Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Slurry transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slurry transport uses several methods: hydraulic conveying; conventional lean slurry conveying; and high concentration slurry disposal (HCSD). The latter, HCSD, is a relatively modern approach, which is used to transfer high throughputs of fine fly ash over long distances (>10 km or 6.2 mi) using high pressure diaphragm pumps with velocities of around 2 m/s. Ash disposal is simple as the ash solidifies easily and the system does not produce the waste water or leachate problems which can often be associated with ash lagoons.

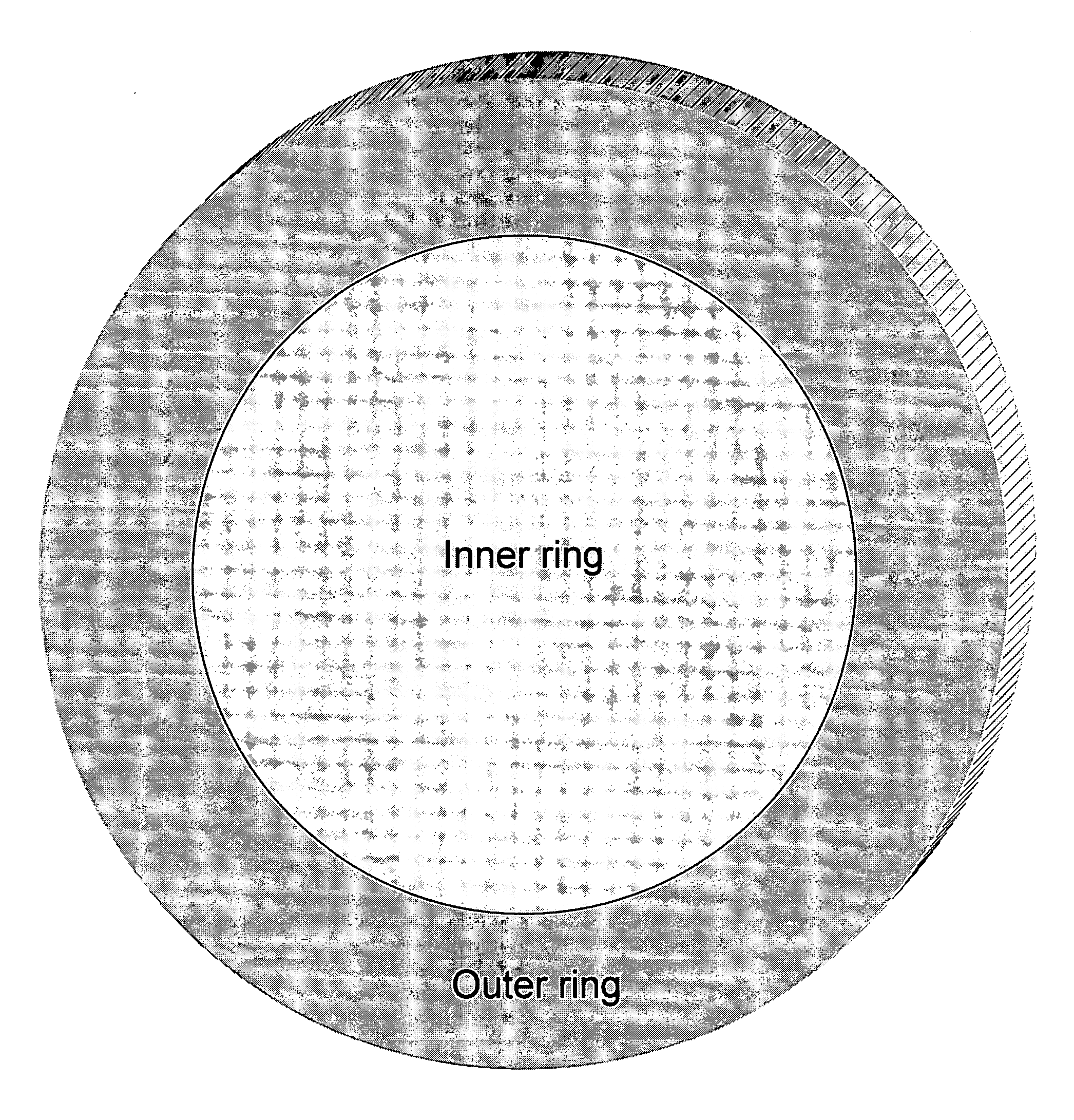

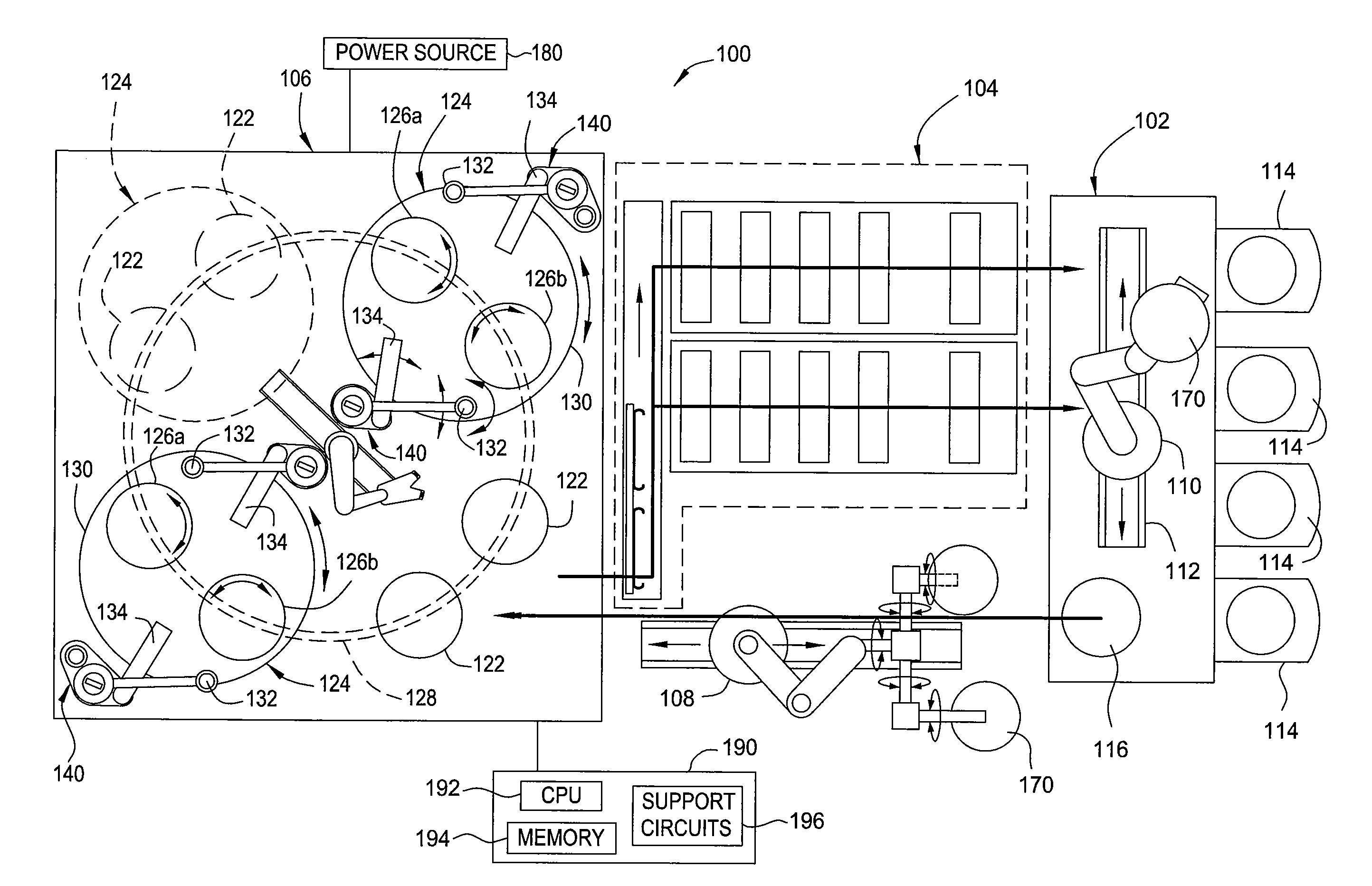

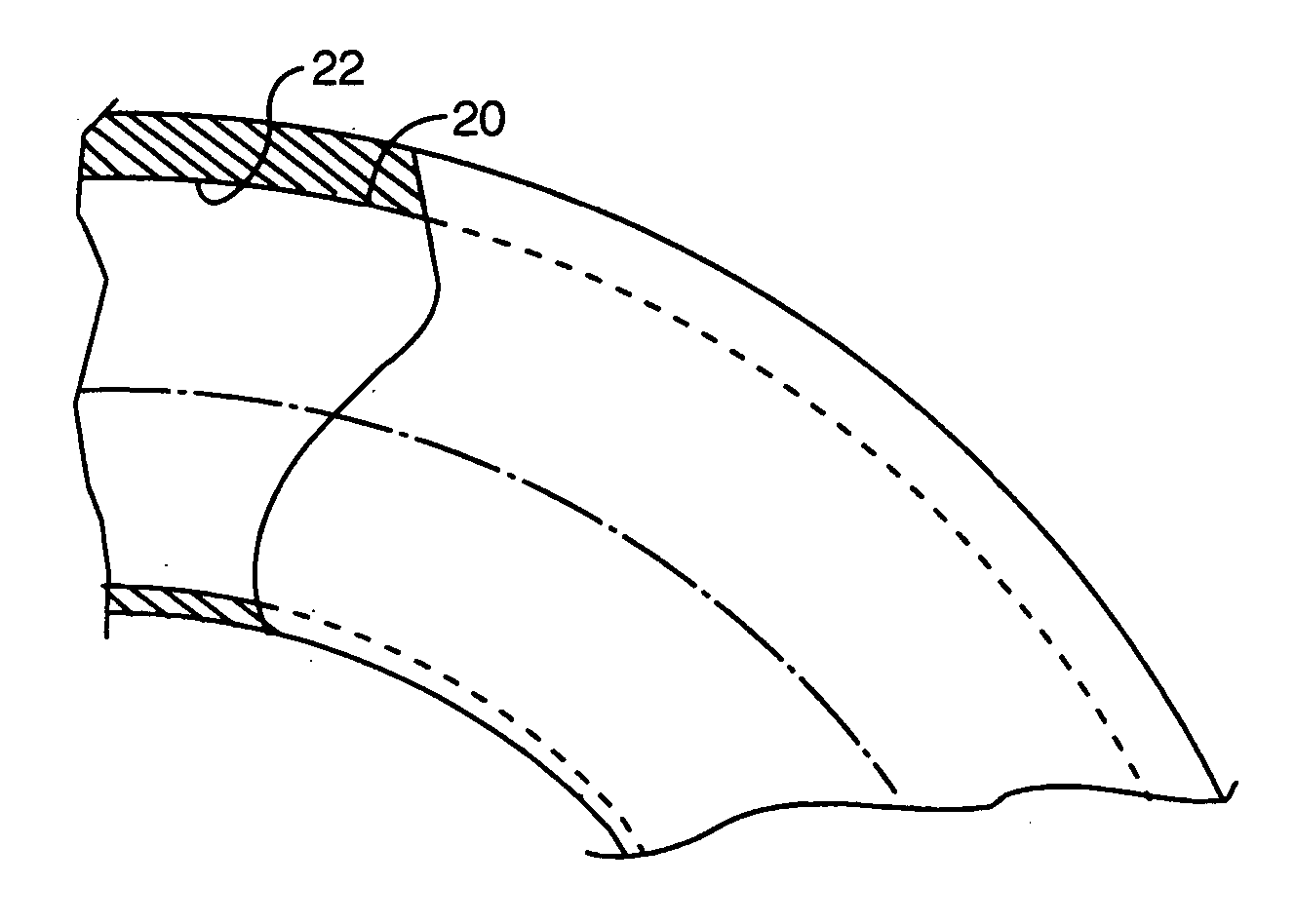

Customized polishing pads for CMP and methods of fabrication and use thereof

ActiveUS20060276109A1Easy to controlImpact on polishing propertyAdditive manufacturing apparatusLapping machinesPorositySurface engineering

The present application relates to polishing pads for chemical mechanical planarization (CMP) of substrates, and methods of fabrication and use thereof. The pads described in this invention are customized to polishing specifications where specifications include (but not limited to) to the material being polished, chip design and architecture, chip density and pattern density, equipment platform and type of slurry used. These pads can be designed with a specialized polymeric nano-structure with a long or short range order which allows for molecular level tuning achieving superior themo-mechanical characteristics. More particularly, the pads can be designed and fabricated so that there is both uniform and nonuniform spatial distribution of chemical and physical properties within the pads. In addition, these pads can be designed to tune the coefficient of friction by surface engineering, through the addition of solid lubricants, and creating low shear integral pads having multiple layers of polymeric material which form an interface parallel to the polishing surface. The pads can also have controlled porosity, embedded abrasive, novel grooves on the polishing surface, for slurry transport, which are produced in situ, and a transparent region for endpoint detection.

Owner:CMC MATERIALS INC

Polishing pad for use in chemical-mechanical planarization of semiconductor wafers and method of making same

InactiveUS6852020B2Prolong lifeSolution to short lifeOther chemical processesAbrasion apparatusFiberSlurry transport

A polishing pad for use in chemical mechanical polishing of substrates that being made of a porous structure comprising a matrix consisting of fibers, such as cotton linter cellulose bound with a thermoset resin, such as phenolic resin. The polishing pad surface has voids in which polishing slurry flows during chemical mechanical polishing of substrates, and in which debris formed during the chemical-mechanical polishing of substrates is temporarily stored for subsequent rinsing away. The polishing surface of the pad is ground to form asperities that aid in slurry transport and polishing, as well as opening the porous structure of the pad. The porous pad contains nanometer-sized filler-particles that reinforce the structure, imparting an increased resistance to wear as compared to prior-art pads. Also disclosed is a method of making the polishing pad.

Owner:RAYBESTOS POWERTRAIN

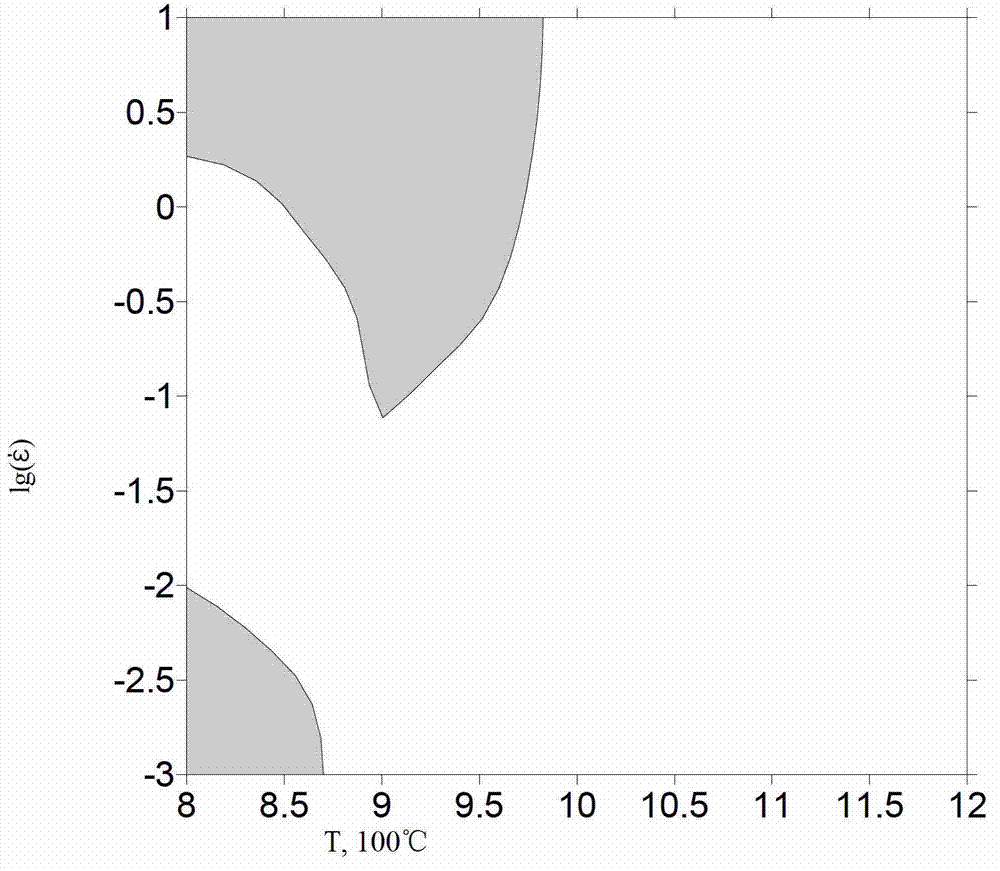

Lower bainite wear-resisting steel tube for slurry transport and production method of steel tube

ActiveCN102776445ASolve the problem of 2-tier structureSolve the wear-resistantSlurry transportFree cooling

The invention discloses a lower bainite wear-resisting steel tube for slurry transport and a production method of the steel tube. The steel tube mainly comprises 0.01-0.50wt% of C, 1.2-5.0wt% of Mn, 0.2-1.8wt% of Cr and the balance Fe. The method comprises the steps of performing alloying the above main components, performing furnace revolving, refining and continuous casting to form a round blank, performing on-line or off-line rolling tabulation, performing air cooling or accelerated cooling to obtain the lower bainite which serves as main tissue, then performing low-temperature tempering and natural cooling or controlling the cooling speed and maintain the normal temperature to obtain the lower bainite wear-resisting steel tube. According to the steel alloy components and the production process, the problem of a two-layer structure of international and civil composite pipes is solved, and the problem that existing pipes in X series, which are used in slurry pipe long-distance transport are not wear-resisting, is also solved.

Owner:攀枝花贝氏体耐磨管道有限公司

Polishing pad for use in chemical-mechanical planarization of semiconductor wafers and method of making same

A polishing pad for use in chemical mechanical polishing of substrates that being made of a porous structure comprising a matrix consisting of fibers, such as cotton linter cellulose bound with a thermoset resin, such as phenolic resin. The polishing pad surface has voids in which polishing slurry flows during chemical mechanical polishing of substrates, and in which debris formed during the chemical-mechanical polishing of substrates is temporarily stored for subsequent rinsing away. The polishing surface of the pad is ground to form asperities that aid in slurry transport and polishing, as well as opening the porous structure of the pad. The porous pad contains nanometer-sized filler-particles that reinforce the structure, imparting an increased resistance to wear as compared to prior-art pads. Also disclosed is a method of making the polishing pad.

