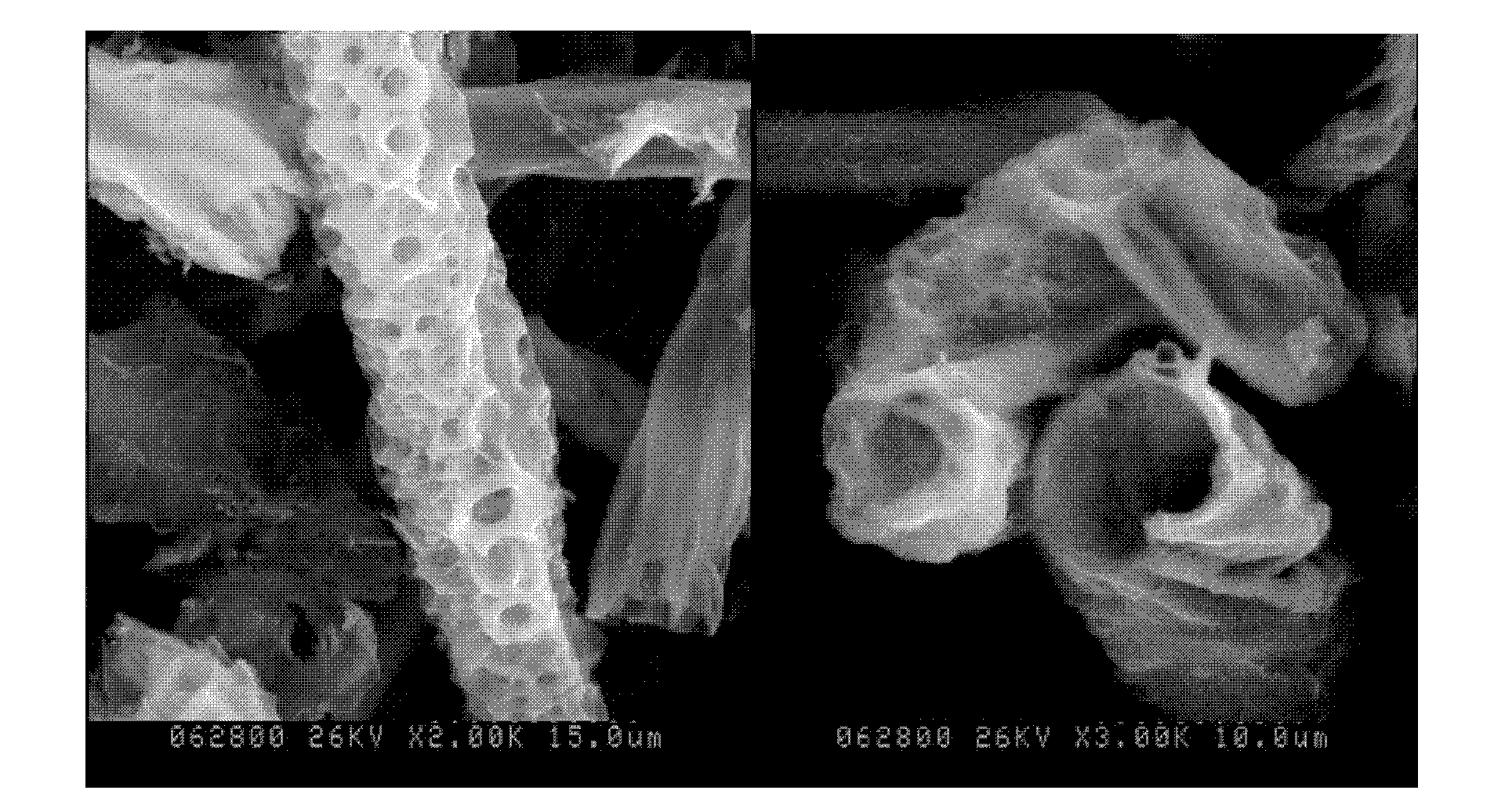

Polishing pad for use in chemical-mechanical planarization of semiconductor wafers and method of making same

InactiveUS6852020B2Prolong lifeSolution to short lifeOther chemical processesAbrasion apparatusFiberSlurry transport

A polishing pad for use in chemical mechanical polishing of substrates that being made of a porous structure comprising a matrix consisting of fibers, such as cotton linter cellulose bound with a thermoset resin, such as phenolic resin. The polishing pad surface has voids in which polishing slurry flows during chemical mechanical polishing of substrates, and in which debris formed during the chemical-mechanical polishing of substrates is temporarily stored for subsequent rinsing away. The polishing surface of the pad is ground to form asperities that aid in slurry transport and polishing, as well as opening the porous structure of the pad. The porous pad contains nanometer-sized filler-particles that reinforce the structure, imparting an increased resistance to wear as compared to prior-art pads. Also disclosed is a method of making the polishing pad.

Owner:RAYBESTOS POWERTRAIN

Water-based drilling fluids

Owner:HERCULES LLC

Water-based drilling fluids

A water-based drilling fluid composition includes water and at least one rheology modifier and / or fluid loss control agent, and at least one other ingredient of polymeric additive, inorganic salts, dispersants, shale stabilizers, weighting agents, or finely divided clay particles, depending upon the desired attributes, wherein the rheology modifier and / or the fluid loss control agent comprises carboxymethylated raw cotton linters (CM-RCL) made from the baled raw cotton linters or comminuted raw cotton linters with increased bulk density.

Owner:HERCULES INC

Process for producing cotton dissolving pulp

The invention relates to a production technique of a dissolved cotton pulp, in particular to a production technique that utilizes the raw material of cotton linters and adopts simple techniques to produce the dissolved cotton pulp with even fiber length, high fibrillation degree, good intensity, less water soluble substances, high methylcellulose content, stable polymerization degree and less dust, has low COD discharge in waste water, and lowers environmental pollution. The dissolved cotton pulp produced by the production technique is mainly used for producing paper that is used for wiping upper-scale precise instruments, steel paper that is used for precise machining, a novel medicine loading agent of microcrystalline cellulose, explosive nitrocellulose, high-level nitrolacquer and building coating materials, etc.