Owner:RAYBESTOS POWERTRAIN +1

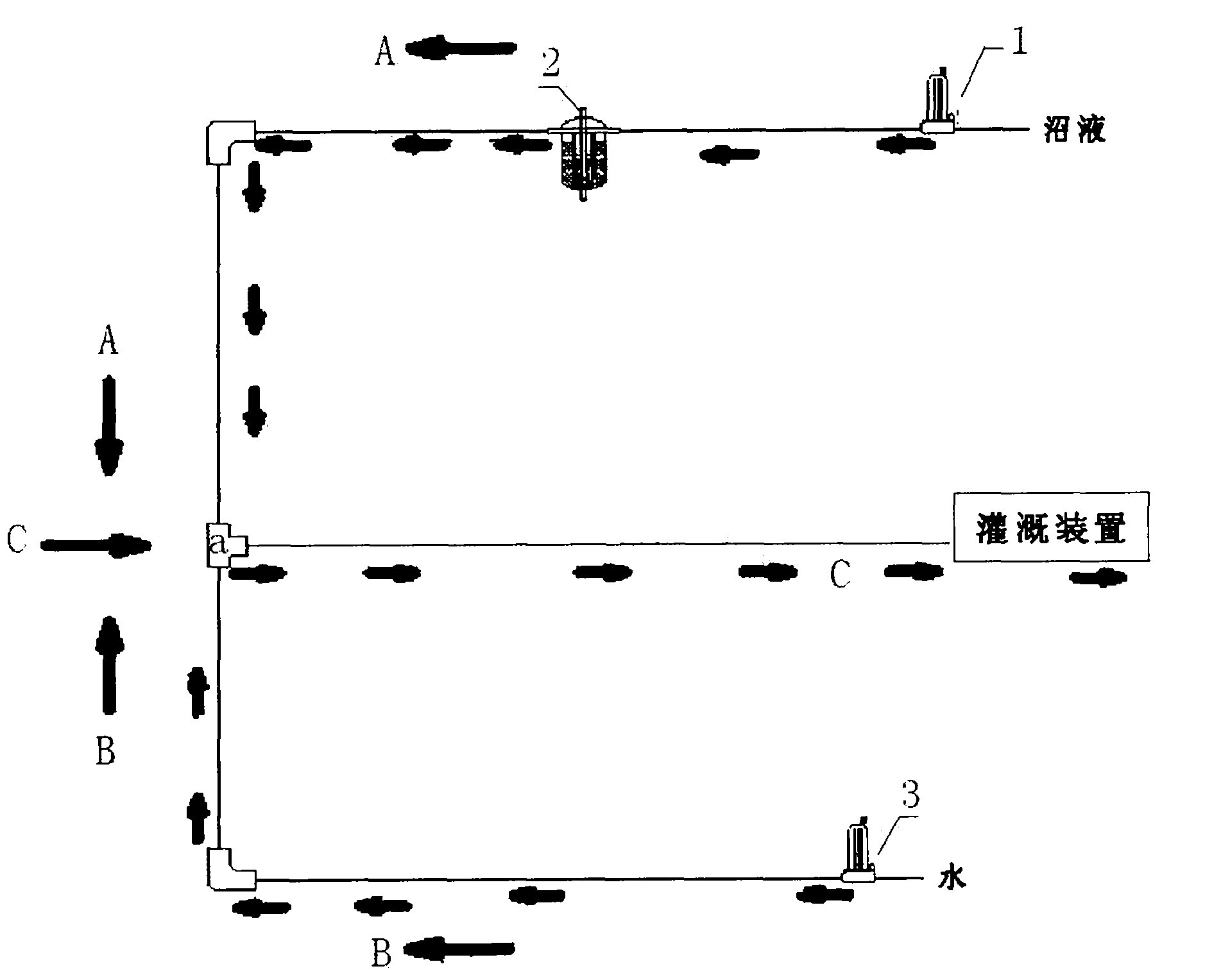

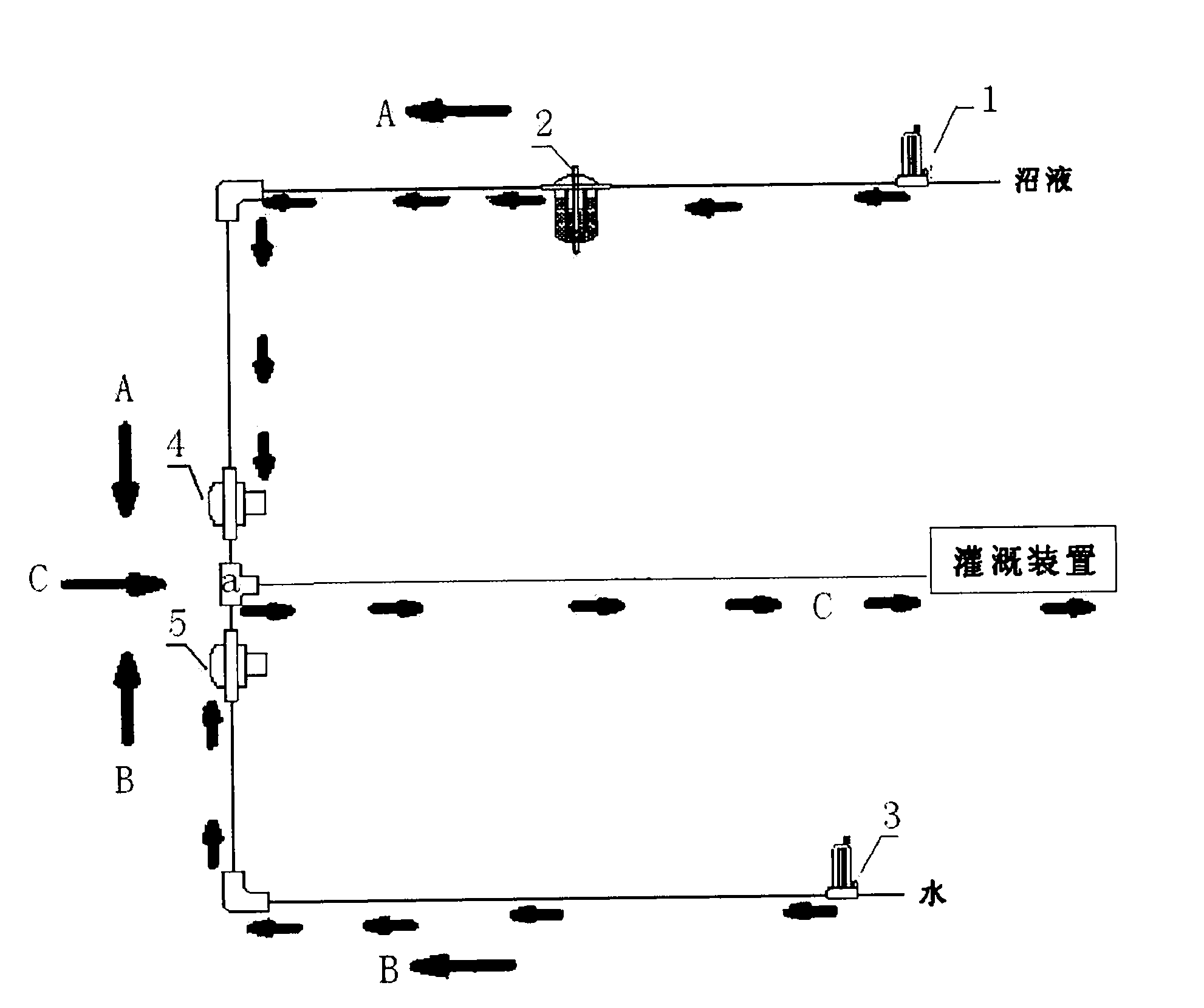

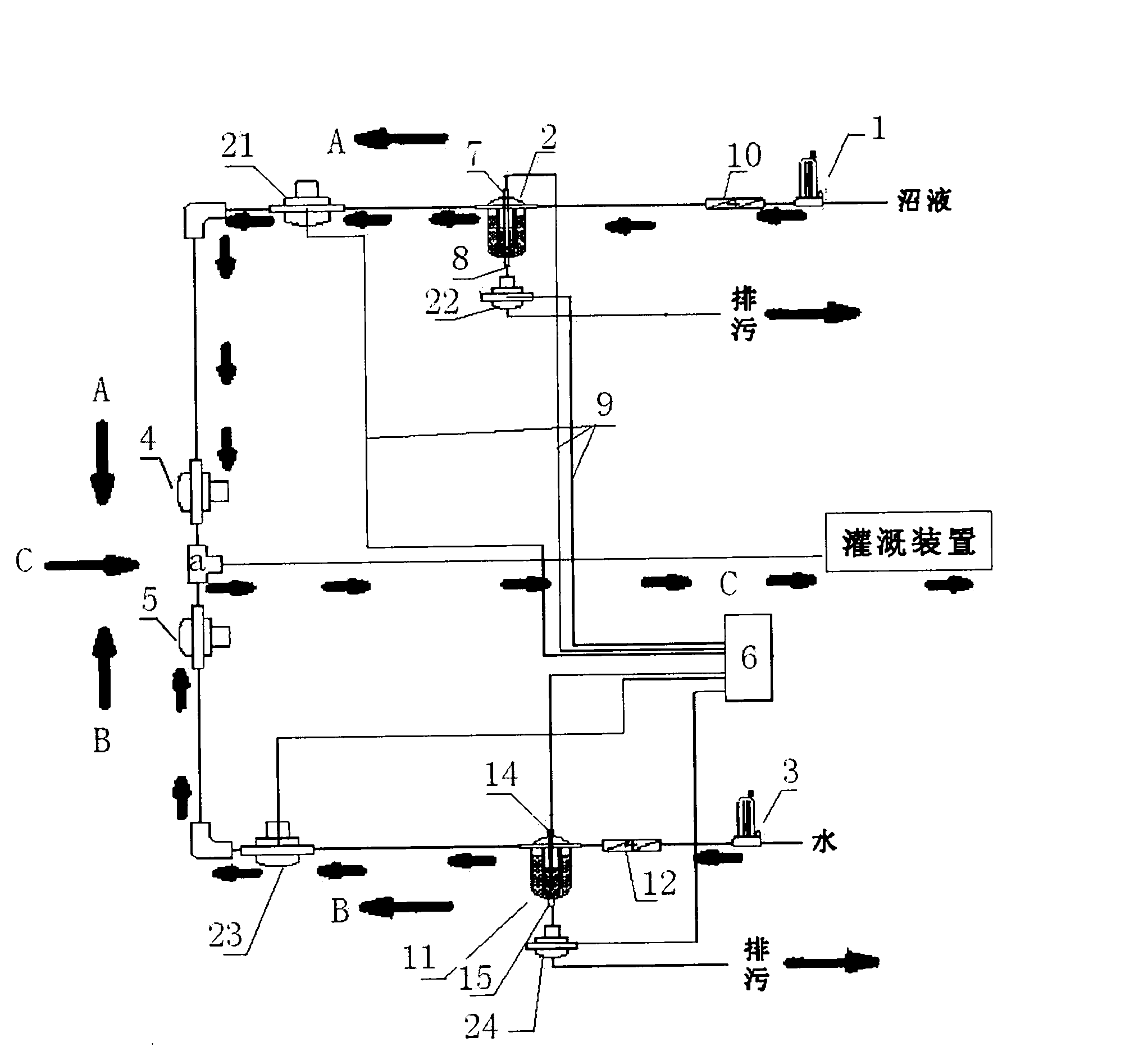

Fertilizing equipment for precipitating, aerating, filtering and proportioning biogas slurry and increasing water-soluble oxygen

InactiveCN101904288ASolve the unreasonable dischargeSolve the pollution of the environmentClimate change adaptationWatering devicesSlurry transportWater soluble

The invention discloses fertilizing equipment for precipitating, aerating, filtering and proportioning biogas slurry and increasing water-soluble oxygen, which performs fertilization and irrigation by using the biogas slurry. The fertilizing equipment comprises a biogas slurry supply pipeline, a clean water supply pipeline and a hybrid output pipeline; an outlet end of the biogas slurry supply pipeline and an outlet end of the clean water supply pipeline are jointly connected with an inlet end of the hybrid output pipeline to be mutually communicated; the biogas slurry supply pipeline is sequentially provided with a biogas slurry supply pump and a biogas slurry filter from the inlet end of the biogas slurry supply pipeline; the clean water supply pipeline is provided with a clean water supply pump; the hybrid output pipeline is connected with an inlet end of an irrigating device; the filtered biogas slurry transported through the biogas slurry supply pump and the biogas slurry filter along the fermentation slurry supply pipeline is converged with the clean water transported through the clean water supply pump along the clean water supply pipeline on a connecting part of the biogas slurry supply pipeline and the clean water supply pipeline with the hybrid output pipeline to be mixed into fertilizer liquid according to a required proportion; and the fertilizer liquid is transported to the irrigating device through the hybrid output pipeline for irrigating crops.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

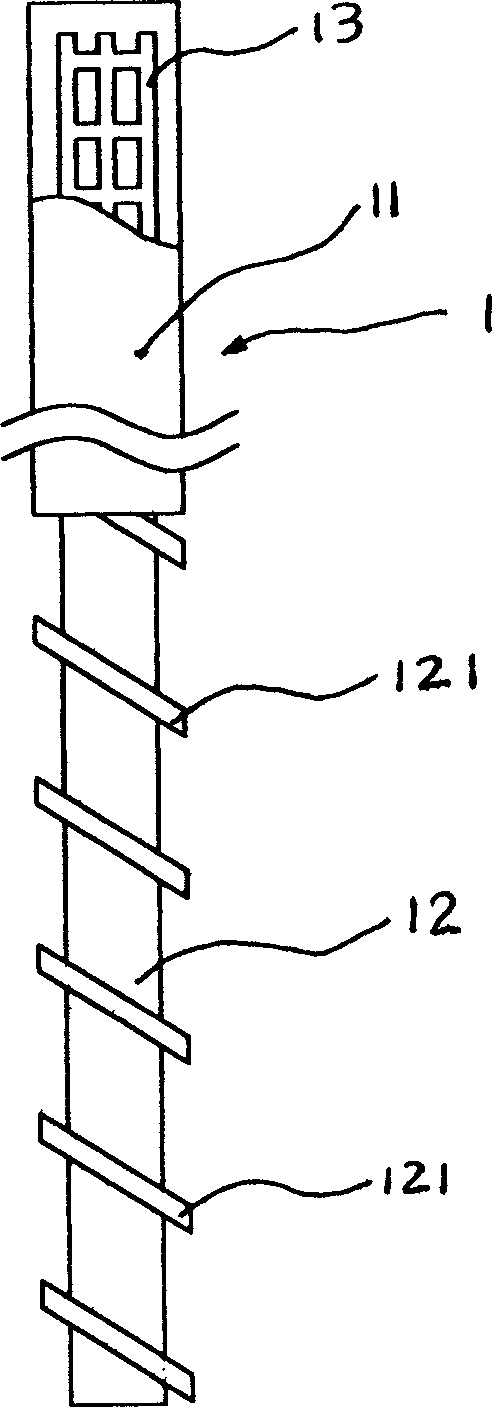

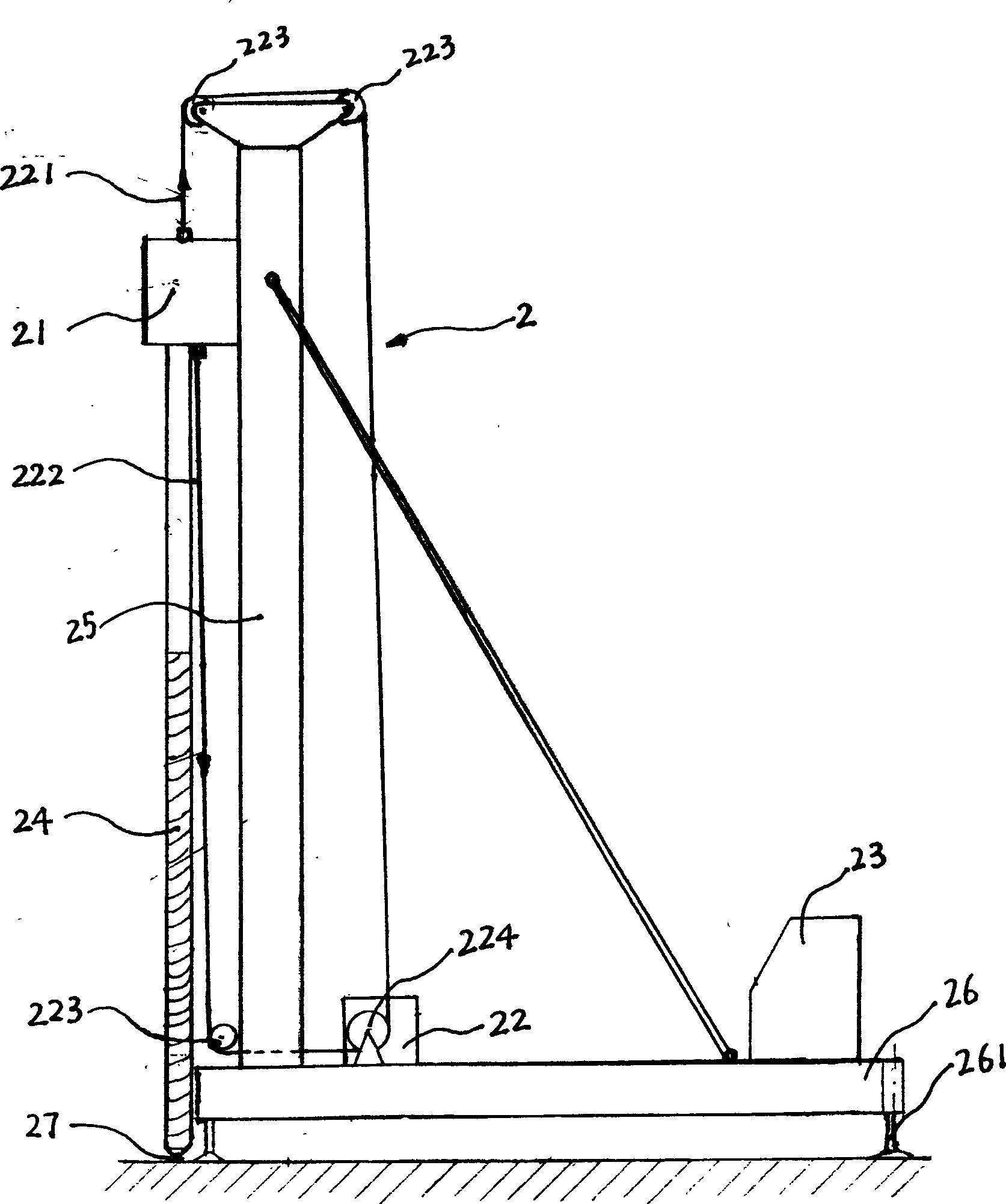

Half screw pile and processing method and apparatus therefor

The invention relates to a semi-screw concrete pile, its processing method and equipment. The pile comprises two integrated part; the top part is a cylindrical pile base, and bottom part is a screw pipe base. The processing equipment comprises a power head with a drawing device fixed on the bottom part, a controlling device, a drilling rod with a drilling bit, a frame and a slurry transporting pipe. The processing method comprises: punching the pile hole by screw compressing pile machine to the designed depth, extruding concrete by the drilling rod bottom end of the screw compressing pile machine, rotating backward and pulling upward the drilling rod to a suitable height, pulling upward directly without rotating until the top part of the pile is finished. The advantages of the invention lies in that: 1. the pore and pile are formed by mechanical one-step compression without noise and residual earth removing; 2. the construction speed is more than 750 linear meters per machine per day; 3. The screw- cylindrical pile extruded by the pump pressure type drilling rod has no break, no shank reducing and higher bearing ability.

Owner:张超 +1

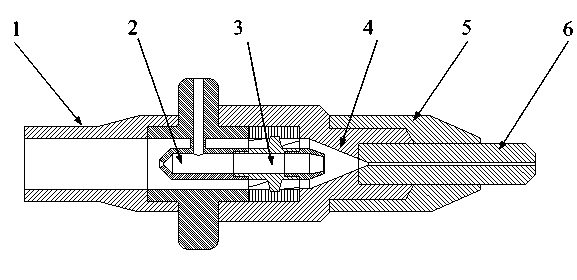

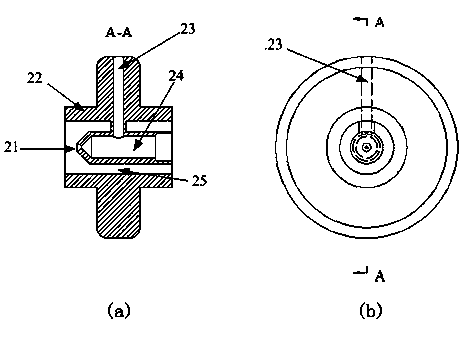

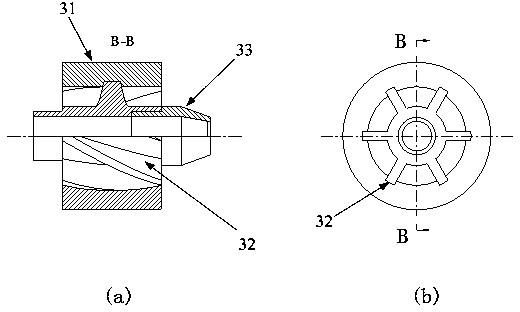

Secondary mixing type annular rotating grinding material jet flow nozzle

The invention discloses a secondary mixing type annular rotating grinding material jet flow nozzle. The secondary mixing type annular rotating grinding material jet flow nozzle comprises a high pressure water supply pipe, a primary mixing chamber, a guiding device, a secondary mixing chamber and a grinding material nozzle which are successively communicated, wherein the guiding device comprises a guiding blade fixing ring, a mixed slurry transporting pipeline and guiding blades which are distributed along the outer surface of the mixed slurry transporting pipeline; the inner wall of the guiding blade fixing ring is provided with a groove which is meshed with the guiding blades, the mixed slurry transporting pipeline and the guiding blades are located in the guiding blade fixing ring, and the two ends of the mixed slurry transporting pipeline are respectively communicated with the primary mixing chamber and the secondary mixing chamber. The secondary mixing type annular rotating grinding material jet flow nozzle provided by the invention has the advantages that the structure is simple, the cost is low, the abrasion of the inner wall of equipment is small, the mixing degree of the grinding material and a working fluid can be greatly improved, the cutting effect is good, the stability is strong, the secondary mixing type annular rotating grinding material jet flow nozzle is suitable for working fluids of various working pressures, and the secondary mixing type annular rotating grinding material jet flow nozzle is suitable for popularizing and using in a large scale.