Owner:山东银鹰股份有限公司

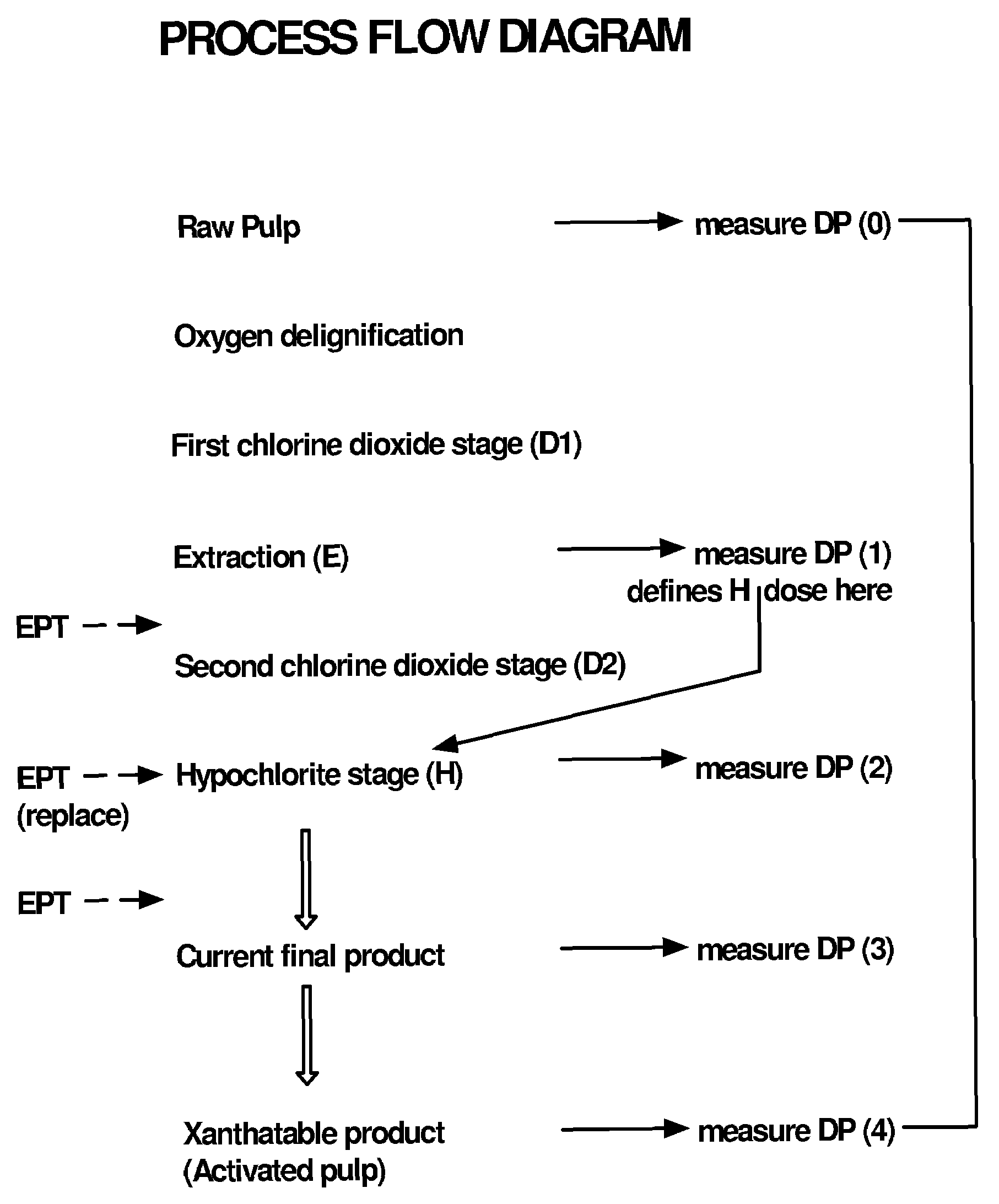

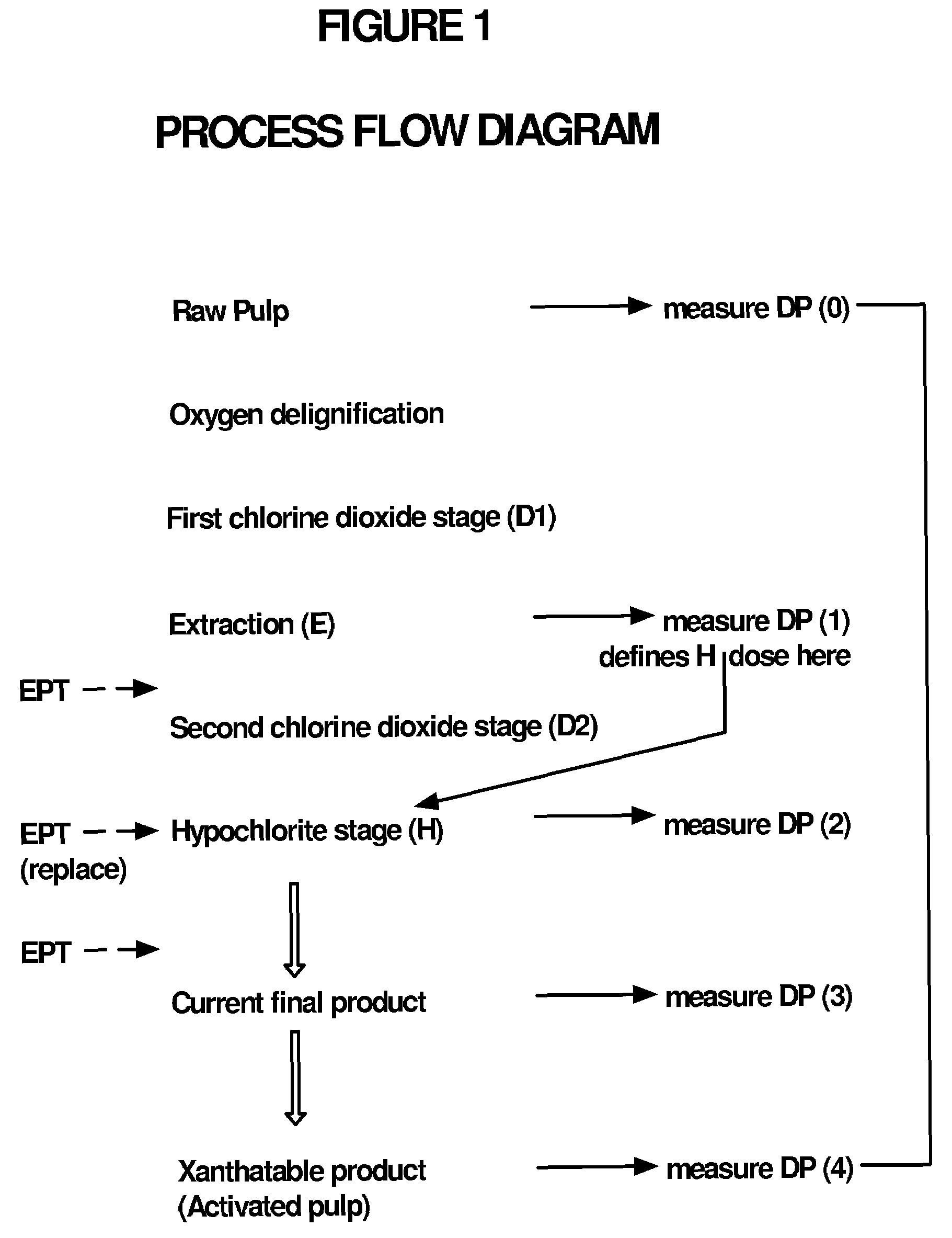

Pulp treatment and process

InactiveUS7267744B2Reduce stepsReduce in quantityElectrolysis componentsWood treatment detailsPulp treatmentCompound (substance)

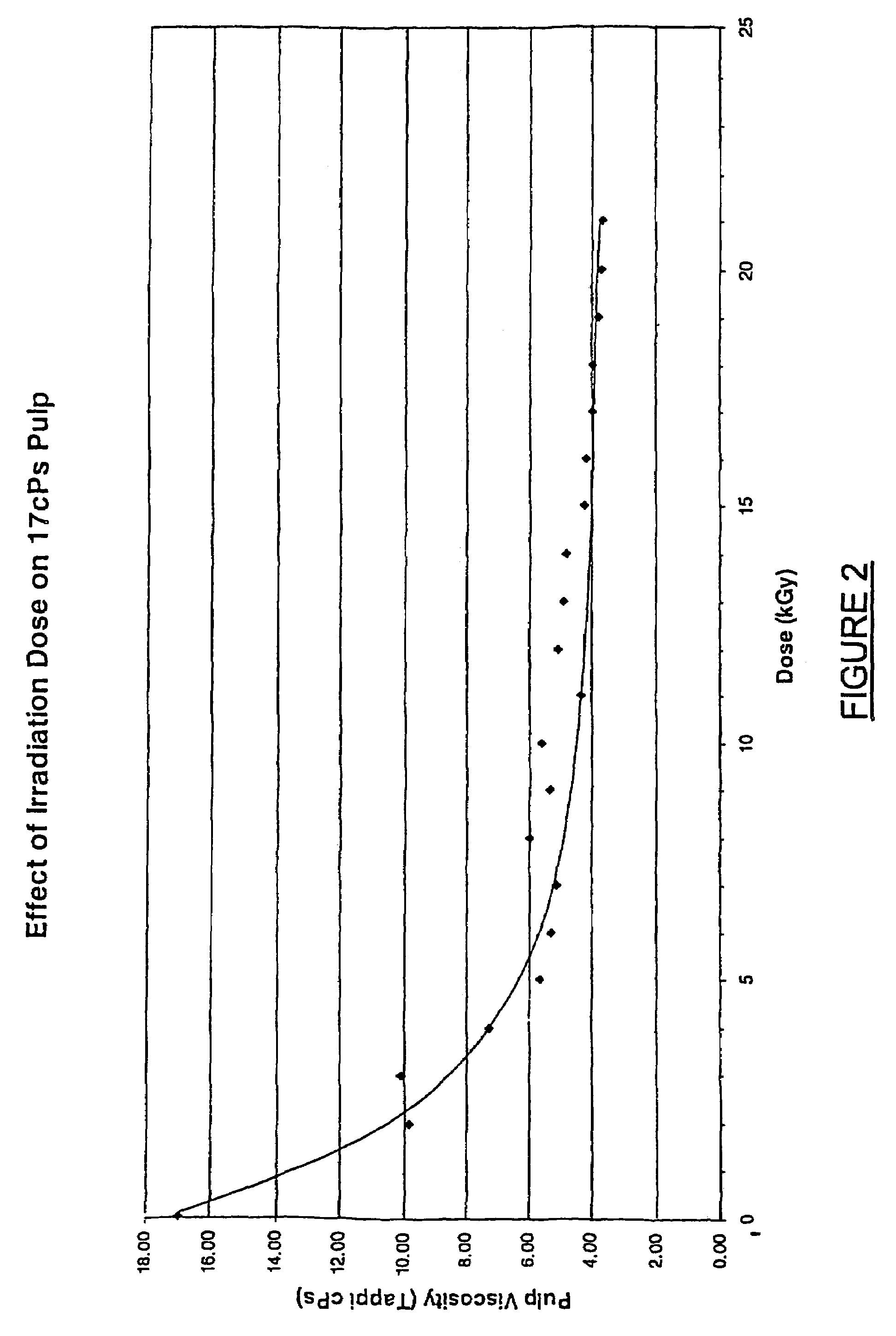

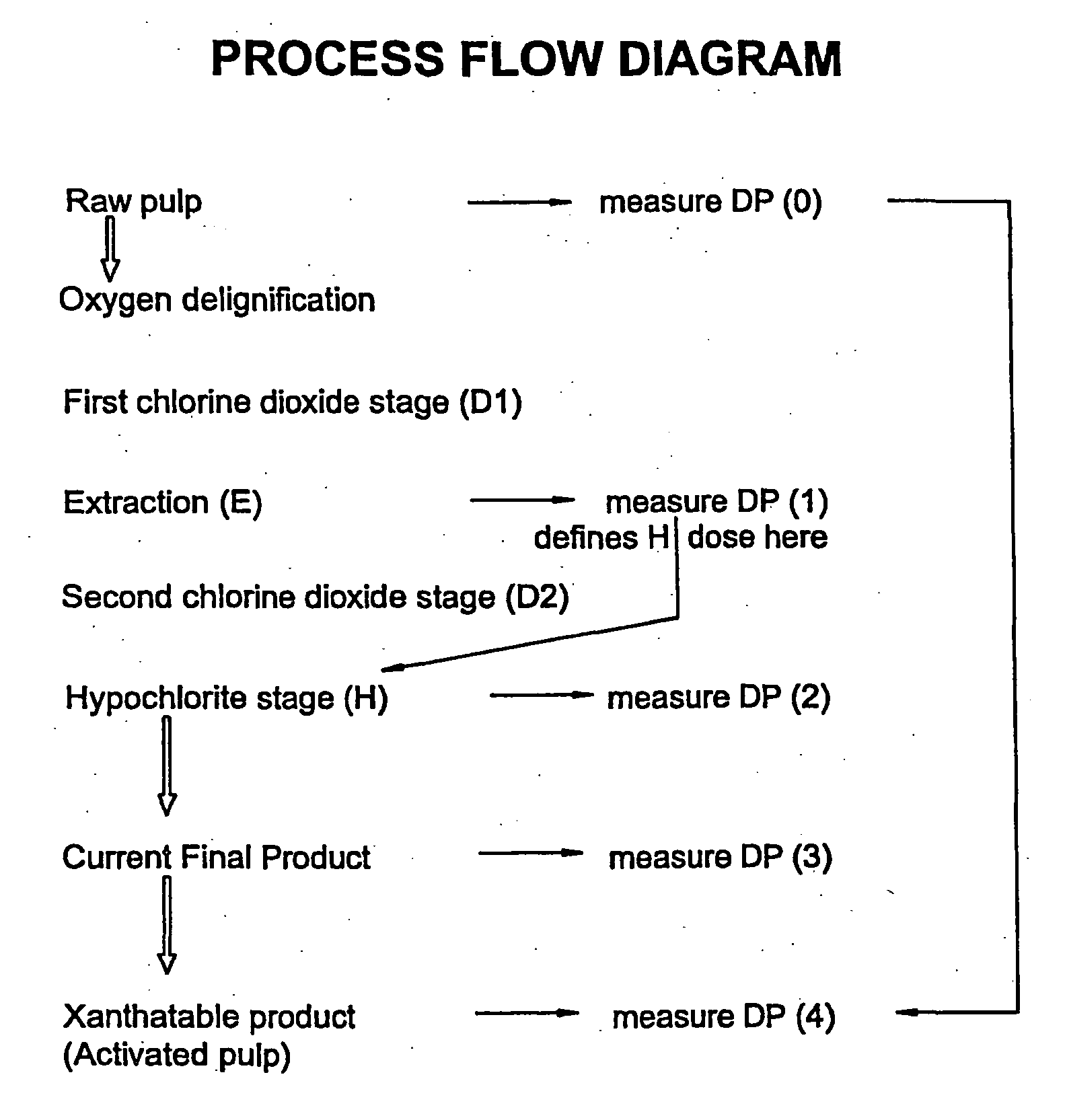

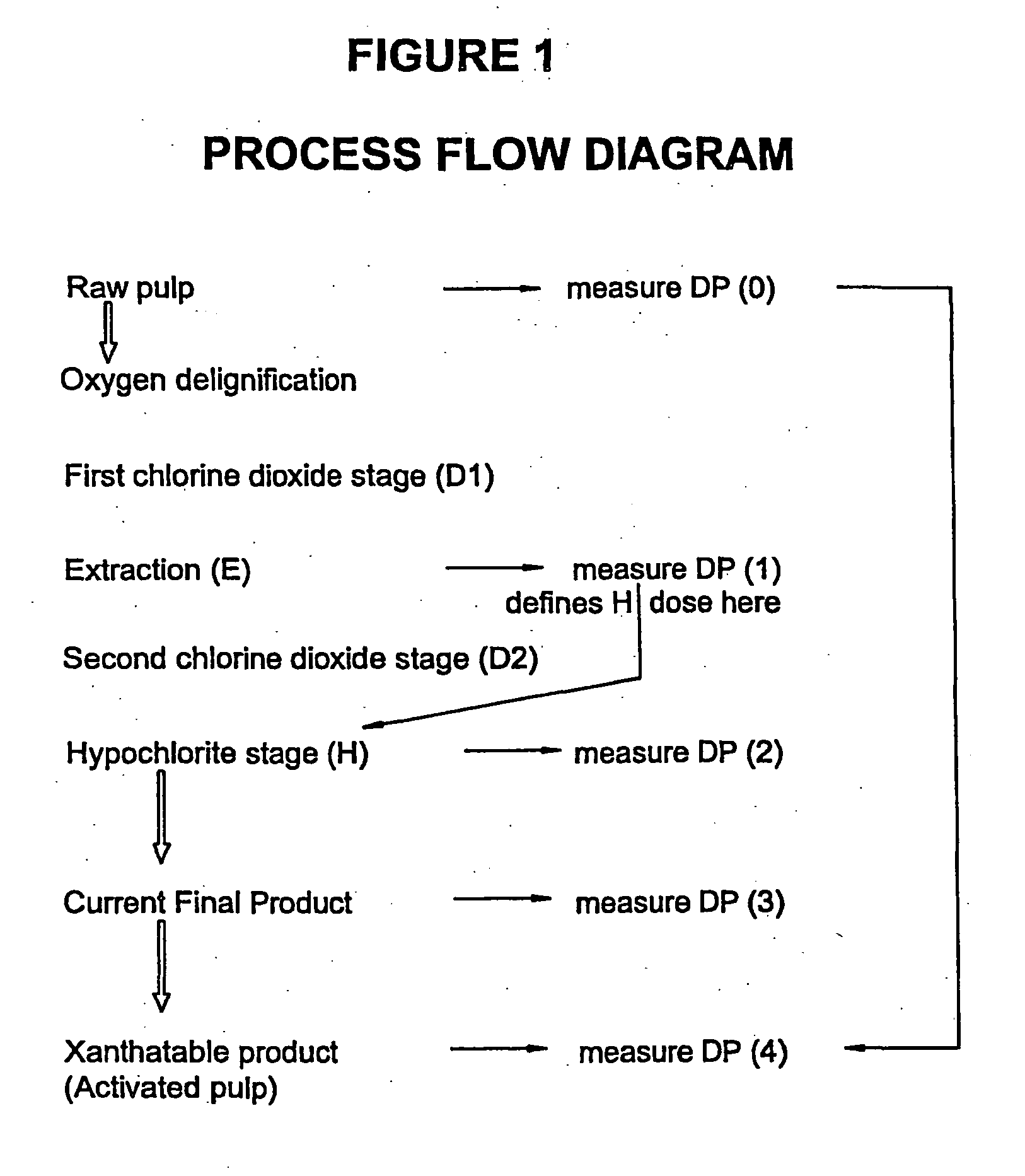

This invention provides a process for treating chemical woodpulp, or chemical cellulose including cotton linter, including the step of applying an electron processing technology (EPT) step to chemical woodpulp, or chemical cellulose, as the case may be, on an in-line basis to provide control of pulp viscosity or degree of polymerization (DP). The invention also provides a method of process control in treating the aforementioned woodpulp or cellulose, including the step of using radiation dose-viscosity relationship curve for applying an EPT step on an in-line basis. The in-line EPT step may, in one form of the invention, replace and hence eliminate a chemical DP reduction step.

Owner:SAPPI LTD

Composite pulp of paper pulp and cotton linter and preparation method thereof

ActiveCN102182090AAchieve recyclingReduce pollutionPaper recyclingPulp bleachingSteepingDissolving pulp

The invention provides a preparation method of composite pulp of paper pulp and cotton linter for viscose. By utilizing the method, the unique performances of fibers such as bamboos, woods, bast fibers, bagasse and the like can be combined with the excellent performances of cotton; any other two or more than two of raw materials such as the paper pulp or the bamboos, the woods, the cotton, the bast fibers and the like can be steamed and cooked independently and can be composited and prepared into dissolved pulp at a bleaching stage after being subjected to a series of process treatments. The varieties of the paper pulp used in the invention are not limited from production methods and raw materials and can be unbleached pulp or bleached pulp; through alkali steeping treatment, the difficulty in steaming and cooking the paper pulp is reduced, the prepared dissolved pulp has high content of alpha cellulose and the steeping liquor can be cyclically utilized; and by utilizing the method, the pollution in the pulping process is less and the cyclic utilization of the alkali liquor can be realized.