Owner:WUHAN UNIV

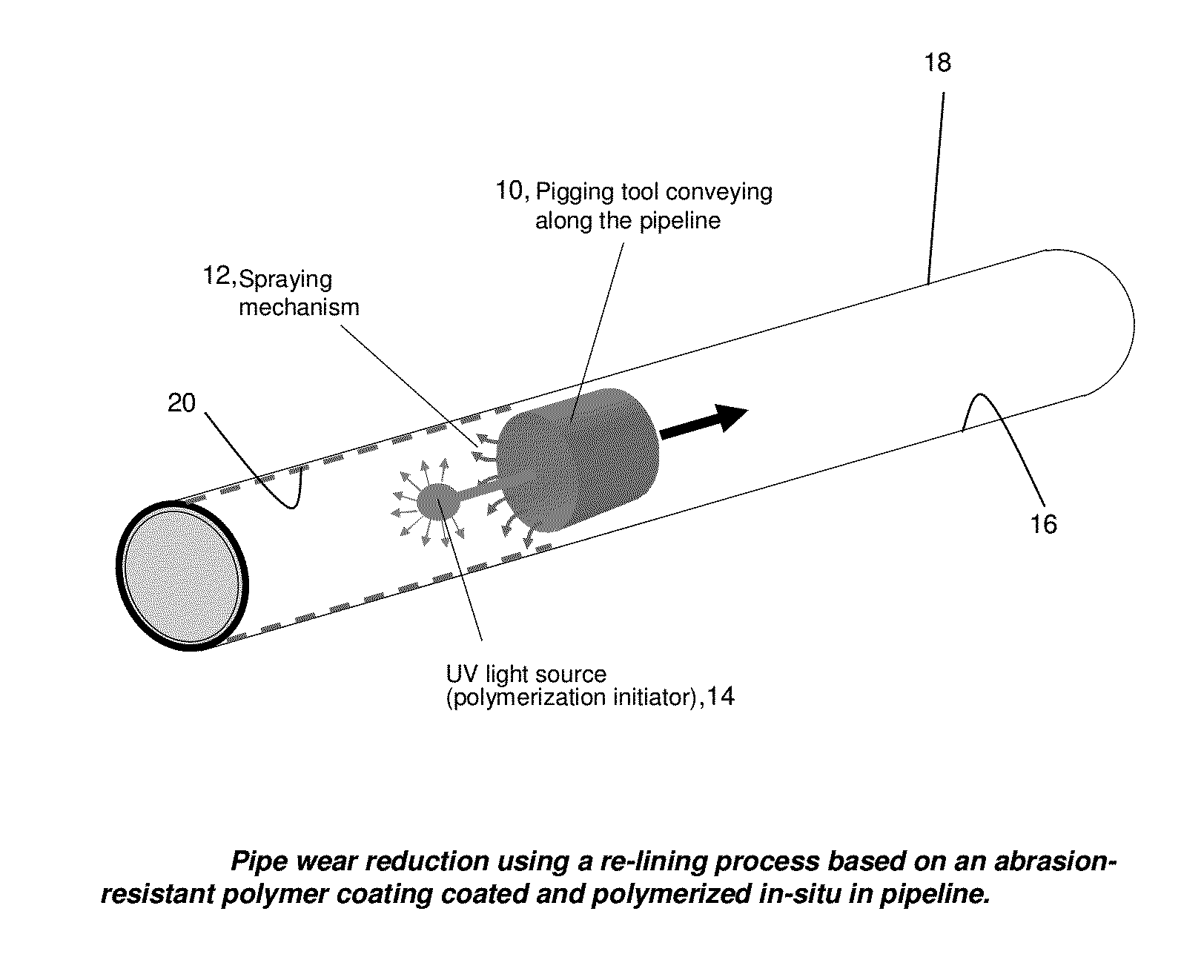

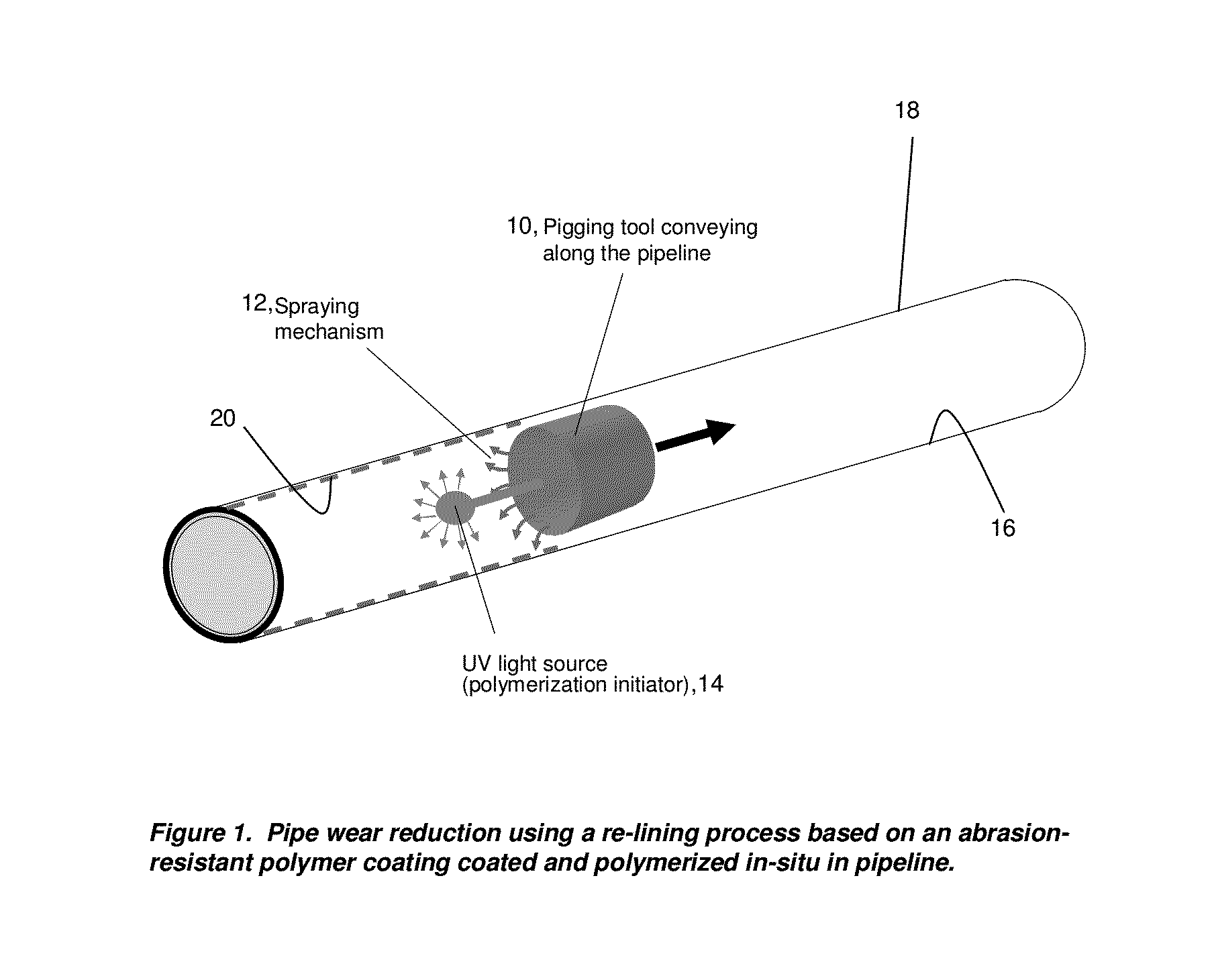

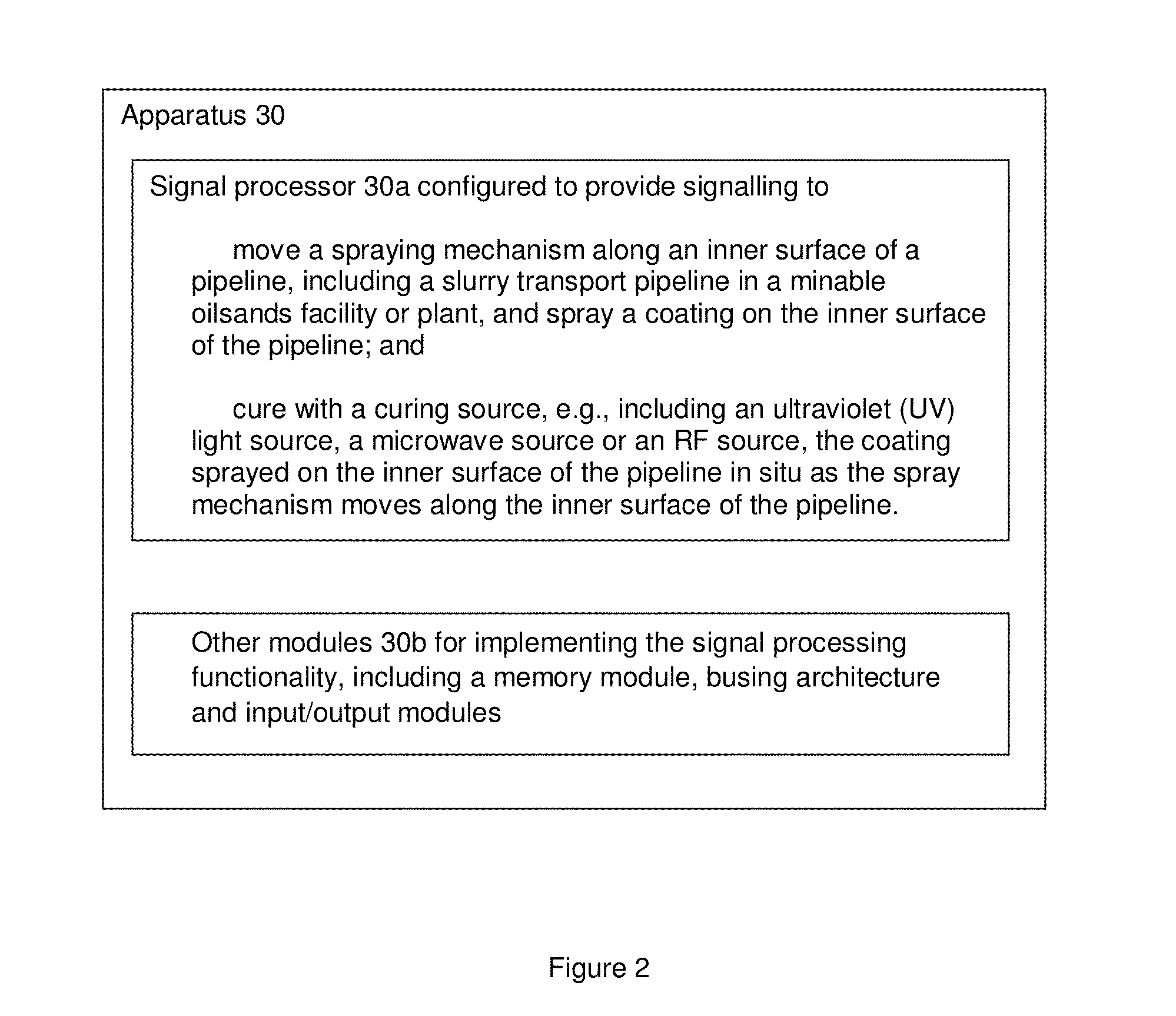

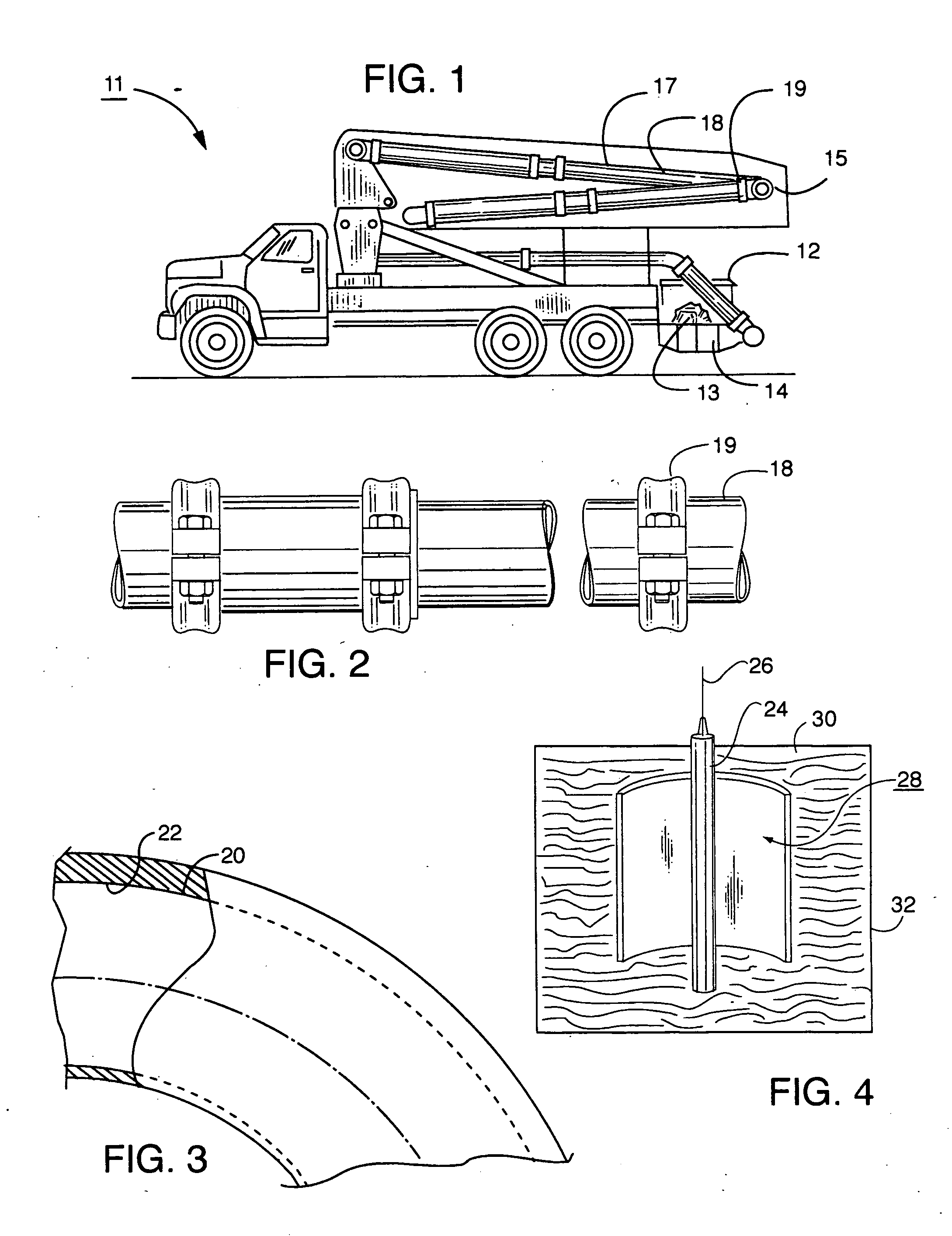

Re-lined pipe technique for wear mitigation in slurry transport pipeline

InactiveUS20150140228A1High degreeHigh abrasionPretreated surfacesCoatingsUltravioletSlurry transport

The present invention provides apparatus, including a pigging tool, that comprises a spraying mechanism configured to move along an inner surface of a pipeline, including a slurry transport pipeline in a minable oilsands facility or plant, and to spray a coating on the inner surface of the pipeline; and a curing source, including an ultraviolet (UV) light source, a microwave source or an RF source, configured to cure the coating sprayed on the inner surface of the pipeline in situ as the spray mechanism moves along the inner surface of the pipeline.

Owner:CIDRA CORP SERVICES

Pile foundation construction mud treatment system and mud treatment process

ActiveCN103951104AGuaranteed reasonablenessGuaranteed pressureMultistage water/sewage treatmentSlurry transportEnvironmental engineering

The invention discloses a pile foundation construction mud treatment system and a mud treatment process, belonging to the technical field of building construction. The mud treatment system comprises a mud pool and a dosing barrel, wherein a stirring device is arranged in the mud pool and the dosing barrel respectively; the mud pool is connected with a mud feeding pump; the dosing barrel is connected with a drug feeding pump; the mud feeding pump and the drug feeding pump are connected with the feed end of a transparent mixed liquid pipe; the transparent mixed liquid pipe is connected with mud-water separation equipment; the bottom of the mud-water separation equipment is connected with a reservoir; the reservoir is connected with a return water pump. The mud treatment system disclosed by the invention fundamentally replaces an original out-dated existing treatment mode, changes the adverse conditions caused by constrained conditions of mud road transportation, mud dock disposal and the like in the existing treatment mode, is helpful for improving the site civilized construction, realizing mud-water separation and ensuring that separated soil is dried and backfilled or externally transported in place and separated water is recycled, solves the city appearance environmental pollution caused by sprinkling and leakage in mud transportation, reduces the treatment cost, realizes green construction, energy conservation and environmental protection, can be continuously operated, and effectively improves the treatment efficiency.

Owner:浙江省地矿建设有限公司

Prestressed concrete anti-corrosion pipe pile automatic assembly line operation platform

ActiveCN103624872BEmission controlSimple and fast operationCeramic shaping plantsInformatizationOperational system

Owner:JIANGSU DONGPU PILE

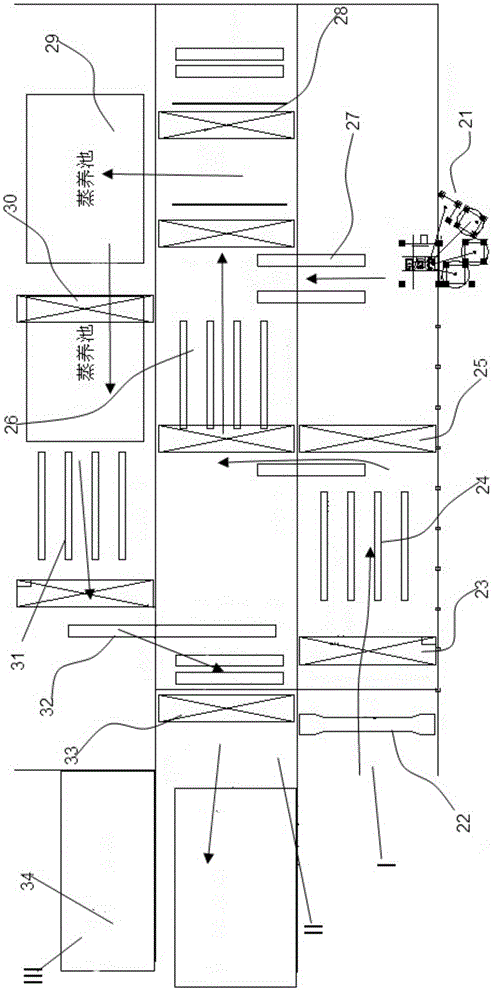

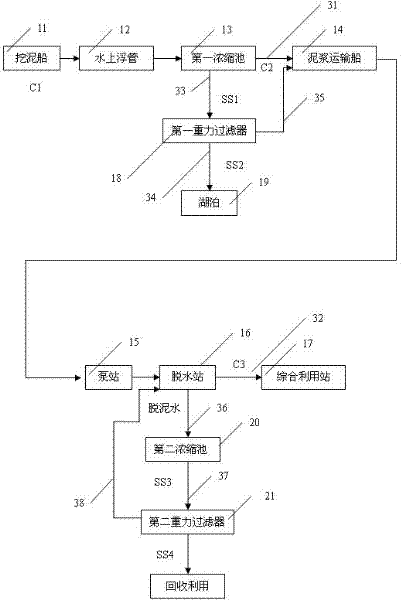

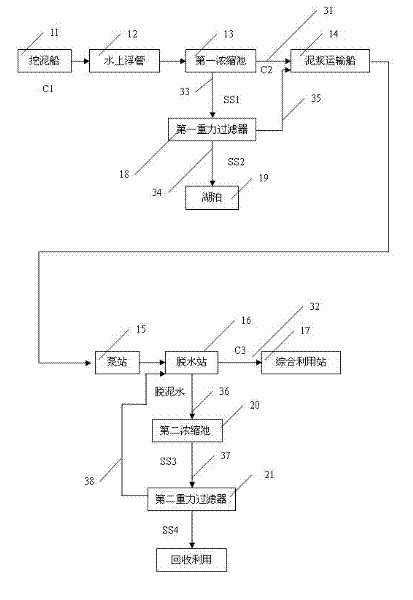

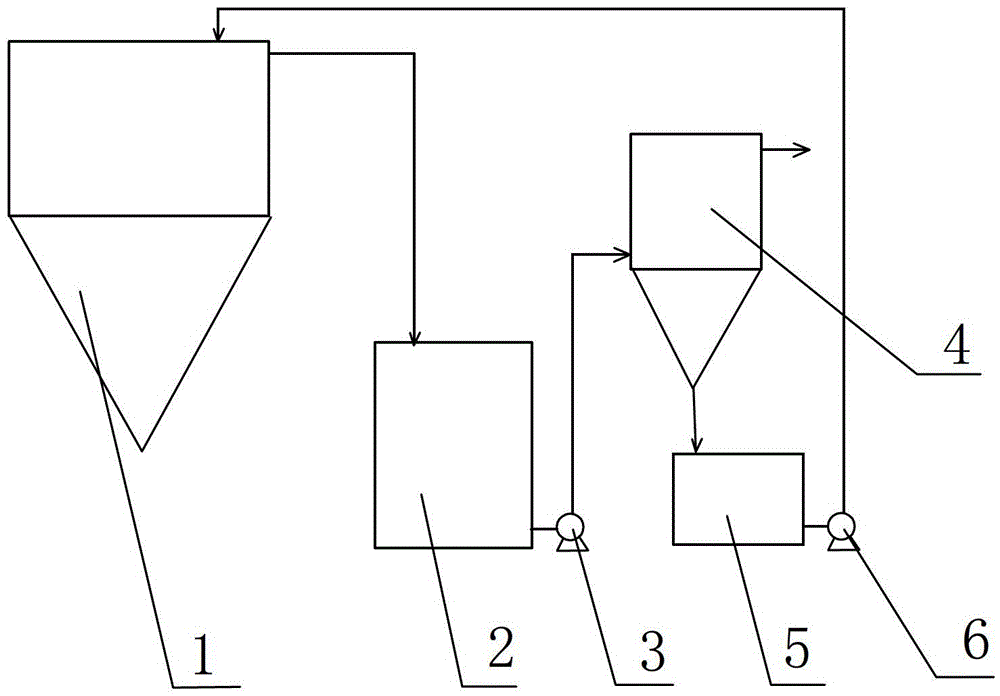

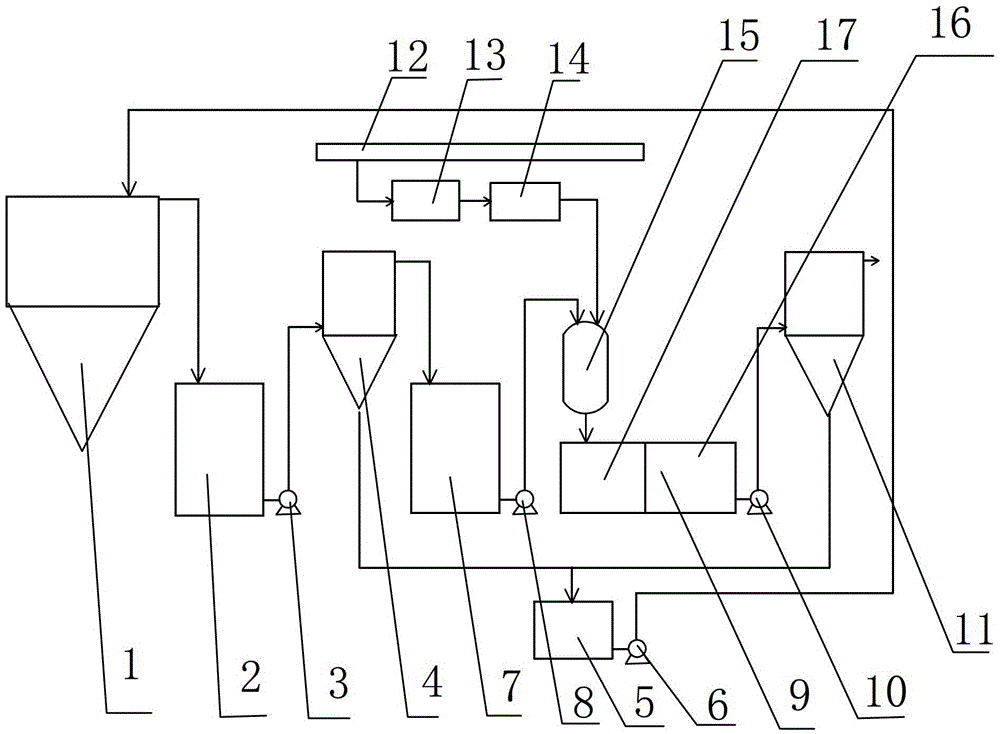

A method and system for removing lake silt

ActiveCN102296656AImprove work efficiencyReduce pollutionSludge treatment by de-watering/drying/thickeningSoil-shifting machines/dredgersSludgeSlurry transport

The invention provides a method and system for eliminating lake sludge. The method comprises the following steps of: 1, pumping sludge deposited on the bottom of a lake by a dredger (11); 2, conveying the sludge to a first concentration basin (13) by a water floating tube (12); 3, conveying the concentrated sludge to a sludge conveying ship (14) through a first channel (31); 4, conveying the sludge to a pump station (15) by the sludge conveying ship (14); 5, conveying the sludge to a dehydrating station (16) by the pump station (15); and 6, treating the sludge by the dehydrating station (16) to obtain filter cakes, and then conveying the filter cakes to a comprehensive utilization station (17) through a second channel (32) for comprehensive utilization. By using the method and system provided by the invention for eliminating the lake sludge, the working efficiency of eliminating the sludge can be increased, the pollution generated by eliminating the sludge can be reduced, and the costof eliminating the sludge can be lowered.

Owner:YUNNAN DAHONGSHAN PIPELINE

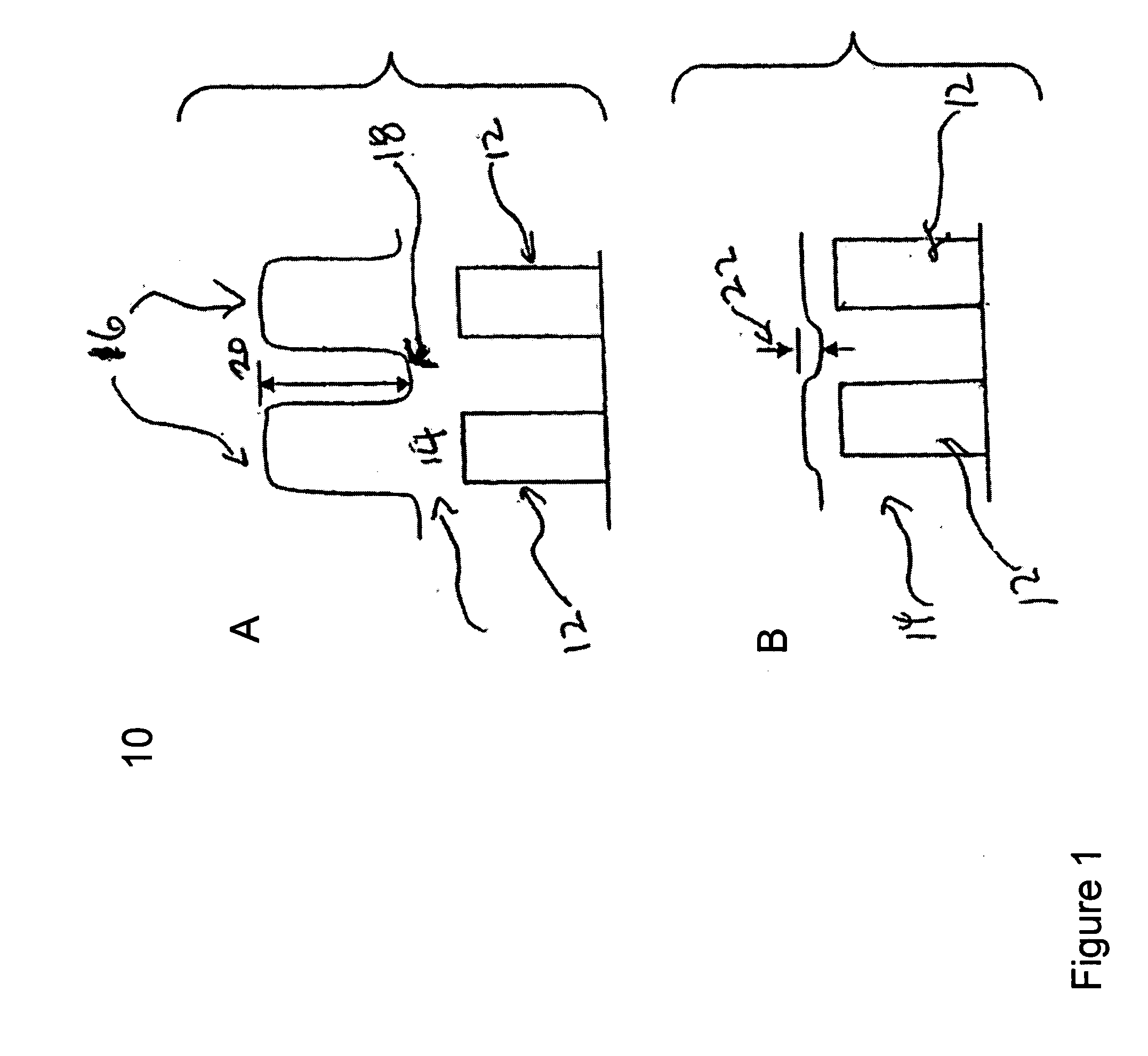

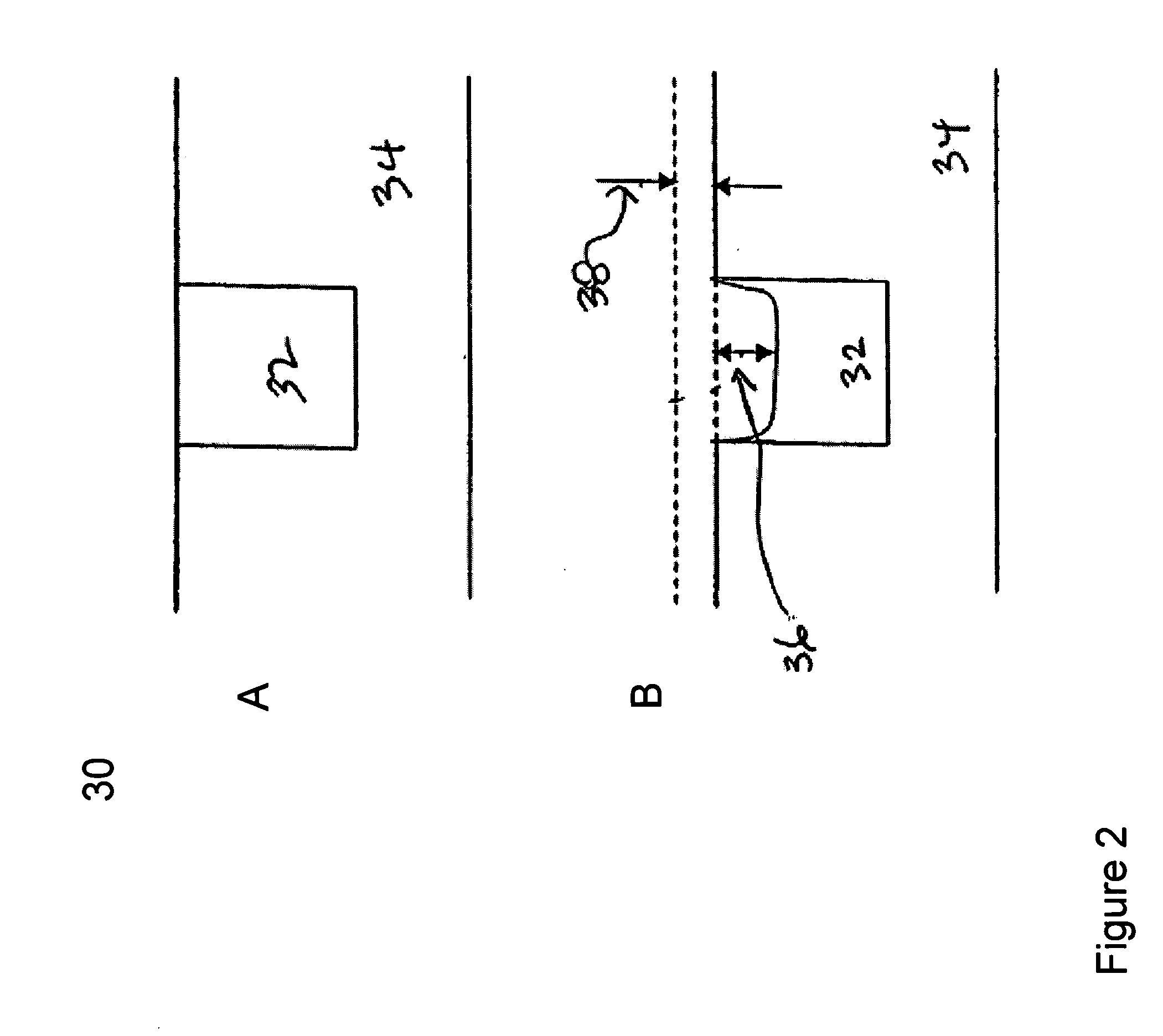

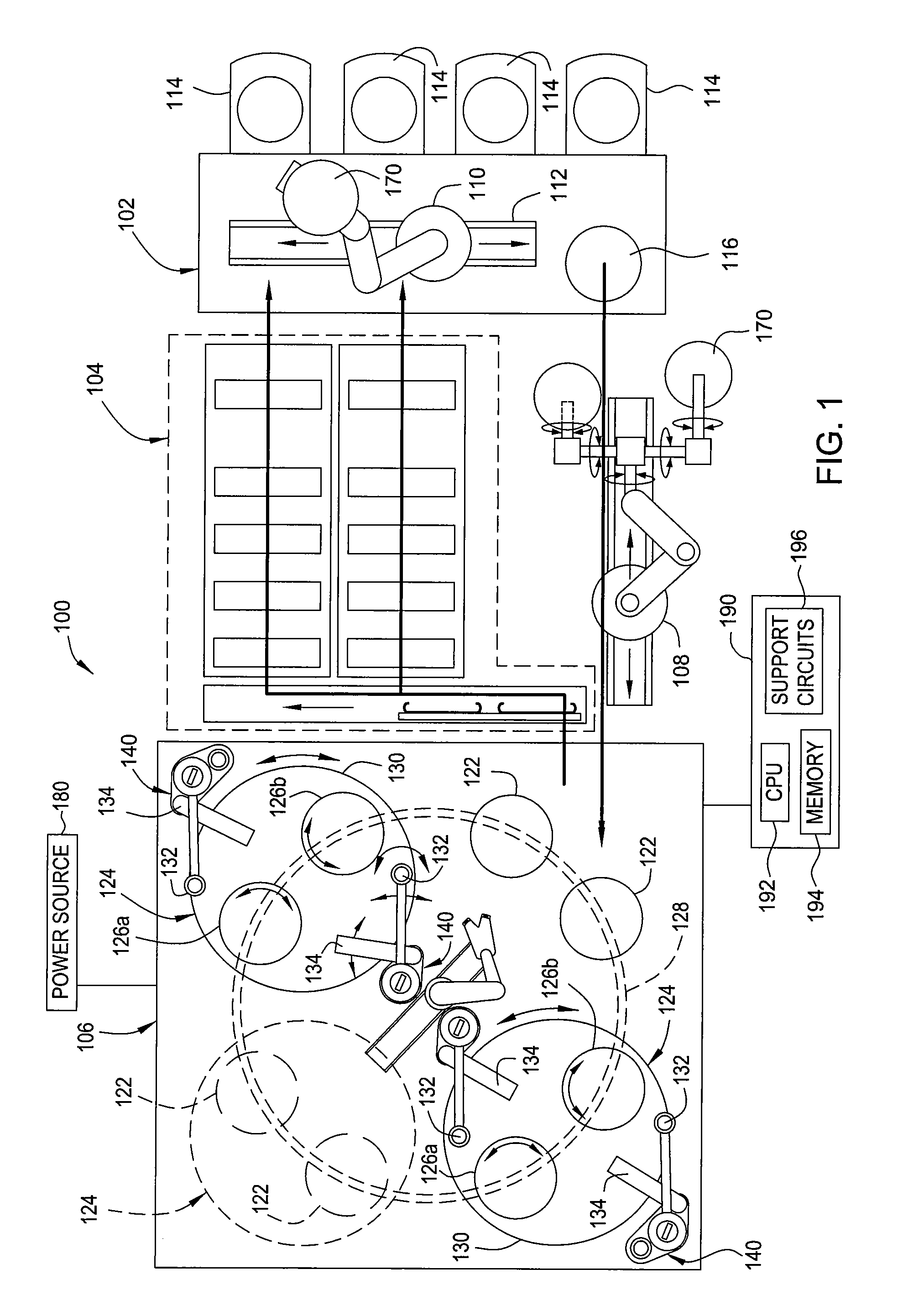

Closed-loop control of cmp slurry flow

InactiveUS20120009847A1Reduce thicknessReduction in polishing pad thicknessSemiconductor/solid-state device manufacturingLapping machinesEngineeringLoop control

Embodiments of the present invention generally relate to methods for chemical mechanical polishing a substrate. The methods generally include measuring the thickness of a polishing pad having grooves or other slurry transport features on a polishing surface. Once the depth of the grooves on the polishing surface is determined, a flow rate of a polishing slurry is adjusted in response to the determined groove depth. A predetermined number of substrates are polished on the polishing surface. The method can then optionally be repeated.