Owner:潍坊欣龙生物材料有限公司

Method for producing high whiteness cotton pulp by using cotton linter

InactiveCN101105012AReduce pollutionReduce dosagePaper material treatmentMaterials preparationMaterial consumption

The invention discloses a simple method for producing high-whiteness cotton pulp from cotton linters as raw materials. The method comprises the steps of material preparation, prehydrolysis, boiling, loosening, desanding, concentration, chloridization, alkali purification, bleaching, acid treatment, desanding, concentration, paper making, and oven-drying. A mixture of NaOH and green oxygen is used in the boiling step. The invention has the advantages of simple and controllable process, low processing load posterior to the boiling step, reduced material consumption, less waste discharge, and low environmental pollution. The produced cotton pulp has high pulping fiber strength, yield and whiteness.

Owner:CHTC HELON

Pulp treatment and process

InactiveUS20040129394A1Reduce environmental problemsSmall DP rangeElectrolysis componentsWood treatment detailsPulp treatmentCompound (substance)

This invention provides a process for treating chemical woodpulp, or chemical cellulose including cotton linter, including the step of applying an electron processing technology (EPT) step to chemical woodpulp, or chemical cellulose, as the case may be, on an in-line basis to provide control of pulp viscosity or degree of polymerisation (DP). The invention also provides a method of process control in treating the aforementioned woodpulp or cellulose, including the step of using radiation dose-viscosity relationship curve for applying an EPT step on an in-line basis. The in-line EPT step may, in one form of the invention, replace and hence eliminate a chemical DP reduction step.

Owner:SAPPI LTD

Air-laid web with hollow synthetic fibers

InactiveUS20040103970A1Increase ratingsIncrease resistanceWood working apparatusAbsorbent padsPolyesterPolyolefin

The present invention relates to a single layer air-laid composition comprising: hollow synthetic fiber, absorbent and a binder system. The hollow fiber comprises from about 10 to about 50 percent by weight of said composition. The hollow synthetic fiber has a denier of between about 2 to about 18. The hollow synthetic fiber is selected from the class of polyolefins, polyesters, polyamides, acrylics, as well as mixtures and copolymers thereof. The absorbent comprises from about 40% to about 80% of the weight of said composition. The absorbent is a natural absorbent, or a synthetic absorbent, or a mixture of these. The natural absorbent is selected from the class of wood pulp fluff, cotton, cotton linters, and regenerated cellulose fibers, or a mixture of these. The synthetic absorbent is selected from the class of agar, pectin, guar gum, and synthetic hydrogel polymers. The binder fiber comprises from about 3 to about 15 percent by weight of said composition.

Owner:INVISTA NORTH AMERICA R L

Process for preparing dissolved pulp by oxidative degradation of linters

ActiveCN101289818AReduce pollutionEmission reduction effect is obviousDigestersPulping with inorganic basesDissolving pulpOxygen

The invention discloses a method for making dissolving pulp by oxidative degradation of cotton linters in the oxidative degradation method, aiming at resolving the problems of serious pollution, low yield, long cycle and insufficient resources, etc. existing in the conventional process of making dissolving pulp. The method comprises the following technological steps of cutting and impurity removal, high consistency mixing pretreatment and impurity removal and poly decreasing by continuous oxidative degradation. The method of the invention has the advantages of improving production speed, improving product quality, saving steam and lowering the generation of pollutants.

Owner:YIBIN GRACE GROUP CO LTD

Ethoxylated raw cotton linters for completion and workover fluids

ActiveUS20070197399A1Maintain good propertiesImprove functional propertiesFluid removalFlushingSodium BentoniteAdditive ingredient

A completion and workover fluid composition comprising, water and at least one rheology modifier and / or fluid loss control agent, and at least one other ingredient selected from the group consisting of inorganic salts, shale inhibitors, corrosion inhibitor, biocide, defoamers and finely divided solids particles (e.g., bentonite, attapulgite, sepiolite, calcium carbonate, etc.), depending upon the desired attributes, wherein the rheology modifier and / or the fluid loss control agent is an ethoxylated raw cotton linters or a modified ethoxylated raw cotton linters. The ethoxylated raw cotton linters provides comparable or better rheology and viscosity properties compared to high molecular weight commercial HECs made from purified cotton linters. These ethoxylated raw cotton linters derivatives are suitable for applications in oil-well servicing fluids, particularly to enhance functional properties of completion and workover fluids used during oil-well drilling operations.

Owner:HERCULES LLC

Production process of bamboo charcoal fiber

InactiveCN102051701AFunction increaseHygroscopicArtificial filaments from cellulose derivativesDry spinning methodsSpinningCellulose acetate

The invention relates to a production process of bamboo charcoal fiber, comprising the following steps: pulverizing bamboo charcoal powder until the particle size is below the micron order, dispersing evenly; preparing cellulose triacetate from refined cotton linters as a raw material, dissolving the cellulose triacetate in dichloromethane to form a 10-50wt% spinning solution, adding bamboo charcoal micro powder to the spinning solution, wherein the weight ratio of the bamboo charcoal micro powder to the cellulose triacetate is 1:(50-100), and preparing bamboo charcoal acetate fiber by a dry spinning method. The invention has high performances of both bamboo charcoal fiber and acetate fiber, the manufactured fabric has the functions of moisture absorption, permeability, antibiosis, bacteriostasis, deodorization, high adsorption, temperature and humidity adjustment, far infrared radiation, electromagnetic radiation prevention and the like, and the fabric is soft, delicate, nonirritating and hypo-allergenic to skin, washable, sunfast, heat resistant, easy to wash, vermin-proof and moisture-proof.

Owner:ZHEJIANG MINXIN ECO TECH

Polishing pad for use in chemical-mechanical planarization of semiconductor wafers and method of making same

A polishing pad for use in chemical mechanical polishing of substrates that being made of a porous structure comprising a matrix consisting of fibers, such as cotton linter cellulose bound with a thermoset resin, such as phenolic resin. The polishing pad surface has voids in which polishing slurry flows during chemical mechanical polishing of substrates, and in which debris formed during the chemical-mechanical polishing of substrates is temporarily stored for subsequent rinsing away. The polishing surface of the pad is ground to form asperities that aid in slurry transport and polishing, as well as opening the porous structure of the pad. The porous pad contains nanometer-sized filler-particles that reinforce the structure, imparting an increased resistance to wear as compared to prior-art pads. Also disclosed is a method of making the polishing pad.

Owner:RAYBESTOS POWERTRAIN +1

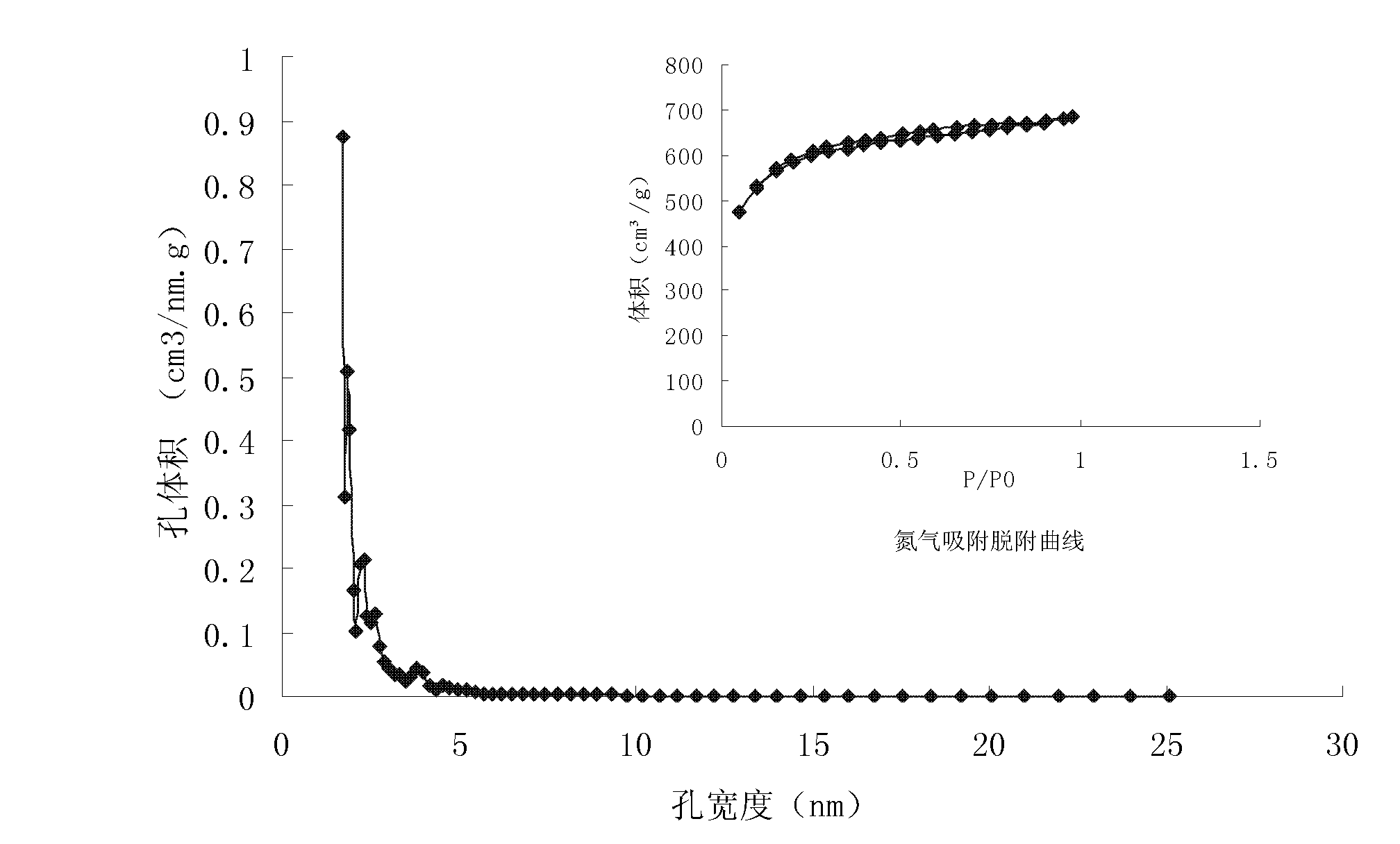

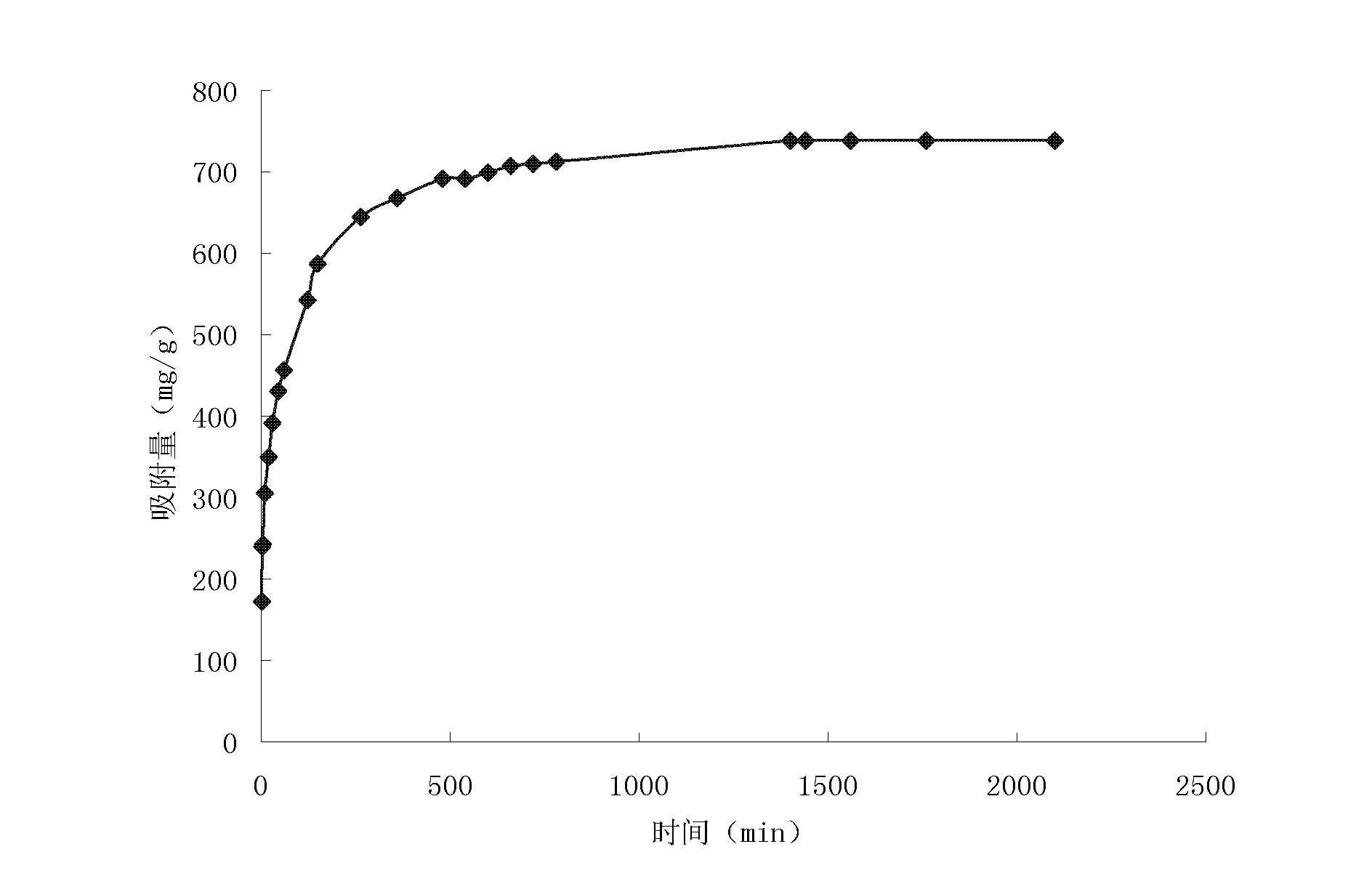

Method for preparing activated carbon fibers with high specific surface by use of cotton linters

InactiveCN102220665ALarge specific surface areaRich in microporesOther chemical processesFibre chemical featuresActivated carbonFiber

The invention relates to a method for preparing activated carbon fibers by the use of cotton linters, comprising the following steps of: placing cotton linters into a fermentation cylinder, inoculating turkey-tail or white rot fungus, performing a fermentation treatment, followed by washing again and drying; placing KOH or NaOH into a reaction vessel, heating until KOH or NaOH is melted; adding the treated cotton linters to the molten NaOH or KOH with the mass ratio of cotton linters to KOH or NaOH being 1:2-4, heating the mixture to the temperature of 600-800 DEG C, and performing a carbonization-activation treatment for 1-1.5 hours. The specific surface of the obtained cotton linter activated carbon fibers is over 2000m<2> / g. The technology provided by the invention is simple and is used to accomplish waste utilization. The prepared activated carbon fibers have large specific surface, strong sorption as well as excellent performance, and can effectively remove harmful pollutants.

Owner:SHANDONG UNIV

Acylation cellophane and producing method thereof

InactiveCN1526754AImprove adhesionGood optical performanceSynthetic resin layered productsCellulosic plastic layered productsSurface layerLiquid-crystal display

In a multi-layer structure of a cellulose acylate film, the averaged degree of acylation of surface layers is controlled in the range of 0.5 to 2.8 by mixing several sorts of cellulose acylates having different averaged degrees of acyation. One of the surface layers is formed on a substrate by casting a solution containing cellulose acylate made of cotton linter. Lubricant particles are added to a solution for the surface layers, and emission compounds to a solution for the inner layers. The obtained cellulose acylate film is excellent in adhesive property to the hydrophobic material without saponification, and adequately used for the polarizing filter, an optical compensation sheet, and liquid crystal display.

Owner:FUJIFILM CORP +1

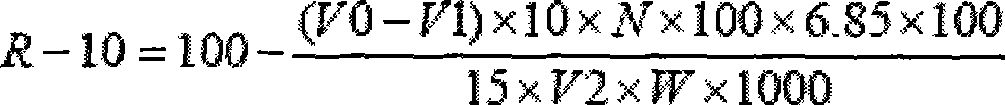

Production process of cotton pulp for cellulose triacetate

ActiveCN101597870AEmission reductionReduce pollutionPulp bleachingPulping with inorganic basesCellulose acetateWastewater

The invention relates to a production process of cotton pulp for cellulose triacetate, in particular to a simple production process of cotton pulp using cotton linter as a raw material; in the whole pulping process, the wastewater COD discharge is as low as 20250-25050mg / l, so that the environmental pollution and sewage treatment pressure can be reduced; on the conditions of stable polymerization, high whiteness and alpha cellulose content, uniform fiber length and proper compactness, the product has low content of methylene dichloride extract and metallic ions, low ash content and low dust, thus being applicable to the industry for producing cellulose triacetate.