Owner:APPLIED MATERIALS INC

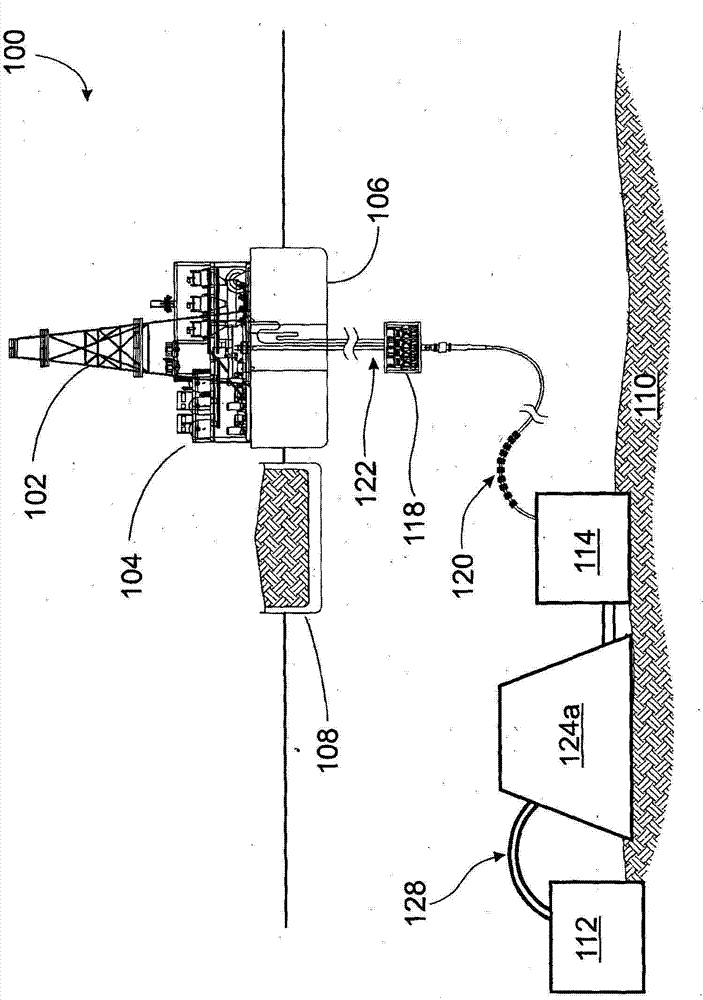

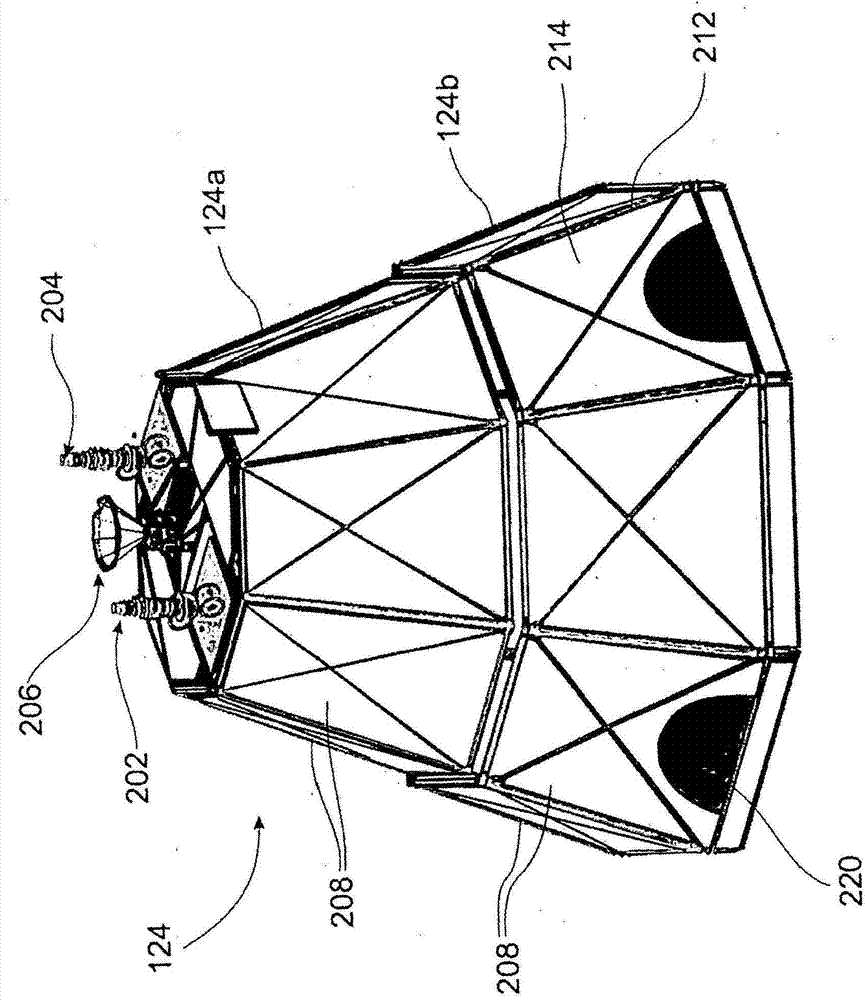

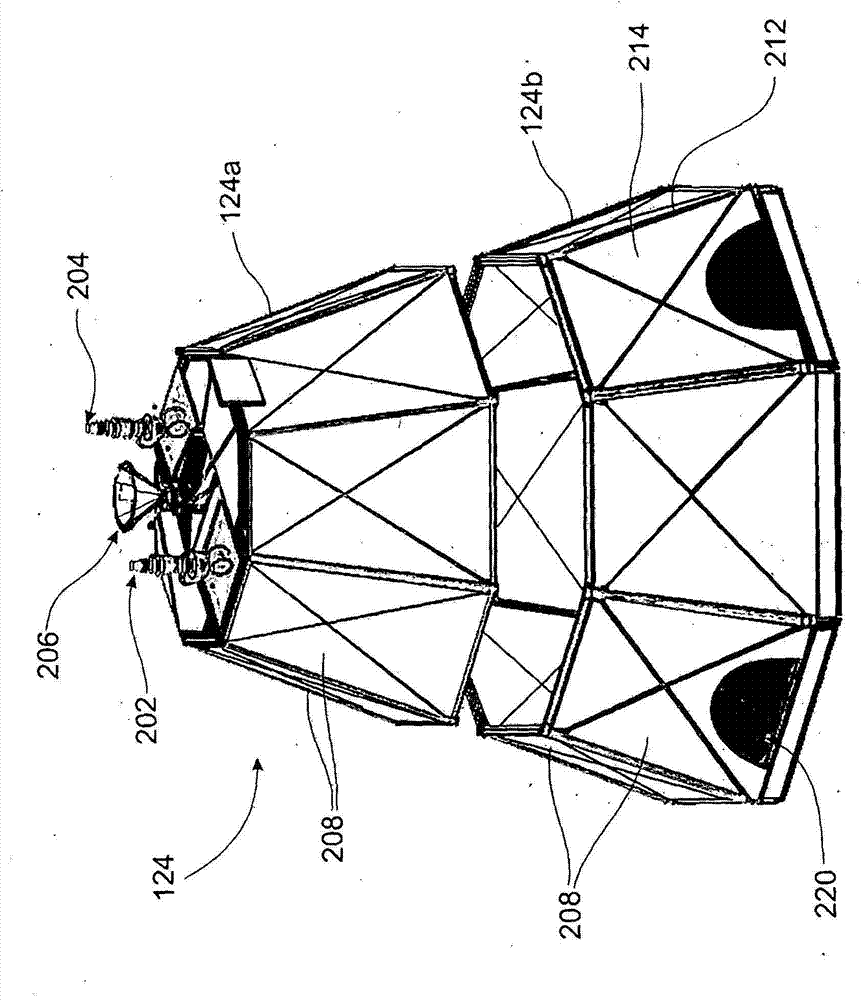

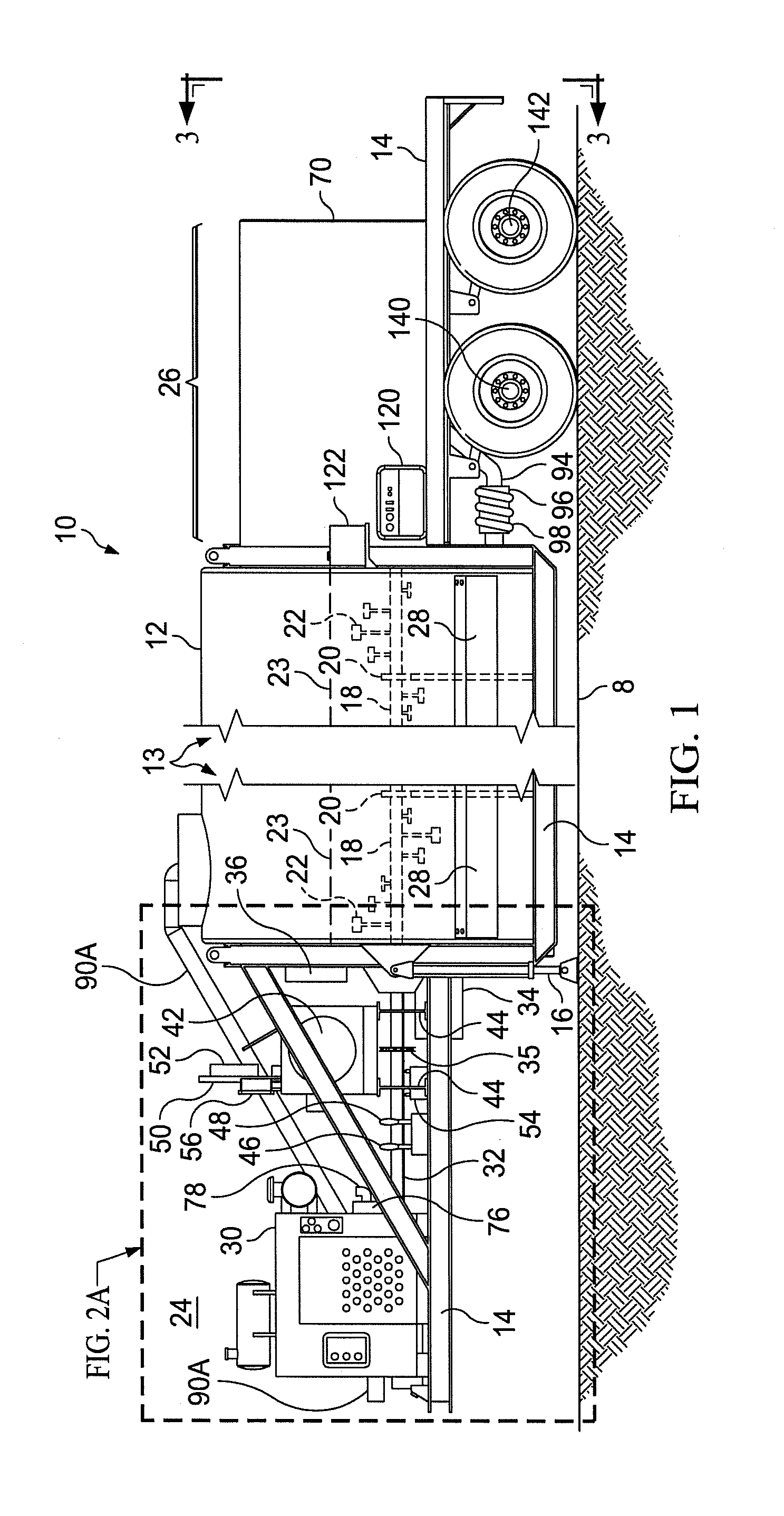

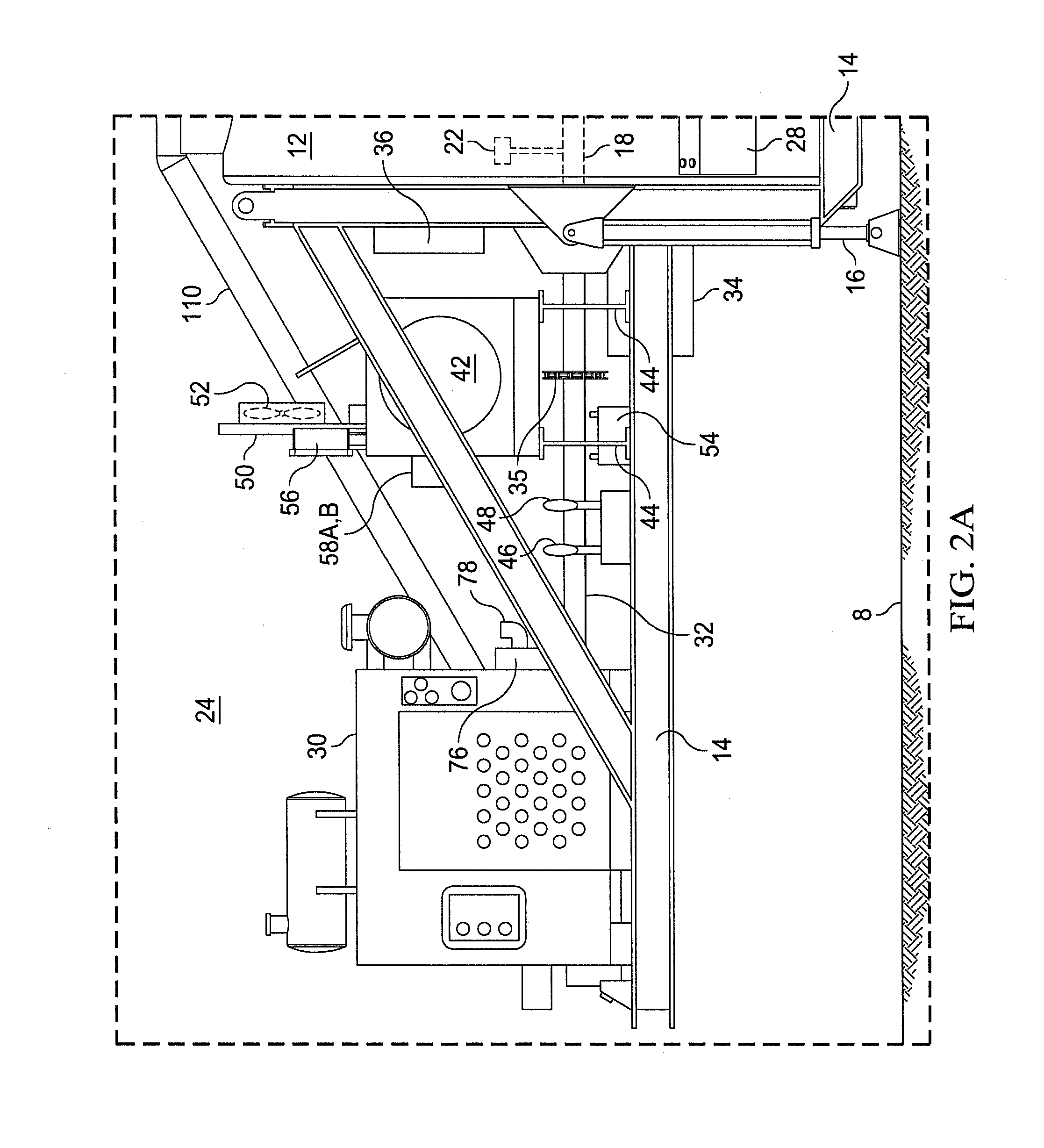

Apparatus and method for seafloor stockpiling

An apparatus for seafloor stockpiling that has a slurry inlet that receives slurry from a seafloor tool via a slurry transfer pipe and walls that, together with the seafloor, define a cavity having a stockpiling volume. The walls are made substantially of a water permeable material, such as a filter fabric or geotextile, that captures and contains seafloor material present in slurry received from the slurry inlet, while permitting egress of water from the slurry. In a preferred form, the seafloor stockpiling device is a hood with an open bottom that is located on a seafloor surface.

Owner:NAUTILUS MINERALS PACIFIC PTY LTD +1

Sludge curing device and method combining vacuum grouting and resistance heating

PendingCN107882013AShorten the consolidation timeHigh strengthSoil preservationElectricityCarrying capacity

The invention discloses a sludge curing device combining vacuum grouting and resistance heating. The sludge curing device comprises a plurality of grouting pipes, water draining plates, a horizontal water draining pipe, resistance wires, a horizontal grout conveying guide pipe, a grout conveying hose, a grout conveying pump and a curing agent grout storage tank. A plurality of grout outlets are formed in each grouting pipe. The multiple grouting pipes communicate with the horizontal grout conveying guide pipe. One water draining plate is arranged between every two adjacent grouting pipes. Themultiple water draining plates communicate with the horizontal water draining pipe. The horizontal water draining pipe communicates with an external water draining pipe. The resistance wires are woundon the water draining plates and electrically connected with a power source arranged in an external power source control box. The horizontal grout conveying guide pipe sequentially communicates withthe grout conveying pump and the curing agent grout storage tank through the grout conveying hose. The invention also discloses a sludge curing method adopting the sludge curing device. The sludge curing method is suitable for shoal sludge for reclaiming land from the sea by building dykes, a shallow soft soil foundation or a deep soft soil foundation, improves the curing degree of the sludge, shortens the curing time and enables the cured sludge to have certain bearing capacity.

Owner:广东赣鸿建设有限公司

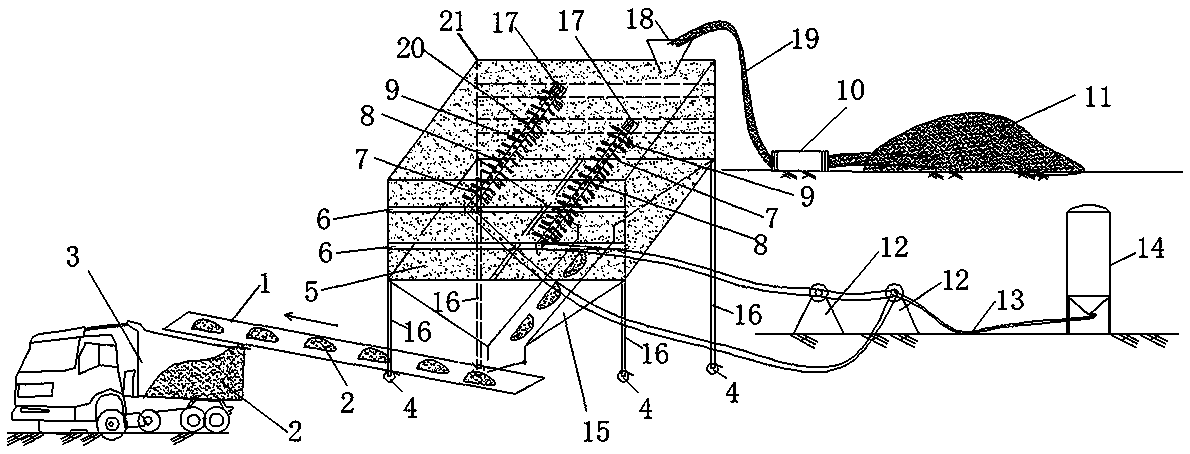

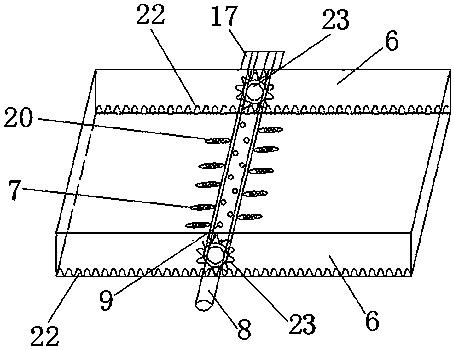

Silt ex-situ solidification treatment device and method

InactiveCN107840555AFlexible moving processQuick responseSludge treatment by de-watering/drying/thickeningFixation/solidifcation sludge treatmentSoil scienceSlurry transport

The invention discloses a silt ex-situ solidification treatment device including a solidification box, a piston type mud transport pump, a mud transport pipe, a slurry transport pump, a slurry transport pipe and a solidification agent slurry storage tank; the piston type mud transport pump transports to-be-treated silt to the solidification box through the mud transport pipe; the solidification box comprises a box body, a stirring device, a mud feeding bucket, a bottom cover and a tilted leaky groove; the mud feeding bucket is arranged at the top of the box body; the inclined leaky slot is arranged at the bottom of the box body; the stirring device includes a stirring rod rolling walking groove, a stirring rod and a stirring motor; a guide line pipe and a slurry spray pipe are formed inside the stirring rod; the slurry spray pipe on the stirring rod communicates with the slurry transport pump and the solidification agent slurry storage tank through the slurry transport pipe successively. The invention also discloses a silt ex-situ solidification treatment method adopting the device; the device and the method are suitable for silt dredging for harbours and waterways, and bottom muddesilting for rivers and lake, and are applied in the fields of environmental protection and building construction to reduce the water content of silt, improve the strength of solidified soil bodies and achieve silt reduction and resource utilization.

Owner:广东胜隆汉华建筑材料科技有限公司

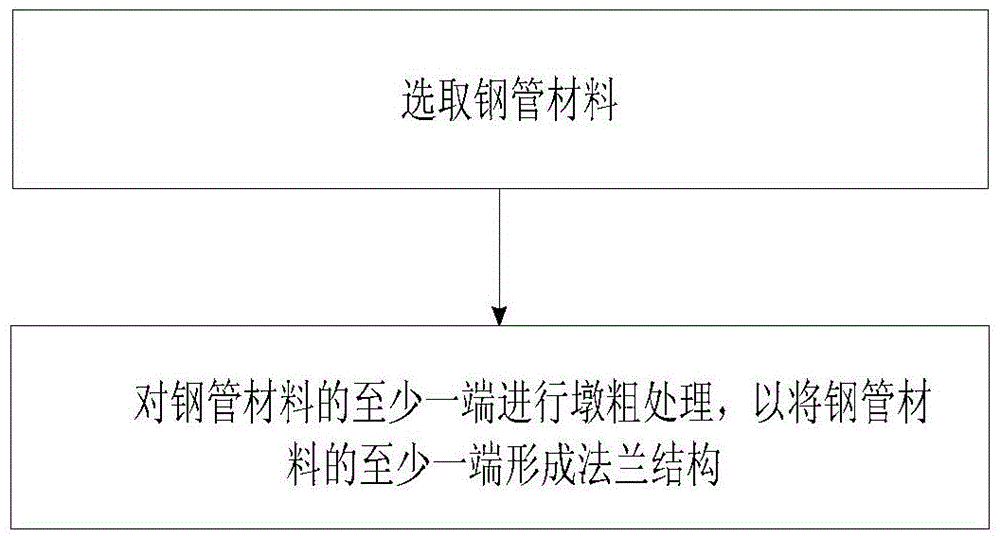

Slurry transporting pipe manufacturing method and slurry transporting pipe

InactiveCN104565559AStable structure and performanceExtended service lifeMetal-working apparatusRigid pipesSlurry transportEngineering

The invention provides a slurry transporting pipe manufacturing method and a slurry transporting pipe. The slurry transporting pipe manufacturing method comprises the steps of selecting a steel pipe material and conducting roughening treatment on at least one end of the steel pipe material so that at least one end of the steel pipe material forms a flange structure. Through the manufacturing method, the problems that the manual and material cost of the transporting pipe in the prior art is high and the service life is short can be solved.

Owner:HENGYANG VALIN STEEL TUBE

Vacuum shaker systems

The invention relates to improvements in vacuum shakers and more specifically to the integration of multiple shaker units to a common vacuum pump system, to apparatus for controlling the airflow through shaker screens, optimization of slurry transport, and to methods of separating drilling fluid from drill cuttings.