Owner:山东银鹰化纤有限公司

Naturally degradative cotton linter plastic film and manufacture process thereof

InactiveCN101629398AEfficient use ofUnable to penetrateWater-repelling agents additionPaper/cardboardFiberParaffin wax

The invention relates to a naturally degradative short linter plastic film and a manufacture process thereof, belonging to the field of plastic films. The manufacture process comprises the following steps: dedusting short linters, ramie short fibers and silk leftover bits; uniformly mixing according to a proportion; cutting short; placing in a cooking boiler; adding NaOH, anthraquinone and water; increasing temperature; keeping pressure; boiling; preparing pulp by a sulphate pulping method; filtering pulp liquid; cleanly flushing filtered substances; adding water to prepare the pulp liquid; beating the pulp liquid at a beating degree of 50 DEG SR; adding daiamid epoxy chloropropane resin and cellulose to uniformly scatter in a pulp scattering machine; diluting with water; forming handsheets in a water circulating handsheet former; airing the handsheets at a room temperature; steeping the handsheets in a whiteruss steeping tank; immediately fishing out and smoothening the handsheets with a brush; enabling the prepared handsheets, i.e. paper-based semi-finished products of non-weaving cloth, to keep still at the room temperature; steeping the semi-finished products in a sizing liquid steeping tank; immediately fishing out and smoothening the semi-finished products; placing the semi-finished products in an oven to prebake so that sizing liquid is fully permeated and stuck to the semi-finished products; and raising the temperature and baking for molding treatment to obtain the naturally degradative short linter plastic film.

Owner:JIANGNAN UNIV +1

Cellulose acetate prepared by taking cotton linter pulp as raw material and preparation method and application thereof

InactiveCN101544698AEasy to operateRaw materials are easy to getCellulose acetateSemipermeable membrane

The invention discloses cellulose acetate prepared by taking cotton linter pulp as the raw material and a preparation method and an application thereof. The cellulose acetate is prepared by pulverizing, activating, acetylizing, hydrolyzing, precipitating, rinsing and drying the cotton linter pulp which is used as the raw material. The cellulose acetate is used for manufacturing textile cellulose acetate filaments, membranes, semipermeable membranes, photosensitive films and other materials. The cellulose acetate is prepared by taking cotton linter pulp as the raw material which is easy to obtain, and the preparation method of the cellulose acetate is easy to operate and ensures good product quality.