Owner:FP MARANGONI INC

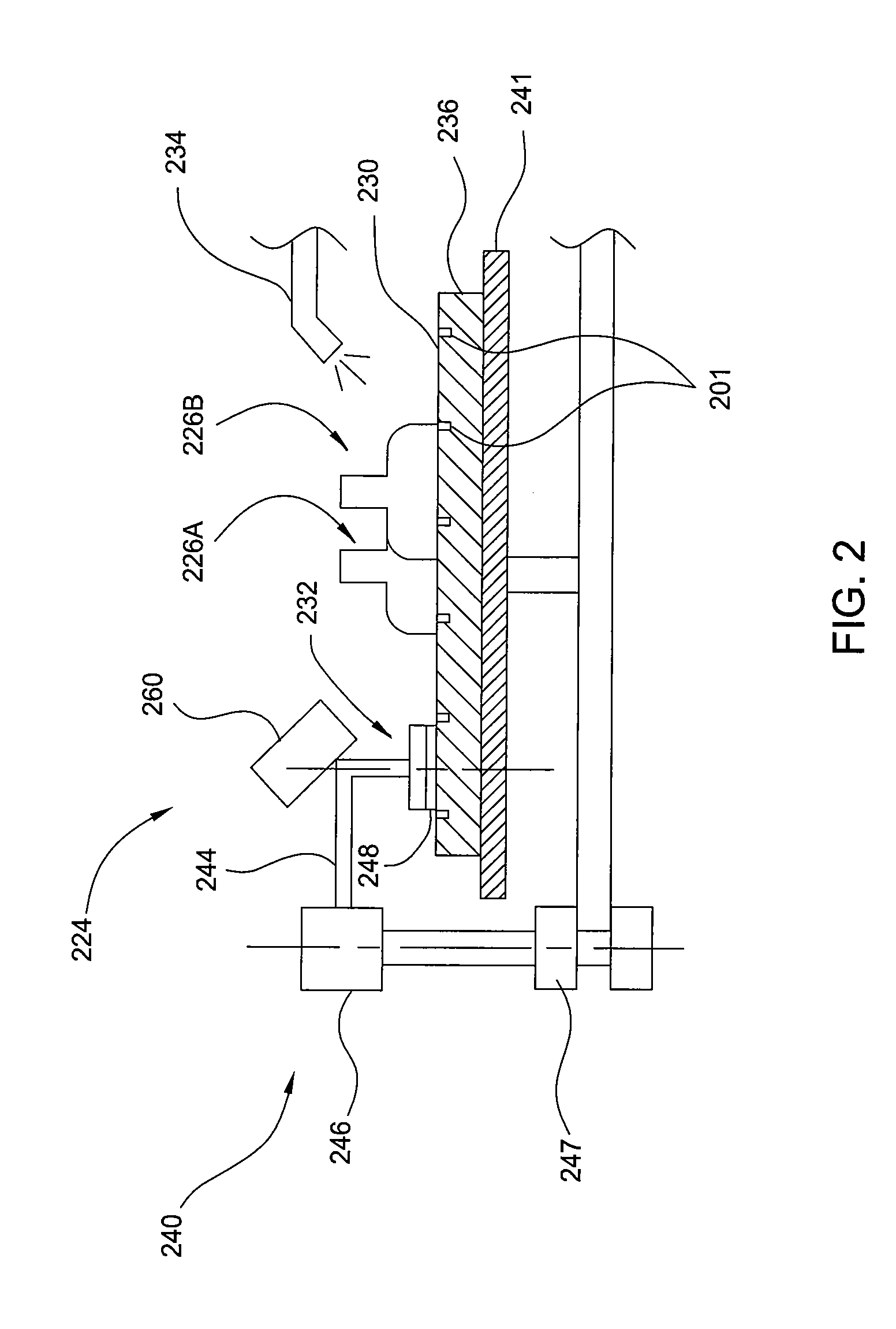

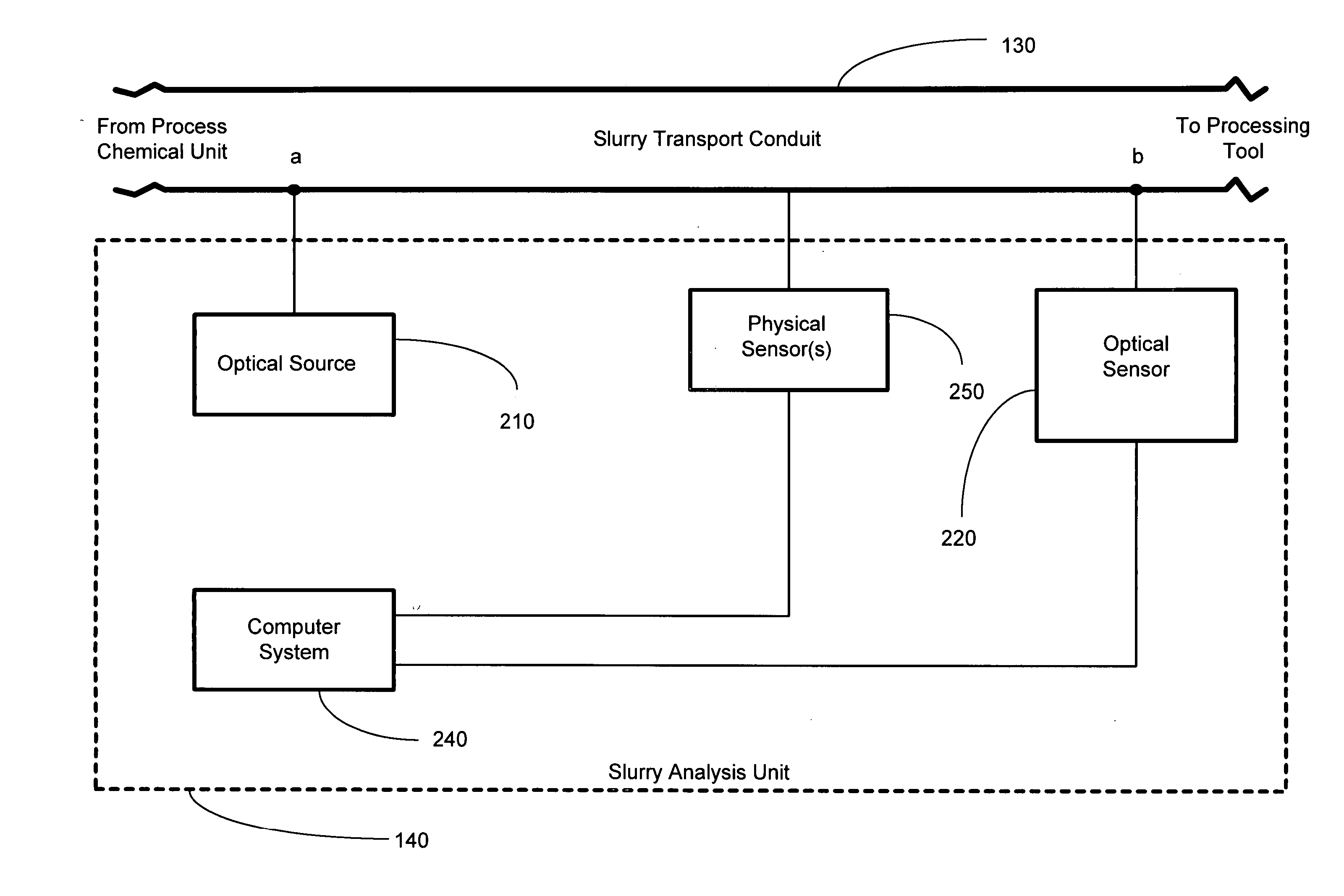

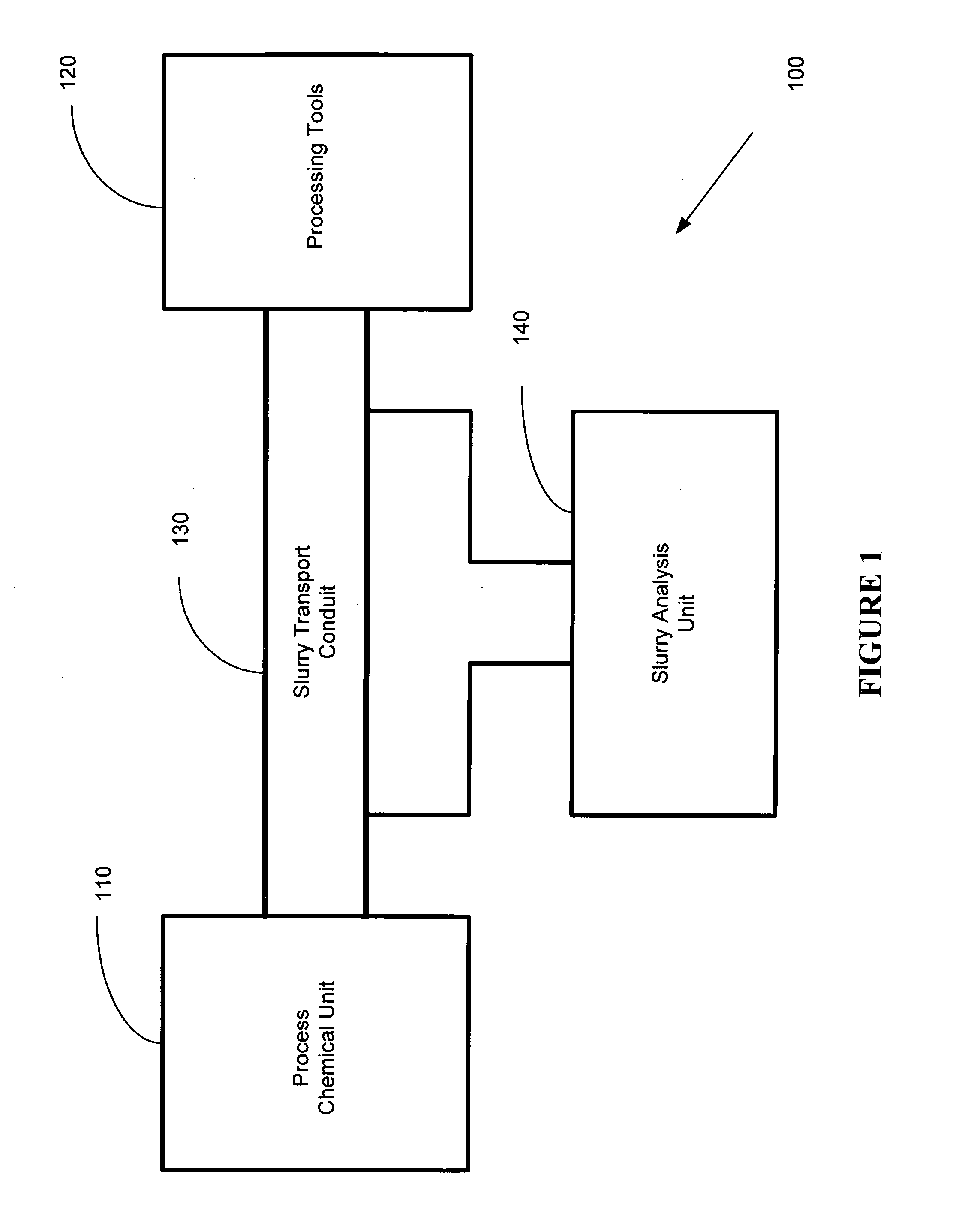

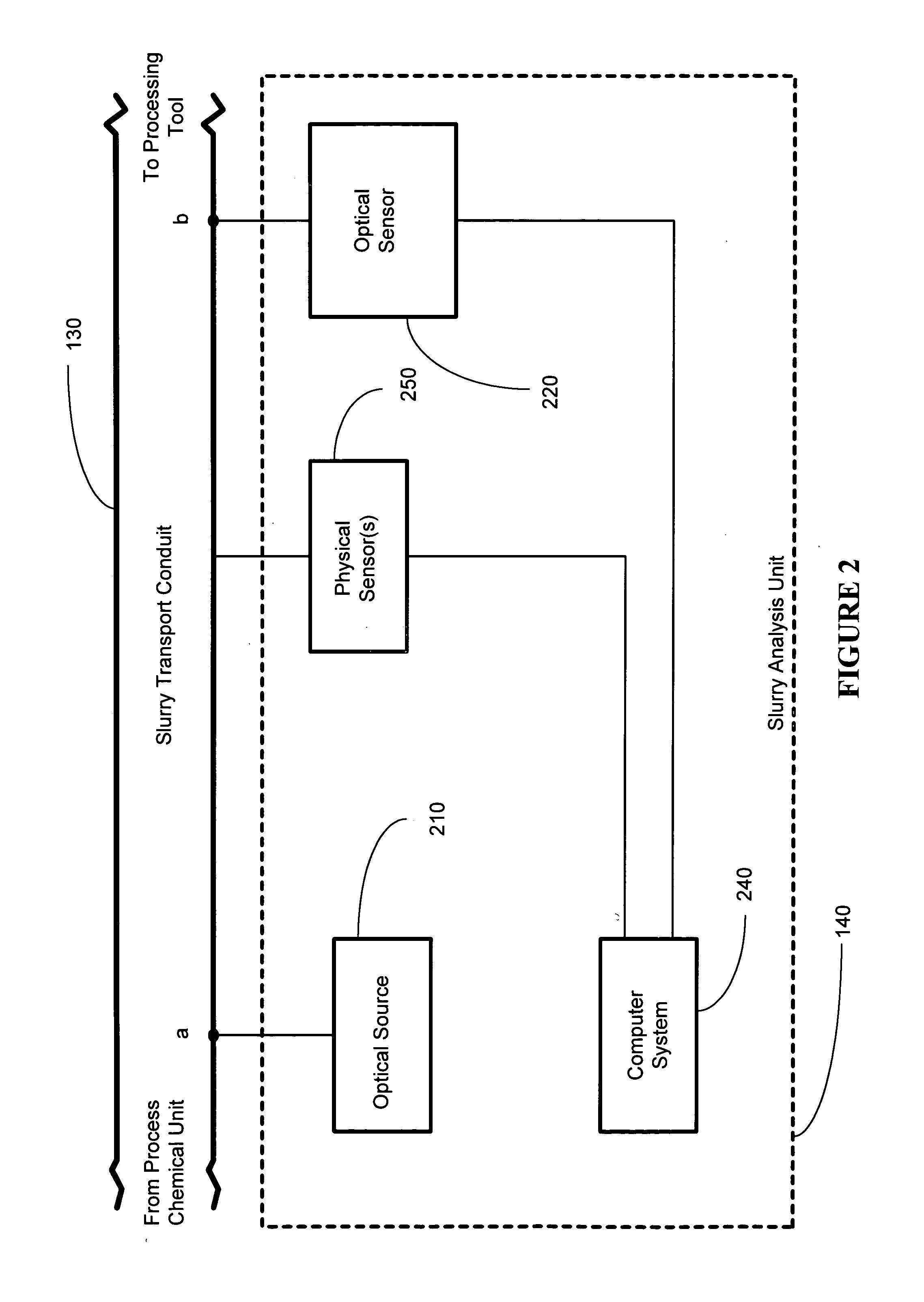

Method and apparatus for monitoring of slurry consistency

InactiveUS20040159399A1Investigating moving fluids/granular solidsSemiconductor/solid-state device manufacturingSlurry transportComputer science

A method and apparatus for performing online monitoring of a physical characteristic of a process material. A request to provide a slurry to a processing tool is received. The slurry is transported through a slurry transport unit, based upon the request, to the processing tool. An online monitoring of a physical characteristic of the slurry is performed. The online monitoring of the slurry includes analyzing an optical signal sent through the slurry to determine whether the physical characteristic of the slurry is within a predetermined level of tolerance.

Owner:MISRA ASHUTOSH +1

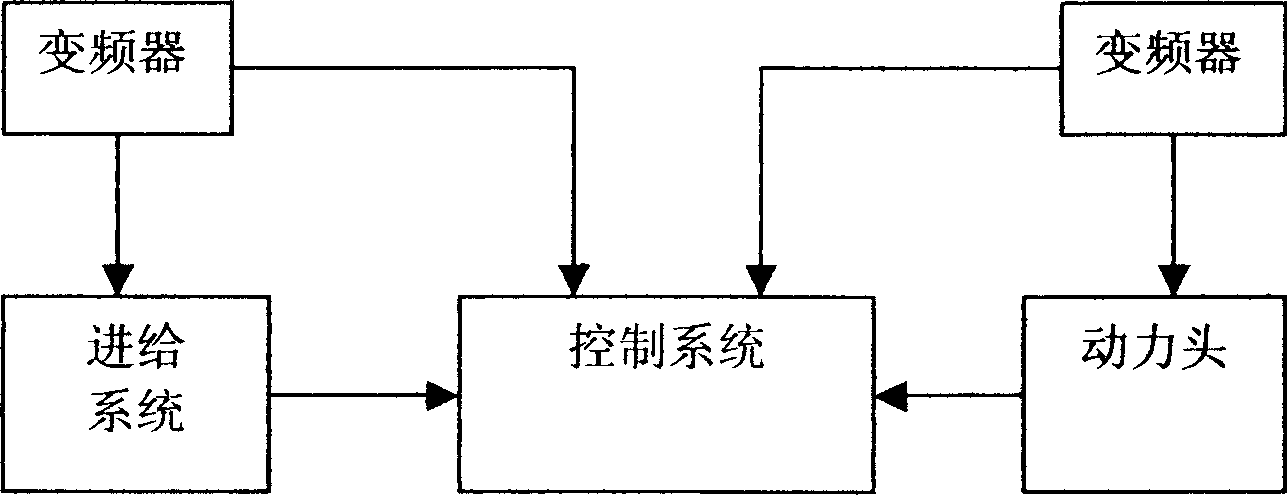

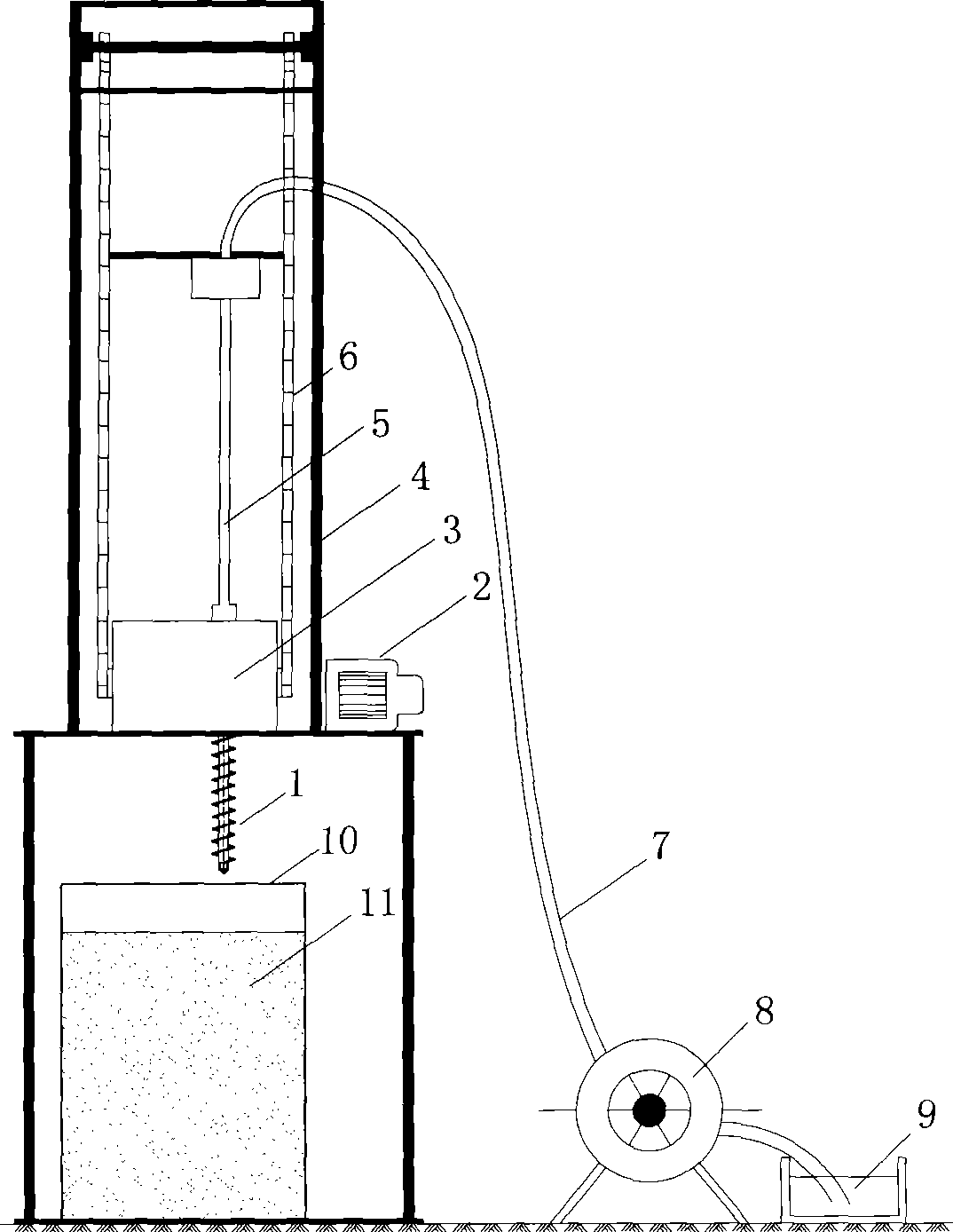

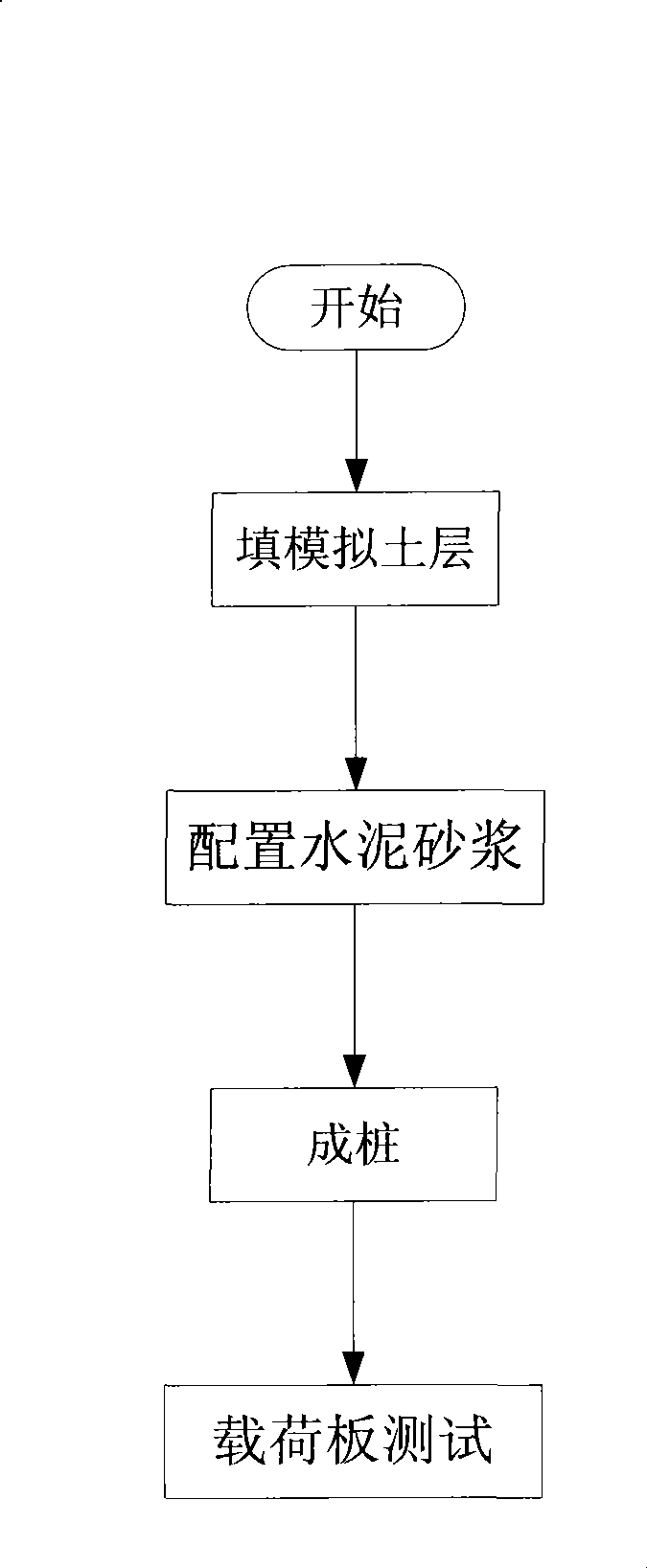

Pile-forming equipment and method of control modulus pile

InactiveCN101435209AReliable carrying capacityRealize quantitative designFoundation testingStress ratioSlurry transport

The invention discloses a pile-forming device and pile-forming method for control modulus pile, belonging to the field of bearing characteristic testing of composite foundation of geotechnical engineering. The device of the invention is composed of a drill bit, a motor, a control platform, a drill frame, a drilling rod, a driving chain, a slurry transporting pipe, a pressure pump, and a model box. The method of the invention includes the steps of filling simulation soil layer, preparing cement slurry, and forming pile. The invention realizes the quantitative design of control deform and control bearing force of the composite foundation, and fully mobilizes the function of the soil among piles by adjusting the stress ratio of the pile soil.

Owner:SOUTHEAST UNIV

Piping for abrasive slurry transport systems

InactiveUS20050081937A1Solution to short lifeEasy to cleanRigid pipesPipe protection against damage/wearSlurry transportAqueous electrolyte

A section of piping for use in transporting abrasive slurries which has improved abrasion resistance is shown. The piping has a tubular metal body with an exposed exterior surface and a generally cylindrical internal surface. The internal surface of the tubular metal body is uniformly plated with a deposit of chromium to give the section of piping a hard chromium case which resists abrasion. The deposit of chromium is applied by exposing the internal surface of the tubular metal body to an aqueous electrolyte solution at a current density and at a plating temperature sufficient to form a chromium deposit of desired thickness on the internal surface.

Owner:SCOT INDS

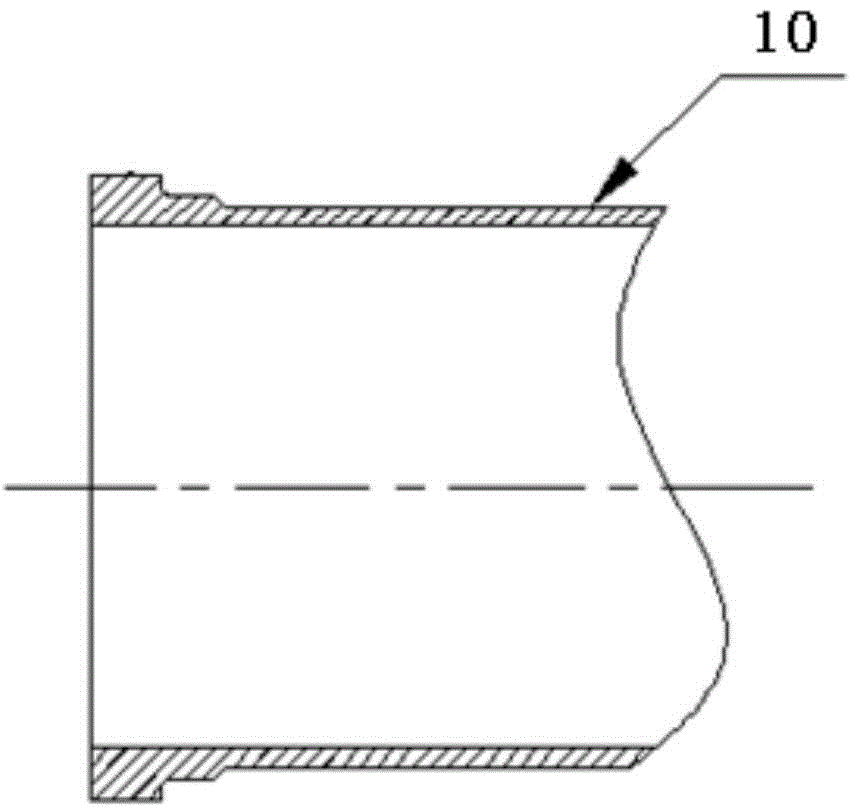

Concrete slurry transporting pipe for concrete pump-car

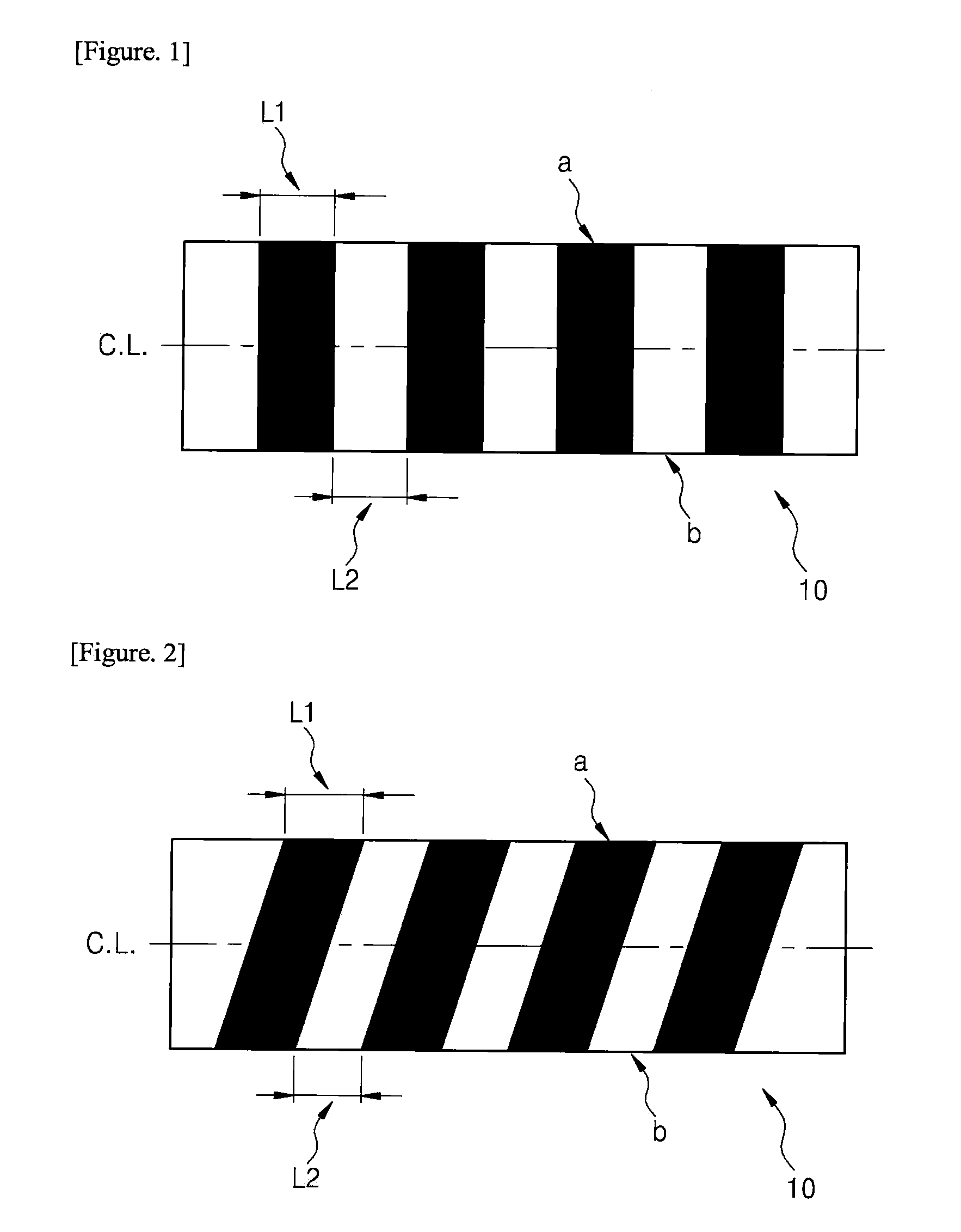

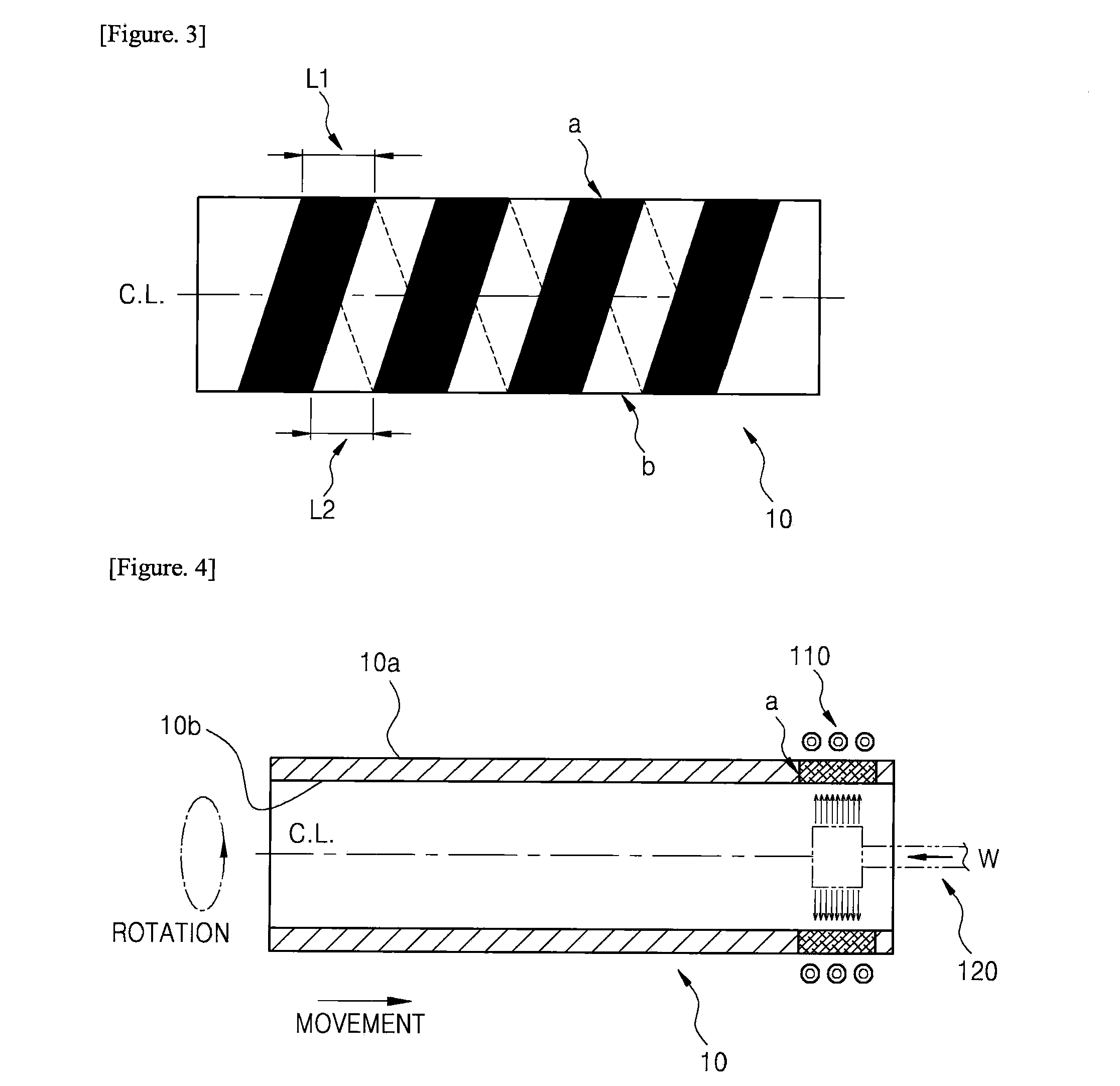

Disclosed is a concrete slurry transporting pipe for concrete pump-cars, which has improved wear resistance to friction with sands or gravels and impact resistance during transportation of concrete slurry. The pipe is a steel pipe made of carbon steel, and includes a heat-treated section having a hardness of Hv 450 or more and formed by induction-heating a portion of an inner or outer surface of the pipe, followed by cooling the heated portion of the inner or outer surface to harden the heated portion, and a non-heat treated section adjoining the heat-treated section. The heat-treated section and the non-heat treated section are alternately formed in a spiral band arrangement along a length of the pipe, and the heat-treated section has a greater width than the non-heat treated section.

Owner:ECO STEEL +1

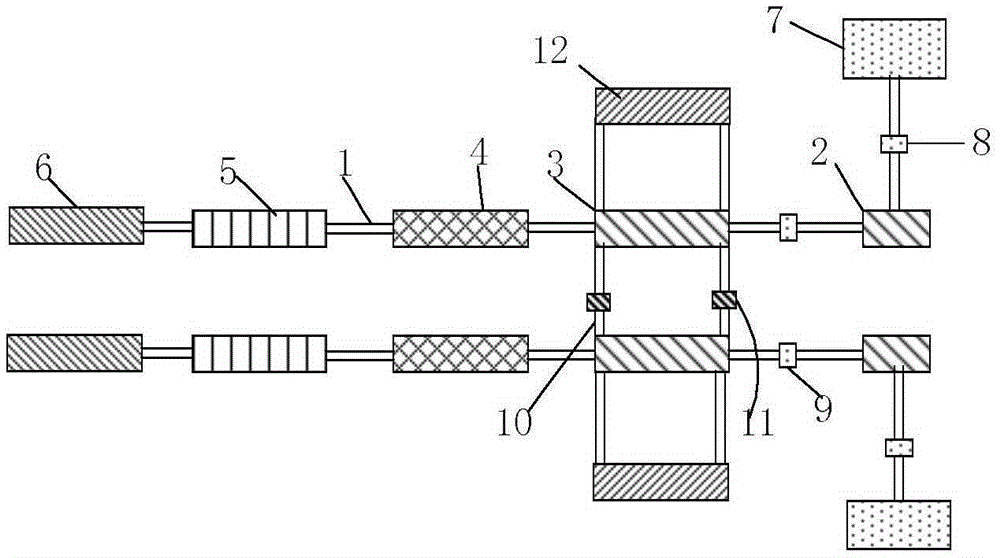

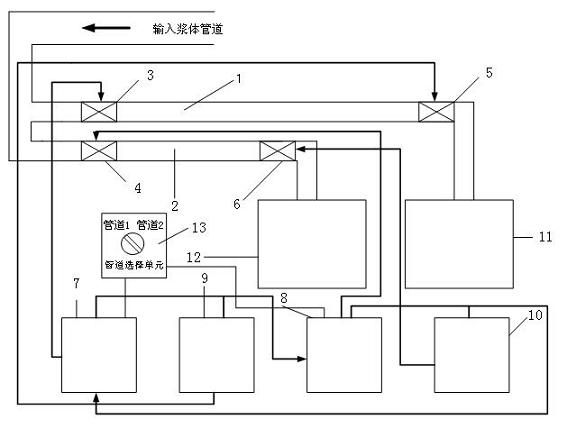

Automatic switching storage device for slurry medium transported through pipeline

ActiveCN102252167AReduce labor intensityGuarantee production safetyPipeline systemsSlurry transportValve opening

The invention provides an automatic switching storage device and method for slurry medium transported through a pipeline. The device comprises a slurry inputting pipeline, at least two slurry transporting pipelines and a pipeline selecting unit, the outlet of each slurry transporting pipeline is connected to a corresponding slurry storage tank, while the inlet of each slurry transporting pipelineis respectively provided with an opening and closing controller, the pipeline selecting unit is simultaneously connected to the opening and closing controller at the inlet of each pipeline and used for selecting one pipeline as the slurry transporting pipeline and providing a valve opening signal to the corresponding opening and closing controller to open the pipeline, furthermore, the opening and closing controller at the inlet of each pipeline simultaneously sends a valve closing signal to other opening and closing controllers at the inlets of other pipelines to close other pipelines so that the slurry is transported to the corresponding storage tank only through the selected pipeline. The medium in the pipeline can be rapidly transported to the specified storage location through the device and method in the invention, in addition, the storage location can be switched automatically.

Owner:YUNNAN DAHONGSHAN PIPELINE

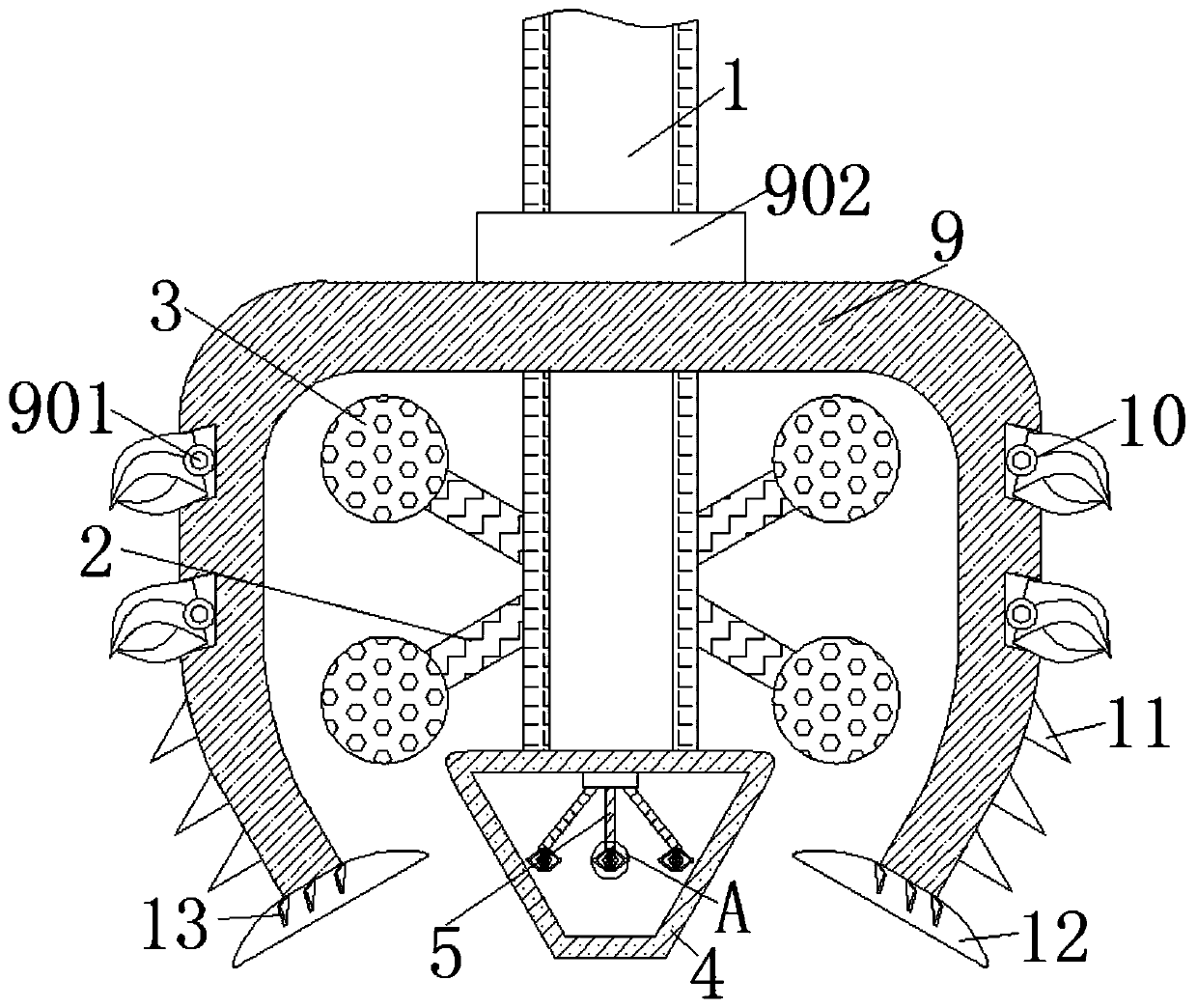

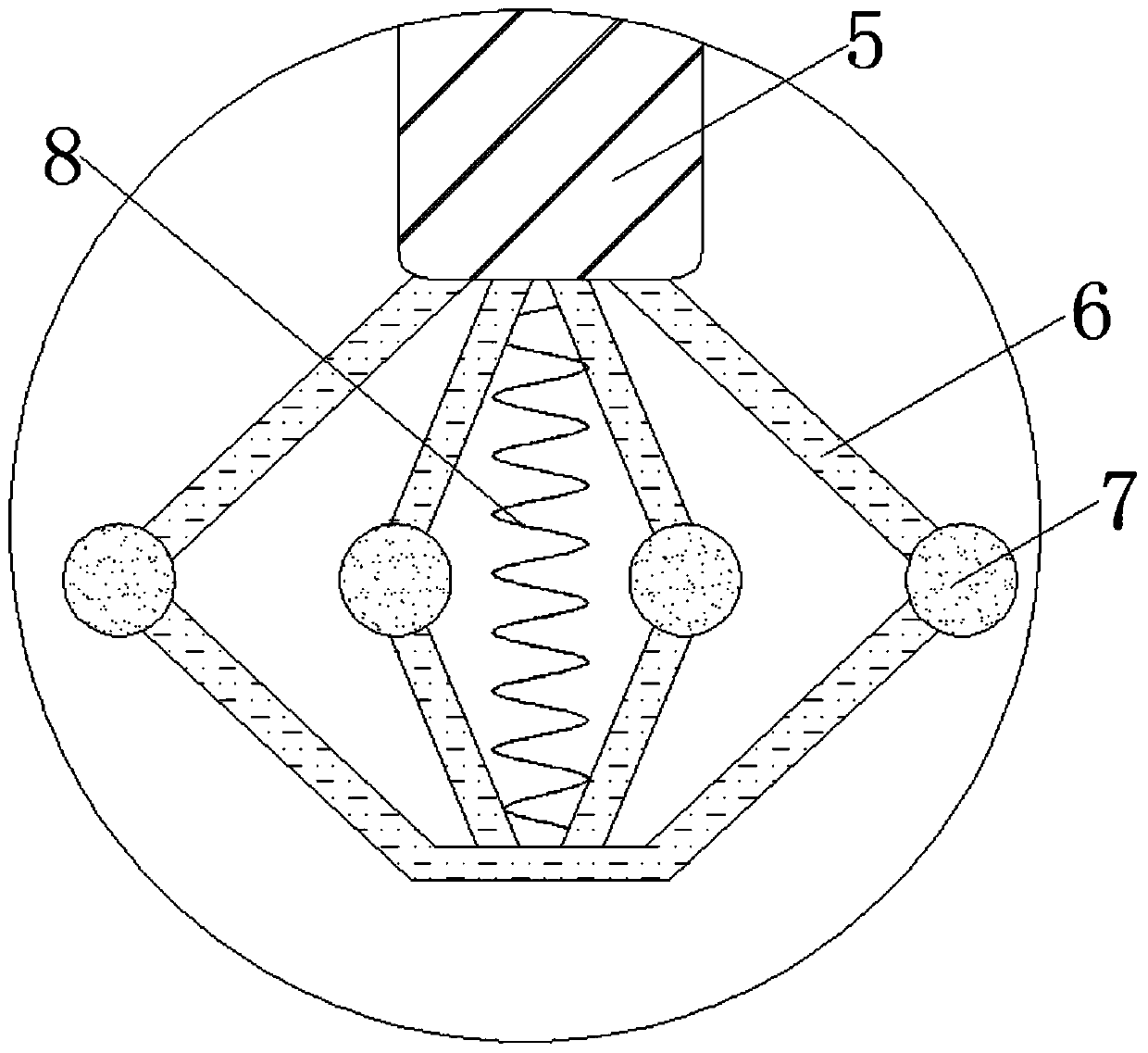

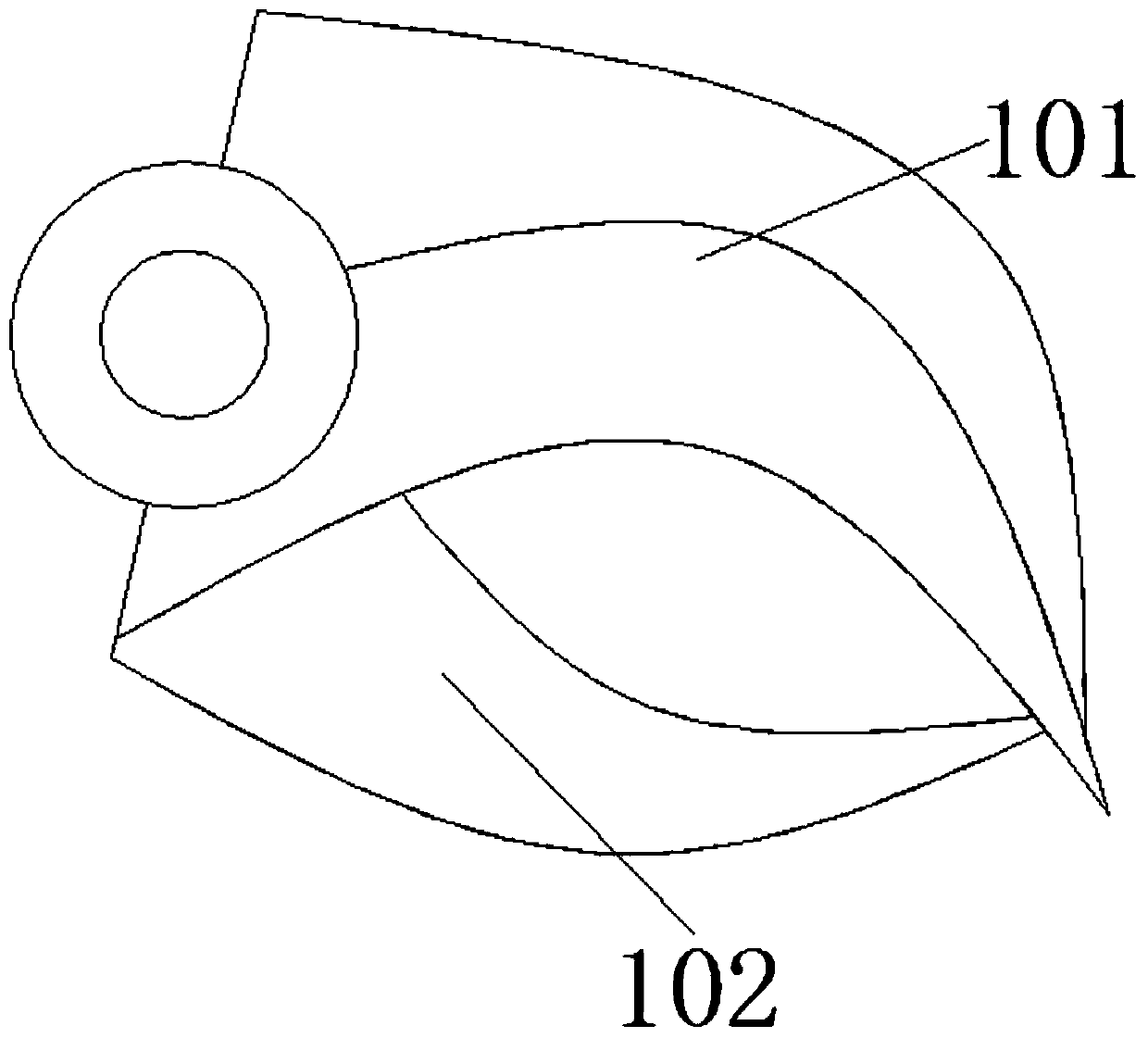

Dredging boat accessory based on centrifugal rotation and capable of ensuring normal transport of mud conveying pipe

InactiveCN110670652AConvenient and effective smashingAvoid cloggingMechanical machines/dredgersMarine engineeringSlurry transport

The invention discloses a dredging boat accessory based on centrifugal rotation and capable of ensuring the normal transport of a mud conveying pipe. The lower end of a mud conveying pipe body penetrates through and extends to the space below a reamer body, and is fixedly provided with fixed suction rods; a suction ball is fixedly installed at one end away from the mud conveying pipe, of each fixed suction rod; a stirring frame is fixedly installed at a low end of the mud conveying pipe body; connection rods are fixedly installed at the upper end in the stirring frame; a hinge rod is fixedly installed at the lower end of each connection rod; and a counter-weight ball is hinged between each two symmetrical hinge rods. Through the cooperative use for the connection rods, the hinge rods and the counter-weight balls, algae mixed with mud can be conveniently and effectively smashed, so that the problem that the mud after being mixed with the algae blocks in the mud conveying pipe body due to clustering or agglomeration, so that the smashed algae cannot be transported to the other side with the highest efficiency, is avoided; and meanwhile, the problem that working personnel are needed to enter water to dredge or transport the mud conveying pipe body to a shore to dredge with much manpower and material resources after the mud conveying pipe body is blocked, is also avoided, so that the working steps are simplified.