Owner:NANTONG CELLULOSE FIBERS CO LTD

Production process of purified cotton with super-high viscosity

InactiveCN103233383AGood cooking effectReduce cooking timePulping with acid salts/anhydridesFiberSodium chlorite

The invention discloses a production process of purified cotton with super-high viscosity, including the steps of to perform fiber opening on cotton linters by using a fiber opening machine, spraying hydrochloric acid conditioning fluid with mass concentration of 0.1% on the opened cotton linters, placing the cotton linters after acid treatment into alkaline activated fluid, adding the activated cotton pulp into cooking liquor for cooking, washing the cooked degreasing cotton, adding sodium chlorite with mass concentration of 0.1-0.3% to perform pre-bleaching for 0.5-1 hour, then washing for 10-20 minutes, adding hydrogen peroxide with mass concentration of 0.3-0.5% to perform bleaching, adding water into white pulp and removing sands, carrying out centrifugal dewatering, dispersing the dehydrated cotton pulp in a grinder, and drying the moisture to obtain a finished product. The production process is sophisticated and has mild reaction condition, and the produced purified cotton has high whiteness and viscosity.

Owner:杨金福

Cellulose pulp and production method thereof

InactiveCN101691407AChemical/chemomechanical pulpNon-woody plant/crop pulpCellulose diacetateCellulose acetate

The invention discloses cellulose pulp and a production method thereof, mainly used for producing cellulose diacetate and cellulose triacetate. In the invention, category II cotton linter, or category III cotton linter with ripeness being 60-70%, or a mixture of category II cotton linter and category III cotton linter are used as the raw material, I type cellulose crystallity of cellulose pulp is within the range of 60-74%, the acetifying reaction has good performance and low cost, and the invention is suitable for commercialized production of cellulose diacetate.

Owner:NANTONG CELLULOSE FIBERS CO LTD +1

Method for preparing cellulose sponge

The invention relates to a method for preparing a cellulose sponge by the steps of activating cellulose wood pulp, reacting with urea to prepare dry cellulose carbamate, dissolving the dry cellulose carbamate in a dilute sodium hydroxide solution at low temperature to form a cellulose carbamate solution, then adding cotton linter, a pore former, color paste and the like to the cellulose carbamate solution for uniformly mixing, ageing at low temperature, putting in boiled water and then cooking to make the cellulose regenerate, forming gaps after the dissolution of the pore former in water, alternatively washing with water and weak acid until neutrality appears, soaking in the water emulsion of a softener, and the like.

Owner:XINJIANG UNIVERSITY

Technique for preparing cotton pulp with high-degree of polymerization for cellulose ether

The invention relates to a process for producing cellulose ether used high polymerised cotton pulp, in particular to a cotton pulp production process mainly used for manufacturing high-viscosity cellulose ethers products, such as carboxymethyl cellulose, hydroxypropyl methylcellulose, etc. by utilizing cotton linters as the raw materials. The process adopts low temperature cooking to prevent carcinogenic toxic substances such as dioxins, organic halides, etc. from being produced through adding chlorine dioxide, thereby having low toxicity, reducing the pollution to the environment, and producing the cotton pulp with high polymerization degree, uniform fiber length, less dust and high alphacellulose content. Besides, the COD discharge amount of the waste water in the practical production is low, and belongs to the low pollutant emission.

Owner:山东银鹰化纤有限公司

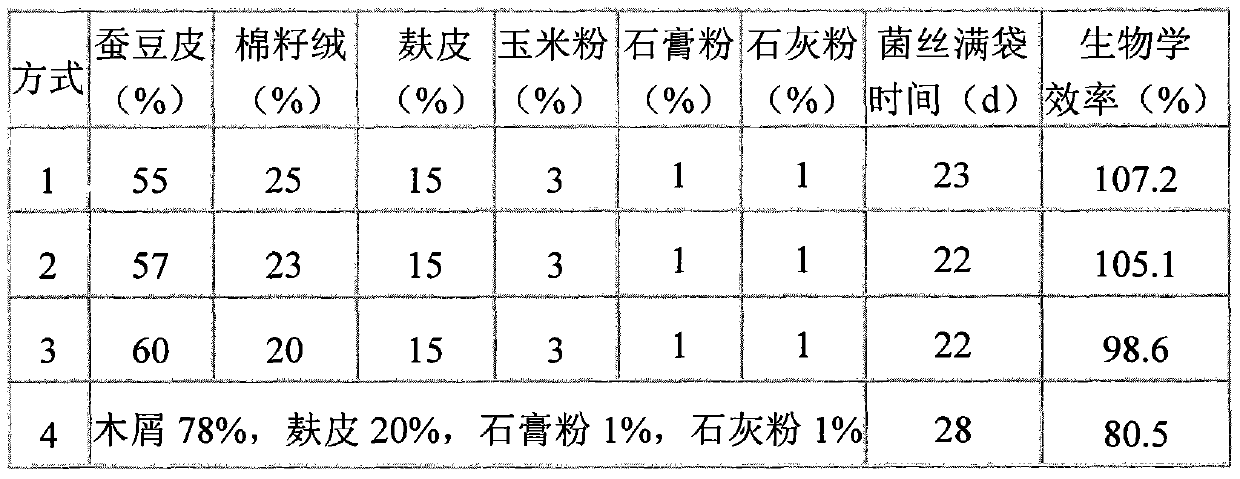

Pholiota nameko cultivation material compatibility and method for preparing cultivation material

InactiveCN103420723AIncrease carbon to nitrogen ratioNutritional balanceFertilizer mixturesPholiotaBroad beans

The invention relates to a pholiota nameko cultivation material which is characterized in that broad bean hulls are used as a main raw material, cotton linters, bran, corn flour, gypsum powder and the like are used as auxiliary materials, and the water content of the cultivation material is 65-66 percent. The invention also relates to a method for preparing the cultivation material. Compared with a saw dust cultivation material, the pholiota nameko cultivation material has the advantages that 1, the cultivation material is reasonable in matching of coarse sand fine grains, and the air permeability and water binding capacity of the cultivation material are increased, so that the growth rate of pholiota namekohypha is increased, and the bagful time is shortened; 2, the cultivation material has a reasonable carbon nitrogen ratio and balanced nutrition and promotes the growing development of sporocarp, and the yield is increased by 20-30 percent; 3, the cultivation raw-material channel is broadened, and the production cost is greatly reduced. The pholiota nameko cultivation material compatibility and the method have the social benefits that a broad bean hull substitution is used for cultivating pholiota nameko, one part of fungus-forest contradiction can be eased, waste is turned into wealth, and energy conservation and emission reduction are facilitated.

Owner:邬金飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com