Owner:杭州富阳锐明科技有限公司

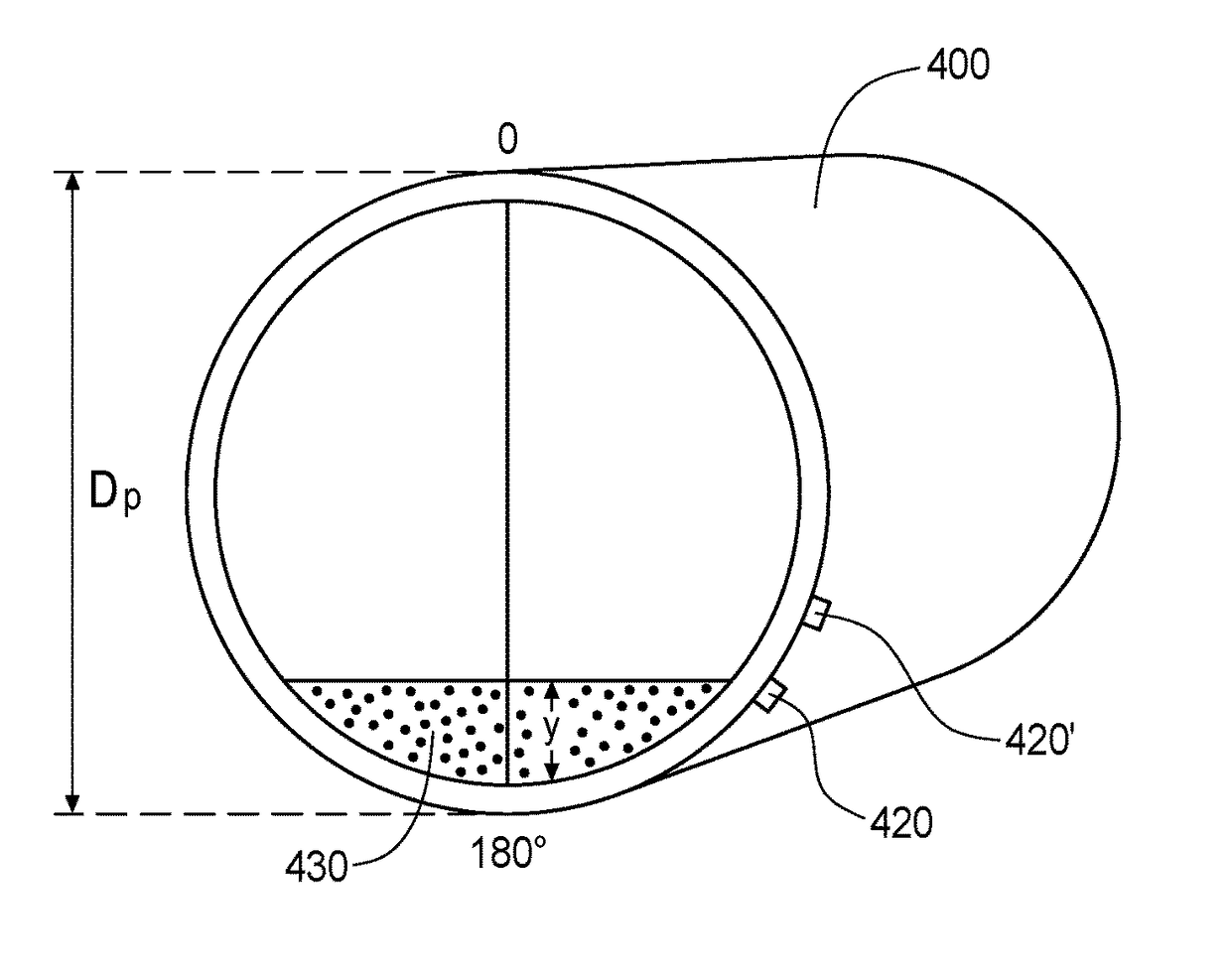

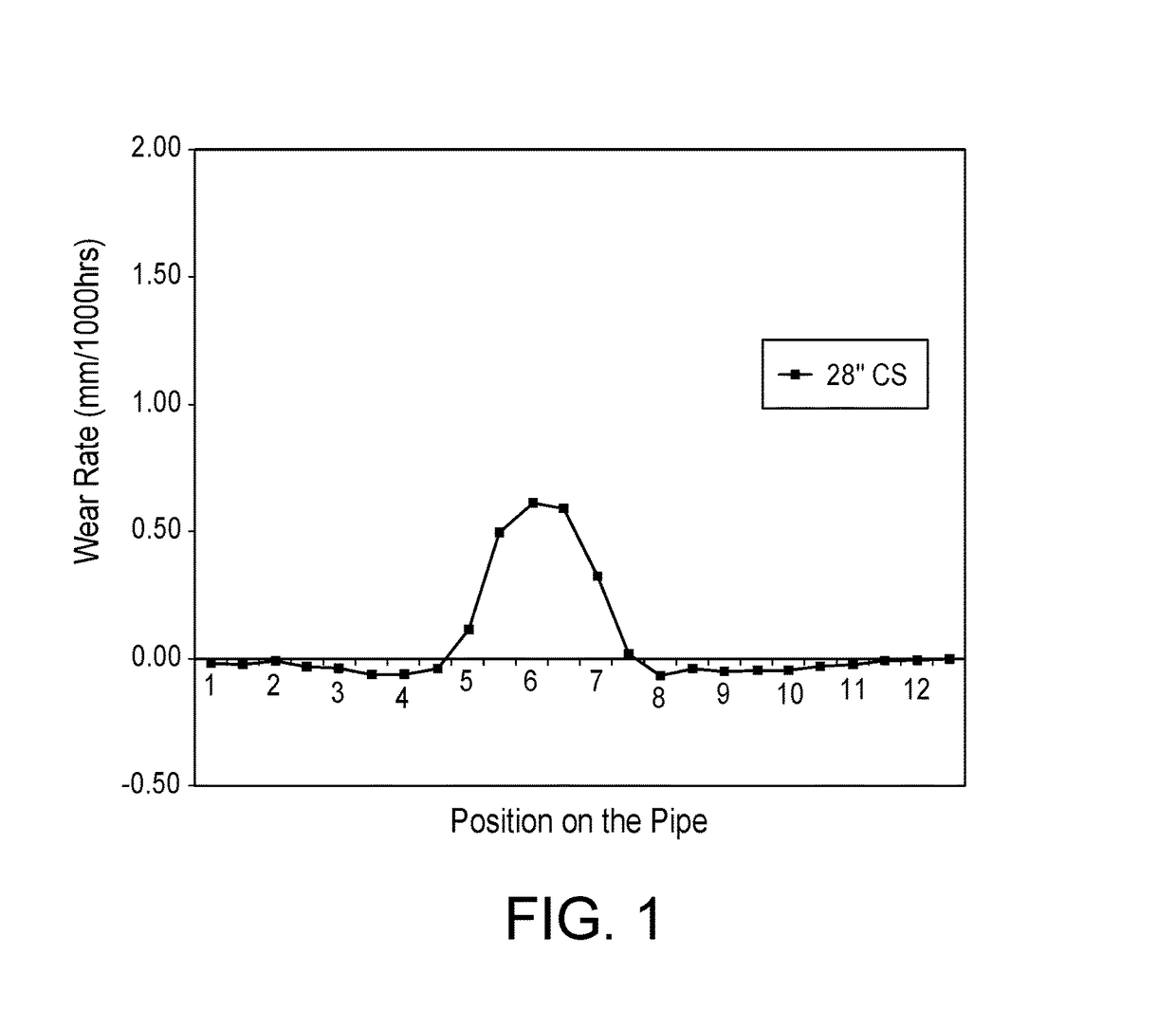

Reduced pipe wear in slurry transport pipelines

InactiveUS9694993B2Reduce wearExtend project lifePipeline systemsBulk conveyorsSlurry transportEngineering

Owner:SYNCRUDE CANADA LTD

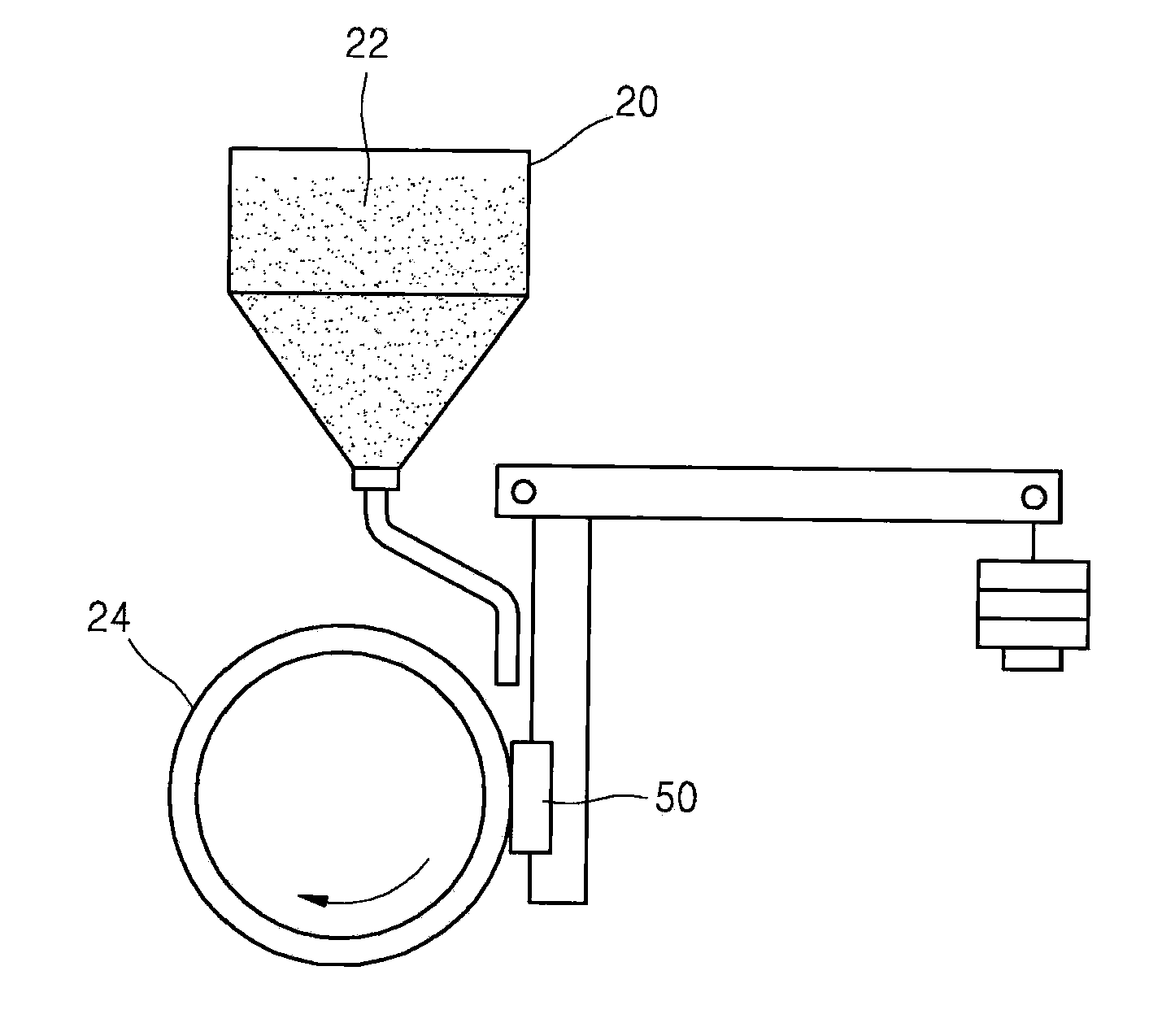

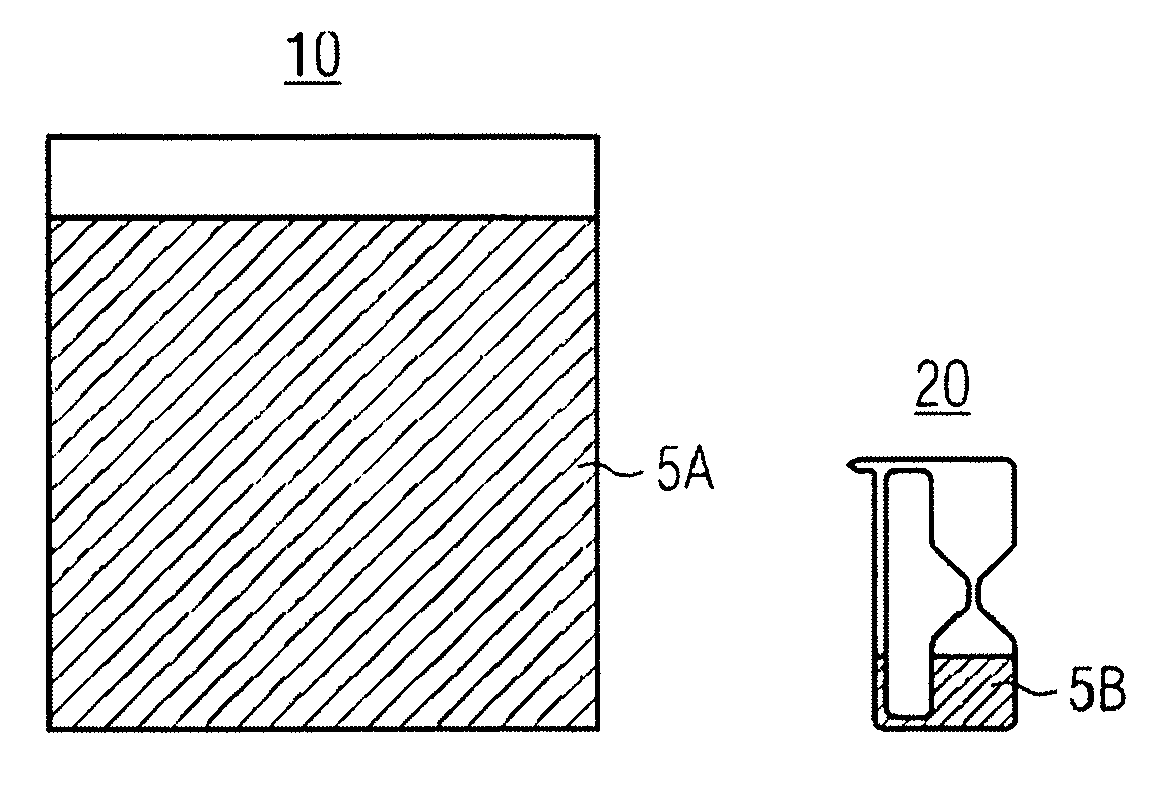

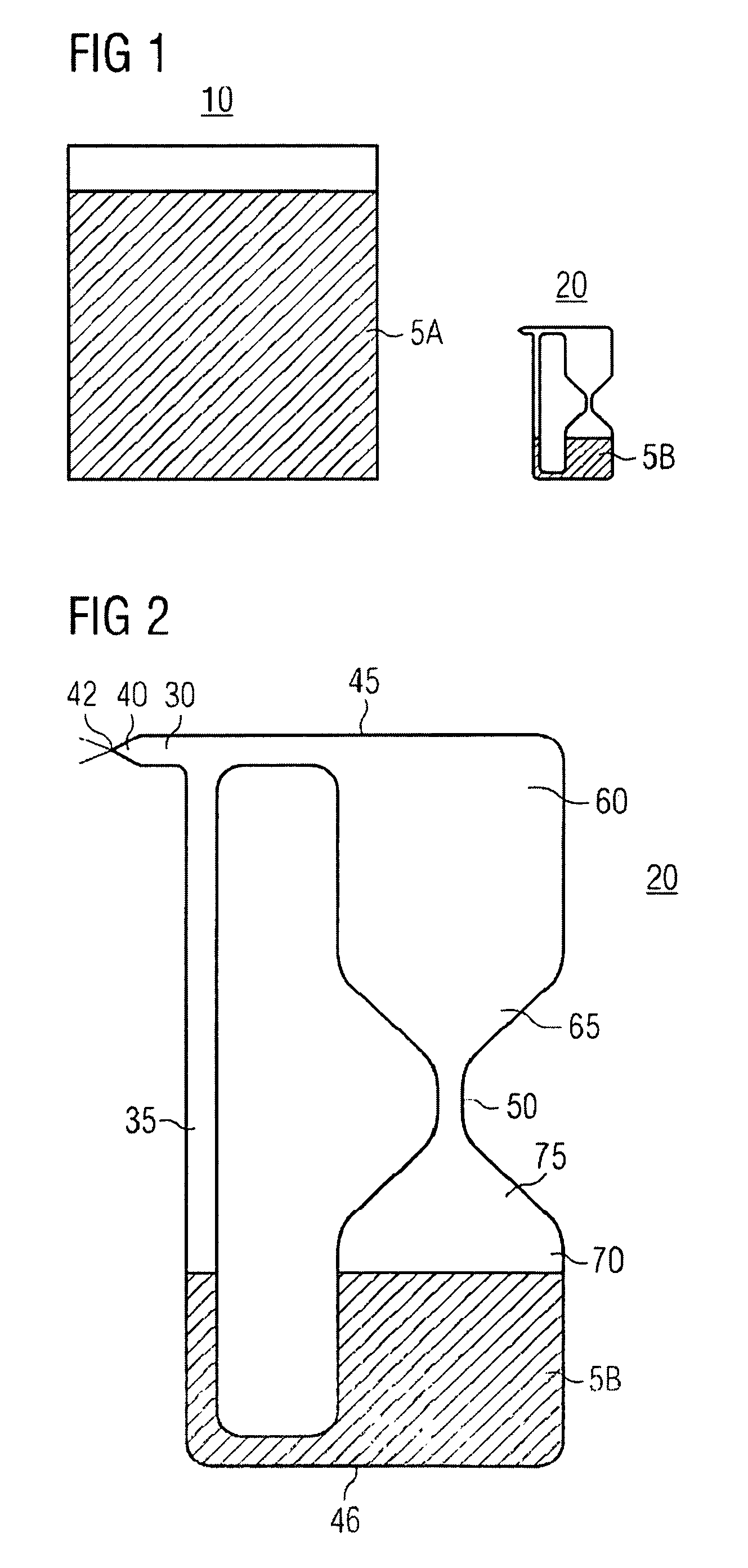

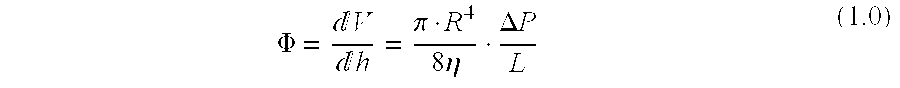

Slurry transport and storage system

An embodiment of the present invention is a transport and storage system for a slurry comprising: a main container; and a test container, the main container and the test container being exposed to the same environmental conditions, the main container and the test container containing a slurry from the same batch, wherein the test container is designed to determine the viscosity of the slurry.

Owner:INFINEON TECH AG

Textile printing pigment powder and preparation method thereof

ActiveCN102505524AReduce the drawbacks affecting solids contentPigment particles are smallDyeing processPigment pastesTextile printerPolymer science

The invention discloses textile printing pigment powder and a preparation method thereof. The formula of the textile printing pigment powder comprises, by weight, 25-40% of a pigment, 4% of a dispersing agent, 1-5% of a moistening agent, 4% of an anti-settling agent and the balance of water. According to the present invention, the state of the printing paste is changed into the powder from the traditional slurry, such that the superfine pigment powder is directly used for printing paste coloring or is diluted through water to add into the printing paste so as to reduce the problems of inconvenient slurry transport and the influence on the solid content due to water evaporation; the pigment particles of the textile printing pigment powder of the present invention are small, and the pigment particles are coated with the dispersing agent and other additives, such that the pigment particles can be uniformly dispersed without influence on the formation of the stable printing paste after the pigment particles are diluted by adding the water or are added to the printing paste; and the textile printing pigment powder of the present invention is convenient to package and transport, and does not cause the solid content change.

Owner:DONGGUAN TONGLING NEW MATERIAL NANO TECH CO LTD

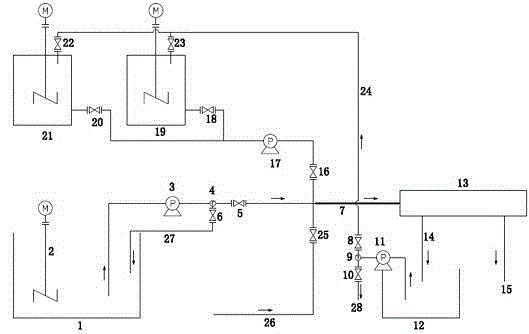

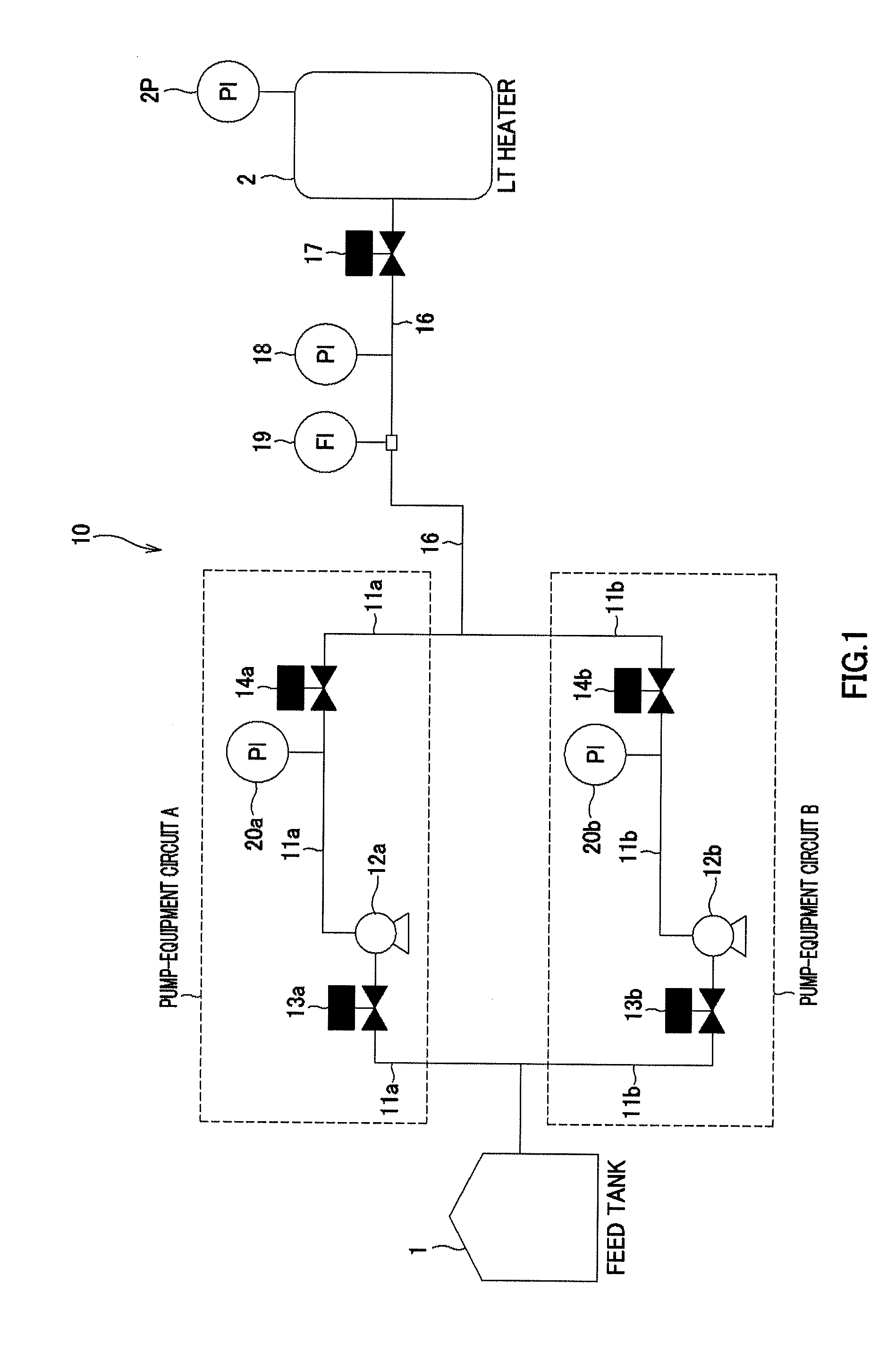

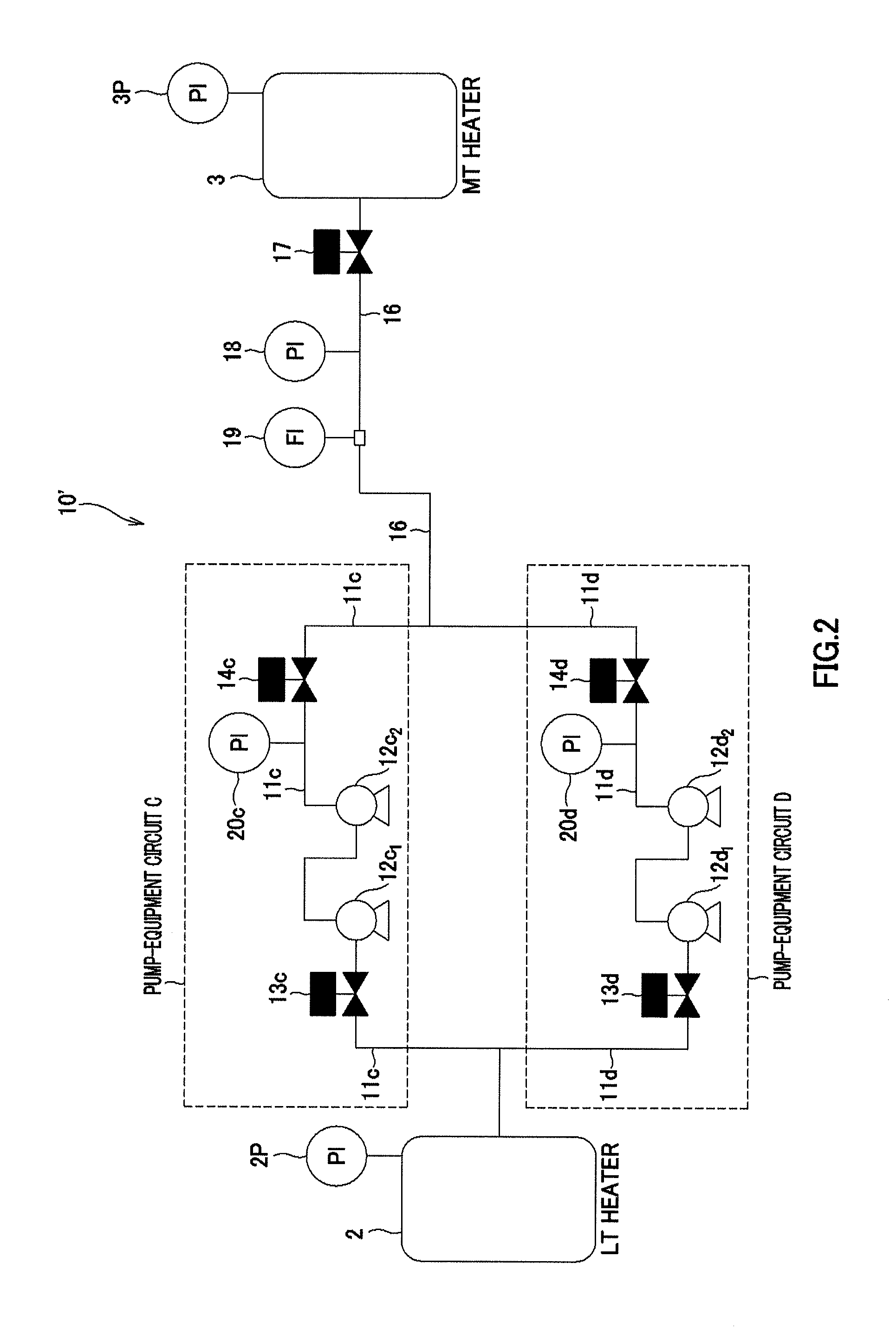

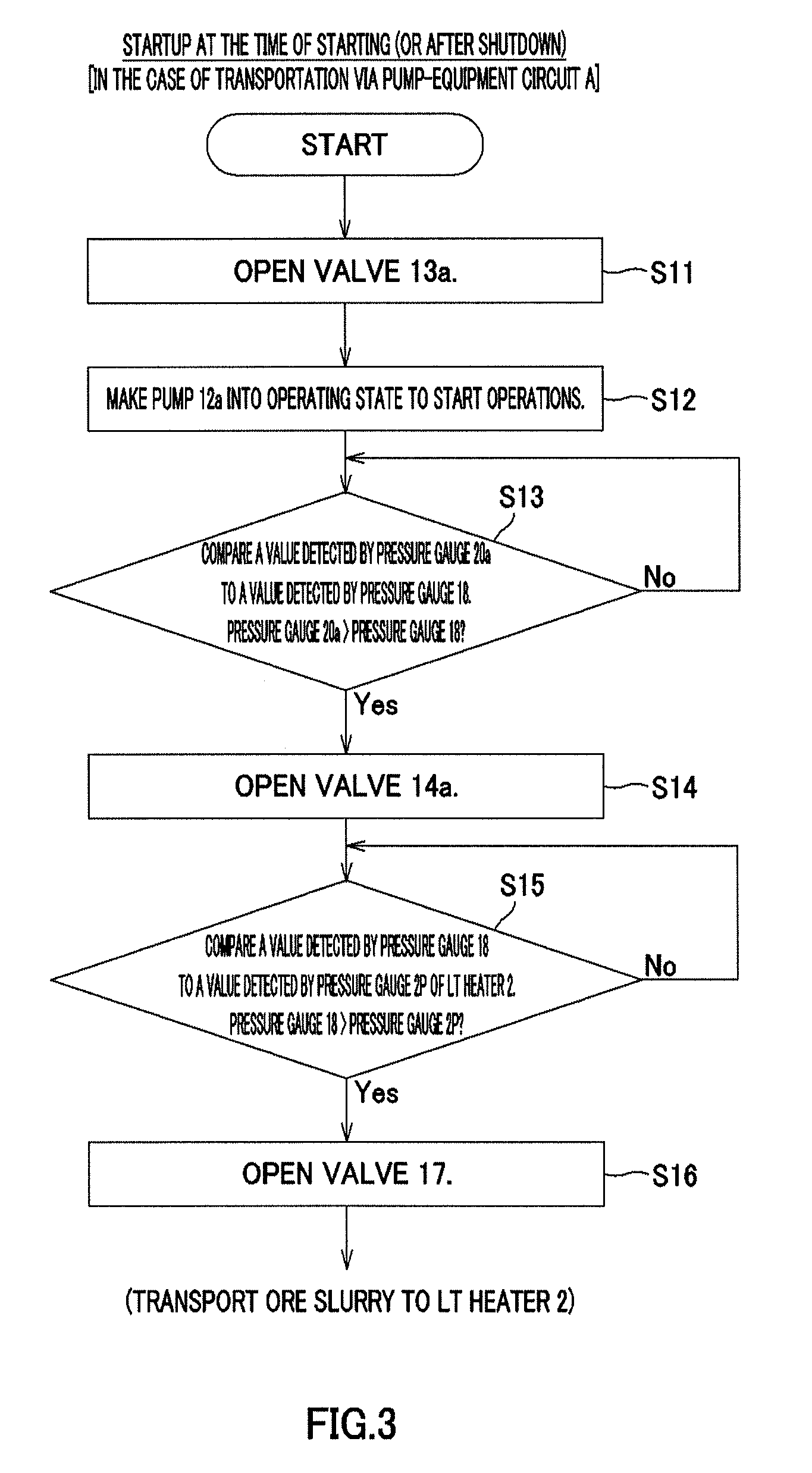

Slurry-transporting facility and slurry transportation control method

ActiveUS20150338027A1Prevent backflowEasy to operatePressurized chemical processDomestic plumbingSlurry transportEngineering

A slurry-transporting facility equipped with a plurality of pump-equipment circuits, whereby a stop of slurry supply to a transport destination at the time of switchover between the pump-equipment circuits for use is prevented to make an efficient operation possible. The slurry-transporting facility includes: pipe arrangements which branch out from a feed tank into the plurality of circuits; a transport pump provided in each of the pipe arrangement; a first valve provided upstream from the transport pump; a second valve provided downstream from the transport pump; and a uniting pipe arrangement formed by joining of the pipe arrangements at a predetermined position and connected to a LT heater. The uniting pipe arrangement is provided with a third valve configured to control the transportation of ore slurry to the LT heater and a pressure gauge configured to measure a pressure in the uniting pipe arrangement.

Owner:SUMITOMO METAL MINING CO LTD

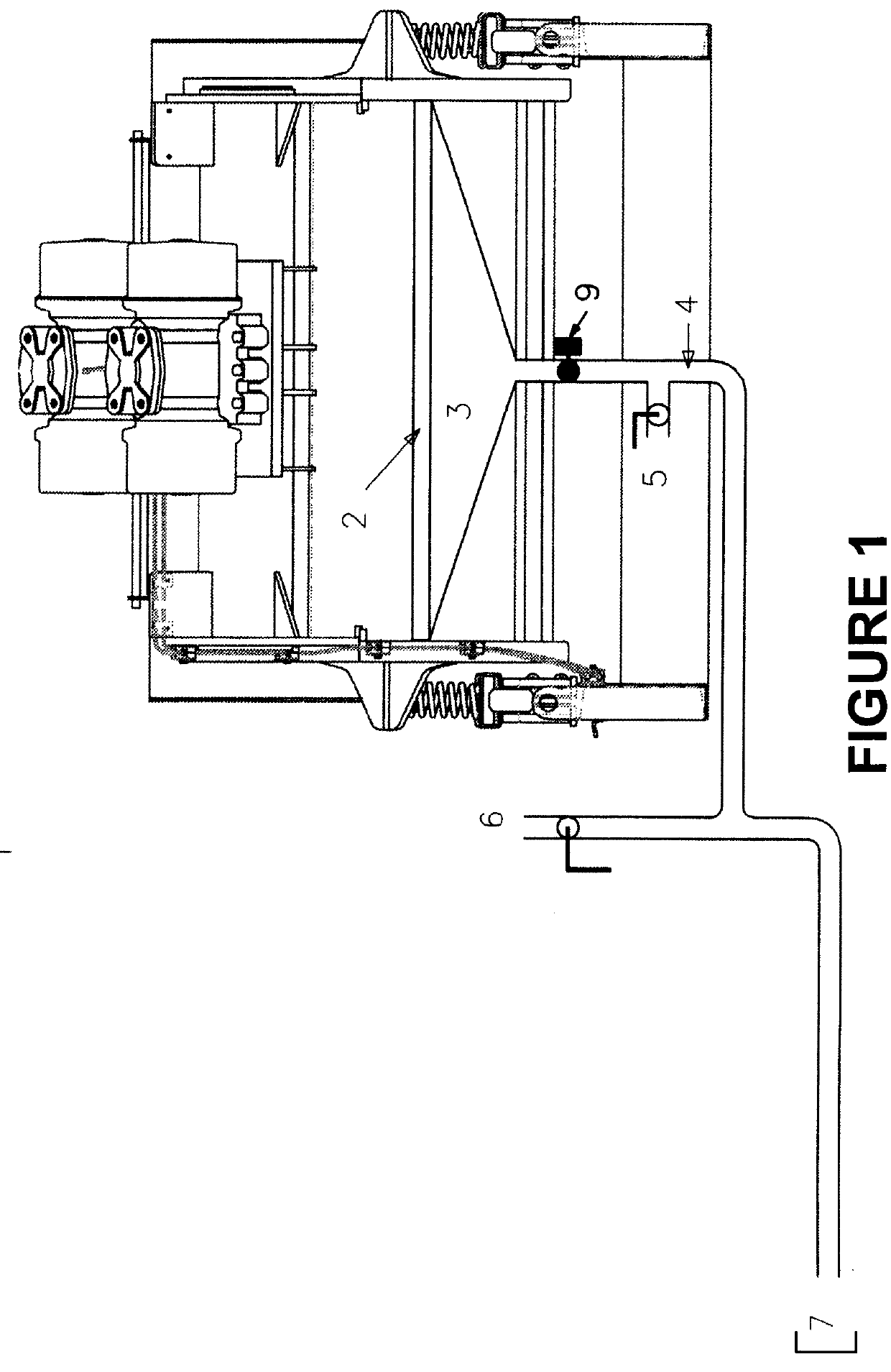

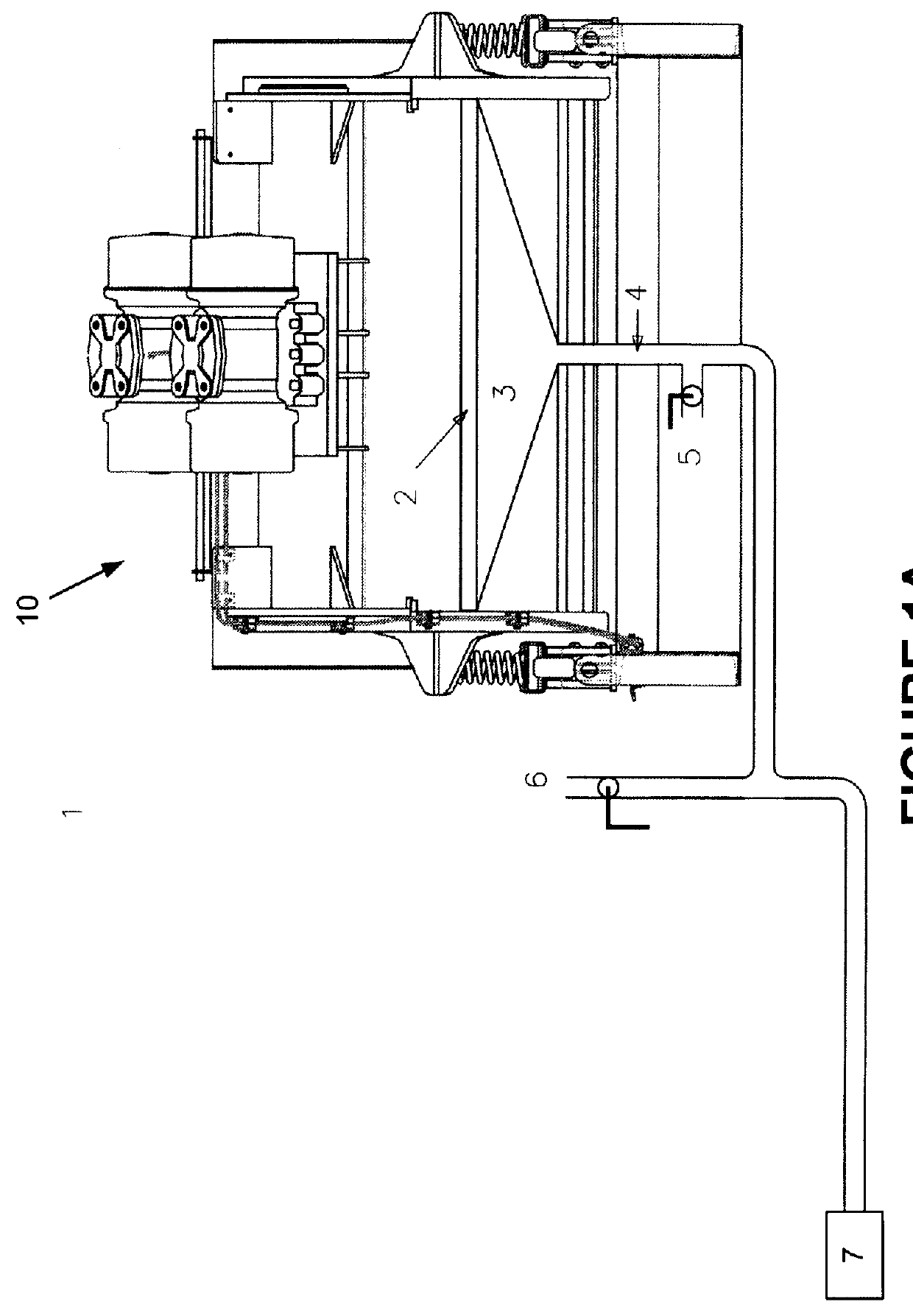

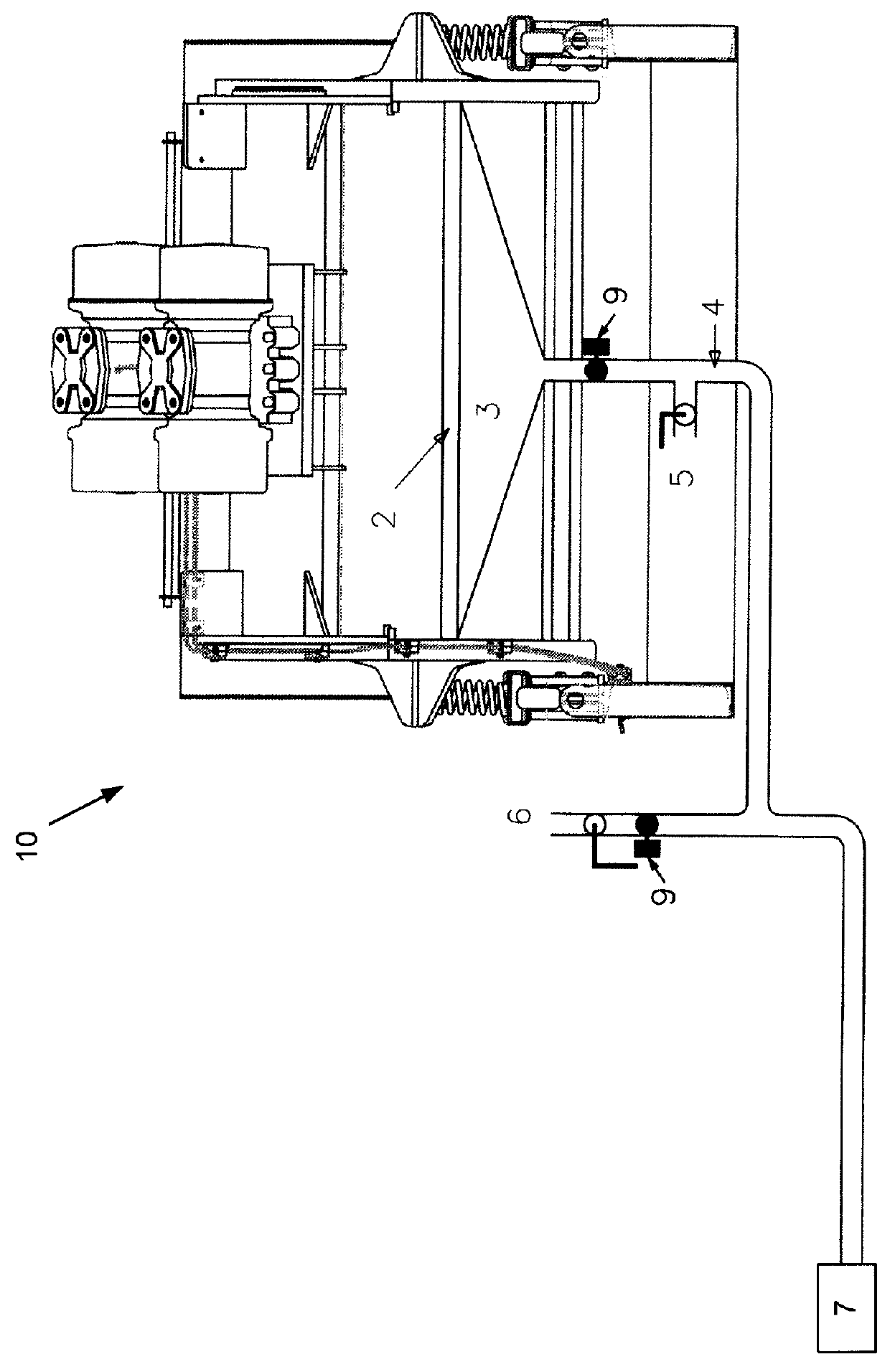

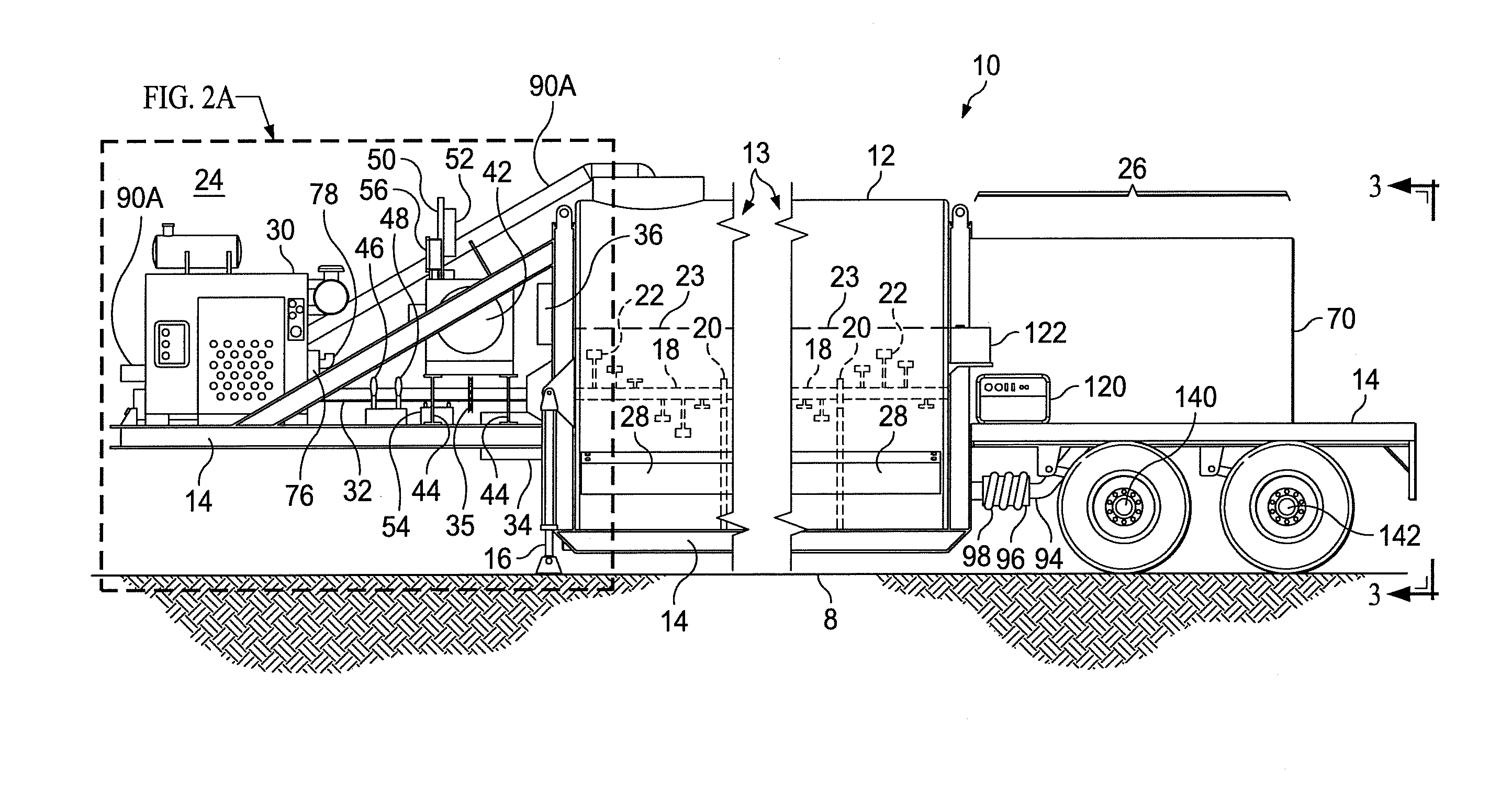

Thermally Enhanced Lime Slurry Apparatus

InactiveUS20150146499A1Positive displacement pump componentsLarge containersHydraulic motorSlurry transport

A single entity lime slurry transport and delivery apparatus is shown having a slurry tank body mounted on a unitary frame. A suction pump on the apparatus delivers slurry to a job site. A power unit on the frame powers a hydraulic mixing motor and the hydraulic suction pump. Selectable thermal management devices are located on the unitary frame, including at least a fuel heater, an engine coolant water heater, a hydraulic fluid warmer and heat exchanger, and heating elements associated with other hydraulic components of the apparatus.

Owner:LHOIST NORTH AMERICA INC

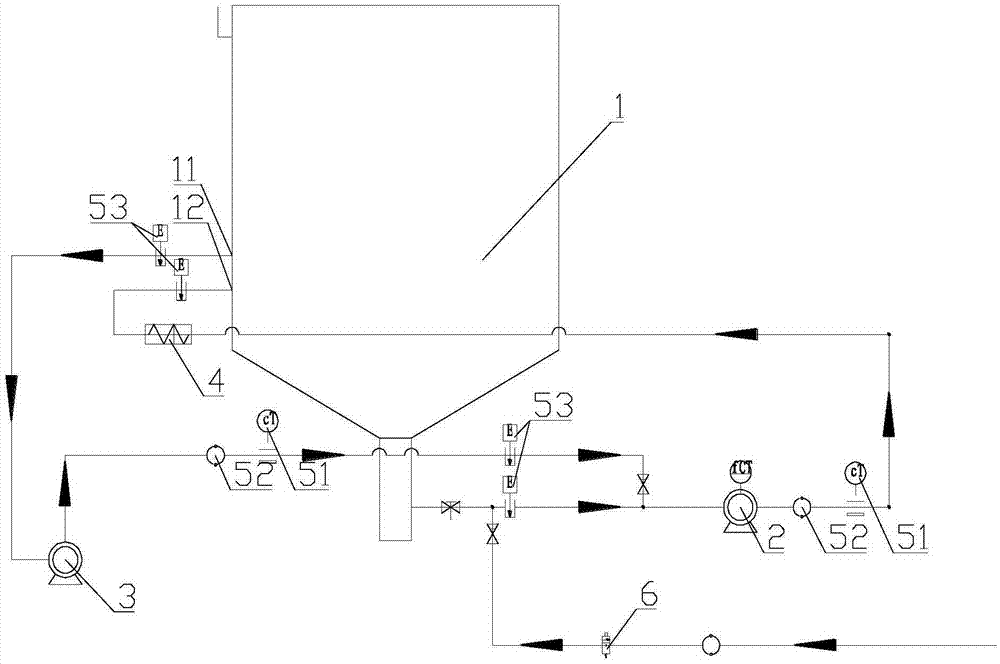

Thickener underflow concentration adjusting system

ActiveCN106861245AWill not overloadAvoid disturbanceSedimentation settling tanksHigh concentrationSlurry transport

The invention discloses a thickener underflow concentration adjusting system including a discharge port communicating with the bottom of a thickener, a high-concentration slurry pump for pumping a high-concentration slurry at the bottom to an upper-layer slurry return port, and a low-concentration slurry pump; one end of the low-concentration slurry pump is connected to a slurry outlet of the thickener, the other end of the low-concentration slurry pump communicates with the high-concentration slurry pump, and the low-concentration slurry pump is used for making a pumped low-concentration slurry mixed with the pumped high-concentration slurry; the slurry outlet is higher than the slurry return port. According to the concentration adjusting system provided by the invention, because the pumped high-concentration slurry and the pumped low-concentration slurry are mixed with each other and then outputted, and the concentration of the slurry transported to the thickener after final mixing is similar to the concentration of a transported part. The concentration in the thickener is increased layer by layer from top to bottom, after a bottom slurry is pumped out, an upper slurry layer moves downwards to supplement, and the concentration at the bottom is reduced. The slurry after mixing cannot have the concentration greatly different from the concentration of the upper-layer slurry, so disturbance to the upper-layer slurry is avoided and dynamic equilibrium of the slurry of all layers is overall maintained.

Owner:FENY

Wastewater treatment and reuse device and process for treating wastewater

ActiveCN104129868BNo need to increase the quantityLow running costDispersed particle separationMultistage water/sewage treatmentReclaimed waterSlurry transport

The invention relates to the field of reclaimed water recycling and particularly relates to a wastewater treatment and recycling device and a wastewater treatment technology. The device includes a dewatering tank used for accommodating wastewater, an regulating tank connected to a water outlet of the dewatering tank, a primary filter, a residue tank connected to the bottom of the first filter, a primary filtering liquid-inlet pump used for pumping the wastewater in the regulating tank into the primary filter, and a residue slurry transporting pump used for transporting residue slurry in the residue tank to the dewatering tank. The residue slurry transporting pump is connected to the dewatering tank. The device is large in wastewater treatment amount, is high in automatic degree, is obvious in treatment effect and is low in operation cost.

Owner:陕西金禹科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com